Page 1

Dual LED Flash Driver with

http://www.BDTIC.com/ADI

FEATURES

Ultracompact solution

Small 2 mm × 1.5 mm 12-ball WLCSP package

Tiny, low profile 2.2 H power inductor

LED current source for local LED grounding and low EMI

Synchronous 2 MHz PWM boost convertor, no external diode

High efficiency: 88% peak

Reduces high levels of input battery current during flash

Limits battery current drain in torch mode

2

I

C programmable

Currents up to 400 mA in flash mode for two LEDs

Currents up to 500 mA in flash mode for one LED with

5% accuracy

Currents up to 160 mA in torch mode with 10% accuracy

Peak inductor current limit

Flash timer

Control

2

I

C-compatible control registers

External STROBE pin

External direct TORCH pin

TX_MASK input to prevent high input battery current levels

Safety

Thermal overload protection

Flash timeout

Inductor fault detection

Output overvoltage

Short circuit protection

Soft start reduces inrush input current

I2C-Compatible Interface

ADP1655

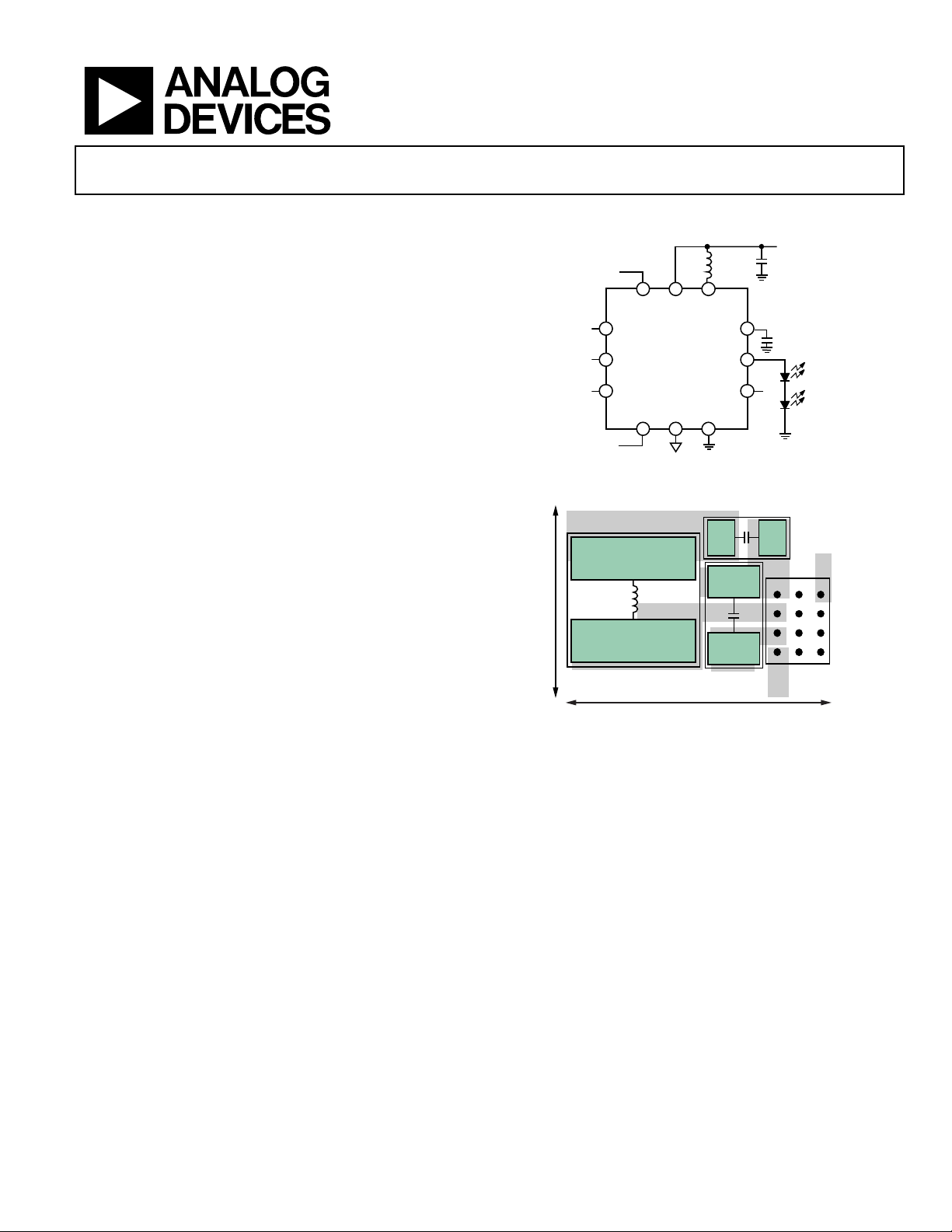

FUNCTIONAL BLOCK DIAGRAM

INPUT VOLTAGE = 2.5V TO 5.5V

2.2µH

STROBE VIN SW

TORCH

ADP1655

SCL/EN1

SDA/EN2

I2C/EN SGND PGND

VOUT

LED_OUT

TX_MASK

Figure 1.

Li-ION +

C1

L1

3mm

INDUCTOR

6.5mm

Figure 2. PCB Layout

10µF

10µF

8028-001

PGND

C2

LED

ANODE

Li-ION +

DIGITAL

INPUT/

OUTPUT

08028-002

APPLICATIONS

Camera-enabled cellular phones and smart phones

Digital still cameras, camcorders, and PDAs

GENERAL DESCRIPTION

The ADP1655 is a very compact, highly efficient, dual white

LED flash driver for high resolution camera phones, which

improves picture and video quality in low light environments.

The device integrates a 2 MHz synchronous inductive boost

convertor, an I

source. The high switching frequency enables the use of a tiny,

low profile 2.2 µH power inductor, and the current source

permits LED cathode grounding for thermally enhanced,

low EMI and compact layouts.

The efficiency is high over the entire battery voltage range to

maximize the input power to LED power conversion and

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

2

C-compatible interface and a 500 mA current

minimize battery current draw during flash events. In addition,

a Tx-mask input permits the flash LED current to reduce quickly

and, therefore, the battery current reduces quickly, during a

GSM power amplifier current burst.

2

The I

C-compatible interface enables the programmability

of timers, currents, and status bit readback for operation

monitoring and safety control.

The ADP1655 comes in a compact 12-ball 0.5 mm pitch

WLCSP package and is specified over the full −40°C to

+125°C junction temperature range.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2009 Analog Devices, Inc. All rights reserved.

Page 2

ADP1655

http://www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Recommended Specifications: Input and Output Capacitance

and Inductance ............................................................................. 4

I2C-Compatible Interface Timing Specifications ..................... 5

Absolute Maximum Ratings ............................................................ 6

Thermal Data ................................................................................ 6

Thermal Resistance ...................................................................... 6

ESD Caution .................................................................................. 6

Pin Configuration and Function Descriptions ............................. 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ...................................................................... 12

White LED Driver ...................................................................... 12

Assist Light and Torch Modes .................................................. 12

2-Bit Logic Interface Mode (I2C/EN = 0) ............................... 13

I2C Interface Mode (I2C/EN = 1) ............................................. 13

State Transitions ......................................................................... 15

I2C Register Map ............................................................................. 16

Safety Features ................................................................................. 19

Overvoltage Fault ....................................................................... 19

Output Capacitor Fault .............................................................. 19

Timeout Fault .............................................................................. 19

Overtemperature Fault .............................................................. 19

Short-Circuit Fault ..................................................................... 19

Current Limit .............................................................................. 19

Amount of LED Detection ........................................................ 19

Input Undervoltage .................................................................... 19

Applications Information .............................................................. 20

External Component Selection ................................................ 20

PCB Layout ...................................................................................... 22

Outline Dimensions ....................................................................... 23

Ordering Guide .......................................................................... 23

REVISION HISTORY

5/09—Revison 0: Initial Version

Rev. 0 | Page 2 of 24

Page 3

ADP1655

http://www.BDTIC.com/ADI

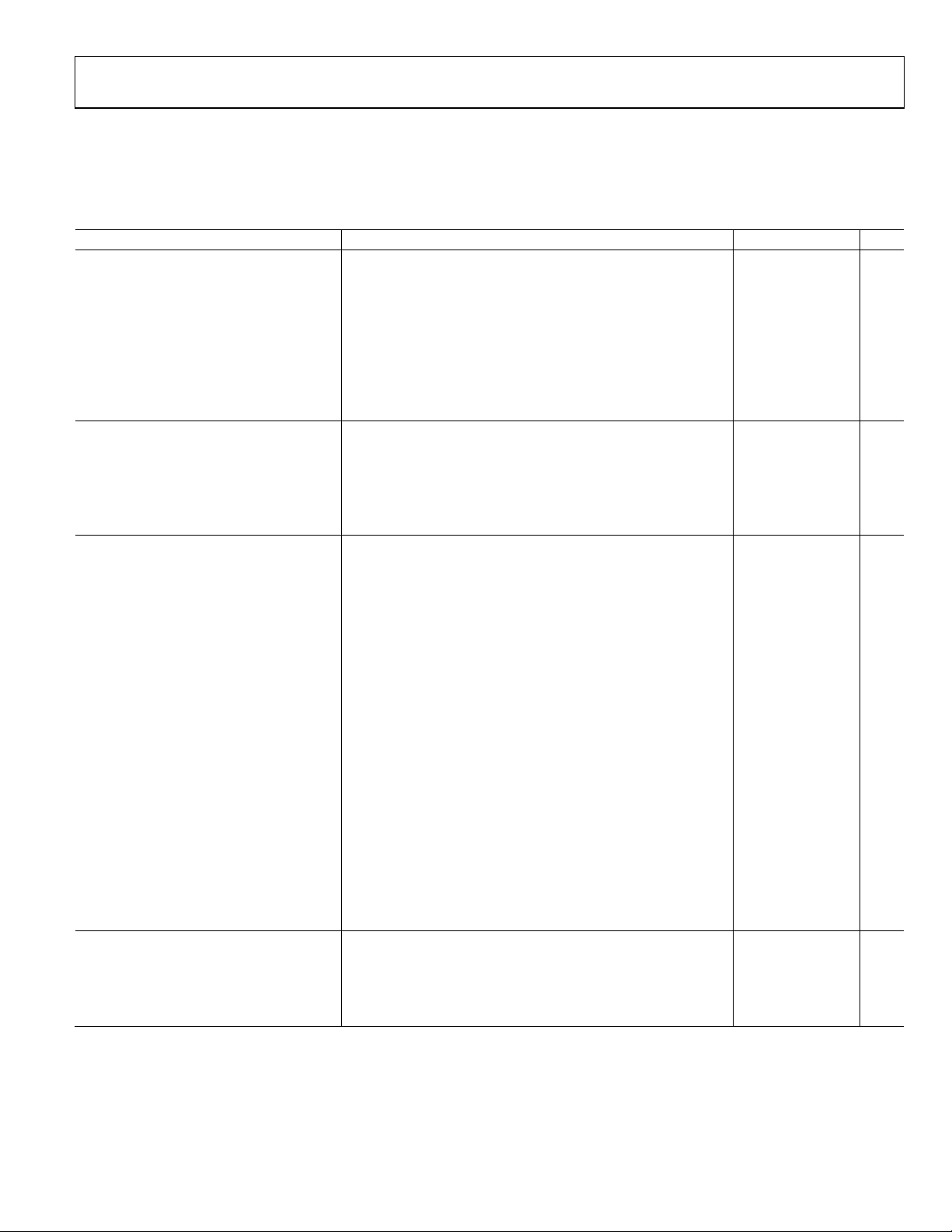

SPECIFICATIONS

VIN = 3.6 V, TJ = −40°C to +125°C for minimum/maximum specifications and TA = 25°C for typical specifications, unless

otherwise noted.

Table 1.

Parameter1 Conditions Min Typ Max Unit

SUPPLY

Input Voltage Range 2.7 5.5 V

Undervoltage Lockout Threshold VIN falling 2.3 2.4 2.5 V

Hysteresis 50 100 150 mV

Shutdown Current TJ = −40°C to +85°C, current into VIN pin, VIN = 2.7 V to 4.5 V 0.3 1 μA

Standby Current TJ = −40°C to +85°C, current into VIN pin, VIN = 2.7 V to 4.5 V 3 10 μA

I2C/EN = SCL/EN1 = SDA/EN2 = 1.8 V

Operating Quiescent Current Torch mode, two LEDs, LED current = 40 mA 5.3 mA

SW Switch Leakage TJ = −40°C to +85°C 1 μA

INPUTS

Input Logic Low Voltage 0.54 V

Input Logic High Voltage 1.26 V

TORCH, STROBE, TX_MASK Pull-Down 350 kΩ

SCL/EN1, SDA/EN2 Pull-Down I2C/EN = 0 V 350 kΩ

TORCH Glitch Filtering Delay From TORCH rising edge to device start 6.3 9 11.7 ms

LED DRIVER

LED Current

Assist Light, Torch I2C/EN = 0, one LED 80 mA

I2C/EN = 0, two LEDs 40 mA

I2C/EN = 1, assist light value setting = 0 (000 binary) 20 mA

I2C/EN = 1, assist light value setting = 7 (111 binary) 160 mA

Flash I2C/EN = 0, one LED 500 mA

I2C/EN = 0, two LEDs 320 mA

I2C/EN = 1, flash value setting = 0 (0000 binary) 200 mA

I2C/EN = 1, one LED, flash value setting = 15 (1111 binary) 500 mA

LED Current Accuracy I

I

I

LED Current Source Headroom2 Flash typical, 400 mA LED current 290 mV

Torch 160 mA 190

LED_OUT Ramp-Up Time 1 ms

LED_OUT Ramp-Down Time 0.5 ms

Maximum Timeout For Flash 850 ms

Timer Accuracy −7.5 +7.5 %

SWITCHING REGULATOR

Switching Frequency 1.85 2 2.15 MHz

Minimum Duty Cycle 9.0 %

N-FET Resistance 135 mΩ

P-FET Resistance 290 mΩ

I2C/EN = 1, two LEDs, flash value setting = 10 to 15 (1010 to

1111 binary)

= 320 mA to 500 mA −5 +5 %

LED

= 60 mA to 320 mA −5 +10 %

LED

= 20 mA to 60 mA −5 +20 %

LED

400 mA

Rev. 0 | Page 3 of 24

Page 4

ADP1655

http://www.BDTIC.com/ADI

Parameter1 Conditions Min Typ Max Unit

SAFETY FEATURES

Thermal Shutdown Threshold

TJ Rising 150 °C

TJ Falling 140 °C

Overvoltage Threshold 9.0 9.5 10.1 V

Coil Peak Current Limit Peak current value setting = 0 (00 binary) 1.13 1.25 1.38 A

Peak current value setting = 1 (01 binary) 1.35 1.5 1.65 A

Peak current value setting = 2 (10 binary) 1.58 1.75 1.93 A

Peak current value setting = 3 (11 binary) 1.8 2.0 2.2 A

LED_OUT Short-Circuit Detection

Comparator Reference Voltage

LED Counting Comparator

Threshold Voltage

LED value setting = 0 (00 binary) 4.3 V

LED value setting = 1 (01 binary) 4.6 V

LED value setting = 2 (10 binary) 4.0 V

LED value setting = 3 (11 binary) 4.9 V

1

All limits at temperature extremes are guaranteed via correlation using standard statistical quality control (SQC).

2

Two LEDs are used for this parameter.

RECOMMENDED SPECIFICATIONS: INPUT AND OUTPUT CAPACITANCE AND INDUCTANCE

1.2 1.3 V

Table 2.

Parameter Symbol Conditions Min Typ Max Unit

CAPACITANCE C

Input TA = −40°C to +125°C 4.0 μF

Output TA = −40°C to +125°C 4.0 20 μF

MINIMUM AND MAXIMUM INDUCTANCE L TA = −40°C to +125°C 1.5 2.8 μH

MIN

Rev. 0 | Page 4 of 24

Page 5

ADP1655

A

http://www.BDTIC.com/ADI

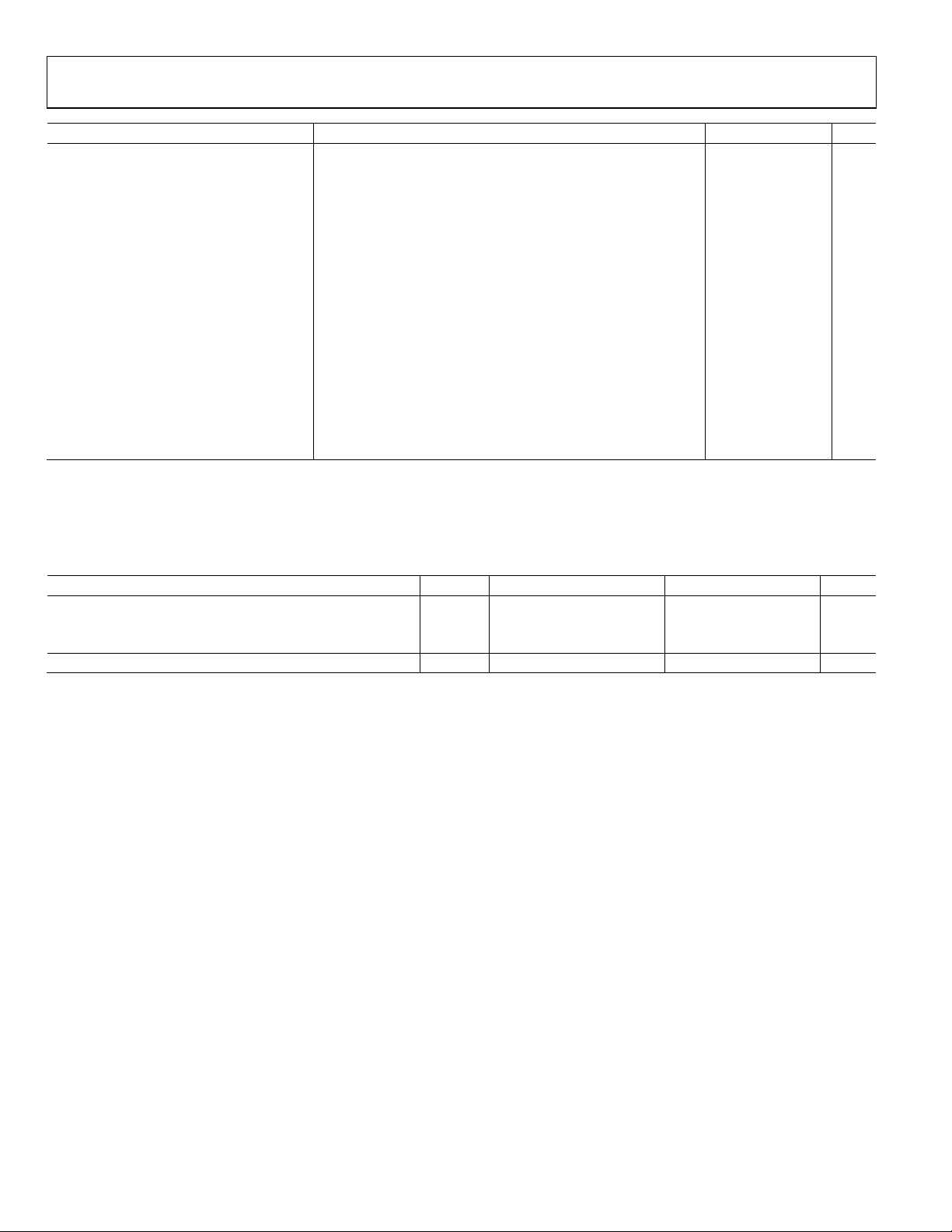

I2C-COMPATIBLE INTERFACE TIMING SPECIFICATIONS

Table 3.

Parameter1 Min Max Unit Description

f

SCL

t

HIGH

t

LOW

t

SU, DAT

t

0 0.9 μs Data hold time

HD, DAT

t

SU, STA

t

HD, STA

t

BUF

t

SU, STO

tR 20 + 0.1 C

tF 20 + 0.1 C

t

SP

CB 400 pF Capacitive load for each bus line

1

Guaranteed by design.

2

CB is the total capacitance of one bus line in picofarads.

400 kHz SCL clock frequency

0.6 μs SCL high time

1.3 μs SCL low time

100 ns Data setup time

0.6 μs Setup time for repeated start

0.6 μs Hold time for start/repeated start

1.3 μs Bus free time between a stop and a start condition

0.6 μs Setup time for stop condition

2

300 ns Rise time of SCL and SDA

B

B

300 ns Fall time of SCL and SDA

0 50 ns Pulse width of suppressed spike

SD

t

LOW

SCL

S

S = START CONDITION

Sr = REPEATED ST ART CONDITI ON

P = STOP CO NDITION

t

R

t

HD, DAT

t

SU, DAT

Figure 3. I

t

F

t

F

t

HIGH

2

C-Compatible Interface Timing Diagram

t

SU, STA

t

HD, STA

Sr P S

t

SP

t

SU, STO

t

BUF

t

R

08028-003

Rev. 0 | Page 5 of 24

Page 6

ADP1655

http://www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 4.

Parameter Rating

VIN, SDA/EN2, SCL/EN1, I2C/EN,

STROBE, TORCH, TX_MASK to SGND

LED_OUT, SW, VOUT to SGND −0.3 V to +12 V

PGND to SGND −0.3 V to +0.3 V

VOUT to LED_OUT −0.3 V to +6 V

Ambient Temperature Range (TA) −40°C to +85°C

Junction Temperature Range (TJ) −40°C to +125°C

Storage Temperature JEDEC J-STD-020

ESD Human Body Model ±2000 V

ESD Charged Device Model ±1000 V

ESD Machine Model ±200 V

−0.3 V to +6 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL DATA

The ADP1655 may be damaged if the junction temperature

limits are exceeded. Monitoring T

is within the specified temperature limits. In applications with

high power dissipation and poor thermal resistance, the maximum

T

may have to be derated. In applications with moderate power

A

dissipation and low PCB thermal resistance, the maximum T

can exceed the maximum limit as long as the T

fication limits. T

of the device is dependent on the TA, the power

J

dissipation (PD) of the device, and the junction-to-ambient

thermal resistance (θ

calculated from the T

= TA + (PD × θJA)

T

J

) of the package. Maximum TJ is

JA

and PD using the following formula:

A

does not guarantee that TJ

A

is within speci-

J

A

THERMAL RESISTANCE

θJA of the package is based on modeling and calculation using

a 4-layer board. θ

is highly dependent on the application and

JA

board layout. In applications where high maximum power dissipation exists, attention to thermal board design is required. The

value of θ

environmental conditions. The specified value of θ

may vary, depending on PCB material, layout, and

JA

is based

JA

on a 4-layer, 4 in × 3 in, 2 1/2 oz copper board, per JEDEC

standards. For more information, see the AN-617 Application

Note, MicroCSP

θ

is specified for a device mounted on a JEDEC 2S2P PCB.

JA

TM

Wafer Level Chip Scale Package.

Table 3. Thermal Resistance

Package Type θJA Unit

12-Ball WLCSP 75 °C/W

ESD CAUTION

Rev. 0 | Page 6 of 24

Page 7

ADP1655

http://www.BDTIC.com/ADI

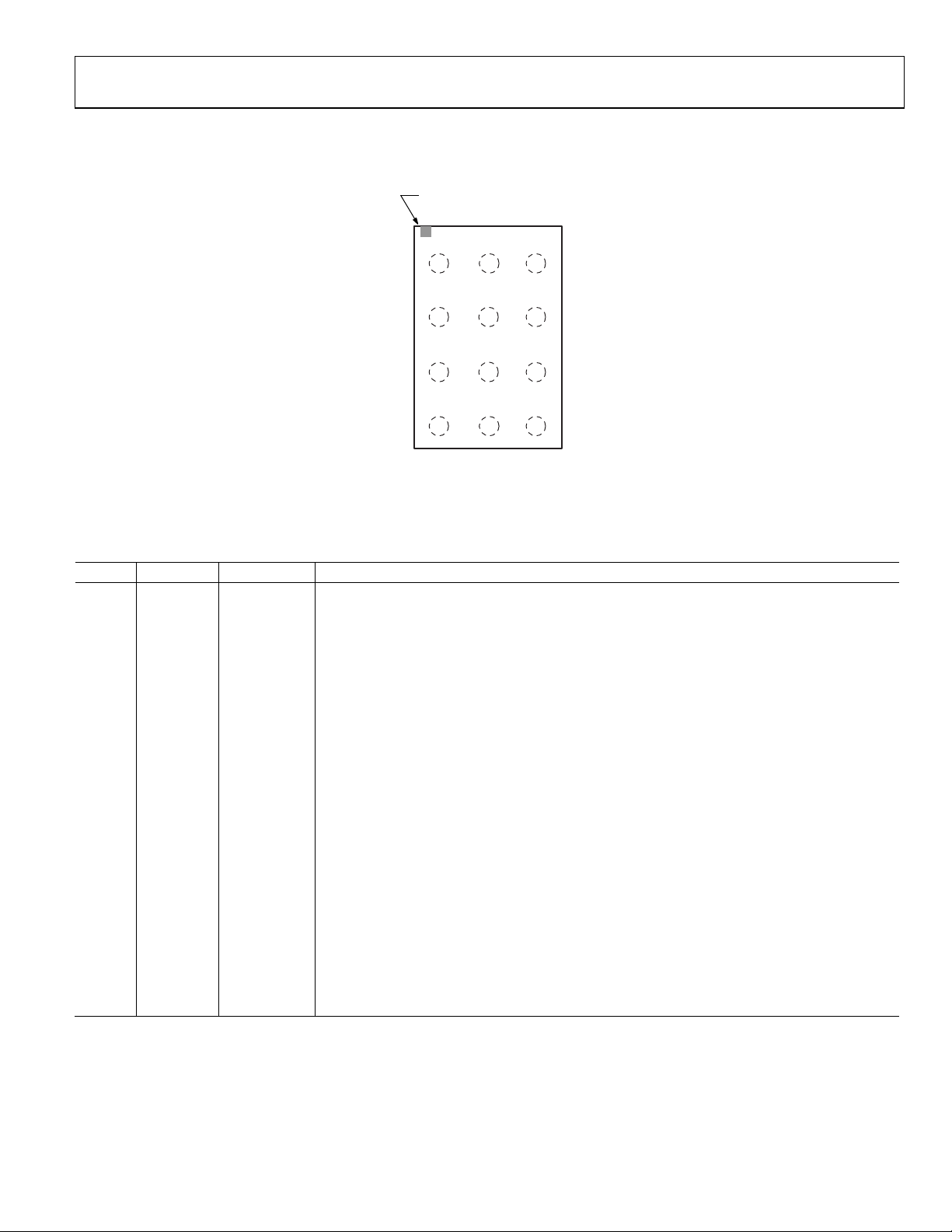

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

BALLA1

INDICATOR

1

PGND SGND VIN

A

23

SW

B

VOUT STROBE I2C/EN

C

LED_OUT SDA/EN2 SCL/EN1

D

(BALL SIDE DO WN)

Not to Scale

Figure 4. Pin Configuration

TORCH

TOP VIEW

TX_MASK

08028-004

Table 5. Pin Function Descriptions

Pin No. Mnemonic Type Description

A1 PGND Ground Ground for Internal Switching FET.

A2 SGND Ground Connect this pin at a single point to the power ground.

A3 VIN Supply

Connect the battery between VIN and PGND. Bypass VIN with a 10 μF, 6.3 V or greater X5R/X7R

capacitor.

B1 SW Output Connect a 2.2 μH inductor between SW and the battery.

B2 TORCH Digital Input This pin enables the torch, provided that the device is not in flash or assist light mode.

B3 TX_MASK Digital Input

Connect a digital signal to the TX_MASK pin. When the logic level is driven high during a flash

event the current is reduced to the torch level.

C1 VOUT Output

VOUT senses the output voltage of the boost converter and provides the input voltage to the LED

current source. The VOUT pin features a comparator to detect an overvoltage condition if the LED

string is open circuited. Connect a 10.0 μF capacitor between VOUT and PGND.

C2 STROBE

Digital Input/

Output

The STROBE input is used to synchronize the timing of the camera module to the LED driver in

2

I

C-compatible interface mode. In 2-bit logic interface mode, this acts as an output, indicating the

number of LEDs attached. STROBE = high indicates two LEDs, whereas STROBE = low indicates

one LED.

C3 I2C/EN Digital Input

A logic low selects the 2-bit logic interface, whereas logic high selects I

2

C-compatible interface. If

I2C/EN is low and SDA/EN2 and SCL/EN1 are low, the driver enters shutdown mode with

consumption < 1 μA.

D1 LED_OUT Output

White LED Anode Connection. Connect LED_OUT to the anode of the white LED. LED_OUT is

internally connected to a programmable PMOS current source, which regulates the LED current.

D2 SDA/EN2

D3 SCL/EN1 Digital Input

Digital Input/

Output

Data Input/Output (SDA). In 2-bit logic interface mode, SDA/EN2 is the second input bit of the

digital interface.

Second Input Bit (EN2). In I

Clock Input (SCL). In 2-bit logic interface mode, SCL/EN1 is the first input bit of the digital interface.

First Input Bit (EN1). In I

2

C mode, SDA is the data input/output of the I2C-compatible interface.

2

C mode, SCL is the clock input of the I2C-compatible interface.

Rev. 0 | Page 7 of 24

Page 8

ADP1655

http://www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

600

500

L = FDSE0312-2R2M

C

=10µF

OUT

Δ: 335 µs

400

(mA)

300

LED

I

200

I

100

0

INPUT VOLTAGE (V)

4.2 4.7 5.23.73.22.7

LIMIT

I

LIMIT

I

LIMIT

I

LIMIT

Figure 5. Maximum Current vs. Input Voltage, One LED

450

400

350

300

250

(mA)

200

LED

I

150

100

50

0

INPUT VOLTAG E (V)

4.2 4. 7 5. 23.73.22.7

I

LIMIT

I

LIMIT

I

LIMIT

I

LIMIT

Figure 6. Maximum Current vs. Input Voltage, Two LEDs;

LED Forward Voltage (Vf) = 4.3 V for each LED

L = FDSE0312-2R2M

C

=10µF

OUT

Δ: 335 µs

– 2.00A

– 1.75A

– 1.50A

– 1.25A

– 2.00A

– 1.75A

– 1.50A

– 1.25A

1

2

3

4

CHANNEL 1 (IL) 0.5A/DIV

08028-005

CHANNEL 2 (I

HPLED

Figure 8. Startup, Two LEDs Flash Mode, I

L = F DSE0312- 2R 2M

C

=10µF

OUT

1

2

3

4

CHANNEL

08028-006

CHANNEL 2 (I

1 (IL) 0.5A/DIV

HPLED

Figure 9. Startup, Two LEDs Assist Light Mode, I

L = FDSE0312-2R2M

C

=10µF

OUT

) 0.2A/DIV

Δ: 180µ s

) 0.2A/DIV

Δ: 180µ s

50µs/DIV

CHANNEL 3 (V

CHANNEL 4 (STRO BE) 5V/DIV

= 400 mA, VIN = 3.6 V

LED

50µs/DIV

CHANNEL 3 (V

CHANNEL 4 (SCL) 5V/ DIV

LED

) 5V/DIV

OUT

OUT

) 5V/DIV

08028-008

08028-009

= 40 mA, VIN = 3.2 V

1

2

3

4

50µs/DIV

CHANNEL

CHANNEL 2 (I

1 (IL) 0.5A/DIV

) 0.2A/DIV

HPLED

Figure 7. Startup, Two LEDs Flash Mode, I

CHANNEL 3 (V

CHANNEL 4 (STRO BE) 5V/DIV

OUT

= 400 mA, VIN = 3.2 V

LED

) 5V/DIV

08028-007

Rev. 0 | Page 8 of 24

1

2

3

4

50µs/DIV

CHANNEL 1 (IL) 0.5A/DIV

CHANNEL 2 (I

HPLED

) 0.2A/DIV

CHANNEL 3 (V

CHANNEL 4 (SCL) 5V/ DIV

Figure 10. Startup, Two LEDs Torch Mode, I

) 5V/DIV

OUT

= 40 mA, VIN = 3.6 V

LED

08028-010

Page 9

ADP1655

C

http://www.BDTIC.com/ADI

L = F D SE0312-2R 2M

C

=10µF

OUT

100

VIN = 3.2V

V

= 3.6V

IN

90

V

= 4.2V

IN

80

70

60

Y (%)

50

1

3

2

4

500ns/DIV

CHANNEL 1 (IL) 0.2A/DIV

CHANNEL 2 (I

HPLED

) 0.1A/DIV

CHANNEL 3 (LED_OUT) 5V/DIV

CHANNEL 4 (SW) 5V /DIV

Figu .6 V re 11. Inductor Current, Two LEDs Flash Mode, I

L = FDSE0312-2R2M

C

=10µF

OUT

1

2

3

4

500ns/DIV

CHANNEL

CHANNEL 2 (I

1 (IL) 0.2A/DIV

HPLED

) 0.02A/DIV

CHANNEL 3 (LED_OUT) 5V/DIV

CHANNEL 4 (SW) 5V/DIV

Figure 12. Inductor Current, Two LEDs Torch Mode, I

= 400 mA, VIN = 3

LED

= 40 mA, VIN = 3.6 V

LED

08028-011

08028-012

40

EFFICIEN

30

20

10

0

10 100

OUTPUT CURRENT (A)

Figure Series 14. Efficiency P

100

VIN = 3.2V

V

= 3.6V

IN

90

V

= 4.2V

IN

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

10 100 1k

Figure 15. Efficiency P

, Two High Power White LEDs in

LED/PIN

OUTPUT CURRENT (A)

, One High Power White LED

LED/PIN

1000

08028-014

08028-015

10

VIN = 3.2V

V

= 3.6V

IN

8

V

= 4.2V

IN

6

4

2

0

–2

ACCURACY (%)

LED

I

–4

–6

–8

–10

04300200100

OUTPUT CURRENT (mA)

Figure 13. LED Current Accuracy vs. Output Current

L = F D SE0312-2R 2M

C

OUT

1

2

3

4

00

500

CHANNEL 1 (IBAT) 1A/DIV

08028-013

CHANNEL 2 (I

Figure 16. Tx Masking Response, TX_MASK = 0 V to 1.8 V,

Rev. 0 | Page 9 of 24

=10µF

Δ:4µs

20µs/DIV

CHANNEL 3 (V

) 0.2A/DIV

HPLED

I

= 40 mA to 400 mA, VIN = 3.2 V

LED

CHANNEL 4 (TX_MAS K) 5V/DIV

OUT

) 5V/DIV

08028-016

Page 10

ADP1655

A

http://www.BDTIC.com/ADI

L = F DSE0312- 2R 2M

C

=10µF

OUT

1

2

3

4

CHANNEL 1 (IBAT) 1A/DIV

CHANNEL 2 (I

HPLED

) 0.2A/DIV

Δ: 260µs

100µs/DIV

CHANNEL 3 (V

CHANNEL 4 (TX_MASK) 5V/DIV

OUT

Figure 17. Tx Masking Response, TX_MASK = 1.8 V to 0 V,

I

= 40 mA to 400 mA, VIN = 3.2 V

LED

) 5V/DIV

08028-017

L = F DSE0312- 2R 2M

C

=10µF

OUT

Δ: 15m

1

CHANNEL 1 (VIN) 0.5V/DI V

CHANNEL 2 (I

HPLED

100µs/DIV

) 20mA/DIV

Figure 20. Line Transient, VIN = 3.2 V to 3.6 V, I

2.4

2.2

= 400 mA

LED

VIN = 3.2V

V

= 3.6V

IN

V

= 4.2V

IN

08028-020

1

2

3

200ms/DIV

CHANNEL

CHANNEL 2 (STRO BE) 1V/DIV

1 (I

HPLED

) 0.1A/DIV

CHANNEL 3 (SCL) 5V/DIV

8028-018

Figure 18. Assist Light and Flash, STROBE Edge Sensitive Mode, Two LEDs,

Timer = 850 ms, I

1

2

3

= 40 mA to 400 mA, VIN = 3.6 V

LED

2.0

1.8

1.6

PEAK CURRENT LIM IT (A)

1.4

1.2

–40 –20 0 20 40 60 80

TEMPERATURE (° C)

08028-021

Figure 21. Coil Peak Current Limit vs. Temperature, Output Mode Register =

00, 01, 10, and 11 (Binary)

1.2

VIN = 2.5V

V

= 3.6V

IN

V

= 4.5V

IN

1.0

0.8

0.6

0.4

SHUTDOWN CURRENT (µA)

0.2

200ms/DIV

CHANNEL 1 (I

CHANNEL 2 (STRO BE) 1V/DIV

HPLED

) 0.1A/DIV

CHANNEL 3 (SCL) 5V/DIV

Figure 19. Assist Light and Flash, STROBE Level Sensitive Mode, Two LEDs,

I

= 40 mA to 400 mA, VIN = 3.6 V

LED

8028-019

Rev. 0 | Page 10 of 24

0

–40 –20 0 20 40 60 80

TEMPERATURE (°C)

Figure 22. Shutdown Current vs. Temperature vs. VIN

08028-022

Page 11

ADP1655

(

http://www.BDTIC.com/ADI

7.0

VIN = 3.2V

V

= 3.6V

IN

V

= 4.2V

IN

6.5

6.0

5.5

(mA)

VIN

I

5.0

4.5

44

42

40

(mA)

LED

I

38

VIN = 3.0V

V

= 3.6V

IN

V

= 5.5V

IN

4.0

–40–200 20406080

TEMPERATURE (°C)

Figure 23. Operating Quiescent Current vs. Temperature, Torch Mode

4.0

3.5

3.0

µA)

2.5

2.0

1.5

STANDBY CURRENT

1.0

0.5

0

–40 –20 0 20 40 60 80 100 120

TEMPERATURE (°C)

VIN = 2.5V

V

= 3.6V

IN

V

= 4.5V

IN

Figure 24. Standby Current vs. Temperature vs. VIN,

I2C/EN = SCL/EN1 = SDA/EN2 = 1.8 V

2.15

2.10

VIN = 3.2V

V

= 3.6V

IN

V

= 4.2V

IN

36

–40–200 20406080100120

08028-023

TEMPERATURE (°C)

08028-026

Figure 26. LED Regulation, Set at 40 mA,

Current Set Register = 001 (Binary)

420

415

410

405

400

(mA)

LED

I

395

390

385

380

–40 –20 0 20 40 60 80 100 120

08028-024

TEMPERATURE (°C)

VIN = 3.0V

V

= 3.6V

IN

V

= 5.5V

IN

08028-027

Figure 27. LED Regulation, Set at 400 mA,

Current Set Register = 1010 (Binary)

2.05

2.00

1.95

SWITCHI NG FREQUENCY (MHz)

1.90

1.85

–40–200 20406080100120

TEMPERATURE (°C)

Figure 25. Switching Frequency vs. Temperature vs. VIN

08028-025

Rev. 0 | Page 11 of 24

Page 12

ADP1655

http://www.BDTIC.com/ADI

THEORY OF OPERATION

The ADP1655 is a high power, white LED driver ideal for

driving white LEDs for use as a camera flash. The ADP1655

includes a boost converter and a current regulator suitable

for powering one or two high power, white LEDs.

The ADP1655 responds to a 2-pin control interface that can

operate in two separate pin-selectable modes: tying the I2C/

EN pin high enables the I

2

C interface; tying the I2C/EN pin

low enables a 2-bit logic interface.

WHITE LED DRIVER

The ADP1655 drives a synchronous boost converter to power

one or two series-connected, high power LEDs. The white

LED driver regulates the high power LED current for accurate

brightness control. The ADP1655 uses an integrated PFET

current regulator.

When the white LED is turned on, the step-up converter output

voltage slew is limited to prevent excessive battery current while

charging the output capacitor. The output voltage of the boost

INPUT VOLTAGE = 2.5V TO 5.5V

L1

VIN

A3 B1 C1

SW

C

PGND

IN

converter is sensed at VOUT. If the output voltage exceeds

the 9.5 V (typical) limit, the white LED driver turns off and

indicates that a fault condition has occurred through the system

registers. This feature prevents damage due to an overvoltage if

the white LED string fails with an open-circuit condition.

Setting the LED regulation currents depends on the 2-pin

control interface used.

ASSIST LIGHT AND TORCH MODES

The ADP1655 features a programmable assist light mode that

provides continuous LED current. The STROBE pin or the 2-bit

logic interface can be used to transition from assist light mode

directly to flash mode. The TORCH pin provides an alternative

means of accessing a continuous LED current mode of operation. Both assist light and torch modes deliver the same current,

which is programmable via the I

C

OUT

PGND

VOUT

2

C-compatible interface.

I2C/EN

SCL/EN1

SDA/EN2

TORCH

STROBE

TX_MASK

2.5V

UVLO

PWM

C3

D3

D2

INTERFACE

B2

CONTROL

C2

B3

CONTROLLER

AND

CURRENT

SENSE

9.5V

OVP

FAULT

REGISTER

THERMAL

PROTECTION

DETECTOR

A1A2

PGNDSGND

PGNDAGND

COUT

HPLED

DRIVER

CURRENT

SENSE

4.35V

HPLED

SHORT

HIGH POW ER LED

CURRENT CONTROL

LED_OUT

D1

PGND

08028-029

Figure 28. Detailed Block Diagram

Rev. 0 | Page 12 of 24

Page 13

ADP1655

http://www.BDTIC.com/ADI

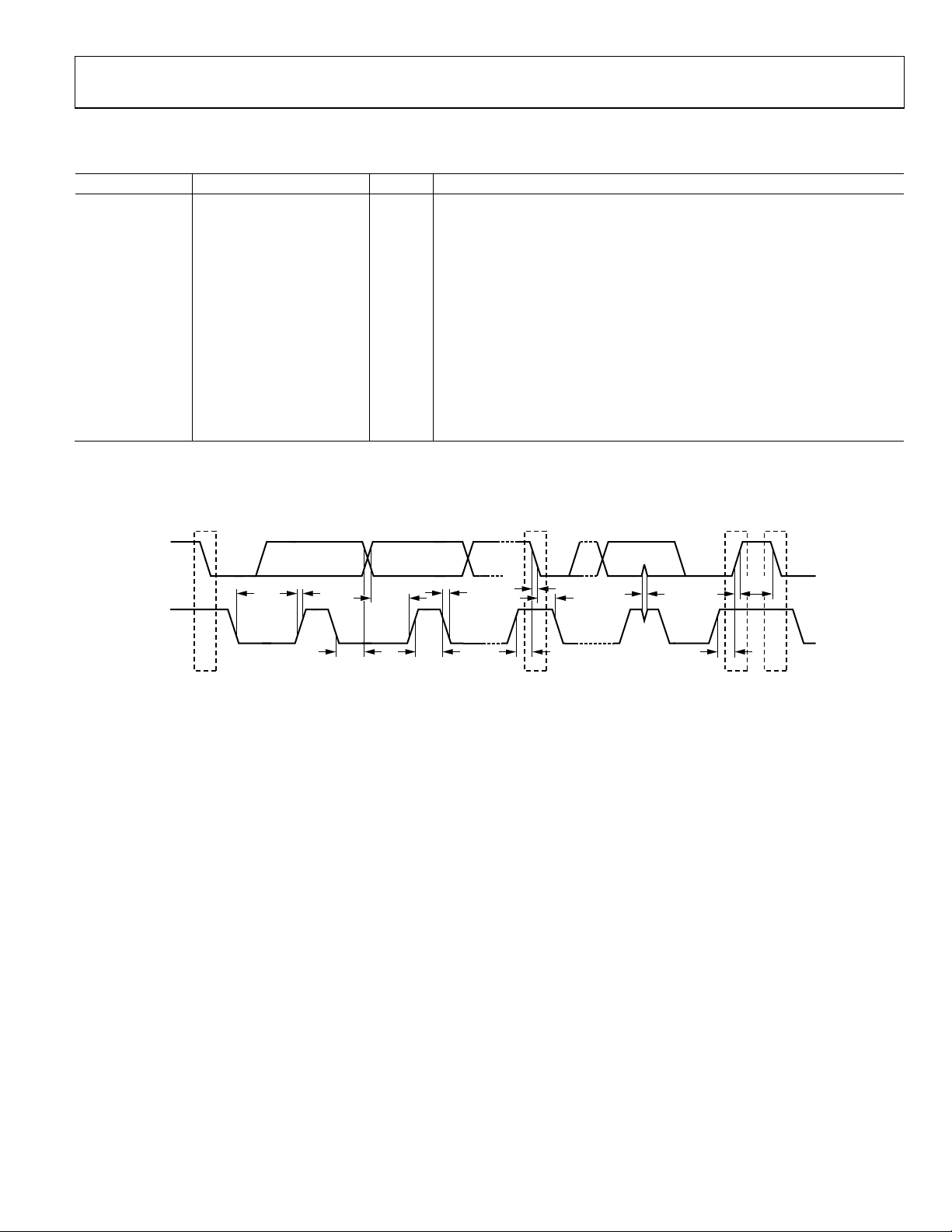

2-BIT LOGIC INTERFACE MODE (I2C/EN = 0)

In 2-bit logic interface mode, the two control pins, EN1 and

EN2, select whether the part is disabled or operating in assist

light mode or flash mode, as outlined in Ta b le 6. Additionally,

the TORCH pin selects torch mode.

Figure 29 illustrates state transitions of 2-bit logic mode controlled by digital inputs EN1, EN2, TORCH, and TX_MASK.

EN1 = 1

EN2 = 1

FLASH

EN1 = 1

EN1 = 0

EXTERNAL

TORCH

When the ADP1655 is in flash mode, the TX_MASK pin can

be used to reduce the battery load. The device remains in flash

mode, but the LED driver output current is reduced to the assist

light level.

Table 6. 2-Bit Logic Interface Mode Selection

Mode

Shutdown 0 0 0 0 0 mA

Torch 0 0 0 1

Assist light 0 0 1 X

Reserved 0 1 0 X 0 mA

Flash 0 1 1 X

EN1 = 0

EN2 = 1

TORCH = 0

TORCH = 1

Figure 29. 2-Bit Logic Mode State Transitions (I2C/EN = 0)

ASSIST

LIGHT

EN2 = 1

EN1 = 1

EN2 = 1

EN2 = 0

SHUTDOWN

EN1 = 0

EN2 = 0

TIMEOUT

I2C/

EN

EN1 EN2 TORCH Output Current

One LED: 80 mA

Two LEDs: 40 mA

One LED: 80 mA

Two LEDs: 40 mA

One LED: 500 mA

Two LEDs: 320 mA

08028-030

I2C INTERFACE MODE (I2C/EN = 1)

The ADP1655 includes an I2C-compatible serial interface for

control of the LED current, as well as for a readback of system

status registers. The I

0x61 in read mode.

2

Table 7. I

C Interface Mode Selection

Mode

Standby 1 X X 0 0 mA

Torch 1 X X 1 20 mA to 160 mA

Assist light 1 X X X 20 mA to 160 mA2

Flash 1 X X X 200 mA to 500 mA2

1

Torch mode has to be enabled from Register 0x04.

2

The output current value depends on the register settings.

Registers values are reset to the default values when VIN supply

falls below the undervoltage (UVLO) level.

Figure 30 illustrates the I

The subaddress content selects which of the five ADP1655

registers is written to first. The ADP1655 sends an acknowledgement to the master after the 8-bit data byte has been written.

The ADP1655 increments the subaddress automatically and starts

receiving a data byte to the following register until the master

sends an I

2

I

C read sequence of a single register. ADP1655 sends the data

2

C stop as shown in Figure 31. Figure 32 shows the

from the register denoted by the subaddress and increments

the subaddress automatically, sending data from the next register until the master sends an I

Figure 33.

State transitions between standby, assist light, flash, and

external torch modes are described in the State Transitions

section and Figure 34.

The register definitions are shown in the I

section. The lowest bit number (0) represents the least

significant bit, and the highest bit number (7) represents

the most significant bit.

2

C chip address is 0x60 in write mode and

I2C/

EN SCL SDA TORCH Output Current

2

C write sequence to a single register.

2

C stop condition as shown in

2

C Register Map

1, 2

Rev. 0 | Page 13 of 24

Page 14

ADP1655

http://www.BDTIC.com/ADI

0 = WRITE

S

01 100 00 0

T

CHIP ADDRESS

0

DP1655 ACK

Figure 30. I

SUBADDRESS

2

C Single Register Write Sequence

00

ADP1655 RECEIVES

DATA

ADP1655 ACK

MASTER

STOP

S

P

ADP1655 ACK

08028-032

0 = WRITE

S

01100 00 0

T

CHIP ADDRESS

0

ADP1655 ACK

SUBADDRESS

REGISTER N

00

ADP1655 ACK

Figure 31. I

ADP1655 RECEIVES

DATA TO REGISTER N

2

C Multiple Register Write Sequence

ADP1655 RECEIVES

DATA TO REGI STER N + 1

ADP1655 ACK

0

ADP1655 RECEIVES

DATA TO LAST REGISTER

ADP1655 ACK

MASTER

STOP

S

0

P

ADP1655 ACK

08028-033

MASTER

0 = WRITE 1 = READ

S

0110000 0

T

CHIP ADDRESS

SUBADDRESS

S

0

0110000 01 0

T

CHIP ADDRESS

ADP1655SENDS

DATA

STOP

10

S

P

ADP1655 ACK

Figure 32. I

ADP1655 ACK

2

C Single Register Read Sequence

ADP1655 ACK

MASTER ACK

08028-034

MASTER

0 = WRITE 1 = READ

S

0110000 0 0 00

T

CHIP ADDRESS CHIP AD DRESS

DP1655 ACK

SUBADDRESS

REGISTER N

S

0110000 01 0

T

DP1655 ACK

Figure 33. I

ADP1655 SENDS

DATA OF REG ISTER N

DP1655 ACK

2

C Multiple Register Read Sequence

ADP1655 SENDS

REGISTER N + 1

MASTER ACK

DATA OF

0

ADP1655 SENDS

DATA OF LAST

MASTER ACK

REGISTER

STOP

1

MASTER ACK

S

P

8028-035

Rev. 0 | Page 14 of 24

Page 15

ADP1655

http://www.BDTIC.com/ADI

STATE TRANSITIONS

When the ADP1655 is in flash mode, the TX_MASK pin can

be used to reduce the battery load. The device remains in flash

mode, but the LED driver output current is reduced to the assist

TX_MASK ENABLED

MODE = ASSIST LIGHT

light level. In Figure 34, if the flash was triggered by the strobe

pin in level-sensitive mode, a timeout triggers a timeout fault,

as defined in the Safety Features section.

TX_MASK = 1

OUTPUT ON

STROBE = 1

EXTERNAL

TORCH

OUTPUT ON

STROBE DISABL ED

MODE = FLASH

EN1 = 0

EN2 = 1

ASSIST

LIGHT

OUTPUT ON

MODE = ASSIST LIGHT

OUTPUT OFF

TORCH NOT

ALLOWE D

Figure 34. I

STROBE = 1

TX_MASK = 0

STROBE DISABLED

MODE = FLASH

TX_MASK = 0

TORCH = 0

2

C Interface Mode: State Transitions

TORCH ALLO WED

MODE = TORCH

FLASH

OUTPUT ON

STROBE = 1

OUTPUT ON

STROBE DISABL ED

MODE = FLAS H

STANDBY

I2C/EN = 1

TIMEOUT

OUTPUT OFF

8028-036

Rev. 0 | Page 15 of 24

Page 16

ADP1655

http://www.BDTIC.com/ADI

I2C REGISTER MAP

The lowest bit number (0) represents the least significant bit, and the highest bit number (7) represents the most significant bit.

Table 8. Design Information Register (Register 0x00)

Bit R/W Reset State

7:0 R 00100001

Table 9. Version Register (Register 0x01)

Bit R/W Reset State

7:0 R 00000001

Table 10. VREF and Timer Register (Register 0x02)

Bit R/W Description

7:6 R/W Reserved

5:4 R/W Number of LEDs detection comparator reference level

00 = 4.3 V (default)

01 = 4.6 V

10 = 4.0 V

11 = 4.9 V

3:0 R/W Flash timer value setting

0000 = 100 ms

0001 = 150 ms

0010 = 200 ms

0011 = 250 ms

0100 = 300 ms

0101 = 350 ms

0110 = 400 ms

0111 = 450 ms

1000 = 500 ms

1001 = 550 ms

1010 = 600 ms

1011 = 650 ms

1100 = 700 ms

1101 = 750 ms

1110 = 800 ms

1111 = 850 ms (default)

Rev. 0 | Page 16 of 24

Page 17

ADP1655

http://www.BDTIC.com/ADI

Table 11. Current Set Register (Register 0x03)

Bit R/W Description

7:4 R/W Flash current value setting

0000 = 200 mA

0001 = 220 mA

0010 = 240 mA

0011 = 260 mA

0100 = 280 mA

0101 = 300 mA

0110 = 320 mA (default for two LEDs)

0111 = 340 mA

1000 = 360 mA

1001 = 380 mA

1010 = 400 mA

1011 = 420 mA

1100 = 440 mA

1101 = 460 mA

1110 = 480 mA

1111 = 500 mA (default for one LED)

3 N/A

2:0 R/W Torch and assist light current value setting

000 = 20 mA

001 = 40 mA (default)

010 = 60 mA

011 = 80 mA

100 = 100 mA

101 = 120 mA

110 = 140 mA

111 = 160 mA

Table 12. Output Mode Register (Register 0x04)

Bit R/W Description

7:6 R/W Inductor peak current limit setting

00 = 1.25 A

01 = 1.5 A

10 = 1.75 A (default)

11 = 2.0 A

5 R/W 0 = edge sensitive

1 = level sensitive (default)

4 R/W 0 = TORCH not allowed

1 = TORCH allowed (default)

3 R/W 0 = LED_OUT off (default)

1 = LED_OUT on

2 R/W 0 = STROBE disabled

1 = STROBE enabled (default)

1:0 R/W Configures LED output mode

00 = standby mode (default)

01 = reserved

10 = assist light mode

11 = flash mode

Rev. 0 | Page 17 of 24

Page 18

ADP1655

http://www.BDTIC.com/ADI

Table 13. Fault Information Register (Register 0x05)

Bit R/W Description

7 R 0 = no fault (default)

1 = overvoltage or C

6 R 0 = no fault (default)

1 = short-circuit fault

5 R 0 = no fault (default)

1 = overtemperature fault

4 R 0 = no fault (default)

1 = timeout 850 ms fault

3 R/W 0 = one LED

1 = two LEDs (default)

2 R Reserved

1 R 0 = no fault (default)

1 = current limit fault

0 R Reserved

Table 14. Input Control Register (Register 0x06)

Bit R/W Description

7:3 Reserved

2 R/W 0 = Strobe 0 triggers flash in level sensitive mode, Strobe 1 > 0 triggers flash in edge sensitive mode

1 = Strobe 1 triggers flash in level sensitive mode, Strobe 0 > 1 triggers flash in edge sensitive mode (default)

1 R/W 0 = TX_MASK function disabled

1 = TX_MASK function allowed (default)

0 R Reserved

OUT

fault

Rev. 0 | Page 18 of 24

Page 19

ADP1655

http://www.BDTIC.com/ADI

SAFETY FEATURES

For critical system conditions, such as output overvoltage,

flash timeout, LED output short circuit, and overtemperature

conditions, the ADP1655 has built-in safety mechanisms. If

one of the fault conditions occurs, the device shuts down and

a corresponding flag is set in the fault information register

(Register 0x05). In I

processor can read the fault information register through the

2

I

C interface to determine the nature of the fault condition

and, consequently, the fault flag is cleared. The device is

disabled until the fault information register is cleared.

In 2-bit logic interface mode, the I

available. To clear a fault, set EN1, EN2, and TORCH low.

2

C interface mode, the system baseband

2

C register readback is not

OVERVOLTAGE FAULT

The ADP1655 contains a comparator at the VOUT pin that

monitors the voltage between VOUT and SGND. If the voltage

exceeds 9.5 V (typical), the ADP1655 shuts down. In I

Bit 7 in the fault information register is read back as high. The

ADP1655 is disabled until the fault is cleared, ensuring protection against an open circuit.

2

C mode,

OUTPUT CAPACITOR FAULT

If no output capacitor is present at the VOUT pin when the

ADP1655 is enabled for a flash, torch, or assist light event,

the part shuts down and Bit 7 in the fault information register

is read back as high. The ADP1655 is disabled until the fault is

cleared. The output capacitor detection scheme does not cause

the VOUT pin to rise above the overvoltage threshold even though

the overvoltage flag (Bit 7) in the fault information register

(Register 5) is set. The overvoltage and output capacitor fault

flags share a single register bit to reduce the required number

of registers.

TIMEOUT FAULT

If the 2-bit logic interface is used, the maximum duration for

flash being enabled (EN1/EN2 = 1) is preset to 850 ms. If EN1

and EN2 remain high for longer than 850 ms, ADP1655 is

disabled until the fault is cleared (EN1, EN2, and TORCH low).

2

In I

C mode, if strobe mode is enabled (Register 0x04, Bit 2),

strobe is set to level sensitive mode (Register 0x04, Bit 5), and

if strobe remains high for longer than 850 ms, the timeout fault

bit, Register 0x05, Bit 4), is read back as high. The ADP1655 is

disabled until the fault is cleared.

OVERTEMPERATURE FAULT

If the junction temperature of the ADP1655 rises above 150°C,

a thermal protection circuit shuts down the device. In I

Bit 5 of the fault information register is read back as high. The

ADP1655 is disabled until the fault is cleared.

2

C mode,

SHORT-CIRCUIT FAULT

The LED_OUT pin features short-circuit protection that

disables the ADP1655 if it detects a short circuit to ground at

the LED_OUT pin. The ADP1655 monitors the LED voltage

when the LED driver is enabled. If the LED_OUT pin remains

below the short-circuit detection threshold during startup, a

short circuit is detected. Bit 6 of the fault information register

is read back as high. The ADP1655 is disabled until the fault is

cleared.

CURRENT LIMIT

The internal switch limits battery current by ensuring that the

peak inductor current does not exceed the programmed limit

(current limit is set by Bit 6 and Bit 7 in the output mode register,

Register 0x04). If the peak inductor current exceeds the limit,

the part shuts down and Bit 1 of the fault information register

is read back as high. The ADP1655 is disabled until the fault is

cleared.

AMOUNT OF LED DETECTION

The ADP1655 is able to detect the amount of LED connected in

series between the LED_OUT pin and the PGND potential. In

2

I

C mode, the detection is enabled with Bit 3 in the output mode

register. The part uses an 80 mA LED driver current setting to

detect the LED forward voltage (Vf) with a voltage comparator

at the start of a flash, torch, or assist light event. If the detected

forward voltage is higher than 4.3 V (typical), Bit 3 of the fault

information register is read back as high.

INPUT UNDERVOLTAGE

The ADP1655 includes an input undervoltage lockout circuit. If

the battery voltage drops below the 2.4 V (typical) input UVLO

threshold, the ADP1655 shuts down. In this case, information

in all registers is lost, and when power is reapplied, a power-on

reset circuit resets the registers to their default conditions.

Rev. 0 | Page 19 of 24

Page 20

ADP1655

http://www.BDTIC.com/ADI

APPLICATIONS INFORMATION

EXTERNAL COMPONENT SELECTION

Selecting the Inductor

The ADP1655 boost converter increases the battery voltage

to allow driving of one or two LEDs, whose combined voltage

drop is higher than the battery voltage plus the current source

headroom voltage. This allows the converter to regulate the

LED current over the entire battery voltage range and with a

wide variation of LED forward voltage.

The inductor saturation current should be greater than the sum

of the dc input current and half the inductor ripple current. A

reduction in the effective inductance due to saturation increases

the inductor current ripple. Suggested inductors are shown in

Tabl e 15 .

Table 15. Suggested Inductors

Value

Vendo r

Toko 2.2 FDSE0312 160 3.1 3 × 3 × 1.2

Toko 2.0 DE2812C 67 1.8 3.0 × 3.2 × 1.22

Coilcraft 2.2 LPS3010 220 1.4 3 × 3 × 1.0

Coilcraft 2.2 LPS3314 100 1.5 3 × 3 × 1.4

(µH) Part No.

Selecting the Input Capacitor

The ADP1655 requires an input bypass capacitor to supply

transient currents while maintaining constant input and output

voltages. The input capacitor carries the input ripple current,

allowing the input power source to supply only the dc current.

Use an input capacitor with a sufficient ripple current rating to

handle the inductor ripple. Increased input capacitance reduces

the amplitude of the switching frequency ripple on the battery.

Because of the dc bias characteristics of ceramic capacitors, a

0603, 6.3 V X5R/X7R, 10 µF ceramic capacitor is preferable.

Higher value input capacitors help to reduce the input voltage

ripple and improve transient response. Maximum input

capacitor current is calculated using the following equation:

≥

II

CIN

)(

MAXLOAD

OUT

IN

V

DCR

(mΩ)

IN

ISAT

Dimensions

(A)

L × W × H (mm)

VVV )( −

OUT

To minimize supply noise, place the input capacitor as close to

the VIN pin of the ADP1655 as possible. As with the output

capacitor, a low ESR capacitor is suggested. A list of suggested

input capacitors is shown in Tab le 1 6 .

Table 16. Suggested Input Capacitors

Vendor Value Part No.

Murata 10 μF, 6.3 V GRM188R60J106ME47 1.6 × 0.8 × 0.8

TDK 10 μF, 6.3 V C1608JB0J106K 1.6 × 0.8 × 0.8

Tayio

Yuden

10 μF, 6.3 V JMK107BJ106MA 1.6 × 0.8 × 0.8

Dimensions

L × W × H (mm)

Selecting the Output Capacitor

The output capacitor maintains the output voltage and supplies

the LED current during NFET power switch on period. It also

stabilizes the loop. A 10.0 µF, 16 V X5R/X7R ceramic capacitor

is suggested.

Note that dc bias characterization data is available from capacitor manufacturers and should be taken into account when

selecting input and output capacitors. 16 V capacitors are

recommended for most two-LED designs. Designs with 1 mm

height restrictions can also use 0603 case size, 16 V capacitors

in parallel. A list of suggested output capacitors is shown in

Tabl e 17 .

Table 17. Suggested Output Capacitors

Vendor Value Part No.

Murata 10.0 μF, 10 V GRM21BR71A106KE51 2 × 1.25 × 1.25

Murata 10.0 μF, 16 V GRM31CR61C106KA88 3.2 × 1.6 × 1.6

Tayio

Yuden

10.0 μF, 16 V EMK212BJ106KG 2 × 1.25 × 1.25

Dimensions

L × W × H (mm)

Higher output capacitor values reduce the output voltage ripple

and improve load transient response. When choosing this value,

it is also important to account for the loss of capacitance due to

output voltage dc bias.

Ceramic capacitors are manufactured with a variety of dielectrics, each with different behavior over temperature and applied

voltage. Capacitors must have a dielectric that ensures the

minimum capacitance over the necessary temperature range

and dc bias conditions. X5R or X7R dielectrics with a voltage

rating of 10.0 V or 16 V are suggested for best performance.

Y5V and Z5U dielectrics are not suggested for use with any

dc-to-dc converter because of their poor temperature and dc

bias characteristics.

Rev. 0 | Page 20 of 24

Page 21

ADP1655

A

I

E

http://www.BDTIC.com/ADI

The worst-case capacitance accounting for capacitor variation

over temperature, component tolerance, and voltage is calculated using the following equation:

= C

C

EFF

× (1 − TEMPCO) × (1 − TOL)

OUT

where:

is the effective capacitance at the operating voltage.

C

EFF

TEMPCO is the worst-case capacitor temperature coefficient.

TOL is the worst-case component tolerance.

In this example, TEMPCO over −40°C to +85°C is assumed to

be 15% for an X5R dielectric, TOL is assumed to be 10%, and

C

is 9.528 F at 1.8 V, as shown in Figure 35.

OUT

Substituting these values in the equation yields

C

= 9.528 F × (1 − 0.15) × (1 − 0.1) = 7.288 F

EFF

12

10

8

6

To guarantee the performance of the ADP1655, it is imperative

that the effects of dc bias, temperature, and tolerances on the

behavior of the capacitors be evaluated for each application.

The peak-to-peak output voltage ripple for the selected output

capacitor and inductor values is calculated using the following

equation:

V

RIPPLE

V

SW

IN

CLf

××××π

=

()

OUT

RIPPLE

=

822

SW

Cf

××

OUT

Capacitors with lower equivalent series resistance (ESR) are

preferred to guarantee low output voltage ripple, as shown in

the following equation:

V

ESR ≤

COUT

RIPPLE

I

RIPPL

The effective capacitance needed for stability, which includes

temperature and dc bias effects, is 4 µF.

PACITANCE (µF)

4

C

2

0

0 2 4 6 8 10121416

DC BIAS VOLTAGE (V)

Figure 35. DC Bias Characteristic of a 16 V, 10 μF Ceramic Capacitor

08028-037

Rev. 0 | Page 21 of 24

Page 22

ADP1655

http://www.BDTIC.com/ADI

PCB LAYOUT

Poor layout can affect performance, causing electromagnetic

interference (EMI) and electromagnetic compatibility (EMC)

problems, ground bounce, and voltage losses. Poor layout can

also affect regulation and stability. A good layout is implemented

using the following rules and shown in Figure 36:

• Place the inductor, input capacitor, and output capacitor

close to the IC using short tracks. These components carry

high switching frequencies and large tracks act as antennas.

V

IN

INPUT

CAPACITO R

PGND

• Route the output voltage path away from the inductor and

SW node to minimize noise and magnetic interference.

• Maximize the size of ground metal on the component side

to help with thermal dissipation.

• Use a ground plane with several vias connecting to the

component side ground to further reduce noise interference on sensitive circuit nodes.

PGND

HIGH

POWER

LED

INDUCTOR

CAPACITO R

Figure 36. Example Layout of the ADP1655 Driving Two White LEDs

OUTPUT

ADP1655

HIGH

POWER

LED

8028-028

Rev. 0 | Page 22 of 24

Page 23

ADP1655

http://www.BDTIC.com/ADI

OUTLINE DIMENSIONS

0.660

0.602

0.544

SEATING

PLANE

0.330

0.310

0.290

1.50

REF

3

2

1

A

B

C

BALL A1

IDENTIFIER

1.54

1.50

1.46

2.04

2.00

1.96

0.022

REF

D

020409-B

TOP VIEW

(BALL SIDE DOWN)

0.380

0.352

0.324

0.04 MAX

COPLANARITY

0.280

0.250

0.220

0.50

REF

1.00

REF

BOTTOM VIEW

(BALL SI DE UP)

Figure 37. 12-Ball Wafer Level Chip Scale Package [WLCSP]

(CB-12-4)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option Branding

ADP1655ACBZ-R71 –40°C to +125°C 12-Ball Wafer Level Chip Scale Package [WLCSP] CB-12-4 LAM

ADP1655-EVALZ1 Evaluation Board

1

Z = RoHS Compliant Part.

Rev. 0 | Page 23 of 24

Loading...

Loading...