Page 1

a

SHARC® Processor

Preliminary Technical Data

SUMMARY

High performance 32-bit/40-bit floating point processor

optimized for high performance automotive audio

processing

Audio decoder and post processor-algorithm support with

32-bit floating-point implementations

Non-volatile memory may be configured to support audio

decoders and post processor-algorithms like PCM, Dolby

Digital EX, Dolby Prologic IIx, Dolby Digital Plus, Dolby

headphone, DTS 96/24, Neo:6, DTS ES, DTS Lossless,

MPEG2 AAC, MPEG2 2channel, MP3, WMAPro, and Multichannel encoder. Functions like Bass management, Delay,

Speaker equalization, Graphic equalization, Decoder/post-

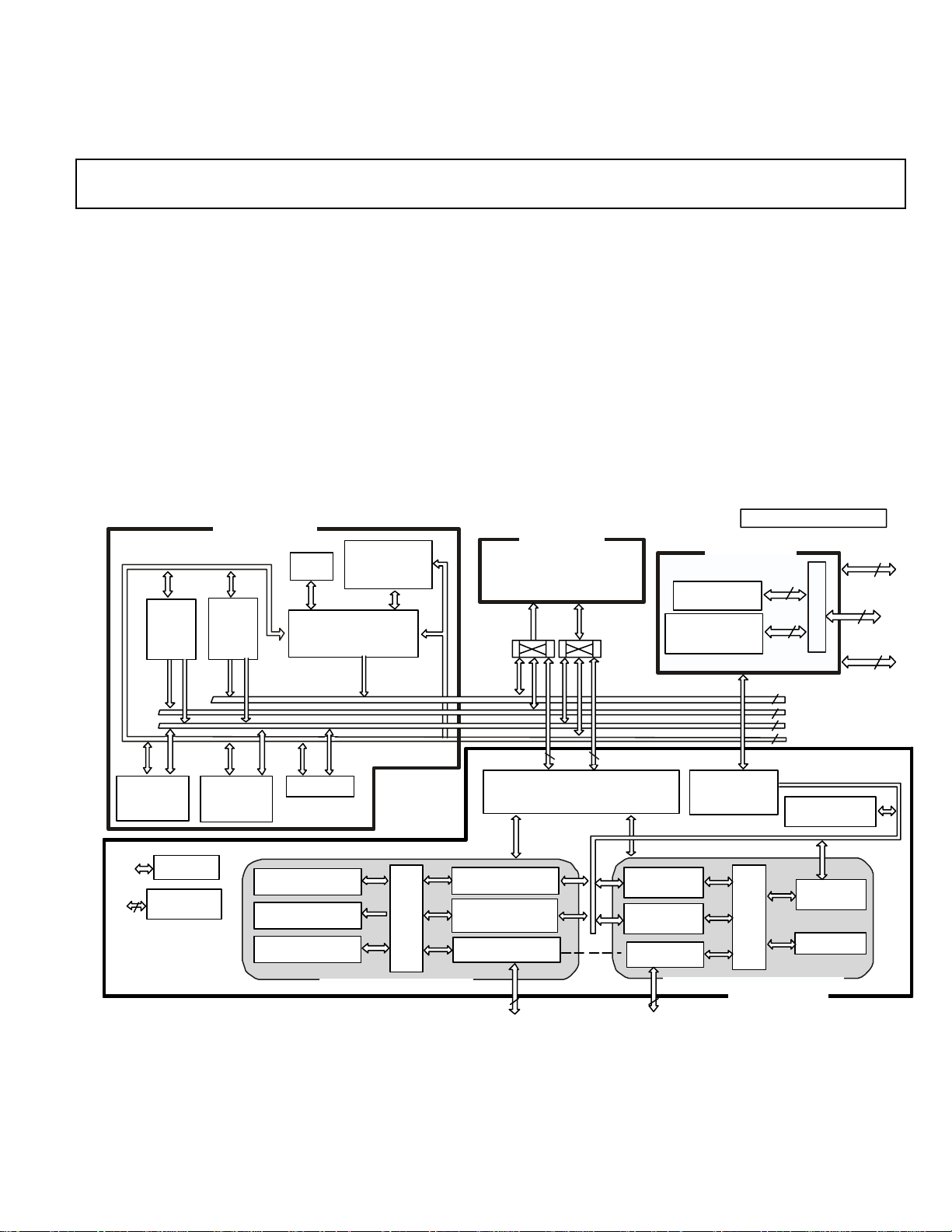

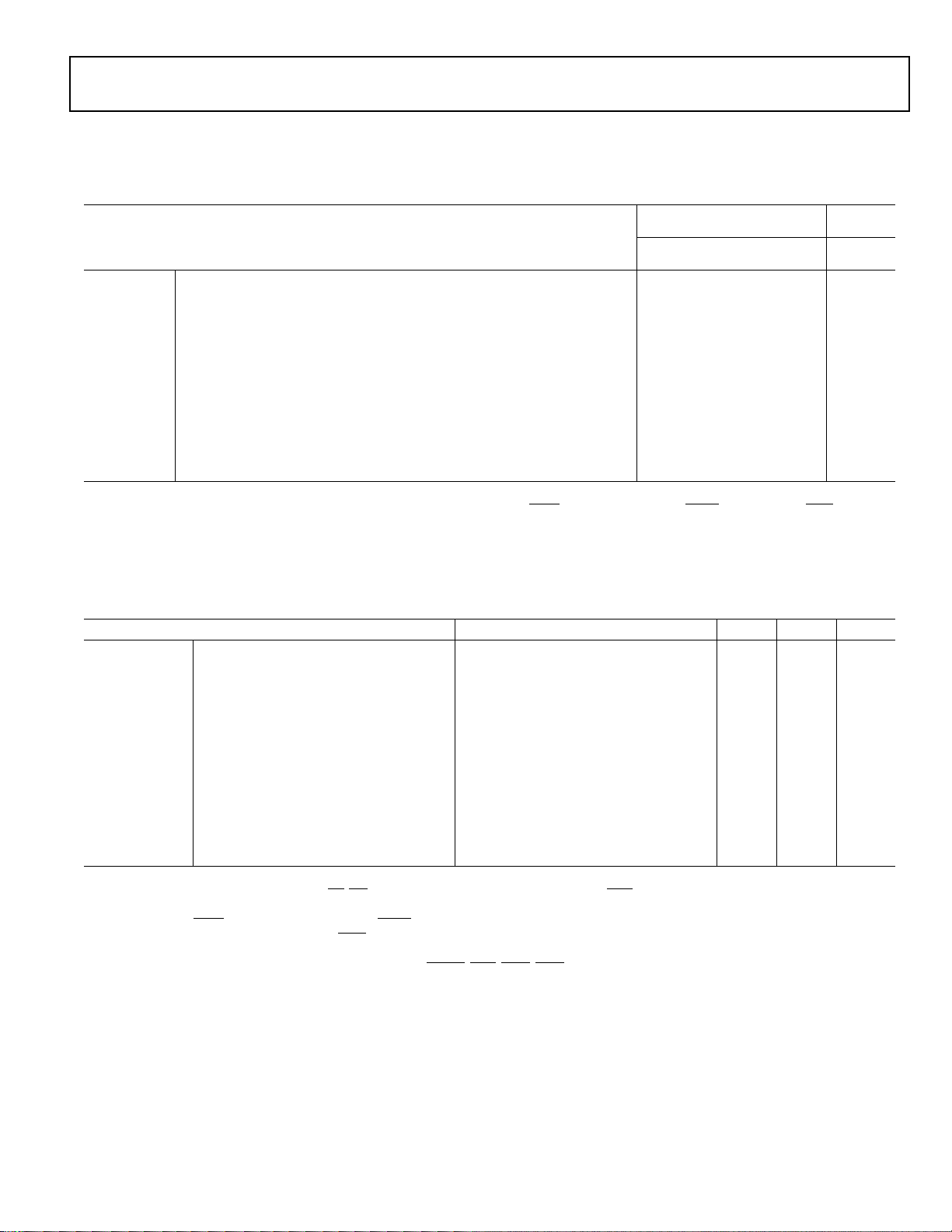

COREPROCESSOR

INSTRUCTION

CACHE

32 X48-BIT

PROGRAM

SE QUENCER

DAG1

8X4X32

PROC ESSING

EL EMEN T

(P EX)

DAG2

8X 4X32

PROC ESSI NG

ELEMENT

(P EY)

TIMER

P X REG ISTER

ADSP-21367

processor algorithm combination support will vary

depending upon the chip version and the system configurations. Please visit www.analog.com

Single-Instruction Multiple-Data (SIMD) computational

architecture

On-chip memory—2M bit of on-chip SRAM and a dedicated

6M bit of on-chip mask-programmable ROM

Code compatible with all other members of the SHARC family

The ADSP-21367 is available with a 400 MHz core instruction

rate with unique audio centric peripherals such as the Digi-

tal Audio Interface, S/PDIF transceiver, serial ports, 8-

channel asynchronous sample rate converter, precision

clock generators and more. For complete ordering infor-

mation, see Ordering Guide on page 47

JTAG TEST & EMULATIO N

4 BLOCKS OF

ON-CHIPMEMORY

2 M B IT R AM , 6 M BI T ROM

ADDR DATA

IOA(24)

IOP REGISTER ( MEMORY MAP PED )

CO NTROL, STATUS, & DATA BUFFERS

IOD(32)

EXTERNAL PORT

SDRAM

CONTROLLER

ASYNCHRONOUS

ME MO RY

INTERFACE

DMA

CONTROLLER

34 CHANNE LS

S

8

N

I

P

L

O

R

3

T

N

O

C

32 PM ADDRESS BUS

32

DMADDRESS BUS

64

PM DATA BUS

64

DM DATA BUS

ME M ORY -T O-

ME M ORY DM A (2 )

24

ADDRE SS

11

CONTROL

32

DATA

PWM (16)

4

GPI O FLAGS/

IRQ/TIMEXP

S

SHARC and the SHARC logo are registered trademarks of Analog Devices, Inc.

Rev. PrA

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective companies.

PREC ISI ON CL OCK

GENERATORS(4)

SRC (8 CHANNELS)

SPDIF(RX/TX)

DIGITAL AUDIO INTERFACE

DAI ROUTINGUNIT

SERIAL PORTS (8)

INPUT DATA PORT/

PDAP

DA I PIN S

20

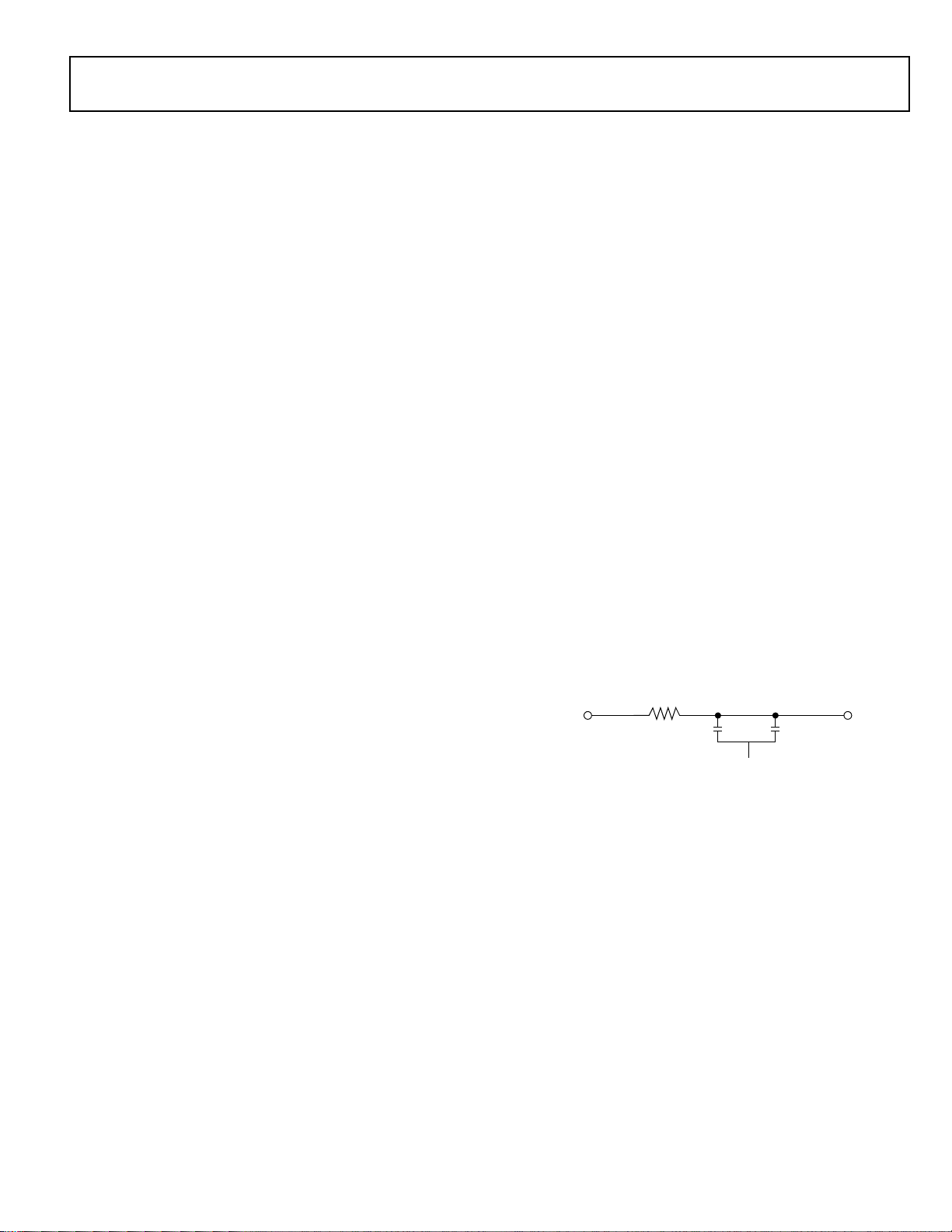

Figure 1. Functional Block Diagram – Processor Core

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106 U.S.A.

Tel:781.329.4700 www.analog.com

Fax:781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

SPIPORT(2)

TWO WIRE

INTERFACE

DPI PINS

DI GI TAL PER IP HE RAL I NTE RF ACE

14

DPI ROUTING UNIT

I/O PROCESSOR

UART (2)

TIMERS (3)

Page 2

ADSP-21367 Preliminary Technical Data

KEY FEATURES – PROCESSOR CORE

At 400 MHz (2.5 ns) core instruction rate, the ADSP-21367

performs 2.4 GFLOPS/800 MMACS

2M bit on-chip SRAM (0.75M Bit in blocks 0 and 1, and 250K

Bit in blocks 2 and 3) for simultaneous access by the core

processor and DMA

6M bit on-chip mask-programmable ROM (3M bit in block 0

and 3M bit in block 1)

Dual Data Address Generators (DAGs) with modulo and bit-

reverse addressing

Zero-overhead looping with single-cycle loop setup, provid-

ing efficient program sequencing

Single Instruction Multiple Data (SIMD) architecture

provides:

Two computational processing elements

Concurrent execution

Code compatibility with other SHARC family members at

the assembly level

Parallelism in busses and computational units allows: Sin-

gle cycle executions (with or without SIMD) of a multiply

operation, an ALU operation, a dual memory read or

write, and an instruction fetch

Transfers between memory and core at a sustained 6.0G

bytes/s bandwidth at 400 MHz core instruction rate

INPUT/OUTPUT FEATURES

DMA Controller supports:

34 zero-overhead DMA channels for transfers between

ADSP-21367 internal memory and a variety of

peripherals

32-bit DMA transfers at core clock speed, in parallel with

full-speed processor execution

32-Bit Wide External Port Provides Glueless Connection to

both Synchronous (SDRAM) and Asynchronous Memory

Devices

Programmable wait state options: 2 to 31 SCLK cycles

Delay-line DMA engine maintains circular buffers in exter-

nal memory with tap/offset based reads

SDRAM accesses at 166MHz and Asynchronous accesses at

66MHz

4 Memory Select lines allows multiple external memory

devices

Digital Audio Interface (DAI) includes eight serial ports, four

Precision Clock Generators, an Input Data Port, an S/PDIF

transceiver, an 8-channel asynchronous sample rate converter, and a Signal Routing Unit

Digital Peripheral Interface (DPI) includes, three timers, two

UARTs, two SPI ports, and a two wire interface port

Outputs of PCG's C and D can be driven on to DPI pins

Eight dual data line serial ports that operate at up to 50M

bits/s on each data line — each has a clock, frame sync and

two data lines that can be configured as either a receiver or

transmitter pair

TDM support for telecommunications interfaces including

128 TDM channel support for newer telephony interfaces

such as H.100/H.110

Up to 16 TDM stream support, each with 128 channels per

frame

Companding selection on a per channel basis in TDM mode

Input data port, configurable as eight channels of serial data

or seven channels of serial data and a single channel of up

to a 20-bit wide parallel data

Signal routing unit provides configurable and flexible con-

nections between all DAI/DPI components

2 Muxed Flag/IRQ

1 Muxed Flag/Timer expired line /MS

1 Muxed Flag/IRQ

lines

pin

/MS pin

DEDICATED AUDIO COMPONENTS

S/PDIF Compatible Digital Audio receiver/transmitter sup-

ports EIAJ CP-340 (CP-1201), IEC-958, AES/EBU standards

Left-justified, I

16, 18, 20 or 24-bit word widths (transmitter)

Sample Rate Converter (SRC) contains a Serial Input Port, De-

emphasis Filter, Sample Rate Converter (SRC) and Serial

Output Port providing up to -128db SNR performance.

Supports Left Justified, I

18 and 16-bit serial formats (input)

Pulse Width Modulation provides:

16 PWM outputs configured as four groups of four outputs

supports center-aligned or edge-aligned PWM waveforms

ROM Based Security features include:

JTAG access to memory permitted with a 64-bit key

Protected memory regions that can be assigned to limit

access under program control to sensitive code

PLL has a wide variety of software and hardware multi-

plier/divider ratios

Dual voltage: 3.3 V I/O, 1.3 V core

Available in 256-ball BGA and 208-lead LQFP Packages (see

Ordering Guide on page 47)

2

S or right-justified serial data input with

2

S, TDM and Right Justified 24, 20,

Rev. PrA | Page 2 of 48 | November 2004

Page 3

TABLE OF CONTENTS

ADSP-21367Preliminary Technical Data

Summary ............................................................... 1

Key Features – Processor Core ................................. 2

Input/Output Features ........................................... 2

Dedicated Audio Components ................................. 2

General Description ................................................. 4

ADSP-21367 Family Core Architecture ...................... 4

SIMD Computational Engine ............................... 4

Independent, Parallel Computation Units ................ 4

Data Register File ............................................... 5

Single-Cycle Fetch of Instruction and Four Operands . 5

Instruction Cache .............................................. 5

Data Address Generators With Zero-Overhead Hardware

Circular Buffer Support .................................... 5

Flexible Instruction Set ....................................... 6

ADSP-21367 Memory ............................................ 6

On-Chip Memory .............................................. 6

External Memory .................................................. 6

SDRAM Controller ............................................ 7

Asynchronous Controller .................................... 7

ADSP-21367 Input/Output Features .......................... 7

DMA Controller ................................................ 7

Digital Audio Interface (DAI) ............................... 7

Serial Ports ....................................................... 8

S/PDIF Compatible Digital Audio Receiver/Transmitter

and Synchronous/Asynchronous Sample

Rate Converter ............................................... 8

Digital Peripheral Interface (DPI) .......................... 8

Serial Peripheral (Compatible) Interface .................. 8

UART Port ...................................................... 8

Timers ............................................................ 9

Two Wire Interface Port (TWI) ............................. 9

Pulse Width Modulation ..................................... 9

ROM Based Security ........................................... 9

System Design ...................................................... 9

Program Booting .............................................. 10

Power Supplies ................................................. 10

Target Board JTAG Emulator Connector ................ 10

Development Tools .............................................. 10

Designing an Emulator-Compatible DSP

Board(Target) .............................................. 11

Evaluation Kit .................................................. 11

Additional Information ......................................... 11

Pin Function Descriptions ........................................ 12

Address Data Modes ............................................ 14

Boot Modes ....................................................... 14

Core Instruction Rate to CLKIN Ratio Modes ............ 14

ADSP-21367 Specifications ....................................... 15

Recommended Operating Conditions ...................... 15

Electrical Characteristics ....................................... 15

Absolute Maximum Ratings ................................... 16

ESD Sensitivity ................................................... 16

Timing Specifications ........................................... 16

Power-Up Sequencing ....................................... 18

Clock Input .................................................... 19

Clock Signals ................................................... 19

Reset ............................................................. 20

Interrupts ....................................................... 20

Core Timer ..................................................... 21

Timer PWM_OUT Cycle Timing ......................... 21

Timer WDTH_CAP Timing ............................... 22

DAI and DPI Pin to Pin Direct Routing ................. 22

Precision Clock Generator (Direct Pin Routing) ...... 23

Flags ............................................................. 24

SDRAM Interface Timing .................................. 25

External Port Bus Request and Grant Cycle Timing .. 26

Serial Ports ..................................................... 27

Input Data Port ............................................... 30

Parallel Data Acquisition Port (PDAP) .................. 31

Sample Rate Converter—Serial Input Port .............. 32

Sample Rate Converter—Serial Output Port ........... 33

SPDIF Transmitter ........................................... 34

SPDIF Receiver ................................................ 36

SPI Interface—Master ....................................... 38

SPI Interface—Slave .......................................... 39

Universal Asynchronous Receiver-Transmitter

(UART) Port—Receive and Transmit Timing ...... 40

JTAG Test Access Port and Emulation .................. 41

Output Drive Currents ......................................... 42

Test Conditions .................................................. 42

Capacitive Loading .............................................. 42

Thermal Characteristics ........................................ 43

Ordering Guide ..................................................... 45

Rev. PrA | Page 3 of 48 | November 2004

Page 4

ADSP-21367 Preliminary Technical Data

GENERAL DESCRIPTION

The ADSP-21367 SHARC processor is a members of the SIMD

SHARC family of DSPs that feature Analog Devices' Super Harvard Architecture. The ADSP-21367 is source code compatible

with the ADSP-2126x, and ADSP-2116x, DSPs as well as with

first generation ADSP-2106x SHARC processors in SISD (Single-Instruction, Single-Data) mode. The ADSP-21367 is a 32bit/40-bit floating point processors optimized for high performance automotive audio applications with its large on-chip

SRAM and mask-programmable ROM, multiple internal buses

to eliminate I/O bottlenecks, and an innovative Digital Audio

Interface (DAI).

As shown in the functional block diagram on page 1, the

ADSP-21367 uses two computational units to deliver a significant performance increase over the previous SHARC processors

on a range of DSP algorithms. Fabricated in a state-of-the-art,

high speed, CMOS process, the ADSP-21367 processor achieves

an instruction cycle time of 2.5 ns at 400 MHz. With its SIMD

computational hardware, the ADSP-21367 can perform 2.4

GFLOPS running at 400 MHz.

Table 1 shows performance benchmarks for the ADSP-21367.

Table 1. ADSP-21367 Benchmarks (at 400 MHz)

Benchmark Algorithm Speed

(at 400 MHz)

1024 Point Complex FFT (Radix 4, with reversal) 23.25 µs

FIR Filter (per tap)

IIR Filter (per biquad)

Matrix Multiply (pipelined)

[3x3] × [3x1]

[4x4] × [4x1]

Divide (y/×) 8.75 ns

Inverse Square Root 13.5 ns

1

Assumes two files in multichannel SIMD mode

1

1

1.25 ns

5.0 ns

11.25 ns

20.0 ns

The ADSP-21367 continues SHARC’s industry leading standards of integration for DSPs, combining a high performance

32-bit DSP core with integrated, on-chip system features.

The block diagram of the ADSP-21367 on page 1, illustrates the

following architectural features:

• Two processing elements, each of which comprises an

ALU, Multiplier, Shifter and Data Register File

• Data Address Generators (DAG1, DAG2)

• Program sequencer with instruction cache

• PM and DM buses capable of supporting four 32-bit data

transfers between memory and the core at every core processor cycle

• Three Programmable Interval Timers with PWM Generation, PWM Capture/Pulse width Measurement, and

External Event Counter Capabilities

•On-Chip SRAM (2M bit)

• On-Chip mask-programmable ROM (6M bit)

• JTAG test access port

The block diagram of the ADSP-21367 on page 1 also illustrates

the following architectural features:

• DMA controller

• Eight full duplex serial ports

• Two SPI-compatible interface ports

• Digital Audio Interface that includes four precision clock

generators (PCG), an input data port (IDP), an S/PDIF

receiver/transmitter, eight channels asynchronous sample

rate converters, eight serial ports, eight serial interfaces, a

20-bit parallel input port, a flexible signal routing unit

(SRU), and a Digital Peripheral Interface (DPI)

ADSP-21367 FAMILY CORE ARCHITECTURE

The ADSP-21367 is code compatible at the assembly level with

the ADSP-2126x, ADSP-21160 and ADSP-21161, and with the

first generation ADSP-2106x SHARC processors. The ADSP21367 shares architectural features with the ADSP-2126x and

ADSP-2116x SIMD SHARC processors, as detailed in the following sections.

SIMD Computational Engine

The ADSP-21367 contains two computational processing elements that operate as a Single-Instruction Multiple-Data

(SIMD) engine. The processing elements are referred to as PEX

and PEY and each contains an ALU, multiplier, shifter and register file. PEX is always active, and PEY may be enabled by

setting the PEYEN mode bit in the MODE1 register. When this

mode is enabled, the same instruction is executed in both processing elements, but each processing element operates on

different data. This architecture is efficient at executing math

intensive DSP algorithms.

Entering SIMD mode also has an effect on the way data is transferred between memory and the processing elements. When in

SIMD mode, twice the data bandwidth is required to sustain

computational operation in the processing elements. Because of

this requirement, entering SIMD mode also doubles the bandwidth between memory and the processing elements. When

using the DAGs to transfer data in SIMD mode, two data values

are transferred with each access of memory or the register file.

Independent, Parallel Computation Units

Within each processing element is a set of computational units.

The computational units consist of an arithmetic/logic unit

(ALU), multiplier, and shifter. These units perform all operations in a single cycle. The three units within each processing

element are arranged in parallel, maximizing computational

throughput. Single multifunction instructions execute parallel

ALU and multiplier operations. In SIMD mode, the parallel

ALU and multiplier operations occur in both processing ele-

Rev. PrA | Page 4 of 48 | November 2004

Page 5

ADSP-21367Preliminary Technical Data

ments. These computation units support IEEE 32-bit singleprecision floating-point, 40-bit extended precision floatingpoint, and 32-bit fixed-point data formats.

Data Register File

A general-purpose data register file is contained in each processing element. The register files transfer data between the

computation units and the data buses, and store intermediate

results. These 10-port, 32-register (16 primary, 16 secondary)

register files, combined with the ADSP-2136x enhanced Harvard architecture, allow unconstrained data flow between

computation units and internal memory. The registers in PEX

are referred to as R0-R15 and in PEY as S0-S15.

Single-Cycle Fetch of Instruction and Four Operands

The ADSP-21367 features an enhanced Harvard architecture in

which the data memory (DM) bus transfers data and the program memory (PM) bus transfers both instructions and data

(see Figure 1 on page 1). With the ADSP-21367’s separate program and data memory buses and on-chip instruction cache,

the processor can simultaneously fetch four operands (two over

each data bus) and one instruction (from the cache), all in a single cycle.

Instruction Cache

The ADSP-21367 includes an on-chip instruction cache that

enables three-bus operation for fetching an instruction and four

data values. The cache is selective—only the instructions whose

fetches conflict with PM bus data accesses are cached. This

cache allows full-speed execution of core, looped operations

such as digital filter multiply-accumulates, and FFT butterfly

processing.

Data Address Generators With Zero-Overhead Hardware Circular Buffer Support

The ADSP-21367’s two data address generators (DAGs) are

used for indirect addressing and implementing circular data

buffers in hardware. Circular buffers allow efficient programming of delay lines and other data structures required in digital

signal processing, and are commonly used in digital filters and

Fourier transforms. The two DAGs of the ADSP-21367 contain

sufficient registers to allow the creation of up to 32 circular buffers (16 primary register sets, 16 secondary). The DAGs

automatically handle address pointer wraparound, reduce overhead, increase performance, and simplify implementation.

Circular buffers can start and end at any memory location.

Flexible Instruction Set

The 48-bit instruction word accommodates a variety of parallel

operations, for concise programming. For example, the

ADSP-21367 can conditionally execute a multiply, an add, and a

subtract in both processing elements while branching and fetching up to four 32-bit values from memory—all in a single

instruction.

ADSP-21367 MEMORY

The ADSP-21367 adds the following architectural features to

the SIMD SHARC family core.

On-Chip Memory

The ADSP-21367 contains two megabits of internal RAM and

six megabits of internal mask-programmable ROM. Each block

can be configured for different combinations of code and data

storage (see Table 2). Each memory block supports single-cycle,

independent accesses by the core processor and I/O processor.

The ADSP-21367 memory architecture, in combination with its

separate on-chip buses, allow two data transfers from the core

and one from the I/O processor, in a single cycle.

The ADSP-21367’s, SRAM can be configured as a maximum of

64K words of 32-bit data, 128K words of 16-bit data, 42K words

of 48-bit instructions (or 40-bit data), or combinations of different word sizes up to three megabits. All of the memory can be

accessed as 16-bit, 32-bit, 48-bit, or 64-bit words. A 16-bit floating-point storage format is supported that effectively doubles

the amount of data that may be stored on-chip. Conversion

between the 32-bit floating-point and 16-bit floating-point formats is performed in a single instruction. While each memory

block can store combinations of code and data, accesses are

most efficient when one block stores data using the DM bus for

transfers, and the other block stores instructions and data using

the PM bus for transfers.

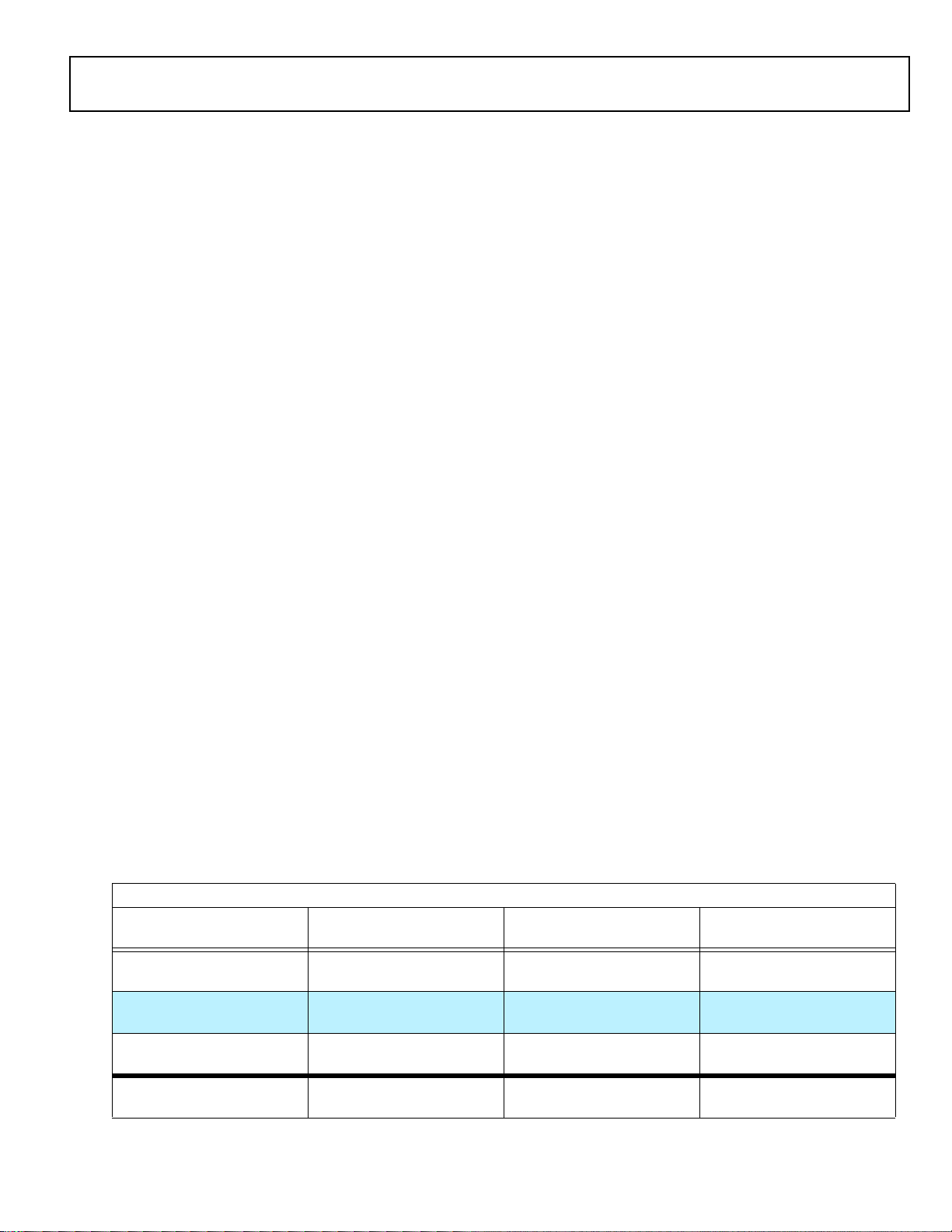

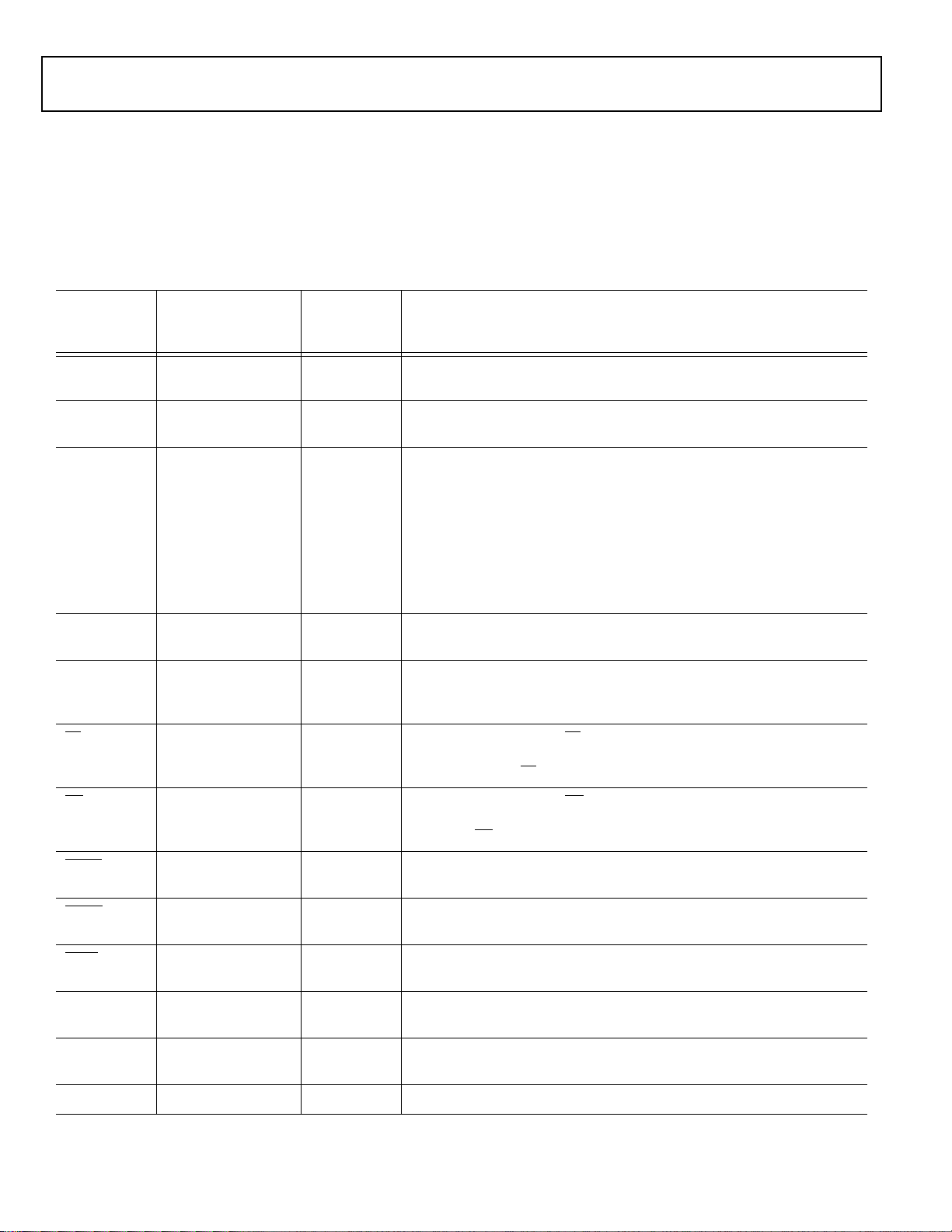

Table 2. ADSP-21367 Internal Memory Space

IOP Registers 0x0000 0000 - 0003 FFFF

Long Word (64 bits) Extended Precision Normal or

Instruction Word (48 bits)

BLOCK 0 ROM

0x0004 0000–0x0004 BFFF

Reserved

0x0004 F000–0x0004 FFFF

BLOCK 0 RAM

0x0004 C000–0x0004 EFFF

BLOCK 1 ROM

0x0005 0000–0x0005 BFFF

BLOCK 0 ROM

0x0008 0000–0x0008 FFFF

Reserved

0x0009 4000–0x0009 FFFF

BLOCK 0 RAM

0x0009 0000–0x0009 3FFF

BLOCK 1 ROM

0x000A 0000–0x000A FFFF

Rev. PrA | Page 5 of 48 | November 2004

Normal Word (32 bits) Short Word (16 bits)

BLOCK 0 ROM

0x0008 0000–0x0009 7FFF

Reserved

0x0009 E0000–0x0009 FFFF

BLOCK 0 RAM

0x0009 8000–0x0009 DFFF

BLOCK 1 ROM

0x000A 0000– 0x000B 7FFF

BLOCK 0 ROM

0x0010 0000–0x0012 FFFF

Reserved

0x0013 C000–0x0013 FFFF

BLOCK 0 RAM

0x0013 0000–0x0013 BFFF

BLOCK 1 ROM

0x0014 0000–0x0016 FFFF

Page 6

ADSP-21367 Preliminary Technical Data

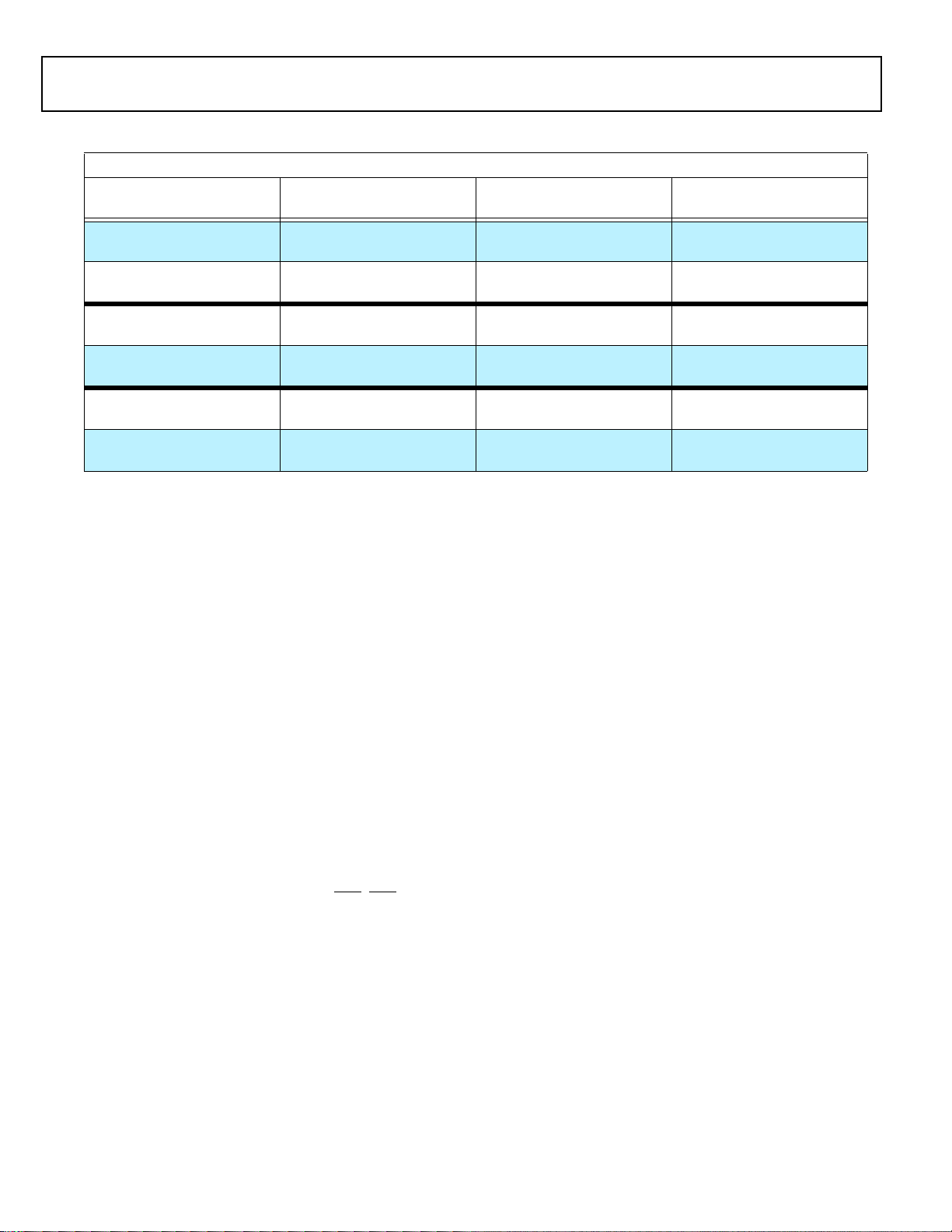

Table 2. ADSP-21367 Internal Memory Space (Continued)

IOP Registers 0x0000 0000 - 0003 FFFF

Long Word (64 bits) Extended Precision Normal or

Instruction Word (48 bits)

Reserved

0x0005 F000–0x0005 FFFF

BLOCK 1 RAM

0x0005 C000–0x0005 EFFF

BLOCK 2 RAM

0x0006 0000–0x0006 0FFF

Reserved

0x0006 1000– 0x0006 FFFF

BLOCK 3 RAM

0x0007 0000–0x0007 0FFF

Reserved

0x0007 1000– 0x0007 FFFF

Reserved

0x000B 4000–0x000B FFFF

BLOCK 1 RAM

0x000B 0000–0x000B 3FFF

BLOCK 2 RAM

0x000C 0000–0x000C 1554

Reserved

0x000C 1555–0x000C 3FFF

BLOCK 3 RAM

0x000E 0000–0x000E 1554

Reserved

0x000E 1555–0x000F FFFF

Normal Word (32 bits) Short Word (16 bits)

Reserved

0x000B E000– 0x000B FFFF

BLOCK 1 RAM

0x000B 8000–0x000B DFFF

BLOCK 2 RAM

0x000C 0000–0x000C 1FFF

Reserved

0x000C 2000–0x000D FFFF

BLOCK 3 RAM

0x000E 0000–0x000E 1FFF

Reserved

0x000E 2000–0x000F FFFF

Reserved

0x0017 C000–0x0017 FFFF

BLOCK 1 RAM

0x0017 0000–0x0017 BFFF

BLOCK 2 RAM

0x0018 0000–0x0018 3FFF

Reserved

0x0018 4000–0x001B FFFF

BLOCK 3 RAM

0x001C 0000–0x001C 3FFF

Reserved

0x001C 4000–0x001F FFFF

Using the DM bus and PM buses, with one bus dedicated to

each memory block, assures single-cycle execution with two

data transfers. In this case, the instruction must be available in

the cache.

EXTERNAL MEMORY

The External Port on the ADSP-21367 SHARC provides a high

performance, glueless interface to a wide variety of industrystandard memory devices. The 32-bit wide bus may be used to

interface to synchronous and/or asynchronous memory devices

through the use of it's separate internal memory controllers: the

first is an SDRAM controller for connection of industry-standard synchronous DRAM devices and DIMMs (Dual Inline

Memory Module), while the second is an asynchronous memory controller intended to interface to a variety of memory

devices. Four memory select pins enable up to four separate

devices to coexist, supporting any desired combination of synchronous and asynchronous device types.

SDRAM Controller

The SDRAM controller provides an interface to up to four separate banks of industry-standard SDRAM devices or DIMMs, at

speeds up to f

each bank can has it's own memory select line (MS0

can be configured to contain between 16M bytes and

128M bytes of memory.

The controller maintains all of the banks as a contiguous

address space so that the processor sees this as a single address

space, even if different size devices are used in the different

banks.

A set of programmable timing parameters is available to configure the SDRAM banks to support slower memory devices. The

memory banks can be configured as either 32 bits wide for maximum performance and bandwidth or 16 bits wide for

minimum device count and lower system cost.

. Fully compliant with the SDRAM standard,

SCLK

–MS3), and

The SDRAM controller address, data, clock, and command pins

can drive loads up to 30 pF. For larger memory systems, the

SDRAM controller external buffer timing should be selected

and external buffering should be provided so that the load on

the SDRAM controller pins does not exceed 30 pF.

Asynchronous Controller

The asynchronous memory controller provides a configurable

interface for up to four separate banks of memory or I/O

devices. Each bank can be independently programmed with different timing parameters, enabling connection to a wide variety

of memory devices including SRAM, ROM, and flash EPROM,

as well as I/O devices that interface with standard memory control lines. Bank0 occupies a 14.7M word window and banks 1, 2,

and 3 occupy a 16M word window in the processor’s address

space but, if not fully populated, these windows are not made

contiguous by the memory controller logic. The banks can also

be configured as 8-bit, 16-bit, or 32-bit wide buses for ease of

interfacing to a range of memories and I/O devices tailored

either to high performance or to low cost and power.

The asynchronous memory controller is capable of a maximum

throughput of 267M bytes/sec using a 66MHz external bus

speed. Other features include 8 to 32-bit and 16 to 32-bit packing and unpacking, booting from Bank Select 1, and support for

delay line DMA.

ADSP-21367 INPUT/OUTPUT FEATURES

The ADSP-21367 I/O processor provides 34 channels of DMA,

as well as an extensive set of peripherals. These include a 20 pin

Digital Audio Interface which controls:

• Eight Serial ports

• S/PDIF Receiver/Transmitter

• Four Precision Clock generators

Rev. PrA | Page 6 of 48 | November 2004

Page 7

ADSP-21367Preliminary Technical Data

• Four Sample Rate Converters

• Internal Data port/Parallel Data Acquisition port

The ADSP-21367 processor also contains a 14 pin Digital

Peripheral Interface which controls:

• Three general-purpose timers

• Two Serial Peripheral Interfaces

•Two Universal Asynchronous Receiver/Transmitters

(UARTs)

2

• A Two Wire Interface/I

C

DMA Controller

The ADSP-21367’s on-chip DMA controller allows data transfers without processor intervention. The DMA controller

operates independently and invisibly to the processor core,

allowing DMA operations to occur while the core is simultaneously executing its program instructions. DMA transfers can

occur between the ADSP-21367’s internal memory and its serial

ports, the SPI-compatible (Serial Peripheral Interface) ports, the

IDP (Input Data Port), the Parallel Data Acquisition Port

(PDAP) or the UART. Thirty-four channels of DMA are available on the ADSP-21367—sixteen via the serial ports, eight via

the Input Data Port, four for the UARTs, two for the SPI interface, two for the external port, and two for memory-to-memory

transfers. Programs can be downloaded to the ADSP-21367

using DMA transfers. Other DMA features include interrupt

generation upon completion of DMA transfers, and DMA

chaining for automatic linked DMA transfers.

Delay Line DMA

The ADSP-21367 processor provides Delay Line DMA functionality. This allows processor reads and writes to external

Delay Line Buffers (and hence to external memory) with limited

core interaction.

Digital Audio Interface (DAI)

The Digital Audio Interface (DAI) provides the ability to connect various peripherals to any of the DSPs DAI pins

(DAI_P20–1).

Programs make these connections using the Signal Routing

Unit (SRU, shown in Figure 1.

The SRU is a matrix routing unit (or group of multiplexers) that

enables the peripherals provided by the DAI to be interconnected under software control. This allows easy use of the DAI

associated peripherals for a much wider variety of applications

by using a larger set of algorithms than is possible with non configurable signal paths.

The DAI also includes eight serial ports, an S/PDIF

receiver/transmitter, four precision clock generators (PCG),

eight channels of synchronous sample rate converters, and an

input data port (IDP). The IDP provides an additional input

path to the ADSP-21367 core, configurable as either eight channels of I

2

S serial data or as seven channels plus a single 20-bit

wide synchronous parallel data acquisition port. Each data

channel has its own DMA channel that is independent from the

ADSP-21367's serial ports.

For complete information on using the DAI, see the ADSP-

2136x SHARC Processor Hardware Reference.

Serial Ports

The ADSP-21367 features eight synchronous serial ports that

provide an inexpensive interface to a wide variety of digital and

mixed-signal peripheral devices such as Analog devices AD183x

family of audio codecs, ADCs, and DACs. The serial ports are

made up of two data lines, a clock and frame sync. The data

lines can be programmed to either transmit or receive and each

data line has a dedicated DMA channel.

Serial ports are enabled via 16 programmable and simultaneous

receive or transmit pins that support up to 32 transmit or 32

receive channels of audio data when all eight SPORTS are

enabled, or eight full duplex TDM streams of 128 channels per

frame.

The serial ports operate at a maximum data rate of 50M bits/s.

Serial port data can be automatically transferred to and from

on-chip memory via dedicated DMA channels. Each of the

serial ports can work in conjunction with another serial port to

provide TDM support. One SPORT provides two transmit signals while the other SPORT provides the two receive signals.

The frame sync and clock are shared.

Serial ports operate in five modes:

• Standard DSP serial mode

2

•Multichannel (TDM) mode with support for Packed I

S

mode

2

S mode

•I

2

•Packed I

S mode

• Left-justified sample pair mode

Left-justified sample pair mode is a mode where in each frame

sync cycle two samples of data are transmitted/received—one

sample on the high segment of the frame sync, the other on the

low segment of the frame sync. Programs have control over various attributes of this mode.

Each of the serial ports supports the left-justified sample pair

2

S protocols (I2S is an industry standard interface com-

and I

monly used by audio codecs, ADCs and DACs such as the

Analog Devices AD183x family), with two data pins, allowing

four left-justified sample pair or I

devices) per serial port, with a maximum of up to 32 I

2

S channels (using two stereo

2

S channels. The serial ports permit little-endian or big-endian

transmission formats and word lengths selectable from 3 bits to

32 bits. For the left-justified sample pair and I

2

S modes, dataword lengths are selectable between 8 bits and 32 bits. Serial

ports offer selectable synchronization and transmit modes as

well as optional µ-law or A-law companding selection on a per

channel basis. Serial port clocks and frame syncs can be internally or externally generated.

The serial ports also contain frame sync error detection logic

where the serial ports detect frame syncs that arrive early (for

example frame syncs that arrive while the transmission/reception of the previous word is occurring). All the serial ports also

share one dedicated error interrupt.

Rev. PrA | Page 7 of 48 | November 2004

Page 8

ADSP-21367 Preliminary Technical Data

S/PDIF Compatible Digital Audio Receiver/Transmitter and Synchronous/Asynchronous Sample Rate Converter

The S/PDIF transmitter has no separate DMA channels. It

receives audio data in serial format and converts it into a

biphase encoded signal. The serial data input to the transmitter

can be formatted as left justified, I

2

S or right justified with word

widths of 16, 18, 20, or 24 bits.

The serial data, clock, and frame sync inputs to the S/PDIF

transmitter are routed through the Signal Routing Unit (SRU).

They can come from a variety of sources such as the SPORTs,

external pins, the precision clock generators (PCGs), or the

sample rate converters (SRC) and are controlled by the SRU

control registers.

The sample rate converter (SRC) contains four SRC blocks and

is the same core as that used in the AD1896 192 kHz Stereo

Asynchronous Sample Rate Converter and provides up to

128dB SNR. The SRC block is used to perform synchronous or

asynchronous sample rate conversion across independent stereo

channels, without using internal processor resources. The four

SRC blocks can also be configured to operate together to convert multichannel audio data without phase mismatches.

Finally, the SRC is used to clean up audio data from jittery clock

sources such as the S/PDIF receiver.

Digital Peripheral Interface (DPI)

The Digital Peripheral Interface provides connections to two

serial peripheral interface ports, two universal asynchronous

receiver-transmitters (UARTs), a Two Wire Interface (TWI), 12

Flags, and three general-purpose timers.

Serial Peripheral (Compatible) Interface

The ADSP-21367 SHARC processor contains two Serial Peripheral Interface ports (SPIs). The SPI is an industry standard

synchronous serial link, enabling the ADSP-21367 SPI compatible port to communicate with other SPI compatible devices. The

SPI consists of two data pins, one device select pin, and one

clock pin. It is a full-duplex synchronous serial interface, supporting both master and slave modes. The SPI port can operate

in a multimaster environment by interfacing with up to four

other SPI compatible devices, either acting as a master or slave

device. The ADSP-21367 SPI compatible peripheral implementation also features programmable baud rate and clock phase

and polarities. The ADSP-21367 SPI compatible port uses open

drain drivers to support a multimaster configuration and to

avoid data contention.

UART Port

The ADSP-21367 processor provides a full-duplex Universal

Asynchronous Receiver/Transmitter (UART) port, which is

fully compatible with PC-standard UARTs. The UART port

provides a simplified UART interface to other peripherals or

hosts, supporting full-duplex, DMA-supported, asynchronous

transfers of serial data. The UART also has multiprocessor communication capability using 9-bit address detection. This allows

it to be used in multidrop networks through the RS-485 data

interface standard. The UART port also includes support for 5

to 8 data bits, 1 or 2 stop bits, and none, even, or odd parity. The

UART port supports two modes of operation:

• PIO (Programmed I/O) – The processor sends or receives

data by writing or reading I/O-mapped UART registers.

The data is double-buffered on both transmit and receive.

• DMA (Direct Memory Access) – The DMA controller

transfers both transmit and receive data. This reduces the

number and frequency of interrupts required to transfer

data to and from memory. The UART has two dedicated

DMA channels, one for transmit and one for receive. These

DMA channels have lower default priority than most DMA

channels because of their relatively low service rates.

The UART port's baud rate, serial data format, error code generation and status, and interrupts are programmable:

• Supporting bit rates ranging from (f

(f

/16) bits per second.

SCLK

/ 1,048,576) to

SCLK

• Supporting data formats from 7 to12 bits per frame.

• Both transmit and receive operations can be configured to

generate maskable interrupts to the processor.

The UART port’s clock rate is calculated as:

f

UART Clock Rate

---------------------------------------- ---------=

16 UART_Divisor×

SCLK

Where the 16-bit UART_Divisor comes from the DLH register

(most significant 8 bits) and DLL register (least significant

8bits).

In conjunction with the general-purpose timer functions, autobaud detection is supported.

Timers

The ADSP-21367 has a total of four timers: a core timer that can

generate periodic software interrupts and three general purpose

timers that can generate periodic interrupts and be independently set to operate in one of three modes:

• Pulse Waveform Generation mode

• Pulse Width Count /Capture mode

• External Event Watchdog mode

The core timer can be configured to use FLAG3 as a Timer

Expired signal, and each general purpose timer has one bidirectional pin and four registers that implement its mode of

operation: a 6-bit configuration register, a 32-bit count register,

a 32-bit period register, and a 32-bit pulse width register. A single control and status register enables or disables all three

general purpose timers independently.

Rev. PrA | Page 8 of 48 | November 2004

Page 9

ADSP-21367Preliminary Technical Data

Two Wire Interface Port (TWI)

The TWI is a bi-directional 2-wire, serial bus used to move 8-bit

data while maintaining compliance with the I2C bus protocol.

The TWI Master incorporates the following features:

• Simultaneous Master and Slave operation on multiple

device systems with support for multi master data

arbitration

• Digital filtering and timed event processing

• 7 and 10 bit addressing

• 100K bits/s and 400K bits/s data rates

• Low interrupt rate

Pulse Width Modulation

The PWM module is a flexible, programmable, PWM waveform

generator that can be programmed to generate the required

switching patterns for various applications related to motor and

engine control or audio power control. The PWM generator can

generate either center-aligned or edge-aligned PWM waveforms. In addition, it can generate complementary signals on

two outputs in paired mode or independent signals in non

paired mode (applicable to a single group of four PWM

waveforms).

The entire PWM module has four groups of four PWM outputs

each. Therefore, this module generates 16 PWM outputs in

total. Each PWM group produces two pairs of PWM signals on

the four PWM outputs.

The PWM generator is capable of operating in two distinct

modes while generating center-aligned PWM waveforms: single

update mode or double update mode. In single update mode the

duty cycle values are programmable only once per PWM period.

This results in PWM patterns that are symmetrical about the

mid-point of the PWM period. In double update mode, a second updating of the PWM registers is implemented at the midpoint of the PWM period. In this mode, it is possible to produce

asymmetrical PWM patterns that produce lower harmonic distortion in three-phase PWM inverters.

ROM Based Security

The ADSP-21367 has a ROM security feature that provides

hardware support for securing user software code by preventing

unauthorized reading from the internal code when enabled.

When using this feature, the processor does not boot-load any

external code, executing exclusively from internal SRAM/ROM.

Additionally, the processor is not freely accessible via the JTAG

port. Instead, a unique 64-bit key, which must be scanned in

through the JTAG or Test Access Port will be assigned to each

customer. The device will ignore a wrong key. Emulation features and external boot modes are only available after the

correct key is scanned.

SYSTEM DESIGN

The following sections provide an introduction to system design

options and power supply issues.

Program Booting

The internal memory of the ADSP-21367 boots at system

power-up from an 8-bit EPROM via the external port, an SPI

master, an SPI slave or an internal boot. Booting is determined

by the Boot Configuration (BOOTCFG1–0) pins (see Table 4 on

page 14). Selection of the boot source is controlled via the SPI as

either a master or slave device, or it can immediately begin executing from ROM.

Power Supplies

The ADSP-21367 has separate power supply connections for the

internal (V

DDINT

), external (V

power supplies. The internal and analog supplies must meet the

1.3V requirement. The external supply must meet the 3.3V

requirement. All external supply pins must be connected to the

same power supply.

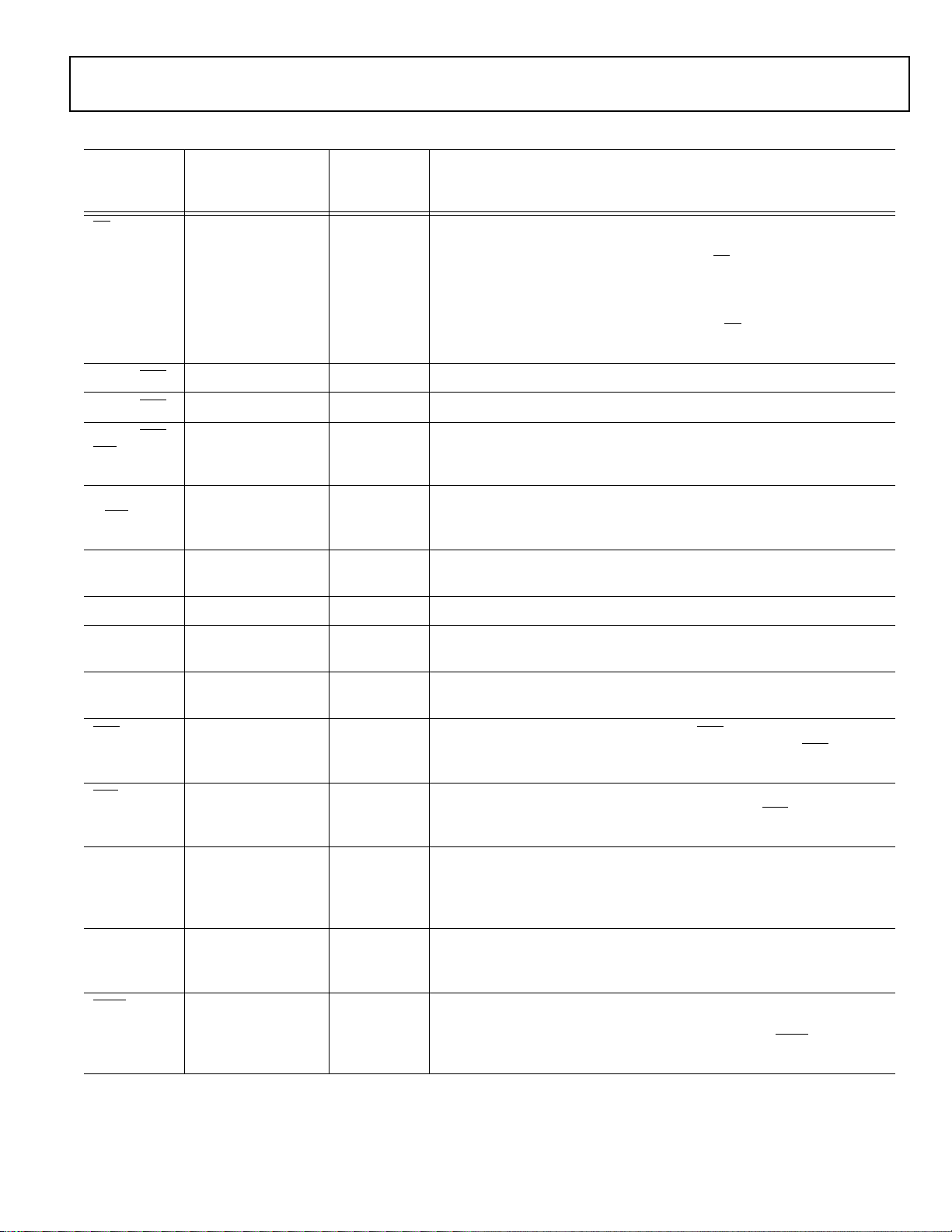

Note that the analog supply (A

clock generator PLL. To produce a stable clock, programs

should provide an external circuit to filter the power input to

the A

pin. Place the filter as close as possible to the pin. For

VDD

an example circuit, see Figure 2. To prevent noise coupling, use

a wide trace for the analog ground (A

decoupling capacitor as close as possible to the pin. Note that

the A

VSS

and A

pins specified in Figure 2 are inputs to the

VDD

processor and not the analog ground plane on the board. For

more information, see Electrical Characteristics on page 15.

10⍀

V

DDINT

Figure 2. Analog Power (A

Target Board JTAG Emulator Connector

Analog Devices DSP Tools product line of JTAG emulators uses

the IEEE 1149.1 JTAG test access port of the ADSP-21367 processor to monitor and control the target board processor during

emulation. Analog Devices DSP Tools product line of JTAG

emulators provides emulation at full processor speed, allowing

inspection and modification of memory, registers, and processor stacks. The processor's JTAG interface ensures that the

emulator will not affect target system loading or timing.

For complete information on Analog Devices’ SHARC DSP

Tools product line of JTAG emulator operation, see the appropriate “Emulator Hardware User's Guide”.

), and analog (A

DDEXT

) powers the ADSP-21367’s

VDD

) signal and install a

VSS

0.01F0.1F

A

VSS

) Filter Circuit

VDD

VDD/AVSS

A

VDD

)

Rev. PrA | Page 9 of 48 | November 2004

Page 10

ADSP-21367 Preliminary Technical Data

DEVELOPMENT TOOLS

The ADSP-21367 is supported with a complete set of

CROSSCORE® software and hardware development tools,

including Analog Devices emulators and VisualDSP++® development environment. The same emulator hardware that

supports other SHARC processors also fully emulates the

ADSP-21367.

The VisualDSP++ project management environment lets programmers develop and debug an application. This environment

includes an easy to use assembler (which is based on an algebraic syntax), an archiver (librarian/library builder), a linker, a

loader, a cycle-accurate instruction-level simulator, a C/C++

compiler, and a C/C++ runtime library that includes DSP and

mathematical functions. A key point for these tools is C/C++

code efficiency. The compiler has been developed for efficient

translation of C/C++ code to DSP assembly. The SHARC has

architectural features that improve the efficiency of compiled

C/C++ code.

The VisualDSP++ debugger has a number of important features. Data visualization is enhanced by a plotting package that

offers a significant level of flexibility. This graphical representation of user data enables the programmer to quickly determine

the performance of an algorithm. As algorithms grow in complexity, this capability can have increasing significance on the

designer’s development schedule, increasing productivity. Statistical profiling enables the programmer to non intrusively poll

the processor as it is running the program. This feature, unique

to VisualDSP++, enables the software developer to passively

gather important code execution metrics without interrupting

the real-time characteristics of the program. Essentially, the

developer can identify bottlenecks in software quickly and efficiently. By using the profiler, the programmer can focus on

those areas in the program that impact performance and take

corrective action.

Debugging both C/C++ and assembly programs with the

VisualDSP++ debugger, programmers can:

• View mixed C/C++ and assembly code (interleaved source

and object information)

• Insert breakpoints

• Set conditional breakpoints on registers, memory,

and stacks

• Trace instruction execution

• Perform linear or statistical profiling of program execution

• Fill, dump, and graphically plot the contents of memory

• Perform source level debugging

• Create custom debugger windows

The VisualDSP++ IDDE lets programmers define and manage

DSP software development. Its dialog boxes and property pages

let programmers configure and manage all of the SHARC development tools, including the color syntax highlighting in the

VisualDSP++ editor. This capability permits programmers to:

• Control how the development tools process inputs and

generate outputs

• Maintain a one-to-one correspondence with the tool’s

command line switches

The VisualDSP++ Kernel (VDK) incorporates scheduling and

resource management tailored specifically to address the memory and timing constraints of DSP programming. These

capabilities enable engineers to develop code more effectively,

eliminating the need to start from the very beginning, when

developing new application code. The VDK features include

Threads, Critical and Unscheduled regions, Semaphores,

Events, and Device flags. The VDK also supports Priority-based,

Preemptive, Cooperative, and Time-Sliced scheduling

approaches. In addition, the VDK was designed to be scalable. If

the application does not use a specific feature, the support code

for that feature is excluded from the target system.

Because the VDK is a library, a developer can decide whether to

use it or not. The VDK is integrated into the VisualDSP++

development environment, but can also be used via standard

command line tools. When the VDK is used, the development

environment assists the developer with many error-prone tasks

and assists in managing system resources, automating the generation of various VDK based objects, and visualizing the

system state, when debugging an application that uses the VDK.

VisualDSP++ Component Software Engineering (VCSE) is

Analog Devices’ technology for creating, using, and reusing

software components (independent modules of substantial

functionality) to quickly and reliably assemble software applications. Download components from the Web and drop them into

the application. Publish component archives from within

VisualDSP++. VCSE supports component implementation in

C/C++ or assembly language.

Use the Expert Linker to visually manipulate the placement of

code and data on the embedded system. View memory utilization in a color-coded graphical form, easily move code and data

to different areas of the processor or external memory with the

drag of the mouse, examine run time stack and heap usage. The

Expert Linker is fully compatible with the existing Linker Definition File (LDF), allowing the developer to move between the

graphical and textual environments.

In addition to the software and hardware development tools

available from Analog Devices, third parties provide a wide

range of tools supporting the SHARC processor family. Hardware tools include SHARC processor PC plug-in cards. Third

party software tools include DSP libraries, real-time operating

systems, and block diagram design tools.

Rev. PrA | Page 10 of 48 | November 2004

Page 11

ADSP-21367Preliminary Technical Data

Designing an Emulator-Compatible DSP Board (Target)

The Analog Devices family of emulators are tools that every

DSP developer needs to test and debug hardware and software

systems. Analog Devices has supplied an IEEE 1149.1 JTAG

Test Access Port (TAP) on each JTAG DSP. Nonintrusive incircuit emulation is assured by the use of the processor’s JTAG

interface—the emulator does not affect target system loading or

timing. The emulator uses the TAP to access the internal features of the processor, allowing the developer to load code, set

breakpoints, observe variables, observe memory, and examine

registers. The processor must be halted to send data and commands, but once an operation has been completed by the

emulator, the DSP system is set running at full speed with no

impact on system timing.

To use these emulators, the target board must include a header

that connects the DSP’s JTAG port to the emulator.

For details on target board design issues including mechanical

layout, single processor connections, signal buffering, signal termination, and emulator pod logic, see the EE-68: Analog Devices

JTAG Emulation Technical Reference on the Analog Devices

website (www.analog.com)—use site search on “EE-68.” This

document is updated regularly to keep pace with improvements

to emulator support.

Evaluation Kit

Analog Devices offers a range of EZ-KIT Lite evaluation platforms to use as a cost effective method to learn more about

developing or prototyping applications with Analog Devices

processors, platforms, and software tools. Each EZ-KIT Lite

includes an evaluation board along with an evaluation suite of

the VisualDSP++ development and debugging environment

with the C/C++ compiler, assembler, and linker. Also included

are sample application programs, power supply, and a USB

cable. All evaluation versions of the software tools are limited

for use only with the EZ-KIT Lite product.

The USB controller on the EZ-KIT Lite board connects the

board to the USB port of the user’s PC, enabling the

VisualDSP++ evaluation suite to emulate the on-board processor in-circuit. This permits the customer to download, execute,

and debug programs for the EZ-KIT Lite system. It also allows

in-circuit programming of the on-board Flash device to store

user-specific boot code, enabling the board to run as a standalone unit without being connected to the PC.

With a full version of VisualDSP++ installed (sold separately),

engineers can develop software for the EZ-KIT Lite or any custom defined system. Connecting one of Analog Devices JTAG

emulators to the EZ-KIT Lite board enables high-speed, nonintrusive emulation.

ADDITIONAL INFORMATION

This data sheet provides a general overview of the ADSP-21367

architecture and functionality. For detailed information on the

ADSP-2136x Family core architecture and instruction set, refer

to the ADSP-2136x SHARC Processor Hardware Reference and

the ADSP-2136x SHARC Processor Programming Reference.

Rev. PrA | Page 11 of 48 | November 2004

Page 12

ADSP-21367 Preliminary Technical Data

PIN FUNCTION DESCRIPTIONS

The following symbols appear in the Type column of TBD:

A = Asynchronous, G = Ground, I = Input, O = Output,

P = Power Supply, S = Synchronous, (A/D) = Active Drive,

(O/D) = Open Drain, and T = Three-State, (pd) = pull-down

resistor, (pu) = pull-up resistor.

Table 3. Pin List

Name Type State During

and After

Reset

ADDR

DATA

23–0

31–0

I/O with programmable

1

PUP

I/O with programmable

Three-state

Three-state

PUP

DAI _P

20–1

DPI _P

14–1

ACK Input with programma-

RD

I/O with programma-

2

PUP

ble

I/O with programma-

3

PUP

ble

1

ble PUP

I/O with programmable

1

PUP

Three-state

Three-state

Description

External Address Bus.

External Data Bus.

Digital Audio Interface Pins

. These pins provide the physical interface to the SRU.

The SRU configuration registers define the combination of on-chip peripheral inputs

or outputs connected to the pin and to the pin’s output enable. The configuration

registers of these peripherals then determines the exact behavior of the pin. Any

input or output signal present in the SRU may be routed to any of these pins. The SRU

provides the connection from the Serial ports, Input data port, precision clock generators and timers, sample rate converters and SPI to the DAI_P20–1 pins These pins

Ω

have internal 22.5 k

pull-up resistors which are enabled on reset. These pull-ups can

be disabled in the DAI_PIN_PULLUP register.

Digital Peripheral Interface.

Memory Acknowledge.

External devices can deassert ACK (low) to add wait states

to an external memory access. ACK is used by I/O devices, memory controllers, or

other peripherals to hold off completion of an external memory access.

External Port Read Enable.

RD is asserted low whenever the processor reads 8-bit

or 16-bit data from an external memory device. When AD15–0 are flags, this pin

remains deasserted. RD

has a 22.5 kΩ internal pull-up resistor.

WR

SDRAS

SDCAS

SDWE

SDCKE Output with program-

SDA10 Output with program-

Output with programmable PUP

Output with programmable PUP

Output with programmable PUP

Output with programmable PUP

mable PUP

mable PUP

1

1

1

1

1

1

SDCLK0 I/O

External Port Write Enable.

WR is asserted low whenever the processor writes 8-bit

or 16-bit data to an external memory devi ce. When AD15–0 are flags, this pin remains

deasserted. WR

has a 22.5 kΩ internal pull-up resistor.

SDRAM Row Address Strobe.

SDRAM column address select.

SDRAM Write Enable.

SDRAM Clock Enable.

SDRAM A10.

SDRAM Clock Configure.

Rev. PrA | Page 12 of 48 | November 2004

Connect to SDRAM’s WE or W buffer pin.

Connect to SDRAM’s CKE pin.

Connect to SDRAM’s RAS pin.

Connect to SDRAM’s CAS pin.

Page 13

Table 3. Pin List

ADSP-21367Preliminary Technical Data

Name Type State During

and After

Reset

MS

0–1

FLAG[0]/IRQ0

I/O with programmable

1

PUP

I/O

FLAG[1]/IRQ1 I/O

FLAG[2]/IRQ2/

MS2

I/O with

programmable

1

pull-

up (for MS mode)

FLAG[3]/TIMEX

P/MS3

I/O with

programmable

1

pull-

up (for MS mode)

TDI Input with pull-up

TDO Output

Description

Memory Select Lines 0–1.

These lines are asserted (low) as chip selects for the corresponding banks of external memory. Memory bank size must be defined in the

ADSP-21062’s system control register (SYSCON) . The MS

lines are decoded memory

3-0

address lines that change at the same time as the other address lines. When no

external memory access is occurring the MS3-0 lines are inactive; they are active

however when a conditional memory access instruction is executed, whether or not

the condition is true. In a multiprocessing system the MS

lines are output by the

3-0

bus master.

FLAG0/Interrupt Request0.

FLAG1/Interrupt Request1.

FLAG2/Interrupt Request/Memory Select2.

FLAG3/Timer Expired/Memory Select3.

Test Data Input (JTAG).

Ω

internal pull-up resistor.

22.5 k

Test Data Output (JTAG).

Provides serial data for the boundary scan logic. TDI has a

Serial scan output of the boundary scan path.

TMS Input with pull-up

TCK Input

TRST

EMU

CLK_CFG

BOOT_CFG

RESET

1–0

Input with pull-up

Output with pull-up

Input

Input

1–0

Input

Test Mode S elec t ( JTAG) .

Used to control the test state machine. TMS has a 22.5 kΩ

internal pull-up resistor.

Test Clock ( JTAG).

Provides a clock for JTAG boundary scan. TCK must be asserted

(pulsed low) after power-up or held low for proper operation of the ADSP-21367.

Te st Re se t (J TAG ).

after power-up or held low for proper operation of the ADSP-21367. TRST

Ω

internal pull-up resistor.

k

Emulation Status.

product line of JTAG emulators target board connector only. EMU

Resets the test state machine. TRST must be asserted (pulsed low)

has a 22.5

Must be connected to the ADSP-21367 Analog Devices DSP Tools

has a 22.5 kΩ

internal pull-up resistor.

Core/CLKIN Ratio Control.

These pins set the start up clock frequency. See Table5

for a description of the clock configuration modes.

Note that the operating frequency can be changed by programming the PLL multiplier and divider in the PMCTL register at any time after the core comes out of reset.

Boot Configuration Select.

These pins select the boot mode for the processor. The

BOOTCFG pins must be valid before reset is asserted. See Tab le 4 for a description of

the boot modes.

Processor Reset.

Resets the ADSP-21367 to a known state. Upon deassertion, there

is a 4096 CLKIN cycle latency for the PLL to lock. After this time, the core begins

program exe cution from the h ardware reset vect or address. The RES ET

input must be

asserted (low) at power-up.

Rev. PrA | Page 13 of 48 | November 2004

Page 14

ADSP-21367 Preliminary Technical Data

Table 3. Pin List

Name Type State During

and After

Reset

XTAL Output

CLKIN

CLKOUT Output

1

Pull-up is always enabled for ID - 000 in uniprocessor mode and ID- 001 in Multiprocessing mode.

2

Pull-up can be enabled/disabled, value of pull-up cannot be programmed.

3

OP is three-statable

Description

Crystal Oscillator Terminal.

crystal.

Local Clock In.

It configures the ADSP-21367 to use either its internal clock generator or an external

clock source. Connecting the necessary components to CLKIN and XTAL enables the

internal clock generator. Connecting the external clock to CLKIN while leaving XTAL

unconnected configures the ADSP-21367 to use the external clock source such as an

external clock oscillator. The core is clocked either by the PLL output or this clock input

depending on the CLKCFG1–0 pin settings. CLKIN may not be halted, changed, or

operated below the specified frequency.

Local Clock O ut.

can be switched between the PLL output clock and reset out by setting bit 12 of the

PMCTREG register. The default is reset out.

Used in conjunction with XTAL. CLKIN is the ADSP-21367 clock input.

CL KOUT c an als o be c onfig ured as a reset out pin.The functionality

ADDRESS/DATA MODES

TBD

BOOT MODES

Used in conjunction with CLKIN to drive an external

Table 4. Boot Mode Selection

BOOTCFG1–0 Booting Mode

00 SPI Slave Boot

01 SPI Master Boot

10 AMI boot via EPROM

CORE INSTRUCTION RATE TO CLKIN RATIO MODES

For details on processor timing, see Timing Specifications and

Figure 3 on page 17.

Table 5. Core Instruction Rate/ CLKIN Ratio Selection

CLKCFG1–0 Core to CLKIN Ratio

00 6:1

01 32:1

10 16:1

Rev. PrA | Page 14 of 48 | November 2004

Page 15

ADSP-21367 SPECIFICATIONS

RECOMMENDED OPERATING CONDITIONS

ADSP-21367Preliminary Technical Data

K Grade

Parameter

V

DDINT

A

VDD

V

DDEXT

2

V

IH

2

V

IL

V

IH_CLKIN

V

IL_CLKIN

T

AMB

1

Specifications subject to change without notice.

2

Applies to input and bidirectional pins: AD15–0, FLAG3–0, DAI_Px, SPICLK, MOSI, MISO, SPIDS, BOOTCFGx, CLKCFGx, RESET, TCK, TMS, TDI, TRST.

3

Applies to input pin CLKIN.

4

See Thermal Characteristics on page 41 for information on thermal specifications.

5

See Engineer-to-Engineer Note (No. TBD) for further information.

1

Internal (Core) Supply Voltage 1.235 1.365 V

Analog (PLL) Supply Voltage 1.235 1.365 V

External (I/O) Supply Voltage 3.13 3.47 V

High Level Input Voltage @ V

Low Level Input Voltage @ V

3

High Level Input Voltage @ V

Low Level Input Voltage @ V

4, 5

Ambient Operating Temperature 0 +70 °C

= max 2.0 V

DDEXT

= min –0.5 +0.8 V

DDEXT

= max 1.74 V

DDEXT

= min –0.5 +1.19 V

DDEXT

Min Max Unit

+ 0.5 V

DDEXT

+ 0.5 V

DDEXT

ELECTRICAL CHARACTERISTICS

Parameter

V

OH

V

OL

4, 5

I

IH

4

I

IL

I

ILPU

I

OZH

I

OZL

I

OZLPU

I

DD-INTYP

AI

DD

11, 12

C

IN

1

Specifications subject to change without notice.

2

Applies to output and bidirectional pins: AD15–0, RD, WR, ALE, FLAG3–0, DAI_Px, SPICLK, MOSI, MISO, EMU, TDO, CLKOUT, XTAL.

3

See Output Drive Currents on page 41 for typical drive current capabilities.

4

Applies to input pins: SPIDS, BOOTCFGx, CLKCFGx, TCK, RESET, CLKIN.

5

Applies to input pins with 22.5 kΩ internal pull-ups: TRST, TMS, TDI.

6

Applies to three-statable pins: FLAG3–0.

7

Applies to three-statable pins with 22.5 kΩ pull-ups: AD15–0, DAI_Px, SPICLK, EMU, MISO, MOSI.

8

Typical internal current data reflects nominal operating conditions.

9

See Engineer-to-Engineer Note (No. TBD) for further information.

10

Characterized, but not tested.

11

Applies to all signal pins.

12

Guaranteed, but not tested.

1

2

2

High Level Output Voltage @ V

Low Level Output Voltage @ V

High Level Input Current @ V

Low Level Input Current @ V

5

6, 7

6

7

8, 9

10

Low Level Input Current Pull-up @ V

Three-State Leakage Current @ V

Three-State Leakage Current @ V

Three-State Leakage Current Pull-up @ V

Supply Current (Internal) t

Supply Current (Analog) A

Input Capacitance fIN=1 MHz, T

Test Conditions Min Max Unit

= min, IOH = –1.0 mA

DDEXT

= min, IOL = 1.0 mA

DDEXT

= max, VIN = V

DDEXT

= max, VIN = 0 V 10 µA

DDEXT

= max, VIN = 0 V 200 µA

DDEXT

= max, VIN = V

DDEXT

= max, VIN = 0 V 10 µA

DDEXT

= max, VIN = 0 V 200 µA

DDEXT

= 5.0 ns, V

CCLK

= max 10 mA

VDD

= 1.3 500 mA

DDINT

=25°C, VIN=1.3V 4.7 pF

CASE

3

3

max 10 µA

DDEXT

max 10 µA

DDEXT

2.4 V

0.4 V

Rev. PrA | Page 15 of 48 | November 2004

Page 16

ADSP-21367 Preliminary Technical Data

ABSOLUTE MAXIMUM RATINGS

Parameter Rating

Internal (Core) Supply Voltage (V

Analog (PLL) Supply Voltage (A

External (I/O) Supply Voltage (V

Input Voltage–0.5 V to V

DDEXT

1

Output Voltage Swing–0.5 V to V

Load Capacitance

Storage Temperature Range

1

1

–65°C to +150°C

DDINT

VDD

DDEXT

DDEXT

1

)

1

)

1

)

–0.3 V to +1.5 V

–0.3 V to +1.5 V

–0.3 V to +4.6 V

+ 0.5 V

1

+ 0.5 V

200 pF

Junction Temperature under Bias 125°C

1

Stresses greater than those listed above may cause permanent damage to the device. These are stress ratings only;

functional operation of the device at these or any other conditions greater than those indicated in the operational

sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended periods

may affect device reliability.

ESD SENSITIVITY

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADSP-21367 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

TIMING SPECIFICATIONS

The ADSP-21367’s internal clock (a multiple of CLKIN) provides the clock signal for timing internal memory, processor

core, serial ports, and parallel port (as required for read/write

strobes in asynchronous access mode). During reset, program

the ratio between the processor’s internal clock frequency and

external (CLKIN) clock frequency with the CLKCFG1–0 pins

(see Table 5 on page 14). To determine switching frequencies

for the serial ports, divide down the internal clock, using the

programmable divider control of each port (DIVx for the serial

ports).

The ADSP-21367’s internal clock switches at higher frequencies

than the system input clock (CLKIN). To generate the internal

clock, the processor uses an internal phase-locked loop (PLL).

This PLL-based clocking minimizes the skew between the system clock (CLKIN) signal and the processor’s internal clock (the

clock source for the parallel port logic and I/O pads).

Note the definitions of various clock periods that are a function

of CLKIN and the appropriate ratio control (Table 6).

Table 6. ADSP-21367 CLKOUT and CCLK Clock

Generation Operation

Timing

Requirements

CLKIN Input Clock 1/t

CCLK Core Clock 1/t

Description Calculation

CK

CCLK

Table 7. Clock Periods

Timing

Requirements

t

CK

t

CCLK

t

PCLK

t

SCLK

t

SDCLK

t

SPICLK

1

where:

SR = serial port-to-core clock ratio (wide range, determined by SPORT

CLKDIV)

SPIR = SPI-to-Core Clock Ratio (wide range, determined by SPIBAUD register)

DAI_Px = Serial Port Clock

SPICLK = SPI Clock

Figure 3 shows Core to CLKIN ratios of 6:1, 16:1 and 32:1 with

external oscillator or crystal. Note that more ratios are possible

and can be set through software using the power management

control register (PMCTL). For more information, see the ADSP-

2136x SHARC Processor Programming Reference.

Use the exact timing information given. Do not attempt to

derive parameters from the addition or subtraction of others.

While addition or subtraction would yield meaningful results

for an individual device, the values given in this data sheet

reflect statistical variations and worst cases. Consequently, it is

not meaningful to add parameters to derive longer times. See

Figure 34 on page 41 under Test Conditions for voltage refer-

ence levels.

Description

1

CLKIN Clock Period

(Processor) Core Clock Period

(Peripheral) Clock Period = 2 × t

Serial Port Clock Period = (t

PCLK

SDRAM Clock Period = (TBD)

SPI Clock Period = (t

PCLK

) × SPIR

CCLK

) × SR

Rev. PrA | Page 16 of 48 | November 2004

Page 17

ADSP-21367Preliminary Technical Data

CLKIN

XTAL

XTAL

OSC

PLLILCLK

PLL

6:1, 16:1,

32:1

CLK-CFG [1: 0]

Figure 3. Core Clock and System Clock Relationship to CLKIN

CLKOUT

CCLK

(CORE CLOCK)

SDCLK

(SDRAM CLOCK)

Switching Characteristics specify how the processor changes its

signals. Circuitry external to the processor must be designed for

compatibility with these signal characteristics. Switching characteristics describe what the processor will do in a given

circumstance. Use switching characteristics to ensure that any

timing requirement of a device connected to the processor (such

as memory) is satisfied.

Timing Requirements apply to signals that are controlled by circuitry external to the processor, such as the data input for a read

operation. Timing requirements guarantee that the processor

operates correctly with other devices.

Rev. PrA | Page 17 of 48 | November 2004

Page 18

ADSP-21367 Preliminary Technical Data

Power-Up Sequencing

The timing requirements for processor startup are given in

Table 8.

Table 8. Power Up Sequencing Timing Requirements (Processor Startup)

Parameter Min Max Unit

Timing Requirements

t

RSTVDD

t

IVDDEVDD

t

CLKVDD

t

CLKRST

t

PLLRST

1

RESET Low Before V

V

on Before V

DDINT

CLKIN Valid After V

DDINT/VDDEXT

DDEXT

DDINT/VDDEXT

on 0 ns

–50 200 ms

Valid 0 200 ms

CLKIN Valid Before RESET Deasserted 10

PLL Control Setup Before RESET Deasserted 20

2

3

µs

µs

Switching Characteristic

t

CORERST

1

Valid V

DDINT/VDDEXT

depending on the design of the power supply subsystem.

2

Assumes a stable CLKIN signal, after meeting worst-case startup timing of crystal oscillators. Refer to your crystal oscillator manufacturer's datasheet for startup time.

Assume a 25 ms maximum oscillator startup time if using the XTAL pin and internal oscillator circuit in conjunction with an external crystal.

3

Based on CLKIN cycles

4

Applies after the power-up sequence is complete. Subsequent resets require a minimum of 4 CLKIN cycles for RESET to be held low in order to properly initialize and

propagate default states at all I/O pins.

5

The 4096 cycle count depends on t

cycles maximum.

Core Reset Deasserted After RESET Deasserted 4096tCK + 2 t

assumes that the supplies are fully ramped to their 1.3 and 3.3 volt rails. Voltage ramp rates can vary from microseconds to hundreds of milliseconds

specification in Table 10. If setup time is not met, 1 additional CLKIN cycle may be added to the core reset time, resulting in 4097

SRST

RESET

t

RSTVDD

V

DDINT

V

DDEXT

CLKIN

CLK_CFG1-0

t

IVDDEVDD

t

CLKVDD

t

CLKRST

CCLK

4,

5

RSTOUT

t

PLLRST

Figure 4. Power-Up Sequencing

Rev. PrA | Page 18 of 48 | November 2004

t

CORERST

Page 19

Clock Input

Table 9. Clock Input

Parameter 400 MHz Unit

Min Max

Timing Requirements

t

CK

t

CKL

t

CKH

t

CKRF

3

t

CCLK

1

Applies only for CLKCFG1–0 = 00 and default values for PLL control bits in PMCTL.

2

Applies only for CLKCFG1–0 = 01 and default values for PLL control bits in PMCTL.

3

Any changes to PLL control bits in the PMCTL register must meet core clock timing specification t

CLKIN

CLKIN Period 15

CLKIN Width Low 6

CLKIN Width High 6

1

1

CLKIN Rise/Fall (0.4V–2.0V) TBD ns

CCLK Period 2.5

t

CK

t

CKH

t

CKL

1

1

.

CCLK

2

320

150

150

2

2

ns

ns

ns

10 ns

ADSP-21367Preliminary Technical Data

Figure 5. Clock Input

Clock Signals

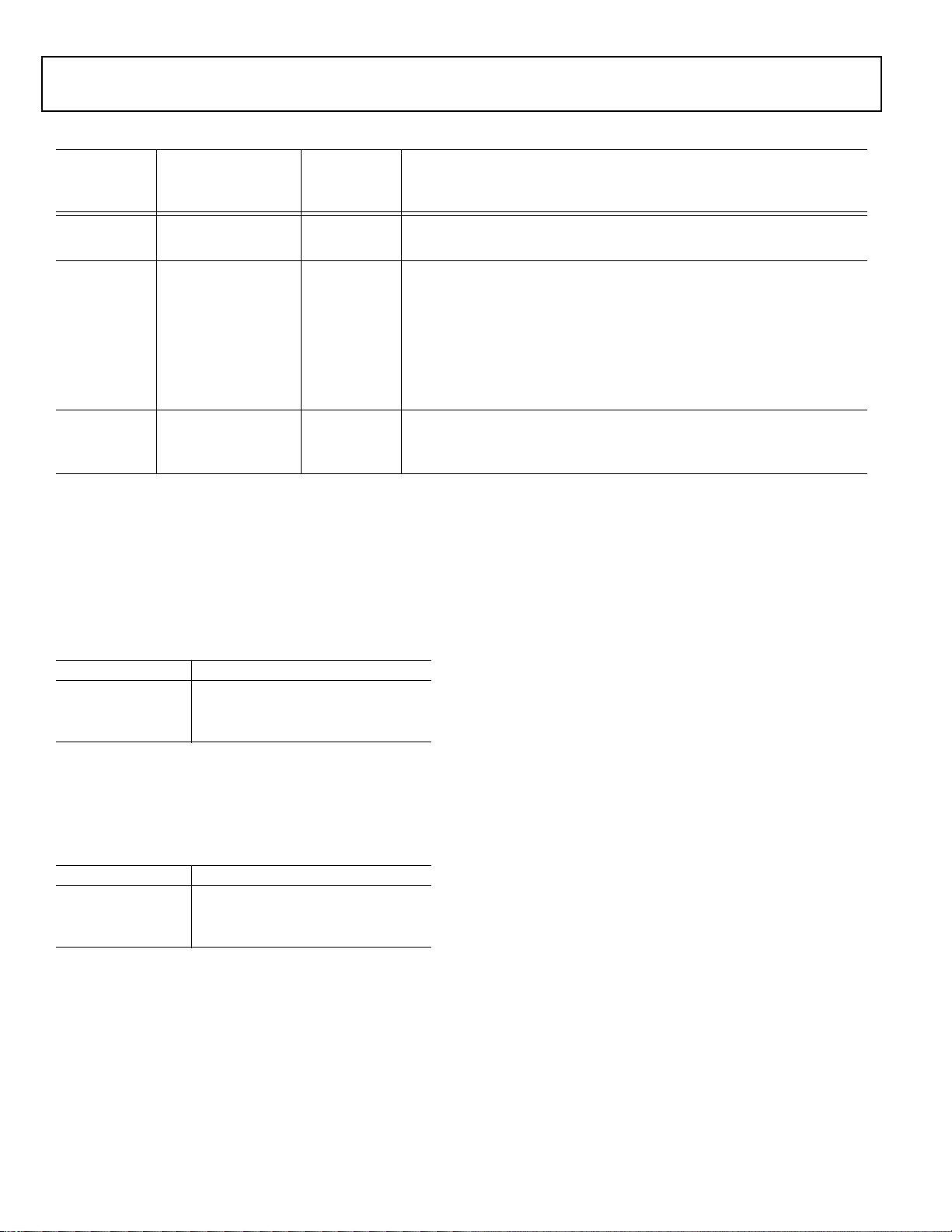

The ADSP-21367 can use an external clock or a crystal. See the

CLKIN pin description in TBD. The programmer can configure

the ADSP-21367 to use its internal clock generator by connecting the necessary components to CLKIN and XTAL. Figure 6

shows the component connections used for a crystal operating

in fundamental mode. Note that the clock rate is achieved using

a 16.67 MHz crystal and a PLL multiplier ratio 16:1

(CCLK:CLKIN achieves a clock speed of 266 MHz). To achieve

the full core clock rate, programs need to configure the multiplier bits in the PMCTL register.

CLKIN XTAL

C1 C2

NOTE: C1 AND C2 ARE SPECIFIC TO CRYSTAL SPECIFIED FOR X1.

CONTACT CRYSTAL MANUFACTURER FOR DETAILS. CRYSTAL

SELECTION MUST COMPLY WITH CLKCFG1-0 = 10 OR = 01.

Figure 6. 400 MHz Operation (Fundamental Mode Crystal)

1M⍀

X1

Rev. PrA | Page 19 of 48 | November 2004

Page 20

ADSP-21367 Preliminary Technical Data

Reset

Table 10. Reset

Parameter Min Max Unit

Timing Requirements

1

t

WRST

t

SRST

1

Applies after the power-up sequence is complete. At power-up, the processor's internal phase-locked loop requires no more than 100 µs while RESET is low, assuming

stable VDD and CLKIN (not including start-up time of external clock oscillator).

Interrupts

The following timing specification applies to the FLAG0,

FLAG1, and FLAG2 pins when they are configured as IRQ0

, and IRQ2 interrupts.

IRQ1