Page 1

200 kHz, 1 A High-Voltage

a

FEATURES

Wide Input Voltage Range: 3.6 V to 30 V

Adjustable and Fixed (3.3 V, 5 V) Output Options

Integrated 1 A Power Switch

Uses Small Surface-Mount Components

Cycle-By-Cycle Current Limiting

Peak Input Voltage (100 ms): 60 V

Thermally Enhanced 8-Lead SOIC Package

Configurable as a Buck, Buck-Boost and SEPIC

Regulator

APPLICATIONS

Industrial Power Systems

PC Peripheral Power Systems

Preregulator for Linear Regulators

Distributed Power Systems

Automotive Systems

Battery Chargers

Step-Down Switching Regulator

ADP3050

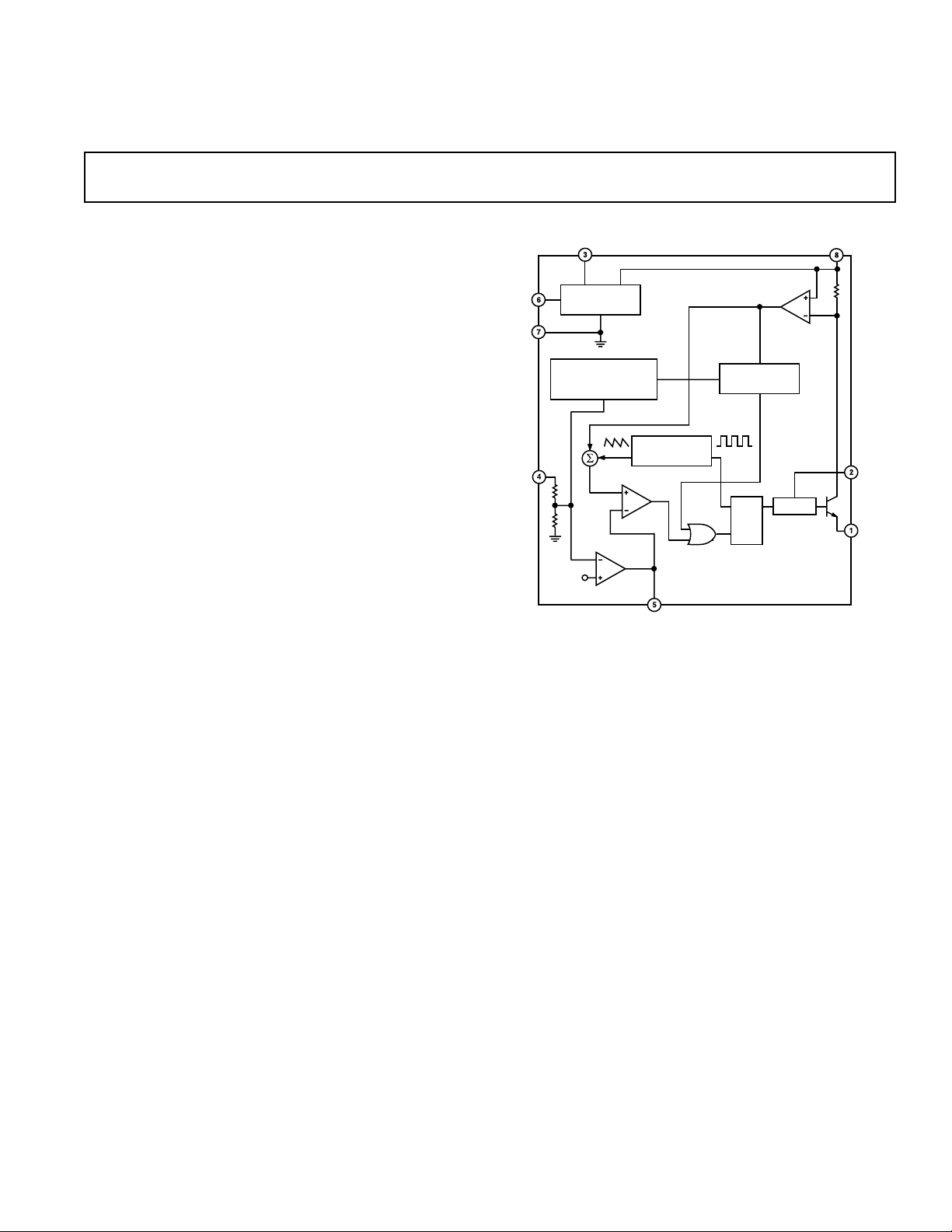

FUNCTIONAL BLOCK DIAGRAM

GND

SD

FB

BIAS

2.5V

REGULATOR

FREQUENCY

AND CURRENT LIMIT

FOLDBACK

+

g

1.2V

m

200kHz

OSCILLATOR

CMP

CURRENT SENSE

AMPLIFIER

CURRENT

LIMIT

SQ DRIVER

R

ADP3050

IN

BOOST

SWITCH

GENERAL DESCRIPTION

The ADP3050 is a current-mode monolithic buck (step-down)

PWM switching regulator that contains a high current 1 A power

switch and all control, logic, and protection functions. It uses a

unique compensation scheme that allows the use of any type of

output capacitor (tantalum, ceramic, electrolytic, OS-CON).

Unlike some buck regulators, the design is not restricted to using

a specific type of output capacitor or ESR value.

A special boosted drive stage is used to saturate the NPN power

switch, providing a system efficiency higher than conventional

bipolar buck switchers. Further efficiency improvements are obtained by using the low voltage regulated output to provide the

device's internal operating current. A high switching frequency

allows the use of small external surface-mount components. A

wide variety of standard off-the-shelf devices can be used, providing a great deal of design flexibility. A complete regulator

design requires only a few external components.

COMP

The ADP3050 includes a shutdown input that places the device

in a low-power mode, reducing the total supply current to under

20 µA. Internal protection features include thermal shutdown

circuitry and a cycle-by-cycle current-limit for the power switch

to provide complete device protection under fault conditions.

The ADP3050 provides excellent line and load regulation,

maintaining typically less than ±3% output voltage accuracy

over temperature and under all input voltage and output current

conditions.

The ADP3050 is specified over the industrial temperature range of

–40°C to +85°C and is available in a thermally enhanced 8-lead

SOIC package.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

Page 2

1

ADP3050–SPECIFICATIONS

Parameter Symbol Conditions Min Typ Max Unit

FEEDBACK

Feedback Voltage V

ADP3050 1.16 1.20 1.24 V

ADP3050-3.3 3.20 3.30 3.40 V

ADP3050-5 4.85 5.00 5.15 V

Line Regulation V

Load Regulation I

Input Bias Current I

ERROR AMPLIFIER

Transconductance

Voltage Gain

2

2

Output Current

ADP3050 COMP = 1.0 V, FB = 1.1 V to 1.3 V ±115 µA

ADP3050-3.3 COMP = 1.0 V, FB = 3.0 V to 3.6 V ±120 µA

ADP3050-5 COMP = 1.0 V, FB = 4.5 V to 5.5 V ±135 µA

OSCILLATOR

Oscillator Frequency

3

Minimum Duty Cycle D

Maximum Duty Cycle D

SWITCH

Average Output Current Limit4I

ADP3050 BOOST = 15 V, FB = 1.1 V 1.0 1.25 1.5 A

ADP3050-3.3 BOOST = 15 V, FB = 3.0 V 1.0 1.25 1.5 A

ADP3050-5 BOOST = 15 V, FB = 4.5 V 1.0 1.25 1.5 A

Peak Switch Current Limit

5

Saturation Voltage BOOST = 15 V, I

Leakage Current 50 nA

SHUTDOWN

Input Voltage Low 0.4 V

Input Voltage High 2.0 V

SUPPLY

Minimum Input Voltage

6

Minimum BIAS Voltage V

Minimum BOOST Voltage V

IN Supply Current I

Normal Mode BIAS = 5.0 V 0.7 1.5 mA

Shutdown Mode SD = 0 V, V

BIAS Supply Current I

BOOST Supply Current I

NOTES

1

All limits at temperature extremes are guaranteed via correlation using standard Statistical Quality Control (SQC).

2

Transconductance and voltage gain measurements refer to the internal amplifier without the voltage divider. To calculate the transconductance and gain of the fixed

voltage parts, divide the values shown by FB/1.20.

3

The switching frequency is reduced when the feedback pin is lower than 0.8 ⫻ FB.

4

See Figure 22 for test circuit.

5

Switch current limit is measured with no diode, no inductor, and no output capacitor.

6

Minimum input voltage is not measured directly, but is guaranteed by other tests. The actual minimum input voltage needed to keep the output in regulation will

depend on output voltage and load current.

Specifications subject to change without notice.

FB

FB

g

m

A

VOL

f

OSC

MIN

MAX

CL(AVG)

I

CL(PEAK)

V

IN

BIAS

BOOST

Q

BIAS

BOOST

(VIN = 10 V, TA = –40ⴗC to +85ⴗC, unless otherwise noted)

Over Line and Temperature

= 10 V to 30 V, no load 0.005 %/V

IN

= 100 mA to 1 A,

LOAD

ADP3050AR Only –1.0 +0.1 +1.0 %/A

ADP3050AR-3.3, ADP3050AR-5 –0.5 +0.1 +0.5 %/A

ADP3050AR Only 0.65 2 µA

1250 µMho

300 V/V

170 200 240 kHz

10 %

90 %

1.5 1.7 2.1 A

= 1 A 0.65 0.95 V

LOAD

3.6 V

3.0 V

3.0 V

≤ 30 V 15 40 µA

IN

BIAS = 5.0 V 4.0 6.0 mA

BOOST = 15 V, ISW = 0.5 A 18 mA

BOOST = 15 V, ISW = 1.0 A 20 40 mA

–2–

REV. 0

Page 3

ADP3050

ABSOLUTE MAXIMUM RATINGS*

IN Voltage

Steady State . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +30 V

Peak (<100 ms) . . . . . . . . . . . . . . . . . . . . . –0.3 V to +60 V

BOOST Voltage

Steady State . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +45 V

Peak (<100 ms) . . . . . . . . . . . . . . . . . . . . . –0.3 V to +65 V

SD, BIAS Voltage . . . . . . . . . . . . . . . . . –0.3 V to IN + 0.3 V

FB Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +8 V

COMP Voltage . . . . . . . . . . . . . . . . . . . –0.3 V to IN + 0.3 V

SWITCH Voltage . . . . . . . . . . . . . . . . . –0.3 V to IN + 0.3 V

Operating Ambient Temperature Range . . . . –40°C to +85°C

Operating Junction Temperature Range . . . –40°C to +125°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

(2-Layer PCB) . . . . . . . . . . . . . . . . . . . . . . . . . . 108°C/W

θ

JA

(4-Layer PCB) . . . . . . . . . . . . . . . . . . . . . . . . . . . 81°C/W

θ

JA

Lead Temperature Range (Soldering, 60 sec.) . . . . . . . . 300°C

*This is a stress rating only; operation beyond these limits can cause the device to

be permanently damaged. Unless otherwise specified, all voltages are referenced

to GND

ORDERING GUIDE

Output Temperature

Model Voltage Range Package*

°

ADP3050AR ADJ –40

ADP3050AR-3.3 3.3 V –40

C to +85°C SO-8

°

C to +85°C SO-8

ADP3050AR-5 5.0 V –40°C to +85°C SO-8

*SO = Small Outline Package

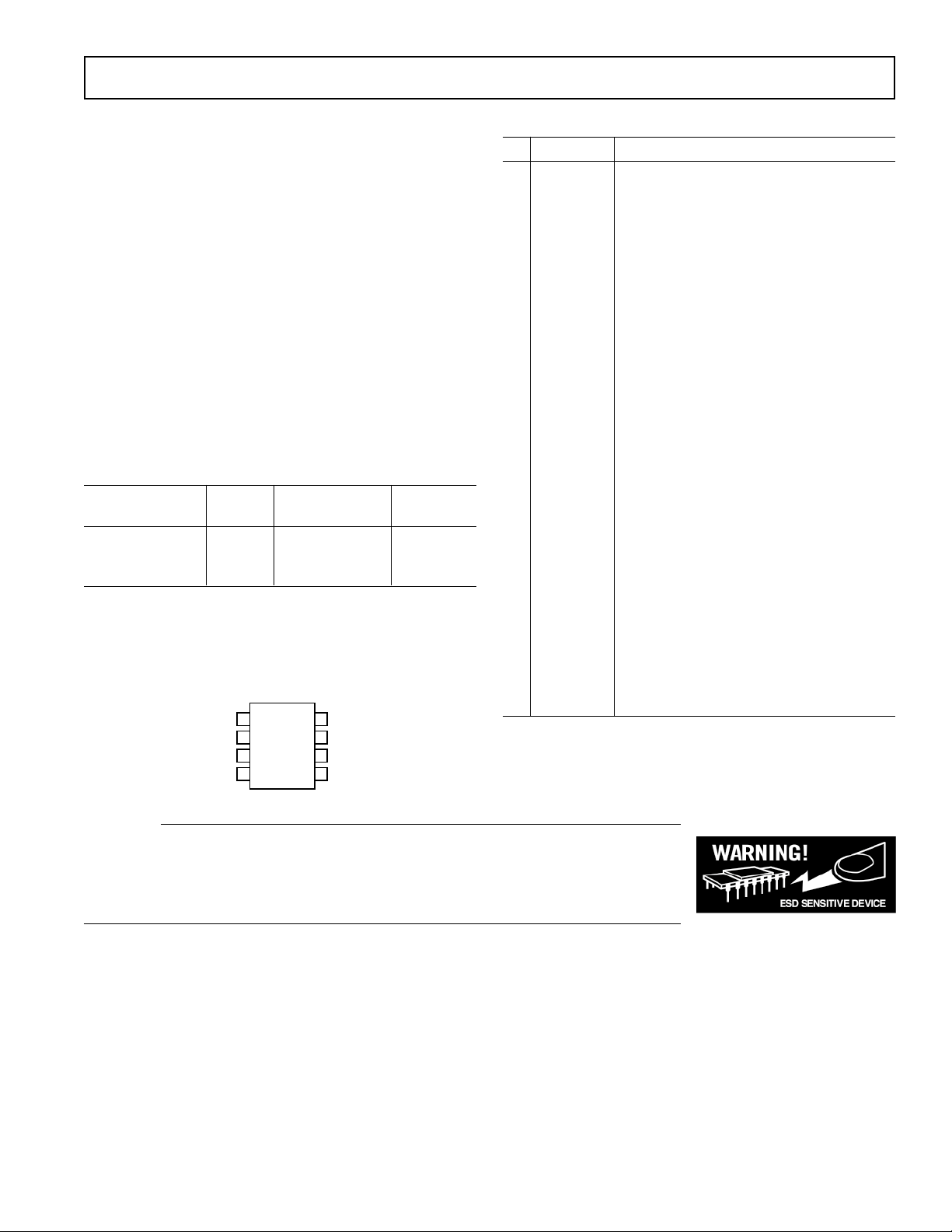

PIN CONFIGURATION

8-Lead SOIC

(R-Suffix)

SWITCH

BOOST

BIAS

FB

1

ADP3050

2

TOP VIEW

3

(Not to Scale)

4

8

7

6

5

IN

GND

SD

COMP

PIN FUNCTION DESCRIPTION

Pin Name Function

1 SWITCH This is the emitter of the internal NPN

power switch. The voltage at this pin switches

between V

and approximately –0.5 V.

IN

2 BOOST This pin is used to provide a boosted voltage

(higher than V

) for the drive stage of the

IN

NPN power switch. With the higher drive

voltage, the power switch can be saturated,

greatly reducing the switch power losses.

3 BIAS Connect this pin to the regulated output

voltage to maximize system efficiency.

When this pin is above 2.7 V, most of the

ADP3050 operating current will be taken

from the output instead of the input supply.

Leave unconnected if not used.

4 FB This feedback pin senses the regulated output

voltage. Connect this pin directly to the output (fixed output versions).

5 COMP This pin is used to compensate the regulator

with an external resistor and capacitor. This

pin can be used to override the control loop,

but the voltage on this pin should not exceed

about 2 V, as the pin is internally clamped to

ensure a fast transient response. Use a pull-up

resistor if this pin is to be pulled higher than 2 V.

6 SD Use this pin to turn the device on and off. If

this feature is not needed, tie this pin directly

.

to V

IN

7 GND Connect this pin to local ground plane.

8 IN Connect this pin to the input supply voltage.

An input bypass capacitor must be placed

close to this pin to ensure proper regulator

operation.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although this device features proprietary ESD protection circuitry, permanent damage may occur

on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

REV. 0

–3–

Page 4

ADP3050

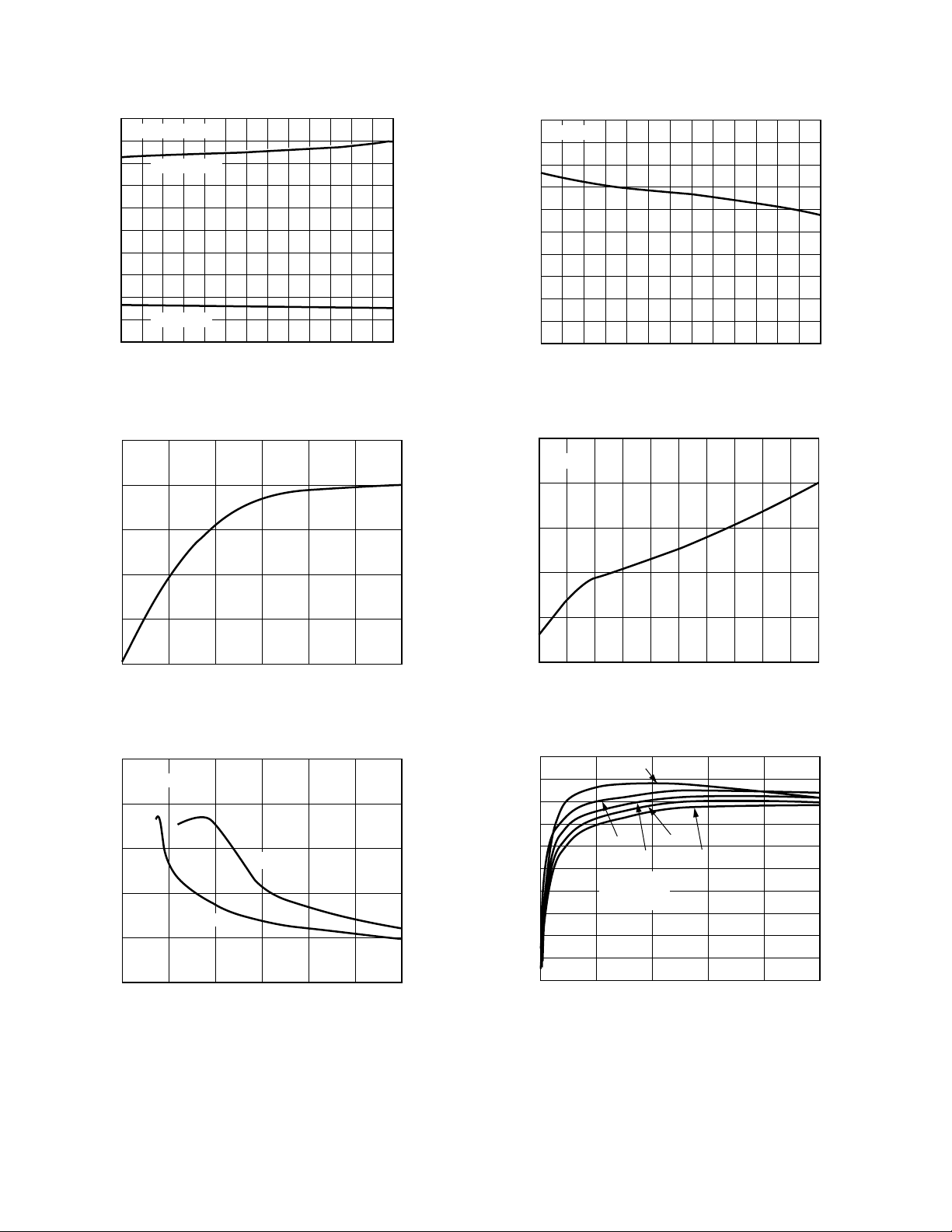

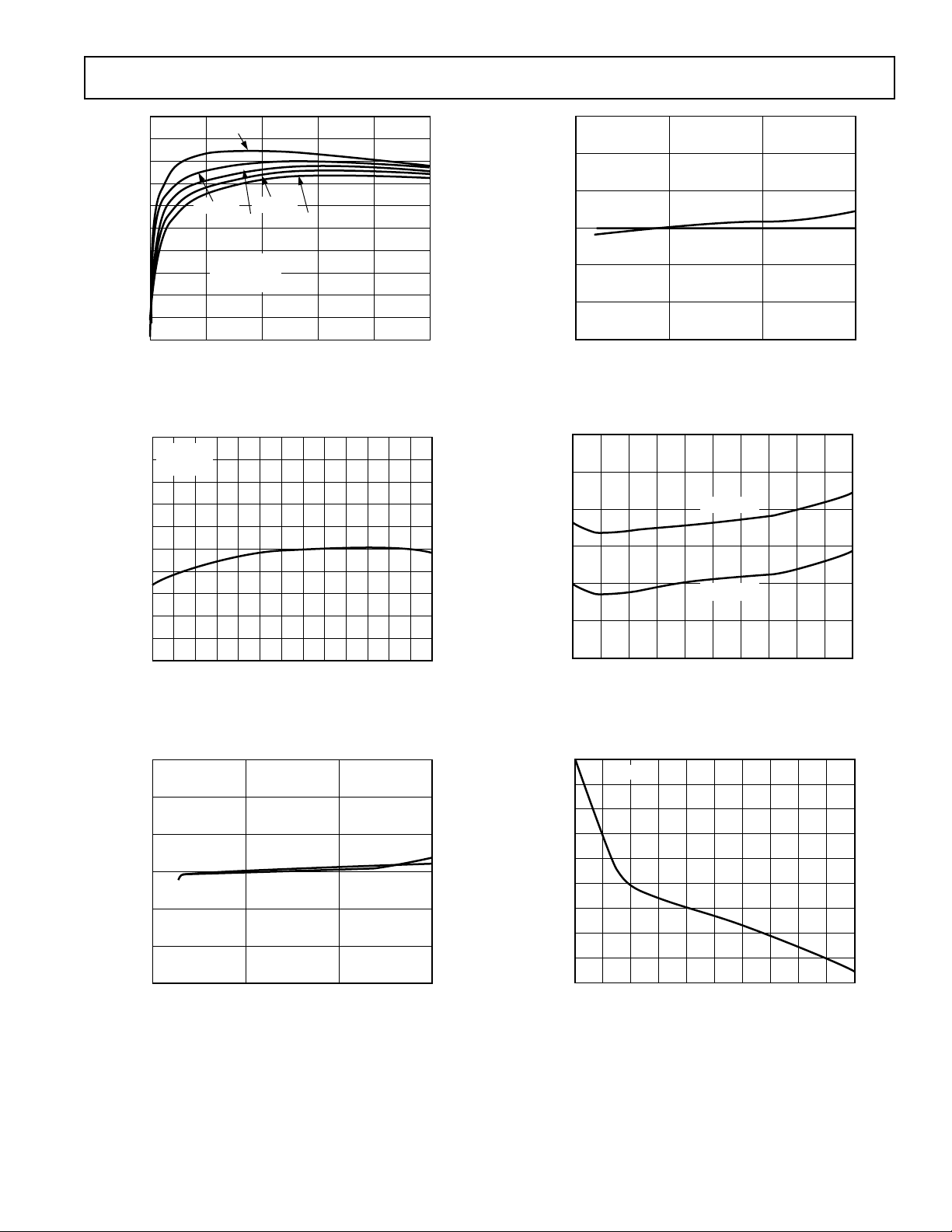

– Typical Characteristics

5.0

VIN = 10V, NO LOAD

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

QUIESCENT OPERATING CURRENT – mA

0.5

0

ⴚ4585ⴚ35

INTO BIAS PIN

INTO VIN PIN

ⴚ25 ⴚ15 ⴚ5

5 152535455565 75

TEMPERATURE – ⴗC

Figure 1. Quiescent Operating Current vs. Temperature

25

20

15

2.0

VIN = 10V

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

AVERAGE OUTPUT CURRENT – A

0.2

0

ⴚ25 ⴚ15 ⴚ5

ⴚ4585ⴚ35

5 152535455565 75

TEMPERATURE – ⴗC

Figure 4. Average Output Current Limit vs. Temperature

25

VIN = 10V

20

15

10

5

SHUTDOWN QUIESCENT CURRENT – A

0

030

10 15 20 25

5

SUPPLY VOLTAGE – V

Figure 2. Shutdown Quiescent Current vs. Supply Voltage

10

BIAS TIED TO V

8

6

4

2

QUIESCENT OPERATING CURRENT – mA

0

030

OUT

V

OUT

V

= 3.3V

OUT

10 15 20 25

5

SUPPLY VOLTAGE – V

= 5V

Figure 3. Quiescent Operating Current vs. Supply Voltage

10

BOOST CURRENT – mA

5

0

0

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

LOAD CURRENT – A

Figure 5. Boost Current vs. Load Current

100

90

80

70

60

50

40

EFFICIENCY – %

30

20

10

0

01k200 400 600 800

VIN = 6V

VIN = 24V

= 12V

V

IN

VIN = 18V

L = 33H

C

IN

C

OUT

VIN = 30V

= 22F

= 100F

OUTPUT CURRENT – mA

Figure 6. 5 V Output Efficiency

1.00.1

–4–

REV. 0

Page 5

ADP3050

INPUT VOLTAGE – V

0

OUTPUT VOLTAGE CHANGE – %

10 20 30

0.6

0.2

0.4

0

ⴚ0.6

ⴚ0.4

ⴚ0.2

V

OUT

= 3.3V

I

LOAD

= 1A

I

LOAD

= 100mA

100

90

80

70

60

50

40

EFFICIENCY – %

30

20

10

0

01k200 400 600 800

= 5V

V

IN

VIN = 12V

VIN = 24V

VIN = 18V

L = 33H

C

= 22F

IN

= 100F

C

OUT

OUTPUT CURRENT – mA

V

IN

= 30V

Figure 7. 3.3 V Output Efficiency

0.5

VIN = 10V

ⴚ0.1

ⴚ0.2

ⴚ0.3

OUTPUT VOLTAGE CHANGE – %

ⴚ0.4

ⴚ0.5

0.4

0.3

0.2

0.1

I

LOAD

0

ⴚ4585ⴚ35

= 1A

ⴚ25 ⴚ15 ⴚ5

5 152535455565 75

TEMPERATURE – ⴗC

Figure 8. Output Voltage Change vs. Temperature

Figure 10. 3.3 V Output Voltage Change vs. Input Voltage

8

7

V

= 5V

6

5

4

MINIMUM INPUT VOLTAGE – V

3

2

0

0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

OUT

V

= 3.3V

OUT

LOAD CURRENT – A

1.00.1

Figure 11. Minimum Input Voltage vs. Load Current

ⴚ0.02

ⴚ0.04

ⴚ0.06

ⴚ0.08

ⴚ0.10

ⴚ0.12

ⴚ0.14

OUTPUT VOLTAGE CHANGE – %

ⴚ0.16

ⴚ0.18

0

VIN = 10V

01.00.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

LOAD CURRENT – A

Figure 12. Load Regulation

0.6

V

= 5V

OUT

0.4

0.2

I

= 1A

0.0

ⴚ0.2

OUTPUT VOLTAGE CHANGE – %

ⴚ0.4

ⴚ0.6

0

LOAD

I

= 100mA

LOAD

10

INPUT VOLTAGE – V

20 30

Figure 9. 5 V Output Voltage Change vs. Input Voltage

REV. 0

–5–

Page 6

ADP3050

0.8

0.7

0.6

VIN = 10V

VSW = 5V/DIV

0.5

0.4

0.3

0.2

SWITCH SATURATION VOLTAGE – V

0.1

0.0

0.1 1.00.2

0.3 0.4 0.5 0.6 0.7 0.8 0.9

LOAD CURRENT – A

Figure 13. Switch Saturation Voltage vs. Load Current

210

VIN = 10V

208

206

204

202

200

198

SWITCHING FREQUENCY – kHz

194

192

190

196

= 250A

I

LOAD

ⴚ

ⴚ

ⴚ25ⴚ15ⴚ

45

35

5

5 152535455565 75

AMBIENT TEMPERATURE – ⴗC

85

Figure 14. Switching Frequency vs. Temperature

0V

= 500mA/DIV

I

L

VIN = 10V

= 5V

V

OUT

= 800mA

I

0A

LOAD

L = 33H

C

= 22F

IN

= 100F

C

OUT

TIME – 1s/DIV

Figure 16. Continuous Conduction-Mode Waveforms

VSW = 5V/DIV

0V

= 500mA/DIV

I

L

0A

TIME – 1s/DIV

VIN = 10V

= 5V

V

OUT

= 100mA

I

LOAD

L = 33H

C

= 22F

IN

= 100F

C

OUT

Figure 17. Discontinuous Conduction-Mode Waveforms

250

200

150

100

SWITCHING FREQUENCY – kHz

VIN = 10V

COMP = 0.4V

50

0

0

NORMALIZED FEEDBACK VOLTAGE – V

0.4 0.6 0.8

Figure 15. Frequency Foldback

V

= 20mV/DIV

5V

1A

0A

1.00.2

OUT

I

LOAD

VIN = 10V

= 5V

V

OUT

= 100mA TO 1A SWITCHED

I

LOAD

L = 33H

C

= 22F

IN

= 100F

C

OUT

TIME – 400s/DIV

Figure 18. Transient Response

–6–

REV. 0

Page 7

ADP3050

VIN = 10V

= 5V

V

OUT

= 19⍀

R

LOAD

L = 33H COILTRONICS

UP2B-330

C

= 22F

IN

= 100F

C

OUT

0V

0A

= 500mA/DIV

I

L

V

= 1V/DIV

OUT

TIME – 100s/DIV

Figure 19. Start-Up from Shutdown

1,500

VIN = 10V, NO LOAD

1,450

1,400

1,350

1,300

1,250

1,200

1,150

TRANSCONDUCTANCE – Mho

1,100

1,050

1,000

ⴚ4585ⴚ35

ⴚ25 ⴚ15 ⴚ5

5 152535455565 75

TEMPERATURE – ⴗC

Figure 20. Error Amplifier Transconductance vs. Temperature

THEORY OF OPERATION

The ADP3050 is a fixed-frequency, current-mode buck regulator.

Current mode systems provide excellent transient response, and

are much easier to compensate than voltage-mode systems. (Refer

to the functional block diagram.) At the beginning of each clock

cycle, the oscillator sets the latch, turning on the power switch.

The signal at the noninverting input of the comparator is a replica

of the switch current (summed with the oscillator ramp). When

this signal reaches the appropriate level set by the output of the

error amplifier, the comparator resets the latch and turns off the

power switch. In this manner, the error amplifier sets the correct

current trip level to keep the output in regulation. If the error

amplifier output increases, more current is delivered to the

output; if it decreases, less current is delivered to the output.

The current sense amplifier provides a signal proportional to

switch current to both the comparator and to a cycle-by-cycle

current limit. If the current limit is exceeded, the latch will be

reset, turning the switch off until the beginning of the next clock

cycle. The ADP3050 has a foldback current limit that reduces

the switching frequency under fault conditions to reduce stress

to the IC and to the external components.

Most of the control circuitry is biased from the 2.5 V internal

regulator. When the BIAS pin is left open, or when the voltage

at this pin is less than 2.7 V, all of the operating current for the

57.6

48.0

38.4

28.8

19.2

MAGNITUDE – dB

ⴚ9.6

ⴚ19.2

ⴚ28.8

ⴚ38.4

9.6

NO LOAD

0

0

1k 10k 100k

FREQUENCY – Hz

220

200

180

160

140

120

100

PHASE – Degrees

80

60

40

20

1M100

Figure 21. Error Amplifier Gain

ADP3050 is drawn from the input supply. When the BIAS pin

is above 2.7 V, the majority of the operating current is then

drawn from this pin (usually tied to the regulator's low-voltage

output) instead of from the higher-voltage input supply. This

can provide substantial efficiency improvements at light-load

conditions, especially for systems where the input voltage is

much higher than the output voltage.

The ADP3050 uses a special drive stage that allows the power

switch to saturate. An external diode and capacitor provide a

boosted voltage to the drive stage that is higher than the input

supply voltage. Overall efficiency is dramatically improved by

using this type of saturating drive stage.

Pulling the SD pin below 0.4 V puts the device in a low-power

mode, shutting off all internal circuitry and reducing the supply

current to under 20 µA.

3.3V

V

OUT

+

4k⍀

C4

100F

R1

C2

1nF

1N5818

12V

V

IN

D1

L1

33H

+

1N914

C3

220nF

C1

22F

D2

1

2

3

4

SWITCH

BOOST

BIAS

FB

GND

SD

COMP

8

IN

7

6

5

U1

ADP3050-3.3

Figure 22. Typical Application Circuit

Setting the Output Voltage

The output of the adjustable version (ADP3050AR) can be set

to any voltage between 1.25 V and 12 V by connecting a resistor

divider to the FB pin as shown in Figure 23.

RR

21

V

12

OUT

.

1=× −

(1)

REV. 0

–7–

Page 8

ADP3050

L1

1N5817

GND

D1

V

1N4148

5V

IN

22H

1

2

3

4

C2

0.01F

SWITCH

BOOST

BIAS

FB

U1

ADP3050

C3

0.22F

R2

C

F

21.5k⍀

D2

20k⍀

C1

+

2 ⴛ 10F

CERAMIC

R1

GND

SD

COMP

8

IN

7

6

5

7.5k⍀

R

C

2.5V

C4

+

2 ⴛ 22F

CERAMIC

C

C

4.7nF

V

OUT

Figure 23. Adjustable Output Application Circuit

APPLICATION INFORMATION

The complete process for designing a step-down switching regulator using the ADP3050 is given in the following sections. Each

section includes a list of recommended devices. These lists do

not include every available device, nor every available manufacturer. They contain only surface-mount devices, but equivalent

through-hole devices can be substituted if needed. In choosing

components, keep in mind what is most important to the design

(efficiency, cost, size, etc.) as these things will ultimately determine which components are used. Also, make sure the design

specifications are clearly defined and that they reflect the worstcase conditions. Key specifications include the minimum and

maximum input voltage, the output voltage and ripple, and the

minimum and maximum load current.

INDUCTOR SELECTION

The inductor value will determine the mode of operation for the

regulator: continuous mode, where the inductor current flows

continuously; or discontinuous mode, where the inductor current

reduces to zero during every switch cycle. Continuous mode is

the best choice for many applications. It provides higher output

power, lower peak currents in the switch, inductor, and diode,

and a lower inductor ripple current (which means lower output

ripple voltage). Discontinuous mode does allow the use of smaller

magnetics, but at a price: lower available load current, and higher

peak and ripple currents. Designs with a high input voltage or a

low load current often operate in discontinuous mode to minimize inductor value and size. The ADP3050 is designed to work

well in both modes of operation.

Continuous Mode

The inductor current in a continuous mode system is a triangular

waveform (equal to the ripple current) centered around a dc value

(equal to the load current). The amount of ripple current is determined by the inductor value, and is usually between 20% and 40%

of the maximum load current. To reduce the inductor size, ripple

currents between 40% and 80% are often used in continuous

mode designs with a high input voltage or a low output current.

The inductor value can be calculated using the following equation:

VV

IN OUT

L

=

−

(MAX)

If

RIPPLE SW

××

V

1

OUT

V

IN

(MAX)

(2)

Where V

lated output voltage, and f

is the maximum input voltage, V

IN(MAX)

is the switching frequency (200 kHz).

SW

is the regu-

OUT

The initial choice for the amount of ripple current may seem arbitrary, but it will serve as a good starting point for finding a standard

off-the-shelf inductor value (i.e., 10 µH, 15 µH, 22 µH, 33 µH, and

47 µH). If a specific inductance value is to be used, simply rearrange

the above equation to find the ripple current. For an 800 mA, 12 V

to 5 V system, and a ripple current of 320 mA (40% of 800 mA) is

chosen, the inductance would be:

−

LH=

12 5

032

.

×

200 10

1

×

5

×= µ

3

12

45 5

.

A 47 µH inductor is the closest standard value, which gives a ripple

current of about 310 mA. The peak switch current is equal to the

load current plus one-half the ripple current (this is also the peak

current for the inductor and the catch diode):

1

I

2

(3)

II

0.8 0.155 0.95 A

=+

SW(PK) OUT(MAX) RIPPLE

=+ =

Pick an inductor with a dc (or saturation) current rating about

20% larger than I

to ensure that the inductor is not running

SW(PK)

near the edge of saturation. For this example, 1.20 ⫻ 0.95 A =

1.14 A, so use an inductor with a dc current rating of at least 1.2 A.

The maximum switch current is internally limited to 1.5 A, and

this limit, along with the ripple current, will determine the maximum load current the system can provide.

If the load current decreases to below one-half the ripple current,

the regulator will operate in discontinuous mode.

Discontinuous Mode

For load currents less than around 0.5 A, discontinuous mode

operation can be used. This will allow the use of a smaller inductor, but the ripple current will be much higher (which means a

higher output ripple voltage). If a larger output capacitor must be

used to reduce the output ripple voltage, the overall system may

actually take up more board area than if a larger inductor was

used. The operation and equations for the two modes are quite

different, but the boundary between these two modes occurs

when the ripple current is equal to twice the load current (when

I

RIPPLE

= 2 ⫻ I

). From this we can use Equation 2 to find the

OUT

minimum inductor value needed to keep the system in continuous mode operation (solve for the inductor value with I

2 ⫻ I

OUT

).

VV

DIS

=

IN OUT

L

−

(MAX)

2

If

×

OUT SW

1

××

V

OUT

V

IN

(MAX)

=

RIPPLE

(4)

Using an inductor below this value will cause the system to operate

in discontinuous mode. For a 400 mA, 24 V to 5 V system:

−

L

.

24 5

≤

DIS

×

204

≤µ

24 7

.

×

200 10

H

1

×

5

×

3

24

If the chosen inductor value is too small, the internal current

limit will trip each cycle and the regulator will have trouble

providing the necessary load current.

Inductor Core Types and Materials

Many types of inductors are currently available. Numerous core

styles along with numerous core materials often make the selection process seem even more confusing. A quick overview of the

–8–

REV. 0

Page 9

ADP3050

types of inductors available will make the selection process a

little easier to understand.

Open-core geometries (bobbin core) are usually less expensive than

closed-core geometries (toroidal core) and can be a good choice for

some applications, but care must be taken when they are used. In

open-core inductors, the magnetic flux is not completely contained

inside the core. The radiating magnetic field will generate ElectroMagnetic Interference (EMI), often inducing voltages onto nearby

circuit board traces. These inductors may not be suitable for systems

that contain very high accuracy circuits or sensitive magnetics. A few

manufacturers have “semiclosed” and “shielded” cores, where an

outer magnetic shield surrounds a bobbin core. These devices have

less EMI than the standard open core, and will usually be smaller

than a closed core.

Most core materials used in surface-mount inductors are either

powdered iron or ferrite. For many designs, material choice will

be arbitrary, but the properties of each material should be recognized. Ferrites will have lower core losses than powdered iron,

but the lower loss means a higher price. Powdered iron cores will

saturate softly (the inductance gradually reduces as current rating

is exceeded), while ferrite cores will saturate much more abruptly

(the inductance rapidly reduces). Kool Mµ

®

is one type of ferrite

that is specially designed to minimize core losses and heat generation (especially at switching frequencies above 100 kHz), but

again, these devices will be more expensive.

Do not overlook the dc winding resistance (DCR) of the inductor.

A high DCR can decrease the system efficiency by 2%–5% for

lower output voltages at heavy loads. To obtain a lower DCR

means using a physically larger inductor, so a trade-off in size

and efficiency must be made. The power loss due to this resistance is simply I

system with an inductor DCR of 100 mΩ, the winding resistance will dissipate (0.8

2

⫻ DCR. For an 800 mA, 5 V to 3.3 V

OUT

2

⫻ 0.1 Ω) = 64 mW. This represents a

power loss to the system of 64 mW/(3.3 V ⫻ 800 mA) = 2.4%.

Typical DCR values will be between 10 mΩ and 200 mΩ.

Choosing an Inductor

Several considerations must be made when choosing an inductor:

cost, size, EMI, core and copper losses, and maximum current

rating. Follow the steps below to choose an inductor that is right

for the system (refer to the calculations and descriptions from the

previous sections). Table I shows an extensive list of inductors

that can be used. Contact the manufacturers for their full product

offering, availability and pricing. They offer many more values

and package sizes to suit numerous applications.

1. Choose a mode of operation, then calculate the inductor

value using the appropriate equation. For continuous mode

systems, a ripple current of 40% the maximum load current

is a good starting point. The inductor value can then be

increased or decreased if desired.

2. Calculate the peak switch current (this will be the maximum

current seen by the inductor). Make sure that the dc (or

saturation) current rating of the inductor is high enough

(around 1.2 times the peak switch current). Inductors with

dc current ratings of at least 1 A should be used for all designs.

This will provide a safety margin for start-up and fault conditions where the inductor current will be higher than normal.

If an inductor’s current rating is exceeded, the core will

saturate, causing the inductance value to decrease and the

inductor’s temperature to increase.

Kool Mµ is a registered trademark of Magnetics, Inc.

REV. 0

–9–

3. Estimate the dc winding resistance based on the inductance

value. A good rule of thumb is to allow about 5 mΩ of resistance per µH of inductance.

4. Pick the core material and type. First decide if an open-core

inductor can be used with the design. If you are not sure,

you can always get a few samples of each type (open core,

semi-closed core, shielded core, and closed core) and try

them out. Do not be discouraged from using open core

inductors simply because they require a little extra care; just

be aware of what to look for if you do use them. They are

quite small and inexpensive, and are used successfully in

many different applications.

OUTPUT CAPACITOR SELECTION

The ADP3050 can be used with any type of output capacitor.

The trade-offs between price, component size, and regulator

performance can be evaluated to determine the best choice for

each application. The Effective Series Resistance (ESR) of the

capacitor plays an important role in both the loop compensation

and the system performance. The ESR provides a “zero” in the

feedback loop, therefore the ESR value must be known so that

the loop can be compensated correctly (most manufacturers

specify maximum ESR in their data sheets). The capacitor ESR

also contributes to the output ripple voltage (V

). Solid tantalum or multilayer ceramic capacitors are

I

RIPPLE

RIPPLE

= ESR ⫻

recommended, providing good performance with a small size

and reasonable cost.

Solid tantalum capacitors have a good combination of low ESR

and high capacitance, and are available from several different

manufacturers (AVX TPS series, Sprague 593D series, Kemet

T495 series, NEMCO LSR series). Capacitance values from 22 µF

to more than 500 µF can be used, but values of 47 µF to 220 µF

will be sufficient for most designs. A smaller value can be used, but

ESR is size-dependent, so a smaller device will have a higher ESR.

Ensure that the capacitor’s ripple current rating is larger than the

inductor ripple current (the ripple current will flow into the output

capacitor).

Multilayer ceramic capacitors can be used in applications where

minimum output voltage ripple is a priority. They have a very low

ESR (a 22 µF ceramic can have an ESR one-fifth that of a 22 µF

solid tantalum), but may require more board area for the same

value of output capacitance. A few manufacturers have recently

improved upon their low voltage ceramic capacitors, providing a

smaller package with a lower ESR (Tokin, Murata, Taiyo Yuden

and AVX). Several ceramics can be used in parallel to give an

extremely low ESR and a good value of capacitance. If your design

is very cost-sensitive and not severely space-limited, several aluminum electrolytic capacitors can be used in parallel (their size and

ESR are larger than ceramic and solid tantalum). OS-CON

capacitors can also be used, but they are typically larger and

more expensive than ceramic or solid tantalum capacitors.

Choosing an Output Capacitor

Use the following steps to choose an appropriate capacitor.

Several choices for output capacitors are contained in Table III.

1. Decide the maximum output ripple voltage for the design,

and this will determine your maximum ESR (remember

that V

RIPPLE

≈ ESR ⫻ I

). Typical output ripple voltages

RIPPLE

range between 0.5% and 2% of the output voltage. To lower

the output voltage ripple, there are only two choices: either

increase the inductor value, or use an output capacitor with a

lower ESR.

Page 10

ADP3050

Table I. Inductor Selection Guide

Max Max Package

Vendor/ Value I

DC

DCR Core Core Dimensions (mm)

Model (µH) (A) (Ω) Type Material W L H

Sumida

CD73 10 1.4 0.08 Open Ferrite 7.0 7.8 3.5

CD73 15 1.2 0.10 Open Ferrite 7.0 7.8 3.5

CD73 22 1.1 0.13 Open Ferrite 7.0 7.8 3.5

CR75 22 1.5 0.11 Open Ferrite 7.0 7.8 5.0

CR75 33 1.2 0.13 Open Ferrite 7.0 7.8 5.0

CR75 47 1.1 0.18 Open Ferrite 7.0 7.8 5.0

CDRH73 10 1.7 0.08 S.C. Ferrite 7.3 7.3 3.4

CDRH73 15 1.3 0.13 S.C. Ferrite 7.3 7.3 3.4

CDRH6D38 22 1.3 0.10 S.C. Ferrite 6.7 6.7 4.0

CDRH6D38 33 1.1 0.12 S.C. Ferrite 6.7 6.7 4.0

CDR105B 22 1.4 0.08 S.C. Ferrite 9.0 10.0 5.0

CDR105B 33 1.2 0.11 S.C. Ferrite 9.0 10.0 5.0

CDR105B 47 1.0 0.14 S.C. Ferrite 9.0 10.0 5.0

COILCRAFT

DO1608 10 1.1 0.14 Open Ferrite 4.6 6.6 2.9

DO3316 10 3.8 0.03 Open Ferrite 9.4 13.0 5.1

DO3316 15 3.0 0.04 Open Ferrite 9.4 13.0 5.1

DO3316 22 2.6 0.05 Open Ferrite 9.4 13.0 5.1

DO3316 33 2.0 0.09 Open Ferrite 9.4 13.0 5.1

DO3316 47 1.6 0.14 Open Ferrite 9.4 13.0 5.1

DT3316 10 2.0 0.06 S.C. Ferrite 9.4 13.0 5.1

DT3316 15 1.8 0.06 S.C. Ferrite 9.4 13.0 5.1

COILTRONICS*

CTX10-1 10 1.9 0.04 Toroid Kool Mµ 8.9 8.9 4.2

CTX20-1 20 1.0 0.14 Toroid Kool Mµ 8.9 8.9 4.2

CTX10-2 10 2.5 0.03 Toroid Kool Mµ 8.9 8.9 6.0

CTX20-2 20 1.3 0.11 Toroid Kool Mµ 8.9 8.9 6.0

CTX33-2 33 1.5 0.09 Toroid Kool Mµ 8.9 8.9 6.0

CTX10-2 40 1.3 0.12 Toroid Kool Mµ 8.9 8.9 6.0

CTX10-1P 10 1.6 0.03 Toroid P.I. 8.9 8.9 4.2

CTX15-1P 15 1.2 0.05 Toroid P.I. 8.9 8.9 4.2

CTX20-1P 20 1.0 0.08 Toroid P.I. 8.9 8.9 4.2

CTX20-2P 20 1.3 0.11 Toroid P.I. 8.9 8.9 6.0

UP2-330 33 1.7 0.10 Open Ferrite 8.8 10.6 5.9

UP2-470 47 1.4 0.15 Open Ferrite 8.8 10.6 5.9

TOKIN

SSB64 10 1.2 0.12 Open Ferrite 6.3 6.3 6.0

SSB64 15 1.0 0.15 Open Ferrite 6.3 6.3 6.0

SSB84 10 1.4 0.10 Open Ferrite 8.3 8.3 6.0

SSB84 15 1.2 0.11 Open Ferrite 8.3 8.3 6.0

SSB84 22 1.2 0.16 Open Ferrite 8.3 8.3 6.0

S.C. = semiclosed, P.I. = powdered iron, Toroid is a closed core.

*Coiltronics toroidal inductors consist of two windings on one core that can be connected in parallel (for a higher current rating) or in series (for a higher inductance value);

consult Coiltronics data sheet.

Table II. Inductor Manufacturers

Company Phone Fax Web Site

Sumida (USA) (847) 956-0666 (847) 956-0702 www.sumida.com

Sumida (Japan) 81-3-3607-5111 81-3-3607-5144 www.sumida.com

Coilcraft (847) 639-6400 (847) 639-1469 www.coilcraft.com

Coiltronics (561) 241-7876 (561) 241-9339 www.coiltronics.com

Tokin (USA) (408) 432-8020 (408) 434-0375 www.tokin.com

Tokin (Japan) 81-22-211-1281 81-22-211-0975 www.tokin.com

–10–

REV. 0

Page 11

ADP3050

2. Decide what type of capacitor to use (tantalum, ceramic,

etc.), then look at the table for some possible devices. Many

more values, sizes, and voltage ratings are available, so contact

each manufacturer for a complete product list. If a certain type

of capacitor must be used and space permits, simply use

several devices in parallel to reduce the total ESR.

3. Check the capacitor voltage rating and ripple current rating

to ensure it will work for your application (these ratings are

derated for higher temperatures, so always check the

manufacturer’s data sheet).

4. Make sure the final choice for the output capacitor has been

optimized for cost, size, availability, and performance while

still meeting the required capacitance. The recommended

capacitance is in the 47 µF to 220 µF range.

CATCH DIODE SELECTION

The recommended catch diode is a type 1N5818 Schottky or an

equivalent. The low forward voltage drop (450 mV typical at 1 A)

and fast switching speed of a Schottky rectifier provide the best

performance and efficiency. The 1N5818 is rated at 30 V reverse

Table III. Capacitor Selection Guide

Max Package

Vendor/ Value ESR* Voltage Dimensions (mm)

Series (F) (⍀) (V) Type W L H

AVX

TPS 100 0.150 6.3 Tantalum 3.2 6.0 2.6

TPS 47 0.150 16 Tantalum 4.3 7.3 2.9

TPS 100 0.100 10 Tantalum 4.3 7.3 2.9

TPS 100 0.125 16 Tantalum 4.3 7.3 2.9

Y5V 10 ~0.040 10 MLC 1.6 3.2 1.5

Y5V 10 ~0.040 16 MLC 2.5 3.2 1.7

Y5V 18 ~0.040 10 MLC 2.5 3.2 1.7

Y5V 22 ~0.040 10 MLC 2.5 3.2 1.7

Sprague

593D 47 0.150 16 Tantalum 4.3 7.3 2.8

593D 68 0.150 16 Tantalum 4.3 7.3 2.8

593D 100 0.100 10 Tantalum 4.3 7.3 2.8

593D 100 0.100 16 Tantalum 4.3 7.3 4.0

Tokin

CU 10 ~0.040 10 MLC 1.6 3.2 1.6

CU 10 ~0.040 25 MLC 2.7 5.7 2.5

CU 18 ~0.040 25 MLC 5.0 5.7 2.5

CU 10 ~0.040 50 MLC 5.0 5.7 3.0

CU 22 ~0.030 25 MLC 5.0 5.7 3.0

*Maximum ESR ratings at 100 kHz; MLC = multilayer ceramic.

voltage and 1 A average forward current. For lower input voltages,

use a lower voltage Schottky to reduce the diode forward voltage

drop and increase overall system efficiency (i.e., a 12 V to 5 V

system does not need a 30 V diode). For automotive applications,

a 60 V Schottky may be necessary. The average forward current for

the catch diode can be calculated by:

–

VV

II

DIODE OUT

=×

(AVG)

IN OUT

V

IN

(5)

For the earlier continuous mode example (12 V to 5 V at 800 mA),

the average diode current would be:

–

IA

DIODE(AVG)

12 5

12

. =× =08

047.

For this system, a 1N5817 would be a good choice (rated at 20 V

and 1 A). Do not use catch diodes rated less than 1 A. Even though

the average current can be less than 1 A under normal operating

conditions, since the diode current will be much higher under fault

conditions. The worst case fault condition for the diode occurs when

the regulator becomes slightly overloaded (sometimes called a soft

REV. 0

Table IV. Capacitor Manufacturers

Company Phone Fax Web Address

AVX (803) 448-9411 (803) 448-1943 www.avxcorp.com

Kemet (864) 963-6300 (864) 963-6521 www.kemet.com

Murata (USA) (800) 831-9172 (770) 436-3030 www.murata.com

Nemco (800) 227-4058 (650) 571-0825 www.nemcocaps.com

Sprague (207) 324-4140 (207) 324-7223 www.vishay.com

Tokin (USA) (408) 432-8020 (408) 434-0375 www.tokin.com

Tokin (Japan) 81-22-211-1281 81-22-211-0975 www.tokin.com

Taiyo Yuden (USA) (800) 348-2496 (847) 925-0899 www.t-yuden.com

Taiyo Yuden (Japan) 81-33-833-5441 81-33-835-4754 www.t-yuden.com

–11–

Page 12

ADP3050

short). This is usually only a problem when the input voltage to output voltage ratio is greater than 2.5. Under this condition, the load

current needed is slightly more than the regulator can provide. The

output voltage then droops slightly, and the switch stays on every

cycle until the internal current limit is reached. Under this condition,

the load current can reach around 1.2 A. For example: a system with

an input voltage of 24 V and an output voltage of 5 V, if a gradual

overload causes the output voltage to droop to 4 V, the average

diode current would be:

–

IA

DIODE(AVG)

24 4

24

=× =12

10..

If the system must survive such gradual overloads for a prolonged

period of time, ensure that the diode chosen can survive these

conditions. A larger 2 A or 3 A diode can be used if necessary.

Choosing a Catch Diode

Use the following steps to pick an appropriate catch diode.

Table V shows several Schottky rectifiers with different reverse

voltage and forward current ratings.

1. The average diode current rating must be sufficient to provide

the required load current (see above calculations). Diodes

rated below 1 A should not be used, even if the average diode

current is much lower.

2. The reverse voltage rating of the catch diode should be at

least the maximum input voltage. Often a higher rating is

chosen (1.2 times the maximum input voltage) to provide a

safety margin.

INPUT CAPACITOR SELECTION

The input bypass capacitor plays an important role in proper

regulator operation, minimizing voltage transients at the input

and providing a short local loop for the switching current. Place

this capacitor close to ADP3050 between the V

and GND pins

IN

using short, wide traces. This input capacitor should have an rms

ripple current rating of at least:

II

CI OUT

N(RMS)

V

OUT

IN

V

V

V

OUT

IN

2

≥× −

(6)

This rating is crucial, as the input capacitor must be able to

withstand the large current pulses present at the input of a stepdown regulator. Values of 20 µF to 50 µF are typical, but the

main criteria for capacitor selection should be the ripple current

and voltage ratings.

Ceramics are an excellent choice for input bypassing due to their

low ESR and high ripple current rating. Ceramics are especially

suited for high input voltages, and are available from many different manufacturers. Tantalums are often used for input bypassing,

but precautions must be taken, as they occasionally fail when

subjected to large inrush currents during power-up. These

surges are common when the regulator input is connected to a

battery or high-capacitance supply. Several manufacturers now

offer surface-mount solid tantalum capacitors that are surge

tested (AVS TPS series, Sprague 593D series, Kemet T495 series,

and NEMCO LSR series), but even these devices can fail if the

current surge occurs when the capacitor voltage is near its maximum rating. For this reason, a 2:1 derating is suggested for

tantalum capacitors used in applications where large inrush currents

are present (i.e., a 20 V tantalum should only be used for an input

voltage up to 10 V). Aluminum electrolytics are the cheapest choice,

but it takes several in parallel to get a good rms current rating.

OS-CON capacitors have a good ESR and ripple current rating,

but they are typically larger and more costly. Refer to Table IV

for a list of capacitor manufacturers.

DISCONTINUOUS MODE RINGING

When operating in discontinuous mode, high frequency ringing

will appear at the switch node when the inductor current has

decreased to zero. This ringing is normal, and is not a result of

loop instability. It is caused by the switch and diode capacitance

reacting with the inductor to form a damped sinusoidal ringing.

This ringing is usually in the range of several megahertz, and is

not harmful to normal circuit operation.

SETTING THE OUTPUT VOLTAGE

The fixed voltage versions of the ADP3050 (3.3 V and 5 V) have

the feedback resistor divider included on-chip. For the adjustable

version, the output voltage is set using two external resistors.

Referring to Figure 23, pick a value for R1 between 10 kΩ and

20 kΩ, then calculate the appropriate value for R2 using:

Table V. Schottky Diode Selection Guide

V

1 A Diodes 2 A Diodes 3 A Diodes

R

15 V 10BQ15 30BQ15

20 V 1N5817 B220 SK32

SK12 B320

B120 NSQ03A02

EC10QS02

30 V V1N5818 B230 SK33

SK13 EC21QS03 B330

B130 NSQ03A03

MBRS130

EC10QS03

40 V 1N5819 B240 SK34

SK14 EC21QS04 B340

B140 MBRS340

MBRS140 30BQ040

10BQ040 NSQ03A04

EC10QS04

RR

21

V

OUT

.

120

1=× −

(7)

It is important to note that the accuracy of these resistors directly

affects the accuracy of the output voltage. The FB pin threshold

variation is ±3%, and the tolerances of R1 and R2 will add to this

Table VI. Schottky Diode Manufacturers

Company Phone Fax

Motorola (602) 244-3576 (602) 244-4015 www.mot.com

MBRSxxx

Diodes, Inc. (805) 446-4800 (805) 446-4850 www.diodes.com

1N58xx, Bxxx, SKxxx

International Rectifier (310) 322-3331 (310) 322-3332 www.irf.com

10BQxxx, 30BQxxx

Nihon Inter Electronic (USA) (661) 867-2555 (661) 867-2698

Nihon Inter Electronic (Japan) 81-33-343-3411 81-33-343-7377

ECxxxxxx, NSQxxxx

–12–

REV. 0

Page 13

ADP3050

to determine the total output variation. Use 1% resistors placed

close to the FB pin to prevent noise pick up.

FREQUENCY COMPENSATION

The ADP3050 uses a unique compensation scheme that allows the

use of any type of output capacitor. The designer is not limited to a

specific type of capacitor nor a specific ESR range. External compensation allows the designer to optimize the loop for transient response

and system performance. The values for R

and CC will set the

C

pole and zero locations for the error amplifier to compensate the

regulator loop.

For tantalum output capacitors, the typical compensation values

are R

= 4 kΩ and CC = 1 nF; for ceramics, the typical values

C

= 4 kΩ and CC = 4.7 nF. These values may not be opti-

are R

C

mized for all designs, but they should provide a good starting

point for selecting the final compensation values. Other types of

output capacitors will require different values of C

between

C

0.5 nF and 10 nF. Typically, the lower the ESR of the output

capacitor, the larger the value for C

. Normal variations in

C

capacitor ESR, output capacitance, and inductor value (due

to production tolerances, changes in operating point, changes

in temperature) will affect the loop gain and phase response.

Always check the final design over its complete operating range

to ensure proper regulator operation.

Adjusting the R

and CC values can optimize the compensation for

C

your system. Use the typical values above as a starting point, then

try increasing and decreasing each independently and observing the

transient response. An easy way to check the transient response of

the design is by observing the output while pulsing the load current

at a rate of around 100 Hz to 1 kHz. There should be some slight

ringing at the output when the load pulses, but this should not be

excessive (just a few rings). The frequency of this ringing shows

the approximate unity gain frequency of the loop. Again, always

check the design over its full operating range of input voltage,

output current, and temperature to ensure that the loop is compensated correctly.

In addition to setting the zero location, R

also sets the high

C

frequency gain of the error amplifier. If this gain is too large,

output ripple voltage will appear at the COMP pin (the output

of the error amplifier) with enough amplitude to interfere with

normal regulator operation. If this happens, subharmonic

switching will occur (the pulsewidth of the switch waveform will

change, even though the output voltage stays regulated). The

voltage ripple at the COMP pin should be kept below about 100

mV to prevent this from occurring. The amount of ripple can be

estimated by the following formula, where g

fier transconductance (g

V g R I ESR

COMP, RIPPLE m C RIPPLE

= 1,250 µMho):

m

=×

()

××

()

is the error ampli-

m

V

FB

×

(8)

V

OUT

For example: a 12 V to 5 V, 800 mA regulator with an inductor

of L = 47 µH has I

= 310 mA (example from earlier section);

RIPPLE

if a 100 µF tantalum output capacitor with a maximum ESR of

100 mΩ and compensation values of R

= 4 kΩ and CC = 1 nF

C

are used. The ripple voltage at the COMP pin will be:

−

V

COMP, RIPPLE

.

120

×=

.

50

37 2

=×××

1 250 10 4 10 0 310 0 1

,..

()

. mV

63

××

()

If this ripple voltage were more than 100 mV, RC would need to

be decreased to prevent subharmonic switching. Typical values

for R

will be in the range of 2 kΩ to 10 kΩ.

C

For output voltages greater than 5 V, it may be necessary to add a

small capacitor in parallel with R2, as shown in Figure 23. This

will improve stability and transient response. For tantalum output

capacitors, the typical value for C

capacitors, the typical value for C

CURRENT LIMIT/FREQUENCY FOLDBACK

is 100 pF. For ceramic output

F

is 400 pF.

F

The ADP3050 uses a cycle-by-cycle current limit to protect the

device under fault and high stress conditions. When the current

limit is exceeded, the power switch turns off until the beginning

of the next oscillator cycle. If the voltage on the feedback pin

drops below 80% of its nominal value, the oscillator frequency

starts to decrease (see Figure 15 in the Typical Performance

Characteristics section). The frequency gradually reduces to a

minimum value of around 80 kHz (this minimum occurs when

the feedback voltage falls to 30% of its nominal value). This

reduces the power dissipation in the IC, the external diode, and

the inductor during short circuit conditions. This frequency

foldback method provides complete device fault protection without interfering with the normal device operation.

BIAS PIN CONNECTION

To help improve efficiency, most of the internal operating current

can be drawn from the lower voltage regulated output voltage

instead of from the input supply. For example, if the input voltage

is 24 V and the output voltage is 5 V, a quiescent current of 4 mA

will waste 96 mW if drawn from the input supply, but only 20 mW

is drawn from the regulated 5 V output. This power savings will be

most evident at high input voltages and low load currents. The output voltage must be 3 V or higher to take advantage of this feature.

BOOSTED DRIVE STAGE

An external capacitor and diode are used to provide the boosted

voltage needed for the special drive stage. If the output voltage is

above 4 V, connect the anode of the boost diode to the regulated

output; for output voltages less than or equal to 3 V, connect it to

the input supply. For some low voltage systems (i.e., 5 V to 3.3 V

converters), the anode of the boost diode can be connected to

either the input or output voltage. During switch off-time, the

boost capacitor is charged up to the voltage at the anode of the

boost diode. When the switch turns on, this voltage is added to

the switch voltage (the boost diode is reverse-biased) providing a

voltage higher than the input supply. The peak voltage appearing

on the BOOST pin will be the sum of the input voltage and the

boost voltage (either V

IN

+ V

or 2 ⫻ VIN). Ensure that this peak

OUT

voltage does not exceed the BOOST pin maximum rating of 45 V.

For most applications, a 1N4148 or 1N914 type diode can be

used with a 220 nF capacitor. A 470 nF capacitor may be needed

for output voltages between 3 V and 4 V. The boost capacitor

should have an ESR less than 2 Ω to ensure that it will be adequately

charged up during switch off-time. Most any type of film or ceramic

capacitor can be used.

START-UP/MINIMUM INPUT VOLTAGE

For most designs, the regulated output voltage provides the

boosted voltage for the drive stage. During startup, the output

voltage is zero, so there is no boosted supply for the drive stage.

REV. 0

–13–

Page 14

ADP3050

To deal with this problem, the ADP3050 contains a backup

drive stage to get everything started. As the output voltage

increases, so will the boost voltage. When the boost voltage

reaches around 2.5 V, the switch drive will transition smoothly

from the backup driver to the boosted driver. If the boost

voltage should decrease below around 2.5 V (i.e., short circuit,

overload condition), the backup stage will again take over to

provide switch drive. The minimum input voltage needed for

the ADP3050 to function correctly is about 3.6 V (this will

ensure proper operation of the internal circuitry), but a small

amount of headroom is needed for all step-down regulators.

The following formula gives the approximate minimum input

voltage needed for a given system, where V

is the switch

SAT

saturation voltage (see Figure 13 for the appropriate value of

V

). Figure 11 also shows the typical minimum input voltage

SAT

needed for 3.3 V and 5 V systems.

VV

+

V

IN

(MIN)

OUT SAT

=

.

085

(9)

THERMAL CONSIDERATIONS

Several factors contribute to IC power dissipation: ac and dc

switch losses, boost current, and quiescent current. The following

formulas can be used to calculate these losses to determine the

power dissipation of the IC. These formulas assume continuous

mode operation, but they provide a reasonable estimate for discontinuous mode systems (do not use these formulas to calculate

efficiency at light loads).

Switch loss:

PIV

=××

SW OUT SAT

V

OUT

+× ××

tI Vf

()

OV OUT IN SW

V

IN

(10)

Boost current loss:

2

(11)

V

IN

P

BOOST

IV

OUTSWOUT

=×

β

Quiescent current loss:

where V

is ~0.6 V at I

SAT

=×

()

Q IN Q OUT BIAS

OUT

+×

()

(12)

= 800 mA (taken from Figure 13), f

SW

PV I V I

is the switch frequency (200 kHz), tOV is the switch current/voltage

β

overlap time (~50 ns),

switch (~50), I

and I

BIAS

is the quiescent current drawn from VIN (~1 mA)

Q

is the quiescent current drawn from V

For example: for a 5 V to 3.3 V system with I

P

=××

08 06

SW

50 10 0 8 5 0 200 10 357

()

PmW

PmW

−

× ××× ×

=× =

BOOST

=×

510 33410 18

()

Q

is the current gain of the NPN power

SW

(~4 mA).

OUT

= 800 mA:

OUT

33

.

.

.

93

..

085033

.

50

−−

33

+××

()

+

50

.

2

.

35

.

.

=

mW

=

For a total IC power dissipation of:

PPPP

=+ +

TOTAL SW BOOST Q

mW

= 410

(13)

The ADP3050 uses a thermally enhanced SO-8 package with a

package thermal resistance, θ

, of around 80°C/W for a four-

JA

layer board (poor layout techniques will result in a higher thermal

resistance). This allows the ADP3050 to provide 1 A load currents

in an SO-8 package. The maximum die temperature, T

, can be

J

calculated using the thermal resistance and the maximum ambient

temperature:

TT P

=+ ×θ

A A TOTAL

J

J

(14)

For the previous example (5 V to 3.3 V at 800 mA system, SO-8

thermally enhanced package using good layout techniques) with

a worst-case ambient temperature of 70°C:

T/.

=°+° × = °70 80 0 41 103CCW C

J

The maximum operating junction (die) temperature is 125°C, so

this system will operate within the safe limits of the ADP3050.

Check the die temperature at minimum and maximum supply

voltages to ensure proper operation under all conditions. The PC

board and its copper traces will provide sufficient heat-sinking,

but be sure to follow the layout suggestions in the Board Layout

Guidelines section. For any design that combines high output

current with high duty cycle and/or high input voltage, the junction temperature must be calculated to ensure normal operation.

Always use the equations in this section to estimate the power

dissipation.

BOARD LAYOUT GUIDELINES

A good board layout is essential when designing a switching

regulator. The high switching currents along with parasitic

wiring inductances can generate significant voltage transients and

cause havoc in sensitive circuits. For best results, keep the main

switching path as tight as possible (keep L1, D1, C

, and C

IN

OUT

close together) and minimize the copper area of the SWITCH and

BOOST nodes (without violating current density requirements) to

reduce the amount of noise coupling into other sensitive nodes.

L1

V

GND

IN

C

IN

IN

ADP3050

+

GND

SWITCH

C

D1

OUT

V

OUT

+

GND

Figure 24. Main Switching Path

The external components should be located as close to the

ADP3050 as possible. For best thermal performance, use wide

copper traces for all IC connections, and always connect the

GND pin to a large piece of copper or ground plane. The additional copper will improve heat transfer from the IC, greatly

reducing the package thermal resistance. Further improvements of the thermal performance can be made by using

multilayer boards and using vias to transfer heat to the other

layers. A single layer board layout is shown in Figure 25. The

amount of copper used for the input, output, and ground

traces can be reduced, but were made large to improve the

thermal performance. For the 5 V and 3.3 V versions, leave

out R1 and R2; for the Adjustable version, remove the trace

that shorts out R2. Route all sensitive traces and components,

such as those associated with the feedback and compensation away

from the BOOST and SWITCH traces.

–14–

REV. 0

Page 15

OUTPUT

GROUND

INPUT

ADP3050

ground), but its operation is quite different. For this topology,

the feedback pin is grounded and the GND pin is tied to the

negative output, allowing the feedback network of the IC to

regulate the negative output voltage.

C1

L1

D2

R2 R1 CC RC

C2

C3

D1

ADP3050

Figure 25. Recommended Board Layout

TYPICAL APPLICATIONS

5 V to 3.3 V Buck (Step-Down) Regulator

The circuit in Figure 26 shows the ADP3050 in a buck configuration. It is used to generate 3.3 V regulated output from 5 V

input voltage with the following specifications:

= 4.5 V to 5.5 V

V

IN

= 3.3 V

V

OUT

I

= 0.75 A

OUT

I

= 0.4 A ⫻ 0.75 A = 0.3 A

1N5817

GND

D1

SD

V

IN

RIPPLE

V

OUT RIPPLE

5V

22H

C3

0.22F

+

= 50 mV

L1

D2

1N4148

C1

22F

1

SWITCH

2

BOOST

3

BIAS

4

FB

ADP3050-3.3

C2

0.01F

U1

GND

COMP

SD

3.3V

V

OUT

+

C5

7.5k⍀

100F

R1

C4

1nF

8

IN

7

6

5

100F

C5

+

V

OUT

ⴚ5V @ 0.5A

SD

V

GND

L1

47H

1N5818

12V

IN

D2

1N4148

C3

0.22F

D1

+

C1

22F

NC

1

SWITCH

2

BOOST

3

BIAS

4

FB

ADP3050-5

C2

0.01F

U1

GND

SD

COMP

8

IN

7

6

5

R1

5.1k⍀

C4

3.3nF

Figure 27. Inverting (Buck-Boost) Regulator

The design procedure used for the standard buck converter cannot

be used for a buck-boost converter due to fundamental differences

in how the output voltage is generated. The switch currents in the

buck-boost are much higher than in the standard buck converter,

thus lowering the available load current. To calculate the maximum

output current for a given maximum switch current use the following

equation:

V

IN

+

VV

IN OUT

××× +

fLVV

2

SW IN OUT

×

×

VV

IN OUT

()

(15)

where I

and V

IN

I

OUT

(MAX)

=

I

SW

SW(MAX)

−

(MAX)

is the switch current limit rating of the ADP3050

is the minimum input voltage. The inductor ripple current

can be estimated using the following equation:

V

OUT

VV

IN OUT

(MAX)

+

(16)

I

RIPPLE

V

IN

(MAX)

=××

Lf

1

SW

For the circuit in Figure 27, the maximum ripple current (at the

maximum input voltage) is:

5

IA

RIPPLE

=

47 10

12

−

63

×

×

200 10

1

×

×

12 5

+−

−

0 375

=

.

High ripple currents are present in both the input and output

capacitors, and their ripple current ratings must be large enough

to sustain the large switching currents present in this topology.

The capacitors should have a ripple current rating of at least:

Figure 26. 5 V to 3.3 V Buck Regulator

INVERTING (BUCK-BOOST) REGULATOR

The circuit in Figure 27 shows the ADP3050 in a buck-boost

configuration, which produces a negative output voltage from a

positive input voltage. This topology looks quite similar to the

buck shown in Figure 26 above (except the IC and the output

filter are now referenced to the negative output instead of

REV. 0

–15–

V

II

RMS OUT

(CIN, COUT)

≈×

V

OUT

IN

(17)

The peak current seen by the diode, switch, and inductor can be

found by rearranging the load current equation:

I

PEAK

VV

+

IN OUT

=

V

IN

II

×

OUT RIPPLE

1

+×

2

(18)

Page 16

ADP3050

The largest peak currents occur at the lowest input voltage. For

this design with a load current of 500 mA:

+−

IA

PEAK

12 5

=

12

×

05

1

+×

0 375 0 9...

2

=

The average current diode will be equal to the load current.

An inductor with a current rating 20% greater than 0.9 A should

be used (rating of at least 1.2 A). Inductors and diodes with ratings

greater than 1 A should always be used, even if the calculated peak

and average currents are lower. This will ensure that start-up and

fault conditions will not overstress the components.

For the buck-boost topology, the input voltage can be less than

the output voltage (i.e., V

= 4 V, V

IN

= –5 V), but the avail-

OUT

able load current will be even lower. The equations given in this

section are valid for input voltages less than and greater than the

output voltage. The voltage seen by the ADP3050 is equal to the

sum of the input and output voltages (the BOOST pin sees the

sum of V

+ 2 ⫻ |V

IN

|). Make sure that the maximum voltage

OUT

ratings of these pins are not exceeded.

Dual Output SEPIC Regulator

For many systems, a dual polarity supply is needed. The circuit

in Figure 28 generates both a positive and a negative 5 V output

using a single magnetic component. The two inductors shown

are actually two separate windings on a single core contained in

a small, surface-mount package. The windings can be connected

in parallel or in series to be used as a single inductor for a conventional buck regulator, or they can be used as a 1:1 transformer,

as in this application. One winding is used as the standard buck

inductor for the +5 V output. The second winding is used to

generate the –5 V output along with D2, C6, and C7.

+

D2

GND

SD

COMP

C7

100F

ⴚ5V @ 0.25A

V

OUT

+5V @ 0.5A

V

OUT

+

C5

5.1k⍀

100F

R1

C4

1nF

8

IN

7

6

5

D1

1N5818

C3

0.22F

*INDUCTOR IS A SINGLE CORE

WITH TWO WINDINGS

COILTRONICS CTX25-4

SD

12V

V

IN

GND

L1*

25H

1N4148

+

C1

22F

L1*

25H

+

C6

100F

D3

1

2

3

4

1N5818

SWITCH

BOOST

BIAS

FB

U1

ADP3050-5

C2

0.01F

Figure 28. Dual Output +5 V and –5 V Regulator

These components form a SEPIC (Single Ended Primary Inductance Converter) using the 1:1 coupled inductor to generate the

negative supply. When the switch is off, the voltage across the buck

winding is equal to V

+ VD (VD is the diode drop). This voltage is

O

generated across the second winding, which is connected to produce

the –5 V supply. The –5 V output would be generated even

without C6 in the circuit, but its inclusion greatly improves the

regulation of the negative output and lowers the inductor ripple

current. The total output current available for both supplies is

limited by the ADP3050 (internally limited to around 1.0 A).

Keeping load currents below 500 mA and 250 mA, for the positive and negative supplies, respectively, will ensure that current

limit is not reached under normal operation. These limits are

not interchangeable; 500 mA cannot be drawn from the –5 V

supply while drawing only 250 mA from the +5 V supply. The

maximum current available from the –5 V output is directly related

to the +5 V load current due to the fact that the +5 V output is

used to regulate both supplies. Typically, the –5 V load current

should be around one-half of the +5 V load current to ensure good

regulation of both outputs. Additionally, the –5 V output should

have a preload (the minimum current level) of 1% to 2% of the

+5 V load current. This will help maintain good regulation of the

–5 V output at light loads.

The ripple voltage of the +5 V output is that of a normal buck

regulator (as described in the Applications Information section).

This ripple voltage is determined by the inductor ripple current

and the ESR of the output capacitor. For the system below, the

positive output voltage ripple is a 30 mV peak-to-peak triangular

wave. The ripple voltage of the –5 V output is a rectangular

wave (due to the rectangular shape of the current waveform into

the –5 V output capacitor). The amplitude of this current waveform is approximately equal to twice the –5 V load current. For

a load current of 200 mA and an ESR of 100 mΩ, the negative

output voltage ripple is around 2 ⫻ 200 mA ⫻ 100 mΩ, or

about 40 mV. The edges of this ripple waveform are quite fast,

which, along with the inductance of the output capacitor, generates

narrow spikes on the negative output voltage. These spikes can

easily be filtered out using an additional 5 µF to 10 µF bypass

capacitor close to the load (the inductance of the PC board

trace and the additional capacitor create a low-pass filter to

remove these high frequency spikes).

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

8-Lead SOIC

(R Suffix)

0.1968 (5.00)

0.1890 (4.80)

8

0.0500

(1.27)

BSC

5

0.2440 (6.20)

41

0.2284 (5.80)

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

0.0098 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

x 45°

0.1574 (4.00)

0.1497 (3.80)

PIN 1

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

C3451–2.5–3/00 (rev. 0)

PRINTED IN U.S.A.

–16–

REV. 0

Loading...

Loading...