Page 1

a

DSP Microcomputer

ADSP-2192M

ADSP-2192M DUAL CORE DSP FEATURES

320 MIPS ADSP-219x DSP in a 144-Lead LQFP Package

with PCI, USB, Sub-ISA, and CardBus Interfaces

3.3 V/5.0 V PCI 2.2 Compliant 33 MHz/32-bit Interface

with Bus Mastering over Four DMA Channels with

Scatter-Gather Support

Integrated USB 1.1 Compliant Interface

Sub-ISA Interface

AC’97 Revision 2.1 Compliant Interface for External

Audio, Modem, and Handset Codecs with DMA

Capability

Dual ADSP-219x Core Processors (P0 and P1) on Each

ADSP-2192M DSP Chip

132K Words of Memory Includes 4K 16-Bit Shared

Data Memory

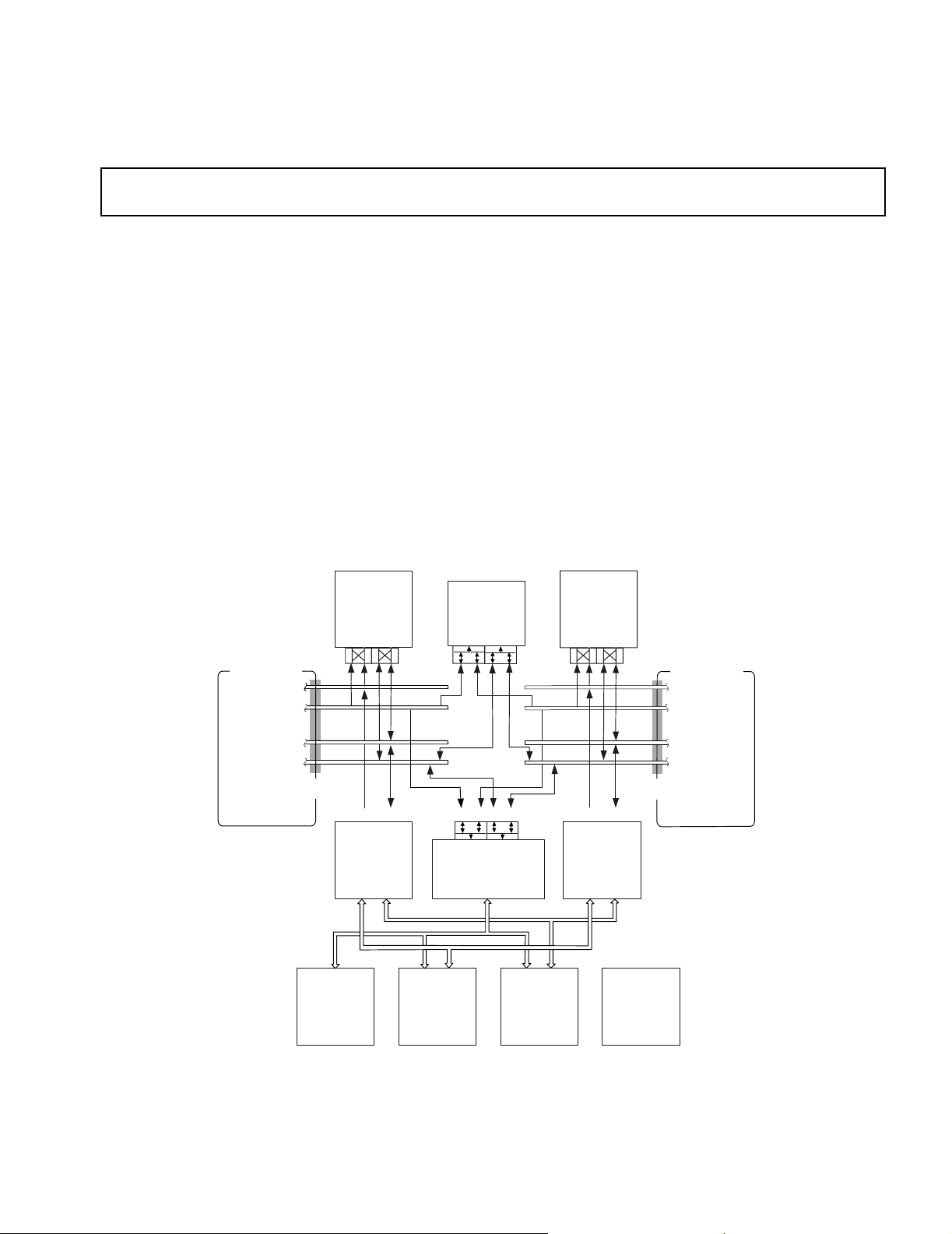

FUNCTIONAL BLOCK DIAGRAM

P0

MEMORY

16K24 PM

64K16 DM

ADSP-219x

DSP CORE

BOOT ROM

ADDR DATA

ADDR DATA

80K Words of On-Chip RAM on P0, Configured as

64K Words On-Chip 16-Bit RAM for Data Memory and

16K Words On-Chip 24-Bit RAM for Program Memory

48K Words of On-Chip RAM on P1, Configured as

32K Words On-Chip 16-Bit RAM for Data Memory and

16K Words On-Chip 24-Bit RAM for Program Memory

4K Words of Additional On-Chip RAM Shared by Both

Cores, Configured as 4K Words On-Chip 16-Bit RAM

Flexible Power Management with Selectable Power-

Down and Idle Modes

Programmable PLL Supports Frequency Multiplication,

Enabling Full Speed Operation from Low Speed

Input Clocks

2.5 V Internal Operation Supports 3.3 V/5.0 V

Compliant I/O

SHARED

MEMORY

4K16 DM

P1

MEMORY

16K24 P M

32K16 DM

BOOT ROM

ADDR DATA

ADSP-219x

DSP CORE

(SEE FIGURE 1

ON PAGE 3)

CORE

INTERFACE

PROCESSOR P0

CONTROLLER

GP I/O PINS

(AND

OPTIONAL

SERIAL

EEPROM)

ADDR DATA

P0 DMA

FIFOS

SERIAL PORT

COMPLIANT

ADDR DATA ADDR DATA

SHARED DSP

I/O MAPPED

REGISTERS

AC'97

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

(SEE FIGURE 1

ON PAGE 3)

CORE

INTERFACE

PROCESSOR P1

P1 DMA

CONTROLLER

FIFOS

HOST PORT

PCI 2. 2

OR

USB 1.1

One Technology Way, P.O.Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel:781/329-4700 www.analog.com

Fax:781/326-8703 © 2002 Analog Devices, Inc. All rights reserved.

JTAG

EMULATION

PORT

Page 2

ADSP-2192M

ADSP-2192M DUAL CORE DSP FEATURES (continued)

Eight Dedicated General-Purpose I/O Pins with Integrated

Interrupt Support

Each DSP Core Has a Programmable 32-Bit Interval Timer

Five DMA Channels Available on Each Core

Boot Methods Include Booting Through PCI Port, USB

Port, or Serial EEPROM

JTAG Test Access Port Supports On-Chip Emulation and

System Debugging

144-Lead LQFP Package

DSP CORE FEATURES

6.25 ns Instruction Cycle Time (Internal), for up to

160 MIPS Sustained Performance

ADSP-218x Family Code Compatible with the Same Easy

to Use Algebraic Syntax

Single-Cycle Instruction Execution

Dual Purpose Program Memory for Both Instruction and

Data Storage

Fully Transparent Instruction Cache Allows Dual Operand

Fetches in Every Instruction Cycle

Unified Memory Space Permits Flexible Address

Generation, Using Two Independent DAG Units

Independent ALU, Multiplier/Accumulator, and Barrel

Shifter Computational Units with Dual 40-Bit

Accumulators

Single-Cycle Context Switch between Two Sets of

Computational and DAG Registers

Parallel Execution of Computation and Memory

Instructions

Pipelined Architecture Supports Efficient Code Execution

at Speeds up to 160 MIPS

Register File Computations with All Nonconditional,

Nonparallel Computational Instructions

Powerful Program Sequencer Provides Zero-Overhead

Looping and Conditional Instruction Execution

Architectural Enhancements for Compiled C/C++ Code

Efficiency

Architecture Enhancements beyond ADSP-218x Family

are Supported with Instruction Set Extensions for

Added Registers, Ports, and Peripherals

TABLE OF CONTENTS

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . 3

DSP Core Architecture . . . . . . . . . . . . . . . . . . . . . . . 3

DSP Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Memory Architecture . . . . . . . . . . . . . . . . . . . . . . . . 4

Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

DMA Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

External Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Internal Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Register Spaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CardBus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using the PCI Interface . . . . . . . . . . . . . . . . . . . . . . . 7

Using the USB Interface . . . . . . . . . . . . . . . . . . . . . 13

General USB Device Definitions . . . . . . . . . . . . . . . 17

Sub-ISA Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PCI Interface to DSP Memory . . . . . . . . . . . . . . . . 22

USB Interface to DSP Memory . . . . . . . . . . . . . . . . 22

AC’97 Codec Interface to DSP Memory . . . . . . . . . 22

Data FIFO Architecture . . . . . . . . . . . . . . . . . . . . . 22

System Reset Description . . . . . . . . . . . . . . . . . . . . 23

Power Management Description . . . . . . . . . . . . . . . 24

Power Regulators . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5 V Regulator Options . . . . . . . . . . . . . . . . . . . . . 24

Low Power Operation . . . . . . . . . . . . . . . . . . . . . . . 25

Clock Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Instruction Set Description . . . . . . . . . . . . . . . . . . . 26

Development Tools . . . . . . . . . . . . . . . . . . . . . . . . . 26

Additional Information . . . . . . . . . . . . . . . . . . . . . . 28

PIN DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . 28

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 30

ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . 31

ESD SENSITIVITY . . . . . . . . . . . . . . . . . . . . . . . . 31

TIMING SPECIFICATIONS . . . . . . . . . . . . . . . . 31

Output Drive Currents . . . . . . . . . . . . . . . . . . . . . . 34

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Test Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Environmental Conditions . . . . . . . . . . . . . . . . . . . 35

144-Lead LQFP Pinout . . . . . . . . . . . . . . . . . . . . . 36

OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . 38

ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . 38

–2– REV. 0

Page 3

ADSP-2192M

GENERAL DESCRIPTION

The ADSP-2192M is a single-chip microcomputer optimized for

digital signal processing (DSP) and other high speed numeric

processing applications, and is ideally suited for PC peripherals.

The ADSP-2192M combines the ADSP-219x family base architecture (three computational units, two data address generators

and a program sequencer) into a chip with two core processors

(see the Functional Block Diagram on Page 1 and Figure 1).

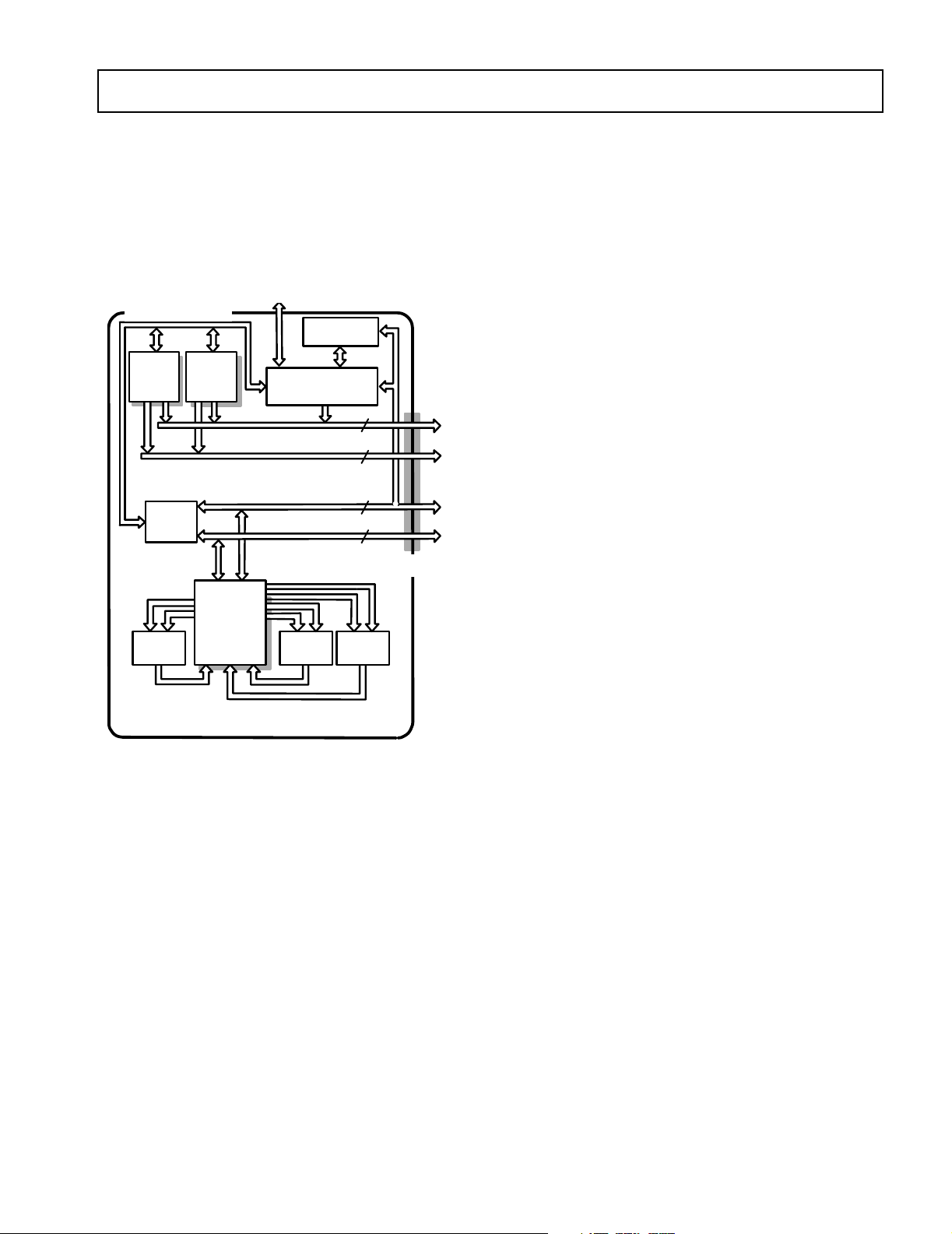

DSP CORE

DAG1

4 4 16

BUS

CONNECT

(PX)

DATA

REGISTER

MULT

FILE

DAG2

4 4 16

INPUT

REGISTERS

RESULT

REGISTERS

16 16-BIT

PM ADDRESS BUS

DM ADDRESS BUS

PM DATA BUS

DM DATA BUS

CACHE

64 24-BIT

PROGRAM

SEQUENCER

BARREL

SHIFTER

ALU

24

24

24

16

CORE

INTERFACE

Figure 1. ADSP-219x DSP Core

The ADSP-2192M includes a PCI-compatible port, a USBcompatible port, an AC’97-compatible port, a DMA controller,

a programmable timer, general-purpose Programmable Flag

pins, extensive interrupt capabilities, and on-chip program and

data memory spaces.

The ADSP-2192M integrates 132K words of on-chip memory

configured as 32K words (24-bit) of program RAM, and 100K

words (16-bit) of data RAM. power-down circuitry is also

provided to reduce power consumption. The ADSP-2192M is

available in a 144-lead LQFP package.

Fabricated in a high speed, low power, CMOS process, the

ADSP-2192M operates with a 6.25 ns instruction cycle time

(320 MIPS) using both cores. All instructions can execute in a

single DSP cycle.

The ADSP-2192M’s flexible architecture and comprehensive

instruction set support multiple operations in parallel. For

example, in one processor cycle, each DSP core within the

ADSP-2192M can:

• Generate an address for the next instruction fetch

• Fetch the next instruction

• Perform one or two data moves

• Update one or two data address pointers

• Perform a computational operation

These operations take place while the processor continues to:

• Receive and/or transmit data through the Host port (PCI

or USB interfaces)

• Receive or transmit data through the AC’97

• Decrement the two timers

DSP Core Architecture

The ADSP-219x architecture is code compatible with the ADSP218x DSP family. Though the architectures are compatible, the

ADSP-219x architecture has many enhancements over the

ADSP-218x architecture. The enhancements to computational

units, data address generators, and program sequencer make the

ADSP-219x more flexible and more compiler friendly.

Indirect addressing options provide addressing flexibility: base

address registers for easier implementation of circular buffering,

pre-modify with no update, post-modify with update, pre- and

post-modify by an immediate 8-bit, twos-complement value.

The ADSP-219x instruction set provides flexible data moves and

multifunction (one or two data moves with a computation)

instructions. Every single-word instruction can be executed in a

single processor cycle. The ADSP-219x assembly language uses

an algebraic syntax for ease of coding and readability. A comprehensive set of development tools supports program development.

The Functional Block Diagram on Page 1 shows the architecture

of the ADSP-219x dual core DSP, while the block diagram of

Figure 1 illustrates the ADSP-219x DSP core. Each core

contains three independent computational units: the multiplier/accumulator (MAC), the ALU, and the shifter. The

computational units process 16-bit data from the register file and

have provisions to support multiprecision computations. The

ALU performs a standard set of arithmetic and logic operations;

division primitives are also supported. The MAC performs

single-cycle multiply, multiply/add, and multiply/subtract operations. The MAC has two 40-bit accumulators that help with

overflow. The shifter performs logical and arithmetic shifts, normalization, denormalization, and derive exponent operations.

The shifter can be used to efficiently implement numeric format

control, including multiword and block floating-point

representations.

Register-usage rules influence placement of input and results

within the computational units. For most operations, the computational units’ data registers act as a data register file,

permitting any input or result register to provide input to any unit

for a computation. For feedback operations, the computational

units let the output (result) of any unit be input to any unit on

–3–REV. 0

Page 4

ADSP-2192M

the next cycle. For conditional or multifunction instructions,

there are restrictions on which data registers may provide inputs

or receive results from each computational unit. For more information, see the ADSP-219x

A powerful program sequencer controls the flow of instruction

execution. The sequencer supports conditional jumps, subroutine calls, and low interrupt overhead. With internal loop

counters and loop stacks, the ADSP-219x core executes looped

code with zero overhead; no explicit jump instructions are

required to maintain loops.

Two data address generators (DAGs) provide addresses for

simultaneous dual operand fetches. Each DAG maintains and

updates four 16-bit address pointers. Whenever the pointer is

used to access data (indirect addressing), it is pre- or postmodified by the value of one of four possible modify registers. A

length value and base address may be associated with each pointer

to implement automatic modulo addressing for circular buffers.

Page registers in the DAGs allow linear or circular addressing

within 64K word boundaries of each of the memory pages, but

these buffers may not cross page boundaries. Secondary registers

duplicate all the primary registers in the DAGs; switching

between primary and secondary registers provides a fast context

switch.

Efficient data transfer in the core is achieved with the use of

internal buses:

• Program Memory Address (PMA) Bus

• Program Memory Data (PMD) Bus

• Data Memory Address (DMA) Bus

• Data Memory Data (DMD) Bus

Program memory can store both instructions and data, permitting the ADSP-219x to fetch two operands in a single cycle, one

from program memory and one from data memory. The DSP’s

dual memory buses also let the ADSP-219x core fetch an operand

from data memory and the next instruction from program

memory in a single cycle.

DSP Peripherals

The Functional Block Diagram on Page 1 shows the DSP’s

on-chip peripherals, which include the Host port (PCI or USB),

AC’97 port, JTAG test and emulation port, flags, and interrupt

controller.

The ADSP-2192M can respond to up to thirteen interrupts at

any given time. A list of these interrupts appears in Table 2.

The AC’97 Codec port on the ADSP-2192M provides a

complete synchronous, full-duplex serial interface. This interface

supports the AC’97 standard.

The ADSP-2192M provides up to eight general-purpose I/O pins

that are programmable as either inputs or outputs. These pins

are dedicated general-purpose Programmable Flag pins.

DSP Instruction Set Reference

.

The programmable interval timer generates periodic interrupts.

A 16-bit count register (TCOUNT) is decremented every

n cycles where n-1 is a scaling value stored in a 16-bit register

(TSCALE). When the value of the count register reaches zero,

an interrupt is generated and the count register is reloaded from

a 16-bit period register (TPERIOD).

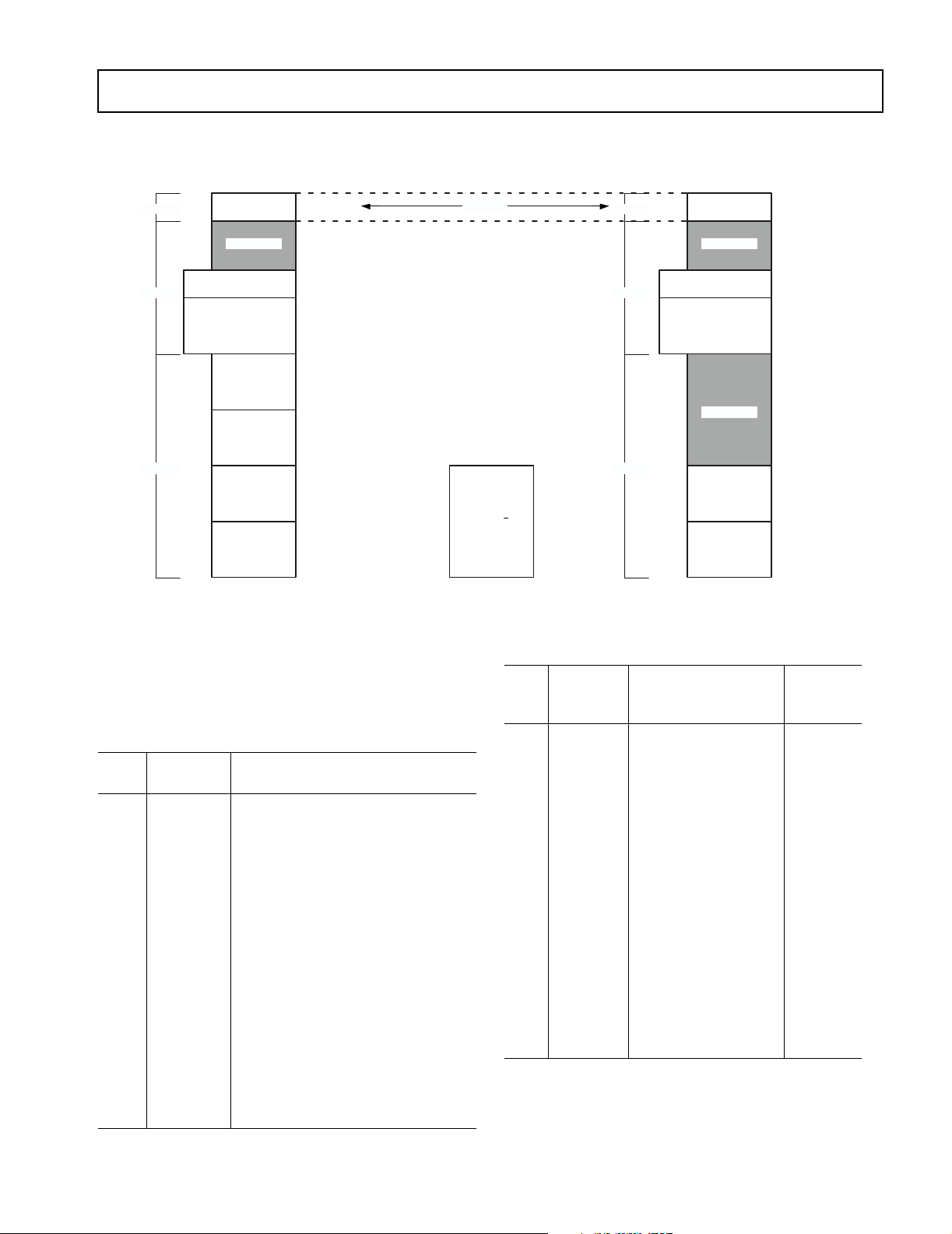

Memory Architecture

The ADSP-2192M provides 132K words of on-chip SRAM

memory. This memory is divided into Program and Data

Memory blocks in each DSP’s memory map. In addition to the

internal memory space, the two cores can address two additional

and separate off-core memory spaces: I/O space and shared

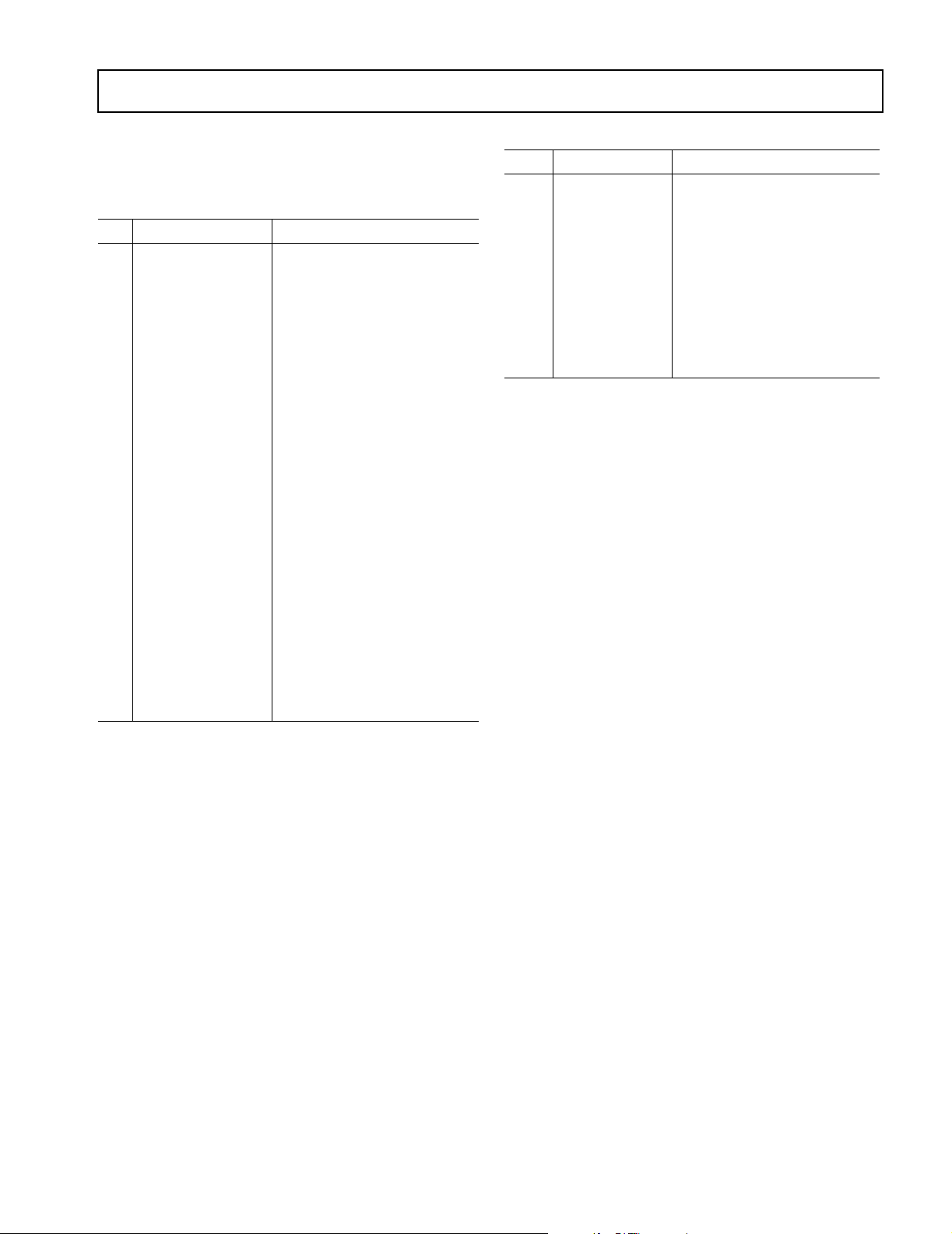

memory space, as shown in Figure 2.

The ADSP-2192M’s two cores can access 80K and 48K locations

that are accessible through two 24-bit address buses, the PMA

and DMA buses.The DSP has three functions that support access

to the full memory map.

• The DAGs generate 24-bit addresses for data fetches from

the entire DSP memory address range. Because DAG

index (address) registers are 16 bits wide and hold the

lower 16 bits of the address, each of the DAGs has its own

8-bit page register (DMPGx) to hold the most significant

eight address bits. Before a DAG generates an address,

the program must set the DAG’s DMPGx register to the

appropriate memory page.

• The Program Sequencer generates the addresses for

instruction fetches. For relative addressing instructions,

the program sequencer bases addresses for relative jumps,

calls, and loops on the 24-bit Program Counter (PC). In

direct addressing instructions (two-word instructions),

the instruction provides an immediate 24-bit address

value. The PC allows linear addressing of the full 24-bit

address range.

• For indirect jumps and calls that use a 16-bit DAG

address register for part of the branch address, the

Program Sequencer relies on an 8-bit Indirect Jump page

(IJPG) register to supply the most significant eight

address bits. Before a cross page jump or call, the program

must set the program sequencer’s IJPG register to the

appropriate memory page.

Each ADSP-219x DSP core has an on-chip ROM that holds boot

routines (See Booting Modes on Page 23.).

Interrupts

The interrupt controller lets the DSP respond to 13 interrupts

with minimum overhead. The controller implements an interrupt

priority scheme as shown in Table 2. Applications can use the

unassigned slots for software and peripheral interrupts. The

DSP’s Interrupt Control (ICNTL) register (shown in Table 3)

provides controls for global interrupt enable, stack interrupt configuration, and interrupt nesting.

–4– REV. 0

Page 5

ADSP-2192M

PAGE 2

PAGE 1

PAGE 0

DSP P0

ME MO RY MA P

SHARED RAM

(1 6 4K )

RESERVED

PROGRAM ROM

24 4K

PROG RAM RAM

(24 16K)

DATA RAM

BL O CK3

(16 16K)

DATA RAM

BL O CK2

(16 16K)

DATA RAM

BL O CK1

(16 16K)

DATA RAM

BL O CK0

(16 16K)

ADDRESS

0 x02 0F FF

0 x02 00 00

0x01 FFFF

0 x01 50 00

0 x01 4F FF

0 x01 40 00

0 x01 3F FF

0 x01 00 00

0x00 FFFF

0 x00 C 000

0 x00 B FFF

0 x00 80 00

0 x00 7F FF

0 x00 40 00

0 x00 3F FF

0 x00 00 00

SAME

SHARED

DSP I/ O

MAPPED

REGISTERS

PAGES 0 255

(16 2 56)

ADDRESS

0xFF FF

0x00 00

PAGE 2

PAGE 1

PAGE 0

DSP P1

MEMORY MAP

SHARED RAM

(1 6 4K )

RESERVED

PROGRAM ROM

24 4K

PROGRAM RAM

(2 4 16K)

RESERVED

DATA RAM

BL O CK1

(1 6 16K)

DATA RAM

BL O CK0

(1 6 16K)

ADDRESS

0 x02 0 FFF

0 x02 0 000

0 x01 F FFF

0 x01 5 000

0 x01 4 FFF

0 x01 4 000

0 x01 3 FFF

0 x01 0 000

0 x00 F FFF

0 x00 8 000

0 x00 7 FFF

0 x00 4 000

0 x00 3 FFF

0 x00 0 000

Figure 2. ADSP-2192M Internal/External Memory, Boot Memory, and I/O Memory Maps

Table 2 shows the interrupt vector and DSP-to-DSP semaphores

at reset of each of the peripheral interrupts. The peripheral interrupt’s position in the IMASK and IRPTL register and its vector

address depend on its priority level, as shown in Table 2.

Table 1. DSP-to-DSP Semaphores Register Table

Flag

Bit Direction Function

0 Output DSP–DSP Semaphore 0

1 Output DSP–DSP Semaphore 1

2 Output DSP–DSP Interrupt

3 Reserved

4 Reserved

5 Reserved

6 Reserved

7 Output Register Bus Lock

8 Input DSP–DSP Semaphore 0

9 Input DSP–DSP Semaphore 1

10 Input DSP–DSP Interrupt

11 Input Reserved

12 Input AC’97 Register–PDC Bus Access

Status

13 Input PDC Interface Busy Status (write

from DSP pending)

14 Input Reserved

15 Input Register Bus Lock Status

Table 2. Vector Table

Vector

Address

Bit Priority Interrupt

Offset

1

0 1 Reset (non-maskable) 0x00

12 Power-Down (non-

0x04

maskable)

2 3 Kernel interrupt

0x08

(single step)

3 4 Stack Status 0x0C

4 5 Mailbox 0x10

56 Timer 0x14

6 7 GPIO 0x18

7 8 PCI Bus Master 0x1C

89 DSP–DSP 0x20

9 10 FIFO0 Transmit 0x24

10 11 FIFO0 Receive 0x28

11 12 FIFO1 Transmit 0x2C

12 13 FIFO1 Receive 0x30

13 14 Reserved 0x34

14 15 Reserved 0x38

15 16 AC’97 Frame 0x3C

1

The interrupt vector address values are represented as offsets from

address 0x01 0000. This address corresponds to the start of Program

Memory in DSP P0 and P1.

–5–REV. 0

Page 6

ADSP-2192M

Interrupt routines can either be nested with higher priority interrupts taking precedence or processed sequentially. Interrupts can

be masked or unmasked with the IMASK register. Individual

interrupt requests are logically ANDed with the bits in IMASK;

the highest priority unmasked interrupt is then selected. The

emulation, power-down, and reset interrupts are nonmaskable

with the IMASK register, but software can use the DIS INT

instruction to mask the power-down interrupt.

Table 3. Interrupt Control (ICNTL) Register Bits

Bit Description

0–3 Reserved

4 Interrupt nesting enable

5 Global interrupt enable

6 Reserved

7 MAC biased rounding enable

8–9 Reserved

10 PC stack interrupt enable

11 Loop stack interrupt enable

12 Low power idle enable

13–15 Reserved

The IRPTL register is used to force and clear interrupts. On-chip

stacks preserve the processor status and are automatically maintained during interrupt handling. To support interrupt, loop, and

subroutine nesting, the PC stack is 33 levels deep, the loop stack

is eight levels deep, and the status stack is 16 levels deep. To

prevent stack overflow, the PC stack can generate a stack level

interrupt if the PC stack falls below three locations full or rises

above 28 locations full.

The following instructions globally enable or disable interrupt

servicing, regardless of the state of IMASK.

ENA INT;

DIS INT;

At reset, interrupt servicing is disabled.

For quick servicing of interrupts, a secondary set of DAG and

computational registers exist. Switching between the primary

and secondary registers lets programs quickly service interrupts,

while preserving the DSP’s state.

DMA Controller

The ADSP-2192M has a DMA controller that supports

automated data transfers with minimal overhead for the DSP

core. Cycle stealing DMA transfers can occur between the

ADSP-2192M’s internal memory and any of its DMA-capable

peripherals. DMA transfers can also be accomplished between

any of the DMA-capable peripherals. DMA-capable peripherals

include the PCI and AC’97 ports. Each individual DMA-capable

peripheral has a dedicated DMA channel. DMA sequences do

not contend for bus access with the DSP core; instead, DMAs

“steal” cycles to access memory. All DMA transfers use the

Program Memory (PMA/PMD) buses shown in the Functional

Block Diagram on Page 1.

External Interfaces

Several different interfaces are supported on the ADSP-2192M.

These include both internal and external interfaces. The three

separate PCI configuration spaces are programmable to set up

the device in various Plug-and-Play configurations.

The ADSP-2192M provides the following types of external interfaces: PCI, USB, Sub-ISA, CardBus, AC’97, and serial

EEPROM. The following sections discuss those interfaces.

PCI 2.2 Host Interface

The ADSP-2192M includes a 33 MHz, 32-bit bus master PCI

interface that is compliant with revision 2.2 of the PCI specification. This interface supports the high data rates.

USB 1.1 Host Interface

The ADSP-2192M USB interface enables the host system to

configure and attach a single device with multiple interfaces and

various endpoint configurations. The advantages of this design

include:

• Programmable descriptors and class-specific command

interpreter.

• An on-chip 8052-compatible MCU allows the user to soft

download different configurations and support standard

or class-specific commands.

• Total of eight user-defined endpoints provided.

Endpoints can be configured as either BULK, ISO, or

INT, and the endpoints can be grouped and assigned to

any interface.

Sub-ISA Interface

In systems that combine the ADSP-2192M chip with other

devices on a single PCI interface, the ADSP-2192M Sub-ISA

mode is used to provide a simpler interface that bypasses the

ADSP-2192M’s PCI interface. In this mode the Combo Master

assumes all responsibility for interfacing the function to the PCI

bus, including provision of Configuration Space registers for the

ADSP-2192M system as a separate PnP function. In Sub-ISA

Mode the PCI Pins are reconfigured for ISA operation.

CardBus Interface

The CardBus standard provides higher levels of performance

than the 16-bit PC Card standard. For example, 32-bit CardBus

cards are able to take advantage of internal bus speeds that can

be as much as four to six times faster than 16-bit PC Cards. This

design provides for a compact, rugged card that can be completely

inserted within its host computer without any external cabling.

Because CardBus performance attains the same high level as the

host platform’s internal (PCI) system bus, it is an excellent way

to add high speed communications to the notebook form factor.

In addition, CardBus PC Cards operate at a power-saving

3.3 volts, extending battery life in most configurations.

This new 32-bit CardBus technology provides up to 132M bytes

per second of bandwidth. This performance makes CardBus an

ideal vehicle to meet the demands of high throughput communications such as ADSL.

–6– REV. 0

Page 7

ADSP-2192M

CardBus PC Cards generate less heat and consume less power.

This is attained by:

• Low voltage operation at 3.3 V

• Software control of clock speed

• Advanced power management mechanism

AC’97 2.1 External Codec Interface

The industry standard AC’97 serial interface (AC-Link) incorporates a 7-pin digital serial interface that links compliant codecs

to the ADSP-2192M. The ACLink implements a bidirectional,

fixed rate, serial PCM digital stream. It handles multiple input

and output audio streams as well as control and status register

accesses using a time division multiplex scheme.

Serial EEPROM Interface

The Serial EEPROM for the ADSP-2192M can overwrite the

following information which is returned during the USB GET

DEVICE DESCRIPTOR command. During the Serial

EEPROM initialization procedure, the DSP is responsible for

writing the USB Descriptor Vendor ID, USB Descriptor Product

ID, USB Descriptor Release Number, and USB Descriptor

Device Attributes registers to change the default settings.

All descriptors can be changed when downloading the RAMbased MCU renumeration code, except for the Manufacturer

and Product, which are supported in the CONFIG DEVICE and

cannot be overwritten or changed by the Serial EEPROM.

• Vendor ID (0x0456)

• Product ID (0x2192)

• Device Release Number (0x0100)

• Device Attributes (0x80FA): SP (1 = self-powered,

0 = bus-powered, default = 0); RW (1 = have remote

wake-up capability, 0 = no remote wake-up capability,

default = 0); C[7:0] (power consumption from bus

expressed in 2 mA units; default = 0xFA 500 mA)

• Manufacturer (ADI)

• Product (ADI Device)

Internal Interfaces

The ADSP-2192M provides three types of internal interfaces:

registers, codec, and DSP memory buses. The following sections

discuss those interfaces.

Register Interface

The register interface allows the PCI interface, USB interface,

and both DSPs to communicate with the I/O Registers. These

registers map into DSP, PCI, and USB I/O spaces.

Register Spaces

Several different register spaces are defined on the ADSP2192M, as described in the following sections.

PCI Configuration Space

These registers control the configuration of the PCI Interface.

Most of these registers are only accessible via the PCI Bus

although a subset is accessible to the DSP for configuration

during the boot.

DSP Core Register Space

Each DSP has an internal register that is accessible with no

latency. These registers are accessible only from within the DSP,

using the REG( ) instruction.

Peripheral Device Control Register Space

This Register Space is accessible by both DSPs, the PCI, SubISA, and USB Buses. Note that certain sections of this space are

exclusive to either the PCI, USB, or Sub-ISA Buses. These

registers control the operation of the peripherals of the ADSP2192M. The DSP accesses these registers using the I/O space

instruction.

USB Register Space

These registers control the operation and configuration of the

USB Interface. Most of these registers are only accessible via the

USB Bus, although a subset is accessible to the DSP.

CardBus Interface

The ADSP-2192M’s PC CardBus interface meets the state and

timing specifications defined for PCMCIA’s PC CardBus

Standard April 1998 Release 6.1. It supports up to three card

functions. Multiple function PC cards require a separate set of

Configuration registers per function. A primary Card Information Structure common to all functions is required. Separate

secondary Card Information Structures, one per function, are

also required. Data for each CIS is loaded by the DSP during

bootstrap loading.

The host PC can read the CIS data at any time. If needed, the

WAIT control can be activated to extend the read operation to

meet bus write access to the CIS data.

Using the PCI Interface

The ADSP-2192M includes a 33 MHz, 32-bit PCI interface to

provide control and data paths between the part and the host

CPU. The PCI interface is compliant with the PCI Local Bus

Specification Revision 2.2. The interface supports bus mastering

as well as bus target interfaces. The PCI Bus Power Management

Interface Specification Revision 1.1 is supported and additional

features as needed by PCI designs are included.

Target/Slave Interface

The ADSP-2192M PCI interface contains three separate functions, each with its own configuration space. Each function

contains four base address registers used to access ADSP-2192M

control registers and DSP memory. Base Address Register

(BAR) 1 is used to point to the control registers. The addresses

specified in these tables are offsets from BAR1 in each of the

functions. PCI memory-type accesses are used to read and write

the registers.

DSP memory accesses use BAR2 or BAR3 of each function.

BAR2 is used to access 24-bit DSP memory; BAR3 accesses

16-bit DSP memory. Maps of the BAR2 and BAR3 registers

appear in Table 8 on Page 11 and Table 9 on Page 12.

The lower half of the allocated space pointed to by each DSP

memory BAR is the DSP memory for DSP core P0. The upper

half is the memory space associated with DSP core P1. PCI

transactions to and from DSP memory use the DMA function

within the DSP core. Thus each word transferred to or from PCI

–7–REV. 0

Page 8

ADSP-2192M

space uses a single DSP clock cycle to perform the internal DSP

data transfer. Byte-wide accesses to DSP memory are not

supported.

I/O type accesses are supported via BAR4. Both the control

registers accessible via BAR1 and the DSP memory accessible

via BAR2 and BAR3 can be accessed with I/O accesses. Indirect

access is used to read and write both the control registers and the

DSP memory. For the control register accesses, an address register points to the word to be accessed while a separate register is

used to transfer the data. Read/write control is part of the address

register. Only 16-bit accesses are possible via the I/O space.

A separate set of registers is used to perform the same function

for DSP memory access. Control for these accesses includes a

24-bit/16-bit select as well as direction control. The data register

for DSP memory accesses is a full 24 bits wide. 16-bit accesses

will be loaded into the lower 16 bits of the register. Table 10 on

Page 14 lists the registers directly accessible from BAR4.

Bus Master Interface

As a bus master, the PCI interface can transfer DMA data

between system memory and the DSP. The control registers for

these transfers are available both to the host and to the DSPs.

Four channels of bus mastering DMA are supported on the

ADSP-2192M.

Two channels are associated with the receive data and two are

associated with the transmit data. The internal DSPs will

typically control initiation of bus master transactions. DMA host

bus master transfers can specify either standard circular buffers

in system memory or perform scatter-gather DMA to host

memory.

Each bus master DMA channel includes four registers to specify

a standard circular buffer in system memory. The Base Address

points to the start of the circular buffer. The Current Address is

a pointer to the current position within that buffer. The Base

Count specifies the size of the buffer in bytes, while the Current

Count keeps track of how many bytes need to be transferred

before the end of the buffer is reached. When the end of the buffer

is reached, the channel can be programmed to loop back to the

beginning and continue the transfers. When this looping occurs,

a Status bit will be set in the DMA Control Register.

The PCI DMA controller can be programmed to perform

scatter-gather DMA, when transferring samples to and from DSP

memory. This mode allows the data to be split up in memory,

and yet be transferable to and from the ADSP-2192M without

processor intervention. In scatter-gather mode, the DMA controller can read the memory address and word count from an

array of buffer descriptors called the Scatter-Gather Descriptor

(SGD) table. This allows the DMA engine to sustain DMA

transfers until all buffers in the SGD table are transferred.

To initiate a scatter-gather transfer between memory and the

ADSP-2192M, the following steps are involved:

1. Software driver prepares a SGD table in system memory.

Each descriptor is eight bytes long and consists of an

address pointer to the starting address and the transfer

count of the memory buffer to be transferred. In any

given SGD table, two consecutive SGDs are offset by

eight bytes and are aligned on a 4-byte boundary. Each

SGD contains:

a.Memory Address (Buffer Start) – 4 bytes

b.Byte Count (Buffer Size) – 3 bytes

c. End of Linked List (EOL) – 1 bit (MSBit)

d.Flag – 1 bit (MSBit – 1)

2. Initialize DMA control registers with transfer-specific

information such as number of total bytes to transfer,

direction of transfer, etc.

3. Software driver initializes the hardware pointer to the

SGD table.

4. Engage scatter-gather DMA by writing the start value to

the PCI channel Control/Status register.

5. The ADSP-2192M will then pull in samples as pointed

to by the descriptors as needed by the DMA engine.

When the EOL is reached, a status bit will be set and the

DMA will end if the data buffer is not to be looped. If

looping is to occur, DMA transfers will continue from

the beginning of the table until the channel is turned off.

6. Bits in the PCI Control/Status register control whether

an interrupt occurs when the EOL is reached or when

the FLAG bit is set.

Scatter-gather DMA uses four registers. In scatter-gather mode

the functions of the registers are mapped as shown in Table 4.

Table 4. Register Mapping in Scatter-Gather Mode

Standard Circular

Buffer Mode

Base Address SGD Table Pointer

Current Address SGD Current Pointer

Base Count SGD Pointer

Current Count Current SGD Count

In either mode of operation, interrupts can be generated based

upon the total number of bytes transferred. Each channel has two

24-bit registers to count the bytes transferred and generate interrupts as appropriate. The Interrupt Base Count register specifies

the number of bytes to transfer prior to generating an interrupt.

The Interrupt Count register specifies the current number left

prior to generating the interrupt. When the Interrupt Count

Scatter-Gather Mode

Function

Address

–8– REV. 0

Page 9

ADSP-2192M

register reaches zero, a PCI interrupt can be generated. Also, the

Interrupt Count register will be reloaded from the Interrupt Base

Count and continue counting down for the next interrupt.

Table 5. PCI Interrupt Register

Bit Name Comments

0 Reserved Reserve

1Rx0 DMA Channel

Interrupt

2Rx1 DMA Channel

Interrupt

3Tx0 DMA Channel

Interrupt

4Tx1 DMA Channel

Interrupt

5 Incoming Mailbox

0 PCI Interrupt

6 Incoming Mailbox

1 PCI Interrupt

7 Outgoing Mailbox

0 PCI Interrupt

8 Outgoing Mailbox

1 PCI Interrupt

9 Reserved

10 Reserved

11 I/O Wake-up I/O Pin Initiated

12 AC’97 Wake-up AC’97 Interface Initiated

13 PCI Master Abort

Interrupt

14 PCI Target Abort

Interrupt

15 Reserved

PCI Interrupts

There are a variety of potential sources of interrupts to the PCI

host besides the bus master DMA interrupts. A single interrupt

INTA

pin,

PCI Interrupt Register consolidates all of the possible interrupt

sources; the bits of this register are shown in Table 5. The register

bits are set by the various sources, and can be cleared by writing

a 1 to the bit(s) to be cleared.

PCI Control Register.

This register must be initialized by the DSP ROM code prior to

PCI enumeration. (It has no effect in ISA or USB mode.) Once

the Configuration Ready bit has been set to 1, the PCI Control

Register becomes read-only, and further access by the DSP to

configuration space is disallowed. The bits of this register are

shown in Table 6.

PCI Configuration Space

The ADSP-2192M PCI Interface provides three separate configuration spaces, one for each possible function. This document

describes the registers in each function, their reset condition, and

how the three functions interact to access and control the ADSP2192M hardware.

is used to signal these interrupts back to the host. The

Receive Channel 0 Bus

Master Transactions

Receive Channel 1 Bus

Master Transactions

Transmit Channel 0 Bus

Master Transactions

Transmit Channel 1 Bus

Master Transactions

PCI to DSP Mailbox 0

Transfer

PCI to DSP Mailbox 1

Transfer

DSP to PCI Mailbox 0

Transfer

DSP to PCI Mailbox 1

Transfer

PCI Interface Master Abort

Detected

PCI Interface Target Abort

Detected

Table 6. PCI Control Register

Bit Name Comments

1–0 PCI Functions

Configured

2 Configuration

Ready

15–3 Reserved

Similarities Between the Three PCI Functions

Each function contains a complete set of registers in the predefined header region as defined in the PCI Local Bus

Specification Revision 2.2. In addition, each function contains

the optional registers to support PCI Bus Power Management.

Generally, registers that are unimplemented or read-only in one

function are similarly defined in the other functions. Each

function contains four base address registers that are used to

access ADSP-2192M control registers and DSP memory.

Base address register (BAR) 1 is used to access the ADSP2192M control registers. Accesses to the control registers via

BAR1 uses PCI memory accesses. BAR1 requests a memory

allocation of 1024 bytes. Access to DSP memory occurs via

BAR2 and BAR3. BAR2 is used to access 24-bit DSP memory

(for DSP program downloading) while BAR3 is used to access

16-bit DSP memory. BAR4 provides I/O space access to both the

control registers and the DSP memory.

Table 7 shows the configuration space headers for the three

spaces. While these are the default uses for each of the configurations, they can be redefined to support any possible function

by writing to the class code register of that function during boot.

Additionally, during boot time, the DSP can disable one or more

of the functions. If only two functions are enabled, they will be

functions 0 and 1. If only one function is enabled, it will be

function 0.

Interactions Between the Three PCI Configurations

Because the configurations must access and control a single set

of resources, potential conflicts can occur between the control

specified by the configuration.

Target accesses to registers and DSP memory can go through any

function. As long as the Memory Space access enable bit is set in

that function, then PCI memory accesses whose addresses match

the locations programmed into a function, BARs 1–3 will be able

to read or write any visible register or memory location within the

ADSP-2192M. Similarly, if I/O space access enable is set, then

PCI I/O accesses can be performed via BAR4.

Within the Power Management section of the configuration

blocks, there are a few interactions. The part will stay in the

highest power state between the three configurations.

00 = One PCI function

enabled, 01 = Two functions,

10 = Three functions

When 0, disables PCI accesses

to the ADSP-2192M (terminated with Retry). Must be set

to 1 by DSP ROM code after

initializing configuration

space. Once 1, cannot be

written to 0.

–9–REV. 0

Page 10

ADSP-2192M

Table 7. PCI Configuration Space 0, 1, and 2

Address Name Reset Comments

0x01–0x00 Vendor ID 0x11D4 Writable from the DSP during initialization

0x03–0x02 Config 0 Device ID 0x2192 Writable from the DSP during initialization

Config 1 Device ID 0x219A Writable from the DSP during initialization

Config 2 Device ID 0x219E Writable from the DSP during initialization

0x05–0x04 Command Register 0x0 Bus Master, Memory Space Capable, I/O Space

Capable

0x07–0x06 Status Register 0x0 Bits enabled: Capabilities List, Fast B2B,

Medium Decode

0x08 Revision ID 0x0 Writable from the DSP during initialization

0x0B–0x09 Class Code 0x48000 Writable from the DSP during initialization

0x0C Cache Line Size 0x0 Read Only

0x0D Latency Timer 0x0

0x0E Header Type 0x80 Multifunction bit set

0x0F BIST 0x0 Unimplemented

0x13–0x10 Base Address 1 0x08 Register Access for all ADSP-2192M Registers,

Prefetchable Memory

0x17–0x14 Base Address2 0x08 24-bit DSP Memory Access

0x1B–0x18 Base Address3 0x08 16-bit DSP Memory Access

0x1F–0x1C Base Address4 0x01 I/O access for control registers and DSP memory

0x23–0x20 Base Address5 0x0 Unimplemented

0x27–0x24 Base Address6 0x0 Unimplemented

0x2B–0x28 Config 0 CardBus CIS Pointer 0x1FF03 CIS RAM Pointer - Function 0 (Read Only)

Config 1 CardBus CIS Pointer 0x1FE03 CIS RAM Pointer - Function 1 (Read Only)

Config 2 CardBus CIS Pointer 0x1FD03 CIS RAM Pointer - Function 2 (Read Only)

0x2D–0x2C Subsystem Vendor ID 0x11D4 Writable from the DSP during initialization

0x2F–0x2E Config 0 Subsystem Device ID 0x2192 Writable from the DSP during initialization

Config 1 Subsystem Device ID 0x219A Writable from the DSP during initialization

Config 2 Subsystem Device ID 0x219E Writable from the DSP during initialization

0x33–0x30 Expansion ROM Base Address 0x0 Unimplemented

0x34 Capabilities Pointer 0x40 Read Only

0x3C Interrupt Line 0x0

0x3D Interrupt Pin 0x1 Uses INTA Pin

0x3E Min_Gnt 0x1 Read Only

0x3F Max_Lat 0x4 Read Only

0x40 Capability ID 0x1 Power Management Capability Identifier

0x41 Next_Cap_Ptr 0x0 Read Only

0x43–0x42 Power Management Capabilities 0x6C22 Writable from the DSP during initialization

0x45–0x44 Power Management Control/Status 0x0 Bits 15 and 8 initialized only on Power-up

0x46 Power Management Bridge 0x0 Unimplemented

0x47 Power Management Data 0x0 Unimplemented

PCI Memory Map

The ADSP-2192M On-Chip Memory is mapped to the PCI

Address Space. Because some ADSP-2192M Memory Blocks

are 24 bits wide (Program Memory) while others are 16 bits

(Data Memory), two different footprints are available in PCI

Address Space. These footprints are available to each PCI

function by accessing different PCI Base Address Registers

(BAR). BAR2 supports 24-bit “Unpacked” Memory Access.

BAR3 supports 16-bit “Packed” Memory Access.

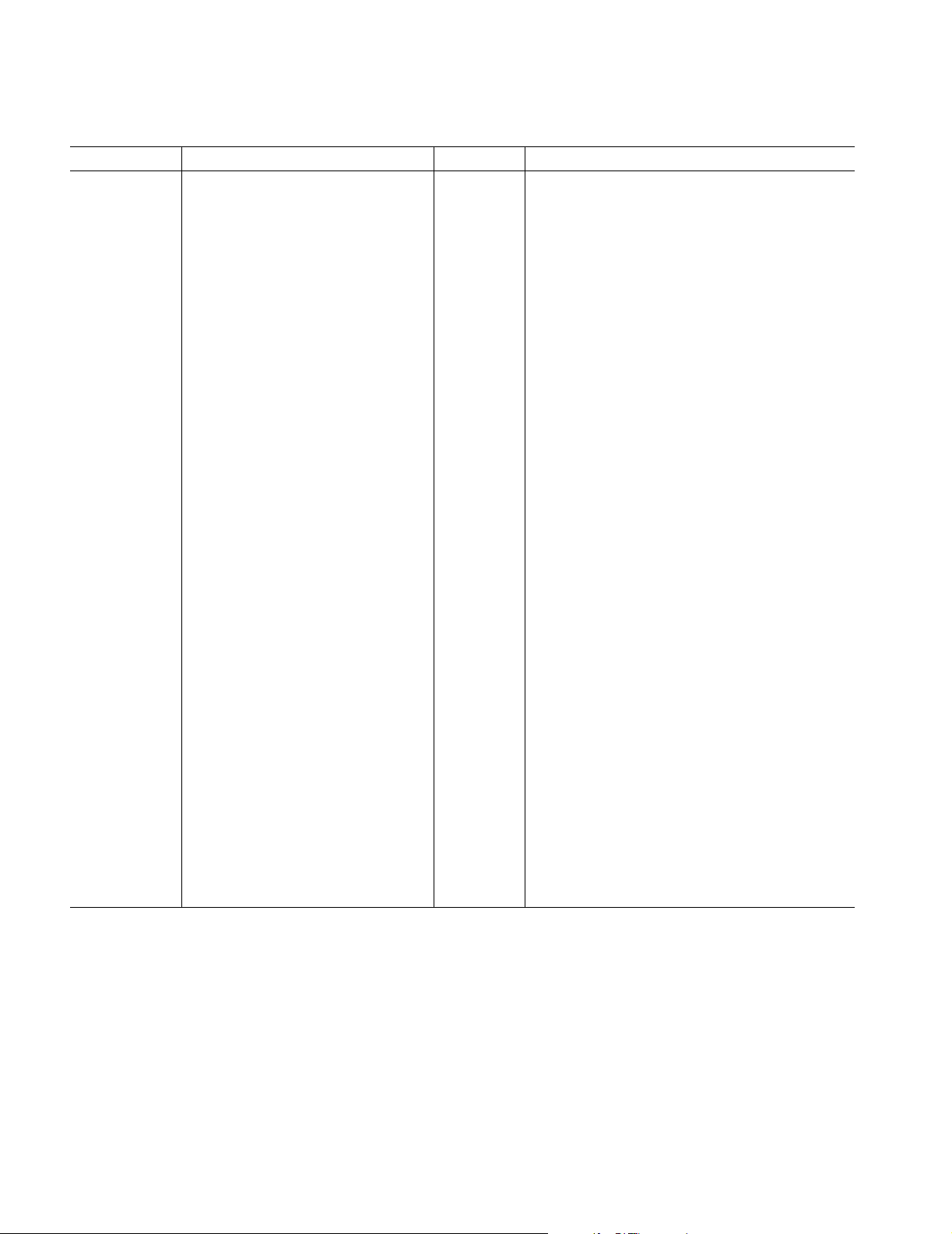

In 24-bit (BAR2) Mode, each 32 bits (four Consecutive PCI

Byte Address Locations, which make up one PCI Data word)

correspond to a single ADSP-2192M Memory Location. BAR2

Mode is typically used for Program Memory Access. Byte3 is

always unused. Bytes[2:0] are used for 24-bit Memory Locations.

As shown in Figure 3, Bytes[2:1] are used for 16-bit Memory

Locations.

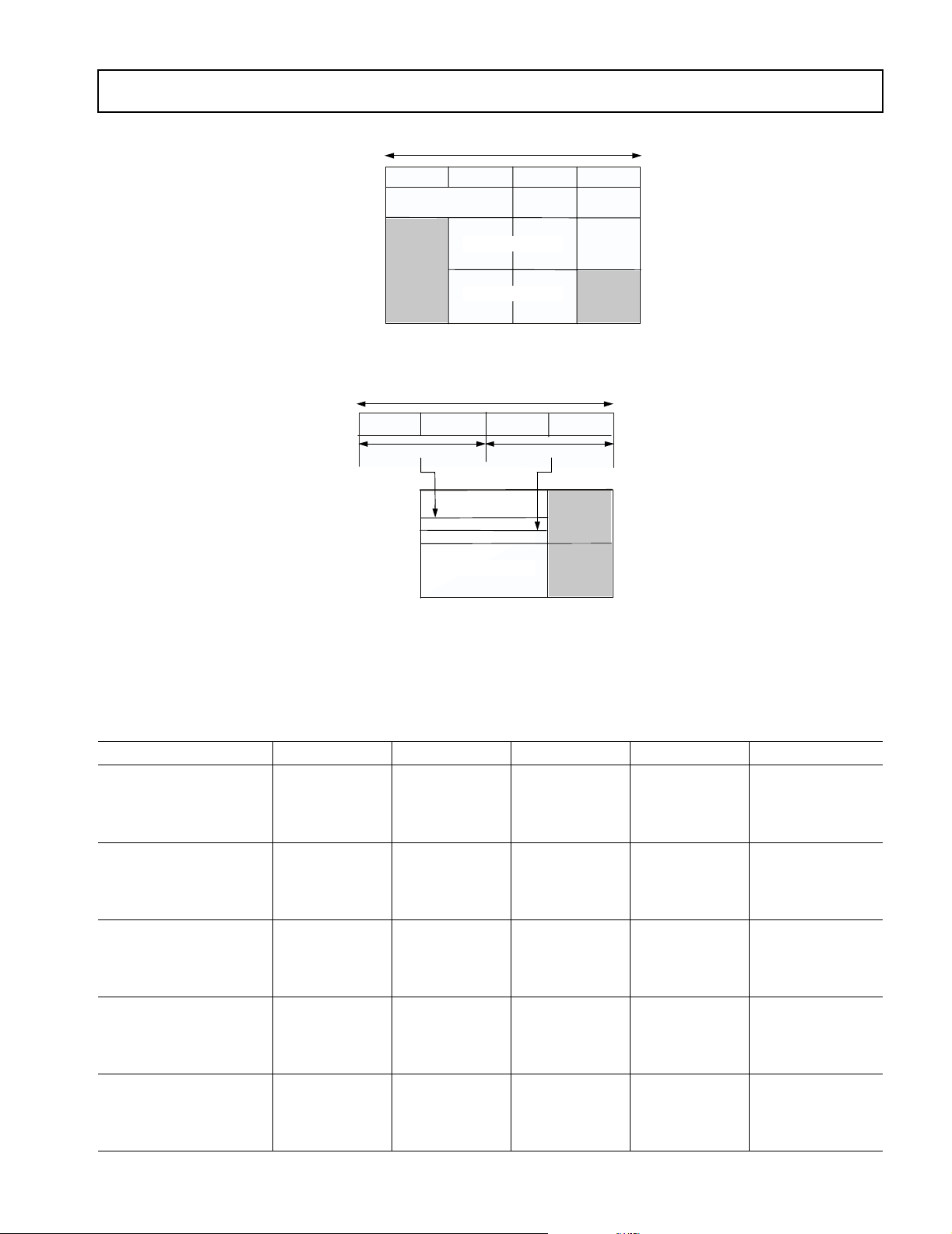

In 16-bit (BAR3) Mode (Figure 4), each 32-bit (four Consecutive PCI Byte Address Locations) PCI Data Word corresponds

to two ADSP-2192M Memory Locations. Bytes[3:2] contain

one 16-bit Data Word, Bytes[1:0] contain a second 16-bit Data

Word. BAR3 Mode is typically used for Data Memory Access.

Only the 16 MSBs of a Data Word are accessed in 24-bit Blocks;

the 8 LSBs are ignored.

–10– REV. 0

Page 11

PCI D WORD

ADSP-2192M

BYTE3 IS

ALWAYS

UNUSED

BYTE0 IS UNUSED

BY 16-BIT MEMORY

LOCATIONS

ALLOWED BYTE

ENABLES:

CBE = 1100

CBE = 0011

PCI BYTE ADDRESS

0x0 0000

0x0 FFFC 0x3FFF

0x1 0000

0x1 FFFC

BYTE3 BYTE0BYTE1BYTE2

16K 24-BIT BLOCK

UNUSED

16K 16-BIT BLOCK

DSP WORD ADDRESS

0x0000

0x4000

UNUSED

0x7FFF

Figure 3. PCI Addressing for 24-Bit and 16-Bit Memory Blocks in 24-Bit Access (BAR2) Mode

PCI DWORD

BYTE3 BYT E0BYTE1BYTE2

PCI BYTE ADDRESS

ALL BYTES ARE USED.

ALLOWED BYTE

ENABLES:

CBE = 1100

CBE = 0011

CBE = 0000

DATAWORDNDATA WORD N + 1

0x0 0000

0x0 7FFE 0x3FFF

0x0 8000

0x0 FFFE

DATA WORD N

DATA WORD N + 1

16K 24-BIT BLOCK

16K 16-BIT BLOCK

UNUSED

UNUSED

DSP WORD ADDRESS

0x0000

0x4000

0x7FFF

Figure 4. PCI Addressing for 24-Bit and 16-Bit Memory Blocks in 16-Bit Access (BAR3) Mode

24-Bit PCI DSP Memory Map (BAR2)

The complete PCI address footprint for the ADSP-2192M DSP

Memory Spaces in 24-bit (BAR2) Mode is shown in Table 8.

Table 8. 24-Bit PCI DSP Memory Map (BAR2 Mode)1

Block Byte3 Byte2 Byte1 Byte0 Offset

DSP P0 Data RAM

Block 0

UNUSED D[15:8] D[7:0] UNUSED 0x0000 0000

UNUSED D[15:8] D[7:0] UNUSED 0x0000 0004

. . . . . . . . . . . . . . .

UNUSED D[15:8] D[7:0] UNUSED 0x0000 FFFC

DSP P0 Data RAM

Block 1

UNUSED D[15:8] D[7:0] UNUSED 0x0001 0000

UNUSED D[15:8] D[7:0] UNUSED 0x0001 0004

. . . . . . . . . . . . . . .

UNUSED D[15:8] D[7:0] UNUSED 0x0001 FFFC

DSP P0 Data RAM

Block 2

UNUSED D[15:8] D[7:0] UNUSED 0x0002 0000

UNUSED D[15:8] D[7:0] UNUSED 0x0002 0004

. . . . . . . . . . . . . . .

UNUSED D[15:8] D[7:0] UNUSED 0x0002 FFFC

DSP P0 Data RAM

Block 3

UNUSED D[15:8] D[7:0] UNUSED 0x0003 0000

UNUSED D[15:8] D[7:0] UNUSED 0x0003 0004

. . . . . . . . . . . . . . .

UNUSED D[15:8] D[7:0] UNUSED 0x0003 FFFC

DSP P0 Program RAM

Block

UNUSED D[23:16] D[15:8] D[7:0] 0x0004 0000

UNUSED D[23:16] D[15:8] D[7:0] 0x0004 0004

. . . . . . . . . . . . . . .

UNUSED D[23:16] D[15:8] D[7:0] 0x0004 FFFC

–11–REV. 0

Page 12

ADSP-2192M

Table 8. 24-Bit PCI DSP Memory Map (BAR2 Mode)1 (continued)

Block Byte3 Byte2 Byte1 Byte0 Offset

DSP P0 Program ROM

Block

Reserved Space RESERVED RESERVED RESERVED RESERVED 0x0005 4000

DSP P1 Data RAM

Block 0

DSP P1 Data RAM

Block 1

Reserved Space UNUSED D[15:8] D[7:0]

DSP P1 Program RAM

Block

DSP P1 Program ROM

Block

Reserved Space RESERVED RESERVED RESERVED RESERVED 0x000D 4000

1

The “. . .” entries in this table indicate the continuation of the pattern shown in the first rows of each section.

UNUSED D[23:16] D[15:8] D[7:0] 0x0005 0000

UNUSED D[23:16] D[15:8] D[7:0] 0x0005 0004

. . . . . . . . . . . . . . .

UNUSED D[23:16] D[15:8] D[7:0] 0x0005 3FFC

. . . . . . . . . . . . . . .

RESERVED RESERVED RESERVED RESERVED 0x0007 FFFC

UNUSED D[15:8] D[7:0] UNUSED 0x0008 0000

UNUSED D[15:8] D[7:0] UNUSED 0x0008 0004

. . . . . . . . . . . . . . .

UNUSED D[15:8] D[7:0] UNUSED 0x0008 FFFC

UNUSED D[15:8] D[7:0] UNUSED 0x0009 0000

UNUSED D[15:8] D[7:0] UNUSED 0x0009 0004

. . . . . . . . . . . . . . .

UNUSED D[15:8] D[7:0] UNUSED 0x0009 FFFC

UNUSED 0x000A 0000

UNUSED D[15:8] D[7:0] UNUSED 0x000A 0004

. . . . . . . . . . . . . . .

UNUSED D[15:8] D[7:0] UNUSED 0x000B FFFC

UNUSED D[23:16] D[15:8] D[7:0] 0x000C 0000

UNUSED D[23:16] D[15:8] D[7:0] 0x000C 0004

. . . . . . . . . . . . . . .

UNUSED D[23:16] D[15:8] D[7:0] 0x000C FFFC

UNUSED D[23:16] D[15:8] D[7:0] 0x000D 0000

UNUSED D[23:16] D[15:8] D[7:0] 0x000D 0004

. . . . . . . . . . . . . . .

UNUSED D[23:16] D[15:8] D[7:0] 0x000D 3FFC

. . . . . . . . . . . . . . .

RESERVED RESERVED RESERVED RESERVED 0x000F FFFC

16-Bit PCI DSP Memory Map (BAR3)

The complete PCI address footprint for the ADSP-2192M DSP

Memory Spaces in 16-bit (BAR3) Mode is shown in Table 9.

Table 9. 16-Bit PCI DSP Memory Map (BAR3 Mode)1

Block Byte3 Byte2 Byte1 Byte0 Offset

DSP P0 Data RAM

Block 0

DSP P0 Data RAM

Block 1

DSP P0 Data RAM

Block 2

D[15:8] D[7:0] D[15:8] D[7:0] 0x0000 0000

D[15:8] D[7:0] D[15:8] D[7:0] 0x0000 0004

. . . . . . . . . . . . . . .

D[15:8] D[7:0] D[15:8] D[7:0] 0x0000 7FFC

D[15:8] D[7:0] D[15:8] D[7:0] 0x0000 8000

D[15:8] D[7:0] D[15:8] D[7:0] 0x0000 8004

. . . . . . . . . . . . . . .

D[15:8] D[7:0] D[15:8] D[7:0] 0x0000 FFFC

D[15:8] D[7:0] D[15:8] D[7:0] 0x0001 0000

D[15:8] D[7:0] D[15:8] D[7:0] 0x0001 0004

. . . . . . . . . . . . . . .

D[15:8] D[7:0] D[15:8] D[7:0] 0x0001 7FFC

–12– REV. 0

Page 13

ADSP-2192M

Table 9. 16-Bit PCI DSP Memory Map (BAR3 Mode)1 (continued)

Block Byte3 Byte2 Byte1 Byte0 Offset

DSP P0 Data RAM

Block 3

DSP P0 Program RAM

Block

DSP P0 Program ROM

Block

Reserved Space RESERVED RESERVED RESERVED RESERVED 0x0002 A000

DSP P1 Data RAM

Block 0

DSP P1 Data RAM

Block 1

Reserved Space RESERVED RESERVED RESERVED RESERVED 0x0005 0000

DSP P1 Program RAM

Block

DSP P1 Program ROM

Block

Reserved Space RESERVED RESERVED RESERVED RESERVED 0x0006 A000

1

The “. . .” entries in this table indicate the continuation of the pattern shown in the first rows of each section.

D[15:8] D[7:0] D[15:8] D[7:0] 0x0001 8000

D[15:8] D[7:0] D[15:8] D[7:0] 0x0001 8004

. . . . . . . . . . . . . . .

D[15:8] D[7:0] D[15:8] D[7:0] 0x0001 FFFC

D[23:16] D[15:8] D[23:16] D[15:8] 0x0002 0000

D[23:16] D[15:8] D[23:16] D[15:8] 0x0002 0004

. . . . . . . . . . . . . . .

D[23:16] D[15:8] D[23:16] D[15:8] 0x0002 7FFC

D[23:16] D[15:8] D[23:16] D[15:8] 0x0002 8000

D[23:16] D[15:8] D[23:16] D[15:8] 0x0002 8004

. . . . . . . . . . . . . . .

D[23:16] D[15:8] D[23:16] D[15:8] 0x0002 9FFC

. . . . . . . . . . . . . . .

RESERVED RESERVED RESERVED RESERVED 0x0003 FFFC

D[15:8] D[7:0] D[15:8] D[7:0] 0x0004 0000

D[15:8] D[7:0] D[15:8] D[7:0] 0x0004 0004

. . . . . . . . . . . . . . .

D[15:8] D[7:0] D[15:8] D[7:0] 0x0004 7FFC

D[15:8] D[7:0] D[15:8] D[7:0] 0x0004 8000

D[15:8] D[7:0] D[15:8] D[7:0] 0x0004 8004

. . . . . . . . . . . . . . .

D[15:8] D[7:0] D[15:8] D[7:0] 0x0004 FFFC

. . . . . . . . . . . . . . .

RESERVED RESERVED RESERVED RESERVED 0x0005 FFFC

D[23:16] D[15:8] D[23:16] D[15:8] 0x0006 0000

D[23:16] D[15:8] D[23:16] D[15:8] 0x0006 0004

. . . . . . . . . . . . . . .

D[23:16] D[15:8] D[23:16] D[15:8] 0x0006 7FFC

D[23:16] D[15:8] D[23:16] D[15:8] 0x0006 8000

D[23:16] D[15:8] D[23:16] D[15:8] 0x0006 8004

. . . . . . . . . . . . . . .

D[23:16] D[15:8] D[23:16] D[15:8] 0x0006 9FFC

. . . . . . . . . . . . . . .

RESERVED RESERVED RESERVED RESERVED 0x0007 FFFC

16-Bit PCI DSP I/O Memory Map (BAR4)

PCI Base Address Register (BAR4) allows indirect access to the

ADSP-2192M Control Registers and DSP Memory. The DSP

Memory Indirect Access Registers accessible from BAR4 are

shown in Table 10.

DSP P0 Memory Indirect Address Space occupies PCI BAR4

Space 0x000000 through 0x01FFFF

DSP P1 Memory Indirect Address Space occupies PCI BAR4

Space 0x020000 through 0x03FFFF

All Indirect DSP Memory Accesses are 24-bit or 16-bit Word

Accesses.

Using the USB Interface

The ADSP-2192M USB design enables the ADSP-2192M to be

configured and attached to a single device with multiple interfaces and various endpoint configurations, as follows:

1. Programmable descriptors and a class-specific command interpreter are accessible through the USB 8052

registers. An 8052 compatible MCU is supported

on-board, to enable soft downloading of different configurations, and support of standard or class-specific

commands.

2. A total of eight user-defined endpoints are provided.

Endpoints can be configured as BULK, ISO, or INT,

and can be grouped.

–13–REV. 0

Page 14

ADSP-2192M

Table 10. 16-Bit PCI DSP I/O Space Indirect Access

Registers Map (BAR4 Mode)

Offset Name Reset Comments

0x03–0x00 Control

Register

Address

0x07–0x04 Control

Register

Data

0x0B–0x08 DSP

Memory

Address

0x0F–0x0C DSP

Memory

Data

USB DSP Register Definitions

For each endpoint, four registers are defined to provide a memor y

buffer in the DSP. These registers are defined for each endpoint

shared by all defined interfaces, for a total of 4

These registers are read/write by the DSP only. They are

described in Table 11.

Table 11. USB DSP Register Definitions

Page Address Name Comment

0x0C 0x0–0x3 DSP Memory Buffer Base

0x0C 0x4–0x5 DSP Memory Buffer Size EP4

0x0C 0x6–0x7 DSP Memory Buffer RD

0x0C 0x8–0x9 DSP Memory Buffer WR

0x0C 0x10–0x13 DSP Memory Buffer Base

0x0C 0x14–0x15 DSP Memory Buffer Size EP5

0x0C 0x16–0x17 DSP Memory Buffer RD

0x0C 0x18–0x19 DSP Memory Buffer WR

0x0C 0x20–0x23 DSP Memory Buffer Base

0x0C 0x24–0x25 DSP Memory Buffer Size EP6

0x0C 0x26–0x27 DSP Memory Buffer RD

0x0C 0x28–0x29 DSP Memory Buffer WR

0x0C 0x30–0x33 DSP Memory Buffer Base

0x0C 0x34–0x35 DSP Memory Buffer Size EP7

0x0C 0x36–0x37 DSP Memory Buffer RD

0x0C 0x38–0x39 DSP Memory Buffer WR

0x0C 0x40–0x43 DSP Memory Buffer Base

0x0C 0x44–0x45 DSP Memory Buffer Size EP8

0x0000 Address and direction

control for register

accesses

0x0000 Data for register

accesses

0x000000 Address and Direction

control for Indirect

DSP memory accesses

0x000000 Data for DSP memory

accesses

8 = 32 registers.

EP4

Addr

EP4

Offset

EP4

Offset

EP5

Addr

EP5

Offset

EP5

Offset

EP6

Addr

EP6

Offset

EP6

Offset

EP7

Addr

EP7

Offset

EP7

Offset

EP8

Addr

Table 11. USB DSP Register Definitions (continued)

Page Address Name Comment

0x0C 0x46–0x47 DSP Memory Buffer RD

Offset

0x0C 0x48–0x49 DSP Memory Buffer WR

Offset

0x0C 0x50–0x53 DSP Memory Buffer Base

Addr

0x0C 0x54–0x55 DSP Memory Buffer Size EP9

0x0C 0x56–0x57 DSP Memory Buffer RD

Offset

0x0C 0x58–0x59 DSP Memory Buffer WR

Offset

0x0C 0x60–0x63 DSP Memory Buffer Base

Addr

0x0C 0x64–0x65 DSP Memory Buffer Size EP10

0x0C 0x66–0x67 DSP Memory Buffer RD

Offset

0x0C 0x68–0x69 DSP Memory Buffer WR

Offset

0x0C 0x70–0x73 DSP Memory Buffer Base

Addr

0x0C 0x74–0x75 DSP Memory Buffer Size EP11

0x0C 0x76–0x77 DSP Memory Buffer RD

Offset

0x0C 0x78–0x79 DSP Memory Buffer WR

Offset

0x0C 0x80–0x81 USB Descriptor Vendor ID

0x0C 0x84–0x85 USB Descriptor Product

ID

0x0C 0x86–0x87 USB Descriptor Release

Number

0x0C 0x88–0x89 USB Descriptor Device

Attributes

USB DSP Memory Buffer Base Addr Register

Points to the base address for the DSP memory buffer assigned

to this endpoint.

BA[17:0] = Memory Buffer Base Address

USB DSP Memory Buffer Size Register

Indicates the size of the DSP memory buffer assigned to this

endpoint.

SZ[15:0] = Memory Buffer Size

USB DSP Memory Buffer RD Pointer Offset Register

The offset from the base address for the read pointer of the

memory buffer assigned to this endpoint.

RD[15:0] = Memory Buffer RD Offset

USB DSP Memory Buffer WR Pointer Offset Register

The offset from the base address for the write pointer of the

memory buffer assigned to this endpoint.

WR[15:0] = Memory Buffer WR Offset

EP8

EP8

EP9

EP9

EP9

EP10

EP10

EP10

EP11

EP11

EP11

–14– REV. 0

Page 15

ADSP-2192M

USB Descriptor Vendor ID

The Vendor ID returned in the GET DEVICE DESCRIPTOR

command is contained in this register. The DSP can change the

Vendor ID by writing to this register during the Serial EEPROM

initialization. The default Vendor ID is 0x0456, which corresponds to Analog Devices, Inc.

V[15:0] = Vendor ID (default = 0x0456)

USB Descriptor Product ID

The Product ID returned in the GET DEVICE DESCRIPTOR

command is contained in this register. The DSP can change the

Product ID by writing to this register during the Serial EEPROM

initialization. The default Product ID is 0x2192.

P[15:0] = Product ID (default = 0x2192)

USB Descriptor Release Number

The Release Number returned in the GET DEVICE DESCRIPTOR command is contained in this register. The DSP can change

the Release Number by writing to this register during the Serial

EEPROM initialization. The default Release Number is 0x0100,

which corresponds to Version 01.00.

R[15:0] = Release Number (default = 0x0100)

USB Descriptor Device Attributes

The device-specific attributes returned in the GET DEVICE

DESCRIPTOR command are contained in this register. The

DSP can change the attributes by writing to this register during

the Serial EEPROM initialization. The default attributes are

0x80FA, which correspond to bus-powered, no remote wake-up,

and max power = 500 mA.

• SP: 1 = self-powered, 0 = bus-powered (default = 0)

• RW: 1 = have remote wake-up capability, 0 = no remote

wake-up capability (default = 0)

• C[7:0] = power consumption from bus, expressed in

2 mA units (default = xFA 500 mA)

USB DSP MCU Register Definitions

MCU registers, described in Table 12, are defined in four

memory spaces that are grouped by the following address ranges:

• 0x0XXX—This address range defines general-purpose

USB status and control registers

• 0x1XXX—This address range defines registers that are

specific to endpoint setup and control

• 0x2XXX—This address range defines the registers used

for REGIO accesses to the DSP register space

• 0x3XXX—This address range defines the MCU program

memory write address space

Table 12. USB MCU Register Definitions

Address Name Comments

0x0000–0x0007 USB SETUP Token Cmd Eight Bytes Total

0x0008–0x000F USB SETUP Token Data Eight Bytes Total

0x0010–0x0011 USB SETUP Counter 16-bit Counter

0x0012–0x0013 USB Control Miscellaneous control including re-attach

0x0014–0x0015 USB Address/Endpoint Address of device/active endpoint

0x0016–0x0017 USB Frame Number Current frame number

0x0030–0x0031 USB Serial EEPROM Mailbox 1 Defined by Analog Devices

0x0032–0x0033 USB Serial EEPROM Mailbox 2 Defined by Analog Devices

0x0034–0x0035 USB Serial EEPROM Mailbox 3 Defined by Analog Devices

0x1000–0x1001 USB EP4 Description Configures endpoint

0x1002–0x1003 USB EP4 NAK Counter

0x1004–0x1005 USB EP5 Description Configures endpoint

0x1006–0x1007 USB EP5 NAK Counter

0x1008–0x1009 USB EP6 Description Configures endpoint

0x100A–0x100B USB EP6 NAK Counter

0x100C–0x100D USB EP7 Description Configures endpoint

0x100E–0x100F USB EP7 NAK Counter

0x1010–0x1011 USB EP8 Description Configures endpoint

0x1012–0x1013 USB EP8 NAK Counter

0x1014–0x1015 USB EP8 Description Configures endpoint

0x1016–0x1017 USB EP9 NAK Counter

0x1018–0x1019 USB EP10 Description Configures endpoint

0x101A–0x101B USB EP10 NAK Counter

0x101C–0x101D USB EP11 Description Configures endpoint

0x101E–0x101F USB EP11 NAK Counter

0x1020–0x1021 USB EP STALL Policy

0x1040–0x1043 USB EP1 Code Download Base Address Starting address for code download on endpoint 1

–15–REV. 0

Page 16

ADSP-2192M

Table 12. USB MCU Register Definitions (continued)

Address Name Comments

0x1044–0x1047 USB EP2 Code Download Base Address Starting address for code download on endpoint 2

0x1048–0x104B USB EP3 Code Download Base Address Starting address for code download on endpoint 3

0x1060–0x1063 USB EP1 Code Current Write Pointer Offset Current write pointer offset for code download on

endpoint 1

0x1064–0x1067 USB EP2 Code Current Write Pointer Offset Current write pointer offset for code download on

endpoint 2

0x1068–0x106B USB EP3 Code Current Write Pointer Offset Current write pointer offset for code download on

endpoint 3

0x2000–0x2001 USB Register I/O Address

0x2002–0x2003 USB Register I/O Data

0x3000–0x3FFF USB MCU Program Memory

USB Endpoint Description Register

The endpoint description register provides the USB core with

information about the endpoint type, direction, and max packet

size. This register is read/write by the MCU only. This register is

defined for endpoints 4–11.

• PS[9:0] MAX Packet Size for endpoint

• LT[1:0] Last transaction indicator bits: 00 = Clear,

01 = ACK, 10 = NAK, or 11 = ERR

• TY[1:0] Endpoint type bits: 00 = DISABLED, 01 = ISO,

10 = Bulk, or 11 = Interrupt

• DR Endpoint direction bit: 1 = IN or 0 = OUT

• TB Toggle bit for endpoint. Reflects the current state of

the DATA toggle bit.

USB Endpoint NAK Counter Register

This register records the number of sequential NAKs that have

occurred on a given endpoint. This register is defined for

endpoints 4–11. This register is read/write by the MCU only.

• N[3:0] NAK counter. Number of sequential NAKs that

have occurred on a given endpoint. When N[3:0] is equal

to the base NAK counter NK[3:0], a zero-length packet

or packet less that maxpacketsize will be issued.

• ST 1 = Endpoint is stalled

USB Endpoint Stall Policy Register

This register contains NAK count and endpoint FIFO error

policy bit. The STALL status bits for endpoints 1–3 are included

as well. This register is read/write by the MCU only.

• ST[3:1] 1 = Endpoint is stalled. ST[1] maps to endpoint

1, ST[2] maps to endpoint 2, etc.

• NK[3:0] Base NAK counter. Determines how many

sequential NAKs are issued before sending zero length

packet on any given endpoint.

• FE FIFO error policy. 1 = When endpoint FIFO is over-

run/underrun, STALL endpoint

USB Endpoint 1 Code Download Base Address Register

This register contains an 18-bit address which corresponds to the

starting location for DSP code download on endpoint 1. This

register is read/write by the MCU only.

USB Endpoint 2 Code Download Base Address Register

This register contains an 18-bit address which corresponds to the

starting location for DSP code download on endpoint 2. This

register is read/write by the MCU only.

USB Endpoint 3 Code Download Base Address Register

This register contains an 18-bit address which corresponds to the

starting location for DSP code download on endpoint 3. This

register is read/write by the MCU only.

USB Endpoint 1 Code Current Write Pointer Offset Register

This register contains an 18-bit address which corresponds to the

current write pointer offset from the base address register for DSP

code download on endpoint 1. The sum of this register and the

EP1 Code Download Base Address Register represents the last

DSP PM location written.

This register is read by the MCU only and is cleared to 3FFFF

(–1) when the Endpoint 1 Code Download Base Address

Register is updated.

USB Endpoint 2 Code Current Write Pointer Offset Register

This register contains an 18-bit address that corresponds to the

current write pointer offset from the base address register for DSP

code download on endpoint 2. The sum of this register and the

EP2 Code Download Base Address Register represents the last

DSP PM location written.

This register is read by the MCU only and is cleared to 3FFFF

(–1) when the Endpoint 2 Code Download Base Address

Register is updated.

USB Endpoint 3 Code Current Write Pointer Offset Register

This register contains an 18-bit address which corresponds to the

current write pointer offset from the base address register for DSP

code download on endpoint 3. The sum of this register and the

EP3 Code Download Base Address Register represents the last

DSP PM location written.

This register is read by the MCU only and is cleared to 3FFFF

(–1) when the Endpoint 3 Code Download Base Address

Register is updated.

–16– REV. 0

Page 17

ADSP-2192M

USB SETUP Token Command Register

This register is defined as eight bytes long and contains the data

sent on the USB from the most recent SETUP transaction. This

register is read by the MCU only.

USB SETUP Token Data Register

If the most recent SETUP transaction involves a data OUT stage,

this register is defined as eight bytes long and contains the data

sent on the USB during the data stage. This is also where the

MCU will write data to be sent in response to a SETUP transaction involving a data IN stage. This register is read/write by the

MCU only.

USB SETUP Counter Register

This register provides information as the total size of the setup

transaction data stage. This register is read/write by the MCU

only.

• C[3:0] Total amount of data (bytes) to be sent/received

during the data stage of the SETUP transaction

USB Register I/O Address Register

This register contains the address of the ADSP-2192M register

that is to be read/written. This register is read/wr ite by the MCU

only.

• A[15] Start ADSP-2192M read/write cycle

• A[14] 1 = WRITE, 0 = READ

• A[13:0] ADSP-2192M address to read/write

USB Register I/O Data Register

This register contains the data of the ADSP-2192M register

which has been read or is to be written. This register is read/write

by the MCU only.

• D[15:0] During READ this register contains the data

read from the ADSP-2192M; during WRITE this register

is the data to be written to the ADSP-2192M.

USB Control Register

This register controls various USB functions. This register is

read/write by the MCU only.

• MO 1 = MCU has completed boot sequence and is ready

to respond to USB commands

• DI 1 = Disconnect CONFIG device and enumerate again

using the downloaded MCU configuration

• BB 1 = After reset boot from MCU RAM; 0 = after reset

boot from MCU ROM

• INT = Active interrupt for the 8052 MCU

• ISE = Current interrupt is for a SETUP token

• IIN = Current interrupt is for an IN token

• IOU = Current interrupt is for an OUT token

• ER = Error in the current SETUP transaction. Generate

STALL condition on EP0.

USB Address/Endpoint Register

This register contains the USB address and active endpoint. This

register is read/write by the MCU only.

• A[6:0] USB address assigned to device

• EP[3:0] USB last active endpoint

USB Frame Number Register

This register contains the last USB frame number. This register

is read by the MCU only.

• FN[10:0] USB frame number

General USB Device Definitions

The following tables define the USB device descriptors: Table 13

describes the USB device descriptor; offset fields 8–13 are userdefinable via Serial EEPROM. Table 14 describes the USB

configuration descriptor; offset fields 7–8 are user-definable via

Serial EEPROM. Table 15, Table 16, and Table 17 describe the

USB string descriptor indexes.

Table 13. CONFIG DEVICE Device Descriptor

Offset Field Description Value

0 bLength Length = 18 bytes 0x12

1 bDescriptorType Type = DEVICE 0x01

2–3 bcdUSB USB Spec 1.1 0x0110

4 bDeviceClass Device class vendor specific 0xFF

5 bDeviceSubClass Device sub-class vendor specific 0xFF

6 bDeviceProtocol Device protocol vendor specific 0xFF

7 bMaxPacketSize Max packet size for EP0 = eight bytes 0x08

8–9 idVendor (L) Vendor ID (L) = 0456 ADI 0x0456

10–11 idProduct (L) Product ID (L) = ADSP-2192M 0x2192

12–13 bcdDevice (L) Device release number = 1.00 0x0100

14 iManufacturer Manufacturer index string 0x01

15 iProduct Product index string 0x02

16 iSerialNumber Serial number index string 0x00

17 bNumConfigurations Number of configurations = 1 0x01

–17–REV. 0

Page 18

ADSP-2192M

Table 14. CONFIG DEVICE Configuration Descriptor

Offset Field Description Value

0 bLength Descriptor Length = nine bytes 0x09

1 bDescriptorType Descriptor Type = Configuration 0x02

2 wTotalLength (L) Total Length (L) 0x12

3 wTotalLength (H) Total Length (H) 0x00

4 bNumInterfaces Number of Interfaces 0x01

5 bConfigurationValue Configuration Value 0x01

6 iConfiguration Index of string descriptor (None) 0x00

7 bmAttributes Bus powered, no wake-up 0x80

8 MaxPower Max power = 500 mA 0xFA

Table 15. CONFIG DEVICE String Descriptor Index 0

Offset Field Description Value

0 bLength Descriptor Length = 4 bytes 0x04

1 bDescriptorType Descriptor Type = String 0x03

2 wLANGID[0] LangID = 0409 (US English) 0x0409

Table 16. CONFIG DEVICE Descriptor Index 1 (Manufacturer)

Offset Field Description Value

0 bLength Descriptor Length = 20 bytes 0x14

1 bDescriptorType Descriptor Type = String 0x03

2–19 bString ADI

Table 17. CONFIG DEVICE String Descriptor Index 2 (Product)

Offset Field Description Value

0 bLength Descriptor Length = 34 bytes 0x22

1 bDescriptorType Descriptor Type = String 0x03

2–31 bString Analog Devices USB Device

Configuration 0, 1, and 2 Device Definition

• FIXED ENDPOINTS

• CONTROL ENDPOINT 0

• Type : Con tro l

• Dir: Bidirectional

• Maxpacketsize: 8

• BULK OUT ENDPOINT 1, 2, 3 = Used for code

download to DSP

• Type : Bu lk

• Dir: OUT

• Maxpacketsize: 64

• PROGRAMMABLE ENDPOINTS: 4 5 6 7 8 9 10 11

• Programmable in:

• Type: via USB Endpoint Description Register

• Direction: via USB Endpoint Description Register

• Maxpacket size: via USB Endpoint Description Register

• Memory Allocation: via DSP Memory Buffer Base Addr,

DSP Memory Buffer Size, DSP Memory Buffer RD

Pointer Offset, DSP Memory Buffer Write Pointer Offset

Registers

Note: The GENERIC endpoints are shared between all

interfaces.

Endpoint 0 Definition

In addition to the normally defined USB standard device

requests, the following vendor specific device requests are

supported with the use of EP0. These requests are issued from

the host driver via normal SETUP transactions on the USB.

USB MCU Code Download

USB MCUCODE is a three-stage control transfer with an OUT

data stage. Stage 1 is the SETUP stage, stage 2 is the data stage

involving the OUT packet, and stage 3 is the status stage. The

length of the data stage is determined by the driver and is specified

by the total length of the MCU code to be downloaded. See

Table 18 for details about the USB MCUCODE (code

download) fields.

USB REGIO (Write)

Address 15–15 = 1 indicates a write to the MCU register space;

Address 15–15 = 0 indicates a write to the DSP register space.

When accessing DSP register space, the MCU must write the

data to be written into the USB Register I/O Data register and

–18– REV. 0

Page 19

ADSP-2192M

Table 18. USB MCUCODE (Code Download)

Offset Field Size Value Description

0 bmRequest 1 0x40 Vendor Request,

OUT

1 bRequest 1 0xA1 USB

MCUCODE

2wValue (L)1XXXAddress 7–0

3 wValue (H) 1 XXX Address 15–8

4 wIndex (L) 1 0x00

5 wIndex (H) 1 0x00

6wLength (L)10xXX

7wLength (H)10xYY

1

Length = XX

bytes

2

Length = YY

bytes

1

XX is user-specified.

2

YY is user-specified.

write the address to be written to the USB Register I/O Address

register. Bit 15 of the USB Register I/O Address register starts

the transaction and Bit 14 is set to one to indicate a WRITE.

USB REGIO (register write) is a three-stage control transfer with

an OUT data stage. Stage 1 is the SETUP stage, stage 2 is the

data stage involving the OUT packet, and stage 3 is the status

stage. See Table 19 for details about the USB REGIO (register

write) fields.

Table 19. USB REGIO (Register Write)

Offset Field Size Value Description

0 bmRequest 1 0x40 Vendor Request,

OUT

1 bRequest 1 0xA0 USB REGIO

2wValue (L)1XXXAddress 7–0

3wValue (H)1XXXAddress 15–8

4 wIndex (L) 1 0x00

5 wIndex (H) 1 0x00

6 wLength (L) 1 0x02 Length =

02 bytes

7 wLength (H) 1 0x00

USB REGIO (Read)

Address 15–15 = 1 indicates a read to the MCU register space;

Address 15–15 = 0 indicates a read to the DSP register space.

When accessing DSP register space, the MCU must write the

address to be read to the USB Register I/O Address register.

Bit 15 of the USB Register I/O Address register starts the transaction, and Bit 14 is set to zero to indicate a READ. The data

read will be placed into the USB Register I/O Data register.

USB REGIO (register read) is a three-stage control transfer with

an IN data stage. Stage 1 is the SETUP stage, stage 2 is the data

stage involving the IN packet, and stage 3 is the status stage. See

Table 20 for details about the USB REGIO (register read) fields.

Table 20. USB REGIO (Register Read)

Offset Field Size Value Description

0 bmRequest 1 0xC0 Vendor Request,

IN

1 bRequest 1 0xA0 USB REGIO