Page 1

Low-Cost Microprocessor

a

FEATURES

Alternative to the ADM1021

On-Chip and Remote Temperature Sensing

No Calibration Necessary

1ⴗC Accuracy for On-Chip Sensor

3ⴗC Accuracy for Remote Sensor

Programmable Overtemperature/Undertemperature

Limits

Programmable Conversion Rate

2-Wire SMBus Serial Interface

Supports System Management Bus (SMBus) Alert

200 mA Max Operating Current

1 mA Standby Current

3 V to 5.5 V Supply

Small 16-Lead QSOP Package

APPLICATIONS

Desktop Computers

Notebook Computers

Smart Batteries

Industrial Controllers

Telecom Equipment

Instrumentation

System Temperature Monitor

*

ADM1021A

PRODUCT DESCRIPTION

The ADM1021A is a two-channel digital thermometer and

undertemperature/overtemperature alarm, intended for use in

personal computers and other systems requiring thermal monitoring and management. The device can measure the temperature

of a microprocessor using a diode-connected PNP transistor, which

may be provided on-chip in the case of the Pentium

processors, or can be a low-cost discrete NPN/PNP device such

as the 2N3904/2N3906. A novel measurement technique cancels

out the absolute value of the transistor’s base emitter voltage, so

that no calibration is required. The second measurement channel

measures the output of an on-chip temperature sensor, to monitor

the temperature of the device and its environment.

The ADM1021A communicates over a two-wire serial interface

compatible with SMBus

standards. Undertemperature and

overtemperature limits can be programmed into the devices over

the serial bus, and an ALERT output signals when the on-chip

or remote temperature is out of range. This output can be used

as an interrupt, or as an SMBus alert.

®

III or similar

D+

D–

*Patents Pending

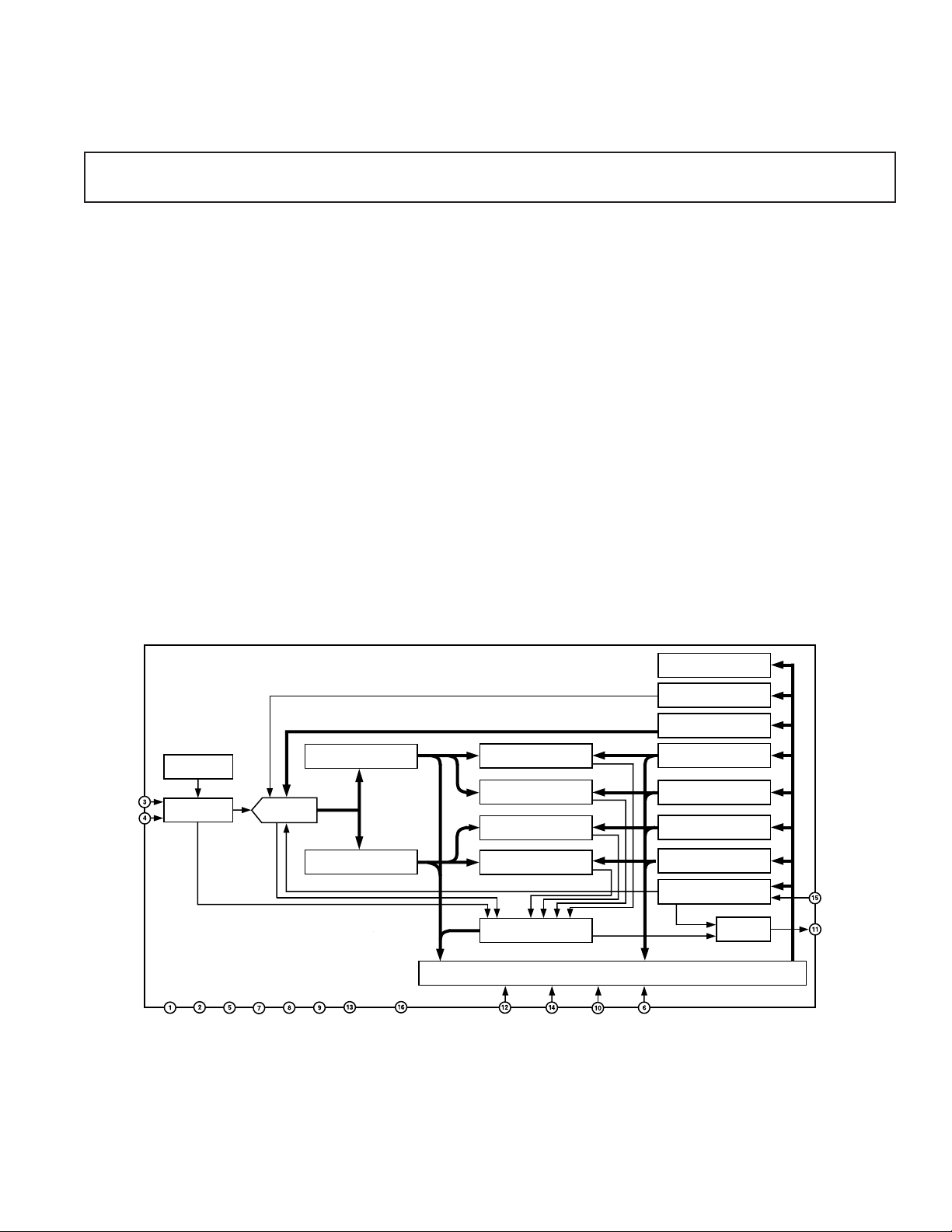

ON-CHIP TEMP.

SENSOR

ANALOG MUX

EXTERNAL DIODE OPEN-CIRCUIT

ADM1021A

NC

NC GND NC NC

V

DD

LOCAL TEMPERATURE

VALUE REGISTER

A-TO-D

CONVERTER

BUSY RUN/STANDBY

REMOTE TEMPERATURE

VALUE REGISTER

GND

FUNCTIONAL BLOCK DIAGRAM

LOCAL TEMPERATURE

LOW LIMIT COMPARATOR

LOCAL TEMPERATURE

HIGH LIMIT COMPARATOR

REMOTE TEMPERATURE

LOW LIMIT COMPARATOR

REMOTE TEMPERATURE

HIGH LIMIT COMPARATOR

STATUS REGISTER

SMBUS INTERFACE

NC

SDATA

SCLK ADD0 ADD1

ADDRESS POINTER

REGISTER

ONE-SHOT

REGISTER

CONVERSION RATE

REGISTER

LOCAL TEMPERATURE

LOW LIMIT REGISTER

LOCAL TEMPERATURE

HIGH LIMIT REGISTER

REMOTE TEMPERATURE

LOW LIMIT REGISTER

REMOTE TEMPERATURE

HIGH LIMIT REGISTER

CONFIGURATION

REGISTER

INTERRUPT

MASKING

NC = NO CONNECT

STBY

ALERT

REV. D

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © 2004 Analog Devices, Inc. All rights reserved.

Page 2

ADM1021A–SPECIFICATIONS

(TA = T

MIN

1

to T

, VDD = 3.0 V to 3.6 V, unless otherwise noted.)

MAX

Parameter Min Typ Max Unit Test Conditions/Comments

POWER SUPPLY AND ADC

Temperature Resolution 1 °C Guaranteed No Missed Codes

Temperature Error, Local Sensor ± 1 °C

–3 +3 °C

Temperature Error, Remote Sensor –3 +3 °CT

= 60°C to 100°C

A

–5 +5 °C

Supply Voltage Range 3 3.6 V Note 2

Undervoltage Lockout Threshold 2.5 2.7 2.95 V V

Undervoltage Lockout Hysteresis 25 mV

Power-On Reset Threshold 0.9 1.7 2.2 V V

Input, Disables ADC, Rising Edge

DD

, Falling Edge

DD

3

POR Threshold Hysteresis 50 mV

Standby Supply Current 1 5 µAV

= 3.3 V, No SMBus Activity

DD

4 µA SCLK at 10 kHz

Average Operating Supply Current 130 200 µA 0.25 Conversions/Sec Rate

Autoconvert Mode, Averaged Over 4 Seconds 225 330 µA2 Conversions/Sec Rate

Conversion Time 65 115 170 ms From Stop Bit to Conversion Complete

(Both Channels)

D+ Forced to D– + 0.65 V

Remote Sensor Source Current 120 205 300 µAHigh Level

71216µALow Level

3

3

D-Source Voltage 0.7 V

Address Pin Bias Current (ADD0, ADD1) 50 µAMomentary at Power-On Reset

SMBUS INTERFACE

Logic Input High Voltage, V

IH

2.2 V VDD = 3 V to 5.5 V

STBY, SCLK, SDATA

Logic Input Low Voltage, V

IL

0.8 V VDD = 3 V to 5.5 V

STBY, SCLK, SDATA

SMBus Output Low Sink Current 6 mA SDATA Forced to 0.6 V

ALERT Output Low Sink Current 1 mA ALERT Forced to 0.4 V

Logic Input Current, I

, I

IH

IL

–1 +1 µA

SMBus Input Capacitance, SCLK, SDATA 5 pF

SMBus Clock Frequency 100 kHz

SMBus Clock Low Time, t

SMBus Clock High Time, t

SMBus Start Condition Setup Time, t

LOW

HIGH

SU:STA

4.7 µst

4 µst

4.7 µs

between 10% Points

LOW

between 90% Points

HIGH

SMBus Repeat Start Condition 250 ns Between 90% and 90% Points

Setup Time, t

SMBus Start Condition Hold Time, t

SMBus Stop Condition Setup Time, t

SU:STA

HD:STA

SU:STO

4 µsTime from 10% of SDATA to 90% of SCLK

4 µsTime from 90% of SCLK to 10% of SDATA

SMBus Data Valid to SCLK 250 ns Time from 10% or 90% of SDATA to 10%

Rising Edge Time, t

SU:DAT

SMBus Data Hold Time, t

SMBus Bus Free Time, t

BUF

HD:DAT

0 µs

4.7 µsBetween Start/Stop Conditions

of SCLK

SCLK Falling Edge to SDATA 1 µsMaster Clocking in Data

Valid Time, t

NOTES

1

T

= 100°C; T

MAX

2

Operation at VDD = 5 V guaranteed by design, not production tested.

3

Guaranteed by design, not production tested.

Specifications subject to change without notice.

MIN

VD, DAT

= 0°C.

–2–

REV. D

Page 3

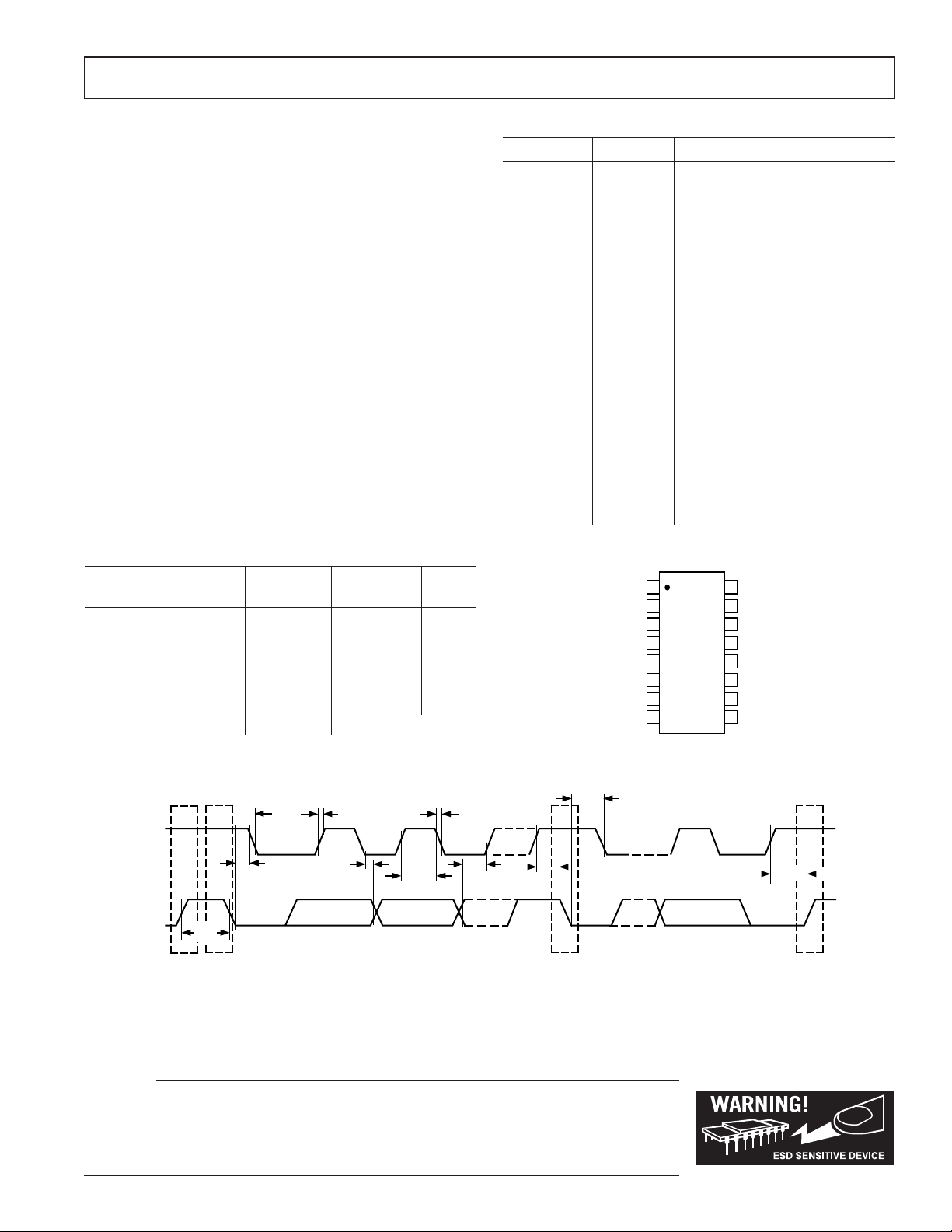

ADM1021A

TOP VIEW

(Not to Scale)

NC = NO CONNECT

NC

V

DD

D+

D–

NC

ADD1

GND

GND

NC

STBY

SCLK

NC

SDATA

ALERT

ADD0

NC

ADM1021A

16

15

14

13

12

11

10

9

1

2

3

4

5

6

7

8

ABSOLUTE MAXIMUM RATINGS*

Positive Supply Voltage (VDD) to GND . . . . . . –0.3 V to +6 V

D+, ADD0, ADD1 . . . . . . . . . . . . . . . –0.3 V to V

+ 0.3 V

DD

D– to GND . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 V to +0.6 V

SCLK, SDATA, ALERT, STBY . . . . . . . . . . . –0.3 V to +6 V

Input Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 50 mA

Input Current, D– . . . . . . . . . . . . . . . . . . . . . . . . . . . . ± 1 mA

ESD Rating, All Pins (Human Body Model) . . . . . . . . 2000 V

Continuous Power Dissipation

Up to 70°C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 650 mW

Derating above 70°C . . . . . . . . . . . . . . . . . . . . . 6.7 mW/°C

Operating Temperature Range . . . . . . . . . . –55°C to +125°C

Maximum Junction Temperature (T

max) . . . . . . . . . . 150°C

J

Storage Temperature Range . . . . . . . . . . . . –65°C to +150°C

Lead Temperature, (Soldering 10 sec) . . . . . . . . . . . . . 300°C

IR Reflow Peak Temperature . . . . . . . . . . . . . . . . . . . . . 220°C

*Stresses above those listed under Absolute Maximum Ratings may cause perma-

nent damage to the device. This is a stress rating only; functional operation of the

device at these or any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute maximum rating

conditions for extended periods may affect device reliability.

THERMAL CHARACTERISTICS

16-Lead QSOP Package: θ

= 150°C/W.

JA

ORDERING GUIDE

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Description

1, 5, 9, 13, 16 NC No Connect

2V

DD

Positive Supply, 3 V to 5.5 V

3D+Positive Connection to Remote

Temperature Sensor

4D–Negative Connection to Remote

Temperature Sensor

6ADD1 Three-State Logic Input, Higher

Bit of Device Address

7, 8 GND Supply 0 V Connection

10 ADD0 Three-State Logic Input, Lower

Bit of Device Address

11 ALERT Open-Drain Logic Output Used as

Interrupt or SMBus Alert

12 SDATA Logic Input/Output, SMBus Serial

Data. Open-Drain Output.

14 SCLK Logic Input, SMBus Serial Clock

15 STBY Logic Input Selecting Normal

Operation (High) or Standby Mode

(Low)

PIN CONFIGURATION

Model Temperature Package Package

Range Description Option

ADM1021AARQ 0°C to 100°C 16-Lead QSOP RQ-16

ADM1021AARQ-REEL 0°C to 100°C 16-Lead QSOP RQ-16

ADM1021AARQ-REEL7 0°C to 100°C 16-Lead QSOP RQ-16

ADM1021AARQZ* 0°C to 100°C 16-Lead QSOP RQ-16

ADM1021AARQZ-REEL* 0°C to 100°C 16-Lead QSOP RQ-16

ADM1021AARQZ-REEL7* 0°C to 100°C 16-Lead QSOP RQ-16

EVAL-ADM1021AEB Evaluation Board

* Z = Pb-Lead free

t

R

t

HD;DAT

t

HIGH

t

F

SCL

SDA

t

LOW

t

HD;STA

t

BUF

S

P

Figure 1. Diagram for Serial Bus Timing

t

SU;DAT

t

SU;STA

t

HD;STA

t

SU;STO

PS

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

ADM1021A features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

REV. D

–3–

Page 4

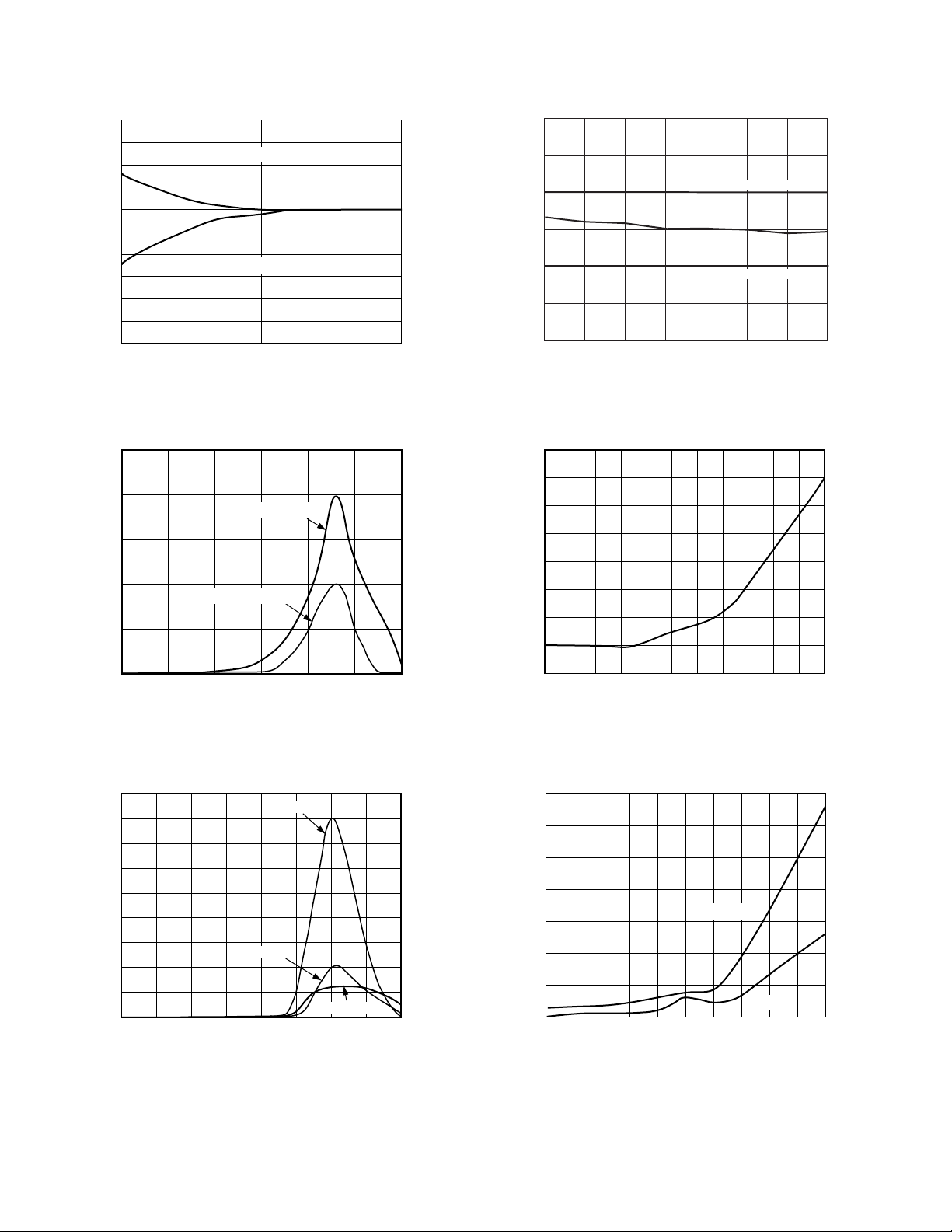

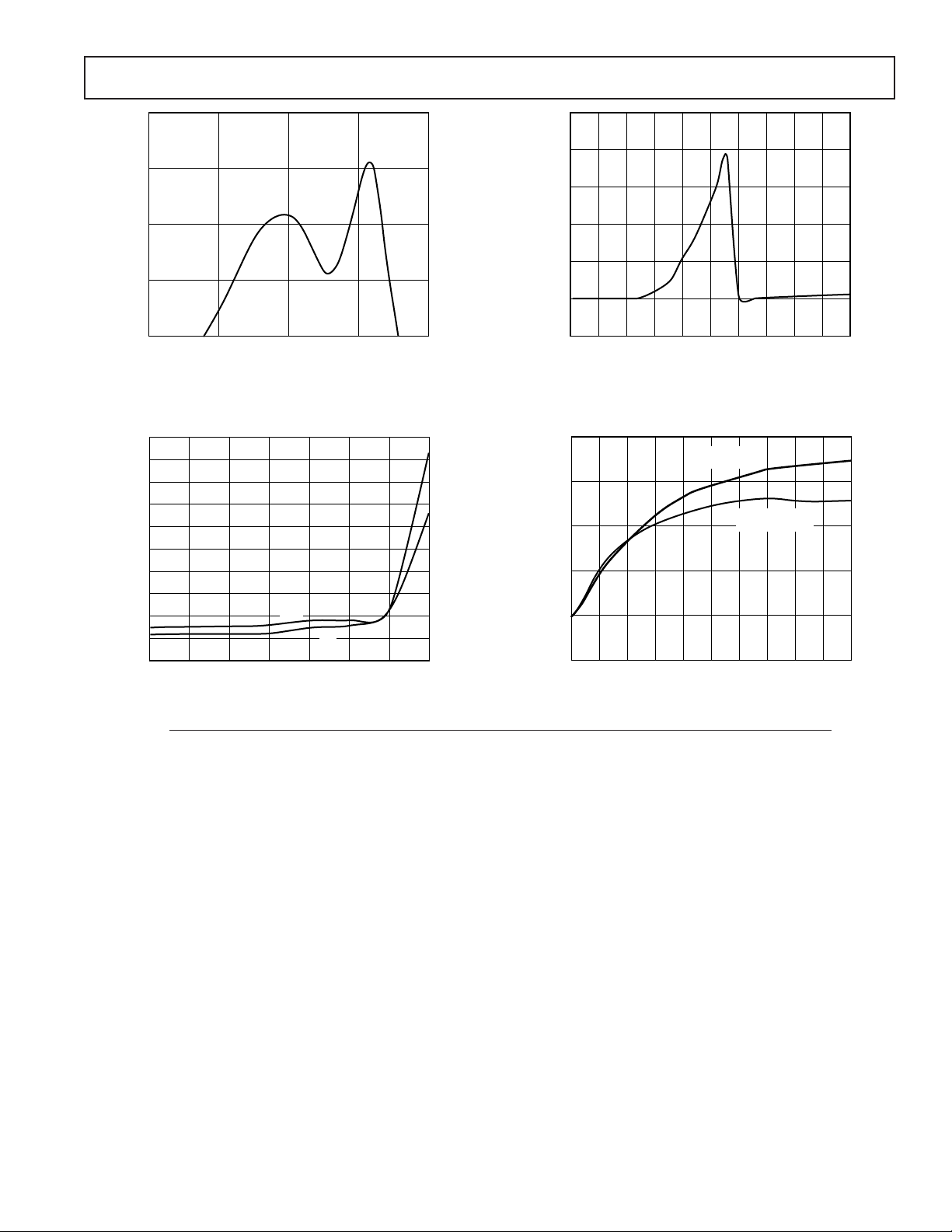

ADM1021A–Typical Performance Characteristics

20

15

10

5

0

–5

–10

–15

TEMPERATURE ERROR – ⴗC

–20

–25

–30

D+ TO GND

D+ TO V

DD

LEAKAGE RESISTANCE – M⍀

101

100

2

1

–1

TEMPERATURE ERROR – ⴗC

–2

–3

60070

50

80

TEMPERATURE – ⴗC

UPPER SPEC LEVEL

DEV10

LOWER SPEC LEVEL

100

90

110

120

TPC 1. Temperature Error vs. PC Board Track Resistance

5

4

250mV p-p REMOTE

3

2

TEMPERATURE ERROR – ⴗC

1

0

100

100mV p-p REMOTE

FREQUENCY – Hz

100M1k 10k 100k 1M 10M

TPC 2. Temperature Error vs. Power Supply Noise

Frequency

9

8

7

6

5

4

3

TEMPERATURE ERROR – ⴗC

2

1

0

10 1k 10k

1

100 100k 1M

100mV p-p

50mV p-p

FREQUENCY – Hz

25mV p-p

10M 100M

TPC 4. Temperature Error of ADM1021A vs. Pentium

III Temperature

14

12

10

8

6

4

2

TEMPERATURE ERROR – ⴗC

0

–1

2

4681012141618202224

CAPACITANCE – nF

TPC 5. Temperature Error vs. Capacitance Between D+

and D–

70

60

50

40

30

20

SUPPLY CURRENT – A

10

0

1

510255075100 1000250 500 750

SCLK FREQUENCY – kHz

VDD = 3.3V

VDD = 5V

TPC 3. Temperature Error vs. Common-Mode Noise

Frequency

–4–

TPC 6. Standby Supply Current vs. Clock Frequency

REV. D

Page 5

ADM1021A

TIME – Seconds

TEMPERATURE – ⴗC

0

25

50

75

100

125

REMOTE

TEMPERATURE

INT

TEMPERATURE

023456789101

4

3

10mV p-p

2

1

TEMPERATURE ERROR – ⴗC

0

100k 1M

10M 100M 1G

FREQUENCY – Hz

TPC 7. Temperature Error vs. Differential-Mode Noise

Frequency

550

500

450

400

350

300

250

200

SUPPLY CURRENT – A

150

100

50

0.125

0.25 0.5 8

CONVERSION RATE – Hz

3.3V

5V

40.0625

21

100

80

60

40

20

SUPPLY CURRENT – A

0

–20

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

SUPPLY VOLTAGE – V

TPC 9. Standby Supply Current vs. Supply Voltage

TPC 8. Operating Supply Current vs. Conversion Rate

FUNCTIONAL DESCRIPTION

The ADM1021A contains a two-channel A-to-D converter with

special input-signal conditioning to enable operation with remote and

on-chip diode temperature sensors. When the ADM1021A is operating normally, the A-to-D converter operates in a free-running mode.

The analog input multiplexer alternately selects either the on-chip

temperature sensor to measure its local temperature, or the remote

temperature sensor. These signals are digitized by the ADC and

the results stored in the Local and Remote Temperature Value

Registers as 8-bit, twos complement words.

The measurement results are compared with local and remote,

high and low temperature limits, stored in four on-chip registers.

Out-of-limit comparisons generate flags that are stored in the

status register, and one or more out-of-limit results will cause

the ALERT output to pull low.

The limit registers can be programmed, and the device controlled and configured, via the serial System Management Bus.

The contents of any register can also be read back via the SMBus.

Control and configuration functions consist of:

•

Switching the device between normal operation and standby

mode.

•

Masking or enabling the ALERT output.

•

Selecting the conversion rate.

On initial power-up, the remote and local temperature values

default to –128°C. Since the device normally powers up converting,

a measurement of local and remote temperature is made and these

values are then stored before a comparison with the stored limits

is made. However, if the part is powered up in standby mode

(STBY pin pulled low), no new values are written to the register

before a comparison is made. As a result, both RLOW and LLOW

are tripped in the Status Register, thus generating an ALERT out-

put. This may be cleared in one of two ways:

1. Change both the local and remote lower limits to –128°C

and read the status register (which in turn clears the ALERT

output).

2. Take the part out of standby and read the status register

(which in turn clears the ALERT output). This will work only

if the measured values are within the limit values.

MEASUREMENT METHOD

A simple method of measuring temperature is to exploit the

negative temperature coefficient of a diode, or the base-emitter

voltage of a transistor, operated at constant current. Unfortunately, this technique requires calibration to null out the effect

of the absolute value of V

TPC 10. Response to Thermal Shock

, which varies from device to device.

BE

REV. D

–5–

Page 6

ADM1021A

IN ⴛ I I

BIAS

V

DD

D+

REMOTE

SENSING

TRANSISTOR

C1*

D–

*

CAPACITOR C1 IS OPTIONAL. IT IS ONLY NECESSARY IN NOISY ENVIRONMENTS.

C1 = 2.2nF TYPICAL, 3nF MAX.

BIAS

DIODE

Figure 2. Input Signal Conditioning

The technique used in the ADM1021A is to measure the change

when the device is operated at two different currents.

in V

BE

This is given by:

∆V

= KT/q × ln(N)

BE

where:

K is Boltzmann’s constant,

q is charge on the electron (1.6 × 10

–19

coulombs),

T is absolute temperature in kelvins,

N is ratio of the two currents.

Figure 2 shows the input signal conditioning used to measure the

output of an external temperature sensor. This figure shows the

external sensor as a substrate transistor, provided for temperature monitoring on some microprocessors, but it could equally

well be a discrete transistor. If a discrete transistor is used, the

collector will not be grounded and should be linked to the base.

To prevent ground noise interfering with the measurement, the

more negative terminal of the sensor is not referenced to ground,

but is biased above ground by an internal diode at the D– input.

If the sensor is operating in a noisy environment, C1 may optionally

be added as a noise filter. Its value is typically 2200 pF, but should

be no more than 3000 pF. See the section on layout considerations

for more information on C1.

To measure ∆V

, the sensor is switched between operating currents

BE

of I and N × I. The resulting waveform is passed through a 65 kHz

low-pass filter to remove noise, then to a chopper-stabilized amplifier that performs the functions of amplification and rectification of

the waveform to produce a dc voltage proportional to ∆V

. This

BE

voltage is measured by the ADC to give a temperature output in

8-bit twos complement format. To reduce the effects of noise

further, digital filtering is performed by averaging the results of

16 measurement cycles.

Signal conditioning and measurement of the internal temperature sensor is performed in a similar manner.

DIFFERENCES BETWEEN THE ADM1021 AND THE ADM1021A

Although the ADM1021A is pin-for-pin compatible with the

ADM1021, there are some differences between the two devices.

Below is a summary of these differences and reasons for the changes.

1. The ADM1021A forces a larger current through the remote

temperature sensing diode, typically 205 µA versus 90 µA

V

OUT+

TO ADC

V

LOWPASS FILTER

f

= 65kHz

C

OUT–

for the ADM1021. The main reason for this is to improve

the noise immunity of the part.

2. As a result of the greater Remote Sensor Source Current the

operating current of the ADM1021A is higher than that of

the ADM1021, typically 205 mA versus 160 mA.

3. The temperature measurement range of the ADM1021A is

0°C to 127°C, compared with –128°C to +127°C for the

ADM1021. As a result, the ADM1021 should be used if

negative temperature measurement is required.

4. The power-on reset values of the remote and local temperature values are –128°C in the ADM1021A as compared with

0°C in the ADM1021. As the part is powered up converting

(except when the part is in standby mode, i.e., Pin 15 is

pulled low) the part will measure the actual values of remote

and local temperature and write these to the registers.

5. The four MSBs of the Revision Register may be used to

identify the part. The ADM1021 Revision Register reads

0xh and the ADM1021A reads 3xh.

6. The power-on default value of the Address Pointer Register

is undefined in the ADM1021A and is equal to 00h in the

ADM1021. As a result, a value must be written to the Address

Pointer Register before a read is done in the ADM1021A.

The ADM1021 is capable of reading back local temperature

without writing to the Address Pointer Register as it defaulted

to the local temperature measurement register at power-up.

7. Setting the mask bit (Bit 7 Config Reg) on the ADM1021A

will mask current and future ALERTs. On the ADM1021

the mask bit will only mask future ALERTs. Any current

ALERT will have to be cleared using an ARA.

TEMPERATURE DATA FORMAT

One LSB of the ADC corresponds to 1°C, so the ADC can theoretically measure from –128°C to +127°C, although the device

does not measure temperatures below 0°C so the actual range is

0°C to 127°C. The temperature data format is shown in Table I.

The results of the local and remote temperature measurements

are stored in the local and remote temperature value registers,

and are compared with limits programmed into the local and

remote high and low limit registers.

–6–

REV. D

Page 7

ADM1021A

Table I. Temperature Data Format

Temperature Digital Output

0°C0 000 0000

1°C0 000 0001

10°C0 000 1010

25°C0 001 1001

50°C0 011 0010

75°C0 100 1011

100°C0 110 0100

125°C0 111 1101

127°C0 111 1111

REGISTERS

The ADM1021A contains nine registers that are used to store

the results of remote and local temperature measurements,

high and low temperature limits, and to configure and control

the device. A description of these registers follows, and further

details are given in Tables II to IV. It should be noted that the

ADM1021A’s registers are dual port, and have different addresses

for read and write operations. Attempting to write to a read address,

or to read from a write address, will produce an invalid result.

Register addresses above 0Fh are reserved for future use or used

for factory test purposes and should not be written to.

Address Pointer Register

The Address Pointer Register itself does not have, nor does it

require, an address, as it is the register to which the first data

byte of every write operation is written automatically. This data

byte is an address pointer that sets up one of the other registers

for the second byte of the write operation, or for a subsequent

read operation.

Value Registers

The ADM1021A has two registers to store the results of local

and remote temperature measurements. These registers are

written to by the ADC and can only be read over the SMBus.

Status Register

Bit 7 of the Status Register indicates when it is high that the

ADC is busy converting. Bits 5 to 3 are flags that indicate the

results of the limit comparisons.

If the local and/or remote temperature measurement is above the

corresponding high temperature limit or below the corresponding

low temperature limit, then one or more of these flags will be set.

Bit 2 is a flag that is set if the remote temperature sensor is opencircuit. These five flags are NOR’d together, so that if any of them

is high, the ALERT interrupt latch will be set and the ALERT

output will go low. Reading the Status Register will clear the five

flag bits, provided the error conditions that caused the flags to be

set have gone away. While a limit comparator is tripped due to a

value register containing an out-of-limit measurement, or the sensor is open-circuit, the corresponding flag bit cannot be reset. A

flag bit can only be reset if the corresponding value register contains an in-limit measurement, or the sensor is good.

Table II. Status Register Bit Assignments

Bit Name Function

7 BUSY 1 When ADC Converting

6 LHIGH* 1 When Local High Temp Limit Tripped

5 LLOW* 1 When Local Low Temp Limit Tripped

4 RHIGH* 1 When Remote High Temp Limit Tripped

3 RLOW* 1 When Remote Low Temp Limit Tripped

2 OPEN* 1 When Remote Sensor Open-Circuit

1–0 Reserved

*These flags stay high until the status register is read or they are reset by POR.

Table III. List of ADM1021A Registers

READ Address (Hex) WRITE Address (Hex) Name Power-On Default

Not Applicable Not Applicable Address Pointer Undefined

00 Not Applicable Local Temp. Value 1000 0000 (80h) (–128°C)

01 Not Applicable Remote Temp. Value 1000 0000 (80h) (–128°C)

02 Not Applicable Status Undefined

03 09 Configuration 0000 0000 (00h)

04 0A Conversion Rate 0000 0010 (02h)

05 0B Local Temp. High Limit 0111 1111 (7Fh) (+127°C)

06 0C Local Temp. Low Limit 1100 1001 (C9h) (–55°C)

07 0D Remote Temp. High Limit 0111 1111 (7Fh) (+127°C)

08 0E Remote Temp. Low Limit 1100 1001 (C9h) (–55°C)

Not Applicable 0F

10 Not Applicable Reserved Undefined

11 11 Reserved Undefined

12 12 Reserved Undefined

13 13 Reserved Undefined

14 14 Reserved Undefined

15 16 Reserved Undefined

17 18 Reserved Undefined

19 Not Applicable Reserved Undefined

20 21 Reserved Undefined

1

One-Shot

2

2

2

2

2

2

2

2

2

FE Not Applicable Manufacturer Device ID 0100 0001 (41h)

FF Not Applicable Die Revision Code 0011 xxxx (3xh)

NOTES

1

Writing to address 0F causes the ADM1021A to perform a single measurement. It is not a data register as such and it does not matter what data is written to it.

2

These registers are reserved for future versions of the device.

REV. D

–7–

Page 8

ADM1021A

The ALERT interrupt latch is not reset by reading the Status

Register, but will be reset when the ALERT output has been

serviced by the master reading the device address, provided the

error condition has gone away and the Status Register flag bits

have been reset.

Configuration Register

Two bits of the configuration register are used. If Bit 6 is 0, which

is the power-on default, the device is in operating mode with the

ADC converting. If Bit 6 is set to 1, the device is in standby

mode and the ADC does not convert. Standby mode can also

be selected by taking the STBY pin low. In standby mode the values stored in the Remote and Local Temperature Registers remain

at the value they were when the part was placed in standby.

Bit 7 of the configuration register is used to mask the ALERT out-

put. If Bit 7 is 0, which is the power-on default, the ALERT output

is enabled. If Bit 7 is set to 1, the ALERT output is disabled.

Table IV. Configuration Register Bit Assignments

Power-On

Bit Name Function Default

7 MASK1 0 = ALERT Enabled 0

1 = ALERT Masked

6 RUN/STOP 0 = Run 0

1 = Standby

5–0 Reserved 0

Conversion Rate Register

The lowest three bits of this register are used to program the conversion rate by dividing the ADC clock by 1, 2, 4, 8, 16, 32, 64,

or 128, to give conversion times from 125 ms (Code 07h) to 16

seconds (Code 00h). This register can be written to and read back

over the SMBus. The higher five bits of this register are unused

and must be set to zero. Use of slower conversion times greatly

reduces the device power consumption, as shown in Table V.

Table V. Conversion Rate Register Codes

Average Supply Current

Data Conversion/secµA Typ at VCC = 3.3 V

00h 0.0625 150

01h 0.125 150

02h 0.25 150

03h 0.5 150

04h 1 150

05h 2 150

06h 4 160

07h 8 180

08h to FFh Reserved

Limit Registers

The ADM1021A has four limit registers to store local and remote,

high and low temperature limits. These registers can be written

to and read back over the SMBus. The high limit registers

perform a > comparison while the low limit registers perform a

< comparison. For example, if the high limit register is programmed as a limit of 80°C, measuring 81°C will result in an

alarm condition. Even though the temperature measurement

range is from 0ⴗ to 127°C, it is possible to program the limit

register with negative values. This is for backwards-compatibility

with the ADM1021.

One-Shot Register

The one-shot register is used to initiate a single conversion and

comparison cycle when the ADM1021A is in standby mode,

after which the device returns to standby. This is not a data

register as such and it is the write operation that causes the oneshot conversion. The data written to this address is irrelevant and

is not stored.

SERIAL BUS INTERFACE

Control of the ADM1021A is carried out via the serial bus. The

ADM1021A is connected to this bus as a slave device, under the

control of a master device. Note that the SMBus and SCL pins

are three-stated when the ADM1021A is powered down and will

not pull down the SMBus.

ADDRESS PINS

In general, every SMBus device has a 7-bit device address (except

for some devices that have extended, 10-bit addresses). When

the master device sends a device address over the bus, the slave

device with that address will respond. The ADM1021A has two

address pins, ADD0 and ADD1, to allow selection of the device

address, so that several ADM1021As can be used on the same

bus, and/or to avoid conflict with other devices. Although only

two address pins are provided, these are three-state, and can be

grounded, left unconnected, or tied to V

, so that a total of

DD

nine different addresses are possible, as shown in Table VI.

It should be noted that the state of the address pins is only sampled

at power-up, so changing them after power-up will have no effect.

Table VI. Device Addresses

ADD0 ADD1 Device Address

00 0011 000

0NC 0011 001

01 0011 010

NC 0 0101 001

NC NC 0101 010

NC 1 0101 011

10 1001 100

1NC 1001 101

11 1001 110

ADD0, ADD1 sampled at power-up only.

The serial bus protocol operates as follows:

1. The master initiates data transfer by establishing a START

condition, defined as a high-to-low transition on the serial

data line SDATA, while the serial clock line SCLK remains

high. This indicates that an address/data stream will follow.

All slave peripherals connected to the serial bus respond to

the START condition and shift in the next eight bits, consisting

of a 7-bit address (MSB first) plus an R/W bit, which determines the direction of the data transfer, i.e., whether data

will be written to or read from the slave device.

The peripheral whose address corresponds to the transmitted

address responds by pulling the data line low during the low

period before the ninth clock pulse, known as the Acknowledge Bit. All other devices on the bus now remain idle while

the selected device waits for data to be read from or written

to it. If the R/W bit is a 0, the master will write to the slave

device. If the R/W bit is a 1, the master will read from the

slave device.

–8–

REV. D

Page 9

ADM1021A

2. Data is sent over the serial bus in sequences of nine clock

pulses, eight bits of data followed by an Acknowledge Bit

from the slave device. Transitions on the data line must occur

during the low period of the clock signal and remain stable

during the high period, as a low-to-high transition when the

clock is high may be interpreted as a stop signal. The number

of data bytes that can be transmitted over the serial bus in a

single read or write operation is limited only by what the

master and slave devices can handle.

3. When all data bytes have been read or written, stop conditions

are established. In write mode, the master will pull the data line

high during the 10th clock pulse to assert a stop condition. In

read mode, the master device will override the acknowledge bit

by pulling the data line high during the low period before the

ninth clock pulse. This is known as No Acknowledge. The

master will then take the data line low during the low period

before the 10th clock pulse, then high during the 10th clock

pulse to assert a stop condition.

191

SCLK

A6

SDATA

START BY

MASTER

A5 A4 A3 A2 A1 A0 D7

FRAME 1

SERIAL BUS ADDRESS BYTE

SCL (CONTINUED)

R/W

ACK. BY

ADM1021A

Any number of bytes of data may be transferred over the serial

bus in one operation, but it is not possible to mix read and write

in one operation, because the type of operation is determined at

the beginning and cannot subsequently be changed without

starting a new operation.

In the case of the ADM1021A, write operations contain either

one or two bytes, while read operations contain one byte.

To write data to one of the device data registers or read data

from it, the Address Pointer Register must be set so that the

correct data register is addressed, data can then be written into

that register or read from it. The first byte of a write operation

always contains a valid address that is stored in the Address

Pointer Register. If data is to be written to the device, the write

operation contains a second data byte that is written to the register selected by the address pointer register.

9

D6

D5 D4 D3 D2 D1

ADDRESS POINTER REGISTER BYTE

1

FRAME 2

D0

ACK. BY

ADM1021A

9

SDA (CONTINUED)

D7 D6

D5 D4 D3 D2 D1

FRAME 3

DATA BYTE

D0

ACK. BY

ADM1021A

STOP BY

MASTER

Figure 3. Writing a Register Address to the Address Pointer Register, then Writing Data to the Selected Register

191

SCLK

SDATA A5 A4

START BY

MASTER

A6

SERIAL BUS ADDRESS BYTE

A3 A2

FRAME 1

A1 A0

R/W

ACK. BY

ADM1021A

D7 D6

D4

D5

ADDRESS POINTER REGISTER BYTE

FRAME 2

D3

D2

D1

9

D0

ACK. BY

ADM1021A

STOP BY

MASTER

Figure 4. Writing to the Address Pointer Register Only

SCLK

SDATA

START BY

MASTER

19

A6

A5 A4 A3 A2 A1 A0 D7

FRAME 1

SERIAL BUS ADDRESS BYTE

R/W

ADM1021A

ACK. BY

1

D6

D5

D4 D3

FRAME 2 DATA BYTE FROM ADM1021A

D2

D1 D0

9

NO ACK.

BY MASTER

STOP BY

MASTER

REV. D

Figure 5. Reading Data from a Previously Selected Register

–9–

Page 10

ADM1021A

This is illustrated in Figure 3. The device address is sent over

the bus followed by R/W set to 0. This is followed by two data

bytes. The first data byte is the address of the internal data register to be written to, which is stored in the Address Pointer

Register. The second data byte is the data to be written to the

internal data register.

When reading data from a register there are two possibilities:

1. If the ADM1021A’s Address Pointer Register value is unknown

or not the desired value, it is first necessary to set it to the

correct value before data can be read from the desired data

register. This is done by performing a write to the ADM1021A

as before, but only the data byte containing the register read

address is sent, as data is not to be written to the register.

This is shown in Figure 4.

A read operation is then performed consisting of the serial

bus address, R/W bit set to 1, followed by the data byte read

from the data register. This is shown in Figure 5.

2. If the Address Pointer Register is known to be already at the

desired address, data can be read from the corresponding data

register without first writing to the Address Pointer Register,

so Figure 4 can be omitted.

NOTES

1. Although it is possible to read a data byte from a data register

without first writing to the Address Pointer Register, if the

Address Pointer Register is already at the correct value, it is

not possible to write data to a register without writing to the

Address Pointer Register, because the first data byte of a

write is always written to the Address Pointer Register.

2. Remember that the ADM1021A registers have different

addresses for read and write operations. The write address

of a register must be written to the Address Pointer if data

is to be written to that register, but it is not possible to read

data from that address. The read address of a register must

be written to the Address Pointer before data can be read

from that register.

ALERT OUTPUT

The ALERT output goes low whenever an out-of-limit measurement is detected, or if the remote temperature sensor is

open-circuit. It is an open-drain and requires a 10 kΩ pull-up to

. Several ALERT outputs can be wire-ANDed together, so

V

DD

that the common line will go low if one or more of the ALERT

outputs goes low.

The ALERT output can be used as an interrupt signal to a processor, or it may be used as an SMBALERT. Slave devices on

the SMBus can normally not signal to the master that they want

to talk, but the SMBALERT function allows them to do so.

One or more ALERT outputs are connected to a common

SMBALERT line connected to the master. When the SMBALERT

line is pulled low by one of the devices, the following procedure

occurs as illustrated in Figure 6.

MASTER

RECEIVES

SMBALERT

NO

START ALERT RESPONSE ADDRESSRDACK DEVICE ADDRESS

MASTER SENDS

ARA AND READ

COMMAND

Figure 6. Use of

DEVICE SENDS

ITS ADDRESS

SMBALERT

ACK

STOP

–10–

1. SMBALERT is pulled low.

2. Master initiates a read operation and sends the Alert Response

Address (ARA = 0001 100). This is a general call address

that must not be used as a specific device address.

3. The device whose ALERT output is low responds to the Alert

Response Address and the master reads its device address. The

address of the device is now known and it can be interrogated

in the usual way.

4. If more than one device’s ALERT output is low, the one with

the lowest device address will have priority, in accordance with

normal SMBus arbitration.

5. Once the ADM1021A has responded to the Alert Response

Address, it will reset its ALERT output, provided that the

error condition that caused the ALERT no longer exists. If

the SMBALERT line remains low, the master will send the

ARA again, and so on until all devices whose ALERT outputs

were low have responded.

LOW POWER STANDBY MODES

The ADM1021A can be put into a low power standby mode

using hardware or software, that is, by taking the STBY input

low, or by setting Bit 6 of the Configuration Register. When

STBY is high, or Bit 6 is low, the ADM1021A operates normally.

When STBY is pulled low or Bit 6 is high, the ADC is inhibited,

so any conversion in progress is terminated without writing the

result to the corresponding value register.

The SMBus is still enabled. Power consumption in the standby

mode is reduced to less than 10 µA if there is no SMBus activity,

or 100 µA if there are clock and data signals on the bus.

These two modes are similar but not identical. When STBY is

low, conversions are completely inhibited. When Bit 6 is set but

STBY is high, a one-shot conversion of both channels can be initiated by writing XXh to the One-Shot Register (address 0Fh).

SENSOR FAULT DETECTION

The ADM1021A has a fault detector at the D+ input that detects

if the external sensor diode is open-circuit. This is a simple

voltage comparator that trips if the voltage at D+ exceeds

– 1V (typical). The output of this comparator is checked

V

CC

when a conversion is initiated, and sets Bit 2 of the Status Register

if a fault is detected.

If the remote sensor voltage falls below the normal measuring

range, for example due to the diode being short-circuited, the

ADC will output –128°C (1000 0000). Since the normal operating temperature range of the device only extends down to 0°C,

this output code will never be seen in normal operation, so it

can be interpreted as a fault condition.

In this respect, the ADM1021A differs from and improves upon

competitive devices that output zero if the external sensor goes

short-circuit. These devices can misinterpret a genuine 0°C

measurement as a fault condition.

If the external diode channel is not being used and is shorted

out, the resulting ALERT may be cleared by writing 80h (–128°C)

to the low limit register.

REV. D

Page 11

ADM1021A

APPLICATIONS INFORMATION

FACTORS AFFECTING ACCURACY

Remote Sensing Diode

The ADM1021A is designed to work with substrate transistors

built into processors, or with discrete transistors. Substrate

transistors will generally be PNP types with the collector connected

to the substrate. Discrete types can be either PNP or NPN,

connected as a diode (base shorted to collector). If an NPN

transistor is used, the collector and base are connected to D+ and

the emitter to D–. If a PNP transistor is used, the collector and

base are connected to D– and the emitter to D+.

The user has no choice in the case of substrate transistors, but if

a discrete transistor is used, the best accuracy will be obtained

by choosing devices according to the following criteria:

1. Base-emitter voltage greater than 0.25 V at 6 µA, at the high-

est operating temperature.

2. Base-emitter voltage less than 0.95 V at 100 µA, at the lowest

operating temperature.

3. Base resistance less than 100 Ω.

4. Small variation in h

control of V

BE

(say 50 to 150), which indicates tight

FE

characteristics.

Transistors such as 2N3904, 2N3906, or equivalents in SOT-23

package are suitable devices to use.

Thermal Inertia and Self-Heating

Accuracy depends on the temperature of the remote-sensing

diode and/or the internal temperature sensor being at the same

temperature as that being measured, and a number of factors

can affect this. Ideally, the sensor should be in good thermal contact with the part of the system being measured, for example the

processor. If it is not, the thermal inertia caused by the mass of

the sensor will cause a lag in the response of the sensor to a temperature change. In the case of the remote sensor this should not

be a problem, as it will be either a substrate transistor in the processor or a small package device such as SOT-23 placed in close

proximity to it.

The on-chip sensor, however, will often be remote from the

processor and will only be monitoring the general ambient temperature around the package. The thermal time constant of the

QSOP-16 package is about 10 seconds.

In practice, the package will have electrical, and hence thermal,

connection to the printed circuit board, so the temperature rise

due to self-heating will be negligible.

LAYOUT CONSIDERATIONS

Digital boards can be electrically noisy environments, and because

the ADM1021A is measuring very small voltages from the

remote sensor, care must be taken to minimize noise induced at

the sensor inputs. The following precautions should be taken:

1. Place the ADM1021A as close as possible to the remote

sensing diode. Provided that the worst noise sources such as

clock generators, data/address buses, and CRTs are avoided,

this distance can be four to eight inches.

2. Route the D+ and D– tracks close together, in parallel, with

grounded guard tracks on each side. Provide a ground plane

under the tracks if possible.

3. Use wide tracks to minimize inductance and reduce noise pickup.

10 mil track minimum width and spacing is recommended.

4. Try to minimize the number of copper/solder joints, which

can cause thermocouple effects. Where copper/solder joints

are used, make sure that they are in both the D+ and D– paths

and at the same temperature.

Thermocouple effects should not be a major problem as 1°C

corresponds to about 240 µV, and thermocouple voltages are

about 3 µV/°C of temperature difference. Unless there are

two thermocouples with a big temperature differential between

them, thermocouple voltages should be much less than 240 µV.

5. Place a 0.1 µF bypass capacitor close to the V

pin, and

DD

2200 pF input filter capacitors across D+, D– close to the

ADM1021A.

GND

D+

D–

GND

10 mil

10 mil

10 mil

10 mil

10 mil

10 mil

10 mil

Figure 7. Arrangement of Signal Tracks

6. If the distance to the remote sensor is more than eight inches,

the use of twisted pair cable is recommended. This will work

up to about 6 to 12 feet.

REV. D

–11–

Page 12

ADM1021A

7. For really long distances (up to 100 feet), use shielded twisted

pair such as Belden #8451 microphone cable. Connect the

twisted pair to D+ and D– and the shield to GND close to

the ADM1021A. Leave the remote end of the shield unconnected to avoid ground loops.

Because the measurement technique uses switched current sources,

excessive cable and/or filter capacitance can affect the measurement. When using long cables, the filter capacitor may be

reduced or removed.

Cable resistance can also introduce errors. 1 Ω series resistance

introduces about 1°C error.

APPLICATION CIRCUITS

Figure 8 shows a typical application circuit for the ADM1021A,

using a discrete sensor transistor connected via a shielded,

twisted pair cable. The pull-ups on SCLK, SDATA, and ALERT

are required only if they are not already provided elsewhere in

the system.

PROCESSOR

SYSTEM BUS

DISPLAY

DISPLAY

CACHE

CD ROM

2 IDE PORTS

USB USB

2 USB PORTS

HARD

DISK

GMCH

ICH

I/O CONTROLLER

HUB

FWH

(FIRMWARE HUB)

PCI BUS

The SCLK and SDATA pins of the ADM1021A can be interfaced directly to the SMBus of an I/O chip. Figure 9 shows how

the ADM1021A might be integrated into a system using this

type of I/O controller.

C1*

2N3904

*C1 IS OPTIONAL

SHIELD

ADM1021A

D+

D–

GND

V

STBY

SCLK

SDATA

ALERT

ADD0

ADD1

DD

0.1F

SET TO REQUIRED

ADDRESS

3.3V

ALL 10k⍀

IN

I/O

OUT

TO CONTROL

CHIP

Figure 8. Typical Application Circuit

D– D+

ADM1021A

SDATA

SCLK

SMBUS

SYSTEM

MEMORY

PCI SLOTS

SUPER

I/O

ALERT

Figure 9. Typical System Using ADM1021A

–12–

REV. D

Page 13

OUTLINE DIMENSIONS

16-Lead Shrink Small Outline Package [QSOP]

(RQ-16)

Dimensions shown in inches

0.193

BSC

ADM1021A

0.065

0.049

0.010

0.004

COPLANARITY

0.004

0.012

0.008

9

8

0.154

BSC

0.069

0.053

SEATING

PLANE

0.236

BSC

0.010

0.006

16

1

PIN 1

0.025

BSC

COMPLIANT TO JEDEC STANDARDS MO-137AB

8ⴗ

0ⴗ

0.050

0.016

REV. D

–13–

Page 14

ADM1021A

Revision History

Location Page

3/04—Data Sheet changed from REV. C to REV. D.

Changes to FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Updated Ordering Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Change to Figure 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4/03—Data Sheet changed from REV. B to REV. C.

Added ESD Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Updated OUTLINE DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3/02—Data Sheet changed from REV. A to REV. B.

Figures and TPCs renumbered . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . UNIVERSAL

Text Change to Figure 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Change to SERIAL BUS INTERFACE section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

–14–

REV. D

Page 15

ADM1021A

REV. D

–15–

Page 16

ADM1021A

C00056–0–3/04(D)

–16–

Loading...

Loading...