Page 1

Synchronous, Step-Down DC-to-DC Controller with

Voltage Tracking and Synchronization

ADP1853

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

Trademarks and registered trademarks are the property of their respective owners.

Fax: 781.461.3113 ©2012 Analog Devices, Inc. All rights reserved.

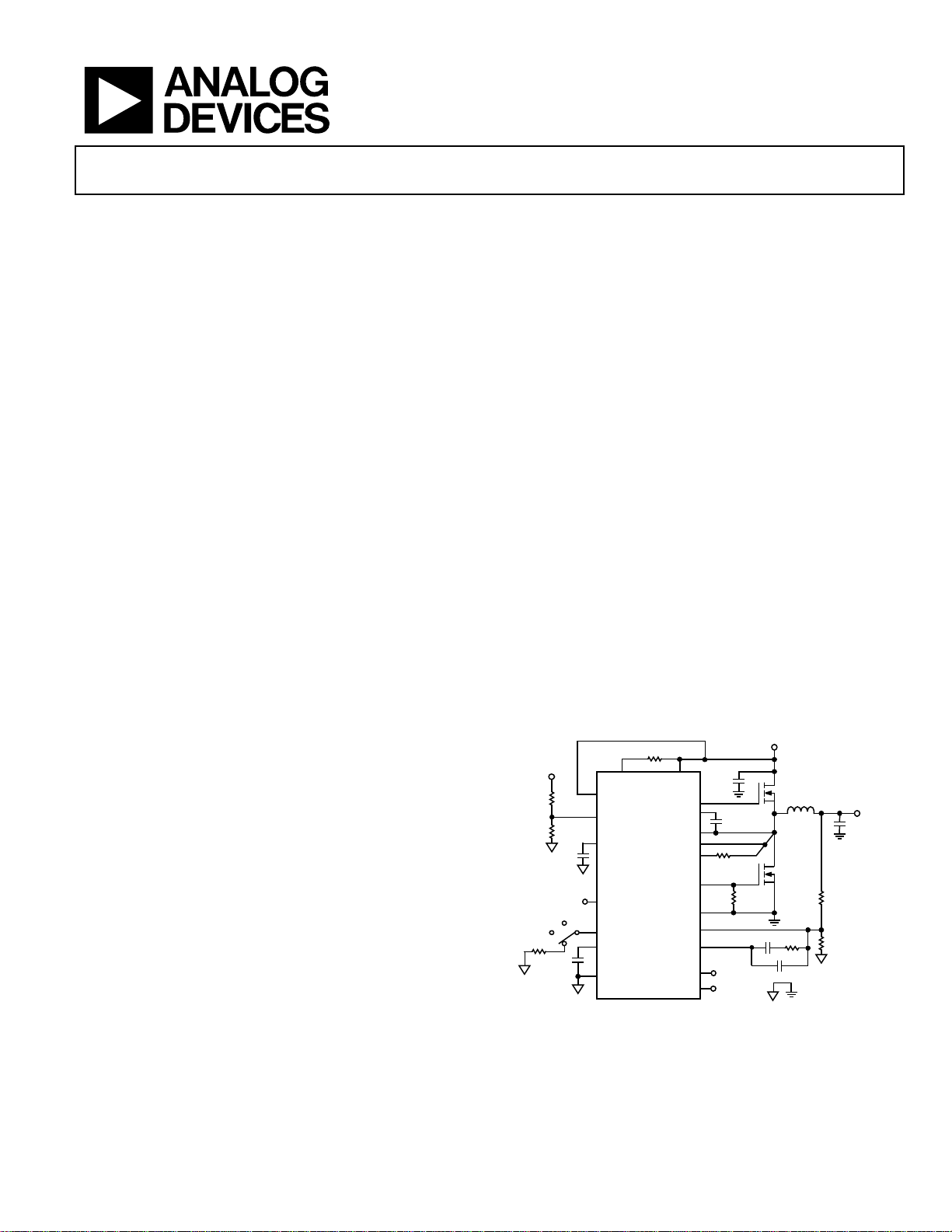

VIN

M2

M1

FB

SW

PGND

VIN

L

DH

BST

DL

R

CSG

R

RAMP

RAMP

PGOOD

SYNC

TRK

SS

ILIM

EN

COMP

CLKOUT

FREQ

VCCO

VOUT

ADP1853

HI

LO

CS

AGND

V

MA

10594-001

Data Sheet

FEATURES

Input voltage range: 2.75 V to 20 V

Output voltage range: 0.6 V to 90% V

Maximum output current of more than 25 A

Current mode architecture with current sense input

Configurable to voltage mode

±1% output voltage accuracy over temperature

Voltage tracking input

Programmable frequency: 200 kHz to 1.5 MHz

Synchronization input

Internal clock output

Power saving mode at light load

Precision enable input

Power good with internal pull-up resistor

Adjustable soft start

Programmable current sense gain

Integrated bootstrap diode

Starts into a precharged load

Externally adjustable slope compensation

Suitable for any output capacitor

Overvoltage and overcurrent-limit protection

Thermal overload protection

Input undervoltage lockout (UVLO)

Available in 20-lead, 4 mm × 4 mm LFCSP

Supported by ADIsimPower™ design tool

APPLICATIONS

Intermediate bus and POL systems requiring sequencing and

tracking, including

Telecom base station and networking

Industrial and Instrumentation

Medical and healthcare

IN

current, improve EMI, and reduce the size of the input bulk

capacitance. The ADP1853 can also be configured as a slave

device for current sharing. Additionally, the ADP1853 includes

accurate tracking, precision enable, and power good functions

for sequencing. The ADP1853 provides a high speed, high peak

current gate driving capability to enable energy efficient power

conversion. The device can be configured to operate in power

saving mode by skipping pulses, reducing switching losses and

improving efficiency at light load and standby conditions.

The accurate current limit allows design within a narrower

range of tolerances and can reduce overall converter size and

cost. The ADP1853 can regulate down to 0.6 V output using a

high accuracy reference with ±1% tolerance over the

temperature range from −40°C to 125°C.

With a wide range input voltage, the ADP1853 is designed to

provide the designer with maximum flexibility for use in a

variety of system configurations; loop compensation, soft start,

frequency setting, power saving mode, current limit, and

current sense gain can all be programmed using external

components. In addition, the external RAMP resistor allows

choosing optimal slope and V

feedforward in both current

IN

and voltage mode for excellent line rejection. The linear

regulator and the boot strap diode for the high-side driver are

internal.

Protection features include undervoltage lock out, overvoltage,

overcurrent/short circuit, and overtemperature.

GENERAL DESCRIPTION

The ADP1853 is a wide range input, dc-to-dc, synchronous

buck controller capable of running from commonly used 3.3 V

to 12 V (up to 20 V) voltage inputs. The device nominally

operates in current mode with valley current sensing providing

the fastest step response for digital loads. It can also be

configured as a voltage mode controller with low noise and

crosstalk for sensitive loads.

The ADP1853 can be used as a master synchronization clock

for the power system and for convenient synchronization

between controllers. The CLKOUT signal can synchronize

other devices in the ADP185x family such that slave devices

are phase-shifted from the master to reduce the input ripple

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without n otice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Figure 1. Typical Operation Circuit

www.analog.com

Page 2

ADP1853 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 6

ESD Caution .................................................................................. 6

Simplified Block Diagram ............................................................... 7

Pin Configuration and Function Descriptions ............................. 8

Typical Performance Characteristics ........................................... 10

Theory of Operation ...................................................................... 12

Control Architecture .................................................................. 12

Oscillator Frequency .................................................................. 12

Synchronization .......................................................................... 13

PWM or Pulse Skip Mode of Operation ................................. 13

CLKOUT Signal .......................................................................... 13

Synchronous Rectifier and Dead Time ................................... 14

Input Undervoltage Lockout ..................................................... 14

Internal Linear Regulator .......................................................... 14

Overvolage Protection ............................................................... 14

Power Good ................................................................................. 14

Short-Circuit and Current-Limit Protection .......................... 15

Enable/Disable Control ............................................................. 15

Thermal Overload Protection .................................................. 16

Interleaved Dual-Phase Operation .......................................... 16

Applications Information .............................................................. 17

ADIsimPower Design Tool ....................................................... 17

Setting the Output Voltage ........................................................ 17

Soft Start ...................................................................................... 17

Setting the Current Limit .......................................................... 17

Accurate Current-Limit Sensing .............................................. 17

Input Capacitor Selection .......................................................... 17

VIN Pin Filter ............................................................................. 18

Boost Capacitor Selection ......................................................... 18

Inductor Selection ...................................................................... 18

Output Capacitor Selection....................................................... 18

MOSFET Selection ..................................................................... 19

Loop Compensation—Voltage Mode ...................................... 20

Loop Compensation—Current Mode ..................................... 21

Switching Noise and Overshoot Reduction ............................ 23

Voltage Tracking ......................................................................... 23

PCB Layout Guidlines ............................................................... 24

Typical Operating Circuits ............................................................ 25

Outline Dimensions ....................................................................... 27

Ordering Guide .......................................................................... 27

REVISION HISTORY

5/12—Revision 0: Initial Version

Rev. 0 | Page 2 of 28

Page 3

Data Sheet ADP1853

POWER SUPPLY

TRSH

HYST

Quiescent Current

IIN

EN = VIN = 12 V, VFB = V

in forced pulse width

4.2

5.7

mA

CCO

IN_SD

TRK

TRK

CSG

CSG

CSG

CSG

Line Regulation of PWM

VFB/VIN

±0.015

%/V

COMP

COMP

OSCILLATOR

OSC

FREQ

FREQ

FREQ

SYNC

FREQ

SYNCMIN

SYNC

CLKOUT fOSC

CLKOUT

CLKOUT

VCCO

VCCO Load Regulation

I

VCCO

= 0 mA to 100 mA

35 mV

VCCO

DROPOUT

VCCO

SPECIFICATIONS

All limits at temperature extremes are guaranteed via correlation using standard statistical quality control (SQC). VIN = 12 V. The

specifications are valid for T

Table 1.

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

Input Voltage VIN 2.75 20 V

Undervoltage Lockout Threshold UVLO

VIN falling 2.35 2.45 2.50 V

Undervoltage Lockout Hysteresis UVLO

EN = VIN = 12 V, VFB = V

Shutdown Current I

ERROR AMPLIFIER

FB Input Bias Current IFB −100 +1 +100 nA

Open-Loop Gain1 80 dB

Gain-Bandwidth Product1 20 MHz

TRK Input Bias Current I

CURRENT SENSE AMPLIFIER GAIN ACS Gain resistor connected to DL,

Gain resistor connected to DL,

Default setting, R

Voltage mode operation, resistor DL to PGND,

OUTPUT CHARACTERICTISTICS

Feedback Accuracy Voltage VFB

= −40°C to +125°C, unless otherwise specified. Typical values are at TA = 25°C.

J

VIN rising 2.55 2.65 2.75 V

0.2 V

modulation (PWM) mode (no switching)

CCO

in PSM mode 2.5 mA

EN = GND, VIN = 5.5 V or 20 V 100 200 µA

0 V ≤ V

≤ 5 V −100 +1 +100 nA

2.6 3 3.4 V/V

R

= 47 kΩ ± 5%

5.2 6 6.8 V/V

R

= 22 kΩ ± 5%

= open 10.5 12 13.5 V/V

0 V/V

R

= 100 kΩ ± 5%

TJ = −40°C to +85°C

TJ = −40°C to +125°C

597 600 603 mV

594 600 606 mV

Load Regulation of PWM1 VFB/V

Frequency f

R

R

R

V

range = 0.9 V to 2.2 V ±0.3 %

= 332 kΩ to AGND 170 200 230 kHz

= 78.7 kΩ to AGND 720 800 880 kHz

= 40.2 kΩ to AGND 1275 1500 1725 kHz

FREQ to AGND 240 300 360 kHz

FREQ to VCCO 480 600 720 kHz

SYNC Input Frequency Range1 f

SYNC Input Pulse Width1 t

SYNC Pin Capacitance to GND C

CLKOUT Frequency Range1 f

CLKOUT Pulse Duty Cycle D

CLKOUT Rise and Fall Time C

R

range from 332 kΩ to 40.2 kΩ 170 1725 kHz

100 ns

5 pF

range from 170 kHz to 1725 kHz 170 1725 kHz

50 %

= 47 pF 10 ns

LINEAR REGULATOR

VCCO Output Voltage I

VCCO Line Regulation VIN = 5.5 V to 20 V, I

= 100 mA 4.7 5.0 5.3 V

= 20 mA 10 mV

VCCO Current Limit1 VCCO drops to 4 V from 5 V 350 mA

VCCO Short-Circuit Current1 VCCO < 0.5 V 370 400 mA

VIN to VCCO Dropout Voltage2 V

I

= 100 mA, VIN ≤ 5 V 0.33 V

Rev. 0 | Page 3 of 28

Page 4

ADP1853 Data Sheet

SYNC Logic Input Low

1.3

V

SYNC

BST

BST

DH or DL Driver RON, Sourcing

R

Sourcing 2 A with a 100 ns pulse

2

Ω

RON

OSC

OSC

OSC

OSC

OSC

COMP, THRES

COMP, HIGH

OVERVOLTAGE AND POWER GOOD

TRK

SOFT START

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

LOGIC INPUTS

EN EN rising 0.57 0.63 0.68 V

EN Hysteresis 0.03 V

EN Input Leakage Current IEN VIN = 2.75 V to 20 V 1 200 nA

SYNC Logic Input High 1.9 V

SYNC Input Pull-Down Resistance R

GATE DRIVERS

DH Rise Time CDH = 3 n F, V

DH Fall Time CDH = 3 n F, V

DL Rise Time CDL = 3 nF 16 ns

DL Fall Time CDL = 3 nF 14 ns

DH to DL Dead Time External 3 nF is connected to DH and DL 25 ns

Current1

Sourcing 1 A with a 100 ns pulse, VIN = 3 V 2.3 Ω

DH or DL Driver RON, Tem p co TC

DH or DL Driver RON, Sinking

Current

1

Sinking 1 A with a 100 ns pulse, VIN = 3 V 2 Ω

DH Maximum Duty Cycle1 f

DH Maximum Duty Cycle1 f

Minimum DH On Time f

Minimum DH Off Time f

Minimum DL On Time f

COMP VOLTAGE RANGE

COMP Pulse Skip Threshold V

COMP Clamp High Voltage V

THERMAL SHUTDOWN

Thermal Shutdown Threshold T

Thermal Shutdown Hysteresis 20

1 MΩ

− VSW = 5 V 16 ns

− VSW = 5 V 14 ns

ON_SOURCE

VIN = 3 V or 12 V 0.3 %/oC

Sinking 2 A with a 100 ns pulse 1.5 Ω

R

ON_SINK

= 300 kHz 90 %

= 1500 kHz 50 %

= 200 kHz to 1500 kHz 85 ns

= 200 kHz to 1500 kHz 345 ns

= 200 kHz to 1500 kHz 295 ns

In pulse skip mode (PSM) 0.9 V

2.2 V

155

TMSD

°C

°C

THRESHOLDS

FB Overvoltage Threshold VOV VFB rising 0.630 0.65 0.670 V

FB Overvoltage Hysteresis 18 mV

FB Undervoltage Threshold VUV VFB falling 0.525 0.55 0.575 V

FB Undervoltage Hysteresis 15 mV

TRK INPUT VOLTAGE RANGE1 0 5 V

FB TO TRK OFFSET VOLTAGE TRK = 0.1 V to 0.57 V; offset = VFB − V

SS Output Current ISS During startup 4.6 6.5 8.4 µA

SS Pull-Down Resistor During a fault condition 3 kΩ

FB to SS offset VSS = 0.1 V to 0.6 V; offset = VFB − VSS −10 +10 mV

−10 0 +10 mV

Rev. 0 | Page 4 of 28

Page 5

Data Sheet ADP1853

PGOOD

Parameter Symbol Test Conditions/Comments Min Typ Max Unit

PGOOD

PGOOD Pull-Up Resistor R

PGOOD Delay 12 µs

Overvoltage or Undervoltage

Minimum Duration

ILIM Threshold Voltage1 Relative to PGND −5 0 +5 mV

ILIM Output Current ILIM = PGND 45 50 55 µA

Current Sense Blanking Period After DL goes high, current limit is not sensed

INTEGRATED RECTIFIER

(BOOST DIODE) RESISTANCE

ZERO CURRENT CROSS OFFSET

(SW TO PGND)

1

Guaranteed by design.

2

Connect VIN to VCCO when VIN < 5.5 V.

1

Internal pull-up resistor to VCCO 12.5 kΩ

This is the minimum duration required to trip

10 µs

the PGOOD signal

100 ns

during this period

At 20 mA forward current 16 Ω

In pulse skip mode only; f

= 300 kHz 0 2 4 mV

OSC

Rev. 0 | Page 5 of 28

Page 6

ADP1853 Data Sheet

BST to SW

−0.3 V to +6 V

BST to PGND to PGND 20 ns Transients

32 V

1, 2

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VIN, EN, RAMP 21 V

FB, COMP, SS, TRK, FREQ, SYNC, VCCO,

−0.3 V to +6 V

PGOOD, CLKOUT

ILIM, SW, CS to PGND −0.3 V to +21 V

BST, DH to PGND −0.3 V to +28 V

DL to PGND −0.3 V to VCCO + 0.3 V

SW, CS to PGND 20 ns Transients 25 V

DL, SW, CS, ILIM to PGND 20 ns

−8 V

Negative Transients

PGND to AGND −0.3 V to +0.3 V

PGND to AGND 20 ns Transients −8 V to +4 V

θJA (Natural Convection)

40°C/W

Operating Junction Temperature Range3 −40°C to +125°C

Storage Temperature Range −65°C to +150°C

Maximum Soldering Lead Temperature 260°C

1

Measured with exposed pad attached to PCB.

2

Junction-to-ambient thermal resistance (θJA) of the package was calculated

or simulated on multilayer PCB.

3

The junction temperature (TJ) of the device is dependent on the ambient

temperature (T

ambient thermal resistance of the package (θ

temperature is calculated from the ambient temperature and power

dissipation using the formula T

) the power dissipation of the device (PD) and the junction to

A

= TA + PD × θJA.

J

). Maximum junction

JA

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Absolute maximum ratings apply individually only, not in

combination. Unless otherwise specified, all other voltages are

referenced to GND.

ESD CAUTION

Rev. 0 | Page 6 of 28

Page 7

Data Sheet ADP1853

BST

PGND

+

–

+

–

+

–

+

–

FB

OV_TH

UV_TH

PGOOD

CURRENT SENSE

AMPLIFIER

DH

DL

ILIM

SW

V

REF

= 0.6V

+

+

–

ERROR

AMPLIFIER

FB

COMP

SS

PWM

COMPARATOR

SLOPE COMPENSATION

AND RAMP GENERAT OR

CURRENT-LIMIT

CONTROL

RAMP

50µA

OV

+

TRK

CS GAIN

DRIVER LOGIC

CONTROL AND

STATE

MACHINE

OVER_LIM

PULSE SKIP

OVER_LIM

LDO

LOGIC

EN

VIN

UVLO

OSCILLATOR

FREQ

SYNC

REF

VCCO

OV

UV

0.6V

THERMAL

SHUTDOWN

AGND

CS

FAULT

OV

LOGIC

OVER_LIM

OV

EN

EN_SW

LOGIC

UV

3kΩ

0.9V

DCM

*0 (ZERO) GAIN IS FOR VOLTAGE MODE WITH RAMP FROM 0.7V TO 2.2V.

ZERO

CROSS

DETECT

12.5kΩ

A

V

= 0,* 3, 6, 12

VCCO

CLK

EN_SW

1MΩ

–

+

CLKOUT

VCCO

VCCO

VCCO

VCCO

SLAVE

SL_TH

FB

SLAVE

0.6V

6.5µA

10594-002

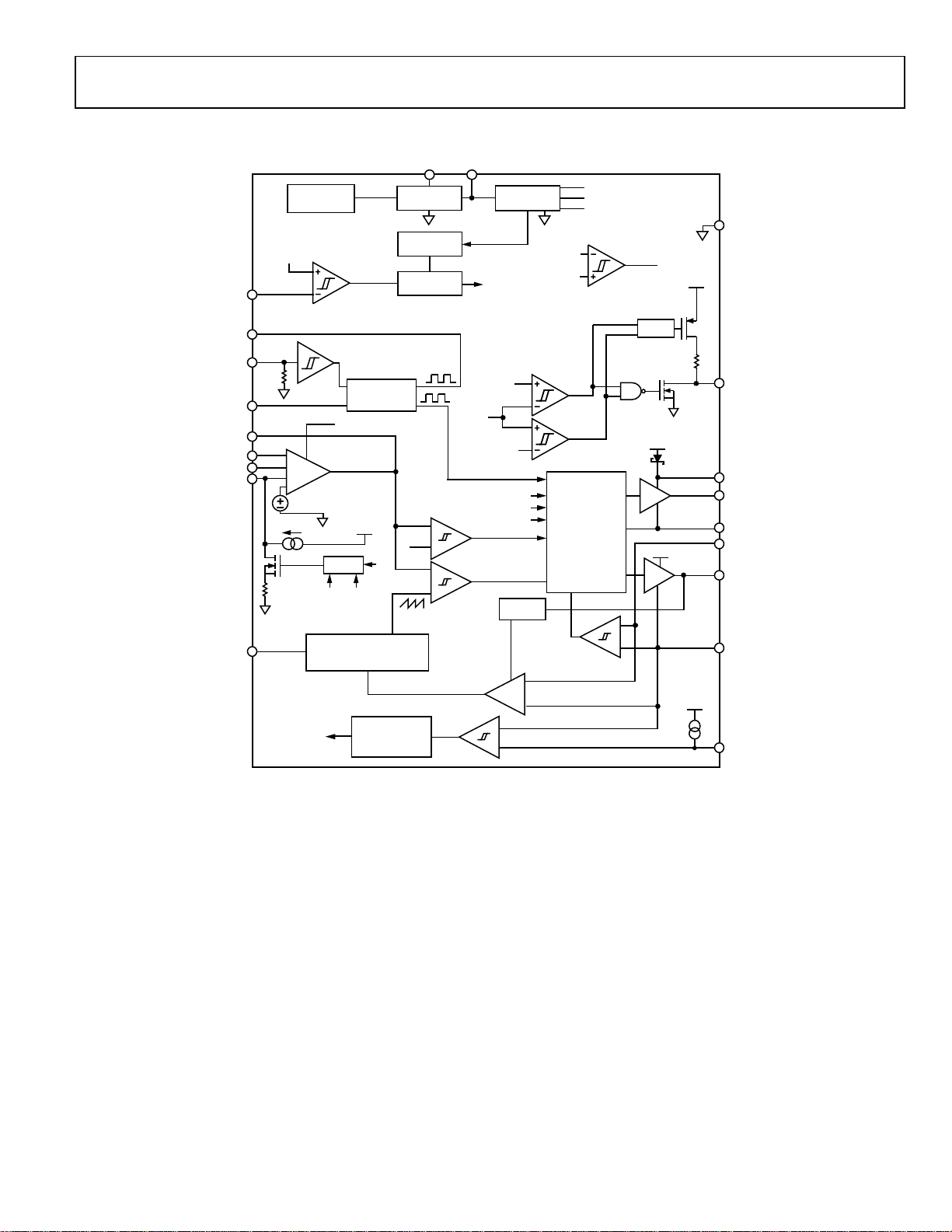

SIMPLIFIED BLOCK DIAGRAM

Rev. 0 | Page 7 of 28

Figure 2.

Page 8

ADP1853 Data Sheet

15

BST

Boot Strapped Upper Rail of High-Side Internal Driver. Connect a 0.1 µF to a 0.22 µF multilayer ceramic capacitor

14

13

12

1

3

4

DH

15

BST

NOTES

1. CONNECT THE BOTTOM OF THE

EXPOSED PAD TO THE SYSTEM

AGND PLANE.

SW

CS

11

DL

EN

FB

2

SS

COMP

5

AGND

7

CLKOUT

6

SYNC

8

VIN

9

VCCO

10

PGND

19

FREQ

20

TRK

18

RAMP

17

PGOOD

16

ILIM

ADP1853

TOP VIEW

10594-003

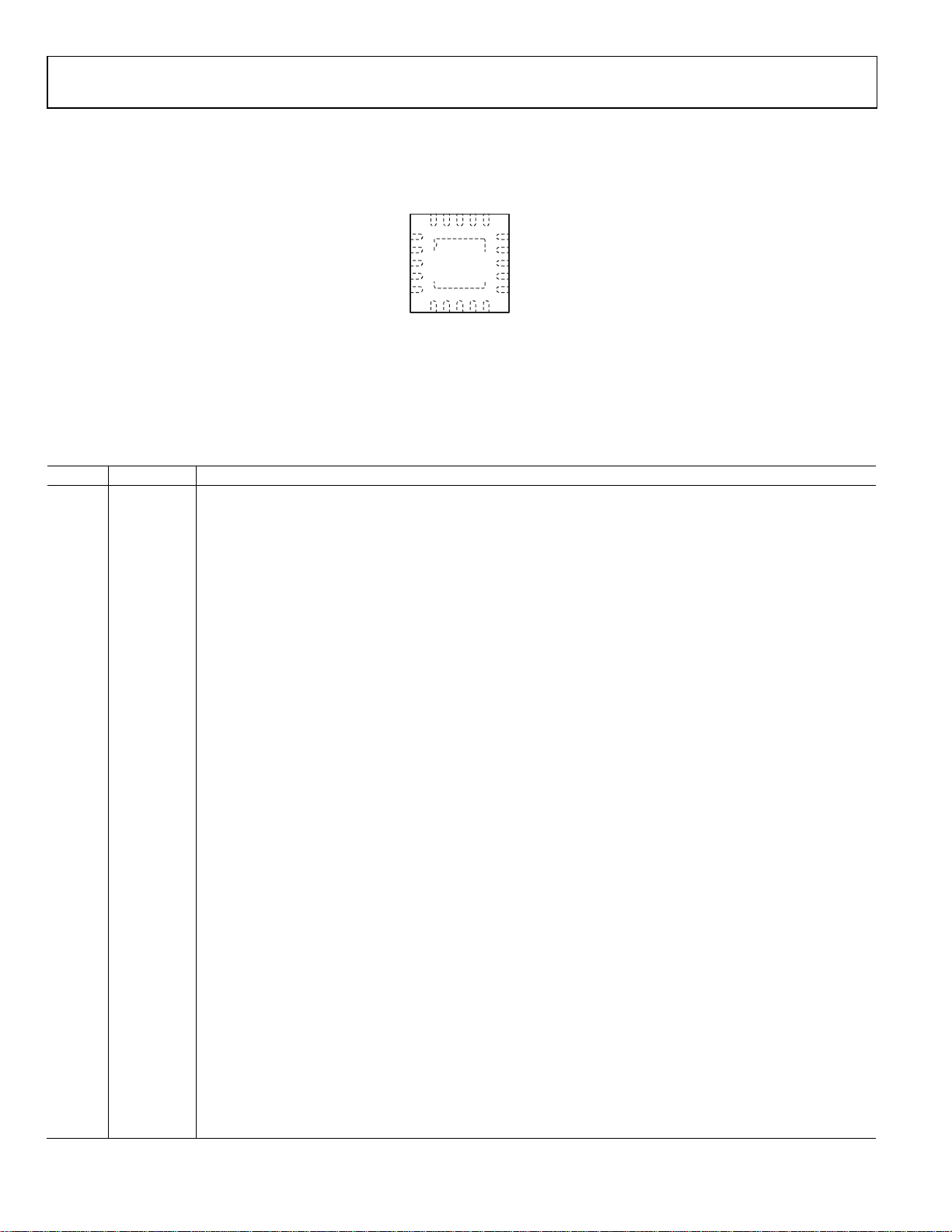

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Figure 3. Pin Configuration

Table 3. Pin Function Descriptions

Pin No. Mnemonic Description

1 EN Enable Input. Drive EN high to turn on the controller, and drive EN low to turn the controller off. Tie EN to VIN for

automatic startup. For a precision UVLO, put an appropriately sized resistor divider from V

midpoint to this pin.

2 SS Soft Start Input. Connect a capacitor from SS to AGND to set the soft start period. This node is internally pulled up

to VCCO through a 6.5 µA current source.

3 FB Output Voltage Feedback. Connect this pin to an output via a resistor divider. Tie FB to VCCO for slave mode

operation in interleaved dual-phase configuration.

4 COMP Compensation Node. Output of the error amplifier. Connect a resistor-capacitor network from COMP to FB to

compensate the regulation control loop. In interleaved dual-phase configuration, tie this pin to the COMP pin of

the second channel.

5 AGND Analog Ground. Connect to the system AGND plane.

6 SYNC Frequency Synchronization Input. This pin accepts an external clock signal with a frequency close to 1× the

internal oscillator frequency, f

, set by the FREQ pin. The controller operates in forced PWM when a periodic clock

OSC

signal is detected at SYNC or when SYNC is high. The resulting switching frequency is 1× the SYNC frequency.

When SYNC is low or left floating, the controller operates in pulse skip mode.

7 CLKOUT

Internal Clock Output. The CLKOUT is 1× the internal oscillator or input SYNC signal frequency, 180° phase-shifted.

This pin can be used to synchronize another

ADP1853 or other controllers.

8 VIN Connect to Main Power Supply. Bypass with a 1 µF or larger ceramic capacitor connected as close to this pin as

possible and AGND.

9 VCCO Output of the Internal Low Dropout Regulator (LDO). The internal circuitry and gate drivers are powered from

VCCO. Bypass VCCO to AGND with a 1 μF or larger ceramic capacitor. The VCCO output remains active even when

EN is low. For operations at V

below 5 V, VIN may be jumped to VCCO. Do not use the LDO to power other auxiliary

IN

system loads.

10 PGND Power Ground. Ground for internal driver. Differential current.

11 DL Low-Side Synchronous Rectifier Gate Driver Output. To program the gain of the current sense amplifier in a current

mode or to set voltage mode control, connect a resistor between DL and PGND. This pin is capable of driving

MOSFETs with a total input capacitance up to 20 nF.

12 CS Current Sense Amplifier Input. Differential current is sensed between CS and PGND. Connect this pin to the

current sense resistor or to the SW pin to sense the current. Tie this pin to PGND for voltage mode operation.

13 SW Power Switch Node. Connect this pin to the source of the high-side N-channel MOSFET and the drain of the low-

14 DH High-Side Switch Gate Driver Output. This pin is capable of driving MOSFETs with a total input capacitance up to

16 ILIM Current-Limit Sense Comparator Inverting Input. Connect a resistor between ILIM and SW to set the current-

side N-channel MOSFET.

20 nF.

(MLCC) between BST and SW. There is an internal boost diode rectifier connected between VCCO and BST.

limit offset. For accurate current-limit sensing, connect ILIM to a current sense resistor at the source of the

low-side MOSFET.

Rev. 0 | Page 8 of 28

to AGND, and tie the

IN

Page 9

Data Sheet ADP1853

Pin No. Mnemonic Description

17 PGOOD Power Good. The open-drain power good indicator logic output with an internal 12.5 kΩ resistor is connected

between PGOOD and VCCO. PGOOD is pulled to ground when the output is outside the regulation window. An

external pull-up resistor is not required. If the controller is configured as a slave in the interleaved dual-phase

application by tying the FB pin high to VCCO, the pulse skip mode is enabled by driving the PGOOD pin low

externally in cases when the master is in pulse skip mode at light loads. Otherwise, if the master is configured to

forced PWM operation, PGOOD of the slave controller must be connected to the PGOOD of the master.

18 RAMP Programmable Current Setting for Slope Compensation. Connect a resistor from RAMP to VIN. The voltage at RAMP

is 0.2 V during operation. This pin is high impedance when the channel is disabled.

19 FREQ Internal Oscillator Frequency, f

resistor between FREQ and AGND. Connect FREQ to AGND for a preprogrammed 300 kHz or tie FREQ to VCCO for

600 kHz operating frequency.

20 TRK Tracking Input. Connect TRK to VCCO if tracking is not used.

EPAD Exposed Pad. Connect the bottom of the exposed pad to the system AGND plane.

. Sets the desired operating frequency between 200 kHz and 1.5 MHz with one

OSC

Rev. 0 | Page 9 of 28

Page 10

ADP1853 Data Sheet

PULSE SKIP

FORCED PW M

100

90

80

70

60

50

40

30

20

10

0

EFFICIENCY (%)

0.1 1 10 100

LOAD (A)

10594-004

CH2 200mV M 100µs 5.0MS/ s

200ns/pt

A CH4 14.2A

2

4

CH4 10A Ω

B

W

B

W

LOAD

CURRENT

VOUT_AC

10594-006

CH2 100mV

M 100µs 250MS/s

4ns/pt

A CH1 12.6V

1

2

CH1 5V

B

W

B

W

VIN

VOUT_AC

10594-008

PULSE SKIP

FORCED PW M

100

90

80

70

60

50

40

30

20

10

0

EFFICIENCY (%)

0.1 1 10 100

LOAD (A)

10594-005

CH2 200mV M 100µs 5.0MS/s

200ns/pt

A CH4 14.2A

4

2

CH4 10A Ω

B

W

B

W

LOAD

CURRENT

VOUT_AC

10594-007

CH2 100mV

M 100µs 250MS/s

4ns/pt

A CH1 12.6V

1

2

CH1 5V

B

W

B

W

VIN

VOUT_AC

10594-009

TYPICAL PERFORMANCE CHARACTERISTICS

12 V

to 3.3 V

IN

, 300 kHz, see Figure 36 for Circuit

OUT

Figure 5. 10 A to 20 A Load Step,

12 V

to 3.3 V

IN

OUT

Figure 4. Efficiency Plot

, 300 kHz, Current Mode

15 V

to 5 V

IN

, 600 kHz, see Figure 35 for Circuit

OUT

Figure 8. 10 A to 20 A Load Step,

12 V

Figure 7. Efficiency Plot

to 3.3 V

IN

, 300 kHz, Voltage Mode

OUT

Figure 6. 9 V to 15 V Line Step,

3.3 V

, 15 A Load, Current Mode

OUT

Figure 9. 9 V to 15 V Line Step,

3.3 V

, 15 A Load, Voltage Mode

OUT

Rev. 0 | Page 10 of 28

Page 11

Data Sheet ADP1853

CH3 10V

M 1.0µs 1.25GS /s

400ps/pt

A CH1 3.6V

1

2

3

CH1 5V

B

W

B

W

CH2 5V

B

W

CLKOUT

DH

SYNC

10594-016

25

35

34

33

32

31

30

29

28

27

26

–40 –20 0 20 40 60 80 100 120 140

DEAD TIME ( ns)

TEMPERATURE (°C)

VIN = 12V

OUTPUT IS LOADED

HS FET = BS C080N03LS

LS FET = BS C030N03LS

DEAD TIME BETWEEN SW FALLING EDGE

AND DL RISING EDGE, I NCLUDING DIODE RECOVERY TIME

10594-011

50

100

150

200

250

300

350

2.5 5.0 7.5 10.0 12.5 15.0 17.5 20.0

TIME (ns)

DH MINIMUM OFF TIME

DH MINIMUM ON TIME

VIN (V)

10594-012

CH3 10V

M 2ms 250kS/s

4µs/pt

A CH1 560mV

1

2

3

CH1 2V

B

W

CH2 1V

B

W

B

W

EN

VOUT

SW

10594-017

25

45

43

41

39

37

35

33

31

29

27

0 2015105

DEAD TIME ( ns)

VIN (V)

T

A

= 25°C

OUTPUT IS LOADED

HS FET = BS C080N03LS

LS FET = BS C030N03LS

DEAD TIME BETWEEN SW FALLING EDGE

AND DL RISING EDGE, I NCLUDING DIODE RECOVERY TIME

10594-014

0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

–40 –15 10 35 60 85 110 135

DRIVER RESI STANCE (Ω)

TEMPERATURE (°C)

VIN = 2.75V, SOURCING

VIN = 12V, SOURCING

VIN = 2.75V, SINKING

VIN = 12V, SINKING

10594-015

Figure 10. Synchronization and CLKOUT, f

Figure 11. Dead Time vs. Temperature

= 300 kHz

SYNC

Figure 13. Soft Start with Precharged Output, 3.3 V

Forced PWM

OUT

Figure 14. Dead Time vs. V

IN

Figure 12. Typical DH Minimum On Time and Off Time

Figure 15. Driver Resistance vs. Temperature

Rev. 0 | Page 11 of 28

Page 12

ADP1853 Data Sheet

065.1

)kHz(568,96)kΩ(

−

×=

OSCFREQ

fR

FREQ

OSC

FF

OSC

Q

Q

R

S

A

CS

V

CS

V

IN

V

IN

A

R

I

RAMP

R

RAMP

C

R

FROM

ERROR AMP

TO

DRIVERS

CS

PGND

10594-022

410

R

FREQ

(kΩ)

360

310

260

210

160

110

60

10

100 400 700 1000 1300 1600 1900

f

OSC

(kHz)

R

FREQ

(kΩ) = 96,568

f

OSC

(kHz)

–1.065

10594-023

THEORY OF OPERATION

The ADP1853 is a fixed frequency, step-down, synchronous

switching controller with integrated drivers and bootstrapping

for external N-channel power MOSFETs. The current mode

control loop can also be configured into the voltage mode. The

controller can be set to operate in pulse skip mode for power

saving at a light load or in forced PWM. The ADP1853 includes

programmable soft start, output overvoltage protection, programmable current limit, power good, and tracking functions.

The controller can operate at a switching frequency between

200 kHz and 1.5 MHz that is programmed with a resistor or

synchronized to an external clock. It also has the internal clock

out signal that can be used to synchronize other devices.

CONTROL ARCHITECTURE

The ADP1853 is based on a fixed frequency, emulated peak

current mode, PWM control architecture. The inductor current

is sensed by the voltage drop measured across the external lowside MOSFET, R

between the low-side MOSFET source and the power ground.

The current is sensed during the off period of the switching

cycle and is conditioned with the internal current sense

amplifier. The gain of the current sense amplifier is programmable to 3 V/V, 6 V/V, or 12 V/V during the controller

power-up initialization before the device starts switching. A

47 kΩ resistor between DL and PGND programs the gain of

3 V/V; a 22 kΩ resistor sets a gain of 6 V/V. Without a resistor,

the gain is programmed to 12 V/V. The output signal of the

current sense amplifier is held, added to the emulated current

ramp in the next switching cycle during the DH on time, and

fed into the PWM comparator, as shown in Figure 16. This

signal is compared with the COMP signal from the error

amplifier and resets the flip-flop, which generates the PWM

pulse. If voltage mode control is selected by placing a 100 kΩ

resistor between DL and PGND, the emulated ramp is fed to the

PWM comparator without adding the current sense signal.

, or across the sense resistor placed in series

DSON

As shown in Figure 16, the emulated current ramp is generated

inside the IC, but offers programmability through the RAMP

pin. Selecting an appropriate value resistor between V

to the

IN

RAMP pin programs a desired slope compensation value, and at

the same time, provides a V

feed forward feature. Control

IN

logic enforces antishoot-through operation to limit cross

conduction of the internal drivers and external MOSFETs.

OSCILLATOR FREQUENCY

The internal oscillator frequency, which ranges from 200 kHz

to 1.5 MHz, is set by an external resistor, R

pin. Some popular f

values are shown in Table 4, and a

OSC

graphical relationship is shown in Figure 17. For instance, a 78.7

kΩ resistor sets the oscillator frequency to 800 kHz.

Furthermore, connecting FREQ to AGND or FREQ to VCCO

sets the oscillator frequency to 300 kHz or 600 kHz,

respectively. For other frequencies that are not listed in Table 4,

the values of R

and f

can be obtained from Figure 17, or use the following

OSC

FREQ

empirical formula to calculate these values:

Table 4. Setting the Oscillator Frequency

R

f

332 kΩ 200 kHz

78.7 kΩ 800 kHz

60.4 kΩ 1000 kHz

51 kΩ 1200 kHz

40.2 kΩ 1500 kHz

FREQ to AGND 300 kHz

FREQ to VCCO 600 kHz

, at the FREQ

FREQ

(Typical)

Figure 16. Simplified Control Architecture

Rev. 0 | Page 12 of 28

Figure 17. R

FREQ

vs. f

OSC

Page 13

Data Sheet ADP1853

CH2 200mVCH1 10V M200µs A CH1 7.8V

1

3

4

2

CH3 20mV CH4 2A Ω

SW

COMP (CH2)

VOUT RIPPLE

INDUCTOR

CURRENT

10594-024

CH2 5VCH1 10V M1µs A CH1 13.4V

1

3

4

2

CH3 20mV CH4 2A Ω

DH

DL

OUTPUT

RIPPLE

INDUCTOR CURRENT

10594-025

SYNCHRONIZATION

The switching frequency of the ADP1853 can be synchronized

to an external clock signal by connecting it to the SYNC pin.

The internal oscillator frequency, programmed by the resistor at

the FREQ pin must be set close to the external clock frequency;

therefore, the external clock frequency may vary between 0.85×

and 1.3× of the internal clock set. The resulting switching

frequency is 1× of the external SYNC frequency. When

synchronized, the ADP1853 operates in PWM.

When an external clock is detected at the first SYNC edge, the

internal oscillator is reset, and the clock control shifts to SYNC.

The SYNC edges then trigger subsequent clocking of the PWM

outputs. The DH rising edge appears approximately 100 ns after

the corresponding SYNC edge, and the frequency is locked to

the external signal. If the external SYNC signal disappears

during operation, the ADP1853 reverts to its internal oscillator.

When the SYNC function is used, it is recommended to connect a

pull-up resistor from SYNC to VCCO so that when the SYNC

signal is lost, the ADP1853 continues to operate in PWM.

PWM OR PULSE SKIP MODE OF OPERATION

The SYNC pin is a multifunctional pin. PWM mode is enabled

when SYNC is connected to VCCO or a high logic. With SYNC

connected to ground or left floating, pulse skip mode is

enabled. Switching SYNC from low to high or high to low on

the fly causes the controller to transition from forced PWM

to pulse skip mode or from pulse skip mode to forced PWM,

respectively, in two clock cycles.

Figure 18. Example of Pulse Skip Mode Under a Light Load

When the output load is greater than the pulse skip threshold

current, that is, when V

reaches the threshold of 0.9 V, the

COMP

ADP1853 exits the pulse skip mode of operation and enters

the fixed frequency discontinuous conduction mode (DCM),

as shown in Figure 19. When the load increases further, the

ADP1853 enters continuous conduction mode (CCM).

Table 5. Mode of Operation

SYNC Pin Mode of Operation

Low Pulse skip mode

High Forced PWM

No Connect Pulse skip mode

Clock Signal Forced PWM

Figure 19. Example of Discontinuous Conduction Mode (DCM) Waveform

The ADP1853 has pulse skip sensing circuitry that allows the

controller to skip PWM pulses, reducing the switching

frequency at light loads and, therefore, maintaining better

efficiency during a light load operation. The resulting output

ripple is larger than that of the fixed frequency forced PWM.

Figure 18 shows the ADP1853 operating in PSM under a light

load. Pulse skip frequency under a light load is dependent on

the inductor, output capacitance, output load, and input and

output voltages.

In forced PWM, the ADP1853 always operates in CCM at any

load; therefore, the inductor current is always continuous.

CLKOUT SIGNAL

The ADP1853 has a clock output, CLKOUT, which can be

used for synchronizing other ADP1853 controllers, thus

eliminating the need for an external clock source. The

CLKOUT frequency is 1× the internal oscillator frequency,

f

, and is 180° out of phase.

OSC

Rev. 0 | Page 13 of 28

Page 14

ADP1853 Data Sheet

ADP1853

VIN

V

IN

= 2.75V TO 5.5V

VCCO

10594-026

CH1 20V CH2 5V

CH3 1V CH4 10V

M100µs A CH1 10V

1

2

4

3

DH

PGOOD

VOUT = 1.8V SHORTE

D TO 2V SOURCE

VIN

10594-027

SYNCHRONOUS RECTIFIER AND DEAD TIME

In the ADP1853, the antishoot-through circuit monitors the

DH to SW and DL to PGND voltages and adjusts the low-side

and high-side drivers to ensure break-before-make switching

that prevents cross-conduction or shoot-through between

the high-side and low-side MOSFETs. This break-before-make

switching is known as dead time, which is not fixed and

depends on how fast the MOSFETs are turned on and off. In

a typical application circuit that uses medium sized MOSFETs

with an input capacitance of approximately 3 nF, the typical

dead time is approximately 25 ns. When small and fast

MOSF E Ts with fast diode recovery times are used, the dead

time can be as low as 13 ns.

INPUT UNDERVOLTAGE LOCKOUT

When the bias input voltage at the VIN pin is less than the

undervoltage lockout (UVLO) threshold of 2.6 V typical, the

switch drivers stay inactive. If EN is high, the controller starts

switching and the VIN pin voltage exceeds the UVLO

threshold.

INTERNAL LINEAR REGULATOR

The internal linear regulator is a low dropout (LDO) VCCO.

VCCO powers up the internal control circuitry and provides

power for the gate drivers. It is guaranteed to have more than

200 mA of output current capability, which is sufficient to

handle the gate driver requirements of typical logic threshold

MOSFETs driven at up to 1.5 MHz. VCCO is always active

and cannot be shut down by the EN signal; however, the overtemperature protection event disables the LDO together with

the controller. Bypass VCCO to AGND with a 1 µF or greater

capacitor.

Because the LDO supplies the gate driver current, the output of

VCCO is subject to sharp transient currents as the drivers

switch and the boost capacitors recharge during each switching

cycle. The LDO has been optimized to handle these transients

without overload faults. Due to the gate drive loading, using the

VCCO output for other external auxiliary system loads is not

recommended.

The LDO includes a current limit that is well above the

expected maximum gate driver load. This current limit also

includes a short-circuit foldback to further limit the VCCO

current in the event of a short-circuit fault.

For an input voltage of less than 5.5 V, it is recommended to

bypass the LDO by connecting VIN to VCCO, as shown in

Figure 20, thus eliminating the dropout voltage. However, if

the input range is 4 V to 7 V, the LDO cannot be bypassed by

shorting VIN to VCCO because the 7 V input has exceeded the

maximum voltage rating of the VCCO pin. In this case, use the

LDO to drive the internal drivers, but keep in mind that there is

a dropout when V

IN

is less t h an 5 V.

Figure 20. Configuration for V

< 5.5 V

IN

OVERVOLAGE PROTECTION

The ADP1853 has a built-in circuit for detecting output overvoltage at the FB node. When the FB voltage, V

, rises above

FB

the overvoltage threshold, the high-side N-channel MOSFET

(NMOSFET) is turned off, and the low-side NMOSFET is

turned on until the V

drops below the undervoltage threshold.

FB

This action is known as the crowbar overvoltage protection.

If the overvoltage condition is not removed, the controller

maintains the feedback voltage between the overvoltage and

undervoltage thresholds, and the output is regulated to within

typically +8% and −8% of the regulation voltage. During an

overvoltage event, the SS node discharges toward zero through

an internal 3 kΩ pull-down resistor. When the voltage at FB

drops below the undervoltage threshold, the soft start sequence

restarts. Figure 21 shows the overvoltage protection scheme in

action in PSM.

Figure 21. Overvoltage Protection in PSM

POWER GOOD

The PGOOD pin is an open-drain NMOSFET with an internal

12.5 kΩ pull-up resistor connected between PGOOD and

VCCO. PGOOD is internally pulled up to VCCO during

normal operation and is active low when tripped. When the

feedback voltage, V

or drops below the undervoltage threshold, the PGOOD output

is pulled to ground after a delay of 12 µs. The overvoltage or

undervoltage condition must exist for more than 10 µs for

PGOOD to become active. The PGOOD output also becomes

active if a thermal overload condition is detected.

Rev. 0 | Page 14 of 28

, rises above the overvoltage threshold

FB

Page 15

Data Sheet ADP1853

CH1 10V M2ms A CH1 11.2V

1

3

4

CH3 500mV CH4 10A Ω

SW

SS

INDUCTOR

CURRENT

10594-028

ADP1853

FBEN

R

TOP

R

BOT

V

OUT

R1

R2

MASTER

SUPPLY

VOLTAGE

10594-029

SHORT-CIRCUIT AND CURRENT-LIMIT PROTECTION

When the output is shorted or the output current exceeds the

current limit set by the current-limit setting resistor (between

ILIM and CS) for eight consecutive cycles, the ADP1853 shuts

off both the high-side and low-side drivers and restarts the soft

start sequence every 10 ms, which is known as hiccup mode.

The SS node discharges to zero through an internal 3 kΩ

resistor during an overcurrent or short-circuit event. Figure 22

shows that the ADP1853 on a high current application circuit

maintains current-limit hiccup mode when the output is

shorted.

ENABLE/DISABLE CONTROL

The EN pin is used to enable or disable the controller ADP1853;

the precision enable typical threshold is 0.63 V. When the

voltage at EN rises above the threshold voltage, the controller is

enabled and starts normal operation after initialization of the

internal oscillator, references, settings, and the soft start period.

When the voltage at EN drops to typically 30 mV (hysteresis)

below the threshold voltage, the driver and the internal

controller circuits in the ADP1853 are turned off. The initial

settings are still valid; therefore re-enabling the controller does

not change the settings until the power at the VIN pin is cycled.

In addition, the EN signal does not shut down the LDO at

VCCO, which is always active when V

threshold.

For the purpose of start-up power sequencing, the startup of the

ADP1853 can be programmed by connecting an appropriate

resistor divider from the master power supply to the EN pin, as

shown in Figure 23. For instance, if the desired start-up voltage

from the master power supply is 10 V, R1 and R2 can be set to

156 kΩ and 10 kΩ, respectively.

is above the UVLO

IN

Figure 22. Current-Limit Hiccup Mode, 20 A Current Limit

Figure 23. Optional Power-Up Sequencing Circuit

Rev. 0 | Page 15 of 28

Page 16

ADP1853 Data Sheet

VIN

M2

M1

FB

SW

PGND

V

IN

L1

DH

BST

DL

R

CSG

R

RAMP

RAMP

PGOOD

SYNC

TRK

SS

ILIM

EN

COMP

CLKOUT

FREQ

VCCO

V

OUT

ADP1853

CS

AGND

MASTER

VIN

M4

M3

FB

SW

PGND

V

IN

L2

DH

BST

DL

R

CSG

R

RAMP

RAMP

PGOOD

SYNC

TRK

SS

ILIM

EN

COMP

CLKOUT

FREQ

VCCO

ADP1853

CS

AGND

SLAVE

10594-030

THERMAL OVERLOAD PROTECTION

The ADP1853 has an internal temperature sensor that senses

the junction temperature of the chip. When the junction

temperature of the ADP1853 reaches approximately 155°C, the

ADP1853 goes into thermal shutdown, the converter is turned

off, and SS discharges toward zero through an internal 3 kΩ

resistor. At the same time, VCCO discharges to zero. When

the junction temperature drops below 135°C, the ADP1853

resumes normal operation after the soft start sequence.

INTERLEAVED DUAL-PHASE OPERATION

Two ADP1853 controllers can be configured to design a

dual-phase, interleaved, step-down, switching dc-to-dc

regulators. In dual-phase operation, the two outputs of the

switching regulators are tied together and can source more

than 50 A of output current depending on the selection of

the power components. See Figure 24 for a configuration of a

typical dual-phase application circuit. Note that only one error

amplifier, in the master ADP1853, works; the error amplifier in

the slave ADP1853 output is turned to tristate by tying FB to

VCCO. The CLKOUT signal from the master is connected to

the SYNC input of the slave controller; the SS signals of the

master and slave are tied together; COMP of the slave must be

tied to COMP of the master; and PGOOD of the slave must be

tied to PGOOD of the master.

Figure 24. Dual-Phase Application

Rev. 0 | Page 16 of 28

Page 17

Data Sheet ADP1853

−

=

FB

FB

OUT

BOTTOP

V

VV

RR

SSSS

Ct

μA5.

6

V6.0

=

μA50

06.1

CS

LPK

ILIM

RIR××

=

SWESRO

PP

O

MININ

fDRIV

DDI

C

)(

)1(

,

×−

−×

=

V

APPLICATIONS INFORMATION

ADIsimPower DESIGN TOOL

The ADP1853 is supported by the ADIsimPower design tool

set. ADIsimPower is a collection of tools that produce complete

power designs optimized to a specific design goal. The tools

allow the user to generate a full schematic, bill of materials, and

calculate performance in minutes. ADIsimPower can optimize

designs for cost, area, efficiency, and parts count while taking

into consideration the operating conditions and limitations of

the IC and all real external components. The ADIsimPower tool

can be found at www.analog.com/ADIsimPower and the user

can request an unpopulated board through the tool.

SETTING THE OUTPUT VOLTAGE

The output voltage is set using a resistive voltage divider from

the output to FB. For R

R

to set the output voltage by using the following equation:

TOP

, use a 1 kΩ to 20 kΩ resistor. Choose

BOT

where:

R

is the high-side voltage divider resistance.

TOP

R

is the low-side voltage divider resistance.

BOT

V

is the regulated output voltage.

OUT

V

is the feedback regulation threshold, 0.6 V.

FB

SOFT START

The soft start period is set by an external capacitor between

SS and AGND. The soft start function limits the input inrush

current and prevents output overshoot. When EN is enabled,

a current source of 6.5 µA starts charging the capacitor, and

the regulation voltage is reached when the voltage at SS reaches

0.6 V. The soft start time is approximated by

The SS pin reaches a final voltage equal to VCCO.

When a controller is disabled, for instance, if EN is pulled low

or experiences an overcurrent limit condition, the soft start

capacitor is discharged through an internal 3 kΩ pull-down

resistor.

SETTING THE CURRENT LIMIT

The current-limit comparator measures the voltage across the

low-side MOSFET to determine the load current.

The current limit is set by an external current-limit resistor,

R

, between ILIM and CS. The current sense pin, ILIM,

ILIM

sources nominally 50 μA to this external resistor. This creates

an offset voltage of R

across the current sense element R

side MOSFET, R

multiplied by 50 μA. When the drop

ILIM

(a sense resistor or low-

CS

) is equal to or greater than this offset

DSON

voltage, the ADP1853 flags a current-limit event.

where:

I

is the peak inductor current.

LPK

ACCURATE CURRENT-LIMIT SENSING

R

of the MOSFET can vary by more than 50% over the

DSON

temperature range. Accurate current-limit sensing is achieved

by adding a current sense resistor from the source of the lowside MOSFET to PGND. Make sure that the power rating of the

current sense resistor is adequate for the application. Figure 25

illustrates the implementation of accurate current-limit sensing.

IN

ADP1853

DH

CS

R

ILIM

ILIM

DL

R

SENSE

10594-031

Figure 25. Accurate Current-Limit Sensing

INPUT CAPACITOR SELECTION

Use two parallel capacitors placed close to the drain of the highside switch MOSFET (one bulk capacitor of sufficiently high

current rating and a 10 μF ceramic decoupling capacitor).

Select an input bulk capacitor based on its ripple current

rating. The minimum input capacitance required for a

particular load is

where:

IO is the output current.

D is the duty cycle.

V

is the desired input ripple voltage.

PP

R

is the equivalent series resistance of the capacitors.

ESR

Rev. 0 | Page 17 of 28

Page 18

ADP1853 Data Sheet

IN

OUT

L

SW

OUT

IN

V

V

If

VV

L ×

∆×

−

=

))4((

1

8

2

222

ESLSWESR

L

OUT

SW

L

OUT

LfRIV

f

I

C

×−×∆−∆

×

∆

≅

ESR

L

OUT

RIV ×∆≅∆

SW

OUT

L

OUT

fV

I

C

×∆

∆

≅

8

2

2

2

)(

OUTOVERSHOOTOUT

STEP

OUT

VVV

LI

C

−∆+

∆

≅

VIN

V

IN

AGND

2Ω TO 10Ω

1µF

ADP1853

10594-032

VIN PIN FILTER

It is recommended to have a low-pass filter at the VIN pin.

Connecting a resistor, between 2 Ω and 10 Ω, in series with

VIN and a 1 µF ceramic capacitor between VIN and AGND

creates a low-pass filter that effectively filters out any unwanted

glitches caused by the switching regulator. Keep in mind that

the input current could be larger than 100 mA when driving

large MOSFETs. A 100 mA across a 10 Ω resistor creates a 1 V

drop, which is the same voltage drop in VCCO. In this case, a

lower resistor value is desirable.

Figure 26. Input Filter Configuration

BOOST CAPACITOR SELECTION

Connect a boost capacitor between the SW and BST pins to

provide the current for the high-side driver during switching.

Choose a ceramic capacitor with a value between 0.1 µF and

0.22 µF.

INDUCTOR SELECTION

For most applications, choose an inductor value such that

the inductor ripple current is between 20% and 40% of the

maximum dc output load current.

Choose the inductor value by the following equation:

where:

L is the inductor value.

f

is the switching frequency.

SW

V

is the output voltage.

OUT

V

is the input voltage.

IN

∆I

is the peak-to-peak inductor ripple current.

L

Check the inductor data sheet to make sure that the saturation

current of the inductor is well above the peak inductor current

of a particular design.

OUTPUT CAPACITOR SELECTION

For maximum allowed switching ripple at the output, choose an

output capacitor that is larger than

where:

∆V

is the target maximum output ripple voltage.

OUT

∆I

is the inductor ripple current.

L

R

is the equivalent series resistance of the output capacitor

ESR

(or the parallel combination of ESR of all output capacitors).

L

is the equivalent series inductance of the output capacitor

ESL

(or the parallel combination of ESL of all capacitors).

The impedance of the output capacitor at the switching

frequency multiplied by the ripple current gives the output

voltage ripple. The impedance is made up of the capacitive

impedance plus the nonideal parasitic characteristics, the

equivalent series resistance (ESR), and the equivalent series

inductance (ESL).

Usually the capacitor impedance is dominated by ESR. The

maximum ESR rating of the capacitor, such as in electrolytic

or polymer capacitors, is provided in the manufacturer’s data

sheet; therefore, the output ripple reduces to

Electrolytic capacitors also have significant ESL, on the order

of 5 nH to 20 nH, depending on type, size, and geometry. PCB

traces contribute some ESR and ESL, as well. However, using

the maximum ESR rating from the capacitor data sheet usually

provides some margin such that measuring the ESL may not be

required.

In the case of output capacitors where the impedance of the

ESR and ESL are small at the switching frequency, for instance,

where the output capacitor is a bank of parallel MLCC capacitors, the capacitive impedance dominates, so the output

capacitance must be larger than

Make sure that the ripple current rating of the output capacitors

is greater than the maximum inductor ripple current.

To meet the requirement of the output voltage overshoot during

load release, the output capacitance should be larger than

where:

∆V

OVERS HOOT

Select the largest output capacitance given by either of the

previous two equations.

is the maximum allowed overshoot.

Rev. 0 | Page 18 of 28

Page 19

Data Sheet ADP1853

DSON

RMSLOAD

C

RIP ×=

2

)(

)(

SWG

PV

G

fQVP ××≅

2

)(

SW

FR

LOAD

IN

T

fttIV

P

×+××

≅

RISEDRIVER

GSW

R

I

Q

t

_

≅

FALLDRIVER

GSW

F

I

Q

t

_

≅

2

GS

GDGSW

Q

QQ +≅

GATE

SOURCEON

SP

DD

RISEDRIVER

RR

VV

I

+

−

≅

_

_

GATE

SINKON

SP

FALLDRIVER

RR

V

I

+

≅

_

_

T

CHS

PPP +≅

DSON

RMSLOAD

CLS

RIP ×=

2

)(

)(

If Q

MOSFET SELECTION

The choice of MOSFET directly affects the dc-to-dc converter

performance. A MOSFET with low on resistance reduces I

losses, and low gate charge reduces transition losses. The

MOSFET should have low thermal resistance to ensure that the

power dissipated in the MOSFET does not result in excessive

MOSFET die temperature.

The high-side MOSFET carries the load current during on time

and usually carries most of the transition losses of the converter.

Typically, the lower the on resistance of the MOSFET, the

higher the gate charge and vice versa. Therefore, it is important

to choose a high-side MOSFET that balances the two losses.

The conduction loss of the high-side MOSFET is determined

by the equation

where:

R

is the MOSFET on resistance.

DSON

The gate charging loss is approximated by the equation

where:

V

is the gate driver supply voltage.

PV

Q

is the MOSFET total gate charge.

G

Note that the gate charging power loss is not dissipated in the

MOSFET but rather in the ADP1853 internal drivers. This

power loss should be taken into consideration when calculating

the overall power efficiency.

The high-side MOSFET transition loss is approximated by the

equation

where:

P

is the high-side MOSFET switching loss power.

T

t

is the rise time in charging the high-side MOSFET.

R

t

is the fall time in discharging the high-side MOSFET.

F

t

and tF can be estimated by

R

2

R

is not given in the data sheet, it can be approximated by

GSW

where:

Q

and QGS are the gate-to-drain and gate-to-source charges

GD

given in the MOSFET data sheet.

I

DRIVER_RISE

and I

DR IV ER_ FAL L

can be estimated by

where:

VDD is the input supply voltage to the driver and is between

2.75 V and 5 V, depending on the input voltage.

V

is the switching point where the MOSFET fully conducts;

SP

this voltage can be estimated by inspecting the gate charge

graph given in the MOSFET data sheet.

R

ON_SOURCE

is the on resistance of the ADP1853 internal driver,

given in Table 1, when charging the MOSFET.

R

is the on resistance of the ADP1853 internal driver,

ON_SINK

given in Table 1, when discharging the MOSFET.

R

is the on gate resistance of MOSFET given in the

GAT E

MOSFET data sheet. If an external gate resistor is added, add

this external resistance to R

GATE

.

The total power dissipation of the high-side MOSFET is the

sum of conduction and transition losses:

The synchronous rectifier, or low-side MOSFET, carries the

inductor current when the high-side MOSFET is off. The lowside MOSFET transition loss is small and can be neglected in

the calculation. For high input voltage and low output voltage,

the low-side MOSFET carries the current most of the time.

Therefore, to achieve high efficiency, it is critical to optimize

the low-side MOSFET for low on resistance. In cases where the

power loss exceeds the MOSFET rating or lower resistance is

required than is available in a single MOSFET, connect multiple

low-side MOSFETs in parallel. The equation for low-side

MOSFET conduction power loss is

where:

Q

is the gate charge of the MOSFET during switching and is

GSW

given in the MOSFET data sheet.

I

DRIVER_RISE

and I

DRIVER_FALL

are the driver current output from the

ADP1853 internal gate drivers.

Rev. 0 | Page 19 of 28

Page 20

ADP1853 Data Sheet

OSW

DF

BODYDIODE

IftVP ×××=

BODYDIODECLSLS

PPP +=

RAMPSW

IN

RAMP

Vf

V

R

××

−

=

pF100

V2.0

μA160

V2.0

μA10 ≤

−

≤

RAMP

IN

R

V

LCπ

f

LC

2

1

=

10

SW

CO

f

f =

SW

P2P1

fff

2

1

==

I

Z

SWCO

Z2Z1

CR

ff

ff

π

2

1

404

====

I

Z

LC

Z2Z1

CR

f

ff

π

2

1

2

===

2

LC

IN

CO

Z1

RAMP

TOP

Z

fV

ffVR

R =

Z1Z

I

fRCπ=2

1

G

(dB)

PHASE

–90°

–270°

f

Z

f

P

C

HF

C

I

R

Z

R

FF

R

TOP

R

BOT

V

OUT

INTERNAL

VREF

EA

FB

COMP

–1 SLOPE

–1 SLOPE

C

FF

+1 SLOPE

10594-033

There is also additional power loss during the time, known as

dead time, between the turn-off of the high-side switch and the

turn-on of the low-side switch, when the body diode of the lowside MOSFET conducts the output current. The power loss in

the body diode is given by

where:

V

is the forward voltage drop of the body diode, typically 0.7 V.

F

t

is the dead time in the ADP1853, typically 30 ns when

D

driving a medium size MOSFETs with input capacitance, C

,

iss

of approximately 3 nF. The dead time is not fixed. Its effective

value varies with gate drive resistance and C

P

BODYDIODE

increases in high load current designs and low voltage

; therefore,

iss

designs.

Then the power loss in the low-side MOSFET is

Note that MOSFET on resistance, R

, increases with

DSON

increasing temperature with a typical temperature coefficient of

o

0.4%/

C. The MOSFET junction temperature (TJ) rise over the

ambient temperature is

T

= TA + θJA × P

J

D

where:

θ

is the thermal resistance of the MOSFET package.

JA

T

is the ambient temperature.

A

P

is the total power dissipated in the MOSFET.

D

LOOP COMPENSATION—VOLTAGE MODE

Set the controller to voltage mode operation by placing a

100 kΩ resistor between DL and PGND. Chose the larger

possible ramp amplitude for the voltage mode below 1.5 V.

The ramp voltage is programmed by a resistor value between

V

and the RAMP pin:

IN

Type III Compensation

Figure 27. Type III Compensation

If the output capacitor ESR zero frequency is greater than ½ of

the crossover frequency, use the Type III compensator as shown

in Figure 27.

Calculate the output LC filter resonant frequency as follows:

(2)

Chose a crossover frequency that is 1/10 of the switching

frequency:

(3)

Set the poles and zeros as follows:

(4)

(5)

The voltage at the RAMP pin is fixed at 0.2 V, and the current

going into RAMP should be between 10 µA and 160 µA. Make

sure that the following condition is satisfied:

For instance, with an input voltage of 12 V, R

less than 73.8 kΩ.

Assuming that the LC filter design is complete, the feedback

control system can be compensated. In general, aluminum

electrolytic capacitors have high ESR; however, if several

aluminum electrolytic capacitors are connected in parallel and

produce a low effective ESR, then Type III compensation is

needed. In addition, ceramic capacitors have very low ESR (only

a few milliohms) making Type III compensation a better choice.

or

(6)

Use the lower zero frequency from Equation 5 or Equation 6.

Calculate the compensator resistor, RZ, as follows:

(1)

(7)

should not be

RAMP

Next, calculate C

:

I

(8)

Because of the finite output current drive of the error amplifier,

CI needs to be less than 10 nF. If it is larger than 10 nF, choose a

larger R

and recalculate RZ and CI until CI is less than 10 nF.

TOP

Rev. 0 | Page 20 of 28

Page 21

Data Sheet ADP1853

Z

SW

HF

RfCπ

=

1

SW

FF

FF

fCRπ

=

1

CSCS

RAMP

RA

L

R

×

××

=

6

107

RAMPSW

IN

RAMP

Rf

V

V

××

−

=

pF100

V2.0

μA160

V2.0

μA10 ≤

−

≤

RAMP

IN

R

V

ADP1853

DH

CS

ILIM

DL

R

ILIM

R

CSG

RAMP

R

RAMP

V

IN

10594-034

Because CHF << CI, calculate CHF as follows:

(9)

The voltage at the RAMP pin is fixed at 0.2 V, and the current

going into RAMP should be between 10 µA and 160 µA. Make

sure that the following condition is satisfied:

Next, calculate the feedforward capacitor, C

R

:

TOP

, assuming RFF <<

FF

(10)

Check that the calculated component values are reasonable.

For instance, capacitors smaller than about 10 pF should be

avoided. In addition, R

values less than 3 kΩ and CI values

Z

greater than 10 nF should be avoided. If necessary, recalculate

the compensation network with a different starting value for

R

. If RZ is too small or CI is too big, start with a larger value

TOP

for R

. This compensation technique should yield a good

TOP

working solution.

When precise compensation is needed, use the ADIsimPower

design tool.

LOOP COMPENSATION—CURRENT MODE

Compensate the ADP1853 error voltage loop in current mode

using Type II compensation.

Setting the Slope Compensation

In a current-mode control topology, slope compensation is

needed to prevent subharmonic oscillations in the inductor

current and to maintain a stable output. The external slope

compensation is implemented by summing the amplified sense

signal and a scaled voltage at the RAMP pin. To set the effective

slope compensation, connect a resistor (R

RAMP pin and the input voltage (V

). R

IN

) between the

RAMP

is calculated by

RAMP

For instance, with an input voltage of 12 V, R

exceed 1.1 MΩ. If the calculated R

10 µA, then select an R

value that produces between

RAMP

produces less than

RAMP

should not

RAMP

10 µA and 15 µA.

Figure 28 illustrates the connection of the slope compensation

resistor, R

, and the current sense gain resistor, R

RAMP

Figure 28. Slope Compensation and CS Gain Connection

CSG

.

where:

L is the inductor value measured in µH.

R

CS and PGND (for instance, R

maximum on resistance).

A

or 12 V/V.

Thus, the voltage ramp amplitude, V

where 100 pF is the effective capacitance of the internal ramp

capacitor, C

V

(mΩ) is resistance of the current sense element between

CS

is the low-side MOSFET

DSON_MAX

is the current sense amplifier gain and is 3 V/ V, 6 V/ V,

CS

, is:

RAMP

, with ±4% tolerance over the temperature and

RAMP

range.

IN

Rev. 0 | Page 21 of 28

Page 22

ADP1853 Data Sheet

V

Setting the Current Sense Gain

The voltage drop across the external low-side MOSFET is

sensed by a current sense amplifier by multiplying the peak

inductor current and the R

of the MOSFET. The result is

DSON

then amplified by a gain factor of 3 V/V, 6 V/V, or 12 V/V,

which is programmable by an external resistor, R

, connected

CSG

to the DL pin. This gain is sensed only during power-up and

not during normal operation. The amplified voltage is summed

with the slope compensation ramp voltage and fed into the

PWM controller for a stable regulation voltage.

The voltage range of the internal node, V

, is between 0.4 V

CS

and 2.2 V. Select the current sense gain such that the internal

minimum amplified voltage (V

maximum amplified voltage (V

or V

is not the same as V

CSMAX

to 2.2 V. Make sure that the maximum V

) is above 0.4 V and the

CSMIN

) is 2.1 V. Note that V

CSMAX

, which has a range of 0.85 V

COMP

(V

COMP

COMPMAX

CSMIN

) does

not exceed 2.2 V to account for temperature and part-to-part

, V

variations. See the following equations for V

V

:

COMPMAX

1

CSMIN

V

COMPMAX

V75.0

2

(V75.0

LOADMAXCSMAX

IN

pF100

R

L

)V2.0(

RAMP

ARIV

_

1

)

L

2

tV

ON

V

CSMAX

CSMIN

CSMINDSON

_

CSMAX

ARIIV

CSMAXDSON

, and

where:

is the minimum amplified voltage of the internal current

V

CSMIN

sense amplifier at zero output current.

is the peak-to-peak ripple current in the inductor.

I

L

R

is the low-side MOSFET minimum on resistance. The

DSON_MIN

zero current level voltage of the current sense amplifier is 0.75 V.

is the maximum amplified voltage of the internal current

V

CSMAX

sense amplifier at the maximum output current.

is the maximum output dc load current.

I

LOADMAX

V

t

ON

Replace R

element, R

is the maximum voltage at the COMP pin.

COMPMAX

is the high-side driver (DH) on time.

with the resistance value of the current sense

DSON

, if it is used.

CS

Type II Compensation

–

1

S

L

O

G

P

R

TOP

R

BOT

E

f

Z

R

Z

FB

INTERNAL

VREF

EA

–

1

S

L

O

P

E

f

P

C

HF

C

I

COMP

10594-035

(dB)

PHASE

–180°

–270°

OUT

Figure 29. Type II Compensation

In this case, use the circuit shown in Figure 29. Calculate the

compensation resistor, R

TOPZ

, with the following equation:

Z

2

S

fCRRR

(11)

CO

OUT

where:

f

is chosen to be 1/10 of fSW.

CO

= ACS × R

R

S

DSON_MIN.

ACS is the current sense gain of either 3 V/V, 6 V/V, or 12 V/V,

set by the gain resistor between DL and PGND.

R

If the current is sensed on a current sense resistor, R

is the low-side MOSFET minimum on resistance.

DSON_MIN

, then RCS

CS

becomes

RAR

CSCSS

Next, choose the compensation capacitor to set the compensation zero, f

, to the lesser of 1/5 of the crossover frequency or ½

Z1

of the LC resonant frequency

ff

f

Z1

SWCO

505

1

2

(12)

CR

I

Z

or

f

Z1

Solving for C

C

I

Solving for C

C

I

f

LC

2

1

2

in Equation 12 yields

I

25

fR

SW

Z

in Equation 13 yields

I

1

fR

LC

Z

(13)

CR

I

Z

(14)

(15)

Rev. 0 | Page 22 of 28

Page 23

Data Sheet ADP1853

SW

P1

ff

2

1

=

HF

Z

P1

CRfπ=2

1

Z

SW

HF

RfCπ

=

1

SWSNUB

IN

SNUB

fCVP ××=

2

+

+

=

TRKB

TRKT

BOT

TOP

MASTEROUT

SLAVEOUT

R

R

R

R

V

V

1

1

_

_

MASTER VOLTAGE

SLAVE VOLTAGE

TIME

VOLTAGE (V)

10594-037

ADP1853

FB

SS

TRK

R

BOT

10kΩ

R

TOP

20kΩ

1.1V

3.3V

V

OUT_MASTER

1.8V

V

OUT_SLAVE

R

TRKB

10kΩ

R

TRKT

20kΩ

C

SS

20nF

10594-038

Use the larger value of CI from Equation 14 or Equation 15.

Because of the finite output current drive of the error amplifier,

C

needs to be less than 10 nF. If it is larger than 10 nF, choose a

I

larger R

Next, choose the high frequency pole, f

and recalculate RZ and CI until CI is less than 10 nF.

TOP

, to be ½ of fSW.

P1

(16)

Because C

<< CI,

HF

(17)

Combine Equation 16 and Equation 17, and solve for C

,

HF

(18)

For maximally precise compensation solutions, use the

ADIsimPower design tool.

SWITCHING NOISE AND OVERSHOOT REDUCTION

To reduce voltage ringing and noise, it is recommended to add

an RC snubber between SW and PGND for high current

applications, as illustrated in Figure 30.

In most applications, R

typically 1.2 nF to 3 nF.

The size of the RC snubber components must be chosen

correctly to handle the power dissipation. The power dissipated

in R

SNUB

is

In most applications, a component size of 0805 for R

sufficient. The RC snubber does not reduce the voltage overshoot. A resistor, shown as R

helps to reduce overshoot and is generally between 2 Ω and

4 Ω. Adding a resistor in series, typically between 2 Ω and

4 Ω, with the gate driver also helps to reduce overshoot. If a

gate resistor is added, then R

is typically 2 Ω to 4 Ω, and C

SNUB

in Figure 30, at the BST pin

RISE

is not needed.

RISE

SNUB

SNUB

is

is

VOLTAGE TRACKING

The ADP1853 includes a tracking feature that tracks a master

voltage. In all tracking configurations, the output can be set as

low as 0.6 V for a given operating condition. The soft start time

setting of the master voltage should be longer than the soft start

of the slave voltage. This forces the rise time of the master

voltage to be imposed on the slave voltage. If the soft start

setting of the slave voltage is longer, the slave comes up more

slowly, and the tracking relationship is not seen at the output.

Two tracking configurations are possible with the ADP1853:

coincident and ratiometric tracking.

Coincident Tracking

The most common application is coincident tracking, used

in core vs. I/O voltage sequencing and similar applications.

Coincident tracking forces the ramp rate of the output voltage

to be the same for the master and slave until the slave output

reaches its regulation. Connect the slave TRK input to a resistor

divider from the master voltage that is the same as the divider

used on the slave FB pin. This forces the slave voltage to be the

same as the master voltage. For coincident tracking, use R

R

TOP

and R

TRKB

= R

, as shown in Figure 32.

BOT

Figure 31. Coincident Tracking

TRKT

=

ADP1853

V

IN

M1

L

R

SNUB

M2

C

SNUB

BST

SW

PGND

DH

DL

R

RISE

Figure 30. Application Circuit with a Snubber

Figure 32. Example of a Coincident Tracking Circuit

V

OUT

C

OUT

10594-036

The ratio of the slave output voltage to the master voltage is a

function of the two dividers.

Rev. 0 | Page 23 of 28

Page 24

ADP1853 Data Sheet

MASTER VOLTAGE

SLAVE VOLTAGE

TIME

VOLTAGE (V)

10594-039

ADP1853

FB

SS

TRK

R

BOT

10kΩ

R

TOP

22.6kΩ

0.55V 0.55V

3.3V

V

OUT_MASTER

1.8V

V

OUT_SLAVE

R

TRKB

10kΩ

R

TRKT

49.9kΩ

C

SS

20nF

10594-040

As the master voltage rises, the slave voltage rises identically.

Eventually, the slave voltage reaches its regulation voltage,

where the internal reference takes over the regulation while

the TRK input continues to increase, thus removing itself from

influencing the output voltage.

To ensure that the output voltage accuracy is not compromised

by the TRK pin being too close in voltage to the reference voltage (V

TRK voltage of the slave channel is at least 30 mV above V

, typically 0.6 V), make sure that the final value of the

FB

.

FB

Ratiometric Tracking

Ratiometric tracking limits the output voltage to a fraction of

the master voltage, as illustrated in Figure 33 and Figure 34. The