Page 1

with Integrated Fractional

-

N PLL and VC

O

ADRF6755

V

Preliminary Technical Data

FEATURES

I/Q modulator with integrated fractional-N PLL and VCO

Gain control span: 47 dB in 1 dB steps

Output frequency range: 300 MHz to 2310 MHz

Output 1 dB compression: 8 dBm

Output IP3: 21 dBm

Noise floor: −162 dBm/Hz

Baseband modulation bandwidth: 600 MHz (3 dB)

Output frequency resolution: 1 Hz

SPI and I2C-compatible serial interfaces

Power supply: 5 V/350 mA

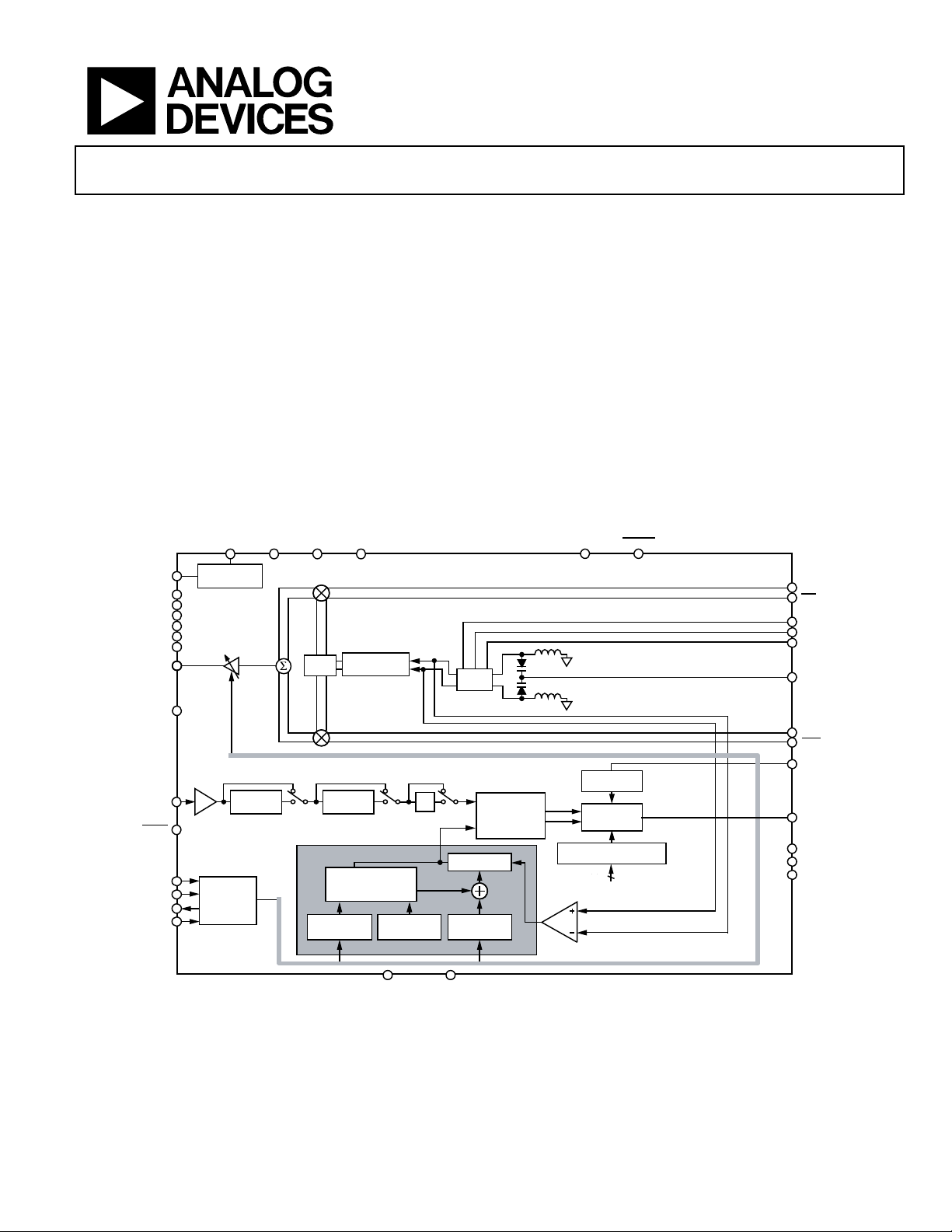

FUNCTIONAL BLOCKDIAGRAM

CC1VCC2VCC3VCC4

300 MHz to 2310 MHz I/Q Modulator

GENERAL DESCRIPTION

The ADRF6755 is a highly integrated quadrature modulator,

frequency synthesizer, and programmable attenuator. The

device covers an operating frequency range from 300 MHz

to 2310 MHz for use in satellite, cellular and broadband

communications.

The ADRF6755 modulator includes a high modulus fractional-N

frequency synthesizer with integrated VCO, providing better

than 1 Hz frequency resolution, and a 47 dB digitally controlled

output attenuator with 1 dB steps.

Control of all the on-chip registers is through a user-selected

SPI interface or I2C interface. The device operates from a single

power supply ranging from 4.75 V to 5.25 V.

LOMON

LOMON

REGOUT

VREG1

VREG2

VREG3

VREG4

VREG5

VREG6

RFOUT

TXDIS

REFIN

REFIN

SDI/SDA

CLK/SCL

SDO

CS

3.3V

REGULATOR

47dB

GAIN CONTROL

RANGE

×2

DOUBLER

SPI/

I2C

INTERFACE

ADRF6755

RFDIVIDER

0°/90°

5-BIT

DIVIDER

THIRD-ORDER

FRACTIONAL

INTERPOLATOR

FRACTIONAL

REGISTER

÷2

MODULUS

25

2

AGND DGND

VCO

CORE

+

FREQUENCY

DETECTOR

–

N-COUNTER

INTEGER

REGISTER

Figure 1.

PHASE

REFERENCE

CHARGE

PUMP

CURRENT SETTING

CR9[7:4]

IBB

IBB

CCOMP1

CCOMP2

CCOMP3

VTUNE

QBB

QBB

RSET

CP

LF3

LF2

LDET

08201-001

Rev. PrD

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2012 Analog Devices, Inc. All rights reserved.

Page 2

ADRF6755

TABLE OF CONTENTS

Features .............................................................................................. 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Specifications ..................................................................................... 3

Timing Characteristics ................................................................ 5

Absolute Maximum Ratings ............................................................ 7

ESD Caution .................................................................................. 7

Pin Configuration and Function Descriptions ............................. 8

Typical Performance Characteristics ........................................... 10

Theory of Operation ...................................................................... 18

Overview...................................................................................... 18

Preliminary Technical Data

SPI Interface ................................................................................ 24

Program Modes .......................................................................... 26

Register Map ................................................................................... 28

Register Map Summary ............................................................. 28

Register Bit Descriptions ........................................................... 29

Suggested Power-Up Sequence ..................................................... 33

Initial Register Write Sequence ................................................ 33

Evaluation Board ............................................................................ 35

General Description ................................................................... 35

Hardware Description ............................................................... 35

PCB Artwork .............................................................................. 38

PLL Synthesizer and VCO ......................................................... 18

Quadrature Modulator .............................................................. 21

Attenuator .................................................................................... 22

Voltage Regulator ....................................................................... 22

I2C Interface ................................................................................ 22

Bill of Materials........................................................................... 41

Outline Dimensions ....................................................................... 42

Ordering Guide .......................................................................... 42

Rev. PrD | Page 2 of 43

Page 3

Preliminary Technical Data ADRF6755

SPECIFICATIONS

VCC = 5 V, TA = 25°C, I/Q inputs = 0.9 V p-p differential sine waves in quadrature on a 500 mV dc bias, REFIN = 80 MHz, PFD = 40 MHz,

baseband frequency = 1 MHz, LOMON off, unless otherwise noted.

Table 1.

Parameter Test Conditions/Comments Min Typ Max Unit

RF OUTPUT RFOUT pin

Operating Frequency Range 300 2310 MHz

Nominal Output Power VIQ = 0.9 V p-p differential −0.5 dBm

Gain Flatness Any 40 MHz ±0.1 dB

Output P1dB 8 dBm

Output IP3 f1BB = 3.5 MHz, f2BB = 4.5 MHz, P

Output Return Loss Attenuator setting = 0 dB −15 dB

LO Carrier Feedthrough Attenuator setting = 0 dB to 47 dB −45 dBc

2× LO Carrier Feedthrough Attenuator setting = 0 dB to 47 dB −45 dBm

Sideband Suppression −45 dBc

Noise Floor I/Q inputs = 0 V p-p differential, Attenuator setting = 0 dB −162 dBm/Hz

Attenuator setting = 0 dB to 21 dB, carrier offset = 15 MHz −147 dBc/Hz

Attenuator setting = 21 dB to 47 dB, carrier offset = 15 MHz −170 dBm/Hz

Harmonics −55 dBc

REFERENCE CHARACTERISTICS REFIN pin

Input Frequency With R divide-by-2 enabled 10 300 MHz

With R divide-by-2 disabled 10 165 MHz

Input Sensitivity AC-coupled 0.4 VREG V p-p

Input Capacitance 10 pF

Input Current ±100 µA

CHARGE PUMP

ICP Sink/Source Programmable, RSET = 4.7 kΩ

High Value 5 mA

Low Value 312.5 µA

Absolute Accuracy 4.0 %

VCO

Gain K

SYNTHESIZER SPECIFICATIONS

Frequency Resolution 1 Hz

Spurs Integer boundary < loop bandwidth −55 dBc

> 256 kHz offset from carrier −65 dBc

>10 MHz offset from carrier −75 dBc

Phase Noise1 LO = 2310 MHz

100 Hz offset −85 dBc/Hz

1 kHz offset −96 dBc/Hz

10 kHz offset −100 dBc/Hz

100 kHz offset −106 dBc/Hz

1 MHz offset −132 dBc/Hz

>15 MHz offset −152 dBc/Hz

Integrated Phase Noise1 1 kHz to 8 MHz integration bandwidth, LO=2310MHz 0.20

Frequency Settling1 Any step size, maximum frequency error = 100 Hz 0.17 ms

Maximum Frequency Step for

No Autocalibration

Phase Detector Frequency 10 40 MHz

25 MHz/V

VCO

Frequency step with no autocalibration routine;

Register CR24, Bit 0 = 1

= −6 dBm per tone 21 dBm

OUT

100/2

RFDIV

kHz

rms

Rev. PrD | Page 3 of 43

Page 4

ADRF6755

INH

INH

INL

Preliminary Technical Data

Parameter Test Conditions/Comments Min Typ Max Unit

GAIN CONTROL

Gain Range 47 dB

Step Size 1 dB

Relative Step Accuracy Fixed frequency, adjacent steps

All attenuation steps ±0.3 dB

Over full frequency range, adjacent steps ±1.5 dB

Absolute Step Accuracy2 47 dB attenuation step −2.0 dB

Output Settling Time Any step; output power settled to ±0.2 dB 15 µs

OUTPUT DISABLE TXDIS pin

Off Isolation RFOUT, Attenuator setting = 0 dB to 47 dB, TXDIS high −100 dBm

LO, Attenuator setting = 0 dB to 47 dB, TXDIS high −80 dBm

2 x LO, Attenuator setting = 0 dB to 47 dB, TXDIS high −50 dBm

Turn-On Settling Time TXDIS high to low: Output power to 90% of envelope 500 ns

Frequency settling to 100Hz 2 µs

Turn-Off Settling Time TXDIS low to high (to −55 dBm) 500 ns

MONITOR OUTPUT

LOMON,

LOMON

pins,

Nominal Output Power −24 dBm

BASEBAND INPUTS

IBB

, QBB,

QBB

pins

IBB,

I and Q Input Bias Level 500 mV

3 dB Bandwidth 600 MHz

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Input High Voltage, V

Input Low Voltage, V

Input Current, I

INH/IINL

CS, TXDIS pins 1.4 V

CS, TXDIS pins 0.6 V

INL

SDI/SDA, CLK/SCL pins 2.1 V

SDI/SDA, CLK/SCL pins 1.1 V

CS, TXDIS, SDI/SDA, CLK/SCL pins ±1 µA

Input Capacitance, CIN CS, TXDIS, SDI/SDA, CLK/SCL pins 10 pF

LOGIC OUTPUTS

Output High Voltage, VOH SDO, LDET pins; IOH = 500 µA 2.8 V

Output Low Voltage, VOL SDO, LDET pins; IOL = 500 µA 0.4 V

SDA (SDI/SDA); IOL = 3 mA 0.4 V

POWER SUPPLIES VCC1, VCC2, VCC3, VCC4, VREG1, VREG2, VREG3, VREG4,

VREG5, VREG6, and REGOUT pins

REGOUT normally connected to VREG1, VREG2, VREG3,

VREG4, VREG5, and VREG6

Voltage Range VCC1, VCC2, VCC3, and VCC4 4.75 5 5.25 V

REGOUT, VREG1, VREG2, VREG3, VREG4, VREG5, and

3.3 V

VREG6

Supply Current VCC1, VCC2, VCC3, and VCC4 combined; REGOUT con-

350 390 mA

nected to VREG1, VREG2, VREG3, VREG4, VREG5, and VREG6

Power Down Current CR29[0]=0, Power Down Modulator

7 mA

CR12[2]=1, Power Down PLL

CR28[4]=1, Power Down RFDIVIDER

CR27[2]=0, Power Down LOMON

Operating Temperature −40 85 °C

1

LBW = 100 kHz at LO = 2310 MHz; ICP = 5 mA.

2

All other attenuation steps have an absolute error of <±2.0 dB.

Rev. PrD | Page 4 of 43

Page 5

Preliminary Technical Data ADRF6755

SC

L

LOW

HD;STA

SU;DAT

SU;

STO

VD;DAT

BUF

08201-003

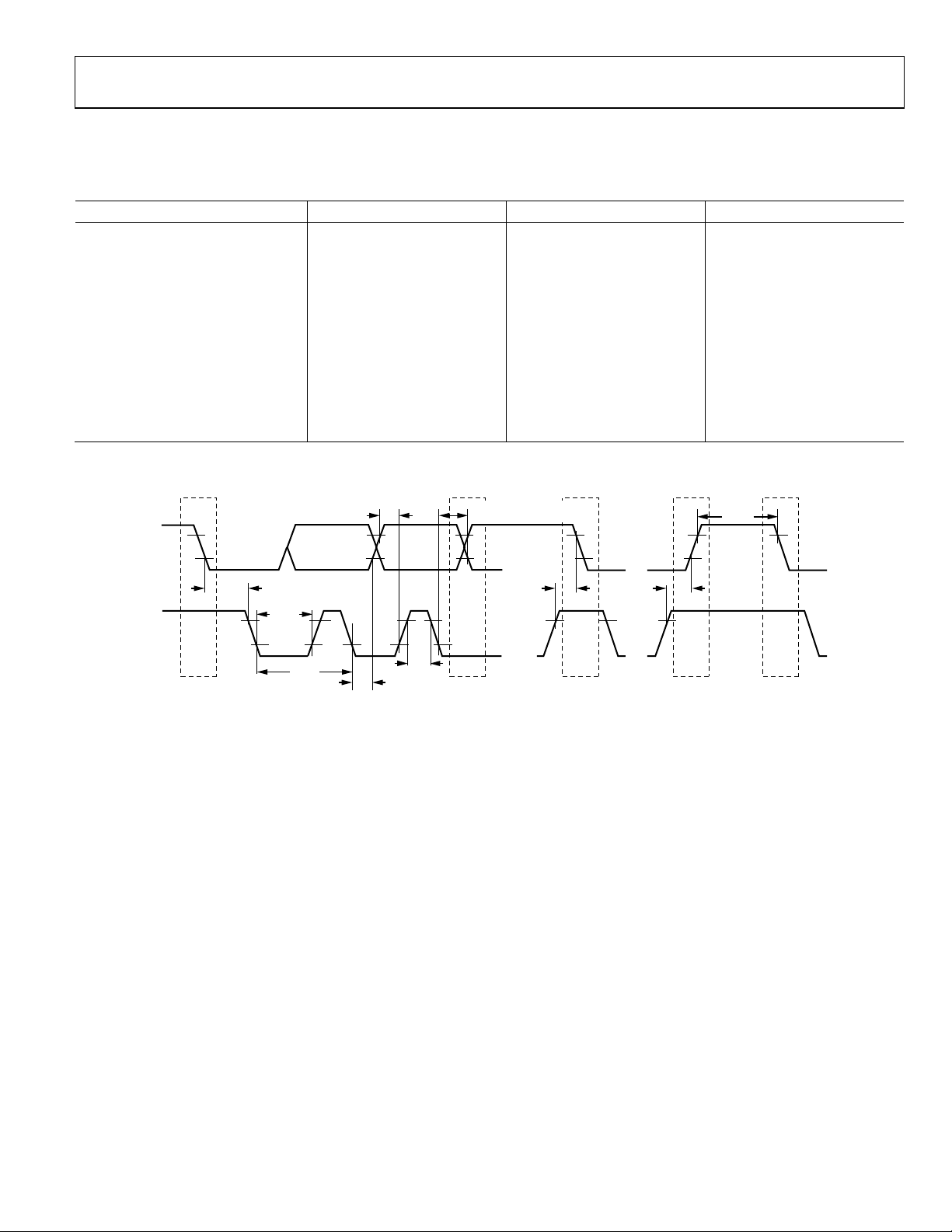

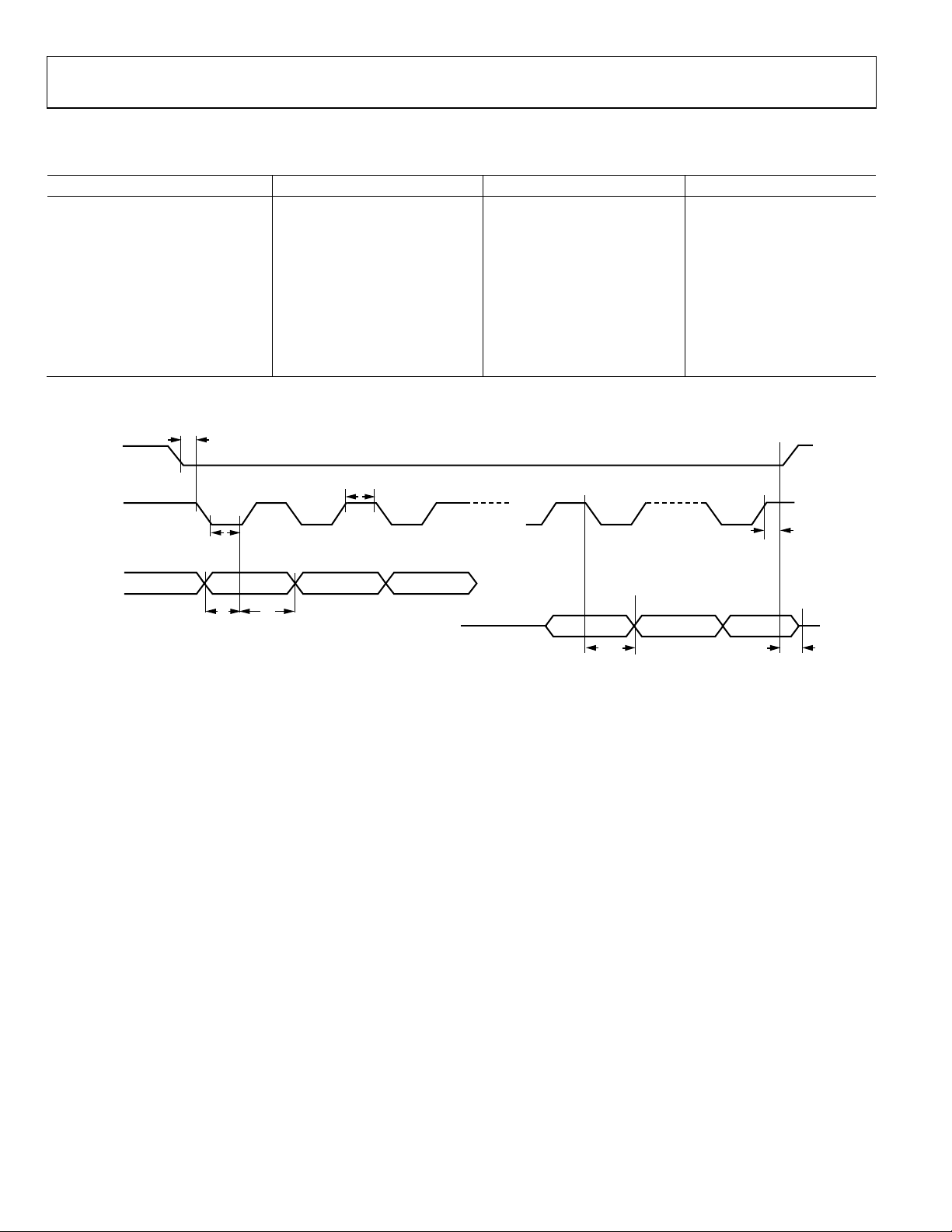

TIMING CHARACTERISTICS

I2C Interface Timing

Table 2.

Parameter1 Symbol Limit Unit

SCL Clock Frequency f

SCL Pulse Width High t

SCL Pulse Width Low t

Start Condition Hold Time t

Start Condition Setup Time t

Data Setup Time t

Data Hold Time t

Stop Condition Setup Time t

Data Valid Time t

Data Valid Acknowledge Time t

Bus Free Time t

1

See Figure 2.

400 kHz max

600 ns min

HIGH

1300 ns min

600 ns min

600 ns min

SU;STA

100 ns min

300 ns min

HD;DAT

600 ns min

900 ns max

900 ns max

VD;ACK

1300 ns min

t

t

SU;DAT

VD;DAT AND

t

VD;ACK (ACK SIGNAL ONLY)

t

BUF

SDA

SCL

t

HD;STA

t

LOW

S S SP

START

CONDITION

1/f

SCL

t

HD;DAT

t

HIGH

t

SU;STA

t

SU;STO

Figure 2. I2C Port Timing Diagram

STOP

CONDITION

Rev. PrD | Page 5 of 43

Page 6

ADRF6755

t

Preliminary Technical Data

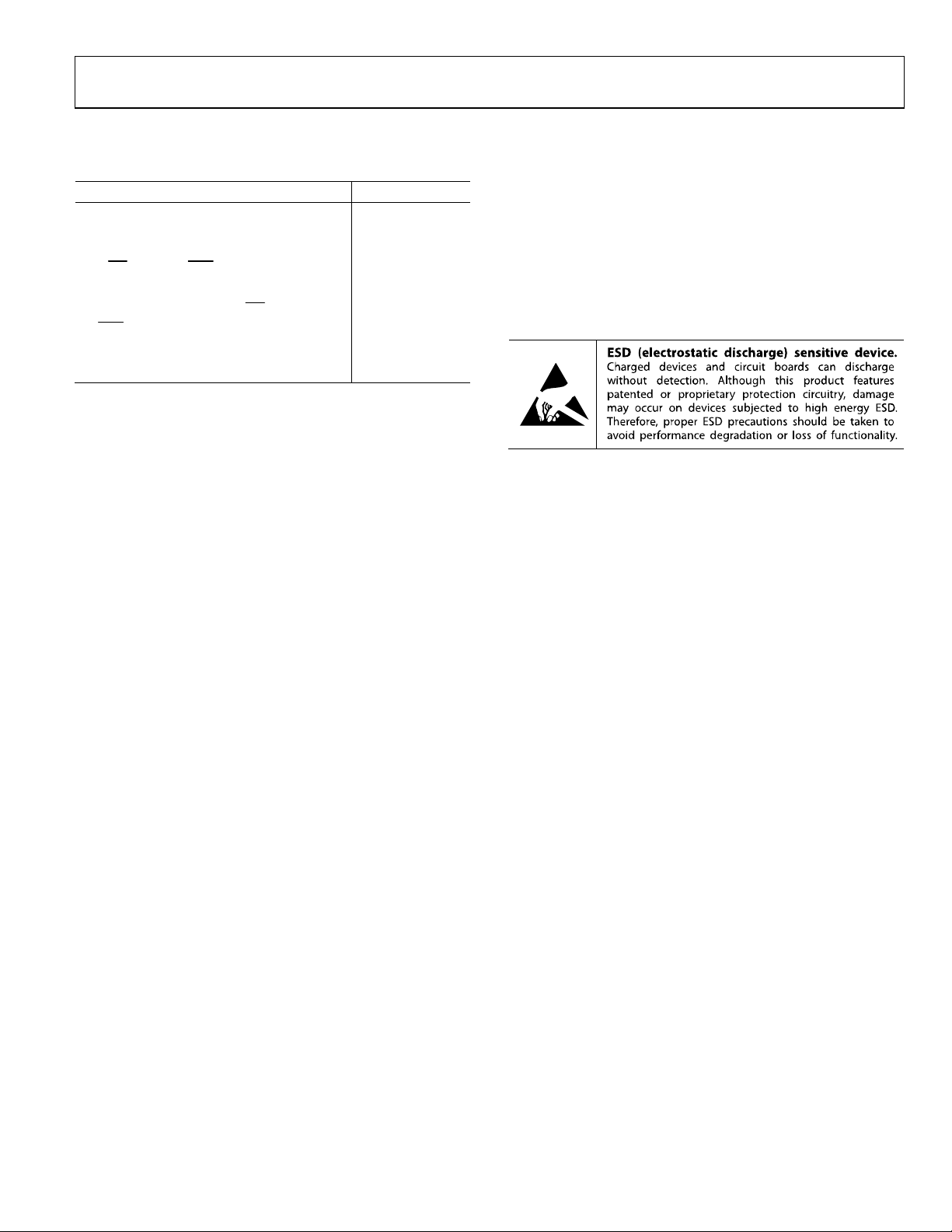

SPI Interface Timing

Table 3.

Parameter1 Symbol Limit Unit

CLK Frequency f

20 MHz max

CLK

CLK Pulse Width High t1 15 ns min

CLK Pulse Width Low t2 15 ns min

Start Condition Hold Time t3 5 ns min

Data Setup Time t4 10 ns min

Data Hold Time t5 5 ns min

Stop Condition Setup Time t6 5 ns min

SDO Access Time t7 15 ns min

CS to SDO High Impedance t8 25 ns max

1

See Figure 3.

3

CS

t

1

CLK

SDI

t

t

2

t

t

5

4

Figure 3. SPI Port Timing Diagram

SDO

t

7

6

t

8

08201-004

Rev. PrD | Page 6 of 43

Page 7

Preliminary Technical Data ADRF6755

ABSOLUTE MAXIMUM RATINGS

Table 4.

Parameter Rating

Supply Voltage VCC1, VCC2, VCC3, and VCC4 −0.3 V to +6 V

Supply Voltage VREG1, VREG2, VREG3, VREG4,

VREG5, and VREG6

IBB,

, QBB, and

IBB

Digital I/O −0.3 V to +4 V

Analog I/O (Other Than IBB,

)

QBB

Maximum Junction Temperature 125°C

Storage Temperature Range −65°C to +150°C

QBB

, QBB, and

IBB

−0.3 V to +4 V

0 V to 2.5 V

−0.3 V to +4 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

ESD CAUTION

Rev. PrD | Page 7 of 43

Page 8

Preliminary Technical Data ADRF6755

SET

T

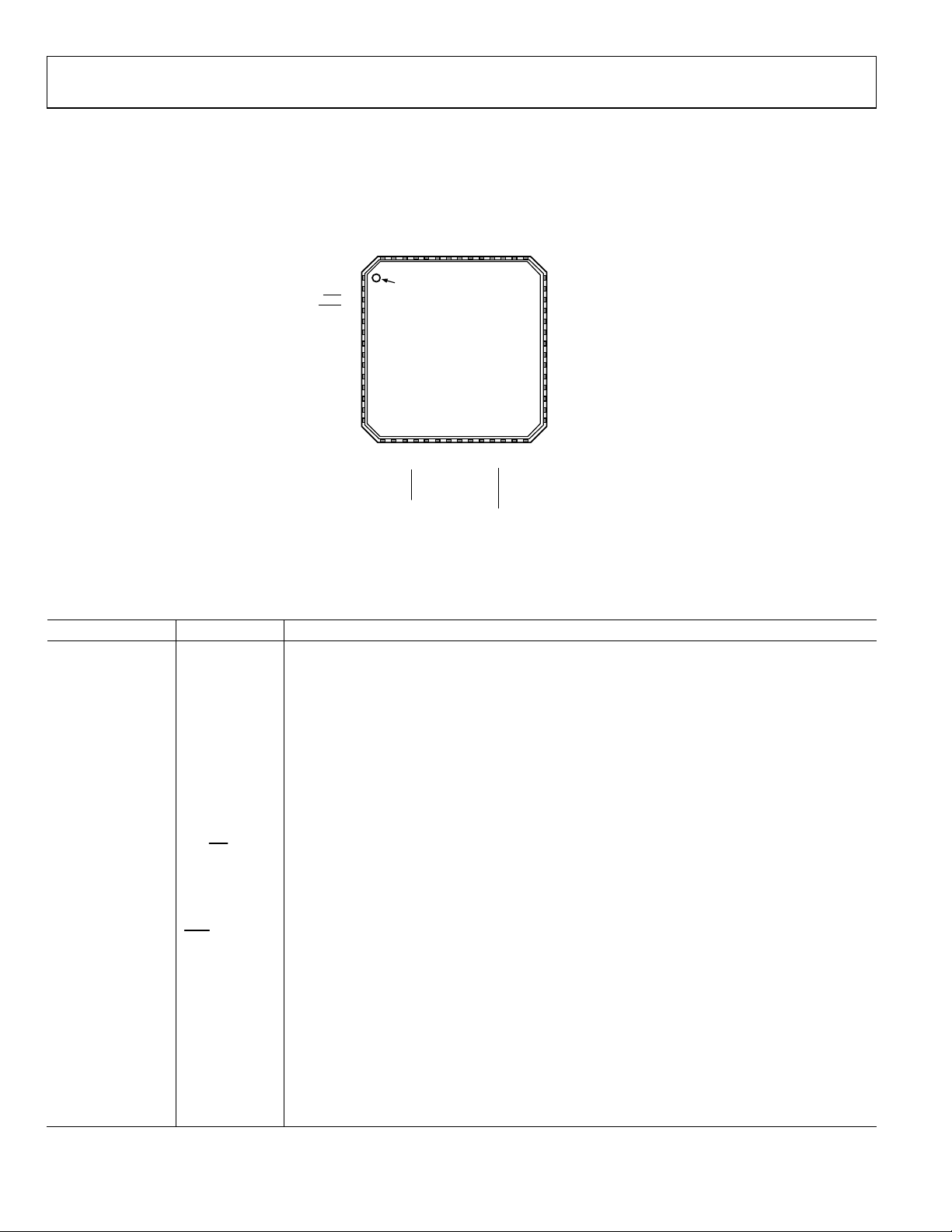

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

D

2

2

N

N

C

C

G

G

C

C

A

A

V

V

3

4

5

6

5

5

5

5

PIN 1

1VCC4

INDICATOR

2IBB

3IBB

4QBB

5QBB

6AGND

7RSET

8LF3

9CP

10LF2

11VCC1

12REGOUT

13VREG1

14VREG2

NOTES

1. CONNECT EXPOSED PAD TO GROUND PLANE VIA

A LOW IMPEDANCE PATH.

6

7

5

1

1

1

3

4

N

I

G

G

F

E

E

E

R

R

R

V

V

ADRF6755

TOP VIEW

(Not to Scale)

8

1

N

I

F

E

R

U

N

N

N

N

O

F

G

G

G

G

R

A

A

A

A

2

8

9

0

1

5

4

4

5

5

1

9

0

2

1

2

22232

D

D

D

D

D

N

N

N

N

N

G

G

G

G

G

A

A

A

A

A

T

D

D

D

D

D

U

S

D

D

O

I

T

X

N

N

E

D

U

G

G

X

D

T

A

A

L

M

4

3

5

6

7

4

4

4

4

4

42 VCC3

41 VCC3

40 AGND

39 AGND

38 VTUNE

37 AGND

36 VREG6

35 CCOMP3

34 CCOMP2

33 CCOMP1

32 DGND

31 VREG5

30 CLK/SCL

29 SDI/SDA

4

5

6

7

8

2

2

2

2

S

D

N

N

O

C

N

O

D

O

S

G

M

M

A

O

O

L

L

08298-005

Figure 4. Pin Configuration

Table 5. Pin Function Descriptions

Pin No. Mnemonic Description

11, 55, 56, 41, 42, 1 VCC1 to VCC4 Positive Power Supplies for I/Q Modulator. Apply a 5 V power supply to VCC1, which should be

decoupled with power supply decoupling capacitors. Connect VCC2, VCC3, and VCC4 to the same

5 V power supply.

12 REGOUT 3.3 V Output Supply. Drives VREG1, VREG2, VREG3, VREG4, VREG5, and VREG6.

13, 14, 15, 16, 31,

36

6, 19, 20, 21, 22, 23,

VREG1 to

VREG6

Positive Power Supplies for PLL Synthesizer, VCO, and Serial Port. Connect these pins to REGOUT

(3.3 V) and decouple them separately.

AGND Analog Ground. Connect to a low impedance ground plane.

24, 37, 39, 40, 46,

47, 49, 50, 51, 52,

53, 54

32 DGND Digital Ground. Connect to the same low impedance ground plane as the AGND pins.

IBB,

2, 3

IBB

Differential In-Phase Baseband Inputs. These high impedance inputs must be dc-biased to approximately 500 mV dc and should be driven from a low impedance source. Nominal characterized ac

signal swing is 450 mV p-p on each pin. This results in a differential drive of 0.9 V p-p with a 500 mV

dc bias, resulting in a single sideband output power of approximately −1.6 dBm. These inputs are

not self-biased and must be externally biased.

4, 5

QBB

, QBB

Differential Quadrature Baseband Inputs. These high impedance inputs must be dc-biased to

approximately 500 mV dc and should be driven from a low impedance source. Nominal characterized ac signal swing is 450 mV p-p on each pin. This results in a differential drive of 0.9 V p-p with

a 500 mV dc bias, resulting in a single sideband output power of approximately −1.6 dBm. These

inputs are not self-biased and must be externally biased.

33, 34, 35 CCOMP1 to

Internal Compensation Nodes. These pins must be decoupled to ground with a 100 nF capacitor.

CCOMP3

38 VTUNE Control Input to the VCO. This voltage determines the output frequency and is derived from

filtering the CP output voltage.

7 RSET Charge Pump Current Set. Connecting a resistor between this pin and ground sets the maximum

charge pump output current. The relationship between ICP and R

is as follows:

Rev. PrD | Page 8 of 43

Page 9

Preliminary Technical Data ADRF6755

SET

CP max

Pin No. Mnemonic Description

5.23

I

CPmax

where R

9 CP Charge Pump Output. When enabled, this output provides ±ICP to the external loop filter, which, in

turn, drives the internal VCO.

27 CS Chip Select, CMOS Input. When CS is high, the data stored in the shift registers is loaded into one of

31 latches. In I2C mode, when CS is high, the slave address of the device is 0x60, and when CS is low,

the slave address is 0x40.

29 SDI/SDA Serial Data Input for SPI Port/Serial Data Input/Output for I2C Port. In SPI mode, this pin is a high

impedance CMOS data input, and data is loaded in an 8-bit word. In I2C mode, this pin is a bidirectional port.

30 CLK/SCL Serial Clock Input for SPI/I2C Port. This serial clock is used to clock in the serial data to the registers.

This input is a high impedance CMOS input.

28 SDO Serial Data Output for SPI Port. Register states can be read back on the SDO data output line.

17 REFIN Reference Input. This high impedance CMOS input should be ac-coupled.

18

REFIN

Reference Input Bar. This pin should be either grounded or ac-coupled to ground.

48 RFOUT RF Output. Single-ended, 50 Ω, internally biased RF output. This pin must be ac-coupled to the

load. Nominal output power is −1.6 dBm for a single sideband baseband drive of 0.9 V p-p differ-

ential on the I and Q inputs (attenuation = minimum).

45 TXDIS Output Disable. This pin can be used to disable the RF output. Connect to high logic level to disable

the output. Connect to low logic level for normal operation.

25, 26 LOMON,

LOMON

Differential Monitor Outputs. These pins provide a replica of the internal local oscillator frequency

(1× LO) at four different power levels: −6 dBm, −12 dBm, −18 dBm, and −24 dBm, approximately.

These open-collector outputs must be terminated with external resistors to REGOUT. These outputs

can be disabled through serial port programming and should be tied to REGOUT if not used.

10, 8 LF2, LF3 No connect pins.

44 LDET Lock Detect. This output pin indicates the state of the PLL: a high level indicates a locked condition,

whereas a low level indicates a loss of lock condition.

43 MUXOUT Muxout. This output is a test output for diagnostic use only. It should be left unconnected by the

customer.

Exposed Paddle EP Exposed Paddle. Connect to ground plane via a low impedance path.

R

SET

= 4.7 kΩ and I

= 5 mA.

Rev. PrD | Page 9 of 43

Page 10

Preliminary Technical Data ADRF6755

odata

vailabl

e

odatavailable

odatavailable

odatavailableodatavailabl

e

odatavailable

TYPICAL PERFORMANCE CHARACTERISTICS

VCC = 5 V, TA = 25°C, I/Q inputs = 0.9 V p-p differential sine waves in quadrature on a 500 mV dc bias, REFIN = 80 MHz, PFD = 40 MHz,

baseband frequency = 1 MHz, LOMON is off, unless otherwise noted. A nominal condition is defined as 25°C, 5.00 V, and worst-case

frequency. A worst-case condition is defined as having the worst-case temperature, supply voltage, and frequency.

Figure 5. Output Power vs. LO Frequency, Supply, and Temperature

Figure 6. Output Power Distribution at Nominal and

Worst-Case Conditions

Figure 8. Sideband Suppression vs. LO Frequency, Supply, and Temperature

Figure 9. Sideband Suppression Distribution at Nominal and

Worst-Case Conditions

Figure 7. Output Power vs. LO Frequency for External VCO Mode

at Nominal Conditions

Figure 10. LO Carrier Feedthrough vs. Attenuation, LO Frequency,

Supply, and Temperature

Rev. PrD | Page 10 of 43

Page 11

Preliminary Technical Data ADRF6755

odatavailable

odata

vailabl

e

odata

vailabl

e

odata

vailabl

e

odatavailable

odata

vailabl

e

Figure 11. LO Carrier Feedthrough Distribution at Nominal and Worst-Case

Conditions and Attenuation Setting

Figure 12. 2 × LO Carrier Feedthrough vs. Attenuation, LO Frequency,

Supply, and Temperature

Figure 14. Output P1dB Compression Point Distribution at Nominal

and Worst-Case Conditions

Figure 15. Output P1dB Compression Point vs. LO Frequency at

Nominal Conditions

Figure 13. Output P1dB Compression Point at Worst-Case LO Frequency

vs. Supply and Temperature

Rev. PrD | Page 11 of 43

Figure 16. Output IP3 Distribution at Nominal and Worst-Case

Conditions

Page 12

ADRF6755

odatavailable

odatavailable

odata

vailabl

e

odata

vailabl

e

odatavailable

odata

vailabl

e

Preliminary Technical Data

Figure 17. Output IP3 vs. LO Frequency at Nominal Conditions

Figure 18. LO Off Isolation vs. Attenuation, LO Frequency, Supply,

and Temperature

Figure 20. Second-Order and Third-Order Harmonic Distortion vs.

Figure 21. Noise Floor at 15 MHz Offset Frequency Distribution at

LO Frequency, Supply, and Temperature

Worst-Case Conditions and Different Attenuation Settings

Figure 19. 2 × LO Off Isolation vs. Attenuation, LO Frequency, Supply,

and Temperature

Figure 22. Noise Floor at 0 dB Attenuation vs. Output Power

at Nominal Conditions

Rev. PrD | Page 12 of 43

Page 13

Preliminary Technical Data ADRF6755

odata

vailabl

e

odata

vailabl

e

odata

vailabl

e

odatavailable

odatavailable

odata

vailabl

e

Figure 23. Normalized I and Q Input Bandwidth

Figure 24. Output Return Loss at Worst-Case Attenuation vs.

LO Frequency, Supply, and Temperature

Figure 26. RF Output Spectral Plot over a 100 MHz Span

Figure 27. RF Output Spectral Plot over a Wide Span

Figure 25. RF Output Spectral Plot over a 10 MHz Span

Rev. PrD | Page 13 of 43

Figure 28. Phase Noise Performance vs. LO Frequency, Supply,

and Temperature

Page 14

ADRF6755

odata

vailabl

e

odatavailable

odatavailable

odata

vailabl

e

odatavailableodatavailabl

e

Preliminary Technical Data

Figure 29. Phase Noise Performance Distribution at Worst-Case Conditions

Figure 30. Integer Boundary Spur Performance vs. LO Frequency,

Supply, and Temperature

Figure 32. Spurs > 10 MHz from Carrier vs. LO Frequency,

Supply, and Temperature

Figure 33. Integrated Phase Noise vs. LO Frequency at

Nominal Conditions

Figure 31. Integer Boundary Spur Distribution at Nominal

and Worst-Case Conditions

Figure 34. Integrated Phase Noise at Nominal and

Worst-Case Conditions

Rev. PrD | Page 14 of 43

Page 15

Preliminary Technical Data ADRF6755

odatavailable

odata

vailabl

e

odatavailable

odata

vailabl

e

odatavailable

odatavailable

Figure 35. PLL Frequency Settling Time at Worst-Case Low Frequency

with Lock Detect Shown

Figure 36. Attenuator Gain vs. LO Frequency by Gain Code,

All Attenuator Code Steps

Figure 38. Attenuator Relative Step Accuracy Distribution at Nominal

and Worst-Case Conditions

Figure 39. Attenuator Relative Step Accuracy Across Full Output

Frequency Range Distribution at Nominal and Worst-Case Conditions

Figure 37. Attenuator Relative Step Accuracy over all Attenuation Steps

vs. LO Frequency, Nominal Conditions

Rev. PrD | Page 15 of 43

Figure 40. Attenuator Relative Step Accuracy over all Attenuation Steps

vs. LO Frequency for External VCO Mode, Nominal Conditions

Page 16

ADRF6755

odatavailable

odata

vailabl

e

odatavailable

odatavailable

odatavailable

odata

vailabl

e

Figure 41. Attenuator Absolute Step Accuracy over all Attenuation Steps

vs. LO Frequency, Nominal Conditions

Preliminary Technical Data

Figure 44. Gain Flatness in any 40 MHz for all Attenuation Steps vs.

LO Frequency at Nominal Conditions

Figure 42. Attenuator Absolute Step Accuracy Distribution at Nominal

and Worst-Case Conditions

Figure 43. Attenuator Absolute Step Accuracy over all Attenuation Steps

vs. LO Frequency for External VCO Mode, Nominal Conditions

Figure 45. Attenuator Settling Time to 0.2 dB and 0.5 dB for Small Steps

(1 dB to 6 dB) at Nominal Conditions

Figure 46. Attenuator Settling Time to 0.2 dB and 0.5 dB for Large Steps

(7 dB to 47 dB) at Nominal Conditions

Rev. PrD | Page 16 of 43

Page 17

Preliminary Technical Data ADRF6755

odata

vailabl

e

odata

vailabl

e

odata

vailabl

e

odatavailable

odata

vailabl

e

Figure 47. Attenuator Settling Time to 0.2 dB and 0.5 dB Distribution

at Nominal and Worst-Case Conditions for Typical Small Step

Figure 48. Attenuator Settling Time to 0.2 dB and 0.5 dB Distribution

at Nominal and Worst-Case Conditions for Worst-Case Small Step

(36 dB to 42 dB)

Figure 50. Attenuator Settling Time to 0.2 dB and 0.5 dB Distribution at

Nominal and Worst-Case Conditions for Worst-Case Large Step

Figure 51. TXDIA Turn-On Settling Time at Worst-Case Supply

(47 dB to 0 dB)

and Temperature

Figure 49. Attenuator Settling Time to 0.2 dB and 0.5 dB Distribution at

Nominal and Worst-Case Conditions for Typical Large Step (0 dB to 47 dB)

Rev. PrD | Page 17 of 43

Page 18

ADRF6755

POWER-DOWN

THEORY OF OPERATION

OVERVIEW

The ADRF6755 device can be divided into the following basic

building blocks:

PLL synthesizer and VCO

Quadrature modulator

Attenuator

Voltage regulator

2

I

C/SPI interface

Each of these building blocks is described in detail in the

sections that follow.

PLL SYNTHESIZER AND VCO

Overview

The phase-locked loop (PLL) consists of a fractional-N frequency

synthesizer with a 25-bit fixed modulus, allowing a frequency

resolution of less than 1 Hz over the entire frequency range. It

also has an integrated voltage-controlled oscillator (VCO) with

a fundamental output frequency ranging from 2310 MHz to

4620 MHz. An RF divider, controlled by Register CR28,

Bits[2:0], extends the lower limit of the frequency range to less

than 600 MHz. This 600 MHz to 4620 MHz frequency output is

then applied to a divide-by-2 quadrature circuit to provide a

local oscillator (LO) ranging from 300 MHz to 2310 MHz to the

quadrature modulator.

Reference Input Section

The reference input stage is shown Figure 52. SW1 and SW2 are

normally closed switches. SW3 is normally open. When powerdown is initiated, SW3 is closed, and SW1 and SW2 are open.

This ensures that there is no loading of the REFIN pin at powerdown.

CONTROL

100kΩ

NC

SW1

NC

SW2

SW3

REFIN

NC

Figure 52. Reference Input Stage

Reference Input Path

The on-chip reference frequency doubler allows the input

reference signal to be doubled. This is useful for increasing the

PFD comparison frequency. Making the PFD frequency higher

improves the noise performance of the system. Doubling the

PFD frequency usually improves the in-band phase noise

performance by up to 3 dBc/Hz.

BUFFER

TO

R-DIVIDER

08201-006

Rev. PrD | Page 18 of 43

Preliminary Technical Data

The 5-bit R-divider allows the input reference frequency

(REFIN) to be divided down to produce the reference clock

to the PFD. Division ratios from 1 to 32 are allowed.

An additional divide-by-2 (÷2) function in the reference input

path allows for a greater division range.

FROM

REFIN

PIN

×2

DOUBLER

Figure 53. Reference Input Path

5-BIT

R-DIVIDER

÷2

The PFD frequency equation is

f

= f

PFD

× [(1 + D)/(R × (1 + T))] (1)

REFIN

where:

f

is the reference input frequency.

REFIN

D is the doubler bit.

R is the programmed divide ratio of the binary 5-bit

programmable reference divider (1 to 32).

T is the ÷2 bit (0 or 1).

If no division is required, then it is recommended that the 5-bit

R-divider and the divide-by-2 are disabled by setting CR5[4] =

0. If an even numbered division is required, then the divide-by2 should be enabled by setting CR5[4] =1 and CR10[6] = 1 and

the remainder of the division should be implemented in the 5bit R-divider. If an odd number division is required then set

CR5[4] = 1 and implement all of the division in the 5-bit Rdivider.

RF Fractional-N Divider

The RF fractional-N divider allows a division ratio in the PLL

feedback path that can range from 23 to 4095. The relationship

between the fractional-N divider and the LO frequency is

described in the following section.

INT and FRAC Relationship

The integer (INT) and fractional (FRAC) values make it

possible to generate output frequencies that are spaced by

fractions of the phase frequency detector (PFD) frequency.

See the Example—Changing the LO Frequency section for

more information.

The LO frequency equation is

LO = f

× (INT + (FRAC/225))/2

PFD

RFDIV

(2)

where:

LO is the local oscillator frequency.

f

is the PFD frequency.

PFD

INT is the integer component of the required division factor

and is controlled by the CR6 and CR7 registers.

FRAC is the fractional component of the required division

factor and is controlled by the CR0 to CR3 registers.

RFDIV is set in Register CR28, Bits[2:0], and controls the

setting of the divider at the output of the PLL.

TO

PFD

Page 19

Preliminary Technical Data ADRF6755

08201-009

odata

vailabl

e

odatavailable

FROM VCO

OUTPUT

DIVIDERS

RF N-DIVIDER N = INT + FRAC/2

N-COUNTER

THIRD-ORDER

FRACTIONAL

INTERPOLATOR

25

TO

PFD

the full LO frequency range. The choice of three 16-band VCOs

and an RFDIVIDER allows the wide frequency range to be

covered without large VCO sensitivity (K

) or resultant poor

VCO

phase noise and spurious performance.

INT

REG

Figure 54. RF Fractional-N Divider

FRAC

VALUE

Phase Frequency Detector (PFD) and Charge Pump

The PFD takes inputs from the R-divider and the N-counter and

produces an output proportional to the phase and frequency difference between them (see Figure 55 for a simplified schematic).

The PFD includes a fixed delay element that sets the width of

the antibacklash pulse, ensuring that there is no dead zone in

the PFD transfer function.

HI

+IN

HI

–IN

UP

Q1D1

U1

CLR1

DELAY

CLR2

DOWN

Q2D2

U2

Figure 55. PFD Simplified Schematic

U3

CHARGE

PUMP

CP

Lock Detect (LDET)

LDET (Pin 44) signals when the PLL has achieved lock to an

error frequency of less than 100 Hz. On a write to Register CR0,

a new PLL acquisition cycle starts, and the LDET signal goes

low. When lock has been achieved, this signal returns high.

Figure 56. V

The VCO displays a variation of K

vs. LO Frequency

TUNE

as V

VCO

varies within

TUNE

the band and from band to band. Figure 57 shows how the

K

varies across the fundamental LO frequency range from

VCO

1155 MHz to 2310 MHz. Note that K

is shown at the LO

VCO

frequency rather than at the VCO frequency. Figure 57 is useful

when calculating the loop filter bandwidth and individual loop

filter components using ADISimPLL™. ADISimPLL is an

Analog Devices, Inc., simulator that aids in PLL design,

particularly with respect to the loop filter. It reports parameters

such as phase noise, integrated phase noise, acquisition time,

and so forth for a particular set of input conditions.

ADISimPLL can be downloaded from www.analog.com.

Voltage-Controlled Oscillator (VCO)

The VCO core in the ADRF6755 consists of three separate VCOs,

each with 16 overlapping bands. This configuration of 48 bands

allows the VCO frequency range to extend from 2310 MHz to

4620 MHz. The three VCOs are divided by a programmable

divider, RFDIVIDER controlled by Register CR28, Bits[2:0].

This divider provides divisions of 1, 2, and 4 to ensure that the

frequency range is extended from 577.5 MHz (2310 MHz/4) to

4620 MHz (4620 MHz/1). A lower limit of only 600 MHz is

required. A divide-by-2 quadrature circuit provides the full LO

frequency range from 300 MHz to 2310 MHz. Figure 56 shows

a sweep of V

vs. LO frequency demonstrating the three VCOs

TUNE

overlapping and the multiple overlapping bands within each

VCO at the LO frequency range of 300 MHz to 2310 MHz. Note

that this plot includes the RFDIVIDER being incorporated to

provide further divisions of the fundamental VCO frequency;

thus, each VCO is used on three different occasions throughout

Rev. PrD | Page 19 of 43

Figure 57. K

vs. LO Frequency

VCO

Autocalibration

The correct VCO and band are chosen automatically by the

VCO and band select circuitry when Register CR0 is updated.

This is referred to as autocalibration. The autocalibration time

is set by Register CR25.

Autocalibration Time = (BSCDIV × 28)/PFD (3)

Page 20

ADRF6755

odatavailable

odata

vailabl

e

where:

BSCDIV = Register CR25, Bits[7:0].

PFD = PFD frequency.

Preliminary Technical Data

1. Calculate the value of RFDIV, which is used to

program Register CR28, Bits[2:0] and CR27, Bit 4

from the following lookup table, Table 6.

For a PFD frequency of 40 MHz, set BSCDIV = 100 to set an

autocalibration time of 70 µs.

Note that BSCDIV must be recalculated if the PFD frequency is

changed. The recommended autocalibration setting is 70 µs.

During this time, the VCO V

of the loop filter and is connected to an internal reference voltage.

A typical frequency acquisition is shown in Figure 58.

Figure 58. PLL Acquisition

After autocalibration, normal PLL action resumes, and the

correct frequency is acquired to within a frequency error of

100 Hz in 170 µs typically. For a maximum cumulative step of

100 kHz/2

CR24, Bit 0. This enables cumulative PLL acquisitions of 100

kHz (for RFDIV= ÷1, 50 kHz for RFDIV=÷2 and so on) or less

to occur without the autocalibration procedure, which improves

acquisition times significantly (see Figure 59).

RFDIV

, autocalibration can be turned off by Register

is disconnected from the output

TUNE

Table 6. RFDIV Lookup Table

LO Frequency (MHz) RFDIVIDER CR28[2:0]

=RFDIV

1155 < LO divide-by-1 000 1

577.5 < LO ≤ 1155 divide-by-2 001 0

300 < LO ≤ 577.5 divide-by-4 010 0

2. Using the following equation, calculate the value of

the N-divider:

RFDIV

N = (2

where:

N is the N-divider value.

RFDIV is the setting in Register CR28, Bits[2:0].

LO is the local oscillator frequency.

f

is the PFD frequency.

PFD

This equation is a different representation of Equation 2.

× LO)/f

(4)

PFD

CR27[4]

Example to Program the Correct LO Frequency

Assume that the PFD frequency is 40 MHz and the required LO

frequency is 1875 MHz.

Step 1. From Table 6, 2

Step 2. N = (1 × 1875E+6)/40E+6 = 46.875

RFDIV

= 1. (RFDIV = 0)

Figure 59. PLL Acquisition Without Autocalibration for a 100 kHz Step

Programming the Correct LO Frequency

There are two steps to programming the correct LO frequency.

The user must calculate the RFDIV value based on the required

LO frequency and PFD frequency, and the N-divider ratio that

is required in the PLL.

Rev. PrD | Page 20 of 43

The N-divider value is composed of integer (INT) and

fractional (FRAC) components according to the following

equation:

N = INT + FRAC/2

INT = 46 and FRAC = 29,360,128

The appropriate registers must then be programmed according to

the register map. The order in which the registers are

programmed is important. Writing to CR0 initiates a PLL

acquisition cycle. If the programmed LO frequency requires a

change in the value of CR27[4] (Table 6. RFDIV Lookup Table),

then CR27 should be the last register programmed, preceded by

CR0. If on the other hand, the programmed LO frequency does

not require a change in the value of CR27[4] it is optional to

omit the write to CR27 and in that case CR0 should be the last

register programmed.

25

(5)

Page 21

Preliminary Technical Data ADRF6755

V-TO-

I

5

QUADRATURE MODULATOR

Overview

A basic block diagram of the ADRF6755 quadrature modulator

circuit is shown in Figure 60. The VCO/RFDIVIDER generates

a signal at the 2× LO frequency, which is then divided down to

give a signal at the LO frequency. This signal is then split into inphase and quadrature components to provide the LO signals that

drive the mixers.

capacitance. The impedance looks like 30 kΩ below 1 MHz and

starts to roll off at higher frequency. A 100 Ω differential

termination is recommended at the baseband inputs, and this

dominates the input impedance as seen by the input baseband

signal. This ensures that the input impedance, as seen by the

input circuit, remains flat across the baseband bandwidth. See

Figure 62 for a typical configuration.

CURRENT OUTPUT DAC

(EXAMPLE: AD9779)

ADRF675

IBB

IBB

RFOUT TO

ATTENUATOR

Figure 60. Block Diagram of the Quadrature Modulator

QUAD

PHASE

SPLITTER

÷2

V-TO-I

QBB

QBB

VCORF DIVIDER

The I and Q baseband input signals are converted to currents by

the V-to-I stages, which then drive the two mixers. The outputs

of these mixers combine to feed the single-ended output. This

single-ended output is then fed to the attenuator and, finally, to

the external RFOUT signal pin.

Baseband Inputs

The baseband inputs, QBB,

QBB

, IBB, and

, must be driven

IBB

from a differential source. The nominal drive level of 0.9 V p-p

differential (450 mV p-p on each pin) should be biased to a

common-mode level of 500 mV dc.

To set the dc bias level at the baseband inputs, refer to Figure 61.

The average output current on each of the AD9779 outputs is

10 mA. A current of 10 mA flowing through each of the 50 Ω

resistors to ground produces the desired dc bias of 500 mV at

each of the baseband inputs.

CURRENT OUTPUT DAC

(EXAMPLE: AD9779)

OUT1_P

OUT1_N

50Ω

50Ω

ADRF6755

IBB

IBB

OUT1_P

OUT1_N

OUT2_N

OUT2_P

Figure 62. Typical Baseband Input Configuration

50Ω

50Ω

50Ω

50Ω

LOWPASS

FILTER

LOWPASS

FILTER

IBB

100Ω

IBB

QBB

100Ω

QBB

The swing of the AD9779 output currents ranges from 0 mA to

20 mA. The ac voltage swing is 1 V p-p single-ended or 2 V p-p

differential with the 50 Ω resistors in place. The 100 Ω differen-

tial termination resistors at the baseband inputs have the effect

of limiting this swing without changing the dc bias condition of

500 mV. The low-pass filter is used to filter the DAC outputs

and remove images when driving a modulator.

Another consideration is that the baseband inputs actually

source a current of 240 µA out of each of the four inputs. This

current must be taken into account when setting up the dc bias

of 500 mV. In the initial example based on Figure 61, an error

of 12 mV occurs due to the 240 µA current flowing through

the 50 Ω resistor. Analog Devices, Inc., recommends that the

accuracy of the dc bias should be 500 mV ±25 mV. It is also

important that this 240 µA current have a dc path to ground.

Optimization

The carrier feedthrough and the sideband suppression performance of the ADRF6755 can be improved over the numbers

specified in Table 1 by using the following optimization

techniques.

Carrier Feedthrough Nulling

OUT2_N

50Ω

50Ω

OUT2_P

Figure 61. Establishing DC Bias Level on Baseband Inputs

The differential baseband inputs (QBB,

QBB

QBB

QBB, IBB

and IBB)

consist of the bases of PNP transistors, which present a high

impedance of about 30 kΩ in parallel with roughly 2 pF of

Rev. PrD | Page 21 of 43

Carrier feedthrough results from dc offsets that occur between

the P and N inputs of each of the differential baseband inputs.

Normally these inputs are set to a dc bias of approximately 500 mV.

However, if a dc offset is introduced between the P and N inputs of

either or both I and Q inputs, the carrier feedthrough is affected

in either a positive or a negative fashion. Note that the dc bias

level remains at 500 mV (average P and N level). The I channel

offset is often held constant while the Q channel offset is varied

until a minimum carrier feedthrough level is obtained. Then,

Page 22

ADRF6755

R/W

while retaining the new Q channel offset, the I channel offset is

adjusted until a new minimum is reached. This is usually performed at a single frequency and, thus, is not optimized over

the complete frequency range. Multiple optimizations at different

frequencies must be performed to ensure optimum carrier feedthrough across the full frequency range.

Sideband Suppression Nulling

Sideband suppression results from relative gain and relative

phase offsets between the I channel and Q channel and can

be optimized through adjustments to those two parameters.

Adjusting only one parameter improves the sideband suppression

only to a point. For optimum sideband suppression, an iterative

adjustment between phase and amplitude is required.

ATTENUATOR

The digital attenuator consists of six attenuation blocks: 1 dB,

2 dB, 4 dB, 8 dB, and two 16 dB blocks; each is separately

controlled. Each attenuation block consists of field effect

transistor (FET) switches and resistors that form either a pishaped or a T-shaped attenuator. By controlling the states of the

FET switches through the control lines, each attenuation block

can be set to the pass state (0 dB) or the attenuation state (n

dB). The various combinations of the six blocks provide the

attenuation states from 0 dB to 47 dB in 1 dB increments.

VOLTAGE REGULATOR

The voltage regulator is powered from a 5 V supply that is

provided by VCC1 (Pin 11) and produces a 3.3 V nominal

regulated output voltage, REGOUT, on Pin 12. This pin must

be connected (external to the IC) to the VREG1 through VREG6

package pins.

The regulator output (REGOUT) should be decoupled by

a parallel combination of 10 pF and 220 µF capacitors. The

220 µF capacitor, which is recommended for best performance,

decouples broadband noise, leading to better phase noise. Each

VREGx pin should have the following decoupling capacitors:

100 nF multilayer ceramic with an additional 10 pF in parallel,

both placed as close as possible to the DUT power supply pins.

X7R or X5R capacitors are recommended. See the Evaluation

Board section for more information.

I2C INTERFACE

The ADRF6755 supports a 2-wire, I2C-compatible serial bus

that drives multiple peripherals. The serial data (SDA) and serial

clock (SCL) inputs carry information between any devices that

are connected to the bus. Each slave device is recognized by

a unique address. The ADRF6755 has two possible 7-bit slave

SLAVEADDRESS[6:0]

1 A5 0 0 0 0 0 X

MSB = 1 SET BY

PIN 27

(CS)

Figure 63. Slave Address Configuration

Rev. PrD | Page 22 of 43

Preliminary Technical Data

addresses for both read and write operations. The MSB of the

7-bit slave address is set to 1. Bit 5 of the slave address is set by

the CS pin (Pin 27). Bits[4:0] of the slave address are set to all

0s. The slave address consists of the seven MSBs of an 8-bit

word. The LSB of the word sets either a read or a write

operation (see Figure 63). Logic 1 corresponds to a read

operation, whereas Logic 0 corresponds to a write operation.

To control the device on the bus, the following protocol must

be followed. The master initiates a data transfer by establishing

a start condition, defined by a high-to-low transition on SDA

while SCL remains high. This indicates that an address/data

stream follows. All peripherals respond to the start condition

and shift the next eight bits (the 7-bit address and the R/W bit).

The bits are transferred from MSB to LSB. The peripheral that

recognizes the transmitted address responds by pulling the data

line low during the ninth clock pulse. This is known as an

acknowledge bit. All other devices then withdraw from the bus

and maintain an idle condition. During the idle condition, the

device monitors the SDA and SCL lines waiting for the start

condition and the correct transmitted address. The R/W bit

determines the direction of the data. Logic 0 on the LSB of the

first byte indicates that the master writes information to the

peripheral. Logic 1 on the LSB of the first byte indicates that the

master reads information from the peripheral.

The ADRF6755 acts as a standard slave device on the bus. The

data on the SDA pin (Pin 29) is eight bits long, supporting the

7-bit addresses plus the R/W bit. The ADRF6755 has 34 subaddresses to enable the user-accessible internal registers. Therefore,

it interprets the first byte as the device address and the second

byte as the starting subaddress. Autoincrement mode is supported,

which allows data to be read from or written to the starting subaddress and each subsequent address without manually addressing

the subsequent subaddress. A data transfer is always terminated

by a stop condition. The user can also access any unique subaddress

register on a one-by-one basis without updating all registers.

Stop and start conditions can be detected at any stage of the data

transfer. If these conditions are asserted out of sequence with

normal read and write operations, they cause an immediate jump

to the idle condition. If an invalid subaddress is issued by the

user, the ADRF6755 does not issue an acknowledge and returns

to the idle condition. In a no acknowledge condition, the SDA

line is not pulled low on the ninth pulse. See Figure 64 and

Figure 65 for sample write and read data transfers, Figure 66 for

the timing protocol, and Figure 2 for a more detailed timing

diagram.

CTRL

0 = WR

1 = RD

Page 23

Preliminary Technical Data ADRF6755

START BIT

STOP BIT

S SLAVEADDR, LSB = 0 (WR) A(S) A(S) A(S)DATASUBADDR A(S) PDATA

S = START BIT P = STOP BIT

A(S) = ACKNOWLEDGE BY SLAVE

Figure 64. I2C Write Data Transfer

S

S = START BIT P = STOP BIT

A(S) = ACKNOWLEDGE BY SLAVE A(M) =ACKNOWLEDGE BY MASTER

Figure 65. I2C Read Data Transfer

SSLAVEADDR, LSB = 0 (WR) SLAVE ADDR, LSB = 1 (RD)A(S) A(S)SUBADDR A(S) DATA A(M) DATA PA(M)

A(M) = NO ACKNOWLEDGE BY MASTER

SLAVEADDRESS SUBADDRESS DATA

08201-018

SDA

SCL

S

SLAVE

ADDR[4:0]

SUBADDR[6:1] DATA[6:1]

D0D7A0A7A5A6

ACKACKWR ACK

P

08201-002

Figure 66. I2C Data Transfer Timing

Rev. PrD | Page 23 of 43

Page 24

ADRF6755

SPI INTERFACE

The ADRF6755 also supports the SPI protocol. The part powers

up in I2C mode but is not locked in this mode. To stay in I2C

mode, it is recommended that the user tie the CS line to either

3.3 V or GND, thus disabling SPI mode. It is not possible to lock

the I2C mode, but it is possible to select and lock the SPI mode.

To select and lock the SPI mode, three pulses must be sent to the

CS pin, as shown in Figure 67. When the SPI protocol is locked

in, it cannot be unlocked while the device is still powered up. To

reset the serial interface, the part must be powered down and

powered up again.

Serial Interface Selection

The CS pin controls selection of the I2C or SPI interface.

Figure 67 shows the selection process that is required to lock

the SPI mode. To communicate with the part using the SPI

protocol, three pulses must be sent to the CS pin. On the third

rising edge, the part selects and locks the SPI protocol. Consistent

with most SPI standards, the CS pin must be held low during all

SPI communication to the part and held high at all other times.

Preliminary Technical Data

SPI Serial Interface Functionality

The SPI serial interface of the ADRF6755 consists of the CS,

SDI (SDI/SDA), CLK (CLK/SCL), and SDO pins. CS is used to

select the device when more than one device is connected to the

serial clock and data lines. CLK is used to clock data in and out

of the part. The SDI pin is used to write to the registers. The

SDO pin is a dedicated output for the read mode. The part

operates in slave mode and requires an externally applied serial

clock to the CLK pin. The serial interface is designed to allow

the part to be interfaced to systems that provide a serial clock

that is synchronized to the serial data.

Figure 68 shows an example of a write operation to the

ADRF6755. Data is clocked into the registers on the rising edge of

CLK using a 24-bit write command. The first eight bits

represent the write command 0xD4, the next eight bits are the

register address, and the final eight bits are the data to be written

to the specific register. Figure 69 shows an example of a read

operation. In this example, a shortened 16-bit write command is

first used to select the appropriate register for a read operation,

the first eight bits representing the write command 0xD4 and

the final eight bits representing the specific register. Then the

CS line is pulsed low for a second time to retrieve data from the

selected register using a 16-bit read command, the first eight

bits representing the read command 0xD5 and the final eight

bits representing the contents of the register being read. Figure

3 shows the timing for both SPI read and SPI write operations.

CS

(STARTING

HIGH)

CS

(STARTING

LOW)

SPI LOCKED ON

THIRD RISING EDGE

SPI LOCKED ON

THIRD RISING EDGE

Figure 67. Selecting the SPI Protocol

CBA

SPI FRAMING

EDGE

CBA

SPI FRAMING

EDGE

08201-019

Rev. PrD | Page 24 of 43

Page 25

Preliminary Technical Data ADRF6755

CLK

08201-020

08201-021

CS

• • •

• • •

SDI D7 D6 D5 D4 D3 D2 D1 D0 D0

START

WRITE

COMMAND [0xD4]

(CONTINUED)

CLK

(CONTINUED)

SDI

(CONTINUED)

CS

• • •

• • •

• • •

D7 D6 D5 D4 D3 D2 D1

REGISTER

ADDRESS

D7 D6 D5 D4 D3 D2 D1 D0

DATA

BYTE

Figure 68. SPI Byte Write Example

CS

CLK

• • •

STOP

• • •

• • •

SDI

CLK

SDI

SDO

CS

D7 D6 D5 D4 D3 D2 D1 D0 D0

START

D7 D6 D5 D4 D3 D2 D1 D0

START

WRITE

COMMAND [0xD4]

READ

COMMAND [0xD5]

D7 D6 D5 D4 D3 D2 D1

REGISTER

ADDRESS

X X X X X X X

D7 D6 D5 D4 D3 D2 D1 D0

XX X X X X X X

DATA

BYTE

Figure 69. SPI Byte Read Example

Rev. PrD | Page 25 of 43

• • •

X

STOP

Page 26

ADRF6755

PROGRAM MODES

The ADRF6755 has 34 8-bit registers to allow program control

of a number of functions. Either an SPI or an I2C interface

can be used to program the register set. For details about the

interfaces and timing, see Figure 63 to Figure 69. The registers

are documented in Table 8 to Table 28.

Several settings in the ADRF6755 are double-buffered. These

settings include the FRAC value, the INT value, the 5-bit

R-divider value, the reference frequency doubler, the R/2

divider, the RFDIV value, and the charge pump current setting.

This means that two events must occur before the part uses a

new value for any of the double-buffered settings. First, the new

value is latched into the device by writing to the appropriate

register. Next, a new write must be performed on Register CR0.

When Register CR0 is written, a new PLL acquisition takes

place.

For example, updating the fractional value involves a write to

Register CR3, Register CR2, Register CR1, and Register CR0.

Register CR3 should be written to first, followed by Register CR2

and Register CR1 and, finally, Register CR0. The new acquisition

begins after the write to Register CR0. Double buffering ensures

that the bits written to do not take effect until after the write to

Register CR0.

12-Bit Integer Value

Register CR7 and Register CR6 program the integer value (INT)

of the feedback division factor (N); see Equation 5 for details.

The INT value is a 12-bit number whose MSBs are programmed

through Register CR7, Bits[3:0]. The LSBs are programmed

through Register CR6, Bits[7:0]. The LO frequency setting is

described by Equation 2. An alternative to this equation is provided by Equation 4, which details how to set the N-divider

value. Note that these registers are double buffered.

25-Bit Fractional Value

Register CR3 to Register CR0 program the fractional value

(FRAC) of the feedback division factor (N); see Equation 5 for

details. The FRAC value is a 25-bit number whose MSB is

programmed through Register CR3, Bit 0. The LSB is

programmed through Register CR0, Bit 0. The LO frequency

setting is described by Equation 2. Again, an alternative to this

equation is described by Equation 4, which details how to set

the N-divider value. Note that these registers are double

buffered.

RFDIV Value

The RFDIV value is dependent on the value of the LO

frequency. The RFDIV value can be selected from the list in

Table 6. Apply the selected RFDIV value to Equation 4, together

with the LO frequency and PFD frequency values, to calculate

the correct N-divider value.

Preliminary Technical Data

Reference Input Path

The reference input path consists of a reference frequency doubler,

a 5-bit reference divider, and a divide-by-2 function (see Figure 53).

The doubler is programmed through Register CR10, Bit 5. The

5-bit divider and divide-by-2 are enabled by programming

Register CR5, Bit 4, and the division ratio is programmed

through Register CR10, Bits[4:0]. The R/2 divider is programmed

through Register CR10, Bit 6. Note that these registers are

double-buffered.

Charge Pump Current

Register CR9, Bits[7:4], specify the charge pump current

setting. With an R

pump current is 5 mA. The following equation applies:

I

= 23.5/R

CPmax

The charge pump current has 16 settings from 312.5 µA to 5 mA.

For the loop filter that is specified in the application solution, a

charge pump current of 5 mA (Register CR9[7:4] = 0xF) gives a

loop bandwidth of 100 kHz, which is the recommended loop

bandwidth setting.

Transmit Disable Control (TXDIS)

The transmit disable control (TXDIS) is used to disable the RF output. TXDIS is normally held low. When asserted (brought high), it

disables the RF output. Register CR14 is used to control which

circuit blocks are powered down when TXDIS is asserted. To meet

both the off isolation power specifications and the turn-on/

turn-off settling time specifications, a value of 0x80 should be

loaded into Register CR14. This effectively ensures that the

attenuator is always enabled when TXDIS is asserted, even if other

circuitry is disabled.

Power-Down/Power-Up Control Bits

The 4 programmable power-up and power-down control bits

are as follows:

Register CR12, Bit 2. Master power control bit for the PLL,

including the VCO. This bit is normally set to a default

value of 0 to power up the PLL.

Register CR28, Bit 4. Controls the RFDIVIDER. This bit is

normally set to a default value of 0 to power up the

RFDIVIDER.

Register CR27, Bit 2. Controls the LO monitor outputs,

LOMON and

outputs are powered down. Setting this bit to 1 powers up

the monitor outputs to one of −6 dBm, −12 dBm, −18 dBm,

or −24 dBm, as controlled by Register CR27, Bits[1:0].

Register CR29, Bit 0. Controls the quadrature modulator

power. The default is 0, which powers down the modulator.

Write a 1 to this bit to power up the modulator.

value of 4.7 kΩ, the maximum charge

SET

SET

LOMON

. The default is 0 when the monitor

Rev. PrD | Page 26 of 43

Page 27

Preliminary Technical Data ADRF6755

Lock Detect (LDET)

Lock detect is enabled by setting Register CR23, Bit 4, to 1. The

Lock Detect circuit is based on monitoring the UP/DN pulses

from the PFD. As acquisition proceeds, the width of these

pulses reduces until they are less than a target width (set by

CR23[2]). At this point a count is initiated which counts the

number of successive PFD cycles where the width of the

UP/DN pulses remains less that the target width. When this

count reaches a target count (set by CR13[6] & CR23[3]), LDET

is set. The truth table for declaring LDET is given in Table 7.

Table 7.Declaring LDET

LDCount1

CR13[6]

0 0 2048

0 1 3072

1 0 4096

1 1 16384

LDCount0

CR23[3]

Number of PFD cycles

to declare LDET

The appropriate setting to use depends on the PFD frequency as

well the desired accuracy when LDET is declared. The LDET

setting does not affect the acquisition time of the PLL. It only

affects the time at which LDET goes HIGH.

VCO Autocalibration

The VCO uses an autocalibration technique to select the correct

VCO and band, as explained in the Autocalibration section.

Register CR24, Bit 0, controls whether the auto-calibration is

enabled. For normal operation, autocalibration needs to be

enabled. However, if using cumulative frequency steps of 100

RFDIV

kHz/2

bit to 1 and then a new acquisition is initiated by writing to

Register CR0.

or less, autocalibration can be disabled by setting this

Attenuator

The attenuator can be programmed from 0 dB to 47 dB in steps

of 1 dB. Control is through Register CR30, Bits[5:0].

Revision Readback

The revision of the silicon die can be read back via Register CR33.

Rev. PrD | Page 27 of 43

Page 28

Preliminary Technical Data ADRF6755

REGISTER MAP

REGISTER MAP SUMMARY

Table 8. Register Map Summary

Register Address (Hex) Register Name Type Description

0x00 CR0 Read/write Fractional Word 4

0x01 CR1 Read/write Fractional Word 3

0x02 CR2 Read/write Fractional Word 2

0x03 CR3 Read/write Fractional Word 1

0x04 CR4 Read/write Reserved

0x05 CR5 Read/write Reference dividers enable

0x06 CR6 Read/write Integer Word 2

0x07 CR7 Read/write Integer Word 1 and muxout control

0x08 CR8 Read/write Reserved

0x09 CR9 Read/write Charge pump current setting

0x0A CR10 Read/write Reference frequency control

0x0B CR11 Read/write Reserved

0x0C CR12 Read/write PLL power-up

0x0D CR13 Read/write Lock Detector Control 2

0x0E CR14 Read/write TXDIS control

0x0F CR15 Read/write Reserved

0x10 CR16 Read/write Reserved

0x11 CR17 Read/write Reserved

0x12 CR18 Read/write Reserved

0x13 CR19 Read/write Reserved

0x14 CR20 Read/write Reserved

0x15 CR21 Read/write Reserved

0x16 CR22 Read/write Reserved

0x17 CR23 Read/write Lock Detector Control 1

0x18 CR24 Read/write Autocalibration

0x19 CR25 Read/write Autocalibration Timer

0x1A CR26 Read/write Reserved

0x1B CR27 Read/write LO monitor output and LO selection

0x1C CR28 Read/write LO selection

0x1D CR29 Read/write Modulator

0x1E CR30 Read/write Attenuator

0x1F CR31 Read only Reserved

0x20 CR32 Read only Reserved

0x21 CR33 Read only Revision code

Rev. PrD | Page 28 of 43

Page 29

Preliminary Technical Data ADRF6755

REGISTER BIT DESCRIPTIONS

Table 9. Register CR0 (Address 0x00), Fractional Word 4

Bit Description1

7 Fractional Word F7

6 Fractional Word F6

5 Fractional Word F5

4 Fractional Word F4

3 Fractional Word F3

2 Fractional Word F2

1 Fractional Word F1

0 Fractional Word F0 (LSB)

1

Double-buffered. Loaded on the write to Register CR0.

Table 10. Register CR1 (Address 0x01), Fractional Word 3

Bit Description1

7 Fractional Word F15

6 Fractional Word F14

5 Fractional Word F13

4 Fractional Word F12

3 Fractional Word F11

2 Fractional Word F10

1 Fractional Word F9

0 Fractional Word F8

1

Double-buffered. Loaded on the write to Register CR0.

Table 11. Register CR2 (Address 0x02), Fractional Word 2

Bit Description1

7 Fractional Word F23

6 Fractional Word F22

5 Fractional Word F21

4 Fractional Word F20

3 Fractional Word F19

2 Fractional Word F18

1 Fractional Word F17

0 Fractional Word F16

1

Double-buffered. Loaded on the write to Register CR0.

Table 12. Register CR3 (Address 0x03), Fractional Word 1

Bit Description

7 Set to ‘0’

6 Set to ‘0’

5 Set to ‘0’

4 Set to ‘0’

3 Set to ‘0’

2 Set to ‘1’

1 Set to ‘0’

0 Fractional Word F24 (MSB)1

1

Double-buffered. Loaded on the write to Register CR0.

Table 13. Register CR5 (Address 0x05), 5-Bit Reference

Divider Enable

Bit Description

7 Set to ‘0’

6 Set to ‘0’

5 Set to ‘0’

4 5-bit R-divider and divide-by-2 enable1

0 = disable 5-bit R-divider and divide-by-2 (default)

1 = enable 5-bit R-divider and divide-by-2

3 Set to ‘0’

2 Set to ‘0’

1 Set to ‘0’

0 Set to ‘0’

1

Double-buffered. Loaded on the write to Register CR0.

Table 14. Register CR6 (Address 0x06), Integer Word 2

Bit Description1

7 Integer Word N7

6 Integer Word N6

5 Integer Word N5

4 Integer Word N4

3 Integer Word N3

2 Integer Word N2

1 Integer Word N1

0 Integer Word N0

1

Double-buffered. Loaded on the write to Register CR0.

Table 15. Register CR7 (Address 0x07), Integer Word 1 and

Muxout Control

Bit Description

[7:4] Muxout control

0000 = tristate

0001 = logic high

0010 = logic low

1101 = RCLK/2

1110 = NCLK/2

3 Integer Word N111

2 Integer Word N101

1 Integer Word N91

0 Integer Word N81

1

Double-buffered. Loaded on the write to Register CR0.

Rev. PrD | Page 29 of 43

Page 30

ADRF6755

Preliminary Technical Data

Table 16. Register CR9 (Address 0x09), Charge Pump

Current Setting

Bit Description

[7:4] Charge pump current1

0000 = 0.31 mA (default)

0001 = 0.63 mA

0010 = 0.94 mA

0011 = 1.25 mA

0100 = 1.57 mA

0101 = 1.88 mA

0110 = 2.19 mA

0111 = 2.50 mA

1000 = 2.81 mA

1001 = 3.13 mA

1010 = 3.44 mA

1011 = 3.75 mA

1100 = 4.06 mA

1101 = 4.38 mA

1110 = 4.69 mA

1111 = 5.00 mA

3 Set to ‘0’

2 Set to ‘0’

1 Set to ‘0’

0 Set to ‘0’

1

Double-buffered. Loaded on the write to Register CR0.

Table 17. Register CR10 (Address 0x0A), Reference

Frequency Control

Bit Description

7 Set to ‘0’1

6 R/2 divider setting1

0 = bypass R/2 divider (default)

1 = select R/2 divider

5 R-doubler enable1

0 = disable doubler (default)

1 = enable doubler

[4:0] 5-bit R-divider setting1

00000 = divide by 32 (default)

00001 = divide by 1

00010 = divide by 2

…

11110 = divide by 30

11111 = divide by 31

1

Double-buffered. Loaded on the write to Register CR0.

Table 18. Register CR12 (Address 0x0C), PLL Power-Up

Bit Description

7 Set to ‘0’

6 Set to ‘0’

5 Set to ‘0’

4 Set to ‘1’

3 Set to ‘1’

2 Power down PLL

0 = power up PLL (default)

1 = power down PLL

1 Set to ‘0’

0 Set to ‘0’

Table 19. Register CR13 (Address 0x0D), Lock Detector

Control 2

Bit Description

7 Set to ‘1’

6 LDCount1. See Table 7

5 Set to ‘1’

4 Set to ‘0’

3 Set to ‘1’

2 Set to ‘0’

1 Set to ‘0’

0 Set to ‘0’

Table 20. Register CR14 (Address 0x0E), TXDIS Control

Bit Description

7 TxDis_LOCLK

0 = LOCLK always running

1 = Stop LOCLK when TxDis = 1

6 TxDis_Diff to Single

0 = D2S always enabled

1 = Disable D2S when TxDis = 1

5 TxDis_attenuator

0 = attenuator always enabled (default)

1 = disable attenuator when TXDIS = 1

4 TxDis_LOBuf

0 = LOBuf always enabled (default)

1 = disable LOBuf when TXDIS = 1

3 TxDis_QuadDiv

0 = QuadDiv always enabled (default)

1 = disable QuadDiv when TXDIS = 1

2 TxDis_VTOI

0 = VTOI always enabled

1 = Disable VTOI when TxDis = 1

1 TxDis_LOX2

0 = LOX2 always enabled (default)

1 = Disable LOX2 when TXDIS = 1

0 TxDis_LOMON

0 = LOMON always enabled (default)

1 = Disable LOMON when TXDIS = 1

Rev. PrD | Page 30 of 43

Page 31

Preliminary Technical Data ADRF6755

Table 21. Register CR23(Address 0x17),Lock Detector Control 1

Bit Description

7 Set to ‘0’

6 Set to ‘1’

5 Set to ‘1’

4 Lock detector enable

0 = lock detector disabled (default)

1 = lock detector enabled

3 Lock detector up/down count, LDCount0

2 Lock detector precision

0 = low, coarse (10 ns)

1 = high, fine (6 ns)

1 Set to ‘0’

0 Set to ‘0’

See Table 7.

Table 22. Register CR24 (Address 0x18), Autocalibration

Bit Description

7 Set to ‘0’

6 Set to ‘0’

5 Set to ‘0’

4 Set to ‘1’

3 Set to ‘1’

2 Set to ‘0’

1 Set to ‘0’

0 Disable autocalibration

0 = enable autocalibration (default)

1 = disable autocalibration

Table 23. Register CR25 (Address 0x19), Autocalibration

Timer

Bit Description

[7:0] Autocalibration timer

Table 24. Register CR27 (Address 0x1B), LO Monitor Output

and LO selection

Bit Description

7 Set to ‘0’

6 Set to ‘0’

5 Set to ‘0’

4 Frequency Range

Set according to Table 6

3 Set to ‘0’

2 Power up LO monitor output

0 = power down (default)

1 = power up

[1:0] Monitor output power into 50 Ω

00 = −24 dBm (default)

01 = −18 dBm

10 = −12 dBm

11 = −6 dBm

Table 25. Register CR28 (Address 0x1C), LO Selection

Bit Description

7 Set to ‘0’

6 Set to ‘0’

5 Set to ‘0’

4 Power Down RFDIVIDER

0 = power up (default)

1 = power down

3 Set to ‘1’

[2:0] RFDIV1

Set according to Table 6

1

Double-buffered. Loaded on the write to Register CR0.

Table 26. Register CR29 (Address 0x1D), Modulator

Bit Description

7 Set to ‘1’

6 Set to ‘0’

5 Set to ‘0’

4 Set to ‘0’

3 Set to ‘0’

2 Set to ‘0’

1 Set to ‘0’

0 Power up modulator

0 = power down (default)

1 = power up

Rev. PrD | Page 31 of 43

Page 32

ADRF6755

Table 27. Register CR30 (Address 0x1E), Attenuator

Bit Description

7 Reserved

6 Attenuator Switch

0 = Switch closed

1 = Switch open

[5:0] Attenuator A5 to Attenuator A0

000000 = 0 dB

000001 = 1 dB

000010 = 2 dB

…

011111 = 31 dB

110000 = 32 dB

110001 = 33 dB

…

111101 = 45 dB

111110 = 46 dB

111111 = 47 dB

Table 28. Register CR33 (Address 0x21), Revision Code1

Bit Description

7 Revision code

6 Revision code

5 Revision code

4 Revision code

3 Revision code

2 Revision code

1 Revision code

0 Revision code

1

Read-only register.

Preliminary Technical Data

Rev. PrD | Page 32 of 43

Page 33

Preliminary Technical Data ADRF6755

SUGGESTED POWER-UP SEQUENCE

INITIAL REGISTER WRITE SEQUENCE

After applying power to the part, perform the initial register write

sequence that follows. Note that Register CR33, Register CR32,

and Register CR31 are read-only registers. Also note that all writable registers should be written to on power-up. Refer to the

Register Map section for more details on all registers.

1. Write Register CR30: 0x00. Set attenuator to 0 dB gain.

2. Write Register CR29: 0x80. Modulator is powered down.

The modulator is powered down by default to ensure that

no spurious signals can occur on the RF output when the

PLL is carrying out its first acquisition. The modulator

should be powered up only when the PLL is locked.

3. Write Register CR28: 0x0X RFDIV depends on the value of

the LO frequency to be used and is set according to Table

6. Note that Register CR28, Bit 3, is set to 1.

4. Write Register CR27: 0xX0. Bit 4 depends on the LO

frequency to be used and is set according to Table 6.

5. Write Register CR26: 0x00. Reserved register.

6. Write Register CR25: 0x64. Autocalibration Timer. This

setting applies for PFD = 40 MHz. For other PFDs, refer to

Equation 3 in the Autocalibration section.

7. Write Register CR24: 0x18. Enable autocalibration.

8. Write Register CR23: 0x70. Enable lock detector and

choose the recommended lock detect timing. This setting

applies to PFD = 40 MHz. For other PFDs, refer to Lock

Detect (LDET) section under Program Modes.

9. Write Register CR22: 0x80. Reserved register.

10. Write Register CR21: 0x00. Reserved register.

11. Write Register CR20: 0x00. Reserved register.

12. Write Register CR19: 0x80. Reserved register.

13. Write Register CR18: 0x00. Reserved register.

14. Write Register CR17: 0x00. Reserved register.

15. Write Register CR16: 0x00. Reserved register.

16. Write Register CR15: 0x00. Reserved register.

17. Write Register CR14: 0x80. Stop LO during TXDIS.

18. Write Register CR13: 0xE8. This setting applies to PFD =

40 MHz. For other PFDs, refer to Lock Detect (LDET)

section under Program Modes.

19. Write Register CR12: 0x18. PLL powered up.

20. Write Register CR11: 0x00. Reserved register.

21. Write Register CR10: Refer to Reference Input Path section.

22. Write Register CR9: 0xF0. With the recommended loop

filter component values and R

= 4.7 kΩ, as shown in

SET

Rev. PrD | Page 33 of 43

Figure 71, the charge pump current is set to 5 mA for

a loop bandwidth of 100 kHz.

23. Write Register CR8: 0x00. Reserved register.

24. Write Register CR7: 0x0X. Set according to Equation 2 in

the Theory of Operation section. Also sets the MUXOUT

pin to tristate.

25. Write Register CR6: 0xXX. Set according to Equation 2 in

the Theory of Operation section.

26. Write Register CR5: Refer to Reference Input Path section.

27. Write Register CR4: 0x01. Reserved register.

28. Write Register CR3: 0000010Xb. Set according to Equation

2 in the Theory of Operation section.

29. Write Register CR2: 0xXX. Set according to Equation 2 in

the Theory of Operation section.

30. Write Register CR1: 0xXX. Set according to Equation 2 in

the Theory of Operation section.

31. Write Register CR0: 0xXX. Set according to Equation 2 in

the Theory of Operation section. Register CR0 must be the

last register written for all the double-buffered bit writes to

take effect.

32. Write to CR27 setting CR27, Bit 4, according to Table 6.

33. Monitor the LDET output or wait 170 µs to ensure that the

PLL is locked.

34. Write Register CR29: 0x81. Power up modulator. The write

to Register CR29 does not need to be followed by a write to

Register CR0 because this register is not double-buffered.

Example—Changing the LO Frequency

Following is an example of how to change the LO frequency

after the initialization sequence. Using an example in which

the PLL is locked to 2000 MHz, the following conditions apply:

f

Divide ratio N = 100, so INT = 100 decimal and FRAC = 0

RFDIVIDER = divider-by-1. See Table 6.

Register CR28[2:0] = 000b

Register CR27[4] = 1b

The INT registers contain the following values:

Register CR7 = 0x00 and Register CR6 = 0x64

The FRAC registers contain the following values:

Register CR3 = 0x08, Register CR2 = 0x00,

Register CR1 = 0x00, and Register CR0 = 0x00