Page 1

500 mA PWM Step-Down DC-DC with

FEATURES

Current mode control for simple loop compensation

Input voltage range: 2.7 V to 5.5 V

Output voltage range: 0.8 V to 5.5 V

Tri-Mode™ operation for high efficiency

550 kHz PWM operating frequency

High accuracy over line, load, and temperature

Micropower shutdown mode

Space-saving MSOP-8 package

APPLICATIONS

Li-ion powered handhelds

MP3 players

PDAs and palmtops

Consumer electronics

Synchronous Rectifier

ADP3051

GENERAL DESCRIPTION

The ADP3051 is a low noise, current mode, pulse width modulator (PWM) step-down converter capable of supplying over

500 mA to output voltages as low as 0.8 V. This device integrates

a low resistance power switch and synchronous rectifier, providing excellent efficiency over the entire output voltage range and

eliminating the need for a large and costly external Schottky

rectifier. Its 550 kHz switching frequency permits the use of

small external components.

Current mode control and external compensation allow the

regulator to be easily optimized for a wide range of operating

conditions. The ADP3051 operates at a constant 550 kHz

frequency at medium to heavy loads; it smoothly transitions

into Tri-Mode operation to save power at light loads. A pincontrolled micropower shutdown mode is also included.

The ADP3051’s 2.7 V to 5.5 V input operating range makes it

ideal for both battery-powered applications as well as those with

3.3 V or 5 V supply buses. It is available in a space-saving, 8-lead

MSOP package.

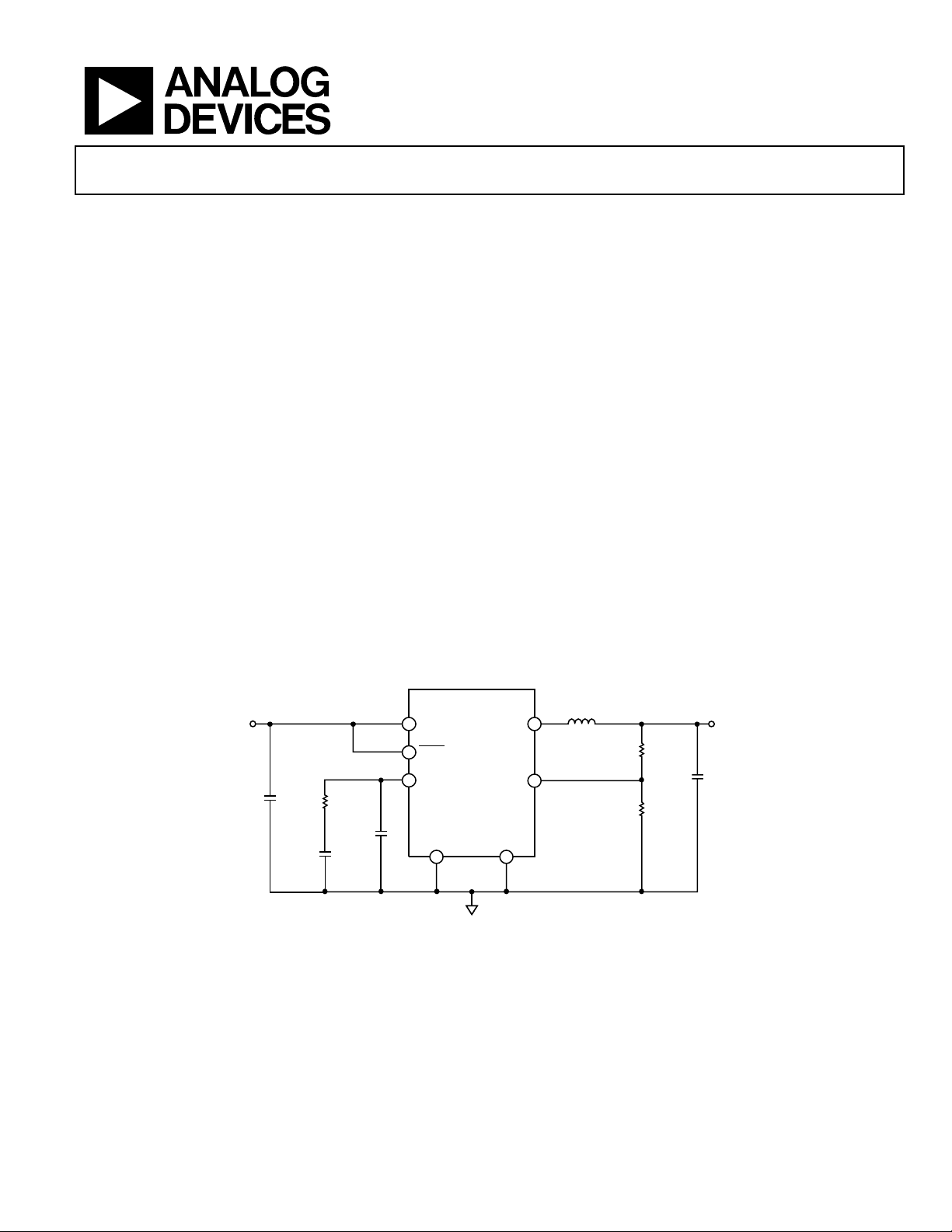

TYPICAL APPLICATION CIRCUIT

V

IN

10µF

3.3V

10kΩ

270pF

27pF

ADP3051

4

IN

SHDN

7

6

COMP FB

PGND GND

28

Figure 1.

SW

10µH

3

12.5kΩ

5

10kΩ

V

1.8V

OUT

10µF

04768-0-001

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

www.analog.com

Page 2

ADP3051

TABLE OF CONTENTS

Specifications..................................................................................... 3

Undervoltage L ockout (UVLO) ............................................... 10

Absolute Maximum Ratings............................................................ 4

ESD Caution.................................................................................. 4

Pin Configuration and Function Descriptions............................. 5

Typical Performance Characteristics............................................. 6

Theory of Operation ........................................................................ 9

PWM Control Mode.................................................................... 9

Tri-Mode Operation..................................................................... 9

100% Duty Cycle Operation ..................................................... 10

Shutdown..................................................................................... 10

REVISION HISTORY

6/04—Revision 0: Initial Version

Short-Circuit Protection and Recovery................................... 10

Applications..................................................................................... 11

Recommended Components .................................................... 11

Design Procedure....................................................................... 11

Output Capacitor Selection....................................................... 12

Circuit Board Layout Considerations...................................... 13

Outline Dimensions....................................................................... 15

Ordering Guide .......................................................................... 15

Rev. 0 | Page 2 of 16

Page 3

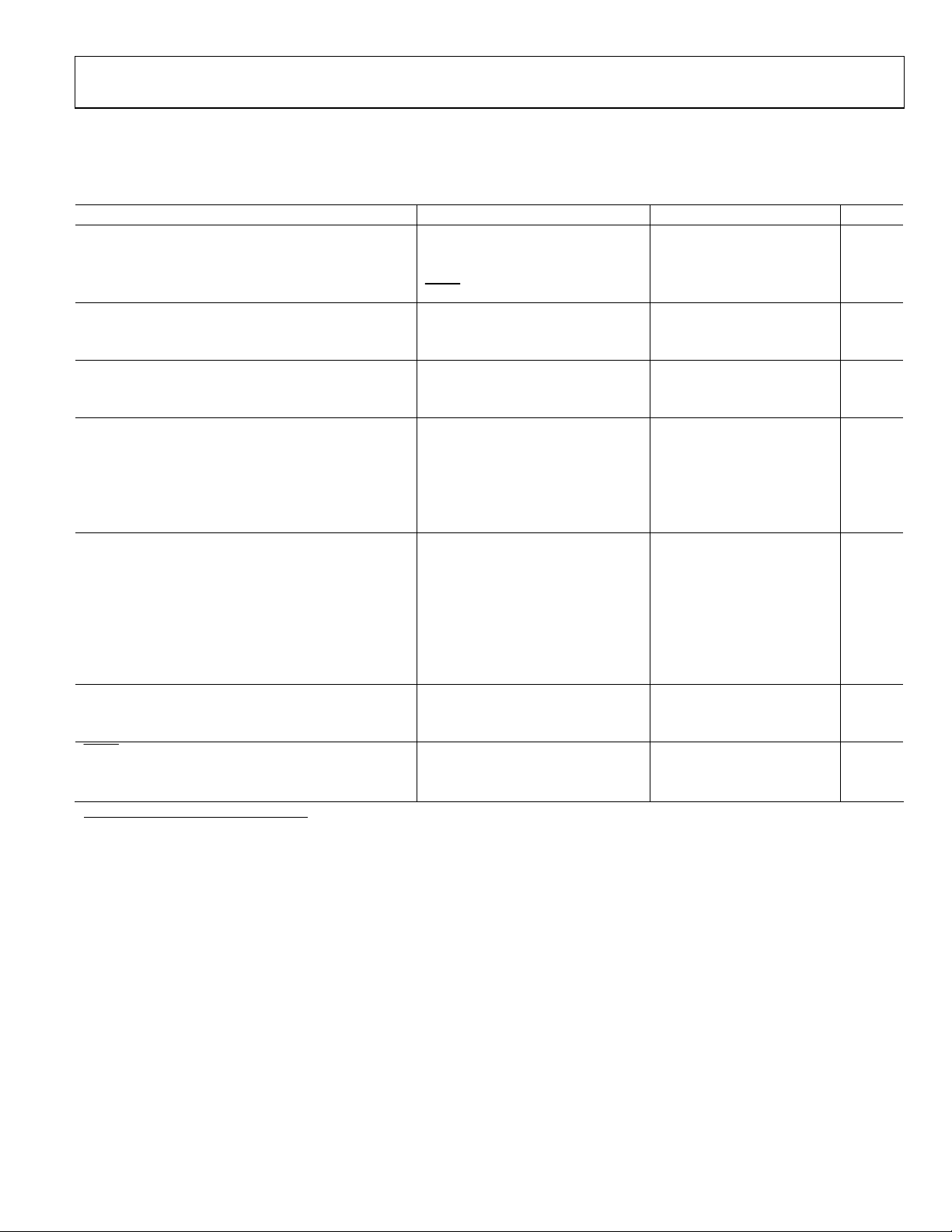

ADP3051

SPECIFICATIONS

VIN = 3.6 V @ TA = –40°C to +85°C, unless otherwise noted.

Table 1.

Parameter Conditions Min Typ Max Unit

SUPPLY

Input Voltage Range 2.7 5.5 V

Quiescent Supply Current VFB = 1.0 V 180 300 µA

Shutdown Supply Current

PWM COMPARATOR

Minimum Duty Ratio 0 %

Maximum Duty Ratio 100 %

OSCILLATOR

Oscillator Frequency V

Foldback Frequency V

OUTPUT STAGE

On Resistance, N Channel ISW = 150 mA 150 mΩ

Switch Leakage Current, N Channel VIN = 5.0 V, VSW = 0 V 1 µA

On Resistance, P Channel FB = GND 190 mΩ

Switch Leakage Current, P Channel VSW = 5.0 V 1 µA

Current Limit Threshold 680 1000 1320 mA

ERROR AMPLIFIER

Feedback Input Bias Current 5 nA

Current Sense Gain 2.9 Ω

Transconductance 0.32 mS

Maximum Sink Current 33 µA

Maximum Source Current 33 µA

UNDERVOLTAGE LOCKOUT

Undervoltage Lockout Threshold VIN rising 1.9 2.6 V

Undervoltage Lockout Hysteresis 55 mV

SHDN INPUT THRESHOLD VOLTAGES

Input High Threshold Voltage Referenced to IN −0.5 V

Input Low Threshold Voltage 0.4 V

1

All limits at temperature extremes are guaranteed via correlation using standard statistical quality control (SQC).

1

SHDN = 0 V

≥ 1.5 V, V

COMP

< 0.3 V 200 kHz

OUT

= 0.7 V 410 550 690 kHz

OUT

TA = 25°C 783 800 821 mV Feedback Regulation Voltage

770 830 mV

10 25 µA

Rev. 0 | Page 3 of 16

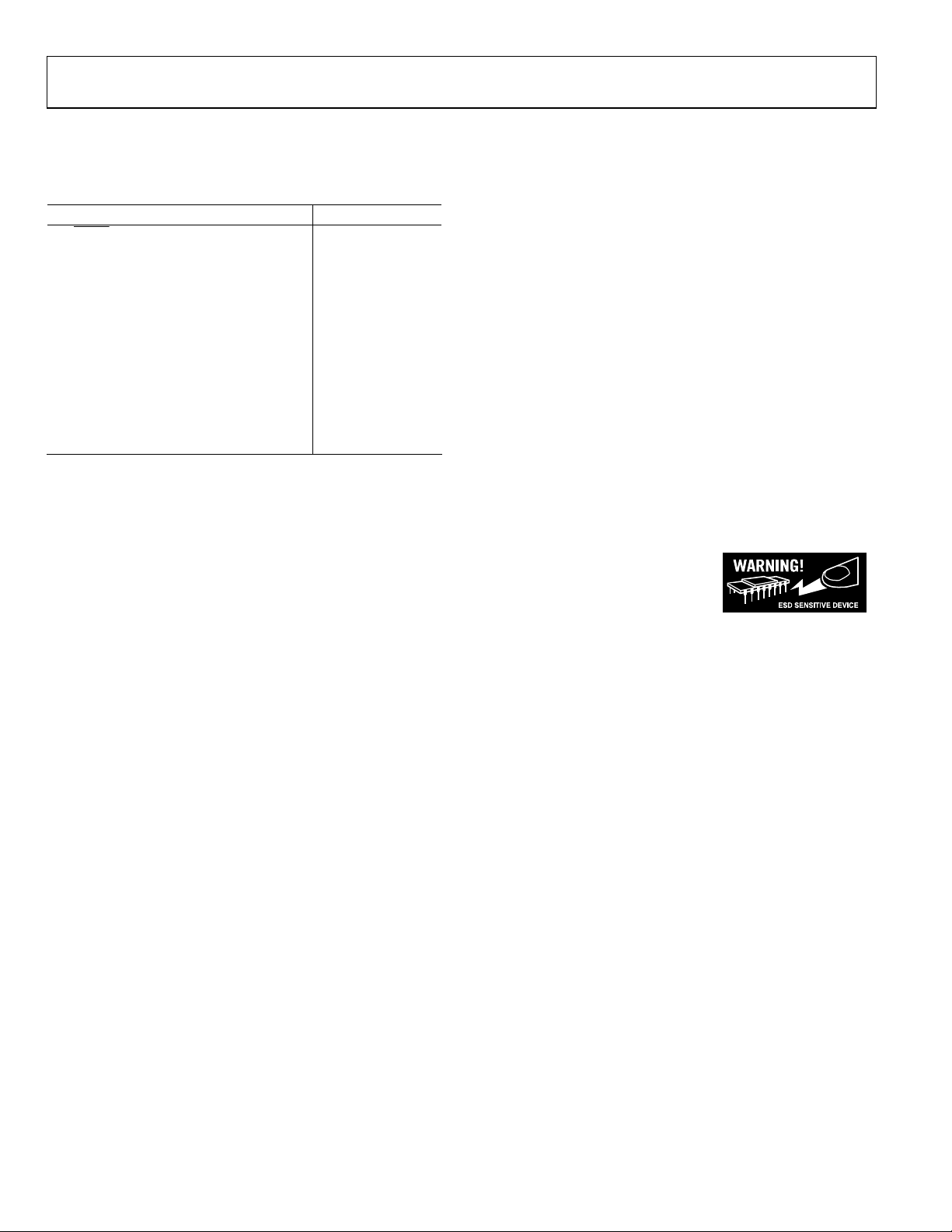

Page 4

ADP3051

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

IN, SHDN, COMP, SW, FB to GND

SW to IN –6 V to +0.3 V

PGND to GND –0.3 V to +0.3 V

Operating Ambient Temperature –40°C to +85°C

Operating Junction Temperature –40°C to +125°C

Storage Temperature –65°C to +150°C

θJA, 2-Layer (SEMI standard board) 159°C/W

θJA, 4-Layer (JEDEC standard board) 116°C/W

Lead Temperature Range

Soldering (10 sec) 300°C

Vapor Phase (60 sec) 215°C

Infrared (15 sec) 220°C

–0.3 V to +6 V

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance degradation or

loss of functionality.

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress rating only; functional operation of the device at these or any

other conditions above those indicated in the operational sections of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability. Absolute maximum ratings apply individually

only, not in combination. Unless otherwise specified, all other

voltages are referenced to GND.

Rev. 0 | Page 4 of 16

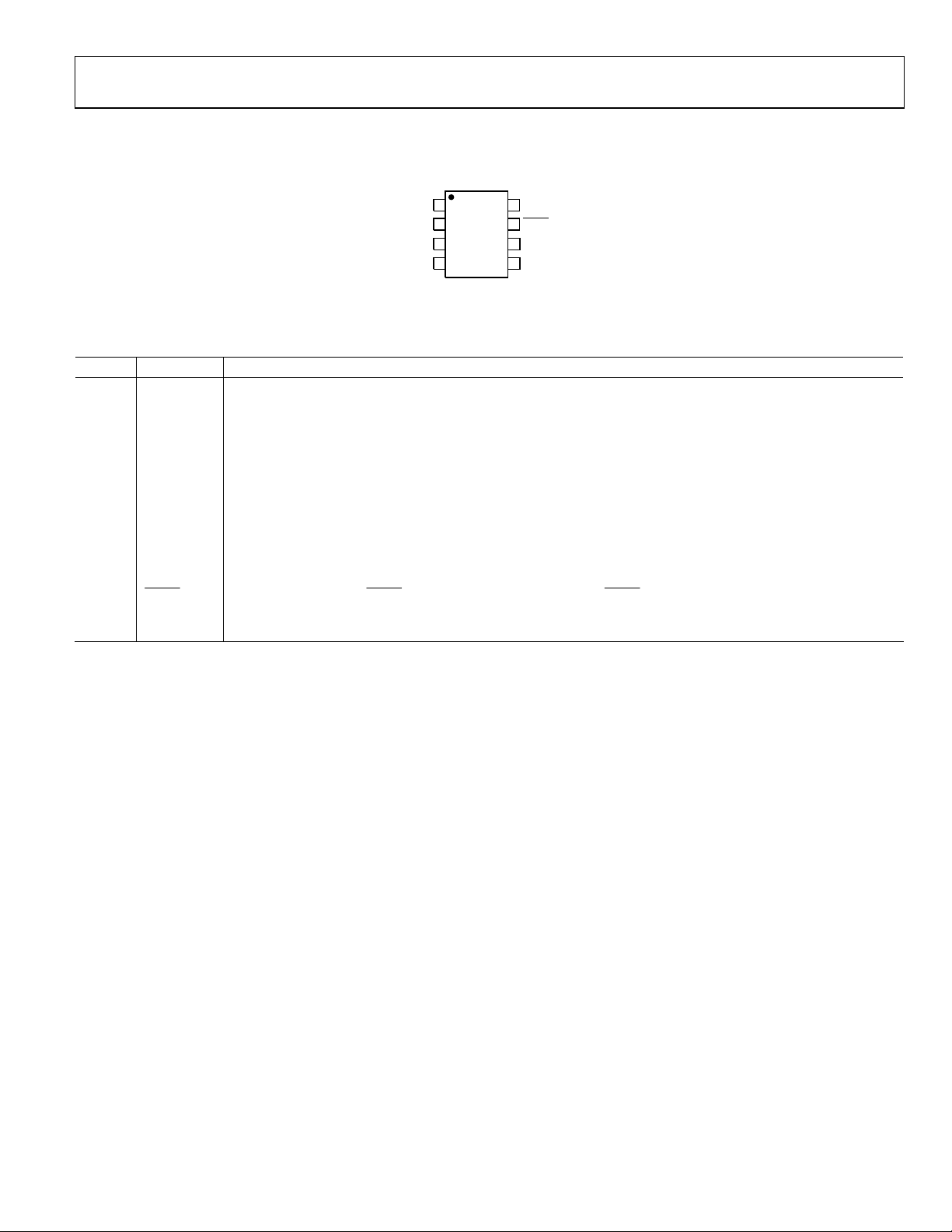

Page 5

ADP3051

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

1

NC

2

PGND

3

SW

4

IN

Figure 2. 8-Lead MSOP Pin Configuration

Table 3. Pin Function Descriptions

Pin No. Mnemonic Description

1 NC No Connect. Not internally connected.

2 PGND

Power Ground. Connect PGND to GND at a single point. Use separate power ground and quiet ground planes for

the power and sensitive analog circuitry, respectively. See the Circuit Board Layout Considerations section.

3 SW

Switching Output. SW connects to the drain of the internal power switch and synchronous rectifier. Connect the

output inductor between SW and the load.

4 IN

Power Source Input. IN is the source of the high side P-channel MOSFET switch, and supplies the internal power to

the ADP3051. Bypass IN to GND with a 0.1 µF or greater ceramic capacitor, placed as close as possible to IN.

5 FB

Feedback Voltage Sense Input. FB senses the output voltage. To set the output voltage, connect a resistive voltage divider from the output voltage to FB. The feedback threshold is 0.8 V. See the Setting the Output Voltage

section.

6 COMP

Feedback Loop Compensation Node. COMP is the output of the internal transconductance error amplifier. Place a

series RC network from COMP to GND to compensate the regulator. See the Compensation Design section.

7

SHDN Shutdown Input. Drive SHDN low to turn off the ADP3051; drive SHDN to within 0.5 V of VIN to turn on the

ADP3051. See the Shutdown section.

8 GND Ground.

ADP3051

TOP VIEW

(Not to Scale)

8

7

6

5

GND

SHDN

COMP

FB

04768-0-021

Rev. 0 | Page 5 of 16

Page 6

ADP3051

TYPICAL PERFORMANCE CHARACTERISTICS

VIN = 3.6V, V

100

90

80

70

EFFICIENCY (%)

60

50

40

1 10010 1000

100

90

= 3.3V, circuit of Figure 20, component values of Table 4, TA = 25°C, unless otherwise specified.

OUT

VIN = 3.6V

V

= 5.5V

IN

V

= 3.3V

OUT

L = 22µH

I

(mA)

LOAD

Figure 3. Output Efficiency vs. Load Current, V

= 2.7V

V

IN

OUT

= 3.3 V

04768-0-002

0.5

0.4

0.3

0.2

0.1

0

–0.1

–0.2

OUTPUT ACCURACY (%)

–0.3

–0.4

–0.5

0 100 200 300 400 500

(mA)

I

LOAD

Figure 6. Output Voltage Error vs. Load Current

600

580

V

V

OUT

= 3.6V

IN

= 2.5V

04768-0-005

80

VIN = 3.6V

70

EFFICIENCY (%)

60

50

40

1 10010 1000

V

= 5.5V

IN

I

LOAD

(mA)

Figure 4. Output Efficiency vs. Load Current, V

100

= 3.6V

90

VIN = 2.5V

80

70

EFFICIENCY (%)

60

50

40

1 10010 1000

V

IN

V

= 5.5V

IN

I

LOAD

(mA)

Figure 5. Output Efficiency vs. Load Current, V

= 2.5V

V

OUT

L = 22µH

C

= 22µF

OUT

= 2.5 V

OUT

V

= 1.2V

OUT

L = 10µH

C

= 22µF

OUT

= 1.2 V

OUT

04768-0-003

04768-0-004

560

= 5.5V

V

IN

540

520

FREQUENCY (kHz)

500

480

–40 –15 10 35 60 85

TEMPERATURE (°C)

V

= 3.6V

IN

VIN = 2.7V

V

OUT

I

LOAD

Figure 7. Oscillator Frequency vs. Temperature

600

550

500

450

400

350

300

250

200

150

OSCILLATOR FREQUENCY (kHz)

100

50

0

0 100 200 300 400 500

(mA)

I

LOAD

Figure 8. Oscillator Frequency vs. Load Current, V

= 3.6 V, V

IN

= 1.2V

= 500mA

OUT

= 1.2 V

04768-0-006

04768-0-007

Rev. 0 | Page 6 of 16

Page 7

ADP3051

CH1 = VIN, CH2 = SW, CH3 = V

= 3.6V, V

V

IN

OUT

= 1.2V, I

LOAD

OUT

= 500mA

, CH4 = IL (1A/DIV)

Figure 9. Start -Up Behav ior

CH2 = IL (100mA/DIV), CH4 = SW

= 3.6V, V

V

IN

= 2.5V, L = 22µH, I

OUT

OUT

= 50mA

Figure 10. Light Load Switching Waveforms

CH2 = IL (500mA/DIV), CH4 = SW

= 3.6V, V

V

IN

= 2.5V, L = 22µH, I

OUT

OUT

= 500mA

Figure 11. Heavy Load Switching Waveforms

04768-0-008

04768-0-009

04768-0-010

CH1 = COMP, CH3 = V

= 3.6V, V

V

IN

OUT

= 2.5V, C

, CH4 = I

OUT

= 22µF, CC = 150pF, RC = 100kΩ

OUT

(50mA TO 490mA)

LOAD

Figure 12. Load Transient Response

CH1 = VIN, CH2 = V

VIN = 3V TO 4V, V

OUT

OUT

= 2.5V, I

LOAD

= 500mA

Figure 13. Line Transient Response

210

200

190

180

)

170

Ω

(m

160

DSON

150

R

140

130

120

110

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

PMOS

NMOS

SUPPLY VOLTAGE (V)

V

I

OUT

OUT

Figure 14. Switch On Resistance vs. Input Voltage

= 2.5V

= 500mA

04768-0-011

04768-0-012

04768-0-013

Rev. 0 | Page 7 of 16

Page 8

ADP3051

240

220

200

A)

µ

180

160

140

120

SUPPLY CURRENT (

100

80

60

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

Figure 15. Quiescent Current vs. Input Voltage

TA = +85°C

TA = +25°C

TA = –40°C

SUPPLY VOLTAGE (V)

V

I

LOAD

OUT

= 1.2V

= 0mA

04768-0-014

1200

1150

1100

1050

1000

950

900

CURRENT LIMIT (A)

850

800

750

700

–40 –15 10 35 60 85

V

= 5.5V

IN

= 3.6V

V

IN

VIN = 2.7V

TEMPERATURE (°C)

V

OUT

Figure 16. Current Limit vs. Input Voltage, V

OUT

= 1.2V

= 1.2 V

04768-0-015

Rev. 0 | Page 8 of 16

Page 9

ADP3051

C

THEORY OF OPERATION

The ADP3051 is a monolithic current mode buck converter

with an integrated high-side switch and low-side synchronous

rectifier. It operates with input voltages between 2.7 V and 5.5 V,

regulates an output voltage down to 0.8 V, and supplies more

than 500 mA of load current. The ADP3051 features patented

Tri-Mode technology to operate in fixed frequency PWM mode

at medium to heavy loads. This improves light-load efficiency

by smoothly transitioning into a variable frequency PWM

mode, and into a single-pulse, current-limited variable

frequency mode at very light loads.

PWM CONTROL MODE

At moderate to high output currents, the ADP3051 operates

in a fixed frequency, peak current control mode to regulate the

output voltage. At the beginning of each cycle, the P-channel

output switch turns on and remains on until the inductor current exceeds the threshold set by the voltage at COMP. When

the P-channel switch turns off, the N-channel synchronous

rectifier turns on for the remainder of the cycle, after which the

cycle repeats.

In current mode, two cascaded control loops combine to regulate the output voltage. The outer voltage control loop senses the

voltage at FB and compares it to the internal 0.8 V reference.

The internal transconductance amplifier forces a current at

COMP proportional to the voltage difference between the reference and FB. By selecting the components between COMP and

GND, the frequency characteristics of the control system give a

stable regulation system.

The inner peak-current control loop monitors the current flowing through the P-channel MOSFET and converts that to a

voltage. This voltage is internally compared to the voltage at

7

SHDN

0.4V

FREQUENCY

FOLDBACK

COMPARATOR

CONTROL

LOGIC

UVLO

COMP, which sets inductor peak current. The error amplifier,

and thus the output voltage, controls the inductor peak current

to regulate the output voltage. An internally generated slope

compensation circuit ensures that the inner current control

loop maintains stable operation over the entire input and output

voltage range.

TRI-MODE OPERATION

The ADP3051 features patented Tri-Mode technology which

allows fixed-frequency, current mode, PWM operation at

medium and heavy loads; smoothly transitions to variable

frequency PWM operation to improve light-load efficiency; and

operates in a single-pulse, current-limited variable frequency

mode at very light loads. These three modes work together to

provide high efficiency over a wide range of load current conditions without the frequency jitter, increased output voltage

ripple, and audible noise generation exhibited by other lightload control schemes.

The ADP3051’s internal oscillator is a key component of its

Tri-Mode operation. Under medium-heavy load conditions, the

oscillator operates at a constant 550 kHz. Under light-load

conditions, the oscillator frequency is decreased to minimize

switching losses, thus improving light-load efficiency. At very

light loads, the oscillator is disabled and the ADP3051 switches

only as required to supply the load current for good light-load

efficiency.

In addition to Tri-Mode operation, the ADP3051 operates in the

200 kHz frequency foldback mode when the voltage at FB is

below 0.3 V for enhanced control of the inductor current under

short-circuit and startup conditions. See the Short-Circuit Protection and Recovery section.

4

IN

VOLTAGE

CURRENT

SENSE

REFERENCE

OSCILLATOR

PWM

6

OMP

ERROR

AMPLIFIER

5

FB

0.8V

g

m

COMPARATOR

18

NC

Figure 17. Simplified Block Diagram

Rev. 0 | Page 9 of 16

GND

SRQ

GATE

DRIVERS

ADP3051

3

2

SW

PGND

04768-0-016

Page 10

ADP3051

100% DUTY CYCLE OPERATION

The ADP3051 is capable of operating at 100% duty cycle, allowing it to regulate output voltages that are very close to the input

voltage. In 100% duty cycle operation, the P-channel switch

remains continuously on, and the dropout voltage is simply the

output current multiplied by the on resistance of the internal

switch and inductor, typically 200 mV at full loads (500 mA).

SHUTDOWN

The ADP3051 is enabled and disabled via its

easily interfaces to open-drain and three-state logic

SHDN

GPIOs. To enable the ADP3051, drive

SHDN

the voltage at IN; to disable the ADP3051, drive

0.4 V. The circuit of Figure 18 shows a simple means of driving

to the proper high and low input states in cases where no

SHDN

open-drain or three-state GPIO is available.

IN

100kΩ

SHDN

SHDN

CONTROL

ADP3051

Figure 18. Shutdown Control Circuit

input.

SHDN

to within 0.5 V of

below

SHDN

04768-0-017

UNDERVOLTAGE LOCKOUT (UVLO)

The ADP3051 includes an internal undervoltage lockout

(UVLO) circuit that turns off the converter if the input

voltage drops below the 2.2 V UVLO threshold. This prevents

uncontrolled behavior if the input voltage drops below the 2.7 V

minimum allowable voltage range. The UVLO circuit includes

55mV of hysteresis to prevent oscillation at the UVLO

threshold.

SHORT-CIRCUIT PROTECTION AND RECOVERY

When starting up or when the output is short circuited, the low

voltage drop across the synchronous rectifier may allow the

inductor current to run away because it rises more during the

on time than it falls during the off time. To protect against this,

the ADP3051 automatically initiates a frequency foldback

operation when the voltage at FB drops below 0.3 V, allowing

the ADP3051 to maintain control of the inductor current under

these conditions.

When operating at higher input voltages (for example, from a

5 V bus), the ADP3051 may exhibit output voltage overshoot

upon startup or after release of an overload condition (see

Figure 9). In such cases, the ADP3051’s limited COMP slew rate

can slow its recovery as the output approaches regulation,

allowing the output voltage to overshoot. If overshoot cannot be

tolerated in an application, the COMP voltage can be limited by

placing a Zener diode from COMP to GND, as shown in Figure 19.

6

COMP

CMPZ4683-ADC

ADP3051

04768-0-023

Figure 19. COMP Zener Clamp to Prevent

Short-Circuit Recovery Output Voltage Overshoot

Rev. 0 | Page 10 of 16

Page 11

ADP3051

V

APPLICATIONS

Where

V

RECOMMENDED COMPONENTS

External component selection for the application circuit shown

in Figure 20 depends on the load current requirements. Certain

tradeoffs between different performance parameters can also be

made. Recommended external component values are given in

Tabl e 4.

ADP3051

V

IN

C

IN

43

7

8

IN

SHDN

GND

SW

FB

COMP

PGND

2

Figure 20. Typical Application Circuit

L

R

A

5

6

C2

R

B

R

C

C1

V

OUT

C

OUT

04768-0-018

DESIGN PROCEDURE

For applications where specific performance is required, component combinations other than those listed in Table 4 may be

more appropriate. A design procedure for selecting the components is provided in the following sections.

Setting the Output Voltage

The regulated output voltage of the ADP3051 is set by selecting

the resistive voltage divider formed by R

Figure 21). The voltage divider drops the output voltage to the

voltage at FB by the equation

and RB (see

A

regulation threshold.

I

, which is calculated by

DIV

Using higher divider current increases accuracy due to the 5 nA

FB input bias current. With

degraded by 0.0625%.

For a given

by the equation

is the output voltage and VFB is the 0.8 V feedback

OUT

R

controls the voltage divider current,

B

I =

FB

DIV

R

B

R

= 100 kΩ, the accuracy is

B

R

, choose the value of RA to set the output voltage

B

A

V

⎝

V

⎛

RR

⎜

B

OUT

FB

−= 1

⎞

⎟

⎠

ADP3051

FB

5

REF

g

m

ERROR

AMPLIFIER

6

COMP

R

C1

C

C2

R

R

Figure 21. Typical Compensation Network

V

OUT

A

B

04768-0-019

R

⎞

⎛

VV 1

FB

OUT

A

+=

⎟

⎜

R

B

⎠

⎝

Table 4. Recommended External Components for Popular Input/Output Voltage Conditions

(Based on I

VIN V

= 500 mA Max and a 60 kHz Crossover Frequency)

LOAD

L (µH) C

OUT

(µF) CIN (µF) RA (kΩ) RB (kΩ) RC (kΩ) C1 (pF) C2 (pF)

OUT

2.5 1.0 6.8 10 10 2.5 10 4.7 470 47

1.8 6.8 10 10 12.5 10 10 270 27

3.6 1.0 6.8 10 10 2.5 10 4.7 470 47

1.8 8.2 10 10 12.5 10 10 270 27

2.5 8.2 10 10 21.3 10 15 180 18

5.0 1.0 8.2 10 10 2.5 10 5.7 470 47

1.8 10 10 10 12.5 10 10 270 27

2.5 10 10 10 21.3 10 15 180 18

3.3 12 10 10 31.3 10 18 150 15

Rev. 0 | Page 11 of 16

Page 12

ADP3051

V

I

∆

V

×××

Inductor Selection

The ADP3051’s high switching frequency allows the use of a

physically small inductor. The inductor ripple current is determined by

()

VVV

−×

IN

OUT

I

=∆

L

Where ∆

IN

I

is the peak-to-peak inductor ripple current and fSW is

L

the switching frequency. As a guideline, the inductor peak-topeak current ripple is typically set to be one-third the maximum

dc load current. Using this guideline and solving for

L

OUT

IN

SW

Simplifying for the known constants

OUT

×=

μH5

L

It is important to ensure that the inductor is capable of handling

the maximum peak inductor current, I

II

LPK

()

MAXLOAD

Finally, the ADP3051’s internal slope compensation is designed

to ensure stability of the inner current mode control loop when

the inductor is chosen so that the down-slope of the inductor

current is less than 320 mA/µs

V

L ≥

OUT

μs/mA320

OUTPUT CAPACITOR SELECTION

The output capacitor should be chosen to meet output voltage

ripple requirements for the application. Output voltage ripple is

a function of the inductor ripple current and the impedance of

the output capacitor at the switching frequency. The magnitude

of the capacitive impedance is

COUT

OUT

LfV

××

SW

()

−××=3

VVV

IN

OUT

()

MAXLOAD

−×

VVV

IN

OUT

MAXLOAD

I

∆

⎛

⎞

L

⎜

⎟

2

⎝

⎠

)(

, determined by

LPK

××

IfV

()

×

IV

IN

+=

1

OUT

fCX××π=2

SW

L,

Where V

ESR

COUT

is the peak-to-peak output ripple voltage and

RIPPLE

is the output capacitor ESR. For capacitors with relatively small capacitance and/or resistance, the capacitance

dominates the output voltage ripple. In this case, choose the

output capacitor by the capacitance using the equation

V

C

OUT

()

C

≥

OUT

8

SW

IN

SW

∆

×××≥22π

L

Vf

OUT

VLf

RIPPLE

Multilayer ceramic (MLC), tantalum, OS-CON, or similar low

ESR capacitors are recommended. Table 5 lists some vendors

that make suitable capacitors.

Table 5. Capacitor Suppliers

Manufacturer Capacitor Type Contact Info

AVX Tantalum www.avxcorp.com

Murata MLCC www.murata.com

Sanyo OS-CON www.sanyovideo.com

Taiyo-Yuden MLCC www.t-yuden.com

Input Capacitor Selection

The input capacitor reduces input voltage ripple caused by

switch currents. Select an input capacitor capable of withstanding the rms input current

()

VVV

−

IN

OUT

V

IN

Where I

II

≥

is the rms ripple rating of the input capacitor. As

CIN(RMS)

OUT

MAXLOADRMSCIN

)()(

with the output capacitor, a low ESR capacitor is recommended

to help to minimize input voltage ripple.

Compensation Design

The ADP3051’s external compensation network allows designers to easily optimize the part’s performance for a particular

application with just a series RC network (R

and C1 of

C

Figure 21) from COMP to GND typically required to

compensate the regulator.

The dc loop gain is given by the equation

For capacitors with relatively large capacitance or high

equivalent series resistance (ESR), e.g., tantalum or electrolytic

A

FB

=

VDC

OUT

RRG

LOADOEAEA

RV

×

CS

capacitors, the ESR dominates the impedance at the switching

frequency; therefore, the output ripple voltage is mainly a function of ESR. In this case, the output capacitor should be chosen

based on the ESR by the equation

ESR∆≤

COUT

RIPPLE

I

L

where:

is the feedback voltage regulation threshold, 0.8 V.

V

FB

is the error amplifier transconductance, 320 µs.

G

EA

is the error amplifier output impedance (10 MΩ).

R

OEA

is the 2.9 Ω current sense gain.

R

CS

R

is the equivalent output resistance, equal to the output

LOAD

voltage divided by the load current.

Rev. 0 | Page 12 of 16

Page 13

ADP3051

The system has three poles and a zero that dominate its frequency response. The first compensation pole is given by

f

=

1

PC

1

OEA

12

CR

××π

The output pole is given by

POUT

1

LOAD

CRf××π=2

OUT

If used, the optional second compensation pole is given by

f

2

PC

1

=

22

CR

××π

C

Finally, the zero can be calculated as

f

ZC

1

=

12

CR

××π

C

Note that the dc loop gain is the inverse of the output load

current, while the output pole, f

, is proportional to the load

POUT

current. Thus, the crossover frequency, which is proportional to

the product of the dc loop gain and the output pole frequency,

remains the same.

To choose the compensation components, first choose the

regulator loop crossover frequency (the frequency where the

loop gain drops to 1 V/V or 0 dB). To determine the desired

crossover frequency, chose it for about one-tenth of the switching frequency or 60 kHz. The required compensation resistor,

, can be determined from the equation

R

C

CRVf

××××π=2

R

Where f

C

C

C

REF

is the crossover frequency. To make sure the phase

OUT

CS

OUT

GV

×

EA

margin is suitable, choose the first compensation capacitor to

set the zero frequency to one-fourth the crossover frequency, or

1

4

RfC××π=2

CC

An optional second compensation capacitor reduces the high

frequency gain to reduce the high frequency noise. If used,

choose the second compensation capacitor to set the second

compensation pole to the switching frequency, or

=

2

1

2

RfC××π

CSW

CIRCUIT BOARD LAYOUT CONSIDERATIONS

A good circuit board layout aids in extracting the most

performance from the ADP3051. Poor circuit layout degrades

the output ripple and the electromagnetic interference (EMI) or

electromagnetic compatibility (EMC) performance.

The evaluation board layout of Figure 24 is optimized for the

ADP3051. Use this layout for best performance. If this layout

needs changing, use the following guidelines:

Use separate analog and power ground planes. Connect the

1.

sensitive analog circuitry (such as compensation and voltage divider components) to analog ground; connect the

power components (such as input and output bypass

capacitors) to power ground. Connect the two ground

planes together near the load to reduce the effects of

voltage dropped on circuit board traces.

Locate C

2.

rate input bypass capacitors for the analog and power

grounds indicated in Guideline 1.

3.

Route the high current path from C

and PGND pins as short as possible.

4.

Route the high current path from C

as short as possible.

5.

Keep high current traces as short and as wide as possible.

6.

Place the feedback resistors as close as possible to the FB

pin to prevent noise pickup.

7.

Place the compensation components as close as possible to

the COMP pin.

Avoid routing high impedance traces, such as FB and

8.

COMP, near the high current traces and components or

near the switch node (SW).

If high impedance traces are routed near high current

9.

and/or the SW node, place a ground plane shield between

the traces.

as close to the IN pin as possible, and use sepa-

IN

, through L, to the SW

IN

through L and C

IN

OUT

Rev. 0 | Page 13 of 16

Page 14

ADP3051

Figure 22. Sample Application Circuit Board Layout (Silkscreen Layer)

Figure 23. Sample Application Circuit Board Layout ( Top Layer)

04768-0-024

04768-0-026

Figure 24. Sample Application Circuit Board Layout (Bottom Layer)

04768-0-025

Rev. 0 | Page 14 of 16

Page 15

ADP3051

OUTLINE DIMENSIONS

3.00

BSC

85

3.00

BSC

PIN 1

0.65 BSC

0.15

0.00

0.38

0.22

COPLANARITY

0.10

COMPLIANT TO JEDEC STANDARDS MO-187AA

BSC

4

SEATING

PLANE

4.90

1.10 MAX

0.23

0.08

8°

0°

0.80

0.60

0.40

Figure 25. 8-Lead Mini Small Outline Package [MSOP]

(RM-8)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Outline Branding

ADP3051ARMZ-REEL7

1

Z = Pb-free part.

1

–40°C to +85°C 8-Lead Mini Small Outline Package [MSOP] RM-8 P3A

Rev. 0 | Page 15 of 16

Page 16

ADP3051

NOTES

© 2004 Analog Devices, Inc. All rights reserved. Trademarks and registered trademarks are the property of their respective owners.

D04768–0–6/04(0)

Rev. 0 | Page 16 of 16

Loading...

Loading...