Page 1

Power Management Unit

VIN2

V

V

FEATURES

Input voltage range: 2.4 V to 5.5 V

Low standby current: 1 μA

Switching frequency: 3 MHz

2

I

C interface

Synchronous Buck 1 regulator: 600 mA

Synchronous Buck 2 regulator: 250 mA

Low dropout regulator (LDO): 150 mA

Internal compensation

Internal soft start

Thermal shutdown

20-lead 4 mm × 4 mm LFCSP

APPLICATIONS

Digital cameras, handsets

Mobile TVs

for Imaging Modules

ADP5020

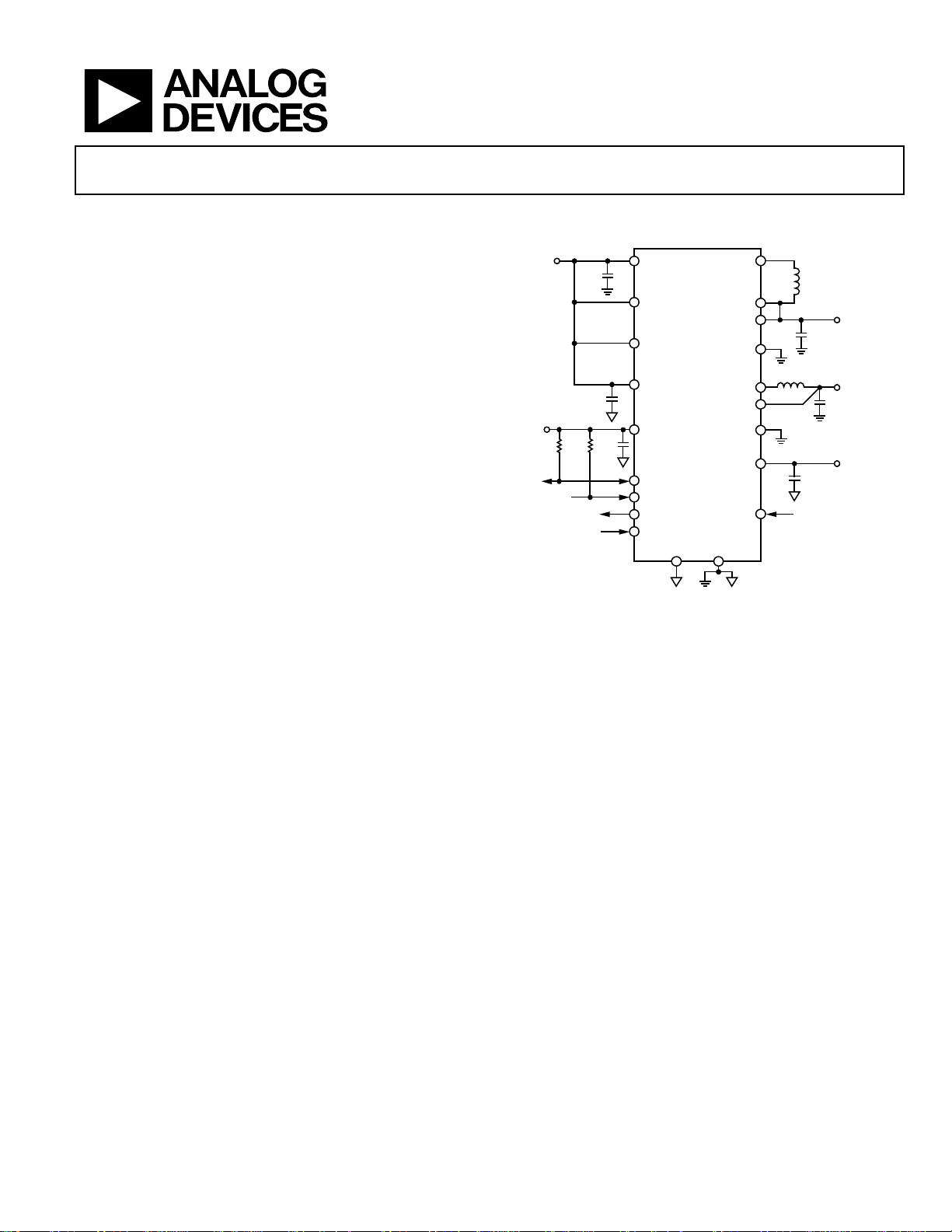

TYPICAL APPLICATIONS CIRCUIT

.4V TO 5.5

V

DD_IO

1.7V TO 3. 6

10kΩ 10kΩ

10µF

VDD1

VDD2

VDD3

ADP5020

VDDA

1µF

VDD_IO

0.1µF

SDA

SCL

XSHTDN

EN/GPIO

DGND AGND

SW1

VOUT1

VOUT1

PGND1

SW2

VOUT2

PGND2

VOUT3

SYNC

2.2µH

EXT. FREQ

9.6/19.2MHz

2.2µH

V

2.5V TO 3. 7V

10µF

V

1.1V TO 1. 8V

4.7µF

V

1.8V TO 3. 3V

1µF

OUT1

OUT2

OUT3

GENERAL DESCRIPTION

The ADP5020 provides a highly integrated power solution that

includes all of the power circuits necessary for a digital imaging

module. It comprises two step-down dc-to-dc converters, one

LDO, and a power sequence controller. All dc-to-dc converters

integrate power pMOSFETs and nMOSFETs, making the system

simpler and more compact and reducing the cost. The ADP5020

has digitally programmed output voltages and buck converters

that can source up to 600 mA. A fixed frequency operation of

3 MHz enables the use of tiny inductors and capacitors. The buck

converters use a voltage mode, constant-frequency PWM control

scheme, and the synchronous rectification is implemented to

reduce the power loss. The Buck 1 regulator operates at up to

93% efficiency.

Figure 1.

The ADP5020 provides high performance, reduces component

count and size, and is lower in cost when compared to conventional designs.

The ADP5020 runs on input voltage from 2.4 V to 5.5 V and

supports one-cell lithium-ion (Li+) batteries. The high performance LDO maximizes noise suppression. The ADP5020 can be

activated via an I

2

C® interface or through a dedicated enable input.

During logic-controlled shutdown, the input is disconnected

from the output source, and the part draws 1 μA typical from

the input source. Other key features include undervoltage lockout

to prevent deep-battery discharge and soft start to prevent input

current overshoot at startup. The ADP5020 is available in a

20-lead LFCSP.

07774-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2009 Analog Devices, Inc. All rights reserved.

Page 2

ADP5020

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Typical Applications Circuit ............................................................ 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Functional Block Diagram .............................................................. 3

Specifications ..................................................................................... 4

Switching Specifications .............................................................. 5

DC-to-DC Conversion Specifications, Buck 1 Regulator ....... 5

DC-to-DC Conversion Specifications, Buck 2 Regulator ....... 6

VOUT3 Specifications, Low Dropout (LDO) Regulator ........ 6

I2C Timing Specifications ............................................................ 7

Absolute Maximum Ratings ............................................................ 8

Thermal Resistance ...................................................................... 8

ESD Caution .................................................................................. 8

Pin Configuration and Function Descriptions ............................. 9

Typical Performance Characteristics ........................................... 10

Theory of Operation ...................................................................... 13

Circuit Operation ....................................................................... 13

Internal Compensation .............................................................. 13

Current Limiting and Short-Circuit Protection ..................... 13

Synchronization .......................................................................... 13

I2C Interface ................................................................................ 13

Undervoltage Lockout ............................................................... 13

Thermal Shutdown .................................................................... 13

Control Registers ............................................................................ 14

Device Address ........................................................................... 14

Register Map ............................................................................... 14

Register Descriptions ................................................................. 14

Power-Up/Power-Down Sequence ............................................... 17

Sequencer .................................................................................... 17

Default Power-On Sequence with EN Pin .............................. 17

Power-On Sequence Using the I2C Interface .............................. 19

Power-Up/Power-Down State Flow ......................................... 20

Applications Information .............................................................. 21

Power Good Status ..................................................................... 21

XSHTDN Logic .......................................................................... 21

Components Selection ............................................................... 21

LDO Input Filter ......................................................................... 22

Layout Recommendations ............................................................. 23

Applications Schematic ............................................................. 23

PCB Board Layout Recommendations .................................... 24

External Component List .......................................................... 24

Outline Dimensions ....................................................................... 25

Ordering Guide .......................................................................... 25

REVISION HISTORY

4/09—Revision 0: Initial Version

Rev. 0 | Page 2 of 28

Page 3

ADP5020

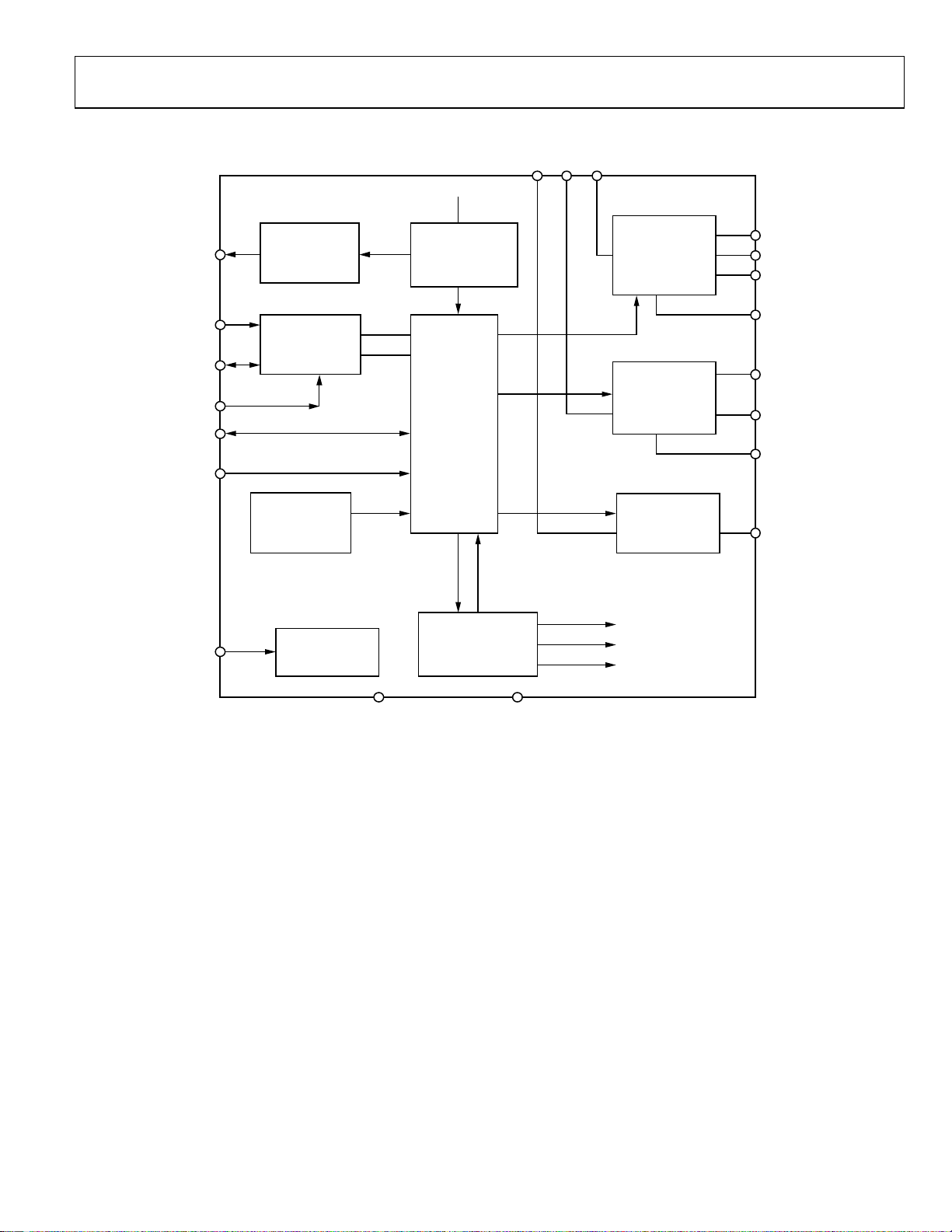

FUNCTIONAL BLOCK DIAGRAM

VDD3

VDD

2 VDD1

VDDA

SW1

XSHTDN

RESET

UVLO

BUCK 1

VOUT1

VOUT1

PGND1

SW2

VOUT2

PGND2

VOUT3

07774-002

VDD_IO

/

GPIO

EN

SYNC

VDDA

SCL

SDA

2

I

C

THERMAL

SHUTDOWN

HOUSE-

KEEPING

DGND

CONTROL

LOGIC

SEQUENCER

BUCK 2

LDO

BUCK1_EN

BUCK2_EN

LDO_EN

AGND

Figure 2.

Rev. 0 | Page 3 of 28

Page 4

ADP5020

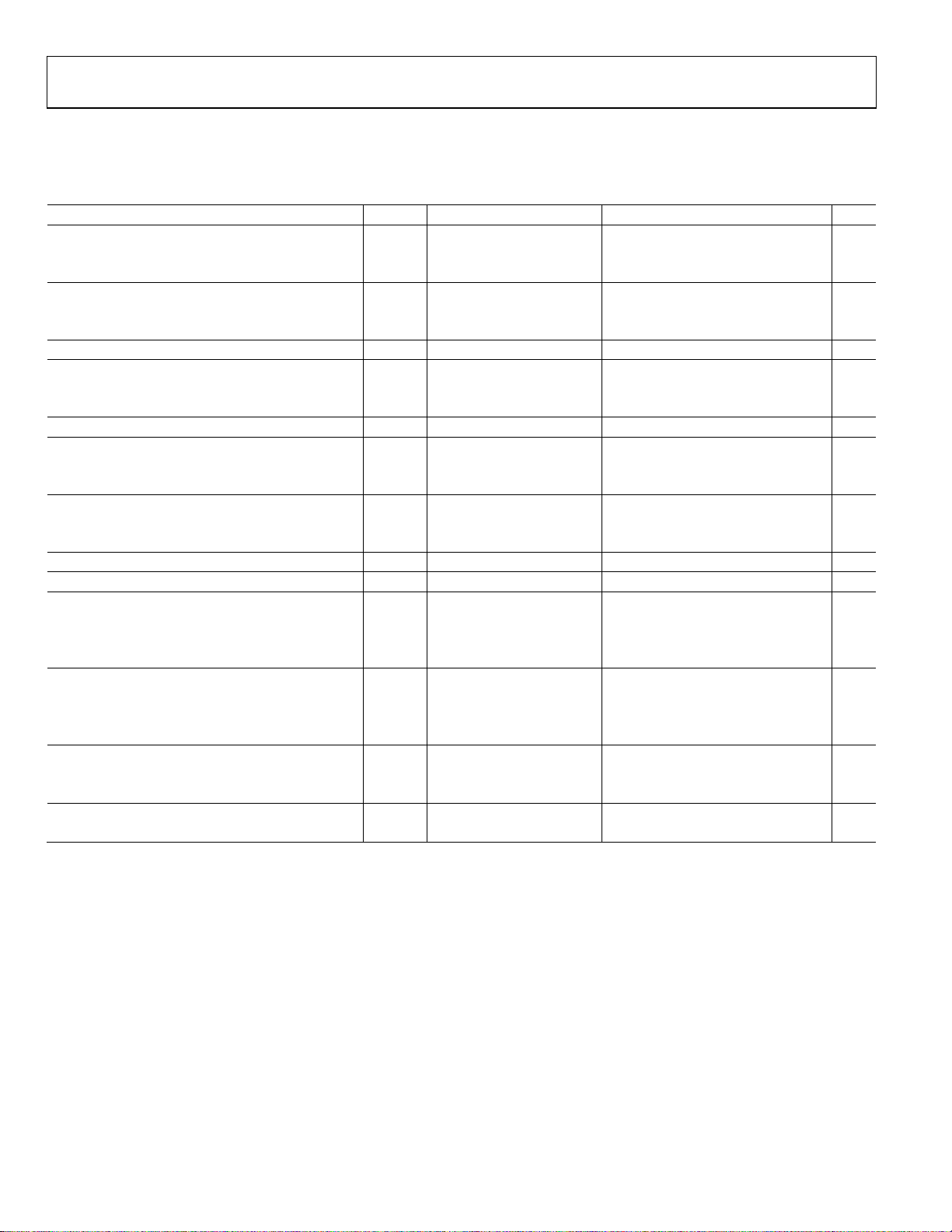

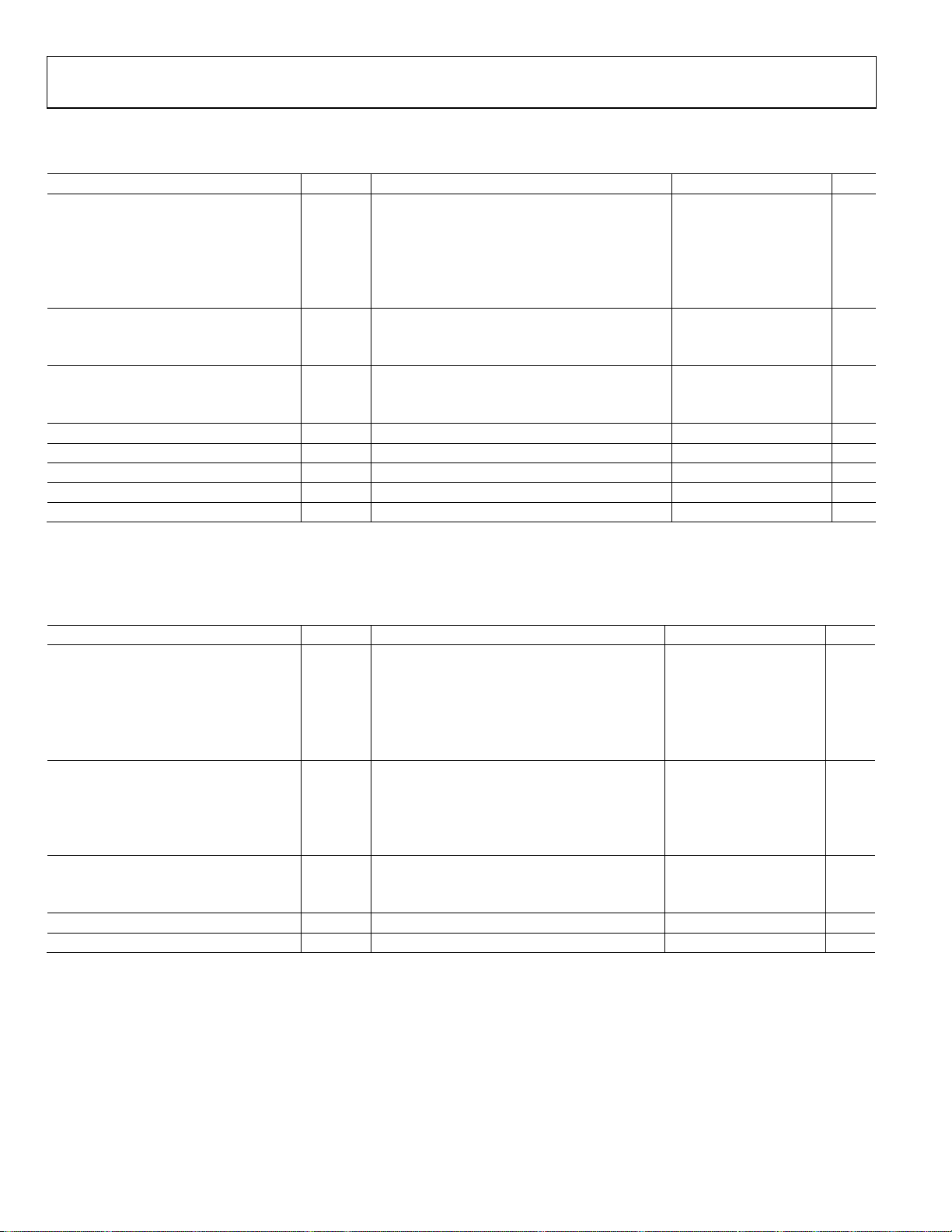

SPECIFICATIONS

TJ = −40°C to +125°C, V

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

OPERATING RANGE

VDDx Operating Voltage Range VDD 2.4 5.5 V

Logic I/O Operating Voltage Range

EN, SDA, SCL CHARACTERISTICS

Low Level Input Voltage VIL 0.3 × V

High Level Input Voltage VIH 0.7 × V

INPUT LOGIC CURRENT ILK Internal pull-down, 1 MΩ −1 +6 μA

XSHTDN, EN/GPIO

Low Level Output Voltage VOL I

High Level Output Voltage VOH I

OUTPUT LOGIC LEAKAGE CURRENT ILK 1 μA

UNDERVOLTAGE LOCKOUT THRESHOLD

Falling V

Rising V

POWER-ON RESET THRESHOLD

Falling V

Rising V

UVLO GLITCH DEBOUNCE TIME VDD > POR levels 50 μs

SHUTDOWN OUTPUT DURATION

POWER GOOD (POK) ACTIVATION DELAY TIME

EN to First Regulator t

First to Second Regulator t

Second to Third Regulator t

NO LOAD CURRENT CHARACTERISTICS

Standby Current I

Lockout Current I

Operating Quiescent Current, Switching

THERMAL CHARACTERISTICS

Thermal Shutdown, TJ Rising TSD

Thermal Shutdown Hysteresis

HOUSEKEEPING BLOCK

Power Good Threshold VPG

1

The V

2

Shutdown output duration is automatic when using the EN pin. To get this delay when using I2C, FORCE_XS must be set to 1.

3

Activation delays apply only when the device is activated through the EN pin or the EN_ALL bit (Address 0x03[4]); the sequencer controls the turning on of the

4

The quiescent current is calculated as though all regulators are powered up.

voltage must be less than or equal to the level on the V

DD_IO

regulators.

= 3.6 V, V

DDx

= 1.8 V, unless otherwise noted.

DD_IO

1

V

2

4

1.7 3.6 V

DD_IO

V

DD_IO

V

DD_IO

= +3 mA 0.2 × V

RST

= −3 mA 0.8 × V

RST

Referenced to V

UVLOF

Referenced to V

UVLOR

Referenced to V

PORF

Referenced to V

PORR

t

XSHTDN line driven low 1 ms

3

XSHTDN

5 ms

REG1

5 ms

REG2

5 ms

REG3

1.8 2.0 V

DDA

2.2 2.4 V

DDA

1.0 1.4 V

DDA

1.6 1.7 V

DDA

V

DD_IO

DD_IO

V

EN = 0 1 5 μA

Q(STNBY)

I

EN = 0, V

LOCK

I

Q

LOAD

supply lines.

DDx

< V

DDA

1 1 μA

UVLOF

= 0 mA 10 15 mA

150

30

°C

°C

70 80 90 %

Rev. 0 | Page 4 of 28

Page 5

ADP5020

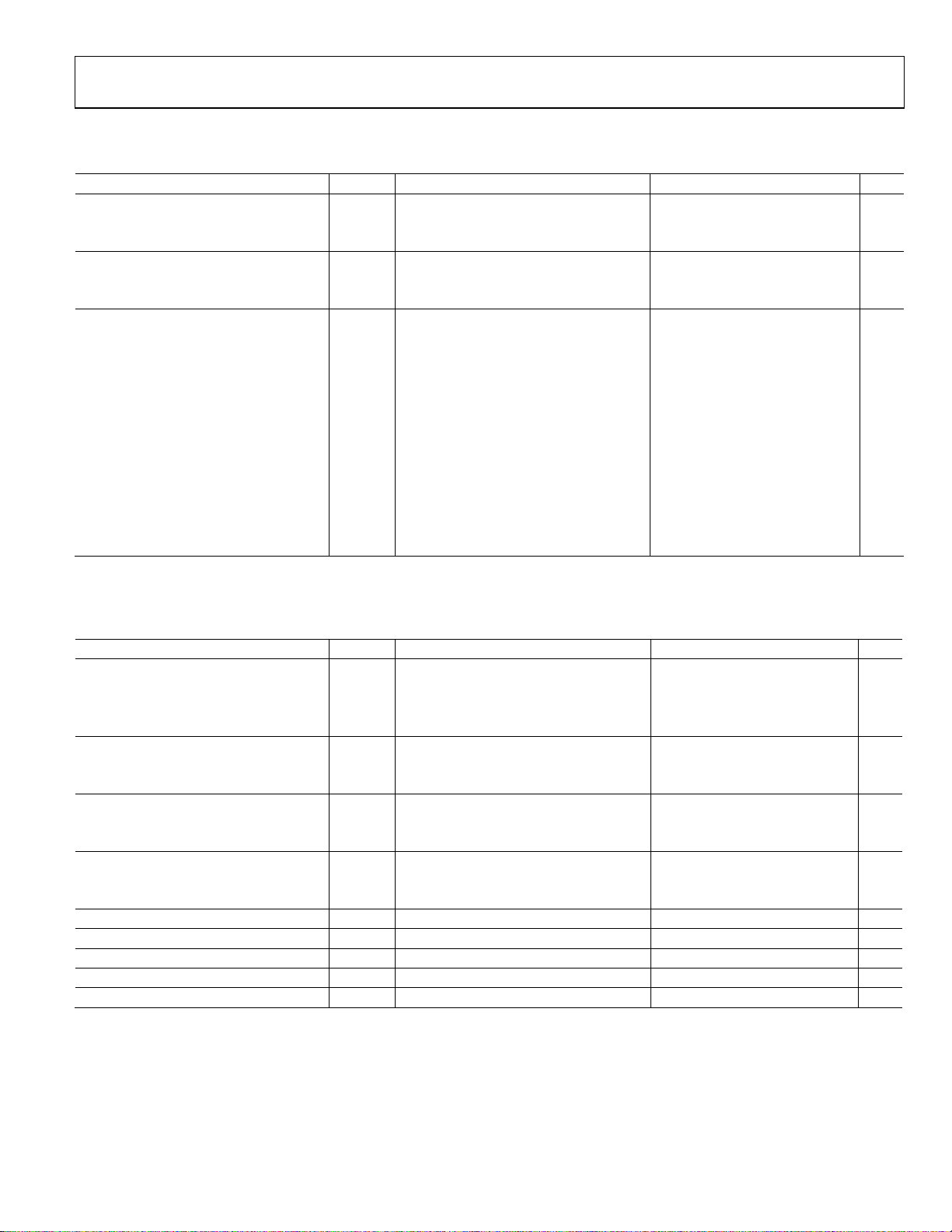

SWITCHING SPECIFICATIONS

Table 2.

Parameter Symbol Conditions Min Typ Max Unit

SWITCHING FREQUENCY

CH1 f

CH2 f

SYNC CLOCK DIVIDER RATIO

RATIO

RATIO

SYNC CHARACTERISTICS

Frequency Range

f

f

Frequency Duty Cycle f

Signal

DC Coupling Level

Low Level Input Voltage VIL 0.3 × V

High Level Input Voltage VIH 0.7 × V

DC Coupling V

AC Coupling Level V

AC Coupling Capacitor 10 nF

Input Current I

Sync disabled 2.5 3 3.6 MHz

SW1

Sync disabled 2.5 3 3.6 MHz

SW2

SYNC_9P6 = 1 3

DIV

SYNC_19P2 = 1 6

DIV

9.6 MHz

SYNC1

19.2 MHz

SYNC2

40 50 60 %

SYNCDUTY

V

DD_IO

V

DD_IO

0 V

SYNC

Sine wave, peak-to-peak 0.5 1.0 V

CAC-PP

SYNC_9P6 = 1, or SYNC_19P2 = 1 50 μA

SYNC

V

DD_IO

V

DD_IO

DC-TO-DC CONVERSION SPECIFICATIONS, BUCK 1 REGULATOR

Table 3.

Parameter Symbol Conditions Min Typ Max Unit

OUTPUT VOLTAGE

VOUT1 REGULATION

CURRENT

POWER

SWITCH CURRENT LIMIT I

MINIMUM ON TIME t

MAXIMUM DUTY CYCLE D

SOFT START TIME t

C

1

See (the BUCK1_VSEL register, Address 0x01) for details. Table 13

2

V

3

V

1

Range

V

3-bit range 2.5 3.7 V

OUT1

Initial Accuracy

Total Accuracy V

Load Regulation I

Line Regulation V

Maximum Output Current I

Quiescent Current I

Low-Side Power nMOSFET R

High-Side Power pMOSFET R

DISCHARGE SWITCH ON RESISTANCE R

OUT

= 3.1 V to 5.5 V, I

DD1

= 3.7 V to 5.5 V, I

DD1

is less than 200 mA. For tight regulation, the supply voltage must be 0.6 V higher than the output voltage.

LOAD

is more than 200 mA. For tight regulation, the supply voltage must be 1.2 V higher than the output voltage.

LOAD

V

BK1MAX

I

QBK1

ID = 400 mA 175 250 mΩ

DSON1

ID = 400 mA 250 400 mΩ

DSON1

0.8 1.2 1.6 A

CL1

55 ns

MIN1

88 95 %

MAX1

1.4 ms

SS1

0.7 1 1.3 kΩ

DIS1

T

= 25°C, V

A

3

, I

DD1

= 20 mA to 600 mA 0.2 %

LOAD

= 1.8 V, V

DDA

3

, V

DD1

= 0 mA 4 6 mA

LOAD

2

, V

DD1

OUT1

2, 3

= 3.3 V, I

DD1

= 50 mA to 600 mA −5 +4 %

LOAD

= 2.5 V to 3.7 V 600 mA

OUT1

= 20 mA

LOAD

−1 +1 %

0.15 %

Rev. 0 | Page 5 of 28

Page 6

ADP5020

DC-TO-DC CONVERSION SPECIFICATIONS, BUCK 2 REGULATOR

Table 4.

Parameter Symbol Conditions Min Typ Max Unit

OUTPUT VOLTAGE

Adjustable Range

Initial Accuracy TA = 25°C, V

Total Accuracy V

Load Regulation I

Line Regulation V

CURRENT

Maximum Output Current I

Quiescent Current I

POWER

Low-Side Power nMOSFET R

High-Side Power pMOSFET R

SWITCH CURRENT LIMIT I

MINIMUM ON TIME t

MAXIMUM DUTY CYCLE D

SOFT START TIME t

C

DISCHARGE SWITCH ON RESISTANCE R

OUT

1

See (the BUCK2_LDO_VSEL register, Address 0x02) for details. Table 14

1

V

4-bit range 1.1 1.8 V

OUT2

= 3.6 V, V

DD2

= 2.5 V to 5 V, I

DD2

= 10 mA to 250 mA 0.2 %

LOAD

= 1.8 V, V

DDA

250 mA

BK2MAX

I

QBK2

ID = 200 mA 240 330 mΩ

DSON2

ID = 200 mA 300 450 mΩ

DSON2

360 630 850 mA

CL2

55 ns

MIN2

87.5 90 %

MAX2

900 μs

SS2

0.7 1 1.3 kΩ

DIS2

= 0 mA 4 6.5 mA

LOAD

LOAD

= 2.5 V to 5 V 0.15 %

DD2

OUT2

= 1.2 V, I

= 20 mA −1 +1 %

LOAD

= 10 mA to 250 mA −5 +4 %

VOUT3 SPECIFICATIONS, LOW DROPOUT (LDO) REGULATOR

Table 5.

Parameter Symbol Conditions Min Typ Max Unit

OUTPUT VOLTAGE

Adjustable Range

Initial Accuracy

Total Accuracy V

Load Regulation I

Line Regulation I

CURRENT

Maximum Output Current I

Dropout Voltage V

Quiescent Current IQ I

Short-Circuit Current Limit 200 400 600 mA

Power Supply Rejection Ratio PSRR

f = 1 kHz, V

f = 10 kHz, V

SOFT START TIME t

C

DISCHARGE SWITCH ON RESISTANCE R

OUT

1

See (the BUCK_LDO_VSEL register, Address 0x02) for details. Table 14

2

V

> V

OUT3

+ L

DD3

1

V

.

DODROP

100 mV step, 4-bit range 1.8 3.3 V

OUT3

T

= 25°C, V

A

= 2.5 V to 5 V, I

DD3

= 10 mA to 100 mA 0.45 0.75 %

LOAD

= 100 mA

LOAD

150 mA

LDOMAX

At 100 mA, V

LDODROP

= 0 mA 45 85 μA

LOAD

70 μs

SS2

0.7 1 1.3 kΩ

DIS8

= 3.6 V, V

DD3

LOAD

2

0.15 0.30 %

= 3.3 V 70 100 mV

OUT3

= 5 V, V

DD3

= 5 V, V

DD3

OUT3

= 1.8 V, I

= 10 mA

LOAD

= 0 mA to 150 mA −5 +4 %

OUT3

OUT3

= 3.3 V, I

= 3.3 V, I

= 50 mA 47 dB

LOAD

= 50 mA 44 dB

LOAD

−1.5 +1.5 %

Rev. 0 | Page 6 of 28

Page 7

ADP5020

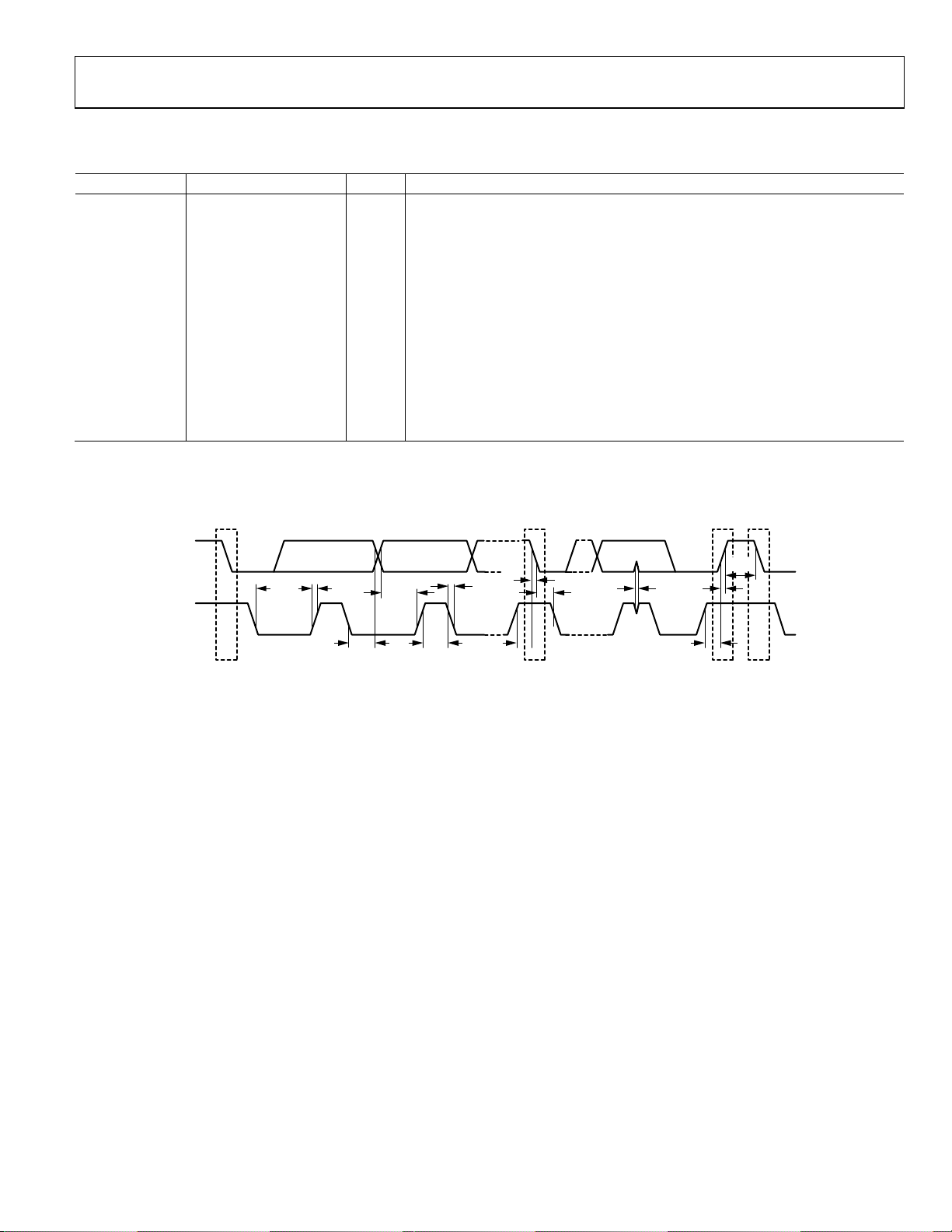

I2C TIMING SPECIFICATIONS

Table 6.

Parameter Min Max Unit Description

f

SCL

t

HIGH

t

LOW

t

SU,DAT

1

t

0 0.9 μs Data hold time

HD,DAT

t

SU,STA

t

HD,STA

t

BUF

t

SU,STO

t

20 + 0.1CB 300 ns Rise time of SCL/SDA

RISE

t

20 + 0.1C

FAL L

t

SP

2

C

B

1

A master device must provide a hold time of at least 300 ns for the SDA signal (referred to the V

2

CB is the total capacitance of one bus line in picofarads (pF).

Timing Diagram

400 kHz SCL clock frequency

0.6 μs SCL high time

1.3 μs SCL low time

100 ns Data setup time

0.6 μs Setup time for repeated start

0.6 μs Hold time for start/repeated start

1.3 μs Bus free time between a stop condition and a start condition

0.6 μs Setup time for stop condition

300 ns Fall time of SCL/SDA

B

0 50 ns Pulse width of suppressed spike

400 pF Capacitive load for each bus line

of the SCL signal) to bridge the undefined region of the SCL falling edge.

IHMIN

SDA

t

LOW

SCL

t

S

S = START CONDI TION

Sr = START REPE ATED CO NDITI ON

P = STOP CO NDITION

HD,DAT

t

RISE

t

SU,DAT

Figure 3. I

t

FALL

t

t

SU,STA

HIGH

2

C Interface Timing Diagram

t

t

FALL

t

HD,STA

Sr P S

tSPt

t

SU,STO

RISE

BUF

07774-003

Rev. 0 | Page 7 of 28

Page 8

ADP5020

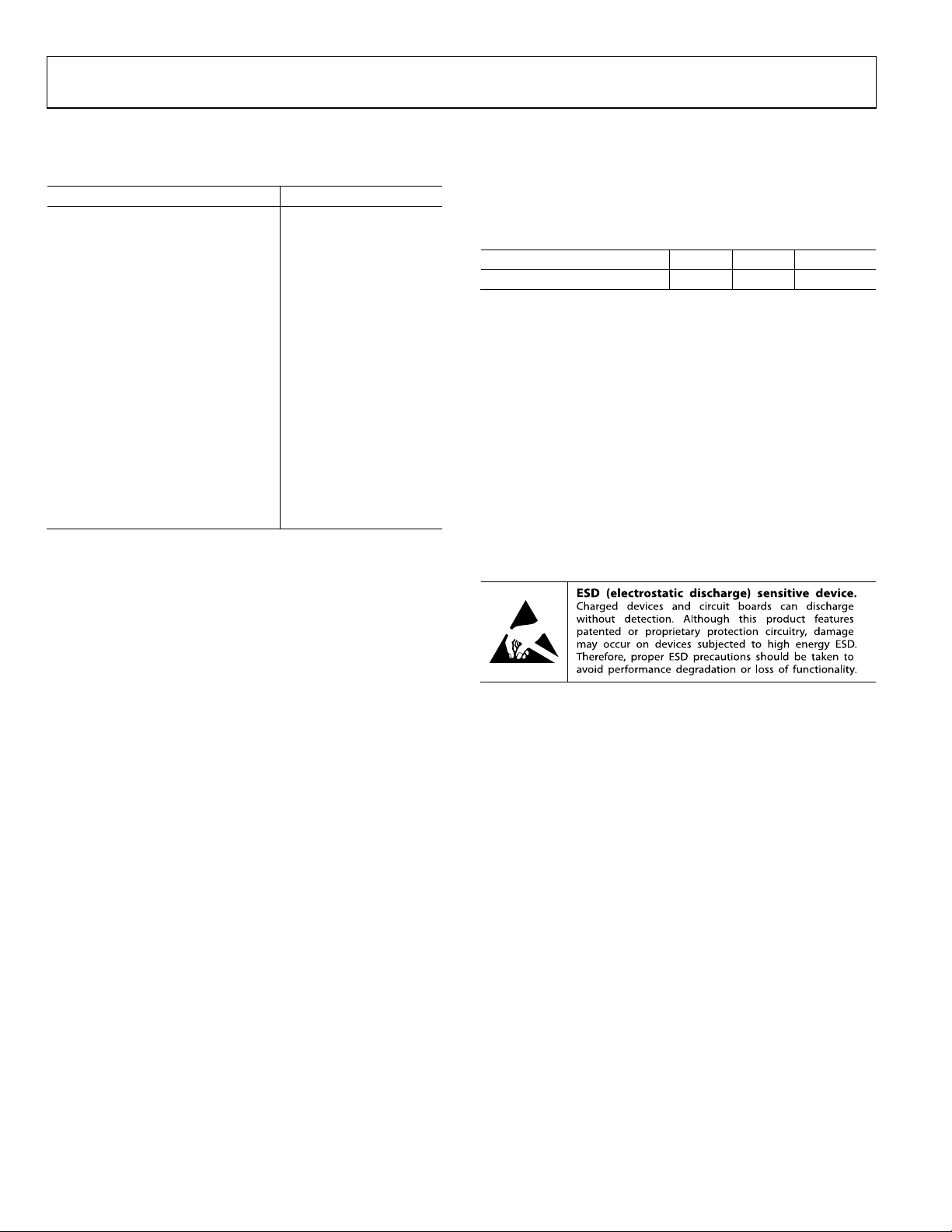

ABSOLUTE MAXIMUM RATINGS

Table 7.

Parameter Rating

VDD1, VDD2, VDD3 −0.3 V to +6 V

SW1, SW2 −0.3 V to +6 V

VOUT1, VOUT2, VOUT3 −0.3 V to +6 V

VDD_IO −0.3V to +3.6 V

EN, SCL, SDA, SYNC, XSHTDN −0.3 V to V

Operating Temperature Range

Ambient −40°C to +85°C

Junction −40°C to +125°C

Storage Temperature Range −65°C to +150°C

Lead Temperature 260°C

Soldering (10 sec) 260°C

Vapor Phase (60 sec) 215°C

Infrared (15 sec) 220°C

V

ESD

Machine Model Range −200 V to +200 V

Human Body Model Range −2000 V to +2000 V

Charged Device Model ±750 V

DD_IO

+ 0.3 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

The ADP5020 can be damaged when the junction temperature

(T

) limits are exceeded. Monitoring the ambient temperature

J

does not guarantee that T

is within the specified temperature

J

limits. In applications with high power dissipation and poor

thermal resistance, the maximum ambient temperature may

have to be derated. In applications having moderate power dissipation and low PCB thermal resistance, the maximum ambient

temperature can exceed the maximum limit as long as the junction

temperature is within specification limits. The T

dependent on the ambient temperature (T

A

of the device is

J

), the power dissipation

(PD) of the device, and the junction-to-ambient thermal resistance

of the package (θ

). Maximum TJ is calculated from TA and PD

JA

using the following formula:

T

= TA + (PD × θJA)

J

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 8. Thermal Resistance

Package Type θJA θ

20-Lead LFCSP (CP-20-4) 47.4 4.3 °C/W

Unit

JC

Thermal Data

Junction-to-ambient thermal resistance (θJA) of the package is

based on modeling and calculation using a 4-layer board. The

junction-to-ambient thermal resistance is highly dependent on

the application and board layout. In applications where high maximum power dissipation exists, attention to thermal board design

is required. The value of θ

may vary, depending on PCB material,

JA

layout, and environmental conditions. The specified value of θ

is based on a 4-layer, 4 in × 3 in, 2 1/2 oz copper board, as per

JEDEC standards. For more information, see the AN-772

Application Note, A Design and Manufacturing Guide for the

Lead Frame Chip Scale Package (LFCSP).

ESD CAUTION

JA

Rev. 0 | Page 8 of 28

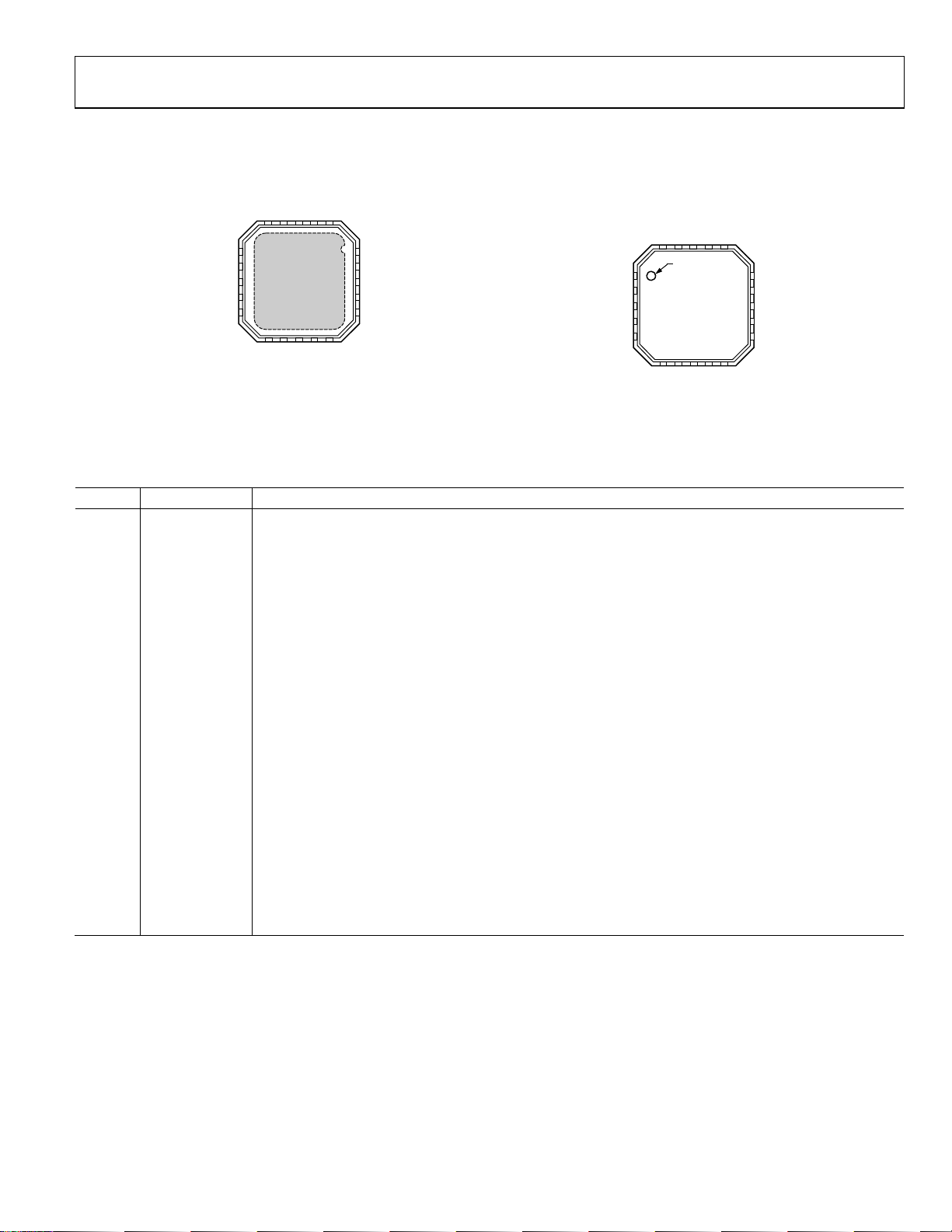

Page 9

ADP5020

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

1

2

SW

VDD1

SW

PGND1

VDD2

19

20

18

17

16

15VOUT1

14VOUT1

13VDD3

12VOUT3

11EN/GPIO

NOTES

1. EXPOSED PAD SHOULD BE CO NNECTED

TO PGND1 AND PGND2.

ADP5020

BOTTOM VIEW

(Not to Scale)

EXPOSED PAD

8

9

10

SCL

VDD_IO

XSHTDN

Figure 4. Pin Configuration (Bottom View)

1 PGND2

2VOUT2

3 VDDA

4AGND

5SYNC

6

7

SDA

GND

D

07774-004

Table 9. Pin Function Descriptions

Pin No. Mnemonic Description

1 PGND2 Power Ground Buck 2.

2 VOUT2 Feedback Buck 2.

3 VDDA Supply Voltage Internal Analog Circuit.

4 AGND Analog Ground.

5 SYNC

Frequency Synchronization. Connect to an external 19.2 MHz or 9.6 MHz clock signal to synchronize the

internal oscillator.

6 DGND Digital Ground.

7 SDA I2C Data.

8 SCL I2C Clock.

9 VDD_IO Supply Voltage for Internal Logic Inputs/Outputs.

10 XSHTDN Shutdown Output, Active Low.

11 EN/GPIO

After power-on reset, this pin is defined as enable (EN). To enable active high, the I

this pin to be an output (GPIO). A weak pull-down resistor is enabled when the pin operates as EN.

12 VOUT3 Regulated Output Voltage from LDO.

13 VDD3 Supply Voltage LDO.

14, 15 VOUT1 Feedback/Driver Buck 1 Output.

16 PGND1 Power Ground Buck 1.

17 SW1 Switch Pin Buck 1.

18 VDD1 Supply Voltage Buck 1.

19 VDD2 Supply Voltage Buck 2.

20 SW2 Switch Pin Buck 2.

EPAD Exposed paddle Exposed pad should be connected to PGND1 and PGND2.

2

1

VDD1

VDD2

SW

20

PIN 1

PGND2

VOUT2

VDDA

AGND

SYNC

1

2

3

4

5

INDICATOR

ADP5020

TOP VIEW

(Not to Scale)

6

DGND

Figure 5. Pin Configuration (Top View)

PGND1

SW

17

16

18

19

15

VOUT1

14

VOUT1

13

VDD3

VOUT3

12

11

EN/GPIO

9

8

7

10

SCL

SDA

VDD_IO

XSHTDN

2

C command can program

07774-005

Rev. 0 | Page 9 of 28

Page 10

ADP5020

TYPICAL PERFORMANCE CHARACTERISTICS

VIN = 4.5 V, V

3.5

3.0

2.5

= 2.8 V, V

OUT1

OUT2

= V

3.3V

3.0V

2.8V

2.5V

OUT3

= 1.8 V, I

= 100 mA, C4 = C1 = 10 μF, C2 = 4.7 μF, C3 = 1 μF, TJ = 25°C, unless otherwise noted.

OUT

95

90

85

2.0

LDO VOLTAGE (V)

1.5

1.0

0 30 60 90 120 150

2.0V

1.8V

LOAD CURRENT (mA)

Figure 6. LDO Load Regulation

LDO OUTPUT = 20mV/DIV

I

= 100mA/DIV

LOAD

TIME = 100µs/DIV

LDO

I

LOAD

Figure 7. LDO Load Transient

V

80

EFFICIENCY (%)

75

70

0 100 200 300 400 500 600

07774-006

LOAD CURRENT (mA)

V

V

V

V

V

V

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

(2.5V)

(2.8V)

(2.9V)

(3.0V)

(3.2V)

(3.3V)

(3.7V)

07774-009

Figure 9. Buck 1, Efficiency vs. Load Current

BUCK 1 OUTPUT = 100mV /DIV

= 100mA/DIV

I

LOAD

TIME = 100µs/DIV

BUCK 1

I

LOAD

07774-007

07774-010

Figure 10. Buck 1 Load Transient Response

3.8

V

(3.7V)

3.6

3.4

3.2

3.0

2.8

2.6

OUTPUT VOLTAGE (V)

2.4

2.2

0

0 100 200 300 400 500 600

OUT7

V

(3.3V)

OUT6

V

(3.0V)

OUT4

V

(2.8V)

OUT2

V

(2.5V)

OUT1

LOAD CURRENT (mA)

V

V

OUT5

OUT3

(3.2V)

(2.9V)

Figure 8. Buck 1 Load Regulation

07774-008

Rev. 0 | Page 10 of 28

1.9

1.8

1.7

1.6

1.5

1.4

1.3

OUTPUT VOLTAGE (V)

1.2

1.1

0

0 50 100 150 200 250 300

LOAD CURRENT (mA)

V

V

V

V

V

V

V

V

OUT8

OUT7

OUT6

OUT5

OUT4

OUT3

OUT2

OUT1

(1.8V)

(1.7V)

(1.6V)

(1.5V)

(1.4V)

(1.3V)

(1.2V)

(1.1V)

Figure 11. Buck 2 Load Regulation

07774-011

Page 11

ADP5020

VIN = 4.5 V, V

0.90

0.85

0.80

= 2.8 V, V

OUT1

OUT2

= V

OUT3

= 1.8 V, I

= 100 mA, C4 = C1 = 10 μF, C2 = 4.7 μF, C3 = 1 μF, TJ = 25°C, unless otherwise noted.

OUT

BUCK 1 OUTPUT = 2V /DIV

BUCK 2 OUTPUT = 1V /DIV

0.75

0.70

0.65

EFFICIENCY (%)

0.60

0.55

0.50

0 50 100 150 200 250 300

LOAD CURRENT (mA)

EFF1 (1.1V)

EFF2 (1.2V)

EFF3 (1.3V)

EFF4 (1.4V)

EFF5 (1.5V)

EFF6 (1.6V)

EFF7 (1.7V)

EFF8 (1.8V)

Figure 12. Buck 2 Efficiency vs. Load Current

BUCK 2 OUTPUT = 50mV /DIV

= 100mA/DIV

I

LOAD

TIME = 100µ s/DIV

BUCK 2

I

LOAD

TIME = 5ms/DIV

BUCK 2

ENABLE

07774-015

07774-012

Figure 15. Startup Sequence of the Three Regulators, Set by Default

BUCK 2 OUTPUT = 1V /DIV

SW2 OUTPUT = 2V/DIV

TIME = 500µ s/DIV

BUCK 2

SW2

Figure 13. Buck 2 Load Transient Response

1.2

1.0

0.8

0.6

0.4

SHUTDOWN CURRENT ( µA)

0.2

0

2.0 2.5 3.0 3.5 4.0 4.5 5.0

I

(µA) @ –40°C

SHTDN

(µA) @ +25°C

I

SHTDN

(µA) @ +125°C

I

SHTDN

INPUT VOLTAGE (V)

Figure 14. Shutdown Current vs. Input Voltage

07774-013

Figure 16. Buck 2 Enable Startup

BUCK 1 OUTPUT = 1V /DIV

SW1 OUTPUT = 2V/DIV

TIME = 500µ s/DIV

BUCK 1

SW1

07774-014

Figure 17. Buck 1 Enable Startup

07774-016

07774-017

Rev. 0 | Page 11 of 28

Page 12

ADP5020

VIN = 4.5 V, V

= 2.8 V, V

OUT1

= V

OUT2

LDO OUTPUT = 1V/DIV

TIME = 50µs/DIV

OUT3

= 1.8 V, I

= 100 mA, C4 = C1 = 10 μF, C2 =4.7 μF, C3 = 1 μF, TJ = 25°C, unless otherwise noted.

OUT

SW2

LDO

Figure 18. LDO Startup

SW1

BUCK 1 OUTPUT = 20mV/DIV

SW1 = 5V/DIV

TIME = 100ns/DIV

BUCK 1

Figure 19. Buck 1 Switching Node Voltage and

Output Ripple Voltage

BUCK 2 OUTPUT = 20mV/DIV

SW2 = 5V/DIV

TIME = 100ns/DIV

BUCK 2

07774-028

07774-030

Figure 20. Buck 2 Switching Node Voltage and

Output Ripple Voltage

BUCK 1 OUTPUT = 2V/ DIV

BUCK 2 OUTPUT = 1V/ DIV

LDO OUTPUT = 1V/DIV

BUCK 1

LDO

BUCK 2

ENABLE

07774-029

ENABLE OUTPUT = 2V/DIV

TIME = 5ms/DIV

07774-031

Figure 21. Three Regulators Turned Off by Sequencer

Rev. 0 | Page 12 of 28

Page 13

ADP5020

THEORY OF OPERATION

CIRCUIT OPERATION

The buck converters use pMOSFET as the upper switch and

nMOSFET as a synchronous rectifier. This synchronous rectification maintains high efficiency for a wide input and output

voltage range. The voltage mode control architecture, which

features a high frequency bandwidth, provides a fast load and

line transient response. The Buck 1 regulator can deliver up to

600 mA with very tight regulation. To minimize cross conduction

and maximize efficiency, an antishoot-through circuit is implemented in the gate driver. The two switching regulators operate

out of phase, reducing input ripple voltage and current.

INTERNAL COMPENSATION

The ADP5020 contains an internal compensation network. The

compensation circuit is designed to make the synchronous buck

converter stable over the input line, output load, and temperature

with specified output capacitors and inductors. In addition, the

high bandwidth control loop design allows for fast load and line

transient response.

CURRENT LIMITING AND SHORT-CIRCUIT PROTECTION

Both buck converters and the LDO have a current limit feature

that allows the ADP5020 to protect itself and any external components during overload and short-circuit conditions. The upper

switch pMOSFET turns off if peak current exceeds the limit.

The nMOSFET is turned on for a longer period until inductor

current drops to 0 A to prevent thermal runaway.

SYNCHRONIZATION

The device has several methods of synchronizing an external

clock with the switching regulators. If the external clock is

9.6 MHz, Bit 6 (SYNC_9P6) in the OPERATIONAL_CONTROL

register (Address 0x04) must be set to 1, and Bit 5 (SYNC_19P2)

must be set to 0. This operation divides the external clock by 3

before it is applied to the switching regulator clock. If the external

clock is 19.2 MHz, Bit 5 (SYNC_19P2) in Address 0x04 must be

set to 1, and Bit 6 (SYNC_9P6) must be set to 0. This opera-tion

divides the external clock by 6 before it is applied to the

switching regulator clock. The synchronous clock can be dc- or

ac-coupled onto the SYNC pin. For ac coupling, Bit 4 (SYNC_AC)

in Address 0x04 is set to 1; for dc coupling, Bit 4 is set to 0.

Operational control is performed by I

I2C INTERFACE

An internal register can be accessed using a synchronous

serial interface that implements the standard I

ADP5020 behaves as a slave device, communicating at normal

speed (100 kHz) or fast speed (400 kHz).

2

C writing to Register 0x04.

2

C interface. The

2

The I

C timing specifications are shown in Tab l e 6, and the I2C

interface timing diagram is shown in Figure 3. The 7-bit slave

address of the ADP5020 is shown in Ta b le 1 0 .

UNDERVOLTAGE LOCKOUT

The undervoltage lockout block contains the UVLO detector

circuits for the battery voltage level. It also contains the status

registers that are required to allow the external application

processor to determine the status of the power supplies. The

most important function of the UVLO circuit is to prevent

converter operation if the supply voltage is too low. The UVLO

falling condition (when the battery voltage decreases from the

operating range level) is set to a typical value of 2.0 V, whereas the

UVLO rising condition (when the supply voltage increases from

zero) is typically 2.2 V.

THERMAL SHUTDOWN

The thermal shutdown block (TSD) prevents device damage

if the die temperature reaches a level greater than 150°C. When

the thermal shutdown limit is reached, the regulator disables

the outputs, while waiting for the die to cool down (typically, to

30°C below the thermal shutdown threshold). There are two

distinct conditions to be considered when recovering from

a thermal shutdown condition:

• The EN pin is low. If the EN pin is low and the device is

operating in I

disabled until the application processor initializes the

parameters and performs the sequencing of the regulators.

The application processor can sense a generic failure condition by detecting a missing acknowledge bit following an

2

I

C command. When a thermal shutdown condition occurs,

Bit 0 (TSD) in the OPERATIONAL_CONTROL register

(Address 0x04) is latched to 1 so that the processor can

recognize the origin of the failure when resuming from

a fault condition. When the TSD bit is set, the application

processor must clear this bit to activate the regulators. If

the TSD bit is not cleared, writing to the regulator enable

bits, Bits[7:4] (BK1_EN, BK2_EN, LDO_EN, and EN_ALL),

in the REG_CONTROL_STATUS register (Address 0x03)

has no effect. The application processor can also force Bit 0

(TSD) to 1. In this case, the operation proceeds as though

a thermal shutdown condition has occurred.

• The EN pin is high. If the EN pin is high, the device resumes

operation automatically from a thermal shutdown condition.

The device resumes performing the predefined regulator

sequence without processor intervention. Bit 0 (TSD) in the

OPERATIONAL_CONTROL register (Address 0x04) is set

to indicate that a thermal shutdown has occurred, and it is

not possible to activate the regulators using an I

mand unless the host sets the TSD bit to 0.

2

C command mode, the outputs remain

2

C com-

Rev. 0 | Page 13 of 28

Page 14

ADP5020

CONTROL REGISTERS

DEVICE ADDRESS

Following a start condition, the bus master must send the address

of the slave it is accessing. The slave address for the ADP5020 is

shown in Tab l e 10 . The Bit 0 defines the operation to be per-

Table 10. Slave Address

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

ADR6 ADR5 ADR4 ADR3 ADR2 ADR1 ADR0 R/W

0 0 1 0 1 0 0 1 or 0

REGISTER MAP

Table 11.

Address Register Name D7 D6 D5 D4 D3 D2 D1 D0

0x00 Revision MAJ[2:0] MIN[2:0] OPT[1:0]

0x01 BUCK1_VSEL Reserved[7:3] BK1_VSEL[2:0]

0x02 BUCK2_LDO_VSEL BK2_VSEL[3:0] LDO_VSEL[3:0]

0x03

0x04

0x05

0x06 to

0x0F

REG_CONTROL_STATUS BK1_EN BK2_EN LDO_EN EN_ALL

OPERATIONAL_CONTROL Reserved SYNC_9P6 SYNC_19P2

EN_CONTROL Reserved[7:2]

Reserved

formed. When this bit is set to Logic 1, a read operation is

selected. When this bit is set to Logic 0, a write operation is

selected.

FORCE_XS

TSD

ENO_DRV

SYNC_

AC

BK1_

PGOOD

BK1_

XSHTDN

BK2_

PGOOD

BK2_

XSHTDN

LDO_

PGOOD

LDO_

XSHTDN

ENO_HIZ_

BAR

REGISTER DESCRIPTIONS

User Accessible Registers

Table 12. Revision Register, Address 0x00

Bit Bit Name Access Default Description

[7:5] MAJ[2:0] R N/A Major revision bits. Used to electronically ID the device version.

[4:2] MIN[2:0] R N/A Minor revision bits. Used to electronically ID the device version.

[1:0] OPT[1:0] R N/A Option bits. Used to electronically ID the option (multiple options on same device family).

Table 13. BUCK1_VSEL Register, Address 0x01

Bit Bit Name Access Default Description

[7:3] Reserved N/A N/A Reserved.

[2:0] BK1_VSEL[2:0] R/W Fuse

000 = 2.5 V.

001 = 2.8 V.

010 = 2.9 V.

011 = 3.0 V.

100 = 3.2 V.

101 = 3.3 V (default).

110 = 3.7 V.

111 = reserved.

Sets the voltage output level of the Buck 1 regulator. Preloads on power-up with values

stored in fuses. Note that this value can be edited by the user in an application.

Rev. 0 | Page 14 of 28

Page 15

ADP5020

Table 14. BUCK2_LDO_VSEL Register, Address 0x02

Bit Bit Name Access Default Description

[7:4] BK2_VSEL[3:0] R/W Fuse

0000 = 1.1 V.

0001 = 1.1 V.

0010 = 1.1 V.

0011 = 1.1 V.

0100 = 1.1 V.

0101 = 1.1 V.

0110 = 1.1 V.

0111 = 1.1 V.

1000 = 1.1 V.

1001 = 1.2 V (default).

1010 = 1.3 V.

1011 = 1.4 V.

1100 = 1.5 V.

1101 = 1.6 V.

1110 = 1.7 V.

1111 = 1.8 V.

[3:0] LDO_VSEL[3:0] R/W Fuse

0000 = 1.8 V (default).

0001 = 1.9 V.

0010 = 2.0 V.

0011 = 2.1 V.

0100 = 2.2 V.

0101 = 2.3 V.

0110 = 2.4 V.

0111 = 2.5 V.

1000 = 2.6 V.

1001 = 2.7 V.

1010 = 2.8 V.

1011 = 2.9 V.

1100 = 3.0 V.

1101 = 3.1 V.

1110 = 3.2 V.

1111 = 3.3 V.

Sets the voltage output level of the Buck 2 regulator. Preloads on power-up with values

stored in fuses. Note that this value can be edited by a user in an application.

Sets the voltage output level of the LDO regulator. Preloads on power-up with values

stored in fuses. Note that this value can be edited by the user in an application.

Rev. 0 | Page 15 of 28

Page 16

ADP5020

Table 15. REG_CONTROL_STATUS Register, Address 0x03

Bit Bit Name Access Default Description

7 BK1_EN R/W 0 1 = turns on the Buck 1 regulator. If the EN pin is high, the sequencer is ignored.

6 BK2_EN R/W 0 1 = turns on the Buck 2 regulator. If the EN pin is high, the sequencer is ignored.

5 LDO_EN R/W 0 1 = turns on the LDO regulator. If the EN pin is high, the sequencer is ignored.

4 EN_ALL R/W 0

3 BK1_PGOOD R 0 Power good status for Buck 1.

1 = power good (POK).

0 = fail.

2 BK2_PGOOD R 0 Power good status for Buck 2.

1 = power good (POK).

0 = fail.

1 LDO_PGOOD R 0 Power good status for LDO.

1 = power good (POK).

0 = fail.

0 FORCE_XS R/W 0 1 = the XSHTDN pin is controlled by the power good signals.

0 = the XSHTDN pin is held low unless the EN pin is high, regardless of regulator status.

If EN is high, this bit is ignored in controlling the XSHTDN pin (acts as if FORCE_XS = 1).

Table 16. OPERATIONAL_CONTROL Register, Address 0x04

Bit Bit Name Access Default Description

7 Reserved N/A N/A Reserved.

6 SYNC_9P6

5 SYNC_19P2

1

R/W 0

1

R/W 0

1 for both SYNC_9P6 and SYNC_19P2 = invalid setting.

4 SYNC_AC

1

R/W 0 1 = the ac path is used for the SYNC input.

0 = the dc path is used (default).

3 BK1_XSHTDN R/W Fuse 0 = power good for Buck 1 must be high for XSHTDN to go high (default).

1 = Buck 1 power good is ignored.

2 BK2_XSHTDN R/W Fuse 0 = power good for Buck 2 must be high for XSHTDN to go high (default).

1 = Buck 2 power good is ignored.

1 LDO_XSHTDN R/W Fuse 0 = LDO power good must be high for XSHTDN to go high (default).

1 = LDO power good is ignored.

0 TSD R/W 0 Shows a latched status of a thermal shutdown (TSD) event.

1 = TSD is active.

1

The SYNC selection bits (SYNC_AC, SYNC_9P6, and SYNC_19P2) cannot be changed while a switching regulator is running.

1 = turns on all regulators, following sequencer programming. BK1_EN, BK2_EN, and

LDO_EN must all be set to 0 for this bit to function.

1 = a 9.6 MHz clock is on the SYNC pin. The SYNC frequency is divided by 3 and used as

clock frequency for switching regulators.

1 = a 19.2 MHz clock is on the SYNC pin. The SYNC frequency is divided by 6 and used as

clock frequency for switching regulators.

0 for both SYNC_9P6 and SYNC_19P2 = clock synchronization is disabled, and the device

operates with the 3 MHz internal clock.

Must be cleared to 0 by user program to enable the regulators. If this bit remains set to 1,

regulator activation is inhibited, as in a thermal shutdown event.

Table 17. EN_CONTROL Register, Address 0x05

Bit Bit Name Access Default Description

[7:2] Reserved N/A N/A Reserved.

1 ENO_HIZ_BAR R/W 0 0 = the EN/GPIO pin is in high impedance, and the EN function is selected.

1 = GPIO output is selected, and the EN function is ignored.

0 ENO_DRV R/W 0 Active only when ENO_HIZ_BAR = 1 (GPIO).

0 = GPIO output is set to low.

1 = GPIO output is set to high.

Rev. 0 | Page 16 of 28

Page 17

ADP5020

POWER-UP/POWER-DOWN SEQUENCE

SEQUENCER

The sequencer is enabled after a low-to-high transition of the

enable pin (EN). When EN is low or programmed as an output, the

sequencing is controlled and timed by the application processor

via the I

Each regulator inside the ADP5020 is controlled by the

sequencer block. The sequencer is factory programmed with

a default turn-on sequence that determines the activation order of

the regulators. The default activation order is listed as follows:

1. Buck 1

2. LDO

3. Buck 2

A low-to-high transition of the EN pin, when programmed

as an input, or an I

REG_CONTROL_STATUS register (Address 0x03), starts the

sequencer.

The activation delay for the first regulator is determined by the

turn-on delay of the band gap, oscillator, and other internal

circuits. Therefore, the first regulator cannot be activated before

a typical 5 ms delay time has elapsed. Delays between the first

and second regulator and from the second to third regulator are

hard coded to a specific time (t

time starts from the moment a regulator has reached the power

good threshold (see Figure 22).

2

C commands.

2

C command setting Bit 4 (EN_ALL) in the

REG1

, t

REG2

, and t

). The delay

REG3

DEFAULT POWER-ON SEQUENCE WITH EN PIN

Figure 22 shows the default regulator sequencing after a low-tohigh transition of the EN pin. The regulator order is factory

programmed and can be changed for specific applications. The

power good signal (POK) turns to high if the regulator voltage

is ≥80% of the target voltage. The second regulator checks the

POK signal of the first regulator and waits the preset delay time

(t

) before turning on. In addition to changing the regulator

REG2

order, it is also possible to disable the unused regulator. Additional

fuses allow disabling of the association between XSHTDN generation and the POK signal for a specific regulator. The power good

signal of an unused regulator must be masked, via dedicated fuse

and user registers, to prevent the XSHTDN output from being

forced low. A host processor controller, connected to the I

can override the masking fuses by accessing the following bits in

the OPERATIONAL_CONTROL register (Address 0x04): Bit 3

(BK1_XSHTDN, for Buck 1), Bit 2 (BK2_XSHTDN, for Buck 2),

and Bit 3 (LDO_XSHTDN, for LDO). Writing 0 to these register

bits requires that power good be true to release the XSHTDN pin

to high. Writing 1 to these bits causes the regu-lator state to be

ignored, and XSHTDN must depend on the active and

unmasked regulators.

The regulators can also be activated individually via the I

commands. The host specifies which regulator is to be turned

on or off by setting or clearing the following selection bits in the

REG_CONTROL_STATUS register (Address 0x03): Bit 7

(BK1_EN), Bit 6 (BK2_EN), or Bit 5 (LDO_EN). When the

regulators are individually activated by I

2

C commands, the auto

sequencing is disabled and the host controls the turn-on and

turn-off timing (see Figure 26).

2

C bus,

2

C

EN

t

REG1

BUCK 1

LDO

BUCK 2

XSHTDN

Figure 22. Automatic Sequencing with EN Low-to-High Transition

POK

t

REG2

Rev. 0 | Page 17 of 28

t

REG3

POK

POK

t

XSHTDN

07774-018

Page 18

ADP5020

Activation Waveforms

VDDx

POR

INTERNAL

POR

EN

2

I

C BUS

BUCK 1

LDO

BUCK 2

XS

HTDN

VDDx

V

UVLOR

2

C SEQUENCER

I

REGISTERS

PROGRAMMING

EN_

ALL = 1

t

REG1

POK

t

REG2

Figure 23. Regulators Are Activated by I

t

REG3

POK

POK

t

XSHTDN

2

C Command

EN_

ALL = 0

07774-019

POR

INTERNAL

POR

EN

2

C SEQUENCER

I

2

C BUS

I

BUCK 1

BUCK 2

HTDN

XS

LD

O

REGIS TERS

PROGRAMMING

t

REG1

t

REG2

Figure 24. Activation Command Using the EN Pin

When activated through the EN pin, the sequencer is affected

2

only by the I

C commands that set or clear the regulator power

good masking bits: Bit 3 (BK1_XSHTDN), Bit 2 (BK2_XSHTDN),

and Bit 1 (LDO_XSHTDN) in the OPERATIONAL_CONTROL

register (Address 0x04). See the Default Power-On Sequence with

EN Pin section for more information. The sequence order of the

regulators is factory programmed through fuses, but the delays

POK

POK

t

REG3

POK

t

XSHTDN

07774-020

between the regulators (t

REG1

, t

REG2

, and t

) are fixed and cannot

REG3

be changed.

The EN_ALL bit (Bit 4) in the REG_CONTROL_STATUS regi-ster

(Address 0x03) has the same functionality as the EN pin. The

sequencer has an antiglitch function that allows it to ignore supply

voltage dip if glitch time is less than 50 μs (see Figure 25).

Rev. 0 | Page 18 of 28

Page 19

ADP5020

POWER-ON SEQUENCE USING THE I2C INTERFACE

When the EN pin is low, the regulator sequence is controlled by

the application processor sending I

activation. When Bit 4 (EN_ALL) in the REG_CONTROL_

STATUS register (Address 0x03) is set to 1, the regulator sequence

is as follows:

VDDx

POR

INTERNAL

POR

EN

2

I

C BUS

BUCK 1

LDO

2

C commands to control the

V

UVLOR

2

C SET/CLEAR

I

xxx_XSHTDN BITS

t

REG1

t

REG2

1. Buck 1

2. LDO

3. Buck 2

This sequence can be factory programmed through fuses.

Unused regulators can also be fuse programmed to be turned

off during sequencing.

V

<50µs

t

REG3

UVLOF

t

BUCK 2

XS

HTDN

XSHTDN

07774-021

Figure 25. Activation and Power Failure Conditions

EN

2

C BUS

I

BUCK 1

LDO

BUCK 2

XSHTDN

BK1_EN

= 1

LD0_EN

= 1

BK2_EN

= 1

FORCE_XS

Figure 26. Individual Activation Through I

= 1

2

C Commands

FORCE_XS

= 0

BK1_EN,

LDO_EN,

BK2_EN = 0

07774-022

Rev. 0 | Page 19 of 28

Page 20

ADP5020

The application processor, together with the regulator power

good signal, controls the XSHTDN pin, as shown in Tabl e 18 .

After a regulator is enabled and no failure condition is detected

(power good = 1 in Bits[3:1] of the REG_CONTROL_STATUS

register, Address 0x03), the level of the XSHTDN pin is controlled by Bit 0 (FORCE_XS) in the REG_CONTROL_STATUS

register. Therefore, the application processor can write to this

register to gain control over the XSHTDN pin. However, if the

EN signal is high, the level on the XSHTDN pin depends on the

power good condition of the regulator.

Table 18. Truth Table

EN

Pin

2

C Regulator Enable

I

Power

Good

FORCE_XS

XSHTDN

Pin

0 0 0 X1 0

0 1 X1 0 0

0 1 0 1 0

0 1 1 1 1

1 X1 1 X1 1

1 X1 0 X1 0

1

X = don’t care.

POWER-UP/POWER-DOWN STATE FLOW

When the device is enabled, the UVLO circuit constantly monitors

UVLOR

UVLOF

),

the supply voltage. If the supply voltage falls below the V

threshold, typically 2.0 V, the regulators are immediately turned

off. All the internal analog circuits are then disabled to save power,

except the power-on reset (POR) circuit, which detects if the supply

voltage is dropping. If the supply voltage is higher than the POR

threshold, the POR circuit keeps the logic circuits operating

properly and retains the internal values of the registers. This

POR threshold is set to approximately 1.4 V.

If the supply voltage goes below the V

threshold, but not

UVLOR

below the POR threshold, the registers are preserved. If the supply

voltage returns to the normal operating level (above V

a new activation does not require initialization of the registers.

However, if the supply voltage goes below the POR level, the

device is held in reset state. When the input voltage resumes the

proper operating level, the host controller must reload the registers.

The additional current required to keep the POR monitoring

circuits alive during UVLO is estimated to be approximately 1 μA.

NO POWER

VDDx > V

POR

LEVEL

INTERNAL

RESET

EN = LOW

STAND BY

STARTUP

SEQUENCER

EN = LOW OR I2C OFF

COMMAND

OR VDDx < V

UVLOF

VDDx < V

EN = HIGH

POR

07774-023

EN = LOW AND 12C OFF

COMMAND

OR VDDx < V

NORMAL

OPERATIO N

END, AND ALL REG ULATIONS ARE

SEQUENCE

POWER GOOD

VDDx < V

UVLOF

I2C

COMMANDS

TSD

POR

DEVICE ENABLED

(EN_ALL OR E N = HIGH)

Figure 27. State Flow

Rev. 0 | Page 20 of 28

Page 21

ADP5020

APPLICATIONS INFORMATION

POWER GOOD STATUS

The ADP5020 constantly monitors the operating conditions.

When a regulator is activated, it checks if the output voltage

level is above 80% (the power good threshold) of the nominal

level for that output. If the output voltage does not reach the

power good threshold, one of the three power good status bits in

the REG_CONTROL_STATUS register (Address 0x03) is cleared.

If the output voltage reaches the power good threshold, one of

the power good status bits in the REG_CONTROL_STATUS

register is set to 1. The REG_CONTROL_STATUS register

contains the following three power good bits: BK1_PGOOD for

the Buck 1 output (Bit 3), BK2_PGOOD for the Buck 2 output

(Bit 2), and LDO_PGOOD for the LDO output (Bit 1).

XSHTDN LOGIC

In addition to the power good information for each enabled

regulator, an XSHTDN signal is generated, as shown in Tab l e 18 . If

one or more regulators are unused in a specific application, the

masking bits for the disabled regulator, which are fuse programmable and I

2

C programmable after device startup, must be

set to 1 to mask the status of the power good signal. Besides having

the masking bits predefined through factory-programmed fuses

(necessary only for operation with the EN signal), the ADP5020

provides three masking bits that are accessible through the I

2

C

interface. These bits are located in the OPERATIONAL_

CONTROL register (Address 0x04), where the BK1_XSHTDN

bit (Bit 3) is the mask (if set to 1) for Buck 1, the BK2_XSHTDN bit

(Bit 2) is the mask (if set to 1) for Buck 2, and the LDO_

XSHTDN bit (Bit 3) is the mask (if set to 1) for the LDO. Additional failures that are verified are the input (VDDA) undervoltage

condition, as described in the Undervoltage Lockout section; and

an overtemperature condition of the die, as described in the

Thermal Shutdown section. As soon as one of these conditions

occurs, the active regulators are immediately turned off, and the

XSHTDN pin is set to 0.

COMPONENTS SELECTION

Buck Inductor

The buck inductor is chosen to meet output ripple current and

ripple voltage requirements with minimum size. The fast load

transient response and wide frequency bandwidth are also important factors for inductor selection. The minimum inductance of the

buck converter is derived from the following equation:

)(

×−

VVV

OUTOUTINMAX

L

MINBUCK

=

where:

V

is the maximum input supply voltage.

INMAX

V

is the regulator output voltage in the buck converter.

OUT

is the converter switching frequency.

f

SW

r is the inductor ripple factor, which is selected as 30%.

(1)

IrfV

×××

OUTSWINMAX

Peak inductor current is calculated in the following equation:

I

= I

LMAX

+ 0.5 × r × I

OUT

(2)

OUT

The calculated minimum Buck 2 inductor value is 2.2 μH. The

maximum peak inductor current is 325 mA. A ceramic inductor

such as the Taiyo Yuden BRL2012T2R2M, with a 600 mA saturation current in a 2 mm × 1.2 mm × 1 mm package, can be used.

For the Buck 1 converter, the calculated minimum inductance is

2.2 μH, with maximum peak current of 690 mA. A ceramic

inductor such as the Taiyo Yuden BRL2518T2R2M, with a 1 A

saturation current in a 2.5 mm × 1.8 mm × 1.2 mm package, is

recommended.

Input Capacitor Selection

The input capacitors are used to decouple the parasitic inductance

of input wires to the converters and to reduce the input ripple

voltage and the switching ac current flow to the battery rail. The

capacitors are selected to support the maximum input operating

voltage and the maximum rms current. The capacitance must also

be large enough to ensure input stability and suppress input ripple.

ESR should as small as possible to decouple the noise. MLCC

ceramic capacitors are a good choice for battery-powered applications because of their high capacitance, small size, and low ESR.

A 10 μF ceramic capacitor (for example, the JMK107BJ106MA-T

from Taiyo Yuden) is recommended.

Output Capacitor Selection

Output capacitor selection should be based on the following three

factors:

• Maximizing the control loop bandwidth of the converter

with the LC filter

• Minimizing the output voltage ripple

• Minimizing the size of the capacitor

Note that the output ripple is the combination of several factors,

including the inductor ripple current (ΔI

), the ESR and ESL

L

output capacitors, and the capacitor impedance at the switching

frequency.

In buck converters, the output ripple can be calculated as

follows:

ΔV

ΔI

OUTRIPPLE

= r × I

L

⎛

= ΔIL

⎜

ESR 4

+

⎜

⎝

OUT

1

8

Cf

××

OUTSW

⎞

⎟

fESL

××+

SW

⎟

⎠

Capacitor manufacturer data sheets show the ESR and ESL

value. In real-life applications, the ripple voltage may be higher

because the equations provided in this data sheet do not consider

parameters such as board/package parasitic inductance and

capacitance. The minimum recommended capacitance is no less

than 4.0 μF for Buck 1, 2.0 μF for Buck 2, and 0.4 μF for the

LDO.

Rev. 0 | Page 21 of 28

Page 22

ADP5020

LDO INPUT FILTER

To improve the LDO input-to-output ripple suppression in the

critical switching frequency range of the buck converters, it may be

necessary to add an LC filter tuned to 1 MHz, as shown in

Figure 28. Additional tests and simulation must be performed

to assess if this filter is necessary.

The filter resonance frequency is determined by the following

equation:

f

LC

1

where L3 = 250 nH, assuming that f

The inductor must be able to withstand the LDO load current,

including the overload condition, which is limited to 400 mA.

(3)

C8L3

××π×=2

= 1 MHz and C8 = 100 nF.

LC

VBATT

C1

10µF

ADP5020

SW1

L1

BUCK 1

LDO

VOUT1

VOUT1

10µF

VDD3

VOUT3

2.2µH

C6

L3

C8

0.1µF

C3

1µF

Figure 28. Optional LDO Input Filter

3.3V

INPUT FILTER

2.8V

LDO

07774-026

Rev. 0 | Page 22 of 28

Page 23

ADP5020

LAYOUT RECOMMENDATIONS

APPLICATIONS SCHEMATIC

ADP5020

INPUT POWER SUPPLIES

PROCESSOR

INTERFACE

GPIO/EN

VBATT

GND

VDDIO

SDA

SCL

SYNC

R1

10kΩR210kΩ

10µF

C4

C6

1.0µF

0.1µF

VDD1

SW1

BUCK 1BUCK 2LDO

VOUT1

VOUT1

PGND1

SW2

VOUT2

PGND2

VOUT3

XSHTDN

VDD2

VDD3

VDDA

VDD_IO

C5

SDA

SCL

SYNC

EN/GPIO

L1

2.2µH

L2

2.2µH

C1

10µF

C2

4.7µF

C3

1.0µF

+VIS

–VIS

+V

CORE

–V

CORE

+VIO

–VIO

XSHTDN

OUTPUT POW ER RAILS

DGND AGND

07774-027

Figure 29. Schematic for Camera Module Applications

Rev. 0 | Page 23 of 28

Page 24

ADP5020

PCB BOARD LAYOUT RECOMMENDATIONS

• Place the input and output capacitors, C1, C2, C3, C4, and

C5, as close as possible to the respective ADP5020 pin, and

make the grounding connection to the ADP5020 ground

pins as short as possible.

• Connect C3, C5, and C6 to the analog ground, and connect

C1, C2, and C4 to the power ground.

• Place the L1 and L2 inductors as close as possible to the

respective output pins.

EXTERNAL COMPONENT LIST

Table 19. Recommended External Components List

Reference

Designator Description Size Proposed Vendor Vendor Part No.

C1, C4 10 μF, X5R, 6.3 V, ±20% 0603 Murata GRM188R60J106M

C1, C4 10 μF, X5R, 6.3 V, ±20% 0603 Taiyo Yuden JMK107BJ106MA

C2 4.7 μF, X5R, 6.3 V, ±10% 0603 Murata GRM188R60J475K

C3 1.0 μF, X5R, 6.3 V, ±10% 0603 Murata GRM155R60J105K

C5 0.1 μF, X5R, 10 V, ±10% 0402 Murata GRM155R61A104K

C6 1.0 μF, X5R, 6.3 V, ±10% 0603 Murata GRM155R60J105K

L1 2.2 μH, DCR = 0.13 Ω, IDC = 1 A 2.5 mm × 1.8 mm × 1.2 mm Taiyo Yuden BRL2518T2R2M

L2 2.2 μH, DCR = 0.23 Ω, IDC = 0.53 A 2.0 mm × 1.2 mm × 1.0 mm Taiyo Yuden BRL2012T2R2M

R1, R2 10 kΩ, 1%, thick film resistor 0402 KOA Speer Electronics RK73H1ETTP1002F

• The power and analog ground planes are recommended to

keep the noise low. Use one layer for power ground and one

layer for analog ground. Tie the power and analog grounds

at a single point.

• Use wide traces to connect the inductor and the input and

output capacitors.

• Add the L3 inductor and the C8 capacitor, if needed, to

improve the LDO noise rejection at the switching frequency of the Buck 1 regulator (3 MHz) because the LDO

PSRR typically degrades at higher frequencies. If switching

noise is not an issue, remove the L3 inductor.

Rev. 0 | Page 24 of 28

Page 25

ADP5020

OUTLINE DIMENSIONS

0.08

0.50

BSC

0.50

0.40

0.30

0.60 MAX

15

11

P

N

I

N

I

2.65

2.50 SQ

2.35

0.25 MIN

D

16

10

20

EXPOSED

(BOTTOM VIEW)

1

PAD

5

6

FOR PRO P ER CONNECTION OF

THE EXPOSED PAD, REFER TO

THE PIN CONFIG UR ATION AND

FUNCTION DESCRIPTIONS

SECTION OF THIS DATA SHEET .

1

R

C

I

A

O

T

090408-B

4.00

PIN 1

INDICATOR

1.00

0.85

0.80

SEATING

PLANE

12° MAX

BSC SQ

TOP VIEW

0.80 MAX

0.65 TYP

0.30

0.23

0.18

COMPLIANT

0.60 MAX

3.75

BSC SQ

0.05 MAX

0.02 NOM

COPLANARITY

0.20 REF

TO

JEDEC STANDARDS M O-220-VGG D- 1

Figure 30. 20-Lead Lead Frame Chip Scale Package [LFCSP_VQ]

4 mm × 4 mm Body, Very Thin Quad

(CP-20-4)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADP5020ACPZ-R71 −40°C to +85°C 20-Lead Lead Frame Chip Scale Package [LFCSP_VQ] CP-20-4

ADP5020CP-EVALZ1 Evaluation Board

1

Z = RoHS Compliant Part.

Rev. 0 | Page 25 of 28

Page 26

ADP5020

NOTES

Rev. 0 | Page 26 of 28

Page 27

ADP5020

NOTES

Rev. 0 | Page 27 of 28

Page 28

ADP5020

NOTES

©2009 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D07774-0-5/09(0)

Rev. 0 | Page 28 of 28

Loading...

Loading...