Page 1

ADSP-21060 Industrial SHARC

®

a

SUMMARY

High Performance Signal Processor for Communica-

tions, Graphics, and Imaging Applications

Super Harvard Architecture

Four Independent Buses for Dual Data Fetch,

Instruction Fetch, and Nonintrusive I/O

32-Bit IEEE Floating-Point Computation Units—

Multiplier, ALU, and Shifter

Dual-Ported On-Chip SRAM and Integrated I/O

Peripherals—A Complete System-On-A-Chip

Integrated Multiprocessing Features

Industrial Temperature Grade Hermetic Ceramic QFP

Package

KEY FEATURES

40 MIPS, 25 ns Instruction Rate, Single-Cycle Instruction

Execution

120 MFLOPS Peak, 80 MFLOPS Sustained Performance

Dual Data Address Generators with Modulo and Bit-

Reverse Addressing

DSP Microcomputer Family

ADSP-21060C/ADSP-21060LC

Efficient Program Sequencing with Zero-Overhead

Looping: Single-Cycle Loop Setup

IEEE JTAG Standard 1149.1 Test Access Port and

On-Chip Emulation

240-Lead Thermally Enhanced CQFP Package

32-Bit Single-Precision and 40-Bit Extended-Precision

IEEE Floating-Point Data Formats or 32-Bit Fixed-

Point Data Format

Parallel Computations

Single-Cycle Multiply and ALU Operations in Parallel

with Dual Memory Read/Writes and Instruction Fetch

Multiply with Add and Subtract for Accelerated FFT

Butterfly Computation

4 Mbit On-Chip SRAM

Dual-Ported for Independent Access by Core Processor

and DMA

Off-Chip Memory Interfacing

4 Gigawords Addressable

Programmable Wait State Generation, Page-Mode

DRAM Support

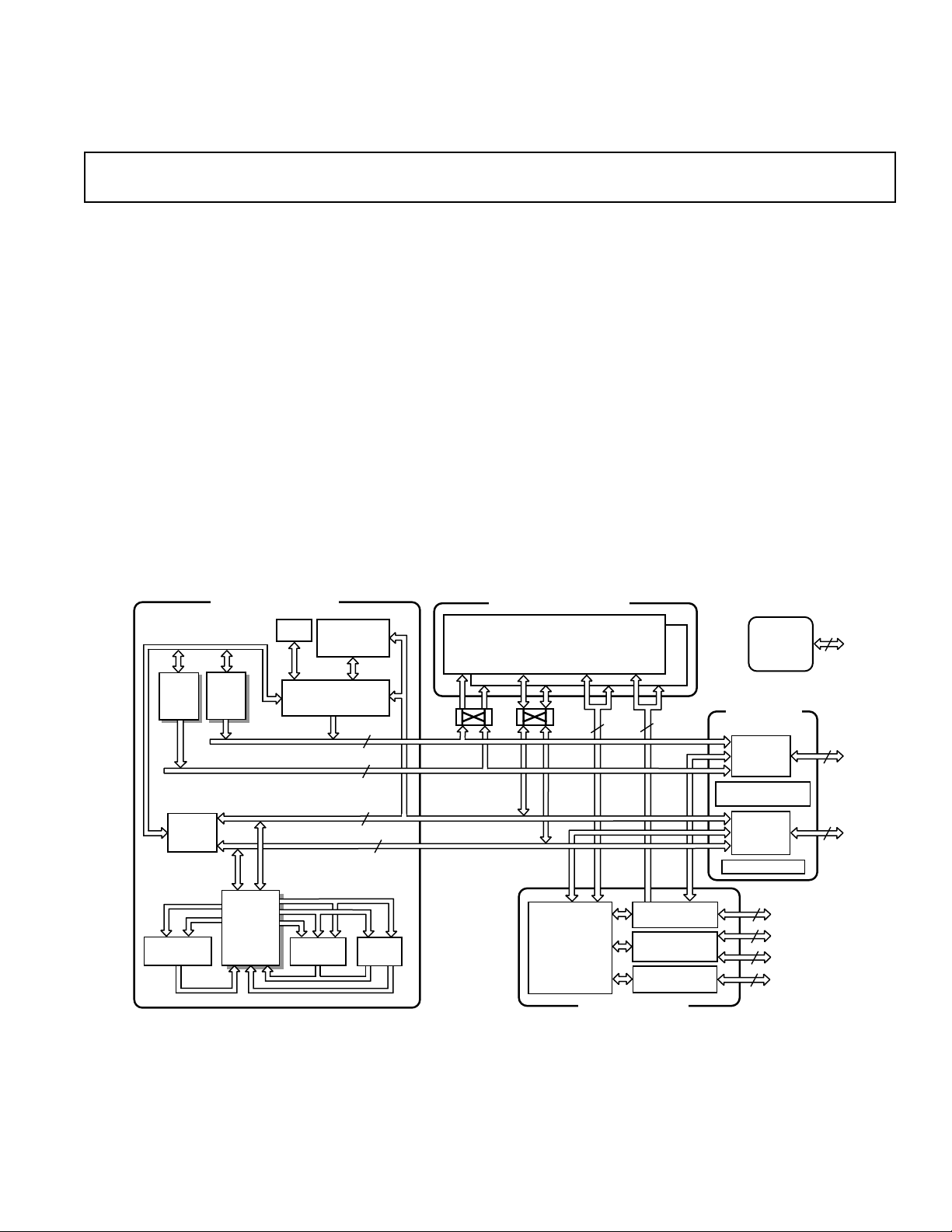

DAG1

8 x 4 x 32

BUS

CONNECT

(PX)

MULTIPLIER

CORE PROCESSOR

TIMER INSTRUCTION

DAG2

8 x 4 x 24

PM ADDRESS BUS

DATA

REGISTER

FILE

16 x 40-BIT

DM ADDRESS BUS

SEQUENCER

PM DATA BUS

DM DATA BUS

BARREL

SHIFTER

CACHE

32 x 48-BIT

PROGRAM

24

32

48

40/32

PROCESSOR PORT I/O PORT

ADDR DATA ADDR

ADDR DATA

ALU

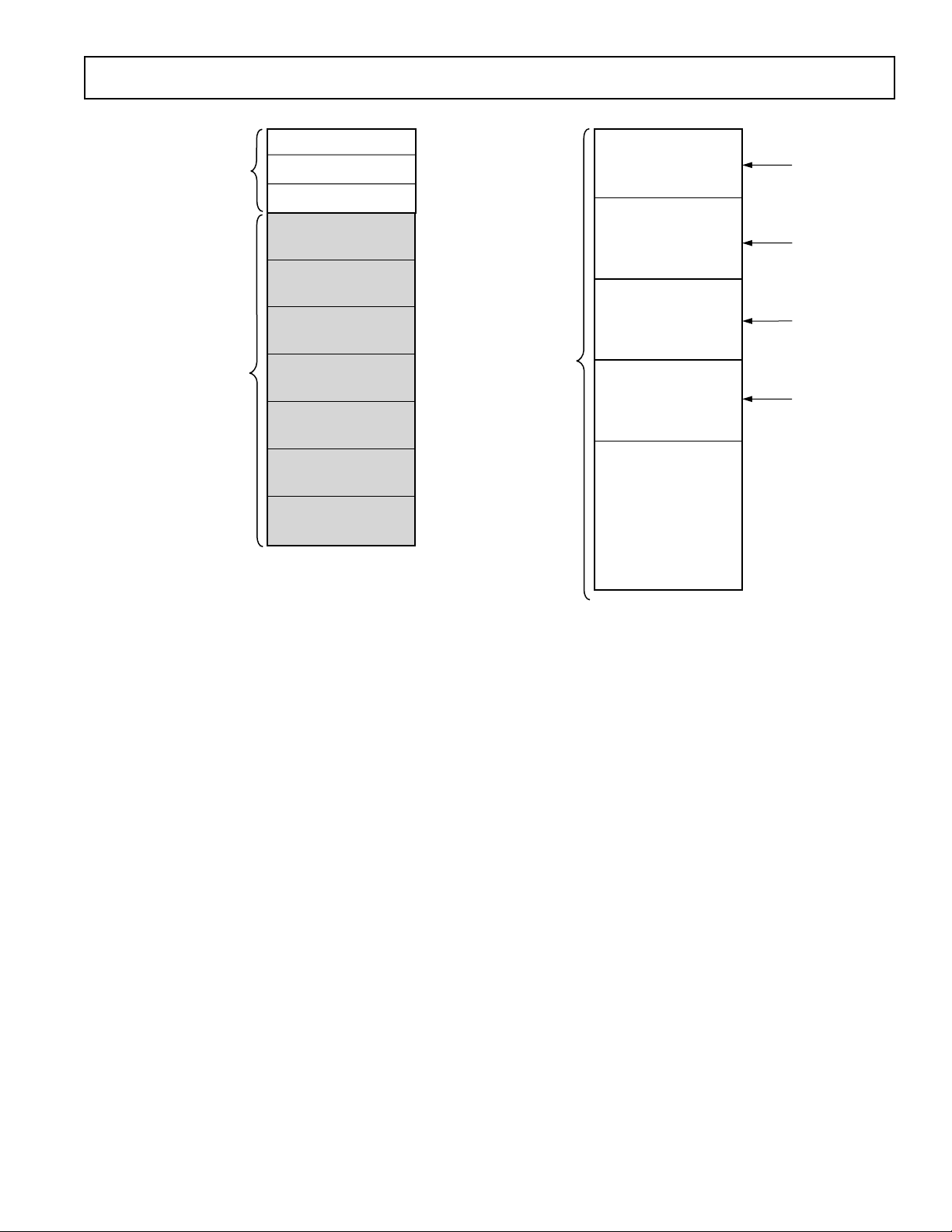

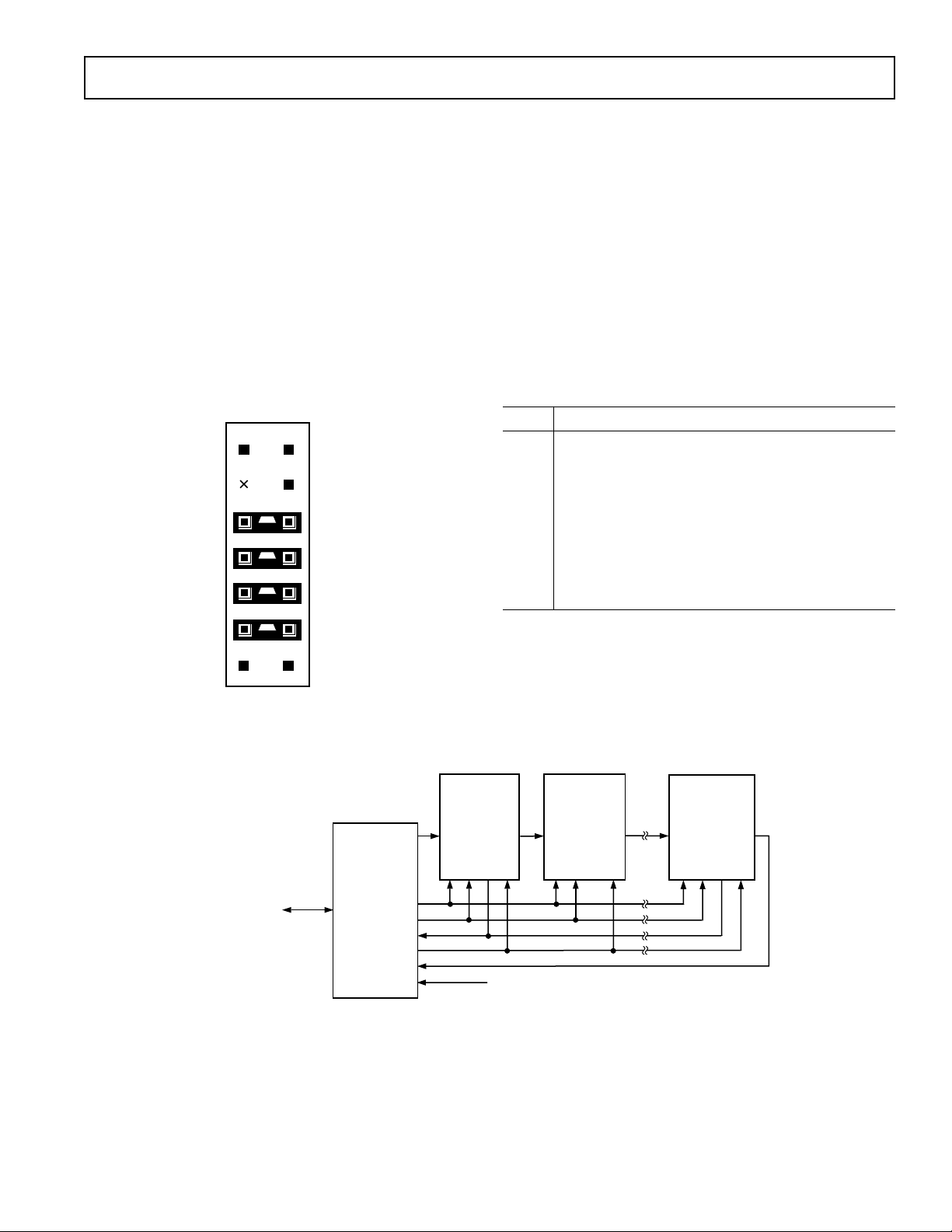

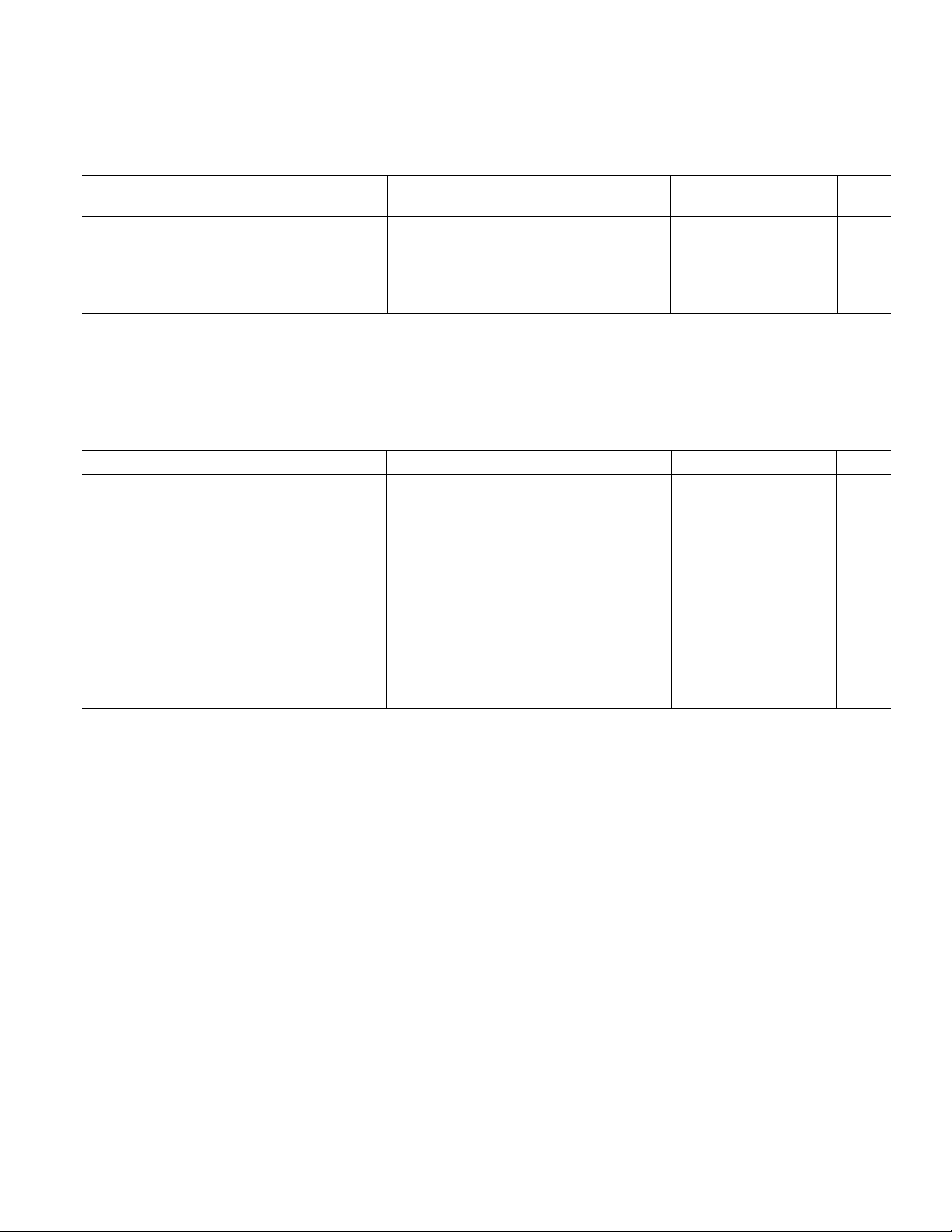

Figure 1. Block Diagram

DUAL-PORTED SRAM

TWO INDEPENDENT

DUAL-PORTED BLOCKS

DATA

DATA

IOD

48

IOP

REGISTERS

(

MEMORY MAPPED)

CONTROL,

STATUS &

DATA BUFFERS

I/O PROCESSOR

BLOCK 0

BLOCK 1

ADDR

IOA

17

DMA

CONTROLLER

SERIAL PORTS

(2)

LINK PORTS

(6)

JTAG

TEST &

EMULATION

EXTERNAL

PORT

ADDR BUS

MUX

MULTIPROCESSOR

INTERFACE

DATA BUS

MUX

HOST PORT

4

6

6

36

7

32

48

SHARC is a registered trademark of Analog Devices, Inc.

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

Page 2

ADSP-21060C/ADSP-21060LC

DMA Controller

10 DMA Channels for Transfers Between ADSP-2106x

Internal Memory and External Memory, External

Peripherals, Host Processor, Serial Ports, or Link

Ports

Background DMA Transfers at 40 MHz, in Parallel with

Full-Speed Processor Execution

Host Processor Interface to 16- and 32-Bit Microprocessors

Host Can Directly Read/Write ADSP-2106x Internal

Memory

TABLE OF CONTENTS

GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 3

ADSP-21000 FAMILY CORE ARCHITECTURE . . . . . . . 4

ADSP-21060C/ADSP-21060LC FEATURES . . . . . . . . . . . 4

DEVELOPMENT TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ADDITIONAL INFORMATION . . . . . . . . . . . . . . . . . . . . . 7

PIN FUNCTION DESCRIPTIONS . . . . . . . . . . . . . . . . . . 8

TARGET BOARD CONNECTOR FOR EZ-ICE

®

PROBE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

RECOMMENDED OPERATING CONDITIONS (5 V) . 13

ELECTRICAL CHARACTERISTICS (5 V) . . . . . . . . . . . 13

POWER DISSIPATION ADSP-21060C (5 V) . . . . . . . . . . 14

RECOMMENDED OPERATING CONDITIONS (3.3 V) 15

ELECTRICAL CHARACTERISTICS (3.3 V) . . . . . . . . . . 15

POWER DISSIPATION ADSP-21060LC (3.3 V) . . . . . . . . 16

ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . 17

TIMING SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . 17

Memory Read—Bus Master . . . . . . . . . . . . . . . . . . . . . . . 20

Memory Write—Bus Master . . . . . . . . . . . . . . . . . . . . . . 21

Synchronous Read/Write—Bus Master . . . . . . . . . . . . . . 22

Synchronous Read/Write—Bus Slave . . . . . . . . . . . . . . . . 24

Multiprocessor Bus Request and Host Bus Request . . . . . 25

Asynchronous Read/Write—Host to ADSP-2106x . . . . . . 27

Three-State Timing—Bus Master, Bus Slave,

HBR, SBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DMA Handshake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Link Ports: 1 × CLK Speed Operation . . . . . . . . . . . . . . 32

Link Ports: 2 × CLK Speed Operation . . . . . . . . . . . . . . 33

Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

JTAG Test Access Port and Emulation . . . . . . . . . . . . . . . 38

OUTPUT DRIVE CURRENTS . . . . . . . . . . . . . . . . . . . . . 39

POWER DISSIPATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

TEST CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

ENVIRONMENTAL CONDITIONS . . . . . . . . . . . . . . . . 42

240-LEAD METRIC CQFP PIN CONFIGURATIONS . . 43

OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . 45

ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

FIGURES

Figure 1. Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

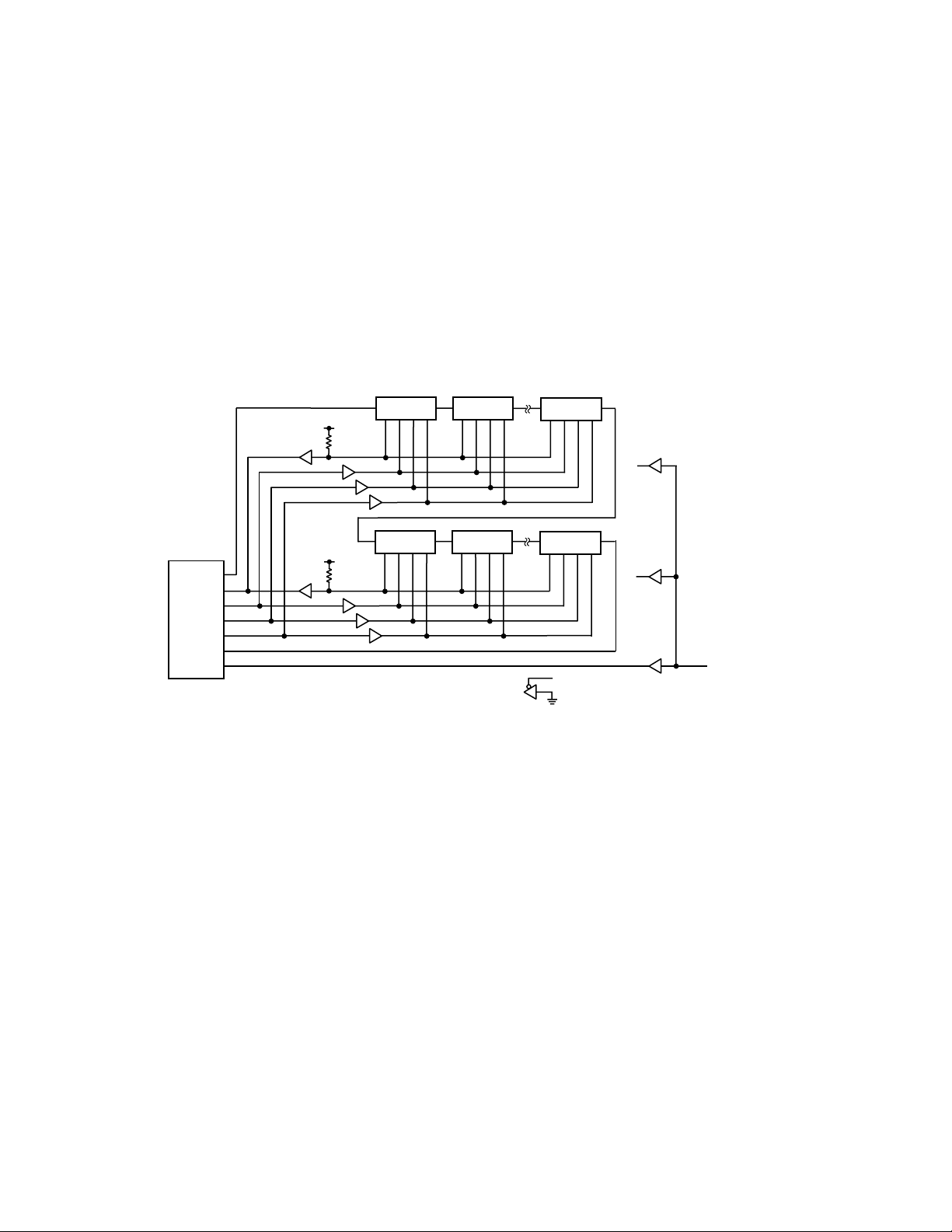

Figure 2. ADSP-2106x System . . . . . . . . . . . . . . . . . . . . . . . 4

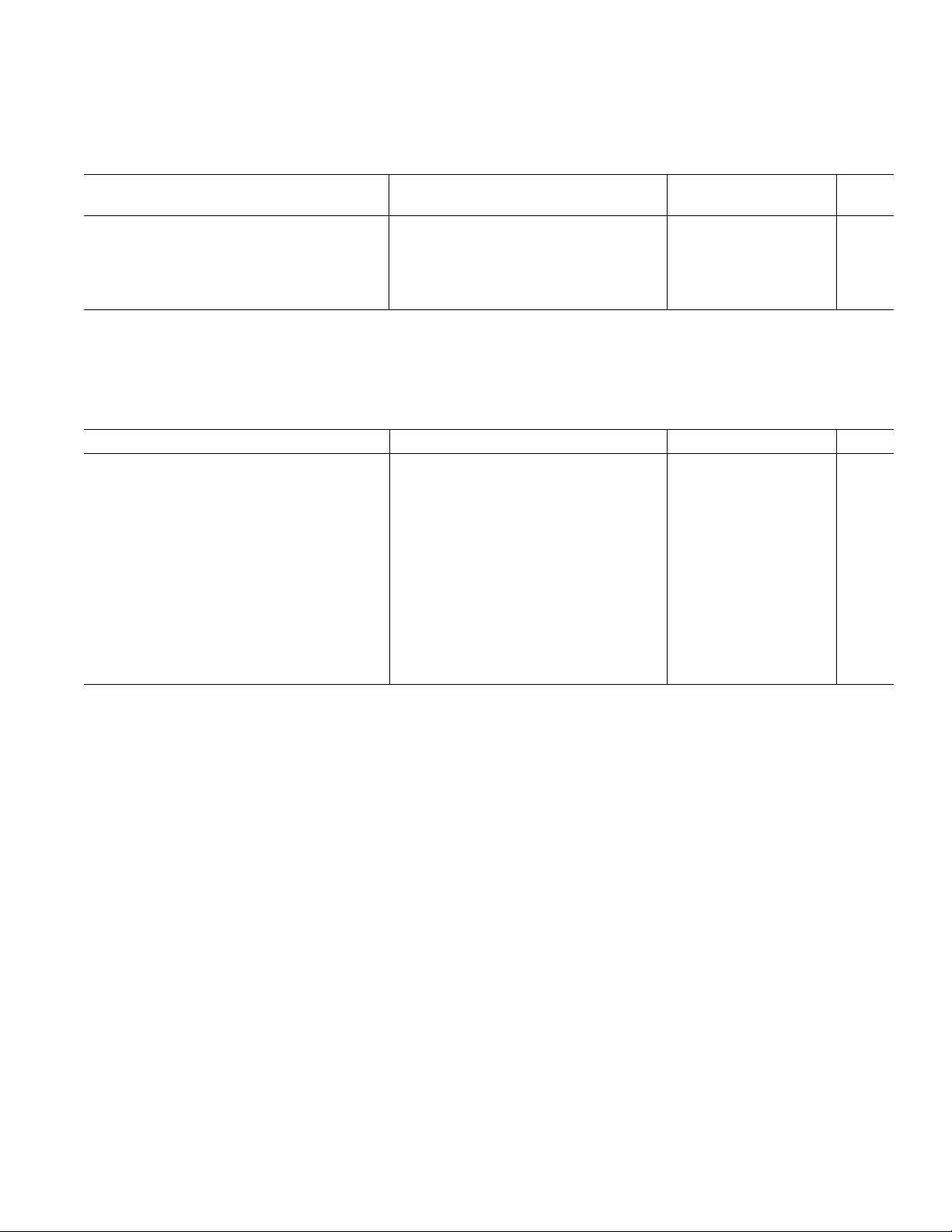

Figure 3. Shared Memory Multiprocessing System . . . . . . . . 6

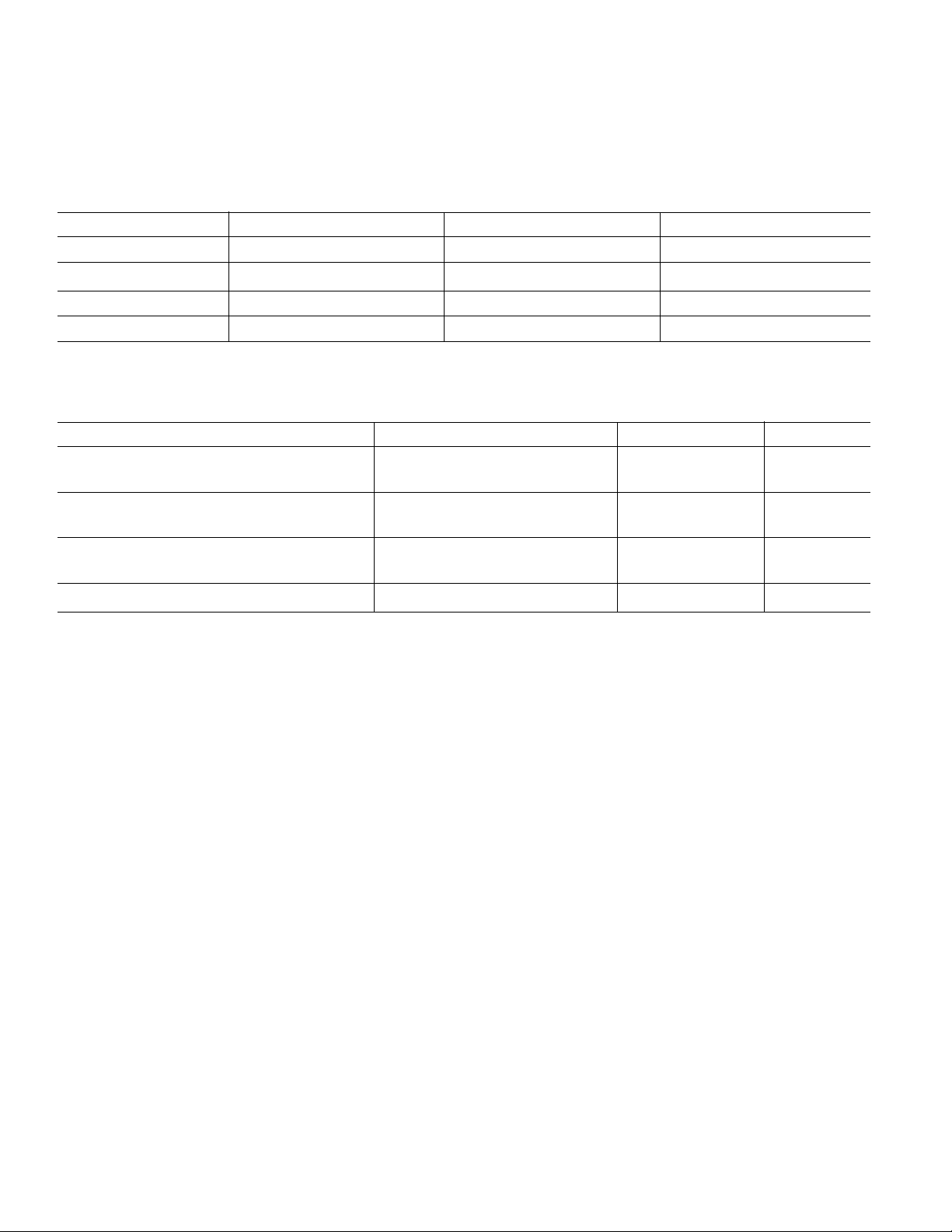

Figure 4. ADSP-21060C/ADSP-21060LC Memory Map . . . 7

Figure 5. Target Board Connector for ADSP-2106x

EZ-ICE Emulator (Jumpers in Place) . . . . . . . . . . . . . . . 11

Figure 6. JTAG Scan Path Connections for Multiple

EZ-ICE is a registered trademark of Analog Devices, Inc.

Multiprocessing

Glueless Connection for Scalable DSP Multiprocessing

Architecture

Distributed On-Chip Bus Arbitration for Parallel Bus

Connect of Up to Six ADSP-2106xs Plus Host

Six Link Ports for Point-to-Point Connectivity and Array

Multiprocessing

240 Mbytes/s Transfer Rate Over Parallel Bus

240 Mbytes/s Transfer Rate Over Link Ports

Serial Ports

Two 40 Mbit/s Synchronous Serial Ports with

Companding Hardware

Independent Transmit and Receive Functions

ADSP-2106x Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 7. JTAG Clocktree for Multiple ADSP-2106x

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Clock Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 9. Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 10. Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 11. Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 12. Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 13. Memory Read—Bus Master . . . . . . . . . . . . . . . . 20

Figure 14. Memory Write—Bus Master . . . . . . . . . . . . . . . 21

Figure 15. Synchronous Read/Write—Bus Master . . . . . . . 23

Figure 16. Synchronous Read/Write—Bus Slave . . . . . . . . . 24

Figure 17. Multiprocessor Bus Request and Host Bus

Request . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 18a. Synchronous REDY Timing . . . . . . . . . . . . . . 27

Figure 18b. Asynchronous Read/Write—Host to

ADSP-2106x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 19a. Three-State Timing (Bus Transition Cycle,

SBTS Assertion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 19b. Three-State Timing (Host Transition Cycle) . . 29

Figure 20. DMA Handshake Timing . . . . . . . . . . . . . . . . . 31

Figure 21. Link Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 22. Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 23. External Late Frame Sync . . . . . . . . . . . . . . . . . 37

Figure 24. IEEE 11499.1 JTAG Test Access Port . . . . . . . 38

Figure 25. Output Enable/Disable . . . . . . . . . . . . . . . . . . . 40

Figure 26. Equivalent Device Loading for AC Measurements

(Includes All Fixtures) . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 27. Voltage Reference Levels for AC Measurements

(Except Output Enable/Disable) . . . . . . . . . . . . . . . . . . . 40

Figure 28. ADSP-2106x Typical Drive Currents

= 5 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

(V

DD

Figure 29. Typical Output Rise Time (10%–90% V

vs. Load Capacitance (V

= 5 V) . . . . . . . . . . . . . . . . . . . 41

DD

DD

)

Figure 30. Typical Output Rise Time (0.8 V–2.0 V)

vs. Load Capacitance (V

= 5 V) . . . . . . . . . . . . . . . . . . . 41

DD

Figure 31. Typical Output Delay or Hold vs. Load Capacitance

(at Maximum Case Temperature) (V

= 5 V) . . . . . . . . . 41

DD

Figure 32. ADSP-2106x Typical Drive Currents

= 3.3 V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

(V

DD

Figure 33. Typical Output Rise Time (10%–90% V

vs. Load Capacitance (V

= 3.3 V) . . . . . . . . . . . . . . . . . 41

DD

DD

)

Figure 34. Typical Output Rise Time (0.8 V–2.0 V) vs. Load

Capacitance (V

= 3.3 V) . . . . . . . . . . . . . . . . . . . . . . . . 42

DD

Figure 35. Typical Output Delay or Hold vs. Load Capacitance

(at Maximum Case Temperature) (V

= 3.3 V) . . . . . . . . 42

DD

–2–

REV. B

Page 3

S

GENERAL DESCRIPTION

The ADSP-2106x SHARC—Super Harvard Architecture Computer—is a signal processing microcomputer that offers new

capabilities and levels of performance. The ADSP-2106x

SHARCs are 32-bit processors optimized for high performance

DSP applications. The ADSP-2106x builds on the ADSP21000 DSP core to form a complete system-on-a-chip, adding a

dual-ported on-chip SRAM and integrated I/O peripherals supported by a dedicated I/O bus.

Fabricated in a high speed, low power CMOS process, the

ADSP-2106x has a 25 ns instruction cycle time and operates

at 40 MIPS. With its on-chip instruction cache, the processor

can execute every instruction in a single cycle. Table I shows

performance benchmarks for the ADSP-2106x.

The ADSP-2106x SHARC represents a new standard of integration for signal computers, combining a high performance

floating-point DSP core with integrated, on-chip system features

including a 4 Mbit SRAM memory host processor interface,

ADSP-21060C/ADSP-21060LC

DMA controller, serial ports, and link port and parallel bus

connectivity for glueless DSP multiprocessing.

Figure 1 shows a block diagram of the ADSP-21060C/

ADSP-21060LC, illustrating the following architectural features:

Computation Units (ALU, Multiplier and Shifter) with a

Shared Data Register File

Data Address Generators (DAG1, DAG2)

Program Sequencer with Instruction Cache

Interval Timer

On-Chip SRAM

External Port for Interfacing to Off-Chip Memory and

Peripherals

Host Port and Multiprocessor Interface

DMA Controller

Serial Ports and Link Ports

JTAG Test Access Port

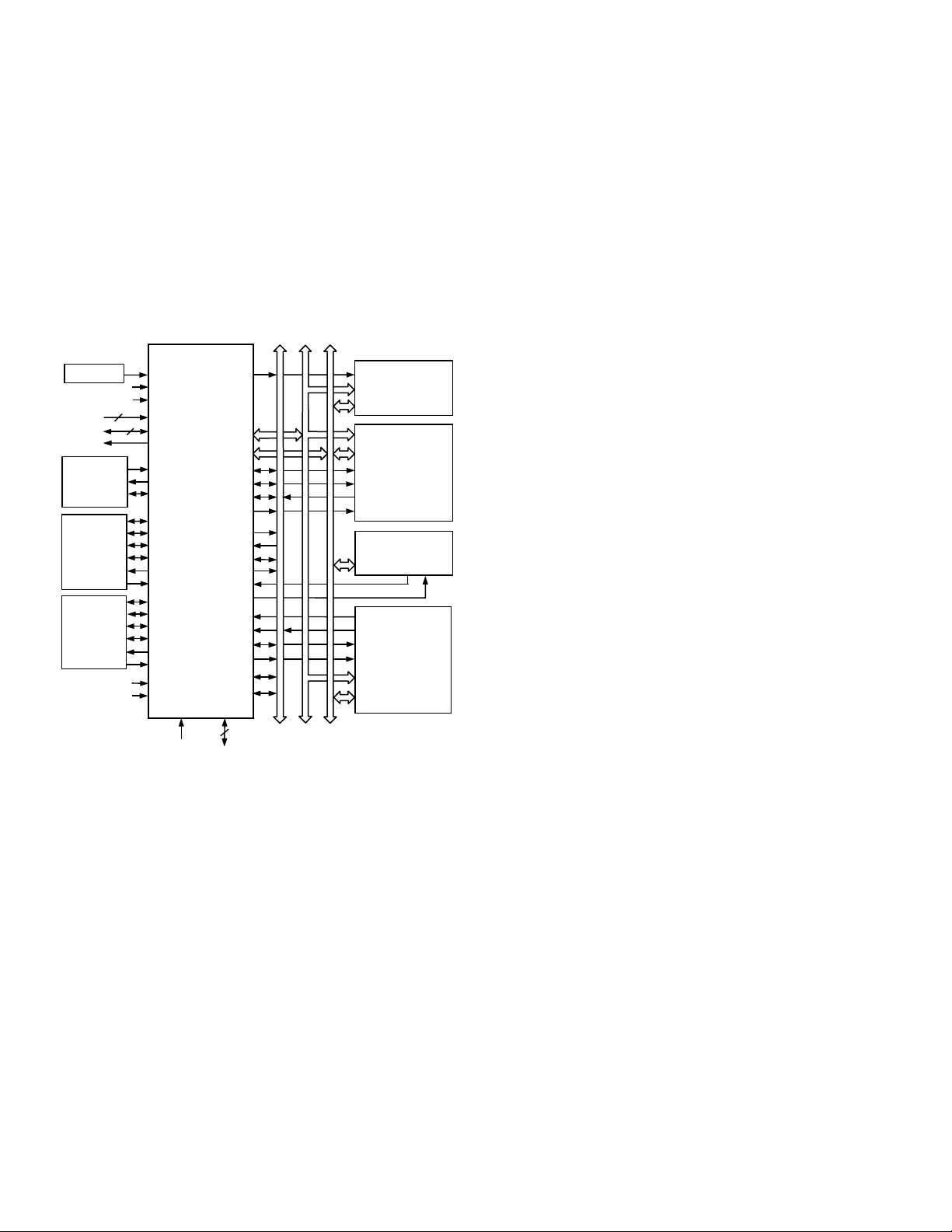

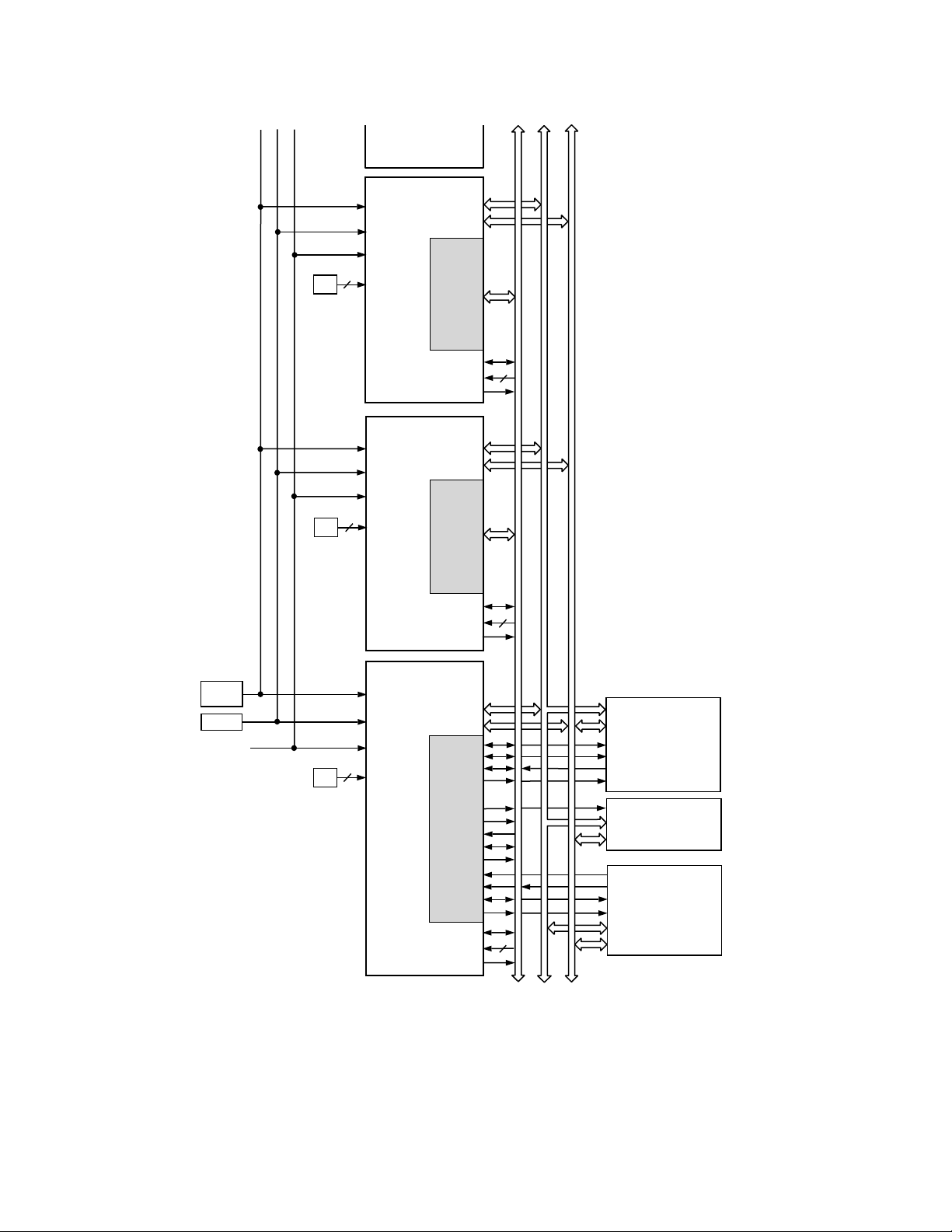

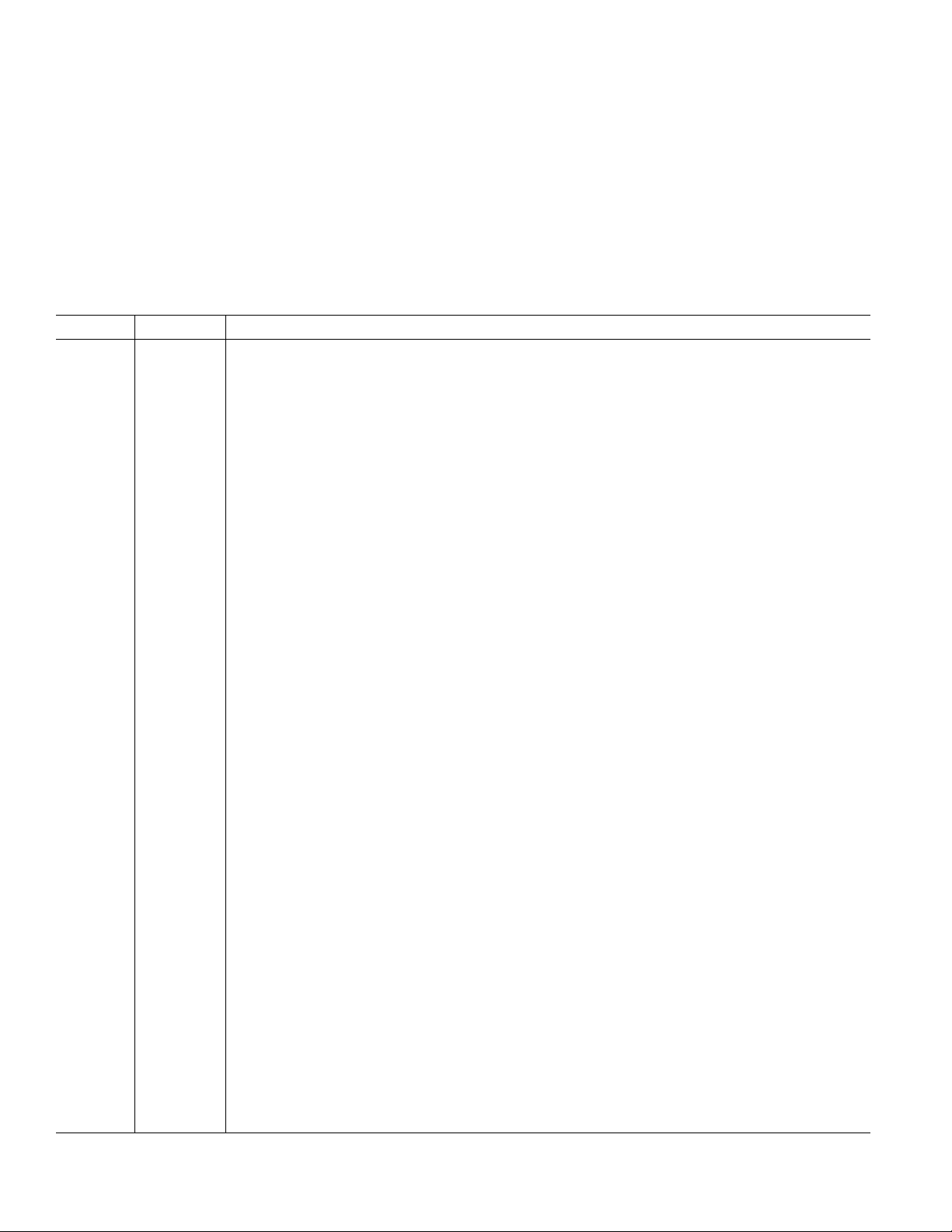

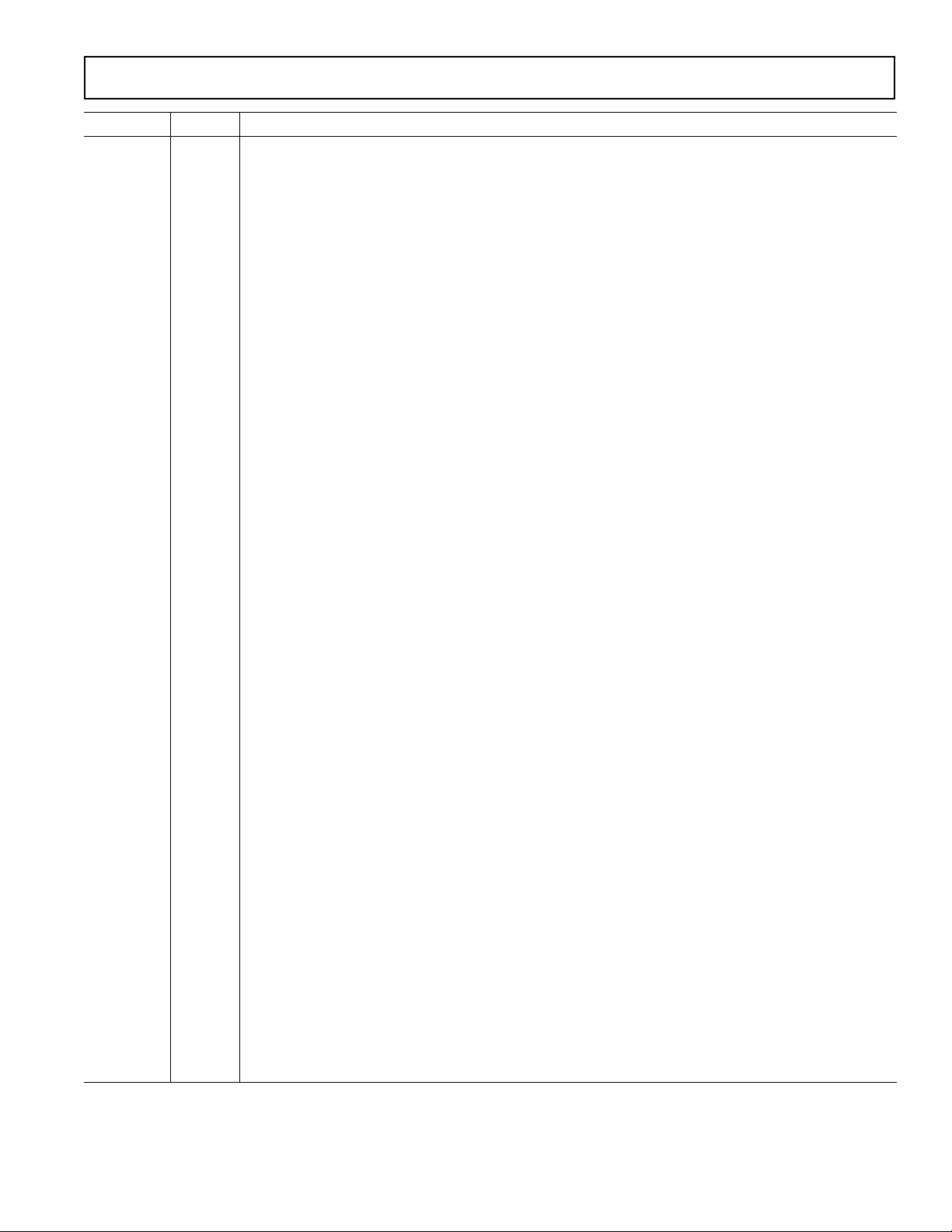

Figure 2 shows a typical single-processor system. A multiprocessing system is shown in Figure 3.

Table I. ADSP-21060C/ADSP-21060LC Benchmarks

(@ 40 MHz)

1024-Pt. Complex FFT 0.46 ms 18,221 cycles

(Radix 4, with Digit Reverse)

FIR Filter (per Tap) 25 ns 1 cycle

IIR Filter (per Biquad) 100 ns 4 cycles

Divide (y/x) 150 ns 6 cycles

Inverse Square Root (1/√x) 225 ns 9 cycles

DMA Transfer Rate 240 Mbytes/s

REV. B

–3–

Page 4

ADSP-21060C/ADSP-21060LC

ADSP-21000 FAMILY CORE ARCHITECTURE

The ADSP-2106x includes the following architectural features

of the ADSP-21000 family core. The ADSP-21060C is codeand function-compatible with the ADSP-21061 and ADSP-21062.

Independent, Parallel Computation Units

The arithmetic/logic unit (ALU), multiplier and shifter all perform single-cycle instructions. The three units are arranged in

parallel, maximizing computational throughput. Single multifunction instructions execute parallel ALU and multiplier operations. These computation units support IEEE 32-bit singleprecision floating-point, extended precision 40-bit floatingpoint, and 32-bit fixed-point data formats.

ADSP-2106x

DATA

CS

ADDR

DATA

ADDR

DATA

OE

PERIPHERALS

WE

(OPTIONAL)

ACK

CS

DMA DEVICE

(OPTIONAL)

DATA

PROCESSOR

INTERFACE

(OPTIONAL)

ADDR

DATA

BOOT

EPROM

(OPTIONAL)

MEMORY

AND

HOST

1x CLOCK

3

LINK

DEVICES

(6 MAXIMUM)

(OPTIONAL)

SERIAL

DEVICE

(OPTIONAL)

SERIAL

DEVICE

(OPTIONAL)

3-0

BMS

ADDR

31-0

DATA

47-0

RD

WR

ACK

MS

PAGE

SBTS

SW

ADRCLK

DMAR1-2

DMAG1-2

CS

HBR

HBG

REDY

BR

CPA

JTAG

7

ADDRESS

CONTROL

3-0

1-6

CLKIN

EBOOT

LBOOT

IRQ

2-0

4

FLAG

3-0

TIMEXP

LxCLK

LxACK

LxDAT

TCLK0

RCLK0

TFS0

RSF0

DT0

DR0

TCLK1

RCLK1

TFS1

RFS1

DT1

DR1

RPBA

ID

2-0

RESET

Figure 2. ADSP-2106x System

Data Register File

A general purpose data register file is used for transferring data

between the computation units and the data buses, and for

storing intermediate results. This 10-port, 32-register (16 primary, 16 secondary) register file, combined with the ADSP21000 Harvard architecture, allows unconstrained data flow

between computation units and internal memory.

Single-Cycle Fetch of Instruction and Two Operands

The ADSP-2106x features an enhanced Harvard architecture in

which the data memory (DM) bus transfers data and the program memory (PM) bus transfers both instructions and data

(see Figure 1). With its separate program and data memory

buses and on-chip instruction cache, the processor can simultaneously fetch two operands and an instruction (from the cache),

all in a single cycle.

Instruction Cache

The ADSP-2106x includes an on-chip instruction cache that

enables three-bus operation for fetching an instruction and two

data values. The cache is selective—only the instructions whose

fetches conflict with PM bus data accesses are cached. This

allows full-speed execution of core, looped operations such as

digital filter multiply-accumulates and FFT butterfly processing.

Data Address Generators with Hardware Circular Buffers

The ADSP-2106x’s two data address generators (DAGs) implement circular data buffers in hardware. Circular buffers allow

efficient programming of delay lines and other data structures

required in digital signal processing, and are commonly used in

digital filters and Fourier transforms. The two DAGs of the

ADSP-2106x contain sufficient registers to allow the creation of

up to 32 circular buffers (16 primary register sets, 16 secondary). The DAGs automatically handle address pointer wraparound, reducing overhead, increasing performance, and

simplifying implementation. Circular buffers can start and end

at any memory location.

Flexible Instruction Set

The 48-bit instruction word accommodates a variety of parallel

operations, for concise programming. For example, the ADSP2106x can conditionally execute a multiply, an add, a subtract

and a branch, all in a single instruction.

ADSP-21060C/ADSP-21060LC FEATURES

Augmenting the ADSP-21000 family core, the ADSP-21060

adds the following architectural features:

Dual-Ported On-Chip Memory

The ADSP-21060C contains four megabits of on-chip SRAM,

organized as two blocks of 2 Mbits each, which can be configured for different combinations of code and data storage.

Each memory block is dual-ported for single-cycle, independent

accesses by the core processor and I/O processor or DMA controller. The dual-ported memory and separate on-chip buses

allow two data transfers from the core and one from I/O, all in a

single cycle.

On the ADSP-21060C, the memory can be configured as a

maximum of 128K words of 32-bit data, 256K words of 16-bit

data, 80K words of 48-bit instructions (or 40-bit data), or combinations of different word sizes up to four megabits. All of

the memory can be accessed as 16-bit, 32-bit, or 48-bit words.

A 16-bit floating-point storage format is supported that effectively doubles the amount of data that may be stored on-chip.

Conversion between the 32-bit floating-point and 16-bit floatingpoint formats is done in a single instruction.

While each memory block can store combinations of code and

data, accesses are most efficient when one block stores data,

using the DM bus for transfers, and the other block stores

instructions and data, using the PM bus for transfers. Using the

DM bus and PM bus in this way, with one dedicated to each

memory block, assures single-cycle execution with two data

transfers. In this case, the instruction must be available in the

cache. Single-cycle execution is also maintained when one of the

data operands is transferred to or from off-chip, via the ADSP2106x’s external port.

–4–

REV. B

Page 5

ADSP-21060C/ADSP-21060LC

Off-Chip Memory and Peripherals Interface

The ADSP-2106x’s external port provides the processor’s interface to off-chip memory and peripherals. The 4-gigaword offchip address space is included in the ADSP-2106x’s unified

address space. The separate on-chip buses—for PM addresses,

PM data, DM addresses, DM data, I/O addresses, and I/O

data—are multiplexed at the external port to create an external

system bus with a single 32-bit address bus and a single 48-bit

(or 32-bit) data bus.

Addressing of external memory devices is facilitated by on-chip

decoding of high-order address lines to generate memory bank

select signals. Separate control lines are also generated for simplified addressing of page-mode DRAM. The ADSP-2106x

provides programmable memory wait states and external

memory acknowledge controls to allow interfacing to DRAM

and peripherals with variable access, hold, and disable time

requirements.

Host Processor Interface

The ADSP-2106x’s host interface allows easy connection to

standard microprocessor buses, both 16-bit and 32-bit, with

little additional hardware required. Asynchronous transfers at

speeds up to the full clock rate of the processor are supported.

The host interface is accessed through the ADSP-2106x’s external port and is memory-mapped into the unified address space.

Four channels of DMA are available for the host interface; code

and data transfers are accomplished with low software overhead.

The host processor requests the ADSP-2106x’s external bus

with the host bus request (HBR), host bus grant (HBG), and

ready (REDY) signals. The host can directly read and write the

internal memory of the ADSP-2106x, and can access the DMA

channel setup and mailbox registers. Vector interrupt support is

provided for efficient execution of host commands.

DMA Controller

The ADSP-2106x’s on-chip DMA controller allows zerooverhead data transfers without processor intervention. The

DMA controller operates independently and invisibly to the

processor core, allowing DMA operations to occur while the

core is simultaneously executing its program instructions.

DMA transfers can occur between the ADSP-2106x’s internal

memory and either external memory, external peripherals or a

host processor. DMA transfers can also occur between the

ADSP-2106x’s internal memory and its serial ports or link

ports. DMA transfers between external memory and external

peripheral devices are another option. External bus packing to

16-, 32-, or 48-bit words is performed during DMA transfers.

Ten channels of DMA are available on the ADSP-2106x—two

via the link ports, four via the serial ports, and four via the

processor’s external port (for either host processor, other

ADSP-2106xs, memory or I/O transfers). Four additional link

port DMA channels are shared with serial port 1 and the external port. Programs can be downloaded to the ADSP-2106x

using DMA transfers. Asynchronous off-chip peripherals can

control two DMA channels using DMA Request/Grant lines

(DMAR1-2, DMAG1-2). Other DMA features include inter-

rupt generation upon completion of DMA transfers and DMA

chaining for automatic linked DMA transfers.

Serial Ports

The ADSP-2106x features two synchronous serial ports that

provide an inexpensive interface to a wide variety of digital and

mixed-signal peripheral devices. The serial ports can operate at

the full clock rate of the processor, providing each with a maximum data rate of 40 Mbit/s. Independent transmit and receive

functions provide greater flexibility for serial communications.

Serial port data can be automatically transferred to and from

on-chip memory via DMA. Each of the serial ports offers TDM

multichannel mode.

The serial ports can operate with little-endian or big-endian

transmission formats, with word lengths selectable from 3 bits to

32 bits. They offer selectable synchronization and transmit

modes as well as optional µ-law or A-law companding. Serial

port clocks and frame syncs can be internally or externally

generated.

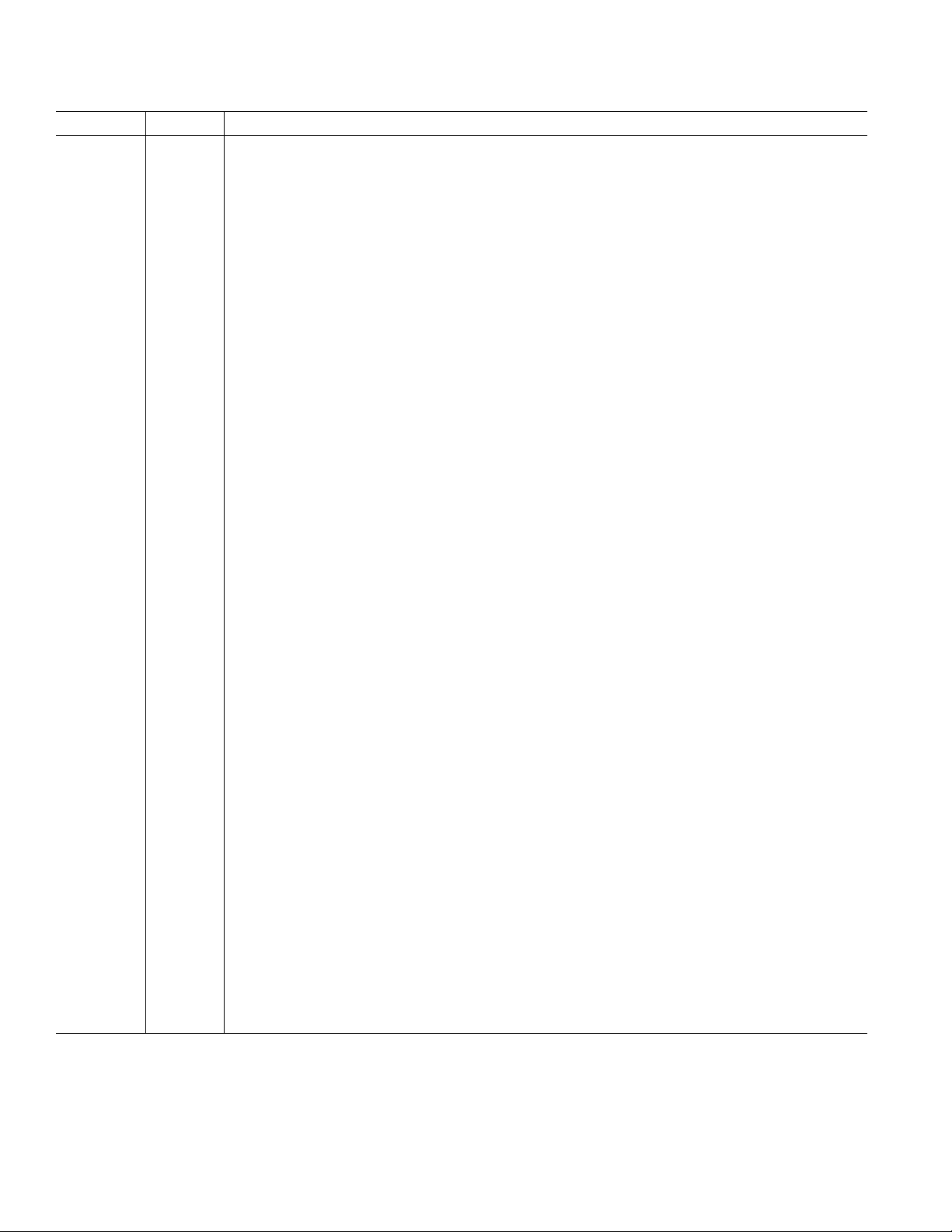

Multiprocessing

The ADSP-2106x offers powerful features tailored to multiprocessing DSP systems. The unified address space (see

Figure 4) allows direct interprocessor accesses of each ADSP2106x’s internal memory. Distributed bus arbitration logic is

included on-chip for simple, glueless connection of systems

containing up to six ADSP-2106xs and a host processor. Master

processor changeover incurs only one cycle of overhead. Bus

arbitration is selectable as either fixed or rotating priority. Bus lock

allows indivisible read-modify-write sequences for semaphores. A

vector interrupt is provided for interprocessor commands. Maximum throughput for interprocessor data transfer is 240 Mbytes/s

over the link ports or external port. Broadcast writes allow simultaneous transmission of data to all ADSP-2106xs and can be used

to implement reflective semaphores.

Link Ports

The ADSP-2106x features six 4-bit link ports that provide additional I/O capabilities. The link ports can be clocked twice per

cycle, allowing each to transfer eight bits per cycle. Link port

I/O is especially useful for point-to-point interprocessor communication in multiprocessing systems.

The link ports can operate independently and simultaneously,

with a maximum data throughput of 240 Mbytes/s. Link port

data is packed into 32- or 48-bit words, and can be directly read

by the core processor or DMA-transferred to on-chip memory.

Each link port has its own double-buffered input and output

registers. Clock/acknowledge handshaking controls link port

transfers. Transfers are programmable as either transmit or

receive.

Program Booting

The internal memory of the ADSP-2106x can be booted at

system power-up from either an 8-bit EPROM, a host processor, or through one of the link ports. Selection of the boot

source is controlled by the BMS (Boot Memory Select),

EBOOT (EPROM Boot), and LBOOT (Link/Host Boot) pins.

32-bit and 16-bit host processors can be used for booting.

REV. B

–5–

Page 6

ADSP-21060C/ADSP-21060LC

ADSP-2106x #6

ADSP-2106x #5

ADSP-2106x #4

3

011 ID

3

010

ADSP-2106x #3

BR

ADDR

DATA

1-2

CLKIN

RESET

RPBA

2-0

CONTROL

ADSP-2106x #2

CLKIN

RESET

RPBA

ID

2-0

CONTROL

ADDR

DATA

BR

1

, BR

, BR

31-0

47-0

CPA

BR

31-0

47-0

CPA

BR

CONTROL

5

4-6

3

5

3-6

2

DATA

ADDRESS

1x

CLOCK

RESET RESET

001

ADSP-2106x #1

CLKIN

RPBA

3

ID

2-0

CONTROL

Figure 3. Shared Memory Multiprocessing System

ADDR

DATA

ACK

MS

BMS

PAGE

SBTS

ADRCLK

HBR

HBG

REDY

CPA

BR

BR

31-0

47-0

RD

WR

SW

CS

CONTROL

3-0

5

2-6

1

DATA

ADDRESS

ADDR

DATA

OE

WE

ACK

CS

CS

ADDR

DATA

ADDR

DATA

GLOBAL

MEMORY

AND

PERIPHERALS

(OPTIONAL)

BOOT

EPROM

(OPTIONAL)

HOST

PROCESSOR

INTERFACE

(OPTIONAL)

–6–

REV. B

Page 7

ADSP-21060C/ADSP-21060LC

INTERNAL

MEMORY

SPACE

MULTIPROCESSOR

MEMORY SPACE

NORMAL WORD ADDRESSING: 32-BIT DATA WORDS

48-BIT INSTRUCTION WORDS

SHORT WORD ADDRESSING: 16-BIT DATA WORDS

IOP REGISTERS

NORMAL WORD ADDRESSING

SHORT WORD ADDRESSING

INTERNAL MEMORY SPACE

OF ADSP-2106x

WITH ID=001

INTERNAL MEMORY SPACE

OF ADSP-2106x

WITH ID=010

INTERNAL MEMORY SPACE

OF ADSP-2106x

WITH ID=011

INTERNAL MEMORY SPACE

OF ADSP-2106x

WITH ID=100

INTERNAL MEMORY SPACE

OF ADSP-2106x

WITH ID=101

INTERNAL MEMORY SPACE

OF ADSP-2106x

WITH ID=110

BROADCAST WRITE

TO ALL

ADSP-2106xs

0x0000 0000

0x0002 0000

0x0004 0000

0x0008 0000

0x0010 0000

0x0018 0000

0x0020 0000

0x0028 0000

0x0030 0000

0x0038 0000

0x003F FFFF

EXTERNAL

MEMORY

SPACE

BANK 0

DRAM

(OPTIONAL)

BANK 1

BANK 2

BANK 3

NONBANKED

0x0040 0000

MS

0

MS

1

MS

2

MS

3

BANK SIZE IS

SELECTED BY

MSIZE BIT FIELD OF

SYSCON

REGISTER.

0xFFFF FFFF

Figure 4. ADSP-21060C/ADSP-21060LC Memory Map

DEVELOPMENT TOOLS

The ADSP-21060C is supported with a complete set of software

and hardware development tools, including an EZ-ICE

Circuit Emulator, EZ-Kit, and development software. The

SHARC

tion and prototyping. The EZ-Kit contains a PC plug-in card

(EZ-LAB

EZ-Kit is a complete low cost package for DSP evalua-

®

) with an ADSP-21062 (5 V) processor. The EZ-Kit

In-

also includes an optimizing compiler, assembler, instruction

level simulator, run-time libraries, diagnostic utilities and a

complete set of example programs.

Analog Devices ADSP-21000 Family Development Software

includes an easy to use Assembler based on an algebraic syntax,

Assembly Library/Librarian, Linker, instruction-level Simulator,

an ANSI C optimizing Compiler, the CBug™ C Source—Level

Debugger and a C Runtime Library including DSP and mathematical functions. The ADSP-21000 Family Development

Software is available for both the PC and Sun platforms.

The ADSP-2106x EZ-ICE

Emulator uses the IEEE 1149.1 JTAG

test access port of the ADSP-2106x processor to monitor and

control the target board processor during emulation. The EZ-ICE

provides full-speed emulation, allowing inspection and modification of memory, registers, and processor stacks. Nonintrusive

in-circuit emulation is assured by the use of the processor’s

JTAG interface—the emulator does not affect target system

loading or timing.

Further details and ordering information are available in the

ADSP-21000 Family Hardware and Software Development Tools

data sheet (ADDS-210xx-TOOLS). This data sheet can be

requested from any Analog Devices sales office or distributor.

In addition to the software and hardware development tools

available from Analog Devices, third parties provide a wide

range of tools supporting the SHARC

ware tools include SHARC

SHARC

VME boards, and daughter and modules with multiple

PC plug-in cards multiprocessor

processor family. Hard-

SHARCs and additional memory. These modules are based on

the SHARCPAC™ module specification. Third Party software

tools include an Ada compiler, DSP libraries, operating systems

and block diagram design tools.

ADDITIONAL INFORMATION

This data sheet provides a general overview of the ADSP-21060C

architecture and functionality. For detailed information on the

ADSP-21000 Family core architecture and instruction set, refer to

the ADSP-2106x SHARC User’s Manual, Second Edition.

CBUG and SHARCPAC are trademarks of Analog Devices, Inc.

EZ-LAB is a registered trademark of Analog Devices, Inc.

REV. B

–7–

Page 8

ADSP-21060C/ADSP-21060LC

PIN FUNCTION DESCRIPTIONS

ADSP-21060C pin definitions are listed below. All pins are

identical on the ADSP-21060C and ADSP-21060LC. Inputs

identified as synchronous (S) must meet timing requirements

with respect to CLKIN (or with respect to TCK for TMS,

TDI). Inputs identified as asynchronous (A) can be asserted

asynchronously to CLKIN (or to TCK for TRST).

Unused inputs should be tied or pulled to VDD or GND,

except for ADDR

, DATA

31-0

, FLAG

47-0

, SW, and inputs that

3-0

DRx, TCLKx, RCLKx, LxDAT

, LxCLK, LxACK, TMS and

3-0

TDI)—these pins can be left floating. These pins have a logiclevel hold circuit that prevents the input from floating

internally.

A = Asynchronous G = Ground I = Input

O = Output P = Power Supply S = Synchronous

(A/D) = Active Drive (O/D) = Open Drain

T = Three-State (when SBTS is asserted, or when the

ADSP-2106x is a bus slave)

have internal pull-up or pull-down resistors (CPA, ACK, DTx,

Pin Type Function

ADDR

31-0

I/O/T External Bus Address. The ADSP-2106x outputs addresses for external memory and peripherals on

these pins. In a multiprocessor system the bus master outputs addresses for read/writes of the internal

memory or IOP registers of other ADSP-2106xs. The ADSP-2106x inputs addresses when a host

processor or multiprocessing bus master is reading or writing its internal memory or IOP registers.

DATA

47-0

I/O/T External Bus Data. The ADSP-2106x inputs and outputs data and instructions on these pins. 32-bit

single-precision floating-point data and 32-bit fixed-point data is transferred over bits 47–16 of the

bus. 40-bit extended-precision floating-point data is transferred over bits 47–8 of the bus. 16-bit short

word data is transferred over bits 31–16 of the bus. In PROM boot mode, 8-bit data is transferred over

bits 23–16. Pull-up resistors on unused DATA pins are not necessary.

MS

3-0

O/T Memory Select Lines. These lines are asserted (low) as chip selects for the corresponding banks of

external memory. Memory bank size must be defined in the ADSP-2106x’s system control register

(SYSCON). The MS

other address lines. When no external memory access is occurring the MS

lines are decoded memory address lines that change at the same time as the

3-0

lines are inactive; they are

3-0

active however when a conditional memory access instruction is executed, whether or not the condition

is true. MS

multiprocessing system the MS

can be used with the PAGE signal to implement a bank of DRAM memory (Bank 0). In a

0

lines are output by the bus master.

3-0

RD I/O/T Memory Read Strobe. This pin is asserted (low) when the ADSP-2106x reads from external memory

devices or from the internal memory of other ADSP-2106xs. External devices (including other ADSP2106xs) must assert RD to read from the ADSP-2106x’s internal memory. In a multiprocessing system

RD is output by the bus master and is input by all other ADSP-2106xs.

WR I/O/T Memory Write Strobe. This pin is asserted (low) when the ADSP-2106x writes to external memory

devices or to the internal memory of other ADSP-2106xs. External devices must assert WR to write to

the ADSP-2106x’s internal memory. In a multiprocessing system WR is output by the bus master and

is input by all other ADSP-2106xs.

PAGE O/T DRAM Page Boundary. The ADSP-2106x asserts this pin to signal that an external DRAM page

boundary has been crossed. DRAM page size must be defined in the ADSP-2106x’s memory control

register (WAIT). DRAM can only be implemented in external memory Bank 0; the PAGE signal can

only be activated for Bank 0 accesses. In a multiprocessing system PAGE is output by the bus master.

ADRCLK O/T Clock Output Reference. In a multiprocessing system ADRCLK is output by the bus master.

SW I/O/T Synchronous Write Select. This signal is used to interface the ADSP-2106x to synchronous

memory devices (including other ADSP-2106xs). The ADSP-2106x asserts SW (low) to provide an

early indication of an impending write cycle, which can be aborted if WR is not later asserted (e.g., in a

conditional write instruction). In a multiprocessing system, SW is output by the bus master and is

input by all other ADSP-2106xs to determine if the multiprocessor memory access is a read or write.

SW is asserted at the same time as the address output. A host processor using synchronous writes must

assert this pin when writing to the ADSP-2106x(s).

ACK I/O/S Memory Acknowledge. External devices can deassert ACK (low) to add wait states to an external

memory access. ACK is used by I/O devices, memory controllers, or other peripherals to hold off

completion of an external memory access. The ADSP-2106x deasserts ACK as an output to add wait

states to a synchronous access of its internal memory. In a multiprocessing system, a slave ADSP2106x deasserts the bus master’s ACK input to add wait state(s) to an access of its internal memory.

The bus master has a keeper latch on its ACK pin that maintains the input at the level to which it was

last driven.

–8–

REV. B

Page 9

ADSP-21060C/ADSP-21060LC

Pin Type Function

SBTS I/S Suspend Bus Three-State. External devices can assert SBTS (low) to place the external bus address,

data, selects and strobes in a high impedance state for the following cycle. If the ADSP-2106x

attempts to access external memory while SBTS is asserted, the processor will halt and the memory

access will not be completed until SBTS is deasserted. SBTS should only be used to recover from host

processor/ADSP-2106x deadlock, or used with a DRAM controller.

IRQ

2-0

FLAG

3-0

TIMEXP O Timer Expired. Asserted for four cycles when the timer is enabled and TCOUNT decrements to

HBR I/A Host Bus Request. Must be asserted by a host processor to request control of the ADSP-2106x’s

HBG I/O Host Bus Grant. Acknowledges an HBR bus request, indicating that the host processor may take

CS I/A Chip Select. Asserted by host processor to select the ADSP-2106x.

REDY (O/D) O Host Bus Acknowledge. The ADSP-2106x deasserts REDY (low) to add wait states to an asynchro-

DMAR1 I/A DMA Request 1 (DMA Channel 7).

DMAR2 I/A DMA Request 2 (DMA Channel 8).

DMAG1 O/T DMA Grant 1 (DMA Channel 7).

DMAG2 O/T DMA Grant 2 (DMA Channel 8).

BR

6-1

ID

2-0

RPBA I/S Rotating Priority Bus Arbitration Select. When RPBA is high, rotating priority for multiprocessor

CPA (O/D) I/O Core Priority Access. Asserting its CPA pin allows the core processor of an ADSP-2106x bus slave

DTx O Data Transmit (Serial Ports 0, 1). Each DT pin has a 50 kΩ internal pull-up resistor.

DRx I Data Receive (Serial Ports 0, 1). Each DR pin has a 50 kΩ internal pull-up resistor.

TCLKx I/O Transmit Clock (Serial Ports 0, 1). Each TCLK pin has a 50 kΩ internal pull-up resistor.

RCLKx I/O Receive Clock (Serial Ports 0, 1). Each RCLK pin has a 50 kΩ internal pull-up resistor.

I/A Interrupt Request Lines. May be either edge-triggered or level-sensitive.

I/O/A Flag Pins. Each is configured via control bits as either an input or output. As an input, it can be

tested as a condition. As an output, it can be used to signal external peripherals.

zero.

external bus. When HBR is asserted in a multiprocessing system, the ADSP-2106x that is bus master

will relinquish the bus and assert HBG. To relinquish the bus, the ADSP-2106x places the address,

data, select and strobe lines in a high impedance state. HBR has priority over all ADSP-2106x bus

requests (BR

) in a multiprocessing system.

6-1

control of the external bus. HBG is asserted (held low) by the ADSP-2106x until HBR is released. In a

multiprocessing system, HBG is output by the ADSP-2106x bus master and is monitored by all others.

nous access of its internal memory or IOP registers by a host. Open drain output (O/D) by default; can

be programmed in ADREDY bit of SYSCON register to be active drive (A/D). REDY will only be

output if the CS and HBR inputs are asserted.

I/O/S Multiprocessing Bus Requests. Used by multiprocessing ADSP-2106xs to arbitrate for bus master-

ship. An ADSP-2106x only drives its own BRx line (corresponding to the value of its ID

inputs) and

2-0

monitors all others. In a multiprocessor system with less than six ADSP-2106xs, the unused BRx pins

should be pulled high; the processor’s own BRx line must not be pulled high or low because it is an

output.

I Multiprocessing ID. Determines which multiprocessing bus request (BR1 – BR6) is used by ADSP-

2106x. ID = 001 corresponds to BR1, ID = 010 corresponds to BR2, etc. ID = 000 in single-processor

systems. These lines are a system configuration selection which should be hardwired or only changed

at reset.

bus arbitration is selected. When RPBA is low, fixed priority is selected. This signal is a system configuration selection which must be set to the same value on every ADSP-2106x. If the value of RPBA is

changed during system operation, it must be changed in the same CLKIN cycle on every ADSP-2106x.

to interrupt background DMA transfers and gain access to the external bus. CPA is an open drain

output that is connected to all ADSP-2106xs in the system. The CPA pin has an internal 5 kΩ pull-up

resistor. If core access priority is not required in a system, the CPA pin should be left unconnected.

REV. B

–9–

Page 10

ADSP-21060C/ADSP-21060LC

Pin Type Function

TFSx I/O Transmit Frame Sync (Serial Ports 0, 1).

RFSx I/O Receive Frame Sync (Serial Ports 0, 1).

LxDAT

LxCLK I/O Link Port Clock (Link Ports 0–5). Each LxCLK pin has a 50 kΩ internal pull-down resistor that is

LxACK I/O Link Port Acknowledge (Link Ports 0–5). Each LxACK pin has a 50 kΩ internal pull-down resistor

EBOOT I EPROM Boot Select. When EBOOT is high, the ADSP-2106x is configured for booting from an 8-

LBOOT I Link Boot. When LBOOT is high, the ADSP-2106x is configured for link port booting. When

BMS I/O/T* Boot Memory Select. Output: Used as chip select for boot EPROM devices (when EBOOT = 1,

CLKIN I Clock In. External clock input to the ADSP-2106x. The instruction cycle rate is equal to CLKIN.

RESET I/A Processor Reset. Resets the ADSP-2106x to a known state and begins execution at the program

TCK I Test Clock (JTAG). Provides an asynchronous clock for JTAG boundary scan.

TMS I/S Test Mode Select (JTAG). Used to control the test state machine. TMS has a 20 kΩ internal pull-up

TDI I/S Test Data Input (JTAG). Provides serial data for the boundary scan logic. TDI has a 20 kΩ internal

TDO O Test Data Output (JTAG). Serial scan output of the boundary scan path.

TRST I/A Test Reset (JTAG). Resets the test state machine. TRST must be asserted (pulsed low) after power-

EMU (O/D) O Emulation Status. Must be connected to the ADSP-2106x EZ-ICE target board connector only.

ICSA O Reserved, leave unconnected.

VDD P Power Supply; nominally 5.0 V dc for 5 V devices or 3.3 V dc for 3.3 V devices. (30 pins).

GND G Power Supply Return. (30 pins).

NC Do Not Connect. Reserved pins which must be left open and unconnected.

3-0

I/O Link Port Data (Link Ports 0–5). Each LxCLK pin has a 50 kΩ internal pull-down resistor that is

enabled or disabled by the LPDRD bit of the LCOM register.

enabled or disabled by the LPDRD bit of the LCOM register.

that is enabled or disabled by the LPDRD bit of the LCOM register.

bit EPROM. When EBOOT is low, the LBOOT and BMS inputs determine booting mode. See table

below. This signal is a system configuration selection that should be hardwired.

LBOOT is low, the ADSP-2106x is configured for host processor booting or no booting. See table

below. This signal is a system configuration selection that should be hardwired.

LBOOT = 0). In a multiprocessor system, BMS is output by the bus master. Input: When low, indicates that no booting will occur and that ADSP-2106x will begin executing instructions from external

memory. See table below. This input is a system configuration selection that should be hardwired.

*Three-statable only in EPROM boot mode (when BMS is an output).

EBOOT LBOOT BMS Booting Mode

1 0 Output EPROM (Connect BMS to EPROM chip select.)

0 0 1 (Input) Host Processor

0 1 1 (Input) Link Port

0 0 0 (Input) No Booting. Processor executes from external memory.

0 1 0 (Input) Reserved

1 1 x (Input) Reserved

CLKIN may not be halted, changed, or operated below the minimum specified frequency.

memory location specified by the hardware reset vector address. This input must be asserted (low) at

power-up.

resistor.

pull-up resistor.

up or held low for proper operation of the ADSP-2106x. TRST has a 20 kΩ internal pull-up resistor.

–10–

REV. B

Page 11

ADSP-21060C/ADSP-21060LC

TARGET BOARD CONNECTOR FOR EZ-ICE PROBE

The ADSP-2106x EZ-ICE Emulator uses the IEEE 1149.1

JTAG test access port of the ADSP-2106x to monitor and control

the target board processor during emulation. The EZ-ICE probe

requires the ADSP-2106x’s CLKIN, TMS, TCK, TRST, TDI,

TDO, EMU, and GND signals be made accessible on the target

system via a 14-pin connector (a 2 row × 7 pin strip header) such

as that shown in Figure 5. The EZ-ICE

probe plugs directly onto

this connector for chip-on-board emulation. You must add this

connector to your target board design if you intend to use the

ADSP-2106x EZ-ICE. The total trace length between the EZICE connector and the furthest device sharing the EZ-ICE

JTAG pins should be limited to 15 inches maximum for guaranteed operation. This length restriction must include EZ-ICE

JTAG signals that are routed to one or more ADSP-2106x

devices, or a combination of ADSP-2106x devices and other

JTAG devices on the chain.

GND

KEY (NO PIN)

BTMS

BTCK

BTRST

BTDI

GND

12

34

56

78

910

9

11 12

13 14

TOP VIEW

EMU

CLKIN (OPTIONAL)

TMS

TCK

TRST

TDI

TDO

Figure 5. Target Board Connector for ADSP-2106x EZ-ICE

Emulator (Jumpers in Place)

The 14-pin, 2-row pin strip header is keyed at the Pin 3 location —

Pin 3 must be removed from the header. The pins must be

0.025 inch square and at least 0.20 inch in length. Pin spacing

should be 0.1 × 0.1 inches. Pin strip headers are available from

vendors such as 3M, McKenzie and Samtec.

The BTMS, BTCK, BTRST and BTDI signals are provided so

the test access port can also be used for board-level testing.

When the connector is not being used for emulation, place

jumpers between the Bxxx pins and the xxx pins. If the test

access port will not be used for board testing, tie BTRST to GND

and tie or pull BTCK up to VDD. The TRST pin must be

asserted after power-up (through BTRST on the connector) or

held low for proper operation of the ADSP-2106x. None of the

Bxxx pins (Pins 5, 7, 9, 11) are connected on the EZ-ICE

probe.

The JTAG signals are terminated on the EZ-ICE probe as

follows:

Signal Termination

TMS Driven through 22 Ω Resistor (16 mA Driver)

TCK Driven at 10 MHz through 22 Ω Resistor (16 mA

Driver)

TRST* Active Low Driven through 22 Ω Resistor (16 mA

Driver) (Pulled Up by On-Chip 20 kΩ Resistor)

TDI Driven by 22 Ω Resistor (16 mA Driver)

TDO One TTL Load, Split Termination (160/220)

CLKIN One TTL Load, Split Termination (160/220)

EMU Active Low 4.7 kΩ Pull-Up Resistor, One TTL Load

(Open-Drain Output from the DSP)

*TRST is driven low until the EZ-ICE probe is turned on by the emulator at

software start-up. After software start-up, TRST is driven high.

Figure 6 shows JTAG scan path connections for systems that

contain multiple ADSP-2106x processors.

REV. B

JTAG

DEVICE

(OPTIONAL)

TDI

TCK

TDO TDO

TMS

TRST

OTHER

JTAG

CONTROLLER

EZ-ICE

JTAG

CONNECTOR

EMU

TRST

TDO

CLKIN

TDI

TCK

TMS

ADSP-2106x

TDI

TCK

OPTIONAL

#1

TMS

TDO

EMU

TRST

Figure 6. JTAG Scan Path Connections for Multiple ADSP-2106x Systems

–11–

ADSP-2106x

TDI

TCK

n

TMS

EMU

TRST

Page 12

ADSP-21060C/ADSP-21060LC

Connecting CLKIN to Pin 4 of the EZ-ICE header is optional.

The emulator only uses CLKIN when directed to perform operations such as starting, stopping and single-stepping multiple

ADSP-21060 in a synchronous manner. If you do not need these

operations to occur synchronously on the multiple processors,

simply tie Pin 4 of the EZ-ICE

header to ground.

If synchronous multiprocessor operations are needed and CLKIN

is connected, clock skew between the multiple ADSP-21060C/

ADSP-21060LC processors and the CLKIN pin on the EZ-ICE

header must be minimal. If the skew is too large, synchronous

operations may be off by one or more cycles between processors. For synchronous multiprocessor operation TCK, TMS,

TDI TDO TDI TDO

5k

*

TDI TDO

CLKIN and EMU should be treated as critical signals in terms

of skew, and should be laid out as short as possible on your

board. If TCK, TMS and CLKIN are driving a large number of

ADSP-21060 (more than eight) in your system, then treat them

as a clock tree using multiple drivers to minimize skew. (See

Figure 7, JTAG Clock Tree, and Clock Distribution in the

High Frequency Design Considerations section of the ADSP-

2106x User’s Manual, Second Edition.)

If synchronous multiprocessor operations are not needed (i.e.,

CLKIN is not connected), just use appropriate parallel termination on TCK and TMS. TDI, TDO, EMU, and TRST are not

critical signals in terms of skew.

For complete information on the SHARC EZ-ICE, see the ADSP-

2100 Family JTAG EZ-ICE User’s Guide and Reference.

TDI TDO

TDI TDO

TDI TDO

TDI

EMU

TCK

TMS

TRST

TDO

CLKIN

5k

*

*

OPEN DRAIN DRIVER OR EQUIVALENT, i.e.,

EMU

Figure 7. JTAG Clocktree for Multiple ADSP-2106x Systems

SYSTEM

CLKIN

–12–

REV. B

Page 13

ADSP-21060C/ADSP-21060LC

ADSP-21060C–SPECIFICATIONS

RECOMMENDED OPERATING CONDITIONS (5 V)

K Grade

Parameter Test Conditions Min Max Unit

V

DD

T

CASE

V

IH1

V

IH2

V

IL

NOTES

1

Applies to input and bidirectional pins: DATA

CPA, TFS0, TFS1, RFS0, RFS1, LxDAT

2

Applies to input pins: CLKIN, RESET, TRST.

ELECTRICAL CHARACTERISTICS (5 V)

Parameter Test Conditions Min Max Unit

V

OH

V

OL

I

IH

I

IL

I

ILP

I

OZH

I

OZL

I

OZHP

I

OZLC

I

OZLA

I

OZLAR

I

OZLS

C

IN

NOTES

11

Applies to output and bidirectional pins: DATA

DMAG2, BR

12

See “Output Drive Currents” for typical drive current capabilities.

13

Applies to input pins: SBTS, IRQ

14

Applies to input pins with internal pull-ups: DR0, DR1, TRST, TMS, TDI.

15

Applies to three-statable pins: DATA

TFSX, RFSX, TDO, EMU. (Note that ACK is pulled up internally with 2 kΩ during reset in a multiprocessor system, when ID

not requesting bus mastership.)

16

Applies to three-statable pins with internal pull-ups: DT0, DT1, TCLK0, TCLK1, RCLK0, RCLK1.

17

Applies to CPA pin.

18

Applies to ACK pin when pulled up. (Note that ACK is pulled up internally with 2 kΩ during reset in a multiprocessor system, when ID

ADSP-21060 is not requesting bus mastership).

19

Applies to three-statable pins with internal pull-downs: LxDAT

10

Applies to ACK pin when keeper latch enabled.

11

Applies to all signal pins.

12

Guaranteed but not tested.

Specifications subject to change without notice.

Supply Voltage 4.75 5.25 V

Case Operating Temperature –40 +100 °C

High Level Input Voltage

High Level Input Voltage

Low Level Input Voltage

High Level Output Voltage

Low Level Output Voltage

High Level Input Current

Low Level Input Current

Low Level Input Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Input Capacitance

, CPA, DT0, DT1, TCLK0, TCLK1, RCLK0, RCLK1, TFS0, TFS1, RFS0, RFS1, LxDAT

6-1

11, 12

, HBR, CS, DMAR1, DMAR2, ID

2-0

47-0

1

2

1, 2

, ADDR

47-0

, LxCLK, LxACK, EBOOT, LBOOT, BMS, TMS, TDI, TCK, HBR, DR0, DR1, TCLK0, TCLK1, RCLK0, RCLK1.

3-0

1

1

3, 4

3

4

5, 6, 7, 8

5, 9

9

7

10

8

6

, ADDR

47-0

, ADDR

31-0

, MS

@ VDD = max 2.0 VDD + 0.5 V

@ VDD = max 2.2 VDD + 0.5 V

@ VDD = min –0.5 +0.8 V

, RD, WR, SW, ACK, SBTS, IRQ

31-0

@ VDD = min, IOH = –2.0 mA

@ VDD = min, IOL = 4.0 mA

@ VDD = max, VIN = V

, FLAG

2-0

2

max 10 µA

DD

, HBG, CS, DMAR1, DMAR2, BR

3-0

2

4.1 V

6-1

0.4 V

@ VDD = max, VIN = 0 V 10 µA

@ VDD = max, VIN = 0 V 150 µA

@ VDD = max, VIN = V

max 10 µA

DD

@ VDD = max, VIN = 0 V 10 µA

@ VDD = max, VIN = V

max 350 µA

DD

@ VDD = max, VIN = 0 V 1.5 mA

@ VDD = max, VIN = 1.5 V 350 µA

@ VDD = max, VIN = 0 V 4.2 mA

@ VDD = max, VIN = 0 V 150 µA

fIN = 1 MHz, T

, MS

31-0

, RD, WR, PAGE, ADRCLK, SW, ACK, FLAG

3-0

, RD, WR, PAGE, ADRCLK, SW, ACK, FLAG

3-0

, RPBA, EBOOT, LBOOT, CLKIN, RESET, TCK.

2-0

, LxCLK, LxACK.

3-0

= 25°C, VIN = 2.5 V 4.7 pF

CASE

, TIMEXP, HBG, REDY, DMAG1,

3-0

, LxCLK, LxACK, BMS, TDO, EMU, ICSA.

3-0

, REDY, HBG, DMAG1, DMAG2, BMS, BR

3-0

= 001 and another ADSP-21060 is

2-0

= 001 and another

2-0

, ID

, RPBA,

2-0

6–1

,

REV. B

–13–

Page 14

ADSP-21060C/ADSP-21060LC

POWER DISSIPATION ADSP-21060C (5 V)

These specifications apply to the internal power portion of VDD only. See the Power Dissipation section of this data sheet for calculation of external supply current and total supply current. For a complete discussion of the code used to measure power dissipation, see

the technical note “SHARC Power Dissipation Measurements.”

Specifications are based on the following operating scenarios:

Operation Peak Activity (I

DDINPEAK

) High Activity (I

DDINHIGH

) Low Activity (I

DDINLOW

)

Instruction Type Multifunction Multifunction Single Function

Instruction Fetch Cache Internal Memory Internal Memory

Core Memory Access 2 per Cycle (DM and PM) 1 per Cycle (DM) None

Internal Memory DMA 1 per Cycle 1 per 2 Cycles 1 per 2 Cycles

To estimate power consumption for a specific application, use the following equation where % is the amount of time your program

spends in that state:

%PEAK × I

DDINPEAK

+ %HIGH × I

DDINHIGH

+ %LOW × I

DDINLOW

+ %IDLE × I

= power consumption

DDIDLE

Parameter Test Conditions Max Unit

I

DDINPEAK

Supply Current (Internal)

1

tCK = 30 ns, VDD = max 745 mA

tCK = 25 ns, VDD = max 850 mA

I

DDINHIGH

Supply Current (Internal)

2

tCK = 30 ns, VDD = max 575 mA

tCK = 25 ns, VDD = max 670 mA

I

DDINLOW

Supply Current (Internal)

2

tCK = 30 ns, VDD = max 340 mA

tCK = 25 ns, VDD = max 390 mA

I

DDIDLE

NOTES

1

The test program used to measure I

power measurements made using typical applications are less than specified.

2

I

3

Idle denotes ADSP-21060C state during execution of IDLE instruction.

is a composite average based on a range of high activity code. I

DDINHIGH

Supply Current (Idle)

DDINPEAK

3

represents worst case processor operation and is not sustainable under normal application conditions. Actual internal

VDD = max 200 mA

is a composite average based on a range of low activity code.

DDINLOW

–14–

REV. B

Page 15

ADSP-21060C/ADSP-21060LC

ADSP-21060LC–SPECIFICATIONS

RECOMMENDED OPERATING CONDITIONS (3.3 V)

K Grade

Parameter Test Conditions Min Max Unit

V

DD

T

CASE

V

IH1

V

IH2

V

IL

NOTES

1

Applies to input and bidirectional pins: DATA

CPA, TFS0, TFS1, RFS0, RFS1, LxDAT

RCLK1.

2

Applies to input pins: CLKIN, RESET, TRST.

Supply Voltage 3.15 3.45 V

Case Operating Temperature –40 +100 °C

High Level Input Voltage

High Level Input Voltage

Low Level Input Voltage

1

2

1, 2

, ADDR

47-0

, LxCLK, LxACK, EBOOT, LBOOT, BMS, TMS, TDI, TCK, HBR, DR0, DR1, TCLK0, TCLK1, RCLK0,

3-0

@ VDD = max 2.0 VDD + 0.5 V

@ VDD = max 2.2 VDD + 0.5 V

@ VDD = min –0.5 0.8 V

, RD, WR, SW, ACK, SBTS, IRQ

31-0

, FLAG

2-0

, HBG, CS, DMAR1, DMAR2, BR

3-0

, ID

6-1

2-0

, RPBA,

ELECTRICAL CHARACTERISTICS (3.3 V)

Parameter Test Conditions Min Max Unit

V

OH

V

OL

I

IH

I

IL

I

ILP

I

OZH

I

OZL

I

OZHP

I

OZLC

I

OZLA

I

OZLAR

I

OZLS

C

IN

NOTES

11

Applies to output and bidirectional pins: DATA

DMAG2, BR

12

See “Output Drive Currents” for typical drive current capabilities.

13

Applies to input pins: ACK SBTS, IRQ

14

Applies to input pins with internal pull-ups: DR0, DR1, TRST, TMS, TDI.

15

Applies to three-statable pins: DATA

TFSX, RFSX, TDO, EMU. (Note that ACK is pulled up internally with 2 kΩ during reset in a multiprocessor system, when ID

is not requesting bus mastership.)

16

Applies to three-statable pins with internal pull-ups: DT0, DT1, TCLK0, TCLK1, RCLK0, RCLK1.

17

Applies to CPA pin.

18

Applies to ACK pin when pulled up. (Note that ACK is pulled up internally with 2 kΩ during reset in a multiprocessor system, when ID

ADSP-21060LC is not requesting bus mastership).

19

Applies to three-statable pins with internal pull-downs: LxDAT

10

Applies to ACK pin when keeper latch enabled.

11

Applies to all signal pins.

12

Guaranteed but not tested.

Specifications subject to change without notice.

High Level Output Voltage

Low Level Output Voltage

High Level Input Current

Low Level Input Current

Low Level Input Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Three-State Leakage Current

Input Capacitance

, CPA, DT0, DT1, TCLK0, TCLK1, RCLK0, RCLK1, TFS0, TFS1, RFS0, RFS1, LxDAT

6-1

11, 12

47-0

1

1

3, 4

3

4

5, 6, 7, 8

5, 9

9

7

10

8

6

@ VDD = min, IOH = –2.0 mA

@ VDD = min, IOL = 4.0 mA

@ VDD = max, VIN = V

@ VDD = max, VIN = 0 V 10 µA

@ VDD = max, VIN = 0 V 150 µA

@ VDD = max, VIN = V

@ VDD = max, VIN = 0 V 10 µA

@ VDD = max, VIN = V

@ VDD = max, VIN = 0 V 1.5 mA

@ VDD = max, VIN = 2 V 350 µA

@ VDD = max, VIN = 0 V 4.2 mA

@ VDD = max, VIN = 0 V 150 µA

fIN = 1 MHz, T

, ADDR

47-0

, HBR, CS, DMAR1, DMAR2, ID

2-0

, ADDR

31-0

, MS

, MS

31-0

, RD, WR, PAGE, ADRCLK, SW, ACK, FLAG

3-0

, RD, WR, PAGE, ADRCLK, SW, ACK, FLAG

3-0

, LxCLK, LxACK.

3-0

= 25°C, VIN = 2.5 V 4.7 pF

CASE

, RPBA, EBOOT, LBOOT, CLKIN, RESET, TCK.

2-0

2

2

max 10 µA

DD

max 10 µA

DD

max 350 µA

DD

, LxCLK, LxACK, BMS, TDO, EMU, ICSA.

3-0

, REDY, HBG, DMAG1, DMAG2, BMS, BR

3-0

2.4 V

0.4 V

, TIMEXP, HBG, REDY, DMAG1,

3-0

= 001 and another ADSP-21060LC

2-0

= 001 and another

2-0

6–1

,

REV. B

–15–

Page 16

ADSP-21060C/ADSP-21060LC

POWER DISSIPATION ADSP-21060LC (3.3 V)

These specifications apply to the internal power portion of VDD only. See the Power Dissipation section of this data sheet for calculation of external supply current and total supply current. For a complete discussion of the code used to measure power dissipation,

see the technical note “SHARC Power Dissipation Measurements.”

Specifications are based on the following operating scenarios:

Operation Peak Activity (I

DDINPEAK

) High Activity (I

DDINHIGH

) Low Activity (I

DDINLOW

)

Instruction Type Multifunction Multifunction Single Function

Instruction Fetch Cache Internal Memory Internal Memory

Core Memory Access 2 per Cycle (DM and PM) 1 per Cycle (DM) None

Internal Memory DMA 1 per Cycle 1 per 2 Cycles 1 per 2 Cycles

To estimate power consumption for a specific application, use the following equation where % is the amount of time your program

spends in that state:

%PEAK × I

DDINPEAK

+ %HIGH × I

DDINHIGH

+ %LOW × I

DDINLOW

+ %IDLE × I

= power consumption

DDIDLE

Parameter Test Conditions Max Unit

I

DDINPEAK

Supply Current (Internal)

1

tCK = 30 ns, VDD = max 540 mA

tCK = 25 ns, VDD = max 600 mA

I

DDINHIGH

Supply Current (Internal)

2

tCK = 30 ns, VDD = max 425 mA

tCK = 25 ns, VDD = max 475 mA

I

DDINLOW

Supply Current (Internal)

2

tCK = 30 ns, VDD = max 250 mA

tCK = 25 ns, VDD = max 275 mA

I

DDIDLE

NOTES

1

The test program used to measure I

power measurements made using typical applications are less than specified.

2

I

3

Idle denotes ADSP-21060LC state during execution of IDLE instruction.

is a composite average based on a range of high activity code. I

DDINHIGH

Supply Current (Idle)

DDINPEAK

3

represents worst-case processor operation and is not sustainable under normal application conditions. Actual internal

VDD = max 180 mA

is a composite average based on a range of low activity code.

DDINLOW

–16–

REV. B

Page 17

ADSP-21060C/ADSP-21060LC

ABSOLUTE MAXIMUM RATINGS (5 V)*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

Input Voltage . . . . . . . . . . . . . . . . . . . . –0.5 V to V

Output Voltage Swing . . . . . . . . . . . . . –0.5 V to V

+ 0.5 V

DD

+ 0.5 V

DD

Load Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 pF

Junction Temperature Under Bias . . . . . . . . . . . . . . . . 130°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (5 seconds) . . . . . . . . . . . . . . . . . . 280°C

*Stresses greater than those listed above may cause permanent damage to the

device. These are stress ratings only, and functional operation of the device at these

or any other conditions greater than those indicated in the operational sections of

this specification is not implied. Exposure to absolute maximum rating conditions

for extended periods may affect device reliability.

ESD SENSITIVITY

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V

readily accumulate on the human body and test equipment and can discharge without

detection. Although the ADSP-21060C/ADSP-21060LC features proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high-energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid

performance degradation or loss of functionality.

ABSOLUTE MAXIMUM RATINGS (3.3 V)*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +4.6 V

Input Voltage . . . . . . . . . . . . . . . . . . . . –0.5 V to V

Output Voltage Swing . . . . . . . . . . . . . –0.5 V to V

Load Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 pF

Junction Temperature Under Bias . . . . . . . . . . . . . . . . . 130°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (5 seconds) . . . . . . . . . . . . . . . . . . . 280°C

*Stresses greater than those listed above may cause permanent damage to the

device. These are stress ratings only, and functional operation of the device at these

or any other conditions greater than those indicated in the operational sections of

this specification is not implied. Exposure to absolute maximum rating conditions

for extended periods may affect device reliability.

WARNING!

ESD SENSITIVE DEVICE

+ 0.5 V

DD

+ 0.5 V

DD

TIMING SPECIFICATIONS

Two speed grades of the ADSP-21060C are offered, 40 MHz

and 33.3 MHz. The specifications shown are based on a

CLKIN frequency of 40 MHz (t

allows specifications at other CLKIN frequencies (within the

min–max range of the t

specification; see Clock Input below).

CK

DT is the difference between the actual CLKIN period and a

CLKIN period of 25 ns:

DT = t

Use the exact timing information given. Do not attempt to

derive parameters from the addition or subtraction of others.

While addition or subtraction would yield meaningful results for

an individual device, the values given in this data sheet reflect

statistical variations and worst cases. Consequently, you cannot

meaningfully add parameters to derive longer times.

= 25 ns). The DT derating

CK

– 25 ns

CK

See Figure 28 under Test Conditions for voltage reference

levels.

Switching Characteristics specify how the processor changes its

signals. You have no control over this timing—circuitry external

to the processor must be designed for compatibility with these

signal characteristics. Switching characteristics tell you what the

processor will do in a given circumstance. You can also use

switching characteristics to ensure that any timing requirement

of a device connected to the processor (such as memory) is

satisfied.

Timing Requirements apply to signals that are controlled by circuitry external to the processor, such as the data input for a

read operation. Timing requirements guarantee that the processor operates correctly with other devices.

(O/D) = Open Drain

(A/D) = Active Drive

REV. B

–17–

Page 18

ADSP-21060C/ADSP-21060LC

ADSP-21060C ADSP-21060LC

40 MHz 33 MHz 40 MHz 33 MHz

Parameter Min Max Min Max Min Max Min Max Unit

Clock Input

Timing Requirements:

t

CK

t

CKL

t

CKH

t

CKRF

Parameter Min Max Min Max Unit

Reset

Timing Requirements:

t

WRST

t

SRST

NOTES

1

Applies after the power-up sequence is complete. At power-up, the processor’s internal phase-locked loop requires no more than 2000 CLKIN cycles while RESET

is low, assuming stable VDD and CLKIN (not including start-up time of external clock oscillator).

2

Only required if multiple ADSP-2106xs must come out of reset synchronous to CLKIN with program counters (PC) equal (i.e., for a SIMD system). Not required

for multiple ADSP-2106xs communicating over the shared bus (through the external port), because the bus arbitration logic synchronizes itself automatically after reset.

CLKIN Period 25 100 30 100 25 100 30 100 ns

CLKIN Width Low 7 7 9.5 9.5 ns

CLKIN Width High 5555ns

CLKIN Rise/Fall (0.4 V–2.0 V) 3 3 3 3 ns

t

CK

CLKIN

t

CKH

t

CKL

Figure 8. Clock Input

ADSP-21060C ADSP-21060LC

RESET Pulsewidth Low

RESET Setup before CLKIN High

1

2

4t

CK

14 + DT/2 t

CK

4t

CK

14 + DT/2 t

CK

ns

ns

CLKIN

t

SRST

RESET

t

WRST

Figure 9. Reset

ADSP-21060C ADSP-21060LC

Parameter Min Max Min Max Unit

Interrupts

Timing Requirements:

t

SIR

t

HIR

t

IPW

NOTES

1

Only required for IRQx recognition in the following cycle.

2

Applies only if t

IRQ2-0 Setup before CLKIN High

IRQ2-0 Hold before CLKIN High

IRQ2-0 Pulsewidth

and t

SIR

requirements are not met.

HIR

2

CLKIN

IRQ2-0

1

1

18 + 3DT/4 18 + 3DT/4 ns

12 + 3DT/4 12 + 3DT/4 ns

2 + t

t

IPW

CK

t

SIR

t

HIR

2 + t

CK

ns

Figure 10. Interrupts

–18–

REV. B

Page 19

ADSP-21060C/ADSP-21060LC

ADSP-21060C ADSP-21060LC

Parameter Min Max Min Max Unit

Timer

Switching Characteristic:

t

DTEX

Parameter Min Max Min Max Unit

Flags

Timing Requirements:

t

SFI

t

HFI

t

DWRFI

t

HFIWR

CLKIN High to TIMEXP 15 15 ns

CLKIN

t

DTEX

TIMEXP

t

DTEX

Figure 11. Timer

ADSP-21060C ADSP-21060LC

FLAG3-0

FLAG3-0

FLAG3-0

FLAG3-0

Setup before CLKIN High

IN

Hold after CLKIN High

IN

Delay after RD/WR Low

IN

Hold after RD/WR Deasserted100 ns

IN

1

1

1

8 + 5DT/16 8 + 5DT/16 ns

0 – 5DT/16 0 – 5DT/16 ns

5 + 7DT/16 5 + 7DT/16 ns

Switching Characteristics:

t

DFO

t

HFO

t

DFOE

t

DFOD

NOTE

1

Flag inputs meeting these setup and hold times will affect conditional instructions in the following instruction cycle.

FLAG3-0

FLAG3-0

RD, WR

FLAG3-0

FLAG3-0

CLKIN High to FLAG3-0

CLKIN High to FLAG3-0

CLKIN

t

DFOE

OUT

CLKIN

IN

Delay after CLKIN High 16 16 ns

OUT

Hold after CLKIN High 4 4 ns

OUT

t

DWRFI

FLAG INPUT

t

Enable 3 3 ns

OUT

Disable 14 14 ns

OUT

t

t

DFO

FLAG OUTPUT

t

t

HFIWR

HFI

SFI

DFO

t

HFO

Figure 12. Flags

t

DFOD

REV. B

–19–

Page 20

ADSP-21060C/ADSP-21060LC

Memory Read—Bus Master

Use these specifications for asynchronous interfacing to memories (and memory-mapped peripherals) without reference to

CLKIN. These specifications apply when the ADSP-2106x is

characteristics also apply for bus master synchronous read/write

timing (see Synchronous Read/Write – Bus Master below). If

these timing requirements are met, the synchronous read/write

timing can be ignored (and vice versa).

the bus master accessing external memory space. These switching

ADSP-21060C ADSP-21060LC

Parameter Min Max Min Max Unit

Timing Requirements:

t

DAD

t

DRLD

t

HDA

t

HDRH

t

DAAK

t

DSAK

Address, Selects Delay to Data Valid

RD Low to Data Valid

Data Hold from Address, Selects

Data Hold from RD High

ACK Delay from Address, Selects

ACK Delay from RD Low

1

3

4

1, 2

3

2, 4

0.5 0.5 ns

2.0 2.0 ns

18 + DT + W 18 + DT + W ns

12 + 5DT/8 + W 12 + 5DT/8 + W ns

14 + 7DT/8 + W 14 + 7DT/8 + W ns

8 + DT/2 + W 8 + DT/2 + W ns

Switching Characteristics:

t

DRHA

t

DARL

t

RW

t

RWR

t

SADADC

W = (number of wait states specified in WAIT register) × t

HI = tCK (if an address hold cycle or bus idle cycle occurs, as specified in WAIT register; otherwise HI = 0).

H = tCK (if an address hold cycle occurs as specified in WAIT register; otherwise H = 0).

NOTES

1

Data Delay/Setup: User must meet t

2

The falling edge of MSx, SW, BMS is referenced.

3

Data Hold: User must meet t

given capacitive and dc loads.

4

ACK Delay/Setup: User must meet t

tion of ACK (High).

Address, Selects Hold after RD High 0 + H 0 + H ns

Address, Selects to RD Low

2

2 + 3DT/8 2 + 3DT/8 ns

RD Pulsewidth 12.5 + 5DT/8 + W 12.5 + 5DT/8 + W ns

RD High to WR, RD, DMAGx Low 8 + 3DT/8 + HI 8 + 3DT/8 + HI ns

Address, Selects Setup before

ADRCLK High

2

HDA

or t

DAD

DRLD

or t

or synchronous spec t

HDRH

or t

DAAK

0 + DT/4 0 + DT/4 ns

CK.

or synchronous spec t

or synchronous specification t

DSAK

SSDATI

. See System Hold Time Calculation under Test Conditions for the calculation of hold times

HSDATI

.

for deassertion of ACK (Low), all three specifications must be met for asser-

SACKC

ADDRESS

MSx, SW

BMS

DATA

ACK

WR, DMAG

ADRCLK

(OUT)

RD

t

SADADC

t

DARL

t

t

RW

t

DRLD

DAD

DAAK

t

t

DSAK

Figure 13. Memory Read—Bus Master

t

t

t

HDRH

DRHA

HDA

t

RWR

–20–

REV. B

Page 21

ADSP-21060C/ADSP-21060LC

Memory Write—Bus Master

Use these specifications for asynchronous interfacing to memories (and memory-mapped peripherals) without reference to

CLKIN. These specifications apply when the ADSP-2106x is

characteristics also apply for bus master synchronous read/write

timing (see Synchronous Read/Write–Bus Master). If these

timing requirements are met, the synchronous read/write timing

can be ignored (and vice versa).

the bus master accessing external memory space. These switching

ADSP-21060C ADSP-21060LC

Parameter Min Max Min Max Unit

Timing Requirements:

t

DAAK

t

DSAK

ACK Delay from Address, Selects

ACK Delay from WR Low

1, 2

1

14 + 7DT/8 + W 14 + 7DT/8 + W ns

8 + DT/2 + W 8 + DT/2 + W ns

Switching Characteristics:

t

DAWH

t

DAWL

t

WW

t

DDWH

t

DWHA

t

DATRWH

t

WWR

t

DDWR

t

WDE

t

SADADC

W = (number of wait states specified in WAIT register) × tCK.

H = tCK (if an address hold cycle occurs, as specified in WAIT register; otherwise H = 0).

I = tCK (if a bus idle cycle occurs, as specified in WAIT register; otherwise I = 0).

NOTES

1

ACK Delay/Setup: User must meet t

tion of ACK (High).

2

The falling edge of MSx, SW, BMS is referenced.

3

See System Hold Time Calculation under Test Conditions for calculation of hold times given capacitive and dc loads.

Address, Selects to WR Deasserted217 + 15DT/16 + W 17 + 15DT/16 + W ns

Address, Selects to WR Low

2

3 + 3DT/8 3 + 3DT/8 ns

WR Pulsewidth 12 + 9DT/16 + W 12 + 9DT/16 + W ns

Data Setup before WR High 7 + DT/2 + W 7 + DT/2 + W ns

Address Hold after WR Deasserted 0.5 + DT/16 + H 0.5 + DT/16 + H ns

Data Disable after WR Deasserted

3

1 + DT/16 + H 6 + DT/16 + H 1 + DT/16 + H 6 + DT/16 + H ns

WR High to WR, RD, DMAGx Low 8 + 7DT/16 + H 8 + 7DT/16 + H ns

Data Disable before WR or RD Low 5 + 3DT/8 + I 5 + 3DT/8 + I ns

WR Low to Data Enabled –1 + DT/16 –1 + DT/16 ns

Address, Selects to ADRCLK High20 + DT/4 0 + DT/4 ns

or t

DAAK

or synchronous specification t

DSAK

for deassertion of ACK (Low), all three specifications must be met for asser-

SACKC

ADDRESS

MSx , SW

BMS

WR

DATA

ACK

RD , DMAG

ADRCLK

(OUT)

t

SADADC

t

DAWL

t

DAWH

t

WW

t

WDE

t

DSAK

t

DAAK

Figure 14. Memory Write—Bus Master

t

DDWH

t

DATRWH

t

DWHA

t

WWR

t

DDWR

REV. B

–21–

Page 22

ADSP-21060C/ADSP-21060LC

Synchronous Read/Write—Bus Master