Page 1

Wide Range Input, Dual/Two-Phase, DC-to-DC

V

Data Sheet

FEATURES

Wide range input: 2.75 V to 20 V

Power stage input voltage: 1 V to 20 V

Output voltage range: 0.6 V up to 90% V

Output current to more than 25 A per channel

Accurate current sharing between channels (interleaved)

Programmable frequency: 200 kHz to 1.5 MHz

180° phase shift between channels for reduced input

capacitance

±0.85% reference voltage accuracy from −40°C to +85°C

Integrated boost diodes

Power saving mode (PSM) at light loads

Accurate power good with internal pull-up resistor

Accurate voltage tracking capability

Independent channel precision enable

Overvoltage and overcurrent limit protection

Externally programmable soft start, slope compensation and

current sense gain

Synchronization input

Thermal overload protection

Input undervoltage lockout (UVLO)

Available in 32-lead 5 mm × 5 mm LFCSP

APPLICATIONS

High current single and dual output intermediate bus and

point of load converters requiring sequencing and

tracking capability, including converters for:

Point-of-load power supplies

Telecom base station and networking

Consumer

Industrial and instrumentation

Healthcare and medical

GENERAL DESCRIPTION

The ADP1850 is a configurable dual output or two-phase, single

output dc-to-dc synchronous buck controller capable of running

from commonly used 3.3 V to 12 V (up to 20 V) voltage inputs.

The device operates in current mode for improved transient

response and uses valley current sensing for enhanced noise

immunity.

The architecture enables accurate current sharing between

interleaved phases for high current outputs.

The ADP1850 is ideal in system applications requiring multiple

output voltages: the ADP1850 includes a synchronization feature to eliminate beat frequencies between switching devices;

provides accurate tracking capability between supplies and

includes precision enable for simple, robust sequencing.

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

IN

Synchronous Buck Controller

ADP1850

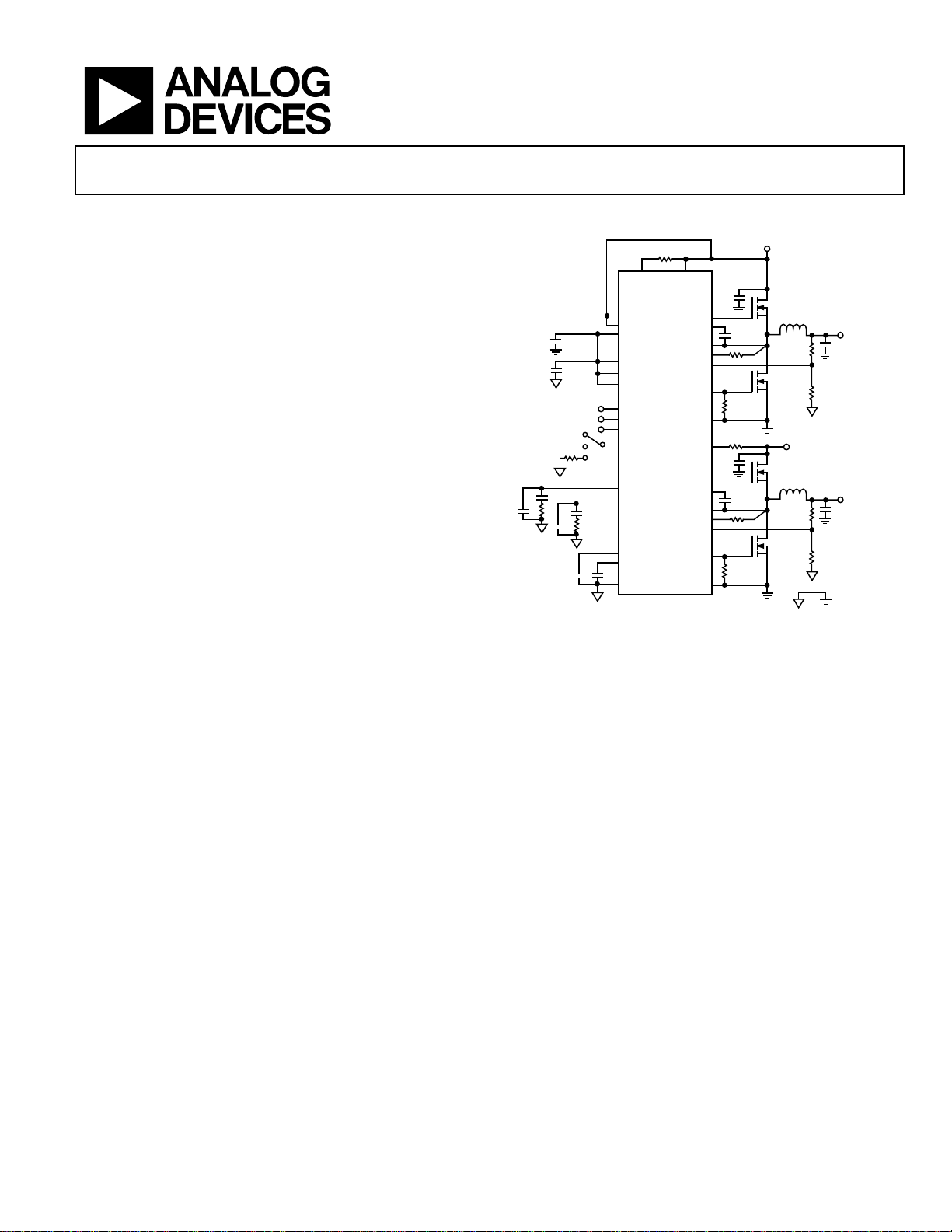

TYPICAL OPERATION CIRCUIT

R

RAMP2

R

R

CSG1

CSG2

IN

M1

L1

R11

M2

R12

V

IN

M3

L2

R21

M4

R22

R

RAMP1

RAMP1

VIN

ADP1850

EN1

EN2

VDL

VCCO

TRK1

TRK2

PGOOD1

PGOOD2

HI

LO

SYNC

FREQ

COMP1

COMP2

SS1

SS2

AGND

DH1

BST1

SW1

ILIM1

FB1

DL1

PGND1

RAMP2

DH2

BST2

SW2

ILIM2

FB2

DL2

PGND2

Figure 1. Single Phase Circuit

The ADP1850 provides high speed, high peak current drive

capability with dead-time optimization to enable energy

efficient power conversion. For low load operation, the device

can be configured to operate in power saving mode (PSM) by

skipping pulses and reducing switching losses to improve the

energy efficiency at light load and standby conditions.

The accurate current limit (±6%) allows the power architect to

design within a narrower range of tolerances and can reduce

overall converter size and cost.

The ADP1850 provides a configurable architecture capable

of wide range input operation to provide the designer with

maximum re-use opportunities and improved time to market.

Additional flexibility is provided by external programmability

of loop compensation, soft start, frequency setting, power

saving mode, current limit and current sense gain can all be

programmed using external components.

The ADP1850 includes a high level of integration in a small size

package. The start-up linear regulator and the boot-strap diode

for the high side drive are included. Protection features include:

undervoltage lock-out, overvoltage, overcurrent/short-circuit

and over temperature. The ADP1850 is available in a compact

32-lead LFCSP 5 mm × 5 mm thermally enhanced package.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010-2012 Analog Devices, Inc. All rights reserved.

V

V

OUT1

OUT2

09440-001

Page 2

ADP1850 Data Sheet

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Typical Operation Circuit ................................................................ 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Absolute Maximum Ratings ............................................................ 5

ESD Caution .................................................................................. 5

Simplified Block Diagram ............................................................... 6

Pin Configuration and Function Descriptions ............................. 7

Typical Performance Characteristics ............................................. 9

Theory of Operation ...................................................................... 12

Control Architecture .................................................................. 12

Oscillator Fre quency .................................................................. 12

Modes of Operation ................................................................... 13

Synchronization .......................................................................... 13

Synchronous Rectifier and Dead Time ................................... 14

Input Undervoltage Lockout ..................................................... 14

Internal Linear Regulator .......................................................... 14

Overvoltage Protection .............................................................. 14

Power Good ................................................................................. 14

Short-Circuit and Current-Limit Protection .......................... 15

Shutdown Control ...................................................................... 15

Thermal Overload Protection ................................................... 15

Applications Information .............................................................. 16

Setting the Output Voltage ........................................................ 16

Soft Start ...................................................................................... 16

Setting the Current Limit .......................................................... 16

Accurate Current-Limit Sensing .............................................. 17

Setting the Slope Compensation .............................................. 17

Setting the Current Sense Gain ................................................ 17

Input Capacitor Selection .......................................................... 18

Input Filter ................................................................................... 18

Boost Capacitor Selection ......................................................... 18

Inductor Selection ...................................................................... 18

Output Capacitor Selection ....................................................... 19

MOSFET Selection ..................................................................... 19

Loop Compensation (Single Phase Operation) ..................... 21

Configuration and Loop Compensation (Dual-Phase

Operation) ................................................................................... 22

Switching Noise and Overshoot Reduction ............................ 22

Voltage Tracking ......................................................................... 23

Indepdendent Power Stage Input Voltage ............................... 24

PCB Layout Guidelines .................................................................. 25

MOSFETs, Input Bulk Capacitor, and Bypass Capacitor ...... 25

High Current and Current Sense Paths ................................... 25

Signal Paths ................................................................................. 25

PGND Plane ................................................................................ 25

Feedback and Current-Limit Sense Paths ............................... 25

Switch Node ................................................................................ 26

Gate Driver Paths ....................................................................... 26

Output Capacitors ...................................................................... 26

Typical Operating Circuits ............................................................ 27

Outline Dimensions ....................................................................... 31

Ordering Guide .......................................................................... 31

REVISION HISTORY

4/12—Rev. 0 to Rev. A

Changes to Setting the Current Sense Gain Section .................. 17

Updated Outline Dimensions ....................................................... 31

11/10—Revision 0: Initial Version

Rev. A | Page 2 of 32

Page 3

Data Sheet ADP1850

SPECIFICATIONS

All limits at temperature extremes are guaranteed via correlation using standard statistical quality control (SQC). VIN = 12 V. The

specifications are valid for T

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

POWER SUPPLY

Input Voltage VIN 2.75 20 V

Undervoltage Lockout Threshold IN

V

Undervoltage Lockout Hysteresis 0.1 V

Quiescent Current IIN

EN1 = EN2 = VIN = 12 V, VFB = V

Shutdown Current I

ERROR AMPLIFIER

FBx Input Bias Current IFB −100 +1 +100 nA

Transconductance Gm Sink or source 1 µA 385 550 715 µS

TRK1, TRK2 Input Bias Current I

CURRENT SENSE AMPLIFIER GAIN ACS

Default setting, R

OUTPUT CHARACTERICTISTICS

Feedback Accuracy Voltage VFB

Line Regulation of PWM ∆VFB/∆VIN ±0.015 %/V

Load Regulation of PWM ∆VFB/∆V

OSCILLATOR

Frequency fSW R

R

R

FREQ to AGND 235 300 345 kHz

FREQ to VCCO 475 600 690 kHz

SYNC Input Frequency Range f

SYNC Input Pulse Width t

SYNC Pin Capacitance to GND C

LINEAR REGULATOR

VCCO Output Voltage I

VCCO Load Regulation I

VCCO Line Regulation VIN = 5.5 V to 20 V, I

VCCO Current Limit1 VCCO drops to 4 V from 5 V 350 mA

VCCO Short-Circuit Current1 VCCO < 0.5 V 370 400 mA

VIN to VCCO Dropout Voltage2 V

LOGIC INPUTS

EN1, EN2 EN1/EN2 rising 0.57 0.63 0.68 V

EN1, EN2 Hysteresis 0.03 V

EN1, EN2 Input Leakage Current IEN V

SYNC Logic Input Low 1.3 V

SYNC Logic Input High 1.9 V

SYNC Input Pull-Down Resistance R

= −40°C to +125°C, unless otherwise specified. Typical values are at TA = 25°C.

J

V

UVLO

rising 2.45 2.6 2.75 V

IN

falling 2.4 2.5 2.6

IN

EN1 = EN2 = V

= 12 V, VFB = V

IN

in PWM mode

CCO

4.5 5.8

(no switching)

in PSM mode 2.8

CCO

EN1 = EN2 = GND, VIN = 5.5 V or 20 V 100 200

IN_SD

0 V ≤ V

TRK

TRK1/VTRK2

Gain resistor connected to DLx,

= 47 kΩ ± 5%

R

CSG

Gain resistor connected to DLx,

= 22 kΩ ± 5%

R

CSG

Gain resistor connected to DLx,

= 100 kΩ ± 5%

R

CSG

= −40°C to +85°C, VFB = 0.6 V

T

J

= −40°C to +125°C, VFB = 0.6 V

T

J

V

COMP

f

SYNC

100 ns

SYNCMIN

5 pF

SYNC

I

DROPOUT

1 MΩ

SYNC

range = 0.9 V to 2.2 V ±0.3 %

COMP

= 340 kΩ to AGND 170 200 235 kHz

FREQ

= 78.7 kΩ to AGND 720 800 880 kHz

FREQ

= 39.2 kΩ to AGND 1275 1500 1725 kHz

FREQ

= 2 × fSW 400 3000 kHz

SYNC

= 100 mA 4.7 5.0 5.3 V

VCCO

= 0 mA to 100 mA, 35 mV

VCCO

= 100 mA, VIN ≤ 5 V 0.33 V

VCCO

= 2.75 V to 20 V 1 200 nA

IN

≤ 5 V −100 +1 +100 nA

2.4 3 3.6 V/V

5.2 6 6.9 V/V

= open 10.5 12 13.5 V/V

CSG

20.5 24 26.5 V/V

−0.85% +0.6 +0.85% V

−1.5% +0.6 +1.5% V

= 20 mA 10 mV

VCCO

Rev. A | Page 3 of 32

mA

mA

µA

Page 4

ADP1850 Data Sheet

Parameter Symbol Conditions Min Typ Max Unit

GATE DRIVERS

DHx Rise Time CDH = 3 nF, V

DHx Fall Time CDH = 3 nF, V

DLx Rise Time CDL = 3 nF 16 ns

DLx Fall Time CDL = 3 nF 14 ns

DHx to DLx Dead Time External 3 nF is connected to DHx and DLx 25 ns

DHx or DLx Driver RON, Sourcing

Current

1

R

Sourcing 2 A with a 100 ns pulse 2 Ω

ON_SOURCE

Sourcing 1 A with a 100 ns pulse, VIN = 3 V 2.3 Ω

DHx or DLx Driver RON, Tempco TC

DHx or DLx Driver RON, Sinking

Current

1

V

RON

R

Sinking 2 A with a 100 ns pulse 1.5 Ω

ON_SINK

= 3 V or 12 V 0.3 %/oC

IN

Sinking 1 A with a 100 ns pulse, VIN = 3 V 2 Ω

DHx Maximum Duty Cycle fSW = 300 kHz 90 %

DHx Maximum Duty Cycle fSW = 1500 kHz 50 %

Minimum DHx On Time fSW = 200 kHz to 1500 kHz 135 ns

Minimum DHx Off Time fSW = 200 kHz to 1500 kHz 335 ns

Minimum DLx On Time fSW = 200 kHz to 1500 kHz 285 ns

COMPx VOLTAGE RANGE

COMPx Pulse Skip Threshold V

COMPx Clamp High Voltage V

In pulse skip mode 0.9 V

COMP,THRES

2.25 V

COMP,HIGH

THERMAL SHUTDOWN

Thermal Shutdown Threshold T

155

TMSD

Thermal Shutdown Hysteresis 20

OVERVOLTAGE AND POWER GOOD

THRESHOLDS

FBx Overvoltage Threshold VOV V

rising 0.635 0.65 0.665 V

FB

FBx Overvoltage Hysteresis 30 mV

FBx Undervoltage Threshold VUV V

falling 0.525 0.55 0.578 V

FB

FBx Undervoltage Hysteresis 30 mV

TRKx INPUT VOLTAGE RANGE 0 5 V

FBx TO TRKx OFFSET VOLTAGE TRKx = 0.1 V to 0.57 V, offset = VFB − V

SOFT START

SSx Output Current ISS During start-up 4.6 6.5 8.4 µA

SSx Pull-Down Resistor During a fault condition 3 kΩ

FBx to SSx Offset VSS = 0.1 V to 0.6 V, offset = VFB − VSS −10 +10 mV

PGOODx

PGOODx Pull-up Resistor R

Internal pull-up resistor to VCCO 12.5 kΩ

PGOOD

PGOODx Delay 12 µs

Over Voltage or Under Voltage

This is the minimum duration required to trip

the PGOOD signal

Minimum Duration

ILIM1, ILIM2 Threshold Voltage1 Relative to PGNDx −5 0 +5 mV

ILIM1, ILIM2 Output Current ILIMx = PGNDx 47 50 53 µA

Current Sense Blanking Period

After DLx goes high, current limit is not sensed

during this period

INTEGRATED RECTIFIER

At 20 mA forward current 16 Ω

(BOOST DIODE) RESISTANCE

ZERO CURRENT CROSS OFFSET

(SWx TO PGNDx)

1

Guaranteed by design.

2

Connect VIN to VCCO when 2.75 V < VIN < 5.5 V.

1

In pulse skip mode only, f

− VSW = 5 V 16 ns

BST

− VSW = 5 V 14 ns

BST

−10 0 +10 mV

TRK

10 µs

100 ns

= 600 kHz 0 2 4 mV

SW

°C

°C

Rev. A | Page 4 of 32

Page 5

Data Sheet ADP1850

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VIN, EN1/EN2, RAMP1/RAMP2 21 V

FB1/FB2, COMP1/COMP2, SS1/SS2, TRK1/TRK2,

FREQ, SYNC, VCCO, VDL, PGOOD1/PGOOD2

ILIM1/ILIM2, SW1/SW2 to PGND1/PGND2 −0.3 V to +21 V

BST1/BST2, DH1/DH2 to PGND1/PGND2 −0.3 V to +28 V

DL1/DL2 to PGND1/PGND2 −0.3V to VCCO + 0.3 V

BST1/BST2 to SW1/SW2 −0.3 V to +6 V

BST1/BST2 to PGND1/PGND2

20 ns Transients

SW1/SW2 to PGND1/PGND2

20 ns Transients

DL1/DL2, SW1/SW2, ILIM1/ILIM2 to

PGND1/PGND2

20 ns Negative Transients

PGND1/PGND2 to AGND −0.3 V to +0.3 V

PGND1/PGND2 to AGND 20 ns Transients −8 V to +4 V

θJA on Multilayer PCB (Natural Convection)

Operating Junction Temperature Range3 −40°C to +125°C

Storage Temperature Range −65°C to +150°C

Maximum Soldering Lead Temperature 260°C

1

Measured with exposed pad attached to PCB.

2

Junction-to-ambient thermal resistance (θJA) of the package was calculated

or simulated on multilayer PCB.

3

The junction temperature, TJ, of the device is dependent on the ambient

temperature, TA, the power dissipation of the device, PD, and the junction-toambient thermal resistance of the package, θJA. Maximum junction

temperature is calculated from the ambient temperature and power

dissipation using the formula: TJ = TA + PD × θJA.

1, 2

−0.3 V to +6 V

32 V

25 V

−8 V

32.6°C/W

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Absolute maximum ratings apply individually only, not in

combination. Unless otherwise specified, all other voltages are

referenced to GND.

ESD CAUTION

Rev. A | Page 5 of 32

Page 6

ADP1850 Data Sheet

V

V

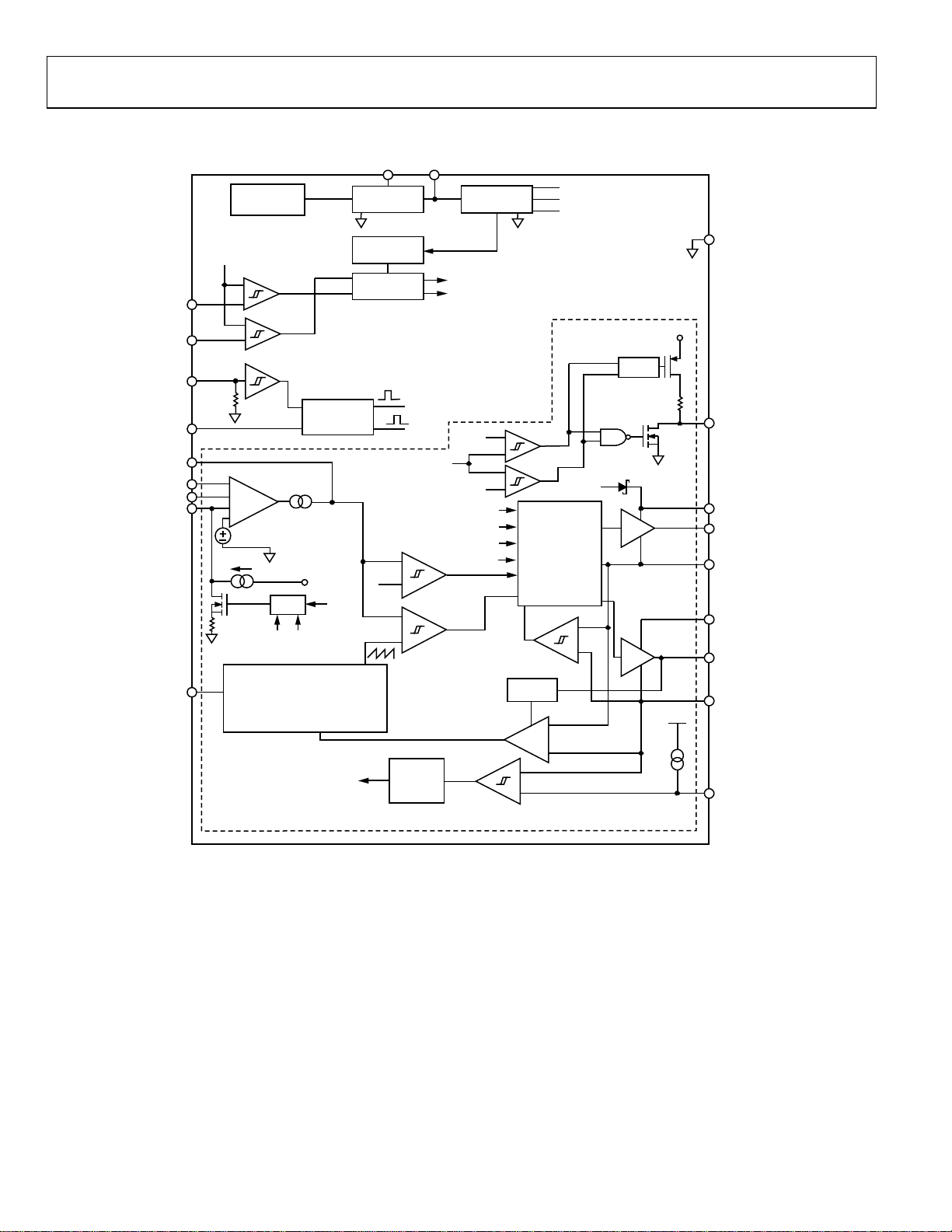

SIMPLIFIED BLOCK DIAGRAM

IN

CCO

THERMAL

SHUTDOWN

LDO

REF

OV

0.6V

UV

EN1

EN2

SYNC

FREQ

COMP1

FB1

TRK1

SS1

RAMP1

0.6V

1MΩ

1kΩ

+

–

+

–

ERROR

AMPLIFIER

–

+

G

m

+

+

V

=

0

.

6

V

R

F

E

6.5µA

LOGIC

FAULT

EN1

SLOPE COMP AND

RAMP GENERATOR

OSCILLAT OR

5V

OV1

OVER_LIM1

OVER_LIM1

UVLO

LOGIC

0.9V

COMPARATOR

CURRENT

CONTROL

PH1

PH2

0.6V

–

+

–

+

PWM

LIMIT

EN1_SW

EN2_SW

DUPLICATE FOR

CHANNEL 2

OV

FB1

UV

SYNC

EN1_SW

OVER_LIM1

OV1

PULSE SKIP

AV = 3, 6, 12, 24

+

–

+

–

DRIVER LOG IC

CONTROL AND

MACHINE

DCM

ZERO CROSS

DETECT

CS GAIN

–

+

+

–

OV1

UV1

VDL

STATE

+

–

CURRENT SENSE

AMPLIFIER

AGND

VCCO

LOGIC

12kΩ

PGOOD1

BST1

DH1

SW1

VDL

DL1

PGND1

VCCO

50µA

ILIM1

9440-003

Figure 2.

Rev. A | Page 6 of 32

Page 7

Data Sheet ADP1850

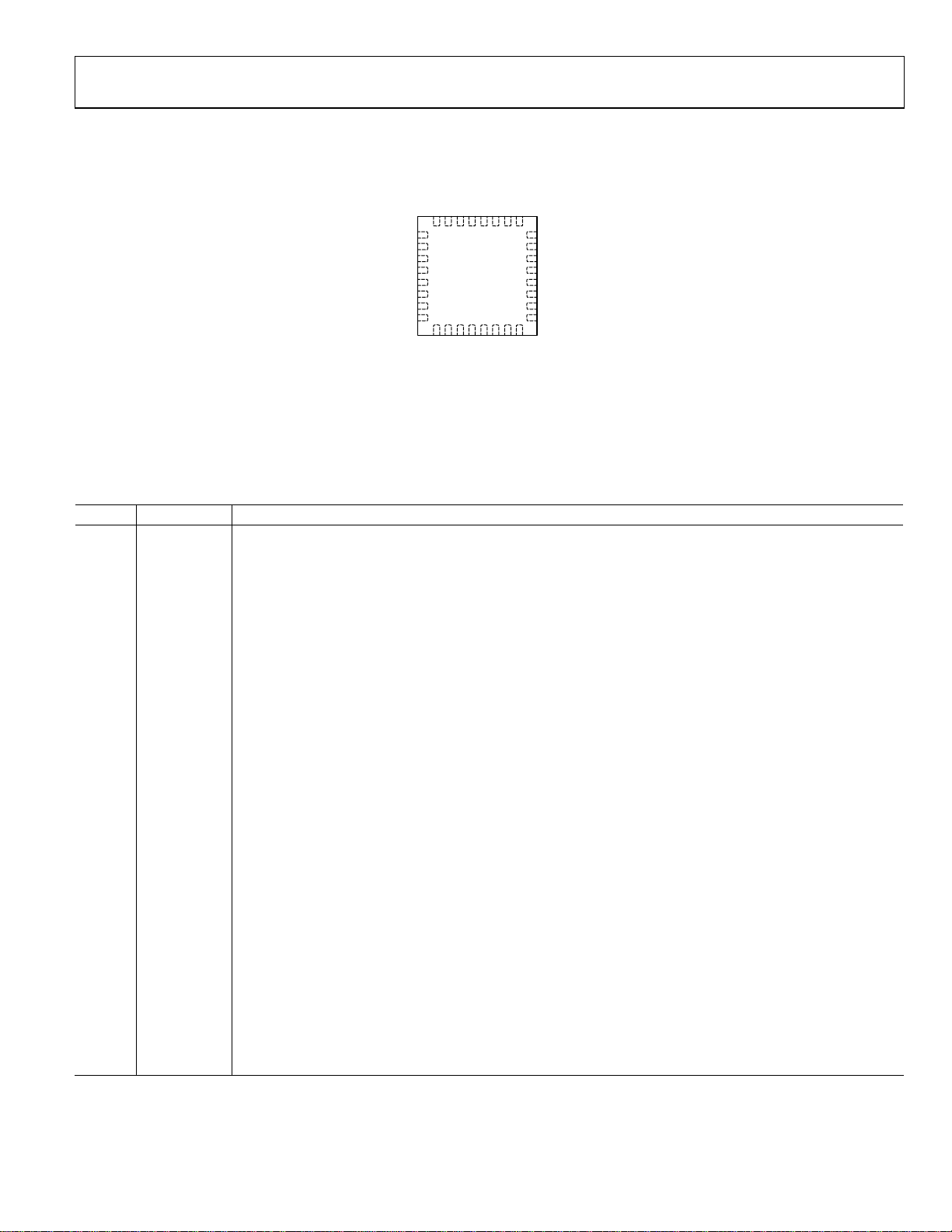

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

TRK1

FB1

COMP1

RAMP1

SS1

PGOOD1

ILIM1

SS2

BST1

25

24

SW1

23

DH1

PGND1

22

DL1

21

20

DL2

19

PGND2

18

DH2

17 SW2

ILIM2

BST2

PGOOD2

09440-004

32313029282726

1

EN1

2

SYNC

VIN

3

4

5

6

7

8

ADP1850

TOP VIEW

(Not to Scale)

9

10111213141516

FB2

TRK2

RAMP2

COMP2

VCCO

VDL

AGND

FREQ

EN2

NOTES

1. CONNECT THE BOTTOM EXPOSED PAD OF THE

LFCSP PACKAGE TO SYST EM AGND PLANE .

Figure 3. Pin Configuration

Table 3. Pin Function Descriptions

Pin No. Mnemonic Description

1 EN1

Enable Input for Channel 1. Drive EN1 high to turn on the Channel 1 controller, and drive EN1 low to turn off the

Channel 1 controller. Tie EN1 to VIN for automatic startup. For a precision UVLO, put an appropriately sized

resistor divider from VIN to AGND and tie the midpoint to this pin.

2 SYNC

Frequency Synchronization Input. Accepts an external signal between 1× and 2.3× of the internal oscillator

frequency, f

, set by the FREQ pin. The controller operates in forced PWM when a signal is detected at SYNC or

SW

when SYNC is high. The resulting switching frequency is ½ of the SYNC frequency. When SYNC is low or left

floating, the controller operates in pulse skip mode. For dual-phase operation, connect SYNC to a logic high or an

external clock.

3 VIN

Connect to Main Power Supply. Bypass with a 1 µF or larger ceramic capacitor connected as close to this pin as

possible and PGNDx.

4 VCCO

Output of the Internal Low Dropout Regulator (LDO). Bypass VCCO to AGND with a 1 F or larger ceramic

capacitor. The VCCO output remains active even when EN1 and EN2 are low. For operation with VIN below 5 V,

VIN may be shorted to VCCO. Do not use the LDO to power other auxiliary system loads.

5 VDL

Power Supply for the Low-Side Driver. Bypass VDL to PGNDx with a 1 µF or greater ceramic capacitor. Connect

VCCO to VDL.

6 AGND Analog Ground.

7 FREQ

Sets the desired operating frequency between 200 kHz and 1.5 MHz with one resistor between FREQ and AGND.

Connect FREQ to AGND for a preprogrammed 300 kHz or FREQ to VCCO for 600 kHz operating frequency.

8 EN2

Enable Input for Channel 2. Drive EN2 high to turn on the Channel 2 controller, and drive EN2 low to turn off the

Channel 2 controller. Tie EN2 to VIN for automatic startup. For a precision UVLO, put an appropriately sized

resistor divider from VIN to AGND, and tie the midpoint to this pin.

9 TRK2 Tracking Input for Channel 2. Connect TRK2 to VCCO if tracking is not used.

10 FB2 Output Voltage Feedback for Channel 2. Connect to Output 2 via a resistor divider.

11 COMP2

Compensation Node for Channel 2. Output of Channel 2 error amplifier. Connect a series resistor-capacitor

network from COMP2 to AGND to compensate the regulation control loop.

12 RAMP2

Connect a resistor from RAMP2 to VIN to set up a ramp current for slope compensation in Channel 2. The voltage

at RAMP2 is 0.2 V. This pin is high impedance when the channel is disabled.

13 SS2

Soft Start Input for Channel 2. Connect a capacitor from SS2 to AGND to set the soft start period. The node is

internally pulled up to 5 V with a 6.5 µA current source.

14 PGOOD2

Power Good. Open-drain power-good indicator logic output with an internal 12 kΩ resistor connected between

PGOOD2 and VCCO. PGOOD2 is pulled to ground when the Channel 2 output is outside the regulation window.

An external pull-up resistor is not required.

Rev. A | Page 7 of 32

Page 8

ADP1850 Data Sheet

Pin No. Mnemonic Description

15 ILIM2

16 BST2

17 SW2

18 DH2

19 PGND2

20 DL2

21 DL1

22 PGND1

23 DH1

24 SW1

25 BST1

26 ILIM1

27 PGOOD1

28 SS1

29 RAMP1

30 COMP1

31 FB1 Output Voltage Feedback for Channel 1. Connect to Output 1 via a resistor divider.

32 TRK1 Tracking Input for Channel 1. Connect TRK1 to VCCO if tracking is not used.

33

(EPAD)

Exposed Pad

(EPAD)

Current Limit Sense Comparator Inverting Input for Channel 2. Connect a resistor between ILIM2 and SW2 to set

the current limit offset. For accurate current limit sensing, connect ILIM2 to a current sense resistor at the source

of the low-side MOSFET.

Boot-Strapped Upper Rail of High Side Internal Driver for Channel 2. Connect a multilayer ceramic capacitor

(0.1 µF to 0.22 µF) between BST2 and SW2. There is an internal boost rectifier connected between VDL and BST2.

Switch Node for Channel 2. Connect to source of the high-side N-channel MOSFET and the drain of the low-side

N-channel MOSFET of Channel 2.

High-Side Switch Gate Driver Output for Channel 2. Capable of driving MOSFETs with total input capacitance up

to 20 nF.

Power Ground for Channel 2. Ground for internal Channel 2 driver. Differential current is sensed between SW2

and PGND2. Use the Kelvin sensing connection technique between PGND2 and source of the low-side MOSFET.

Low-Side Synchronous Rectifier Gate Driver Output for Channel 2. To set the gain of the current sense amplifier,

connect a resistor between DL2 and PGND2. Capable of driving MOSFETs with a total input capacitance up to 20 nF.

Low-Side Synchronous Rectifier Gate Driver Output for Channel 1. To set the gain of the current sense amplifier,

connect a resistor between DL1 and PGND1. Capable of driving MOSFETs with a total input capacitance up to 20 nF.

Power Ground for Channel 1. Ground for internal Channel 1 driver. Differential current is sensed between SW1

and PGND1. Use the Kelvin sensing connection technique between PGND1 and source of the low-side MOSFET.

High-Side Switch Gate Driver Output for Channel 1. Capable of driving MOSFETs with a total input capacitance

up to 20 nF.

Power Switch Node for Channel 1. Connect to source of the high-side N-channel MOSFET and the drain of the

low-side N-channel MOSFET of Channel 1.

Boot-Strapped Upper Rail of High Side Internal Driver for Channel 1. Connect a multilayer ceramic capacitor

(0.1 µF to 0.22 µF) between BST1 and SW1. There is an internal boost diode or rectifier connected between VDL

and BST1.

Current Limit Sense Comparator Inverting Input for Channel 1. Connect a resistor between ILIM1 and SW1 to set

the current limit offset. For accurate current limit sensing, connect ILIM1 to a current sense resistor at the source

of the low-side MOSFET.

Power Good. Open-drain power-good indicator logic output with an internal 12 kΩ resistor connected between

PGOOD1 and VCCO. PGOOD1 is pulled to ground when the Channel 1 output is outside the regulation window.

An external pull-up resistor is not required.

Soft Start Input for Channel 1. Connect a capacitor from SS1 to AGND to set the soft start period. This node is

internally pulled up to 5 V with a 6.5 µA current source.

Connect a resistor from RAMP1 to VIN to set up a ramp current for slope compensation in Channel 1. The voltage

at RAMP2 is 0.2 V. This pin is high impedance when the channel is disabled.

Compensation Node for Channel 1. Output of Channel 1 error amplifier. Connect a series resistor-capacitor

network from COMP1 to AGND to compensate the regulation control loop.

Connect the bottom exposed pad of the LFCSP package to the system AGND plane.

Rev. A | Page 8 of 32

Page 9

Data Sheet ADP1850

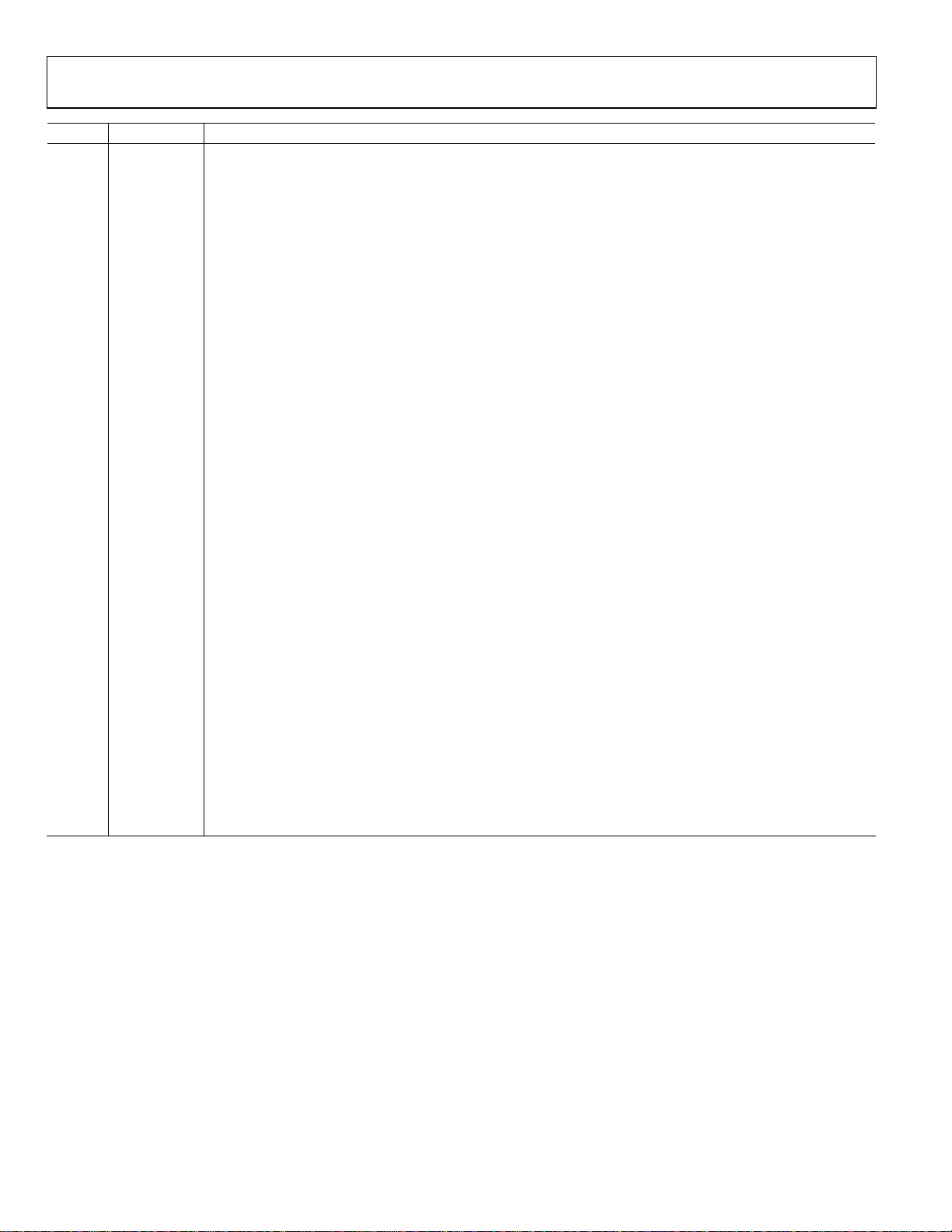

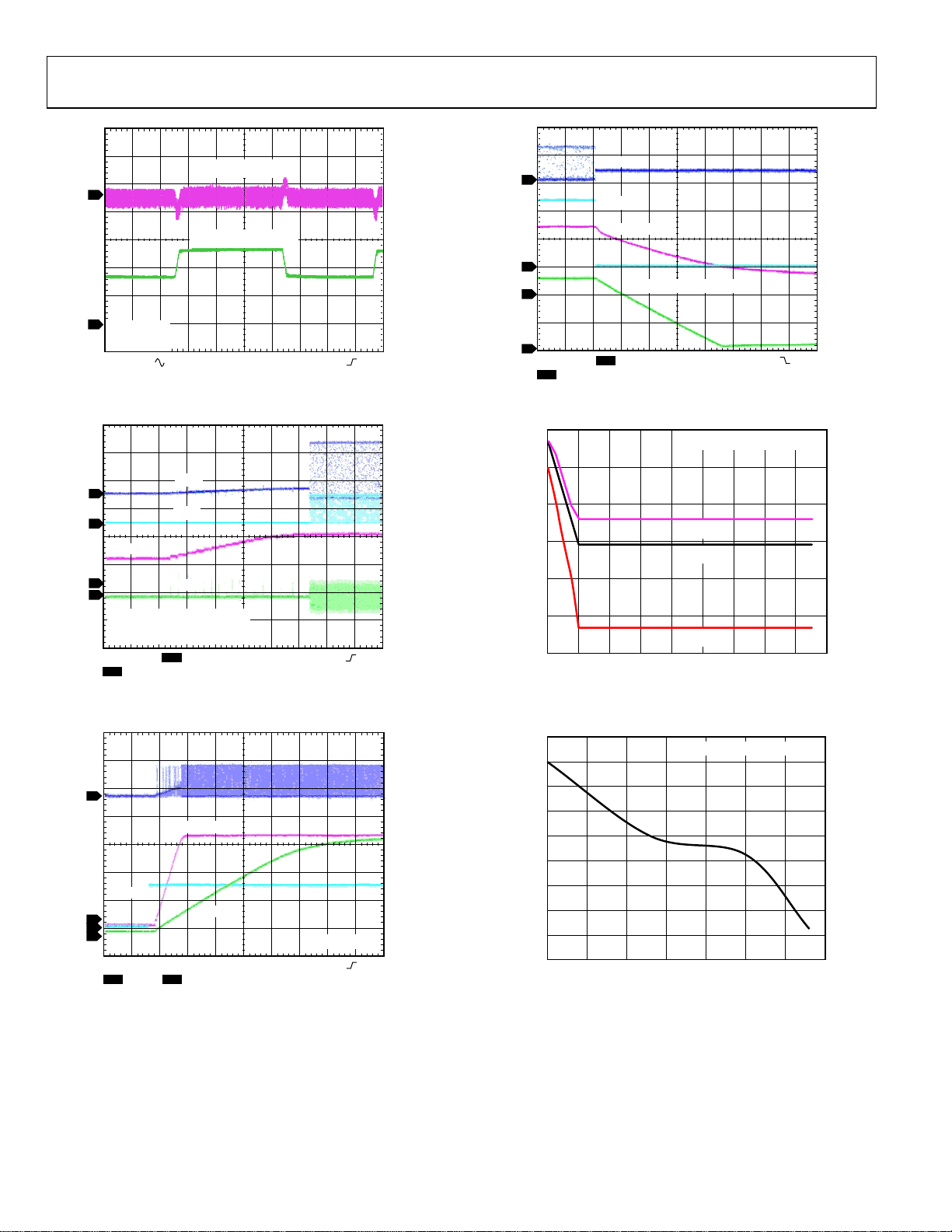

TYPICAL PERFORMANCE CHARACTERISTICS

100

90

VO = 3.3V, PSM

80

70

60

50

= 1.8V, PSM

V

O

40

EFFICIENCY (%)

30

20

10

0

0.01 0.1 1 10 100

V

V

O

= 1.8V, PWM

O

LOAD (A)

= 3.3V, PWM

V

= 12V, 600kHz

IN

Figure 4. Efficiency Plot of Figure 44

100

90

80

VO = 5V, PSM

70

60

50

40

VO = 5V, PWM

EFFICIENCY (%)

30

20

10

0

0.01 0. 1 1 10

VO = 1.8V, PW M

LOAD (A)

VO = 1.8V, P SM

V

= 12V, 750kHz

IN

Figure 5. Efficiency Plot of Figure 45

0

09440-005

09440-006

5.10

5.05

5.00

4.95

4.90

4.85

VCCO (V)

4.80

4.75

4.70

4.65

5 7 9 11131517

NO LOAD O N LDO

100mA LOAD ON LDO

VIN (V)

Figure 7. LDO Line Regulation

6

5

4

3

VCCO (V)

2

1

0

0123456

VIN (V)

Figure 8. VCCO vs. V

IN

09440-008

09440-009

–0.05

–0.10

∆VCCO (V)

–0.15

–0.20

–0.25

50mA LOAD

100mA LOAD

2.5 3.0 3. 5 4. 0 4.5 5.0

VIN (V)

Figure 6. LDO Load Regulation

09440-007

Rev. A | Page 9 of 32

1

2

3

CH1 10V

CH3 5V

SW1

SW2

SYNC 600kHz

CH2 10V M1µs A CH1 5.60V

Figure 9. An Example of Synchronization, f

= 600 kHz

SYNC

09440-010

Page 10

ADP1850 Data Sheet

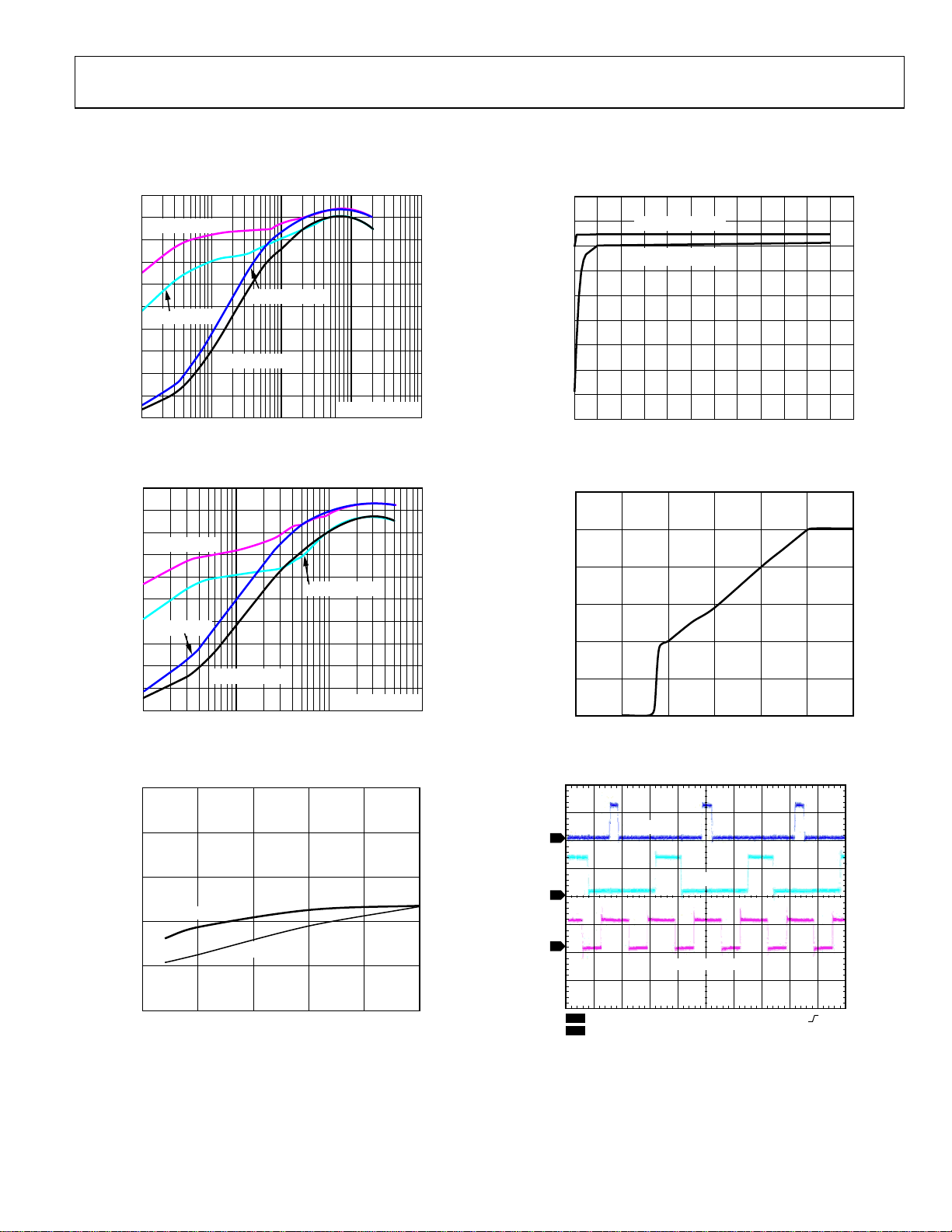

OUTPUT RESPONSE

1

8A TO 13A STEP LOAD

4

VIN = 12V

V

= 3.3V

OUT

CH1 20mV

B

W

CH4 5A Ω

M200µs A CH4 11.5A

Figure 10. Step Load Transient of Figure 44

= 1.8V

DH1

DL1

IL1

CH2 5VCH1 5V

CH4 1A Ω

M1ms A CH1 2.4V

1

2

VOUT1

3

4

VIN = 12V

V

OUT

OUTPUT PRECHARGED TO 1V

CH3 1V

Figure 11. Soft Start into Precharged Output

SW1

1

PGOOD1

VCCO (CH3)

2

V

, PRELOADED (CH4)

CH2 2VCH1 10V

CH4 2V Ω

OUT

M10ms A CH2 3.76V

09440-014

3

4

09440-011

CH3 2V

Figure 13. Thermal Shutdown Waveform

0.5

0

–0.5

(%)

SW

f

–1.0

–1.5

CHANGE IN

–2.0

–2.5

09440-012

3 5 7 9 11 13 15 17 19 21

Figure 14. Change in f

REFERENCED AT VIN = 2.75V

600kHz

300kHz

850kHz

VIN (V)

vs. VIN

SW

09440-015

1

3

2

4

SW

EN

CH3 1V

V

(CH3)

OUT

SS (CH4)

CSS = 100nF

CH2 2VCH1 10V

CH4 1V

M10ms A CH2 1.52V

Figure 12. Enable Start-Up Function

09440-013

Rev. A | Page 10 of 32

2.0

1.5

1.0

0.5

(%)

SW

f

0

–0.5

–1.0

CHANGE IN

–1.5

–2.0

–2.5

–40 –15 10 35 60 85 110 135

Figure 15. f

VIN = 12V; REFERENCED AT 25° C

TEMPERATURE (° C)

vs. Temperature

SW

09440-016

Page 11

Data Sheet ADP1850

350

300

250

200

TIME (ns)

150

100

50

2.5 5.0 7.5 10.0 12.5 15.0 17.5 20.0

DH MINIMUM OFF TIME

DH MINIMUM ON TIME

VIN (V)

Figure 16. Typical DH Minimum On Time and Off Time

4

3

2

1

0

–1

–2

–3

CHANGE IN MI NIMUM ON/OFF TIME (%)

–4

–40 –15 10 35 60 85 110 135

DH MINIMUM OFF TIME

DH MINIMUM ON TIME

TEMPERATURE (°C)

Figure 17. DH Minimum On Time and Off Time Over Temperature

35

VIN = 12V

OUTPUT IS LOADED

34

HS FET = BS C080N03LS

LS FET = BSC030N03LS

33

32

31

30

29

DEAD TIME (n s)

28

27

26

DEAD TIME BET WEEN SW FAL LING EDGE

AND DL RISING EDGE, I NCLUDING DI ODE RECOVE RY TIME

25

–40 –20 0 20 40 60 80 100 120 140

TEMPERATURE (°C)

Figure 18. Dead Time vs. Temperature

09440-017

09440-018

09440-019

45

43

41

39

37

35

33

DEAD TIME (n s)

31

29

27

DEAD TIME BETWEE N SW FAL LING EDGE

AND DL RISI NG EDGE, INCLUDI NG DIODE RECOVERY TIME

25

0215105

Figure 19. Dead Time vs. V

600

580

560

540

520

500

(µS)

m

G

480

460

440

420

400

–40 –15 10 35 60 85 110 135

TEMPERATURE (°C)

Figure 20. G

4.5

4.0

3.5

3.0

2.5

2.0

1.5

DRIVER RESISTANCE (Ω)

1.0

0.5

VIN = 2.75V, SO URCING

0

–40 –15 10 35 60 85 110 135

of Error Amplifier vs. Temperature

m

VIN = 12V, SOURCING

TEMPERATURE (°C)

TA = 25°C

OUTPUT IS LOADE D

HS FET = BSC080N03LS

LS FET = BSC030N03LS

VIN (V)

VIN = 2.75V, SI NKING

VIN = 12V, SINKING

IN

VIN = 2.75V TO 20V

Figure 21. Driver Resistance vs. Temperature

0

09440-020

09440-021

09440-022

Rev. A | Page 11 of 32

Page 12

ADP1850 Data Sheet

THEORY OF OPERATION

The ADP1850 is a current mode, dual-channel, step-down

switching controller with integrated MOSFET drivers for external

N-channel synchronous power MOSFETs. The two outputs are

phase shifted 180°. This reduces the input RMS ripple current,

thus minimizing required input capacitance. In addition, the

two outputs can be combined for dual-phase PWM operation

that can deliver more than 50 A output current and the two

channels are optimized for current sharing.

The ADP1850 can be set to operate in pulse skip high efficiency

mode (power saving mode) under light load or in forced PWM.

The integrated boost diodes in the ADP1850 reduce the overall

system cost and component count. The ADP1850 includes

programmable soft start, output overvoltage protection, programmable current limit, power good, and tracking function. The

ADP1850 can be set to operate in any switching frequency

between 200 kHz and 1.5 MHz with one external resistor.

CONTROL ARCHITECTURE

The ADP1850 is based on a fixed frequency, current mode,

PWM control architecture. The inductor current is sensed

by the voltage drop measured across the external low-side

MOSFET, R

(valley inductor current). The current sense signal is further

processed by the current sense amplifier. The output of the

current sense amplifier is held, and the emulated current ramp

is multiplexed and fed into the PWM comparator as shown in

Figure 22. The valley current information is captured at the end

of the off period, and the emulated current ramp is applied at

that point when the next on cycle begins. An error amplifier

integrates the error between the feedback voltage and the

generated error voltage from the COMPx pin (from error

amplifier in Figure 22).

V

I

RAMP

As shown in Figure 22, the emulated current ramp is generated

inside the IC but offers programmability through the RAMPx

pin. Selecting an appropriate value resistor from V

RAMPx pin programs a desired slope compensation value and,

at the same time, provides a feed forward feature. The benefits

realized by deploying this type of control scheme are that there

is no need to worry about the turn-on current spike corrupting

the current ramp. Also, the current signal is stable because the

, during the off period of the switching cycle

DSON

OSC Q

V

R

RAMP

IN

C

R

FROM

ERROR AMP

V

CS

IN

A

R

S

R

A

CS

Figure 22. Simplified Control Architecture

FF

Q

TO

DRIVERS

FROM

LOW-SIDE

MOSFET

to the

IN

09440-023

current signal is sampled at the end of the turn-off period,

which gives time for the switch node ringing to settle. Other

benefits of using current mode control scheme still apply, such

as simplicity of loop compensation. Control logic enforces

antishoot-through operation to limit cross conduction of the

internal drivers and external MOSFETs.

OSCILLATOR FREQUENCY

The internal oscillator frequency, which ranges from 200 kHz

to 1.5 MHz, is set by an external resistor, R

pin. Some popular f

values are shown in Tab l e 4, and a graph-

SW

ical relationship is shown in Figure 23. For instance, a 78.7 kΩ

resistor sets the oscillator frequency to 800 kHz. Furthermore,

connecting FREQ to AGND or FREQ to VCCO sets the oscillator frequency to 300 kHz or 600 kHz, respectively. For other

frequencies that are not listed in Ta bl e 4, the values of R

and f

can be obtained from Figure 23, or use the following

SW

empirical formula to calculate these values:

065.1

−

×=

fR

SWFEQ

)kHz(96568)k(

Table 4. Setting the Oscillator Frequency

R

fSW (Typical)

FREQ

332 kΩ 200 kHz

78.7 kΩ 800 kHz

60.4 kΩ 1000 kHz

51 kΩ 1200 kHz

40.2 kΩ 1500 kHz

FREQ to AGND 300 kHz

FREQ to VCCO 600 kHz

410

360

310

260

(kΩ)

210

FREQ

R

160

110

60

10

100 400 700 1000 1300 1600 19 00

Figure 23. R

R

f

FREQ

SW

(kHz)

(kΩ) = 96,568

vs. f

FREQ

FREQ

f

SW

, at the FREQ

FREQ

–1.065

(kHz)

SW

09440-024

Rev. A | Page 12 of 32

Page 13

Data Sheet ADP1850

MODES OF OPERATION

The SYNC pin is a multifunctional pin. PWM mode is enabled

when SYNC is connected to VCCO or a high logic. With SYNC

connected to ground or left floating, the pulse skip mode is

enabled. Switching SYNC from low to high or high to low on

the fly causes the controller to transition from forced PWM

to pulse skip mode or pulse skip mode to forced PWM, respectively, in two clock cycles.

1

2

3

DH1

DL1

OUTPUT

RIPPLE

Table 5. Mode of Operation Truth Table

SYNC Pin Mode of Operation

Low Pulse skip mode

High Forced PWM or two-phase operation

No Connect Pulse skip mode

Clock Signal Forced PWM or two-phase operation

The ADP1850 has a pulse skip sensing circuitry that allows the

controller to skip PWM pulses, thus, reducing the switching

frequency at light loads and, therefore, maintaining high

efficiency during a light load operation. The switching

frequency is a fraction of the natural oscillator frequency and

is automatically adjusted to regulate the output voltage. The

resulting output ripple is larger than that of the fixed frequency

forced PWM. Figure 24 shows that the ADP1850 operates in

PSM under a very light load. Pulse skip frequency under light

load is dependent on the inductor, output capacitance, output

load, and input and output voltages.

SW1

1

COMP1 (CH2)

3

4

2

CH3 20mV

Figure 24. Example of Pulse Skip Mode Under Light Load

VOUT RIPPLE

INDUCTOR

CURRENT

CH2 200mVCH1 10V

CH4 2A Ω

M200µs A CH1 7.8V

09440-025

When the output load is greater than the pulse skip threshold

current, that is, V

reaches the threshold of 0.9 V, the

COMP

ADP1850 exits the pulse skip mode of operation and enters

the fixed frequency discontinuous conduction mode (DCM),

as shown in Figure 25. When the load increases further, the

ADP1850 enters CCM.

4

CH3 20mV

Figure 25. Example of Discontinuous Conduction Mode (DCM) Waveform

INDUCTOR CURRENT

CH2 5VCH1 10V

CH4 2A Ω

M1µs A CH1 13.4V

09440-026

In forced PWM, the ADP1850 always operates in CCM at any

load. The inductor current is always continuous, thus, efficiency

is poor at light loads.

SYNCHRONIZATION

The switching frequency of the ADP1850 can be synchronized

to an external clock by connecting SYNC to a clock signal. The

external clock should be between 1× and 2.3× of the internal

oscillator frequency, f

of the external SYNC frequency because the SYNC input is

divided by 2, and the resulting phases are used to clock the two

channels alternately. In synchronization, the ADP1850 operates

in PWM.

When an external clock is detected at the first SYNC edge, the

internal oscillator is reset, and the clock control shifts to SYNC.

The SYNC edges then trigger subsequent clocking of the PWM

outputs. The DH1/DH2 rising edges appear approximately 100 ns

after the corresponding SYNC edge, and the frequency is locked

to the external signal. Depending on the start-up conditions of

Channel 1 and Channel 2, either Channel 1 or Channel 2 can be

the first channel synchronized to the rising edge of the SYNC

clock. If the external SYNC signal disappears during operation,

the ADP1850 reverts to its internal oscillator. When the SYNC

function is used, it is recommended to connect a pull-up resistor

from SYNC to VCCO so that when the SYNC signal is lost, the

ADP1850 continues to operate in PWM.

. The resulting switching frequency is ½

SW

Rev. A | Page 13 of 32

Page 14

ADP1850 Data Sheet

V

SYNCHRONOUS RECTIFIER AND DEAD TIME

The synchronous rectifier (low-side MOSFET) improves efficiency

by replacing the Schottky diode that is normally used in an

asynchronous buck regulator. In the ADP1850, the antishootthrough circuit monitors the SW and DL nodes and adjusts the

low-side and high-side drivers to ensure break-before-make

switching which prevents cross-conduction or shoot-through

between the high-side and low-side MOSFETs. This breakbefore-make switching is known as dead time, which is not

fixed and depends on how fast the MOSFETs are turned on

and off. In a typical application circuit that uses medium sized

MOSFETs with input capacitance of approximately 3 nF, the

typical dead time is approximately 30 ns. When small and fast

MOSFETs with fast diode recovery time are used, the dead time

can be as low as 13 ns.

INPUT UNDERVOLTAGE LOCKOUT

When the bias input voltage, VIN, is less than the undervoltage

lockout (UVLO) threshold, the switch drivers stay inactive.

When V

exceeds the UVLO threshold, the switchers start

IN

switching.

INTERNAL LINEAR REGULATOR

The internal linear regulator is low dropout (LDO) meaning it

can regulate its output voltage, VCCO. VCCO powers up the

internal control circuitry and provides power for the gate

drivers. It is guaranteed to have more than 200 mA of output

current capability, which is sufficient to handle the gate drive

requirements of typical logic threshold MOSFETs driven at up

to 1.5 MHz. VCCO is always active and cannot be shut down by

the EN1 and EN2 pins. Bypass VCCO to AGND with a 1 µF or

greater capacitor.

Because the LDO supplies the gate drive current, the output of

VCCO is subject to sharp transient currents as the drivers

switch and the boost capacitors recharge during each switching

cycle. The LDO has been optimized to handle these transients

without overload faults. Due to the gate drive loading, using the

VCCO output for other external auxiliary system loads is not

recommended.

The LDO includes a current limit well above the expected

maximum gate drive load. This current limit also includes a

short-circuit fold back to further limit the VCCO current in the

event of a short-circuit fault.

The VDL pin provides power to the low-side driver. Connect

VDL to VCCO. Bypass VDL to PGNDx with a 1 µF (minimum)

ceramic capacitor, which must be placed close to the VDL pin.

For an input voltage less than 5.5 V, it is recommended to

bypass the LDO by connecting VIN to VCCO, as shown in

Figure 26, thus eliminating the dropout voltage. However, if

the input range is 4 V to 7 V, the LDO cannot be bypassed by

shorting VIN to VCCO because the 7 V input has exceeded the

maximum voltage rating of the VCCO pin. In this case, use the

LDO to drive the internal drivers, but keep in mind that there is

a dropout when V

is less than 5 V.

IN

Rev. A | Page 14 of 32

= 2.75V TO 5. 5V

IN

VIN VCCO

ADP1850

09440-027

Figure 26. Configuration for V

< 5.5 V

IN

OVERVOLTAGE PROTECTION

The ADP1850 has a built-in circuit for detecting output overvoltage at the FB node. When the FB voltage, V

, rises above

FB

the overvoltage threshold, the low-side N-channel MOSFET

(NMOSFET) is immediately turned on, and the high-side

NMOSFET is turned off until the V

drops below the

FB

undervoltage threshold. This action is known as the crowbar overvoltage protection. If the overvoltage condition is

not removed, the controller maintains the feedback voltage

between the overvoltage and undervoltage thresholds, and the

output is regulated to within typically +8% and −8% of the

regulation voltage. During an overvoltage event, the SS node

discharges toward zero through an internal 3 kΩ pull-down

resistor. When the voltage at FBx drops below the undervoltage

threshold, the soft start sequence restarts. Figure 27 shows the

overvoltage protection scheme in action in PSM.

1

2

3

4

CH1 20.0V CH2 5.00V

CH3 1.00V CH4 10.0V

DH1

PGOOD1

VO1 = 1.8V SHORTED T O 2V SOURCE

VIN

M100µs A CH1 10.0V

Figure 27. Overvoltage Protection in PSM

09440-028

POWER GOOD

The PGOODx pin is an open-drain NMOSFET with an internal

12 kΩ pull-up resistor connected between PGOODx and VCCO.

PGOODx is internally pulled up to VCCO during normal

operation and is active low when tripped. When the feedback

voltage, V

below the undervoltage threshold, the PGOODx output is

pulled to ground after a delay of 12 µs. The overvoltage or

undervoltage condition must exist for more than 10 µs for

PGOODx to become active. The PGOODx output also

becomes active if a thermal overload condition is detected.

, rises above the overvoltage threshold or drops

FB

Page 15

Data Sheet ADP1850

SHORT-CIRCUIT AND CURRENT-LIMIT PROTECTION

When the output is shorted or the output current exceeds the

current limit set by the current limit setting resistor (between

ILIMx and SWx) for eight consecutive cycles, the ADP1850

shuts off both the high-side and low-side drivers and restarts

the soft start sequence every 10 ms, which is known as hiccup

mode. The SS node discharges to zero through an internal 1 kΩ

resistor during an overcurrent or short-circuit event. Figure 28

shows that the ADP1850 on a high current application circuit is

entering current limit hiccup mode when the output is shorted.

1

3

4

CH1 10V

CH3 500mV

Figure 28. Current Limit Hiccup Mode, 20 A Current Limit

CH4 10A Ω

SW1

SS1

INDUCTOR CURRENT

M2ms A CH1 11.2V

09440-029

SHUTDOWN CONTROL

The EN1 and EN2 pins are used to enable or disable Channel 1

and Channel 2 of the ADP1850. The precision enable (minimum)

threshold for EN1/EN2 is 0.57 V. When the voltage at EN1/EN2

rises above the threshold voltage, the ADP1850 is enabled and

starts normal operation after the soft start period. And when

the voltage at EN1/EN2 drops typically 30 mV (hysteresis)

below the threshold voltage, the switchers and the internal

circuits in the ADP1850 are turned off. Note that EN1/EN2

cannot shut down the LDO at VCCO, which is always active.

For the purpose of start-up power sequencing, the startup of the

ADP1850 can be programmed by connecting an appropriate

resistor divider from the master power supply to the EN1/EN2

pin, as shown in Figure 29. For instance, if the desired start-up

voltage from the master power supply is 10 V, R1 and R2 can be

set to 156 kΩ and 10 kΩ, respectively.

MASTER

SUPPLY VOLTAGE

R1

R2

Figure 29. Optional Power-Up Sequencing Circuit

ADP1850

EN1

OR

EN2

FB1

OR

FB2

V

OUT1

R

TOP

R

BOT

09440-030

THERMAL OVERLOAD PROTECTION

The ADP1850 has an internal temperature sensor that senses

the junction temperature of the chip. When the junction

temperature of the ADP1850 reaches approximately 155°C, the

ADP1850 goes into thermal shutdown, the converter is turned

off, and SS discharges toward zero through an internal 1 kΩ

resistor. At the same time, VCCO discharges to zero. When the

junction temperature drops below 135°C, the ADP1850 resumes

normal operation after the soft start sequence.

Rev. A | Page 15 of 32

Page 16

ADP1850 Data Sheet

×

APPLICATIONS INFORMATION

SETTING THE OUTPUT VOLTAGE

The output voltage is set using a resistive voltage divider from

the output to FB. The voltage divider divides down the output

voltage to the 0.6 V FB regulation voltage to set the regulation

output voltage. The output voltage can be set to as low as 0.6 V

and as high as 90% of the power input voltage.

The maximum input bias current into FB is 100 nA. For a 0.15%

degradation in regulation voltage and with 100 nA bias current,

the low-side resistor, R

in 67 µA of divider current. For R

, must be less than 9 kΩ, which results

BOT

, use a 1 k to 20 k resistor.

BOT

A larger value resistor can be used but results in a reduction in

output voltage accuracy due to the input bias current at the FBx

pin, while lower values cause increased quiescent current

consumption. Choose R

to set the output voltage by using

TOP

the following equation:

⎛

OUT

⎜

RR

=

BOTTOP

⎜

V

⎝

⎞

VV

−

FB

⎟

⎟

FB

⎠

where:

R

is the high-side voltage divider resistance.

TOP

is the low-side voltage divider resistance.

R

BOT

is the regulated output voltage.

V

OUT

V

is the feedback regulation threshold, 0.6 V.

FB

The minimum output voltage is dependent on f

DH on time. The maximum output voltage is dependent on f

and minimum

SW

SW

the minimum DH off time, and the IR drop across the high-side

NMOSFET and the DCR of the inductor. For example, with f

SW

of

600 kHz (or 1.67 µs) and a minimum on time of 130 ns, the

minimum duty cycle is approximately 7.8% (130 ns/1.67 µs). If

V

is 12 V and the duty cycle is 7.8%, then the lowest output is

IN

0.94 V. As an example for the maximum output voltage, if V

5 V, f

is 600 kHz, and the minimum DH off time is 395 ns

SW

is

IN

(335 ns DH off time plus approximately 60 ns total dead time),

then the maximum duty cycle is 76%. Therefore, the maximum

output is approximately 3.8 V. If the IR drop across the highside NMOSFET and the DCR of the inductor is 0.5 V, then the

absolute maximum output is 4.5 V (5 V − 0.5 V), independent of

f

and duty cycle.

SW

SOFT START

The soft start period is set by an external capacitor between

SS1/SS2 and AGND. The soft start function limits the input

inrush current and prevents output overshoot.

When EN1/EN2 is enabled, a current source of 6.5 µA starts

charging the capacitor, and the regulation voltage is reached

when the voltage at SS1/SS2 reaches 0.6 V.

The soft start period is approximated by

V6.0

=

Ct

SSSS

A5.6

,

The SSx pin reaches a final voltage equal to VCCO. If the output

voltage is precharged prior to turn-on, the ADP1850 prevents

reverse inductor current, which discharges the output capacitor.

Once the voltage at SSx exceeds the regulation voltage (typically

0.6 V), the reverse current is reenabled to allow the output

voltage regulation to be independent of load current.

Furthermore, in dual-phase operation, where SS1 is shorted to

SS2, the current source is doubled to 13 µA during the soft start

sequence.

When a controller is disabled, for instance, EN1/EN2 is pulled

low or experiences an overcurrent limit condition, the soft start

capacitor is discharged through an internal 3 kΩ pull-down

resistor.

SETTING THE CURRENT LIMIT

The current limit comparator measures the voltage across the

low-side MOSFET to determine the load current.

The current limit is set by an external current limit resistor,

R

, between ILIMx and SWx. The current sense pin, ILIMx,

ILIM

sources nominally 50 A to this external resistor. This creates an

offset voltage of R

across the low-side MOSFET, R

this offset voltage, the ADP1850 flags a current limit event.

Because the ILIMx current and the MOSFET, R

process and temperature, the minimum current limit should be

set to ensure that the system can handle the maximum desired

load current. To do this, use the peak current in the inductor,

which is the desired output current limit level plus ½ of the

ripple current, the maximum R

highest expected temperature, and the minimum ILIM current.

Keep in mind that the temperature coefficient of the MOSFET,

R

, is typically 0.4%/oC.

DSON

R

=

ILIM

where:

I

is the peak inductor current.

LPK

multiplied by 50 A. When the drop

ILIM

, is equal to or greater than

DSON

of the MOSFET at its

DSON

RI

LPK

MAXDSON

A47_μ

, vary over

DSON

Rev. A | Page 16 of 32

Page 17

Data Sheet ADP1850

ACCURATE CURRENT-LIMIT SENSING

R

of the MOSFET can vary by more than 50% over the

DSON

temperature range. Accurate current limit sensing is achieved

by adding a current sense resistor from the source of the lowside MOSFET to PGNDx. Make sure that the power rating of the

current sense resistor is adequate for the application. Apply the

previous equation and calculate R

with R

. Figure 30 illustrates the implementation of accurate

SENSE

by replacing R

ILIM

DSON_MAX

current limit sensing.

V

IN

ADP1850

DHx

SWx

R

ILIM

ILIMx

DLx

R

SENSE

Figure 30. Accurate Current Limit Sensing

09440-031

SETTING THE SLOPE COMPENSATION

In a current-mode control topology, slope compensation is

needed to prevent subharmonic oscillations in the inductor

current and to maintain a stable output. The external slope

compensation is implemented by summing the amplified sense

signal and a scaled voltage at the RAMPx pin. To implement the

slope compensation, connect a resistor between RAMPx and

the input voltage. The resistor, R

9

107××

R

RAMP

=

L

RA

MAXDSONCS

_

where:

9

7 × 10

is an internal parameter.

L is the inductance (with units in H) of the inductor.

R

A

is the low-side MOSFET maximum on resistance.

DSON_MAX

is the gain, either 3 V/V, 6 V/V, 12 V/V, or 24 V/V, of the

CS

current sense amplifier (see the Setting the Current Sense Gain

section for more details).

R

is temperature dependent and can vary as much as

DSON

o

0.4%/

C. Choose R

at the maximum operating temperature.

DSON

The voltage at RAMPx is fixed at 0.2 V, and the current going

into RAMPx should be between 10 µA and 160 µA. Make sure

that the following condition is satisfied:

V

A10 μ≤

≤μ

V2.0

−

IN

R

RAMP

For instance, with an input voltage of 12 V, R

exceed 1.1 MΩ. If the calculated R

then select an R

value that produces between 10 µA and 15 µA.

RAMP

Figure 31 illustrates the connection of the slope compensation

resistor, R

, and the current sense gain resistor, R

RAMP

, is calculated by

RAMP

A160

should not

RAMP

produces less than 10 µA,

RAMP

CSG

.

Rev. A | Page 17 of 32

V

ILIM

IN

R

CSG

09440-032

R

RAMP

RAMP

ADP1850

DHx

SWx

R

ILIMx

DLx

Figure 31. Slope Compensation and CS Gain Connection

SETTING THE CURRENT SENSE GAIN

The voltage drop across the external low-side MOSFET is

sensed by a current sense amplifier by multiplying the peak

inductor current and the R

then amplified by a gain factor of either 3 V/V, 6 V/V, 12 V/V,

or 24 V/V, which is programmable by an external resistor, R

connected to the DLx pin. This gain is sensed only during

power-up and not during normal operation. The amplified

voltage is summed with the slope compensation ramp voltage

and fed into the PWM controller for a stable regulation voltage.

The voltage range of the internal node, V

and 2.2 V. Select the current sense gain such that the internal

minimum amplified voltage (V

maximum amplified voltage (V

or V

is not the same as V

CSMAX

to 2.25 V. Make sure that the maximum V

not exceed 2.2 V to account for temperature and part-to-part

variations. See the following equations for V

V

:

COMPMAX

CSMIN

V +

COMPMAX

V75.0

−

IN

=

pF100

where:

V

is the minimum amplified voltage of the internal current

CSMIN

sense amplifier at zero output current.

V

is the maximum amplified voltage of the internal current

CSMAX

sense amplifier at maximum output current.

R

is the low-side MOSFET minimum on resistance. The

DSON_MIN

zero-current level voltage of the current sense amplifier is 0.75 V.

I

is the peak-to-peak ripple current in the inductor.

LPP

I

is the maximum output dc load current.

LOADMAX

V

is the maximum voltage at the COMP pin.

COMPMAX

100 pF is an internal parameter.

t

is the high-side driver (DH) on time.

ON

of the MOSFET. The result is

DSON

, is between 0.4 V

CS

) is above 0.4 V and the

CSMIN

) is 2.1 V. Note that V

CSMAX

, which has a range of 0.85 V

COMP

COMP

1

LPP

2

(75.0

LOADMAXCSMAX

)V2.0(

R

×

RAMP

_

1

)

LPP

2

tV

ON

V

CSMAX

(V

CSMIN

ARIV ××−=

CSMINDSON

COMPMAX

, V

CSMAX

_

CSG

CSMIN

) does

, and

ARIIVV ××−+=

CSMAXDSON

,

Page 18

ADP1850 Data Sheet

−

INPUT CAPACITOR SELECTION

The input current to a buck converter is a pulse waveform. It is

zero when the high-side switch is off and approximately equal

to the load current when it is on. The input capacitor carries the

input ripple current, allowing the input power source to supply

only the direct current. The input capacitor needs sufficient

ripple current rating to handle the input ripple, as well as an

ESR that is low enough to mitigate input voltage ripple. For the

usual current ranges for these converters, it is good practice to

use two parallel capacitors placed close to the drains of the

high-side switch MOSFETs (one bulk capacitor of sufficiently

high current rating and a 10 F ceramic decoupling capacitor,

typically).

Select an input bulk capacitor based on its ripple current rating.

First, determine the duty cycle of the output.

V

OUT

D =

The input capacitor RMS ripple current is given by

where:

I

is the output current.

O

D is the duty cycle

The minimum input capacitance required for a particular load is

C

where:

V

is the desired input ripple voltage.

PP

is the equivalent series resistance of the capacitor.

R

ESR

If an MLCC capacitor is used, the ESR is near 0, then the

equation is simplified to

The capacitance of MLCC is voltage dependent. The actual

capacitance of the selected capacitor must be derated according to

the manufacturer’s specification. In addition, add more bulk

capacitance, such as by using electrolytic or polymer capacitors,

as necessary for large step load transients. Make sure the

current ripple rating of the bulk capacitor exceeds the

maximum input current ripple of a particular design.

V

IN

)1( DDII

−=

ORMS

DDI

)1(

−×

MININ

IC

,

MININ

O

×−

PP

DD

−×=)1(

fV

×

PP

SW

O

=

,

fDRIV

)(

SWESRO

Rev. A | Page 18 of 32

INPUT FILTER

Normally a 0.1 µF or greater value bypass capacitor from the

input pin (VIN) to AGND is sufficient for filtering out any

unwanted switching noise. However, depending on the PCB

layout, some switching noise can enter the ADP1850 internal

circuitry; therefore, it is recommended to have a low pass filter

at the VIN pin. Connecting a resistor, between 2 Ω and 5 Ω, in

series with VIN and a 1 µF ceramic capacitor between VIN and

AGND creates a low pass filter that effectively filters out any

unwanted glitches caused by the switching regulator. Keep in

mind that the input current could be larger than 100 mA when

driving large MOSFETs. A 100 mA across a 5 Ω resistor creates

a 0.5 V drop, which is the same voltage drop in VCCO. In this

case, a lower resistor value is desirable.

2Ω TO 5Ω

V

IN

1µF

Figure 32. Input Filter Configuration

ADP1850

VIN

AGND

09440-033

BOOST CAPACITOR SELECTION

To lower system component count and cost, the ADP1850 has

an integrated rectifier (equivalent to the boost diode) between

VCCO and BSTx. Choose a boost ceramic capacitor with a

value between 0.1 µF and 0.22 µF; this capacitor provides the

current for the high-side driver during switching.

INDUCTOR SELECTION

The output LC filter smoothes the switched voltage at SWx. For

most applications, choose an inductor value such that the

inductor ripple current is between 20% and 40% of the

maximum dc output load current. Generally, a larger inductor

current ripple generates more power loss in the inductor and

larger voltage ripples at the output. Check the inductor data

sheet to make sure that the saturation current of the inductor is

well above the peak inductor current of a particular design.

Choose the inductor value by the following equation:

V

VV

IN

=

L ×

SW

Δ×

where:

L is the inductor value.

f

is the switching frequency.

SW

V

is the output voltage.

OUT

is the input voltage.

V

IN

ΔI

is the peak-to-peak inductor ripple current.

L

OUT

If

OUT

V

IN

L

Page 19

Data Sheet ADP1850

Δ

××≅

OUTPUT CAPACITOR SELECTION

Choose the output bulk capacitor to set the desired output voltage

ripple. The impedance of the output capacitor at the switching

frequency multiplied by the ripple current gives the output

voltage ripple. The impedance is made up of the capacitive

impedance plus the nonideal parasitic characteristics, the

equivalent series resistance (ESR), and the equivalent series

inductance (ESL). The output voltage ripple can be

approximated by

⎞

⎟

×+

Lf

ESLSW

⎟

⎠

LfIRIVf

×Δ−Δ−Δ

ESLSW

OUT

⎛

⎜

RIV 4

L

ESR

⎜

⎝

1

+Δ≅Δ

×

Cf

8

SW

OUT

where:

ΔV

is the output ripple voltage.

OUT

ΔI

is the inductor ripple current.

L

R

is the equivalent series resistance of the output capacitor (or

ESR

the parallel combination of ESR of all output capacitors).

L

is the equivalent series inductance of the output capacitor

ESL

(or the parallel combination of ESL of all capacitors).

Solving C

in the previous equation yields

OUT

I

Δ

C

OUT

L

×

≅

8

SW

OUT

1

4

L

ESR

L

Usually the capacitor impedance is dominated by ESR. The

maximum ESR rating of the capacitor, such as in electrolytic or

polymer capacitors, is provided in the manufacturer’s data

sheet; therefore, output ripple reduces to

RIV ×Δ≅Δ

L

OUT

ESR

Electrolytic capacitors also have significant ESL, on the order of

5 nH to 20 nH, depending on type, size, and geometry. PCB

traces contribute some ESR and ESL, as well. However, using

the maximum ESR rating from the capacitor data sheet usually

provides some margin such that measuring the ESL is not

usually required.

In the case of output capacitors where the impedance of the

ESR and ESL are small at the switching frequency, for instance,

where the output capacitor is a bank of parallel MLCC capacitors, the capacitive impedance dominates and the output

capacitance equation reduces to

Δ

I

OUT

L

×Δ

fV

SW

≅

C

OUT

8

Make sure that the ripple current rating of the output capacitors

is greater than the maximum inductor ripple current.

During a load step transient on the output, for instance, when

the load is suddenly increased, the output capacitor supplies the

load until the control loop has a chance to ramp the inductor

current. This initial output voltage deviation results in a voltage

droop or undershoot. The output capacitance, assuming 0 Ω

SR, required to satisfy the voltage droop requirement is

approximated by

I

C

≅

OUT

STEP

×Δ

fV

SWDROOP

where:

∆I

is the step load.

STEP

∆V

is the voltage droop at the output.

DROOP

When a load is suddenly removed from the output, the energy

stored in the inductor rushes into the capacitor, causing the

output to overshoot. The output capacitance required to satisfy

the output overshoot requirement can be approximated by

2

LI

Δ

C

≅

OUT

STEP

2

)(

−Δ+

2

VVV

OUTOVERSHOOTOUT

where:

∆V

OVERSH OOT

is the overshoot voltage during the step load.

Select the largest output capacitance given by any of the

previous three equations.

MOSFET SELECTION

The choice of MOSFET directly affects the dc-to-dc converter

performance. A MOSFET with low on resistance reduces I

losses, and low gate charge reduces transition losses. The

MOSFET should have low thermal resistance to ensure that the

power dissipated in the MOSFET does not result in excessive

MOSFET die temperature.

The high-side MOSFET carries the load current during on time

and usually carries most of the transition losses of the converter.

Typically, the lower the on resistance of the MOSFET, the

higher the gate charge and vice versa. Therefore, it is important

to choose a high-side MOSFET that balances the two losses. The

conduction loss of the high-side MOSFET is determined by the

equation

⎛

⎞

2

×≅

)(

V

OUT

⎜

RIP

DSONLOADC

⎟

⎜

⎝

⎟

V

IN

⎠

where:

R

is the MOSFET on resistance.

DSON

The gate charging loss is approximated by the equation

PV

G

fQVP

SWG

where:

V

is the gate driver supply voltage.

PV

is the MOSFET total gate charge.

Q

G

Note that the gate charging power loss is not dissipated in the

MOSFET but rather in the ADP1850 internal drivers. This

power loss should be taken into consideration when calculating

the overall power efficiency.

2

R

Rev. A | Page 19 of 32

Page 20

ADP1850 Data Sheet

+

≅

××=

+

=

The high-side MOSFET transition loss is approximated by the

equation

)(

fttIV

×+××

IN

P

≅

T

LOAD

FR

SW

2

where:

P

is the high-side MOSFET switching loss power.

T

is the rise time in charging the high-side MOSFET.

t

R

t

is the fall time in discharging the high-side MOSFET.

F

and tF can be estimated by

t

R

Q

GSW

GSW

RISEDRIVER

_

FALLDRIVER

_

t

≅

R

I

Q

t

≅

F

I

where:

Q

is the gate charge of the MOSFET during switching and is

GSW

given in the MOSFET data sheet.

I

DRIVER_RISE

and I

DRIVER_FALL

are the driver current put out by the

ADP1850 internal gate drivers.

If Q

is not given in the data sheet, it can be approximated by

GSW

Q

GS

QQ +≅

GDGSW

2

where:

and QGS are the gate-to-drain and gate-to-source charges

Q

GD

given in the MOSFET data sheet.

I

DRIVER_RISE

and I

DRIVER_FALL

I

RISEDRIVER

_

I

_

FALLDRIVER

can be estimated by

≅

≅

DD

_

SOURCEON

V

SP

_

SINKON

VV

−

SP

RR

+

GATE

RR

+

GATE

where:

V

is the input supply voltage to the driver and is between 2.75 V

DD

and 5 V, depending on the input voltage.

V

is the switching point where the MOSFET fully conducts;

SP

this voltage can be estimated by inspecting the gate charge

graph given in the MOSFET data sheet.

R

is the on resistance of the ADP1850 internal driver,

ON_SOURCE

given in Tab l e 1 when charging the MOSFET.

R

is the on resistance of the ADP1850 internal driver,

ON_SINK

given in Tab l e 1 when discharging the MOSFET.

R

is the on gate resistance of MOSFET given in the

GATE

MOSFET data sheet. If an external gate resistor is added, add

this external resistance to R

GATE

.

The total power dissipation of the high-side MOSFET is the

sum of conduction and transition losses:

PPP

CHS

T

The synchronous rectifier, or low-side MOSFET, carries the

inductor current when the high-side MOSFET is off. The lowside MOSFET transition loss is small and can be neglected in

the calculation. For high input voltage and low output voltage,

the low-side MOSFET carries the current most of the time.

Therefore, to achieve high efficiency, it is critical to optimize

the low-side MOSFET for low on resistance. In cases where the

power loss exceeds the MOSFET rating or lower resistance is

required than is available in a single MOSFET, connect multiple

low-side MOSFETs in parallel. The equation for low-side

MOSFET conduction power loss is

2

⎡

RIP 1)(

⎢

DSONLOADCLS

⎣

⎤

V

OUT

−×≅

⎥

V

IN

⎦

There is also additional power loss during the time, known as

dead time, between the turn-off of the high-side switch and the

turn-on of the low-side switch, when the body diode of the lowside MOSFET conducts the output current. The power loss in

the body diode is given by

IftVP ×

BODYDIODE

DF

OSW

where:

V

is the forward voltage drop of the body diode, typically 0.7 V.

F

is the dead time in the ADP1850, typically 30 ns when driving

t

D

some medium-size MOSFETs with input capacitance, C

, of

iss

approximately 3 nF. The dead time is not fixed. Its effective

value varies with gate drive resistance and C

, so P

iss

BODYDIODE

increases in high load current designs and low voltage designs.

Then the power loss in the low-side MOSFET is

PPP

BODYDIODECLSLS

Note that MOSFET, R

ture with a typical temperature coefficient of 0.4%/

MOSFET junction temperature (T

, increases with increasing tempera-

DSON

) rise over the ambient

J

o

C. The

temperature is

T

= TA + θJA × P

J

D

where:

θ

is the thermal resistance of the MOSFET package.

JA

is the ambient temperature.

T

A

P

is the total power dissipated in the MOSFET.

D

Rev. A | Page 20 of 32

Page 21

Data Sheet ADP1850

LOOP COMPENSATION (SINGLE PHASE OPERATION)

As with most current mode step-down controller, a transconductance error amplifier is used to stabilize the external voltage

loop. Compensating the ADP1850 is fairly easy; an RC compensator is needed between COMPx and AGND. Figure 33 shows

the configuration of the compensation components: R

C

, and CC2. Because CC2 is very small compared to C

COMP

to simplify calculation, C

is ignored for the stability

C2

compensation analysis.

ADP1850

COMPx

R

C

COMP

C2

C

COMP

AGND

Figure 33. Compensation Components

G

0.6V

m

FBx

09440-034

The open loop gain transfer function at angular frequency, s, is

given by

V

GGsH

m

REF

OUT

COMP

CS

V

××××=

FILTER

where:

G

is the transconductance of the error amplifier, 500 µS.

m

G

is the tranconductance of the power stage.

CS

is the impedance of the compensation network.

Z

COMP

Z

is the impedance of the output filter.

FILTER

V

= 0.6 V.

REF

with units of A/V is given by

G

CS

G

=

CS

1

RA

×

(2)

MINDSONCS

_

where:

A

is the current sense gain of either 3 V/V, 6 V/V, 12 V/V, or

CS

24 V/V set by the gain resistor between DLx and PGNDx.

R

If a sense resistor, R

then G

is the low-side MOSFET minimum on resistance.

DSON_MIN

, is added in series with the low-side FET,

S

becomes

CS

G+×=

CS

1

_ SMINDSONCS

)(

RRA

Because the zero produced by the ESR of the output capacitor is

not needed to stabilize the control loop, assuming ESR is small

the ESR is ignored for analysis. Then Z

1

Z

FILTER

Because C

=

is small relative to C

C2

RZ

(3)

sC

OUT

, Z

COMP

1

1

COMPCOMP

sC

=+=

COMP

is given by

FILTER

can be simplified to

COMP

×+

CsR

COMPCOMP

sC

COMP

,

COMP

,

COMP

)()()( sZsZ

(1)

(4)

At the crossover frequency, the open-loop transfer function is

unity or 0 dB, H (f

Equation 3, Z

COMP

fZ

CROSSCOMP