Datasheet ADM202EARW, ADM202EARU, ADM202EARN, ADM202EAN, ADM1181AAN Datasheet (Analog Devices)

Page 1

EMI/EMC-Compliant, 15 kV ESD Protected,

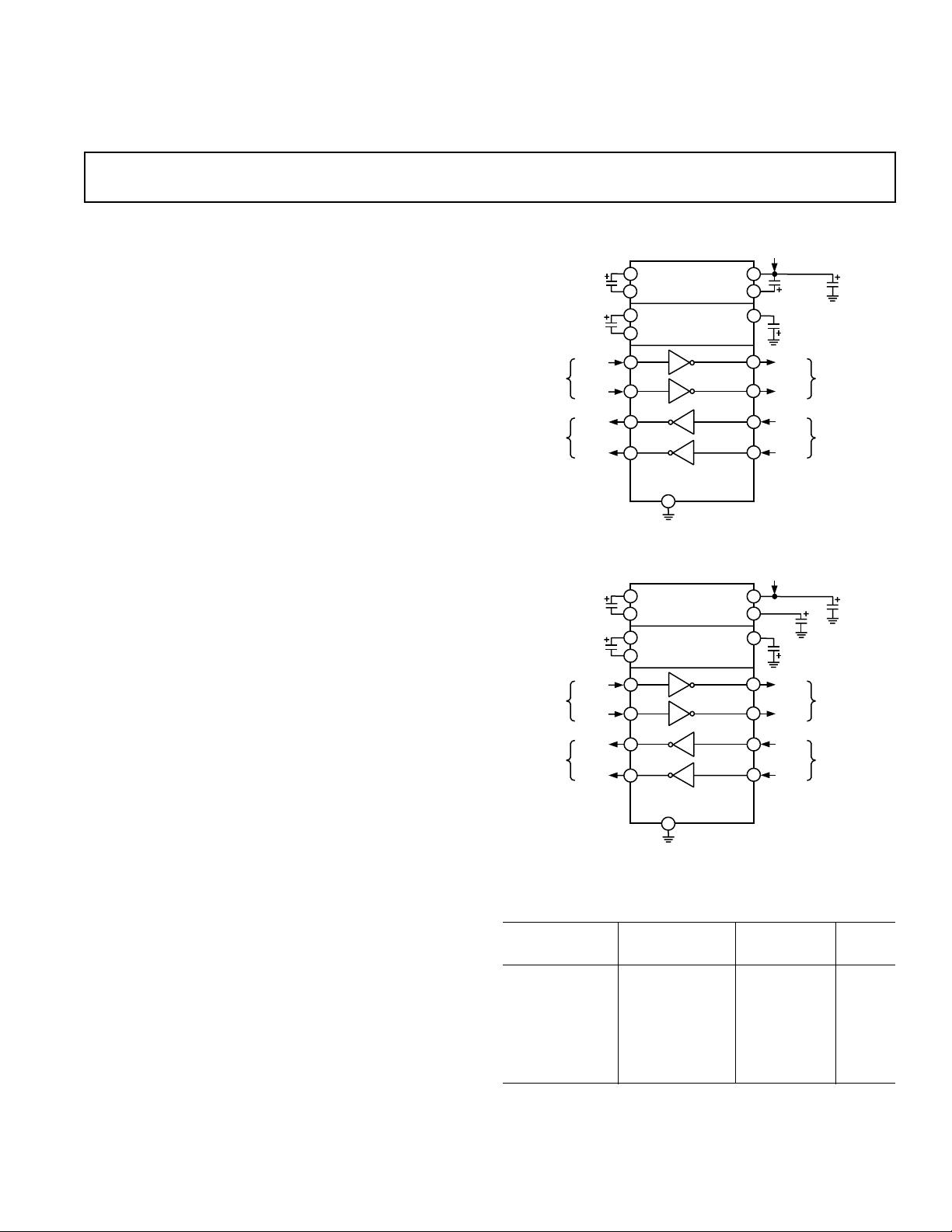

C1+

C1–

C2+

C2–

V

CC

0.1F

10V

0.1F

10V

V+

V–

+5V TO +10V

VOLTAGE

DOUBLER

3

1

2

5V INPUT

C3

0.1F

10V

4

5

+10V TO –10V

VOLTAGE

INVERTER

6

C4

0.1F

10V

14

11

T1

OUT

T1

IN

16

C5

0.1F

10V

7

10

T2

OUT

T2

IN

12

13

8

9

ADM1181A

R1

OUT

R2

OUT

R1

IN

R2

IN

CMOS

INPUTS

CMOS

OUTPUTS

EIA/TIA-232

OUTPUTS

EIA/TIA-232

INPUTS

*

15

*

INTERNAL 5k PULL-DOWN RESISTOR ON EACH RS-232 INPUT

GND

C1+

C1–

C2+

C2–

V

CC

0.1F

10V

0.1F

10V

V+

V–

+5V TO +10V

VOLTAGE

DOUBLER

3

1

2

5V INPUT

C3

0.1F

6.3V

4

5

+10V TO –10V

VOLTAGE

INVERTER

6

C4

0.1F

10V

14

11

T1

OUT

T1

IN

16

C5

0.1F

7

10

T2

OUT

T2

IN

12

13

89

ADM202E

R1

OUT

R2

OUT

R1

IN

R2

IN

CMOS

INPUTS

CMOS

OUTPUTS

EIA/TIA-232

OUTPUTS

EIA/TIA-232

INPUTS

*

15

*

INTERNAL 5k PULL-DOWN RESISTOR ON EACH RS-232 INPUT

GND

T1

T2

R1

R2

T1

T2

R1

R2

a

FEATURES

Complies with 89/336/EEC EMC Directive

ESD Protection to IEC1000-4-2 (801.2)

8 kV: Contact Discharge

15 kV: Air-Gap Discharge

15 kV: Human Body Model

EFT Fast Transient Burst Immunity (IEC1000-4-4)

Low EMI Emissions (EN55022)

230 kbits/s Data Rate Guaranteed

TSSOP Package Option

Upgrade for MAX202E, 232E, LT1181A

APPLICATIONS

General-Purpose RS-232 Data Link

Portable Instruments

PDAs

GENERAL DESCRIPTION

The ADM202E and ADM1181A are robust, high speed,

2-channel RS232/V.28 interface devices that operate from a

single 5 V power supply. Both products are suitable for operation in harsh electrical environments and are compliant with the

EU directive on EMC (89/336/EEC). Both the level of electromagnetic emissions and immunity are in compliance. EM

immunity includes ESD protection in excess of ±15 kV on all

I/O lines, Fast Transient burst protection (1000-4-4) and Radiated Immunity (1000-4-3). EM emissions include radiated and

conducted emissions as required by Information Technology

Equipment EN55022, CISPR22.

The ADM202E and ADM1181A conform to the EIA-232E

and CCITT V.28 specifications and operate at data rates up to

230 kbps.

Four external 0.1 µF charge pump capacitors are used for the

voltage doubler/inverter permitting operation from a single

5 V supply.

The ADM202E provides a robust pin-compatible upgrade for

existing ADM202, ADM232L or MAX202E/MAX232E sockets. It is available in a 16-lead DIP, wide and narrow SO and

also a space saving TSSOP package. The TSSOP package gives

a 44% space saving over SOIC.

The ADM1181A provides a robust pin compatible upgrade for

the LTC1181A, and it is available in 16-lead DIP and 16-lead

SO packages.

REV. B

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

RS-232 Line Drivers/Receivers

ADM202E/ADM1181A

FUNCTIONAL BLOCK DIAGRAMS

ORDERING GUIDE

Temperature Package Package

Model Range Description Option

ADM202EAN –40°C to +85°C Plastic DIP N-16

ADM202EARW –40°C to +85°C Wide SOIC R-16W

ADM202EARN –40°C to +85°C Narrow SOIC R-16N

ADM202EARU –40°C to +85°C TSSOP RU-16

ADM1181AAN –40°C to +85°C Plastic DIP N-16

ADM1181AARW –40°C to +85°C Wide SOIC R-16W

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2001

Page 2

(VCC = 5.0 V 10%, C1–C4 = 0.1 F. All specifications

ADM202E/ADM1181A–SPECIFICATIONS

T

to T

MIN

unless otherwise noted.)

MAX

Parameter Min Typ Max Unit Test Conditions/Comments

DC CHARACTERISTICS

Operating Voltage Range 4.5 5.0 5.5 Volts

Power Supply Current 2.5 6.0 mA No Load

V

CC

13 18 mA RL = 3 kΩ to GND

LOGIC

Input Logic Threshold Low, V

Input Logic Threshold High, V

CMOS Output Voltage Low, V

CMOS Output Voltage High, V

INL

INH

OL

OH

2.4 V T

3.5 V I

Logic Pull-Up Current 12 ±25 µAT

0.8 V T

0.4 V I

IN

IN

= 3.2 mA

OUT

= –1 mA

OUT

= 0 V

IN

RS-232 RECEIVER

EIA-232 Input Voltage Range –30 +30 V

EIA-232 Input Threshold Low 0.4 1.2 V

EIA-232 Input Threshold High 1.6 2.4 V

EIA-232 Input Hysteresis 0.4 V

EIA-232 Input Resistance 3 5 7 kΩ TA = 0°C to 85°C

RS-232 TRANSMITTER

Output Voltage Swing ± 5.0 ± 9.0 Volts All Transmitter Outputs

Loaded with 3 kΩ to Ground

Transmitter Output Resistance 300 Ω V

= 0 V, V

CC

OUT

= ±2 V

RS-232 Output Short Circuit Current ± 10 ± 60 mA

TIMING CHARACTERISTICS

Maximum Data Rate 230 kbps R

= 3 kΩ to 7 kΩ, CL = 50 pF to 1000 pF

L

Receiver Propagation Delay

TPHL 0.1 1 µs

TPLH 0.3 1 µs

Transmitter Propagation Delay 1.0 1.5 µsR

Transition Region Slew Rate 3 8 30 V/µsR

= 3 kΩ, CL = 1000 pF

L

= 3 kΩ, CL = 1000 pF

L

Measured from +3 V to –3 V or

–3 V to +3 V

EM IMMUNITY

ESD Protection (I/O pins) ± 15 kV Human Body Model

± 15 kV IEC1000-4-2 Air Discharge

± 8 kV kV IEC1000-4-2 Contact Discharge

EFT Protection (I/O pins) ± 2 kV IEC1000-4-4

EMI Immunity 10 V/m IEC1000-4-3

Specifications subject to change without notice.

ABSOLUTE MAXIMUM RATINGS*

(TA = 25°C unless otherwise noted)

VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +6 V

V+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . (V

– 0.3 V) to +14 V

CC

V– . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +0.3 V to –14 V

Input Voltages

. . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to (V+, +0.3 V)

T

IN

R

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 30 V

IN

Output Voltages

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 15 V

T

OUT

R

. . . . . . . . . . . . . . . . . . . . . . . –0.3 V to (VCC + 0.3 V)

OUT

Short Circuit Duration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Continuous

T

OUT

Power Dissipation

Power Dissipation N-16 . . . . . . . . . . . . . . . . . . . . . . 450 mW

(Derate 6 mW/°C above 50°C)

, Thermal Impedance . . . . . . . . . . . . . . . . . . . . 117°C/W

θ

JA

Power Dissipation R-16 . . . . . . . . . . . . . . . . . . . . . . . 450 mW

(Derate 6 mW/°C above 50°C)

, Thermal Impedance . . . . . . . . . . . . . . . . . . . . 158°C/W

θ

JA

Power Dissipation RU-16 . . . . . . . . . . . . . . . . . . . . . 500 mW

(Derate 6 mW/°C above 50°C)

, Thermal Impedance . . . . . . . . . . . . . . . . . . . . 158°C/W

θ

JA

Operating Temperature Range

Industrial (A Version) . . . . . . . . . . . . . . . . –40°C to +85°C

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature (Soldering, 10 sec) . . . . . . . . . . . . . . 300°C

ESD Rating (MIL-STD-883B) (I/O Pins) . . . . . . . . . . ± 15 kV

ESD Rating (IEC1000-4-2 Air) (I/O Pins) . . . . . . . . . ± 15 kV

ESD Rating (IEC1000-4-2 Contact) (I/O Pins) . . . . . . ±8 kV

EFT Rating (IEC1000-4-4) (I/O Pins) . . . . . . . . . . . . . ± 2 kV

*This is a stress rating only and functional operation of the device at these or any

other conditions above those indicated in the operation sections of this specification is not implied. Exposure to absolute maximum rating conditions for extended

periods of time may affect reliability.

–2–

REV. B

Page 3

ADM202E/ADM1181A

C1+

C1–

C2+

C2–

V

CC

0.1F

10V

0.1F

10V

V+

V–

+5V TO +10V

VOLTAGE

DOUBLER

5V INPUT

C3

0.1F

10V

+10V TO –10V

VOLTAGE

INVERTER

C4

0.1F

10V

T1

T1

OUT

T1

IN

C5

0.1F

10V

T2

OUT

T2

IN

T2

R1

R2

ADM1181A

R1

OUT

R2

OUT

R1

IN

R2

IN

CMOS

INPUTS

CMOS

OUTPUTS

EIA/TIA-232

OUTPUTS

EIA/TIA-232

INPUTS

*

*

INTERNAL 5k PULL-DOWN RESISTOR ON EACH RS-232 INPUT

GND

14

13

12

11

16

15

10

98

1

2

3

4

7

6

5

TOP VIEW

(Not to Scale)

C1+

R1

IN

T1

OUT

GND

V

CC

V+

C1–

C2+

T2

IN

T1

IN

R1

OUT

C2–

V–

T2

OUT

R2

IN

R2

OUT

ADM202E

ADM1181A

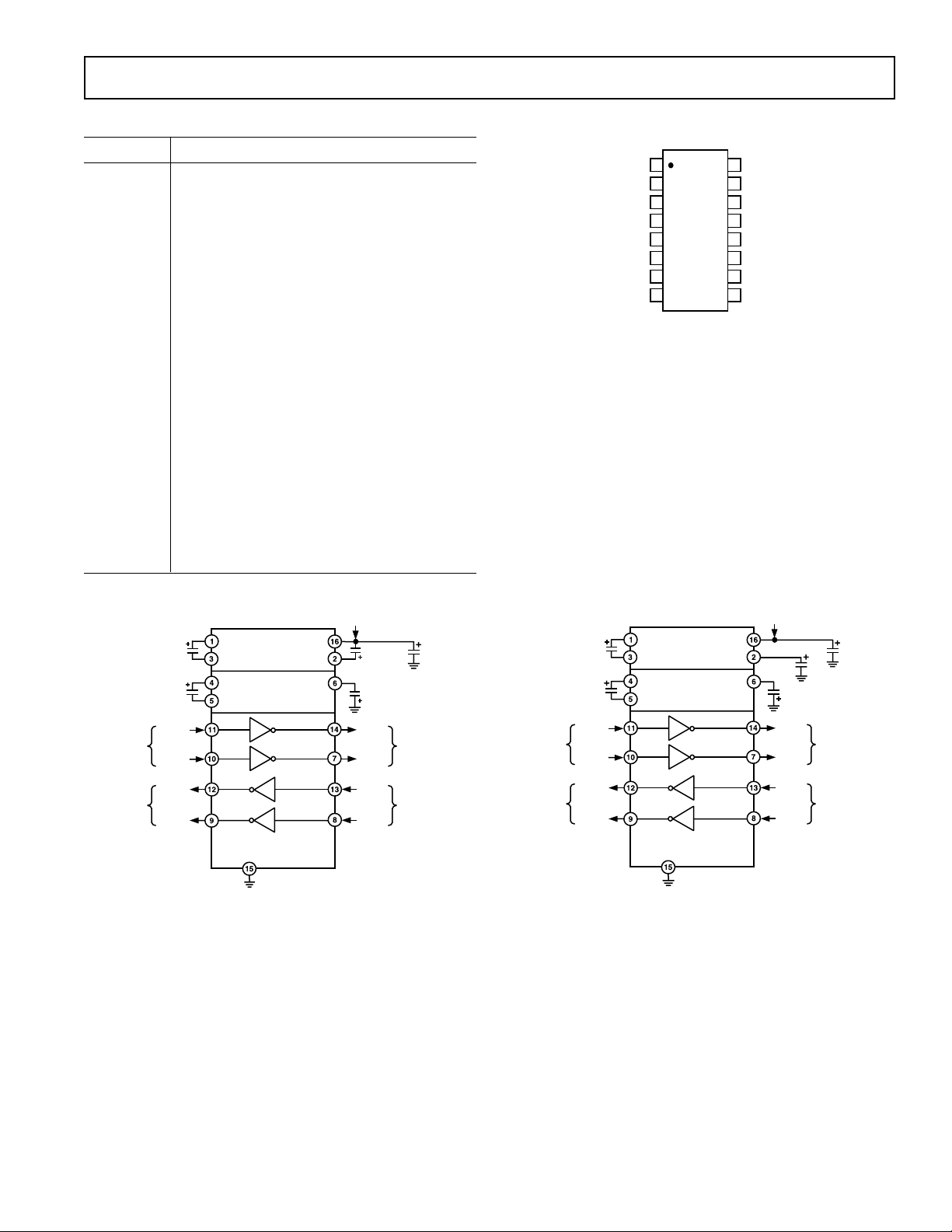

PIN FUNCTION DESCRIPTION

Mnemonic Function

V

CC

Power Supply Input: 5 V ± 10%.

V+ Internally Generated Positive Supply

(+9 V nominal).

V– Internally Generated Negative Supply

(–9 V nominal).

GND Ground Pin. Must Be Connected to 0 V.

C1+, C1– External Capacitor 1 is connected between

these pins. 0.1 µF capacitor is recommended

but larger capacitors up to 47 µF may be used.

C2+, C2– External Capacitor 2 is connected between

these pins. 0.1 µF capacitor is recommended

but larger capacitors up to 47 µF may be used.

T

IN

Transmitter (Driver) Inputs. These inputs

accept TTL/CMOS levels.

T

OUT

Transmitter (Driver) Outputs. These are

RS-232 signal levels (typically ± 9 V).

R

IN

Receiver Inputs. These inputs accept RS-232

signal levels. An Internal 5 kΩ pull-down resistor to GND is connected on each input.

R

OUT

Receiver Outputs. These are CMOS output

logic levels.

PIN CONNECTIONS

0.1F

10V

0.1F

10V

CMOS

INPUTS

CMOS

OUTPUTS

T1

T2

R1

OUT

R2

OUT

*

INTERNAL 5k PULL-DOWN RESISTOR ON EACH RS-232 INPUT

C1+

C1–

C2+

C2–

IN

IN

GND

ADM202E Typical Operating Circuit

REV. B

+5V TO +10V

VOLTAGE

DOUBLER

+10V TO –10V

VOLTAGE

INVERTER

T1

T2

R1

R2

ADM202E

5V INPUT

V

CC

V+

V–

C3

0.1F

6.3V

C4

0.1F

10V

T1

T2

R1

R2

OUT

OUT

IN

IN

C5

0.1F

EIA/TIA-232

OUTPUTS

EIA/TIA-232

INPUTS

*

ADM1181A Typical Operating Circuit

–3–

Page 4

ADM202E/ADM1181A

GENERAL DESCRIPTION

The ADM202E/ADM1181E are ruggedized RS-232 line drivers/

receivers. Step-up voltage converters coupled with level shifting

transmitters and receivers allow RS-232 levels to be developed

while operating from a single 5 V supply.

Features include low power consumption, high transmission

rates and compatibility with the EU directive on Electromagnetic compatibility. EM compatibility includes protection

against radiated and conducted interference including high

levels of Electrostatic Discharge.

All inputs and outputs contain protection against Electrostatic

Discharges up to ±15 kV and Electrical Fast Transients up to

± 2 kV. This ensures compliance to IE1000-4-2 and IEC1000-4-4

requirements.

The devices are ideally suited for operation in electrically harsh

environments or where RS-232 cables are frequently being

plugged/unplugged. They are also immune to high RF field

strengths without special shielding precautions.

CMOS technology is used to keep the power dissipation to an

absolute minimum allowing maximum battery life in portable

applications.

The ADM202E/ADM1181A is a modification, enhancement

and improvement to the AD230–AD241 family and its derivatives. It is essentially plug-in compatible and does not have

materially different applications.

CIRCUIT DESCRIPTION

The internal circuitry consists of four main sections. These are:

1. A charge pump voltage converter

2. 5 V logic to EIA-232 transmitters

3. EIA-232 to 5 V logic receivers.

4. Transient protection circuit on all I/O lines

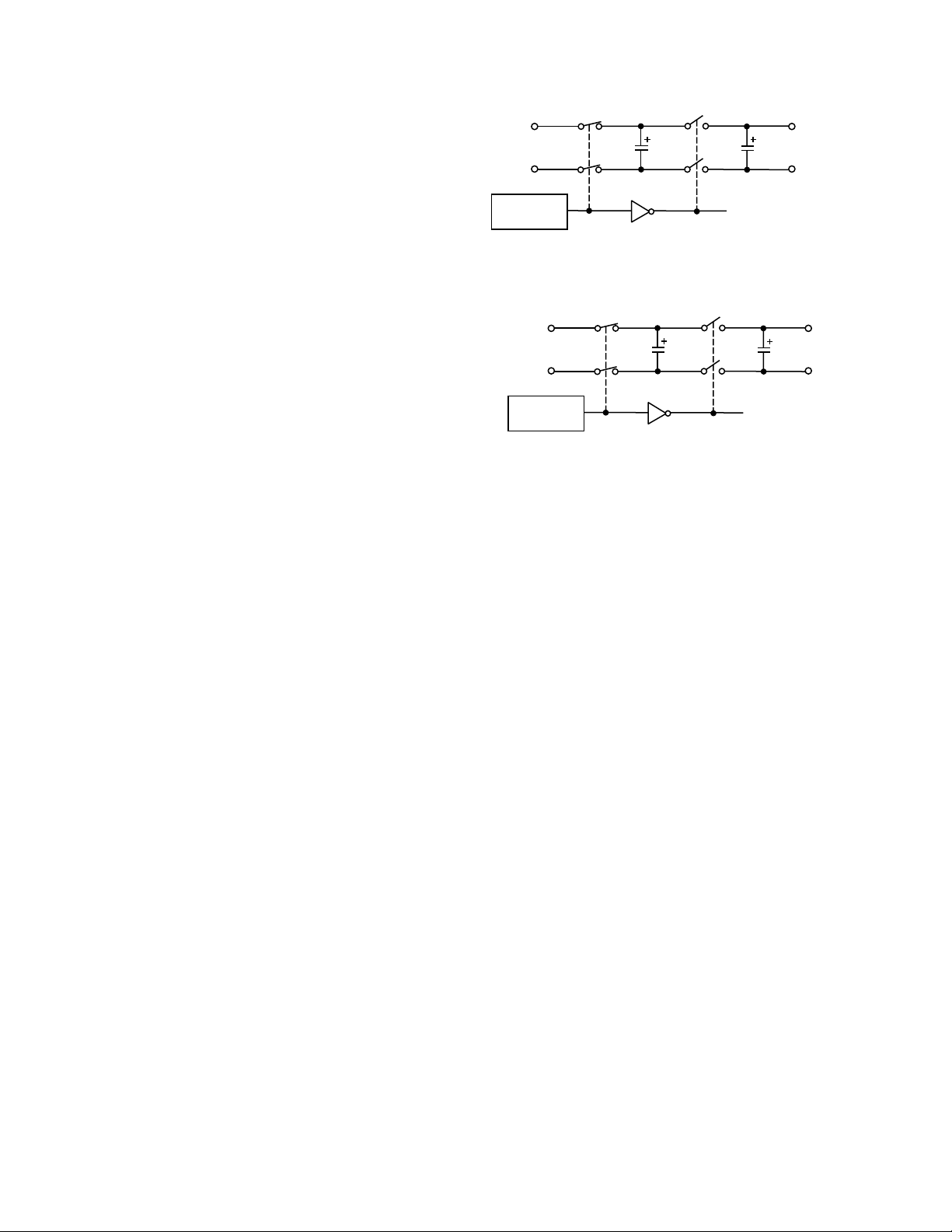

Charge Pump DC-DC Voltage Converter

The charge pump voltage converter consists of an 200 kHz

oscillator and a switching matrix. The converter generates a

± 10 V supply from the input 5 V level. This is done in two

stages using a switched capacitor technique as illustrated below.

First, the 5 V input supply is doubled to 10 V using capacitor C1

as the charge storage element. The 10 V level is then inverted to

generate –10 V using C2 as the storage element.

Capacitors C3 and C4 are used to reduce the output ripple.

Their values are not critical and can be increased if desired. On

the ADM202E, capacitor C3 is shown connected between V+

and VCC, while it is connected between V+ and GND on the

ADM1181A. It is acceptable to use either configuration with both

the ADM202E and ADM1181A. If desired, larger capacitors

(up to 47 µF) can be used for capacitors C1–C4. This facilitates

direct substitution with older generation charge pump RS-232

transceivers.

V

CC

GND

INTERNAL

OSCILLATOR

S1

S2

NOTE: C3 CONNECTS BETWEEN V+ AND GND ON THE ADM1181A

C1

S3

S4

C3

V+ = 2V

V

CC

CC

Figure 1. Charge Pump Voltage Doubler

S3

S4

C4

GND

V– = –(V+)

FROM

VOLTAGE

DOUBLER

V+

GND

INTERNAL

OSCILLATOR

S1

S2

C2

Figure 2. Charge Pump Voltage Inverter

Transmitter (Driver) Section

The drivers convert 5 V logic input levels into RS-232 output

levels. With V

= 5 V and driving an RS-232 load, the output

CC

voltage swing is typically ±9 V.

Receiver Section

The receivers are inverting level shifters which accept RS-232

input levels and translate them into 5 V logic output levels.

The inputs have internal 5 kΩ pull-down resistors to ground

and are also protected against overvoltages of up to ±30 V.

Unconnected inputs are pulled to 0 V by the internal 5 kΩ pulldown resistor. This, therefore, results in a Logic 1 output level

for unconnected inputs or for inputs connected to GND.

The receivers have Schmitt trigger inputs with a hysteresis level

of 0.5 V. This ensures error-free reception for both noisy inputs

and for inputs with slow transition times.

HIGH BAUD RATE

The ADM202E/ADM1181A feature high slew rates permitting

data transmission at rates well in excess of the EIA/RS-232-E

specifications. RS-232 voltage levels are maintained at data rates

up to 230 kb/s even under worst case loading conditions. This

allows for high speed data links between two terminals or indeed

it is suitable for the new generation I

modem standards which

SDN

requires data rates of 230 kbps. The slew rate is internally controlled to less than 30 V/µs in order to minimize EMI interference.

–4–

REV. B

Page 5

ADM202E/ADM1181A

ESD/EFT TRANSIENT PROTECTION SCHEME.

The ADM202E/ADM1181A use protective clamping structures

on all inputs and outputs which clamp the voltage to a safe level

and dissipate the energy present in ESD (Electrostatic) and EFT

(Electrical Fast Transients) discharges. A simplified schematic

of the protection structure is shown in Figure 3. Each input and

output contains two back-to-back high speed clamping diodes.

During normal operation with maximum RS-232 signal levels,

the diodes have no effect as one or the other is reverse biased

depending on the polarity of the signal. If however the voltage exceeds about 50 V in either direction, reverse breakdown

occurs and the voltage is clamped at this level. The diodes are

large p-n junctions that are designed to handle the instantaneous current surge which can exceed several amperes.

The transmitter outputs and receiver inputs have a similar protection structure. The receiver inputs can also dissipate some of

the energy through the internal 5 kΩ resistor to GND as well as

through the protection diodes.

The protection structure achieves ESD protection up to ±15 kV

and EFT protection up to ±2 kV on all RS-232 I/O lines. The

methods used to test the protection scheme are discussed later.

Typical Performance Characteristics

RECEIVER

INPUT

R1

R

IN

RX

D1

D2

Figure 3a. Receiver Input Protection Scheme

RX

OUT

D1

D2

TRANSMITTER

OUTPUT

T

Figure 3b. Transmitter Output Protection Scheme

80

70

60

50

40

dBV

30

20

10

0

START 30.0MHz STOP 200.0MHz

TPC 1. EMC Radiated Emissions

LIMIT

80

70

60

50

40

dBV

30

20

10

0

0.3 300.6 1

LOG FREQUENCY – MHz

3610

TPC 2. EMC Conducted Emissions

LIMIT

REV. B

–5–

Page 6

ADM202E/ADM1181A

–Typical Performance Characteristics

9

7

5

3

1

O/P – V

–1

X

T

–3

–5

–7

–9

0 2500

1000 1500 2000

500

LOAD CAPACITANCE – pF

115KBPS

230KBPS

460KBPS

460KBPS

230KBPS

115KBPS

3000

TPC 3. Transmitter Output Voltage High/Low vs.

Load Capacitance @ 115 kbps, 230 kbps and 460 kbps

15

TX O/P HI

10

T

O/P HI LOADED

X

5

15

10

5

0

O/P – V

X

T

–5

–10

–15

24681012

014

I

LOAD

– mA

TX O/P HI

TX O/P LO

TPC 6. Transmitter Output Voltage Low/High vs.

Load Current

1

T

0

O/P – V

X

T

–5

–10

–15

4 4.5 5

V

CC

TX O/P LO LOADED

– V

T

X

O/P LO

5.5

TPC 4. Transmitter Output Voltage High/Low vs. V

15

10

5

0

V+, V– – V

–5

–10

–15

05

10 15 20 25

I

– mA

LOAD

30

TPC 5. Charge Pump V+, V– vs. Current

CC

2

T

Ch1 5.00V Ch2 5.00V M 2.00s Ch1 400mV

TPC 7. 230 kbps Data Transmission

300

250

200

150

IMPEDANCE –

100

50

0

4.5 5 5.5

V

– V

V–

V+

TPC 8. Charge Pump Impedance vs. V

64

CC

–6–

REV. B

Page 7

ADM202E/ADM1181A

100

I

PEAK

– %

90

10

TIME t

30ns

60ns

0.1 TO 1ns

ESD TESTING (IEC1000-4-2)

IEC1000-4-2 (previously 801-2) specifies compliance testing

using two coupling methods, contact discharge and air-gap

discharge. Contact discharge calls for a direct connection to the

unit being tested. Air-gap discharge uses a higher test voltage

but does not make direct contact with the unit under test. With

air discharge, the discharge gun is moved towards the unit under

test developing an arc across the air gap, hence the term air-gap

discharge. This method is influenced by humidity, temperature,

barometric pressure, distance and rate of closure of the discharge

gun. The contact-discharge method while less realistic is more

repeatable and is gaining acceptance in preference to the airgap method.

Although very little energy is contained within an ESD pulse,

the extremely fast rise time coupled with high voltages can cause

failures in unprotected semiconductors. Catastrophic destruction can occur immediately as a result of arcing or heating. Even

if catastrophic failure does not occur immediately, the device

may suffer from parametric degradation which may result in

degraded performance. The cumulative effects of continuous

exposure can eventually lead to complete failure.

I/O lines are particularly vulnerable to ESD damage. Simply

touching or plugging in an I/O cable can result in a static discharge which can damage or completely destroy the interface

product connected to the I/O port. Traditional ESD test methods such as the MIL-STD-883B method 3015.7 do not fully

test a product’s susceptibility to this type of discharge. This test

was intended to test a product’s susceptibility to ESD damage

during handling. Each pin is tested with respect to all other

pins. There are some important differences between the traditional test and the IEC test:

a. The IEC test is much more stringent in terms of discharge

energy. The peak current injected is over four times greater.

b. The current rise time is significantly faster in the IEC test.

c. The IEC test is carried out while power is applied to the device.

It is possible that the ESD discharge could induce latch-up in the

device under test. This test therefore is more representative of a

real-world I/O discharge where the equipment is operating normally with power applied. For maximum peace of mind, however,

both tests should be performed therefore ensuring maximum

protection both during handling and later during field service.

HIGH

VOLTAGE

GENERATOR

R1

C1

R2

DEVICE

UNDER TEST

100

90

– %

PEAK

I

36.8

10

t

RL

t

DL

TIME t

Figure 5. Human Body Model ESD Current Waveform

Figure 6. IEC1000-4-2 ESD Current Waveform

The ADM202E/ADM1181E products are tested using both the

above mentioned test methods. All pins are tested with respect

to all other pins as per the MIL-STD-883B specification. In

addition all I/O pins are tested as per the IEC test specification.

The products were tested under the following conditions:

a. Power-On

b. Power-Off

There are four levels of compliance defined by IEC1000-4-2.

The ADM202E/ADM1181A products meet the most stringent

compliance level for both contact and for air-gap discharge. This

means that the products are able to withstand contact discharges

in excess of 8 kV and air-gap discharges in excess of 15 kV.

REV. B

ESD TEST METHOD R2 C1

H. BODY MIL-STD883B 1.5k 100pF

IEC1000-4-2 330 150pF

Figure 4. ESD Test Standards

–7–

Page 8

ADM202E/ADM1181A

Table I. IEC1000-4-2 Compliance Levels

Level Contact Discharge Air Discharge

1 2 kV 2 kV

2 4 kV 4 kV

3 6 kV 8 kV

4 8 kV 15 kV

Table II. ADM202E/ADM1181A ESD Test Results

ESD Test Method I/O Pins

MIL-STD-883B ± 15 kV

IEC1000-4-2

Contact ± 8 kV

Air ± 15 kV

FAST TRANSIENT BURST TESTING (IEC1000-4-4)

IEC1000-4-4 (previously 801-4) covers electrical fast-transient/

burst (EFT) immunity. Electrical fast transients occur as a

result of arcing contacts in switches and relays. The tests simulate the interference generated when for example a power relay

disconnects an inductive load. A spark is generated due to the

well known back EMF effect. In fact the spark consists of a

burst of sparks as the relay contacts separate. The voltage appearing on the line therefore consists of a bust of extremely fast

transient impulses. A similar effect occurs when switching on

fluorescent lights.

The fast transient burst test defined in IEC1000-4-4 simulates

this arcing and its waveform is illustrated in TPC 8. It consists

of a burst of 2.5 kHz to 5 kHz transients repeating at 300 ms

intervals. It is specified for both power and data lines.

V

t

300ms 15ms

5ns

V

A simplified circuit diagram of the actual EFT generator is illustrated in Figure 8.

The transients are coupled onto the signal lines using an EFT

coupling clamp. The clamp is 1 m long and it completely surrounds the cable providing maximum coupling capacitance

(50 pF to 200 pF typ) between the clamp and the cable. High

energy transients are capacitively coupled onto the signal lines.

Fast rise times (5 ns) as specified by the standard result in very

effective coupling. This test is very severe since high voltages are

coupled onto the signal lines. The repetitive transients can often

cause problems where single pulses do not. Destructive latchup

may be induced due to the high energy content of the transients.

Note that this stress is applied while the interface products are

powered up and are transmitting data. The EFT test applies

hundreds of pulses with higher energy than ESD. Worst case

transient current on an I/O line can be as high as 40 A.

C

R

HIGH

VOLTAGE

SOURCE

R

C

C

C

L

Z

S

D

M

50

OUTPUT

Figure 8. IEC1000-4-4 Fast Transient Generator

Test results are classified according to the following:

1. Normal performance within specification limits.

2. Temporary degradation or loss of performance that is

self-recoverable.

3. Temporary degradation or loss of function or performance

that requires operator intervention or system reset.

4. Degradation or loss of function that is not recoverable due

to damage.

The ADM202E/ADM1181A have been tested under worst-case

conditions using unshielded cables and meet Classification 2.

Data transmission during the transient condition is corrupted,

but it may be resumed immediately following the EFT event

without user intervention.

50ns

t

0.2/0.4ms

Figure 7. IEC1000-4-4 Fast Transient Waveform

–8–

REV. B

Page 9

ADM202E/ADM1181A

IEC1000-4-3 RADIATED IMMUNITY

IEC1000-4-3 (previously IEC801-3) describes the measurement

method and defines the levels of immunity to radiated electromagnetic fields. It was originally intended to simulate the

electromagnetic fields generated by portable radio transceivers

or any other device which generates continuous wave radiated

electromagnetic energy. Its scope has since been broadened to

include spurious EM energy which can be radiated from fluorescent lights, thyristor drives, inductive loads, etc.

Testing for immunity involves irradiating the device with an EM

field. There are various methods of achieving this including use

of anechoic chamber, stripline cell, TEM cell, GTEM cell. A

stripline cell consists of two parallel plates with an electric field

developed between them. The device under test is placed within

the cell and exposed to the electric field. There are three severity

levels having field strengths ranging from 1 V to 10 V/m. Results

are classified in a similar fashion to those for IEC1000-4-2.

1. Normal Operation.

2. Temporary Degradation or loss of function that is selfrecoverable when the interfering signal is removed.

3. Temporary degradation or loss of function that requires

operator intervention or system reset when the interfering

signal is removed.

4. Degradation or loss of function that is not recoverable due

to damage.

The ADM202E/ADM1181A products easily meet Classification 1 at the most stringent (Level 3) requirement. In fact field

strengths up to 30 V/m showed no performance degradation, and

error-free data transmission continued even during irradiation.

ducted emissions. It is, therefore, important that the switches in

the charge pump guarantee break-before-make switching under

all conditions so that instantaneous short circuit conditions do

not occur.

The ADM202E has been designed to minimize the switching

transients and ensure break-before-make switching thereby

minimizing conducted emissions. This has resulted in the

level of emissions being well below the limits required by the

specification. No additional filtering/decoupling other than the

recommended 0.1 µF capacitor is required.

Conducted emissions are measured by monitoring the mains

line. The equipment used consists of a LISN (Line Impedance

Stabilizing Network) that essentially presents a fixed impedance

at RF, and a spectrum analyzer. The spectrum analyzer scans

for emissions up to 30 MHz and a plot for the ADM202E is

shown in Figure 11.

V

CC

GND

INTERNAL

OSCILLATOR

S1

S2

C1

S3

S4

C3

V+ = 2V

V

CC

CC

Figure 9. Charge Pump Voltage Doubler

ø

1

Table III. Test Severity Levels (IEC1000-4-3)

Level Field Strength V/m

11

23

310

EMISSIONS/INTERFERENCE

EN55 022, CISPR22 defines the permitted limits of radiated

and conducted interference from Information Technology (IT)

equipment. The objective of the standard is to minimize the

level of emissions both conducted and radiated.

For ease of measurement and analysis, conducted emissions are

assumed to predominate below 30 MHz and radiated emissions

are assumed to predominate above 30 MHz.

CONDUCTED EMISSIONS

This is a measure of noise that gets conducted onto the mains

power supply. Switching transients from the charge pump that

are 20 V in magnitude and contain significant energy can lead to

conducted emissions. Other sources of conducted emissions can

be due to overlap in switch on-times in the charge pump voltage

converter. In the voltage doubler shown below, if S2 has not

fully turned off before S4 turns on, this results in a transient

current glitch between V

and GND which results in con-

CC

ø

2

SWITCHING GLITCHES

Figure 10. Switching Glitches

80

70

60

50

40

dBV

30

20

10

0

0.3 300.6 1

LOG FREQUENCY – MHz

36

10

LIMIT

Figure 11. ADM202E Conducted Emissions Plot

REV. B

–9–

Page 10

ADM202E/ADM1181A

RADIATED EMISSIONS

Radiated emissions are measured at frequencies in excess of

30 MHz. RS-232 outputs designed for operation at high baud

rates while driving cables can radiate high frequency EM energy.

The reasons already discussed that cause conducted emissions

can also be responsible for radiated emissions. Fast RS-232 output transitions can radiate interference, especially when lightly

loaded and driving unshielded cables. Charge pump devices are

also prone to radiating noise due to the high frequency oscillator

and high voltages being switched by the charge pump. The

move towards smaller capacitors in order to conserve board

space has resulted in higher frequency oscillators being employed

in the charge pump design. This has resulted in higher levels of

emission, both conducted and radiated.

The RS-232 outputs on the ADM202E products feature a

controlled slew rate in order to minimize the level of radiated

emissions, yet are fast enough to support data rates up to

230 kBaud.

Figure 13 shows a plot of radiated emissions vs. frequency. This

shows that the levels of emissions are well within specifications

without the need for any additional shielding or filtering components. The ADM202E was operated at maximum baud rates and

configured as in a typical RS-232 interface.

Testing for radiated emissions was carried out in a shielded

anechonic chamber.

RADIATED NOISE

DUT

TO

TURNTABLE

ADJUSTABLE

ANTENNA

RECEIVER

Figure 12. Radiated Emissions Test Setup

80

70

60

50

40

dBV

30

20

10

0

START 30.0MHz STOP 200.0MHz

LIMIT

Figure 13. ADM202E Radiated Emissions Plot

–10–

REV. B

Page 11

OUTLINE DIMENSIONS

16

9

81

0.256 (6.50)

0.246 (6.25)

0.177 (4.50)

0.169 (4.30)

PIN 1

0.201 (5.10)

0.193 (4.90)

SEATING

PLANE

0.006 (0.15)

0.002 (0.05)

0.0118 (0.30)

0.0075 (0.19)

0.0256 (0.65)

BSC

0.0433 (1.10)

MAX

0.0079 (0.20)

0.0035 (0.090)

0.028 (0.70)

0.020 (0.50)

8

0

16

18

9

PIN 1

0.840 (21.34)

0.745 (18.92)

0.280 (7.11)

0.240 (6.10)

SEATING

PLANE

0.060 (1.52)

0.015 (0.38)

0.210 (5.33)

MAX

0.022 (0.558)

0.014 (0.356)

0.160 (4.06)

0.115 (2.93)

0.100

(2.54)

BSC

0.070 (1.77)

0.045 (1.15)

0.130

(3.30)

MIN

0.195 (4.95)

0.115 (2.93)

0.015 (0.381)

0.008 (0.204)

0.325 (8.25)

0.300 (7.62)

Dimensions shown in inches and (mm).

ADM202E/ADM1181A

16

1

PIN 1

0.0118 (0.30)

0.0040 (0.10)

0.1574 (4.00)

0.1497 (3.80)

0.4133 (10.50)

0.3977 (10.00)

0.050 (1.27)

BSC

0.0192 (0.49)

0.0138 (0.35)

SOIC (Narrow) Package

0.3937 (10.00)

0.3859 (9.80)

16 9

SOIC (Wide) Package

(R-16W)

9

0.2992 (7.60)

0.2914 (7.40)

0.4193 (10.65)

8

0.3937 (10.00)

0.1043 (2.65)

0.0926 (2.35)

SEATING

0.0125 (0.32)

PLANE

0.0091 (0.23)

(R-16N)

0.2440 (6.20)

81

0.2284 (5.80)

0.0291 (0.74)

0.0098 (0.25)

8

0

TSSOP Package

(RU-16)

C00066–0–2/01 (rev. B)

45

0.0500 (1.27)

0.0157 (0.40)

DIP Package

(N-16)

0.0098 (0.25)

0.0040 (0.10)

SEATING

PLANE

PIN 1

0.0500

(1.27)

BSC

0.0688 (1.75)

0.0532 (1.35)

0.0192 (0.49)

0.0138 (0.35)

0.0099 (0.25)

0.0075 (0.19)

0.0196 (0.50)

0.0099 (0.25)

8°

0°

0.0500 (1.27)

0.0160 (0.41)

x 45°

ADM202E/ADM1181A–Revision History

Location Page

Data Sheet changed from REV. B to REV. B.

Deletion of one ESD Rating in ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Removal of one column in Table II . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

REV. B

–11–

PRINTED IN U.S.A.

Loading...

Loading...