Page 1

ADS7845

FEATURES

● 5-WIRE TOUCH SCREEN INTERFACE

● RATIOMETRIC CONVERSION

● SINGLE SUPPLY: 2V to 5V

● UP TO 125kHz CONVERSION RATE

● SERIAL INTERFACE

● PROGRAMMABLE 8- OR 12-BIT RESOLUTION

● AUXILIARY ANALOG INPUTS

● FULL POWER-DOWN CONTROL

®

DESCRIPTION

The ADS7845 is a 12-bit sampling analog-to-digital

converter (ADC) with a synchronous serial interface

and low on-resistance switches for driving touch

screens. Typical power dissipation is 750µW at a

125kHz throughput rate and a +2.7V supply. The

reference voltage (V

REF

) can be varied between 1V and

+VCC, providing a corresponding input voltage range

of 0V to V

REF

. The device includes a shutdown mode

which reduces typical power dissipation to under

0.5µW. The ADS7845 is guaranteed down to 2.7V

operation.

Low power, high speed, and on-board switches make

the ADS7845 ideal for battery-operated systems such

as personal digital assistants with resistive touch screens

and other portable equipment. The ADS7845 is available in a 16-lead SSOP package and is guaranteed

over the –40°C to +85°C temperature range.

APPLICATIONS

● PERSONAL DIGITAL ASSISTANTS

● PORTABLE INSTRUMENTS

● POINT-OF-SALES TERMINALS

● PAGERS

● TOUCH-SCREEN MONITORS

©

1998 Burr-Brown Corporation PDS-1497A Printed in U.S.A. December, 1998

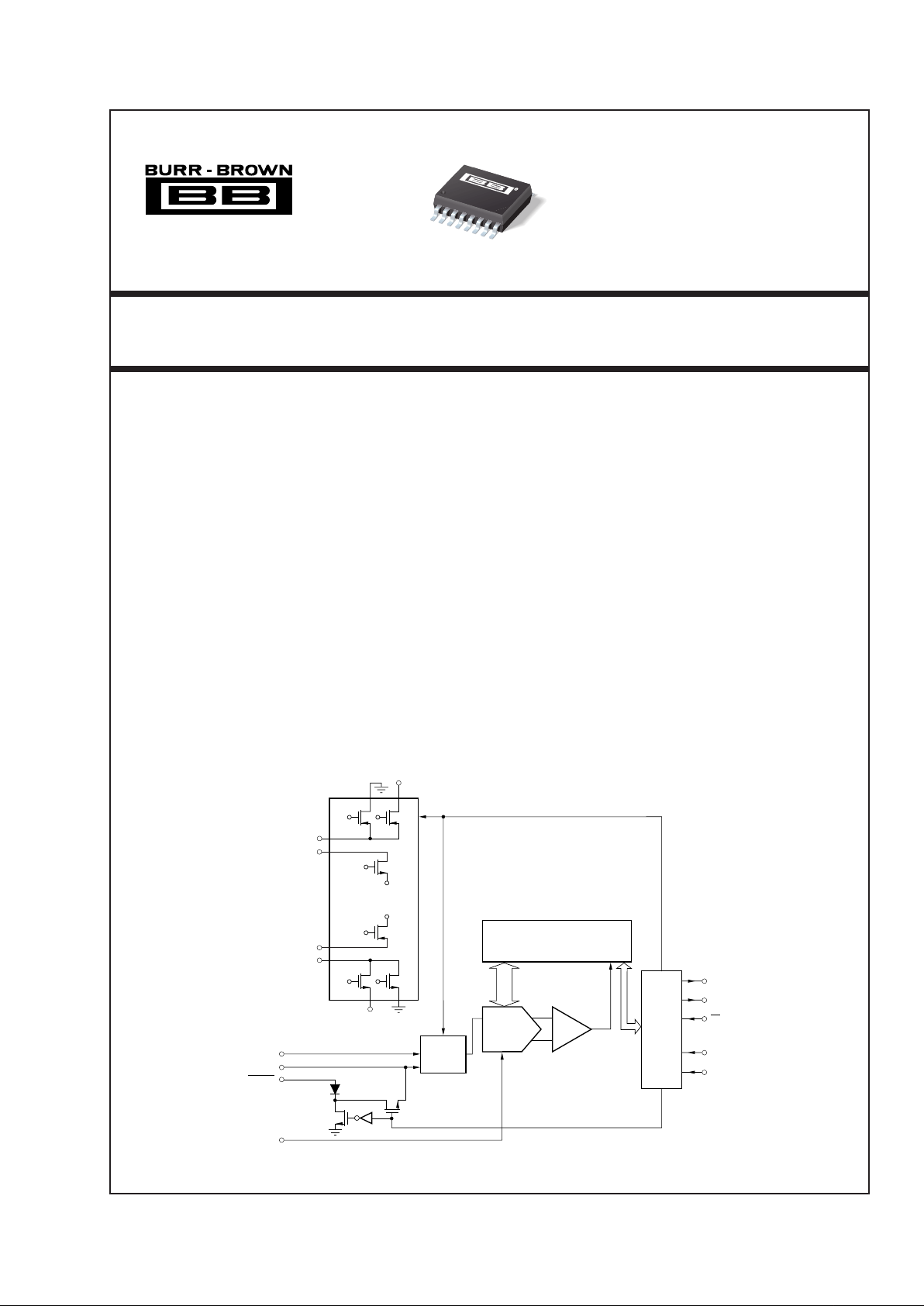

TOUCH SCREEN CONTROLLER

CDAC

SAR

ADS7845

Comparator

MUX

Serial

Data

Interface

and

Control

DOUT

BUSY

CS

DCLK

DIN

UR

LR

UL

LL

AUX IN

WIPER

PENIRQ

V

REF

GND

Driver

+V

CC

+V

CC

GND

+V

CC

GND

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111

Twx: 910-952-1111 • Internet: http://www.burr-brown.com/ • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

ADS7845

Page 2

®

2

ADS7845

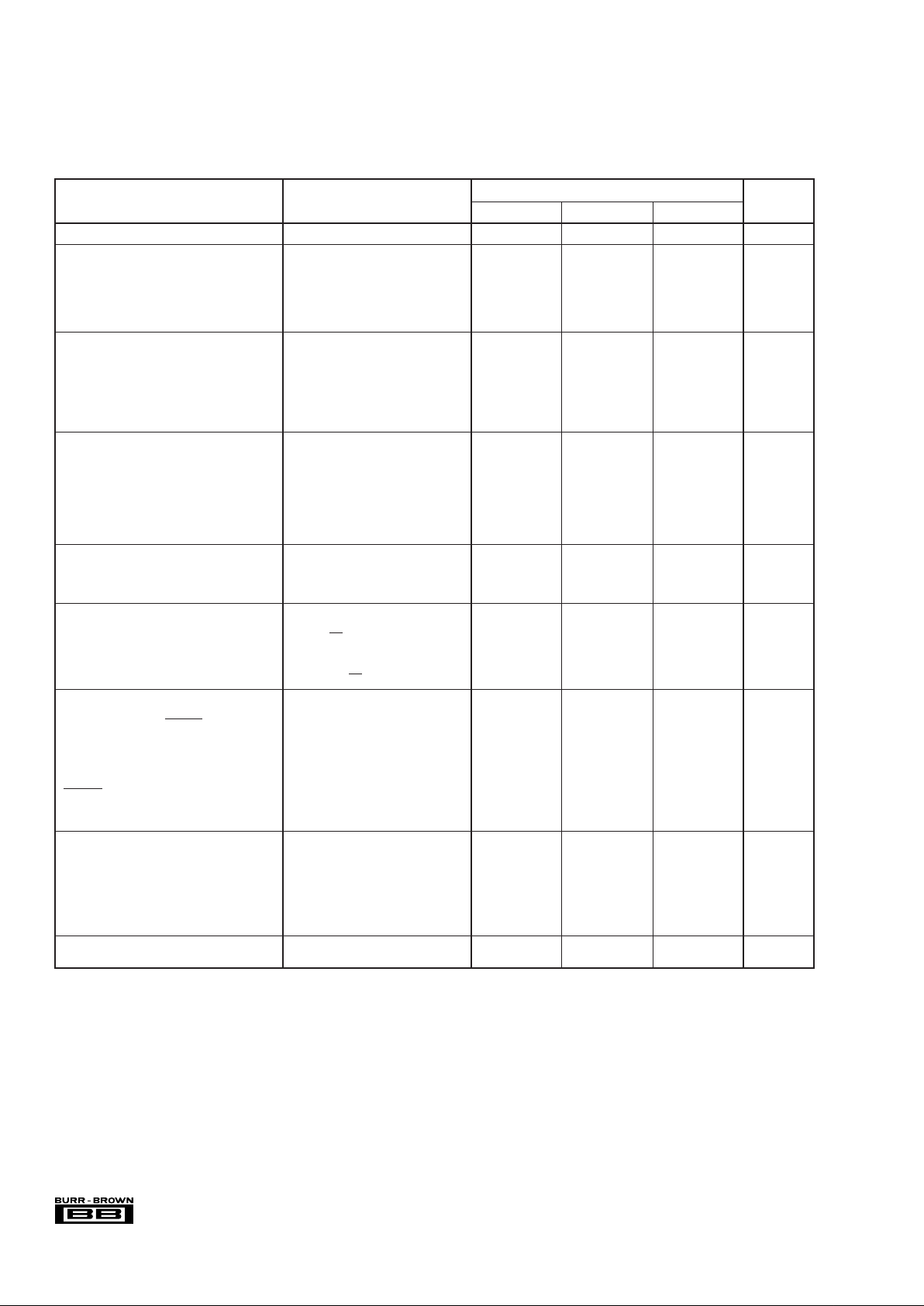

PARAMETER CONDITIONS MIN TYP MAX UNITS

RESOLUTION 12 Bits

ANALOG INPUT

Full-Scale Input Span Positive Input - Negative Input 0 V

REF

V

Absolute Input Range Positive Input –0.2 +V

CC

+0.2 V

Negative Input –0.2 +0.2 V

Capacitance 25 pF

Leakage Current 0.1 µA

SYSTEM PERFORMANCE

No Missing Codes 11 Bits

Integral Linearity Error ±2 LSB

(1)

Offset Error ±6 LSB

Gain Error ±4 LSB

Noise 30 µVrms

Power Supply Rejection Ratio 70 dB

SAMPLING DYNAMICS

Conversion Time 12 Clk Cycles

Acquisition Time 3 Clk Cycles

Throughput Rate 125 kHz

Multiplexer Settling Time 500 ns

Aperture Delay 30 ns

Aperture Jitter 100 ps

Channel-to-Channel Isolation V

IN

= 2.5Vp-p at 50kHz 100 dB

SWITCH DRIVERS

On-Resistance

UL, UR 7 Ω

LL, LR 7 Ω

REFERENCE INPUT

Range 1.0 +V

CC

V

Resistance CS = GND or +V

CC

5GΩ

Input Current 13 40 µA

f

SAMPLE

= 12.5kHz 2.5 µA

CS = +V

CC

0.001 3 µA

DIGITAL INPUT/OUTPUT

Logic Family CMOS

Logic Levels, Except PENIRQ

V

IH

| I

IH

| ≤ +5µA+V

CC

• 0.7 +VCC +0.3

V

IL

| I

IL

| ≤ +5µA –0.3 +0.8 V

V

OH

IOH = –250µA+V

CC

• 0.8 V

V

OL

IOL = 250µA 0.4 V

PENIRQ

V

OL

TA = 0°C to +85°C, 100kΩ Pull-Up 0.8 V

Data Format Straight Binary

POWER SUPPLY REQUIREMENTS

+V

CC

Specified Performance

(2)

2.7 5.5 V

Quiescent Current 280 650 µA

f

SAMPLE

= 12.5kHz 220 µA

Shutdown Mode with 3 µA

DCLK = DIN = +V

CC

Power Dissipation +VCC = +2.7V 1.8 mW

TEMPERATURE RANGE

Specified Performance –40 +85 °C

SPECIFICATIONS

At TA = –40°C to +85°C, +VCC = +2.7V, V

REF

= +2.5V, f

SAMPLE

= 125kHz, f

CLK

= 16 • f

SAMPLE

= 2MHz, 12-bit mode, and digital inputs = GND or +VCC, unless

otherwise noted.

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

ADS7845E

NOTE: (1) LSB means Least Significant Bit. With V

REF

equal to +2.5V, one LSB is 610µV. (2) ADS7845 will operate down to 2.0V.

Page 3

®

3

ADS7845

PIN NAME DESCRIPTION

1+V

CC

Power Supply, 2.0V to 5V.

2 UL Upper Left Panel Driver (V

CC

ON/OFF)

3 UR Upper Right Panel Driver (switch between V

CC

and GND)

4 LL Lower Left Panel Driver (switch between GND

and V

CC

)

5 LR Lower Right Panel Driver (GND ON/OFF)

6 GND Ground

7 WIPER Panel Input

8 AUXIN Auxiliary Input

9V

REF

Voltage Reference Input

10 +V

CC

Power Supply, 2.0V to 5V.

11 PENIRQ Pen Interrupt. Open anode output (requires 10kΩ

to 100kΩ pull-up resistor externally).

12 DOUT Serial Data Output. Data is shifted on the falling

edge of DCLK. This output is high impedance

when CS is HIGH.

13 BUSY Busy Output. This output is high impedance when

CS is HIGH.

14 DIN Serial Data Input. If CS is LOW, data is latched on

rising edge of DCLK.

15 CS Chip Select Input. Controls conversion timing and

enables the serial input/output register.

16 DCLK External Clock Input. This clock runs the SAR con-

version process and synchronizes serial data I/O.

PIN CONFIGURATION

Top View SSOP

PIN DESCRIPTION

ABSOLUTE MAXIMUM RATINGS

(1)

+V

CC

to GND ........................................................................ –0.3V to +6V

Analog Inputs to GND ............................................ –0.3V to +V

CC

+ 0.3V

Digital Inputs to GND .............................................–0.3V to +V

CC

+ 0.3V

Power Dissipation .......................................................................... 250mW

Maximum Junction Temperature................................................... +150°C

Operating Temperature Range ........................................–40°C to +85°C

Storage Temperature Range ......................................... –65°C to +150°C

Lead Temperature (soldering, 10s) ............................................... +300°C

NOTE: (1) Stresses above those listed under “Absolute Maximum Ratings”

may cause permanent damage to the device. Exposure to absolute maximum

conditions for extended periods may affect device reliability.

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and

installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be

more susceptible to damage because very small parametric

changes could cause the device not to meet its published specifications.

MAXIMUM

INTEGRAL PACKAGE SPECIFICATION

LINEARITY DRAWING TEMPERATURE ORDERING TRANSPORT

PRODUCT ERROR (LSB) PACKAGE NUMBER

(1)

RANGE NUMBER

(2)

MEDIA

ADS7845E ±2 16-Lead SSOP 322 –40°C to +85°C ADS7845E Rails

"" """ADS7845E/2K5 Tape and Reel

NOTES: (1) For detailed drawing and dimension table, please see end of data sheet, or Appendix C of Burr-Brown IC Data Book. (2) Models with a slash (/) are

available only in Tape and Reel in the quantities indicated (e.g., /2K5 indicates 2500 devices per reel). Ordering 2500 pieces of “ADS7845E/2K5” will get a single

2500-piece Tape and Reel. For detailed Tape and Reel mechanical information, refer to Appendix B of Burr-Brown IC Data Book.

PACKAGE/ORDERING INFORMATION

1

2

3

4

5

6

7

8

+V

CC

UL

UR

LL

LR

GND

WIPER

AUXIN

DCLK

CS

DIN

BUSY

DOUT

PENIRQ

+V

CC

V

REF

16

15

14

13

12

11

10

9

ADS7845

Page 4

®

4

ADS7845

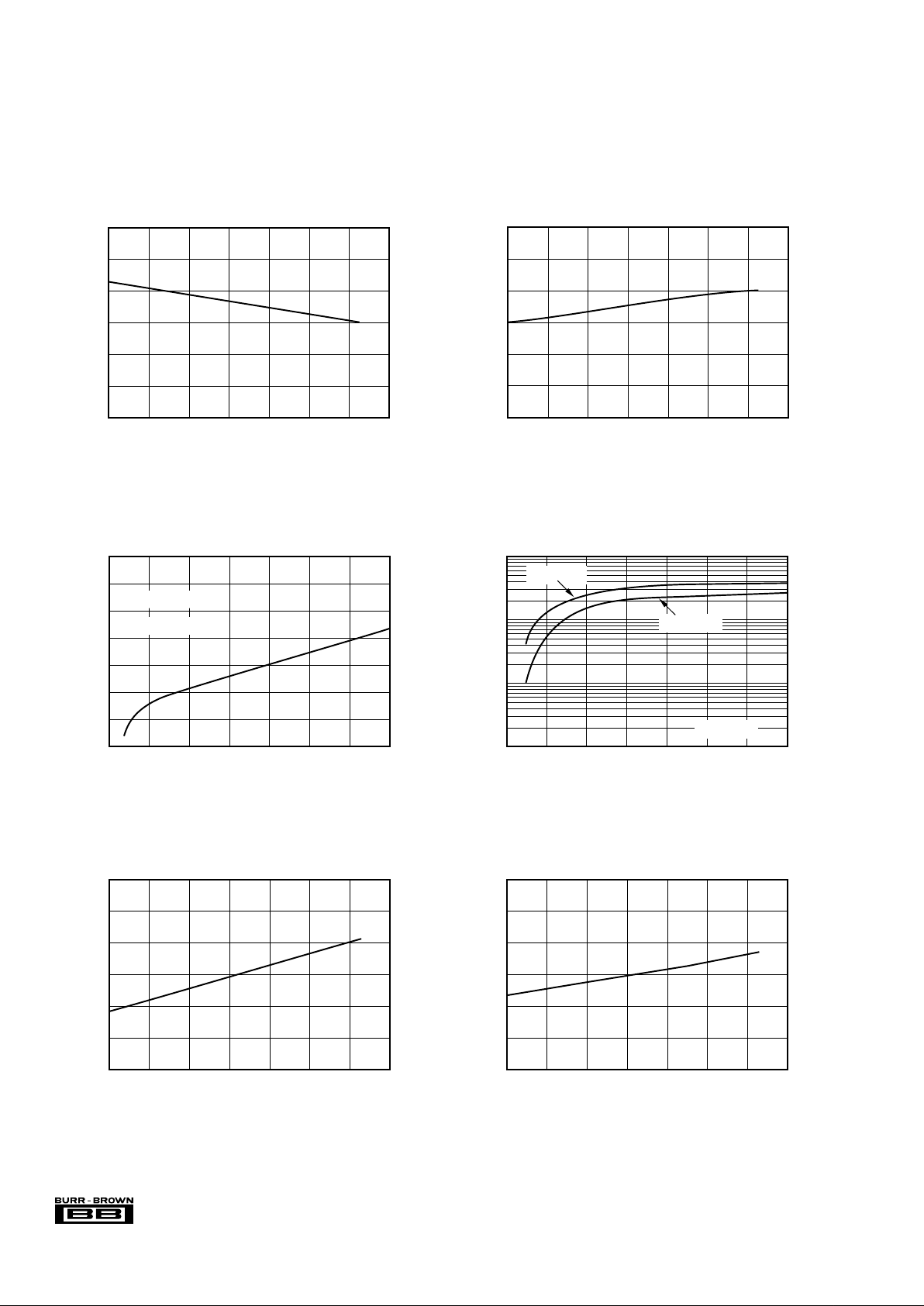

TYPICAL PERFORMANCE CURVES

At TA = +25°C, +VCC = +2.7V, V

REF

= +2.5V, f

SAMPLE

= 125kHz, and f

CLK

= 16 • f

SAMPLE

= 2MHz, unless otherwise noted.

SUPPLY CURRENT vs +V

CC

3.51.5 2 52.5 4

+V

CC

(V)

Supply Current (µA)

400

350

300

250

200

150

100

50

4.53

f

CLOCK

= 200kHz

V

REF

= +VCC

SUPPLY CURRENT vs TEMPERATURE

20–40 100–20 0 40

Temperature (°C)

Supply Current (µA)

400

350

300

250

200

150

100

60 80

POWER-DOWN SUPPLY CURRENT

vs TEMPERATURE

20–40 100–20 0 40

Temperature (°C)

Supply Current (nA)

140

120

100

80

60

40

20

60 80

MAXIMUM SAMPLE RATE vs +V

CC

3.51.5 2 52.5 4

+V

CC

(V)

Sample Rate (Hz)

1M

100k

10k

1k

4.53

V

REF

= +VCC

12-Bit Mode

8-Bit Mode

CHANGE IN GAIN vs TEMPERATURE

20–40 100–20 0 40

Temperature (°C)

Delta from +25°C (LSB)

0.15

0.10

0.05

0.00

–0.05

–0.10

–0.15

60 80

CHANGE IN OFFSET vs TEMPERATURE

20–40 100–20 0 40

Temperature (°C)

Delta from +25°C (LSB)

0.6

0.4

0.2

0.0

–0.2

–0.4

–0.6

60 80

Page 5

®

5

ADS7845

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°C, +VCC = +2.7V, V

REF

= +2.5V, f

SAMPLE

= 125kHz, and f

CLK

= 16 • f

SAMPLE

= 2MHz, unless otherwise noted.

REFERENCE CURRENT vs SAMPLE RATE

750 12525 50 100

Sample Rate (kHz)

Reference Current (µA)

14

12

10

8

6

4

2

0

REFERENCE CURRENT vs TEMPERATURE

20–40 100–20 0 40

Temperature (°C)

Reference Current (µA)

18

16

14

12

10

8

6

60 80

2

1.8

1.6

1.4

1.2

1

0.8

0.6

0.4

0.2

0

LSB Error

20 40 60 80 100 120 140 160 180 200

Sampling Rate (kHz)

MAXIMUM SAMPLING RATE vs R

IN

INL: R = 2kΩ

INL: R = 500Ω

DNL: R = 2kΩ

DNL: R = 500Ω

SWITCH ON RESISTANCE vs TEMPERATURE

(X+, Y+: +V

CC

to Pin; X–, Y–: Pin to GND)

20–40 100–20

UL

LL

40

Temperature (°C)

R

ON

(Ω)

16

14

12

10

8

6

4

2

60 800

UR

LR

SWITCH ON RESISTANCE vs +V

CC

(X+, Y+: +VCC to Pin; X–, Y–: Pin to GND)

3.5252.5

UL

LL LR

4

+V

CC

(V)

R

ON

(Ω)

16

14

12

10

8

6

4

2

4.53

UR

Page 6

®

6

ADS7845

THEORY OF OPERATION

The ADS7845 is a classic Successive Approximation Register (SAR) analog-to-digital (A/D) converter. The architecture is based on capacitive redistribution which inherently

includes a sample/hold function. The converter is fabricated

on a 0.6µs CMOS process.

The basic operation of the ADS7845 is shown in Figure 1.

The device requires an external reference and an external

clock. It operates from a single supply of 2.0V to 5.25V. The

external reference can be any voltage between 1V and +VCC.

The value of the reference voltage directly sets the input

range of the converter. The average reference input current

depends on the conversion rate of the ADS7845.

The analog input to the converter is provided via the WIPER

input. In the measurement mode, the lower right corner of the

panel is connected to GND and the upper left corner is

connected to VCC. When the lower left corner is connected to

GND and the upper right corner is connected to VCC, a “Y”

measurement is made. When the lower left corner is connected to VCC and the upper right corner is connected

to GND, a “X” measurement is made. By maintaining a

differential input to the converter and a differential reference

architecture, it is possible to negate the switch’s on-resistance

error (should this be a source of error for the particular

measurement).

ANALOG INPUT

Figure 2 shows a block diagram of the input multiplexer on

the ADS7845, the differential input of the A/D converter, and

the converter’s differential reference. Table I and Table II

show the relationship between the A2, A1, A0, and SER/DFR

control bits and the configuration of the ADS7845. The

control bits are provided serially via the DIN pin—see the

Digital Interface section of this data sheet for more details.

When the converter enters the hold mode, the voltage difference between the +IN and –IN inputs (see Figure 2) is

captured on the internal capacitor array. The input current on

the analog inputs depends on the conversion rate of the

device. During the sample period, the source must charge the

internal sampling capacitor (typically 25pF). After the capacitor has been fully charged, there is no further input

current. The rate of charge transfer from the analog source to

the converter is a function of conversion rate.

A2 A1 A0 DRV1 DRV2 AUXIN

INTERRUPT

–IN

(1)

X POSITION Y POSITION +REF

(1)

–REF

(1)

0 0 1 ON GND OFF ON +V

REF

GND

1 0 1 ON GND ON OFF +V

REF

GND

0 1 0 ON GND OFF OFF +V

REF

GND

1 1 0 DOUT GND OFF OFF +V

REF

GND

TABLE I. Input Configuration—Single-Ended Reference Mode (SER/DFR HIGH).

NOTE: (1) Internal node, for clarification only—not directly accessible by the user.

A2 A1 A0 DRV1 DRV2 AUXIN

INTERRUPT

–IN

(1)

X SWITCHES Y SWITCHES +REF

(1)

–REF

(1)

0 0 1 ON LR OFF ON UL LR

1 0 1 ON LR ON OFF UL LR

0 1 0 ON GND OFF OFF +V

REF

GND

1 1 0 DOUT GND OFF OFF +V

REF

GND

NOTE: (1) Internal node, for clarification only—not directly accessible by the user.

TABLE II. Input Configuration—Differential Reference Mode (SER/DFR LOW).

FIGURE 1. Basic Operation of the ADS7845.

+V

CC

UL

UR

LL

LR

GND

WIPER

AUXIN

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

DCLK

CS

DIN

BUSY

DOUT

PENIRQ

+V

CC

V

REF

Serial/Conversion Clock

Chip Select

Serial Data In

Converter Status

Serial Data Out

+

1µF

to

10µF

(Optional)

+2.7V to +5V

ADS7845

Auxiliary Input

WIPER

0.1µF

Pen Interrupt

External reference required

with auxiliary input. Otherwise,

NC in differential mode or

V

CC

or external V

REF

in

single-ended mode.

100kΩ (optional)

0.1µF

Page 7

®

7

ADS7845

FIGURE 2. Simplified Diagram of ADS7845 Input and Panel Drivers.

REFERENCE INPUT

The voltage difference between +REF and –REF (see Figure

2) sets the analog input range. The ADS7845 will operate

with a reference in the range of 1V to +VCC. There are several

critical items concerning the reference input and its wide

voltage range. As the reference voltage is reduced, the analog

voltage weight of each digital output code is also reduced.

This is often referred to as the Least Significant Bit (LSB)

size and is equal to the reference voltage divided by 4096.

Any offset or gain error inherent in the A/D converter will

appear to increase, in terms of LSB size, as the reference

voltage is reduced. For example, if the offset of a given

converter is 2 LSBs with a 2.5V reference, it will typically be

5 LSBs with a 1V reference. In each case, the actual offset of

the device is the same, 1.22mV. With a lower reference

voltage, more care must be taken to provide a clean layout

including adequate bypassing, a clean (low noise, low ripple)

power supply, a low-noise reference, and a low-noise input

signal.

The voltage into the V

REF

input is not buffered and directly

drives the capacitor digital-to-analog converter (CDAC) portion of the ADS7845. Typically, the input current is 13µA

with V

REF

= 2.5V and f

SAMPLE

= 125kHz. This value will vary

by a few microamps depending on the result of the conversion. The reference current diminishes directly with both

conversion rate and reference voltage. As the current from the

reference is drawn on each bit decision, clocking the converter more quickly during a given conversion period will not

reduce overall current drain from the reference.

There is also a critical item regarding the reference when

making measurements where the switch drivers are on. For

this discussion, it’s useful to consider the basic operation of

the ADS7845 as shown in Figure 1. This particular application shows the device being used to digitize a resistive

touch screen. A measurement of the current Y position of

the pointing device is made with the WIPER input to the

A/D converter, turning on the UL and UR drivers to VCC,

grounding LL and LR, and digitizing the voltage on the

WIPER (see Figure 3 for a block diagram).

FIGURE 3. Simplified Diagram of Single-Ended Reference

(SER/DFR HIGH).

A/D CONVERTER

–REF

+REF Drivers

+IN

–IN

LL

LR

GND

SER/DFR

(Shown LOW)

UR

UL

+V

CC

PENIRQ V

REF

WIPER

AUXIN

A/D Converter

+V

CC

GND

V

REF HI

WIPER

UR

LR

UL

LL

V

REF LO

GND

GND

GND+V

CC

IN

LOW

Page 8

®

8

ADS7845

Under the situation outlined so far, it would not be possible

to achieve a zero volt input or a full-scale input regardless of

where the pointing device is on the touch screen because

some voltage is lost across the internal switches. In addition,

the internal switch resistance is unlikely to track the resistance of the touch screen, providing an additional source of

error.

This situation can be remedied as shown in Figure 4. By

setting the SER/DFR bit LOW, the +REF and –REF inputs

are connected directly to Y+ and Y–. This makes the analogto-digital conversion ratiometric. The result of the conversion is always a percentage of the external resistance, regardless of how it changes in relation to the on-resistance of

the internal switches. NOTE: There is an important consideration regarding power dissipation when using the

ratiometric mode of operation. See the Power Dissipation

section for more details.

processor and the converter consists of 8 clock cycles. One

complete conversion can be accomplished with three serial

communications, for a total of 24 clock cycles on the DCLK

input.

The first 8 clock cycles are used to provide the control byte

via the DIN pin. When the converter has enough information

about the following conversion to set the input multiplexer,

switches, and reference inputs appropriately, the converter

enters the acquisition (sample) mode and, if needed, the

internal switches are turned on. After three more clock

cycles, the control byte is complete and the converter enters

the conversion mode. At this point, the input sample/hold

goes into the hold mode and the internal switches may

turn off. The next 12 clock cycles accomplish the actual

analog-to-digital conversion. If the conversion is ratiometric

(SER/DFR LOW), the internal switches are on during the

conversion. A 13th clock cycle is needed for the last bit of

the conversion result. Three more clock cycles are needed to

complete the last byte (DOUT will be LOW). These will be

ignored by the converter.

Control Byte

Also shown in Figure 5 is the placement and order of the

control bits within the control byte. Tables III and IV give

detailed information about these bits. The first bit, the ‘S’ bit,

must always be HIGH and indicates the start of the control

byte. The ADS7845 will ignore inputs on the DIN pin until

the start bit is detected. The next three bits (A2 - A0) select

the active panel drivers (see Tables I and II and Figure 2).

The MODE bit determines the number of bits for each

conversion, either 12 bits (LOW) or 8 bits (HIGH).

The SER/DFR bit controls the reference mode: either singleended (HIGH) or differential (LOW). (The differential mode

is also referred to as the ratiometric conversion mode.) In

FIGURE 4. Simplified Diagram of Differential Reference

(SER/DFR LOW).

As a final note about the differential reference mode, it must

be used with +VCC as the source of the +REF voltage and

cannot be used with V

REF

. It is possible to use a high

precision reference on V

REF

and single-ended reference

mode for measurements which do not need to be ratiometric.

Or, in some cases, it could be possible to power the converter directly from a precision reference. Most references

can provide enough power for the ADS7845, but they might

not be able to supply enough current for the external load

(such as a resistive touch screen).

DIGITAL INTERFACE

Figure 5 shows the typical operation of the ADS7845’s digital

interface. This diagram assumes that the source of the digital

signals is a microcontroller or digital signal processor with

a basic serial interface. Each communication between the

BIT NAME DESCRIPTION

7 S Start Bit. Control byte starts with first HIGH bit on

DIN. A new control byte can start every 15th clock

cycle in 12-bit conversion mode or every 11th clock

cycle in 8-bit conversion mode.

6 - 4 A2 - A0 Channel Select Bits. Along with the SER/DFR bit,

these bits control the setting of the multiplexer input,

switches, and reference inputs, as detailed in Tables

I and II.

3 MODE 12-Bit/8-Bit Conversion Select Bit. This bit controls

the number of bits for the following conversion: 12

bits (LOW) or 8 bits (HIGH).

2 SER/DFR Single-Ended/Differential Reference Select Bit. Along

with bits A2 - A0, this bit controls the setting of the

multiplexer input, switches, and reference inputs, as

detailed in Tables I and II.

1 - 0 PD1 - PD0 Power-Down Mode Select Bits. See Table V for

details.

TABLE IV.Descriptions of the Control Bits within the

Control Byte.

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

(MSB) (LSB)

S A2 A1 A0 MODE

SER/DFR

PD1 PD0

TABLE III. Order of the Control Bits in the Control Byte.

A/D Converter

+V

CC

GND

V

REF HI

WIPER

UR

LR

UL

LL

V

REF LO

IN

LO

GND

+V

CC

GND

GND+V

CC

Page 9

®

9

ADS7845

single-ended mode, the converter’s reference voltage is

always the difference between the V

REF

and GND pins. In

differential mode, the reference voltage is the difference

between the currently enabled switches. See Tables I and II

and Figures 2 through 4 for more information. The last two

bits (PD1 - PD0) select the power- down mode as shown in

Table V. If both inputs are HIGH, the device is always

powered up. If both inputs are LOW, the device enters a

power-down mode between conversions. When a new conversion is initiated, the device will resume normal operation

instantly—no delay is needed to allow the device to power

up and the very first conversion will be valid. There are two

power-down modes: one where PENIRQ is disabled and

one where it is enabled.

PD1 PD0 PENIRQ DESCRIPTION

0 0 Enabled Power-down between conversions. When each

conversion is finished, the converter enters a

LOW power mode. At the start of the next conversion, the device instantly powers up to full

power. There is no need for additional delays to

assure full operation and the very first conversion

is valid. The LR– switch is on while in power-down.

0 1 Disabled Same as mode 00, except PENIRQ is disabled.

The LR– switch is off while in power-down mode.

1 0 Disabled Reserved for future use.

1 1 Disabled No power down between conversions, device is

always powered.

FIGURE 5. Conversion Timing, 24 Clocks per Conversion, 8-Bit Bus Interface. No DCLK Delay Required with Dedicated

Serial Port.

TABLE V. Power-Down Selection.

FIGURE 6. Conversion Timing, 16 Clocks per Conversion, 8-Bit Bus Interface. No DCLK Delay Required with Dedicated

Serial Port.

1

DCLK

CS

81

11

DOUT

BUSY

S

DIN

CONTROL BITS

S

CONTROL BITS

1098765 43210

11 10 9

81 18

t

ACQ

AcquireIdle Conversion Idle

1

DCLK

CS

81

11

DOUT

BUSY

DRIVERS 1 AND 2

(1)

(SER/DFR HIGH)

DRIVERS 1 AND 2

(1, 2)

(SER/DFR LOW)

(MSB)

(START)

(LSB)

A2S

ON

ON

OFF OFF

OFF OFF

DIN

A1 A0

MODE

SER/

DFR

PD1 PD0

1098765 4 3210 Zero Filled...

81 8

NOTES: (1) For Y Position, Driver 1 is ON and Driver 2 is OFF. For X Position, Driver 1 is OFF and Driver 2 is ON. LR

will turn on when power-down mode is entered and PD1, PD0 = 00B. (2) Drivers will remain on if power-down mode is

11

B

(no power down) until selected input channel, reference mode, or power-down mode is changed, or CS is HIGH.

Page 10

®

10

ADS7845

16 Clocks per Conversion

The control bits for conversion n+1 can be overlapped with

conversion ‘n’ to allow for a conversion every 16 clock

cycles, as shown in Figure 6. This figure also shows possible

serial communication occurring with other serial peripherals

between each byte transfer between the processor and the

converter. This is possible provided that each conversion

completes within 1.6ms of starting. Otherwise, the signal

that has been captured on the input sample/hold may droop

enough to affect the conversion result. Note that the ADS7845

is fully powered while other serial communications are

taking place during a conversion.

Digital Timing

Figure 7 and Table VI provide detailed timing for the digital

interface of the ADS7845.

15 Clocks per Conversion

Figure 8 provides the fastest way to clock the ADS7845.

This method will not work with the serial interface of most

microcontrollers and digital signal processors as they are

generally not capable of providing 15 clock cycles per serial

transfer. However, this method could be used with Field

Programmable Gate Arrays (FPGAs) or Application Specific Integrated Circuits (ASICs). This effectively increases

the maximum conversion rate of the converter beyond the

values given in the Specification table, which assume 16

clock cycles per conversion.

SYMBOL DESCRIPTION MIN TYP MAX UNITS

t

ACQ

Acquisition Time 1.5 µs

t

DS

DIN Valid Prior to DCLK Rising 100 ns

t

DH

DIN Hold After DCLK HIGH 10 ns

t

DO

DCLK Falling to DOUT Valid 200 ns

t

DV

CS Falling to DOUT Enabled 200 ns

t

TR

CS Rising to DOUT Disabled 200 ns

t

CSS

CS Falling to First DCLK Rising 100 ns

t

CSH

CS Rising to DCLK Ignored 0 ns

t

CH

DCLK HIGH 200 ns

t

CL

DCLK LOW 200 ns

t

BD

DCLK Falling to BUSY Rising 200 ns

t

BDV

CS Falling to BUSY Enabled 200 ns

t

BTR

CS Rising to BUSY Disabled 200 ns

TABLE VI. Timing Specifications (+VCC = +2.7V and

Above, TA = –40°C to +85°C, C

LOAD

= 50pF).

FIGURE 7. Detailed Timing Diagram.

FIGURE 8. Maximum Conversion Rate, 15 Clocks per Conversion.

PD0

t

BDV

t

DH

t

CH

t

CL

t

DS

t

CSS

t

DV

t

BD

t

BD

t

TR

t

BTR

t

D0

t

CSH

DCLK

CS

11

DOUT

BUSY

DIN

10

1

DCLK

CS

11

DOUT

BUSY

A2S

DIN

A1 A0

MODE

SGL/

DIF

PD1 PD0

109876543210 111098765432

A1 A0

15 1 15 1

A2SA1A0

MODE

SGL/

DIF

PD1 PD0

A2S

Page 11

®

11

ADS7845

Data Format

The ADS7845 output data is in Straight Binary format as

shown in Figure 9. This figure shows the ideal output code

for the given input voltage and does not include the effects

of offset, gain, or noise.

FIGURE 9. Ideal Input Voltages and Output Codes.

8-Bit Conversion

The ADS7845 provides an 8-bit conversion mode that can

be used when faster throughput is needed and the digital

result is not as critical. By switching to the 8-bit mode, a

conversion is complete four clock cycles earlier. This could

be used in conjunction with serial interfaces that provide 12bit transfers or two conversions could be accomplished with

three 8-bit transfers. Not only does this shorten each conversion by four bits (25% faster throughput), but each conversion can actually occur at a faster clock rate. This is because

the internal settling time of the ADS7845 is not as critical—

settling to better than 8 bits is all that is needed. The clock

rate can be as much as 50% faster. The faster clock rate and

fewer clock cycles combine to provide a 2x increase in

conversion rate.

POWER DISSIPATION

There are two major power modes for the ADS7845: full power

(PD1 - PD0 = 11B) and auto power-down (PD1 - PD0 = 00B).

When operating at full speed and 16-clocks per conversion (as

shown in Figure 6), the ADS7845 spends most of its time

acquiring or converting. There is little time for auto powerdown, assuming that this mode is active. Therefore, the difference between full power mode and auto power-down is negligible. If the conversion rate is decreased by simply slowing the

frequency of the DCLK input, the two modes remain approximately equal. However, if the DCLK frequency is kept at the

maximum rate during a conversion but conversions are simply

done less often, the difference between the two modes is

dramatic.

Figure 10 shows the difference between reducing the DCLK

frequency (“scaling” DCLK to match the conversion rate) or

maintaining DCLK at the highest frequency and reducing

the number of conversions per second. In the later case, the

converter spends an increasing percentage of its time in

power-down mode (assuming the auto power-down mode is

active).

Another important consideration for power dissipation is the

reference mode of the converter. In the single-ended reference mode, the converter’s internal switches are on only

when the analog input voltage is being acquired (see Figure

5). Thus, the external device, such as a resistive touch

screen, is only powered during the acquisition period. In the

differential reference mode, the external device must be

powered throughout the acquisition and conversion periods

(see Figure 5). If the conversion rate is high, this could

substantially increase power dissipation.

LAYOUT

The following layout suggestions should provide the most

optimum performance from the ADS7845. However, many

portable applications have conflicting requirements concerning power, cost, size, and weight. In general, most

portable devices have fairly “clean” power and grounds

because most of the internal components are very low

power. This situation would mean less bypassing for the

converter’s power and less concern regarding grounding.

Still, each situation is unique and the following suggestions

should be reviewed carefully.

For optimum performance, care should be taken with the

physical layout of the ADS7845 circuitry. The basic SAR

architecture is sensitive to glitches or sudden changes on the

power supply, reference, ground connections, and digital

inputs that occur just prior to latching the output of the

analog comparator. Thus, during any single conversion for

an ‘n-bit’ SAR converter, there are n ‘windows’ in which

Output Code

0V

FS = Full-Scale Voltage = V

REF

(1)

1 LSB = V

REF

(1)

/4096

FS – 1 LSB

11...111

11...110

11...101

00...010

00...001

00...000

1 LSB

NOTES: (1) Reference voltage at converter: +REF–(–REF). See Figure 2.

(2) Input voltage at converter, after multiplexer: +IN–(–IN). See Figure 2

Input Voltage

(2)

(V)

FIGURE 10. Supply Current vs Directly Scaling the Fre-

quency of DCLK with Sample Rate or Keeping

DCLK at the Maximum Possible Frequency.

10k 100k1k 1M

f

SAMPLE

(Hz)

Supply Current (µA)

100

10

1

1000

f

CLK

= 2MHz

f

CLK

= 16 • f

SAMPLE

TA = 25°C

+V

CC

= +2.7V

Page 12

®

12

ADS7845

large external transient voltages can easily affect the conversion result. Such glitches might originate from switching

power supplies, nearby digital logic, and high power devices. The degree of error in the digital output depends on

the reference voltage, layout, and the exact timing of the

external event. The error can change if the external event

changes in time with respect to the DCLK input.

With this in mind, power to the ADS7845 should be clean

and well bypassed. A 0.1µF ceramic bypass capacitor should

be placed as close to the device as possible. A 1µF to 10µF

capacitor may also be needed if the impedance of the

connection between +VCC and the power supply is high.

The reference should be similarly bypassed with a 0.1µF

capacitor. If the reference voltage originates from an op

amp, make sure that it can drive the bypass capacitor without

oscillation. The ADS7845 draws very little current from the

reference on average, but it does place larger demands on the

reference circuitry over short periods of time (on each rising

edge of DCLK during a conversion).

The ADS7845 architecture offers no inherent rejection of

noise or voltage variation in regards to the reference input.

This is of particular concern when the reference input is tied

to the power supply. Any noise and ripple from the supply

will appear directly in the digital results. While high frequency noise can be filtered out, voltage variation due to line

frequency (50Hz or 60Hz) can be difficult to remove.

The GND pin should be connected to a clean ground point.

In many cases, this will be the “analog” ground. Avoid

connections which are too near the grounding point of a

microcontroller or digital signal processor. If needed, run a

ground trace directly from the converter to the power supply

entry or battery connection point. The ideal layout will

include an analog ground plane dedicated to the converter

and associated analog circuitry.

In the specific case of use with a resistive touch screen, care

should be taken with the connection between the converter

and the touch screen. Since resistive touch screens have

fairly low resistance, the interconnection should be as short

and robust as possible. Longer connections will be a source

of error, much like the on-resistance of the internal switches.

Likewise, loose connections can be a source of error when

the contact resistance changes with flexing or vibrations.

PENIRQ Output

The pen interrupt output function is detailed in Figure 11. By

connecting a pull-up resistor to VCC (typically 100kΩ), the

PENIRQ output is HIGH. While in the power-down mode,

with PD0 = PD1 = 0, the lower-right panel corner is

connected to GND and the PENIRQ output is connected to

the WIPER input. When the panel is touched, the PENIRQ

output goes LOW, due to the current path through the panel

to GND, initiating an interrupt to the processor. During the

measurement cycles for X and Y position, the PENIRQ

output diode will be internally connected to GND and the

WIPER disconnected from the PENIRQ diode to eliminate

any leakage current from the pull-up resistor to flow through

the WIPER, thus causing no errors.

In addition, when the DIN has selected A2 = 1, A1 = 1,

A0 = 0, and the ADS7845 is commanded into the powerdown mode (PD0 and PD1 = 0) and CS is LOW (when CS

is HI, the DOUT line is high impedance), the DOUT will be

LOW (all “0”s) during no touch and HI (all “1”s) when the

panel is touched. This feature eliminates the need for an

additional port to detect panel touch. Since all panels have

end resistance, all “0”s and all “1”s are an unused set of

codes.

FIGURE 11. PENIRQ Functional Block Diagram.

+V

CC

100kΩ

UR

OFFOFF

OFF

LR

ON

WIPER

UR, LL

Driver

PENIRQ

UL

LL

Loading...

Loading...