Page 1

1.5 A LED Flash Driver with

V

T

FEATURES

Ultracompact solution

Small, 2 mm × 1.5 mm, 12-ball WLCSP package

Thin, 3 mm × 3 mm × 0.75 mm, 10-lead LFCSP package

Smallest footprint, 1 mm height, 1 H power inductor

LED current source for local LED grounding

Simplified routing to/from LED

Improved LED thermals

Synchronous 3 MHz PWM boost converter, no external diode

High efficiency: 90% peak

Reduces high levels of input battery current during flash

Limits battery current drain in torch mode

2

I

C programmable

Currents up to 1500 mA in flash mode for 1 LED with

±7% accuracy over all conditions

Currents up to 200 mA in torch mode

Programmable dc battery current limit (4 settings)

Programmable flash timer up to 1600 ms

Low VBAT mode to reduce LED current automatically

4-bit ADC for LED V

Control

2

I

C-compatible control registers

External STROBE and torch input pins

2 transmitter mask (TxMASK) inputs

Safety

Thermal overload protection

Inductor fault detection

LED short-/open-circuit protection

APPLICATIONS

Camera-enabled cellular phones and smart phones

Digital still cameras, camcorders, and PDAs

, die/LED temperature readback

F

I2C-Compatible Interface

ADP1650

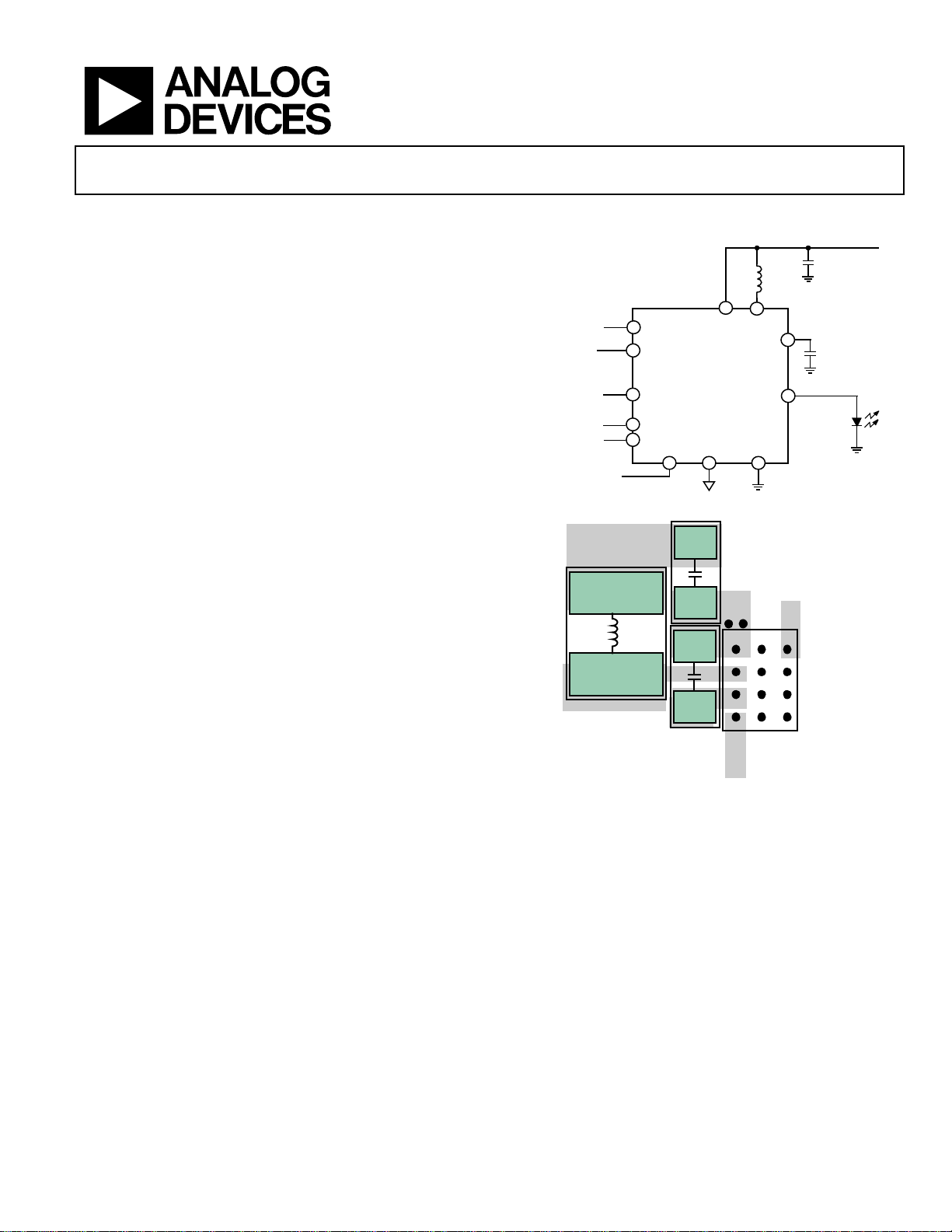

FUNCTIONAL BLOCK DIAGRAM

INPUT VO LTAGE = 2.7V TO 5.0

1.0µH

VIN

LED_OUT

PGND

LED

ANODE

SW

VOUT

PGND

Li-ION +

TX1/TORCH

X2/ILED/ADC

L1

AREA = 16.4mm

GPIO1

GPIO2

ADP1650

STROBE

SCL

SDA

EN SGND

Li-ION +

INDUCTOR

2

Figure 2. PCB Layout (WLCSP)

Figure 1.

1

C

C2

10µF

10µF

MAX 1.5A

DIGITAL

INPUT/

OUTPUT

08837-001

8837-002

GENERAL DESCRIPTION

The ADP1650 is a very compact, highly efficient, single white

LED flash driver for high resolution camera phones that

improves picture and video quality in low light environments.

The device integrates a programmable 1.5 MHz or 3 MHz

synchronous inductive boost converter, an I

2

C-compatible

interface, and a 1500 mA current source. The high switching

frequency enables the use of a tiny, 1 mm high, low cost, 1 µH

power inductor, and the current source permits LED cathode

grounding for thermally enhanced, low EMI, and compact

layouts.

The LED driver maximizes efficiency over the entire battery

voltage range to maximize the input-power-to-LED-power

conversion and to minimize battery current draw during flash

Rev. C

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

events. A programmable dc battery current limit safely maximizes

LED current for all LED V

and battery voltage conditions.

F

Two independent TxMASK inputs permit the flash LED current

and battery current to reduce quickly during a power amplifier

current burst. The I

2

C-compatible interface enables the programmability of timers, currents, and status bit readback for

operation monitoring and safety control.

The ADP1650 is available in a compact 12-ball, 0.5 mm pitch

WLCSP package and a 10-lead LFCSP package, and operates

within specification over the full −40°C to +125°C junction

temperature range.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010–2011 Analog Devices, Inc. All rights reserved.

Page 2

ADP1650

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Recommended Specifications: Input and Output Capacitance

and Inductance ............................................................................. 5

I2C-Compatible Interface Timing Specifications ..................... 5

Absolute Maximum Ratings............................................................ 6

Thermal Data ................................................................................ 6

Thermal Resistance ...................................................................... 6

ESD Caution.................................................................................. 6

Pin Configurations and Function Descriptions ........................... 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ...................................................................... 12

White LED Driver ...................................................................... 12

Modes of Operation ................................................................... 12

Assist Light.................................................................................. 13

Flash Mode .................................................................................. 13

Assist-to-Flash Operation ......................................................... 13

Torch Mode .................................................................................13

Torch-to-Flash Mode................................................................. 14

TxMASK Operation................................................................... 14

Frequency Foldback................................................................... 14

Indicator LED Driver................................................................. 14

Low Battery LED Current Foldback........................................ 14

Programmable Battery DC Current Limit.............................. 15

Analog-to-Digital Converter Operation................................. 15

5 V Output Operation ............................................................... 16

Safety Features................................................................................. 18

Short-Circuit Fault..................................................................... 18

Overvoltage Fault ....................................................................... 18

Dynamic Overvoltage Mode (DOVP) .................................... 18

Timeout Fault.............................................................................. 18

Overtemperature Fault.............................................................. 18

Indicator LED Fault ................................................................... 18

Current Limit.............................................................................. 18

Input Undervoltage.................................................................... 18

Soft Start ...................................................................................... 18

Reset Using the Enable (EN) Pin ............................................. 18

Clearing Faults............................................................................ 18

I2C Interface ................................................................................ 19

I2C Register Map............................................................................. 20

Applications Information.............................................................. 26

External Component Selection ................................................ 26

PCB Layout...................................................................................... 28

Outline Dimensions....................................................................... 29

Ordering Guide .......................................................................... 29

REVISION HISTORY

4/11—Rev. B to Rev. C

Added 10-Lead LFCSP Package........................................Universal

Changes to Features Section, General Description Section, and

Figure 2 Caption ............................................................................... 1

Changes to Table 1............................................................................ 3

Changes to Table 5............................................................................ 6

Added Figure 5; Renumbered Sequentially .................................. 7

Changes to Table 6............................................................................ 7

Changes to PCB Layout Section and Figure 45 Caption........... 28

Added Figure 46.............................................................................. 28

Updated Outline Dimensions....................................................... 29

Changes to Ordering Guide.......................................................... 29

2/11—Rev. A to Rev. B

Changes to Features Section and General Description Section . 1

Changes to Switching Regulator, Voltage Output Mode, VOUT

Voltage Parameter and Digital Inputs/GPIO, Torch Glitch

Filtering Delay Parameter, Table 1.................................................. 3

Rev. C | Page 2 of 32

Changed GND to Power Ground Throughout .............................6

Changed IL to I

IBAT to I

Change to Figure 10 Caption...........................................................8

Change to Figure 11 Caption...........................................................9

Changed LED_MOD = 10 to LED_MOD = 11 in Figure 32 ... 14

Changes to Analog-to-Digital Converter Operation Section and

Figure 37 .......................................................................................... 15

Changes to Selecting the Output Capacitor Section.................. 26

6/10—Rev. 0 to Rev. A

Changes to Contact Information.....................................................1

5/10—Revision 0: Initial Version

, ILED to I

L

Throughout..................................................................8

BAT

, LED OUT to LED_OUT, and

LED

Page 3

ADP1650

SPECIFICATIONS

1

V

= 3.6 V, TJ = −40°C to +125°C for minimum/maximum specifications, and TA = 25°C for typical specifications, unless otherwise noted.

IN

Table 1.

Parameter2 Conditions Min Typ Max Unit

SUPPLY

Input Voltage Range 2.7 5.0 V

Undervoltage Lockout Threshold VIN falling 2.3 2.4 2.5 V

Undervoltage Lockout Hysteresis 50 100 150 mV

Shutdown Current (IQ), EN = 0 V TJ = −40°C to +85°C, current into VIN pin, VIN = 2.7 V to 4.5 V 0.2 1 μA

Standby Current (I

Operating Quiescent Current Torch mode, LED current = 100 mA 5.3 mA

SW Switch Leakage TJ = −40°C to +85°C, V

T

LED DRIVER

LED Current

Assist Light, Torch Assist light value setting = 0 (000 binary) 25 mA

Assist light value setting = 7 (111 binary) 200 mA

Flash Flash value setting = 0 (00000 binary) 300 mA

Flash value setting = 24 (11000 binary) 1500 mA

LED Current Error—WLCSP I

I

I

I

LED Current Error—LFCSP I

I

I

I

LED Current Source Headroom—WLCSP Flash, 1200 mA LED current 290 mV

Torch, 200 mA LED current 190 mV

LED Current Source Headroom—LFCSP Flash, 1200 mA LED current 370 mV

Torch, 200 mA LED current 220 mV

LED_OUT Ramp-Up Time 0.6 ms

LED_OUT Ramp-Down Time 0.1 ms

SWITCHING REGULATOR

Switching Frequency Switching frequency = 3 MHz 2.8 3 3.2 MHz

Switching frequency = 1.5 MHz 1.4 1.5 1.6 MHz

Minimum Duty Cycle Switching frequency = 3 MHz 14 %

Switching frequency = 1.5 MHz 7 %

nFET Resistance—WLCSP 60 mΩ

pFET Resistance—WLCSP 50 mΩ

nFET Resistance—LFCSP 77 mΩ

pFET Resistance—LFCSP 85 mΩ

Voltage Output Mode

VOUT Voltage—WLCSP 4.575 5.000 5.425 V

VOUT Voltage—LFCSP 4.575 5.000 5.500 V

Output Current 500 mA

Line Regulation I

Load Regulation −0.7 %/A

), EN = 1.8 V TJ = −40°C to +85°C, current into VIN pin, VIN = 2.7 V to 4.5 V 3 10 μA

STBY

3

= 4.5 V 2 μA

= 25°C, V

J

= 700 mA to 1100 mA −6 +6 %

LED

= 300 mA to 650 mA, 1150 mA to 1500 mA −7 +7 %

LED

= 75 mA to 200 mA −10 +10 %

LED

= 25 mA to 50 mA −15 +15 %

LED

= 700 mA to 1100 mA −6 +6 %

LED

= 300 mA to 650 mA, 1150 mA to 1500 mA −7 +7 %

LED

= 75 mA to 200 mA −10 +10 %

LED

= 25 mA to 50 mA −15 +18 %

LED

at VOUT = 300 mA 0.3 %/V

LOAD

3

SW

SW

= 4.5 V 0.5 μA

Rev. C | Page 3 of 32

Page 4

ADP1650

Parameter2 Conditions Min Typ Max Unit

Pass-Through Mode Transition, Flash

VIN to LED_OUT, Entry 1200 mA LED current 580 mV

VIN to LED_OUT, Exit 1200 mA LED current 435 mV

Pass-Through Mode Transition, Torch

VIN to LED_OUT, Entry 200 mA LED current 380 mV

VIN to LED_OUT, Exit 200 mA LED current 285 mV

DIGITAL INPUTS/GPIO

Input Logic Low Voltage 0.54 V

Input Logic High Voltage 1.26 V

GPIO1, GPIO2, STROBE Pull-Down 390 kΩ

Torch Glitch Filtering Delay From torch rising edge to device start 5.5 7 7.5 ms

INDICATOR LED

LED Current Accuracy −22 +22 %

Short-Circuit Detection Threshold 1.2 V

Open-Circuit Detection Threshold 2.45 V

ADC

Resolution 4 Bits

Error External voltage mode 0 ±1 LSB

V

V

Input Voltage Range, GPIO2 External voltage mode 0 0. 5 V

SAFETY FEATURES

Maximum Timeout For Flash 1600 ms

Timer Accuracy −7.0 +7.0 %

DC Current Limit DC current value setting = 0 (00 binary) 1.35 1.5 1.65 A

DC current value setting = 1 (01 binary) 1.55 1.75 1.95 A

DC current value setting = 2 (10 binary) 1.8 2.0 2.2 A

DC current value setting = 3 (11 binary) 2.02 2.25 2.5 A

Low VBAT Mode Transition Voltage

Error 3.2 %

Hysteresis 50 mV

Coil Peak Current Limit Peak current value setting = 0 (00 binary) 1.55 1.75 1.95 A

Peak current value setting = 1 (01 binary) 2.02 2.25 2.5 A

Peak current value setting = 2 (10 binary) 2.47 2.75 3.0 A

Peak current value setting = 3 (11 binary) 2.7 3.0 3.3 A

Overvoltage Detection Threshold 5.15 5.5 5.9 V

LED_OUT Short-Circuit Detection

Comparator Reference Voltage

Thermal Shutdown Threshold

TJ Rising 150 °C

TJ Falling 140 °C

1

VIN is the input voltage to the circuit.

2

All limits at temperature extremes are guaranteed via correlation using standard statistical quality control (SQC).

3

VSW is the voltage on the SW switch pin.

mode, TJ = 25°C ±1 LSB

F

mode, TJ = −40°C to +125°C ±1.5 LSB

F

1.2 1.3 V

Rev. C | Page 4 of 32

Page 5

ADP1650

A

RECOMMENDED SPECIFICATIONS: INPUT AND OUTPUT CAPACITANCE AND INDUCTANCE

Table 2.

Parameter Symbol Conditions Min Typ Max Unit

CAPACITANCE C

Input TA = −40°C to +125°C 4.0 10 μF

Output TA = −40°C to +125°C 3.0 10 20 μF

MINIMUM AND MAXIMUM INDUCTANCE L TA = −40°C to +125°C 0.6 1.0 1.5 μH

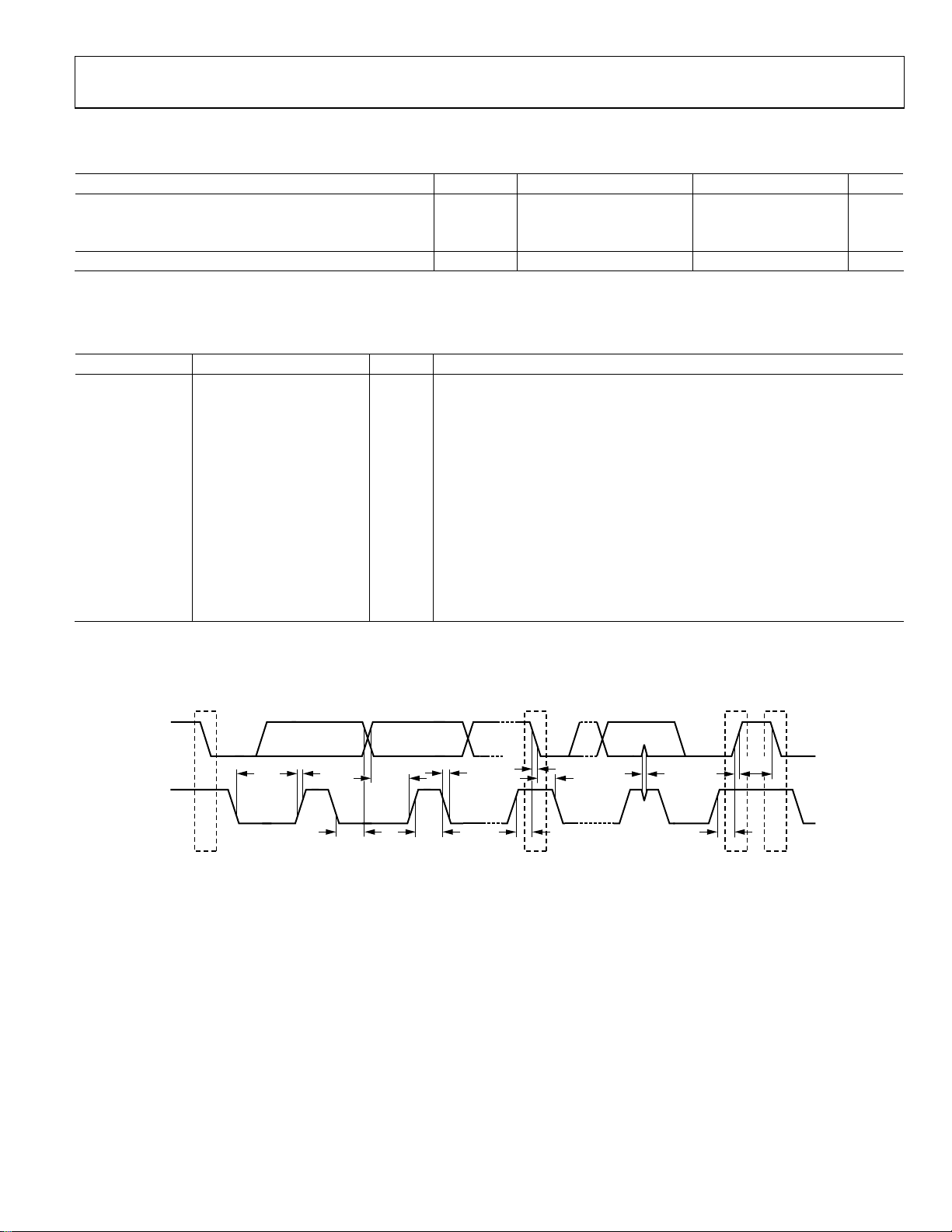

I2C-COMPATIBLE INTERFACE TIMING SPECIFICATIONS

Table 3.

Parameter1 Min Max Unit Description

f

SCL

t

HIGH

t

LOW

t

SU, DAT

t

0 0.9 μs Data hold time

HD, DAT

t

SU, STA

t

HD, STA

t

BUF

t

SU, STO

tR 20 + 0.1 C

tF 20 + 0.1 C

t

SP

2

C

400 pF Capacitive load for each bus line

B

1

Guaranteed by design.

2

CB is the total capacitance of one bus line in picofarads.

400 kHz SCL clock frequency

0.6 μs SCL high time

1.3 μs SCL low time

100 ns Data setup time

0.6 μs Setup time for repeated start

0.6 μs Hold time for start/repeated start

1.3 μs Bus free time between a stop and a start condition

0.6 μs Setup time for stop condition

2

300 ns Rise time of SCL and SDA

B

2

B

300 ns Fall time of SCL and SDA

0 50 ns Pulse width of suppressed spike

MIN

SD

t

LOW

SCL

S

S = START CONDI TION

Sr = REPEATED START CONDITIO N

P = STOP CONDITION

t

R

t

HD, DAT

t

SU, DAT

Figure 3. I

t

F

t

F

t

HIGH

2

C-Compatible Interface Timing Diagram

t

SU, STA

t

HD, STA

Sr P S

Rev. C | Page 5 of 32

t

SP

t

SU, STO

t

BUF

t

R

08837-003

Page 6

ADP1650

ABSOLUTE MAXIMUM RATINGS

Table 4.

Parameter Rating

VIN, SDA, SCL, EN, GPIO1, GPIO2, STROBE,

LED_OUT, SW, VOUT to Power Ground

PGND to SGND −0.3 V to +0.3 V

Ambient Temperature Range (TA) −40°C to +85°C

Junction Temperature Range (TJ) −40°C to +125°C

Storage Temperature JEDEC J-STD-020

ESD Human Body Model ±2000 V

ESD Charged Device Model ±500 V

ESD Machine Model ±150 V

−0.3 V to +6 V

THERMAL RESISTANCE

θJA of the package is based on modeling and calculation using

a 4-layer board. θ

board layout. In applications where high maximum power dissipation exists, attention to thermal board design is required. The

value of θ

JA

environmental conditions. The specified value of θ

on a 4-layer, 4 in × 3 in, 2 ½ oz copper board, per JEDEC

standards. For more information, see the AN-617 Application

Note, MicroCSP™ Wafer Level Chip Scale Package.

θ

is specified for a device mounted on a JEDEC 2S2P PCB.

JA

is highly dependent on the application and

JA

may vary, depending on PCB material, layout, and

is based

JA

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL DATA

The ADP1650 may be damaged if the junction temperature

limits are exceeded. Monitoring T

is within the specified temperature limits. In applications with

high power dissipation and poor thermal resistance, the maximum

T

may have to be derated. In applications with moderate power

A

dissipation and low PCB thermal resistance, the maximum T

can exceed the maximum limit as long as the T

fication limits. T

of the device is dependent on the TA, the power

J

dissipation (PD) of the device, and the junction-to-ambient

thermal resistance (θ

calculated from the T

= TA + (PD × θJA)

T

J

) of the package. Maximum TJ is

JA

and PD using the following formula:

A

does not guarantee that TJ

A

is within speci-

J

A

Table 5. Thermal Resistance

Package Type θJA Unit

12-Ball WLCSP 75 °C/W

10-Lead LFCSP 42.5 °C/W

ESD CAUTION

Rev. C | Page 6 of 32

Page 7

ADP1650

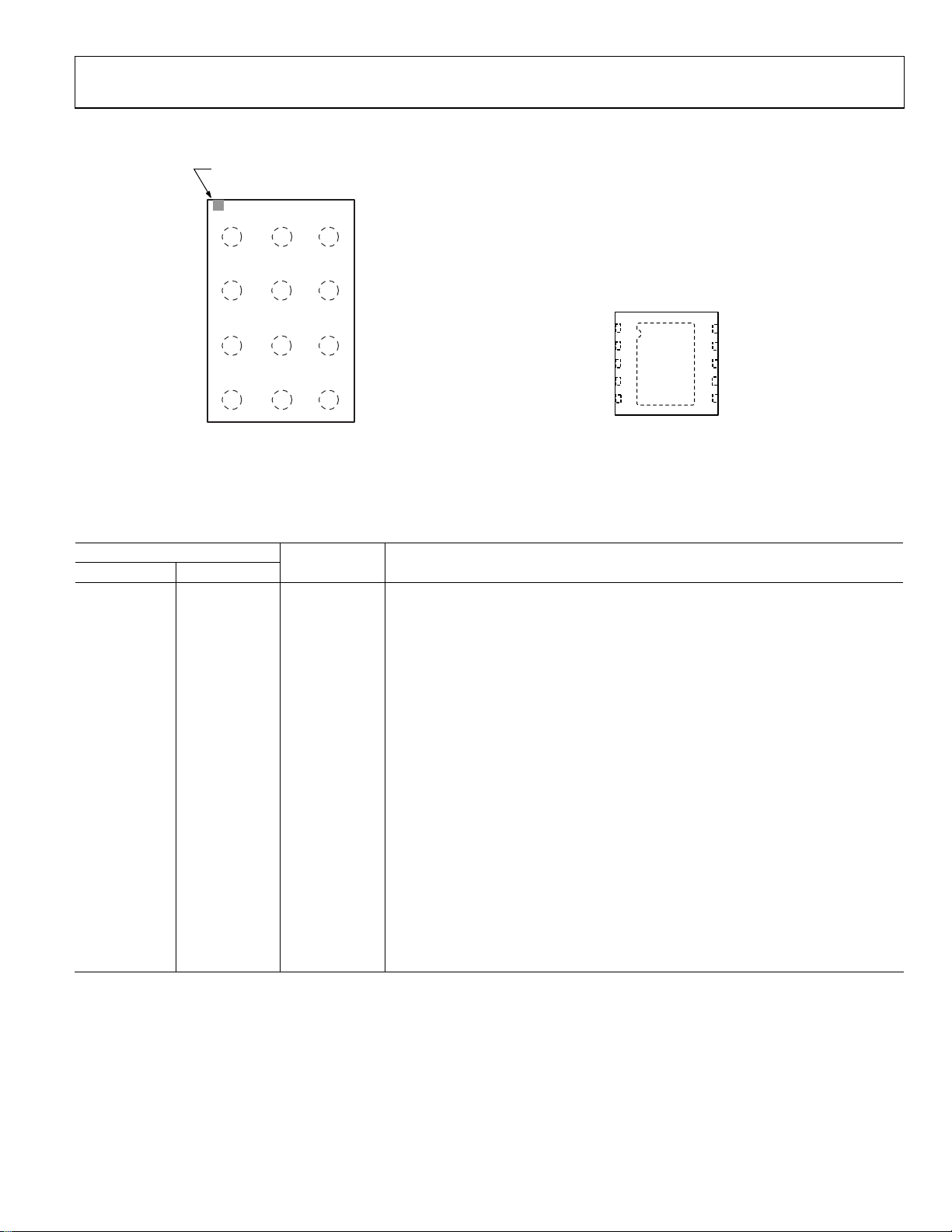

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

BALL A1

INDICATOR

1

PGND SGND VIN

A

23

SW

B

VOUT STROBE EN

C

LED_OUT SDA SCL

D

GPIO2

TOP VIEW

(BALL S IDE DOWN)

Not to Scale

GPIO1

1VIN

2GPIO2

ADP1650

3GPIO1

TOP VIEW

4SDA

5SCL

NOTES

1. THE EXPO SED PADDLE MUS T BE CONNECTED

08837-004

TO GRO UND.

10 STRO BE

9EN

8SW

7VOUT

6LED_OUT

08837-070

Figure 4. WLCSP Pin Configuration Figure 5. LFCSP Pin Configuration

Table 6. Pin Function Descriptions

Pin No.

WLCSP LFCSP Mnemonic Description

A1 N/A1 PGND Power Ground.

A2 N/A1 SGND Signal Ground.

A3 1 VIN Input Voltage for the Device. Connect an input bypass capacitor close to this pin.

B1 8 SW Boost Switch. Connect the power inductor between SW and the input capacitor.

B2 2 GPIO2

ILED/TX2/ADC. Mode is register selectable. Red indicator LED current source or

TxMASK2 or ADC input.

ILED Mode. Connect to red LED anode. Connect the LED cathode to power ground.

TxMASK2 Mode. Reduces the current to the programmable TxMASK2 current.

ADC Mode. This pin is used as the input pin for the ADC.

B3 3 GPIO1

Torch/TX1. Mode is register selectable. External torch mode or TxMASK1 input.

Torch Mode. Enables the integrated circuit (IC) in direct torch mode.

TxMASK1 Mode. Reduces the flash current to the programmable TxMASK1 current.

C1 7 VOUT

Boost Output. Connect an output bypass capacitor very close to this pin. This is the

output for the 5 V external voltage mode.

C2 10 STROBE

Strobe Signal Input. This pin synchronizes the flash pulse to the image capture. In

most cases, this signal comes directly from the image sensor.

C3 9 EN

Enable. Set EN low to bring the quiescent current (I

) to <1 μA. Registers are set to

Q

their defaults when EN is brought from low to high.

D1 6 LED_OUT LED Current Source. Connect this pin to the anode of the flash LED.

D2 4 SDA I2C Data Signal in I2C Mode.

D3 5 SCL I2C Clock Signal in I2C Mode.

0 EPAD Exposed Pad. Connect the exposed pad to the ground plane for the LFCSP version.

1

N/A means not applicable.

Rev. C | Page 7 of 32

Page 8

ADP1650

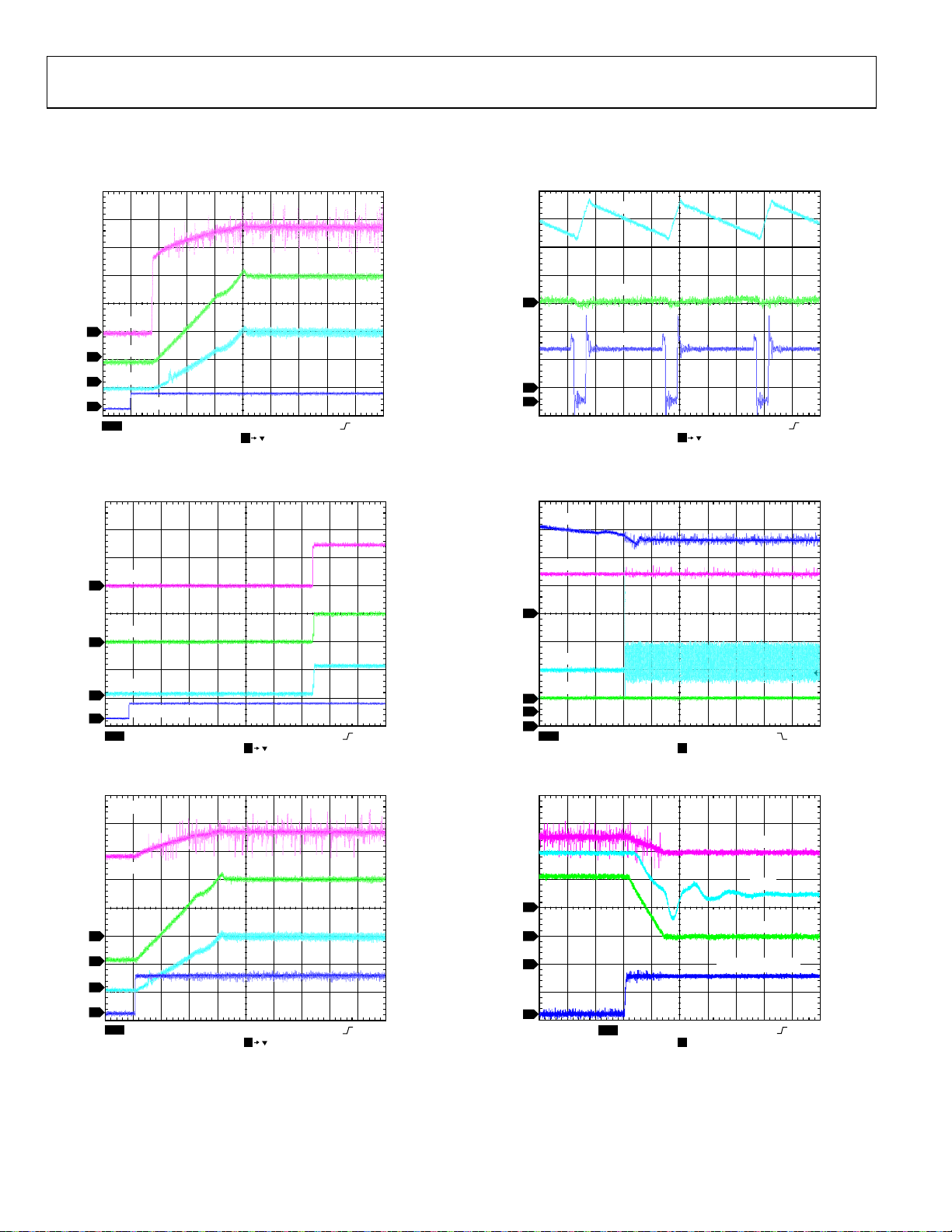

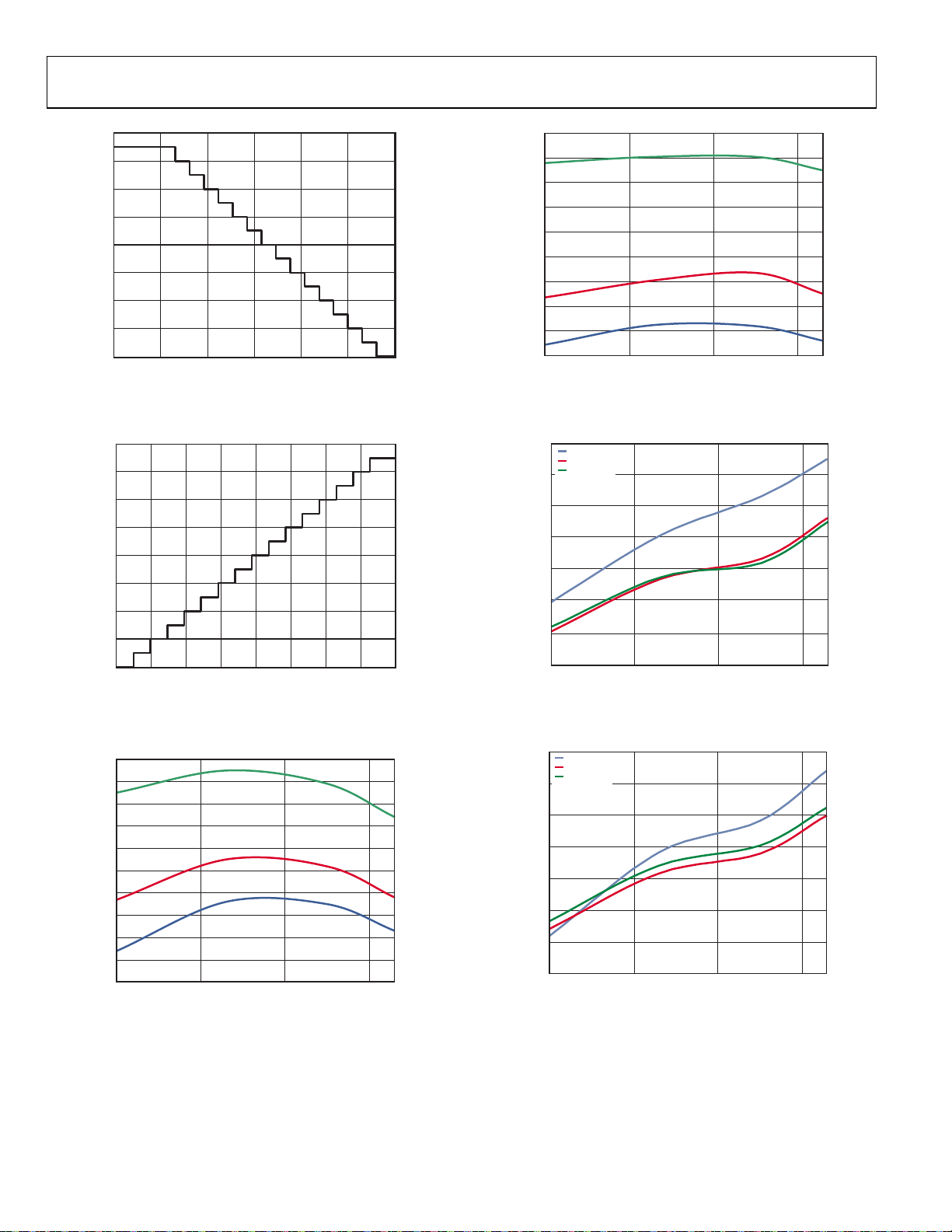

TYPICAL PERFORMANCE CHARACTERISTICS

IL = inductor current, I

LED_OUT

3

I

LED

4

I

L

2

STROBE

1

CH1 5V CH2 1A Ω

Figure 6. Startup Flash Mode, V

= LED current, LED_OUT = LED output, I

LED

CH4 500mA ΩCH3 1V

M100µs A CH1 400mV

T 402.2µs

= 3.6 V, I

IN

= 1500 mA

LED

= battery current.

BAT

I

L

I

4

2

1

08837-025

CH1 2V CH2 100m A Ω

Figure 9. Switching Waveforms, Flash Mode, I

VIN

LED

SW

CH4 25mA Ω

M100ns A CH1 1.6V

T 4.16007ms

= 1500 mA

LED

08837-031

LED_OUT

3

I

LED

4

I

L

2

GPIO1 (Torch)

1

CH1 5V CH2 100mA Ω

CH4 100mA ΩCH3 2V

Figure 7. Startup Torch Mode, V

VIN = 3.6V

LED_OUT

3

I

LED

4

I

L

2

STR

1

CH1 2V CH2 1A Ω

CH4 500mA ΩCH3 1V

M1.00ms A CH1 600mV

T 4.16ms

= 3.6 V, I

IN

M100µs A CH1 440mV

T 394.6µs

Figure 8. 100 mA Torch to 1500 mA Flash Transition

= 100 mA

LED

LED_OUT

3

I

L

I

LED

2

08837-026

08837-028

1

4

CH1 5V CH2 100m A Ω

CH4 100mA ΩCH3 2V

M1ms A CH2 88mA

T 30.40%

Figure 10. Pass-Through to Boost Mode Transition, I

LED_OUT

I

BAT

3

I

4

2

1

CH1 2V

CH2 1A Ω

CH4 500mA ΩCH3 1V

M10µs A CH1 680mV

T 30.60%

LED

GPIO1 (TxMASK1)

= 100 mA

LED

08837-032

08837-035

Figure 11. Entry into TxMASK1 Mode

Rev. C | Page 8 of 32

Page 9

ADP1650

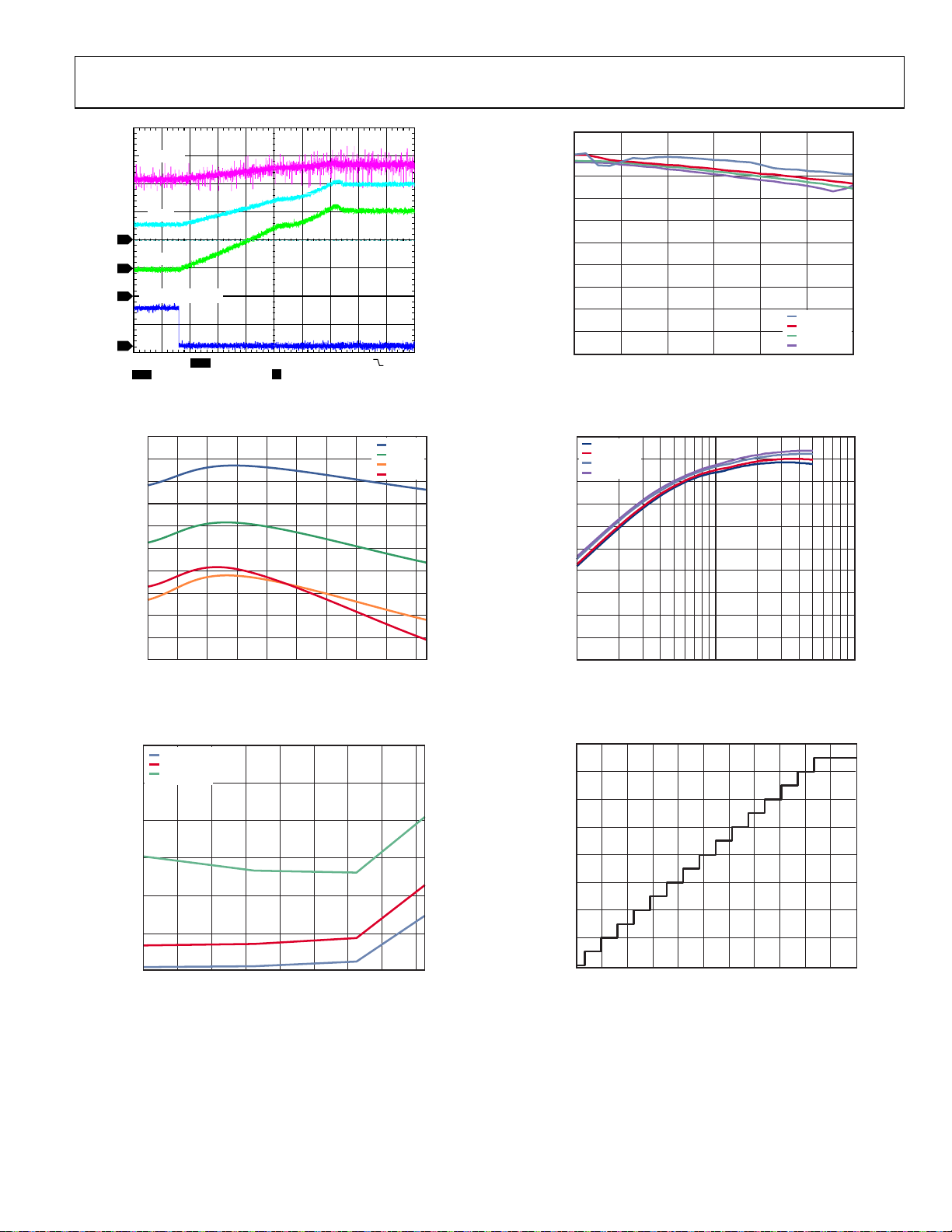

C

C

100

LED_OUT

I

BAT

2

I

LED

3

4

GPIO1 ( TxMASK1)

1

CH2 2V

CH4

1A Ω M40µs A CH1 680mV

CH2

CH4 500mA Ω1V

T 16%

Figure 12. Exit from TxMASK1 Mode

08837-036

90

80

70

60

Y (%)

50

40

EFFICIEN

30

20

10

0

0.30.50.70.91.11.31.5

LED CURRENT (A)

VIN = 4.2V

V

= 3.6V

IN

V

= 3.4V

IN

V

= 3.2V

IN

Figure 15. Flash Mode Efficiency vs. LED Current

8837-044

3.04

3.03

3.02

3.01

3.00

2.99

(MHz)

SW

f

2.98

2.97

2.96

2.95

2.94

2.7 3.0 3.3 3.6 3.9 4.2 4. 5 4.8 5.1 5.4

INPUT VOLTAGE (V)

–40°C

+25°C

+85°C

+125°C

Figure 13. Switching Frequency vs. Supply Voltage (3 MHz Mode)

6

VIN = 2.7V

= 3.6V

V

IN

= 4.5V

V

IN

5

4

3

2

STANDBY CURRENT (µA)

1

100

VIN = 2.7V

= 3.0V

V

IN

90

80

70

60

Y (%)

50

40

EFFICIEN

30

20

10

08837-038

= 3.6V

V

IN

= 4.2V

V

IN

0

0.01 0. 1 1

OUTPUT CURRENT (A)

08837-045

Figure 16. Voltage Regulation Mode Efficiency vs. Load Current

1111

1110

1100

1010

1000

0110

ADC RESULT (Bin ary)

0100

0010

0

–40 –20 0 20 40 60 80 100 120

TEMPERATURE (°C)

Figure 14. Standby Current vs. Temperature

08837-043

0000

0 50 100 150 200 250 300 350 400 450 500 550

ADC INPUT VOLTAGE (mV)

Figure 17. ADC External Voltage Mode Transfer Characteristic

08837-059

Rev. C | Page 9 of 32

Page 10

ADP1650

1111

1110

1100

1010

1000

0110

ADC RESULT (Binary)

0100

0010

0000

0 25 50 75 100 125 150

DIE TEMPERATURE (°C)

Figure 18. ADC Die Temperature Mode Transfer Characteristic

08837-060

295

294

293

292

291

290

289

CODE 1000 MIDPOINT (mV)

288

287

286

–40 10 60 110

= 5V

V

IN

V

= 3.6V

IN

V

= 2.7V

IN

TEMPERATURE (°C)

08837-063

Figure 21. ADC External Voltage Mode, Code 1000, Midpoint vs. Temperature

1111

1110

1100

1010

1000

0110

ADC RESULT (Bin ary)

0100

0010

0000

2.8 3.0 3. 2 3. 4 3. 6 3.8 4. 0 4. 2 4. 4

LED_OUT VOLTAGE (V)

Figure 19. ADC LED V

3.760

3.755

3.750

3.745

3.740

3.735

3.730

3.725

CODE 1000 MIDPO INT (V)

3.720

3.715

3.710

–40 10 60 110

Figure 20. ADC LED V

Mode Transfer Characteristic

F

V

= 5.0V

IN

V

IN

VIN = 2.7V

TEMPERATURE (°C)

Mode, Code 1000, Midpoint vs. Temperature

F

= 3.6V

1.0

VIN = 3.2V

V

= 3.6V

IN

V

= 4.2V

IN

0.5

0

–0.5

–1.0

–1.5

LED CURRENT ERROR (%)

LED CURRENT ERROR (%)

–2.0

–2.5

–40 10 60 110

8837-061

Figure 22. LED Current Accuracy vs. Temperature, I

0.5

VIN = 3.2V

V

= 3.6V

IN

V

= 4.2V

IN

0

–0.5

–1.0

–1.5

–2.0

LED CURRENT ERROR (%)

–2.5

–3.0

–40 10 60 110

08837-062

TEMPERATURE (°C)

TEMPERATURE (°C)

= 1200 mA

LED

08837-066

08837-067

Figure 23. LED Current Accuracy vs. Temperature, I

= 800 mA

LED

Rev. C | Page 10 of 32

Page 11

ADP1650

3.0

VIN = 3.2V

= 3.6V

V

IN

LED CURRENT ERRO R (%)

2.5

2.0

1.5

1.0

0.5

–0.5

–1.0

–1.5

–2.0

= 4.2V

V

IN

0

–40 10 60 110

TEMPERATURE (°C)

Figure 24. LED Current Error vs. Temperature, I

= 1500 mA

LED

08837-068

1.0

VIN = 3.2V

= 3.6V

V

IN

= 4.2V

V

IN

0.5

0

–0.5

–1.0

–1.5

LED CURRENT ERROR (%)

LED CURRENT ERROR (%)

–2.0

–2.5

–40 10 60 110

TEMPERATURE (°C)

Figure 25. LED Current Error vs. Temperature, I

= 1000 mA

LED

08837-069

Rev. C | Page 11 of 32

Page 12

ADP1650

V

THEORY OF OPERATION

The ADP1650 is a high power, I2C programmable white LED

driver ideal for driving white LEDs for use as a camera flash.

The ADP1650 includes a boost converter and a current

regulator suitable for powering one high power white LED.

WHITE LED DRIVER

The ADP1650 drives a synchronous 3 MHz boost converter as

required to power the high power LED. If the sum of the LED

forward voltage and current regulator voltage is higher than

the battery voltage, the boost turns on. If the battery voltage is

higher than the sum of the LED V

age, the boost is disabled and the part operates in pass-through

mode. The ADP1650 uses an integrated PFET high-side current

regulator for accurate brightness control.

and current regulator volt-

F

INPUT VOLTAGE =

VIN

L1

1µF

SW

2.7V TO 5. 0

PGND

C

IN

10µF

MODES OF OPERATION

Once the enable pin is high, the device can be set into the four

modes of operation using the LED_MOD bits in Register 0x04,

via the I

LED_MOD = [00] sets the device in standby mode, consuming

3 µA (typical).

LED_MOD = [01] sets the device in fixed VOUT = 5 V output

mode.

LED_MOD = [10] sets the device in assist light mode with

continuous LED current.

LED_MOD = [11] sets the device in flash mode with current up

to 1.5 A available for up to 1.6 sec.

2

C-compatible interface.

C

OUT

10µF

PGND

VOUT

HPLED

DRIVER

CURRENT

SENSE

HPLED

SHORT

HIGH POWER LED

CURRENT CONTROL

PGNDAGND

LED_OUT

25mA TO 1.5A

PGND

PGNDSGND

08837-006

SCL

SDA

STROBE

EN

2.4V

TORCH

IO1_CFG[5:4]

UVLO

PWM

CONTROLL ER

INTERFACE

AND

CONTROL

TXMASK1 TXMASK2

VIN

ILED

IO2_CFG[7:6]

GPIO1 GPIO2

CURRENT

SENSE

4-BIT

ADC

5.5V

OVP

REGISTER

IC THERMAL

SENSING

LED_OUT PIN

FAULT

Figure 26. Detailed Block Diagram

Rev. C | Page 12 of 32

Page 13

ADP1650

A

ASSIST LIGHT

The assist light provides continuous current programmable

from 25 mA to 200 mA. Set the assist light current using the

I_TOR bits (in Register 0x03). To enable assist, set LED_MOD

to assist light mode and set OUTPUT_EN = 1 (in Register 0x04).

Disable assist light mode by setting LED_MOD to standby

mode or setting OUTPUT_EN = 0.

I(ASSIST)

LED CURRENT

0A

I2C DATA BUS

REG 0x03, I_TOR = XXX mA

REG 0x04, OUTPUT _EN = 1

LED_MOD = 10

Figure 27. Enabling Assist Light Mode

REG 0x04, OUTPUT_EN = 0

FLASH MODE

Flash mode provides 300 mA to 1.5 A for a programmable time

of up to 1.6 seconds. Set the flash current using the I_FL bits (in

Register 0x03) and the maximum flash duration with the FL_TIM

bits (in Register 0x02). To enable flash mode, set LED_MOD

to flash mode and set OUTPUT_EN = 1. Enable flash without

STROBE by setting STR_MODE (in Register 0x04) to 0 (software

strobe). When STR_MODE is in hardware strobe mode, setting

the STROBE pin high enables flash and synchronizes it to the

image sensor. Hardware strobe mode has two modes for timeout:

level sensitive and edge sensitive.

I(FLASH)

LED CURR ENT

0A

STROBE

I(FLASH)

LED CURR ENT

I2C DATA BUS

0A

STROBE

REG 0x02, FL_TIM = XXXX ms

REG 0x03, I_FL = XXXXX mA

REG 0x04, OUT PUT_EN = 1

STR_LV = 0

LED_MOD = 11

FL_TIM

ADP1650 SETS OUTPUT_EN TO 0.

ADP1650 SETS LE D_MOD TO 00.

08837-009

Figure 29. Flash Operation: Edge-Sensitive Mode

In edge-sensitive mode, a positive edge on the STROBE pin

enables the flash, and the FL_TIM bits set the flash duration.

08837-007

ASSIST-TO-FLASH OPERATION

SH)

I(FL

LED CURRENT

I(ASSIST)

0A

STROBE

I2C D ATA BUS

REG 0x02, FL_T IM = XXXX ms

REG 0x03, I_TOR = XXX mA

REG 0x03, I_FL = XXXXX mA

REG 0x04, OUT PUT_EN = 1

LED_MOD = 10

Figure 30. Enabling Assist to Flash (Level-Sensitive) Mode

ADP1650 SETS OUT PUT_EN TO 0.

ADP1650 SETS LED_MOD TO 00.

STR_LV = 1

08837-010

The STR_POL bit in Register 0x07 changes the default enable of

STROBE from low to high to high to low. Additional image

sensor-specific assist/flash enable modes are included in the

device, and information on these is available on request from

the Analog Devices, Inc., sales team.

TORCH MODE

I2C DATA BUS

REG 0x02, FL _TIM = XXXX ms

REG 0x03, I_FL = XXXXX mA

REG 0x04, OUT PUT_EN = 1

LED_MOD = 11

STR_LV = 1

ADP1650 SETS OUTPUT_EN TO 0.

ADP1650 SETS LE D_MOD TO 00.

08837-008

Figure 28. Flash Operation: Level-Sensitive Mode

In level-sensitive mode, the duration of STROBE high sets the

duration of the flash up to the maximum time set by the

FL_TIM timeout. If STROBE is kept high longer than the

duration set by FL_TIM, a timeout fault disables the flash.

Rev. C | Page 13 of 32

Set the assist/torch light current using the I_TOR bits. To enable

torch mode using a logic signal, set LED_MOD to standby mode

and OUTPUT_EN = 1, and then bring GPIO1 high. Disable

external torch mode by setting GPIO1 low or programming

OUTPUT_EN = 0. Bringing GPIO1 low during torch mode

automatically sets OUTPUT_EN = 0. To enable torch mode

again, program OUTPUT_EN = 1, and bring GPIO high again.

I(ASSIST)

LED CURRENT

GPIO 1 (TORC H)

I2C DATA BUS

0A

REG 0x03, I_TO R = XXX mA

REG 0x04, OUTPUT _EN = 1

LED_MOD = 00

ADP1650 SETS OUTP UT_EN TO 0

Figure 31. Enabling External Torch Mode Using GPIO1

08837-065

Page 14

ADP1650

TORCH-TO-FLASH MODE

The driver can move directly from external torch mode (using

GPIO1) to flash mode by bringing STROBE high before GPIO1

= torch is brought low. Bringing torch low before STROBE goes

high prevents the flash from firing when STROBE goes high.

The ADP1650 returns to standby mode after a successful flash

and sets OUTPUT_EN = 0.

I(FLASH)

LED CURRENT

I(ASSIST)

0A

STROBE

TORCH

I2C D ATA BUS

REG 0x02, FL_TIM = XXXX ms

IO1_CFG = 01, TORCH

REG 0x03, I_T OR = XXX mA

REG 0x03, I _FL = XXX XX mA

REG 0x04, OUTPUT_EN = 1

LED_MOD = 00

Figure 32. Enabling Flash Mode from External Torch Mode

ADP1650 SETS OUTPUT_EN TO 0

STR_LV = 1

TxMASK OPERATION

When the ADP1650 is in flash mode, the TxMASK1 and

TxMASK2 functions reduce the battery load in response to the

system enabling a power amplifier. The device remains in flash

mode, but the LED driver output current reduces to the programmed TxMASK light level in less than 21 µs.

I(FLASH)

LED CURRENT

I(TXMASK1)

0A

TXMASK1

(GPIO1)

STROBE

08837-064

FREQUENCY FOLDBACK

Frequency foldback is an optional mode that optimizes

efficiency by reducing the switching frequency to 1.5 MHz

when VIN is slightly less than VOUT. Enable frequency

foldback by setting FREQ_FB = 1 in Register 0x04.

INDICATOR LED DRIVER

The indicator LED driver on GPIO2 provides a programmable

current source of between 2.75 mA and 11 mA for driving a red

privacy LED. The current level is programmed by the I_ILED

bits in Register 0x07. The circuit consists of a programmable

current source and a monitoring circuit that uses comparators

to determine whether the indicator LED is shorted or open. The

threshold for detection of a short is 1.2 V (maximum) and an

open circuit is 2.45 V (minimum). The indicator LED must not

be used at the same time as a flash or assist/torch event.

LOW BATTERY LED CURRENT FOLDBACK

As the battery discharges, the lower battery voltage results in

higher peak currents through the battery ESR, which may cause

early shutdown of the phone. The ADP1650 features an optional

low battery detection option, which reduces the flash current

(to a programmable level) when the battery voltage falls below a

programmable level.

VIN

50mV HY S

V(V_VB_LO)

STROBE

I2CDATABUS

REG 0x09 , I_VB_LO = XXXX mA

V_VB_LO = XXX V

REG 0x04, OUTPUT_EN = 1

LED_MOD = 10

Figure 34. Register 0x09 Sets the Battery Voltage Threshold Level and the

Reduced LED Current Level

GLITCH < 50µs IGNORED

FL_VB_LO = 1

ADP1650 SETS O UTPUT_EN TO 0.

ADP1650 SETS LE D_MOD TO 00.

08837-012

I2CDATABUS

REG 0x02 , IO 1_CFG = 10

FL_TIM = XXXX ms

REG 0x03, I_FL = XXXXX mA

REG 0x06, I_T X1 = XXXX mA

REG 0x04, OUT PUT_EN = 1

LED_MOD = 11

STR_LV = 1

FL_TX1 = 1

ADP1650 SETS OUT PUT_EN TO 0.

ADP1650 SETS LED_M OD TO 00.

Figure 33. TxMASK1 Operation During Flash (Level-Sensitive) Mode

The device selects the TxMASK1 or TxMASK2 current level

based on whether the TxMASK1 or TxMASK2 input is used.

After a TxMASK1 or TxMASK2 occurs, a flag is set in the fault

information register. When the TxMASK signal goes low again,

the LED current goes back to the full flash level in a controlled

manner to avoid overshoots on the battery current. If both

TxMASK inputs are set high simultaneously, the TXMASK1

current level is used.

Rev. C | Page 14 of 32

Table 7. VDD Level at Which the VBAT Low Function Is

Enabled

Bit Name VDD Level

V_VB_LO 000 = disabled (default)

001 = 3.3 V

010 = 3.35 V

8837-011

011 = 3.4 V

100 = 3.45 V

101 = 3.5 V

110 = 3.55 V

111 = 3.6 V

Set V_VB_LO = 000 to disable the low battery current foldback.

Page 15

ADP1650

PROGRAMMABLE BATTERY DC CURRENT LIMIT

The ADP1650 has four optional programmable input dc current

limits that limit the maximum battery current that can be taken

over all conditions. This allows higher LED currents to be used

in a system with significant variation in LED forward voltage

(V

) and supply battery voltage without risk of the current

F

allocated to the flash being exceeded.

ANALOG-TO-DIGITAL CONVERTER OPERATION

The internal 4-bit analog-to-digital converter (ADC) is configurable to measure the LED V

or an external voltage using the GPIO2 pin. Read the 4-bit

resolution output code back from Register 0x08 using the I

interface.

, integrated circuit (IC) die temperature,

F

2

C

Table 8. Input DC Current Limit Setting the LED Current

Bit Name Current Limit

IL_DC 00 = 1.5 A

01 = 1.75 A

10 = 2.0 A (default)

11 = 2.25 A

During startup of the flash, if the battery current does not reach

the dc current limit, the LED current is set to the current value

of the I_FL bits. If the battery current does hit the programmed

dc current limit on startup, the LED current does not increase

further. The dc current limit flag is set in the fault information

register. The I_FL bits in Register 0x03 are set to the actual LED

current and are available for readback.

NO LIM IT LED C URRENT

ACTUAL LED CURRENT

STROBE

I2C DATA BUS

REG 0x02, FL_TIM = XXXX ms

REG 0x03, I_FL = XXXXX mA

IL_DC_EN = 1

IL_DC = XX A

REG 0x04, OUTPUT_EN = 1

STR_LV = 1

LED_MOD = 11

Figure 35. DC Current Limit Operation in a Low Battery, High LED V

ADP1650 SETS OUTPUT_EN TO 0.

ADP1650 SETS LED_MOD TO 00.

ADP1650 SETS FL_IDC (REG 0x05) TO 1.

ADP1650 SETS I_FL TO ACTUAL LED CURRENT.

Case

F

08837-013

The camera system shown in Figure 36 can adjust the image

sensor settings based on the known reduced LED current for a

low battery and a high V

NO

LED CURRENT =

PROGAMMED LED

CURRENT

STROBE

LED.

F

SELECT FLASH CURRENT

SELECT MAX BATTE RY CURRENT

PREFLASH STROBE

DC LIMIT HIT?

YES

LED CURRENT =

REDUCED LED CURR ENT

BATTERY CURRE NT =

PROGRAMM ED DC LIMI T

I2C READ LED CURREN T

EN

IC TEMPERATURE

SDA

SCL

INTERFACE/

CONTROL

ADC_VAL[5:2]

SENSOR

ADC_EN[1:0]

4-BIT ADC

GPIO2

LED_OUT

PTC

Figure 37. Available ADC Modes in the ADP1650

The ADC can perform the conversion either immediately on an

2

I

C command, or it can delay the conversion until the next time

the ADP1650 exits an active mode. Delayed conversion can be

useful, for example, for measuring the IC temperature at the

end of a timed flash period. To set up a delayed conversion, set

ADC_EN to the required mode while OUTPUT_EN = 0. Then

set the ADP1650 to the desired output mode (torch, flash assist

light, or 5 V output) and set OUTPUT_EN = 1. The ADC conversion is performed when the ADP1650 exits the chosen mode.

To perform an immediate conversion, set ADC_EN to the

required mode during ADP1650 operation (OUTPUT_EN = 1).

Note that an ADC conversion cannot be performed when the

ADP1650 is idle. This is interpreted as an attempt to set up a

delayed conversion.

LED VF Mode

The ADC can measure the LED VF in both flash and assist/

torch modes. In torch mode, set ADC_EN = 01 to begin a

conversion. The value can be read back from the ADC_VAL[5:2]

bits 1 ms after the conversion has started. Assist/torch mode,

rather than flash mode, is best in the handset production test to

verify the LED V

START CONVE RSION

(INTERNAL S IGNAL)

.

F

1ms

08837-015

ADJUST IMAG E SENSO R

STROBE

Figure 36. Use of the DC Current Limit in an Optimized Camera System

08837-014

Figure 38. ADC Timing for All Modes Except V

In flash mode, set ADC_EN = 01. The conversion happens just

before the timeout occurs; therefore, the FL_TIM bits set when

the ADC sample occurs. This allows the V

Rev. C | Page 15 of 32

2

I

C DATA BUS

REG 0x08, ADC_EN = 01

ADC_VAL[5:2]

AVAILABLE F OR READ

Measurement in Flash Mode

F

to settle from the

F

08837-016

Page 16

ADP1650

=

V

initial peak as the junction temperature of the LED stabilizes.

An LED temperature vs. flash time profile for the handset PCB

design can be generated during the design phase by varying the

FL_TIM bits from the lowest to the highest setting and collecting a

V

sample on each flash.

F

I(FLASH)

LED CURRENT

START CO NVERSIO N

(INTERNAL SIGNAL)

I2C DATA BUS

0A

STROBE

REG 0x02, FL_TIM = XX XX ms

REG 0x03, I_FL = XXXXX mA

REG 0x04, O UTPUT _EN = 1

STR_LV = 0

LED_MOD = 11

Figure 39. ADC Timing for V

FL_TIM

ADC_VAL[5:2]

AVAILABL E FOR READ

REG 0x08, AD C_EN = 01

Measurement in Flash Mode

F

t

S

= 1ms

Die Temperature Mode

The ADC measures the IC die temperature and provides the

2

result to the I

C interface. This is useful during the design phase

of the flash system to optimize PCB layout for the best thermal

design.

08837-017

Write ADC_EN = 10 to begin a die temperature measurement.

The value can be read back from the ADC_VAL[5:2] bits 1 ms

after the conversion has started. The most stable and accurate

value of die temperature is available at the end of the flash pulse.

External Voltage Mode

The ADC measures the voltage on the GPIO2 pin when the

GPIO2 is configured as an ADC input by setting IO2_CFG =

11. One example is using an external temperature-dependent

resistor to create a voltage based on the temperature of the flash

LED. The EN line can be used for biasing to reduce leakage

current when the flash is not being used.

5 V OUTPUT OPERATION

The ADP1650 can be used as a 5 V boost to supply up to 500 mA

for an audio voltage rail or keypad LED driver voltage. To move

into voltage regulation mode, the OUTPUT_EN bit must be set

to 0. To enable the 5 V output, set LED_MOD[1:0] = 01, and set

OUTPUT_EN = 1. The ADP1650 sets the VOUT pin to 5 V

and disconnects VOUT from LED_OUT. The VOUT pin is

connected to the SW node when the ADP1650 is not enabled.

VOUT should not be connected directly to a positive external

voltage source because this causes current to flow from VOUT

to the battery.

2.7V TO 5. 0

10µF

VOUT = 5.0V

10µF

VDD

KEYPAD

LED DRIV ER

GND

VIN

SGND

INPUT VOLTAGE

1.0µH

SWSTROBE

VOUT*

LED_OUT

PGND

ON

3.2 MEGAPIXEL

TO 5.0 MEGAPIXE L

CMOS IMAGE SENSOR

APPLICATIONS PROCESSOR

SDA, SCL

EN

*THE VOUT P IN IS CONNECT ED TO T HE SW NODE W HEN THE ADP1650 I S NOT ENABLED. VOUT S HOULD NOT BE CONNECTED DI RECTLY T O A POSITIVE

EXTERNAL VO LTAGE S OURCE BECAUSE THI S WILL CAUSE CURRENT TO FLOW FROM VOUT TO THE BATTERY.

OFF

2

I

C BUS

POWER-ON RESET

GPIO2

SCL

SDA

EN

GPIO1

ADP1650

Figure 40. ADP1650 Voltage Regulation Mode: LED Driver Application

08837-018

Rev. C | Page 16 of 32

Page 17

ADP1650

V

3.2 TO 5.0 MEGAPIXEL

CMOS IMAGE SENSOR

APPLICATIONS PROCESSOR

SDA, SCL

EN

ON

OFF

I2C BUS

POWER-ON

RESET

2.7V TO 5.0

10µF

VOUT = 5. 0V ±8.5%, IMAX = 500mA

10µF

0.1µF

AUDIO IN+

AUDIO IN–

SHUTDOWN

47nF

47nF

VDD

IN+

IN–

SD

80kΩ

80kΩ

GPIO2

SCL

SDA

EN

GPIO1

VIN

ADP1650

SGND

INPUT VOLTAGE =

1.0µH

SWSTROBE

VOUT

LED_OUT

PGND

Figure 41. ADP1650 Voltage Regulation Mode: Class-D Audio Application

160kΩ

MODULATOR

(Σ-∆)

160kΩ

INTERNAL

BIAS

OSCILLATOR

FET

DRIVER

GND

SSM2315

OUT+

OUT–

POP/CLICK

SUPPRESSION

08837-019

Rev. C | Page 17 of 32

Page 18

ADP1650

SAFETY FEATURES

For critical fault conditions, such as output overvoltage, flash

timeout, LED output short circuit, and overtemperature

conditions, the ADP1650 has built-in protection modes. If a

critical fault occurs, OUTPUT_EN (Register 0x04) is set to 0,

and the driver shuts down. The appropriate fault bit is set in the

fault information register (Register 0x05). The processor can

read the fault information register through the I

determine the nature of the fault condition. When the fault

register is read, the corresponding fault bit is cleared.

If a noncritical event such as an indicator LED open/short or a

TxMASK1 or TxMASK2 event occurs, or the dc current limit or

soft inductor current limit is hit, the LED driver continues

operating. The corresponding information bits are set in the

fault information register until the processor reads them.

2

C interface to

SHORT-CIRCUIT FAULT

When the flash driver is disabled, the high-side current regulator

disconnects the dc path between the battery and the LED, protecting the system from an LED short circuit. The LED_OUT

pin features short-circuit protection that monitors the LED

voltage when the LED driver is enabled. If the LED_OUT pin

remains below the short-circuit detection threshold, a short

circuit is detected. Bit 6 of the fault information register is set

high. The ADP1650 remains disabled until the processor clears

the fault register.

OVERVOLTAGE FAULT

The ADP1650 contains a comparator at the VOUT pin that

monitors the voltage between VOUT and GND. If the voltage

exceeds 5.5 V (typical), the ADP1650 shuts down. Bit 7 in the

fault information register is read back as high. The ADP1650 is

disabled until the fault is cleared, ensuring protection against an

open circuit.

DYNAMIC OVERVOLTAGE MODE (DOVP)

Dynamic OVP mode is a programmable feature that limits the

VOUT voltage exceeding the OVP level while maintaining as

much current as possible through the LED. This mode prevents

an overvoltage fault in the case of a much higher than expected

LED forward voltage. If the LED forward voltage reduces due to

the LED temperature rising, the ADP1650 moves out of DOVP

mode and regulates the LED at the programmed current level.

Set Bit 7 of Register 0x07 high to enable dynamic OVP mode.

TIMEOUT FAULT

When external strobe mode is enabled (Register 0x04, Bit 2),

and strobe is set to level-sensitive mode (Register 0x04, Bit 5),

if the strobe pin remains high for longer than the programmed

timeout period, the timeout fault bit (Register 0x05, Bit 4) is

read back as high. The ADP1650 remains disabled until the

processor clears the fault register.

OVERTEMPERATURE FAULT

If the junction temperature of the ADP1650 rises above 150°C,

a thermal protection circuit shuts down the device. Bit 5 of the

fault information register is set high. The ADP1650 remains

disabled until the processor clears the fault register.

INDICATOR LED FAULT

The GPIO2 pin features open- and short-circuit protection in

the indicator LED mode. If a short or open circuit occurs, Bit 2

of the fault information register is set high. The indicator LED

regulator ensures that no damage occurs to the IC during a fault.

CURRENT LIMIT

The internal switch limits battery current by ensuring that the

peak inductor current does not exceed the programmed limit

(current limit is set by Bit 6 and Bit 7 in Register 0x04). The

default mode of the ADP1650 is soft current limit mode. If the

peak inductor current hits the limit, Bit 1 of the fault information register is set, and the inductor and LED current cannot

increase further. The ADP1650 continues to operate. If the

ADP1650 has soft current limit disabled and the peak inductor

current exceeds the limit, the part shuts down and Bit 1 of the

fault information register is set high. In this case, ADP1650

remains disabled until the processor clears the fault register.

INPUT UNDERVOLTAGE

The ADP1650 includes a battery undervoltage lockout circuit.

During 5 V or LED operation, if the battery voltage drops below

the 2.4 V (typical) input UVLO threshold, the ADP1650 shuts

down. A power-on reset circuit resets the registers to their

default conditions when the voltage rises above the UVLO

rising threshold.

SOFT START

The ADP1650 has a soft start mode that controls the rate of

increase of battery current at startup by digitally controlling the

output current ramp. The maximum soft start time is 0.6 ms.

RESET USING THE ENABLE (EN) PIN

A low-to-high transition on the EN pin resets all registers to

their default values. Bringing EN low reduces the I

(typical).

to 0.2 µA

Q

CLEARING FAULTS

The information bits and faults in Register 0x05 clear

automatically when the processor reads the fault register.

Rev. C | Page 18 of 32

Page 19

ADP1650

I2C INTERFACE

The ADP1650 includes an I2C-compatible serial interface for

control of the LED current, as well as for readback of system

status registers. The I

mode and 0x61 in read mode). Additional I

available on request.

2

C chip address is 0x30 (0x60 in write

S

01 100 00 0

T

2

C addresses are

CHIP ADDRESS

0 = WRITE

0

DP1650 ACK

Figure 42. I

0 = WRITE 1 = READ

S

011000 0 0

T

CHIP ADDRESS

SUBADDRESS

Figure 42 illustrates the I

The subaddress content selects which of the nine ADP1650

registers is written to. The ADP1650 sends an acknowledgment

to the master after the 8-bit data byte has been written. Figure 43

shows the I

The register definitions are shown in the I

section.

00

SUBADDRESS

2

C Single Register Write Sequence

S

0

0110000 01 0

T

CHIP ADDRESS

ADP1650 RECEIVES

ADP1650 ACK

2

C write sequence to a single register.

2

C read sequence of a single register.

2

C Register Map

MASTER

STOP

S

P

DATA

ADP1650 ACK

AD P1650 SEN DS

DATA

08837-021

MASTER

STOP

S

10

P

ADP1650 ACK

Figure 43. I

ADP1650 ACK

2

C Single Register Read Sequence

ADP1650 ACK

MASTER ACK

08837-020

Rev. C | Page 19 of 32

Page 20

ADP1650

I2C REGISTER MAP

The lowest bit number (0) represents the least significant bit, and the highest bit number (7) represents the most significant bit.

Table 9. Design Information Register (Register 0x00)

Bit R/W Reset State

[7:0] R 00100010

Table 10. VREF and Timer Register (Register 0x02)

Bit Name Bit R/W Description

IO2_CFG [7:6] R/W

IO1_CFG [5:4] R/W

FL_TIM [3:0] R/W Flash timer value setting

GPIO2 configuration

00 = high impedance (default)

01 = indicator LED

10 = TxMASK2 operation mode

11 = analog input (to ADC)

GPIO1 configuration

00 = high impedance (default)

01 = torch

10 = TxMASK1 operation mode

11 = reserved

0000 = 100 ms

0001 = 200 ms

0010 = 300 ms

0011 = 400 ms

0100 = 500 ms

0101 = 600 ms

0110 = 700 ms

0111 = 800 ms

1000 = 900 ms

1001 = 1000 ms

1010 = 1100 ms

1011 = 1200 ms

1100 = 1300 ms

1101 = 1400 ms

1110 = 1500 ms

1111 = 1600 ms (default)

Rev. C | Page 20 of 32

Page 21

ADP1650

Table 11. Current Set Register (Register 0x03)

Bit Name Bit R/W Description

I_FL [7:3] R/W Flash current value setting

00000 = 300 mA

00001 = 350 mA

00010 = 400 mA

00011 = 450 mA

00100 = 500 mA

00101 = 550 mA

00110 = 600 mA

00111 = 650 mA

01000 = 700 mA

01001 = 750 mA

01010 = 800 mA

01011 = 850 mA

01100 = 900 mA

01101 = 950 mA

01110 = 1000 mA (default)

01111 = 1050 mA

10000 = 1100 mA

10001 = 1150 mA

10010 = 1200 mA

10011 = 1250 mA

10100 = 1300 mA

10101 = 1350 mA

10110 = 1400 mA

10111 = 1450 mA

11000 = 1500 mA

I_TOR [2:0] R/W Torch and assist light current value setting

000 = 25 mA

001 = 50 mA

010 = 75 mA

011 = 100 mA (default)

100 = 125 mA

101 = 150 mA

110 = 175 mA

111 = 200 mA

Rev. C | Page 21 of 32

Page 22

ADP1650

Table 12. Output Mode Register (Register 0x04)

Bit Name Bit R/W Description

IL_PEAK [7:6] R/W Inductor peak current limit setting

00 = 1.75 A

01 = 2.25 A

10 = 2.75 A (default)

11 = 3.0 A

STR_LV 5 R/W 0 = edge sensitive

1 = level sensitive (default)

FREQ_FB 4 R/W 0 = frequency foldback to 1.5 MHz not allowed (default)

1 = frequency foldback to 1.5 MHz allowed

OUTPUT_EN 3 R/W 0 = output off (default)

1 = output on

STR_MODE 2 R/W 0 = software strobe mode (software flash occurs when output is enabled in flash mode)

1 = hardware strobe mode (the STROBE pin must go high for flash) (default)

LED_MOD [1:0] R/W Configures LED output mode

00 = standby mode (default)

01 = voltage output mode, VOUT = 5 V

10 = assist light mode

11 = flash mode

Table 13. Fault Information Register (Register 0x05)

Bit Name Bit R/W Description

FL_OVP 7 R 0 = no fault (default)

1 = overvoltage fault

FL_SC 6 R 0 = no fault (default)

1 = short-circuit fault

FL_OT 5 R 0 = no fault (default)

1 = overtemperature fault

FL_TO 4 R 0 = no fault (default)

1 = timeout fault

FL_TX1 3 R 0 = no TxMASK1 operation mode during last flash (default)

1 = TxMASK1 operational mode occurred during last flash

FL_IO2 2 R If GPIO2 is configured as TxMASK2

0 = no TxMASK2 operations mode during last flash (default)

1 = TxMASK2 operational mode occurred during last flash

If GPIO2 is configured as ILED

0 = no fault (default)

1 = indicator LED fault

FL_IL 1 R 0 = no fault (default)

1 = inductor peak current limit fault

FL_IDC 0 R 0 = programmed dc current limit not hit (default)

1 = programmed dc current limit hit

Rev. C | Page 22 of 32

Page 23

ADP1650

Table 14. Input Control Register (Register 0x06)

Bit Name Bit R/W Description

I_TX2 [7:4] R/W TxMASK2 operational mode foldback current

0000 = 100 mA

0001 = 150 mA

0010 = 200 mA

0011 = 250 mA

0100 = 300 mA

0101 = 350 mA

0110 = 400 mA (default)

0111 = 450 mA

1000 = 500 mA

1001 = 550 mA

1010 = 600 mA

1011 = 650 mA

1100 = 700 mA

1101 = 750 mA

1110 = 800 mA

1111 = 850 mA

I_TX1 [3:0] R/W TxMASK1 operational mode foldback current

0000 = 100 mA

0001 = 150 mA

0010 = 200 mA

0011 = 250 mA

0100 = 300 mA

0101 = 350 mA

0110 = 400 mA (default)

0111 = 450 mA

1000 = 500 mA

1001 = 550 mA

1010 = 600 mA

1011 = 650 mA

1100 = 700 mA

1101 = 750 mA

1110 = 800 mA

1111 = 850 mA

Rev. C | Page 23 of 32

Page 24

ADP1650

Table 15. Additional Mode Register, AD_MOD (Register 0x07)

Bit Name Bit R/W Description

DYN_OVP 7 R/W Dynamic OVP

0 = dynamic OVP off (default)

1 = dynamic OVP on

SW_LO 6 R/W Force 1.5 MHz switching frequency

0 = disabled (default)

1 = enabled

STR_POL 5 R/W Strobe polarity

0 = active low

1 = active high (default)

I_ILED [4:3] R/W Indicator LED current

00 = 2.75 mA (default)

01 = 5.5 mA

10 = 8.25 mA

11 = 11 mA

IL_DC [2:1] R/W Input dc current limit setting LED current

00 = 1.5 A

01 = 1.75 A

10 = 2.0 A (default)

11 = 2.25 A

IL_DC_EN 0 R/W Input dc current limit

0 = disabled (default)

1 = enabled

Table 16. Additional Mode Register, ADC (Register 0x08)

Bit Name Bit R/W Description

Reserved 7 R/W Test mode

0 = disabled (default)

1 = enabled

FL_VB_LO 6 R Programmed VBAT low threshold status; low battery mode must be enabled in Register 0x09

0 = VDD is greater than the VBAT low threshold (default)

1 = VDD is less than the VBAT low threshold

ADC_VAL [5:2] R/W ADC readback value; four bits (see Figure 17, Figure 18, and Figure 19)

ADC_EN [1:0] R/W ADC enable mode

00 = disabled (default)

01 = LED V

10 = die temperature measurement

11 = external voltage mode

measurement

F

Rev. C | Page 24 of 32

Page 25

ADP1650

Table 17. Battery Low Mode Register (Register 0x09)

Bit Name Bit R/W Description

CL_SOFT 7 R/W Soft inductor peak current limit

0 = disabled (ADP1650 is disabled when the inductor peak current limit is hit)

1 = enabled (default)

I_VB_LO [6:3] R Current setting for VBAT low mode

0000 = 300 mA

0001 = 350 mA

0010 = 400 mA

0011 = 450 mA

0100 = 500 mA

0101 = 550 mA

0110 = 600 mA

0111 = 650 mA

1000 = 700 mA

1001 = 750 mA

1010 = 800 mA (default)

1011 = 850 mA

1100 = 900 mA

1101 = 950 mA

1110 = 1000 mA

1111 = 1050 mA

V_VB_LO [2:0] R/W VDD level where VBAT low function is enabled

000 = disabled (default)

001 = 3.3 V

010 = 3.35 V

011 = 3.4 V

100 = 3.45 V

101 = 3.5 V

110 = 3.55 V

111 = 3.6 V

Rev. C | Page 25 of 32

Page 26

ADP1650

APPLICATIONS INFORMATION

EXTERNAL COMPONENT SELECTION

Selecting the Inductor

The ADP1650 boost converter increases the battery voltage

to allow driving of one LED, whose voltage drop is higher than

the battery voltage plus the current source headroom voltage.

This allows the converter to regulate the LED current over the

entire battery voltage range and with a wide variation of LED

forward voltage.

The inductor saturation current should be greater than the sum

of the dc input current and half the inductor ripple current. A

reduction in the effective inductance due to saturation increases

the inductor current ripple. Tab le 1 8 provides a list of recommended inductors.

Selecting the Input Capacitor

The ADP1650 requires an input bypass capacitor to supply

transient currents while maintaining constant input and output

voltages. The input capacitor carries the input ripple current,

allowing the input power source to supply only the dc current.

Increased input capacitance reduces the amplitude of the

switching frequency ripple on the battery. Due to the dc bias

characteristics of ceramic capacitors, a 0603, 6.3 V, X5R/X7R,

10 µF ceramic capacitor is preferable.

Higher value input capacitors help to reduce the input voltage

ripple and improve transient response.

To minimize supply noise, place the input capacitor as close to

the VIN pin of the ADP1650 as possible. As with the output

capacitor, a low ESR capacitor is required. Tab le 1 9 provides a

list of suggested input capacitors.

Selecting the Output Capacitor

The output capacitor maintains the output voltage and supplies

the LED current during the NFET power switch on period. It also

stabilizes the loop. The recommended capacitor is a 10 µF, 6.3 V,

X5R/X7R ceramic capacitor.

Note that dc bias characterization data is available from capacitor manufacturers and should be taken into account when

selecting input and output capacitors. The 6.3 V capacitors are

best for most designs. Tabl e 20 provides a list of recommended

output capacitors.

Higher output capacitor values reduce the output voltage ripple

and improve load transient response. When choosing this value,

it is also important to account for the loss of capacitance due to

output voltage dc bias.

Ceramic capacitors have a variety of dielectrics, each with different

behavior over temperature and applied voltage. Capacitors must

have a dielectric that ensures the minimum capacitance over the

necessary temperature range and dc bias conditions. X5R or X7R

dielectrics with a voltage rating of 6.3 V or 10 V are recommended

for best performance. Y5V and Z5U dielectrics are not recommended for use with any dc-to-dc converter because of their

poor temperature and dc bias characteristics.

Table 18. Suggested Inductors

Vendor Value (µH) Part No. DCR (mΩ) ISAT (A) Dimensions L × W × H (mm)

Toko 1.0 FDSD0312 41.5 4.5 3.0 × 3.0 × 1.2

Toko 1.0 DFE2520 50 3.4 2.5 × 2.0 × 1.2

Coilcraft 1.0 XFL3010 43 2.4 3.0 × 3.0 × 1.0

Murata 1.0 LQM32P_G0 60 3 3.2 × 2.5 × 1.0

FDK 1.0 MIPS3226D 40 3 2.5 × 2.0 × 1.2

Table 19. Suggested Input Capacitors

Vendor Value Part No. Dimensions L × W × H (mm)

Murata 10 μF, 6.3 V GRM188R60J106ME47 1.6 × 0.8 × 0.8

TDK 10 μF, 6.3 V C1608JB0J106K 1.6 × 0.8 × 0.8

Taiyo Yuden 10 μF, 6.3 V JMK107BJ106MA 1.6 × 0.8 × 0.8

Table 20. Suggested Output Capacitors

Vendor Value Part No. Dimensions L × W × H (mm)

Murata 10 μF, 6.3 V GRM188R60J106ME47 1.6 × 0.8 × 0.8

TDK 10 μF, 6.3 V C1608JB0J106K 1.6 × 0.8 × 0.8

Taiyo Yuden 10 μF, 6.3 V JMK107BJ106MA 1.6 × 0.8 × 0.8

Rev. C | Page 26 of 32

Page 27

ADP1650

A

The worst-case capacitance accounting for capacitor variation

over temperature, component tolerance, and voltage is calculated using the following equation:

C

= C

EFF

× (1 − TEMPCO) × (1 − TOL)

OUT

where:

C

is the effective capacitance at the operating voltage.

EFF

TEMPCO is the worst-case capacitor temperature coefficient.

TOL is the worst-case component tolerance.

In this example, the 10 F X5R capacitor has the following

characteristics:

TEMPCO from −40°C to +85°C is 15%.

TOL is 10%.

C

at VOUT (MAX) = 5 V, is 3 F, as shown in Figure 44.

OUT

10

0

–10

–20

–30

–40

–50

–60

PACITANCE CHANGE (%)

C

–70

–80

–90

1.260

DC BIAS VOLTAGE (V)

6.305.043.782.52

Figure 44. DC Bias Characteristic of a 3 × 6.3 V, 10 μF Ceramic Capacitor

Substituting these values in the equation yields

= 3 F × (1 − 0.15) × (1 − 0.1) = 2.29 F

C

EFF

The effective capacitance needed for stability, which includes

temperature and dc bias effects, is 3.0 F.

08837-022

Rev. C | Page 27 of 32

Page 28

ADP1650

A

PCB LAYOUT

Poor layout can affect performance, causing electromagnetic

interference (EMI) and electromagnetic compatibility (EMC)

problems, ground bounce, and power losses. Poor layout can

also affect regulation and stability. Figure 45 shows optimized

layouts implemented using the following guidelines:

• Place the inductor, input capacitor, and output capacitor

close to the IC using short tracks. These components carry

high switching frequencies and large currents.

• Route the trace from the inductor to the SW pin with as

wide a trace as possible. The easiest path is through the

center of the output capacitor.

• Route the LED_OUT path away from the inductor and SW

node to minimize noise and magnetic interference.

Li-ION +

• Maximize the size of ground metal on the component side

to help with thermal dissipation.

• Use a ground plane with two to three vias connecting to the

component side ground near the output capacitor to

reduce noise interference on sensitive circuit nodes.

• With the LFCSP package, six to eight thermal vias connect

the ground paddle to the main PCB ground plane.

• Analog Devices applications engineers can be contacted

through the Analog Devices sales team to discuss different

layouts based on system design constraints.

1

C

L1

INDUCTOR

AREA = 16.4mm

2

C2

PGND

LED

ANODE

Li-ION +

DIGIT AL

INPUT/

OUTPUT

8837-023

Figure 45. Layout of the ADP1650 Driving a High Power White LED (WLCSP)

Li-ION +

C1

VIN

GPIO2

O

PI

G

SDA

SCL

PGND

STROBE

EN

1

GND

SW

VOUT

LED_OUT

L1

INDUCTOR

C2

VOUT

DP1650

PGND

08837-024

Figure 46. Example Layout of the ADP1650 Driving a High Power White LED (LFCSP)

Rev. C | Page 28 of 32

Page 29

ADP1650

OUTLINE DIMENSIONS

0.660

0.602

0.544

SEATING

PLANE

0.330

0.310

0.290

1.50

REF

3

2

1

A

B

C

BALL A1

IDENTIFIER

1.54

1.50

1.46

2.04

2.00

1.96

0.022

REF

TOP VIE W

(BALL SIDE DOWN)

PIN 1 INDEX

AREA

0.80

0.75

0.70

SEATING

PLANE

0.50

0.380

0.352

0.324

0.04 MAX

COPLANARITY

0.280

0.250

0.220

REF

Figure 47. 12-Ball Wafer Level Chip Scale Package [WLCSP]

(CB-12-4)

Dimensions shown in millimeters

2.48

3.10

3.00 SQ

2.90

TOP VIEW

0.30

0.25

0.20

0.50

0.40

0.30

0.05 MAX

0.02 NOM

0.20 REF

2.38

2.23

6

EXPOSED

PAD

5

BOTTOM VIEW

FOR PROPER CONNECTION OF

THE EXPOSED PAD, REFER TO

THE PIN CONFIGURATION AND

FUNCTION DESCRIPTIONS

SECTION OF THIS DATA SHEET.

0.50 BSC

10

1

Figure 48. 10-Lead Lead Frame Chip Scale Package [LFCSP_WD]

3 mm × 3 mm Body, Very Very Thin, Dual Lead

(CP-10-9)

Dimensions shown in millimeters

1.00

REF

P

I

(

N

R

1.74

1.64

1.49

N

I

D

1

I

.

0

BOTTOM VIEW

(BALLSIDE UP)

A

R

O

T

C

)

5

1

121009-A

D

020409-B

ORDERING GUIDE

Model1 Temperature Range Package Description Package Option2 Branding

ADP1650ACBZ-R7 −40°C to +125°C 12-Ball Wafer Level Chip Scale Package [WLCSP] CB-12-4 LE4

ADP1650ACPZ-R7 −40°C to +125°C 10-Lead Frame Chip Scale Package [LFCSP_WD] CP-10-9 LGX

ADP1650CB-EVALZ Evaluation Board WLCSP Package

ADP1650CP-EVALZ Evaluation Board LFCSP Package

1

Z = RoHS Compliant Part.

2

This package option is halide free.

Rev. C | Page 29 of 32

Page 30

ADP1650

NOTES

Rev. C | Page 30 of 32

Page 31

ADP1650

NOTES

Rev. C | Page 31 of 32

Page 32

ADP1650

NOTES

©2010–2011 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D08837-0-4/11(C)

Rev. C | Page 32 of 32

Loading...

Loading...