Page 1

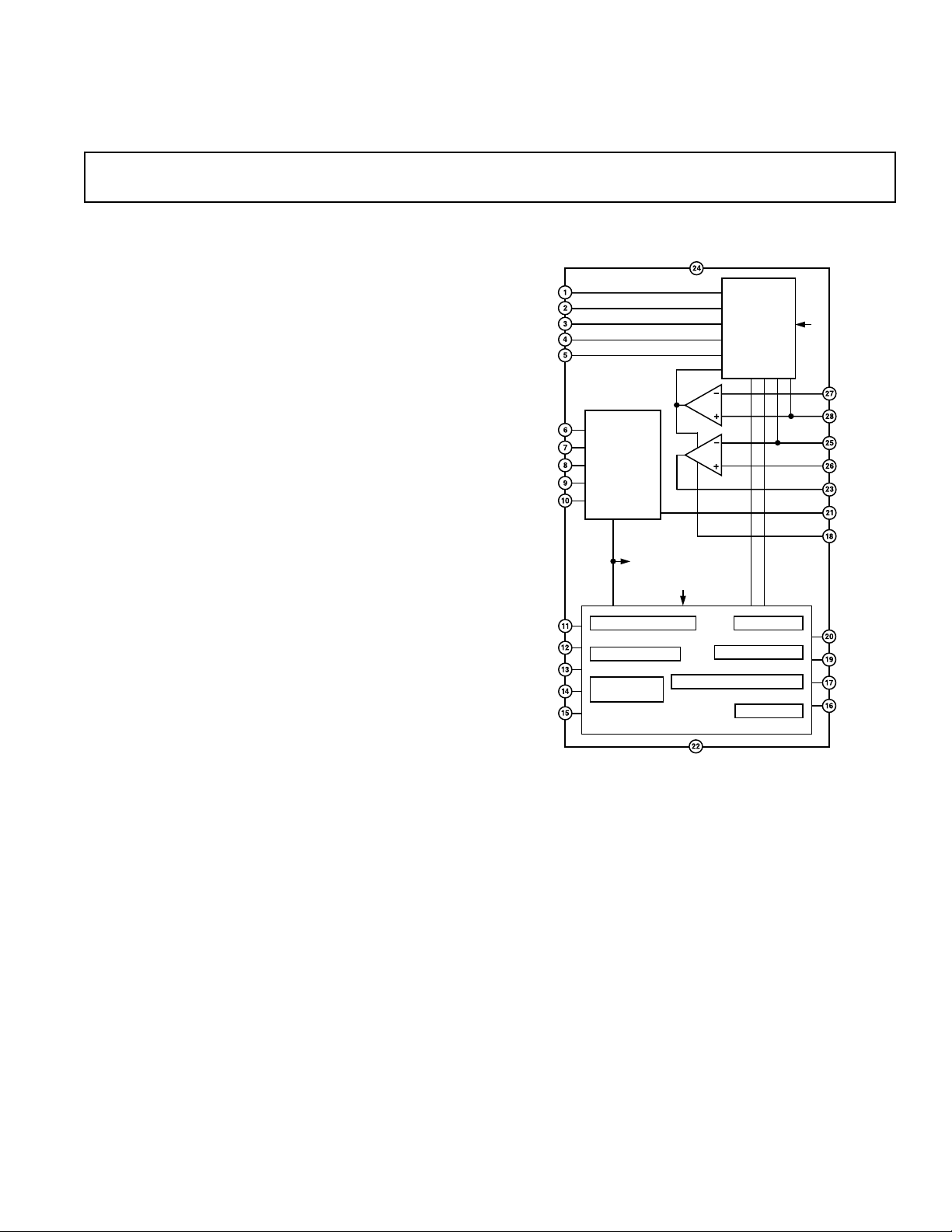

IMVP-II-Compliant

BOMSEL

HYSTERESIS

AND

SHIFT-SETTING

DSLPSEL

VID4

VID3

VID2

VID1

VID0

CS+

CS–

ADP3422

VR

CLIM

CORE

PROGRAMMED

DAC

AND

FIXED

REFERENCE

VCC

VCC

VR

GND

COREFB

SS

DRVLSD

CLAMP

RAMP

REG

OUT

DACOUT

SWFB

EN

UVLO AND MAIN BIAS

SR CONTROL

PWRGD MONITOR

PWRGD BLANKER

SS-HICCUP TIMER AND OCP

OVP AND RVP

OP MODE

SELECTOR

POWER MANAGEMENT

SD

PWRGD

DPRSLP

DSLP

BOM

CPUSET

HYSSET

FSHIFT

DSHIFT

BSHIFT

a

Core Power Controller for Mobile CPUs

FEATURES

Certified IMVP-II Controller

Excellent Transient Containment

Minimum Number of Output Capacitors

Fast, Smooth, Output Transition During VID Code Change

Current Limit with Hiccup Protection

Transient-Glitch-Free Power Good

Low Shutdown Current

Soft Start Eliminates In-Rush Current Surge

Adaptive Noise-Blanking Enhancement for Speed and

Stability

Highly Redundant Over-Voltage and Reverse-Voltage

Protection

Controls Synchronous Rectifier for Improved Battery Life

APPLICATIONS

IMVP-II Enabled Core DC/DC Converters

Fixed-Voltage Mobile CPU Core DC/DC Converters

Notebook/Laptop Power Supplies

Programmable Output Power Supplies

ADP3422

FUNCTIONAL BLOCK DIAGRAM

GENERAL DESCRIPTION

The ADP3422 is a hysteretic dc-dc buck converter controller to

power a mobile processor’s core. The optimized low voltage

design is powered from the 3.3 V system supply. The output

voltage is set by a 5-bit VID code. To accommodate the transition

time required by the newest processors for on-the-fly VID

changes, the ADP3422 features high-speed operation to allow a

minimized inductor size that results in the fastest change of

current to the output. To further allow for the minimum number

of output capacitors to be used, the ADP3422 features active

voltage positioning that can be optimally compensated to ensure a

superior load transient response. The output signal interfaces

with the ADP3415 MOSFET driver that is optimized for high

speed and high efficiency for driving both the upper and lower

(synchronous) MOSFETs of the buck converter.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

Page 2

ADP3422–SPECIFICATIONS

1

ELECTRICAL CHARACTERISTICS

( V

DACOUT

), V

REG

= V

CS–

= V

= 1.25 V, V

VID

CPUSET

(0 ≤ TA ≤ 85ⴗC, High (H) = VCC, Low (L) = 0 V, VCC = 3.3 V, SD = H, V

= 0 V, R

= 100 k⍀, C

OUT

= 10 pF, CSS = 47 nF, R

OUT

= 5 k⍀ to VCC, R

PWRGD

to VCC, HYSSET, BSHIFT, DSHIFT, and FSHIFT are open, BOM = H, DSLP = H, DPRSLP = L, SWFB = L, unless otherwise noted. Current sunk

by a pin has a positive sign, sourced by a pin has a negative sign.)

Parameter Symbol Conditions Min Typ Max Unit

SUPPLY-UVLO-SHUTDOWN

Normal Supply Current I

UVLO Supply Current I

Shutdown Supply Current I

CC

CC(UVLO)

CCSD

SD = L 1 µA

615 mA

200 µA

UVLO Threshold

VCC Rising Up, VSS = 0 V 2.95 V

VCC Falling, VSS Floating 2.7 V

50 mV

VCC/2

UVLO Hysteresis V

Shutdown Threshold (CMOS Input) V

V

CCH

V

CCL

CCHYS

SDTH

POWERGOOD

Core Feedback Threshold Voltage V

PowerGood Output Voltage V

COREFBH

PWRGD

(Open Drain Output) V

Blanking Time t

PWRGD,BLNK

0.9 V < V

V

COREFB

V

COREFB

V

COREFB

V

COREFB

V

COREFB

COREFB

2

VCC = 3.3 V 100 µs

< 1.675 V

DAC

Rising 1.12 V

Falling 1.095 V

Rising 0.88 V

Falling 0.855 V

= V

DACOUT

= 0.8 V

DACOUT

0.95 V

0 0.8 V

DAC

DAC

DAC

DAC

CC

1.145 V

1.12 V

0.905 V

0.88 V

V

SOFT-START/HICCUP TIMER

Charge/Discharge Current I

Soft-Start Enable/Hiccup V

SS

SSEN

Termination Threshold V

Soft-Start Termination/Hiccup V

SSTERM

Enable Threshold V

VSS = 0.5 V –16 µA

= 0.5 V, VCC = 2.5 V 0.6 µA

V

SS

V

= 1.25 V,

REG

= V

RAMP

Falling 150 200 mV

V

SS

V

Rising 200 mV

SS

V

= V

RAMP

Rising 2.05 V

SS

COREFB

COREFB

= 1.27 V

= 1.27 V

VSS Falling 2.0 V

VID DAC

VID Input Threshold (CMOS Inputs) V

VID Input Current I

VID0...4

VID0...4

VID 0...4 = L 10 40 µA

0.8 0.7 V

(Internal Active Pull-up)

Output Voltage V

Output Voltage Accuracy ⌬V

Output Voltage Settling Time

3

t

DACS

DAC

DAC/VDAC

4

See VID Code Table 1 0.600 1.750 V

–0.85 +0.85 %

1.3 µs

CORE COMPARATOR

Input Offset Voltage V

Input Bias Current I

Output Voltage V

Propagation Delay Time

Rise and Fall Time

3

2

Blanking Time t

COREOS

REG

OUT_H

V

OUT_L

t

RMPOUT_PD

6

t

OUT_R

6

t

OUT_F

BLNK

V

= 1.25 V ±1.5 mV

REG

V

REG

= V

= 1.25 V ±0.3 µA

RAMP

VCC = 3.0 V 2.5 3.0 V

VCC = 3.6 V 0 0.4 V

5

50 ns

310 ns

310 ns

OUT L-H Transition 75 ns

OUT H-L Transition 140 ns

Switch Feedback Threshold V

SWFB_TH

VCC/2 V

(CMOS Input)

COREFB

CLAMP

CC

= V

DAC

= 5.1 k⍀

DAC

DAC

DAC

DAC

CC

V

V

V

V

V

V

–2–

REV. 0

Page 3

ADP3422

Parameter Symbol Conditions Min Typ Max Unit

HYSTERESIS SETTING

Hysteresis Current I

Hysteresis Reference Voltage V

SHIFT SETTING

Battery-Shift Current I

Battery-Shift Reference Voltage V

DeepSleep-Shift Current I

DeepSleep-Shift Reference Voltage V

CPU-FID-Shift Current I

CPU-FID-Shift Reference Voltage V

SHIFT CONTROL INPUTS

BOM Threshold V

(CMOS Input)

DSLP Threshold V

(IO-Level CMOS Input)

DPRSLP Mode Threshold V

(CMOS Input)

CURRENT LIMIT COMPARATOR

Input Offset Voltage V

Input Bias Current I

Hysteresis Current I

Propagation Delay Time t

RAMP_H

HYSSET

RAMPB

BSHIFT

RAMPD

DSHIFT

RAMPF

FSHIFT

BOM

DSLP

DPRSLP

CLIMOS

CS+

CS–

5

CLPD

V

= 1.25 V

REG

V

I

V

I

I

V

I

I

V

I

I

V

I

I

= V

COREFB

HYSSET

RAMP

HYSSET

HYSSET

RAMP

HYSSET

HYSSET

RAMP

HYSSET

HYSSET

RAMP

HYSSET

HYSSET

DAC

= 0 ±1 µA

= 1.23 V, BOM = H

= –10 µA +8 +10 +12 µA

= –100 µA +89 +100 +111 µA

= 1.27 V, BOM = H

= –10 µA –8 –10 –12 µA

= –100 µA –89 –100 –111 µA

= 1.23 V, BOM = L

= –10 µA +6.4 +8 +9.6 µA

= –100 µA +71 +80 +89 µA

= 1.27 V, BOM = L

= –10 µA –6.4 –8 –9.6 µA

= –100 µA –71 –80 –89 µA

1.61 1.7 1.79 V

V

= 1.25 V –92.5 –100 –107.5 µA

VID

I

= –100 µA, BOM = L

BSHIFT

DSLP = H, V

V

= 1.25 V –92.5 –100 –107.5 µA

VID

= –100 µA, BOM = H

I

DSHIFT

DSLP = L, V

V

= 1.25 V –92.5 –100 –107.5 µA

VID

I

= –100 µA, BOM = L

FSHIFT

DSLP = H, V

CPUSET

CPUSET

CPUSET

= 0 V

= 0 V

= 2 V

V

V

V

DAC

DAC

DAC

V

V

V

VCC/2 V

0.9 V

VCC/2 V

V

= 1.25 V ±0.2 ±6mV

CS–

V

= 1.25 V –0.3 µA

CS+

V

V

V

V

V

V

= V

COREFB

= V

REG

CS+

CS+

CS+

CS+

CS–

I

HYSSET

= 1.23 V BOM = H

I

HYSSET

I

HYSSET

= 1.27 V, BOM = H –1.5 –3 µA

I

HYSSET

I

HYSSET

= 1.23 V, BOM = L

I

HYSSET

I

HYSSET

= 1.27 V, BOM = L

I

HYSSET

I

HYSSET

= 1.23 V

RAMP

= 1.25 V

= 0 –0.6 –3 µA

= –10 µA –27 –31.5 –36 µA

= –100 µA –270 –301.5 –333 µA

= –10 µA –18 –21.5 –25 µA

= –100 µA –180 –201.5 –223 µA

= –10 µA –21 –25.5 –30 µA

= –100 µA –226 –241.5 –267 µA

= –10 µA –14 –17.5 –21 µA

= –100 µA –144 –161.5 –179 µA

65 ns

REV. 0

–3–

Page 4

ADP3422–SPECIFICATIONS

(continued)

Parameter Symbol Conditions Min Typ Max Unit

LOW-SIDE DRIVE CONTROL

Output Voltage (CMOS Output) V

Output Current I

DRVLSD

DRVLSD

DPRSLP = H 0.4 V

DPRSLP = L 0.7 V

V

DRVLSD

= 1.5 V

CC

V

CC

V

DPRSLP = L +0.4 mA

DPRSLP = H –0.4 mA

OVER/REVERSE VOLTAGE

PROTECTION

Over-Voltage Threshold V

COREFB,OVPVCOREFB

V

Reverse-Voltage Threshold V

COREFB,RVPVCOREFB

V

Output Current (Open Drain Output) I

CLAMP

V

V

V

NOTES

1

All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods.

2

Two test conditions:

1. PWRGD is OK but forced to fail by applying an out-of-the-CoreGood-window voltage (V

after the moment that BOM or DPRSLP is asserted/deasserted. PWRGD should not fail immediately, only with the specified blanking delay time.

2. PWRGD is forced to fail (V

BOM or DPRSLP is asserted/deasserted. PWRGD should not go high immediately, only with the specified blanking delay time.

3

Guaranteed by characterization.

4

Measured from 50% of VID code transition amplitude to the point where V

5

40 mV p-p amplitude impulse with 20 mV overdrive. Measured from the input threshold intercept point to 50% of the output voltage swing.

6

Measured between the 30% and 70% points of the output voltage swing.

Specifications subject to change without notice.

COREFB,BAD

= 1.0 V at V

= 1.25 V setting) but gets into the CoreGood-window (V

VID

Rising 2.0 2.2 V

Falling 1.8 V

COREFB

Falling –0.3 V

Rising –0.05 V

COREFB

= 1.5 V

CLAMP

= 2.2 V 10 µA

COREFB

COREFB

DACOUT

= V

settles within ± 1% of its steady state value.

= 1.25 V 1 4 mA

DACOUT

COREFB,BAD

= 1.0 V at V

= 1.25 V setting) to the COREFB pin right

VID

COREFB,GOOD

= 1.25 V) right after the moment that

–4–

REV. 0

Page 5

ADP3422

ABSOLUTE MAXIMUM RATINGS*

PIN CONFIGURATION

Input Supply Voltage (VCC) . . . . . . . . . . . . . . –0.3 V to +7 V

UVLO Input Voltage . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

All Other Inputs/Outputs . . . . . . . . . –0.3 V to (VCC + 0.3 V)

Operating Ambient Temperature Range . . . . . . . 0°C to 85°C

Junction Temperature Range . . . . . . . . . . . . . . . 0°C to 150°C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98°C/W

θ

JA

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . 300°C

*This is a stress rating only; operation beyond these limits can cause the device to

be permanently damaged.

ORDERING GUIDE

Temperature Package Package

HYSSET

CPUSET

FSHIFT

DSHIFT

BSHIFT

VID4 (MSB)

VID3

VID2

VID1

VID0 (LSB)

BOM

DSLP

DPRSLP

PWRGD

1

2

3

4

5

6

ADP3422

7

TOP VIEW

(Not to Scale)

8

9

10

11

12

13

14

Model Range Description Option

ADP3422JRU 0°C to 85°C Thin Shrink Small RU-28

Outline (TSSOP)

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the ADP3422 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

28

CS–

CS+

27

REG

26

RAMP

25

VCC

24

23

OUT

GND

22

21

DACOUT

20

COREFB

SS

19

18

SWFB

17

DRVLSD

16

CLAMP

15

SD

WARNING!

ESD SENSITIVE DEVICE

REV. 0

–5–

Page 6

ADP3422

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Function

1 HYSSET Hysteresis Set. This is an analog I/O pin whose output is a voltage reference and whose input is a

current that is programmed by an external resistance to ground. The current is used in the IC to set

the hysteretic currents for the Core Comparator and the Current Limit Comparator. Modification of the

resistance will affect both the hysteresis of the feedback regulation and the current limit set point and

hysteresis. The application circuit suggests a resistor divider, as this pin’s functionality is used to supply a

divided reference voltage to another high-impedance pin.

2 CPUSET CPU Set. This is a high-impedance analog input pin to which a reference voltage is applied via a

resistor divider (e.g., from the HYSSET pin). The applied reference to this pin sets a threshold that

lies between two VID codes, each of which represents the Battery Optimized Mode (BOM) VID code

of a certain CPU. At startup of the CPU regulator, the BOM VID code is received and the corresponding

DACOUT voltage is compared against the CPUSET voltage. The type of CPU is then categorized

as being in one of two frequency categories, the lower of which has a lower BOM VID code. The

information is latched into the IC and, if the lower frequency CPU has been detected, is used to add

a downward shift of the regulated core voltage to the optimum level. The shift is performed using the

FSHIFT and RAMP pins.

3 FSHIFT Frequency Shift. This is an analog I/O pin whose output is a voltage reference and whose input is a

current that is programmed by an external resistance to ground. The current is used in the IC to

set a switched bias current out of the RAMP pin, depending on whether it is activated by the

latched function of the CPUSET pin. When activated, this added bias current creates a downward

shift of the regulated core voltage to a predetermined optimum level for regulation corresponding

to the frequency range of the CPU.

4 DSHIFT Deep Sleep Shift. This is an analog I/O pin whose output is a voltage reference and whose input is a

current that is programmed by an external resistance to ground. The current is used in the IC to

set a switched bias current out of the RAMP pin, depending on whether it is activated by the DSLP

signal. When activated, this added bias current creates a downward shift of the regulated core voltage

to a predetermined optimum level for regulation corresponding to Deep Sleep mode of CPU operation.

5 BSHIFT Battery Optimized Mode Shift. This is an analog I/O pin whose output is a voltage reference and

whose input is a current that is programmed by an external resistance to ground. The current is

used in the IC to set a switched bias current out of the RAMP pin, depending on whether it is activated by

the BOM signal. When activated, this added bias current creates a downward shift of the regulated core

voltage to a predetermined optimum level for regulation corresponding to Battery Optimized Mode of

CPU operation.

6 VID4 VID Input. Most significant bit.

7 VID3 VID Input

8 VID2 VID Input

9 VID1 VID Input

10 VID0 VID Input. Least significant bit.

11 BOM Battery Optimized Mode (active low). This is a digital input pin coming from a system signal

corresponding to Battery Optimized Mode of the CPU operation in its active low state and Performance

Optimized Mode (POM) in its disactivated high state. The signal controls the optimal positioning

of the core voltage regulation level according to the functionality of the BSHIFT and RAMP pins.

It is also used to initiate a blanking period for the PWRGD signal (to disable its response to a pending

dynamic core voltage change according to the VID code) whenever a signal transition occurs.

12 DSLP Deep Sleep Mode (active low). This is a digital input pin coming from a system signal which, in

its active state, corresponds to Deep Sleep mode of the CPU, which is a subset operating mode of

either BOM or POM operation. The signal controls the optimal positioning of the core voltage regulation

level according to the functionality of the DSHIFT and RAMP pins.

–6–

REV. 0

Page 7

ADP3422

Pin No. Mnemonic Function

13 DPRSLP Deeper Sleep Mode (active high). This is a digital input pin coming from a system signal corresponding to

Deeper Sleep mode of the CPU operation in its active high state. It is used to initiate a blanking period

for the PWRGD signal (to disable its response to a pending dynamic core voltage change according to the

VID code) whenever a signal transition occurs.

14 PWRGD Power Good (active high). This is an open drain output pin which, via the assistance of an external

pull-up resistor, indicates that the core voltage is within the specified tolerance of the VID programmed

value or else in a VID transition state as indicated by a recent state transition of either the BOM or

DPRSLP pins. PWRGD is deactivated (pulled low) when the IC is disabled or in UVLO mode or

soft-start. The open drain output allows external ORing with other open drain/collector powergood indicators.

15 SD Shutdown (active low). This is a digital input pin coming from a system signal which, in its active

state, shuts down the IC operation, placing the IC in its lowest quiescent current state for maximum

power savings.

16 CLAMP Clamp (active high). This is an open drain output pin which, via the assistance of an external pull-up

resistor, indicates that the core voltage should be clamped for its protection. To allow the highest

level of protection, the CLAMP signal is developed using both a redundant reference and a redundant feedback path with respect to those of the main regulation loop. It is also latched. In a

preferred and more conservative configuration, the core voltage is clamped by an external FET.

The initial protection function is served when it is activated by detection of either an overvoltage or a

reverse-voltage condition on the COREFB pin. A backup protection function due to loss of the

latched signal at IC power-off is served by connecting the pull-up resistor to a system “ALWAYS”

regulator output (e.g., V5_ALWAYS). If the external FET is used, this implementation will keep the

core voltage clamped until the ADP3422 has power reapplied, thus keeping protection for the

CPU even after a hard-failure power-down and restart (e.g., a shorted top FET).

17 DRVLSD Drive-Low Shutdown (active low). This is a digital output pin which, in its active state, indicates that

the lower FET of the core VR should be disabled. In the suggested application schematic this pin is

directly connected to the pin of the same name on the ADP3415 or other driver IC. The pin is normally

asserted in the light load condition, but its assertion will be deactivated by the consideration of a

number of dynamic conditions where operation of the lower FET may be needed.

18 SWFB Switched Node Feedback. This is a high-impedance analog input pin that is used to allow the

ON-time noise blanking function to terminate earlier than its internally preset time by its indication

that the turn-ON of the upper FET has occurred. A resistor must be inserted between the pin and the

switched node of the core VR so that the input can be clamped (at ~7V) and is not exposed to

high voltage. This pin can also be shorted to ground if the need for this speed enhancement is

deemed unnecessary.

19 SS Soft Start. This is an analog I/O pin whose output is a controlled current source used to charge or

discharge an external grounded capacitor and whose input is the detected voltage that is indicative of

elapsed time. The pin controls the soft start time of the IC as well as the hiccup cycle time during

short circuit. Hiccup operation is a feature that was added to reduce short circuit power dissipation by

more than an order of magnitude, while still allowing an automatic restart when the short is removed.

20 COREFB Core Feedback. This is a high-impedance analog input pin that is used to monitor the output voltage

for setting the proper state of the PWRGD and CLAMP pins. It is generally recommended to

RC-filter the noise from the monitored core voltage, as suggested by the application schematic.

21 DACOUT VID-Programmed Digital-to-Analog Converter Output. This voltage is the reference voltage for output

voltage regulation.

22 GND Ground

23 OUT Driver Command Output Signal. This is a digital output pin which is used to command the state of the

switched node via the driver. It should be connected to the IN pin of the ADP3415 or similar driver.

24 VCC Power Supply

REV. 0

–7–

Page 8

ADP3422

Pin No. Mnemonic Function

25 RAMP Regulation Ramp Feedback Input. This is a high-impedance analog input pin which is used for providing

negative feedback of the hysteretically-controlled output. Several switched current sources also

appear at this input, most notably the cycle-by-cycle hysteresis-setting switched current programmed by

the HYSSET pin. The external resistive termination at this pin sets the magnitude of the hysteresis

applied to the regulation loop.

26 REG Regulation Voltage Summing Input. This is a high-impedance analog input pin into which the voltage

reference of the feedback loop allows the summing of both the DACOUT voltage and the core voltage for

programming the output resistance of the core voltage regulator. This is also the pin at which an optimized

transient response can be tailored using Analog Devices’ patented ADOPT™ design technique.

27 CS+ Current Limit Positive Sense. This is a high-impedance analog input pin that is normally connected to the

positive node of the current sense resistor.

28 CS– Current Limit Negative Sense. This is a high-impedance analog input pin that is normally connected via

a current-limit programming resistor to the negative node of the current sense resistor. A hystereticallycontrolled current—three times the current programmed at the HYSSET pin—flows out of this pin

and develops a current-limit-setting voltage across that resistor. This voltage must be exceeded by the

inductor current generated current sense voltage in order to trigger the current limit function. When it is

triggered, the current flowing out of this pin is reduced—to two-thirds of its previous value—producing

hysteresis in the current limit operation.

ADOPT is a trademark of Analog Devices, Inc.

–8–

REV. 0

Page 9

10000

100

–100

020

HYSTERESIS CURRENT – A

40 60 80 100

0

OUT = HIGH, RHYS = 17k⍀

OUT = HIGH, RHYS = 170k⍀

OUT = LOW, RHYS = 170k⍀

OUT = LOW, RHYS = 17k⍀

TEMPERATURE – ⴗC

100

0.01

0.1 1 10 100

1

10

0.1

TIMING CAPACITANCE – nF

SOFT-START TIME – ms

NORMAL OPERATING MODE

1000

100

UVLO MODE

10

Typical Performance Characteristics–ADP3422

SUPPLY CURRENT – A

1

SHUTDOWN MODE

0.1

0 10020

40 60 80

TEMPERATURE – ⴗC

TPC 1. Supply Current vs. Temperature

1.765

1.750

1.735

0.605

DAC OUTPUT – V

0.600

0.595

0 10020

+0.85%

FULL SCALE

–0.85%

+0.85%

ZERO SCALE

–0.85%

40 60 80

AMBIENT TEMPERATURE – ⴗC

TPC 2. DAC Output Voltage vs. Temperature

TPC 4. Core Hysteresis Current vs. Temperature

0

–50

OUT = LOW, R

–100

–150

–200

OUT = LOW, R

– PIN CURRENT – A

L

–250

C

–300

OUT = HIGH, R

–350

020

TPC 5. Current Limit Programming Current

vs. Temperature

= 170k⍀

HYSSET

HYSSET

HYSSET

OUT = HIGH, R

= 17k⍀

= 17k⍀

40 60 80 100

TEMPERATURE – ⴗC

HYSSET

= 170k⍀

HIGH

POWER GOOD

LOW

–15 15–10 –5510

TPC 3. Power Good vs. Relative Core Voltage Variation

REV. 0

RELATIVE CORE VOLTAGE – %

0

TPC 6. Soft-Start Time vs. Timing Capacitance

–9–

Page 10

ADP3422

APPLICATION INFORMATION

This application section presents both the theoretical background

and the detailed procedure for designing dc/dc converters with

the ADP3422 controller for mobile CPUs. The ADP3422 is

used in a unique ripple regulator (also called hysteretic regulator)

configuration, which allows employing ADOPT, Analog Devices’

optimal voltage positioning technique to implement the output

desired voltage impedance statically and dynamically, as required

by Intel’s IMVP-2 specification.

Hysteretic Regulator

Figure 1 shows the conventional hysteretic regulator and the

characteristic waveforms. The operation is as follows. During

the time the upper transistor, Q1, is turned on, the inductor

current, I

V

OUT

, and also the output voltage, V

L

reaches the upper threshold of the hysteretic comparator,

, increase. When

OUT

Q1 is turned off, Q2 is turned on, and the inductor current and also

the output voltage begin to decrease. The cycle repeats after

reaches the lower threshold of the hysteretic comparator.

V

OUT

V

IN

Q1

Q2

V

H

L

I

V

L

V

SW

C

R

V

REF

OUT

O

E

LOAD

V

OUT

V

H

V

SW

I

L

Figure 1. Conventional Hysteretic Regulator and Its

Characteristic Waveforms

The switching frequency is determined by the equivalent series

resistance R

of the output capacitor, the inductance L of the

E

inductor, the input and output voltages, and the hysteresis

V

of the comparator. It is as follows:

H

RLVVVV

( – )

EHIN OUT OUT

f

=

V

IN

(1)

Since there is no voltage-error amplifier in the hysteretic regulator,

its response to any change in the load current or the input voltage is virtually instantaneous. Therefore, the hysteretic regulator

represents the fastest possible dc/dc converter control technique.

A slight disadvantage of the hysteretic regulator is that its frequency

varies with the input and output voltages. In a typical mobile CPU

converter application, the worst-case frequency variation due to

the input voltage variation is in the order of 30%, which is usually acceptable. In the simplest implementation of the hysteretic

converter, shown in Figure 1, the frequency also varies proportionally with the ESR of the output capacitor. Since the initial value

is often poorly controlled, and the ESR of electrolytic capacitors

also changes with temperature and age, practical ESR variations

can easily lead to a frequency variation on the order of three to

one. However, using the ADP3422 controller in a modified

hysteretic topology eliminates the dependence of the operating

frequency on the ESR. In addition, the modification allows the

optimal implementation, ADOPT, of the Intel’s IVMP-2 load-line

specification. Figure 2 shows the modified hysteretic regulator.

V

IN

Q1

Q2

V

H

L

I

R

L

CS

C

OC

R

C

R

D

V

OUT

C

O

LOAD

R

E

V

REF

Figure 2. Modified Hysteretic Regulator with ADOPT

The implementation requires adding a resistive divider (RC and

) between the reference voltage and the output, and connecting

R

D

the tap of the divider to the noninverting input of the hysteretic

comparator. A capacitor, C

) of the divider.

ber (R

C

, is placed across the upper mem-

OC

It is easily shown that the output impedance of the converter can

be no less than the ESR of the output capacitor. A straightforward derivation demonstrates that the output impedance of the

converter in Figure 2 can be minimized to equal the ESR, R

,

E

when the following two equations are valid (neglecting PCB

trace resistance for now):

RRRR

DCECS

–

=

R

CS

(2)

and

2

CR

OC

=

RR

OE

CS D

(3)

C

From (3), the series resistance is:

R

R

CS

E

=

R

D

+1

R

C

(4)

This is the ADOPT configuration and design procedure that

allows the maximum possible ESR to be used while meeting a

given load-line specification.

It can be seen from (4) that unless R

R

will be always smaller than RE. An advantage of the circuit

CS

of Figure 2 is that if we select the ratio R

the additional dissipation introduced by the series resistance R

is zero or RC is infinite,

D

well above unity,

D/RC

CS

will be negligible. Another interesting feature of the circuit in

Figure 2 is that the ac voltage across the two inputs of the hysteretic comparator is now equal only to the ac voltage across

. This is due to the presence of the capacitor COC, which

R

CS

effectively couples the ac component of the output voltage to the

noninverting input voltage of the comparator. Since the comparator sees only the ac voltage across R

, in the circuit of

CS

Figure 2 the dependence of the switching frequency on the ESR

of the output capacitor is completely eliminated. Equation (5)

presents the expression for the switching frequency.

RLVVV V

( – )

CSHIN OUT OUT

f

=

V

IN

(5)

–10–

REV. 0

Page 11

7V–21V

V_DC

C23

C22

C21

C20

C19

C18

C17

ADP3422

C33

CORE

V

C32

C31

C30

C29

C28

C27

150F

150F

150F

150F

150F

150F

150F

10F

10F

10F

10F

10F

10F

0.1F

L1

0.66H

CS

R

D1

V_5S

BAR43S

C3

C2

C1

C12

0.1F

1000pF

0.1F

10F

C16

0.1F

C15

0.1F

10

BST

ADP3415

IN

12345

Q2

Q1

IR7807V IR7807V

987

SW

DRVH

SD

DRVLSD

CORE_ON

D2

D3

GND

DLY

6

DRVL

VCC

R7

Q3 Q4 Q5

IR7811W IR7811W IR7811W

V_3S

CSF

CSF

R

C

A

R

CL

R

C

OC

R

C

D

R

C8

R6

2.7⍀

28272625242322212019181716

CS–

C4

10pF

CS+

REG

C5

10pF

RAMP

VCC

C6

OUT

R9

C9

10nF

1F

47nF

0.1F

GND

DACOUT

COREFB

C26

C25

C24

V_5 ALWAYS

C10

R12

SS

150F

150F

150F

Q6

IR7807V

R15

5.1k⍀

10k⍀

CLAMP

DRVLSD

CORE_ON

15

SD

SS

C

SWFB

REV. 0

ADP3422

HYSSET

CPUSET

FSHIFT

234

DSHIFTRBSHIFT

FSHIFT

R

R

DSHIFT

SET2

R

SET1

R

1

Figure 3. Application Circuit

–11–

BSHIFT

VID4

VID3

VR_VID4

VR_VID3

VID2

VR_VID2

56789

VID1

VID0

BOM

1011121314

VR_VID1

VR_VID0

GMUXSEL

DSLP

DPRSLP

DPSLP

DPRSLPVR

PWRGD

V_3S

R19

5.1k⍀

Page 12

ADP3422

Application Schematic

Figure 3 shows the simplified application schematic of the

ADP3422 control IC. The ADP3422, together with its companion dual MOSFET driver IC, the ADP3415, controls a

hysteretic converter that generates the core voltage for the CPU.

Design Procedure—Power Stage Components

The first step of the converter design is to select the MOSFETs

to be used based on acceptable dc and switching losses. For this

selection, the designer is referred to the MOSFET manufacturers who may provide not only a recommendation for the

MOSFETs to be used for the specific application, but also

data and/or guidelines for determining an acceptable maximum operating frequency.

With this information, the next step is to choose an inductance

value—usually the smallest available value, that will yield an

acceptable ripple current. A ripple current 30%~60% of the

maximum core current is recommended. Inductance, frequency,

and ripple current are related by formula (6), derived from (5):

L

1(– )

=

fI

MAX RPP

IM VID VID

V

IM

(6)

VVV

where:

L = inductance value

f

= maximum acceptable switching frequency

MAX

I

= selected peak-to-peak ripple current

RPP

V

= maximum input voltage

IM

V

= nominal programmed VID voltage

VID

Assuming f

= 1.25 V, the required inductance value is L = 729 nH.

V

VID

= 250 kHz, I

MAX

= 8 A, VIM = 20 V, and

RPP

A standard value of 660 nH is available.

The next step is to select the current sensing resistor, R

CS

. The

restrictions are that (1) the resistance should not be higher than

the core converter output impedance defined by Intel’s IMVP-2

specification, and (2) the resistance should not be so low that

the errors in reading the current sense signal become a problem.

The IMVP-2 specification requires that the converter output

impedance, R

, be 4 mΩ. An RCS value of above one-quarter

OUT

of the nominal output impedance provides sufficient protection

against errors in the current sense signal. The chosen value is

= 1.5 mΩ.

R

CS

Also, the power dissipation, P

, should be calculated to ensure

CS

that a properly sized resistor is selected:

PRI

CS CS O MAX=()

where I

O(MAX)

example I

O(MAX)

2

is the maximum output current. In this design

= 19 A. The resulting dissipation of the current

(7)

sense resistor is 542 mW.

The final step in finishing the design of the power stage is selecting the output capacitors. There are two primary considerations

in choosing those capacitors. The total ESR may not exceed the

output resistance required by Intel’s IMVP-2 specification. Also

the total capacitance must be checked to make sure that it is

sufficient to prevent overshoot beyond the voltage step caused

by the ESR during a full load transient, according to the formula:

LI I

( – )

×

O MAX O MIN

C

OMIN

()

=

where I

is the minimum rated current for the normal

O(MIN)

operation region of the CPU where I

() ()

RV

×

OUT L

O(MAX)

(8)

can occur, and VL is

the voltage applied across the inductor in order to ramp the

current in the direction of the load step. The minimum CPU

voltage represents a critical performance limit that must not be

violated during a load step increase. Therefore, the minimum

capacitance must never be less than the calculated value when

using V

= V

L

I(MIN)

– V

in (8) the voltage applied across the

VID

inductor to ramp up the current. However, overshoot would still

occur unless the capacitance is greater than the calculated value

= V

when using V

L

in (8). The magnitude of the overshoot is

VID

given by:

L

V

OS

I

=+

O MAX

C

O

I

RPP

() () ()

2

2

–––

22

+

IVRIV

O MIN VID OUT O MAX VID

[]

(9)

For this design example, output capacitors with a capacitance

of 150 µF and a maximum ESR of 20 mΩ are chosen. Given

the target of R

= 4 mΩ, five capacitors would be needed to

OUT

achieve a total ESR of not more than 4 mΩ. The total capacitance of five of these capacitors is 750 µF. This capacitance is

greater than the value required for a load step increase, even

for an input voltage as low as 6 V; but it is less than what is

needed to prevent an overshoot for a load step decrease, where

only the output voltage is applied across the inductor to ramp

down the current to the minimum value. Assuming that the

minimum current is zero, the overshoot above V

is 89 mV.

VID

Design Procedure—Control Circuit Components

The output resistance is implemented by using the proper ratio

of two resistors, which connect to the REG pin. One resistor,

, connects to the DAC reference and the other, RC, connects

R

D

to the core voltage. From (2):

RRRRR

DCET CS

where R

––

=

R

CS

is the PCB trace resistance between the current sense

T

(10)

resistor and the CPU measurement point.

There is no inherent restriction on the absolute value of either

R

or RC, but values in the single kΩ range are recommended.

D

These resistors can now be selected.

–12–

REV. 0

Page 13

ADP3422

A capacitor is required across RC to achieve optimal compensation.

This ensures that the output voltage does not bounce back temporarily right after a load transient, i.e., the output impedance of

the converter is purely resistive. The bounce-back is undesirable

because it increases the peak-to-peak deviation in the output

voltage. From (3), the optimal capacitance value is:

CR

OC

=

RR

OE

CD

value should be selected as close to

OC

(11)

C

At this point, the exact C

the calculated one as possible. It is generally recommended to

choose the nearest value of C

is calculated. Optionally, C

the values of R

and RC can be reselected to satisfy the previous

D

which is not greater than what

OC

can be chosen first arbitrarily and

OC

two equations.

The output impedance is now set.

The next step in the design is to determine the value of the

hysteresis-setting resistor, R

current. R

connects between the RAMP pin and RCS on the

A

, which sets the inductor ripple

A

inductor side and is determined by:

R

A

where t

IR Vt RL

RPP CS IM D OFF CS

=

D(OFF)

– /

I

2

()

H

(12)

is the turn-off delay time of the power converter,

including delays through the ADP3422, ADP3415, and the

external MOSFETs, and I

is a user-programmed current set

H

by a resistor on the ADP3422’s HYSSET pin, which sets the

current that is hysteretically switched in and out of the RAMP

pin. Assuming a turn-off delay of 50 ns and a hysteresis-setting

current of 30 µA, the calculated value of R

is 162 Ω.

A

To protect the converter, the hysteretic current limiting should

be set. The current limit programming resistor, R

, which

CL

connects between the CS– pin and the core output is given by:

kR I I

R

I CS O MAX RPP

=

CL

where k

is a margin factor for the current limit setting. A

I

typical value for k

I

+(/)

()

I

3

H

2

(13)

might be 1.15, which would set the current

limit point 15% above the maximum rated core current. Using

the preceding design target values, a value of 441 Ω for R

CL

is

calculated.

In order to optimize the power savings by always using the

minimum allowed CPU supply voltage, the IMVP-2 specification introduces two operating-mode-dependent voltage shifts.

The first shift is for optimizing the output voltage when the

battery-optimized-mode (BOM) VID code is selected. The

shift is achieved by connecting a resistor, R

BSHIFT

, between

the BSHIFT pin and ground. The shift will be used whenever

the BOM pin is driven low, indicating that the BOM VID

code is selected. The shift is given by:

V

BSHIFT

R

–

A

BSHIFT

V

VID BOM

=+

R

R

D

1

,

R

C

(14)

The second shift is for optimizing the output voltage when the

Deep Sleep operating mode is selected in conjunction with

either the POM or BOM VID codes. This shift is achieved by

connecting a resistor, R

, between the DSHIFT pin and

DSHIFT

ground. The shift will be used whenever the DPSLP pin is

driven low. The shift is given by:

V

DSHIFT

–

R

A

DSHIFT

V

VID BOM

=+

R

R

D

1

,

R

C

(15)

PRINTED CIRCUIT BOARD LAYOUT

CONSIDERATIONS

The following guidelines are recommended for optimal performance of the ADP3422 and ADP3415 in a power converter.

The circuitry is considered in three parts: the power switching

circuitry, the output filter, and the control circuitry.

Placement Overview

1. For ideal component placement, the output filter capacitors

will divide the power switching circuitry from the control

section. As an approximate guideline, considered on a

single-sided PCB, the best layout would have components

aligned in the following order: ADP3415, MOSFETs and

input capacitor, output inductor, current sense resistor, output

capacitors, control components and ADP3422. Note that

the ADP3422 and ADP3415 are completely separated for

an ideal layout, which is only possible with a two-chip solution.

This will minimize jitter in the control caused by having the

driver and MOSFETs close to the control and give more

freedom in the layout of the power switching circuitry.

2. Whenever a power dissipating component (e.g., a power

MOSFET) is soldered to a PCB, the liberal use of vias, both

directly on the mounting pad and immediately surrounding

it, is recommended. Two important reasons for this are:

improved current rating through the vias (if it is a current

path), and improved thermal performance—especially if

the vias extend to the opposite side of the PCB where a

plane can more readily transfer heat to air.

Power Switching Circuitry

ADP3415, MOSFETs, and Input Capacitors

3. Locate the ADP3415 near the MOSFETs so the parasitic

inductance in the gate drive traces and the trace to the SW

pin is small, and so that the ground pins of the ADP3415

are closely connected to the lower MOSFET’s source.

4. Locate at least one substantial (i.e., > ~10 µF) input bypass

MLC capacitor close to the MOSFETs so that the physical

area of the loop enclosed in the electrical path through the

bypass capacitor and around through the top and bottom

MOSFETs (drain-source) is small. This is the switching

power path loop.

5. Make provisions for thermal management of all the

MOSFETs. Heavy copper and wide traces to ground and

power planes will help to pull the heat out. Heat sinking

by a metal tap soldered in the power plane near the

MOSFETs will help. Even just small airflow can help

tremendously. Paralleled MOSFETs will help spread the

heat, even if the on-resistance is higher.

REV. 0

–13–

Page 14

ADP3422

6. An external “antiparallel” schottky diode (across the bottom

MOSFET) may help efficiency a small amount (< ~1 %); a

MOSFET with a built in antiparallel schottky is more effective. For an external schottky, it should be placed next to

the bottom MOSFET or it may not be effective at all. Also,

a higher current rating (bigger device with lower voltage

drop) is more effective.

7. The ground pin of the ADP3415 should be connected into

the power switching circuitry ground plane, and the VCC

bypass capacitor should be close to the VCC pin and connected into the same ground plane.

Output Filter

Output Inductor and Capacitors, Current Sense Resistor

8. Locate the current sense resistor very near to the output

capacitors.

9. PCB trace resistances from the current sense resistor to the

output capacitors, and from the output capacitors to the

load should be minimized, known (calculated or measured),

and compensated for as part of the design if it is significant.

(Remote sensing is not sufficient for relieving this requirement!) A square section of 1-ounce copper trace has a

resistance of ~500 mW. Using 2~3 squares of copper can

make a noticeable impact on a 15 A design.

10. Whenever high currents must be routed between PCB layers,

vias should be used liberally to create several parallel current

paths so that the resistance and inductance introduced by

these current paths is minimized and the via current rating is

not exceeded.

11. The ground connection of the output capacitors should be

close to the ground connection of the lower MOSFET and

it should be a ground plane. Current may pulsate in this

path if the power source ground is closer to the output

capacitors than the power switching circuitry, so a close

connection will minimize the voltage drop.

Control Circuitry

ADP3422, Control Components

12. If the placement overview cannot be followed, then in order

to avoid introducing ground noise from the power switching

stage into the control circuitry, the ground pin of the

ADP3422 should be Kelvin-connected into the ground plane

near the output capacitors. All other control components

should be grounded on that same signal ground.

13. If critical signal lines (i.e., signals from the current sense

resistor leading back to the ADP3422) must cross through

power circuitry, it is best if a signal ground plane can be

interposed between those signal lines and the traces of the

power circuitry. This serves as a shield to minimize noise

injection into the signals at the expense of making signal

ground a bit noisier.

14. Absolutely avoid crossing any signal lines over the switching

power path loop, described previously.

15. Accurate voltage positioning depends on accurate current

sensing, so the control signals which monitor the voltage

differentially across the current sense resistor should be

kelvin connected.

16. The RC filter used for the current sense signal should be

located near the control components.

Table I. VID Code

VID4 VID3 VID2 VID1 VID0 V

0 0 0 0 0 1.750

0 0 0 0 1 1.700

0 0 0 1 0 1.650

0 0 0 1 1 1.600

0 0 1 0 0 1.550

0 0 1 0 1 1.500

0 0 1 1 0 1.450

0 0 1 1 1 1.400

0 1 0 0 0 1.350

0 1 0 0 1 1.300

0 1 0 1 0 1.250

0 1 0 1 1 1.200

0 1 1 0 0 1.150

0 1 1 0 1 1.100

0 1 1 1 0 1.050

0 1 1 1 1 1.000

1 0 0 0 0 0.975

1 0 0 0 1 0.950

1 0 0 1 0 0.925

1 0 0 1 1 0.900

1 0 1 0 0 0.875

1 0 1 0 1 0.850

1 0 1 1 0 0.825

1 0 1 1 1 0.800

1 1 0 0 0 0.775

1 1 0 0 1 0.750

1 1 0 1 0 0.725

1 1 0 1 1 0.700

1 1 1 0 0 0.675

1 1 1 0 1 0.650

1 1 1 1 0 0.625

1 1 1 1 1 0.600

VID

–14–

REV. 0

Page 15

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

28-Lead Thin Shrink Small Outline Package (TSSOP)

(RU-28)

0.386 (9.80)

0.378 (9.60)

ADP3422

PIN 1

0.006 (0.15)

0.002 (0.05)

SEATING

PLANE

28

0.0256 (0.65)

BSC

0.0118 (0.30)

0.0075 (0.19)

15

0.177 (4.50)

0.169 (4.30)

141

0.0433 (1.10)

MAX

0.0079 (0.20)

0.0035 (0.090)

0.256 (6.50)

0.246 (6.25)

8ⴗ

0ⴗ

0.028 (0.70)

0.020 (0.50)

REV. 0

–15–

Page 16

C01882–.8–10/01(0)

–16–

PRINTED IN U.S.A.

Loading...

Loading...