Datasheet ADP3338AKC-5, ADP3338AKC-3.3, ADP3338AKC-2.85, ADP3338AKC-2.5, ADP3338AKC-1.8 Datasheet (Analog Devices)

Page 1

High-Accuracy Ultralow IQ, 1 A, anyCAP

V

IN

OUT

ADP3338

1F

1F

V

OUT

GND

IN

®

a

FEATURES

High Accuracy Over Line and Load: 0.8% @ 25C,

1.4% Over Temperature

Ultralow Dropout Voltage: 190 mV (Typ) @ 1 A

Requires Only C

anyCAP = Stable with Any Type of Capacitor

(Including MLCC)

Current and Thermal Limiting

Low Noise

2.7 V to 8 V Supply Range

–40C to +85C Ambient Temperature Range

SOT-223 Package

APPLICATIONS

Notebook, Palmtop Computers

SCSI Terminators

Battery-Powered Systems

Bar Code Scanners

Camcorders, Cameras

Home Entertainment Systems

Networking Systems

DSP/ASIC Supply

= 1 F for Stability

O

Low Dropout Regulator

ADP3338

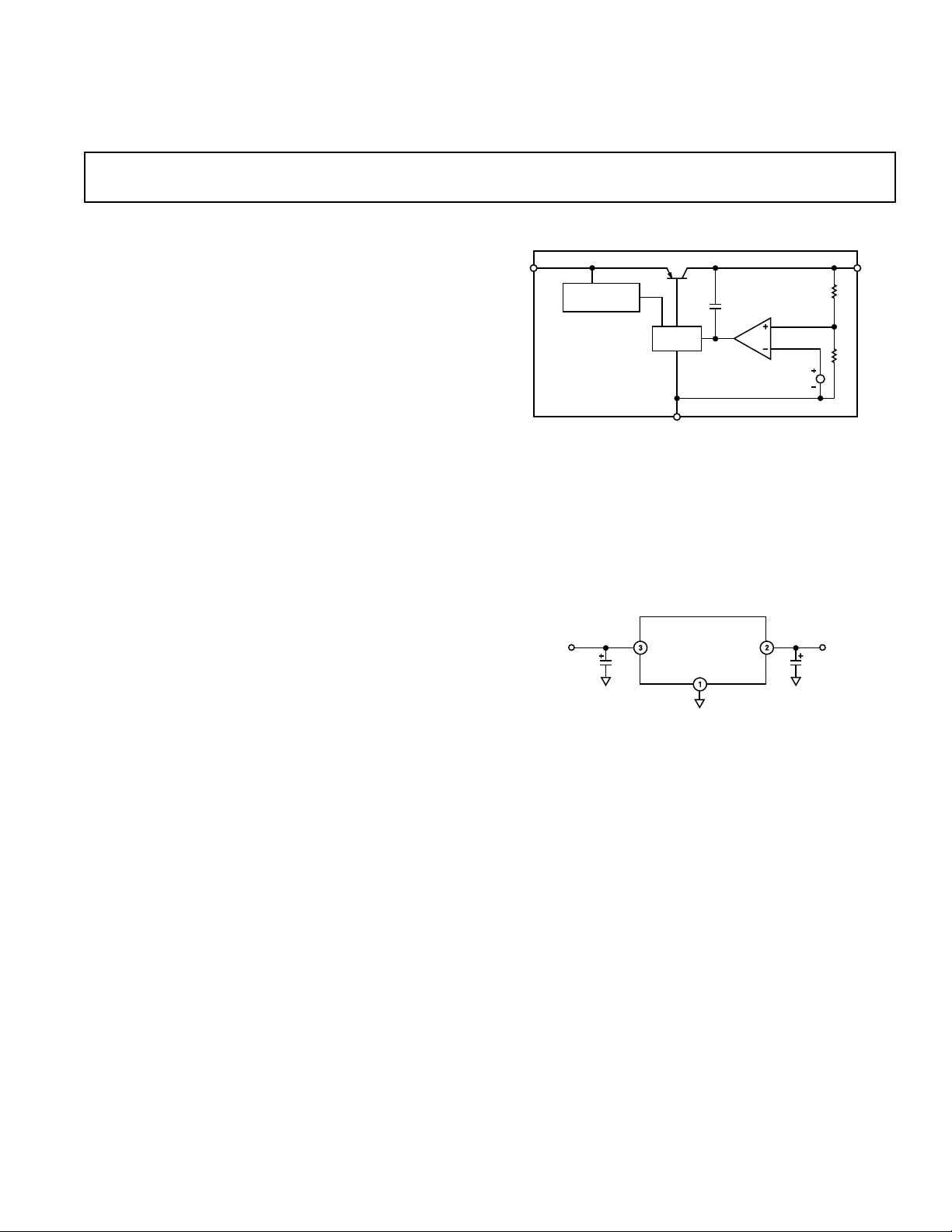

FUNCTIONAL BLOCK DIAGRAM

IN

THERMAL

PROTECTION

Q1

DRIVER

GND

CC

ADP3338

g

m

BANDGAP

REF

OUT

R1

R2

GENERAL DESCRIPTION

The ADP3338 is a member of the ADP33xx family of precision

low dropout anyCAP voltage regulators. The ADP3338 operates with an input voltage range of 2.7 V to 8 V and delivers a

load current up to 1 A. The ADP3338 stands out from the

conventional LDOs with a novel architecture and an enhanced

process that enables it to offer performance advantages and

higher output current than its competition. Its patented design

requires only a 1 µF output capacitor for stability. This device

is insensitive to output capacitor Equivalent Series Resistance

(ESR), and is stable with any good quality capacitor, including

ceramic (MLCC) types for space-restricted applications. The

ADP3338 achieves exceptional accuracy of ±0.8% at room

temperature and ± 1.4% over temperature, line and load variations. The dropout voltage of the ADP3338 is only 190 mV

(typical) at 1 A. This device also includes a safety current limit

and thermal overload protection. The ADP3338 has ultralow

quiescent current 110 µA (typical) in light load situations.

anyCAP is a registered trademark of Analog Devices Inc.

Figure 1. Typical Application Circuit

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

Page 2

ADP3338–SPECIFICATIONS

1, 2, 3

(VIN = 6.0 V, CIN = C

noted.)

= 1 F, TJ = –40C to +125C, unless otherwise

OUT

Parameter Symbol Conditions Min Typ Max Unit

OUTPUT

Voltage Accuracy V

OUT

Line Regulation V

Load Regulation I

Dropout Voltage V

DROP

VIN = V

I

T

V

I

T

V

I

T

T

T

V

OUTNOM

= 0.1 mA to 1 A

L

= 25°C

J

= V

IN

OUTNOM

= 0.1 mA to 1 A

L

= –40°C to +125°C

J

= V

IN

OUTNOM

= 50 mA to 1 A

L

= 150 °C

J

= V

IN

OUTNOM

= 25°C

J

= 0.1 mA to 1 A 0.006 mV/mA

L

= 25°C

J

= 98% of V

OUT

+ 0.4 V to 8 V –0.8 +0.8 %

+ 0.4 V to 8 V –1.4 +1.4 %

+ 0.4 V to 8 V –1.6 +1.6 %

+ 0.4 V to 12 V 0.04 mV/V

OUTNOM

IL = 1 A 190 400 mV

= 500 mA 125 200 mV

I

L

I

= 100 mA 70 150 mV

Peak Load Current I

Output Noise V

LDPK

NOISE

L

VIN = V

OUTNOM

+ 1 V 1.6 A

f = 10 Hz–100 kHz, CL = 10 µF95µV rms

IL = 1 A

GROUND CURRENT

In Regulation I

In Dropout I

GND

GND

IL = 1 A 9 30 mA

I

= 500 mA 4.5 15 mA

L

= 100 mA 0.9 3 mA

I

L

I

= 0.1 mA 110 190 µA

L

VIN = V

OUTNOM

– 100 mV 190 600 µA

IL = 0.1 mA

NOTES

1

All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC) methods.

2

Application stable with no load.

3

VIN = 2.7 V for models with V

Specifications subject to change without notice.

OUTNOM

≤ 2.2 V.

–2–

REV. 0

Page 3

ADP3338

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Input Supply Voltage . . . . . . . . . . . . . . . . . . –0.3 V to +8.5 V

Power Dissipation . . . . . . . . . . . . . . . . . . . Internally Limited

Operating Ambient Temperature Range . . . . –40°C to +85°C

Operating Junction Temperature Range . . . –40°C to +150°C

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62.3°C/W

θ

JA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26.8°C/W

θ

JC

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . . 300°C

Vapor Phase (60 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . 215°C

Infrared (15 sec) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220°C

*This is a stress rating only; operation beyond these limits can cause the device to

be permanently damaged. Unless otherwise specified, all voltages are referenced

to GND.

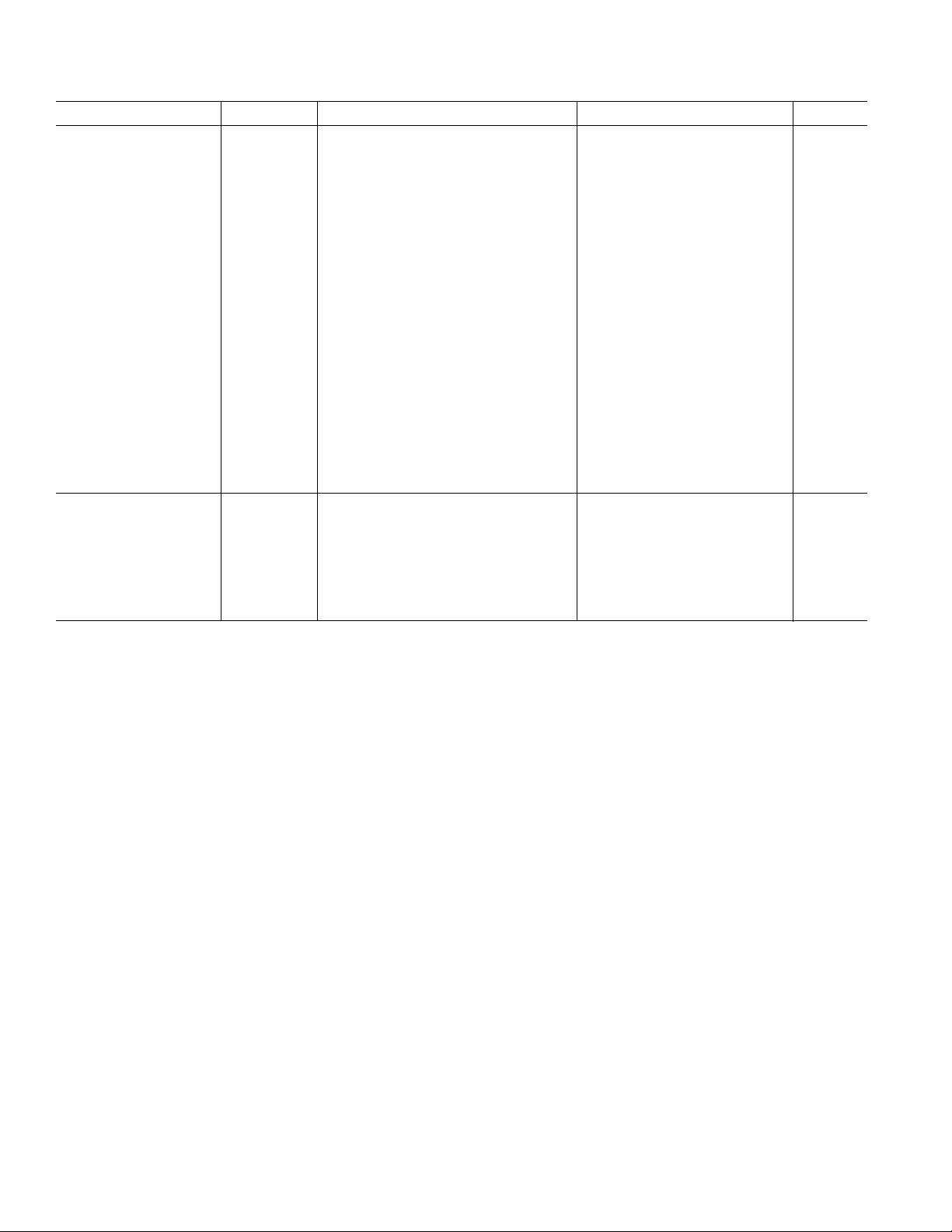

PIN CONFIGURATION

ADP3338

OUT

TOP VIEW

(Not to Scale)

ORDERING GUIDE

PIN FUNCTION DESCRIPTIONS

Pin

No. Mnemonic Function

1 GND Ground Pin.

2 OUT Output of the Regulator. Bypass to

ground with a 1 µF or larger capacitor.

3 IN Regulator Input. Bypass to ground with

a 1 µF or larger capacitor.

3

IN

OUT

2

GND

1

Output Package Package

Model Voltage* Option Description

ADP3338AKC-1.8 1.8 V KC (SOT-223) Plastic Surface Mount

ADP3338AKC-2.5 2.5 V KC (SOT-223) Plastic Surface Mount

ADP3338AKC-2.85 2.85 V KC (SOT-223) Plastic Surface Mount

ADP3338AKC-3.3 3.3 V KC (SOT-223) Plastic Surface Mount

ADP3338AKC-5 5 V KC (SOT-223) Plastic Surface Mount

*Contact the factory for other voltage options.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although

the ADP3338 features proprietary ESD protection circuitry, permanent damage may occur on

devices subjected to high-energy electrostatic discharges. Therefore, proper ESD precautions are

recommended to avoid performance degradation or loss of functionality.

REV. 0

–3–

Page 4

ADP3338

–Typical Performance Characteristics

(TA = 25C unless otherwise noted.)

2.515

V

= 2.5V

OUT

2.510

2.505

2.500

OUTPUT VOLTAGE – V

2.495

2.490

2.5 4.5

INPUT VOLTAGE – V

6.5 8.5

IL = 0A

IL = 0.5A

IL = 1A

10.5

TPC 1. Line Regulation Output

Voltage vs. Supply Voltage

12

V

= 2.5V

OUT

= 6V

V

IN

10

8

6

4

GROUND CURRENT – mA

2

0

0 0.2

0.4 0.6 0.8

OUTPUT LOAD – A

TPC 4. Ground Current vs. Load

Current

12.5

1.0

2.504

2.503

2.502

2.501

2.500

2.499

2.498

OUTPUT VOLTAGE – V

2.497

2.496

2.495

0

LOAD CURRENT – A

VIN = 6V

0.60.40.2

0.6 0.8 1.0

TPC 2. Output Voltage vs. Load

Current

0.2

0.1

OUTPUT VOLTAGE – %

–0.05

0.4

V

= 2.5V

OUT

= 6V

V

IN

0.3

0

–40 –20

0 20 40 60 80 100 120

JUNCTION TEMPERATURE – C

IL = 0.5A

IL = 0.3A

IL = 1A

IL = 0.7A

IL = 0A

TPC 5. Output Voltage Variation %

vs. Junction Temperature

300

250

200

150

100

GROUND CURRENT – A

50

0

0246 8

INPUT VOLTAGE – V

V

OUT

I

LOAD

= 2.5V

= 0A

10 12

TPC 3. Ground Current vs. Supply

Voltage

18

16

14

12

10

GROUND CURRENT – mA

I

= 1A

LOAD

I

= 700mA

LOAD

I

= 500mA

LOAD

I

= 300mA

LOAD

8

6

4

2

0

–40

–20 0 20 40 60 80 100 120 140 150

JUNCTION TEMPERATURE – C

TPC 6. Ground Current vs. Junction

Temperature

250

200

150

100

DROPOUT – mV

V

= 2.5V

OUT

50

0

0 0.2 1.0

0.4 0.6 0.8

LOAD CURRENT – A

TPC 7. Dropout Voltage vs.

Load Current

V

= 2.5V

OUT

3

2

1

0

INPUT/OUTPUT VOLTAGE – V

= 2.5

R

LOAD

012345678910

TIME – sec

TPC 8. Power-Up/Power-Down

–4–

V

= 2.5V

OUT

C

= 1F

OUT

2.51

R

= 2.5

LOAD

2.50

2.49

VOLTS

4.5

3.5

80

120 140 180

TIME – s

TPC 9. Line Transient Response

REV. 0

Page 5

ADP3338

0

200

TIME – s

VIN = 6V

C

OUT

= 10F

1

2.5

2.4

2.6

T

400 600 800

A VOLTS

V

= 2.5V

OUT

C

= 10F

OUT

2.51

R

= 2.5

LOAD

2.50

2.49

VOLTS

4.5

3.5

80

120 140 180

TIME – s

TPC 10. Line Transient Response

2.5

0.0

VOLTS

1.5

A

1.0

0.5

0.0

0.4

400m

SHORT

FULL SHORT

0.6 0.8 1

TIME – s

VIN = 6V

TPC 13. Short-Circuit Current

s

VIN = 6V

C

OUT

R

LOAD

= 1F

= 2.5

2.6

2.5

2.4

1

A VOLTS

0

T

300 600 800

200

TIME –

TPC 11. Load Transient Response

0

V

= 2.5V

OUT

–10

–20

–30

–40

–50

–60

–70

RIPPLE REJECTION – dB

–80

–90

10 100 1k 10k 100k 1M

CL = 10F

I

= 1A

L

CL = 1F

I

= 0

L

FREQUENCY – Hz

CL = 1F

I

= 1A

L

CL = 10F

I

= 0

L

TPC 14. Power Supply Ripple

Rejection

TPC 12. Load Transient Response

300

250

200

150

= 1A

I

100

RMS NOISE – V

50

0

010 50

L

I

= 0A

L

20 30 40

CL – F

TPC 15. RMS Noise vs. C

L

(10 Hz–100 kHz)

100

10

1

0.1

CL = 10F

0.01

0.001

VOLTAGE NOISE SPECTRAL DENSITY – V/ Hz

10 100

1k

FREQUENCY – Hz

TPC 16. Output Noise Density

REV. 0

10k

CL = 1F

100k

1M

–5–

Page 6

ADP3338

THEORY OF OPERATION

The new anyCAP LDO ADP3338 uses a single control loop for

regulation and reference functions. The output voltage is sensed

by a resistive voltage divider consisting of R1 and R2 which is

varied to provide the available output voltage option. Feedback

is taken from this network by way of a series diode (D1) and a

second resistor divider (R3 and R4) to the input of an amplifier.

INPUT

Q1

NONINVERTING

WIDEBAND

DRIVER

ADP3338

COMPENSATION

CAPACITOR

PTAT

V

g

m

OS

R4

GND

ATTENUATION

(V

BANDGAP/VOUT

CURRENT

R3

PTAT

D1

OUTPUT

)

R1

C

LOAD

(a)

R

LOAD

R2

Figure 2. Functional Block Diagram

A very high-gain error amplifier is used to control this loop. The

amplifier is constructed in such a way that equilibrium produces a large, temperature-proportional input, “offset voltage”

that is repeatable and very well controlled. The temperatureproportional offset voltage is combined with the complementary

diode voltage to form a “virtual bandgap” voltage, implicit in

the network, although it never appears explicitly in the circuit.

Ultimately, this patented design makes it possible to control

the loop with only one amplifier. This technique also improves

the noise characteristics of the amplifier by providing more flexibility on the trade-off of noise sources that leads to a low noise design.

The R1, R2 divider is chosen in the same ratio as the bandgap

voltage to the output voltage. Although the R1, R2 resistor divider

is loaded by the diode D1 and a second divider consisting of R3

and R4, the values can be chosen to produce a temperature-stable

output. This unique arrangement specifically corrects for the loading of the divider, thus avoiding the error resulting from base

current loading in conventional circuits.

The patented amplifier controls a new and unique noninverting

driver that drives the pass transistor, Q1. The use of this special

noninverting driver enables the frequency compensation to

include the load capacitor in a pole-splitting arrangement to

achieve reduced sensitivity to the value, type, and ESR of the

load capacitance.

Most LDOs place very strict requirements on the range of ESR

values for the output capacitor because they are difficult to stabilize

due to the uncertainty of load capacitance and resistance. Moreover, the ESR value, required to keep conventional LDOs stable,

changes depending on load and temperature. These ESR limitations make designing with LDOs more difficult because of their

unclear specifications and extreme variations over temperature.

With the ADP3338 anyCAP LDO, this is no longer true. It

can be used with virtually any good quality capacitor, with no

constraint on the minimum ESR. This innovative design allows

the circuit to be stable with just a small 1 µF capacitor on the

output. Additional advantages of the pole-splitting scheme include

superior line noise rejection and very high regulator gain, which

leads to excellent line and load regulation. An impressive ± 1.4%

accuracy is guaranteed over line, load, and temperature.

Additional features of the circuit include current limit and thermal shutdown.

V

IN

C1

1F

OUT

ADP3338

GNDIN

C2

1F

V

OUT

Figure 3. Typical Application Circuit

A

PPLICATION INFORMATION

CAPACITOR SELECTION

Output Capacitor

The stability and transient response of the LDO is a function of

the output capacitor. The ADP3338 is stable with a wide range

of capacitor values, types, and ESR (anyCAP). A capacitor as

low as 1 µF is all that is needed for stability. A higher capacitance

may be necessary if high output current surges are anticipated or

if the output capacitor cannot be located near the output and

ground pins. The ADP3338 is stable with extremely low ESR

capacitors (ESR ≈ 0), such as Multilayer Ceramic Capacitors

(MLCC) or OSCON. Note that the effective capacitance of

some capacitor types fall below the minimum over temperature

or with dc voltage.

Input Capacitor

An input bypass capacitor is not strictly required but it is recommended in any application involving long input wires or high

source impedance. Connecting a 1 µF capacitor from the

input to ground reduces the circuit’s sensitivity to PC board

layout and input transients. If a larger output capacitor is necessary, a larger value input capacitor is also recommended.

OUTPUT CURRENT LIMIT

The ADP3338 is short-circuit protected by limiting the pass

transistor’s base drive current. The maximum output current is

limited to about 2 A. See TPC 13.

–6–

REV. 0

Page 7

ADP3338

THERMAL OVERLOAD PROTECTION

The ADP3338 is protected against damage due to excessive power

dissipation by its thermal overload protection circuit. Thermal

protection limits the die temperature to a maximum of 160°C.

Under extreme conditions (i.e., high ambient temperature and

power dissipation) where the die temperature starts to rise above

160°C, the output current will be reduced until the die temperature has dropped to a safe level.

Current and thermal limit protections are intended to protect

the device against accidental overload conditions. For normal

operation, the device’s power dissipation should be externally

limited so that the junction temperature will not exceed 150°C.

CALCULATING POWER DISSIPATION

Device power dissipation is calculated as follows:

PVV I V I

=−

()

D IN OUT LOAD IN GND

Where I

and V

and I

LOAD

are the input and output voltages respectively.

OUT

are load current and ground current, V

GND

Assuming worst-case operating conditions are I

I

= 10 mA, VIN = 3.3 V and V

GND

×+

= 2.5 V, the device power

OUT

×

()

LOAD

IN

= 1.0 A,

dissipation is:

P V V mA V mA mW

=

()

D

+

()

=3 3 2 5 1000 3 3 10 833. – ..

So, for a junction temperature of 125°C and a maximum ambient temperature of 85°C, the required thermal resistance from

junction to ambient is:

°°

125 85

CC

θJA=

PRINTED CIRCUIT BOARD LAYOUT CONSIDERATIONS

0 833

.

–

W

=°

48

CW

/

The SOT-223’s thermal resistance, θJA, is determined by the

sum of the junction-to-case and the case-to-ambient thermal

resistances. The junction-to-case thermal resistance, θ

, is

JC

determined by the package design and specified at 26.8°C/W.

However, the case-to-ambient thermal resistance is determined

by the printed circuit board design.

As shown in Figures 4a–c, the amount of copper the ADP3338

is mounted to affects the thermal performance. When mounted

to 2 oz. copper with just the minimal pads, Figure 4a, the θ

is

JA

126.6°C/W. By adding a small copper pad under the ADP3338,

Figure 4b, reduces the θ

pad to 1 square inch, Figure 4c, reduces the θ

to 102.9°C/W. Increasing the copper

JA

even further

JA

to 52.8°C/W.

a. b. c.

Figure 4. PCB Layouts

Use the following general guidelines when designing printed

circuit boards:

1. Keep the output capacitor as close to the output and ground

pins as possible.

2. Keep the input capacitor as close to the input and ground

pins as possible.

3. PC board traces with larger cross sectional areas will remove

more heat from the ADP3338. For optimum heat transfer,

specify thick copper and use wide traces.

4. The thermal resistance can be decreased by adding a copper

pad under the ADP3338 as shown in Figure 4b.

5. If possible, utilize the adjacent area to add more copper

around the ADP3338. Connecting the copper area to the

output of the ADP3338, as shown in Figure 4c, is best but

will improve thermal performance even if it is connected to

other signals.

6. Use additional copper layers or planes to reduce the thermal

resistance. Again, connecting the other layers to the output

of the ADP3338 is best, but not necessary. When connecting

the output pad to other layers use multiple vias.

REV. 0

–7–

Page 8

ADP3338

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

3-Lead Surface Mount

KC (SOT-223)

0.124 (3.15)

0.116 (2.95)

0.146 (3.70)

0.130 (3.30)

0.033 (0.85)

0.026 (0.65)

0.067 (1.70)

0.060 (1.50)

0.004 (0.10)

0.0008 (0.02)

1 3 2

0.0905 (2.30)

NOM

0.264 (6.70)

0.248 (6.30)

0.181 (4.60)

NOM

4

0.041 (1.05)

0.033 (0.85)

SEATING

PLANE

0.287 (7.30)

0.264 (6.70)

0.051 (1.30)

0.043 (1.10)

10 MAX

16

10

16

10

C02050–1.5–6/01(0)

0.25 (0.35)

0.010 (0.25)

–8–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...