Page 1

a

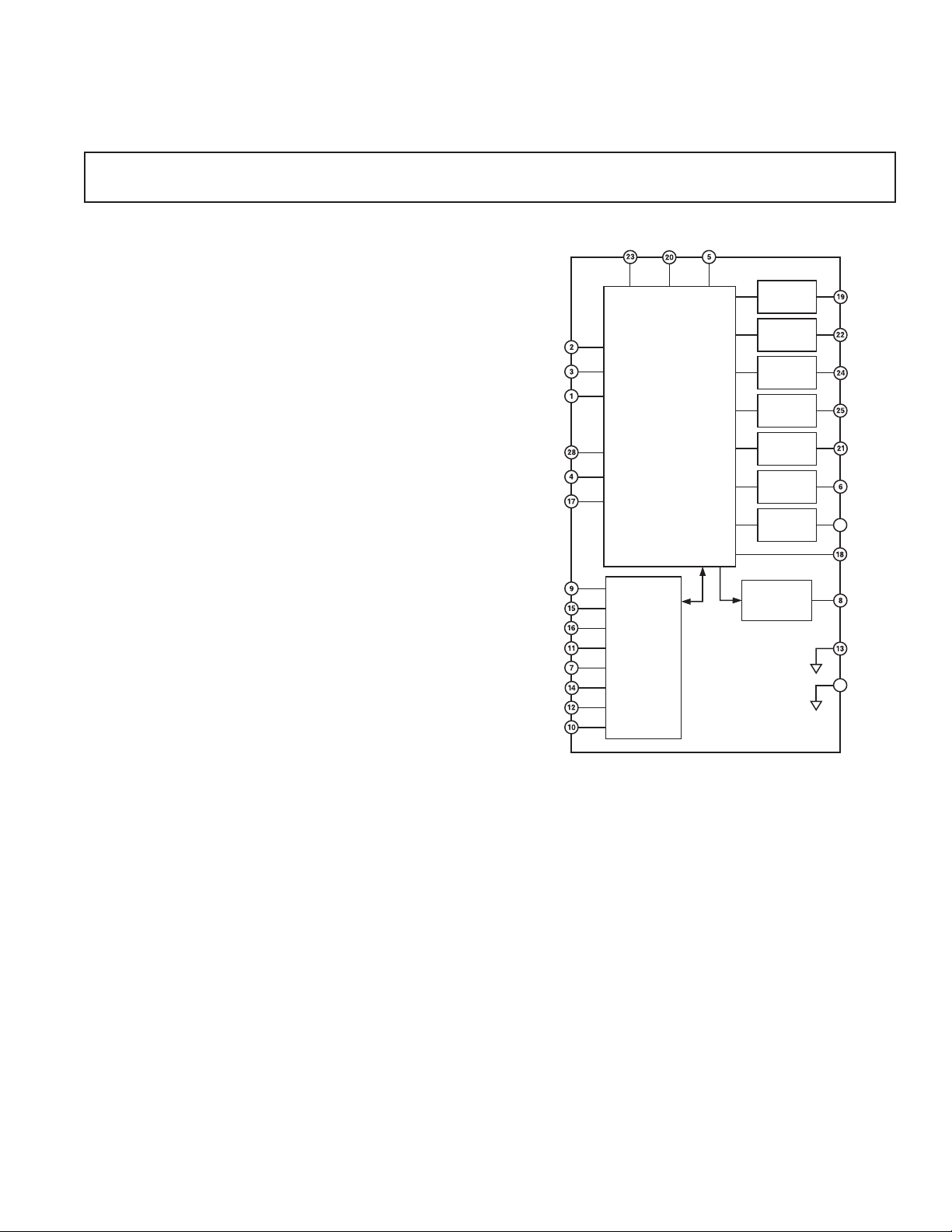

GSM Power Management System

ADP3408

FEATURES

Handles All GSM Baseband Power Management

6 LDOs Optimized for Specific GSM Subsystems

Li-Ion and NiMH Battery Charge Function

Optimized for the AD20msp430 Baseband Chipset

APPLICATIONS

GSM/DCS/PCS/CDMA Handsets

GENERAL DESCRIPTION

The ADP3408 is a multifunction power system chip optimized

for GSM handsets, especially those based on the Analog Devices

AD20msp430 system solution. It contains six LDOs, one to

power each of the critical GSM subblocks. Sophisticated controls are available for power-up during battery charging, keypad

interface, and RTC alarm. The charge circuit maintains low

current charging during the initial charge phase and provides an

end-of-charge signal when a Li-ion battery is being charged.

The ADP3408 is specified over the temperature range of –20°C to

+85°C and is available in a narrow body TSSOP 28-lead package

or 5 mm 5 mm LFCSP 32-lead package.

PWRONKEY

ROWX

PWRONIN

TCXOEN

SIMEN

RESCAP

CHRDET

EOC

CHGEN

GATEIN

BATSNS

ISENSE

GATEDR

CHRIN

FUNCTIONAL BLOCK DIAGRAM

VBAT VBAT2 VRTCIN

SIM

LDO

DIGITAL

CORE LDO

ANALOG

LDO

POWER-UP

SEQUENCING

AND

PROTECTION

LOGIC

BATTERY

CHARGE

CONTROLLER

ADP3408

TCXO

LDO

MEMORY

LDO

RTC

LDO

REF

BUFFER

BATTERY

CHARGE

DIVIDER

26

27

VSIM

VCORE

VAN

VTCXO

VMEM

VRTC

REFOUT

RESET

MVBAT

DGND

AGND

REV. A

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

(Pin Assignment Is for TSSOP Option)

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

Page 2

1

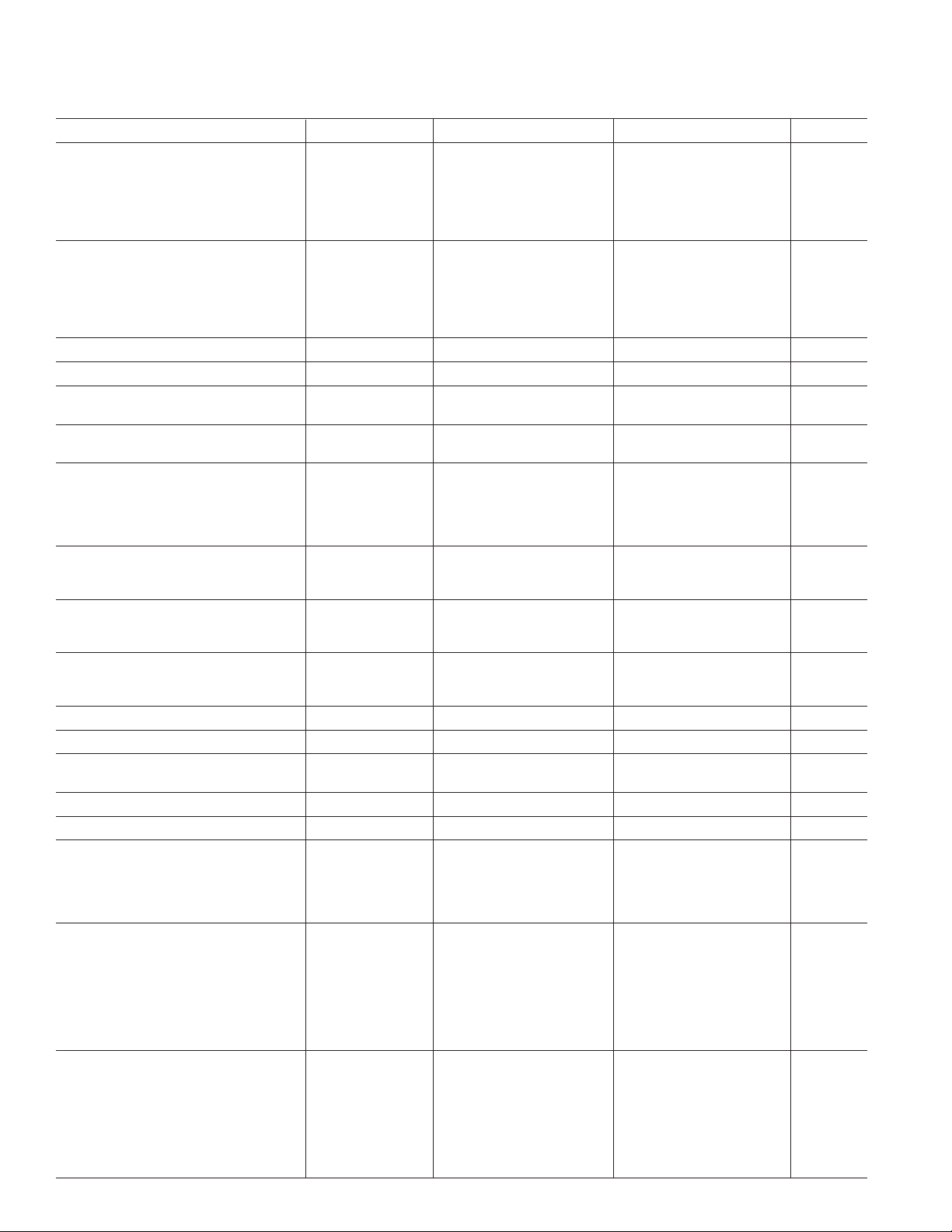

ADP3408–SPECIFICATIONS

CVMEM = 2.2 F, VTCXO = 0.22 F, CVRTC = 0.1 F, CVBAT = 10 F, minimum loads applied on all outputs, unless otherwise noted.)

Parameter Symbol Condition Min Typ Max Unit

SHUTDOWN SUPPLY CURRENT ICC

VBAT ≤ 2.5 V VBAT = VBAT2 = 2.3 V 7 20

(Deep Discharged Lockout Active)

2.5 V < VBAT ≤ 3.2 V VBAT = VBAT2 = 3.0 V 30 55

(UVLO Active)

VBAT > 3.2 V VBAT = VBAT2 = 4.0 V 45 80

OPERATING GROUND CURRENT IGND VBAT = 3.6 V

VSIM, VCORE, VMEM, VRTC On Minimum Loads 225 300

All LDOs On Minimum Loads 345 450

UVLO ON THRESHOLD VBAT 3.2 3.3 V

UVLO HYSTERESIS VBAT 200 mV

DEEP DISCHARGED LOCKOUT ON VBAT 2.4 2.75 V

THRESHOLD

DEEP DISCHARGED LOCKOUT VBAT 100 mV

HYSTERESIS

INPUT HIGH VOLTAGE V

(TCXOEN, SIMEN, 2.0 V

CHGEN, GATEIN)

PWRONIN (ADP3408-1.8) 1.1 V

PWRONIN (ADP3408-2.5) 2.0 V

INPUT LOW VOLTAGE V

(PWRONIN, TCXOEN, SIMEN,

CHGEN, GATEIN)

INPUT HIGH BIAS CURRENT I

(PWRONIN, TCXOEN, SIMEN,

CHGEN, GATEIN)

INPUT LOW BIAS CURRENT I

(PWRONIN, TCXOEN, SIMEN,

CHGEN, GATEIN)

PWRONKEY INPUT HIGH VOLTAGE V

PWRONKEY INPUT LOW VOLTAGE V

PWRONKEY INPUT PULL-UP 70 100 130 kΩ

RESISTANCE TO VBAT

THERMAL SHUTDOWN THRESHOLD

THERMAL SHUTDOWN HYSTERESIS 45 ºC

ROWX CHARACTERISTICS

ROWX Output Low Voltage V

ROWX Output High Leakage I

Current V(ROWX) = 5 V 1 µA

SIM CARD LDO (VSIM)

Output Voltage VSIM Line, Load, Temp 2.80 2.85 2.92 V

Line Regulation VSIM Min Load 2 mV

Load Regulation VSIM 50 µA ≤ I

Output Capacitor Required for Stability C

Dropout Voltage V

DIGITAL CORE LDO (VCORE)

Output Voltage

ADP3408ARU-2.5 VCORE Line, Load, Temp 2.40 2.45 2.50 V

ADP3408ARU-1.8 VCORE Line, Load, Temp 1.75 1.80 1.85 V

Line Regulation VCORE Min Load 2 mV

Load Regulation VCORE 50 µA ≤ I

Output Capacitor Required for Stability C

IH

IL

IH

IL

IH

IL

2

OL

IH

O

DO

O

(–20C ≤ TA ≤ +85C, VBAT = VBAT2 = 3 V–5.5 V, CVSIM = CVCORE = CVAN =

µ

A

µ

A

µ

A

µ

A

µ

A

Maximum Loads 1.0 3.0 % of max

load

current

0.3 V

1.0 µA

–1.0

µ

A

0.7 VBAT V

0.3 VBAT V

160 ºC

PWRONKEY = Low

IOL = 200 µA 0.4 V

PWRONKEY = High

≤ 20 mA, 1 mV

LOAD

VBAT = 3.6 V

2.2 µF

VO = V

I

LOAD

– 100 mV,

INITIAL

= 20 mA 35 100 mV

≤ 100 mA, 7 mV

LOAD

VBAT = 3.6 V

2.2 µF

–2–

REV. A

Page 3

ADP3408

Parameter Symbol Condition Min Typ Max Unit

RTC LDO

REAL-TIME CLOCK LDO/

COIN CELL CHARGER (VRTC)

Maximum Output Voltage

ADP3408ARU-2.5 VRTC 1 µA ≤ I

ADP3408ARU-1.8 VRTC 1 µA ≤ I

Off Reverse Input Current I

Output Capacitor Required for Stability C

L

O

VBAT = 2.15 V, TA = 25°C 0.5 µA

ANALOG LDO (VAN)

Output Voltage VAN Line, Load, Temp 2.40 2.45 2.50 V

Line Regulation VAN Min Load 2 mV

Load Regulation VAN 50 µA ≤ I

VBAT = 3.6 V

Output Capacitor Required for Stability C

Ripple Rejection

Output Noise Voltage V

O

VBAT/ f = 217 Hz 65 dB

VAN VBAT = 3.6 V

NOISE

f = 10 Hz to 100 kHz 80 µV rms

I

LOAD

VBAT = 3.6 V

TCXO LDO (VTCXO)

Output Voltage

ADP3408-2.5 VTCXO Line, Load, Temp 2.66 2.715 2.77 V

ADP3408-1.8 VTCXO Line, Load, Temp 2.711 2.750 2.789 V

Line Regulation VTCXO Min Load 2 mV

Load Regulation VTCXO 50 µA ≤ I

VBAT = 3.6 V

Output Capacitor Required for Stability C

Dropout Voltage V

Ripple Rejection

Output Noise Voltage V

O

DO

VBAT/ f = 217 Hz 65 dB

VTCXO VBAT = 3.6 V

NOISE

VO = V

I

LOAD

f = 10 Hz to 100 kHz 80 µV rms

I

LOAD

VBAT = 3.6 V

MEMORY LDO (VMEM)

Output Voltage VMEM Line, Load, Temp 2.744 2.80 2.856 V

Line Regulation

Load Regulation

VMEM

VMEM 50 µA < I

Min Load

VBAT = 3.6 V

Output Capacitor Required for Stability C

Dropout Voltage I

O

LOAD

I

LOAD

REFOUT

Output Voltage VREFOUT Line, Load, Temp 1.19 1.210 1.23 V

Line Regulation VREFOUT Min Load 0.2 mV

Load Regulation VREFOUT 0 µA < I

VBAT = 3.6 V

Ripple Rejection VBAT/ f = 217 Hz 65 75 dB

VREFOUT VBAT = 3.6 V, I

Maximum Capacitive Load C

Output Noise Voltage V

O

NOISE

f = 10 Hz to 100 kHz, 40 µV rms

VBAT = 3.6 V

RESET GENERATOR (RESET)

Output High Voltage V

Output Low Voltage V

Output Current I

Delay Time per Unit Capacitance T

Applied to RESCAP Pin

OH

OL

OL

I

OH

D

IOH = 500 µAV

IOL = –500 µA 0.25 V

V

OL

VOH = V

BATTERY VOLTAGE DIVIDER

Divider Ratio BATSNS/MVBAT TCXOEN = High 2.32 2.35 2.37

Divider Impedance at MVBAT Z

O

Divider Leakage Current TCXOEN = Low 1

Divider Resistance TCXOEN = High 215 300 385 kΩ

≤ 10 µA 2.39 2.45 2.51 V

LOAD

≤ 10 µA 1.80 1.95 2.1 V

LOAD

0.1 µF

≤ 130 mA, 8 mV

LOAD

2.2 µF

= 130 mA

≤ 20 mA, 1 mV

LOAD

0.22 µF

– 100 mV 160 310 mV

INITIAL

= 20 mA

= 20 mA,

2mV

< 60 mA, 3 mV

LOAD

2.2 µF

= 60 mA 80 180 mV

= 80 mA 107 210 mV

< 50 µ

LOAD

LOAD

A

= 50 µA

0.5 mV

100 pF

– 0.25 V

MEM

= 0.25 V, 1 mA

– 0.25 V 1 mA

MEM

0.6 1.2 2.4 ms/nF

59.5 85 110 kΩ

µ

A

REV. A

–3–

Page 4

ADP3408

Parameter Symbol Condition Min Typ Max Unit

BATTERY CHARGER

Charger Output Voltage BATSNS 4.35 V ≤ CHRIN ≤ 10 V

CHGEN = Low, No Load

CHRIN = 10 V 4.155 4.230 V

CHGEN = Low, No Load

0C < TA < 50C

Load Regulation ∆BATSNS CHRIN = 5 V 15 mV

0 ≤ CHRIN – ISENSE

< Current Limit Threshold

CHGEN = Low

CHRDET On Threshold CHRIN – BATSNS 30 90 150 mV

CHRDET Hysteresis 40 mV

CHRDET Off Delay

4

CHRIN < VBAT 6 ms/nF

CHRIN Supply Current CHRIN = 5 V 0.6 mA

BATTERY CHARGER

Current Limit Threshold CHRIN – ISENSE

High Current Limit CHRIN = 5 V DC 142 160 190 mV

(UVLO Not Active) VBAT = 3.6 V

CHGEN = Low

CHRIN = 5 V DC 149 160 180 mV

VBAT = 3.6 V

CHGEN = Low

0C < TA < 50C

Low Current Limit VBAT = 2 V 20 35 mV

(UVLO Active) CHGEN = Low

CHRIN = 5 V

ISENSE Bias Current 200 µA

End-of-Charge Signal Threshold CHRIN – ISENSE CHRIN = 5 V DC 14 35 mV

VBAT > 4.0 V

CHGEN = Low

EOC Reset Threshold VBAT CHGEN = Low 3.82 3.96 4.10 V

GATEDR Transition Time tR, t

F

CHRIN = 5 V 0.1 1 µs

VBAT > 3.6 V

CHGEN = High, CL = 2 nF

GATEDR High Voltage V

OH

CHRIN = 5 V 4.5 V

VBAT = 3.6 V

CHGEN = High,

GATEIN = High

IOH = –1 mA

GATEDR Low Voltage V

OL

CHRIN = 5 V 0.5 V

VBAT = 3.6 V

CHGEN = High

GATEIN = Low

I

= 1 mA

Output High Voltage V

(EOC, CHRDET)

Output Low Voltage V

(EOC, CHRDET)

OH

OL

OL

IOH = –250 µA 2.4 V

IOL = +250 µA 0.25 V

Battery Overvoltage BATSNS CHRIN = 7.5 V 5.30 5.50 5.70 V

Protection Threshold CHGEN = High

(GATEDR → High) GATEIN = Low

Battery Overvoltage BATSNS CHRIN = 7.5 V 200 mV

Protection Hysteresis CHGEN = High

GATEIN = Low

NOTES

1

All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods.

2

This feature is intended to protect against catastrophic failure of the device. Maximum allowed operating junction temperature is 125ºC. Operation beyond

125ºC could cause permanent damage to the device.

3

No isolation diode present between charger input and battery.

4

Delay set by external capacitor on the RESCAP pin.

Specifications subject to change without notice.

3

4.150 4.200 4.250 V

–4–

REV. A

Page 5

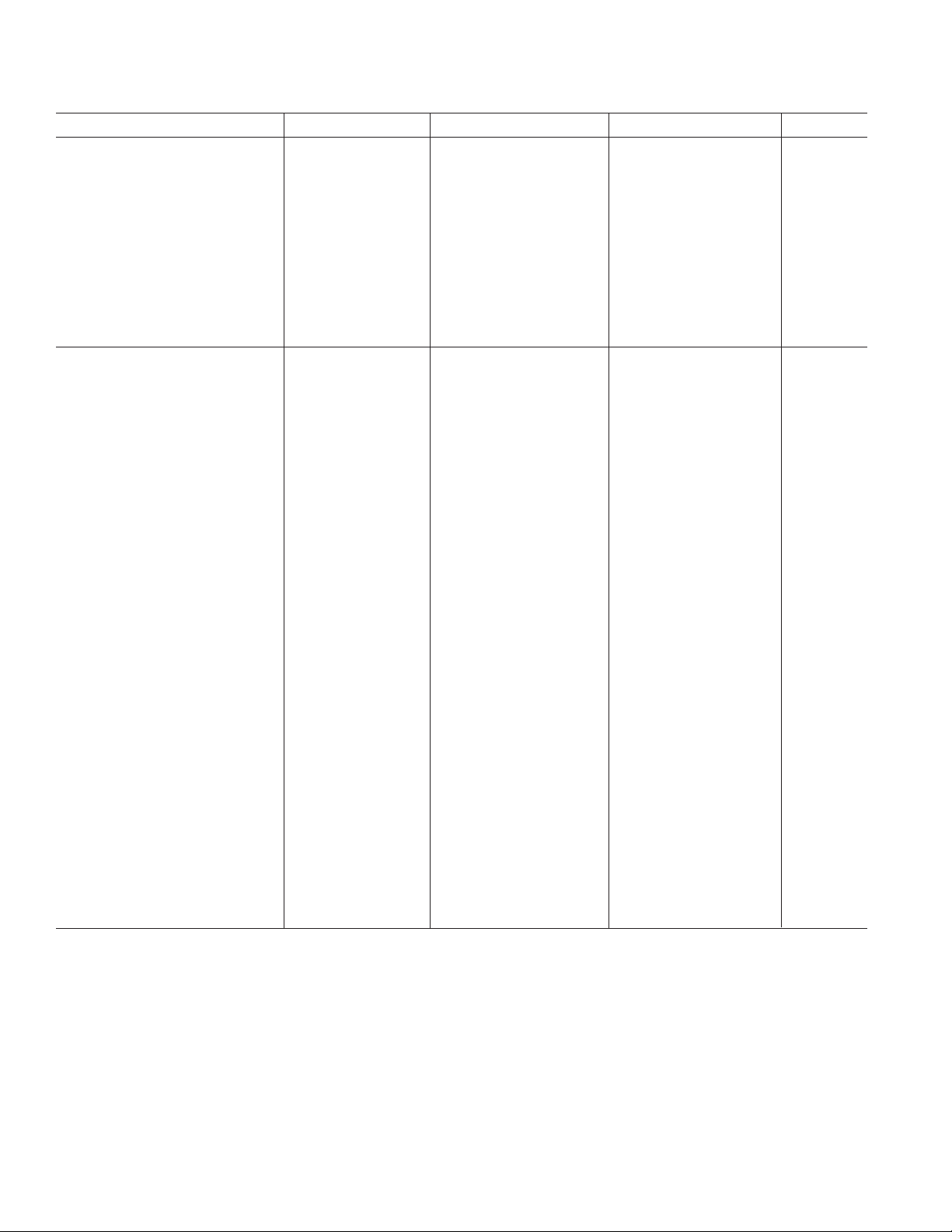

ABSOLUTE MAXIMUM RATINGS*

Voltage on any pin with respect to

any GND Pin . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +10 V

Voltage on any pin may not exceed VBAT, with the following

exceptions: CHRIN, GATEDR, ISENSE

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Operating Ambient Temperature Range . . . . . –20°C to +85°C

Maximum Junction Temperature . . . . . . . . . . . . . . . . . 125°C

, Thermal Impedance (TSSOP-28)

JA

4-Layer JEDEC PCB . . . . . . . . . . . . . . . . . . . . . . . . 68°C/W

2-Layer SEMI PCB . . . . . . . . . . . . . . . . . . . . . . . . . 98°C/W

, Thermal Impedance (LFCSP)

JA

4-Layer JEDEC PCB . . . . . . . . . . . . . . . . . . . . . . . . 32°C/W

2-Layer SEMI PCB . . . . . . . . . . . . . . . . . . . . . . . . 108°C/W

Lead Temperature Range (Soldering, 60 sec) . . . . . . . . 300°C

*This is a stress rating only; operation beyond these limits can cause the device

to be permanently damaged.

ORDERING GUIDE

Core LDO

Output Temperature Package

Model Voltage Range Option

ADP3408ARU-2.5 2.5 V –20°C to +85°C RU-28

ADP3408ACP-2.5 2.5 V –20°C to +85°C CP-32

ADP3408ARU-1.8 1.8 V –20°C to +85°C RU-28

ADP3408ACP-1.8 1.8 V –20°C to +85°C CP-32

ADP3408

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the ADP3408 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. A

–5–

WARNING!

ESD SENSITIVE DEVICE

Page 6

ADP3408

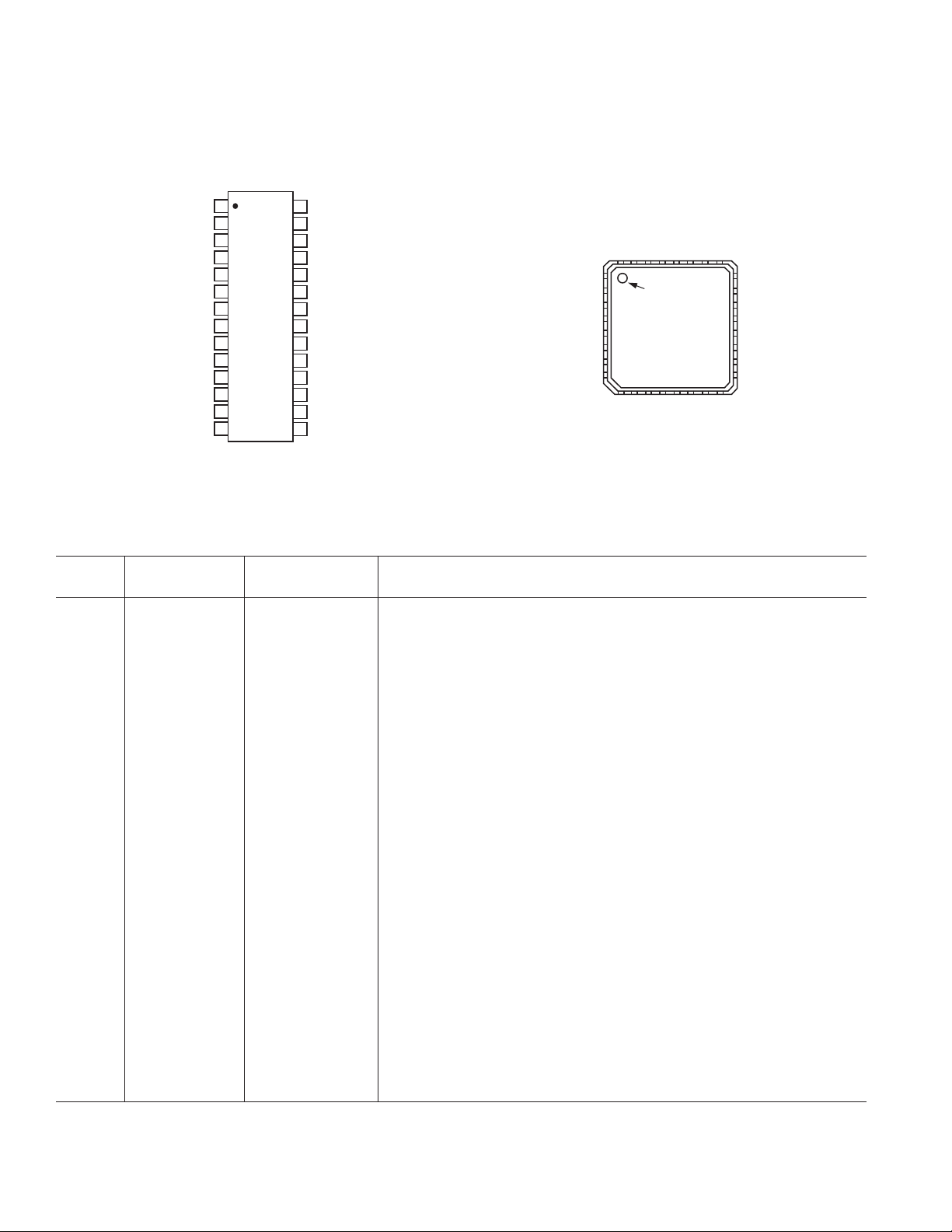

PIN CONFIGURATIONS

NC

32

1

2

3

4

5

6

7

8

9

GATEDR

LFCSP (CP)

ROWX

PWRONKEY

PWRONIN

TCXOEN

282726

ADP3408

TOP VIEW

ACP

11

121314

EOC

DGND

ISENSE

AGND

CHGEN

313029

PIN 1

INDICATOR

(Not to Scale)

TOP VIEW

10

NC

REFOUT

VTCXO

25

16

15

RESET

RESCAP

24

23

22

21

20

19

18

17

PWRONIN

PWRONKEY

ROWX

SIMEN

VRTCIN

VRTC

BATSNS

MVBAT

CHRDET

CHRIN

GATEIN

GATEDR

DGND

ISENSE

TSSOP (RU)

1

2

3

4

5

6

ADP3408

7

ARU

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

TCXOEN

AGND

REFOUT

VTCXO

VAN

VBAT

VCORE

VMEM

VBAT2

VSIM

RESET

RESCAP

CHGEN

EOC

SIMEN

VRTCIN

VRTC

BATSNS

MVBAT

CHRDET

CHRIN

GATEIN

PIN FUNCTION DESCRIPTIONS

TSSOP LFCSP

Pin Pin Mnemonic Function

129 PWRONIN Power On/Off Signal from Microprocessor

230 PWRONKEY Power On/Off Key

331 ROWX Power Key Interface Output

41 SIMEN SIM LDO Enable

52 VRTCIN RTC LDO Input Voltage

63 VRTC Real-Time Clock Supply/Coin Cell Battery Charger

74 BATSNS Battery Voltage Sense Input

85 MVBAT Divided Battery Voltage Output

96 CHRDET Charge Detect Output

10 7 CHRIN Charger Input Voltage

11 8 GATEIN Microprocessor Gate Input Signal

12 9 GATEDR Gate Drive Output

13 11 DGND Digital Ground

14 12 ISENSE Charge Current Sense Input

15 13 EOC End of Charge Signal

16 14 CHGEN Charger Enable for GATEIN, NiMH Pulse Charging

17 15 RESCAP Reset Delay Time

18 16 RESET Main Reset

19 18 VSIM SIM LDO Output

20 19 VBAT2 Battery Input Voltage 2

21 20 VMEM Memory LDO Output

22 21 VCORE Digital Core LDO Output

23 22 VBAT Battery Input Voltage

24 23 VAN Analog LDO Output

25 25 VTCXO TCXO LDO Output

26 26 REFOUT Output Reference

27 27 AGND Analog Ground

28 28 TCXOEN TCXO LDO Enable and MVBAT Enable

10, 17, 24, 32 NC No Connection

NC

VAN

VBAT

VCORE

VMEM

VBAT2

VSIM

NC

–6–

REV. A

Page 7

ADP3408

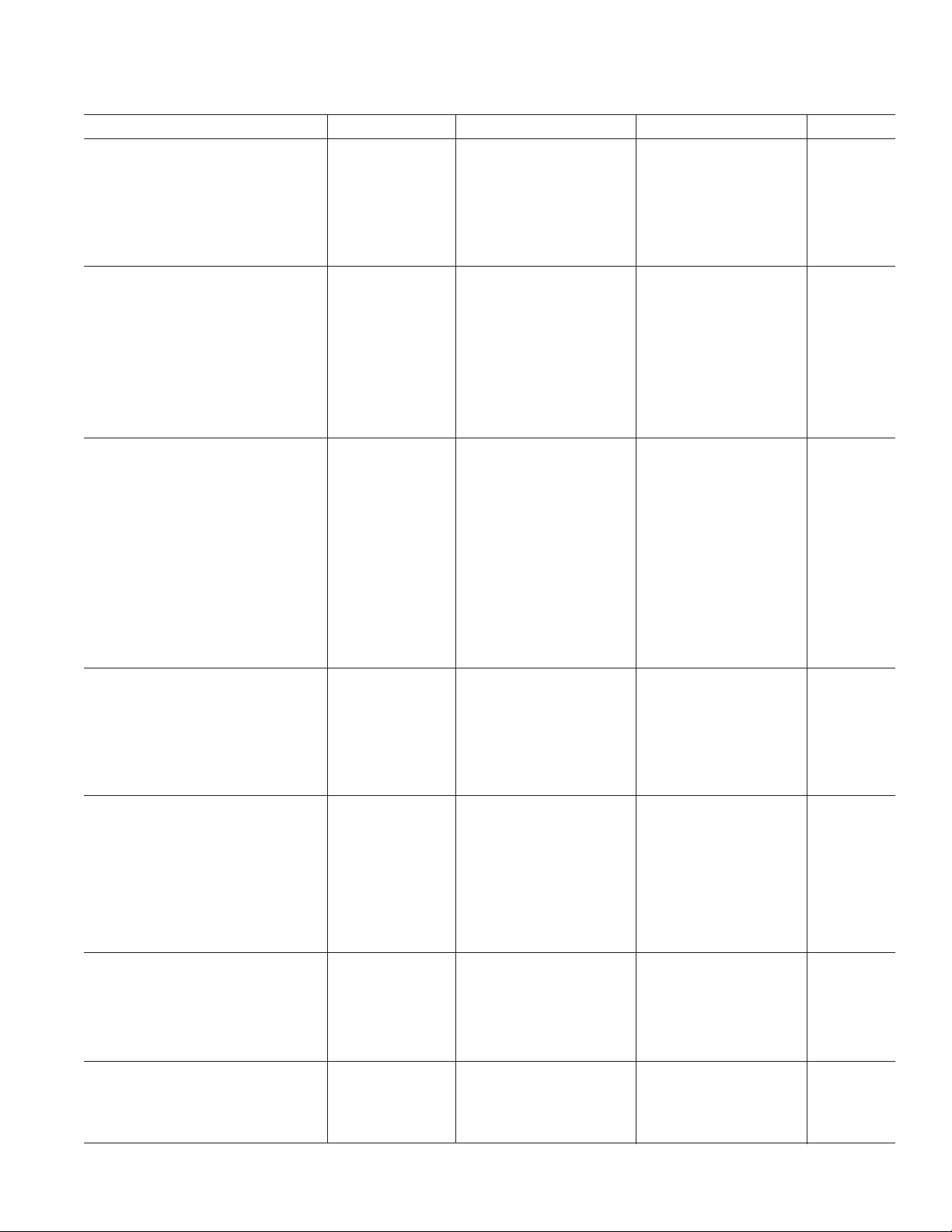

Table I. LDO Control Logic

DDLO

UVLO*

CHRDET

PWRONKEY

PWRONIN

TCXOEN

SIMEN

VSIM

VCORE

VAN and REFOUT

VTCXO

VMEM

VRTC

PHONE STATUS

State #1

Battery Deep Discharged L XXXXLXOFFOFFOFFOFFOFFOFFOFF

State #2

Phone Off H L X X X L X OFF OFF OFF OFF OFF ON OFF

State #3

Phone Off,

Turn-On Allowed H H L H L L X OFF OFF OFF OFF OFF ON OFF

State #4

Charger Applied H H H X X L L OFF ON ON ON ON ON OFF

State #5

Phone Turned On by

User Key H H X L X L L OFF ON ON ON ON ON OFF

State #6

Phone Turned On by BB H H L H H L L OFF ON OFF OFF ON ON OFF

State #7

Enable SIM Card H H L H H L H ON ON OFF OFF ON ON OFF

State #8

Phone and TCXO

LDO Kept On by BB H H L HHHHONONONONONONON

MVBAT

*UVLO is active only when phone is turned off. UVLO is ignored once the phone is turned on.

REV. A

–7–

Page 8

ADP3408

–Typical Performance Characteristics

450

ALL LDO, MVBAT, REFOUT,

ON_MIN_LOAD (SIMEN = H,

400

TCXOEN = H)

350

300

– A

250

GND

I

200

150

100

3.0 3.5 4.0 4.5 5.0 5.5

VSIM, VCORE, VMEM, VRTC,

ON_MIN_LOAD (SIMEN = H,

TCXOEN = L)

VCORE, VMEM, VRTC,

ON_MIN_LOAD (SIMEN = L,

TCXOEN = L)

VBAT – V

TPC 1. Ground Current vs. Battery

Voltage

180

160

VTCXO

140

120

100

80

60

VSIM

40

DROPOUT VOLTAGE – mV

20

0

020406080

LOAD CURRENT – mA

VMEM

10000

+85C

1000

– A

VRTC

I

100

10

+25C

0 0.5 1.0 1.5 2.0 2.5

–20C

VRTC – V

TPC 2. RTC I/V Characteristic

3.2

VBAT

3.0

VTCXO

10mV/DIV

VMEM

10mV/DIV

TIME – 100s/DIV

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

REVERSE LEAKAGE CURRENT – A

0

25 30 35 40 45 50 55 60 65 70 75 80 85

RTC REVERSE LEAKAGE

(VBAT = FLOAT)

RTC REVERSE LEAKAGE

(VBAT = 2.3V)

TEMPERATURE – C

TPC 3. VRTC Reverse Leakage

Current vs. Temperature

3.2

VBAT

3.0

VTCXO

10mV/DIV

VMEM

10mV/DIV

TIME – 100s/DIV

TPC 4. Dropout Voltage vs. Load

Current

3.2

VBAT

3.0

VCORE

VAN

VSIM

10mV/DIV

10mV/DIV

10mV/DIV

TIME – 100s/DIV

TPC 7. Line Transient Response,

Minimum Loads

TPC 5. Line Transient Response,

Minimum Loads

3.2

VBAT

3.0

VAN

VCORE

VSIM

10mV/DIV

10mV/DIV

10mV/DIV

TIME – 100s/DIV

TPC 8. Line Transient Response,

Maximum Loads

TPC 6. Line Transient Response,

Maximum Loads

20mA

LOAD

VTCXO

10mV/DIV

TIME – 200s/DIV

3mA

TPC 9. VTCXO Load Step

–8–

REV. A

Page 9

LOAD

20mA

3mA

LOAD

60mA

5mA

LOAD

ADP3408

100mA

10mA

VSIM

5mV/DIV

TIME – 200s/DIV

TPC 10. VSIM Load Step

130mA

LOAD

VAN

10mV/DIV

TIME – 200s/DIV

10mA

TPC 13. VAN Load Step

VMEM

10mV/DIV

TIME – 200s/DIV

TPC 11. VMEM Load Step

PWRONIN (2V/DIV)

VAN (100mV/DIV)

VSIM (100mV/DIV)

VCORE (100mV/DIV)

TIME – 400s/DIV

TPC 14. Turn On Transient by

PWRONIN, Minimum Load (Part 1)

VCORE

10mV/DIV

TIME – 200s/DIV

TPC 12. VCORE Load Step

PWRONIN (2V/DIV)

REFOUT

(100mV/DIV)

VMEM (100mV/DIV)

VTCXO (100mV/DIV)

TIME – 100s/DIV

TPC 15. Turn On Transient by

PWRONIN, Minimum Load (Part 2)

PWRONIN (2V/DIV)

VAN (100mV/DIV)

VSIM (100mV/DIV)

VCORE (100mV/DIV)

TIME – 20s/DIV

TPC 16. Turn On Transient by

PWRONIN, Maximum Load (Part 1)

PWRONIN (2V/DIV)

REFOUT

(100mV/DIV)

VMEM (100mV/DIV)

VTCXO (100mV/DIV)

TIME – 20s/DIV

TPC 17. Turn On Transient by

PWRONIN, Maximum Load (Part 2)

80

70

VAN

60

50

40

MLCC OUTPUT CAPS

VBAT = 3.2V, FULL LOADS

30

20

RIPPLE REJECTION – dB

10

0

4 100k10 100 1k 10k

FREQUENCY – Hz

VTCXO

VCORE

REFOUT

TPC 18. Ripple Rejection vs. Frequency

REV. A

–9–

Page 10

ADP3408

TEMPERATURE – C

4.25

4.24

4.23

4.22

4.21

4.20

4.19

4.18

4.17

4.16

4.15

40–20 0 20 60 80 100 120–40

CHARGER V

OUT

– V

80

REFOUT

70

60

50

40

30

20

RIPPLE REJECTION – dB

10

0

2.5 3.32.6 2.7 2.8 2.9 3.0 3.1 3.2

VCORE

VAN

VTCXO

VBAT – V

VSIM

VMEM

FREQUENCY =

217Hz MAX LOADS

TPC 19. Ripple Rejection vs. Battery

Voltage

4.24

VIN = 5.0V

= 250m

R

SENSE

4.23

4.22

4.21

OUTPUT VOLTAGE – V

600

FULL LOAD

500

400

300

200

100

VOLTAGE SPECTRAL NOISE DENSITY – nV/ Hz

VAN

TCXO

REF

0

10 100k100 1k 10k

FREQUENCY – Hz

MLCC CAPS

TPC 20. Output Noise Density

4.24

R

= 250m

SENSE

4.23

I

= 500mA

LOAD

4.22

I

= 10mA

LOAD

OUTPUT VOLTAGE – V

4.21

TPC 21. Charger V

ture, V

= 5.0 V, I

IN

LOAD

vs. Tempera-

OUT

= 10 mA

4.20

0 200 400 600 800

TPC 22. Charger V

I

LOAD

– mA

OUT

vs. I

(VIN = 5.0 V)

LOAD

4.20

5678910

TPC 23. Charger V

INPUT VOLTAGE – V

vs. V

OUT

IN

–10–

REV. A

Page 11

100k

ADP3408

VBAT2VRTCINVBAT

SIM LDO

VBAT

S

Q

UVLO

UVLO

DEEP

DISCHARGED

VREF

EN

OUT

DGND

VSIM

PWRONKEY

ROWX

PWRONIN

SIMEN

TCXOEN

RESCAP

CHRDET

EOC

CHGEN

GATEIN

BATSNS

ISENSE

GATEDR

CHRIN

CHARGER

DETECT

CONTROLLER

PROCESSOR

Li-ION

BATTERY

CHARGE

AND

CHARGE

INTERFACE

R

OVER TEMP

SHUTDOWN

RESET

GENERATOR

DIGITAL CORE LDO

VBAT

VREF

EN

ANALOG LDO

VBAT

VREF

EN

VBAT

VREF

EN

MEMORY LDO

VBAT

VREF

EN

VBAT

VREF

EN

DGND

AGND

TCXO LDO

AGND

DGND

RTC LDO

DGND

OUT

PG

OUT

OUT

OUT

OUT

VCORE

VA N

RESET

VTCXO

VMEM

VRTC

REV. A

MVBAT

EN REF

BUFFER

AGND

ADP3408

1.21V

+

–

Figure 1. Functional Block Diagram (TSSOP Option Pin Number)

EOC

CHGEN

D1

10BQ015

Q1

SI3441DY

R1

0.2C11nF

GATEIN

BATSNS

GATEDR

ISENSE

CHRIN (10V MAX)

CHRDET

ADP3408

BATTERY

CHARGE

CONTROLLER

Figure 2. Battery Charger Typical Application (TSSOP Option Pin Number)

–11–

REFOUT

AGND

DGND

Page 12

ADP3408

PWRONKEY

KEYPADROW

CHARGER IN

PWRON

POWERKEY

KEYPADROW

GPIO

VRTC

AUXADC

GPIO

CHARGER IN

GPIO

PWRON

GPIO

VRTC

AUXADC

GPIO

GPIO

SUPERCAP

COIN CELL

SI3441

Li-ION or NiMH

BATTERY

CAPACITOR

TYPE BACKUP

COIN CELL

0.33

SI3441DY

10BQ015

Li-ION NIMH

BATTERY

R1

0.33

Q1

D1

10BQ015

D1

U1

TCXOEN

AGND

REFOUT

VTCXO

VAN

VBAT

VCORE

VMEM

VBAT2

VSIM

RESET

RESCAP

CHGEN

EOC

R2

10

C3, 10F

C4

0.1F

C5

2.2F

C6

2.2F

C8

2.2FC90.22F

C7

2.2F

PWRONIN

PWRONKEY

ROWX

SIMEN

VRTCIN

ADP3408

C1

0.1F

R1

Q1

C2, 1nF

VRTC

BATSNS

MVBAT

CHRDET

CHRIN

GATEIN

GATEDR

DGND

ISENSE

C10

0.1F

CLKON

REF

VTCXO

VAN

VCORE

VMEM

VSIM

RESET

GPIO

GPIO

Figure 3a. Typical Application Circuit (TSSOP Option)

TCXOEN (CLKON)

REFOUT

VTCXO

VAN

VCORE

VMEM

VSIM

RESET

GPIO

GPIO

C1

0.1F

C2

1nF

1

2

3

4

5

6

7

8

SIMEN

VRTCIN

VRTC

BATSNS

MVBAT

CHRDET

CHRIN

GATEIN

GATEDR

R2

10

C9

25

26

27

28

29

30

31

32

NC

ROWX

PWRONKEY

ADP3408

NC

DGND

9

111213

10

TCXOEN

PWRONIN

U1

EOC

ISENSE

AGND

CHGEN

14

REFOUT

RESCAP

15

VTCXO

VBAT

VCORE

VMEM

VBAT2

VSIM

RESET

16

NC

VAN

NC

24

23

22

21

20

19

18

17

C3

10FC40.1FC52.2FC62.2FC72.2F

C8

2.2F

0.22F

C10

0.1F

Figure 3b. Typical Application Circuit (LFCSP Option)

–12–

REV. A

Page 13

THEORY OF OPERATION

INPUT VOLTAGE – V

1.2

0

3.0 6.03.5

POWER DISSIPATION – W

4.0 4.5 5.0 5.5

1.0

0.8

0.6

0.4

0.2

ADP3408-1.8

ADP3408-2.5

The ADP3408 is a power management chip optimized for use

with GSM baseband chipsets in handset applications. Figure 1

shows a block diagram of the ADP3408.

The ADP3408 contains several blocks:

• Six Low Dropout Regulators (SIM, Core, Analog, Crystal

Oscillator, Memory, Real-Time Clock)

• Reset Generator

• Buffered Precision Reference

• Lithium Ion Charge Controller and Processor Interface

• Power-On/-Off Logic

• Undervoltage Lockout

• Deep Discharge Lockout

These functions have traditionally been done either as a discrete

implementation or as a custom ASIC design. The ADP3408

combines the benefits of both worlds by providing an integrated

standard product in which every block is optimized to operate in

a GSM environment while maintaining a cost competitive solution.

Figure 3 shows the external circuitry associated with the ADP3408.

Only a minimal number of support components are required.

Input Voltage

The input voltage range of the ADP3408 is 3 V to 5.5 V and is

optimized for a single Li-ion cell or three NiMH cells. The type

of battery, the package type, and the Core LDO output voltage

all affect the amount of power that the ADP3408 needs to dissipate. The thermal impedance of the TSSOP package is 68°C/W

for four-layer boards. The thermal impedance of the CSP package is 32°C/W for four-layer boards.

The end of charge voltage for high capacity NiMH cells can be

as high as 5.5 V. This results in a worst-case power dissipation

for the ADP3408-1.8 as high as 1.07 W for NiMH cells. The

power dissipation for the ADP3408-2.5 is just slightly lower at 1 W.

A fully charged Li-ion battery is 4.25 V, where the ADP3408-

2.5 can dissipate a maximum power of 0.56 W in either

package. However, the ADP3408-1.8 can have a maximum

dissipation of 0.64 W, so only the CSP package can handle the

power dissipation at 85°C.

However, high battery voltages normally occur only when the

battery is being charged and the handset is not in conversation

mode. In this mode, there is a relatively light load on the LDOs.

The worst-case power dissipation should be calculated based on

the actual load currents and voltages used.

Figure 4a shows the maximum power dissipation as a function

of the input voltage. Figure 4b shows the maximum allowable

power dissipation as a function of ambient temperature.

ADP3408

Figure 4a. Power Dissipation vs. Input Voltage

1.2

1.0

0.8

0.6

0.4

POWER DISSIPATION – W

0.2

0

–20 0

Figure 4b. Allowable Package Power Dissipation vs.

Temperature

Low Dropout Regulators (LDOs)

The ADP3408 high performance LDOs are optimized for their

given functions by balancing quiescent current, dropout voltage,

regulation, ripple rejection, and output noise. 2.2 µF tantalum

or MLCC ceramic capacitors are recommended for use with the

core, memory, SIM, and analog LDOs. A 0.22 µF capacitor is

recommended for the TCXO LDO.

LFCSP

32C/W

20 40 60 80

AMBIENT TEMPERATURE – C

TSSOP

68C/W

REV. A

–13–

Page 14

ADP3408

NON-CHARGING

MODE

CHGEN = HIGH

CHARGING MODE

GATEIN = PULSED

NO

CHARGER OFF

GATEIN = HIGH

CHRIN > BATSNS

VBAT > UVLO

LOW CURRENT

CHARGE MODE

V

SENSE

NiMH

VBAT > 5.5V

YES

NiMH

VBAT < 5.5V

YES

CHARGER

DETECTER

YES

NO

= 20mV

NO

NO

YES

NiMH

NO

NO

BATTERY

TYPE

Li+

CHGEN = LOW

HIGH CURRENT

CHARGE MODE

V

= 160mV

SENSE

VBAT > 4.2V

YES

CONSTANT

VOLTA G E MODE

I

< I END

CHARGE

OF CHARGE

YES

EOC = HIGH

TERMINATE CHARGE

CHREN = HIGH

GATEIN = HIGH

Figure 5. Battery Charger Flow Chart

Digital Core LDO (VCORE)

The digital core LDO supplies the baseband circuitry in the handset (baseband processor and baseband converter). The LDO has

been optimized for very low quiescent current at light loads, as this

LDO is on at all times.

Memory LDO (VMEM)

The memory LDO supplies the peripheral subsystems of the

baseband processor including GPIO, display, and SIM interfaces as

well as memory. The LDO has also been optimized for low quiescent current and will power up at the same time as the core LDO.

Analog LDO (VAN)

This LDO has the same features as the core LDO. It has furthermore been optimized for good low frequency ripple rejection for

use with the baseband converter sections in order to reject the

ripple coming from the RF power amplifier. VAN is rated to a

130 mA load, which is sufficient to supply the complete analog

section of the baseband converter, such as the AD652l.

TCXO LDO (VTCXO)

The TCXO LDO is intended as a supply for a temperaturecompensated crystal oscillator, which needs its own ultralow

noise supply. VTCXO is rated for 5 mA of output current and is

turned on along with the analog LDO when TCXOEN is asserted.

Note that for the ADP3408-2.5, the TCXO output has been

optimized for the AD6524 (Othello), while the ADP3408-1.8

has been optimized for the AD6534 (Othello One).

RTC LDO (VRTC)

The RTC LDO charges up a capacitor-type backup coin cell to

run the Real-Time Clock module. It has been designed to charge

electric double layer capacitors such as the PAS621 from Kanebo.

The PAS621 has a small physical size (6.8 mm diameter) and a

nominal capacity of 0.3 F, giving many hours of backup time.

The ADP3408 supplies current both for charging the coin cell

and for the RTC module. In addition, it features a very low

quiescent current since this LDO is running all the time, even

when the handset is switched off. It also has reverse current

protection with low leakage, which is needed when the main

battery is removed and the coin cell supplies the RTC module.

SIM LDO (VSIM)

The SIM LDO generates the voltage needed for 3 V SIMs. It is

rated for 20 mA of supply current and can be controlled completely independently of the other LDOs.

Reference Output (REFOUT)

The reference output is a low noise, high precision reference with

a guaranteed accuracy of 1.5% over temperature. The reference

can be used with the baseband converter. Note that the reference

in the AD6521 has an initial accuracy of 10%, but can be

calibrated to within 1%.

Power ON/OFF

The ADP3408 handles all issues regarding the powering ON

and OFF of the handset. It is possible to turn on the ADP3408

in three different ways:

• Pulling the PWRONKEY Low

• Pulling PWRONIN High

• CHRIN exceeds CHRDET Threshold

Pulling the PWRONKEY low is the normal way of turning on the

handset. This will turn on all the LDOs , except the SIM LDO, as

long as the PWRONKEY is held low. When the VCORE LDO

comes into regulation, the RESET timer is started. After timing

out, the RESET pin goes high, allowing the baseband processor

to start up. With the baseband processor running, it can poll the

ROWX pin of the ADP3408 to determine if the PWRONKEY has

been depressed and pull PWRONIN high. Once the PWRONIN

is taken high, the PWRONKEY can be released. Note that by

monitoring the ROWX pin, the baseband processor can detect a

second PWRONKEY press and turn the LDOs off in an orderly

manner. In this way, the PWRONKEY can be used for ON/

OFF control.

Pulling the PWRONIN pin high is how the alarm in the Real-Time

Clock module will turn the handset on. Asserting PWRONIN

will turn on the core and memory LDOs, starting up the

baseband processor.

–14–

REV. A

Page 15

ADP3408

Applying an external charger can also turn on the handset. This

will turn on all the LDOs, except the SIM LDO, again starting

up the baseband processor. Note that if the battery voltage is

below the undervoltage lockout threshold, applying the adapter

will not start up the LDOs.

Deep Discharge Lockout (DDLO)

The DDLO block in the ADP3408 has two functions:

• To shut off the VRTC LDO in the event that the main battery

discharges to below the RTC LDO’s output voltage. This will

force the Real-Time Clock to run off the backup coin cell or

double layer capacitor.

• To shut down the handset in the event that the software fails

to turn off the phone when the battery drops below 2.9 V to

3.0 V. The DDLO will shut down the handset when the

battery falls below 2.4 V to prevent further discharge and

damage to the cells.

Undervoltage Lockout (UVLO)

The UVLO function in the ADP3408 prevents startup when the

initial voltage of the battery is below the 3.2 V threshold. If the

battery voltage is this low with no load, there is insufficient

capacity left to run the handset. When the battery voltage is

greater than 3.2 V, for example, when inserting a fresh battery,

the UVLO comparator trips and the threshold is reduced to

3.0 V. This allows the handset to start normally until the

battery decays to below 3.0 V. Note that the DDLO has enabled the RTC LDO under this condition.

Once the system is started and the core and memory LDOs are

up and running, the UVLO function is disabled. The ADP3408

is then allowed to run until the battery voltage reaches the

DDLO threshold, typically 2.4 V. Normally, the battery voltage

is monitored by the baseband processor and usually shuts off the

phone at around 3.0 V.

If the handset is off, and the battery voltage drops below 3.0 V,

the UVLO circuit disables startup and puts the ADP3408 into

UVLO shutdown mode. In this mode the ADP3408 draws very

low quiescent current, typically 30 µA. The RTC LDO is still

running until the DDLO disables it. In this mode the ADP3408

draws 5 µA of quiescent current. NiMH batteries can reverse

polarity if the three-cell battery voltage drops below 3.0 V, which

will degrade the batteries’ performance. Lithium ion batteries

will lose their capacity if repeatedly overdischarged, so minimizing

the quiescent currents helps prevent battery damage.

RESET

The ADP3408 contains a reset circuit that is active at both

power-up and power-down. The RESET pin is held low at

initial power-up. An internal power good signal is generated by

the core LDO when its output is up, which starts the reset delay

timer. The delay is set by an external capacitor on RESCAP:

=×12.

ms

nF

C

(1)

t

RESET RESCAP

At power-off, RESET will be kept low to prevent any baseband

processor starts.

Overtemperature Protection

The maximum die temperature for the ADP3408 is 125°C. If

the die temperature exceeds 160°C, the ADP3408 will disable

all the LDOs except the RTC LDO. The LDOs will not be

re-enabled before the die temperature is below 125°C, regardless of the state of PWRONKEY, PWRONIN, and CHRDET.

This ensures that the handset will always power-off before the

ADP3408 exceeds its absolute maximum thermal ratings.

Battery Charging

The ADP3408 battery charger can be used with lithium ion

(Li+) and nickel metal hydride (NiMH) batteries. The charger

initialization, trickle charging, and Li+ charging are implemented in hardware. Battery type determination and NiMH

charging must be implemented in software.

The charger block works in three different modes:

• Low Current (Trickle) Charging

• Lithium Ion Charging

• Nickel Metal Hydride Charging

Charge Detection

The ADP3408 charger block has a detection circuit that determines if an adapter has been applied to the CHRIN pin. If the

adapter voltage exceeds the battery voltage by 90 mV, the

CHRDET output will go high. If the adapter is then removed

and the voltage at the CHRIN pin drops to only 45 mV above

the BATSNS pin, CHRDET goes low.

Trickle Charging

When the battery voltage is below the UVLO threshold, the

charge current is set to the low current limit, or about 10% of

the full charge current. The low current limit is determined by

the voltage developed across the current sense resistor. Therefore, the trickle charge current can be calculated by:

mV

I

CHR TRICKLE

()

=

20

R

SENSE

(2)

Trickle charging is performed for deeply discharged batteries

to prevent undue stress on either the battery or the charger.

Trickle charging will continue until the battery voltage exceeds

the UVLO threshold.

Once the UVLO threshold has been exceeded, the charger will

switch to the default charge mode, the LDOs will start up, and

the baseband processor will start to run. The processor must

then poll the battery to determine which chemistry is present

and set the charger to the proper mode.

Lithium Ion Charging

For lithium ion charging, the CHGEN input must be low. This

allows the ADP3408 to continue charging the battery at the full

current. The full charge current can be calculated by using:

mV

I

CHR FULL

()

=

160

R

SENSE

(3)

If the voltage at BATSNS is below the charger’s output voltage

of 4.2 V, the battery will continue to charge in the constant

current mode. If the battery has reached the final charge voltage,

a constant voltage is applied to the battery until the charge

current has reduced to the charge termination threshold. The

charge termination threshold is determined by the voltage across

the sense resistor. If the battery voltage is above 4.0 V and the

voltage across the sense resistor has dropped to 14 mV, an Endof-Charge signal is generated and the EOC output goes high. See

Figure 6.

REV. A

–15–

Page 16

ADP3408

t

ms

nF

C

RESET RESCAP

=×12.

ICHG

VBAT

EOC

TIME

Figure 6. End of Charge

The baseband processor can either let the charger continue to

charge the battery for an additional amount of time or terminate

the charging. To terminate the charging, the processor must pull

the GATEIN and CHGEN pins high.

NiMH Charging

For NiMH charging, the processor must pull the CHGEN pin

high. This disables the internal Li+ mode control of the gate

drive pin. The gate drive must now be controlled by the baseband processor. By pulling GATEIN high, the GATEDR pin is

driven high, turning the PMOS off. By pulling the GATEIN pin

low, the GATEDR pin is driven low, and the PMOS is turned

on. So, by pulsing the GATEIN input, the processor can charge

a NiMH battery. Note that when charging NiMH cells, a current-limited adapter is required.

During the PMOS off periods, the battery voltage needs to be

monitored through the MVBAT pin. The battery voltage is

continually polled until the final battery voltage is reached, at

which time the charge can either be terminated or the frequency

of the pulsing reduced. An alternative method of determining

the end of charge is to monitor the temperature of the cells and

terminate the charging when a rapid rise in temperature is detected.

Battery Voltage Monitoring

The battery voltage can be monitored at MVBAT during charging and discharging to determine the condition of the battery.

An internal resistor divider can be connected to BATSNS when

both the digital and analog baseband sections are powered up. To

enable MVBAT, both PWRONIN and TCXOEN must be high.

The ratio of the voltage divider is selected so that the 2.4 V

maximum input of the AD6521’s auxiliary ADC will correspond

with the maximum battery voltage of 5.5 V. The divider will be

disconnected from the battery when the baseband sections are

powered down.

APPLICATION INFORMATION

Input Capacitor Selection

For the input (VBAT, VBAT2, and VRTCIN) of the ADP3408,

a local bypass capacitor is recommended. Use a 10 µF, low

ESR capacitor. Multilayer ceramic chip (MLCC) capacitors

provide the best combination of low ESR and small size, but

may not be cost effective. A lower cost alternative may be to use

a 10 µF tantalum capacitor with a small (1 µF to 2 µF) ceramic

in parallel.

Separate inputs for the SIM LDO and the RTC LDO are supplied

for additional bypassing or filtering. The SIM LDO has VBAT2

as its input and the RTC LDO has VRTCIN.

LDO Capacitor Selection

The performance of any LDO is a function of the output capacitor.

The core, memory, SIM, and analog LDOs require a 2.2 µF

capacitor, and the TCXO LDO requires a 0.22 µF capacitor.

Larger values may be used, but the overshoot at startup will

increase slightly. If a larger output capacitor is desired, be sure

to check that the overshoot and settling time are acceptable for

the application.

All the LDOs are stable with a wide range of capacitor types and

ESR (anyCAP

®

technology). The ADP3408 is stable with extremely

low ESR capacitors (ESR ~ 0), such as Multilayer Ceramic

Capacitors (MLCC), but care should be taken in their selection.

Note that the capacitance of some capacitor types show wide

variations over temperature or with dc voltage. A good quality

dielectric capacitor, X7R or better, is recommended.

The RTC LDO can have a rechargeable coin cell or an electric

double-layer capacitor as a load, but an additional 0.1 µF ceramic

capacitor is recommended for stability and best performance.

RESET Capacitor Selection

RESET is held low at power-up. An internal power good signal

starts the reset delay when the core LDO is up. The delay is set

by an external capacitor on RESCAP:

(4)

A 100 nF capacitor will produce a 120 ms reset delay. The

current capability of RESET is minimal (a few hundred nA)

when VCORE is off to minimize power consumption. When

VCORE is on, RESET is capable of driving 500 µA.

Setting the Charge Current

The ADP3408 is capable of charging both lithium ion and

NiMH batteries. For NiMH batteries, the charge current is

limited by the adapter. For lithium ion batteries, the charge

current is programmed by selecting the sense resistor, R1.

The lithium ion charge current is calculated using:

mV

I

CHR

Where V

V

SENSE

==

R

is the high current limit threshold voltage. Or if

SENSE

160

11

R

(5)

the charge current is known, R1 can be found.

mV

V

SENSE

R

1 ==

I

CHR CHR

160

I

(6)

Similarly, the trickle charge current and the end of charge current can be calculated:

I

TRICKLE

mV

V

SENSE

== =

R

20 14

11 1

I

,

EOC

R

R

mV

(7)

Example: Assume an 800 mAh capacity lithium ion battery and a 1C

charge rate. R1 = 200 mΩ, I

= 100 mA, and I

TRICKLE

= 70 mA.

EOC

anyCAP is a registered trademark of Analog Devices Inc.

–16–

REV. A

Page 17

Appropriate sense resistors are available from the following

vendors:

Vishay Dale

IRC

Panasonic

Charger FET Selection

The type and size of the pass transistor is determined by the

threshold voltage, input-output voltage differential, and charge

current. The selected PMOS must satisfy the physical, electrical, and thermal design requirements.

To ensure proper operation, the minimum V

the ADP3408

GS

can provide must be enough to turn on the FET. The available

gate drive voltage can be estimated using the following:

VV V V

=−−

GS ADAPTER MIN GATEDR SENSE

()

(8)

where:

V

ADAPTER(MIN)

gate drive “low” voltage, 0.5 V, and V

is the minimum adapter voltage, V

is the maximum

SENSE

GATEDR

is the

high current limit threshold voltage.

The difference between the adapter voltage (V

ADAPTER

) and the

final battery voltage (VBAT) must exceed the voltage drop due

to the blocking diode, the sense resistor, and the on resistance of

the FET at maximum charge current, where:

VV VVVBAT

=−−−

DS ADAPTER MIN DIODE SENSE

The R

DS(ON)

R

DS ON

()

()

of the FET can then be calculated.

V

DS

=

I

CHR MAX

()

(9)

(10)

The thermal characteristics of the FET must be considered

next. The worst-case dissipation can be determined using:

PV VVUVLO I

=−−−

()

DISS ADAPTER MAX DIODE SENSE CHR

()

×

(11)

It should be noted that the adapter voltage can be either

preregulated or nonregulated. In the preregulated case, the

difference between the maximum and minimum adapter voltage

is probably not significant. In the unregulated case, the adapter

voltage can have a wide range specified. However, the maximum

voltage specified is usually with no load applied. So, the worst-case

power dissipation calculation will often lead to an over-specified

pass device. In either case, it is best to determine the load

characteristics of the adapter to optimize the charger design.

For example:

V

ADAPTER(MIN)

V

ADAPTER(MAX)

V

DIODE

V

SENSE

V

GATEDR

= 5 V – 0.5 V – 160 V = 4.34 V

V

GS

= 5.0 V

= 6.5 V

= 0.5 V at 800 mA

= 160 mV

= 0.5 V

Therefore, choose a low threshold voltage FET.

ADP3408

VV VVVBAT

=

DS ADAPT MIN DIODE SENSE

VV VV mV

==

5–0.5 – 0.160 – 4.2 140

R

PV VVUVLO I

DISS ADAPT MAX DIODE SENSE CHR

PVVV AW

DISS

===

DS ON

()

I

CHR MAX

=

()

6.5 – 0.5 – 0.160 – 3.2 0.8 2.11

=

()

Appropriate PMOS FETs are available from the following

vendors:

Siliconix

IR

Fairchild

Charger Diode Selection

The diode, D1, shown in Figure 2, is used to prevent the battery from

discharging through the PMOS’s body diode into the charger’s

internal bias circuits. Choose a diode with a current rating high

enough to handle the battery charging current and a voltage

rating greater than VBAT. The blocking diode is required for

both lithium and nickel battery types.

Printed Circuit Board Layout Considerations

Use the following general guidelines when designing printed

circuit boards:

1. Connect the battery to the VBAT, VBAT2, and VRTCIN

pins of the ADP3408. Locate the input capacitor as close to

the pins as possible.

2. VAN and VTCXO capacitors should be returned to AGND.

3. VCORE, VMEM, and VSIM capacitors should be returned

to DGND.

4. Split the ground connections. Use separate traces or planes

for the analog, digital, and power grounds and tie them together

at a single point, preferably close to the battery return.

5. Run a separate trace from the BATSNS pin to the battery to

prevent voltage drop error in the MVBAT measurement.

6. Kelvin-connect the charger’s sense resistor by running separate traces to the CHRIN and ISENSE pins. Make sure that the

traces are terminated as close to the resistor’s body as possible.

7. Use the best industry practice for thermal considerations

during the layout of the ADP3408 and charger components.

Careful use of copper area, weight, and multilayer construction all contribute to improved thermal performance.

–––

()

mV

V

DS

()

()

140

mA

800

–––

m

175 Ω

×=

×

REV. A

–17–

Page 18

ADP3408

LFCSP Layout Consideration

The CSP package has an exposed die paddle on the bottom that

efficiently conducts heat to the PCB. To achieve the optimum

performance from the CSP package, special consideration must

be given to the layout of the PCB. Use the following layout

guidelines for the CSP package:

1. The pad pattern is given in Figure 7. The pad dimension

should be followed closely for reliable solder joints while

maintaining reasonable clearances to prevent solder bridging.

0.08

0.70

5.36

3.80

3.56

3.96

0.50

0.20

0.30

Figure 7. LFCSP Pad Pattern (Dimensions Shown in

Millimeters)

2. The thermal pad of the CSP package provides a low thermal

impedance path to the PCB. Therefore, the PCB must be

properly designed to effectively conduct the heat away from

the package. This is achieved by adding thermal vias to the

PCB, which provide a thermal path to the inner or bottom

layers. See Figure 8 for the recommended via pattern. Note

that the via diameter is small. This is to prevent the solder

from flowing through the via and leaving voids in the thermal

pad solder joint.

Note that the thermal pad is attached to the die substrate, so

the thermal planes that the vias attach the package to must

be electrically isolated or connected to VBAT. Do not con-

nect the thermal pad to ground.

The paste mask for the thermal pad needs to be designed for

the maximum coverage to effectively remove the heat from

the package. However, due to the presence of thermal vias

and the large size of the thermal pad, eliminating voids may

not be possible. Also, if the solder paste coverage is too large,

solder joint defects may occur. Therefore, it is recommended

to use multiple small openings over a single big opening in

designing the paste mask. The recommended paste mask

pattern is given in Figure 9. This pattern will result in about

80% coverage, which should not degrade the thermal performance of the package significantly.

CREATE SOLDER PASTE WEB FOR APPROX. 80% COVERAGE

125 MICRONS WIDE TO SEPARATE SOLDER PASTE AREAS

THERMAL PAD AREA

Figure 9. LFCSP Paste Mask Pattern

5. The recommended paste mask stencil thickness is

0.125 mm. A laser cut stainless steel stencil with trapezoidal walls should be used.

A “No Clean,” Type 3 solder paste should be used for

mounting the LFCSP package. Also, a nitrogen purge during

the reflow process is recommended.

6. The package manufacturer recommends that the reflow tem-

perature should not exceed 220C and the time above liquidus

is less than 75 seconds. The preheat ramp should be

3C/second or lower. The actual temperature profile depends

on the board’s density and must be determined by the assembly house as to what works best.

ARRAY OF 9 VIAS

0.60

1.18

1.18

0.60

0.25mm DIAMETER 35m PLATING

THERMAL PAD AREA

Figure 8. LFCSP via Pattern (Dimensions Shown in

Millimeters)

3. The solder mask opening should be about 120 microns

(4.7 mils) larger than the pad size resulting in minimum 60

microns (2.4 mils) clearance between the copper pad and

solder mask.

4. The paste mask opening is typically designed to match the

pad size used on the peripheral pads of the LFCSP package.

This should provide a reliable solder joint as long as the

stencil thickness is about 0.125 mm.

–18–

REV. A

Page 19

OUTLINE DIMENSIONS

28-Lead Thin Shrink Small Outline Package [TSSOP]

(RU-28)

Dimensions shown in millimeters

9.80

9.70

9.60

ADP3408

PIN 1

INDICATOR

PIN 1

0.15

0.05

COPLANARITY

12 MAX

1.00

0.90

0.80

28

0.65

BSC

0.30

0.10

0.19

COMPLIANT TO JEDEC STANDARDS MO-153AE

15

141

SEATING

PLANE

1.20

MAX

4.50

4.40

4.30

0.20

0.09

6.40 BSC

32-Lead Frame Chip Scale Package [LFCSP]

(CP-32)

Dimensions shown in millimeters

5.00

BSC SQ

TOP

VIEW

SEATING

PLANE

4.75

BSC SQ

0.70 MAX

0.65 NOM

0.30

0.25 REF

0.23

0.18

COMPLIANT TO JEDEC STANDARDS MO-220-VHHD-2

0.05 MAX

0.02 NOM

COPLANARITY

0.60 MAX

0.50

BSC

0.50

0.40

0.30

0.08

25

24

17

16

8

0

0.60 MAX

BOTTOM

VIEW

3.50

REF

0.75

0.60

0.45

PIN 1

32

9

INDICATOR

1

3.25

SQ

3.10

2.95

8

REV. A

–19–

Page 20

ADP3408

Revision History

Location Page

11/02—Data Sheet changed from REV. 0 to REV. A

Changes to GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Note added to FUNCTIONAL BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Changes to SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Changes to ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ß

Changes to ORDERING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Updated PIN CONFIGURATIONS added . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Changes to PIN FUNCTION DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Edits to Figures 1 and 2 captions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Edit to Figure 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Edits to Figure 3 (changed to Figure 3a) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 3b added . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 4 replaced with Figures 4a and 4b . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Changes to Input Voltage section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Text added to TCXO LDO (VTCXO) section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Edits to RTC LDO (VRTC) section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Edits to Reference Output (REFOUT) section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Edits to Trickle Charging section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Edits to Equation 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Edit to Settling the Charge Current section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Addition of LFCSP Layout Considerations section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

New Figure 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

New Figure 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

New Figure 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Add 32-Lead LFCSP Package Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

C02623–0–12/02(A)

–20–

–20–

PRINTED IN U.S.A.

REV. A

Loading...

Loading...