Page 1

5-Bit or 6-Bit Programmable 2-,3-,4-Phase

V

FEATURES

Selectable 2-, 3- or 4-phase operation at up to 1 MHz per

phase

±14.5 mV worst-case mV differential sensing error over

temperature

Logic-level PWM outputs for interface to external high

power drivers

Active current balancing between all output phases

Built-in power good/crowbar blanking supports on-the-fly

VID code changes

Digitally programmable output can be switched between

VRM 9 (5-bit) and VRD 10 (6-bit) VID codes

Programmable short-circuit protection with programmable

latch-off delay

APPLICATIONS

Desktop PC power supplies for:

Next-generation Intel

VRM modules

GENERAL DESCRIPTION

The ADP3181 is a highly efficient multiphase synchronous

buck-switching regulator controller optimized for converting

a 12 V main supply into the core supply voltage required by

high performance Intel processors. It uses an internal 6-bit

DAC to read a voltage identification (VID) code directly from

the processor, which is used to set the output voltage. The

CPUID input selects whether the DAC codes match the

VRM 9 or VRD 10 specifications. It uses a multimode PWM

architecture to drive the logic-level outputs at a programmable

switching frequency that can be optimized for VR size and

efficiency. The phase relationship of the output signals can

be programmed to provide 2-, 3-, or 4-phase operation,

allowing for the construction of up to four complementary

buck-switching stages.

® processors

Synchronous Buck Controller

ADP3181

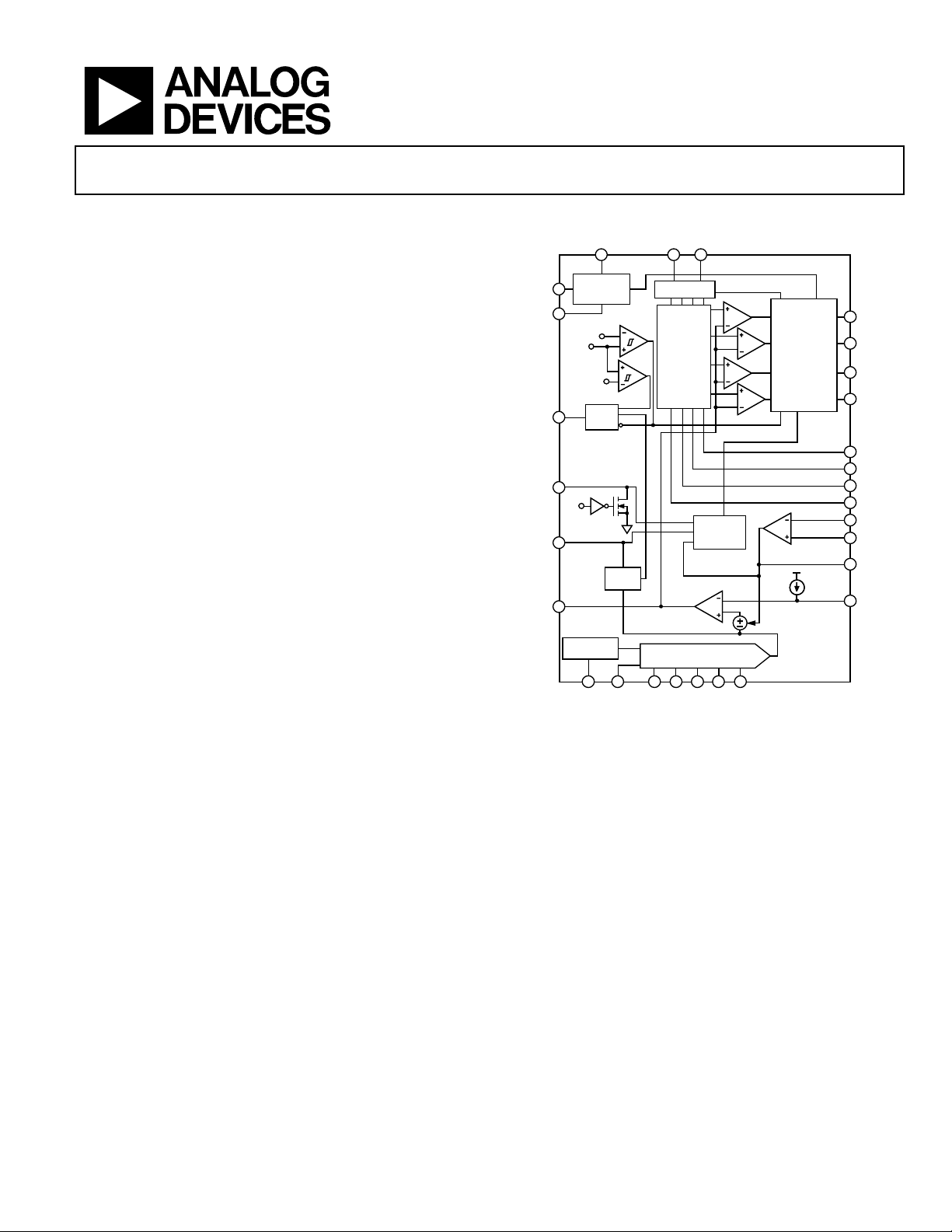

FUNCTIONAL BLOCK DIAGRAM

GND

PWRGD

ILIMIT

DELAY

COMP

11

EN

19

10

15

12

UVLO

SHUTDOWN

AND BIAS

DAC + 300mV

CSREF

DAC – 250mV

DELAY

EN

9

PRECISION

REFERENCE

CC

28 1314

SOFT

START

VID4 VID3 VID2 VID1 VID0FBRTN CPUID

OSCILLATOR

CURRENT-

BALANCING

CIRCUIT

VID

DAC

1234576

Figure 1.

RTRAMPADJ

CMP

CMP

CURRENT-

LIMITING

CIRCUIT

CMP

CMP

CROWBAR

ADP3181

ENSET

RESET

RESET

2-/3-/4-PHASE

DRIVER LOGIC

RESET

RESET

CURRENT

LIMIT

27

26

25

24

23

22

21

20

17

16

18

8

PWM1

PWM2

PWM3

PWM4

SW1

SW2

SW3

SW4

CSSUM

CSREF

CSCOMP

FB

04796-0-001

The ADP3181 also includes programmable no-load offset and

slope functions to adjust the output voltage as a function of the

load current so that it is always optimally positioned for a

system transient. The ADP3181 provides accurate and reliable

short-circuit protection, adjustable current limiting, and a

delayed power good output that accommodates on-the-fly

output voltage changes requested by the CPU.

The device is specified over the commercial temperature range

of 0°C to +85°C and is available in a 28-lead TSSOP package.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

Page 2

ADP3181

TABLE OF CONTENTS

Specifications..................................................................................... 3

Tes t Ci rc ui t s ....................................................................................... 5

Absolute Maximum Ratings............................................................ 6

Pin Configuration and Function Descriptions............................. 7

Typical Performance Characteristics............................................. 8

Theory of Operation ........................................................................ 9

Start-up Sequence......................................................................... 9

Master Clock Frequency............................................................ 10

Output Voltage Differential Sensing ........................................10

Output Current Sensing ............................................................ 11

Active Impedance Control Mode............................................. 11

Current Control Mode and Thermal Balance .......................11

Volt a ge C ont r o l Mo d e................................................................ 11

Soft Start ......................................................................................12

Current Limit, Short-Circuit, and Latch-Off Protection....... 12

Application Information................................................................ 15

Setting the Clock Frequency..................................................... 15

Soft-Start and Current-Limit Latch-Off Delay Times........... 15

Inductor Selection...................................................................... 15

Designing an Inductor............................................................... 16

Output Droop Resistance.......................................................... 16

Inductor DCR Temperature Correction ................................. 17

Output Offset.............................................................................. 17

C

Selection ............................................................................... 17

out

Power MOSFETS ........................................................................ 18

Ramp Resistor Selection............................................................ 19

Current Limit Setpoint.............................................................. 20

Feedback Loop Compensation Design.................................... 20

C

Selection and Input Current di/dt Reduction.................. 21

IN

Building a Switchable VR9/VR10 Design ............................... 22

Dynamic VID.............................................................................. 13

Power Good Monitoring ...........................................................13

Output Crowbar .........................................................................13

Output Enable and UVLO ........................................................ 13

REVISION HISTORY

5/04—Revision 0: Initial Version

Layout and Component Placement ............................................. 23

General Recommendations....................................................... 23

Outline Dimensions....................................................................... 24

Ordering Guide .......................................................................... 24

Rev. 0 | Page 2 of 24

Page 3

ADP3181

SPECIFICATIONS

VCC = 12 V, FBRTN = GND, TA = 0°C to +85°C, unless otherwise noted.

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

ERROR AMPLIFIER

Output Voltage Range

Accuracy V

2

V

COMP

FB

0.7 3.1 V

Relative to nominal DAC output, referenced to

FBRTN, CSSUM = CSCOMP. See Figure 2.

Line Regulation

Input Bias Current I

FBRTN Current I

Output Current I

∆V

FB

FBRTN

O(ERR)

FB

Gain Bandwidth Product GBW

Slew Rate C

VCC = 10 V to 14 V 0.05 %

14 15.5 17

100 140

FB forced to V

COMP = FB 20 MHz

(ERR)

= 10 pF 25

COMP

VID INPUTS

Input Low Voltage V

IL(VID)

CPUID > 4.5 V 0.8 V

CPUID < 4.0 V 0.4 V

Input High Voltage V

IH(VID)

CPUID > 4.5 V 2.0 V

CPUID < 4.0 V 0.8 V

Input Current I

VID

VID(x) = 0 V, CPUID > 4.5 V 40 70

VID(x) = 0 V, CPUID < 4.0 V 20 35

Pull-up Resistance R

VID

40 60

Internal Pull-up Voltage CPUID > 4.5 V 2.25 2.5 2.75 V

CPUID < 4.0 V 1.1 1.25 1.4 V

VID Transition Delay Time

2

VID code change to FB change 400 ns

No CPU Detection Turn-off Delay Time2 VID code change to 11111 to PWM going low 400 ns

CPUID INPUT

Input Low Voltage V

Input High Voltage V

IL(CPUID)

IH(CPUID)

0.4 V

0.8 4.0 V

VR 9 Detection Threshold Voltage 4.0 4.5 V

Input Current I

Pull-up Resistance R

CPUID

CPUID

CPUID = 0 V 20 3.5

4.0 60

OSCILLATOR

Frequency Range

Frequency Variation f

Output Voltage V

RAMPADJ Output Voltage V

RAMPADJ Input Current Range I

2

f

OSC

PHASE

RT

RAMPADJ

RAMPADJ

0.25 4 MHz

TA = 25°C, RT = 250 kΩ, 4-phase

= 25°C, RT = 115 kΩ, 4-phase

T

A

= 25°C, RT = 75 kΩ, 4-phase

T

A

RT = 100 kΩ to GND

RAMPADJ – FB

0 100

CURRENT SENSE AMPLIFIER

Offset Voltage V

Input Bias Current I

OS(CSA)

BIAS(CSSUM)

Gain Bandwidth Product GBW

Slew Rate C

CSSUM – CSREF. See Figure 3.

10 MHz

(CSA)

= 10 pF 10

CSCOMP

Input Common-Mode Range CSSUM and CSREF 0 2.7 V

Positioning Accuracy

∆V

FB

See Figure 4.

Output Voltage Range 0.05 2.7 V

Output Current I

CSCOMP

500

1

−14.5

– 3% 500

OUT

+14.5 mV

155 200 245 kHz

400 kHz

600 kHz

1.9 2.0 2.1 V

−50

−3

−50

+50 mV

+3 mV

+50 nA

−77 −80 −83

µA

µA

µA

V/µs

µA

µA

kΩ

µA

kΩ

µA

V/µs

mV

µA

Rev. 0 | Page 3 of 24

Page 4

ADP3181

Parameter Symbol Conditions Min Typ Max Unit

CURRENT BALANCE CIRCUIT

Common-Mode Range V

Input Resistance R

Input Current I

Input Current Matching

SW(X)CM

SW(X)

SW(X)

∆I

SW(X)

CURRENT LIMIT COMPARATOR

Output Voltage

Normal Mode V

In Shutdown V

Output Current, Normal Mode I

Maximum Output Current

2

Current Limit Threshold Voltage V

ILIMIT(NM)

ILIMIT(SD)

ILIMIT(NM)

60

CL

Current Limit Setting Ratio VCL/I

DELAY Normal Mode Voltage V

DELAY Overcurrent Threshold V

Latch-off Delay Time t

DELAY(NM)

DELAY(OC)

DELAY

SOFT START

Output Current, Soft-start Mode I

Soft-start Delay Time t

DELAY(SS)

DELAY(SS)

ENABLE INPUT

Input Low Voltage V

Input High Voltage V

Input Current, Input Voltage Low I

Input Current, Input Voltage High I

IL(EN)

IH(EN)

IL(EN)

IH(EN)

POWER GOOD COMPARATOR

Undervoltage Threshold V

Overvoltage Threshold V

Output Low Voltage V

PWRGD(UV)

PWRGD(OV)

OL(PWRGD)IPWRGD(SINK)

Power Good Delay Time

During Soft Start2

VID Code Changing 100 250

VID Code Static 200 ns

Crowbar Trip Point V

CROWBAR

Crowbar Reset Point Relative to FBRTN 630 700 770 mV

Crowbar Delay Time t

CROWBAR

VID Code Changing 100 250

VID Code Static 400 ns

PWM OUTPUTS

Output Low Voltage V

Output High Voltage V

OL(PWM)

OH(PWM)

SUPPLY

DC Supply Current 5 10 mA

UVLO Threshold Voltage V

UVLO

UVLO Hysteresis 0.7 0.9 1.1 V

−600

SW(X) = 0 V 20 30 40

SW(X) = 0 V 4 7 10

SW(X) = 0 V

−5

+200 mV

kΩ

µA

+5 %

EN > 0.8 V, R

EN < 0.4 V, I

EN > 0.8 V, R

= 250 kΩ

ILIMIT

= −100 µA

ILIMIT

= 250 kΩ

ILIMIT

2.9 3 3.1 V

400 mV

12

µA

µA

V

R

R

R

CSREF

ILIMIT

DELAY

DELAY

DELAY

– V

= 250 kΩ

= 250 kΩ

= 250 kΩ, C

CSCOMP

, R

= 250 kΩ

ILIMIT

DELAY

= 12 nF

During start-up, DELAY < 2.4 V 15 20 25

R

= 250 kΩ, C

DELAY

= 12 nF, VID code = 011111

DELAY

105 125 145 mV

10.4

mV/µA

2.9 3 3.1 V

1.7 1.8 1.9 V

1.5 ms

µA

1 ms

0.4 V

0.8 V

EN = 0 V

−1

EN = 1.25 V 10 25

Relative to nominal DAC output

−180 −250 −320

1

µA

µA

mV

Relative to nominal DAC output 230 300 370 mV

= 4 mA 225 400 mV

R

DELAY

= 250 kΩ, C

= 12 nF, VID Code = 011111

DELAY

1 ms

µs

Relative to nominal DAC output 230 300 370 mV

Overvoltage to PWM going low

µs

I

PWM(SINK)

I

PWM(SOURCE)

= −400 µA

= 400 µA

160 500 mV

4.0 5 V

VCC rising 6.5 6.9 7.3 V

1

All limits at temperature extremes are guaranteed via correlation using standard statistical quality control (SQC).

2

Guaranteed by design or bench characterization, not tested in production.

Rev. 0 | Page 4 of 24

Page 5

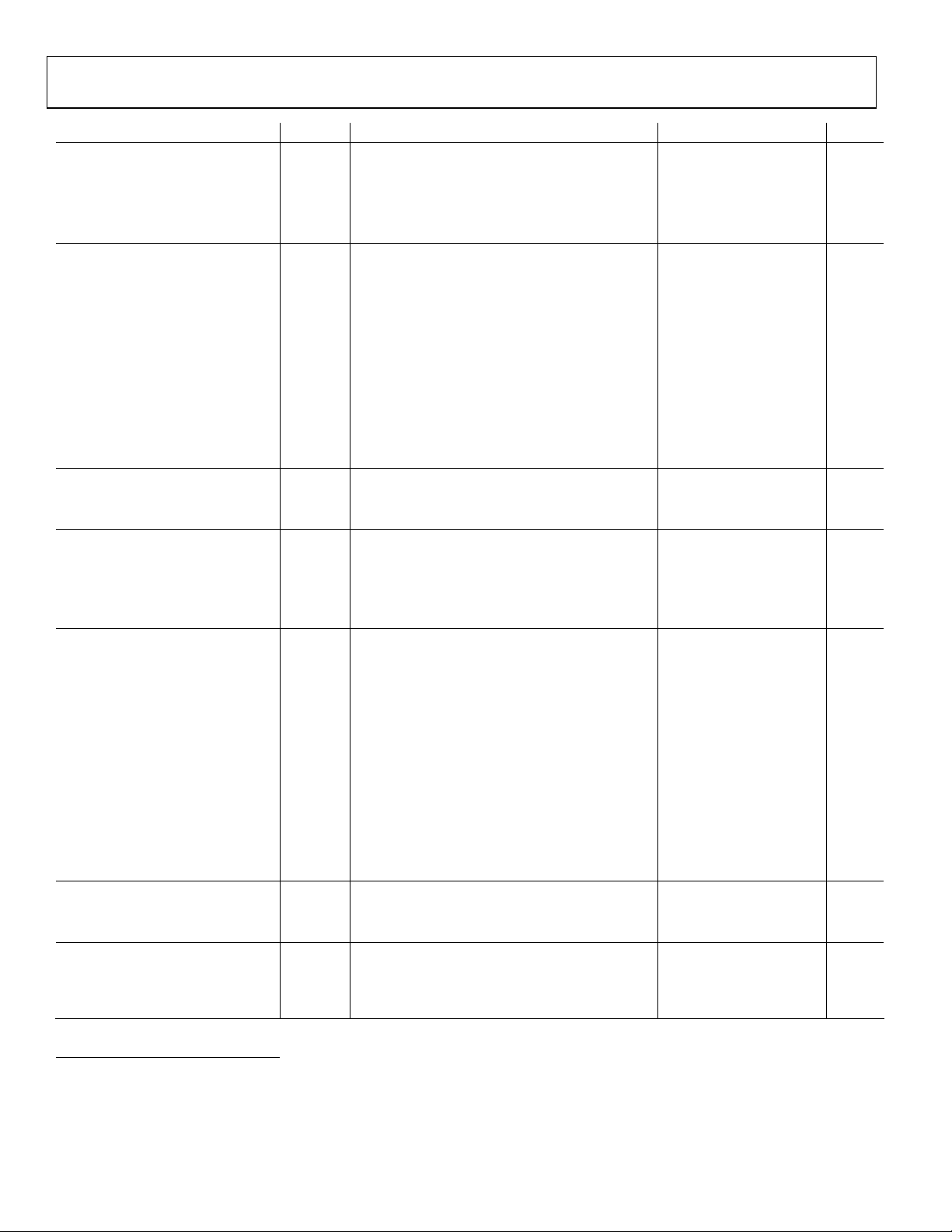

ADP3181

5

TEST CIRCUITS

ADP3181

VCC

PWM1

PWM2

PWM3

PWM4

SW1

SW2

SW3

SW4

GND

CSCOMP

CSSUM

CSREF

ILIMIT

-BIT CODE

12nF

1.25V

1kΩ

250kΩ

1

VID4

2

VID3

3

VID2

4

VID1

5

VID0

6

CPUID

7

FBRTN

8

FB

9

COMP

10

PWRGD

11

EN

12

DELAY

13

RT

14

RAMPADJ

Figure 2. Closed-Loop Output Voltage Accuracy

ADP3181

VCC

100nF

28

18

17

16

19

CSCOMP

CSSUM

CSREF

GND

VOS=

12V

39kΩ

1kΩ

1.0V

28

+

27

26

25

24

23

22

21

20

19

18

20kΩ

17

16

15

250kΩ

CSCOMP–1V

40

100nF1µF

100nF

04796-0-005

12V

04796-0-004

ADP3181

VCC

V = 80mV

∆

28

FB

8

COMP

9

CSCOMP

18

CSSUM

17

CSREF

16

GND

19

– FB

V = 0mV

∆

04796-0-006

200kΩ

∆

V

1.0V

12V

10kΩ

200kΩ

100nF

∆

VFB = FB

Figure 4. Positioning Voltage

Figure 3. Current Sense Amplifier V

OS

Rev. 0 | Page 5 of 24

Page 6

ADP3181

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VCC

FBRTN

VID0 to VID4, CPUID, EN, DELAY, ILIMIT,

CSCOMP, RT, PWM1 to PWM4, COMP

SW1 to SW4

All other inputs and outputs

Storage temperature

Operating ambient temperature range 0°C to 85°C

Operating junction temperature 125°C

Thermal impedance (θJA) 100°C/W

Lead temperature

Soldering (10 sec) 300°C

Infrared (15 sec) 260°C

−0.3 V to +15 V

−0.3 V to +0.3 V

−0.3 V to +5.5 V

−5 V to +25 V

−0.3 V to VCC +0.3 V

−65°C to +150°C

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Absolute maximum ratings apply individually only, not in

combination. Unless otherwise specified all other voltages are

referenced to GND.

Rev. 0 | Page 6 of 24

Page 7

ADP3181

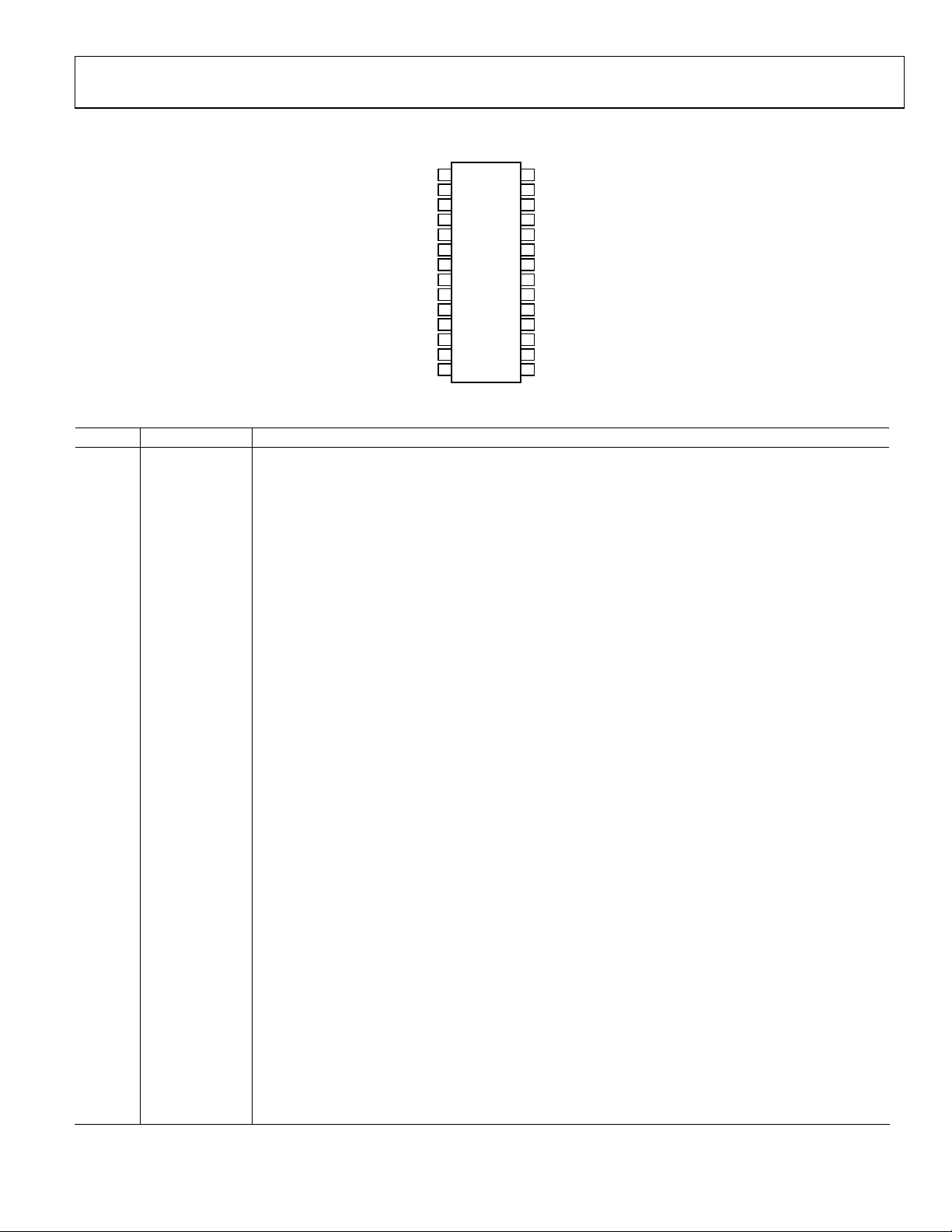

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

VID4

VID3

VID2

VID1

VID0

CPUID

FBRTN

FB

COMP

PWRGD

EN

DELAY

RT

RAMPADJ

1

2

3

4

5

6

ADP3181

7

TOP VIEW

8

(Not to Scale)

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VCC

PWM1

PWM2

PWM3

PWM4

SW1

SW2

SW3

SW4

GND

CSCOMP

CSSUM

CSREF

ILIMIT

04796-0-011

Figure 5. Pin Configuration

Table 3. Pin Function Descriptions

Pin No. Name Description

1 to 5 VID4 to VID0 Voltage Identification DAC Inputs. These five pins are pulled up to an internal reference, providing a

Logic 1 if left open. When in normal mode, the DAC output programs the FB regulation voltage based

on the condition of the CPUID pin (see Table 4 and Table 5). Leaving VID4 through VID0 open results in the

ADP3181 going into a “no CPU” mode, shutting off its PWM outputs.

6 CPUID

CPU DAC Code Selection Input. When this pin is pulled > 4.5 V, the internal DAC reads its inputs based on

the VR 9 VID table (see Table 4). When this pin is < 4 V, the DAC reads its inputs based on the VR 10 VID

table (see Table 5) and treats CPUID as the VID5 input.

7 FBRTN Feedback Return. VID DAC and error amplifier reference for remote sensing of the output voltage.

8 FB

Feedback Input. Error amplifier input for remote sensing of the output voltage. An external resistor

between this pin and the output voltage sets the no-load offset point.

9 COMP Error Amplifier Output and Compensation Point.

10 PWRGD

Power Good Output. Open-drain output that signals when the output voltage is outside of the proper

operating range.

11 EN Power Supply Enable Input. Pulling this pin to GND disables the PWM outputs.

12 DELAY

Soft-start Delay and Current Limit Latch-off Delay Setting Input. An external resistor and capacitor

connected between this pin and GND sets the soft-start ramp-up time and the overcurrent latch-off

delay time.

13 RT

Frequency Setting Resistor Input. An external resistor connected between this pin and GND sets the

oscillator frequency of the device.

14 RAMPADJ

PWM Ramp Current Input. An external resistor from the converter input voltage to this pin sets the internal

PWM ramp.

15 ILIMIT

Current Limit Setpoint/Enable Output. An external resistor from this pin to GND sets the current limit

threshold of the converter. This pin is actively pulled low when the ADP3181 EN input is low, or when VCC

is below its UVLO threshold, to signal to the driver IC that the driver high-side and low-side outputs should

go low.

16 CSREF

Current Sense Reference Voltage Input. The voltage on this pin is used as the reference for the current

sense amplifier and the power good and crowbar functions. This pin should be connected to the common

point of the output inductors.

17 CSSUM

Current Sense Summing Node. External resistors from each switch node to this pin sum the average

inductor currents together to measure the total output current.

18 CSCOMP

Current Sense Compensation Point. A resistor and capacitor from this pin to CSSUM determine the slope of

the load line and the positioning loop response time.

19 GND Ground. All internal biasing and the logic output signals of the device are referenced to this ground.

20 to 23 SW4 to SW1

Current Balance Inputs. Inputs for measuring the current level in each phase. The SW pins of unused

phases should be left open.

24 to 27 PWM4 to PMW1

Logic-level PWM Outputs. Each output is connected to the input of an external MOSFET driver such as the

ADP3413 or ADP3418. Connecting the PWM3 and/or PWM4 outputs to GND causes that phase to turn off,

allowing the ADP3181 to operate as a 2-, 3-, or 4-phase controller.

28 VCC Supply Voltage for the Device.

Rev. 0 | Page 7 of 24

Page 8

ADP3181

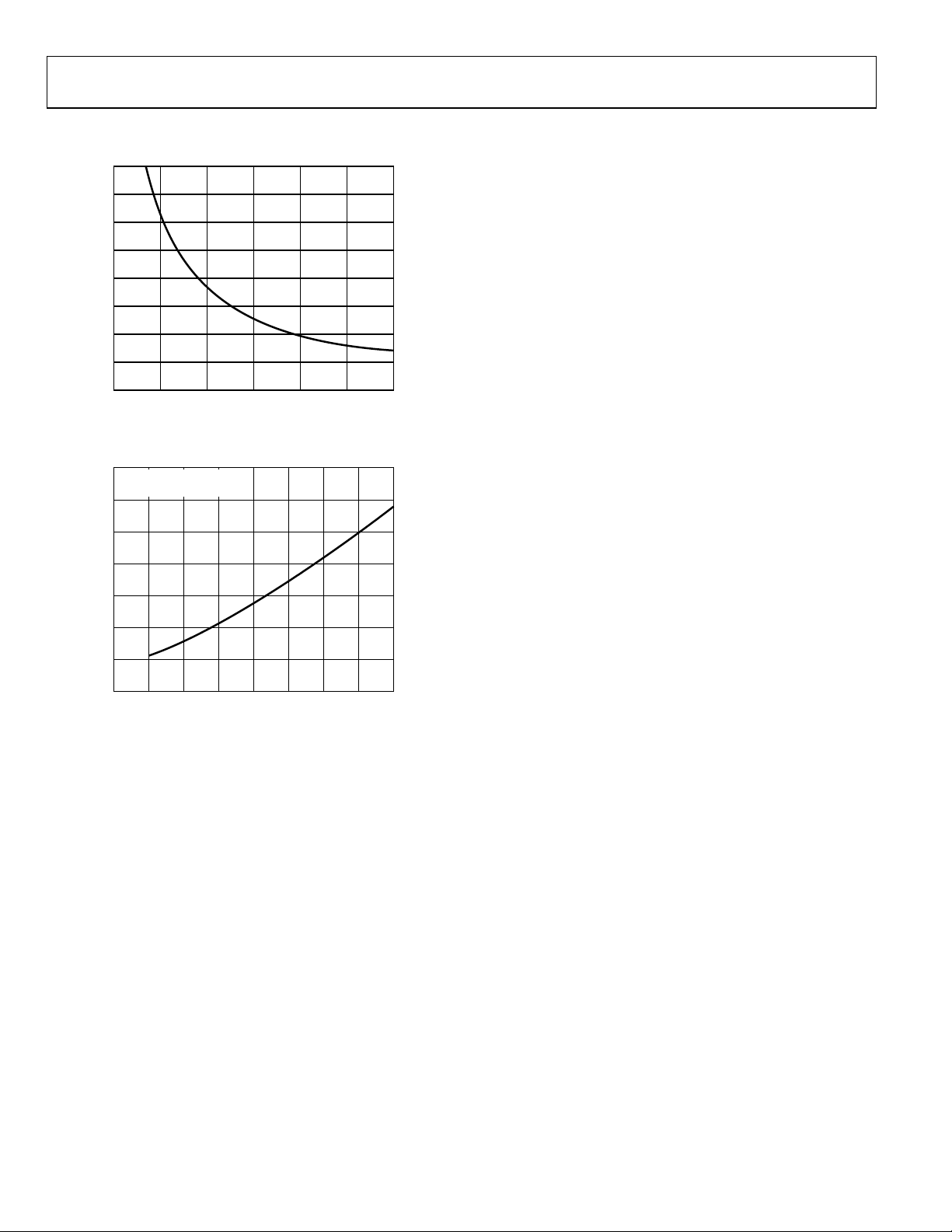

TYPICAL PERFORMANCE CHARACTERISTICS

4

3

2

1

MASTER CLOCK FREQUENCY (MHz)

0

0 50 100 150 200 250 300

Figure 6. Master Clock Frequency vs. R

5.3

TA = 25°C

4-PHASE OPERATION

5.2

5.1

5.0

4.9

4.8

SUPPLY CURRENT (mA)

4.7

4.6

0 4.03.53.02.52.01.51.00.5

RT VALUE (kΩ)

T

OSCILLATOR FREQUENCY (MHz)

Figure 7. Supply Current vs. Oscillator Frequency

04796-0-002

04796-0-003

Rev. 0 | Page 8 of 24

Page 9

ADP3181

THEORY OF OPERATION

The ADP3181 combines a multimode, fixed-frequency PWM

control with multiphase logic outputs for use in 2-, 3-, and

4-phase synchronous buck CPU core supply power converters.

The internal VID DAC can be used in the Intel 5-bit VRM 9 or

6-bit VRD/VRM 10 designs, depending on the setting of the

CPUID pin. Multiphase operation is important for producing

the high currents and low voltages demanded by today’s microprocessors. Handling the high currents in a single-phase

converter places high thermal demands on the components

in the system such as the inductors and MOSFETs. The

multimode control of the ADP3181 ensures a stable, high

performance topology for

• Balancing currents and thermals between phases.

• High speed response at the lowest possible switching

frequency and output decoupling.

• Minimizing thermal switching losses due to lower

frequency operation.

• Tight load line regulation and accuracy.

• High current output from 4-phase operational design.

• Reduced output ripple due to multiphase cancellation.

• PC board layout noise immunity.

• Ease of use and design due to independent component

selection.

• Flexibility in operation for tailoring design to low cost or

high performance.

START-UP SEQUENCE

Two functions are set during the start-up sequence: the number

of active phases and the VID DAC configuration. The number

of operational phases and their phase relationship is determined

by internal circuitry that monitors the PWM outputs. Normally,

the ADP3181 operates as a 4-phase PWM controller. Grounding

the PWM4 pin programs 3-phase operation, and grounding the

PWM3 and PWM4 pins programs 2-phase operation.

When the ADP3181 is enabled, the controller outputs a voltage

on PWM3 and PWM4 that is approximately 675 mV. An

internal comparator checks each pin’s voltage versus a threshold

of 300 mV. If the pin is grounded, it is below the threshold and

the phase is disabled. The output resistance of the PWM pin is

approximately 5 kΩ during this detection time. Any external

pull-down resistance connected to the PWM pin should not be

less than 25 kΩ to ensure proper operation.

PWM1 and PWM2 are disabled during the phase detection

interval, which occurs during the first two clock cycles of the

internal oscillator. After this time, if the PWM output was not

grounded, the 5 kΩ resistance is removed and it switches

between 0 V and 5 V. If the PWM output was grounded, it

remains off.

The PWM outputs are logic-level devices intended for driving

external gate drivers such as the ADP3418. Because each phase

is monitored independently, operation approaching 100% duty

cycle is possible. Also, more than one output can be on at a time

for overlapping phases.

The VID DAC configuration is determined by the voltage at the

CPUID pin. If this pin is pulled up to > 4.5 V, the VID DAC

operates with five inputs and generates the VR 9 output voltage

range as shown in Table 4. If CPUID is < 4 V, the VID DAC

treats CPUID as the VID5 input of VR 10, and operates as a 6bit DAC using the output voltage range given in Table 5.

Table 4. VR 9 VID Codes for the ADP3181, CPUID > 4.25

VID4 VID3 VID2 VID1 VID0 Output

1 1 1 1 1 No CPU

1 1 1 1 0 1.100 V

1 1 1 0 1 1.125 V

1 1 1 0 0 1.150 V

1 1 0 1 1 1.175 V

1 1 0 1 0 1.200 V

1 1 0 0 1 1.225 V

1 1 0 0 0 1.250 V

1 0 1 1 1 1.275 V

1 0 1 1 0 1.300 V

1 0 1 0 1 1.325 V

1 0 1 0 0 1.350 V

1 0 0 1 1 1.375 V

1 0 0 1 0 1.400 V

1 0 0 0 1 1.425 V

1 0 0 0 0 1.450 V

0 1 1 1 1 1.475 V

0 1 1 1 0 1.500 V

0 1 1 0 1 1.525 V

0 1 1 0 0 1.550 V

0 1 0 1 1 1.575 V

0 1 0 1 0 1.600 V

0 1 0 0 1 1.625 V

0 1 0 0 0 1.650 V

0 0 1 1 1 1.675 V

0 0 1 1 0 1.700 V

0 0 1 0 1 1.725 V

0 0 1 0 0 1.750 V

0 0 0 1 1 1.775 V

0 0 0 1 0 1.800 V

0 0 0 0 1 1.825 V

0 0 0 0 0 1.850 V

Rev. 0 | Page 9 of 24

Page 10

ADP3181

Table 5. VR 10 VID Codes for the ADP3181, CPUID Used as a VID5 Input

VID4 VID3 VID2 VID1 VID0 CPUID Output VID4 VID3 VID2 VID1 VID0 CPUID Output

1 1 1 1 1 1 No CPU 1 1 0 1 0 0 1.2125 V

1 1 1 1 1 0 No CPU 1 1 0 0 1 1 1.2250 V

0 1 0 1 0 0 0.8375 V 1 1 0 0 1 0 1.2375 V

0 1 0 0 1 1 0.8500 V 1 1 0 0 0 1 1.2500 V

0 1 0 0 1 0 0.8625 V 1 1 0 0 0 0 1.2625 V

0 1 0 0 0 1 0.8750 V 1 0 1 1 1 1 1.2750 V

0 1 0 0 0 0 0.8875 V 1 0 1 1 1 0 1.2875 V

0 0 1 1 1 1 0.9000 V 1 0 1 1 0 1 1.3000 V

0 0 1 1 1 0 0.9125 V 1 0 1 1 0 0 1.3125 V

0 0 1 1 0 1 0.9250 V 1 0 1 0 1 1 1.3250 V

0 0 1 1 0 0 0.9375 V 1 0 1 0 1 0 1.3375 V

0 0 1 0 1 1 0.9500 V 1 0 1 0 0 1 1.3500 V

0 0 1 0 1 0 0.9625 V 1 0 1 0 0 0 1.3625 V

0 0 1 0 0 1 0.9750 V 1 0 0 1 1 1 1.3750 V

0 0 1 0 0 0 0.9875 V 1 0 0 1 1 0 1.3875 V

0 0 0 1 1 1 1.0000 V 1 0 0 1 0 1 1.4000 V

0 0 0 1 1 0 1.0125 V 1 0 0 1 0 0 1.4125 V

0 0 0 1 0 1 1.0250 V 1 0 0 0 1 1 1.4250 V

0 0 0 1 0 0 1.0375 V 1 0 0 0 1 0 1.4375 V

0 0 0 0 1 1 1.0500 V 1 0 0 0 0 1 1.4500 V

0 0 0 0 1 0 1.0625 V 1 0 0 0 0 0 1.4625 V

0 0 0 0 0 1 1.0750 V 0 1 1 1 1 1 1.4750 V

0 0 0 0 0 0 1.0875 V 0 1 1 1 1 0 1.4875 V

1 1 1 1 0 1 1.1000 V 0 1 1 1 0 1 1.5000 V

1 1 1 1 0 0 1.1125 V 0 1 1 1 0 0 1.5125 V

1 1 1 0 1 1 1.1250 V 0 1 1 0 1 1 1.5250 V

1 1 1 0 1 0 1.1375 V 0 1 1 0 1 0 1.5375 V

1 1 1 0 0 1 1.1500 V 0 1 1 0 0 1 1.5500 V

1 1 1 0 0 0 1.1625 V 0 1 1 0 0 0 1.5625 V

1 1 0 1 1 1 1.1750 V 0 1 0 1 1 1 1.5750 V

1 1 0 1 1 0 1.1875 V 0 1 0 1 1 0 1.5875 V

1 1 0 1 0 1 1.2000 V 0 1 0 1 0 1 1.6000 V

MASTER CLOCK FREQUENCY

The clock frequency of the ADP3181 is set with an external

resistor connected from the RT pin to ground. The frequency

follows the graph in Figure 6. To determine the frequency per

phase, the clock is divided by the number of phases in use. If

PWM4 is grounded, then divide the master clock by 3 for the

frequency of the remaining phases. If PWM3 and 4 are

grounded, divide by 2. If all phases are in use, divide by 4.

OUTPUT VOLTAGE DIFFERENTIAL SENSING

The ADP3181 combines differential sensing with a high

accuracy VID DAC and reference and a low offset error

amplifier to maintain a worst-case specification of ±14.5 mV

differential sensing error over its full operating output voltage

and temperature ranges. The output voltage is sensed between

the FB and FBRTN pins. FB should be connected through a

resistor to the regulation point, usually the remote sense pin of

the microprocessor. FBRTN should be connected directly to the

remote sense ground point. The internal VID DAC and

precision reference are referenced to FBRTN, which has a

minimal current of 100 µA to allow accurate remote sensing.

The internal error amplifier compares the output of the DAC to

the FB pin to regulate the output voltage.

Rev. 0 | Page 10 of 24

Page 11

ADP3181

OUTPUT CURRENT SENSING

The ADP3181 provides a dedicated current sense amplifier

(CSA) to monitor the total output current for proper voltage

positioning versus load current and for current limit detection.

Sensing the load current at the output gives the total average

current being delivered to the load, which is an inherently more

accurate method than peak current detection or sampling the

current across a sense element such as the low-side MOSFET.

This amplifier can be configured several ways depending on the

objectives of the system:

• Output inductor ESR sensing without a thermistor for

lowest cost.

• Output inductor ESR sensing with a thermistor for

improved accuracy with tracking of inductor temperature.

• Sense resistors for highest accuracy measurements.

The positive input of the CSA is connected to the CSREF pin,

which is connected to the output voltage. The inputs to the

amplifier are summed together through resistors from the

sensing element (such as the switch node side of the output

inductors) to the inverting input, CSSUM. The feedback resistor

between CSCOMP and CSSUM sets the gain of the amplifier,

and a filter capacitor is placed in parallel with this resistor. The

gain of the amplifier is programmable by adjusting the feedback

resistor to set the load line required by the microprocessor. The

current information is then given as the difference of CSREF –

CSCOMP. This difference signal is used internally to offset the

VID DAC for voltage positioning and as a differential input for

the current limit comparator.

To provide the best accuracy for the sensing of current, the CSA

has been designed to have a low offset input voltage. Also, the

sensing gain is determined by external resistors so that it can be

made extremely accurate.

ACTIVE IMPEDANCE CONTROL MODE

For controlling the dynamic output voltage droop as a function

of output current, a signal proportional to the total output

current at the CSCOMP pin can be scaled to equal the droop

impedance of the regulator times the output current. This droop

voltage is then used to set the input control voltage to the

system. The droop voltage is subtracted from the DAC reference

input voltage directly to tell the error amplifier where the output

voltage should be. This differs from previous implementations

and allows enhanced feed-forward response.

CURRENT CONTROL MODE AND THERMAL BALANCE

The ADP3181 has individual inputs for each phase, which are

used for monitoring the current in each phase. This information

is combined with an internal ramp to create a current balancing

feedback system that has been optimized for initial current

balance accuracy and dynamic thermal balancing during

operation. This current balance information is independent of

the average output current information used for the positioning

described previously.

The magnitude of the internal ramp can be set to optimize

the transient response of the system. It is also monitors the

supply voltage for feed-forward control for changes in the

supply. A resistor connected from the power input voltage to

the RAMPADJ pin determines the slope of the internal PWM

ramp. Detailed information about programming the ramp is

given in the Application Information section.

If desired, external resistors can be placed in series with

individual phases to create an intentional current imbalance if

desired, such as when one phase may have better cooling and

can support higher currents. Resistors RSW1 through RSW4

(see the typical application circuit in Figure 10) can be used for

adjusting thermal balance. It is best to have the ability to add

these resistors during the initial design, so make sure

placeholders are provided in the layout.

To increase the current in any phase, make R

larger (make R

balancing). Increasing R

= 0 for the hottest phase; do not change during

SW

to only 500 Ω makes a substantial

SW

increase in phase current. Increase each R

for that phase

SW

value by small

SW

amounts to achieve balance, starting with the coolest phase first.

VOLTAGE CONTROL MODE

A high gain bandwidth voltage mode error amplifier is used for

the voltage-mode control loop. The control input voltage to the

positive input is set via the VID logic. This voltage is also offset

by the droop voltage for active positioning of the output voltage

as a function of current, commonly known as active voltage

positioning. The output of the amplifier is the COMP pin,

which sets the termination voltage for the internal PWM ramps.

The negative input (FB) is tied to the output sense location with

a resistor, RB, and is used for sensing and controlling the output

voltage at this point. A current source from the FB pin flowing

through RB is used for setting the no-load offset voltage from

the VID voltage. The no-load voltage is negative with respect to

the VID DAC. The main loop compensation is incorporated in

the feedback network between FB and COMP.

Rev. 0 | Page 11 of 24

Page 12

ADP3181

SOFT START

The power-on ramp-up time of the output voltage is set with

a capacitor and resistor in parallel from the DELAY pin to

ground. The RC time constant also determines the current limit

latch off time as explained in the following section. In UVLO or

when EN is a logic low, the DELAY pin is held at ground. After

the UVLO threshold is reached and EN is a logic high, the

DELAY capacitor is charged with an internal 20 µA current

source. The output voltage follows the ramping voltage on the

DELAY pin, limiting the in-rush current. The soft-start time

depends on the value of VID DAC and C

effect from R

. Refer to the Application Information section

DLY

for detailed information on setting C

If either EN is taken low or VCC drops below UVLO, the

DELAY capacitor is reset to ground to be ready for another

soft-start cycle. Figure 8 shows the typical start-up waveforms

for the ADP3181.

, with a secondary

DLY

.

DLY

drops below 1.8 V. The current-limit latch-off delay time is thus

set by the RC time constant discharging from 3 V to 1.8 V. The

Application Information section discusses the selection of C

and R

DLY

.

DLY

Because the controller continues to cycle the phases during the

latch-off delay time, if the short is removed before the 1.8 V

threshold is reached, the controller returns to normal operation.

The recovery characteristic depends on the state of PWRGD. If

the output voltage is within the PWRGD window, the controller

resumes normal operation. However, if short circuit has caused

the output voltage to drop below the PWRGD threshold, a softstart cycle is initiated.

The latch-off function can be reset either by removing and

reapplying VCC to the ADP3181, or by pulling the EN pin low

for a short time. To disable the short-circuit latch-off function,

the external resistor to ground should be left open, and a high

value (>1 MΩ) resistor should be connected from DELAY to

VCC. This prevents the delay capacitor from discharging so the

1.8 V threshold is never reached. The resistor has an impact on

the soft-start time because the current through it adds to the

internal 20 µA current source.

Figure 8. Typical S tart-up Waveforms

Channel 1: PWRGD, Channel 2: CSREF,

Channel 3: DELAY, Channel 4: COMP

CURRENT LIMIT, SHORT-CIRCUIT, AND LATCHOFF PROTECTION

The ADP3181 compares a programmable current-limit setpoint

to the voltage from the output of the current sense amplifier.

The level of current limit is set with the resistor from the

ILIMIT pin to ground. During normal operation, the voltage on

ILIMIT is 3 V. The current through the external resistor is internally scaled to give a current-limit threshold of 10.4 mV/µA. If

the difference in voltage between CSREF and CSCOMP rises

above the current-limit threshold, the internal current-limit

amplifier controls the internal COMP voltage to maintain the

average output current at the limit.

After the limit is reached, the 3 V pull-up on the DELAY pin is

disconnected, and the external delay capacitor is discharged

through the external resistor. A comparator monitors the

DELAY voltage and shuts off the controller when the voltage

Figure 9. Overcurrent Latch-off Waveforms

Channel 1: CSREF, Channel 2: DELAY,

Channel 3: COMP, Channel 4: Phase 1 Switch Node

During start-up when the output voltage is below 200 mV, a

secondary current limit is active because the voltage swing of

CSCOMP cannot go below ground. This secondary current

limit controls the internal COMP voltage to the PWM

comparators to 2 V. This limits the voltage drop across the lowside MOSFETs through the current balance circuitry.

There is also an inherent per phase current limit that protects

individual phases if one or more phases stops functioning

because of a faulty component. This limit is based on the

maximum normal mode COMP voltage.

Rev. 0 | Page 12 of 24

Page 13

ADP3181

DYNAMIC VID

The ADP3181 incorporates the ability to dynamically change

the VID input while the controller is running. This allows the

output voltage to change while the supply is running and

supplying current to the load. This is commonly referred to as

VID on-the-fly (OTF). A VID OTF event can occur under

either light load or heavy load conditions. The processor signals

the controller by changing the VID inputs in multiple steps

from the start code to the finish code. This change can be either

positive or negative.

When a VID input changes state, the ADP3181 detects the

change and ignores the DAC inputs for a minimum of 400 ns.

This time is to prevent a false code due to logic skew while the

five VID inputs are changing. Additionally, the first VID change

initiates the PWRGD and CROWBAR blanking functions for a

minimum of 250 µs to prevent a false PWRGD or CROWBAR

event. Each VID change resets the internal timer.

POWER GOOD MONITORING

The power good comparator monitors the output voltage via

the CSREF pin. The PWRGD pin is an open-drain output

whose high level (when connected to a pull-up resistor)

indicates that the output voltage is within the nominal limits

specified based on the VID voltage setting. PWRGD goes low

if the output voltage is outside of this specified range, if all of

the VID DAC inputs are high, or whenever the EN pin is

pulled low. PWRGD is blanked during a VIDOTF event for a

period of 250 µs to prevent false signals during the time the

output is changing.

OUTPUT CROWBAR

As part of the protection for the load and output components of

the supply, the PWM outputs are driven low (turning on the

low-side MOSFETs) when the output voltage exceeds the upper

crowbar threshold. This crowbar action stops once the output

voltage falls below the release threshold of about 700 mV.

Turning on the low-side MOSFETs pulls down the output as the

reverse current builds up in the inductors. If the output

overvoltage is due to a short of the high-side MOSFET, this

action current-limits the input supply or blows its fuse,

protecting the microprocessor from destruction.

OUTPUT ENABLE AND UVLO

The input supply (VCC) to the controller must be higher than

the UVLO threshold and the EN pin must be higher than its

logic threshold for the ADP3181 to begin switching. IF UVLO is

less than the threshold or the EN pin is a logic low, the device is

disabled. This holds the PWM outputs at ground, shorts the

DELAY capacitor to ground, and holds the ILIMIT pin at

ground.

In the application circuit, the ILIMIT pin should be connected

to the OD pins of the ADP3418 drivers. Because ILIMIT is

grounded, this disables the drivers such that both DRVH and

DRVL are grounded. This feature is important to prevent discharging of the output capacitors when the controller is shut off.

If the driver outputs were not disabled, a negative voltage could

be generated on the output due to the high current discharge of

the output capacitors through the inductors.

The PWRGD circuitry also incorporates an initial turn-on delay

time based on the DELAY ramp. The PWRGD pin is held low

until the DELAY pin reaches 2.8 V. The time between when the

PWRGD undervoltage threshold is reached and when the

DELAY pin reaches 2.8 V provides the turn-on delay time. This

time is incorporated into the soft-start ramp. To ensure a 1 ms

delay time on PWRGD, the soft-start ramp must also be > 1 ms.

Refer to the Application Information section for detailed

information on setting C

DLY

.

Rev. 0 | Page 13 of 24

Page 14

ADP3181

K

VIN RTN

V

12V

L1

IN

1.6µH

1N4148WS

470µF/16V× 6

NICHICON PW SERIES

+

C1 C6

D1

+

D2

1N4148WS

C7

4.7µF

D3

1N4148WS

C11

4.7µF

D4

1N4148WS

C15

4.7µF

1

2

3

4

1

2

3

4

1

2

3

4

ADP3418

BST

IN

OD

VCC

ADP3418

BST

IN

OD

VCC

ADP3418

BST

IN

OD

VCC

C9

4.7µF

C8

U2

100nF

8

DRVH

7

SW

6

PGND

5

DRVL

Q2

IPD06N03L

C12

U3

100nF

8

DRVH

7

SW

6

PGND

5

DRVL

Q5

IPD06N03L

C16

U4

100nF

8

DRVH

7

SW

6

PGND

5

DRVL

Q8

IPD06N03L

Q1

IPD12N03L

Q3

IPD06N03L

C13

4.7µF

Q4

IPD12N03L

Q6

IPD06N03L

C17

4.7µF

Q7

IPD12N03L

Q9

IPD06N03L

L2

600nH/1.6mΩ

C10

4.7nF

R1

2.2Ω

L3

600nH/1.6mΩ

C14

4.7nF

R2

2.2Ω

L4

600nH/1.6mΩ

C18

4.7nF

R3

2.2Ω

100kΩ, 5%

FUJITSU RE SERIES

RTH

820µF/2.5V

8mΩ ESR (EACH)

+

C21

×

8

C28

10µF × 23

MLCC

SOCKET

V

CC(CORE)

+

IN

0.8375V – 1.6V

65A AVG, 74A P

V

CC(CORE) RTN

POWER

GOOD

ENABLE

*FOR A DESCRIPTION OF

OPTIONAL R

SEE THE THEORY OF

OPERATION SECTION.

RESISTORS,

SW

C

DLY

12nF

C

B

1.5nF

R

B

1.33kΩ

R4

10Ω

R

DLY

330kΩ

C

390pF

+

C19

C20

1µF

33µF

R

A

16.9kΩ

249kΩ

R

383kΩ

FROM CPU

C

FB

33pF

R

A

R

T

10

11

12

13

14

1

VID4

2

VID3

3

VID2

4

VID1

5

VID0

6

CPUID

7

FBRTN

8

FB

9

COMP

PWRGD

EN

DELAY

RT

RAMPADJ

U1

ADP3181

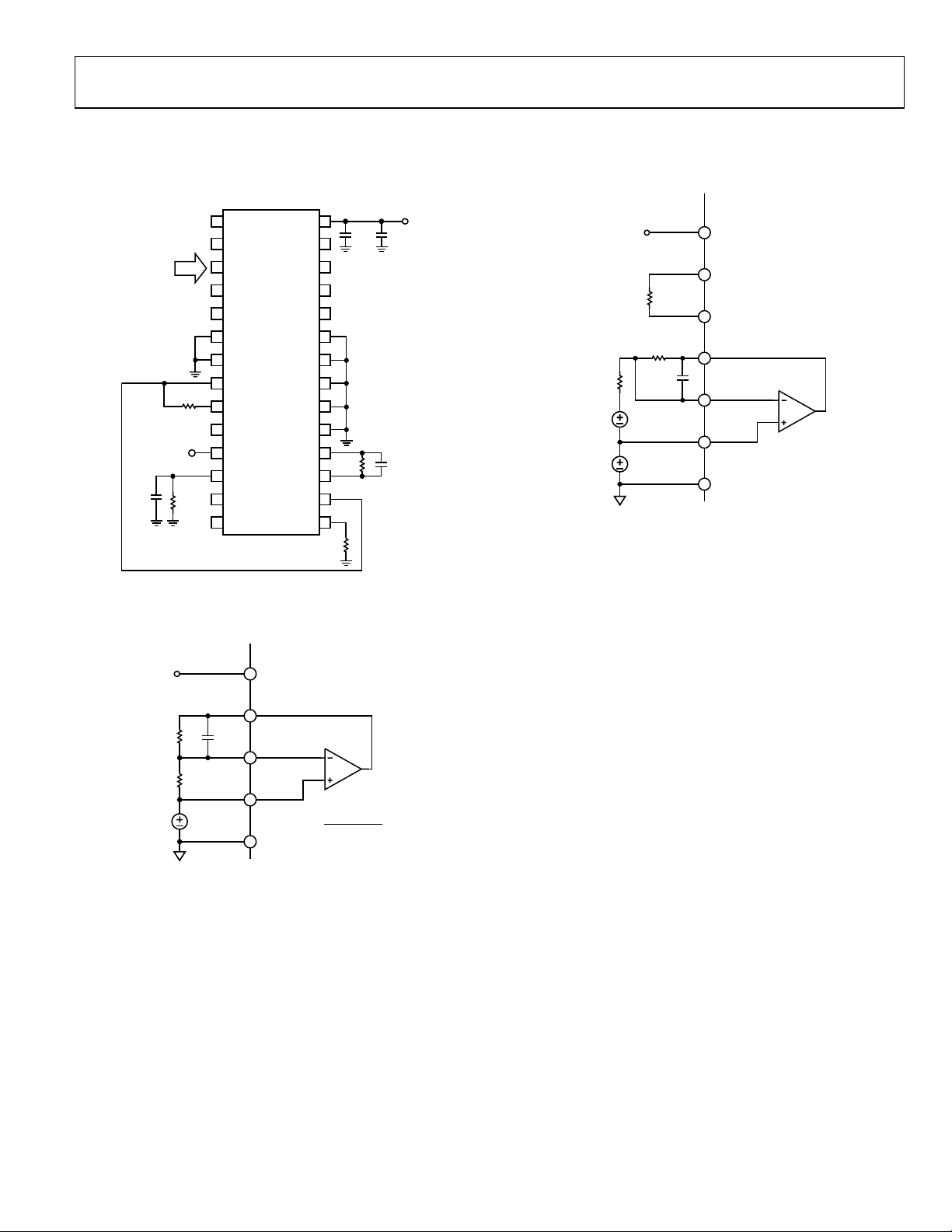

Figure 10. Typical VR 10 Application Circuit

Rev. 0 | Page 14 of 24

VCC

PWM1

PWM2

PWM3

PWM4

SW1

SW2

SW3

SW4

GND

CSCOMP

CSSUM

CSREF

ILIMIT

28

27

26

25

24

23

22

21

20

19

18

17

C

2.2nF

16

15

R

CS1

SW2

*

C

1.5nF

CS2

R

SW1

*

R

SW3

*

R

CS1

35.7kΩ

R

LIM

200kΩ

R

CS2

73.2kΩ

R

PH3

124kΩ

R

PH2

124kΩ

R

PH1

124kΩ

04796-0-008

Page 15

ADP3181

×

t

−

−××

(

)

×Ω×

APPLICATION INFORMATION

The design parameters for a typical ADP3181 CPU application

are as follows:

• Input voltage (V

• VID setting voltage (V

) = 12 V

IN

) = 1.500 V

VID

• Duty cycle (D) = 0.125

• Nominal output voltage at no load (V

• Nominal output voltage at 65 A load (V

• Static output voltage drop based on a 1.5 mΩ load line (R

) = 1.480 V

ONL

) = 1.3825 V

OFL

O

from no load to full load:

– V

V∆ = V

ONL

• Maximum output current (I

= 1.480 V – 1.3825 V = 97.5 mV

OFL

) = 65 A

O

• Number of phases (n) = 3

• Switching frequency per phase (f

) = 330 kHz

SW

SETTING THE CLOCK FREQUENCY

The ADP3181 uses a fixed-frequency control architecture. The

frequency is set by an external timing resistor (R

). The clock

T

frequency and the number of phases determine the switching

frequency per phase, which relates directly to switching losses

and the sizes of the inductors and input and output capacitors.

With n = 3 for three phases, a clock frequency of 990 kHz sets

the switching frequency, f

, of each phase to 330 kHz, which

SW

represents a practical trade-off between the switching losses and

the sizes of the output filter components. Figure 6 shows that to

achieve a 990 kHz oscillator frequency, the correct value for R

T

is 200 kΩ. For good initial accuracy and frequency stability, it is

recommended to use a 1% resistor.

SOFT-START AND CURRENT-LIMIT LATCH-OFF DELAY TIMES

Because the soft-start, PWRGD delay, and current-limit latchoff delay functions all share the DELAY pin, these three

parameters must be considered together. The first step is to set

for the PWRGD delay ramp. This ramp is generated with a

C

DLY

×

V8.22

has a second-

DLY

is kept

DLY

t

PWRGD

VV

−−

VID

PWRGD(UV)

DLY

can

UVPWRGD

(1)

is

20 µA internal current source. The value of R

order impact on the soft-start time because it sinks part of the

current source to ground. However, as long as R

greater than 200 kΩ, this effect is minor. The value for C

be approximated using

C

DLY

where t

⎛

⎜

⎜

⎝

PWRGD

V8.2

−µ=

A20

is the desired PWRGD delay time and V

VID

VV

×

R

DLY

⎞

)(

UVPWRGD

⎟

⎟

⎠

−−

the undervoltage threshold for the PWRGD comparator.

Assuming an R

time of 1 µs, C

calculated using

t

=

ss

Once C

DLY

)

current limit latch off time using:

R×=

DLY

If the result for R

time should be considered by recalculating the equation for

C

or a longer latch-off time should be used. In no case should

DLY,

R

be less than 200 kΩ. In this example, a delay time of 2 ms

DLY

gives R

= 333 kΩ. The closest standard 5% value is 330 kΩ.

DLY

Substituting 330 kΩ back into Equations 1 and 2 shows that the

PWRGD delay and soft-start times do not change significantly.

INDUCTOR SELECTION

The choice of inductance for the inductor determines the ripple

current in the inductor. Less inductance leads to more ripple

current, which increases the output ripple voltage and conduction losses in the MOSFETs, but allows using smaller size

inductors and, for a specified peak-to-peak transient deviation,

less total output capacitance. Conversely, a higher inductance

means lower ripple current and reduced conduction losses, but

requires larger-size inductors and more output capacitance for

the same peak-to-peak transient deviation. In any multiphase

converter, a practical value for the peak-to-peak inductor ripple

current is less than 80% of the maximum dc current in the same

inductor. Equation 4 shows the relationship between the

inductance, oscillator frequency, and peak-to-peak ripple

current in the inductor. Equation 4 determines the minimum

inductance based on a given output ripple voltage:

I

=

RIPPLE

VID

L

≥

)(

Intel recommends that the ripple voltage should not exceed

10 mV peak-to-peak at the socket. Solving Equation 4 for a

12 mV peak-to-peak output ripple voltage at the regulator’s

output to allow for drops through the PCB traces yields

≥L

of 250 kΩ and a desired a PWRGD delay

DLY

is 12 nF. The soft-start delay time can then be

DLY

VC

VIDDLY

(2)

V

VID

−µ

A20

R

×

2

DLY

has been chosen, R

2

DELAY

C

(3)

DLY

is less than 200 kΩ, a smaller soft-start

DLY

DV

SW

)1(

(4)

Lf

×

Vf

×

RIPPLE

SW

VID

O

can be calculated for the

DLY

DnDRV

×−×

))(1()1(

(5)

375.01875.0m5.1V5.1

−×

mV12kHz330

×

=

(6)

nH310

Rev. 0 | Page 15 of 24

Page 16

ADP3181

If the ripple voltage is less than that designed for, the inductor

can be made smaller until the ripple value is met. This allows

optimal transient response and minimum output decoupling.

The smallest possible inductor should be used to minimize the

number of output capacitors. A 300 nH inductor is a good

choice to start, and it gives a calculated ripple current of 13.3 A,

which is 61% of the full load current of 21.7 A. The inductor

should not saturate at the peak current of 29 A, and should be

able to handle the sum of the power dissipation caused by the

average current of 22 A in the winding and the core loss.

Another important factor in the inductor design is the DCR,

which is used for measuring the phase currents. A large DCR

causes excessive power losses, while too small a value leads to

increased measurement error. A good rule is to have the DCR

be about 1 to 1½ times the droop resistance (R

DESIGNING AN INDUCTOR

Once the inductance and DCR are known, the next step is to

design an inductor or find a standard inductor that comes as

close as possible to meeting the overall design goals. It is also

important to have the inductance and DCR tolerance specified

to keep the accuracy of the system controlled. Using 15% for the

inductance and 8% for the DCR (at room temperature) are

reasonable tolerances that most manufacturers can meet.

The first decision in designing the inductor is to choose the

core material. Several possibilities for providing low core loss

at high frequencies include the powder cores (Kool-Mµ® from

Magnetics, Inc. or Micrometals) and the gapped soft ferrite

cores (3F3 or 3F4 from Philips). Low frequency powdered

iron cores should be avoided due to their high core loss,

especially when the inductor value is relatively low and the

ripple current is high.

The best choice for a core geometry is a closed-loop types, such

as potentiometer cores, PQ, U, and E cores, or toroids. A good

compromise between price and performance are cores with a

toroidal shape. There are many useful references for quickly

designing a power inductor, such as

Magnetic Designer Software Intusoft

•

(http://www.intusoft.com)

•

Designing Magnetic Components for High Frequency

DC-DC Converters, McLyman, Kg Magnetics,

ISBN 1-883107-00-08

Selecting a Standard Inductor

The companies listed in Table 6 can provide design consultation

and deliver power inductors optimized for high power

applications upon request.

).

O

Table 6. Power Inductor Manufacturers

Company Contact Website

Coilcraft (847) 639-6400 http://www.coilcraft.com

Coiltronics (561) 752-5000 http://www.coiltronics.com

Sumida Electric

(510) 668-0660 http://www.sumida.com

Company

Vishay (402) 563-6506 http://www.vishay.com

OUTPUT DROOP RESISTANCE

The design requires that the regulator output voltage measured

at the CPU pins drops when the output current increases. The

specified voltage drop corresponds to a dc output resistance

).

(R

O

The output current is measured by summing together the

voltage across each inductor and then passing the signal

through a low-pass filter. This summer-filter is the CS amplifier

configured with resistors R

(filter). The output resistance of the regulator is set by these

equations, where R

R

R ×=

C×=

CS

O

R

CS

L

is the DCR of the output inductors:

L

R

(7)

L

XPH

)(

L

(8)

RR

CS

One has the flexibility of choosing either R

to start with R

solve for R

R

R

CS

R

R

CS

in the range of 100 kΩ to 200 kΩ, and then

PH(X)

by rearranging Equation 7. Using 100 kΩ for R

CS

O

×=

R

)(

L

XPH

Ωm5.1

mΩ6.1

Next, use equation 8 to solve for C

=

C

CS

nH300

×

The closest standard value for C

value is not a standard value, recalculate for the closest 1%

resistor values for R

. This can be quickly calculated by multiplying the

for C

CS

original values of R

to the actual value used. For best accuracy, CCS should be a

C

CS

and R

CS

and R

CS

5% or 10% NPO capacitor. For this example, the actual values

used for R

and R

CS

are 104.2 kΩ and 111.1 kΩ. The closest

PH(X)

standard 1% value for R

should not be rounded yet.

(summers) and RCS and CCS

PH(X)

or R

CS

PH(X).

Ωk8.93Ωk100

=×=

:

CS

nF0.2

=

Ωk8.93Ωm6.1

is 1.8 nF. If the calculated

CS

using the final value selected

PH(X)

by the ratio of the calculated

PH(X)

is 110 kΩ. RCS is used later and

PH(X)

It is best

PH(X)

:

Rev. 0 | Page 16 of 24

Page 17

ADP3181

×

××=

+−×

=

−

−

INDUCTOR DCR TEMPERATURE CORRECTION

With the inductor’s DCR being used as the sense element,

and copper wire being the source of the DCR, one needs to

compensate for temperature changes of the inductor’s winding.

Fortunately, copper has a well known temperature coefficient

(TC) of 0.39%/°C.

is designed to have an opposite and equal percentage

If R

CS

change in resistance to that of the wire, it cancels the temperature variation of the inductor’s DCR. Due to the nonlinear

nature of NTC thermistors, Resistors R

CS1

and R

(see Figure 11) to linearize the NTC and produce the desired

temperature tracking.

PLACE AS CLOSE AS POSSIBLE

TO NEAREST INDUCTOR

OR LOW-SIDE MOSFET

R

TH

R

ADP3181

CSCOMP

18

CSSUM

17

CSREF

16

Figure 11. Temperature Compensation Circuit Values

C

CS

1.8nF

R

CS1

PH1

R

CS2

The following procedure yields values to use for R

(the thermistor value at 25°C) for a given RCS value.

R

TH

Select an NTC to be used based on type and value. Because

1.

there is not a value yet, start with a thermistor with a value

close to R

. The NTC should also have an initial tolerance

CS

of better than 5%.

2.

Based on the type of NTC, find its relative resistance value

at two temperatures. The temperatures that work well

are 50°C and 90°C. We call these resistance values A

(A is R

(50°C)/RTH(25°C)) and B (B is RTH(90°C)/RTH(25°C)).

TH

The NTC’s relative value is always 1 at 25°C.

are needed

CS2

TO

SWITCH

NODES

R

R

PH2

KEEP THIS PATH

AS SHORT AS POSSIBLE

AND WELL AWAY FROM

SWITCH NODE LINES

, R

CS1

PH3

CS2

SENSE

, and

R

=

TH

Calculate R

thermistor available. Also compute a scaling factor k based on

the ratio of the actual thermistor value used relative to the

computed one:

k = (10)

R

Calculate values for R

TO

V

OUT

For this example, R

previous section to be 104.2 kΩ, so a thermistor value of

100 kΩ is started with. In available 0603 size thermistors,

there is a Vishay NTHS0603N01N1003JR NTC thermistor

with A = 0.3602 and B = 0.09174. From these, r

= 0.7195 and rTH = 1.0751 can be computed. Solving for RTH

r

CS2

yields 112.05 kΩ, so when 100 kΩ is chosen, k = 0.8925. Finally,

and R

R

04796-0-009

CS1

the closest 1% resistor values yields a choice of 35.7 kΩ or

78.7 kΩ.

OUTPUT OFFSET

The Intel specification requires that, at no load, the nominal

output voltage of the regulator be offset to a lower value than

the nominal voltage corresponding to the VID code. The offset

is set by a constant current source flowing out of the FB pin

) and flowing through RB. The value of RB can be found

(I

FB

using Equation 12. The closest standard 1% resistor value is 1.33

kΩ.

= (12)

R

B

1

1

1

−

1

R

()

CS2

VID

rr

−

TH

CALCULATEDTH

CS1CS2

= rTH × RCS, then select the closest value of

ACTUALTH

()

and R

CS1

rkRR

(11)

CS1CSCS1

has already been calculated in the

CS

using the following:

CS2

))()1((

rkkRR ×

CS2CSCS2

= 0.3796,

CS1

are found to be 35.30 kΩ and 78.11 kΩ. Selecting

VV

ONL

I

FB

Find the relative value of R

3.

temperatures. This is based on the percentage change

required for each of these

CS

V480.1V5.1

=BR

μA15

=

Ωk33.1

needed, which can be 0.39%/°C initially. These values are

(r1 is 1/(1+ TC × (T1 − 25))) and

r

1

(r2 is 1/(1 + TC × (T2 − 25)))

r

2

where TC = 0.0039, T1 = 50°C, and T2 = 90°C.

4.

Compute the relative values for R

CS1

, R

, and RTH:

CS2

C

SELECTION

OUT

The required output decoupling for the regulator is typically

recommended by Intel for various processors and platforms.

One can also use some simple design guidelines to determine

what is required. These guidelines are based on having both

()

R

=

CS2

R

=

CS1

1

()

()

A

−

1

1

−

r

−

CS2

A

rr

−

1

()

() ( )

11

CS2

()

−×+×−×−××−

11

−−×−×−×−×

21

rABrBArrBA

1221

(9)

BArABrBA

Rev. 0 | Page 17 of 24

bulk and ceramic capacitors in the system.

Page 18

ADP3181

The first thing is to select the total amount of ceramic capacitance. This is based on the number and type of capacitor to be

used. The best location for ceramics is inside the socket, with

12 to 18 of size 1206 being the physical limit. Others can be

placed along the outer edge of the socket as well.

The combined ceramic values of 200 µF to 300 µF are recommended, made of multiple 10 µF or 22 µF capacitors. Select the

number of ceramics and find the total ceramic capacitance (C

Next, there is an upper limit imposed on the total amount of

bulk capacitance (C

voltage stepping of the output (voltage step V

lower limit based on meeting the critical capacitance for load

release for a given maximum load step I

) when one considers the VID on-the-fly

X

in time tV), and a

V

:

MAX

Using ten 560 µF OSCONs with an ESR of 12 mΩ each yields

= 5.6 mF with an RX = 1.2 mΩ (making the new limits on C

C

X

X

2.4 mF to 8.8 mF, which is still within the acceptable range).

One last check should be made to ensure that the ESL of the

bulk capacitors (L

) is low enough to limit the initial high

X

frequency transient spike. This can be tested using

2

×≤

).

Z

X

L

X

In this example, L

which satisfies this limitation. If the L

RCL

O

Z

2

=Ω×≤

is 400 pH for the ten OSCSON capacitors,

X

(15)

pH893m3.1μF230

of the chosen bulk

X

capacitor bank is too large, the number of MLC capacitors must

be increased.

C

C

≥

MINX

)(

≤

()

MAXX

L

22

RnK

O

⎛

×

IL

VID

STEP

××

VRn

VID

O

⎛

⎜

V

⎜

⎜

⎝

⎞

⎛

V

ERR

⎟

⎜

nK 1where

(14)

⎟

⎜

V

V

⎠

⎝

⎜

⎜

⎝

V

V

=

⎞

⎟

−

C

(13)

Z

⎟

⎠

Note that for this multimode control technique, all ceramic

designs can be used as long as the conditions of Equations 11,

12, and 13 are satisfied.

POWER MOSFETS

2

⎛

⎜

t

v

⎜

⎝

nKR

V

VID

V

V

O

×+×× 11

L

⎞

⎞

⎟

⎟

⎟

⎠

−

C

⎟

⎟

⎠

Z

−

For this example, the N-channel power MOSFETs have been

selected for one high-side switch and two low-side switches per

phase. The main selection parameters for the power MOSFETs

are V

voltage (the supply voltage to the ADP3418) dictates whether

standard threshold or logic-level threshold MOSFETs must

be used. With V

where R

transient specification, R

If the C

VID on-the-fly specification and may require the use of a

smaller inductor or more phases (and may have to increase the

switching frequency to keep the output ripple the same).

is the ESR of the bulk capacitor bank. To meet the

X

cannot be greater than 3 times RO.

X

is larger than C

X(MIN)

, the system does not meet the

X(MAX)

(V

The maximum output current, I

requirement for the low-side (synchronous) MOSFETs. In the

ADP3181, currents are balanced between phases, so the current

in each low-side MOSFET is the output current divided by the

total number of MOSFETs (n

In this example, there are twelve 22 µF 1206 MLC capacitors

(CZ = 264 µF). The VID-on-the-fly step change is 12.5 mV in

5 µs. Solving for the bulk capacitance, assuming that R

= RO,

X

dominant, the following expression shows the total power being

dissipated in each synchronous MOSFET in terms of the ripple

current per phase (I

and where k = 4.6, yields

⎛

⎜

C

C

⎛

⎜

⎜

⎜

⎝

=

≥

()

MINX

⎜

⎝

≤

()

MAXX

⎛

⎜

1

+

⎜

⎝

mF9.23

×

A60nH600

−

×Ω×

V5.1m3.13

mV250nH600

×

22

×Ω××

××××

nH320mV450

×

⎞

⎟

=

⎟

⎠

mF92.5μF230

Knowing the maximum output current being designed for and

×

V5.1m3.16.43

2

⎞

⎞

Ωm31.4.63V51.μs150

⎟

⎟

−

⎟

⎟

⎟

⎠

⎠

F2301

µ−

the maximum allowed power dissipation, one can find the

required R

an ambient temperature of 50°C, a safe limit for P

(assuming 2 D-paks) at 120°C junction temperature. Here, for

example (65 A maximum), R

This R

this must be accounted for this when making this selection.

, QG , C

GS(TH)

< 2.5 V) are recommended.

GS(TH)

1 (16)

()

SF

DS(ON)

is also at a junction temperature of about 120°C, so

DS(SF)

, C

, and R

ISS

RSS

~10 V, logic-level threshold MOSFETs

GATE

) and average total output current (IO).

R

⎡

⎛

⎞

I

O

⎜

⎟

⎢

×−=

DP ×

⎜

⎟

n

⎢

SF

⎝

⎠

⎣

. The minimum gate drive

DS(ON)

determines the R

O,

). With conduction losses being

SF

22

⎤

⎞

×

In

R

⎟

⎥

R

()

⎟

n

SF

⎠

SFDS

⎥

⎦

12

⎛

1

⎜

×+

⎜

⎝

for the MOSFET. For D-PAK MOSFETs up to

is 1 W

SF

(per MOSFET) < 8.7 mW.

DS(SF)

DS(ON)

Rev. 0 | Page 18 of 24

Page 19

ADP3181

M

×

(

×−×

Another important factor for the synchronous MOSFET is

the input capacitance and feedback capacitance. The ratio

of the feedback to input needs to be small (less than 10%

is recommended) to prevent accidental turn-on of the

synchronous MOSFETs when the switch node goes high.

Also, the time to switch the synchronous MOSFETs off should

not exceed the non-overlap dead time of the MOSFET driver

(40 ns typical for the ADP3418). The output impedance of

the driver is about 2 Ω, and the typical MOSFET input gate

resistances are about 1 Ω – 2 Ω, so a total gate capacitance

of less than 6000 pF should be adhered to. Because there

are two MOSFETs in parallel, the input capacitance for each

synchronous MOSFET should be limited to 3000 pF.

The high-side (main) MOSFET has to be able to handle two

main power dissipation components: conduction and switching

losses. The switching loss is related to the amount of time it

takes for the main MOSFET to turn on and off, and to the

current and voltage that are being switched. Basing the switching speed on the rise and fall time of the gate driver impedance

and MOSFET input capacitance, the following expression

provides an approximate value for the switching loss per main

MOSFET, where n

()

MFS

Here, R

is the total gate resistance (2 Ω for the ADP3418

G

is the total number of main MOSFETs:

MF

IV

×

fP ×××

××= 2 (17)

SW

OCC

n

F

n

MF

R

G

C

ISS

n

and about 1 Ω for typical high speed switching MOSFETs,

making R

= 3 Ω), and C

G

is the input capacitance of the

ISS

main MOSFET. It is interesting to note that adding more main

MOSFETs (n

) does not really help the switching loss per

MF

MOSFET because the additional gate capacitance slows down

switching. The best thing to reduce switching loss is to use

lower gate capacitance devices.

The conduction loss of the main MOSFET is given by the

following, where R

×=

DP ×

() ()

MFC

is the on resistance of the MOSFET:

DS(MF)

22

⎡

⎛

⎞

I

O

⎜

⎟

⎢

⎜

⎟

n

⎢

MF

⎝

⎠

⎣

12

⎛

1

⎜

×+

⎜

⎝

⎤

⎞

×

In

R

⎟

⎥

⎟

n

⎥

MF

⎠

⎦

R

(18)

MFDS

Typically, for main MOSFETs, one wants the highest speed

(low C

) device, but these usually have higher on resistance.

ISS

One must select a device that meets the total power dissipation

(about 1.5 W for a single D-PAK) when combining the

switching and conduction losses.

For this example, an Infineon IPD12N03L was selected as the

main MOSFET (three total; n

(max) and R

= 14 mΩ (max at TJ = 120ºC), and an

DS(MF)

= 3), with a C

MF

= 1460 pF

ISS

Infineon IPD06N03L as the synchronous MOSFET (six total;

n

= 6), with C

SF

(max at T

= 2370 pF (max) and R

ISS

= 120ºC). The synchronous MOSFET C

J

= 8.3 mΩ

DS(SF)

is less than

ISS

3000 pF, satisfying that requirement. Solving for the power

dissipation per MOSFET at I

= 65 A and IR = 13 A yields 900

O

mW for each synchronous MOSFET and 1.6 W for each main

MOSFET. These numbers work well considering that there is

usually more PCB area available for each main MOSFET versus

each synchronous MOSFET.

One last thing to consider is the power dissipation in the driver

for each phase. This is best described in terms of the Q

MOSFETs and is given by the following, where Q

gate charge for each main MOSFET and Q

is the total gate

GSF

G

is the total

GMF

for the

charge for each synchronous MOSFET:

⎡

f

SW

P ×

=

⎢

DRV

⎢

⎣

()

MF

n

2

×

Also shown is the standby dissipation factor (I

⎤

+×+××

VIQnQn

⎥

⎥

⎦

× VCC) for the

CC

(19)

CCCCGSFSFGMF

driver. For the ADP3418, the maximum dissipation should be

less than 400 mW. For example, with I

nC and Q

= 34.3 nC, 260 mW is found in each driver, which

GSF

= 7 mA, Q

CC

GMF

= 22.8

is below the 400 mW dissipation limit.

RAMP RESISTOR SELECTION

The ramp resistor (RR) is used for setting the size of the internal

PWM ramp. The value of this resistor is chosen to provide the

best combination of thermal balance, stability, and transient

response. The following expression is used for determining the

optimum value:

LA

R

=

R

R

=

R

where A

balancing amplifier gain, R

resistance, and C

closest standard 1% resistor value is 226 kΩ.

The internal ramp voltage magnitude can be calculated using

V

=

R

=

V

R

The size of the internal ramp can be made larger or smaller. If it

is made larger, stability and transient response improve, but

thermal balance degrades. Likewise, if the ramp is made smaller,

thermal balance improves at the sacrifice of transient response

and stability. The factor of 3 in the denominator of Equation 20

sets a ramp size that gives an optimal balance for good stability,

transient response, and thermal balance.

R

3

D

CRA

×××

R

DS

(20)

nH0600.2

×

pF5Ωm2.453

×××

is the internal ramp amplifier gain, AD is the current

R

is the total low-side MOSFET on

DS

is the internal ramp capacitor value. The

R

VDA

)

1

VIDR

××

fCR

RR

SW

kΩ813

=

(21)

()

V51.1250.10.2

×−×

××

=

kHz267pF5Ωk833

Vm51.0

Rev. 0 | Page 19 of 24

Page 20

ADP3181

(

)

×

(

)

×−×

−

(

)

(

)

=

×

CURRENT LIMIT SETPOINT

To select the current limit setpoint, it is necessary to find the

resistor value for R

ADP3181 is set with a 3 V source (V

of 10 mV/µA (A

=

R

LIM

where I

LIM

is the average current limit for the output of the

LIM

supply. For example, using 90 A for I

which 221 kΩ can be chosen as the nearest 1% value.

The per phase current limit described earlier has its limit

determined by the following:

≅ (23)

I +

PHLIM

. The current limit threshold for the

LIM

) across R

LIM

). R

LIM

×

×

can be found using the following:

LIM

VA

LIMLIM

(22)

RI

O

, R

LIM

LIM

−−

()

MAXCOMP

×

RA

D

()

VVV

R

MAXDS

BIAS

I

R

2

with a gain

LIM

is 222.2 kΩ and for

FEEDBACK LOOP COMPENSATION DESIGN

Optimized compensation of the ADP3181 allows the best

possible response of the regulator’s output to a load change. The

basis for determining the optimum compensation is to make

the regulator and output decoupling appear as an output

impedance that is entirely resistive over the widest possible

frequency range, including dc, and equal to the droop resistance

(R

). With the resistive output impedance, the output voltage

O

droops in proportion to the load current at any load current

slew rate; this ensures optimal positioning and allows the

minimization of the output decoupling.

With the multimode feedback structure of the ADP3181, one

needs to set the feedback compensation to make the converter’s

output impedance working in parallel with the output

decoupling meet this goal. Several poles and zeros created by

the output inductor and decoupling capacitors (output filter)

need to be compensated for.

where the maximum COMP voltage (V

the COMP pin bias voltage (V

balancing amplifier gain (A

R

of 5.3 mΩ (low-side on resistance at 150°C), there

DS(MAX)

BIAS

) is 5. Using VR of 0.7 V, and

D

COMP(MAX)

) is 1.2 V, and the current

) is 3.3 V,

is a per-phase limit of 52 A.

This limit can be adjusted by changing the ramp voltage V

, but

R

make sure not to set the per-phase limit lower than the average

per-phase current (I

E

R

E

A

O

()

X

O

D

RRCT

LIM/n

'

).

VR

×

L

RARnR

+×+×=

DS

L

X

R

O

RT

+

V

VID

Ωm2.45Ωm31.3 =

+×+×=

−

RR

'

O

×+−×=

R

X

12

X

V630.Ωm61.

×

+

V51.

()

VDnL

×−××

×××

VRCn

VID

O

×

A type-three compensator on the voltage feedback is adequate