Page 1

600kHz/1.25MHz Step-Up

www.BDTIC.com/ADI

Preliminary Technical Data

FEATURES

Fully integrated 1.5 A , 0.15 Ω power switch

Pin-selectable 600 kHz or 1.25 MHz PWM frequency

1.8 V minimum input voltage

Adjustable output voltage up to 20 V

Adjustable soft start

Input undervoltage lockout

Thermal shutdown

MSOP 8-lead package

APPLICATIONS

TFT LCD bias supplies

Portable applications

Industrial/instrumentation equipment

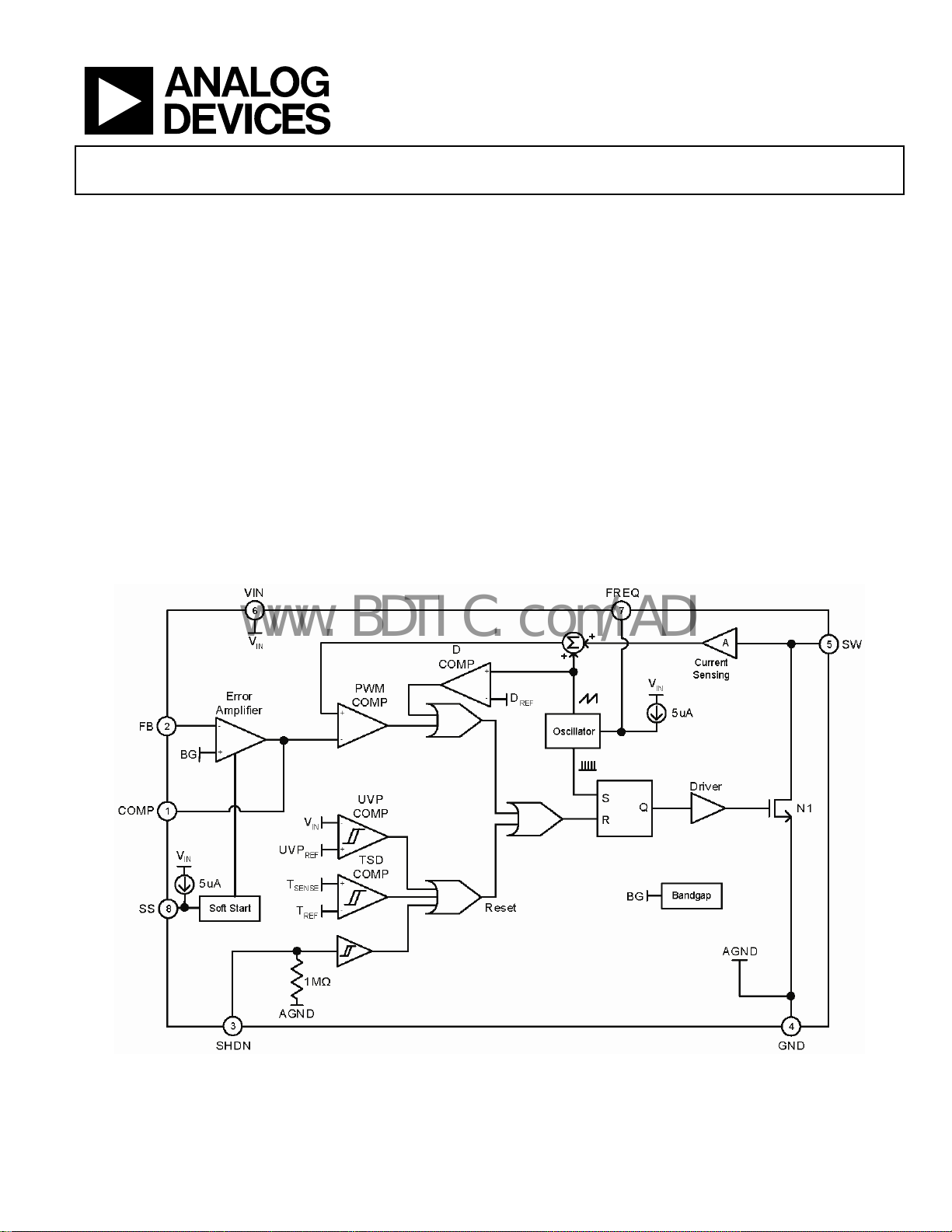

FUNCTIONAL BLOCK DIAGRAM

PWM DC-DC Switching Converter

ADP1612

GENERAL DESCRIPTION

The ADP1612 is a step-up dc-to-dc switching converter with an

integrated 1.5 A, 0.15 Ω power switch capable of providing an

output voltage as high as 20 V. With a package height of less

than 1.1 mm, the ADP1612 is optimal for space-constrained

applications such as portable devices or thin film transistor

(TFT) liquid crystal displays (LCDs).

The ADP1612 operates in pulse-width modulation (PWM)

current mode with up to 90% efficiency. Adjustable soft start

prevents inrush currents at startup. The pin-selectable

switching frequency and PWM current-mode architecture

allow for excellent transient response, easy noise filtering, and

the use of small, cost-saving external inductors and capacitors.

The ADP1612 is offered in the lead-free 8-lead MSOP and

operates over the temperature range of −40 °C to +85 °C.

Figure 1.Functional Block Diagram

Rev. PrA

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

Page 2

ADP1612 Preliminary Technical Data

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Absolute Maximum Ratings............................................................ 4

Thermal Resistance ...................................................................... 4

ESD Caution.................................................................................. 4

Pin Configuration and Function Descriptions............................. 5

Typical Performance Characteristics ............................................. 6

Theory of Operation ........................................................................ 7

Current-Mode PWM Operation................................................ 7

Frequency Selection ..................................................................... 7

Soft Start .........................................................................................7

Thermal Shutdown .......................................................................8

On/Off Control..............................................................................8

Applications Information.................................................................9

Setting the Output Voltage...........................................................9

Choosing the Input and Output Capacitors........................... 10

Diode Selection........................................................................... 10

Loop Compensation .................................................................. 10

Soft Start Capacitor.................................................................... 11

Typical Application Circuits ......................................................... 12

Layout Guidelines........................................................................... 13

Outline Dimensions....................................................................... 14

Ordering Guide............................................................................... 14

REVISION HISTORY

6/08—Rev. PrA

Rev. PrA | Page 2 of 14

Page 3

Preliminary Technical Data ADP1612

www.BDTIC.com/ADI

SPECIFICATIONS

Specifications with standard typeface are for TJ = 25 °C, and those in bold face type apply over the full operating temperature range (TJ =

-40 °C to + 125 °C). Unless otherwise specified, V

characterization using standard statistical quality control (SQC), unless otherwise noted.

Table 1.

Parameter Symbol Conditions Min Typ Max Unit

SUPPLY

Input Voltage VIN

Quiescent Current

Non-switching State IQ V

Non-switching State IQ V

Shutdown I

Switching State

Switching State

1

2

OUTPUT

Output Voltage V

Load Regulation I

Overall Regulation Line, load, temperature

REFERENCE

Feedback Voltage VFB TBD TBD TBD V

Line Regulation VIN = 2.5 V to 5.5 V TBD TBD %/V

ERROR AMPLIFIER

Transconductance G

Voltage Gain AV 60 dB

FB Input Bias Current V

SWITCH

SW On Resistance R

SW Leakage Current VSW = 20 V 0.01 10 μA

Peak Current Limit

3

I

OSCILLATOR

Oscillator Frequency fSW FREQ = GND TBD 600 TBD kHz

FREQ = VIN TBD 1.25 TBD MHz

Maximum Duty Cycle D

FREQ Pin Current I

SHUTDOWN

Shutdown Input Voltage Low VIL Non-switching state, V

Shutdown Input Voltage High VIH Switching state, V

Shutdown Input Bias Current I

SOFT START

SS Charging Current VSS = 0 V TBD 5 TBD μA

UNDERVOLTAGE LOCKOUT

4

UVLO Threshold Rising VIN rising 1.7

UVLO Threshold Falling VIN falling TBD 1.65 V

1

This parameter specifies the average current while switching internally and with SW (Pin 5) floating.

2

This parameter specifies the average current while switching internally and with SW (Pin 5) floating.

3

Current limit is a function of duty cycle. See Typical Performance Characteristics section for typical values over operating ranges.

4

UVLO

= 3.6 V. All limits at temperature extremes are guaranteed by correlation and

IN

1.8

= 1.5 V, FREQ = VIN 900 TBD μA

FB

= 1.5 V, FREQ = GND 900 TBD

FB

V

QSHDN

IQSW f

IQSW f

V

OUT

= 0 V 0.01 2 μA

SHDN

= 600 kHz, no load 2 TBD mA

SW

= 1.23 MHz, no load 4 TBD mA

SW

IN

= 10 mA to 150 mA, V

LOAD

= 8 V TBD mV/mA

OUT

TBD

MEA ΔI = 5 μA

= TBD V 10 TBD nA

FB

ISW = 1.0 A 150 TBD mΩ

DSON

V

CL

COMP = open, VFB = 1 V, FREQ = VIN TBD 90 TBD %

MAX

FREQ

V

SDHN

= 8 V TBD 1.5 TBD A

OUT

FREQ = GND TBD 5 TBD uA

= 1.8 V to 6 V 0.95 0.3 V

IN

= 1.8 V to 6 V 1.6 0.95 V

IN

= 1.6 V 1 TBD μA

SHDN

160 μA/V

6

20

%

1.8

V

V

V

Rev. PrA | Page 3 of 14

Page 4

ADP1612 Preliminary Technical Data

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

VIN, SHDN, FB to GND −0.3 V to 6.5 V

FREQ to GND -0.3 V to VIN+ 0.3 V

COMP to GND 1.0 V to 1.6 V

SS to GND -0.3 V to 1.3 V

SW to GND 21 V

RMS SW Pin Current 1.2 A

Operating Ambient Temperature

Range

Operating Junction Temperature

Range

Storage Temperature Range −65 °C to + 150 °C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

−40 °C to + 85 °C

−40 °C to + 125 °C

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 3. Thermal Resistance

Package Type θJA θ

8 Lead MSOP

2-Layer Board

4-Layer Board

Maximum Power Dissipation

TBD TBD

TBD TBD

TBD TBD mW

Unit

JC

°C/W

°C/W

ESD CAUTION

Rev. PrA | Page 4 of 14

Page 5

Preliminary Technical Data ADP1612

www.BDTIC.com/ADI

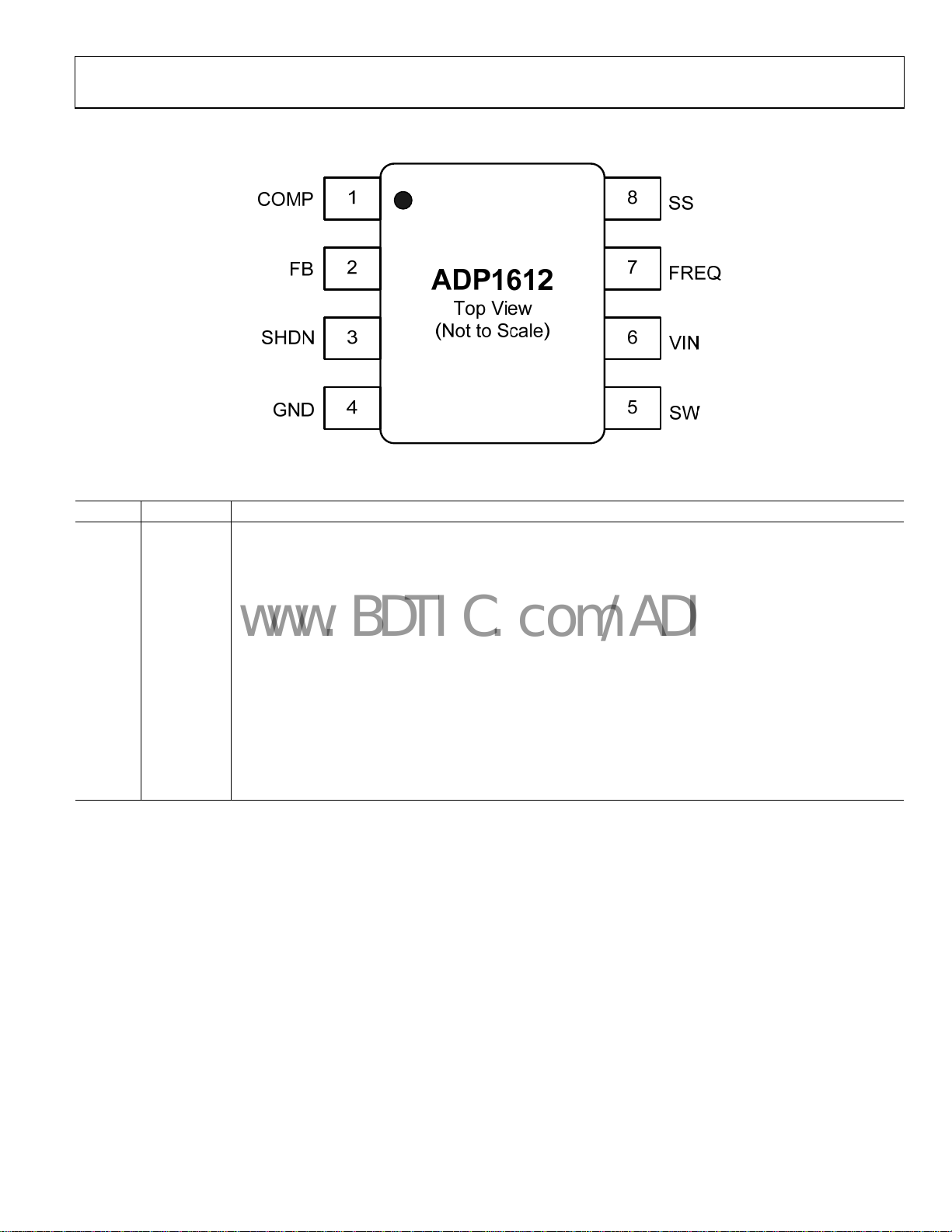

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Figure 2.Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 COMP Compensation input. Connect a series resistor-capacitor network from COMP to GND to compensate the

regulator.

2 FB Output voltage feedback input. Connect a resistive voltage divider from the output voltage to FB to set the

regulator output voltage.

3 SHDN Shutdown input. Drive SHDN low to shut down the regulator; drive SHDN high to turn it on.

4 GND Ground.

5 SW Switching output. Connect the power inductor from the input voltage to SW and connect the external rectifier

from SW to the output voltage to complete the step-up converter.

6 VIN Main power supply input. VIN powers the ADP1612 internal circuitry. Connect VIN to the input source voltage.

Bypass VIN to GND with a 10 μF or greater capacitor as close to the ADP1612 as possible.

7 FREQ Frequency Setting Input. FREQ controls the switching frequency. Connect FREQ to GND to program the oscillator

to 600 kHz, or connect FREQ to VIN to program it to 1.25 MHz. If FREQ is left floating, the part will default to

600kHz.

8 SS Soft start timing capacitor input. Connect a capacitor from SS to GND brings up the output slowly at power-up

and reduce in-rush current.

Rev. PrA | Page 5 of 14

Page 6

ADP1612 Preliminary Technical Data

www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

Figure 3

Figure 4

Figure 6

Figure 7

Figure 5

Rev. PrA | Page 6 of 14

Figure 7

Page 7

Preliminary Technical Data ADP1612

www.BDTIC.com/ADI

THEORY OF OPERATION

Figure 8. Block Diagram with Application Circuit

The ADP1612 current-mode step-up switching converter

converts a 1.8 V to 6 V input voltage up to an output voltage as

high as 20 V. The 1.5 A internal switch allows a high output

current, and the high 600 kHz/1.25 MHz switching frequency

allows tiny external components. The switch current is

monitored on a pulse-by-pulse basis to limit it to 1.5 A, typical.

CURRENT-MODE PWM OPERATION

The ADP1612 utilizes a current mode PWM control scheme to

regulate the output voltage over all load conditions. The output

voltage is monitored at FB through a resistive voltage divider.

The voltage at FB is compared to the internal TBD V reference

by the internal transconductance error amplifier to create an

error voltage at COMP. The switch current is internally

measured and added to the stabilizing ramp, and the resulting

sum is compared to the error voltage at COMP to control the

PWM modulator. This current-mode regulation system allows

fast transient response, while maintaining a stable output

voltage. By selecting the proper resistor-capacitor network from

COMP to GND, the regulator response is optimized for a wide

range of input voltages, output voltages, and load conditions.

FREQUENCY SELECTION

The ADP1612’s frequency is user-selectable to operate at either

600 kHz to optimize the regulator for high efficiency or to 1.25

MHz for small external components. Connect FREQ to Vin for

1.25 MHz operation, or connect FREQ to GND for 600 kHz

operation. If FREQ is left floating, the part will default to 600

kHz.

SOFT START

To prevent input inrush current at startup, connect a capacitor

from SS to GND to set the soft start period. When the

ADP1612 is in shutdown (SHDN is at GND) or the input

voltage is below the 1.65V undervoltage lockout voltage, SS is

internally shorted to GND to discharge the soft start capacitor.

Once the ADP1612 is turned on, SS sources 5μA, typical, to the

soft start capacitor at startup. As the soft start capacitor charges,

it limits the voltage at COMP. Because of the current-mode

regulator, the voltage at COMP is proportional to the switch

peak current, and, therefore, the input current. By slowly

charging the soft start capacitor, the input current ramps slowly

to prevent it from overshooting excessively at startup.

Rev. PrA | Page 7 of 14

Page 8

ADP1612 Preliminary Technical Data

www.BDTIC.com/ADI

THERMAL SHUTDOWN

The ADP1612 includes thermal shutdown protection. If the die

temperature exceeds 150 ºC, typical, the thermal shutdown will

turn off the NMOS power device, significantly reducing power

dissipation in the device, and preventing output voltage

regulation. The NMOS power device will remain off until the

die temperature reduces to 120 ºC, typical. The soft-start

capacitor will be discharged during thermal shutdown to ensure

low output voltage overshoot and inrush currents when

regulation resumes.

ON/OFF CONTROL

The SHDN input turns the ADP1612 regulator on or off. Drive

SHDN low to turn off the regulator and reduce the input

current to 0.1uA, typical. Drive SHDN high to turn on the

regulator.

When the step-up dc–dc switching converter is turned off, there

is a dc path from the input to the output through the inductor

and output rectifier. This causes the output voltage to remain

slightly below the input voltage by the forward voltage of the

rectifier, preventing the output voltage from dropping to zero

when the regulator is shut down. Figure 11 in the Application

Circuit section shows the application circuit to disconnect the

output voltage from the input voltage at shutdown.

Rev. PrA | Page 8 of 14

Page 9

Preliminary Technical Data ADP1612

−

×

×

www.BDTIC.com/ADI

APPLICATIONS INFORMATION

SETTING THE OUTPUT VOLTAGE

The ADP1612 features an adjustable output voltage range of VIN

to 20 V. The output voltage is set by the resistor voltage divider

(R1 and R2, Figure 8.) from the output voltage (V

TBD V feedback input at FB. Use the following formula to

determine the output voltage:

(

OUT

Use an R2 resistance of 10 kΩ or less to prevent output voltage

errors due to the 0.1uA FB input bias current. Choose R1 based

on the following formula:

×=

RR

21 (2)

+×=

OUT

−

TBD

⎛

⎜

⎝

)

211 RRTBDV

TBDV

⎞

⎟

⎠

(1)

OUT

) to the

INDUCTOR SELECTION

The inductor is an essential part of the step-up switching

converter. It stores energy during the on-time, and transfers that

energy to the output through the output rectifier during the offtime. Use inductance in the range of 4.7 μH to 22 μH. In

general, lower inductance values have higher saturation current

and lower series resistance for a given physical size. However,

lower inductance results in higher peak current that can lead to

reduced efficiency and greater input and/or output ripple and

noise. A peak-to-peak inductor ripple current close to 30% of

the maximum dc input current typically yields an optimal

compromise.

For determining the inductor ripple current in continuous

operation, the input (V

the switch duty cycle (D) by the following equation:

) and output (V

IN

) voltages determine

OUT

D

= (3)

Using the duty cycle and switching frequency, f

the on-time by the following equation:

t =

ON

The inductor ripple current (ΔI

I

=Δ (5)

L

Solving for the inductance value, L,

L

= (6)

Make sure that the peak inductor current (the maximum input

current plus half the inductor ripple current) is below the rated

saturation current of the inductor. Likewise, make sure that the

maximum rated rms current of the inductor is greater than the

maximum dc input current to the regulator.

For duty cycles greater than 50%, which occur with input

voltages greater than one-half the output voltage, slope

compensation is required to maintain stability of the currentmode regulator. For stable current-mode operation, ensure that

the selected inductance is equal to or greater than L

LL

MIN

>

D

VV

INOUT

V

OUT

, determine

SW

D

(4)

f

SW

) in steady state is

L

tV

ONIN

L

tV

ONIN

I

Δ

L

:

MIN

=>

()

2

−

xVVR

INOUTDSON

V 0.55

×

f

SW

(7)

5.0

Table 5. Inductor Manufacturers

Vendor Part L (μH) Max DC Current Max DCR (mΩ) Height (mm)

Sumida

847-956-0666

www.sumida.com

www.coilcraft.com

www.tokoam.com

CMD4D11-4R7MC 4.7 0.75 216 1.2

CDRH4D28-100 10 1.00 128 3.0

CDRH5D18-220 22 0.80 290 2.0

CR43-4R7 4.7 1.15 109 3.5

CR43-100 10 1.04 182 3.5

DS1608-472 4.7 1.40 60 2.9 Coilcraft 847-639-6400

DS1608-103 10 1.00 75 2.9

D52LC-4R7M 4.7 1.14 87 2.0 Toko 847-297-0070

D52LC-100M 10 0.76 150 2.0

Rev. PrA | Page 9 of 14

Page 10

ADP1612 Preliminary Technical Data

I

V

V

V

V

−

www.BDTIC.com/ADI

CHOOSING THE INPUT AND OUTPUT CAPACITORS

The ADP1612 requires input and output bypass capacitors to

supply transient currents while maintaining constant input and

output voltage. Use a low ESR (equivalent series resistance),

10 μF or greater input capacitor to prevent noise at the

ADP1612 input. Place the capacitor between V

and GND as

IN

close to the ADP1612 as possible. Ceramic capacitors are

preferred because of their low ESR characteristics. Alternatively,

use a high value, medium ESR capacitor in parallel with a 0.1 μF

low ESR capacitor as close to the ADP1612 as possible.

The output capacitor maintains the output voltage and supplies

current to the load while the ADP1612 switch is on. The value

and characteristics of the output capacitor greatly affect the

output voltage ripple and stability of the regulator. Use a low

ESR output capacitor; ceramic dielectric capacitors are

preferred.

For very low ESR capacitors such as ceramic capacitors, the

ripple current due to the capacitance is calculated as follows. In

continuous mode, because the capacitor discharges during the

on-time, t

, the charge removed from the capacitor, QC, is the

ON

load current multiplied by the on-time. Therefore, the output

voltage ripple (ΔV

V

OUT

C

OUT

Q

OUT

) is

t

×

L

C

ON

==Δ

C

(8)

OUT

where:

C

is the output capacitance,

OUT

I

is the average inductor current,

L

ON

D

(9)

f

SW

t =

and

V

OUT

IN

(10)

D−=

OUT

Choose the output capacitor based on the following equation:

I

C

OUT

L

≥

SW

OUT

−×

)(

IN

(11)

VVf

Δ××

OUTOUT

Table 6. Capacitor Manufacturers

Vendor Phone No. Web Address

AVX 408-573-4150 www.avxcorp.com

Murata 714-852-2001 www.murata.com

Sanyo 408-749-9714 www.sanyovideo.com

Taiyo–Yuden 408-573-4150 www.t-yuden.com

DIODE SELECTION

The output rectifier conducts the inductor current to the output

capacitor and load while the switch is off. For high efficiency,

minimize the forward voltage drop of the diode. For this reason,

Schottky rectifiers are recommended. However, for high

voltage, high temperature applications, where the Schottky

rectifier reverse leakage current becomes significant and can

degrade efficiency, use an ultrafast junction diode.

Make sure that the diode is rated to handle the average output

load current. Many diode manufacturers derate the current

capability of the diode as a function of the duty cycle. Verify

that the output diode is rated to handle the average output load

current with the minimum duty cycle. The minimum duty cycle

of the ADP1612 is

where

D

VV

= (12)

MIN

V

IN(MAX)

V

OUT

is the maximum input voltage.

)(

MAXINOUT

Table 7. Schottky Diode Manufacturers

Vendor Phone No. Web Address

Motorola 602-244-3576 www.mot.com

Diodes, Inc. 805-446-4800 www.diodes.com

Sanyo 310-322-3331 www.irf.com

LOOP COMPENSATION

The ADP1612 uses external components to compensate the

regulator loop, allowing optimization of the loop dynamics for a

given application.

The step-up converter produces an undesirable right-half plane

zero in the regulation feedback loop. This requires compensating the regulator such that the crossover frequency occurs well

below the frequency of the right-half plane zero. The right-half

plane zero is determined by the following equation:

V

V

OUT

2

⎞

R

IN

LOAD

⎟

×

⎟

⎠

(13)

L

×π

⎛

⎜

=2)(

RHPF

Z

⎜

⎝

where:

F

(RHP) is the right-half plane zero.

Z

is the equivalent load resistance or the output voltage

R

LOAD

divided by the load current.

To stabilize the regulator, make sure that the regulator crossover

frequency is less than or equal to one-fifth of the right-half

plane zero and less than or equal to one-fifteenth of the

switching frequency.

Rev. PrA | Page 10 of 14

Page 11

Preliminary Technical Data ADP1612

π

C

×

www.BDTIC.com/ADI

The regulator loop gain is

FB

V

IN

V

OUT

ZGZG

OUTCSCOMPMEA

where

A ×××××=

V

VL

V

OUT

(14)

where:

A

is the loop gain.

VL

is the feedback regulation voltage, TBD V.

V

FB

is the regulated output voltage.

V

OUT

is the input voltage.

V

IN

is the error amplifier transconductance gain.

G

MEA

is the impedance of the series RC network from COMP to

Z

COMP

GND.

is the current sense transconductance gain (the inductor

G

CS

current divided by the voltage at COMP), which is internally set

by the ADP1612.

is the impedance of the load and output capacitor.

Z

OUT

To determine the crossover frequency, it is important to note

that, at that frequency, the compensation impedance (Z

dominated by the resistor, and the output impedance (Z

COMP

OUT

) is

) is

dominated by the impedance of the output capacitor. So, when

solving for the crossover frequency, the equation (by definition

of the crossover frequency) is simplified to

V

V

IN

FB

A

|| =

VL

V

V

OUT

OUT

GRG

CSCOMPMEA

1

×××××=

π

2

××

Cf

OUTC

(15)

1

where:

is the crossover frequency.

f

C

R

is the compensation resistor.

COMP

Solving for R

R

COMP

For V

= TBD, G

FB

COMP

=

,

2

= 160 μS, and GCS = TBD S,

MEA

VVCf

××××

OUTOUTOUTC

(16)

GGVV

×××

CSMEAINFB

The capacitor, C2, is chosen to cancel the zero introduced by

output capacitance ESR.

Solving for C2,

C2

For low ESR output capacitance such as with a ceramic capacitor, C2 is optional. For optimal transient performance, the

R

COMP

load transient response of the ADP1612. For most applications,

the compensation resistor should be in the range of 10 kΩ to

400 kΩ, and the compensation capacitor should be in the range

of 100 pF to 2 nF.

SOFT START CAPACITOR

The voltage at SS ramps up slowly by charging the soft start

capacitor (C

The soft start capacitor limits the rate of voltage rise on the

COMP pin, which in turn limits the peak switch current at

startup.

A 47 nF soft start capacitor results in negligible input current

overshoot at startup, and so is suitable for most applications.

However, if an unusually large output capacitor is used, a longer

=

COMP

C

is the compensation capacitor.

COMP

REF

FB

2

ESR

=

R

COMP

and C

COMP

) with an internal 5 μA current source.

SS

soft start period is required to prevent input inrush current.

VVCfTBD

××××

R

COMP

=

V

IN

OUTOUTOUTC

(17)

Once the compensation resistor is known, set the zero formed

by the compensation capacitor and resistor to one-fourth of the

crossover frequency, or

Conversely, if fast startup is a requirement, the soft start

capacitor can be reduced or even removed, allowing the

ADP1612 to start quickly, but allowing greater peak switch

.

current

2

RfC××π

ERROR AMP

Figure 9. Compensation Components

OUT

(19)

(18)

COMPC

g

COMP

m

1

R

C

C2

C

C

04906-026

might need to be adjusted by observing the

Rev. PrA | Page 11 of 14

Page 12

ADP1612 Preliminary Technical Data

www.BDTIC.com/ADI

TYPICAL APPLICATION CIRCUITS

R4

BAV99

VGL

BZT52C5VIS

200

C6

D9

D8

F

10

D7

C5

10nF

C4

10nF

D5

D4

BAV99

D3

C1

10nF

L1

D2

BAV99

R3

200

C3

10

F

C2

1

F

VGH

D5

BZT52C22

V

IN

C

IN

C

SS

Figure 10. Step Up Regulator

Figure 11. Step-Up Regulator with True Shutdown

ADP1612

VIN

ON

3

SHDN

7

FREQ

8 1

SS

SW

FB

COMP

GND

4

Figure 12. TFT LCD Bias Supply

Figure 13. SEPIC Converter

D1

56

2

R

COMP

C

COMP

V

OUT

R1

R2

C

OUT

Rev. PrA | Page 12 of 14

Page 13

Preliminary Technical Data ADP1612

www.BDTIC.com/ADI

LAYOUT GUIDELINES

For high efficiency, good regulation, and stability, a welldesigned printed circuit board layout is required.

Follow these guidelines when designing printed circuit boards

(see Figure 8):

• Keep the low ESR input capacitor, C

GND.

• Keep the high current path from C

L1, to SW and PGND as short as possible.

• Keep the high current path from C

rectifier, D1, and the output capacitor, C

possible.

• Keep high current traces as short and as wide as possible.

• Place the feedback resistors as close to FB as possible to

prevent noise pickup. Connect the ground of the feedback

, close to VIN and

IN

through the inductor,

IN

through L1, the

IN

, as short as

OUT

network directly to an AGND plane that makes a Kelvin

connection to the GND pin.

• Place the compensation components as close as possible to

COMP. Connect the ground of the compensation network

directly to an AGND plane that makes a Kelvin connection

to the GND pin.

• Connect the SS capacitor as close to the device as possible.

Connect the ground of the SS capacitor to an AGND plane

that makes a Kelvin connection to the GND pin.

• Avoid routing high impedance traces near any node

connected to SW or near the inductor to prevent radiated

noise injection.

Rev. PrA | Page 13 of 14

Page 14

ADP1612 Preliminary Technical Data

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

3.00

BSC

85

3.00

BSC

PIN 1

0.65 BSC

4.90

BSC

4

0.15

0.00

0.38

0.22

COPLANARITY

0.10

COMPLIANT TO JEDEC STANDARDS MO-187AA

Figure 14. 8-Lead Mini Small Outline Package [MSOP]

1.10 MAX

0.23

SEATING

PLANE

Dimensions shown in millimeters

0.08

(RM-8)

8°

0°

0.80

0.60

0.40

ORDERING GUIDE

Model Temperature Range Package Description Package Option Branding

ADP1612ARMZ-R7

1

Z = Pb-free part.

1

−40°C to +85°C 8-Lead Mini Small Outline Package [MSOP] RM-8 P11

©2008 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

PR06772-0-6/08(PrA)

Rev. PrA | Page 14 of 14

Loading...

Loading...