Page 1

4 Channel High Current LED Driver with

Preliminary Technical Data

FEATURES

Highly integrated feature set gives a high brightness LED

driver solution with minimal external components.

Four current sink channels with adjustable currents from 0 to

500 mA.

DC LED dimming for noiseless operation.

2% (max) matching between LED channels.

5% (max) LED current accuracy.

Operates from Vin of 7.5 V to 30 V. Higher voltages easily

accomplished with small external circuit.

Operates with LED anode supply voltages up to 100 Vdc.

Feedback output controls external power source for optimal

efficiency and safety.

Multiple ADP8140 ICs can be operated in parallel and control

one power supply.

Secondary side control of isolated power supplies without

need of a TL431.

Dedicated DIM pin for output current reduction.

Easy connection of a temperature thermister or light sensor.

Provides robust protection of the entire system:

- Power supply overvoltage protection

- LED Over temperature protection

- LED Short protection

- LED Open protection

- IC Over temperature protection

- Shorted ISET protection

- Open ISET and EN protection

Standby mode for low current consumption

Fault indicator output

Available in a thermally enhanced LFCSP package (4x4 mm)

GENERAL DESCRIPTION

The ADP8140 provides high current control of up to four LED

drivers. Each driver can sink up to 500 mA. The sink current

is programmed for all four drivers with one external resistor.

The device features a feedback output which controls an

external power supply for optimal efficiency. The ADP8140

also protects the LEDs, power supply, and itself against thermal

Adaptable Power Control

ADP8140

APPLICATIONS

High brightness LED lighting

Large format LED backlighting

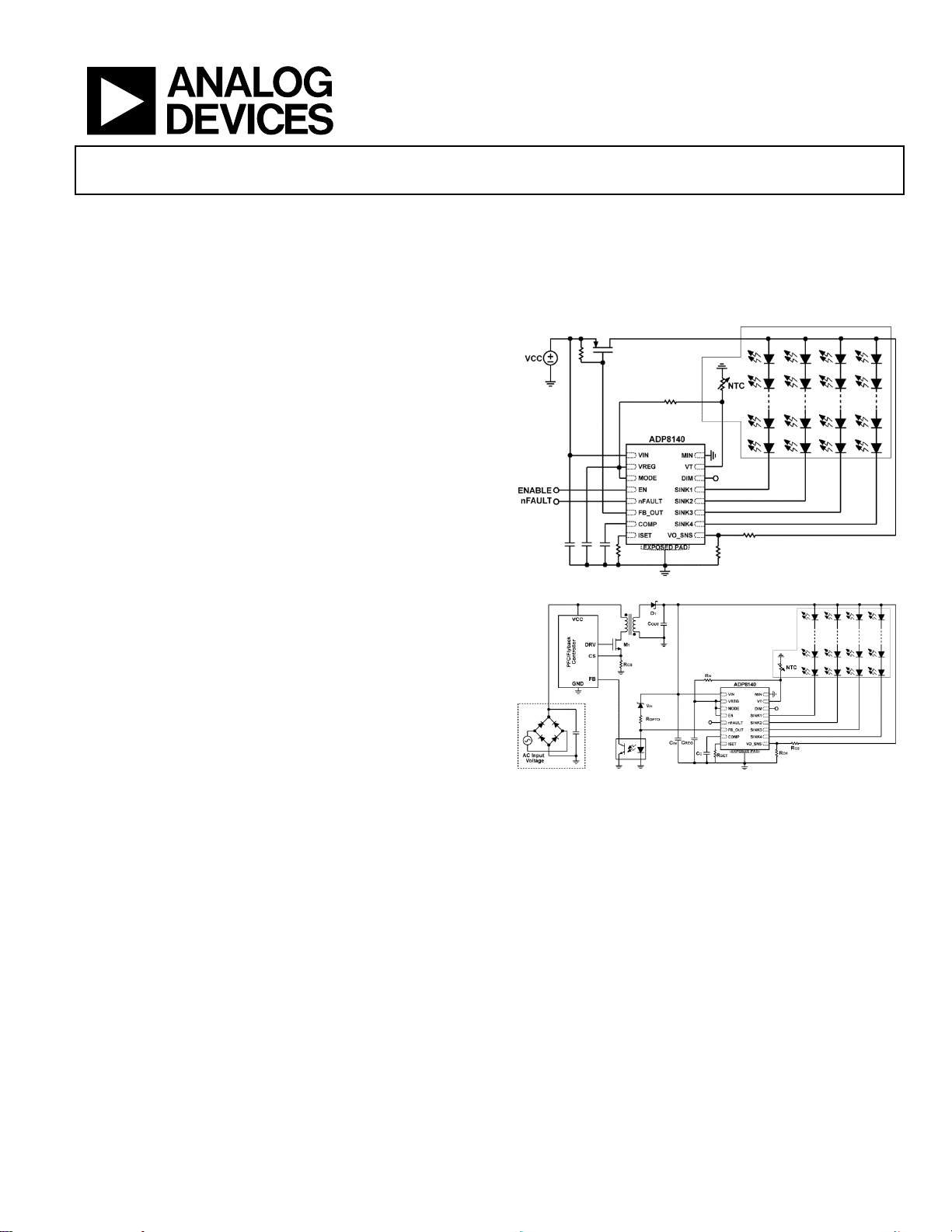

TYPICAL OPERATING CIRCUITS

Figure 1. ADP8140 used with Shunt Regulator

Figure 2. ADP8140 used as Secondary Side Controller

events, short circuits, overvoltages, and LED open circuits.

Multiple ADP8140 ICs are easily connected in parallel to drive

additional LED strings, or higher current LEDs. The ADP8140

is available in a small, thermally enhanced, LFCSP (lead frame

chip scale package).

Rev. PrA

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 © 2012 Analog Devices, Inc. All rights reserved.

Page 2

ADP8140 Preliminary Technical Data

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Typical Operating CircuitS .............................................................. 1

General Description ......................................................................... 1

Revision History .......................... Error! Bookmark not defined.

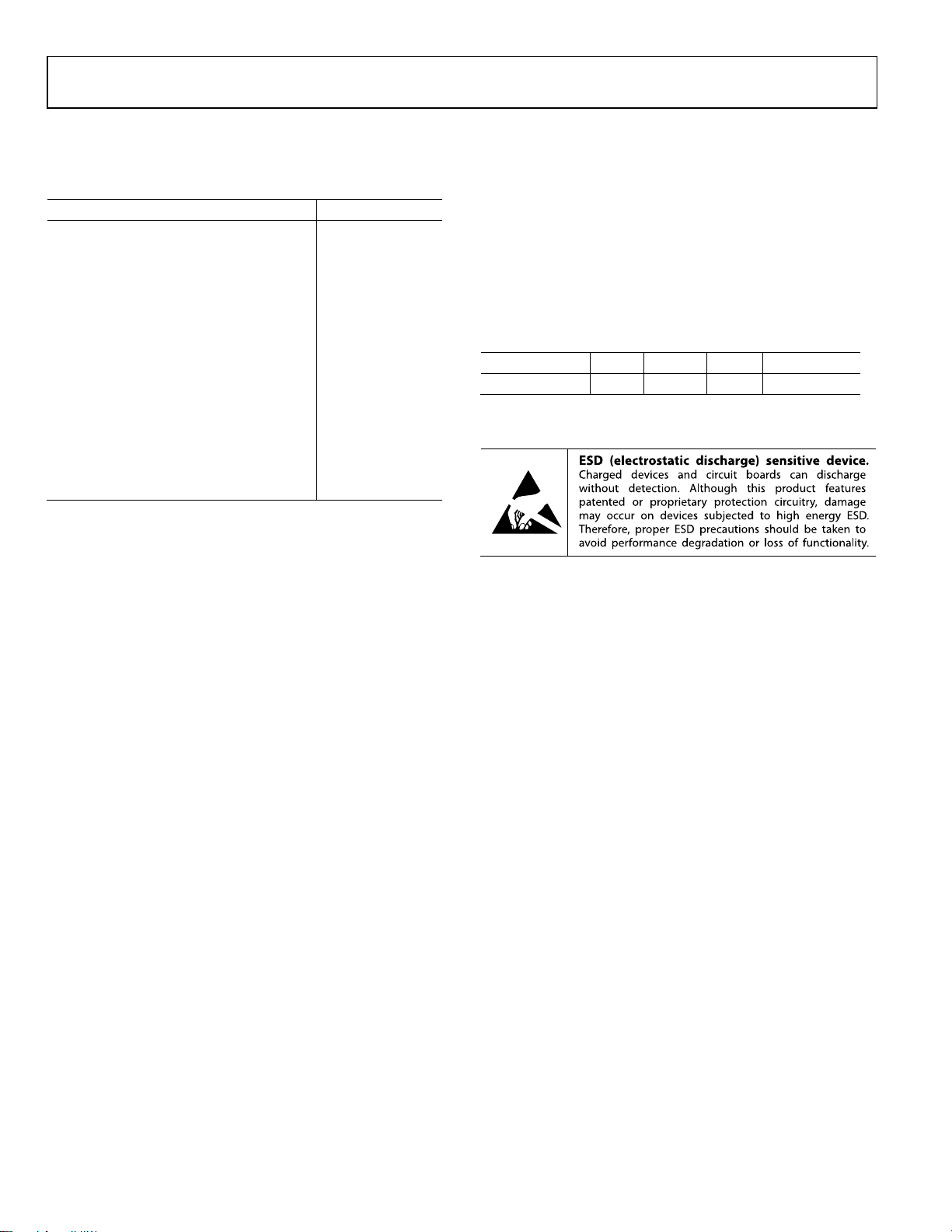

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 6

Maximum Temperature Ranges ................................................. 6

Thermal Resistance ...................................................................... 6

ESD Caution .................................................................................. 6

Pin Configurations and Function Descriptions ........................... 7

Theory of Operation ........................................................................ 8

Current Sinks ................................................................................ 9

Power Control Operation ............................................................ 9

MODE Pin Operation .................................................................. 9

Error Amplifier Power Control .................................................. 9

Low gain Buffer Power Control .................................................. 9

Using Multiple ADP8140 ICs ................................................... 10

Reducing the LED Current with the DIM Pin ....................... 10

Implementing LED Thermal Protection ................................. 10

Effect of LED Vf Mismatch ....................................................... 11

Managing the ADP8140’s Power Dissipation ......................... 12

ADP8140 Fault Protections ...................................................... 13

Startup Sequence ........................................................................ 13

Die Temperature Protection ..................................................... 14

Overvoltage Protection .............................................................. 14

Operating the ADP8140 From Higher Input Voltages ......... 14

Layout Guidelines....................................................................... 15

ADP8140 + 24 Vdc Input .......................................................... 16

ADP8140 Secondary Side Control Design example .............. 16

ADP8140 and 24Vdc Rail Design Example ............................ 17

Multiple ADP8140s With a 24Vdc Rail Design Example ..... 17

Outline Dimensions ....................................................................... 18

Ordering Guide ............................................................................... 18

Rev. PrA | Page 2 of 18

Page 3

ADP8140 Preliminary Technical Data

SPECIFICATIONS

VIN = 12 V, EN=3.0V. Typical values are at TJ = 25°C and are not guaranteed. Minimum and maximum limits are guaranteed from TJ =

−40°C to +125°C, unless otherwise noted.

Table 1.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

SUPPLY

Input Voltage

Operating Range VIN 7.5 30.0 V

Undervoltage Lockout V

UVLO Hysteresis V

Quiescent Current IQ

During Standby I

During Operation I

During Operation I

During Operation I

REG Output

REG Output Voltage VREG VIN=7.5, 12, 24 V, IREG=1 mA 2.85 3.0 3.15 V

REG Source Current IREG VIN=7.5, 12, 24 V 15 mA

REG Load Regulation VREG1 VIN=7.5, 12, 24 V, IREG=0.1 mA to 15

FEEDBACK OUTPUT

FB_OUT EA Accuracy VEA 430 450 470 mV

FB_OUT NMOS Pulldown FB_PD SINKx=0V, FB_OUT = 5.0V 12.0 15.0 18.0 mA

FB_OUT Fault Current FB_FC Fault activated, FB_OUT = 3.0 V. TBD 1 µA

Amplifier transconductance COMPgm TBD 50 TBD µmho

Transconductance amplifier

output sink/source current

Transconductance amplifier

output sink/source current

Transconductance amplifier

output resistance

Low gain EA Gbuff Gain in buffer mode

Low gain BW Low gain buffer mode 100 kHz

ISET

ISET Accuracy 500mA ILED

ISET Accuracy 350mA ILED

ISET Accuracy 100mA ILED

ISET shorted current ISET = GND TBD 570 TBD mA

ISET open current ISET = OPEN 13 TBD mA

CURRENT SINKS

Current sink headroom

voltage at max current

Sink matching at max current I

7.3 7.5 V

UVLO

150 mV

UVLO_HYS

EN = 0 V, all SINKx Zener clamps and

Q(STBY)

TBD 250 A

VREG remain active, IREG=0µA

EN = 3 V, VIN=7.5 V TBD 8.0 mA

Q(ACTIVE1)

EN = 3 V, VIN=12 V TBD 8.0 mA

Q(ACTIVE2)

EN = 3 V, VIN=28 V TBD 8.0 mA

Q(ACTIVE3)

TBD TBD V/mA

mA

COMP

COMP

COMP pin output source current TBD 500 TBD µA

SOURCE

COMP pin output sink current TBD 2.0 TBD mA

SINK

COMPRO 20 MΩ

-5% 4.0 +5%

Gbuff=Vcomp/MIN(Vsinkx)

RSET=5.11 kΩ, SINK

500

RSET=7.32 kΩ, SINK

350

RSET=25.5 kΩ, SINK

100

V

ILED = 95% * ILED

HR_500

Matching = (MAX ISINK – MIN

MATCH1

=450mV -5% 500 +5% mA

1:4

=450mV -5% 350 +5% mA

1:4

=450mV -5% 100 +5% mA

1:4

VEA

500

mV

MIN

TBD 2 %

ISINK)/(MAX ISINK + MIN ISINK)*100

Rev. PrA | Page 3 of 18

Page 4

ADP8140 Preliminary Technical Data

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

Sink matching at mid current I

SINKx leakage current I

Channel Overvoltage

Threshold

Channel Overvoltage

Hysteresis

Channel Clamp (low) Current

Channel Clamp (high)

Threshold

Channel Clamp (high)

Hysteresis

Channel Clamp (high)

Current

INPUT CONTROLS

Input Threshold (low) VIL EN 0.5 V

Input Threshold (high) VIH EN 1.2 V

EN input resistance REN EN=1.2 V 400 k Ω

Mode pin pullup current IM 0V<Vmode<Vreg 18 20 22 µA

Mode Threshold 1 30.1k VM1 Threshold for increasing mode voltage

Mode Threshold 2 49.9k VM2 Threshold for increasing mode voltage

Mode Threshold 3 VM3 Threshold for increasing mode voltage

LED Scaling Controls

DIM and VT limit voltage VT

Dimming Accuracy VT = 1 V, ILED=350 mA.

DIM pin Frequency Range 140 Hz 40 kHz

MIN comparator hysteresis VMIN

THERMAL FOLDBACK (internal)

Thermal Foldback Threshold TFB

Thermal Shutdown

Hysteresis

FAU LT D ETEC T I O N

Fault Threshold FAULT

VO_SNS Hysteresis VOSNS

Fault Threshold FAULT

Fault Hysteresis FAULT

Fault Filter t

V

bias current I

O_SNS

Matching = (MAX ISINK – MIN

MATCH2

TBD 2 %

ISINK)/(MAX ISINK + MIN ISINK)*100

SINKx pin = 4V. 100 TBD µA

SINK(LKG)

CH

Threshold on SINKx to trigger CH_OVP

CLMP_LO

TBD 5.5 TBD V

fault and Channel Clamp (low)

CH

I

CLMP_LO

CH

Hysteresis after CH

CLMP_HYS

is triggered. TBD 1.0 TBD V

CLMP_LO

Channel pulldown current when

SINKx> CH

Threshold on SINKx to trigger Channel

CLMP_HI

CLMP_LO

-20% ISET +20% mA

13.5 15.0 16.5 V

Clamp (high)

CH

I

CLMP_HI

Hysteresis after CH

CLMP_HYS

is triggered. TBD 2.8 TBD V

CLMP_HI

Channel pulldown current when

SINKx> CH

CLMP_HI

-20% 510 +20% mA

TBD 0.45 TBD V

to enter DC Buffer operation.

TBD 0.75 TBD V

to enter PWM Buffer operation.

TBD 1.25 TBD V

to enter PWM EA operation.

VT (and DIM if MODE=GND) voltage to

LIMIT

TBD 2.0 TBD V

produce 100% Iout

TBD 175 TBD mA

DIM=1V, MODE=GND, ILED=350mA.

DIM=50%, 32kHz, MODE=VREG.

70 mV

HYS

TBD 130 TBD °C

THRES

TSD

TBD 20 TBD °C

HYS

Threshold for VO_SNS comparator -2% 1.2 +2% V

THRESH

Hysteresis for VO_SNS comparator 50 mV

HYS

Threshold for nFAULT comparator -5% 1.2 +5% V

THRESH

Hysteresis for nFAULT comparator 100 mV

HYS

Vo_sns and nFAULT shutdown noise

FAULT

10 Us

filter

0 TBD µA

VOSNS

Rev. PrA | Page 4 of 18

Page 5

ADP8140 Preliminary Technical Data

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

nFAULT pulldown nFAULTPD Fault activated, nFAULT=0.5V TBD 3.0 TBD mA

SINK Fault Threshold SFD

Threshold to remove a sink from the

THRESH

FB loop after a CH_OVP or VOUT_OVP

fault

TBD 75 100 mV

Rev. PrA | Page 5 of 18

Page 6

ADP8140 Preliminary Technical Data

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VIN, FB_OUT to GND −0.3 V to +31 V

SINK1,2,3,4 to GND −0.3 V to +21 V

VREG, COMP, ISET, VMIN to GND −0.3 V to +3.6 V

DIM, VT to GND −0.3 V to +5.0 V

All other pins to GND −0.3 V to +6.0 V

Operating Ambient Temperature Range –40°C to +105°C1

Operating Junction Temperature Range –40°C to +125°C

Maximum Junction Temperature 150°C

Storage Temperature Range –45°C to +150°C

Soldering Conditions JEDEC J-STD-020

ESD (Electrostatic Discharge)

Human Body Model (HBM) ± 2.0 kV

Machine Model (MM) ± TBD V

Charged Device Model (CDM) ± TBD kV

1

The maximum operating junction temperature (T

maximum operating ambient temperature (T

Temperature Ranges section for more information.

) supersedes the

J(MAX)

). See the Maximum

A(MAX)

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Absolute maximum ratings apply individually only, not in

combination. Unless otherwise specified, all voltages are

referenced to GND.

THERMAL RESISTANCE

θJA (junction to air) is specified for the worst-case conditions,

that is, a device soldered in a circuit board for surface-mount

packages. The θ

and θJC (junction to case) are determined

JA

according to JESD51-9 on a 4-layer printed circuit board (PCB)

with natural convection cooling. The LFCSP exposed pad must

be soldered to GND.

Table 3. Thermal Resistance

Package Type θJA θJB θ

Unit

JC

LFCSP 33.2 12.4 2.4 °C/W

ESD CAUTION

MAXIMUM TEMPERATURE RANGES

The maximum operating junction temperature (T

supersedes the maximum operating ambient temperature

(T

). Therefore, in situations where the ADP8866 is

A(MAX)

exposed to poor thermal resistance and a high power

dissipation (P

), the maximum ambient temperature may need

D

to be derated. In these cases, the ambient temperature

maximum can be calculated with the following equation:

T

A(MAX)

= T

J(MAX)

− (θJA × P

D(MAX)

).

J(MAX)

)

Rev. PrA | Page 6 of 18

Page 7

ADP8140 Preliminary Technical Data

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

Figure 3. LFCSP Pin Configuration

Table 4. Pin Function Descriptions

Pin

Mnemonic Description

No.

1 Vin Supply voltage input (7.5 V to 30 V).

2 VREG Regulated 3.0 V (typ) source. Connect a 2.2 uF capacitor from REG to ground.

3 MODE If MODE = GND, then then the part is placed into DC EA operation.

If MODE=VREG, then the part is placed into PWM EA operation.

If MODE=30.1 kΩ resistor to GND, then the part is placed into DC Low Gain Buffer operation.

If MODE=49.9 kΩ resistor to GND, then the part is placed into PWM Low Gain Buffer operation.

Never leave the MODE pin floating. See the MODE Section for more information.

4 EN Enable input. Pull high (above V

(typical) resistor.

5 nFAULT Fault output. This pin must be connected to an external pullup resistor. If using multiple ADP8140

ICs in parallel, all the nFAULT pins must be connected together.

6 FB_OUT Control signal for external power stage. The action of this pin depends on the MODE setting.

7 COMP Control signal for external power stage. The action of this pin depends on the MODE setting.

8 ISET Connect a resistor to ground to set the output current. If left floating, the current sinks are set to 14

mA.

9 VO_SNS Power stage output voltage sensing input. Connect this pin through a resistor divider to the top of

the LED strings.

10 SINK4 Current sink for LED channel 4.

11 SINK3 Current sink for LED channel 3.

12 SINK2 Current sink for LED channel 2.

13 SINK1 Current sink for LED channel 1.

14 DIM DIM input. This pin takes a PWM or DC voltage and reduces or PWM’s the output current. The

action of this pin depends on the MODE setting.

15 VT Analog current reduction pin. Typically connected to a thermister to reduce the LED output current

as the temperature increases.

16 MIN Sets the minimum voltage threshold for the VT pin. VT voltages below the MIN voltage will turn the

LEDs off

EPAD GND Ground. Connect the exposed paddle of the LFCSP to GND.

) to enable the part. EN is internally pulled low with a 400 kΩ

IH(MIN)

Rev. PrA | Page 7 of 18

Page 8

ADP8140 Preliminary Technical Data

THEORY OF OPERATION

The ADP8140 provides high current control of up to four LED

channels. Each driver can sink up to 500 mA. One external

resistor programs the sink current for all four channels. The

device features a feedback output that controls an external

power supply for optimal efficiency. The ADP8140 also

protects the LEDs, power supply, and itself against thermal

events, short circuits, and LED open circuits. Multiple

ADP8140 ICs are easily connected in parallel to drive additional

LED strings, or higher current LEDs.

Figure 4. Detailed Block Diagram

Rev. PrA | Page 8 of 18

Page 9

ADP8140 Preliminary Technical Data

CURRENT SINKS

The ADP8140 contains four internal current sinks. Each

current sink is capable of delivering 0-500 mA. To ensure

accurate regulation the voltage on the current sinks must be

greater than their maximum headroom voltage given in Table 1.

This headroom voltage varies somewhat with input voltage and

LED output current. The current is set with an external

resistor, Rset, using the following equation:

RsetkΩ

Several sinks can be combined together for higher currents per

string. For example, two sinks can be shorted together to give 2

strings, each at 1 A. Or four sinks combined to give one string

at up to 2.0 A.

Each current sink has a maximum rated voltage of 20V.

However, the maximum output voltage driving all the current

sinks, through the LEDs, is allowed to exceed 20 V. Therefore,

the ADP8140 can be safely used in conjunction with power

supplies that produce over 100 V for their output. An example

is provided at the end of this document.

(eq 1)

indicates that less power is required for the LEDs. This

operation makes the FB_OUT ideal for any power control

application that does not normally have an error amplifier. The

two primary applications for this are:

1. Controlling an optocoupler on the secondary side of

an isolated power supply

2. Controlling a PMOS transistor to regulate power in a

fixed output voltage supply.

POWER CONTROL OPERATION

The ADP8140 controls a power stage with its COMP and

FB_OUT pins. This allows the IC to optimize the efficiency

and protection of the LEDs. There are two power control

modes that the ADP8140 operates in: Error Amplifier and Low

Gain Buffer. The MODE pin is used to select the power control

mode.

MODE PIN OPERATION

The MODE pin is used to set one of four possible modes of

operation. The condition of the MODE pin effects the DIM pin

input (see “Reducing the LED Current with the DIM” Pin

section) and the power mode (see “Power Control Operation”)

MODE DIM Pin Mode Power Control

GND

30.1 k to GND

49.9 k to GND

VREG

Analog Voltage Error Amplifier

Analog Voltage Low Gain Buffer

PWM Signal Low Gain Buffer

PWM Signal Error Amplifier

ERROR AMPLIFIER POWER CONTROL

In the Error Amplifier Power Control mode, the ADP8140

takes the minimum voltage of the 4 current sinks and applies it

to the inverting input of an internal error amplifier. The output

of this error amplifier connects to the FB_OUT inverting buffer.

The FB_OUT pin outputs a current which indicates power

control. A higher FB_OUT sink current indicates that more

power is required to the LEDs. A lower FB_OUT sink current

Rev. PrA | Page 9 of 18

Figure 5. Error Amplifier Power Control

Depending on the power stage used, an RC network will need

to be connected to the COMP pin. The COMP pin connects to

the output of the FB_OUT transconductance amplifier. The

gain of this amplifier is:

∙∙

1∙∙

1∙∙

Placing a capacitor from COMP to ground adds a pole to the

control loop according to:

2∙∙

1

Placing a resistor in series with that capacitor adds a pole and a

zero.

2∙∙

1

where COMP

and COMPgm are given in Table 1

RO

General values and configurations are available for most setups

using the Error Amplifier power control can be seen in the

Applications section of this document.

LOW GAIN BUFFER POWER CONTROL

In the Low Gain Buffer Power Control mode, the ADP8140

takes the minimum voltage of the 4 current sinks, multiplies

that by Gbuff (4.0 typ, see Table 1) and outputs it to the COMP

pin. The COMP pin can then be connected to the input of a

switched mode power supply controller (SMPS). This mode is

Page 10

ADP8140 Preliminary Technical Data

useful for connecting the ADP8140 to power stages that already

have their own error amplifier. The bandwidth of the low gain

buffer is 100kHz (typ), therefore the SMPS IC’s compensation

should be set to give a total loop crossover frequency below this.

Figure 6. Low Gain Buffer Power Control

A voltage of 4.0 * 0.45 V = 1.8V will appear on the COMP pin

when the system is in steady state operation. This 1.8V must be

divided down to match the error amplifier reference of the

SMPS IC. Typically this reference is 1.2 V or 600mV.

In this mode, it is important to connect the nFAULT pin to the

EN of the SMPS IC. This will ensure that the power delivery is

immediately shutdown in the event of a fault. The FB_OUT pin

can be left floating or connected to GND. It should not be tied

to COMP or any other pin.

General values and configurations are available for most setups

using the Low Gain Buffer power control can be seen in the

Applications section of this document.

USING MULTIPLE ADP8140 ICS

Multiple ADP8140 ICs can be combined in parallel to control

the same supply. This is advantageous to control more than 4

strings of LEDs or to drive higher currents. For example, using

two ADP8140 ICs, four LED strings can be driven at 1000 mA

each. Or two strings can be driven at 2.0 A each.

When using multiple ADP8140 ICs in parallel to control one

power supply, all of the nFAULT pins must be connected

together. If any nFAULT pin goes low, all ADP8140 ICs

respond to the event. Most applications will work best if the EN

and DIM pins are also connected amongst the ADP8140 ICs,

though it is not required. The VT pins may also be connected

together, or separate NTC sensors can be used for each

ADP8140.

REDUCING THE LED CURRENT WITH THE DIM PIN

The DIM pin can reduce the output current with either an

analog voltage or a PWM signal. The ADP8140’s response to

the DIM pin depends on the condition of the MODE pin.

If MODE pin voltage is below 0.7V, then the DIM pin

functions as an analog voltage input. A DIM voltage of 2V, or

greater, does not impact the output current. A DIM voltage of

0V, reduces the output current to 0 mA. Any DIM voltage

between 2V and 0V will linearly scale the output current.

Figure 8. Reducing the output current by applying an analog voltage to the

DIM pin.

If MODE is set to a voltage greater than 0.7V, then a PWM

duty cycle applied to the DIM pin is internally filtered and used

to scale the output currents.

Figure 7. Multiple ADP8140 ICs powered off of one supply (Low Gain Buffer

Control shown).

Rev. PrA | Page 10 of 18

Figure 9. Reducing the average output current by pulse width modulating

the current sinks with the DIM pin.

IMPLEMENTING LED THERMAL PROTECTION

The ADP8140 controller has a VT pin which can be connected

to an external NTC (negative temperature coefficient) resistor.

This NTC is typically placed on the LED heat sink. Selecting

the value of the NTC and the resistor in the network shapes the

slope of the VT voltage in response to the LED temperature.

VT voltages above 2V produce no reduction in output current.

Page 11

ADP8140 Preliminary Technical Data

Below 2V, the output current is reduced 1% per 20 mV. The

LED channels are set to 0 mA when the voltage on the VT pin

is below the voltage on the MIN pin. If the VT pin voltage rises

above the MIN threshold, plus some hysteresis, then the

current sinks are re-enabled at their current set by the VT pin.

Figure 10. Using an external NTC to implement LED thermal protection.

In place of an NTC resistor, a light sensor can be used on the

VT pin. This will dim or brighten the LEDs in response to the

lighting conditions.

temperature should be relatively consistent. Given a Vf

distribution, the maximum voltage that will appear on any of

the SINK pins can be statistically calculated. For example,

suppose a mean Vf of 3.5 V and a normal distribution with a

standard deviation of 70 mV (This gives a Vf spread of 3.2 to

3.8 V -- much larger than is normally seen within one lot of

LEDs). A statistical analysis of such a distribution reveals the

following graph of the maximum voltage that may appear on

any of the SINK pins:

Figure 12. Statistical analysis of the voltage on the SINKx Pins given a

normal distribution of Vfs with a standard deviation of 70 mV . Note, the Max

value is the average plus 6 standard deviations of the distribution.

Figure 11. Using a light sensor to dim the LEDs with increasing light

intensity.

EFFECT OF LED VF MISMATCH

The forward voltage (Vf) of each LED varies from unit to unit.

In general, LEDs within the same wafer lot will have a normal

distribution with a standard deviation of about 20 mV. The

electrical specification for Vf given in the LED’s datasheet will

always be much wider than this. It is sometimes necessary to

consult the LED’s manufacturer directly for a more realistic

gauge of the Vf’s variation. Using the information on the Vf

variation, we can calculate two very important parameters in

any multi string LED design:

1. The maximum current sink voltage

2. The maximum current sink power dissipation

The ADP8140 always controls the FB_OUT pin to regulate the

output voltage to provide the minimum amount of headroom

voltage on the current sinks. One of the current sinks will be

regulated to V

three SINK pins will vary based on the distribution of Vfs. For

a given lot of LEDs, the Vf and the change in Vf with

(typ 450 mV). The voltage seen on the other

REFEA

Note that even with 30 LEDs per channel, the average and

maximum (average plus six standard deviations) SINKx

voltages remain relatively small. The value is well below the

ADP8140’s threshold for shorted LED protection (see the

Channel OVP information in the Overvoltage Protection

section below).

The second item impacted by the LED Vf variation, the

maximum current sink power dissipation, derives directly from

the voltages present at each current sink. Specifically, the

ADP8140’s power dissipation can be represented as:

Pdiss = (V

SINK1

+ V

SINK2

+ V

SINK3

+ V

SINK4

) * ILED

Again, a statistical analysis based on the LED’s Vf distribution

can be performed to predict the total power dissipation within

the ADP8140. For the same distribution used above and an

LED current of 350 mA, the following graph gives the average

and maximum power dissipations:

Rev. PrA | Page 11 of 18

Page 12

ADP8140 Preliminary Technical Data

Figure 13. Statistical analysis of the total (all 4 strings) power dissipation

for a normal distribution of Vfs with a standard deviation of 70 mV and an

LED current of 350 mA . Note, the Max value is the average plus 6 standard

MANAGING THE ADP8140’S POWER DISSIPATION

Now that the predicted power dissipation is known, the next

step is to determine if the ADP8140’s package is able to

adequately dissipate that power. The maximum power that the

ADP8140 is able to dissipate is found by following this

procedure:

Maximum ADP8140 Tj (before entering thermal foldback) =

130°C

Maximum Board Temperature = 85°C

Psi_Jb = 12.4 °C/W (Given in Table TBD)

Assume 100% of the power dissipates through the exposed pad

to the board.

Max Pdiss = (Tj – Tboard) / Psi_Jb

= (130 – 85) / 12.4 = 3.6 W

For high power dissipations (Pdiss) it is imperative to follow

the layout guidelines given in the Layout Guidelines section.

deviations of the distribution.

Rev. PrA | Page 12 of 18

Page 13

ADP8140 Preliminary Technical Data

ADP8140 FAULT PROTECTIONS

To ensure the safety of the LEDs, the ADP8140 IC, and the

power source, the ADP8140 includes a comprehensive array of

detection and protection features. These include:

- Power supply overvoltage protection

- LED Over temperature protection

- LED Short protection

- LED Open protection

- IC Over temperature protection

- Shorted ISET protection

- Open ISET and EN protection

The features are summarized on the flow chart of Figure 14.

Figure 14. ADP8140 Fault Flow Chart

STARTUP SEQUENCE

To start the ADP8140 VIN must be applied in excess of the

UVLO threshold and the EN pin must be high. However, even

with EN low, the VREG pin produces a constant 3.0V on its

output. VREG can be used as a low current supply, as needed.

Rev. PrA | Page 13 of 18

In this operation, with EN low, the ADP8140 consumes no

more than 250 μA.

When EN also goes high, then the sinks startup. There is an 8

ms delay, a time necessary for the DIM mode to determine the

PWM state of its input. When the sinks are enabled, the

Page 14

ADP8140 Preliminary Technical Data

nFAULT pin is released and the COMP and FB_OUT pins

begin their normal regulation. When EN goes low, the SINK

pins are left on for another 100us to bleed off any voltage from

the power stage. The part then enters low current consumption

operation.

Figure 15. Startup timing and signals

DIE TEMPERATURE PROTECTION

As explained above, a higher voltage on the ADP8140’s sink

pins creates a higher power dissipation within the ADP8140. If

this increase in power dissipation causes the die temperature on

the ADP8140 to rise above 130°C (typ), then the IC

automatically begins to reduce the output current on all four

sinks. If the die temperature continues to rise, then the

ADP8140 shuts down all the current sinks and releases the

pulldown on the FB_OUT pin. When the temperature drops

below 130°C, the ADP8140 restarts. If the fault or high power

dissipation persists, then the sequence repeats.

OVERVOLTAGE PROTECTION

An LED open circuit can result from a bad solder connection

or damaged LED. An open LED string results in the current

sink headroom falling to a very low level. The feedback loop

naturally interprets this as a request for more power, and so the

FB_OUT current is increased. This can quickly lead to a case

where the output voltage is too high. This increase in output

voltage is detected by either the VO_SNS pin or the SINKx

pins.

The VO_SNS pin senses the output voltage of the power supply

through an external resistor divider. VO_SNS is then

compared to an internal threshold (1.2 V typical). If the

output voltage rises such that the VO_SNS pin is greater than

1.2 V, then an output overvoltage fault (VOUT_OVP) is

declared. During a VOUT_OVP fault, the FB_OUT pulldown

NMOS is released, causing the power stage to shutdown. The

LED current sinks are left enabled during this event. When

VO_SNS drops to 1.15 V (typical), the FB_OUT function

resumes its normal operation.

Alternatively, the output voltage may not rise high enough to

trigger VO_SNS, but it may rise high enough to cause one of

the SINKx pins to exceed 5.0V (typical). Or a shorted LED may

cause the SINKx pins to exceed this level. To prevent excessive

power dissipation and damage to the IC, when a SINKx pin

rises above 5.0 V, a channel over voltage (CH_OVP) fault is

declared. During a CH_OVP fault, the FB_OUT pulldown

NMOS is released, causing the power stage to shutdown. The

LED current sinks are left enabled during this event. When the

SINKx voltage drops to 5.0 V (typical), the FB_OUT function

resumes its normal operation.

Continued output overvoltage operation degrades efficiency

and can affect the lifetime of passive components. Therefore,

when an overvoltage condition is detected (either VOUT_OVP

or CH_OVP), then any open LED current sinks are identified

and removed from the feedback loop.

During a VOUT_OVP or CH_OVP event, the nFAULT pin is

pulled low. nFAULT is released high when the overvoltage

condition has ended.

OPERATING THE ADP8140 FROM HIGHER INPUT

VOLTAGES

The ADP8140 is capable of operating from an input voltage

(Vin) range of 7.5 to 30 V. However, higher voltages can be

used to power the ADP8140, as long as an appropriate current

limiting circuit is used.

It is sometimes sufficient to limit the voltage on VIN by placing

a Zener diode on VIN and limiting the current with a resistor

from the input voltage to the VIN pin. This method could be

used if standby power dissipation is not an issue.

Alternatively, if the supply voltage range is small, an additional

Zener between the supply and VIN will shift the voltage at the

VIN pin below 30 V. This method adds minimal power

dissipation in both standby and active modes.

However, a more robust voltage limiter uses a Zener, an NPN,

and two resistors. This simple circuit gives the required

operating Iq during normal operation, but also reduces the

standby current when the ADP8140 is disabled. The circuit is

shown in Figure 16.

Rev. PrA | Page 14 of 18

Page 15

ADP8140 Preliminary Technical Data

RLIM limits the maximum current during transients. A value

of a few hundred ohms is sufficient. When the ADP8140 is

active, the additional, worst case, power dissipation from this

limit circuitry is given by:

Figure 16. VIN current limiting circuit for high input voltages

VZ is selected to be below the minimum value of the ADP8140’s

active VIN clamp (given in Table 1). The VIN voltage will be

regulated to V

– 0.7 V. The resistor, RZ, should be selected to

Z

limit the current when the ADP8140 is disabled, yet still

provide enough current to reverse bias the Zener and drive the

NPN when the ADP8140 is active. The current through R

is

Z

given by:

IRZ = (Vcc – VZ) / RZ

A value of 100 μA at the minimum expected Vcc is generally

sufficient. Even at maximum Vcc, this will only contribute a

few mW of power dissipation during standby.

∆

0.7∙

48 24 0.7∙374

LAYOUT GUIDELINES

1. The exposed pad of the ADP8140 must be properly

connected to a heat sink. This includes soldered to the board

and connected to a large plane of ground metal with an array of

thermal vias.

2. The ADP8140 has been designed for easy layout with single

sided metal core substrates. If FR4 substrate used, thermal vias

must be used between the LFCSP exposed pad and a large

ground trace on the opposite side of the board.

Rev. PrA | Page 15 of 18

Page 16

ADP8140 Preliminary Technical Data

ADP8140 + 24 VDC INPUT

Figure 17.

ADP8140 SECONDARY SIDE CONTROL DESIGN EXAMPLE

Figure 18.

Rev. PrA | Page 16 of 18

Page 17

ADP8140 Preliminary Technical Data

ADP8140 AND 24VDC RAIL DESIGN EXAMPLE

Figure 19.

MULTIPLE ADP8140S WITH A 24VDC RAIL DESIGN EXAMPLE

Figure 20.

Rev. PrA | Page 17 of 18

Page 18

ADP8140 Preliminary Technical Data

OUTLINE DIMENSIONS

Figure 21. Lead Frame Chip Scale Package (LFCSP)

ORDERING GUIDE

Model1 Temperature Range Package Description Package Option

ADP8140ACPZ_TBD -40 to +125°C LFCSP, Tape and Reel LFCSP

1

Z = RoHS Compliant Part.

©

2012

Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

PR10935-0-7/12(PrA)

Rev. PrA | Page 18 of 18

Loading...

Loading...