Page 1

Single-Chip, DSP-Based

a

FEATURES

26 MIPS Fixed-Point DSP Core

Single Cycle Instruction Execution (38.5 ns)

ADSP-21xx Family Code Compatible

16-Bit Arithmetic and Logic Unit (ALU)

Single Cycle 16-Bit 16-Bit Multiply and Accumulate

Into 40-Bit Accumulator (MAC)

32-Bit Shifter (Logical and Arithmetic)

Multifunction Instructions

Single Cycle Context Switch

Zero Overhead Looping

Conditional Instruction Execution

Two Independent Data Address Generators

Memory Configuration

2K 24-Bit Internal Program Memory RAM

2K 24-Bit Internal Program Memory ROM

1K 16-Bit Internal Data Memory RAM

14-Bit Address Bus and 24-Bit Data Bus for External

Memory Expansion

High Resolution Multichannel ADC

12-Bit Pipeline Flash Analog-to-Digital Converter

Eight Dedicated Analog Inputs

Simultaneous Sampling Capability

All Eight Inputs Converted in <2 s

4.0 V p-p Input Voltage Range

PWM Synchronized or External Convert Start

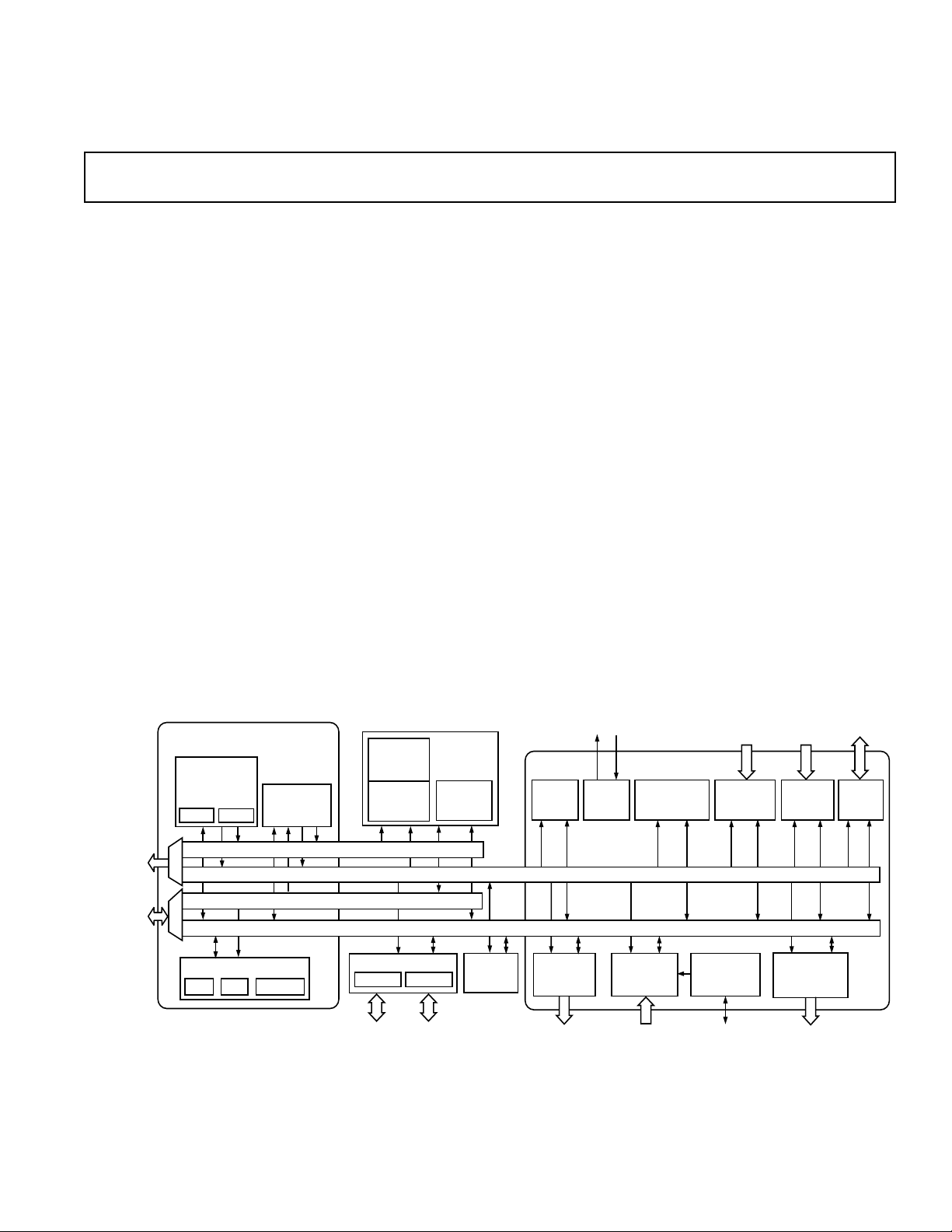

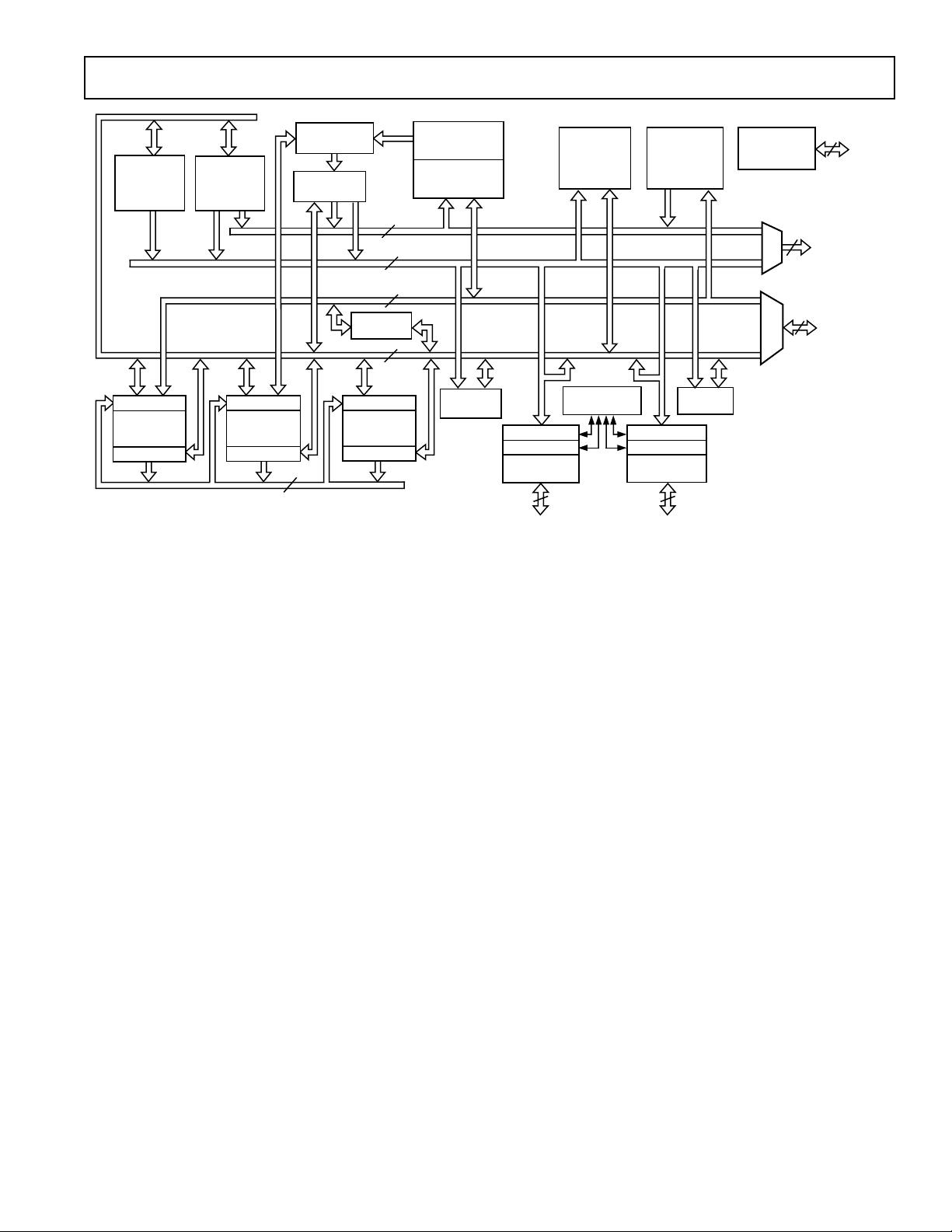

FUNCTIONAL BLOCK DIAGRAM

High Performance Motor Controller

ADMC401

Internal or External Voltage Reference

Out-of-Range Detection

Voltage Reference

Internal 2.0 V 2.0% Voltage Reference

Three-Phase 16-Bit PWM Generation Unit

Programmable Switching Frequency, Dead Time and

Minimum Pulsewidth

Edge Resolution of 38.5 ns

One or Two Updates per Switching Period

Hardware Polarity Control

Individual Enable/Disable of Each Output

High Frequency Chopping Mode

Dedicated Shutdown Pin (PWMTRIP)

Additional Shutdown Pins in I/O System

High Output Sink and Source Capability (10 mA)

Incremental Encoder Interface Unit

Quadrature Rates to 17.3 MHz

Programmable Filtering of Encoder Inputs

Alternative Frequency and Direction Mode

Two Registration Inputs to Latch Count Value

Optional Hardware Reset of Counter

Single North Marker Mode

Count Error Monitor Function

Dedicated 16-Bit Loop Timer (Periodic Interrupts)

Companion Encoder Event (1/T) Timer

(Continued on Page 14)

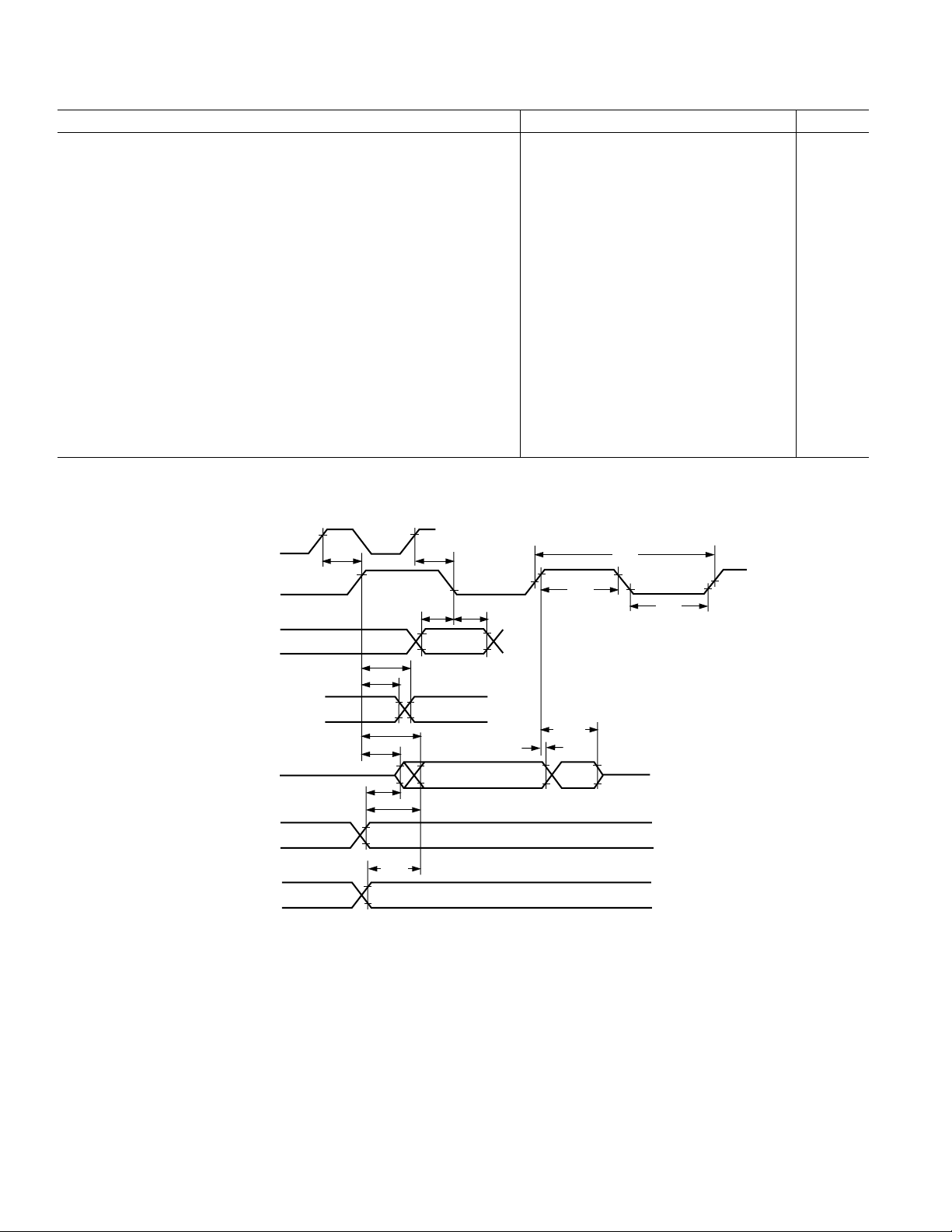

EXTERNAL

ADDRESS

BUS

EXTERNAL

DATA

BUS

26 MIPS DSP CORE

DATA

ADDRESS

GENERATORS

DAG 1

DAG 2

PROGRAM MEMORY ADDRESS

DATA MEMORY ADDRESS

PROGRAM MEMORY DATA

DATA MEMORY DATA

ARITHMETIC UNITS

ALU

MAC

PROGRAM

SEQUENCER

SHIFTER

PM

ROM

2K 24

PM

RAM

2K 24

SERIAL PORTS

SPORT 0

SPORT 1

MEMORY

DM

RAM

1K 16

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

MOTOR CONTROL

PERIPHERALS

WATCH-

TIMER

INTERVAL

TIMER

2 CHANNEL

AUXILIARY

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

DOG

PWM

POWER-

ON

RESET

INTERRUPT

CONTROLLER

8 CHANNEL

12-BIT ADC

ENCODER

INTERFACE

PRECISION

VOLTAGE

REFERENCE

EVENT

CAPTURE

UNIT

16-BIT

PWM

GENERATION

DIGITAL

I/O

UNIT

Page 2

ADMC401–SPECIFICATIONS

(VDD = AVDD = 5 V 5%, GND = AGND = 0 V, T

RECOMMENDED OPERATING CONDITIONS

CLKIN = 13 MHz, unless otherwise noted)

B Grade

Parameter Min Max Unit

V

AV

T

DD

AMB

Digital Supply Voltage 4.75 5.25 V

Analog Supply Voltage 4.75 5.25 V

DD

Ambient Operating Temperature –40 +85 °C

ELECTRICAL CHARACTERISTICS

Parameter Test Conditions Min Max Unit

V

IH

V

IL

V

OH

V

OL

V

OH

V

OL

I

IH

I

IH

I

IH

I

IL

I

IL

I

IL

I

OZH

I

OZL

I

DD

I

DD

I

DD

C

I

C

O

NOTES

1

Bidirectional pins: D0–D23, RFS0, RFS1, TFS0, TFS1, SCLK0 and SCLK1, PIO0–PIO11.

2

Input only pins: PWMTRIP, PWMPOL, PWMSR, RESET, EIA, EIB, EIZ, EIS, ETU0, ETU1, DR1A, DR1B, DR0, CLKIN, CONVST, MMAP, BMODE, BR

and PWD.

3

Programmable I/O Pins (PIO0–PIO11).

4

Output pins: PWMSYNC, AUX0, AUX1, CLKOUT, DT0, DT1, BG, BGH, PMS, DMS, BMS, RD, WR, PWDACK and A0–A13.

5

Output pins: AH, AL, BH, BL, CH and CL.

6

Although specified for TTL outputs, all ADMC401 outputs are CMOS-compatible and will drive to VDD–0.3 V and GND+0.3 V assuming no dc loads.

7

Input only pins RESET, EIA, EIB, EIZ, EIS, ETU0, ETU1, DR1A, DR1B, DR0, CLKIN, CONVST, MMAP, BMODE, BR and PWD.

8

Input pins with internal pull-down PIO0–PIO11 and PWMTRIP.

9

Input pins with internal pull-up, PWMPOL and PWMSR.

10

Three-statable pins: A0–A13, D0–D23, PMS, DMS, BMS, RD, WR, DT0, DT1, RFS0, RFS1, TFS0, TFS1, SCLK0, SCLK1.

11

Idle refers execution of the IDLE instruction. Deasserted pins are driven to VDD or GND. Current reflects device operation with CLKOUT disabled.

12

Current reflects device operating with no output loads.

13

Guaranteed but not tested.

14

Output Pin Capacitance is the capacitive load for any three-state output pin.

Specifications subject to change without notice.

HI-Level Input Voltage

LO-Level Input Voltage

HI-Level Output Voltage

LO-Level Output Voltage

HI-Level Output Voltage

LO-Level Output Voltage

HI-Level Input Current

HI-Level Input Current

HI-Level Input Current

LO-Level Input Current

LO-Level Input Current

LO-Level Input Current

HI-Level Three-State Leakage Current

LO-Level Three-State Leakage Current

Digital Supply Current (Idle)

Digital Supply Current (Dynamic)

Analog Supply Current @ AVDD = max 60 mA

Input Pin Capacitance

Output Pin Capacitance

1, 2, 3

1, 2, 3

1, 3, 4, 5, 6

1, 3, 4, 5, 6

5

5

7

8

9

7

8

9

13

13, 14

@ VDD = max 2.0 V

@ VDD = min 0.8 V

@ VDD = min, IOH = –1.0 mA 2.4 V

@ V

= min, IOH = –0.1 mA VDD – 0.3 V

DD

@ VDD = min, IOL = 2.0 mA 0.4 V

@ VDD = min, IOH = –10.0 mA 2.4 V

@ VDD = min, IOL = 10.0 mA 1.2 V

@ VDD = max, VIN = VDD max 10 µA

@ VDD = max, VIN = V

@ VDD = max, VIN = V

max 100 µA

DD

max 10 µA

DD

@ VDD = max, VIN = 0 V 10 µA

@ VDD = max, VIN = 0 V 10 µA

10

10

11

12

@ VDD = max, VIN = 0 V 100 µA

@ VDD = max, VIN = V

max 10 µA

DD

@ VDD = max, VIN = 0 V 10 µA

@ VDD = max 40 mA

@ VDD = max 110 mA

VIN = 2.5 V, fIN = 1 MHz, 8 pF

= +25°C

T

AMB

VIN = 2.5 V, fIN = 1 MHz, 8 pF

T

= +25°C

AMB

= –40C to +85C,

AMB

–2–

REV. B

Page 3

ADMC401

ANALOG-TO-DIGITAL CONVERTER

(VDD = AVDD = 5 V 5%, GND = AGND = 0 V, T

VIN0 to VIN7 = 4.0 V p-p, V

= 2.0 V, unless otherwise noted)

REF

= –40C to +85C, CLKIN = 13 MHz,

AMB

Parameter Test Conditions Min Typ Max Unit

AC SPECIFICATIONS

SNR Signal to Noise Ratio fIN = 1.0 kHz 68 70 dB

SNRD Signal to Noise and Distortion f

THD Total Harmonic Distortion f

CTLK Channel-Channel Crosstalk f

= 1.0 kHz 66 69 dB

IN

= 1.0 kHz –76 –70 dB

IN

= 1.0 kHz –89 –72 dB

IN

CMRR Common-Mode Rejection Ratio –90 –72 dB

PSRR Power Supply Rejection Ratio 0.025 0.1 % FSR

ACCURACY

INL Integral Nonlinearity ± 0.6 ± 1.5 LSB

DNL Differential Nonlinearity ± 0.5 ± 1.0 LSB

No Missing Codes 12 Bits Guaranteed

Zero Error 0.1 0.25 % FSR

Gain Error

1

0.4 1.0 % FSR

TEMPERATURE DRIFT

Zero Error 0.025 % FSR

Gain Error

1

0.025 % FSR

INPUT VOLTAGE

V

IN

C

IN

Voltage Span 4.0 V p-p

Input Capacitance

2

10 pF

CONVERSION TIME

t

CONV

NOTES

1

Excludes Internal Voltage Reference Error.

2

Analog Input Pins VIN0 to VIN7.

Typical values are neither tested nor guaranteed.

Specifications subject to change without notice.

Total Conversion Time All 8 Channels 1.88 µs

VOLTAGE REFERENCE

(VDD = AVDD = 5 V 5%, GND = AGND = 0 V, T

4.0 V p-p, V

= 2.0 V, unless otherwise noted)

REF

= –40C to +85C, CLKIN = 13 MHz, VIN0 to VIN7 =

AMB

Parameter Test Conditions Min Typ Max Unit

V

REF

Output Voltage Reference SENSE = REFCOM 1.96 2.0 2.04 V

Output Voltage Tolerance

1

SENSE = REFCOM 6 mV

Output Current 1.0 mA

Load Regulation 1.0 mA Load Current 0.3 1.5 mV

Power Supply Rejection Ratio 0.1 1.5 mV

Reference Input Resistance 8 kΩ

NOTES

1

Relative tolerance due to temperature change, T

Specifications subject to change without notice.

POWER-ON RESET

(GND = AGND = 0 V, T

MIN

to T

.

MAX

= –40C to +85C, CLKIN = 13 MHz, unless otherwise noted)

AMB

Parameter Test Conditions Min Typ Max Unit

V

RST

V

HYST

Specifications subject to change without notice.

Reset Threshold Voltage 3.25 4.0 V

Hysteresis Voltage 75 mV

REV. B

–3–

Page 4

ADMC401

WARNING!

ESD SENSITIVE DEVICE

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +7 V

Input Voltage . . . . . . . . . . . . . . . . . . . . . –0.3 V to V

Output Voltage Swing . . . . . . . . . . . . . . –0.3 V to V

Operating Temperature Range (Ambient) . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (5 sec) . . . . . . . . . . . . . . . . . . . . . . +280°C

*Stresses above those listed under absolute maximum ratings may cause permanent

damage to the device. These are stresses only; functional operation of the device

at these or any other conditions above those indicated in the operational section of

this specification is not implied. Exposure to absolute maximum rating conditions

for extended periods may affect device reliability.

Temperature Instruction Package Package

Model Range Rate Description Option

ADMC401BST –40°C to +85°C 26 MHz 144-Lead Plastic Thin Quad Flatpack (LQFP) ST-144

ADMC401-ADVEVALKIT Development Tool Kit

ADMC401-PB Evaluation/Processor Board

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADMC401 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high-energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

+ 0.3 V

DD

+ 0.3 V

DD

ORDERING GUIDE

Timing Parameters

GENERAL NOTES

Use the exact timing information given. Do not attempt to

derive parameters from the addition or subtraction of others.

While addition or subtraction would yield meaningful results for

an individual device, the values given in this data sheet reflect

statistical variations and worst cases. Consequently, you cannot

meaningfully add up parameters to derive longer times.

TIMING NOTES

Switching characteristics specify how the processor changes its

signals. You have no control over this timing; it is dependent on

the internal design. Timing requirements apply to signals that

are controlled outside the processor, such as the data input for a

read operation.

Timing requirements guarantee that the processor operates

correctly with another device. Switching characteristics tell you

what the device will do under a given circumstance. Also, use

the switching characteristics to ensure any timing requirement

of a device connected to the processor (such as memory) is

satisfied.

MEMORY REQUIREMENTS

This chart links common memory device specification names

and ADMC401 timing parameters for your convenience.

Common

Parameter Memory Device

Name Function Specification Name

t

ASW

t

AW

t

WRA

t

DW

t

DH

t

RDD

t

AA

A0–A13, DMS, PMS Address Setup to

Setup before WR Low Write Start

A0–A13, DMS, PMS Address Setup to

before WR Deasserted Write End

A0–A13, DMS, PMS Address Hold Time

Hold after WR Deasserted

Data Setup before WR High Data Setup Time

Data Hold after WR High Data Hold Time

RD Low to Data Valid OE to Data Valid

A0–A13, DMS, PMS, Address Access Time

BMS to Data Valid

–4–

REV. B

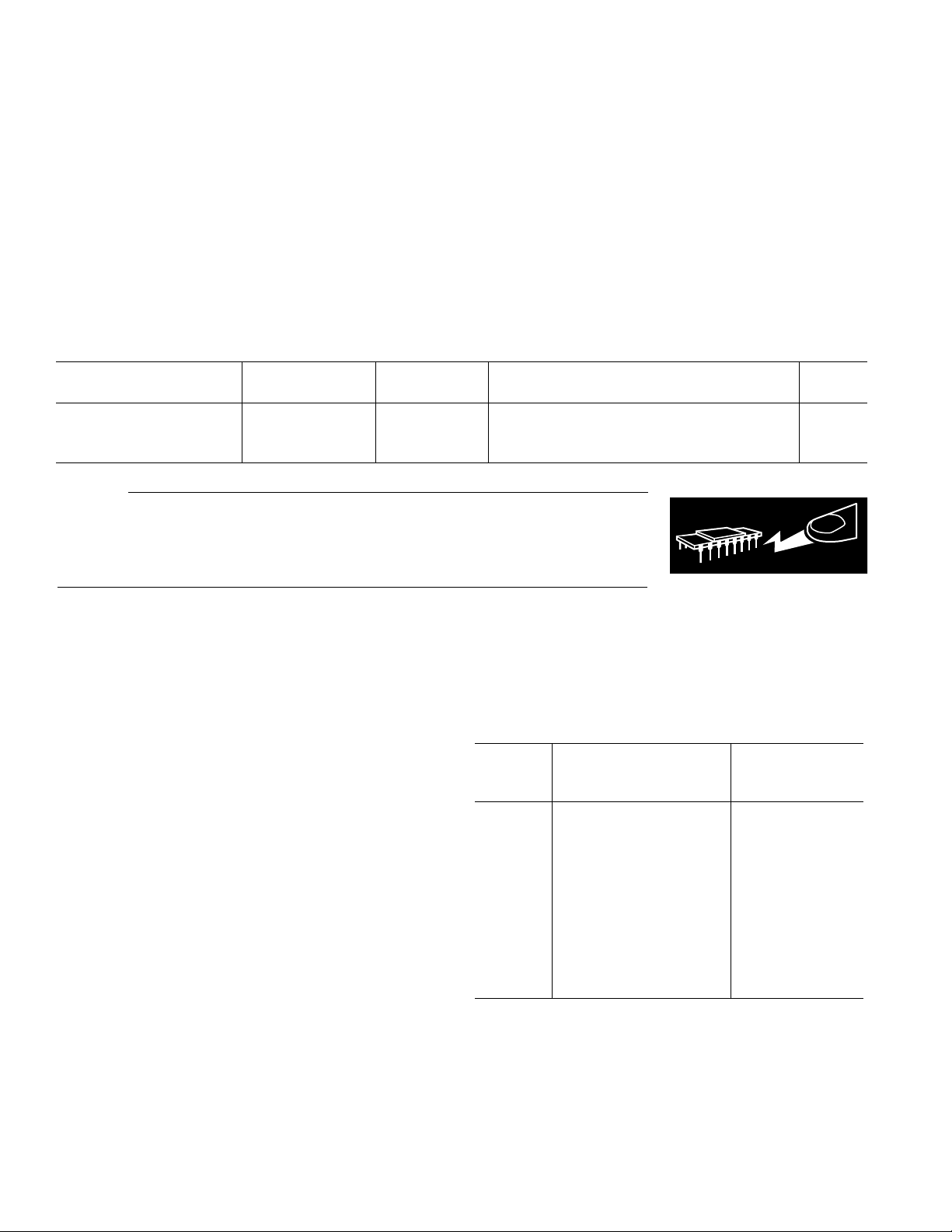

Page 5

ADMC401

Parameter Min Max Unit

Clock Signals

t

is defined as 0.5t

CK

with a frequency equal to half the instruction rate; a 13 MHz

clock (which is equivalent to 76.9 ns) yields a 38.5 ns processor

cycle (equivalent to 26 MHz). t

0.5t

period should be substituted for all relevant timing

CKI

parameters to obtain specification value.

Example: t

= 0.5tCK – 10 ns = 0.5 (38.5 ns) – 10 ns = 9.25 ns.

CKH

Timing Requirements:

t

CKI

t

CKIL

t

CKIH

Switching Characteristics:

t

CKL

t

CKH

t

CKOH

Control Signals

Timing Requirement:

t

RSP

PWM Shutdown Signals

Timing Requirements:

t

PWMTPW

t

PIOPWM

ADC Signals

Timing Requirements:

t

CSI

t

CSE

NOTE

1

Applies after power-up sequence is complete. Internal phase lock loop requires no more than 2000 CLKIN cycles assuming stable CLKIN (not including crystal

oscillator start-up time).

The ADMC401 uses an input clock

CKI.

values within the range of

CK

CLKIN Period 76.9 150 ns

CLKIN Width Low 20 ns

CLKIN Width High 20 ns

CLKOUT Width Low 0.5t

CLKOUT Width High 0.5t

– 10 ns

CK

– 10 ns

CK

CLKIN High to CLKOUT High 0 20 ns

CK

CK

CK

CK

CK

1

ns

ns

ns

ns

ns

RESET Width Low 5t

PWMTRIP Width Low t

PIO Width Low 2t

Internal Convert Start Width High 2t

External Convert Start Width High 2t

REV. B

CLKIN

CLKOUT

t

t

CKI

CKIL

t

CKL

Figure 1. Clock Signals

–5–

t

CKOH

t

CKIH

t

CKH

Page 6

ADMC401

Parameter Min Max Unit

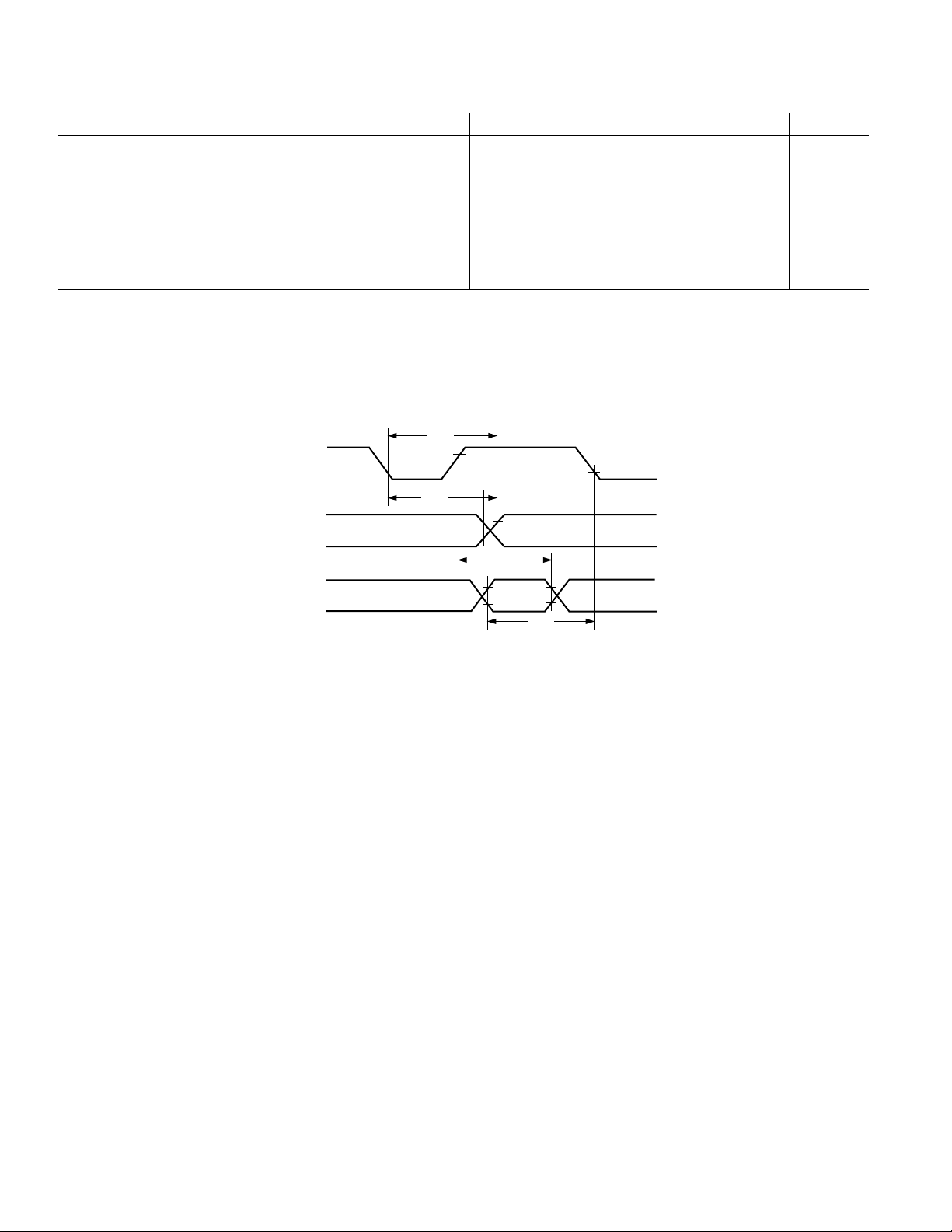

Interrupts and Flags

Timing Requirements:

t

t

IFS

IFH

IRQx or FI Setup before CLKOUT Low

IRQx or FI Hold after CLKOUT High

Switching Characteristics:

t

FOH

t

FOD

NOTES

1

If IRQx and FI inputs meet t

the following cycle. (Refer to “Interrupt Controller Operation” in the Program Control chapter of the ADSP-2100 Family User’s Manual, Third Edition for further

information on interrupt servicing.)

2

Edge-sensitive interrupts require pulsewidths greater than 10 ns; level-sensitive interrupts must be held low until serviced.

3

IRQx = IRQ0 and IRQ1.

4

Flag Output = FL1 and FO.

Flag Output Hold after CLKOUT Low

Flag Output Delay from CLKOUT Low

and t

IFS

setup/hold requirements, they will be recognized during the current clock cycle; otherwise the signals will be recognized on

IFH

CLKOUT

FLAG

OUTPUTS

1, 2, 3

1, 2, 3

4

4

0.25tCK + 15 ns

0.25t

CK

ns

0.5tCK – 7 ns

0.5tCK + 5 ns

t

FOD

t

FOH

t

IFH

IRQx

FI

t

IFS

Figure 2. Interrupts and Flags

–6–

REV. B

Page 7

ADMC401

Parameter Min Max Unit

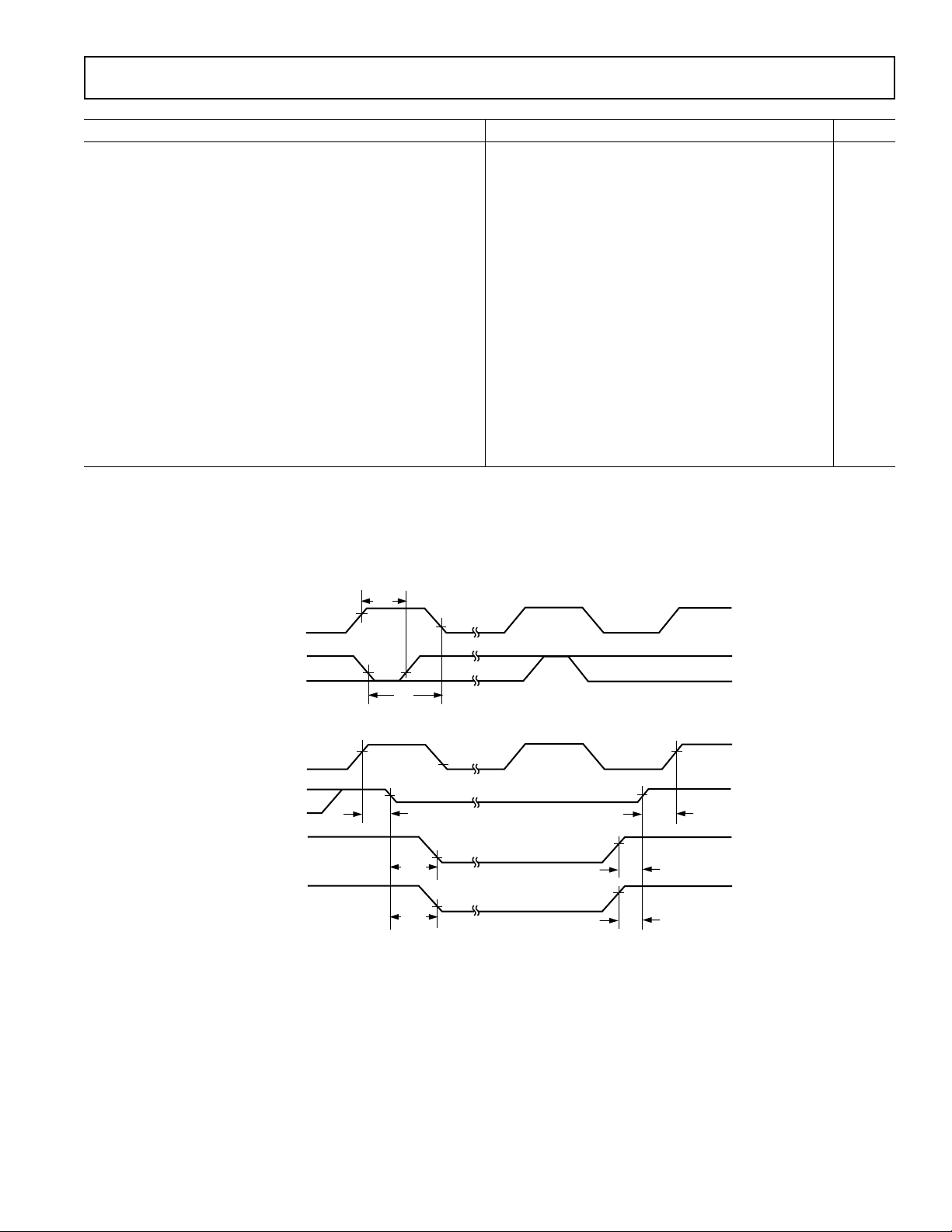

Bus Request/Grant

Timing Requirements:

t

BH

t

BS

BR Hold after CLKOUT High

BR Setup before CLKOUT Low

Switching Characteristics:

t

SD

CLKOUT High to DMS, PMS, BMS, 0.25tCK + 10 ns

RD, WR Disable

t

SDB

DMS, PMS, BMS, RD, WR

Disable to BG Low 0 ns

t

SE

BG High to DMS, PMS, BMS,

RD, WR Enable 0 ns

t

SEC

DMS, PMS, BMS, RD, WR

Enable to CLKOUT High 0.25t

t

SDBH

t

SEH

NOTES

1

BR is an asynchronous signal. If BR meets the setup/hold requirements, it will be recognized during the current clock cycle; otherwise the signal will be recognized

on the following cycle. Refer to the ADSP-2100 Family User’s Manual, Third Edition for BR/BG cycle relationships.

2

BGH is asserted when the bus is granted and the processor requires control of the bus to continue.

DMS, PMS, BMS, RD, WR

Disable to BGH Low

BGH High to DMS, PMS, BMS,

RD, WR Enable

2

2

1

1

0.25tCK +2 ns

0.25tCK + 17 ns

– 7 ns

CK

0ns

0ns

CLKOUT

BR

CLKOUT

PMS, DMS

BMS, RD

WR

BG

BGH

t

BH

t

BS

t

SD

t

SDB

t

SDBH

Figure 3. Bus Request–Bus Grant

t

SEC

t

SE

t

SEH

REV. B

–7–

Page 8

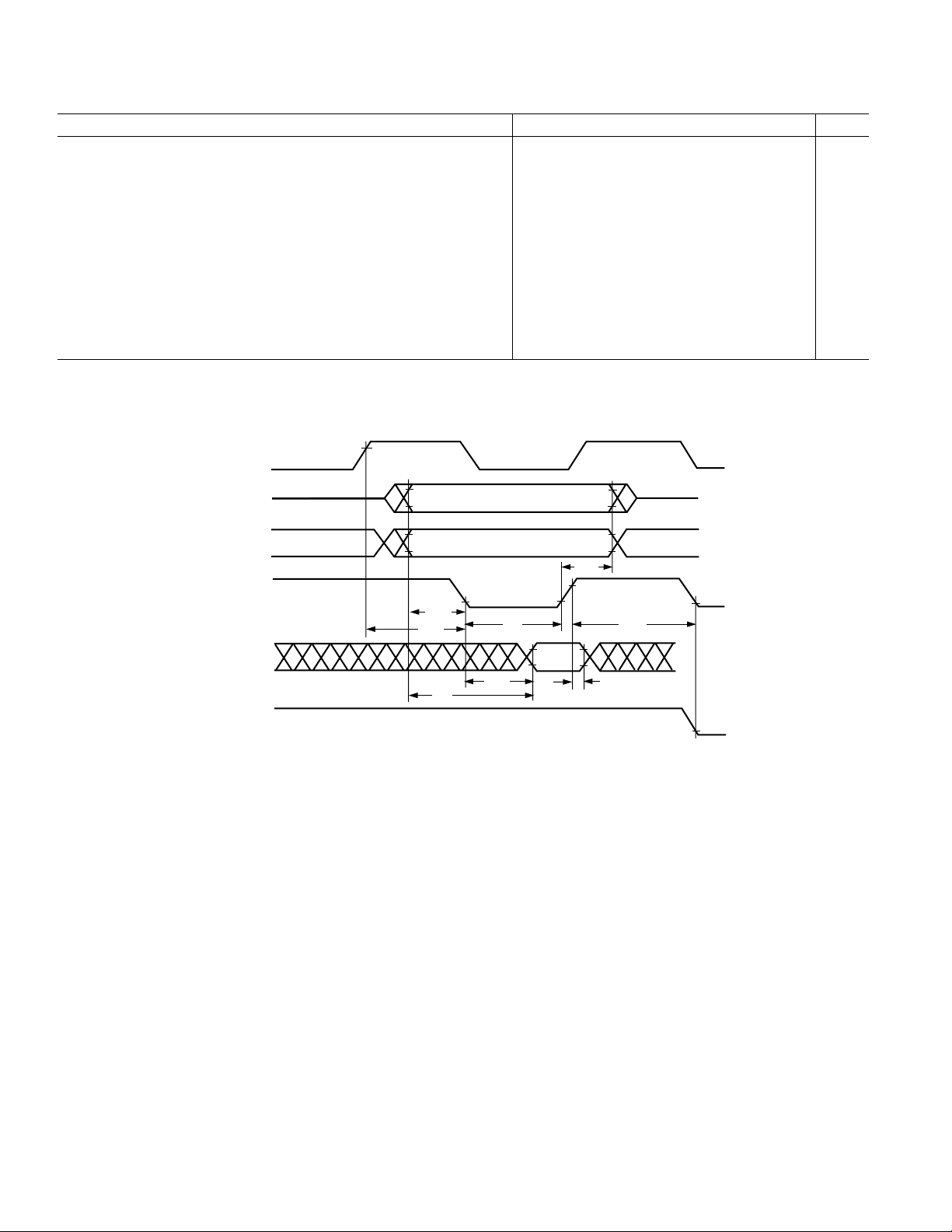

ADMC401

Parameter Min Max Unit

Memory Read

Timing Requirements:

t

RDD

t

AA

t

RDH

Switching Characteristics:

t

RP

t

CRD

t

ASR

t

RDA

t

RWR

w = wait states × tCK.

RD Low to Data Valid 0.5tCK – 11 + w ns

A0–A13, PMS, DMS, BMS to Data Valid 0.75tCK – 12 + w ns

Data Hold from RD High 0 ns

RD Pulsewidth 0.5tCK – 5 + w ns

CLKOUT High to RD Low 0.25tCK – 5 0.25tCK + 7 ns

A0–A13, PMS, DMS, BMS Setup before RD Low 0.25tCK – 6 ns

A0–A13, PMS, DMS, BMS Hold after RD Deasserted 0.25tCK – 3 ns

RD High to RD or WR Low 0.5t

CLKOUT

A0–A13

– 5 ns

CK

DMS, PMS

BMS

RD

WR

t

RDA

t

ASR

t

CRD

D

t

AA

t

RP

t

RDD

t

RWR

t

RDH

Figure 4. Memory Read

–8–

REV. B

Page 9

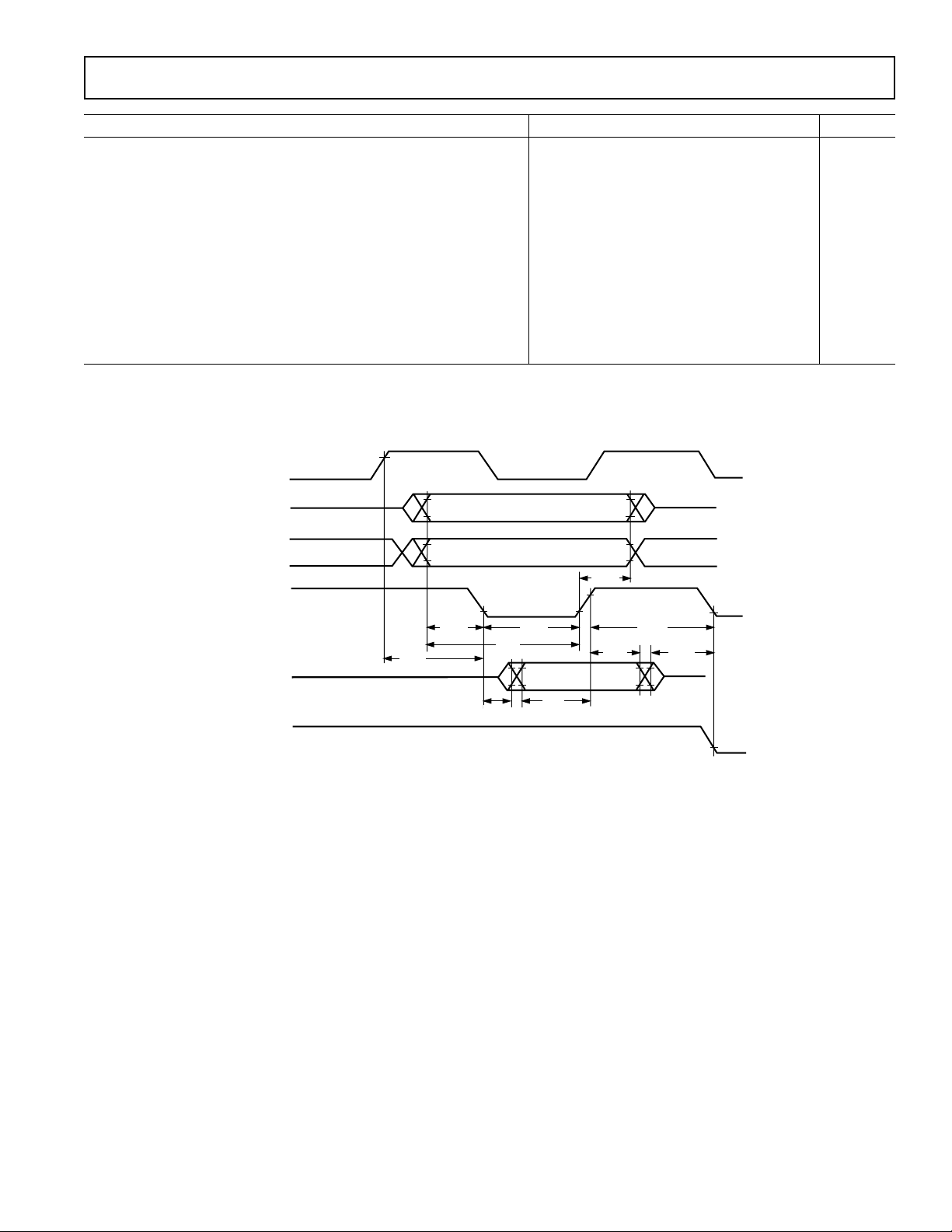

ADMC401

Parameter Min Max Unit

Memory Write

Switching Characteristics:

t

DW

t

DH

t

WP

t

WDE

t

ASW

t

DDR

t

CWR

t

AW

t

WRA

t

WWR

w = wait states × tCK.

Data Setup before WR High 0.5t

Data Hold after WR High 0.25t

– 7 + w ns

CK

– 2 ns

CK

WR Pulsewidth 0.5tCK – 5 + w ns

WR Low to Data Enabled 0 ns

A0–A13, DMS, PMS Setup before WR Low 0.25t

– 6 ns

CK

Data Disable before WR or RD Low 0.25tCK – 6 ns

CLKOUT High to WR Low 0.25t

A0–A13, DMS, PMS, Setup before WR Deasserted 0.75t

A0–A13, DMS, PMS Hold after WR Deasserted 0.25t

– 5 0.25tCK + 7 ns

CK

– 9 + w ns

CK

– 3 ns

CK

WR High to RD or WR Low 0.5tCK – 5 ns

CLKOUT

A0–A13

DMS, PMS

WR

RD

t

WRA

t

ASW

t

CWR

D

t

WP

t

AW

t

t

WDE

DW

t

WWR

t

DH

t

DDR

Figure 5. Memory Write

REV. B

–9–

Page 10

ADMC401

(

)

Parameter Min Max Unit

Serial Ports

Timing Requirements:

t

SCK

t

SCS

t

SCH

t

SCP

Switching Characteristics:

t

CC

t

SCDE

t

SCDV

t

RH

t

RD

t

SCDH

t

TDE

t

TDV

t

SCDD

t

RDV

SCLK Period 50 ns

DR/TFS/RFS Setup before SCLK Low 5 ns

DR/TFS/RFS Hold after SCLK Low 10 ns

SCLK

CLKOUT High to SCLK

Width 20 ns

IN

OUT

0.25t

CK

0.25t

+ 15 ns

CK

SCLK High to DT Enable 0 ns

SCLK High to DT Valid 20 ns

TFS/RFS

TFS/RFS

Hold after SCLK High 0 ns

OUT

Delay from SCLK High 20 ns

OUT

DT Hold after SCLK High 0 ns

TFS(Alt) to DT Enable 0 ns

TFS(Alt) to DT Valid 20 ns

SCLK High to DT Disable 20 ns

RFS (Multichannel, Frame Delay Zero) to DT Valid 20 ns

CLKOUT

SCLK

DR

RFS

TFS

RFS

OUT

TFS

OUT

TFS

alternate

frame mode

multichannel mode,

RFS

frame delay 0

MFD = 0

DT

t

CC

IN

IN

t

t

t

RD

t

RH

SCDV

SCDE

t

TDE

t

TDV

t

CC

t

SCS tSCS

t

t

SCDH

t

RDV

SCDD

t

SCK

t

SCP

t

SCP

Figure 6. Serial Ports

–10–

REV. B

Page 11

ADMC401

POWER DISSIPATION

To determine total power dissipation in a specific application,

the following equation should be applied for each output:

2

DD

× f

C × V

C = load capacitance, f = output switching frequency.

Example:

In an application where external data memory is used and no

other outputs are active, power dissipation is calculated as

follows:

Assumptions:

• External data memory is accessed every cycle with 50% of the

address pins switching.

• External data memory writes occur every other cycle with

50% of the data pins switching.

• Each address and data pin has a 10 pF total load at the pin.

• The application operates at V

Total Power Dissipation = P

= VDD × (IDD Digital + IDD Analog)

P

INT

(C × V

2

× f) is calculated for each output:

DD

# of

Pins C V

Address, DMS 8 × 10 pF × 52 V × 26 MHz = 52.00 mW

Data Output, WR 9 × 10 pF × 52 V × 13 MHz = 29.25 mW

RD 1 × 10 pF × 52 V × 13 MHz = 3.25 mW

CLKOUT 1 × 10 pF × 52 V × 26 MHz = 6.50 mW

Total power dissipation for this example is P

= 5.0 V and t

DD

+ (C × V

INT

2

f

DD

= 38.5 ns.

CK

2

× f)

DD

+ 91 mW.

INT

91.00 mW

INPUT

OUTPUT

0.0V

0.3V

1.5V

2.0V

1.5V

3.0V

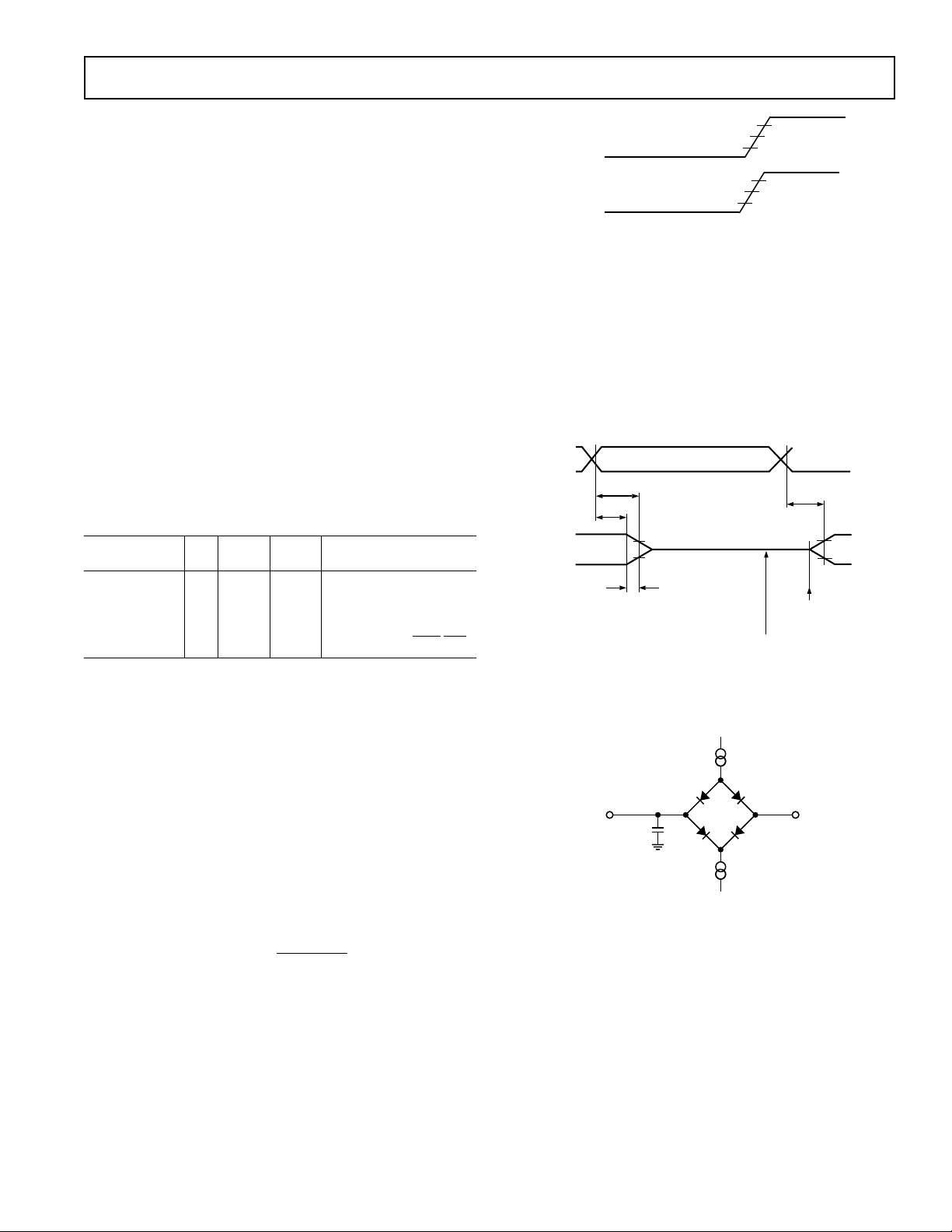

Figure 7. Voltage Reference Levels for AC Measurements (Except Output Enable/Disable)

Output Enable Time

Output pins are considered to be enabled when that have made

a transition from a high-impedance state to when they start

driving. The output enable time (t

) is the interval from when

ENA

a reference signal reaches a high or low voltage level to when

the output has reached a specified high or low trip point, as

shown in the Output Enable/Disable diagram. If multiple pins

(such as the data bus) are enabled, the measurement value is

that of the first pin to start driving.

REFERENCE

SIGNAL

t

(MEASURED)

OUTPUT

(MEASURED)

V

OH

V

OL

MEASURED

t

DIS

V

(MEASURED) – 0.5V

OH

(MEASURED) +0.5V

V

OL

t

DECAY

OUTPUT STOPS

DRIVING

HIGH-IMPEDANCE STATE. TEST CONDITIONS CAUSE

THIS VOLTAGE LEVEL TO BE APPROXIMATELY 1.5V.

t

ENA

V

(MEASURED)

2.0V

1.0V

OUTPUT STARTS

DRIVING

V

(MEASURED)

OH

OL

Figure 8. Output Enable/Disable

TEST CONDITIONS

Output Disable Time

Output pins are considered to be disabled when they have

stopped driving and started a transition from the measured

output high or low voltage to a high impedance state. The output disable time (t

) is the difference of t

DIS

MEASURED

and t

DECAY

,

as shown in the Output Enable/Disable diagram. The time is the

interval from when a reference signal reaches a high or low

voltage level to when the output voltages have changed by 0.5 V

from the measured output high or low voltage. The decay time,

, is dependent on the capacitative load, CL, and the cur-

t

DECAY

rent load, i

, on the output pin. It can be approximated by the

L

following equation:

CV

× 05.

t

DECAY

L

=

I

L

from which

tt t

=−

DIS MEASURED DECAY

is calculated. If multiple pins (such as the data bus) are disabled, the measurement value is that of the last pin to stop

driving.

I

OL

OUTPUT

PIN

TO

50pF

I

OH

+1.5V

Figure 9. Equivalent Device Loading for AC Measurements (Including All Fixtures)

REV. B

–11–

Page 12

ADMC401

PIN FUNCTION DESCRIPTION

Pin Pin Pin Pin Pin Pin Pin Pin

No. Name No. Name No. Name No. Name

1 A9 37 RFS1/IRQ0/SROM 73 GND 109 CONVST

2 A8 38 TFS1/IRQ1 74 D10 110 GND

3 A7 39 SCLK1 75 D9 111 VDD

4 A6 40 DR0 76 D8 112 GND

5 VDD 41 DT0 77 D7 113 AVDD

6 A5 42 RFS0 78 D6 114 AVSS

7 A4 43 TFS0 79 D5 115 VIN7

8 A3 44 SCLK0 80 D4 116 V

9 GND 45 VDD 81 D3 117 VIN6

10 A2 46 GND 82 GND 118 REFCOM

11 A1 47 PWMTRIP 83 D2 119 VIN5

12 A0 48 PWMSYNC 84 D1 120 CAPT

13 PWD 49 CL 85 D0 121 VIN4

14 PWDACK 50 CH 86 P11 122 BSHAN

15 BR 51 VDD 87 P10 123 ASHAN

16 NC 52 GND 88 P9 124 VIN0

17 NC 53 BL 89 P8 125 CAPB

18 BMODE 54 BH 90 VDD 126 VIN1

19 MMAP 55 AL 91 GND 127 CML

20 VDD 56 AH 92 P7 128 VIN2

21 GND 57 BGH 93 P6 129 GAIN

22 PWMSR 58 D23 94 P5 130 VIN3

23 POR 59 D22 95 P4 131 SENSE

24 RESET 60 D21 96 P3 132 AVSS

25 GND 61 D20 97 P2 133 AVDD

26 GND 62 D19 98 GND 134 BMS

27 GND 63 GND 99 P1 135 PMS

28 PWMPOL 64 D18 100 P0 136 DMS

29 CLKIN 65 D17 101 AUX1 137 RD

30 XTAL 66 D16 102 AUX0 138 GND

31 CLKOUT 67 D15 103 ETU1 139 BG

32 VDD 68 D14 104 ETU0 140 WR

33 GND 69 D13 105 EIS 141 A13

34 DR1A/FI 70 D12 106 EIZ 142 A12

35 DRIB/FI 71 VDD 107 EIB 143 A11

36 DT1/FO 72 D11 108 EIA 144 A10

NC: These pins must be left unconnected

REF

–12–

REV. B

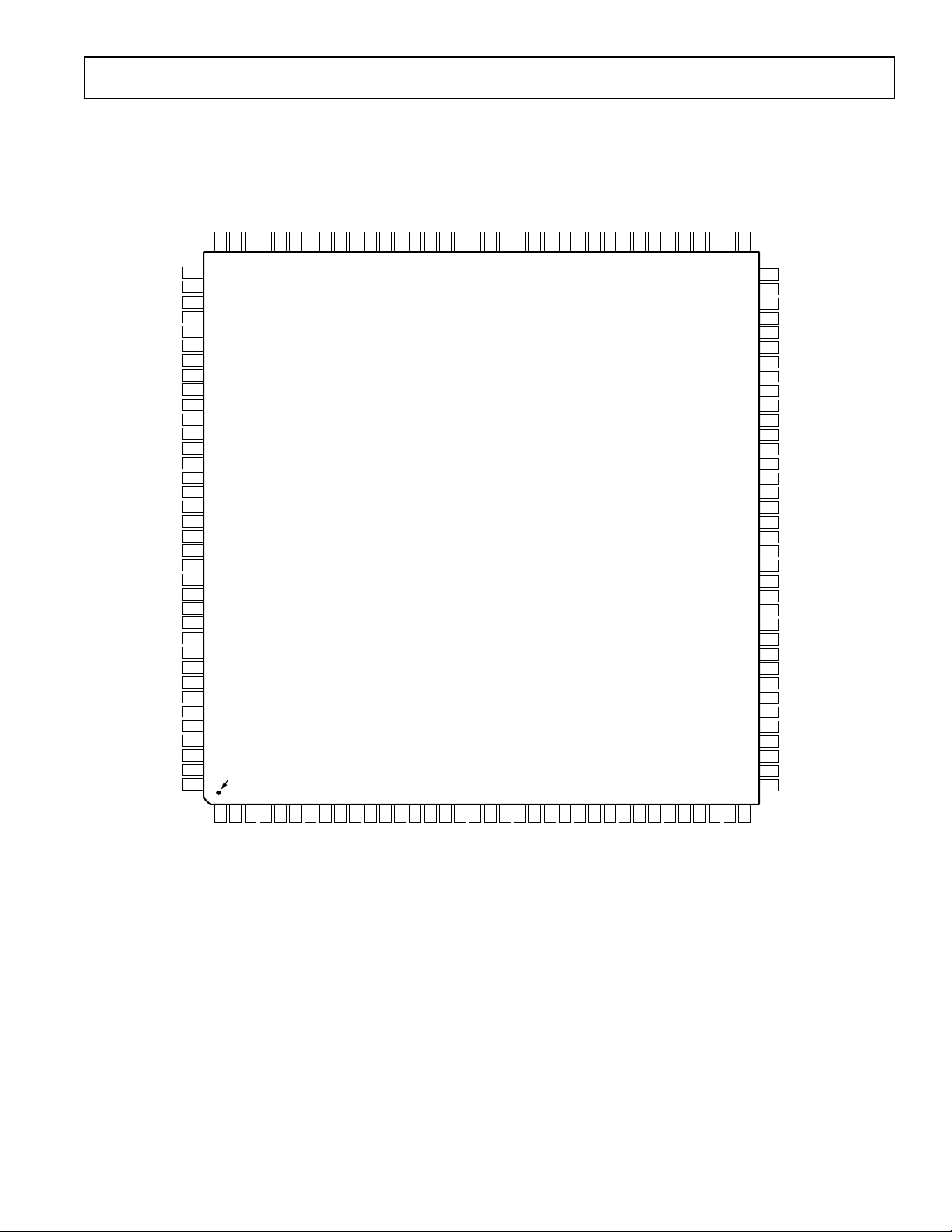

Page 13

PIN CONFIGURATION

A9A8A7

A6

VDD

A5A4A3

GND

A2A1A0

PWD

PWDACK

BRNCNC

BMODE

MMAP

VDD

GND

PWMSR

POR

RESET

GND

GND

GND

PWMPOL

CLKIN

XTAL

CLKOUT

VDD

GND

DR1A/F1

DR1B/FI

DT1/FO

P1

GNDP2P3P4P5P6P7

GND

VDDP8P9

P10

P11D0D1D2GNDD3D4D5D6D7D8D9D10

GND

EIA

EIB

EIZ

EIS

ETU0

ETU1

AUX0

AUX1

P0

D11

VDD

D12

D13

D14

D15

D16

D17

D18

GND

D19

D20

D21

D22

D23

BGH

AH

AL

BH

BL

GND

VDD

CH

CL

PWMSYNC

PWMTRIP

GND

VDD

SCLK0

TFS0

RFS0

DT0

DR0

SCLK1

TFS1/IRQ1

RFS1/IRQ0/SROM

CONVST

GND

VDD

GND

AVDD

AVSS

VIN7

V

REF

VIN6

REFCOM

VIN5

CAPT

VIN4

BSHAN

ASHAN

VIN0

CAPB

VIN1

CML

VIN2

GAIN

VIN3

SENSE

AVSS

AVDD

BMS

PMS

DMS

RD

GND

BG

WR

A13

A12

A11

A10

NC = NO CONNECT

PIN 1

IDENTIFIER

TOP VIEW

(Not to Scale)

ADMC401

1920212223242526272829303132333435

36

101112131415161718

123456789

9089888786858483828180797877767574

73

999897969594939291

108

107

106

105

104

103

102

101

100

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

ADMC401

REV. B

–13–

Page 14

ADMC401

(Continued from Page 1)

Programmable Digital I/O (PIO) Port

12-Pin Configurable Digital I/O Port

Flexible Interrupt Generation

Four Dedicated PIO Interrupt Vectors

Each I/O Line Configurable as PWM Shutdown

Two 8-Bit Auxiliary PWM Outputs

Programmable Switching Frequency

Independent or Offset Modes

Two-Channel Event Timer (Capture) Unit

Configurable Event Definition

Single-Shot or Free-Running Modes

Peripheral Interrupt Controller

Manages Peripheral Interrupts

16-Bit Watchdog Timer

Internal Power-On Reset System

Programmable 16-Bit Interval Timer with Prescaler

Two Double Buffered Synchronous Serial Ports

Boot Load Protocols via SPORT1:

Synchronous E

UART Boot Loader with Autobaud

Synchronous Master or Slave Boot Loader

Debugger Interface via SPORT1:

UART Interface with Autobaud

Synchronous Master or Slave Interface

Full Debugger for Program Development

Industrial Temperature Range –40C to +85C

Operating Voltage 5.0 V 5%

Package: 144-Lead LQFP

GENERAL DESCRIPTION

2

PROM/SROM Booting

The ADMC401 is a single-chip DSP-based controller, suitable

for high performance control of ac induction motors (ACIM),

permanent magnet synchronous motors (PMSM), brushless dc

motors (BDCM) and switched reluctance (SR) motors in industrial applications. The ADMC401 integrates a 26 MIPS, fixedpoint DSP core with a complete set of motor control peripherals

that permits fast motor control in a highly integrated environment.

The DSP core of the ADMC401 is the ADSP-2171 which is

completely code compatible with the ADSP-21xx DSP family

(as well as other members of the integrated motor controllers of

the ADMC3xx family) and combines three computational units,

data address generators and a program sequencer. The computational units comprise an ALU, a multiplier/accumulator (MAC)

and a barrel shifter. The DSP core also adds instructions for bit

manipulation, squaring (x

2

), biased rounding and global interrupt masking. In addition, two flexible double-buffered, bidirectional synchronous serial ports are included in the ADMC401.

The ADMC401 provides 2K × 24-bit internal program memory

RAM, 2K × 24-bit internal program memory ROM and 1K ×

16-bit internal data memory RAM. The program and data

memory RAM can be boot loaded through the serial port from

either a serial E

2

PROM, through a UART connection (either

from external host microprocessor or from the Motion Control

Debugger) or via a synchronous serial interface from a host

microprocessor. Alternatively, the internal program and data

memory RAM may be booted from an external device across the

address and data buses. The program memory ROM includes a

monitor that adds software debugging features through the serial

port.

Additionally, the ADMC401 device adds significant external

memory and peripheral expansion capabilities by making available the full address and data bus of the DSP core. This feature

permits expansion of both external program and data memory

and means that the DSP core can address up to 14K × 24 bits of

external program memory and up to 13K × 16 bits of external

data memory.

The ADMC401 contains a number of special purpose, motor

control peripherals. The first is a high performance, 8-channel,

12-bit ADC system with dual channel simultaneous sampling

ability across 4 pair of inputs. An internal precision voltage reference is also available as part of the ADC system. In addition, a

three-phase, 16-bit, center-based PWM generation unit can be

used to produce high-accuracy PWM signals with minimal processor overhead. The ADMC401 also contains a flexible incremental encoder interface unit for position sensor feedback;

two adjustable-frequency auxiliary PWM outputs, 12 lines of

digital I/O; a 2-channel event capture system; a 16-bit watchdog

timer; two 16-bit interval timers (one of which can be linked to

the encoder interface unit) and an interrupt controller that manages all peripheral interrupts. Finally, the ADMC401 contains

an integrated power-on-reset (POR) circuit that can be used to

generate the required reset signal for the device on power-on.

–14–

REV. B

Page 15

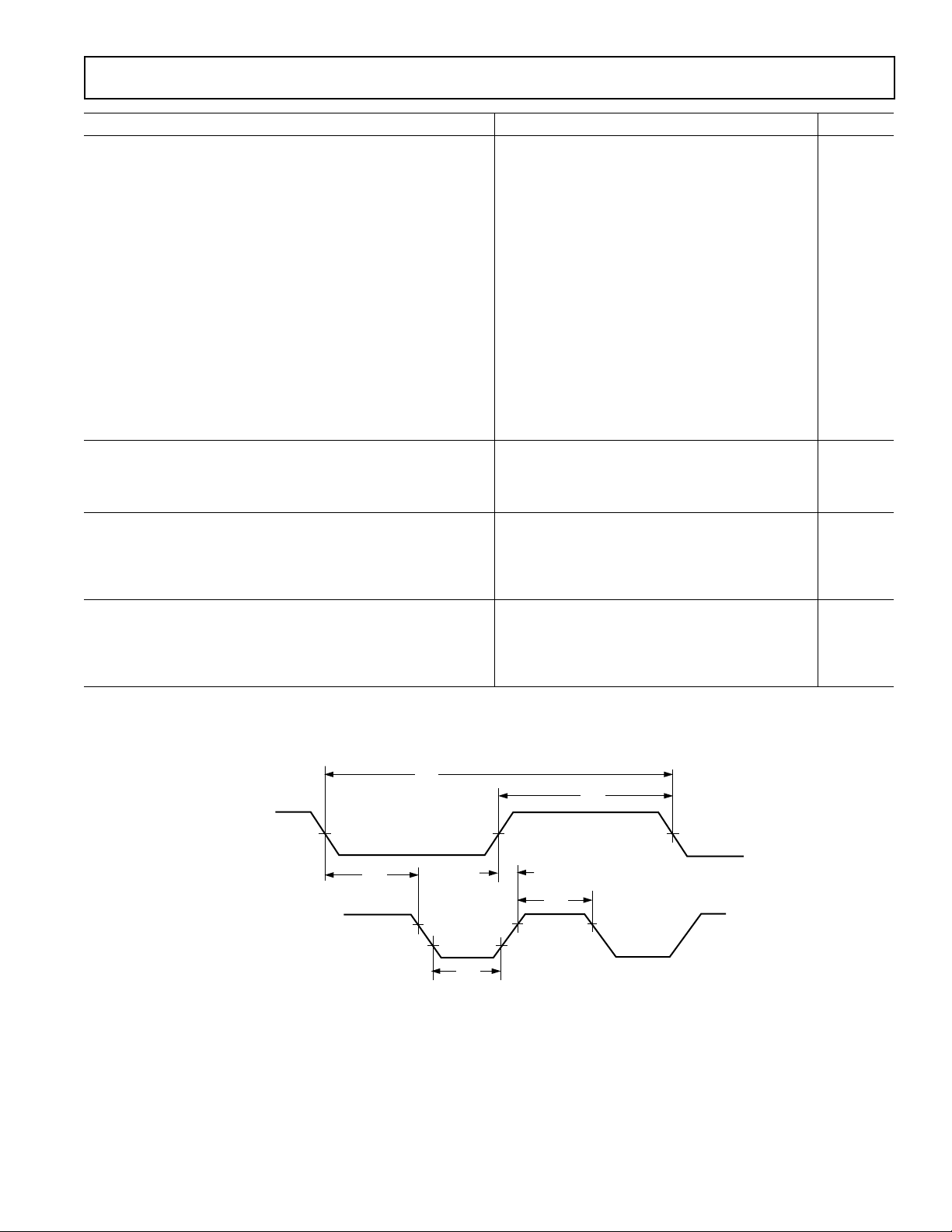

ADMC401

DATA

ADDRESS

GENERATOR

#1

INPUT REGS

ALU

OUTPUT REGS

DATA

ADDRESS

GENERATOR

#2

INPUT REGS

OUTPUT REGS

MAC

INSTRUCTION

PROGRAM

SEQUENCER

16

R BUS

REGISTER

OUTPUT REGS

PM ROM

2K 24

PM RAM

2K 24

CONTROL

LOGIC

PMA BUS

DMA BUS

PMD BUS

DMD BUS

TRANSMIT REG

RECEIVE REG

SERIAL

PORT 0

5

14

14

24

BUS

EXCHANGE

16

INPUT REGS

SHIFTER

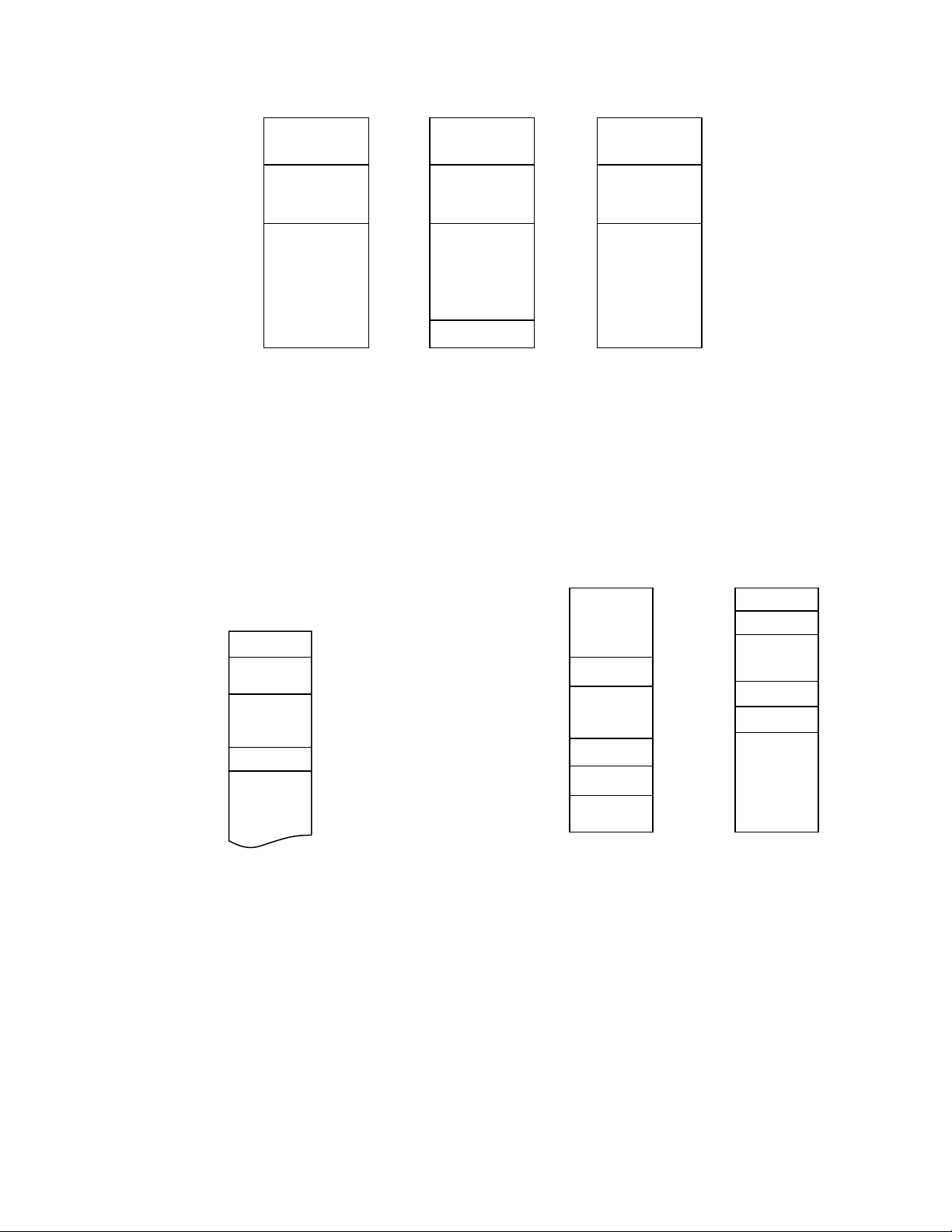

Figure 10. DSP Core Block Diagram

DM RAM

1K 16

COMPANDING

CIRCUITRY

BOOT

ADDRESS

GENERATOR

TRANSMIT REG

RECEIVE REG

SERIAL

PORT 1

6

TIMER

POWER DOWN

CONTROL

LOGIC

14

24

2

EXTERNAL

ADDRESS BUS

EXTERNAL

DATA BUS

ARCHITECTURE OVERVIEW

Figure 10 is a functional block diagram of the DSP core of the

ADMC401. The DSP core is based on the fixed-point ADSP2171 core that is a member of the fixed-point ADSP-21xx

family of general purpose DSPs from Analog Devices Inc.

The ADSP-2171 flexible architecture and comprehensive instruction set allow the processor to perform multiple operations

in parallel.

In one processor cycle (38.5 ns with a 13 MHz crystal) the DSP

core can:

• Generate the next program address.

• Fetch the next instruction.

• Perform one or two data moves.

• Update one or two data address pointers.

• Perform a computational operation.

This all takes place while the ADMC401 continues to:

• Receive and transmit through the serial ports.

• Decrement the interval timers.

• Generate PWM signals.

• Convert the ADC input signals.

• Operate the encoder interface unit.

• Operate all other peripherals including the auxiliary PWM and

event timer subsystem.

The processor contains three independent computational units:

the arithmetic and logic unit (ALU), the multiplier/accumulator

(MAC) and the shifter. The computational units process 16-bit

data directly and have provisions to support multiprecision

computations. The ALU performs a standard set of arithmetic

and logic operations; division primitives are also supported. The

MAC performs single-cycle multiply, multiply/add, multiply/

subtract operations with 40 bits of accumulation. The shifter

performs logical and arithmetic shifts, normalization, denormalization and derive exponent operations. The shifter can be used

to implement numeric format control efficiently, including

floating-point representations. The internal result (R) bus directly connects the computational units so that the output of

any unit may be the input of any unit on the next cycle.

A powerful program sequencer and two dedicated data address

generators ensure efficient delivery of operands to these computational units. The sequencer supports conditional jumps, subroutine calls and returns in a single cycle. With internal loop

counters and loop stacks, the ADMC401 executes looping code

with zero overhead; no explicit jump instructions are required to

maintain the loop.

REV. B

–15–

Page 16

ADMC401

Two data address generators (DAGs) provide addresses for

simultaneous dual operand fetches from data memory and program memory. Each DAG maintains and updates four address

pointers (I registers). Whenever the pointer is used to access

data (indirect addressing), it is post-modified by the value in

one of four modify (M) registers. A length value may be associated with each pointer (L registers) to implement automatic

modulo addressing for circular buffers. The circular buffering

feature is also used by the serial ports for automatic data transfers to and from on-chip memory. DAG1 generates only data

memory addresses but provides an optional bit-reversal capability. DAG2 may generate either program or data memory addresses, but has no bit-reversal capability.

Efficient data transfer is achieved with the use of five internal

buses:

• Program Memory Address (PMA) Bus.

• Program Memory Data (PMD) Bus.

• Data Memory Address (DMA) Bus.

• Data Memory Data (DMD) Bus.

• Result (R) Bus.

Program memory can store both instructions and data, permitting the ADMC401 to fetch two operands in a single cycle, one

from internal program memory and one from internal data

memory. The ADMC401 can fetch an operand from on-chip

program memory and the next instruction in the same cycle.

The ADMC401 writes data from its 16-bit registers to the 24bit program memory using the PX register to provide the lower

eight bits. When it reads data (not instructions) from 24-bit

program memory to a 16-bit data register, the lower eight bits

are placed in the PX register.

The ADMC401 can respond to a number of distinct DSP core

and peripheral interrupts. The DSP core interrupts include

serial port receive and transmit interrupts, timer interrupts,

software interrupts and external interrupts. In addition, there is

a master RESET signal. The motor control peripherals also

produce interrupts to the DSP core.

The two serial ports (SPORTs) provide a complete synchronous

serial interface with optional companding in hardware and a

wide variety of framed and unframed data transmit and receive

modes of operation. Each SPORT can generate an internal

programmable serial clock or accept an external serial clock.

Boot loading of both the program and data memory RAM of the

ADMC401 can be through the serial port SPORT1. Alternatively the ADMC401 can be boot loaded from an external bytewide memory connected to the external address and data buses.

After reset, seven wait states are automatically generated. This

permits, for example, a 38.5 ns ADMC401 to use an external

250 ns EPROM as boot memory. The internal boot address

generator provides the addresses for booting from an external

byte-wide memory.

A programmable interval counter is also included in the DSP

core and can be used to generate periodic interrupts. A 16-bit

count register (TCOUNT) is decremented every n processor

cycles, where n-1 is a scaling value stored in the 8-bit TSCALE

register. When the value of the counter reaches zero, an interrupt is generated and the count register is reloaded from a 16bit period register (TPERIOD).

The ADMC401 instruction set provides flexible data moves and

multifunction (one or two data moves with a computation)

instructions. Each instruction is executed in a single 38.5 ns

processor cycle (for a 13 MHz crystal). The ADMC401 assembly language uses an algebraic syntax for ease of coding and

readability. A comprehensive set of development tools supports

program development.

Serial Ports

The ADMC401 incorporates two complete synchronous serial

ports (SPORT0 and SPORT1) for serial communications and

multiprocessor communication. The following is a brief list of

the capabilities of the ADMC401 SPORTs. Refer to the ADSP-

2100 Family User’s Manual, Third Edition for further details.

• SPORTs are bidirectional and have a separate, double buffered transmit and receive section.

• SPORTs can use an external serial clock or generate their

own serial clock internally.

• SPORTs have independent framing for the receive and trans-

mit sections. Sections run in a frameless mode or with frame

synchronization signals internally or externally generated.

Frame synchronization signals are active high or inverted,

with either of two pulsewidths and timings.

SPORTs support serial data word lengths from 3 bits to 16

bits and provide optional A-law and µ-law companding.

• SPORT receive and transmit sections can generate unique

interrupts on completing a data word transfer.

• SPORTs can receive and transmit an entire circular buffer of

data with only one overhead cycle per data word. An interrupt is generated after a data buffer transfer.

• SPORT0 has a multichannel interface to selectively receive

and transmit a 24-word or 32-word, time-division multiplexed, serial bitstream.

• SPORT1 can be configured to have two external interrupts

(IRQ0 and IRQ1), and the Flag In and Flag Out signals. The

internally generated serial clock may still be used in this

configuration.

The following are additional capabilities of the ADMC401

SPORTs that are not part of the ADSP-21xx products:

• SPORT1 is the input for single pin program and data

memory boot loading. The RFS1 pin can be configured

internally to the ADMC401 as an SROM/E

signal.

• SPORT1 has two data receive pins (DR1A and DR1B). The

DR1A pin is intended only for synchronous data receive

from the external E

the data receive pin for a general purpose SPORT after booting or as the data receive pin for other boot load modes or as

the UART/debugger interface. The DR1A and DR1B pins

are internally multiplexed onto the one data receive pin of

the SPORT. The particular data receive pin selected is determined by Bit 4 of the MODECTRL register.

2

PROM. The DR1B pin can be used as

2

PROM reset

–16–

REV. B

Page 17

ADMC401

PIN FUNCTION DESCRIPTION

The ADMC401 is available in an 144-lead TQFP package. Table

I contains the pin descriptions.

Table I. Pin List

Pin #

Group of Input/

Name Pins Output Function

A13–A0 14 O Address Lines

D23–D0 24 I/O Data Lines

PMS, DMS, BMS 3 O External Memory Select Lines

RD, WR 2 O External Memory Read/Write Enable

MMAP 1 I Memory Map Select

POR 1 O Internal Power On Reset Output

RESET 1 I Processor Reset Input

CLKOUT 1 O Processor Clock Output

CLKIN, XTAL 2 I, O External Clock or Quartz Crystal

Input

BR 1 I Bus Request

BG, BGH 2 O Bus Grant and Bus Hang Control

BMODE 1 I Boot Mode Select

PWD, PWDACK 2 I, O Power-Down and Power-Down

Acknowledge

SPORT0 5 I/O Serial Port 0 Pins (TFS0, RFS0,

DT0, DR0, SCLK0)

SPORT1 6 I/O Serial Port 1 (TFS1/IRQ1, RFS1/

IRQ0/SROM, DT1/FO, DR1A/FI,

DR1B/FI, SCLK1)

VIN0–VIN7 8 I Analog Inputs

ASHAN, BSHAN 2 I Inverting Inputs to Sample and

Hold Amplifiers

GAIN 1 I Analog Input for Gain Calibration

V

REF

REFCOM 1 GND Reference Common

CML 1 O Common-

CAPT, CAPB 2 O Noise Reduction Pins

SENSE 1 I Voltage Reference Select

CONVST 1 I External Convert Start

AH-CL 6 O PWM Outputs

PWMTRIP 1 I PWM Shutdown Signal

PWMPOL 1 I PWM Polarity Control

PWMSYNC 1 O PWM Synchronization Output

PWMSR 1 I PWM Switched Reluctance Mode

PIO0–PIO11 12 I/O Digital I/O Port

ETU0, ETU1 2 I Event Timer Inputs

AUX0–AUX1 2 O Auxiliary PWM Outputs

EIA, EIB, EIZ,

EIS 4 I Encoder Interface Inputs and

NC 2 No Connect

AVDD 2 SUP Analog Power Supply

AVSS 2 GND Analog Ground

VDD 8 SUP Digital Power Supply

GND 16 GND Digital Ground

1 I/O Reference Voltage Input/Output

Mode

Level (Midsupply)

Control

External Registration Inputs

INTERRUPT OVERVIEW

The ADMC401 can respond to different interrupt sources, some

of which are internal DSP core interrupts and others from the

motor control peripherals. The DSP core interrupts include a:

• Power up (or RESET) interrupt.

• A peripheral (or IRQ2) interrupt.

• A SPORT0 receive and a SPORT0 transmit interrupt.

• A SPORT1 receive (or IRQ0) and a SPORT1 transmit (or

IRQ1) interrupt.

• Two software interrupts.

• An interval timer timeout interrupt.

• A power-down interrupt.

In addition, the motor control peripherals add other interrupts

that include:

• A PWMSYNC interrupt.

• An ADC end of conversion interrupt.

• An encoder loop timer timeout interrupt.

• Five peripheral input/output (PIO) interrupts.

• An event timer interrupt.

• An encoder count error interrupt.

• A PWM trip interrupt.

The interrupts are internally prioritized and individually maskable

except for the nonmaskable power-down interrupt.

Memory Map

The ADMC401 has two distinct memory types; program memory

and data memory (in addition to external boot memory). In

general, program memory contains user code and coefficients,

while the data memory is used to store variables and data during

program execution. Both program memory RAM and ROM is

provided internally on the ADMC401. The program memory

map of the ADMC401 can be altered depending on the state of

the MMAP and BMODE pins. The various program memory

maps are illustrated in Figure 11 for the permissible settings of

MMAP and BMODE. The state of these pins also impact the

way in which the internal memory of the ADMC401 is booted,

as described later.

There is 2K of internal ROM on the ADMC401. Setting the

ROMENABLE bit on the Data Memory Wait State Control

Register (at address DM (0x3FFE)) enables the ROM. When the

ROMENABLE bit is set to 1, addressing program memory in the

ROM range will access the on-chip ROM. When ROMENABLE

is set to zero, addressing program memory in this range will

access external program memory. The ROMENABLE bit is

initialized to zero after reset unless MMAP and BMODE = 1.

When MMAP = BMODE = 0, the ADMC401 provides 2K × 24

bits of internal program memory RAM starting at address

0x0000 that is booted from a byte-wide interface on the address

and data buses. Following boot loading, program execution

starts at address 0x0000. In this mode, the remainder of the

program memory space, a 12K × 24-bit block starting at address

0x1000, is assigned to external memory.

When MMAP = BMODE = 1, the program memory map is

identical to the previous case, but ROMENABLE defaults to 1 at

reset, and execution starts from the internal program memory

ROM located at address 0x0800. This permits the internal (and

external if desired) memory to be boot loaded across the various

serial interfaces on SPORT1.

REV. B

–17–

Page 18

ADMC401

O

0

O

0

0x0000

0x07FF

0x0800

0x0FFF

0x1000

0x3FFF

2K INTERNAL RAM

(BOOTED FROM

BYTE-WIDE EPROM)

2K INTERNAL ROM

(ROMENABLE = 1)

OR

2K EXTERNAL

(ROMENABLE = 0)

12K EXTERNAL

MEMORY

MMAP = 0

BM

DE =

0x0000

0x07FF

0x0800

0x0FFF

0x1000

0x3800

0x3FFF

2K EXTERNAL

MEMORY

2K INTERNAL ROM

(ROMENABLE = 1)

2K EXTERNAL

(ROMENABLE = 0)

10K EXTERNAL

MEMORY

2K INTERNAL RAM

MMAP = 1

BM

Figure 11. Program Memory Map of ADMC401

When MMAP = 1 and BMODE = 0, the internal program

memory RAM is mapped to the top of the program memory space

(starting at address 0x3800) and no boot loading occurs. Program

execution starts from external program memory at address 0x0000.

Only with ROMENABLE = 1 are the internal ROM monitor

and debugger features of the ADMC401 available for program

development. Additionally, certain spaces of the memory map

have predefined functions as illustrated in Figure 12 where it

can be seen that address space 0x0000 to 0x005F is reserved for

the interrupt vector table.

0x000

VECTOR TABLE

0x05F

0x060

0x7FF

0x800

0xFEF

0xFF0

0xFFF

0x1000

USER

PROGRAM

SPACE

ROM

MONITOR

RESERVED

EXTERNAL

MEMORY

Figure 12. Detailed View of Program Memory Map with

MMAP = BMODE = 1

The program memory interface can generate 0 to 7 wait states

for external memory devices. The program memory wait state

field (PWAIT) in the System Control Register controls the number

of inserted wait states and defaults to 7. The structure of the

System Control Register is shown at the end of the data sheet.

The data memory map of the ADMC401 is shown in Figure 13.

The internal data memory RAM of the ADMC401 is arranged

as a single 1K × 16-bit block starting at address 0x3800. In

addition, there are two 1K blocks of reserved data memory

space; one block starting at address 0x2000 that is reserved for

the peripheral registers and one starting at address 0x3C00 that

is reserved for internal DSP core registers. Data memory wait

states are controlled by the DWAIT0, DWAIT1, DWAIT2,

0x0000

2K INTERNAL RAM

(BOOTED VIA

SPORT1)

2K INTERNAL ROM

(ROMENABLE

DEFAULTS TO 1

DURING RESET)

12K EXTERNAL

MEMORY

MMAP = 1

BMODE = 1

OR

DE =

0x07FF

0x0800

0x0FFF

0x1000

0x3FFF

DWAIT3 and DWAIT4 fields of the Data Memory Wait State

Register (MEMWAIT) as illustrated in Figure 13. Following

reset, DWAIT0 = DWAIT1 = DWAIT2 = DWAIT 3 =

DWAIT4 = 7. However, in standalone mode with MMAP =

BMODE = 1, the internal monitor code writes 0 to these five

fields. For correct operation DWAIT2 must always be 0. The

configuration of the MEMWAIT register is shown at the end of

the data sheet.

0x0000

0x1FFF

0x2000

0x23FF

0x2400

0x37FF

0x3800

0x3B5F

0x3B60

0x3BFF

0x3C00

0x3FFF

8K EXTERNAL

MEMORY

PERIPHERAL

REGISTERS

5K EXTERNAL

MEMORY

INTERNAL USER

RAM

RESERVED BY

MONITOR

DSP CORE

REGISTERS/

RESERVED

0x0000

0x03FF

0x0400

0x07FF

0x0800

0x2FFF

0x3000

0x3400

0x3800

0x3FFF

DWAIT0

DWAIT1

DWAIT2

DWAIT3

DWAIT4

NO WAIT

STATES

Figure 13. Data Memory Map of the ADMC401

ROM Code

The 2K × 24-bit block of internal program memory ROM starting at address 0x800 contains a monitor function that can be

used to download and execute user programs via the serial port.

In addition, the monitor function supports an interactive mode

in which commands are received and processed from a host that

is configured as a UART device. An example of such a host is

the Windows-based Motion Control Debugger that is part of

the software development system for the ADMC401. In the

interactive mode, the host can access both the internal DSP and

peripheral motor control registers of the ADMC401, read and

write to both program and data memory, implement breakpoints and perform single-step operation as part of the program

debugging cycle. Again, this debugging feature is only available

when ROMENABLE = 1.

–18–

REV. B

Page 19

ADMC401

SYSTEM INTERFACE

CLOCK SIGNALS

The ADMC401 uses an input clock with a frequency equal to

half the instruction rate; a 13 MHz input clock yields a 38.5 ns

processor cycle (which is equivalent to 26 MHz). Normally

instructions are executed in a single processor cycle. All device

timing is relative to the internal instruction rate, which is indicated by the CLKOUT signal (when enabled). Throughout this

data sheet, the period of the CLKIN signal is denoted by t

The DSP instruction period is t

signal), and t

= 0.5 × t

CK

CKI

CLKIN signal is used, corresponding to t

(the period of the CLKOUT

CK

. For 26 MIPS operation, a 13 MHz

= 76.9 ns and t

CKI

CKI

.

CK

= 38.5 ns. Additionally, tCK is the fundamental time increment

of the motor control peripherals. Therefore, unless otherwise

specified, the motor control peripherals are clocked at a rate

equal to CLKOUT. The ADMC401 can be clocked by either a

crystal or by an external clock source. The CLKIN input cannot

be halted, changed in frequency, or operated below the specified

minimum frequency during normal operation.

If an external clock source is used, it should be a TTL-compatible

signal running at half the instruction rate. The signal is connected to the CLKIN pin of the ADMC401. In this mode, with

an external clock signal, the XTAL pin must be left unconnected.

Because the ADMC401 includes an on-chip oscillator circuit,

an external crystal may be used instead of a clock source. The

crystal should be connected across the CLKIN and XTAL pins.

A parallel-resonant, fundamental frequency, microprocessorgrade crystal should be used. The frequency value selected for

the crystal should be equal to half the desired instruction rate

for the processor. Figure 15 shows a 13 MHz crystal properly

connected to yield a 26 MHz processor rate.

The CLKOUT output can be enabled and disabled by the

CLKODIS bit of the SPORT0 Autobuffer Control Register,

DM (0x3FF3). However, extreme care must be exercised when

using this bit (and is thus discouraged) since disabling CLKOUT

effectively disables all motor control peripherals, except the

watchdog timer.

RESET AND POWER-ON RESET CIRCUIT

The RESET pin initiates a complete hardware reset of the

ADMC401 when pulled low. The RESET signal must be asserted

when the device is powered up to assure proper initialization.

The ADMC401 contains an integrated power-on reset circuit

that provides an output reset signal, POR, from the ADMC401

on power up and if the power supply voltage falls below the

threshold level. The ADMC401 may be reset from an external

source using the RESET signal or alternatively the internal

power-on reset circuit may be used by connecting the POR pin

to the RESET pin. During power-up the RESET line must be

activated for long enough to allow the DSP core’s internal clock

to stabilize. The power-up sequence is defined as the total time

required for the crystal oscillator to stabilize after a valid V

DD

is

applied to the processor and for the internal phase locked loop

(PLL) to lock onto the specific crystal frequency. A minimum of

2000t

cycles will ensure that the PLL has locked (this does not

CKI

include the crystal oscillator start-up time).

The operation of the internal power-on reset circuit is illustrated

in Figure 14. On power-up, the circuit maintains the POR pin

low until it detects that the V

line has attained the threshold

DD

voltage, V

level. As soon as the threshold voltage is attained,

RST

the power on reset circuit enables a 17-bit counter that is

clocked at the CLKOUT rate. While the counter is counting the

POR pin is held low. When the counter overflows, after a time:

tms

RST

16 9

=× × =2 38 5 10 2 52

–

..

the POR pin is brought high and if the POR and RESET pins

are connected, the device is brought out of reset.

The internal power-on reset circuit also acts as a power supply

monitor and puts the POR pin at a LO level if it detects a voltage less than V

RST–VHYST

, where V

is the hysteresis voltage

HYST

built into the POR circuit. The supply voltage must then exceed

to initiate another power-on reset sequence.

V

RST

V

VDD

POR

V

RST

t

RST

RST

- V

HYST

t

RST

Figure 14. Operation of Power-On Reset (POR) Circuit of

ADMC401

The master reset (RESET = LO) causes a Full System Reset,

which sets all internal stack pointers to the empty stack condition, masks all interrupts, clears the MSTAT register, restores

the program counter to its initial value and performs a full reset

of all of the motor control peripherals including the watchdog

timer. Following a power-up, it is possible to initiate a Full

System Reset by simply pulling the RESET low. For these

resets, there is no need to wait for PLL stabilization and the

RESET signal must meet the minimum pulsewidth specification, t

. To generate the external RESET signal, it is recom-

RSP

mended to use either an RC circuit with a Schmitt trigger or a

commercially available reset IC.

Separate from a Full System Reset, a software controlled Peripheral Reset (excluding the watchdog timer) is achieved by toggling

the DSP FL2 flag with the following code segment:

PRESET: SET FL2;

TOGGLE FL2;

TOGGLE FL2;

RTS;

A full DSP and peripheral reset (except the watchdog timer

itself) will occur automatically on a watchdog trip.

EXTERNAL MEMORY INTERFACE

The ADMC401 can address 14K × 24 bits of external program

memory and up to 13K × 16 bits of external data memory. The

ADMC401 provides the address on a 14-bit address bus

(A13–A0). Instructions or data are transferred across the 24-bit

data bus (D23–D0) during program memory accesses. During

data memory accesses, data is transferred on the 16 most significant bits (D23–D8) of the data bus. For a dual off-chip fetch,

the data from program memory is read first, then the data from

data memory. The program memory select pin, PMS, is activated during external program memory accesses and can be

used as a chip select signal for the external program memory

devices. Similarly, for external data memory accesses, the DMS

pin is activated.

REV. B

–19–

Page 20

ADMC401

Two control lines indicate the direction of the transfer. Memory

read, RD, is active low, signaling a read from external memory

and memory write; WR, is active low, signaling a write to external memory. Typically, the PMS line is connected to the CE

(chip enable) of the external program memory and the RD line

is connected to the CE line of the external data memory. The

RD line is connected to the OE (output enable) and the WR

line is connected to the WE (write enable) of both memories.

On-chip accesses (to internal program memory RAM and ROM)

do not drive any of the external signals. The PMS, RD and the

WR lines remain high (deasserted) and the address and data

buses are three-stated during these internal accesses. Similarly,

internal accesses to data memory (including internal DM RAM

and peripheral and DSP core memory mapped registers) do not

drive external signals and the DMS, RD and the WR lines remain high (deasserted) and the address and data buses are also

three-stated.

External peripherals can also be connected externally and memory

mapped to the external memory space of the ADMC401. The

16 MSBs of the external data bus are connected internally to the

16 bits of the internal data memory bus. Therefore, the data

lines D23–D8 should be used for 16-bit peripherals.

BOOT LOADING

Standalone Mode (MMAP = BMODE = 1)

Boot loading of the ADMC401 may occur in a number of different ways and is determined by the state of both the MMAP and

BMODE pins. If both MMAP and BMODE are tied to V

(HI), the ADMC401 is placed in the so-called standalone mode

and execution starts from internal program memory ROM at

address 0x0800 following a power-on or reset. This starts execution of the internal monitor function that first performs some

initialization functions (including writing 0 to the three data

memory wait state fields) and copies a default interrupt vector

table to addresses 0x0000–0x005F of program memory RAM.

The monitor program next clears Bit 4 of the MODECTRL

register to connect the DR1A pin to the internal data receive

port (DR1) of SPORT1. In addition, Bit 5 of the MODECTRL

register is set. This connects the FL1 port of the DSP core to

the RFS1/SROM pin to act as a reset for a serial memory device.

The monitor next attempts to boot load from an external Serial

ROM (SROM) or Serial E

wire connection of Figure 15. This SROM or E

2

PROM on SPORT1 using the three

2

PROM should be

programmed with the protocol of the MAKEPROM utility

provided with the Motion Control Debugger. The monitor

program first toggles the RFS1/SROM pin of the ADMC401 to

reset the serial memory device with the following code segment:

SROMRESET: SET FL1;

TOGGLE FL1;

TOGGLE FL1;

RTS;

If a properly programmed SROM or E

2

PROM is connected to

SPORT1, data is clocked synchronously into the ADMC401 at

a rate of 1 Mb/s. Both internal and external program and data

memory RAM can be loaded from the SROM/E

2

PROM, up to

the available capacity of the serial memory device. After the

entire boot load is complete, program execution begins at address 0x0060. This is where the first instruction of the user code

should be placed.

DD

ADMC401

CLKOUT

V

DD

MMAP

BMODE

RESET

XTAL

13MHz

CLKIN

DR1A

SCLK1

RFS1/ SROM

DATA

CLK

RESET

20pF

20pF

SERIAL ROM

2

E

OR

PROM

Figure 15. Basic System Configuration in Standalone

Mode

If boot loading from an SROM or E2PROM is unsuccessful, the

monitor code reconfigures SPORT1 as a UART (setting both

Bit 4 and Bit 5 of the MODECTRL register) and attempts to

receive commands from an external device on this serial port

using the DR1B pin. The monitor now waits for two bytes of

information. These bytes are received asynchronously so that no

clock is needed. The first byte is the autobaud byte and it is

used to calculate the baud rate at which data is being received.

This is known as the autobaud feature. The ADMC401 will

automatically lock onto the baud rate of the external device if

it is sent a byte of 0x70. The maximum baud rate that the

ADMC401 will lock onto is 300 kb/s for a 26 MHz CLKOUT.

The second byte of information received is the header byte that

uniquely identifies to the monitor which type of interface it is

connected to. There are six different interfaces supported on the

ADMC401. These includes:

• A UART boot loader such as from a Motorola 68HC11

communicating over its Serial Communications Interface

(SCI) port.

• A synchronous slave boot loader (the clock is external).

• A synchronous master boot loader (the ADMC401 provides

the clock).

• A UART debugger interface such as the Motion Control

Debugger from Analog Devices. The monitor then processes

commands received from the debugger over the UART

interface.

• A synchronous master debugger interface.

• A synchronous slave debugger interface.

Detailed information on these software interfaces can be

found in the “UART Boot Loader Protocol” and “UART

Debugger Protocol” appendices of the ADMC401 Developer’s

Reference Manual.

Byte-Wide EPROM Boot Mode (MMAP = BMODE = 0)

If both the MMAP and BMODE pins are tied to GND, the

ADMC401 operates in the so-called EPROM Boot mode. In this

mode the entire internal program memory, or any portion of it,

can be loaded from an external source using a boot sequence

over the memory interface. To allow boot loading from inexpensive 8-bit wide EPROM devices, the processor loads data one

byte at a time. The boot sequence can also be initiated after

reset by software.

Boot memory is organized into eight pages, each of which is 8k

bytes long. Every fourth byte of a page is an empty byte except

for the first one, which contains the page length. Each set of

three bytes between successive empty bytes contains one 24-bit

instruction to be loaded into the internal PM RAM of the DSP.

–20–

REV. B

Page 21

ADMC401

The page length is read first and then bytes are loaded from the

top of the page downwards. This causes shorter booting times

for shorter pages. The length of the boot page is given as:

page length = (number of 24-bit PM words/8) – 1

That is, a page length of 0 causes the boot address generator to

generate byte addresses for eight words that reside in 32 sequential EPROM locations.

A PROM splitter utility (SPL21), part of the Motion Control

Debugger tool set, calculates the proper page length for your

program and orders the bytes of your program according to the

proper protocol. More detailed information about the use of

this PROM splitter utility can be found in the “Booting from

External EPROM with MMAP = BMODE = 0” chapter of the

ADMC401’s Developer’s Reference Manual.

Following a reset, if both MMAP and BMODE are LO, the

boot sequence always boot loads page 0. After reset, boot loading can occur under program control from any one of up to

eight different boot pages. The boot page select field (BPAGE)

in the memory mapped System Control Register specifies which

boot page is to be loaded. To boot from a specific boot page,

first set the BPAGE bits to the desired value and set the boot

force bit (BFORCE) of the System Control Register to initiate a

boot sequence.

The ADMC401 can boot its internal program memory from a

single byte-wide CMOS EPROM such as the 27C64 or the

27C512. A low cost commodity-grade EPROM with an industry-standard access time can be used. The number of wait states

for the boot memory access is selected in the BWAIT field of

the System Control Register. This field can be set to any value

from 0 to 7 to set the number of wait states. The default value

for the BWAIT field is 7 so that seven wait states are inserted

into the reset-initiated boot loading sequence.

Timing of the boot memory access is identical to that of external

program memory or external data memory accesses, except that

the active strobe is BMS rather than PMS or DMS. To address

eight pages of 8K bytes each, 16 address lines are needed. The

least significant 14 bits are output on the 14-bit address bus

(A13 to A0) while the most significant two bits are output on

the 2 MSBs of the data bus (D23 and D22) during boot memory

accesses. The data is read from the middle eight bits of the data

bus (D15 to D8).

The development tools for the ADMC401 support the creation

of EPROM target files capable of boot loading both internal and

external program and data memory.

External Memory Mode (BMODE = 0, MMAP = 1)

In this mode, with BMODE tied to GND and MMAP tied to

V

, the ADMC401 is placed in external memory mode and

DD

there is no boot loading. The effect of this mode is that the

internal 2K bank of program memory RAM is relocated from

the bottom of memory (starting at address 0x0000) to the top of

the program memory space (at address 0x3800). In this mode,

program execution starts at external memory address 0x0000, at

which point the first instruction must be placed.

The mode in which BMODE = 1 and MMAP = 0 is not allowed

on the ADMC401 and is an illegal state. The operation of the

ADMC401 is neither guaranteed nor defined with BMODE = 1

and MMAP = 0.

BUS REQUEST/GRANT

The ADMC401 can relinquish control of the external data and

address buses to an external device. The external device requests

the bus by asserting (low) the bus request signal BR. BR is an

asynchronous input and if the ADMC401 is not performing an

external access, it responds to the active BR input in the following processor cycle by:

• Three-stating the data and address buses and the PMS,

DMS, BMS, RD and WR output drivers.

• Asserting the bus grant (BG) signal, and

• Halting program execution (unless Go Mode is enabled).

If Go Mode is enabled, (using the ENA G-MODE instruction)

the ADMC401 continues to execute instructions from its internal memory. It will not halt program execution until it encounters an instruction that requires an external access, which includes

an access to any motor control peripheral register. If Go Mode

is not enabled, the ADMC401 always halts before granting the

bus. The processor’s internal state is not affected by granting

the bus, and the serial ports remain active during a bus grant,

whether or not the processor core halts.

If the ADMC401 is performing an external access when the BR

signal is asserted, it will not grant the buses until the cycle after

the access completes. The entire instruction does not need to be

completed when the bus is granted. If a single instruction requires two external accesses, the bus will be granted between the

two accesses. The second access is performed after BR is removed. When the BR input is released, the ADMC401 releases

the BG signal, re-enables the output drivers and continues program execution from the point where it stopped. BG is always

deasserted in the same cycle that the removal of BR is recognized.

The bus request feature operates at all times, including when

the ADMC401 is booting and when RESET is active. During

RESET, BG is asserted in the same cycle that BR is recognized.

During booting, the bus is granted after the completion of loading of the current byte (including any wait states). Using the bus

request during booting is one way to bring the booting operation

under control of a host computer.

The ADMC401 has an additional output, Bus Grant Hang,

BGH, which lets it operate in a multiprocessor system with a

minimum number of wasted cycles. The BGH pin asserts when

the ADMC401 is ready to execute an instruction but is stopped

because the external bus is granted to another device. The other

device can release the bus by deasserting bus request. Once the

bus is released, the ADMC401 deasserts BG and BGH and

executes the external access.

POWER-DOWN MODES

The ADMC401 includes a power-down feature that allows the

device to enter a very low power dormant state through hardware or software control. In the power-down mode:

• Internal clocks are disabled

• Processor registers and memory contents are maintained

• Ability to recover from power-down in less than 100t

cycles

• Interrupt support for housekeeping code before entering

power-down and after recovering from power-down

• User-selectable power-up context

CKI

REV. B

–21–

Page 22

ADMC401

Entering Power-Down

The power-down sequence is initiated by applying a high-to-low

transition on the PWD pin or by setting the power-down force

control bit (PDFORCE) of the SPORT1 autobuffer/powerdown control register. The DSP core then vectors to the nonmaskable power-down interrupt vector at address 0x002C. Care

must be taken to ensure that multiple power-down interrupts do

not occur or else stack overflow may result. The interrupt service routine at address 0x002C can be used to execute any number of housekeeping instructions prior to the processor entering

the power-down mode. Typically, this is used to configure the

power-down state, disable on-chip peripherals and clear pending

interrupts. The DSP subsequently enters the power-down mode

when it executes the IDLE instruction (while PWD is asserted).

The processor may take either one or two cycles to power down,

depending on internal clock states during execution of the IDLE

instruction. All register and memory contents are maintained in

power-down. Also, all active outputs are held in whatever state

they are in before going into power-down. If an RTI instruction

is executed before the IDLE instruction, the processor returns

from the power-down interrupt and the power-down sequence is

aborted.

Exiting Power-Down

The power-down mode can be exited with the use of the PWD

pin or with the RESET pin. There are also several user-selectable modes for startup from power-down which specify a startup delay as well as specify the program flow after startup. This

allows the program to resume from where it left off before

power-down, or for the program context to be cleared. Applying

a low-to-high transition on the PWD pin will take the processor

out of power-down. The amount of time it takes for the processor to come out of power-down is controllable with the delay

startup from power-down control bit (XTALDELAY, Bit 14 of

the Power-Down Control Register or SPORT1 Autobuffer

Control Register). If this bit is cleared, no additional delay over

the quick startup (100 cycles) is introduced. If this bit is set, a

delay of 4096 cycles is introduced.

The context for exiting power-down is set by Bit 12 (PUCR) of

the Power-Down Control Register. If this bit is cleared, after

exiting power-down the processor will continue to execute instructions following the IDLE instruction after the low-to-high

transition on the PWD pin. When the RTI instruction is encountered in the interrupt service routine for the power-down,

operation is returned to the main routine. If the PUCR bit is

set, for a “clear context”, the processor resumes operation from

power-down by clearing the PC, STATUS, LOOP and CNTR

registers. The IMASK and ASTAT registers are cleared and the

SSTAT goes to 0x55. The processor starts execution at address

0x0000.

Active output pins retain their states during power-down. In

addition, interrupts are latched and can be serviced if the

ADMC401 exits power-down with PUCR = 0. It is possible to

clock data into or out of the serial ports during power-down

by supplying an external serial clock. Data clocked into the

ADMC401 will remain in the RX registers. These activities