Page 1

a

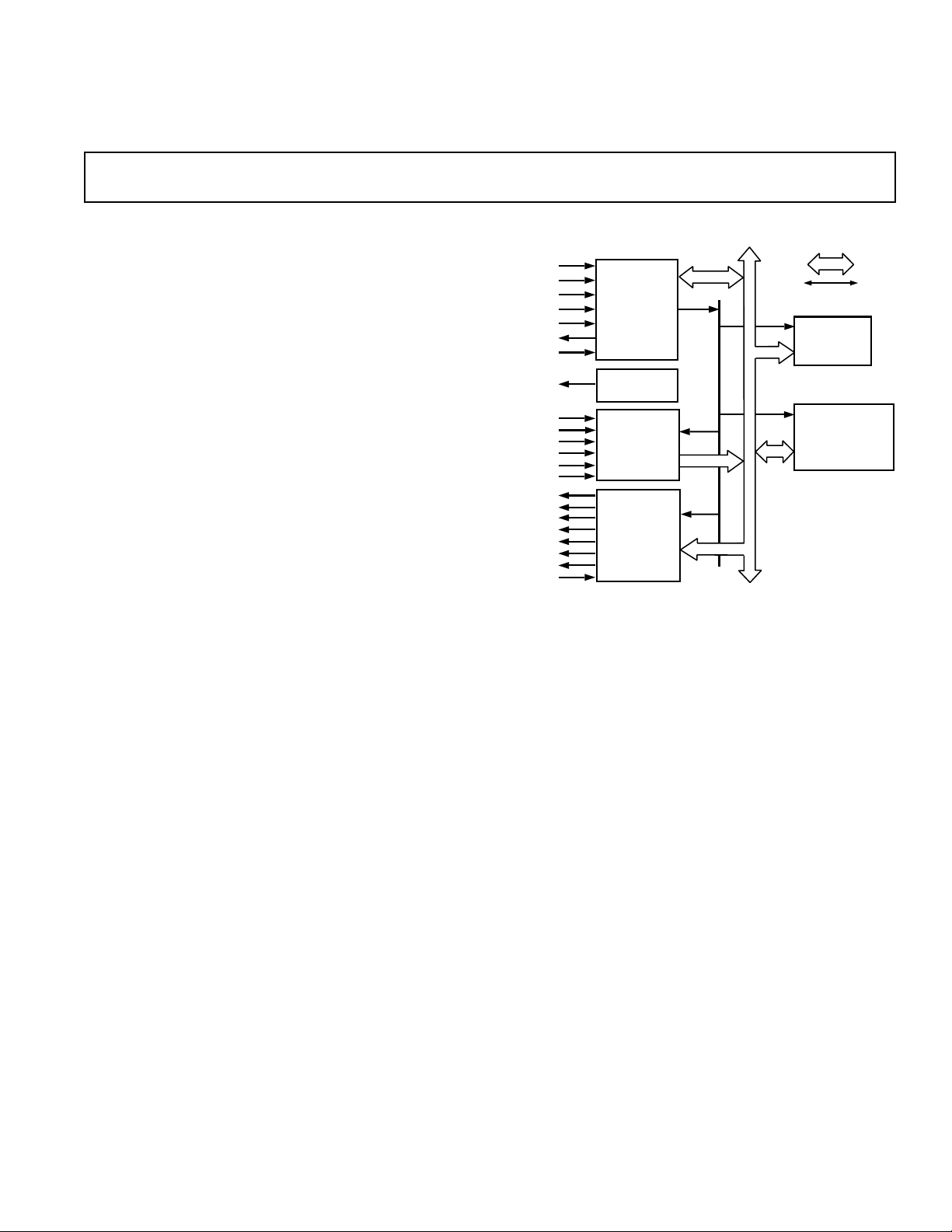

Motion Coprocessor

ADMC200

FEATURES

Analog Input Block

11-Bit Resolution Analog-to-Digital (A/D) Converter

4 Single-Ended Simultaneously Sampled Analog Inputs

3.2 s Conversion Time/Channel

0 V–5 V Analog Input Range

Internal 2.5 V Reference

PWM Synchronized Sampling Capability

12-Bit PWM Timer Block

Three-Phase Center-Based PWM

1.5 kHz–25 kHz PWM Switching Frequency Range

Programmable Deadtime

Programmable Pulse Deletion

PWM Synchronized Output

External PWM Shutdown

Vector Transformation Block

12-Bit Vector Transformations

Forward and Reverse Clarke Transformations

Forward and Reverse Park Rotations

2.9 s Transformation Time

DSP & Microcontroller Interface

12-Bit Memory Mapped Registers

Twos Complement Data Format

6.25 MHz to 25 MHz Operating Clock Range

68-Lead PLCC Package

Single 5 V DC Power Supply

Industrial Temperature Range

GENERAL DESCRIPTION

The ADMC200 is a motion coprocessor that can be used with

either microcontrollers or digital signal processors (DSP). It

provides the functionality that is required to implement a digital

control system. In a typical application, the DSP or microcontroller performs the control algorithms (position, speed,

torque and flux loops) and the ADMC200 provides the necessary motor control functions: analog current data acquisition,

vector transformation, and PWM drive signals.

PRODUCT HIGHLIGHTS

Simultaneous Sampling of Four Inputs

A four channel sample and hold amplifier allows three-phase

motor currents to be sampled simultaneously, reducing errors

from phase coherency. Sample and hold acquisition time is

1.6 µs and conversion time per channel is 3.2 µs (using a 12.5 MHz

system clock).

FUNCTIONAL BLOCK DIAGRAM

DATABUS

RESET

WR

A0–3

RD

CS

IRQ

CLK

REFOUT

REFIN

CONVST

AUX

PWMSYNC

AP

BP

CP

STOP

EMBEDDED

CONTROL

SEQUENCER

INTERNAL

REFERENCE

U

V

W

A

B

C

11-BIT

A/D

CONVERTER

12-BIT

PWM TIMER

BLOCK

D0 – D11

CONTROL BUS

CONTROL

REGISTERS

VECTOR

TRANSFORMATION

BLOCK

Flexible Analog Channel Sequencing

The ADMC200 support acquisition of 2, 3, or 4 channels per

group. Converted channel results are stored in registers and the

data can be read in any order. The sampling and conversion

time for two channels is 8 µs, three channels is 11.2 µs, and four

channels is 14.4 µs (using a 12.5 MHz system clock).

Embedded Control Sequencer

The embedded control sequencer off-loads the DSP or microprocessor, reducing the instructions required to read analog input channels, control PWM timers and perform vector transformations. This frees the host processor for performing control

algorithms.

Fast DSP/Microprocessor Interface

The high speed digital interface allows direct connection to

16-bit digital signal processors and microprocessors. The

ADMC200 has 12 bit memory mapped registers with twos

complement data format and can be mapped directly into the

data memory map of a DSP. This allows for a single instruction

read and write interface.

Integration

The ADMC200 integrates a four channel simultaneous sampling analog-to-digital converter, analog reference, vector transformation, and three-phase PWM timers into a 68-lead PLCC.

Integration reduces cost, board space, power consumption, and

design and test time.

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2000

Page 2

(VDD = +5 V 5%; AGND = DGND = 0 V; REFIN = 2.5 V; External Clock =

ADMC200–SPECIFICATIONS

Parameter ADMC200AP Units Conditions/Comments

ANALOG-TO-DIGITAL CONVERTER

Resolution 11 Bits Twos Complement Data Format

Relative Accuracy ± 2 LSB max Integral Nonlinearity

Differential Nonlinearity ±2 LSB max

Bias Offset Error ± 5 LSB max Any Channel

Bias Offset Match 4 LSB max Between Channels

Full-Scale Error ± 6 LSB max Any Channel

Full-Scale Error Match 4 LSB max Between Channels

Conversion Time/Channel 40 System CLK Cycles

Signal-to-Noise Ratio (SNR)

2

Channel-to-Channel Isolation Sine Wave Applied to Unselected Channels

Two-/Three-Phase Mode –58 dB max

Three-/Three-Phase Mode –55 dB max

ANALOG INPUTS

Input Voltage Level 0–5 Volts

Analog Input Current 100 µA max

Input Capacitance 10 pF typ

TRACK AND HOLD

Aperture Delay 200 ns max Any Channel

Aperture Time Delay Match 20 ns max Between Channels

SHA Acquisition Time 20 System CLK Cycles

Droop Rate 5 mV/ms max

REFERENCE INPUT

Voltage Level 2.5 V dc

Reference Input Current 50 µA max

REFERENCE OUTPUT

Voltage Level 2.5 Volts

Voltage Level Tolerance ± 5 % max Full Load

Drive Capability ± 200 µA max

LOGIC

V

IL

V

IH

V

OL

V

OH

Input Leakage Current 1 µA max

Three-State Leakage Current 1 µA max

Input Capacitance 20 pF typ

PWM TIMERS

Resolution 12 Bits

Programmable Deadtime Range 0–10.08 µs

Programmable Deadtime Increments 2 System CLK Cycles 160 ns

Programmable Pulse Deletion Range 0–10.16 µs

Programmable Deletion Increments 1 System CLK Cycle 80 ns

Minimum PWM Frequency 1.5 kHz Resolution Varies with PWM Switching Frequency

VECTOR TRANSFORMATION Park & Clarke Transformation

Radius Error 0.7 % max

Angular Error 30 arc min max

Reverse Transformation Time 37 System CLK Cycles

Forward Transformation Time 40 System CLK Cycles

EXTERNAL CLOCK INPUT

Range 6.25–25 MHz If > 12.5 MHz, Then It Is Necessary to Divide Down

INTERNAL SYSTEM CLOCK

Range 6.25–12.5 MHz

POWER SUPPLY CURRENT

I

DD

NOTES

1

Measurements made with external reference.

2

Tested with PWM Switching Frequency of 25 kHz.

Specifications subject to change without notice.

1

60 dB min fIN = 600 Hz Sine Wave, f

0.8 V max

2.0 V min

0.4 V max I

4.5 V min I

20 mA max

12.5 MHz; TA = –40C to +85C unless otherwise noted)

SAMPLE

= 400 µA, VDD = 5 V

SINK

= 20 µA, VDD = 5 V

SOURCE

(10 MHz Clock: 20 kHz = 9 Bits, 10 kHz = 10 Bits,

5 kHz = 11 Bits, 2.5 kHz = 12 Bits). Higher Frequencies are Available with Lower Resolution

via SYSCTRL Register

= 55 kHz, 600 Hz

–2–

REV. B

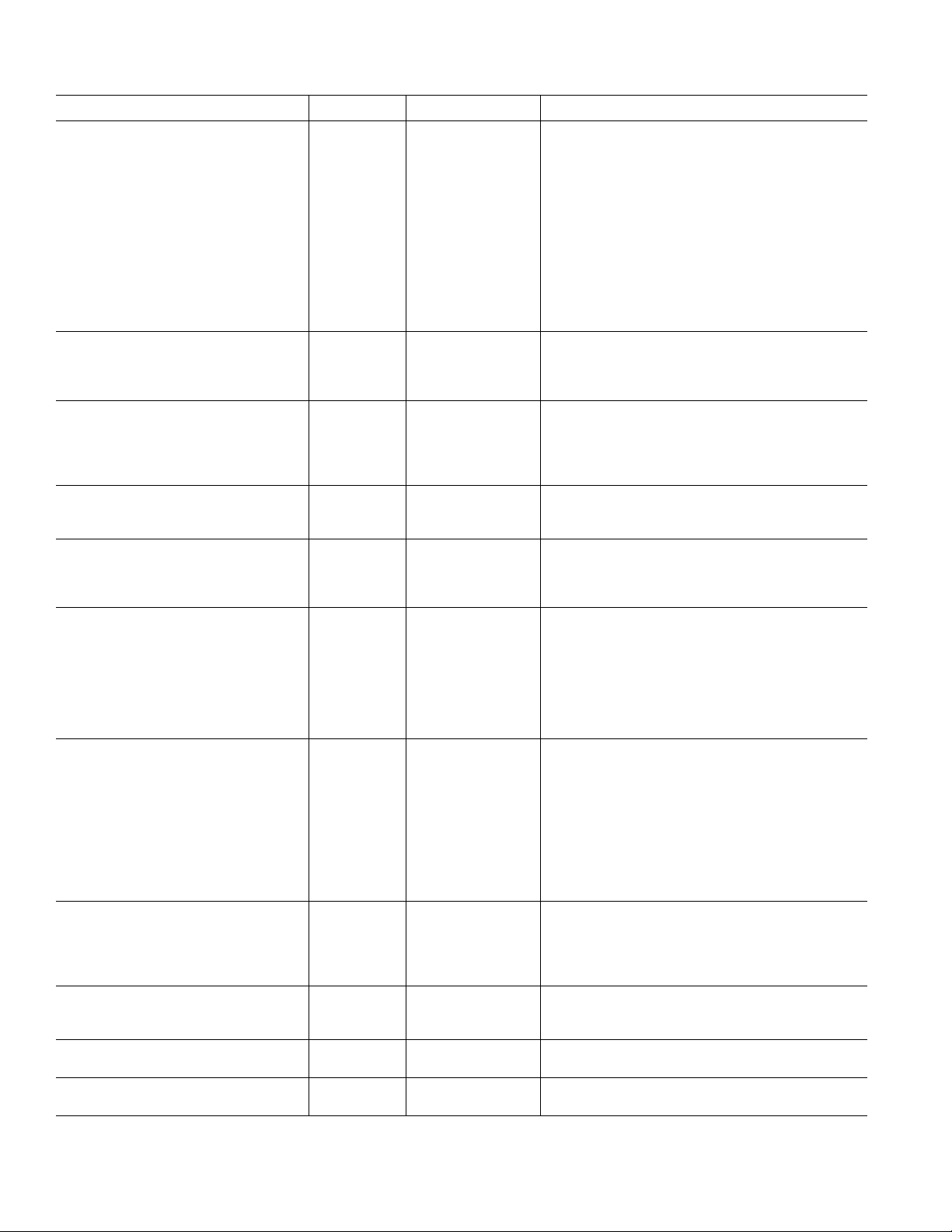

Page 3

ADMC200

Table I. Timing Specifications (VDD = 5 V 5%; TA = –4

0C to +85C)

Number Symbol Timing Requirements Min Max Units

1t

2t

3t

4t

5t

6t

7t

8t

9t

10 t

11 t

12 t

13 t

14 t

15 t

9

16 t

17 t

18 t

19 t

20 t

21 t

22 t

23 t

24 t

NOTE

1

All WRITES to the ADMC200 must occur within 1 system clock cycle (0 wait states).

clk CLK Period 40 160 ns

per

clk CLK Pulsewidth, High 20 ns

pwh

clk CLK Pulsewidth, Low 20 ns

pwl

csb_wrb CS Low before Falling Edge of WR 0ns

su

addr_wrb ADDR Valid before Falling Edge of WR 0ns

su

data_wrb DATA Valid before Rising Edge of WR 13 ns

su

wrb_data DATA Hold after Rising Edge of WR 4.5 ns

hd

wrb_addr ADDR Hold after Rising Edge of WR 4.5 ns

hd

wrb_csb CS Hold after Rising Edge of WR 4.5 ns

hd

1

wrb

pwl

1

wrb

pwh

wrb_clk_h

hd

wrb_clk_h

su

wrb_clk_l

su

clk_wrb_l

hd

csb_rdb CS Low before Falling Edge of RD 0ns

su

addr_rdb ADDR Valid before Falling Edge of RD 0ns

su

rdb_addr ADDR Hold after Rising Edge of RD 0ns

hd

rdb_csb CS Hold after Rising Edge of RD 0ns

hd

rdb RD Pulsewidth, Low 20 ns

pwl

rdb RD Pulsewidth, High 20 ns

pwh

rdb_clk_h RD Low before Rising Edge of CLK 7.5 ns

su

rdb_clk_h RD Low after Rising Edge of CLK 7.5 ns

hd

resetb RESET Pulsewidth, Low 2 × t

pwl

1

1

1

1

WR Pulsewidth, Low 20 ns

WR Pulsewidth, High 20 ns

WR Low after Rising Edge of CLK 7 ns

WR High before Rising Edge of CLK 7 ns

WR High before Falling Edge of CLK 10 ns

WR High after Falling Edge of CLK 10 ns

clk ns

per

Number Symbol Switching Characteristics Min Max Units

25 t

rdb_data DATA Valid after Falling Edge of RD 23 ns

dly

26 thdrdb_data DATA Hold after Rising Edge of RD 0ns

CLK

CLK

RESET

1

2

3

Figure 1. Clock Input Timing

24

Figure 2. Reset Input Timing

CLK

12

CS

A0–A3

WR

DATA

4

NOTE:

ALL WRITES TO THE ADMC200 MUST OCCUR WITHIN

ONE SYSTEM CLOCK CYCLE (i.e. 0 WAIT STATES)

5

13

15

9

8

11

10

6

7

14

Figure 3. Write Cycle Timing Diagram

REV. B

–3–

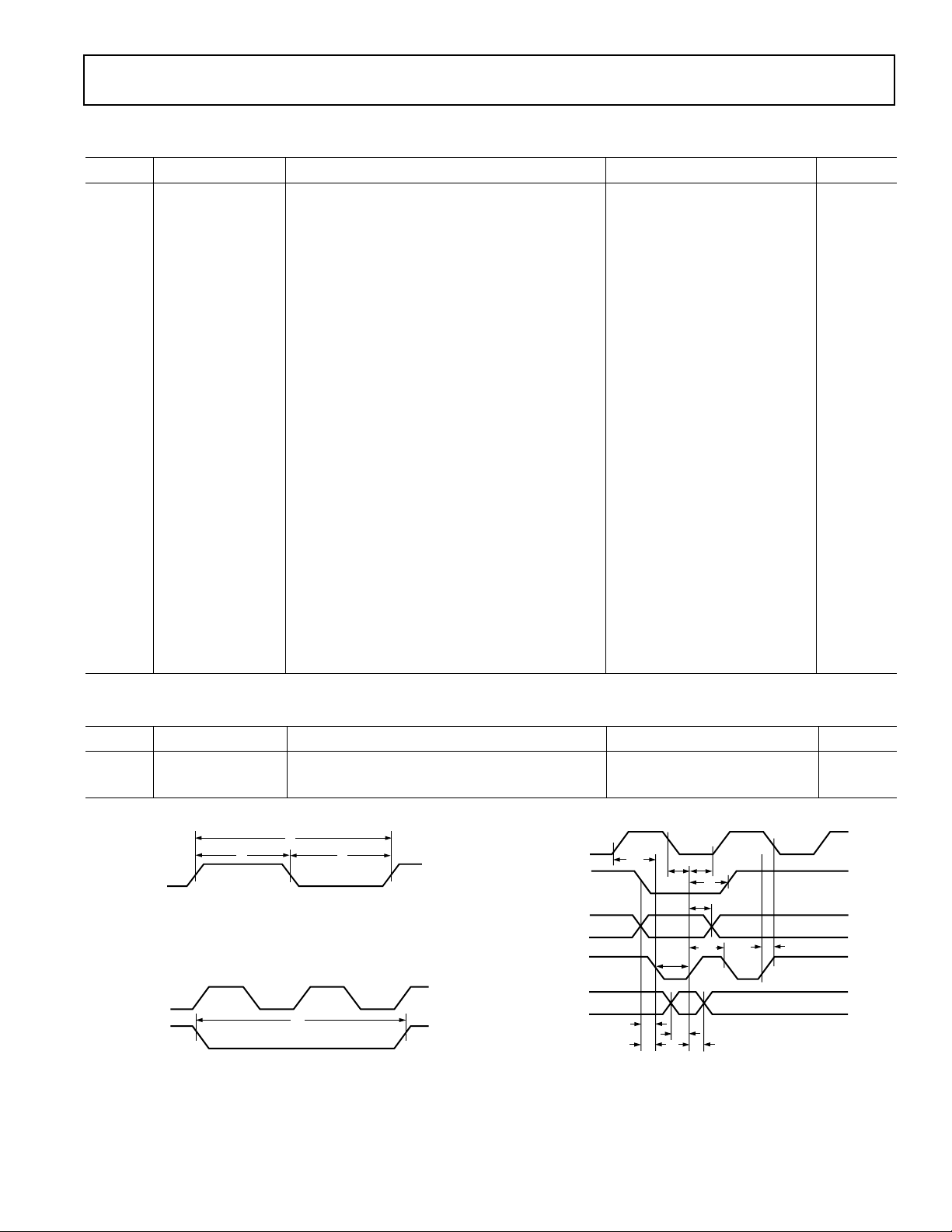

Page 4

ADMC200

CLK

CS

A0–A3

23

22

20

RD

DATA

16

17

25

Figure 4. Read Cycle Timing Diagram

ABSOLUTE MAXIMUM RATINGS*

Supply Voltage (VDD) . . . . . . . . . . . . . . . . . . –0.3 V to +7.0 V

Digital Input Voltage . . . . . . . . . . . . . . . . . . . . . –0.3 V to V

Analog Input Voltage . . . . . . . . . . . . . . . . . . . . . –0.3 V to V

Analog Reference Input Voltage . . . . . . . . . . . . –0.3 V to V

Digital Output Voltage Swing . . . . . . . . . . . . . . –0.3 V to V

Analog Reference Output Swing . . . . . . . . . . . . –0.3 V to V

DD

DD

DD

DD

DD

Operating Temperature . . . . . . . . . . . . . . . . . –40°C to +85°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . +280°C

*Stresses greater than those listed above may cause permanent damage to the

device. These are stress ratings only; functional operation of the device at these or

any other conditions greater than those indicated in the operational sections of this

specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

21

26

18

19

ORDERING GUIDE

Part Temperature Package Package

Number Range Description Option

ADMC200AP –40°C to +85°C 68-Lead PLCC P-68A

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the ADMC200 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

–4–

REV. B

Page 5

PIN DESIGNATIONS

ADMC200

Pin Mnemonic Type Description

1 D9 BIDIR Data Bit 9

2 D10 BIDIR Data Bit 10

3 D11 BIDIR Data Bit 11, MSB

4–9 NC No Connect

10 V

DD

11 A3 I/P Address Bit 3, MSB

12 A2 I/P Address Bit 2

13 A1 I/P Address Bit 1

14 A0 I/P Address Bit 0, LSB

15 NC No Connect

16 RESET I/P Chip Reset

17 CONVST I/P A/D Conversion Start

18 IRQ O/P Interrupt Request (Pull-Up Required)

19 V

DD

20 DGND GND Digital Ground

21 CLK I/P External Clock Input

22 WR I/P Write Select

23 RD I/P Output Enable/Read

24 CS I/P Chip Select

25 NC No Connect

26 V

DD

27 AGND GND Analog Ground

28 AGND GND Analog Ground

29 U I/P Analog Input U

30 V I/P Analog Input V

31 W I/P Analog Input W

32 SGND GND Analog Signal Ground

33 REFIN I/P Analog Reference Input

34–36 NC No Connect

37 AUX I/P Auxiliary Analog Input

38 REFOUT O/P Internal 2.5 V Analog Reference

39 V

DD

40 DGND GND Digital Ground

SUP +5 V Digital Power Supply

SUP +5 V Digital Power Supply

SUP +5 V Analog Power Supply

SUP +5 V Digital Power Supply

Pin Mnemonic Type Description

41 DGND GND Digital Ground

42 DGND GND Digital Ground

43 DGND GND Digital Ground

44 V

DD

SUP +5 V Digital Power Supply

45 NC No Connect

46 DGND GND Digital Ground

47 STOP I/P PWM Timer Output Disable

48 PWMSYNC O/P PWM Synchronization Output

49 CP O/P PWM Timer Output C

Prime

50 C O/P PWM Timer Output C

51 BP O/P PWM Timer Output B

Prime

52 NC No Connect

53 B O/P PWM Timer Output B

54 AP O/P PWM Timer Output A

Prime

55 A O/P PWM Timer Output A

56 DGND GND Digital Ground

57 DGND GND Digital Ground

58 DGND GND Digital Ground

59 V

DD

SUP +5 V Digital Power Supply

60 D0 BIDIR Data Bit 0, LSB

61 D1 BIDIR Data Bit 1

62 D2 BIDIR Data Bit 2

63 D3 BIDIR Data Bit 3

64 D4 BIDIR Data Bit 4

65 D5 BIDIR Data Bit 5

66 D6 BIDIR Data Bit 6

67 D7 BIDIR Data Bit 7

68 D8 BIDIR Data Bit 8

Pin Types Pin Types

10

V

DD

11

A3

12

A2

13

A1

14

A0

15

NC

16

RESET

17

CONVST

18

IRQ

19

V

DD

20

DGND

21

CLK

22

WR

23

RD

24

CS

25

NC

26

V

DD

NC = NO CONNECT

PIN CONFIGURATION

NC

NC

NC

NC

9618765 686766656463624321

NC

NC

D11

D10

D9

ADMC200

TOP VIEW

(Not to Scale)

27 4328 29 30 31 32 33 34 35 36 37 38 39 40 41 42

U

V

AGND

W

AGND

SGND

NC

REFIN

NC

D7

D8

PIN 1

IDENTIFIER

NC

AUX

D5

D6

DD

V

REFOUT

D4

DGND

D3

DGND

D2

D1

DGND

DGND

60

D0

59

V

58

DGND

57

DGND

56

DGND

55

A

54

AP

53

B

52

NC

51

BP

50

C

49

CP

48

PWMSYNC

47

STOP

46

DGND

45

NC

44

V

I/P = Input Pin BIDIR = Bidirectional Pin

O/P = Output Pin SUP = Supply Pin

GND = Ground Pin

DD

DD

REV. B

–5–

Page 6

ADMC200

ANALOG INPUT BLOCK

The ADMC200 contains an 11-bit resolution, successive approximation analog-to-digital (A/D) converter with twos complement

output data format. The analog input range is ±2.5 V (0 V–5 V)

with a 2.5 V offset as defined by REFIN. The on-chip 2.5 V ±

5% reference is utilized by connecting the REFOUT pin to the

REFIN pin.

The A/D conversion time is determined by the system clock frequency, which can range from 6.25 MHz to 12.5 MHz. The

Sample and Hold (SHA) acquisition time is 20 system clock

cycles and is independent of the number of channels sampled

and/or digitized. The input stage to the A/D converter is a four

channel SHA which allows the four channels to be held simultaneously and then sequentially digitized. Forty system clock

cycles are required to complete each A/D conversion. The analog channel sampling is flexible and is programmable through

the SYSCTRL register. The minimum number of channels per

conversion is two. The throughput time of the analog acquisition block can be calculated as follows:

tAA= t

SHA

+ (n × t

CONV

)

where

= analog acquisition time,

t

AA

n = # channels,

t

= SHA acquisition time (20 × system clock period),

SHA

= conversion time (40 × system clock period) per channel.

t

CONV

A/D Conversions are initiated via the CONVST pin. A synchronizing pulse (PWMSYNC) is provided at the beginning of

each PWM cycle. This pulse can be used to synchronize the

A/D conversion process to the PWM switching frequency.

Operating the A/D Converter

The A/D converter can be set up to convert a sequence of channels as defined in the SYSCTRL register (see Table V). Always

write 0 to both Bits 0 and 1 of the SYSCTRL register. The default channel select mode after RESET is to convert channels V

and W only. This is two-/three-phase mode. Three-/three-phase

mode converts channels U, V, W and/or AUX. Three-/threephase mode is achieved by writing a 1 to Bit 3 of the SYSCTRL

register. After the conversion process is complete, the channels

can be read in any order.

There are two methods that can be used to indicate when the

A/D conversions are completed and the data is ready: interrupt

driven and software timing.

Interrupt Driven Method

Interrupts can be used to indicate the end of conversion for a

group of channels. Before beginning any A/D conversions, Bit 7

of the SYSCTRL register must be set to 1 to enable A/D conversion interrupts. Then, when an A/D conversion is complete,

an interrupt will be generated. After an interrupt is detected

Bit 0 of the SYSSTAT register must be checked to determine if

the A/D converter was the source. Reading the SYSSTAT register automatically clears the interrupt flag bits.

Software Timing Method

An alternative method is to use the DSP or microcontroller to

keep track of the amount of time elapsed between CONVST

and the expected completion time (n × t

CONV

).

Reading Results

The 11-bit A/D conversion results for channels U, V, W and

AUX are stored in the ADCU, ADCV, ADCW and ADCAUX

registers respectively. The twos complement data is left justified

and the LSB is set to zero. The relationship between input voltage and output coding is shown in Figure 5.

011111111110

000000000000

100000000000

OUTPUT

CODE

0V

FULL-SCALE

TRANSITION

FS = 5V

LSB =

2.5

INPUT VOLTAGE

5V

2048

5V–1LSB

Figure 5. Transfer Function

Sample and Hold

After powering up the ADMC200, bring the RESET pin low for

a minimum of two clock cycles in order to enable A/D conversions. Before initiating the first conversion (CONVST) after a

reset, the SHA time of 20 system clock cycles must occur. A

conversion is initiated by bringing CONVST high for a minimum of one system clock cycle. The SHA goes into hold mode

at the falling edge of clock.

Following completion of the A/D conversion process, a minimum of 20 system clock cycles are required before initiating another conversion in order to allow the sample and hold circuitry

to reacquire the input signals.

If a CONVST is initiated before the 20 clock cycles have

elapsed, the embedded control sequencer will delay conversion

until this requirement is met.

PWM TIMER BLOCK OVERVIEW

The PWM timers have 12-bit resolution and support programmable pulse deletion and deadtime. The ADMC200 generates

three center-based signals A, B, and C based upon user-supplied

duty cycles values. The three signals are then complemented

and adjusted for programmable deadtime to produce the six

outputs. The ADMC200 PWM master switching frequency can

range from 2.5 kHz to 20 kHz, when using a 10 MHz system

clock. The master frequency selection is set as a fraction of the

PWMTM register. If the system clock is 10 MHz, then the

minimum edge resolution available is 100 ns.

The output format of the PWM block is active LO. There is an

external input to the PWM timers (STOP) that will disable all

six outputs within one system clock when the input is HIGH.

The ADMC200 has a PWM Synchronization output

(PWMSYNC) which brings out the master switching frequency

from the PWM timers. The width of the PWMSYNC pulse is

equal to one system clock cycle. For example, if the system clock

is 10 MHz, the PWMSYNC width would be equal to 100 ns.

PWM Master Switching Period Selection

The switching time is set by the PWMTM register which should

be loaded with a value equal to the system clock frequency

divided by the desired master switching frequency. For example, if the desired switching frequency is 8 kHz and the system clock frequency is 10 MHz, then the PWMTM register

should be loaded with 1250 (10 MHz/8 kHz). The PWMCHA,

PWMCHB, and PWMCHC registers are loaded with the

–6–

REV. B

Page 7

ADMC200

I

y

I

x

ρ

I

q

I

d

ROTOR

REFERENCE

FRAME AXIS

90°

desired on-time and their values would be calculated as a ratio

of the PWMTM register value. Note: Desired Pulse Density =

(PWMCHx register)/( PWMTM register).

The beginning of each PWM cycle is marked by the PWMSYNC

signal. New values of PWMCHA, PWMCHB and PWMCHC

must all be loaded into their respective registers at least four system clock cycles before the beginning of a new PWM cycle. All

three registers must be updated for any of them to take effect.

New PWM on/off times are calculated during these four clock

cycles and therefore the PWMCHA, PWMCHB and PWMCHC

registers must be loaded before this time. If this timing requirement is not met, then the PWM outputs may be invalid during

the next PWM cycle.

PWM Example

The following example uses a system clock speed of 10 MHz.

The desired PWM master switching frequency is 8 kHz and the

desired on-time for the timers A, B and C are 25%, 50% and

10% respectively. The values for the PWMCHA, PWMCHB,

and PWMCHC registers must be calculated as ratios of the

PWMTM register (1250 in this example). To achieve these

duty cycles, load the PWMCHA register with 313 (1250 ×

0.25), PWMCHB with 625 (1250 × 0.5) and PWMCHC with

125 (1250 × 0.1).

Programmable Deadtime

With perfectly complemented PWM drive signals and nonideal

switching characteristics of the power devices, both transistors

in a particular leg might be switched on at the same time, resulting in either a power supply trip, inverter trip or device destruction. In order to prevent this, a delay must be introduced

between the complemented signal edges. For example, the rising edge of AP occurs before the falling edge of A, and the falling edge of the complemented A occurs after the rising edge of

A. This capability is known as programmable deadtime.

The ADMC200 programmable deadtime value is loaded into

the 7-bit PWMDT register, in which the LSB is set to zero internally, which means the deadtime value is always divisible by

two. With a 10 MHz system clock, the 0–126 range of values in

PWMDT yield a range of deadtime values from 0 µs to 12.6 µs

in 200 ns steps. Figure 6 shows PWM timer A with a programmable deadtime of PWMDT.

PWMTM

full off (0%) and its prime to full on (100%). This is valid for

A, AP, B, BP, C and CP. This feature would be used in an environment where the inverter’s power transistors have a minimum switching time. If the user-specified duty cycle would

result in a pulse duration shorter than the minimum switching

time of the transistors, then pulse deletion should be used to

prevent this occurrence. With a 10 MHz system clock, the 0–

127 range of values in PWMPD yield a range of deadtime values

from 0 µs to 12.7 µs in 100 ns steps.

External PWM Shutdown

There is an external input pin (STOP) to the PWM timers that

will disable all six outputs when it goes HIGH. When the STOP

pin goes HIGH, the PWM timer outputs will all go HIGH

within one system clock cycle. When the STOP pin goes

LOW, the PWM timer outputs are re-enabled within one system

clock cycle. If external PWM shutdown isn’t required, tie the

STOP pin LOW.

VECTOR TRANSFORMATION BLOCK OVERVIEW

The Vector Transformation Block performs both Park and

Clarke coordinate transformations to control a three-phase

motor (Permanent Magnet Synchronous Motor or Induction

Motor) via independent control of the decoupled rotor torque

and flux currents. The Park and Clarke transformations combine

to convert three-phase stator current signals into two orthogonal

rotor referenced current signals I

and Iq. Id represents the flux

d

or magnetic field current and Iq represents the torque generating current. The I

and Iq current signals are used by the

d

processor’s motor torque control algorithm to calculate the

required direct V

and quadrature Vq voltage components for the

d

motor. The forward Park and Clarke transformations are used

to convert the V

and Vq voltage signals in the rotor reference

d

frame to three phase voltage signals (U, V, W) in the stator

reference frame. These are then scaled by the processor and

written to the ADMC200’s PWM registers in order to drive the

inverter. The figures below illustrate the Clarke and Park Transformations respectively.

I

y

I

x

120°

I

w

I

120°

I

u

120°

v

A

PWMCHA - PWMDT

Three-Phase Equivalent

Stator Currents Two-Phase Currents

Figure 7. Reverse Clarke Transformation

AP

PWMCHA + PWMDT

Figure 6. Programmable Deadtime Example

Pulse Deletion

The pulse deletion feature prevents a pulse from being generated when the user-specified duty cycle results in a pulse duration shorter than the user-specified deletion value. The pulse

deletion value is loaded into the 7-bit register PWMPD. When

the user-specified on-time for a channel would result in a calculated pulsewidth less than the value specified in the PWMPD

register, then the PWM outputs for that channel would be set to

REV. B

–7–

Rotating Stationary

Reference Frame Reference Frame

Figure 8. Reverse Park Transformation

Page 8

ADMC200

3

V

q

V

d

ρ

90°

V

y

V

x

Stationary Rotating

Reference Frame Reference Frame

Figure 9. Forward Park Transformation

V

y

V

x

120°

W

120°

U

V

120°

Equivalent Three-Phase Stator

Two-Phase Voltage Voltage

Figure 10. Forward Clarke Transformation

Operating/Using the Vector Transformation Block

After powering up the ADMC200, RESET must be driven

low for a minimum of two clock cycles to enable vector

transformations.

The vector transformation block can perform either a forward or

reverse transformation.

Reverse Transformation is defined by the following operations:

(a) Clarke: 3-phase current signals to 2-phase current signals

followed by (b) Park: 2-phase current signals cross multiplied by

sin ρ, cos ρ which effectively measures the current components

with respect to the rotor (stationary) where ρ is the electrical

angle of the rotor field with respect to the stator windings.

Forward transformation is defined by the following operations:

(a) Park: 2-phase voltage signals cross multiplied by sin ρ, cos ρ

followed by (b) Clarke: 2-phase to 3-phase voltage signal

conversion.

In order to provide maximum flexibility in the target system, the

ADMC200 operates in an asynchronous manner. This means

that the functional blocks (analog input, reverse transformation,

forward transformation and PWM timers) operate independently of each other. The reverse and forward vector transformation operations cannot occur simultaneously. All vector

transformation registers, except for RHO/RHOP, are twos

complement. RHO/RHOP are unsigned ratios of 360°. For example, 45° would be 45/360 × 2

12

.

Performing a Reverse Transformation

A reverse transformation is initiated by writing to the reverse

rotation angle register RHO and operates on the values in the

PHIP1, PHIP2 and PHIP3 registers. When the reverse transformation is in 2/3 mode, PHIP1 is calculated from PHIP2 and

PHIP3. This is used in systems where only two phase currents

are measured. The reverse transformation 2/3 mode is set by

clearing Bit 10 in the SYSCTRL register and is the default

mode after RESET.

In order to perform a reverse transformation, first write to the

PHIP2 and PHIP3 registers, and to the PHIP1 register if not in

2/3 mode. Then initiate the transformation by writing the reverse rotation angle to the RHO register.

The reverse rotation will be completed in 37 system clock cycles

after the rotation is initiated. If Bit 6 of the system control register is set, then an interrupt will be generated on completion.

When an interrupt occurs, the user must check Bit 1 of the

SYSSTAT register to determine if the vector transformation

block was the source of the interrupt.

During the vector transformation, the vector transformation

registers must not be written to or the vector rotation results

will be invalid.

Reverse Clarke Transformation

The first operation is the Clarke transformation in which the

three phase motor current signals (I

sine and cosine orthogonal signals (I

, Iv, Iw) are converted to

u

and Iy). These signals

x

represent the equivalent currents in a two-phase ac machine and

is the signal format required for the Park rotation. The threephase input signals are of the form:

PHIP1 I

PHIP2 I

PHIP3 I

and the Park rotation requires inputs in the form I

I

sin θ, therefore we need to generate Is sin θ.

s

= Is cosθ

u

= Is cos (θ + 120)

v

= Is cos (θ + 240)

w

cos θ and

s

This is calculated from:

IY I

sin θ =

s

After the reverse transform, registers I

1

(Is cos (θ + 240) – Is cos (θ +120))

and I

contain the 2-

x

y

phase input current information.

In the case where 2 of 3-phase information (PHIP2/3 only) is

provided, then PHIP1 will be derived from the simple fact that

all sum to zero. This value is then placed in the IX register.

IX = I

= Is cos θ = – Is cos (θ + 120) – Is cos (θ + 240)

x

Reverse Park Rotation

IX/IY are then processed together with the digital angle ρ

(RHO) by a Park rotation. If the input signals are I

and Iy,

x

then the rotation can be described by:

ID I

IQ I

= Ix × cos ρ + Iy × sin ρ

d

= –Iy × sin ρ + Iy × cos ρ

q

where ID and IQ are the outputs of the Park rotation.

Cos ρ and sin ρ are required for the Park rotation, and are calculated internally.

Substituting for I

ID I

IQ I

d

q

and Iy in the above yields:

x

= Is cos θ × cos ρ + Is sin θ × sin ρ = Is cos (θ – ρ)

= Is sin θ × cos ρ – Is cos θ × sin ρ = Is sin (θ – ρ)

Performing a Forward Transformation

In order to perform a forward rotation, write values to the VD

and VQ registers and then initiate the transformation by writing

the rotation angle to the register RHOP. The forward transformation will only operate correctly when Bit 10 in the

SYSCTRL register is set (i.e., in 3/3 mode).

The forward rotation will be completed in 40 system clock

cycles after the rotation is initiated. If Bit 6 of the system control register is set, then an interrupt will be generated on

–8–

REV. B

Page 9

ADMC200

completion. When an interrupt occurs, the user must check Bit

1 of the system status register, SYSSTAT, to determine if the

vector transformation block was the source of the interrupt.

During the vector transformation, the transformation registers

must not be written to or the vector rotation results will be invalid.

Forward Park Rotation

If the input signals are represented by Vd and Vq, then the transformation can be described by:

VX V

VY V

where V

= Vd × cos ρ – V

x

= Vd × sin ρ + Vq × cos ρ

y

and Vy are the outputs of the Park Rotation, and are

x

×

sin ρ

q

the inputs to the reverse Clarke transformation.

Forward Clarke Transformation (2 to 3 Phase)

The second operation to be applied to the above results, is the

Forward Clarke Transformation where 2 phase (stator) voltage

signals are converted to 3 phase (stator) voltage signals.

For the inverse Clarke transform we require three phase outputs of the form below:

PHV1 V cos α

PHV2 V cos (α + 120)

PHV3 V cos (α + 240)

We have two quadrature voltages (V cosα and V sinα) available.

PHV2 V cos (α + 120) =

PHV3 V cos (α + 240) =

INTERRUPT GENERATION

1

–

× V cosα –

2

1

–

× V cosα+

2

3

× V sin α

2

3

× V sin α

2

There are two interrupt sources on the ADMC200 that may be

independently enabled to generate interrupts. The first

interrupt source is the Analog Input Block, which, if enabled,

generates an interrupt at the end of conversion. The second interrupt source is the Vector Transformation Block, which,

if enabled, generates an interrupt at the end of a Vector

Transformation.

When a 1 is stored in Bit 7 of the SYSCTRL register, ADC

interrupts are enabled. When a 1 is stored in Bit 6 of the

SYSCTRL register, Vector Transformation interrupts are enabled. Upon a reset of the chip, both bits are set to the default

condition, 0, thus disabling all interrupts.

When an enabled interrupt occurs, Bit 11 of the SYSSTAT

register becomes a 1. If that interrupt had been an ADC interrupt, Bit 0 of SYSSTAT register would also be set to 1. If that

interrupt had been a Vector Transformation interrupt, Bit 1 of

SYSSTAT would be set to 1. Whenever the SYSSTAT register

is read, these three bits go back to their default state, 0, immediately after their values are loaded onto the data bus. Upon a reset, these three bits also go to their default state, 0.

The IRQ pin has an open-drain driver, which will drive it low at

the appropriate times, but the user must supply an external

pull-up resistor to bring the node back high when it is not being

pulled low.

The IRQ pin operates in one of two modes, edge mode or level

mode. In edge mode, when an enabled interrupt occurs, the

IRQ pin will be driven low for one system clock period. In level

mode, when an enable interrupt occurs, the IRQ pin will be

driven low, and will remain low until the SYSSTAT register is

read. The combination of level mode and the open-drain driver

allows multiple interrupt sources in an application to drive a

single interrupt input line on the host DSP or microprocessor.

Edge mode or level mode is determined with Bit 8 of the

SYSCTRL register. Edge mode (0) is the default; a 1 in this bit

will put the IRQ pin into level mode.

The recommended method of using the interrupt generation

capability is to set edge or level mode, enable the appropriate

interrupts, and then monitor the IRQ line. After the IRQ pin

goes low, the SYSSTAT register of the ADMC200 should be

read, (1) to determine if it was this chip that caused the interrupt, if other lines are wired together with this IRQ pin, and (2)

if it was this chip, to determine if it was generated by the Analog

Input Block or the Vector Transformation Block. Once this

is done, the appropriate interrupt handling routine may be

executed.

APPLICATION NOTE LIST

1. AN-407 AC Motor Control Experiments Using the ADMC200

Evaluation Board

2. AN-408 AC Motor Control Using the ADMC200 Motion

Coprocessor

3. AN-409 Advanced Motor Control Techniques Using the

ADMC200 Motion Coprocessor

POWER SUPPLY CONNECTIONS AND SETUP

The nominal positive power supply level (VDD) is +5 V ± 5%.

The positive power supply V

ADMC200 V

pins (10, 19, 26, 39, 44, 59). The SGND pin

DD

should be connected to all

DD

(32) and both AGND pins (27, 28) should be star point connected at a point close to the AGND pins of the ADMC200.

The DGND pins (20, 40, 41, 42, 43, 46, 56, 57, 58) should

also be connected to AGND pins close to the ADMC200.

Power supplies should be decoupled at the power pins using a

0.1 µF capacitor. A 220 nF capacitor must also be connected as

close as possible between REFIN (Pin 33) and SGND (Pin 32).

In addition, the IRQ requires a 15 K pull-up to the V

DSP/CONTROLLER INTERFACE

supply.

DD

The ADMC200 has a 12 bit bidirectional parallel port for interfacing with Analog Devices’ ADSP-2100 DSP family or microcontrollers/microprocessors.

The ADMC200 coprocessor is designed to be conveniently interfaced to ADI’s family of fixed-point DSPs. Figures 11 and 12

show the interfacing between the ADMC200 and the ADSP2101/2105/2115, ADSP-2171, ADSP-2181, TMS320C2x

DSPs. In the case of the TMS320C2x, some glue logic is required to decode the RD/WR lines and invert the CLKOUT1

signal.

The ADSP-2101/2105/2115 CLKOUT frequency equals the

crystal/clock frequency of its CLKIN. This signal (CLKOUT)

can be used to directly drive the CLK line (Pin 21) on the

ADMC200. The ADMC200 coprocessor can be operated with

a clock frequency between the range of 6.25 MHz and 25 MHz.

If the clock frequencies are greater than 12.5 MHz, then it is

necessary to internally divide down the external clock to derive

the ADMC200’s system clock (via SYSCTRL register).

REV. B

–9–

Page 10

ADMC200

ADDRESS BUS

V

DD

CS

IRQ

RD

WR

CLK

A0–A3

ADMC200

D0–D11*

A0–A13

ADSP-2101/

ADSP-2105/

ADSP-2115–20MHz

ADSP-2171–10MHz

ADSP-2181–10MHz

D0–D23

*NOTE:

BY MAPPING THE ADMC200 DATA BUS TO THE TWELVE HIGHEST BITS

OF THE ADSP DATA BUS, FULL-SCALE OUTPUTS FROM THE ADC

CAN BE REPRESENTED BY ± 1.0 IN FIXED POINT ARITHMETIC.

DMS

IRQ2

CLKOUT

RD

WR

ADDRESS

DECODE

EN

DATA BUS

Figure 11. ADI Digital Signal Processor/Microcomputer

ADDRESS BUS

V

DD

CS

IRQ

RD

WR

CLK

A0–A3

ADMC200

D0–D11

A0–A15

TMS320C20

TMS320C25

TMS320C25-50

D0–D15

INTn

STRB

R/W

CLKOUT1

IS

ADDRESS

DECODE

EN

DATA BUS

Figure 12. TI Second-Generation Devices TMS320C20/

C25/C25–50

In the case of the ADSP-2171/2181, the system clock is internally

scaled; a 10 MHz system clock will derive a 20 MHz CLKOUT.

In the case of the TMS320C2x, the CLKOUT1 signal is derived

from the system clock divided by a factor of 4; consequently a

50 MHz TMS320C25-50 will derive a 12.5 MHz CLKOUT1 for

use by the ADMC200.

Note: A pull-up resistor is required on the IRQ (Pin 18) output

from the ADMC200. The STOP (Pin 47) must be tied low if

not in use.

SYSTEM CLOCK FREQUENCY

The nominal range of the input clock for the ADMC200 is

6.25 MHz to 25 MHz. The external CLK frequency can be internally divided down by 2 by writing to Bit 5 of the SYSCTRL

register. If the external CLK is faster than 12.5 MHz then it is

necessary to internally divide it down.

REGISTER ADDRESSING

Four address lines (A0 through A3) are used in conjunction

with the control lines (CS, WR, RD,) to select registers 0

through 15. The CS and RD control lines are active low. The

registers are given symbolic names.

Table II.

Pin Function

CS Enables the ADMC200 register interface

(connect via chip select logic-active low)

RD Places data from the internal register onto the

data bus

WR Loads the internal register with data on the

data bus on its positive edge

Table III. Write Registers

Name A3A2A1A

Register Function

0

RHO 0000 Load RHO (ρ) and Start Reverse Transform

PHIP1/VD 0001 Reverse Rotation Direct Input/Forward Direct Input

PHIP2/VQ 0010 Reverse Rotation Direct Input/Forward Direct Input

PHIP3 0011 Reverse Rotation Direct Input

RHOP 0100 Load RHOP(ρ) and Start Forward Transform

PWMTM 0101 PWM Master Switching Period

PWMCHA 0110 PWM Channel A On-Time

PWMCHB 0111 PWM Channel B On-Time

PWMCHC 1000 PWM Channel C On-Time

PWMDT 1001 PWM Programmable Deadtime (7-Bit Register)

PWMPD 1010 PWM Pulse Deletion Value (7-Bit Register)

1011 Reserved

1100 Reserved

SYSCTRL 1101 System Control

1110 Reserved

1111 Reserved

–10–

REV. B

Page 11

Table IV. Read Registers

ADMC200

Name A3A2A1A

Register Function

0

ID/PHV1/VX 0000 Reverse Rotation Result (IDS)/Forward Result Cos +0°

IQ/PHV2 0001 Reverse Rotation Result (I

)/Forward Cos +120°

QS

IX/PHV3 0010 Reverse Clarke Cos + 0°/Forward Result Cos +240°

IY/VY 0011 Reverse Clarke Cos +90°/Forward Cos +90°

0100 Reserved

ADCV 0101 A/D Conversion Result Channel V

ADCW 0110 A/D Conversion Result Channel W

ADCAUX 0111 A/D Conversion Result Auxiliary Channel

ADCU 1000 A/D Conversion Result Channel U

1001 Reserved

1010 Reserved

1011 Reserved

1100 Reserved

SYSCTRL 1101 System Control

SYSSTAT 1110 System Status

1111 Reserved

DESCRIPTION OF THE REGISTERS

Table V. System Control (SYSCTRL) Registers

All unspecified register locations are reserved.

SYSCTRL System Control Register (See Table V and VI)

SYSSTAT System Status Register (See Table VII)

ADCU These registers contain the results from the first

ADCV three analog input channels U, V, and W. The

ADCW output data format is twos complement and

therefore Bit 0 is always zero as the A/D

converter has 11-bit resolution.

ADCAUX This register contains the conversion result

of the auxiliary channel.

PWMTM PWM Master Switching Period

PWMCHA PWM Channel A on-time

PWMCHB PWM Channel B on-time

PWMCHC PWM Channel C on-time

PWMDT PWM Programmable Deadtime Value

PWMPD PWM Programmable Pulse Deletion Value

ID/IQ These are the results of the reverse rotation

(torque and flux components).

PHV1/2/3 These are the results from the forward

Clarke Transformation.

PHIP1/2/3 The inputs for reverse vector transformation

(Clarke and Park).

IX/IY These registers contain the results of the Clarke

transformation that are the inputs to the reverse

Park rotation.

VX, VY VX , VY contain the results of the forward

Park rotation.

RHOP RHOP is the angle used during the forward vec-

tor transformation. Writing to the RHOP register causes the forward rotation to start based on

values in RHOP, VD and VQ registers.

RHO RHO is the angle used during the reverse vector

transformation. Writing to this register starts

the reverse rotation using the values in the

RHO, PHIP1/2/3 registers.

RHO and RHOP are unsigned ratios of 360°.

For example, 45 degrees would be 45/360 × 2

12

Bit Function Default

0 Reserved, Must Be 0 0

1 Reserved, Must Be 0 0

3 Enables U Channel Conversion

(1 = Enable) Three/Three-Phase Mode 0

4 Enables AUX Channel Conversion

(0 = Disable, 1 = Enable) 0

5 Divide External Clock by 2

(0 = No, 1 = Yes) 0

6 Park Interrupt Enable 0

7 ADC Interrupt Enable

(0 = Disable, 1 = Enable) 0

8 IRQ Pin Format (Edge or Level Based

Interrupt Requests) (0 = Edge) 0

10 Reverse Rotation (0 = 2/3, 1 = 3/3)

Forward Rotation (1 = Enable) 0

Bit 0, 1 Reserved for future use. Always write 0 to these bits.

Bit 3 Channel U Conversion Enable. If Bit 3 is set to 1, then

Channel U will be converted along with V, W and/or

AUX. This bit selects three-/three-phase mode.

Bit 4 Aux Channel Conversion Enable. If Bit 4 is set to

1, then the AUX input will be converted along with

the channels V, W and/or U.

Bit 5 If Bit 5 = 1, then the external clock will be divided by

two to derive the system clock. If the external clock

frequency is greater than 12.5 MHz, then this bit must

be set.

Bit 6 Park Interrupt Enable. This bit allows interrupts to

be generated when the Park rotation is completed.

Bit 7 ADC Interrupt Enable. This bit allows interrupts to

be generated via the IRQ pin when the analog-todigital conversion process is complete.

.

RESET

REV. B

–11–

Page 12

ADMC200

Bit 8 IRQ Pin Format—Edge or Level Interrupt Selection.

If Bit 8 is set to 0, then an interrupt will cause a pulse

of one system clock to be generated on the IRQ pin.

If Bit 8 is set to 1, then an interrupt causes the IRQ

output to go LOW (logic 0). The IRQ output pin

will remain LOW until the SYSSTAT register is read.

Bit 10 If Bit 10 is set to 1, then the reverse Park transforma-

tion will be formed in 3/3 mode. For Forward

transformations, this bit must be set to 1.

Table VI. SYSCTRL Analog Input Channel Selection

Bit 3 Bit 4 Channels Converted Mode

0 0 V, W (Default) Two/Three Phase

0 1 V, W, AUX Two/Three Phase

1 0 U, V, W Three/Three Phase

1 1 U, V, W, AUX Three/Three Phase

Table VII. System Status Register (SYSSTAT)

1

RESET

Bit Function Default

0 A/D Conversion

Completion Interrupt

(1 = True) 0

1 Vector Transformation

Completion Interrupt

(1 = True) 0

4 Rotation Results are Valid

(1 = Valid) X

2

11 IRQ Generated from This 0

Device (1 = True)

NOTES

1

Reading this register clears the interrupt status flags Bits 0, 1 and 11.

2

Undefined until the first Vector Transformation has started

Bit 0 A/D Conversion Completion Interrupt. This register

is set to 1 when the A/D conversion process has completed and ADC interrupts have been enabled in the

SYSCTRL register.

Bit 1 Interrupt Status. This register is set to 1 when the

Vector Transformation is completed and the Vector

Transformation completion interrupts have been

enabled.

Bit 4 This bit is set to 1 when the rotation results are valid.

Bit 11 If any interrupt source on the ADMC200 occurs, then

this bit is set to 1.

C2071a–1.5–4/00 (rev. B)

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

68-Lead Plastic Leaded Chip Carrier (PLCC)

(P-68A)

61

60

44

43

0.175 (4.45)

0.169 (4.29)

0.104 (2.64) TYP

0.050

(1.27)

TYP

0.925 (23.50)

0.895 (22.73)

0.019 (0.48)

0.017 (0.43)

0.029 (0.74)

0.027 (0.69)

PIN 1

IDENTIFIER

BOTTOM VIEW

(PINS UP)

PRINTED IN U.S.A.

0.995 (25.27)

0.985 (25.02)

9

10

(PINS DOWN)

26

27

0.954 (24.23)

0.950 (24.13)

PIN 1

IDENTIFIER

TOP VIEW

SQ

SQ

–12–

REV. B

Loading...

Loading...