Page 1

a

5-Bit Programmable Synchronous

Switching Regulator Controller

®

for Pentium

II Processor

ADP3152

FEATURES

5-Bit Digitally Programmable 1.8 V to 3.5 V Output

Voltage

Dual N-Channel Synchronous Driver

Total Output Accuracy 61% (08C to 708C)

High Efficiency

Current-Mode Operation

Short Circuit Protection

Power Good Output

Integrated Overvoltage Protection Crowbar

16-Lead SOIC Package

VRM 8.2 Compatible

APPLICATIONS

Desktop PC Power Supply for:

Pentium II Processor

Pentium Pro Processor

Pentium Processor

AMD–K6 Processor

VRM Modules

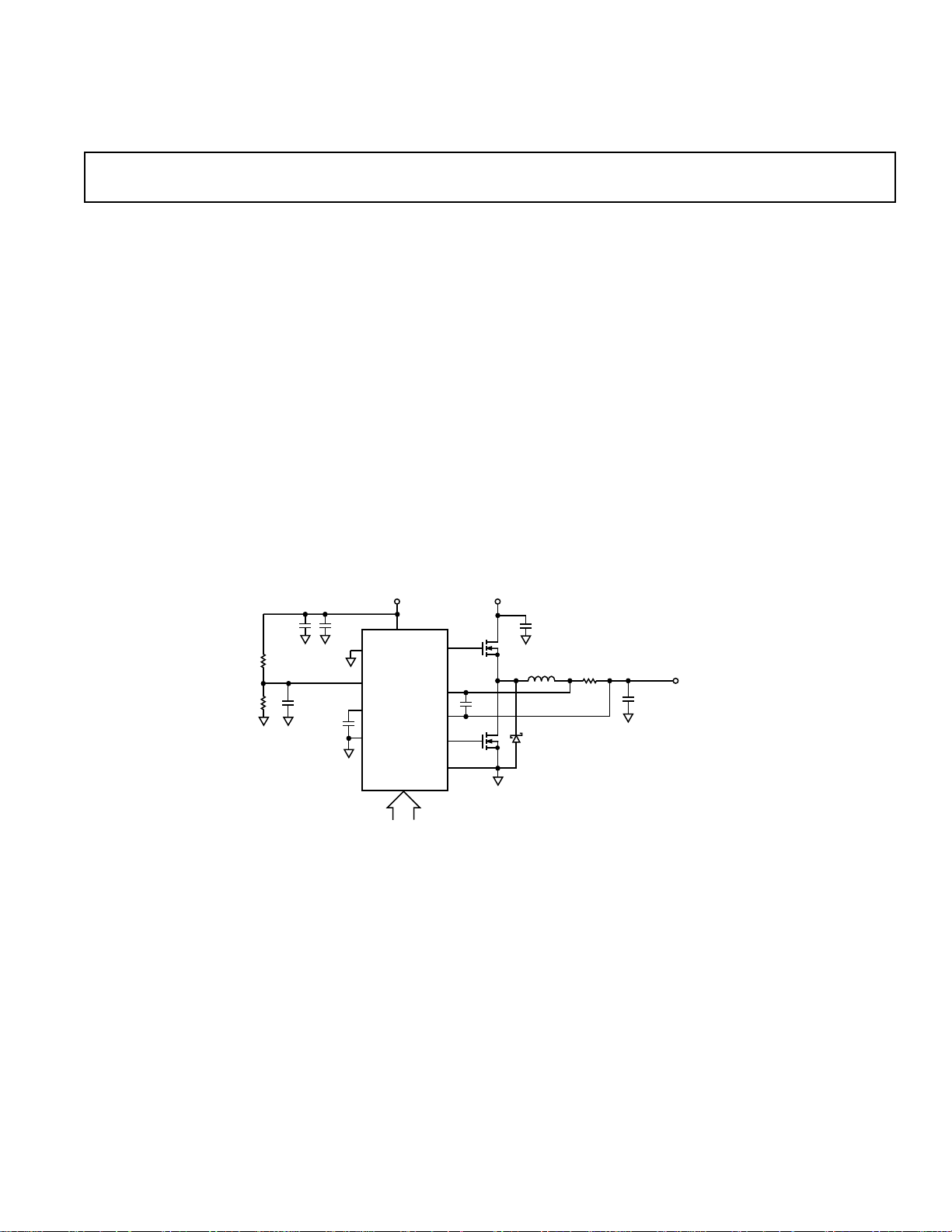

V

CC

+12V

C

COMP

150pF

1mF

SD

ADP3152

CMP

C

T

AGND

VID0–VID4

V

CC

DRIVE1

SENSE+

SENSE–

DRIVE2

PGND

22mF

R1

R2

IRL3103

1nF

IRL3103

GENERAL DESCRIPTION

The ADP3152 is a highly efficient synchronous switching regulator controller optimized for Pentium II Processor applications

where 5 V is stepped down to a digitally controlled output voltage between 1.8 V and 3.5 V. Using a 5-bit DAC to read a

voltage identification (VID) code directly from the processor,

the ADP3152 uses a current mode constant off-time architecture to generate its precise output voltage.

The ADP3152 drives two N-channel MOSFETS in a synchronous rectified buck converter, at a maximum switching frequency of 250 kHz. Using the recommended loop compensation

and guidelines, the ADP3152 provides a dc/dc converter that

meets Intel’s stringent transient specifications with a minimum

number of output capacitors and smallest footprint. Additionally,

the current mode architecture also provides guaranteed short

circuit protection and adjustable current limiting.

V

IN

+5V

+

C

IN

L

R

2.5mH

10BQ015

SENSE

6.7mV

V

O

1.8V–3.5V

+

14A

C

O

5-BIT CODE

Figure 1. Typical Application

Pentium is a registered trademark of Intel Corporation.

All other trademarks are the property of their respective holders.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1998

Page 2

ADP3152–SPECIFICATIONS

(08C ≤ TA ≤ +708C, V

= 12 V, VIN = 5 V, unless otherwise noted)

CC

Parameter Symbol Conditions Min Typ Max Units

OUTPUT ACCURACY

1.8 V Output Voltage V

O

With Respect to Nominal –1.0 1.0 %

2.8 V Output Voltage Output Voltage (Figure 13) –1.0 1.0 %

3.5 V Output Voltage –1.0 1.0 %

OUTPUT VOLTAGE LINE ∆V

O

I

= 10 A (Figure 2)

LOAD

REGULATION VIN = 4.75 V to 5.25 V 0.05 %

OUTPUT VOLTAGE LOAD ∆V

O

REGULATION 200 mA < I

INPUT DC SUPPLY CURRENT

Normal Mode I

1

Q

Shutdown T

(Figure 2)

< 14 A 0.1 %

LOAD

VSD = 0.8 V 3.7 4.5 mA

= +25°C, VID Pins Floating 140 250 µA

A

CURRENT SENSE THRESHOLD

VOLTAGE V8–V

VID PINS THRESHOLD V

, V1–V

16

7

V7 Forced to V

4

– 3% 125 145 165 mV

OUT

Low 0.6 V

High 2.0 V

VID PINS INPUT CURRENT I16, I1–I

VID0–VID4 PULL-UP RESISTANCE R

C

PIN DISCHARGE CURRENT I

T

OFFTIME t

DRIVER OUTPUT TRANSITION t

VID

9

OFF

, t

R

F

TIMES T

POSITIVE POWER GOOD TRIP POINT V

NEGATIVE POWER GOOD TRIP POINT V

POWER GOOD RESPONSE TIME t

CROWBAR TRIP POINT V

PWRGD

PWRGD

PWRGD

CROWBAR

VID

4

= 0 V 110 220 µA

20 30 kΩ

T

= +25°C

A

in Regulation 65 µA

V

OUT

V

= 0 V 2 10 µA

OUT

C

= 150 pF 1.8 2.45 3.2 µs

T

CL = 7000 pF (Pins 13, 14)

= +25°C 120 200 ns

A

Output Coming Into Regulation 5 8 %

Output Coming Into Regulation –8 –5 %

500 µs

% Above Output Voltage 9 15 24 %

ERROR AMPLIFIER

OUTPUT IMPEDANCE RO

ERR

145 kΩ

ERROR AMPLIFIER

TRANSCONDUCTANCE GM

ERR

2.2 mmho

ERROR AMPLIFIER MINIMUM

OUTPUT VOLTAGE V

CMPMIN

V7 Forced to V

+ 3% 0.8 V

OUT

ERROR AMPLIFIER MAXIMUM

OUTPUT VOLTAGE V

CMPMAXV7

ERROR AMPLIFIER BANDWIDTH –3 dB BW

ERR

Forced to V

– 3% 2.4 V

OUT

CMP = Open 500 kHz

SHUTDOWN (SD) PIN

Low Threshold SD

High Threshold SD

Input Current SD

NOTES

1

Dynamic supply current is higher due to the gate charge being delivered to the external MOSFETS.

All limits at temperature extremes are guaranteed via correlation using standard quality control methods.

Specifications are subject to change without notice.

L

H

IB

Part Active 0.6 V

Part in Shutdown 2.0 V

10 µA

–2– REV. 0

Page 3

ADP3152

WARNING!

ESD SENSITIVE DEVICE

PIN FUNCTION DESCRIPTIONS

Pin Mnemonic Function

1–4, 16 VID1–VID4, VD0 Voltage Identification DAC Input Pins. These pins are internally pulled up to V

logic one if left open. Leaving all five DAC inputs open results in placing the ADP3152 into

shutdown.

5 AGND Analog Ground Pin. This pin must be routed separately to the (–) terminal of C

6 SD Shutdown Pin. A logic high will place the ADP3152 in shutdown and disable the output. This

pin is internally pulled down.

7 SENSE– Connects to the internal resistor divider which, along with the VID code, sets the output volt-

age. Pin 7 is also the (–) input for the current comparator.

8 SENSE+ The (+) input for the current comparator. A threshold between Pins 8 and 7 set by the error

9C

T

amplifier in conjunction with R

External Capacitor CT from Pin 9 to ground sets the off time of the device.

, sets the current trip point.

SENSE

10 CMP Error Amplifier Compensation Point. The current comparator threshold increases with the Pin

10 voltage.

11 PWRGD Power Good Pin. An open drain signal to indicate that the output voltage is within a ±5% regu-

lation band.

12 V

CC

Input Voltage Pin.

13 DRIVE2 Gate Drive for the bottom synchronous N-channel MOSFET. The voltage at Pin 13 swings

from ground to V

CC

.

14 DRIVE1 Gate Drive for the top primary N-channel MOSFET. The voltage at Pin 14 swings from ground

to V

.

CC

15 PGND Driver Power Ground. Connects to the source of the bottom N-channel MOSFET and to the

(–) terminal of CIN.

providing a

REG

.

OUT

ABSOLUTE MAXIMUM RATINGS*

PIN CONFIGURATION

Input Supply Voltage (Pin 12) . . . . . . . . . . . . –0.3 V to +16 V

VID0–VID4, SD, PWRGD, CMP, CT . . . . . . . –0.3 V to V

DRIVE1, DRIVE2, SENSE+, SENSE– . . . . . . –0.3 V to V

Operating Temperature Range . . . . . . . . . . . . . 0°C to +70°C

Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 150°C

␣ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110°C/W

θ

JA

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature Range (Soldering 10 sec) . . . . . . . .+300°C

*This is a stress rating only; operation beyond these limits can cause the device to

be permanently damaged.

CC

CC

VID1

VID2

VID3

VID4

AGND

SD

SENSE–

SENSE+

1

2

3

ADP3152

4

TOP VIEW

5

(Not to Scale)

6

7

8

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

ADP3152AR 0°C to +70°C 16-Lead SOIC R-16A/SO-16

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADP3152 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

16

15

14

13

12

11

10

9

VID0

PGND

DRIVE1

DRIVE2

V

CC

PWRGD

CMP

C

T

–3–REV. 0

Page 4

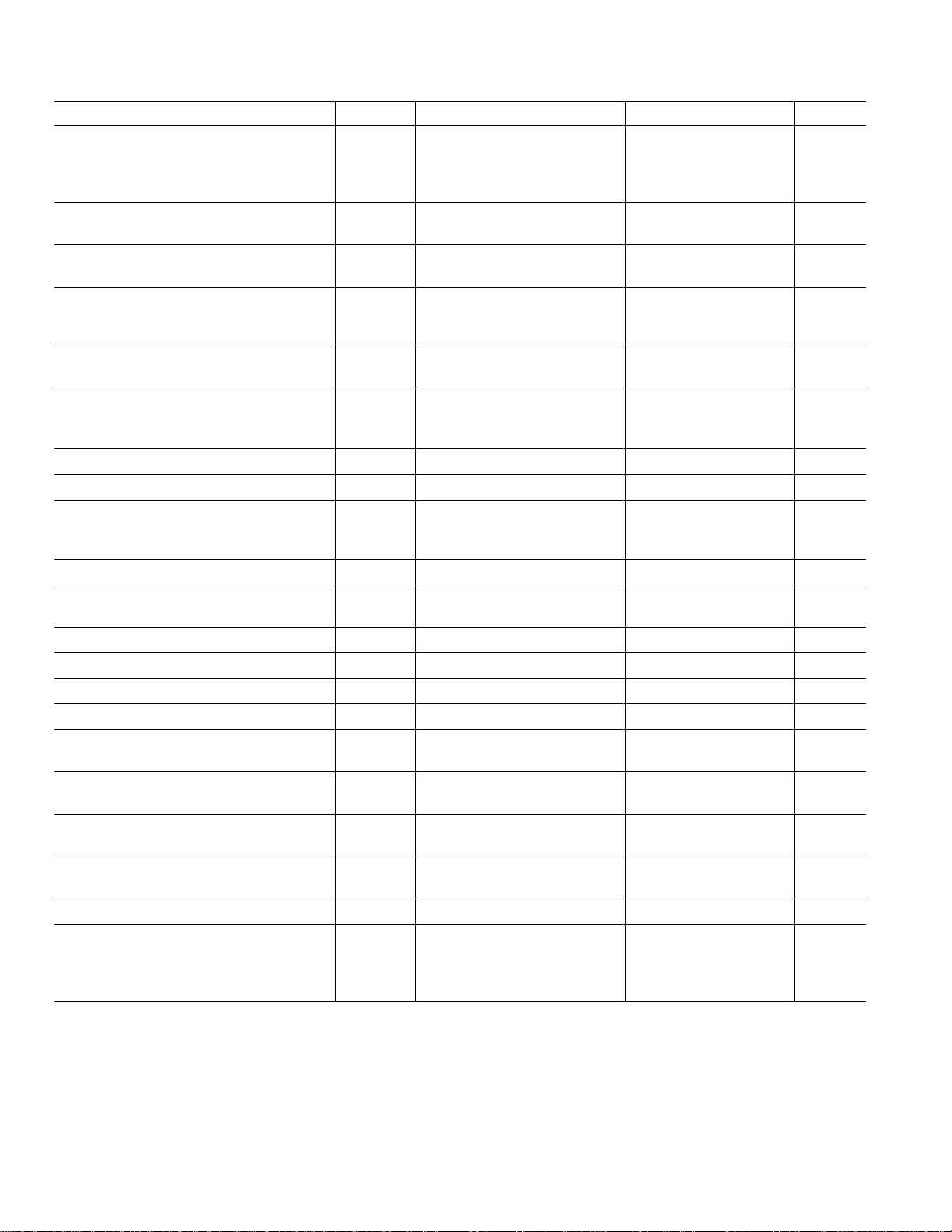

ADP3152

mP

SYSTEM

2nF

C

1mF

COMP

220V

22V

IRL3103

IRL3103

220V

3 32700mF/10V

++++

L1

2.5mH

10BQ015

1mF

R

SENSE

6.7mV

L2

1.7mH

V

+5V RTN

+12V RTN

2700mF 3 6 (10V)

+ + + + +

+

100kV VCC + 12V

+

22mF

ADP3152

1

2

3

4

5

6

7

8

VID1

VID2

VID3

VID4

AGND

SD

SENSE–

SENSE+

VID0

PGND

DRIVE1

DRIVE2

V

PWRGD

CMP

C

16

15

14

13

12

CC

11

10

9

T

C

T

150pF

R1

150kV

R2

39kV

1nF

Figure 2. Typical Application for Pentium II

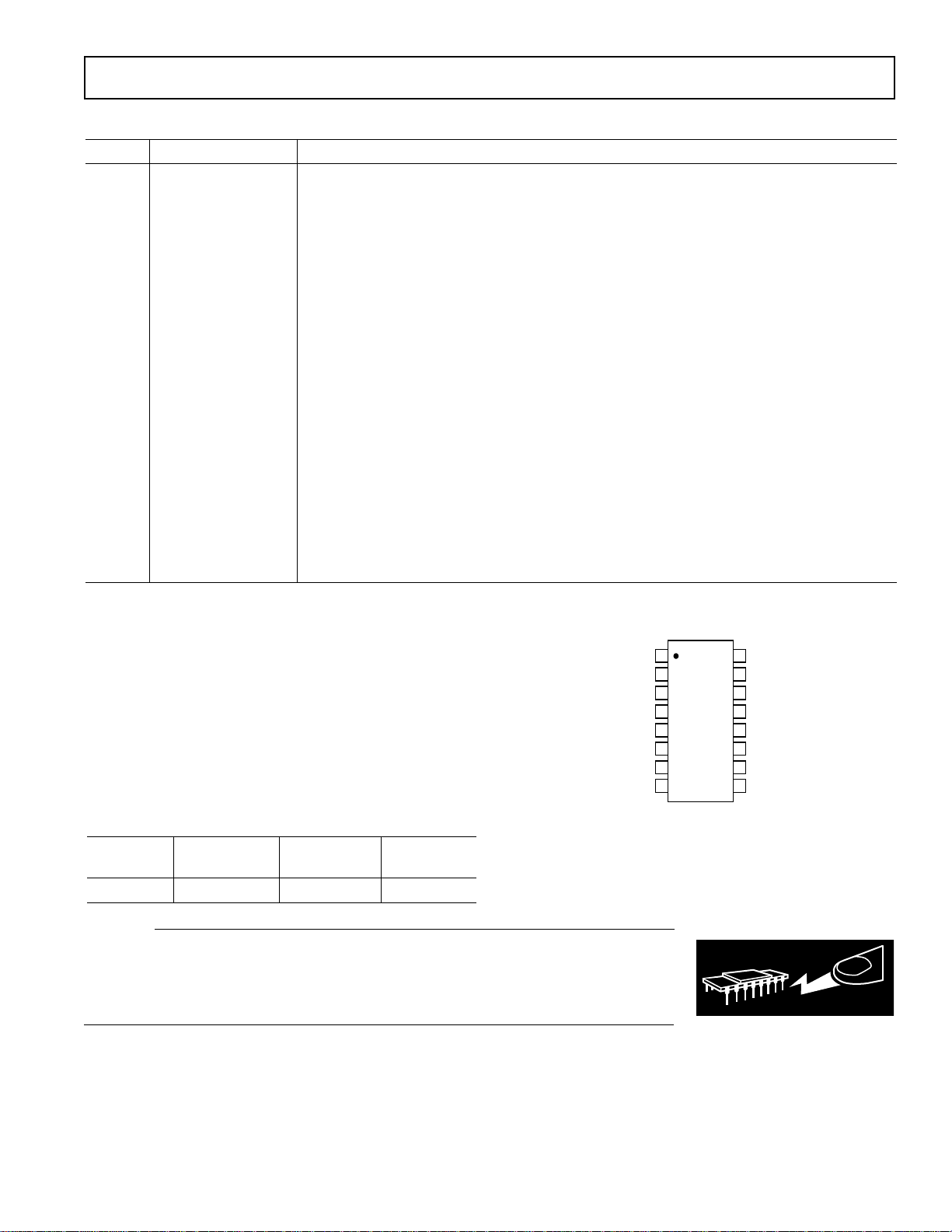

SENSE–

8

7

ADP3152

REFERENCE

2R

1.20V

16

VID0

1

VID1

2

g

m

V

REF

R

VID2

3

VID3

SD

DRIVE1 DRIVE2 PGND

V

CC

12 14 13 15

NONOVERLAP

6

IN

V

T2

DRIVE

CROWBAR

S

Q

R

CMPT

V

REF

CMPI

AGND

+ 15%

V

REF

PWRGD

+ 5% V

V

T1

SENSE+

115

DELAY

– 5%

REF

IN

+ 5V

V

O

1.8V–3.5V

0-14A

RTN

4

OFF-TIME

CONTROL

9

C

T

SENSE–

10

CMP

DAC

VID4

Figure 3. Functional Block Diagram

–4– REV. 0

Page 5

OPERATING FREQUENCY – kHz

45 397

58 83 134

GATE CHARGE CURRENT – mA

45

40

0

20

15

10

5

35

25

30

Qn + Qn = 100nC

10ms/DIV

OUTPUT CURRENT

14A TO 1A

OUTPUT VOLTAGE

20mV/DIV

OUTPUT ACCURACY – %

NUMBER OF PARTS

15

0

–0.55

–0.5

–0.45

25

20

10

5

–0.4

–0.35

–0.3

–0.25

–0.2

–0.15

–0.1

–0.05

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

0.5

TA = +258C

SEE FIGURE 13

Typical Performance Characteristics–ADP3152

100

95

90

85

V

= +2.0V

OUT

80

EFFICIENCY – %

75

70

65

4.2 5.6 7.0 9.8 11.2 12.68.4

1.4 2.8 14.0

OUTPUT CURRENT – Amps

V

OUT

V

SEE FIGURE 2

= +3.5V

= +2.8V

OUT

Figure 4. Efficiency vs. Output Current

V

= +3.5V, I

OUT

PRIMARY

N-DRIVE

1

2

DRIVER OUTPUT

SECONDARY

N-DRIVE

DRIVER OUTPUT

SEE FIGURE 2

= 10A

OUT

450

400

350

300

250

200

150

FREQUENCY – kHz

100

50

0

50 100 800

200 300 400 500 600 700

TIMING CAPACITOR – pF

Figure 5. Frequency vs. Timing

Capacitor

SEE FIGURE 2

2

Figure 6. Gate Charge Supply Current vs. Operating Frequency

DRIVE 1 AND 2 = 5V/DIV

Figure 7. Gate Switching Waveforms

OUTPUT VOLTAGE

20mV/DIV

OUTPUT CURRENT

1A TO 14A

Figure 10. Transient Response,

1A–14 A of Figure 2 Circuit

500ns/DIV

Figure 8. Driver Transition Waveforms

100ns/DIV

Figure 9. Transient Response, 14 A–1A

of Figure 2 Circuit

VCC VOLTAGE

5V/DIV

3

REGULATOR

OUTPUT VOLTAGE

1V/DIV

4

10ms

Figure 11. Power-On Start-Up

Waveforms

–5–REV. 0

Figure 12. Output Accuracy

Distribution, V

OUT

= 2.8 V

Page 6

ADP3152

12V

V

DRIVE1

DRIVE2

SENSE+

SENSE–

PGND

CC

+

1mF

0.1mF

V

OUT

5-BIT

4700pF

1.2V

CODE

1kV

100kV

␣

VID0–

VID4

SD

CMP

C

T

ADP3152

AGND

OP27

0.1mF

Figure 13. Closed-Loop Test Circuit for Accuracy

APPLICATION INFORMATION

The ADP3152 uses a current-mode, constant-off-time control

technique to switch a pair of external N-channel MOSFETs in

a synchronous rectified buck converter application. Due to the

constant-off-time operation, no slope compensation is needed.

A unique feature of the constant-off-time control technique is

that the converter’s frequency becomes a function of the ratio of

input voltage to output voltage. The off time is determined by

the value of the external capacitor connected to the C

pin.

T

The on time varies in such a way that a regulated output voltage is maintained.

The output voltage is sensed by an internal voltage divider that

is connected to the Sense– pin. A voltage-error amplifier g

m

compares the values of the divided output voltage with a reference voltage. The reference voltage is set by an onboard 5-bit

DAC, which reads the code present at the voltage identification

(VID) pins and converts it to a precise value between 600 mV

and 1.167 V. Refer to Table I for the output voltage vs. VID pin

code information.

During continuous-inductor-current mode of operation, the

voltage-error amplifier g

and the current comparator CMPI

m

are the main control elements. During the on time of the high

side MOSFET, the current comparator CMPI monitors the

voltage between the Sense+ and Sense– pins. When the voltage

level between the two pins reaches the threshold level V

T1

, the

high side drive output is switched to zero, which turns off the

high side MOSFET. The timing capacitor C

is now discharged

T

at a rate determined by the off time controller. In order to

maintain a ripple current in the inductor, which is independent

of the output voltage, the discharge current is made proportional to the value of the output voltage (measured at the

Sense– pin). While the timing capacitor is discharging, the low

side drive output goes high, turning on the low side MOSFET.

When the voltage level on the timing capacitor has discharged

to the threshold voltage level V

, comparator CMPT resets

T2

the SR flip-flop. The output of the flip-flop forces the low side

drive output to go low and the high side drive output to go high.

As a result, the low side switch is turned off and the high side

switch is turned on. The sequence is then repeated. As the load

current increases, the output voltage starts to decrease. This

causes an increase in the output of the voltage-error amplifier,

which, in turn, leads to an increase in the current comparator

threshold V

thus tracking the load current.

T1,

Table I. Output Voltage vs. VID Code

VID4 VID3 VID2 VID1 VID0 VOUT

0 1 1 1 1 1.80

0 1 1 1 0 1.80

0 1 1 0 1 1.80

0 1 1 0 0 1.80

0 1 0 1 1 1.80

0 1 0 1 0 1.80

0 1 0 0 1 1.80

0 1 0 0 0 1.80

0 0 1 1 1 1.80

0 0 1 1 0 1.80

0 0 1 0 1 1.80

0 0 1 0 0 1.85

0 0 0 1 1 1.90

0 0 0 1 0 1.95

0 0 0 0 1 2.00

0 0 0 0 0 2.05

1 1 1 1 1 Shutdown

1 1 1 1 0 2.10

1 1 1 0 1 2.20

1 1 1 0 0 2.30

1 1 0 1 1 2.40

1 1 0 1 0 2.50

1 1 0 0 1 2.60

1 1 0 0 0 2.70

1 0 1 1 1 2.80

1 0 1 1 0 2.90

1 0 1 0 1 3.00

1 0 1 0 0 3.10

1 0 0 1 1 3.20

1 0 0 1 0 3.30

1 0 0 0 1 3.40

1 0 0 0 0 3.50

To prevent cross conduction of the external MOSFETs, feedback is incorporated to sense the state of the driver output pins.

Before the low side drive output can go high, the high side drive

output must be low. Likewise, the high side drive output is

unable to go high while the low side drive output is high.

Power Good

The ADP3152 has an internal monitor which monitors the

output voltage and drives the PWRGD pin of the device. This

pin is an open drain output whose high level (when connected

to a pull-up resistor) indicates that the output voltage has been

within a ±5% regulation band of the targeted value for more

than 500 µs. The PWRGD pin will go low if the output is outside the regulation band for more than 500 µs.

Output Crowbar

An added feature of using an N-channel MOSFET as the synchronous switch is the ability to crowbar the output with the

same MOSFET. If the output voltage is 15% greater than the

desired regulated value, the ADP3152 will turn on the lower

MOSFET, which will current-limit the source power supply or

blow its fuse, pull down the output voltage, and thus save the

–6– REV. 0

Page 7

ADP3152

expensive microprocessor from destruction. The crowbar function releases at approximately 50% of the nominal output voltage. For example, if the output is programmed to 2.0 V, but is

pulled up to 2.3 V or above, the crowbar will turn on the lower

MOSFET. If in this case the output is pulled down to less than

1.0 V, the crowbar will release, allowing the output voltage to

recover to 2.0 V.

Shutdown

The ADP3152 has a shutdown pin which is pulled logic low by

an internal resistor. In this condition the device functions normally. This pin should be pulled high externally to disable the

output drives.

Calculation of Component Values

The design parameters for a typical 300 MHz Pentium II application (Figure 2) are as follows:

Input voltage: V

Auxiliary input: V

Output voltage: V

= 5 V

IN

CC

= 2.8 V

O

= 12 V

Maximum output current:

= 14.2 Adc

I

OMAX

Minimum output current:

= 0.8 Adc

I

OMIN

Static tolerance of the supply voltage for the processor core:

= 100 mV

∆V

OST+

= –60 mV

∆V

OST–

Transient tolerance (for less than 2 µs) of the supply voltage for

the processor core when the load changes between the minimum

and maximum values with a di/dt of 30 A/µs:

= 130 mV

∆V

OTR+

= –130 mV

∆V

OTR–

Input current di/dt when the load changes between the minimum and maximum values: less than 0.1 A/µs

The above requirements correspond to Intel’s published power

supply requirements based on VRM 8.2 guidelines.

CT Selection for Operating Frequency

The ADP3152 uses a constant-off-time architecture with t

OFF

determined by an external timing capacitor CT. Each time the

high side N-channel MOSFET switch turns on, the voltage

across C

C

T

is reset to approximately 3.3 V. During the off time,

T

is discharged by a constant current of 65 µA to 2.3 V, that is

by 1 V. The value of the off time is calculated from the preferred continuous-mode operating frequency. Assuming a nominal operating frequency of f

= 2.8 V, the corresponding off time is:

of V

O

= 200 kHz at an output voltage

NOM

The timing capacitor can be calculated from the equation:

×65 µA

t

OFF

C

=

T

1V

=143 pF

The converter operates at the nominal operating frequency only

at the above specified V

and at light load. At higher VO, and

O

heavy load, the operating frequency decreases due to the parasitic voltage drops across the power devices. The actual minimum frequency at V

= 2.8 V is calculated to be 160 kHz (see

O

Equation 1 below). Where

I

IN

R

IN

is the input dc current (assuming an efficiency

of 90%, I

= 9 A)

IN

is the resistance of the input filter (estimated

value: 7 mΩ)

R

DS(ON)HSF

is the resistance of the high side MOSFET

(estimated value: 10 mΩ)

R

DS(ON)LSF

is the resistance of the low side MOSFET

(estimated value: 10 mΩ)

R

SENSE

is the resistance of the sense resistor

(estimated value: 7 mΩ)

R

L

is the resistance of the inductor (estimated

value: 6 mΩ)

CO Selection—Determining the ESR

The selection of the output capacitor is driven by the required

ESR and capacitance C

. The ESR must be small enough that

O

both the resistive voltage deviation due to a step change in the

load current and the output ripple voltage stay below the values

defined in the specification of the supplied microprocessor. The

capacitance, C

, must be large enough that the output is held

O

up while the inductor current ramps up or down to the value

corresponding to the new load current.

The total static tolerance of the Pentium II processor is 160 mV.

Taking into account the ±1% setpoint accuracy of the ADP3152,

and assuming a 0.5% (or 14 mV) peak-to-peak ripple, the allowed static voltage deviation of the output voltage when the

load changes between the minimum and maximum values is

0.08 V. Assuming a step change of ∆I = I

OMAX–IOMIN

= 13.4 A,

and allocating all of the total allowed static deviation to the

contribution of the ESR sets the following limit:

R

=ESR

E MAX

()

MAX1

=

0.08

13.4

= 5. 9 m Ω

t

= 1–

OFF

MIN

1

=

t

OFF

f

V

×

VIN– IINRIN– I

V

O

V

IN

– IINRIN– I

IN

1

=2.2 µs

f

NOM

OMAX(RDS(ON)HSF+RSENSE+RL

OMAX(RDS(ON)HSF+RSENSE+RL

– R

)–V

O

DS(ON)LSF

=160 kHz

)

(1)

–7–REV. 0

Page 8

ADP3152

The output filter capacitor must have an ESR of less than

5.9 mΩ. One can use, for example, six FA type capacitors from

Panasonic, with 2700 µF capacitance, 10 V voltage rating, and

34 mΩ ESR. The six capacitors have a total typical ESR of

~ 5 mΩ when connected in parallel.

Inductor Selection

The minimum inductor value can be calculated from ESR, off

time, dc output voltage and allowed peak-to-peak ripple voltage.

L

MIN1

V

OtOFFRE( MAX )

=

V

RIPPLE , p −p

2.8 ×2. 2 µ×5.9 m

=

14 m

= 2.6 µH

The minimum inductance gives a peak-to-peak ripple current of

2.15 A, or 15% of the maximum dc output current I

OMAX

.

The inductor peak current in normal operation is:

I

LPEAK

= I

OMAX

+ I

/2 = 15.3 A

RPP

The inductor valley current is:

I

LVALLEY

= I

LPEAK

– I

RPP

= 13 A

The inductor for this application should have an inductance

of 2.6 µH at full load current and should not saturate at the

worst-case overload or short circuit current at the maximum

specified ambient temperature. A suitable inductor is the

CTX12-13855 from Coiltronics, which is 4.4 µH at 1 A and

about 2.5 µH at 14.2 A.

Tips for Selecting Inductor Core

Ferrite designs have very low core loss, so the design should

focus on copper loss and on preventing saturation. Molypermalloy,

or MPP, is a low loss core material for toroids, and it yields the

smallest size inductor, but MPP cores are more expensive than

ferrite cores or the Kool Mµ

®

cores from Magnetics, Inc. The

lowest cost core is made of powdered iron, for example the #52

material from Micrometals, Inc., but yields the largest size

inductor.

CO Selection—Determining the Capacitance

The minimum capacitance of the output capacitor is determined

from the requirement that the output be held up while the inductor current ramps up (or down) to the new value. The minimum capacitance should produce an initial dv/dt which is equal

(but opposite in sign) to the dv/dt obtained by multiplying the

di/dt in the inductor and the ESR of the capacitor.

– I

I

C

MIN

OMAX

=

RE(di /dt )

OMIN

14.2–0.8

=

5.9 m (2.2 / 4.4 µH)

= 4.5 mF

In the above equation the value of di/dt is calculated as the

smaller voltage across the inductor (i.e., V

rather than VO)

IN–VO

divided by the maximum inductance (4.4 µH) of the CTX12-

13855 inductor from Coiltronics. The parallel-connected six

2700 µF/10 V FA series capacitors from Panasonic have a total

capacitance of 16,200 µF, so the minimum capacitance require-

ment is met with ample margin.

R

SENSE

The value of R

is based on the required output current.

SENSE

The current comparator of the ADP3152 has a threshold range

that extends from 0 mV to 125 mV (minimum). Note that the

full 125 mV range cannot be used for the maximum specified

nominal current, as headroom is needed for current ripple, transients and inductor core saturation.

The current comparator threshold sets the peak of the inductor

current yielding a maximum output current I

which equals

OMAX,

the peak value less half of the peak-to-peak ripple current. Solving for R

and allowing a margin for tolerances inside the

SENSE

ADP3152 and in the external component values yields:

= (125 mV)/[1.2(I

R

SENSE

OMAX

+ I

RPP

/2)] = 6.8 m

Ω

A practical solution is to use three 20 mΩ resistors in parallel,

with an effective resistance of about 6.7 mΩ.

Once R

I

SC(PK)

I

SC(PK)

has been chosen, the peak short-circuit current

SENSE

can be predicted from the following equation:

= (145 mV)/R

= (145 mV)/(6.7 mΩ) = 21.5 A

SENSE

The actual short-circuit current is less than the above calculated

value because the off time rapidly increases when the

I

SC(PK)

output voltage drops below 1 V. The relationship between the

off time and the output voltage is:

C

×1V

≈

360 kΩ

T

V

O

+2 µA

t

OFF

With a short across the output, the off time will be about

70 µs. During that off time the inductor current gradually de-

cays. The amount of decay depends on the L/R time constant in

the output circuit. With an inductance of 2.5 µH and total resis-

tance of 23 mΩ, the time constant will be 108 µs, which yields a

valley current of 11.3 A and an average short-circuit current of

about 16.3 A. To safely carry the short-circuit current, the sense

resistor must have a power rating of at least 16.3 A

2

× 6.8 mΩ =

1.8 W.

Current Transformer Option

An alternative to using low value and high power current sense

resistor is to reduce the sensed current by using a low cost current transformer and a diode. The current can then be sensed

with a small-size, low cost SMT resistor. If we use a transformer

with one primary and 50 secondary turns, the worst-case resistor

dissipation is reduced to a fraction of a mW. Another advantage

of using this option is the separation of the current and voltage

sensing, which makes the voltage sensing more accurate.

Power MOSFET

Two external N-channel power MOSFETs must be selected for

use with the ADP3152, one for the main switch, and an identical one for the synchronous switch. The main selection parameters for the power MOSFETs are the threshold voltage V

and the on resistance R

DS(ON)

.

GS(TH)

–8– REV. 0

Page 9

ADP3152

The minimum input voltage dictates whether standard threshold

or logic-level threshold MOSFETs must be used. For V

standard threshold MOSFETs (V

is expected to drop below 8 V, logic-level threshold MOSFETs

V

IN

(V

MOSFETs with V

of V

The maximum output current I

< 2.5 V) are strongly recommended. Only logic-level

GS(TH)

should be used.

CC

ratings higher than the absolute maximum

GS

OMAX

< 4 V) may be used. If

GS(TH)

determines the R

> 8 V,

IN

DS(ON)

requirement for the two power MOSFETs. When the ADP3152

is operating in continuous mode, the simplifying assumption can

be made that one of the two MOSFETs is always conducting

the average load current.

= 5 V and VO = 2.8 V, the maximum duty ratio of the

For V

IN

high side FET is:

D

MAXHF

= (1–f

MIN

× t

) =(1–160 kHz

OFF

× 2.2 µs) = 65%

The maximum duty ratio of the low side (synchronous rectifier)

FET is:

D

MAXLF

= 1 – D

MAXHF

= 35%

The maximum rms current of the high side FET is:

I

RMSLS

= [D

MAXHF (ILVALLEY2

+ I

LPEAK

2

+ I

LVALLEYILPEAK

)/3]

0.5

= 11.5 Arms

The maximum rms current of the low side FET is:

I

RMSLS

= [D

MAXLF (ILVALLEY2

+ I

LPEAK

2

+ I

LVALLEYILPEAK

)/3]

0.5

= 8.41 Arms

The R

for each FET can be derived from the allowable

DS(ON)

dissipation. If we allow 5% of the maximum output power for

FET dissipation, the total dissipation will be:

P

FETALL

= 0.05 VOI

OMAX

= 2 W

Allocating two-thirds of the total dissipation for the high side

FET and one-third for the low side FET, the required minimum

FET resistances will be:

R

DS(ON)HSF(MIN)

R

DS(ON)LSF(MIN)

= 1.33/11.52 = 10 m

= 0.67/8.412 = 9.5 m

Ω

Ω

Note that there is a tradeoff between converter efficiency and

cost. Larger FETs reduce the conduction losses and allow higher

efficiency but lead to increased cost. If efficiency is not a major

concern the Fairchild MOSFET NDP6030L or International

Rectifier IRL3103 is an economical choice for both the high side

and low side positions. Those devices have an R

= 10 V and at 25°C. The low side FET is turned on with

at V

GS

DS(ON)

of 14 mΩ

at least 10 V. The high side FET, however, is turned on with

only 12 V – 5 V = 7 V. If we check the typical output characteristics of the device in the data sheet, we find that for an output

current of 10 A, and at a V

gives a R

DS(ON)

= VDS/I

above the one specified at a V

of 7 V, the VDS is 0.15 V, which

GS

= 15 mΩ. This value is only slightly

D

of 10 V, so the resistance in-

GS

crease due to the reduced gate drive can be neglected. We have

to modify, however, the specified R

est FET junction temperature of 140°C by a R

at the expected high-

DS(ON)

DS(ON)

multiplier,

using the graph in the data sheet. In our case:

R

DS(ON)MULT

Using this multiplier, the expected R

= 1.7

at 140°C is 1.7 × 14

DS(ON)

= 24 mΩ.

The high side FET dissipation is:

P

DFETHS

= I

RMSHS

2

R

DS(ON)

+ 0.5 VINI

LPEAKQGfMAX/IG

= 3.72 W

where the second term represents the turn-off loss of the FET.

(In the second term, Q

the gate for turn-off and I

sheet, Q

is about 50 nC –70 nC and the gate drive current

G

is the gate charge to be removed from

G

is the gate current. From the data

G

provided by the ADP3152 is about 1 A.)

The low side FET dissipation is:

P

DFETLS

= I

RMSLS

2

R

DS(ON)

= 1.7 W

(Note that there are no switching losses in the low side FET.)

To remove the dissipation of the chosen FETs, proper heatsinks

should be used. The Thermalloy 6030 heatsink has a thermal

impedance of 13°C/W with convection cooling. With this heatsink, the junction-to-ambient thermal impedance of the chosen

high side FET θ

will be 13 (heatsink-to-ambient) + 2 (junc-

JAHS

tion-to-case) + 0.5 (case-to-heatsink) = 15.5°C/W.

At full load and at 50°C ambient temperature, the junction

temperature of the high side FET is:

T

JHSMAX

= TA +

θ

JAHS PDFETHS

= 105°C

A smaller heatsink may be used for the low side FET, e.g., the

Thermalloy type 7141 (θ = 20.3°C/W). With this heatsink, the

thermal impedance θ

for the low side FET = 33.8°C/W.

JALS

The low side FET junction temperature is:

T

JLSMAX

= TA +

θ

JALS PDFETLS

= 106°C

All of the above calculated junction temperatures are safely

below the 175°C maximum specified junction temperature of

the selected FET.

The maximum operating junction temperature of the ADP3152

is calculated as follows:

= TA +

JICMAX

is the drive power. From the data sheet, θ

DR

where θ

is the junction to ambient thermal impedance of the

JA

ADP3152 and P

T

is equal to 110°C/W and I

θ

JA (IICVCC

= 2.7 mA. PDR can be calculated as

IC

+ PDR)

JA

follows:

= (C

P

DR

RSS

+ C

ISS)VCC

2

f

MAX

= 307 mW

The result is:

= 86°C

T

JICMAX

–9–REV. 0

Page 10

ADP3152

CIN Selection and Input Current di/dt Reduction

In continuous-inductor-current mode, the source current of the

high side MOSFET is a square wave with a duty ratio of V

. To keep the input ripple voltage at a low value, one or

V

IN

/

O

more capacitors with low equivalent series resistance (ESR) and

adequate ripple-current rating must be connected across the

input terminals. The maximum rms current of the input bypass

capacitors is:

I

CINRMS

≈ [V

O(VIN

– VO)]

0.5

I

OMAX

/V

= 7 Arms

IN

Let us select the FA-type capacitor with 2700 µF capacitance

and 10 V voltage rating. The ESR of that capacitor is 34 mΩ

and the allowed ripple current at 100 kHz is 1.94 A. At 105°C

we would need to connect at least four such capacitors in parallel to handle the calculated ripple current. At 50°C ambient,

however, the ripple current can be increased, so three capacitors

in parallel are adequate.

The ripple voltage across the three paralleled capacitors is:

V

CINRPL

= I

[ESRIN/3 + D

OMAX

MAXHF

/(3C

)] <140 mV p-p

IN fMIN

To further reduce the effect of the ripple voltage on the system

supply voltage bus and to reduce the input-current di/dt to

below the recommended maximum of 0.1 A/µs, an additional

small inductor (L > 1.7 µH @ 10 A) should be inserted between

the converter and the supply bus (see Figure 2).

Feedback Loop Compensation Design

To keep the peak-to-peak output voltage deviation as small as

possible, the low frequency output impedance (i.e., the output

resistance) of the converter should be made equal to the ESR of

the output capacitor. That can be achieved by having a single-pole

roll-off of the voltage gain of the g

error amplifier, where the pole

m

frequency coincides with the ESR zero of the output capacitor. A

gain with single-pole roll-off requires that the g

amplifier is termi-

m

nated by the parallel combination of a resistor and capacitor. The

required resistor value can be calculated from the equation:

36 × R

where g

SENSE

g

145 kΩiR

()

m

= 2.2 ms and the quantities 36 and 145 kΩ are charac-

m

=R

COMP

E

teristic of the ADP3152. The calculated compensating resistance is:

= 31 k

R1iR2 = R

COMP

Ω

The compensating capacitance is determined from the equality

of the pole frequency of the error amplifier gain and the zero

frequency of the impedance of the output capacitor.

C

COMP

=

R

ECOUT

R

COMP

5 m ×16.2 mF

=

31 kΩ

= 2.6 nF

In the application circuit we tested, we found that the compensation scheme shown in Figure 2 gave the optimal response to

meet the Pentium II dc/dc static and transient specifications

with sufficient margins including the ADP3152’s initial error

tolerance, the PCB layout trace resistances, and the external

component parasitics. If we increase the load resistance to the

COMP pin, the static regulation will improve. The load transient

response, however, will get worse. In Figure 2, if we decrease the

R1 = 150 kΩ resistor vs. the R2 = 39 kΩ resistor, the regulation

band will shift positive in relation to the 2.8 V. If we increase

the R1 resistor, the regulation band will shift negative. It may be

necessary to adjust these resistor values to obtain the best static

and dynamic regulation compliance depending on the output

capacitor ESR and the parasitic trace resistances of the PCB

layout.

BOARD LAYOUT

A multilayer PCB is recommended with a minimum of two

copper layers. One layer on top should be used for traces interconnecting low power SMT components. The ground terminals

of those components should be connected with vias to the bottom traces connecting directly to the ADP3152 ground pins.

One layer should be a power ground plane. If four layers are

possible, one additional layer should be an internal system

ground plane, and one additional layer can be used for other

system interconnections.

When laying out the printed circuit board, the following checklist should be used to ensure proper operation of the ADP3152.

It is advisable to follow the evaluation board layout as closely as

possible. If necessary, contact Analog Devices Application Engineering for layout suggestions.

–10– REV. 0

Page 11

ADP3152

Board Layout Guidelines

1. The power loop should be routed on the PCB to encompass

small areas to minimize radiated switching noise energy to

the control circuit and thus to avoid circuit problems caused

by noise. This technique also helps to reduce radiated EMI.

The power loop includes the input capacitors, the two

MOSFETs, the sense resistor, the inductor, and the output

capacitors. The ground terminals of the input capacitors, the

low side FET, the ADP3152, and the output capacitors

should be connected together with short and wide traces. It is

best to use an internal ground plane.

2. The PGND (power ground) pin of the ADP3152 must return to the grounded terminals of the input and output capacitors and to the source of the low side MOSFET with the

shortest and widest traces possible. The AGND (analog

ground) pin has to be connected to the ground terminals of

the timing capacitor and the compensating capacitor, again

with the shortest leads possible, and before it is connected to

the PGND pin.

3. The positive terminal of the input capacitors must be connected to the drain of the high side MOSFET. The source

terminal of this FET is connected to the drain of the low side

FET, (whose source is connected to the ground plane direct)

with the widest and shortest traces possible. To kill parasitic

ringing at the input of the buck inductor due to parasitic

capacitances and inductances, a small (L >3 mm) ferrite

bead is recommended to be placed in the drain lead of the

low side FET. Also, to minimize dissipation of the high side

FET, a low voltage 1 A Schottky diode can be connected

between the input of the buck inductor and the source of the

low side FET.

4. The positive terminal of the bypass capacitors of the +12 V

supply must be connected to the V

pin of the ADP3152

IN

with the shortest leads possible. The negative terminals must

be connected to the PGND pin of the ADP3152.

5. The sense pins of the ADP3152 must be connected to the

sense resistor with as short traces as possible. Make sure that

the two sense traces are routed together with minimum separation (<1 mm). The output side of the sense resistor should

be connected to the V

wide PCB traces as possible to reduce the V

pin(s) of the CPU with as short and

CC

voltage drop.

CC

(Each square unit of 1 ounce Cu-trace has a resistance of

~0.53 mΩ. At 14 A, each mΩ of PCB trace resistance between current sense resistor output and V

terminal(s) of

CC

the CPU will reduce the regulated output voltage by 14 mV.

The filter capacitors to ground at the sense terminals of the

IC should be as close as possible (<8 mm) to the ADP3152.

The common ground of the optional filter capacitors should

be connected to the AGND pin of the ADP3152 with the

shortest traces possible (<10 mm).

6. The microprocessor load should be connected to the output

terminals of the converter with the widest and shortest traces

possible. Use overlapping traces in different layers to minimize interconnection inductance.

–11–REV. 0

Page 12

ADP3152

0.1574 (4.00)

0.1497 (3.80)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

16-Lead SOIC

(R-16A/SO-16)

0.3937 (10.00)

0.3859 (9.80)

16 9

0.2440 (6.20)

81

0.2284 (5.80)

C3260–8–4/98

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

PIN 1

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

0.0099 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

x 45°

–12–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...