Page 1

A

Precision Four Degrees of Freedom Sensor

FEATURES

Digital gyroscope with range scaling

±75°/sec, ±150°/sec, ±300°/sec settings

Triaxis digital accelerometer: ±3 g

Wide sensor bandwidth: 330 Hz

Autonomous operation and data collection

No external configuration commands required

Start-up time: 180 ms

Sleep mode recovery time: 4 ms

Factory-calibrated sensitivity, bias, and alignment

Calibration temperature range: −40°C to +85°C

SPI-compatible serial interface

Embedded temperature sensor

Programmable operation and control

Automatic and manual bias correction controls

Bartlett window FIR filter length, number of taps

Digital I/O: data-ready, alarm indicator, general-purpose

Alarms for condition monitoring

Sleep mode for power management

DAC output voltage

Enable external sample clock input: up to 1.2 kHz

Single-command self-test

Single-supply operation: 4.75 V to 5.25 V

2000 g shock survivability

Operating temperature range: −40°C to +85°C

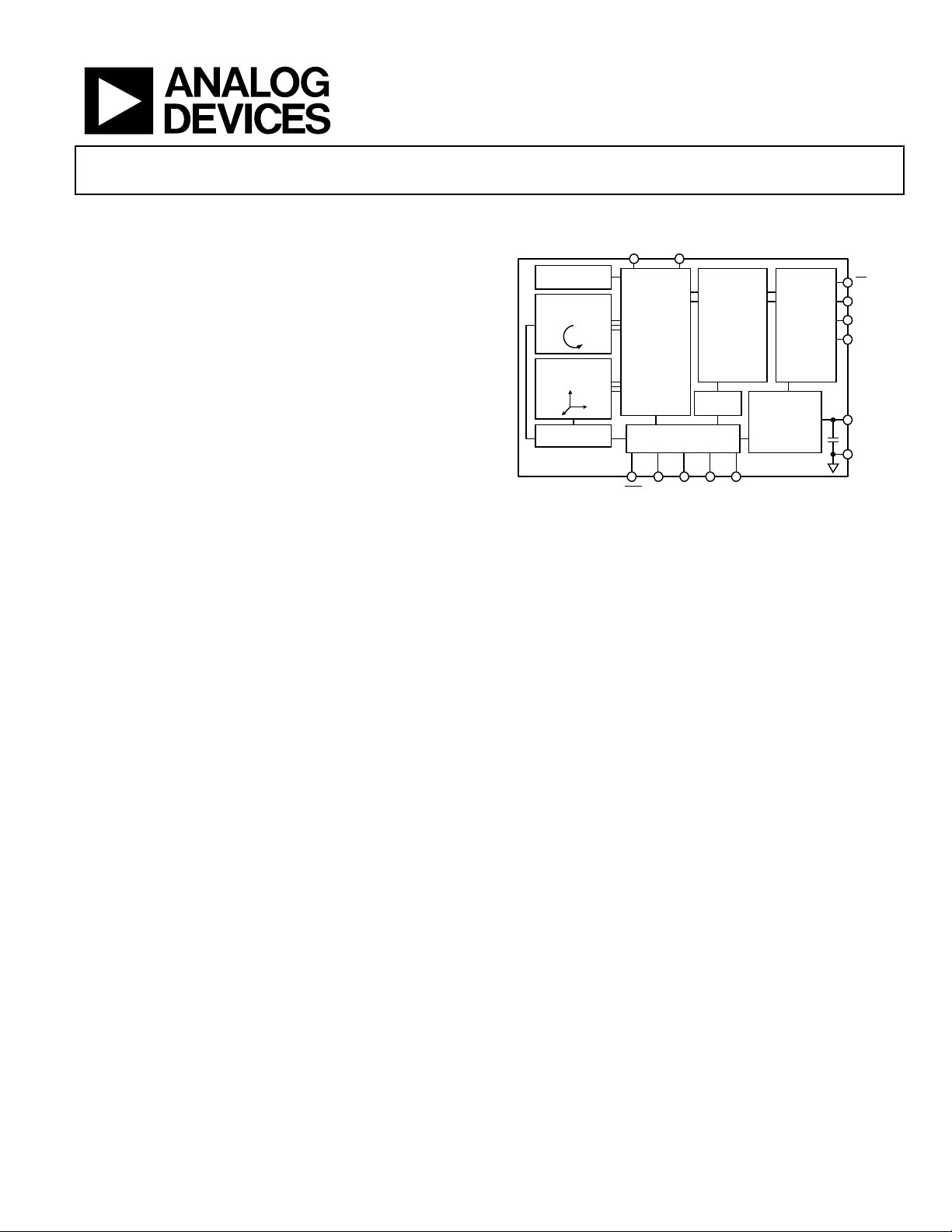

FUNCTIONAL BLOCK DIAGRAM

TEMPERATURE

SENSOR

MEMS

ANGULAR RATE

SENSOR

TRIAXIS MEMS

ACCELERATION

SENSOR

SELF-TEST

ADIS16305

UX_

AUX_

ADC

DAC

SIGNAL

CONDITIONING

AND

CONVERSION

DIGITAL

CONTROL

RST

CALIBRATION

DIGITAL

PROCESSING

ALARMS

DIO3DIO2DIO1

Figure 1.

ADIS16305

AND

DIO4

OUTPUT

REGISTERS

AND SPI

INTERFACE

POWER

MANAGEMENT

CS

SCLK

DIN

DOUT

VCC

GND

9020-001

APPLICATIONS

Medical instrumentation

Robotics

Platform controls

Navigation

GENERAL DESCRIPTION

The iSensor® ADIS16305 is a complete inertial system that

includes a gyroscope and triaxis accelerometer. Each sensor in

the ADIS16305 combines industry-leading iMEMS® technology

with signal conditioning that optimizes dynamic performance.

The factory calibration characterizes each sensor for sensitivity,

bias, alignment, and linear acceleration (gyro bias). As a result, each

sensor has its own dynamic compensation formulas that provide

accurate sensor measurements over a variety of conditions.

The ADIS16305 provides a simple, cost-effective method for

integrating accurate, multiaxis, inertial sensing into industrial

systems, especially when compared with the complexity and

investment associated with discrete designs. All necessary motion

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

testing and calibration are part of the production process at the

factory, greatly reducing system integration time. Tight orthogonal

alignment simplifies inertial frame alignment in navigation systems.

An improved SPI interface and register structure provide faster data

collection and configuration control. The ADIS16305 uses a pinout

that is compatible with the ADIS1635x, ADIS1636x, and

ADIS1640x families, when used with an interface flex connector.

This compact module is approximately 23 mm × 31 mm × 8 mm

and provides a standard connector interface, which enables

horizontal or vertical mounting.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010 Analog Devices, Inc. All rights reserved.

Page 2

ADIS16305

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Specifications .................................................................. 5

Absolute Maximum Ratings ............................................................ 6

ESD Caution .................................................................................. 6

Pin Configuration and Function Descriptions ............................. 7

Typical Performance Characteristics ............................................. 8

Theory of Operation ........................................................................ 9

Basic Operation ............................................................................ 9

Reading Sensor Data .................................................................... 9

Device Configuration .................................................................. 9

Memory Map .............................................................................. 10

Burst Read Data Collection ...................................................... 11

Output Data Registers ............................................................... 11

Orientation Angles ..................................................................... 12

Calibration ................................................................................... 13

Operational Control ................................................................... 13

Input/Output Functions ............................................................ 15

Diagnostics .................................................................................. 16

Product Identification ................................................................ 17

Applications Information .............................................................. 18

Interface Printed Circuit Board (PCB) .................................... 18

Gyroscope Bias Optimization ................................................... 18

Outline Dimensions ....................................................................... 19

Ordering Guide .......................................................................... 19

REVISION HISTORY

7/10—Revision 0: Initial Version

Rev. 0 | Page 2 of 20

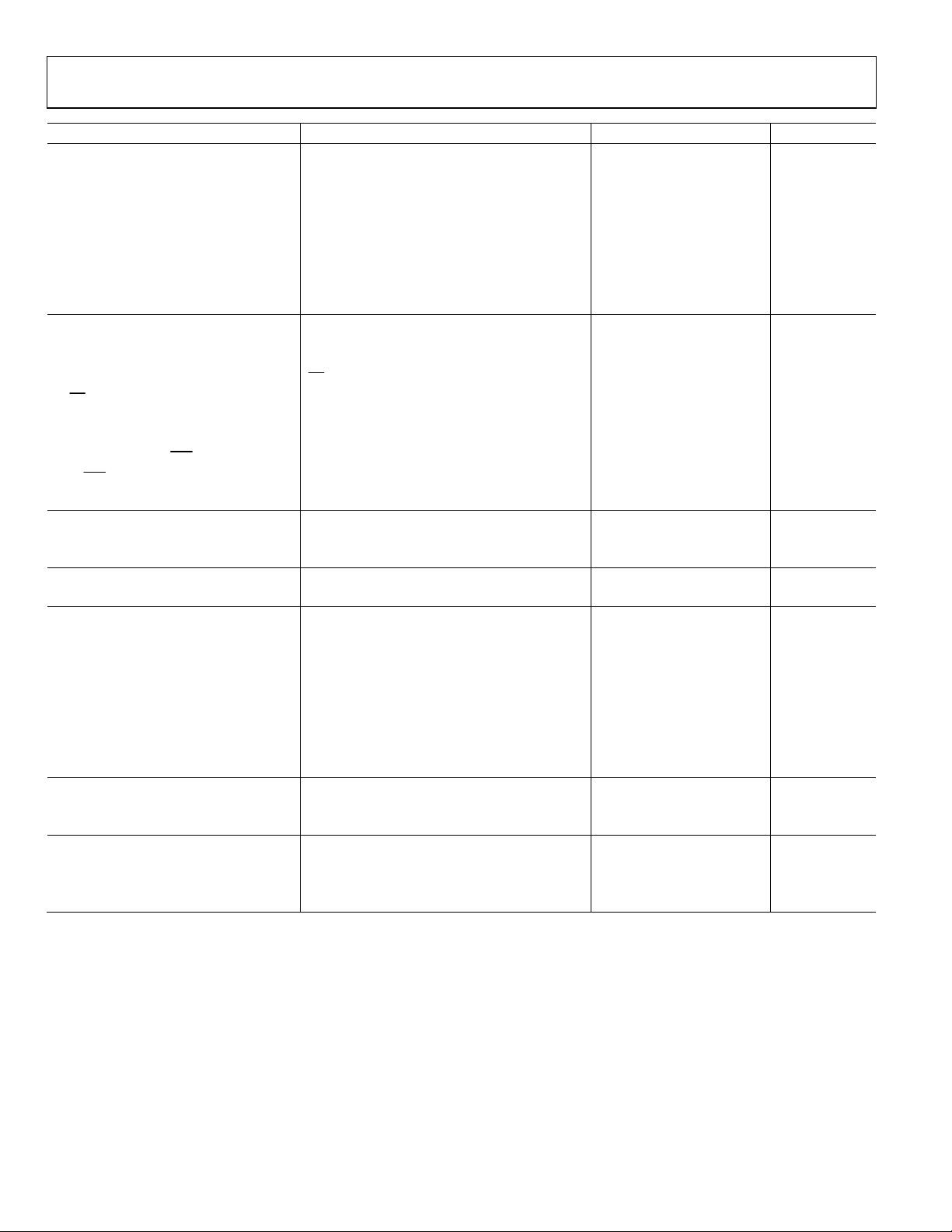

Page 3

ADIS16305

SPECIFICATIONS

TA = 25°C, VCC = 5.0 V, angular rate = 0°/sec, dynamic range = ±300°/sec ± 1 g, unless otherwise noted.

Table 1.

Parameter Test Conditions Min Typ Max Unit

GYROSCOPE

Dynamic Range ±300 ±350 °/sec

Initial Sensitivity TA = 25°C, dynamic range = ±300°/sec 0.0495 0.05 0.0505 °/sec/LSB

T

T

Sensitivity Temperature Coefficient −40°C ≤ TA ≤ +85°C 20 ppm/°C

Misalignment Reference to z-axis accelerometer, TA = 25°C ±0.1 Degrees

Nonlinearity Best-fit straight line 0.1 % of FS

Initial Bias Error TA = 25°C, ±1 σ ±3 °/sec

In-Run Bias Stability TA = 25°C, 1 σ, SMPL_PRD = 0x01 0.006 °/sec

Angular Random Walk TA = 25°C, 1 σ, SMPL_PRD = 0x01 1.85 °/√hr

Bias Temperature Coefficient −40°C ≤ TA ≤ +85°C 0.006 °/sec/°C

Linear Acceleration Effect on Bias Any axis, 1 σ (MSC_CTRL Bit[7] = 1) 0.02 °/sec/g

Voltage Sensitivity VCC = 4.75 V to 5.25 V 0.32 °/sec/V

Output Noise TA = 25°C, ±300°/sec range, no filtering 0.73 °/sec rms

Rate Noise Density TA = 25°C, f = 25 Hz, ±300°/sec, no filtering 0.04 °/sec/√Hz rms

3 dB Bandwidth 330 Hz

Sensor Resonant Frequency 14.5 kHz

Self-Test Change in Output Response ±300°/sec range setting ±696 ±1400 ±2449 LSB

ACCELEROMETERS Each axis

Dynamic Range ±3 ±3.6

Initial Sensitivity 25°C 0.594 0.6 0.606 mg/LSB

Sensitivity Temperature Coefficient −40°C ≤ TA ≤ +85°C 25 ppm/°C

Misalignment Axis-to-axis, TA = 25°C, Δ = 90° ideal ±0.1 Degrees

Axis-to-frame (package), TA = 25°C ±0.5 Degrees

Nonlinearity Best-fit straight line ±0.3 % of FS

Initial Bias Error TA = 25°C, ±1 σ ±60 mg

In-Run Bias Stability TA = 25°C, 1 σ, SMPL_PRD = 0x01 0.037 mg

Velocity Random Walk TA = 25°C, 1 σ, X axis and Y axis 0.1 m/sec/√hr

T

Bias Temperature Coefficient −40°C ≤ TA ≤ +85°C 0.3 mg/°C

Output Noise TA = 25°C, no filtering, X axis and Y axis 4.25 mg rms

T

Noise Density TA = 25°C, no filtering, X axis and Y axis 225 μg/√Hz rms

T

3 dB Bandwidth 330 Hz

Sensor Resonant Frequency 5.5 kHz

Self-Test Change in Output Response X axis and Y axis 500 1100 1700 LSB

Z axis 90 450 860 LSB

ADC INPUT

Resolution 12 Bits

Integral Nonlinearity ±2 LSB

Differential Nonlinearity ±1 LSB

Offset Error ±4 LSB

Gain Error ±2 LSB

Input Range 0 3.3 V

Input Capacitance During acquisition 20 pF

= 25°C, dynamic range = ±150°/sec 0.025 °/sec/LSB

A

= 25°C, dynamic range = ±75°/sec 0.0125 °/sec/LSB

A

g

= 25°C, 1 σ, Z axis 0.16 m/sec/√hr

A

= 25°C, no filtering, Z axis 6.5 mg rms

A

= 25°C, no filtering, Z axis 340 μg/√Hz rms

A

Rev. 0 | Page 3 of 20

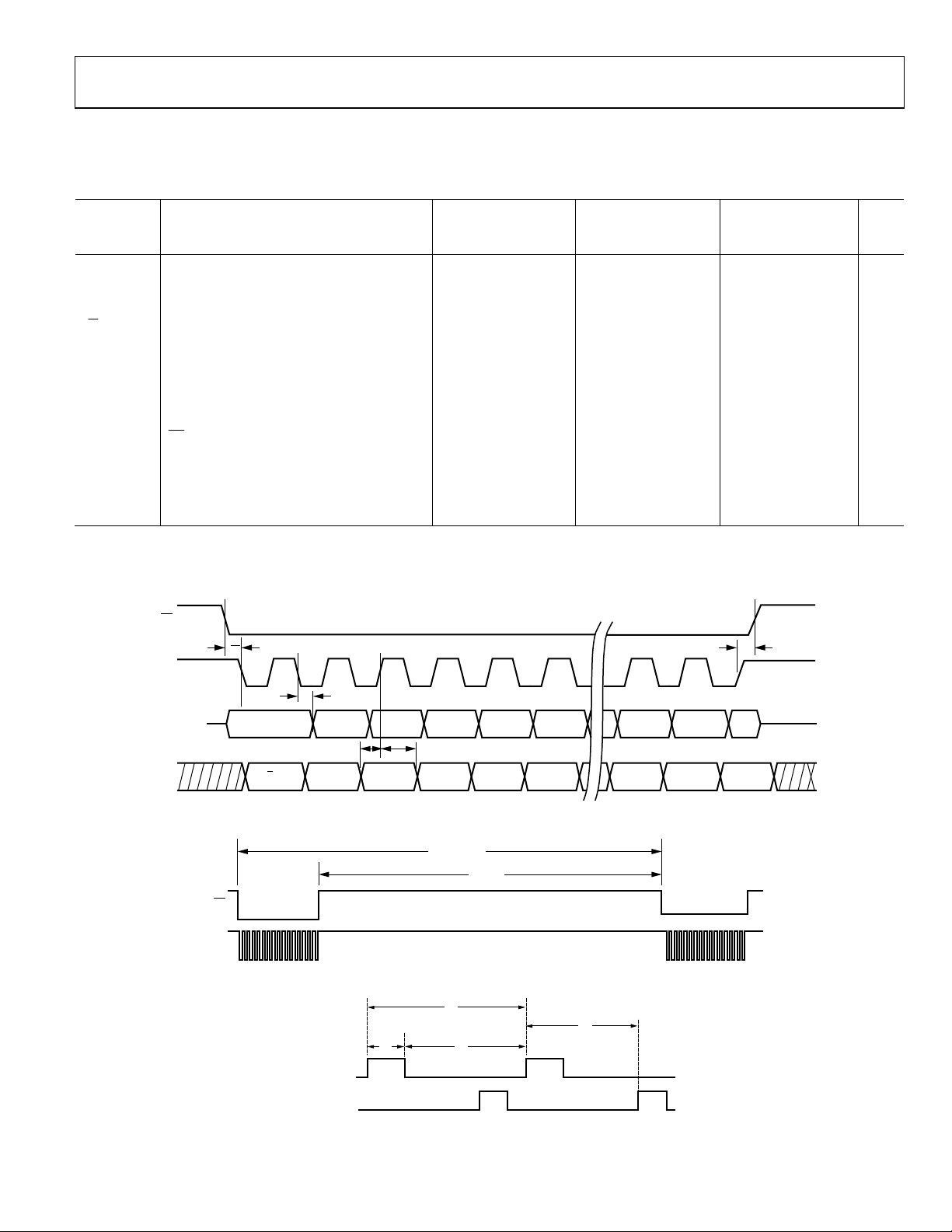

Page 4

ADIS16305

Parameter Test Conditions Min Typ Max Unit

DAC OUTPUT 5 kΩ/100 pF to GND

Resolution 12 Bits

Relative Accuracy For Code 101 to Code 4095 ±4 LSB

Differential Nonlinearity ±1 LSB

Offset Error ±5 mV

Gain Error ±0.5 %

Output Range 0 3.3 V

Output Impedance 2 Ω

Output Settling Time 10 μs

LOGIC INPUTS1

Input High Voltage, V

Input Low Voltage, V

CS Wake-Up Pulse Width

Logic 1 Input Current, I

Logic 0 Input Current, I

All Pins Except RST

RST Pin

Input Capacitance, CIN 10 pF

DIGITAL OUTPUTS1

Output High Voltage, VOH I

Output Low Voltage, VOL I

FLASH MEMORY Endurance2 10,000 Cycles

Data Retention3 T

FUNCTIONAL TIMES4 Time until data is available

Power-On Start-Up Time Normal mode, SMPL_PRD ≤ 0x09 180 ms

Low power mode, SMPL_PRD ≥ 0x0A 250 ms

Reset Recovery Time Normal mode, SMPL_PRD ≤ 0x09 55 ms

Low power mode, SMPL_PRD ≥ 0x0A 120 ms

Sleep Mode Recovery Time 4 ms

Flash Memory Test Time Normal mode, SMPL_PRD ≤ 0x09 20 ms

Low power mode, SMPL_PRD ≥ 0x0A 90 ms

Automatic Self-Test Time 12 ms

CONVERSION RATE SMPL_PRD = 0x01 to 0xFF 0.413 819.2 SPS

Clock Accuracy ±3 %

Sync Input Clock 1.2 kHz

POWER SUPPLY Operating voltage range, VCC 4.75 5.0 5.25 V

Power Supply Current Low power mode at 25°C 18 mA

Normal mode at 25°C 42 mA

Sleep mode at 25°C 500 μA

1

The digital I/O signals are driven by an internal 3.3 V supply, and the inputs are 5 V tolerant.

2

Endurance is qualified as per JEDEC Standard 22, Method A117, and measured at −40°C, +25°C, +85°C, and +125°C.

3

The retention lifetime equivalent is at a junction temperature (TJ) of 85°C as per JEDEC Standard 22, Method A117. Retention lifetime decreases with junction temperature.

4

These times do not include thermal settling and internal filter response times (330 Hz bandwidth), which may impact overall accuracy.

2.0 V

INH

0.8 V

INL

signal to wake up from sleep mode

CS

0.55 V

20 μs

V

INH

V

INL

= 3.3 V ±0.2 ±10 μA

IH

= 0 V

IL

−40 −60 μA

−1 mA

= 1.6 mA 2.4 V

SOURCE

= 1.6 mA 0.4 V

SINK

= 85°C 20 Years

J

Rev. 0 | Page 4 of 20

Page 5

ADIS16305

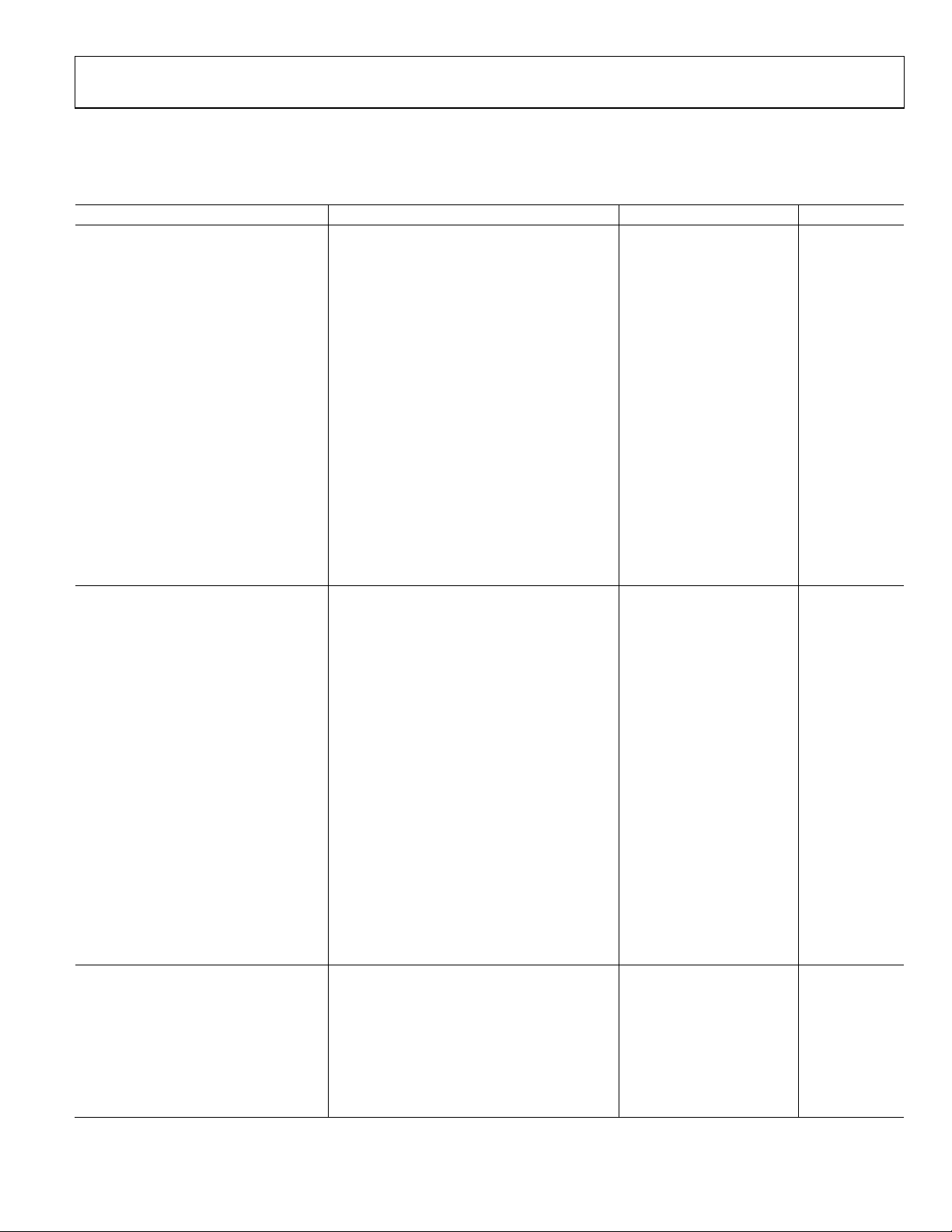

TIMING SPECIFICATIONS

TA = 25°C, VCC = 5 V, unless otherwise noted.

Table 2.

Normal Mode

(SMPL_PRD ≤ 0x09)

Parameter Description Min1 Typ Max Min1 Typ Max Min1 Typ Max Unit

f

Serial clock 0.01 2.0 0.01 0.3 0.01 1.0 MHz

SCLK

t

Stall period between data 9 75 1/f

STALL

t

Read rate 40 100 μs

READRATE

tCS Chip select to clock edge 48.8 48.8 48.8 ns

t

DOUT valid after SCLK edge 100 100 100 ns

DAV

t

DIN setup time before SCLK rising edge 24.4 24.4 24.4 ns

DSU

t

DIN hold time after SCLK rising edge 48.8 48.8 48.8 ns

DHD

t

, t

SCLKR

SCLK rise/fall times (not shown in figures) 5 12.5 5 12.5 5 12.5 ns

SCLKF

tDR, tDF DOUT rise/fall times (not shown in figures) 5 12.5 5 12.5 5 12.5 ns

t

SFS

t

1

high after SCLK edge

CS

Input sync positive pulse width 5 5 μs

5 5 5 ns

tx Input sync low time 100 100 μs

t

2

t

3

1

Guaranteed by design and characterization, but not tested in production.

Input sync to data-ready output 600 600 μs

Input sync period 833 833 μs

Timing Diagrams

Low Power Mode

(SMPL_PRD ≥ 0x0A) Burst Read

μs

SCLK

CS

SCLK

DOUT

DIN

t

CS

1 2 3 4 5 6 15 16

t

DAV

MSB DB14

R/W A5A6 A4 A3 A2

DB13 DB12 DB10DB11 DB2 LSBDB1

t

DSU

t

DHD

D2

D1 LSB

t

SFS

09020-002

Figure 2. SPI Timing and Sequence

t

READRATE

t

STALL

CS

SCLK

09020-003

Figure 3. Stall Time and Data Rate

t

3

t

2

t

X

09020-004

SYNC

CLOCK (DIO 4)

DATA

READY

t

1

Figure 4. Input Clock Timing Diagram

Rev. 0 | Page 5 of 20

Page 6

ADIS16305

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Acceleration

Any Axis, Unpowered 2000 g

Any Axis, Powered 2000 g

VCC to GND −0.3 V to +6.0 V

Digital Input Voltage to GND −0.3 V to +5.3 V

Digital Output Voltage to GND −0.3 V to VCC + 0.3 V

Analog Input to GND −0.3 V to +3.6 V

Operating Temperature Range −40°C to +85°C

Storage Temperature Range −65°C to +125°C

1

Extended exposure to temperatures outside the specified temperature

range of −40°C to +85°C can adversely affect the accuracy of the factory

calibration. For best accuracy, store the parts within the specified operating

range of −40°C to +85°C.

2

Although the device is capable of withstanding short-term exposure to

150°C, long-term exposure threatens internal mechanical integrity.

1, 2

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Table 4. Package Characteristics

Package Type θJA θ

24-Lead Module 39.8°C/W 14.2°C/W 6.1 grams (max)

ESD CAUTION

Device Weight

JC

Rev. 0 | Page 6 of 20

Page 7

ADIS16305

A

Y

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

DIS16305

TOP VIEW

(Not to Scale)

DIO3

SCLK

DIN

DIO1

DIO2

VCC

GND

GND

DNC

DNC

AUX_ADC

DNC

1

23456789101112131415161718192021222324

CS

RST

VCC

VCC

DNC

DNC

DNC

AUX_DAC

DNC

09020-005

DOUT

DIO4/CLKIN

NOTES

1. MATING CONNECTOR: SAMTEC FTSH-112-03

OR EQUIVALENT .

2. DNC = DO NOT CONNECT.

GND

Figure 5. ADIS16305 Pin Configuration

Z-AXIS

a

Z

g

Z

-AXIS

a

Y

NOTES

1. THE ARROW DIRECTION ASS OCIATED WITH

THE DIRECTION OF MOTION THAT PRODUCES A POSITIVE RESPONSE IN

EACH ACCELEROMETER AND GYROSCO PE OUTPUT REGISTER.

a

,

a

, AND

Z

Y

g

INDICATES

Z

X-AXIS

a

X

09020-006

Figure 6. Axial Orientation

Table 5. Pin Function Descriptions

Pin No. Mnemonic Type1 Description

1 DIO3 I/O Configurable Digital Input/Output.

2 DIO4/CLKIN I/O Configurable Digital Input/Output or Sync Clock Input.

3 SCLK I SPI Serial Clock.

4 DOUT O SPI Data Output. Clocks output on SCLK falling edge.

5 DIN I SPI Data Input. Clocks input on SCLK rising edge.

6

CS

I SPI Chip Select.

7, 9 DIO1, DIO2 I/O Configurable Digital Input/Output.

8

RST

I Reset.

10, 11, 12 VCC S Power Supply.

13, 14, 15 GND S Power Ground.

16, 17, 18, 19, 22, 23, 24 DNC N/A Do Not Connect.

20 AUX_DAC O Auxiliary, 12-Bit DAC Output.

21 AUX_ADC I Auxiliary, 12-Bit ADC Input.

1

I/O is input/output, I is input, O is output, S is supply, and N/A is not applicable.

Rev. 0 | Page 7 of 20

Page 8

ADIS16305

A

A

TYPICAL PERFORMANCE CHARACTERISTICS

1

0.01

0.1

LLAN VARIANCE (°/sec)

0.01

ROOT

0.001

0.1 1 10 100 1k 10k

Tau (sec)

Figure 7. Gyroscope Allan Variance

+1σ

MEAN

–1σ

09020-007

0.001

Z-AXIS

LLAN VARIANCE (g)

0.0001

ROOT

0.00001

X- AND Y-

AXES

0.1 1 10 100 1k 10k

Tau (sec)

Figure 8. Accelerometer Allan Variance

9020-008

Rev. 0 | Page 8 of 20

Page 9

ADIS16305

THEORY OF OPERATION

BASIC OPERATION

The ADIS16305 is an autonomous sensor system that starts up

after it has a valid power supply voltage and begins producing

inertial measurement data. After each sample cycle, the sensor

data is loaded into the output registers, and DIO1 pulses high,

which provides a new data-ready control signal for driving

system-level interrupt service routines. In a typical system, a

master processor accesses the output data registers through the

SPI interface, using the connection diagram shown in Figure 9.

Tabl e 6 provides a generic functional description for each pin on

the master processor. Ta b le 7 describes the typical master processor

settings for communicating with the ADIS16305.

I/O LINES ARE COMPATIBLE WITH

3.3V OR 5V L OGIC LEVELS

VDD

SYSTEM

PROCESSOR

SPI MASTER

SS

SCLK

MOSI

MISO

IRQ DIO1

Figure 9. Electrical Connection Diagram

6

3

5

4

7

Table 6. Generic Master Processor Pin Names and Functions

Pin Name Function

SS

Slave select

IRQ Interrupt request

MOSI Master output, slave input

MISO Master input, slave output

SCLK Serial clock

Table 7. Generic Master Processor SPI Settings

Processor Setting Description

Master ADIS16305 is a slave

SCLK Rate ≤ 2 MHz1 Normal mode, SMPL_PRD[7:0] ≤ 0x09

SPI Mode 3 CPOL = 1 (polarity), CHPA = 1 (phase)

MSB First Mode Bit sequence

16-Bit Mode Shift register/data length

1

For burst read, SCLK rate ≤ 1 MHz. For low power mode, SCLK rate ≤ 300 kHz.

CS

SCLK

DIN

DOUT

NOTES

1. DOUT BITS ARE PRODUCED O NLY WHEN THE P REVIOUS 16-BIT DIN SEQ UENCE STARTS WI TH R/W = 0.

R/W

A6 A5 A4 A3 A2 A1 A0 DC7 DC6 DC5 DC4 DC3 DC2 DC1 DC0

10

ADIS16305

CS

SCLK

DIN

DOUT

13 14 15

5V

11 12

SPI SLAVE

09020-009

Figure 11. SPI Communication Bit Sequence

Rev. 0 | Page 9 of 20

The user registers provide addressing for all input/output

operations on the SPI interface. Each 16-bit register has two

7-bit addresses: one for its upper byte and one for its lower byte.

Tabl e 8 lists the lower byte address for each register, and Figure 10

shows the generic bit assignments.

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

UPPER BYTE

Figure 10. Generic Register Bit Assignments

LOWER BYTE

READING SENSOR DATA

Although the ADIS16305 produces data independently, it operates

as an SPI slave device that communicates with system (master)

processors using the 16-bit segments displayed in Figure 11.

Individual register reads require two of these 16-bit sequences. The

first 16-bit sequence provides the read command bit (

R

/W = 0)

and the target register address (A6 to A0). The second sequence

transmits the register contents (D15 to D0) on the DOUT line.

For example, if DIN = 0x0A00, the contents of XACCL_OUT are

shifted out on the DOUT line during the next 16-bit sequence.

The SPI operates in full-duplex mode, which means that the master

processor can read the output data from DOUT while using the

same SCLK pulses to transmit the next target address on DIN.

DEVICE CONFIGURATION

The user register memory map (see Table 8) identifies configuration

registers with either a W or R/W. Configuration commands also

use the bit sequence shown in Figure 11. If the MSB = 1, the last

eight bits (DC7 to DC0) in the DIN sequence are loaded into the

memory address associated with the address bits (A6 to A0).

For example, if DIN = 0xA11F, 0x1F is loaded into Address 0x21

(XACCL_OFF, upper byte) at the conclusion of the data frame.

The master processor initiates the backup function by setting

GLOB_CMD[3] = 1 (DIN = 0xBE04). This command copies

the user registers into their assigned flash memory locations

and requires the power supply to stay within its normal operating

range for the entire 50 ms process. The FLASH_CNT register

provides a running count of these events for monitoring the

long-term reliability of the flash memory.

R/W

A6 A5

D0D1D2D3D4D5D6D7D8D9D10D11D12D13D14D15

D13D14D15

09020-011

09020-010

Page 10

ADIS16305

MEMORY MAP

Table 8. User Register Memory Map

Name R/W Flash Backup Address1 Default Register Description Bit Function

FLASH_CNT R Yes 0x00 N/A2 Flash memory write count See Table 28

SUPPLY_OUT R No 0x02 N/A2 Power supply measurement See Table 9

GYRO_OUT R No 0x04 N/A2 Gyroscope output See Table 9

Reserved N/A2 N/A2 0x06 N/A2 Reserved N/A2

Reserved N/A2 N/A2 0x08 N/A2 Reserved N/A2

XACCL_OUT R No 0x0A N/A2 X-axis accelerometer output See Table 9

YACCL_OUT R No 0x0C N/A2 Y-axis accelerometer output See Table 9

ZACCL_OUT R No 0x0E N/A2 Z-axis accelerometer output See Table 9

TEMP_OUT R No 0x10 N/A2 Gyroscope temperature measurement See Table 9

PITCH_OUT R No 0x12 N/A2 Pitch angle output (x-axis) See Table 9

ROLL_OUT R No 0x14 N/A2 Roll angle output (y-axis) See Table 9

AUX_ADC R No 0x16 N/A2 Auxiliary ADC output See Table 9

Reserved N/A2 N/A2 0x18 N/A2 Reserved N/A2

GYRO_OFF R/W Yes 0x1A 0x0000 Gyroscope bias offset factor See Tab le 1 6

PITCH_OFF R Yes 0x1C N/A2 Pitch angle offset factor See Table 1 8

ROLL_OFF R Yes 0x1E N/A2 Roll angle offset factor See Table 18

XACCL_OFF R/W Yes 0x20 0x0000 X-axis acceleration bias offset factor See Table 17

YACCL_OFF R/W Yes 0x22 0x0000 Y-axis acceleration bias offset factor See Table 17

ZACCL_OFF R/W Yes 0x24 0x0000 Z-axis acceleration bias offset factor See Table 17

ALM_MAG1 R/W Yes 0x26 0x0000 Alarm 1 amplitude threshold See Table 3 0

ALM_MAG2 R/W Yes 0x28 0x0000 Alarm 2 amplitude threshold See Table 3 0

ALM_SMPL1 R/W Yes 0x2A 0x0000 Alarm 1 sample size See Table 31

ALM_SMPL2 R/W Yes 0x2C 0x0000 Alarm 2 sample size See Table 31

ALM_CTRL R/W Yes 0x2E 0x0000 Alarm control See Table 32

AUX_DAC R/W No 0x30 0x0000 Auxiliary DAC data See Table 25

GPIO_CTRL R/W No 0x32 0x0000 Auxiliary digital input/output control See Table 23

MSC_CTRL R/W Yes 0x34 0x0006 Miscellaneous control: data-ready, self-test See Table 24

SMPL_PRD R/W Yes 0x36 0x0001 Internal sample period (rate) control See Table 20

SENS_AVG R/W Yes 0x38 0x0402 Dynamic range and digital filter control See Table 22

SLP_CNT W No 0x3A 0x0000 Sleep mode control See Table 21

DIAG_STAT R No 0x3C 0x0000 System status See Table 29

GLOB_CMD W N/A2 0x3E 0x0000 System command See Table 19

Reserved N/A2 N/A2 0x40 to 0x51 N/A2 Reserved N/A2

LOT_ID1 R Yes 0x52 N/A2 Lot Identification Code 1 See Table 35

LOT_ID2 R Yes 0x54 N/A2 Lot Identification Code 2 See Table 35

PROD_ID R Yes 0x56 0x3FB1 Product identification See Table 35

SERIAL_NUM R Yes 0x58 N/A2 Serial number See Table 35

1

Each register contains two bytes. The address of the lower byte is displayed. The address of the upper byte is equal to the address of the lower byte plus 1.

2

N/A stands for not applicable.

Rev. 0 | Page 10 of 20

Page 11

ADIS16305

BURST READ DATA COLLECTION

Burst read data collection is a process-efficient method for collecting

data from the ADIS16305. In burst read, all output registers are

clocked out on DOUT, 16 bits at a time, in sequential data cycles

(each separated by one SCLK period). To start a burst read sequence,

set DIN = 0x3E00. The contents of each output register are then

shifted out on DOUT, starting with SUPPLY_OUT and ending with

AUX _ADC (see Figure 13). The addressing sequence shown in

Tabl e 8 determines the order of the outputs in burst read.

Gyroscopes

The gyroscope output register, GYRO_OUT, uses a 14-bit, twos

complement digital format. When using the factory-default range

of ±300°/sec, each LSB translates into 0.05°/sec. Ta bl e 10 offers

some examples for translating the digital data into rotation rate

measurements. When the dynamic rage is set to ±150°/sec,

divide the rotation rate numbers in Table 10 by a factor of two.

When the dynamic rage is set to ±75°/sec, divide the rotation

rate numbers in Tab l e 1 0 by a factor of four.

OUTPUT DATA REGISTERS

Each output data register uses the format in Figure 12 and Ta ble 9 .

Figure 6 shows the positive direction for each inertial sensor. The

ND bit is equal to 1 when the register contains unread data. The

EA bit is high when any error/alarm flag in the DIAG_STAT

register is equal to 1.

MSB FOR 14-BIT OUTPUT

ND EA

MSB FOR 12-BIT OUTPUT

Figure 12. Output Register Bit Assignments

Table 9. Output Data Register Formats

Name Address Scale Reference

SUPPLY_OUT 0x02 Power supply Table 13

GYRO_OUT1 0x04 Gyroscope Table 10

XACCL_OUT 0x0A Acceleration (x) Table 11

YACCL_OUT 0x0C Acceleration (y) Table 1 1

ZACCL_OUT 0x0E Acceleration (z) Table 11

TEMP_OUT2 0x10 Temperature Table 14

PITCH_OUT 0x12 Pitch angle Table 12

ROLL_OUT 0x14 Roll angle Table 12

AUX_ADC 0x16 ADC measurement Table 15

1

Assumes that the scaling is set to ±300°/sec. This factor scales with the range.

2

0x0000 = 25°C (±5°C).

Note that the codes in Tab l e 10, Ta bl e 1 1 , Tab l e 12 , Ta ble 13,

Tabl e 14 , and Ta bl e 15 assume typical sensitivity values.

09020-012

Table 10. Rotation Rate, Twos Complement Format

Rotation Rate Decimal Hex Binary

+300°/sec +6000 LSB 0x1770 XX01 0111 0111 0000

+0.1°/sec +2 LSB 0x0002 XX00 0000 0000 0010

+0.05°/sec +1 LSB 0x0001

0°/sec 0 LSB 0x0000

−0.05°/sec −1 LSB 0x3FFF

−0.1°/sec −2 LSB 0x3FFE

XX00 0000 0000 0001

XX00 0000 0000 0000

XX11 1111 1111 1111

XX11 1111 1111 1110

−300°/sec −6000 LSB 0x2890 XX10 1000 1001 0000

Accelerometers

The accelerometer output registers, XACCL_OUT, YACCL_OUT,

and ZACCL_OUT, use a 14-bit, twos complement digital format.

Tabl e 11 offers some examples for translating the digital data

into linear acceleration measurements

Table 11. Acceleration, Twos Complement Format

Acceleration Decimal Hex Binary

+3.3 g +5500 LSB 0x157C XX01 0101 0111 1100

+1.2 mg +2 LSB 0x0002 XX00 0000 0000 0010

+0.6 mg +1 LSB 0x0001

0 g 0 LSB 0x0000

−0.6 mg −1 LSB 0x3FFF

−1.2 mg −2 LSB 0x3FFE

XX00 0000 0000 0001

XX00 0000 0000 0000

XX11 1111 1111 1111

XX11 1111 1111 1110

−3.3 g −5500 LSB 0x2A84 XX10 1010 1000 0100

SCLK

DIN

DOUT

123 910

0x3E00

PREVIOUS

DON’T CARE

SUPPLY_OUT GYRO_OUT ROLL_OUT

Figure 13. Burst Read Sequence

45CS

XACCL_OUT YACCL_OUT

AUX_ADC

09020-013

Rev. 0 | Page 11 of 20

Page 12

ADIS16305

Y

X

V

ORIENTATION ANGLES

The ROLL_OUT and PITCH_OUT registers provide a tilt

angle calculation based on the accelerometer measurements.

The zero reference is the point at which the z-axis faces gravity

for a north-east-down (NED) configuration. Tab l e 12 displays

a number of examples for the 13-bit, twos complement digital

format in both of these registers. Figure 14 provides the physical

references and formulas that produce these orientation angles.

Table 12. Orientation Angles, Twos Complement Format

Angle Decimal Hex Binary

+180° +4091 0x0FFB XXX0 1111 1111 1011

+90 +2045 0x07FD XXX0 0111 1111 1101

+0.088° +2 LSB 0x0002 XXX0 0000 0000 0010

+0.044° +1 LSB 0x0001 XXX0 0000 0000 0001

0° 0 LSB 0x0000 XXX0 0000 0000 0000

−0.044° −1 0x1FFF XXX1 1111 1111 1111

−0.088° −2 0x1FFE XXX1 1111 1111 1110

−90° −2045 0x1803 XXX1 1000 0000 0011

−179.96° −4090 0x1006 XXX1 0000 0000 0110

-AXIS

φ

ROLL

FRONT VIEW

φ

= ROLL_OUT = a TAN

ROLL

a

Y

a

Y

a

Z

a

Z

Z-AXIS

a

Z

Z-AXIS

Table 13. Power Supply, Offset Binary Format

Supply Voltage Decimal Hex Binary

5.25 V 2171 LSB 0x87B XXXX 1000 0111 1011

5.002418 V 2069 LSB 0x815 XXXX 1000 0001 0101

5 V 2068 LSB 0x814

4.997582 V 2067 LSB 0x813

4.75 V 1964 LSB 0x7AC XXXX 0111 1010 1100

XXXX 1000 0001 0100

XXXX 1000 0001 0011

Internal Temperature

The TEMP_OUT register provides an internal measurement for

temperature and uses 12-bit, twos complement for its digital format.

Tabl e 14 provides several numerical examples of this format.

This is an internal temperature measurement, which can vary

from ambient conditions outside of the package.

Table 14. Temperature, Twos Complement Format

Temperature Decimal Hex Binary

+105°C +588 LSB 0x24C XXXX 0010 0100 1100

+85°C +441 LSB 0x1B9 XXXX 0001 1011 1001

+25.272°C +2 LSB 0x002

+25.136°C +1 LSB 0x001

+25°C 0 LSB 0x000

+24.864°C −1 LSB 0xFFF

+24.728°C −2 LSB 0xFFE

−40°C −478 LSB 0xE22 XXXX 1110 0010 0010

XXXX 0000 0000 0010

XXXX 0000 0000 0001

XXXX 0000 0000 0000

XXXX 1111 1111 1111

XXXX 1111 1111 1110

Analog Input (ADC)

The AUX_ADC register provides access to the auxiliary ADC

input channel measurements and uses 12-bit, offset binary as its

digital format. The ADC is a 12-bit successive approximation

converter that has an input circuit equivalent to the one shown

in Figure 15. The maximum input is 3.3 V. The ESD protection

diodes can handle 10 mA without causing irreversible damage.

The on resistance (R1) of the switch has a typical value of 100 Ω.

The sampling capacitor, C2, has a typical value of 16 pF.

CC

φ

-AXIS

PITCH

φ

=PITCH_OUT = a TAN

PITCH

SIDE VIEW

a

Y

× SIN (

Φ

ROLL

a

X

–a

X

) +

a

COS (

Φ

ROLL

)

Z

Figure 14. Orientation for PITCH_OUT and ROLL_OUT Angles

Power Supply

The SUPPLY_OUT register provides an internal measurement

for the power supply voltage and uses a 12-bit, offset binary

digital format. Table 1 3 provides several numerical examples

of this format.

D

C1

D

Figure 15. Equivalent Analog Input Circuit

9020-014

(Conversion Phase: Switch Open,

Track Phase: Switch Closed)

Table 15. ADC Measurement, Offset Binary Format

Input Voltage Decimal Hex Binar y

3.3 V 4095 LSB 0xFFF XXXX 1111 1111 1111

1 V 1241 LSB 0x4D9 XXXX 0100 1101 1001

1.6118 mV 2 LSB 0x002

805.9 μV 1 LSB 0x001

C2

R1

09020-015

XXXX 0000 0000 0010

XXXX 0000 0000 0001

0 V 0 LSB 0x000 XXXX 0000 0000 0000

Rev. 0 | Page 12 of 20

Page 13

ADIS16305

CALIBRATION

Manual Bias Calibration

The bias offset registers in Tab l e 1 6 and Tab l e 1 7 provide a manual

adjustment function for the output of each sensor. For example,

if GYRO_OFF = 0x1FF6 (DIN = 0x9B1F, 0x9AF6), the GYRO_OUT

offset shifts by −10 LSBs, or −0.125°/sec.

Table 16. GYRO_OFF Bit Descriptions

Bits Description (Default = 0x0000)

[15:13] Not used.

[12:0]

Table 17. XACCL_OFF, YACCL_OFF, ZACCL_OFF

Bit Descriptions

Bits Description (Default = 0x0000)

[15:12] Not used.

[11:0]

Frame Alignment

The PITCH_OFF and ROLL_OFF registers (see Tab l e 1 8) provide

the angular orientation difference between the inertial frame

(internal) and the external frame (package). They follow the same

orientation as PITCH_OUT and ROLL_OUT, as shown in Figure 14.

Table 18. PITCH_OFF, ROLL_OFF Bit Descriptions

Bits Description

[15:10] Not used.

[9:0] Data bits. Twos complement, 0.014°/LSB.

Gyroscope Automatic Bias Null Calibration

Set GLOB_CMD[0] = 1 (DIN = 0xBE01) to execute the automatic

bias null calibration function. This function measures the

gyroscope output register and then loads the gyroscope offset

register with the opposite value to provide a quick bias calibration.

All sensor data is then reset to 0, and the flash memory is updated

automatically within 50 ms (see Tabl e 19 ).

Gyroscope Precision Automatic Bias Null Calibration

Set GLOB_CMD[4] = 1 (DIN = 0xBE10) to execute the precision

automatic bias null calibration function. This function takes the

sensor offline for 30 sec while it collects a set of data and calculates

more accurate bias correction factors for each gyroscope. After

this function is executed, the newly calculated correction factor

is loaded into the gyroscope offset registers, all sensor data is

reset to 0, and the flash memory is updated automatically within

50 ms (see Tabl e 19 ).

Restoring Factory Calibration

Set GLOB_CMD[1] = 1 (DIN = 0xBE02) to execute the factory

calibration restore function. This function resets each user calibration

register to 0x0000 (see Tab le 1 6 and Ta ble 1 7), resets all sensor

data to 0, and automatically updates the flash memory within

50 ms (see Tabl e 19 ).

Data bits. Twos complement, 0.0125°/sec per LSB.

Typical adjustment range = ±50°/sec.

Data bits. Twos complement, 0.6 mg/LSB. Typical

adjustment range = ±1.22 g.

Linear Acceleration Bias Compensation (Gyroscope)

Set MSC_CTRL[7] = 1 (DIN = 0xB486) to enable correction for

low frequency acceleration influences on gyroscope bias. Note

that the DIN sequence also preserves the factory default condition

for the data-ready function (see Tab l e 2 4 ).

OPERATIONAL CONTROL

Global Commands

The GLOB_CMD register provides trigger bits for several useful

functions. Setting the assigned bit to 1 starts each operation,

which returns the bit to 0 after completion. For example, set

GLOB_CMD[7] = 1 (DIN = 0xBE80) to execute a software reset,

which stops the sensor operation and runs the device through

its start-up sequence. This sequence includes loading the control

registers with their respective flash memory locations prior to

producing new data. Reading the GLOB_CMD register

(DIN = 0x3E00) starts the burst read sequence.

Table 19. GLOB_CMD Bit Descriptions

Bit(s) Description

[15:8] Not used

[7] Software reset command

[6:5] Not used

[4] Precision autonull command

[3] Flash update command

[2] Auxiliary DAC data latch

[1] Factory calibration restore command

[0] Autonull command

Internal Sample Rate

The SMPL_PRD register provides discrete sample rate settings

using the bit assignments in Tabl e 20 and the following equation:

t

= tB × (NS + 1)

S

For example, when SMPL_PRD[7:0] = 0x0A, the sample rate is

149 SPS.

Table 20. SMPL_PRD Bit Descriptions

Bit(s) Description (Default = 0x0001)

[15:8] Not used

[7] Time base (tB)

0 = 0.61035 ms, 1 = 18.921 ms

[6:0] Increment setting (NS)

Internal sample period = tS = tB × (NS + 1)

The default sample rate setting of 819.2 SPS provides optimal

performance. For systems that value slower sample rates, keep the

internal sample rate at 819.2 SPS. Use the programmable filter

(SENS_AVG) to reduce the bandwidth, which helps to prevent

aliasing. The data-ready function (MSC_CTRL) can drive an

interrupt routine that uses a counter to help ensure data coherence

at reduced rates.

Rev. 0 | Page 13 of 20

Page 14

ADIS16305

Power Management

Setting SMPL_PRD ≥ 0x0A also sets the sensor to low power

mode. For systems that require lower power dissipation, insystem characterization helps users to quantify the associated

performance trade-offs. In addition to sensor performance, this

mode affects SPI data rates (see Tab l e 2 ). Set SLP_CNT[8] = 1

(DIN = 0xBB01) to start the indefinite sleep mode, which requires

CS

a

assertion (high to low), reset, or power cycle to wake up.

Use SLP_CNT[7:0] to put the device into sleep mode for a specified

period. For example, SLP_CNT[7:0] = 0x64 (DIN = 0xBA64)

puts the ADIS16305 to sleep for 50 sec.

Table 21. SLP_CNT Bit Descriptions

Bit(s) Description

[15:9] Not used

[8] Indefinite sleep mode; set to 1

[7:0] Programmable sleep time bits, 0.5 sec/LSB

Sensor Bandwidth

The signal chain for each MEMS sensor has several filter stages,

which shape their frequency response. Figure 16 provides a block

diagram for both gyroscope and accelerometer signal paths.

Tabl e 22 provides additional information for digital filter

configuration.

FROM

GYROSCOPE

SENSOR

ACCELERATION

LPF LPF

404Hz

FROM

SENSOR

Figure 16. MEMS Analog and Digital Filters

757Hz

LPF

330Hz

N N

N N

m

N = 2

m = SENS_AVG[2:0]

Digital Filtering

The N blocks in Figure 16 are part of the programmable lowpass filter, which provides additional noise reduction on the

inertial sensor outputs. This filter contains two cascaded averaging

filters that provide a Bartlett window, FIR filter response (see

Figure 17). For example, set SENS_AVG[2:0] = 100 (DIN = 0xB804)

to set each stage to 16 taps. When used with the default sample

rate of 819.2 SPS, this value reduces the sensor bandwidth to

approximately 16 Hz.

0

–20

–40

–60

–80

MAGNITUDE (dB)

–100

N = 2

–120

–140

N = 4

N = 16

N = 64

0.001 0.01 0.1 1

Figure 17. Bartlett Window, FIR Filter Frequency Response

FREQUENCY (Rat io)

(Phase Delay = N Samples)

09020-017

Dynamic Range

The SENS_AVG[10:8] bits provide three dynamic range settings

for this gyroscope. The lower dynamic range settings (±75°/sec and

±150°/sec) limit the minimum filter tap sizes to maintain resolution.

For example, set SENS_AVG[10:8] = 010 (DIN = 0xB902) for

a measurement range of ±150°/sec. Because this setting can

influence the filter settings, program SENS_AVG[10:8] and

then SENS_AVG[2:0] if more filtering is required.

Table 22. SENS_AVG Bit Descriptions

Bit(s) Description

[15:11] Not used

[10:8] Measurement range (sensitivity) selection

100 = ±300°/sec (default condition)

9020-016

010 = ±150°/sec, filter taps ≥ 4 (Bits[2:0] ≥ 0x02)

001 = ±75°/sec, filter taps ≥ 16 (Bits[2:0] ≥ 0x04)

[7:3]

[2:0]

Not used

Number of taps in each stage, N = 2M;

maximum setting = 6 (110), N = 2

6

= 64 taps/stage

Rev. 0 | Page 14 of 20

Page 15

ADIS16305

INPUT/OUTPUT FUNCTIONS

General-Purpose I/O

DIO1, DIO2, DIO3, and DIO4 are configurable, general-purpose

I/O lines that serve multiple purposes according to the following

control register priority: MSC_CTRL, ALM_CTRL, and

GPIO_CTRL. For example, set GPIO_CTRL = 0x080C

(DIN = 0xB20C, and then 0xB308) to configure DIO1 and

DIO2 as inputs and DIO3 and DIO4 as outputs, with DIO3

set low and DIO4 set high.

In this configuration, read GPIO_CTRL (DIN = 0x3200) to

monitor the digital state of DIO1 and DIO2.

Table 23. GPIO_CTRL Bit Descriptions

Bit(s) Description

[15:12] Not used

[11] General-Purpose I/O Line 4 (DIO4) data level

[10] General-Purpose I/O Line 3 (DIO3) data level

[9] General-Purpose I/O Line 2 (DIO2) data level

[8] General-Purpose I/O Line 1 (DIO1) data level

[7:4] Not used

[3] General-Purpose I/O Line 4 (DIO4) direction control

(1 = output, 0 = input)

[2] General-Purpose I/O Line 3 (DIO3) direction control

(1 = output, 0 = input)

[1] General-Purpose I/O Line 2 (DIO2) direction control

(1 = output, 0 = input)

[0] General-Purpose I/O Line 1 (DIO1) direction control

(1 = output, 0 = input)

Input Clock Configuration

The input clock function allows for external control over-

sampling in the ADIS16305. Set SMPL_PRD[7:0] = 0x00 (DIN

= 0xB600) to enable this function. See Tabl e 2 and Figure 4 for

timing information.

Data-Ready I/O Indicator

The factory default sets DIO1 as a positive data-ready indicator

signal. The MSC_CTRL[2:0] bits provide configuration options

for changing the default. For example, set MSC_CTRL[2:0] = 100

(DIN = 0xB404) to change the polarity of the data-ready signal

on DIO1 for interrupt inputs that require negative logic inputs

for activation. The pulse width is between 100 μs and 200 μs

over all conditions.

Table 24. MSC_CTRL Bit Descriptions

Bit(s) Description

[15:12] Not used

[11] Memory test (cleared upon completion)

(1 = enabled, 0 = disabled)

[10] Internal self-test enable (cleared upon completion)

(1 = enabled, 0 = disabled)

[9] Manual self-test, negative stimulus

(1 = enabled, 0 = disabled)

[8] Manual self-test, positive stimulus

(1 = enabled, 0 = disabled)

[7] Linear acceleration bias compensation for gyroscopes

(1 = enabled, 0 = disabled)

[6] Point of percussion alignment, accelerometer

(1 = enabled, 0 = disabled)

[5:3] Not used

[2] Data ready enable

(1 = enabled, 0 = disabled)

[1] Data ready polarity

(1 = active high, 0 = active low)

[0] Data ready line select

(1 = DIO2, 0 = DIO1)

Auxiliary DAC

The 12-bit AUX_DAC line can drive its output to within 5 mV

of the ground reference when it is not sinking current. As the

output approaches 0 V, the linearity begins to degrade (~100 LSB

beginning point). As the sink current increases, the nonlinear

range increases. The DAC latch command moves the values of

the AUX_DAC register into the DAC input register, enabling

both bytes to take effect at the same time.

Table 25. AUX_DAC Bit Descriptions

Bits Description

[15:12] Not used

[11:0] Data bits, scale factor = 0.8059 mV/LSB

Offset binary format, 0 V = 0 LSB

Table 26. Setting AUX_DAC = 1 V

DIN Description

0xB0D9 AUX_DAC[7:0] = 0xD9 (217 LSB).

0xB104 AUX_DAC[15:8] = 0x04 (1024 LSB).

0xBE04 GLOB_CMD[2] = 1.

Move values into the DAC input register, resulting in

a 1 V output level.

Rev. 0 | Page 15 of 20

Page 16

ADIS16305

DIAGNOSTICS

Self-Test

The self-test function allows the user to verify the mechanical

integrity of each MEMS sensor. It applies an electrostatic force to

each sensor element, which results in mechanical displacement

that simulates a response to actual motion. Ta ble 1 lists the

expected response for each sensor, which provides pass/fail

criteria. Set MSC_CTRL[10] = 1 (DIN = 0xB504) to run the

internal self-test routine, which exercises all inertial sensors,

measures each response, makes pass/fail decisions, and reports

them to error flags in the DIAG_STAT register. This process takes

35 ms to complete and report the results to DIAG_STAT[5],

DIAG_STAT[10], and DIAG_STAT[15:13]. MSC_CTRL[10]

resets itself to 0 after completing the routine. The MSC_CTRL[9:8]

bits provide manual control over the self-test function for

investigation of potential failures. Tab l e 2 7 outlines an example

test flow for using this option to verify the gyroscope function.

Table 27. Manual Self-Test Example Sequence

DIN Description

0xB601 SMPL_PRD[7:0] = 0x01, sample rate = 819.2 SPS

0xB904 SENS_AVG[15:8] = 0x04, gyro range = ±300°/sec

0xB802 SENS_AVG[7:0] = 0x02, four-tap averaging filter

Delay = 50 ms

0x0400 Read GYRO_OUT

0xB502 MSC_CTRL[9] = 1, gyroscope negative self-test

Delay = 50 ms

0x0400 Read GYRO_OUT

0xB501

Delay = 50 ms

0x0400 Read GYRO_OUT

0xB500 MSC_CTRL[15:8] = 0x00

While the self-test still functions when the device is in motion,

zero motion typically produces the most reliable results. The

settings in Table 27 are flexible and allow for optimization

around speed and noise influence. For example, using fewer

filtering taps decreases delay times but increases the possibility

of noise influence.

Flash Memory Management

The FLASH_CNT register (see Ta ble 2 8) provides a tool for

managing the flash memory’s endurance. The FLASH_CNT

register increments every time there is a write to the flash

memory. Figure 18 quantifies the relationship between data

retention and junction temperature.

Determine whether the bias in the gyroscope

output changed according to the self-test

response specified in Table 1

MSC_CTRL[9:8] = 01, gyroscope/accelerometer

positive self-test

Determine whether the bias in the gyroscope

output changed according to the self-test

response specified in Table 1

Rev. 0 | Page 16 of 20

Table 28. FLASH_CNT Bit Descriptions

Bits Description

[15:0] Binary counter for writing to flash memory

600

450

300

RETENTION (Years)

150

0

30 40

55 70 85 100 125 135 150

JUNCTION TEM P ERATURE (°C)

Figure 18. Flash/EE Memory Data Retention

09020-018

Checksum Test

Set MSC_CTRL[11] = 1 (DIN = 0x9D08) to verify the flash

memory integrity against the factory check sum and read

DIAG_STAT[6] to check the results 20 ms after the command.

Status

The error flags provide indicator functions for common system

level issues. All of the flags are cleared (set to 0) after each

DIAG_STAT register read cycle. If an error condition remains,

the error flag returns to 1 during the next sample cycle. The

DIAG_STAT[1:0] bits do not require a read of this register to

return to 0. If the power supply voltage goes back into range,

these two flags are cleared automatically.

Table 29. DIAG_STAT Bit Descriptions

Bit(s) Description

[15] Z-axis accelerometer self-test failure (1 = fail, 0 = pass)

[14] Y-axis accelerometer self-test failure (1 = fail, 0 = pass)

[13] X-axis accelerometer self-test failure (1 = fail, 0 = pass)

[12:11]

Not used

[10] Gyroscope self-test failure (1 = fail, 0 = pass)

[9] Alarm 2 status (1 = active, 0 = inactive)

[8] Alarm 1 status (1 = active, 0 = inactive)

[7]

Not used

[6] Flash test, checksum flag (1 = fail, 0 = pass)

[5] Self-test diagnostic error flag (1 = fail, 0 = pass)

[4] Sensor overrange (1 = fail, 0 = pass)

[3] SPI communication failure (1 = fail, 0 = pass)1

[2] Flash update failure (1 = fail, 0 = pass)

[1]

Power supply > 5.25 V (1 = power supply > 5.25 V,

0 = power supply ≤ 5.25 V)

[0]

Power supply < 4.75 V (1 = power supply < 4.75 V,

0 = power supply ≥ 4.75 V)

1

The SPI error flag in DIAG_STAT[3] goes to 1 when the number of SCLKs is

not equal to an integer multiple of 16.

Page 17

ADIS16305

Alarm Registers

The alarm function provides monitoring for two independent

conditions. The ALM_CTRL register provides control inputs

for trigger source, data filtering (prior to comparison), static

comparison, dynamic rate-of-change comparison, and output

indicator configurations. The ALM_MAGx registers establish

the trigger threshold and polarity configurations. Table 33 gives

an example of how to configure a static alarm. The ALM_SMPLx

registers provide the number of samples to use in the dynamic

rate-of-change configuration. The period equals the number in

the ALM_SMPLx register multiplied by the sample period time,

which is established by the SMPL_PRD register. See Table 34 for

an example of how to configure the sensor for this type of function.

Table 30. ALM_MAG1, ALM_MAG2 Bit Descriptions

Bit(s) Description

[15] Comparison polarity (1 = greater than, 0 = less than)

[14] Not used

[13:0] Data, matches the format of the trigger source

Table 31. ALM_SMPL1, ALM_SMPL2 Bit Descriptions

Bits Description

[15:8] Not used

[7:0] Data bits: number of samples (both 0x00 and 0x01 = 1)

Table 32. ALM_CTRL Bit Designations

Bits Value Description

[15:12] Alarm 2 trigger source selection

0000 Disable

0001 Power supply output

0010 Gyroscope output

0011 Not used

0100 Not used

0101 X-axis accelerometer output

0110 Y-axis accelerometer output

0111 Z-axis accelerometer output

1000 Temperature output

1001 Pitch angle output

1010 Roll angle output

1011 Auxiliary ADC measurement

[11:8] Alarm 1 trigger source selection (see Bits[15:12])

[7] Rate of change (ROC) enable for Alarm 2

1 = rate of change, 0 = static level

[6] Rate of change (ROC) enable for Alarm 1

1 = rate of change, 0 = static level

[5] Not used

[4] Comparison data filter setting1

1 = filtered data, 0 = unfiltered data

[3] Not used

[2] Alarm output enable (1 = enable, 0 = disable)

[1] Alarm output polarity (1 = high, 0 = low)

[0] Alarm output line select (1 = DIO2, 0 = DIO1)

1

Incline outputs (pitch, roll) always use filtered data in this comparison.

Table 33. Alarm Configuration Example 1

DIN Description

0xAF55, ALM_CTRL = 0x5517

0xAE17 Alarm 1 input = XACCL_OUT

Alarm 2 input = XACCL_OUT

Static level comparison, filtered data

DIO2 output indicator, positive polarity

0xA783, ALM_MAG1 = 0x8341

0xA641 Alarm 1 is true if XACCL_OUT > +0.5 g

0xA93C, ALM_MAG2 = 0x3CBF

0xA8BF Alarm 2 is true if XACCL_OUT < −0.5 g

Table 34. Alarm Configuration Example 2

DIN Description

0xAF76, ALM_CTRL = 0x76C7

0xAEC7 Alarm 1 input = YACCL_OUT

Alarm 2 input = ZACCL_OUT

Rate-of-change comparison, unfiltered data

DIO2 output indicator, positive polarity

0xB601 SMPL_PRD = 0x0001

Sample rate = 819.2 SPS

0xAA08 ALM_SMPL1 = 0x0008

Alarm 1 rate-of-change period = 9.77 ms

0xAC50 ALM_SMPL2 = 0x0050

Alarm 2 rate-of-change period = 97.7 ms

0xA783, ALM_MAG1 = 0x8341

0xA641

0xA93C, ALM_MAG2 = 0x3CBF

0xA8BF

Alarm 1 is true when Δ XACCL_OUT > 0.5 g over a

period of 9.77 ms

Alarm 1 is true when Δ XACCL_OUT < −0.5 g over a

period of 97.7 ms

PRODUCT IDENTIFICATION

Table 35 provides a summary of the registers that identify the

product: PROD_ID, which identifies the product type; LOT_ID1

and LOT_ID2, the 32-bit lot identification code; and SERIAL_NUM,

which displays the 12-bit serial number. All four registers are

two bytes in length. When using the SERIAL_NUM value to

calculate the serial number, mask off the upper four bits and

convert the remaining 12 bits to a decimal number.

Table 35. Identification Registers

Register Name Address Description

LOT_ID1 0x52 Lot Identification Code 1

LOT_ID2 0x54 Lot Identification Code 2

PROD_ID 0x56 ADIS16305: 0x3FB1 (16,305)

SERIAL_NUM 0x58 Serial number, 0 to 4095

Rev. 0 | Page 17 of 20

Page 18

ADIS16305

APPLICATIONS INFORMATION

INTERFACE PRINTED CIRCUIT BOARD (PCB)

The ADIS16305/PCBZ includes one ADIS16305ALMZ, one

interface PCB, and one interface flex. This combination simplifies

the process of prototype connections of the ADIS16305AMLZ

with an existing processor system.

J1 and J2 are dual-row, 2 mm (pitch) connectors that work with

a number of ribbon cable systems, including 3M Part Number

152212-0100-GB (ribbon crimp connector) and 3M Part Number

3625/12 (ribbon cable). Figure 19 provides a hole pattern design

for installing the ADIS16305/PCBZ so that the flex fits well in

between the ADIS16305AMLZ and the interface PCB. Figure 20

provides the pin assignments for each connector, and the pin

descriptions match those listed in Tabl e 5. The ADIS16305 does

not require external capacitors for normal operation; therefore,

the interface PCB does not use the C1/C2 pads (not shown in

Figure 19).

2.20 × 2

33.77 23.75

12 11

3.30 × 4

GYROSCOPE BIAS OPTIMIZATION

The factory calibration addresses initial bias errors along with

temperature-dependent bias behaviors. Installation and certain

environmental conditions can introduce modest bias errors. The

precision autonull command provides a simple predeployment

method for correcting these errors to an accuracy of approximately

0.008°/sec, using an average of 30 sec. Set GLOB_CMD[4] = 1

(DIN = BE10) to start this operation. Averaging the sensor output

data for 100 sec can provide incremental performance gains, as

well. Controlling device rotation, power supply, and temperature

during these averaging times helps to ensure optimal accuracy

during this process. Refer to the AN-1041 Application Note for

more information about optimizing performance.

21

27.00

13.50

ADIS16305AMLZ

SCF-140379-01

INTERFACE PCB

J1

12 11

21

J2

Figure 19. Physical Diagram for Mounting the ADIS16305/PCBZ

RST

CS

DNC

GND

GND

VCC

J1

1

3

5

7

9

11

2

4

6

8

10

12

SCLK

DOUT

DIN

GND

VCC

VCC

AUX_ADC

AUX_DAC

GND

DNC

DNC

DIO2

1 2

3 4

5 6

7 8

9 10

11 12

Figure 20. J1/J2 Pin Assignments for Interface PCB

15.05

30.10

9020-019

J2

GND

DIO3

DIO4

DNC

DNC

DIO1

09020-020

Rev. 0 | Page 18 of 20

Page 19

ADIS16305

8

OUTLINE DIMENSIONS

31.25

31.00

30.75

13.60

13.50

13.40

13.60

13.50

13.40

23.25

23.00

22.75

.00 MAX

2.55

2.30

2.05

TOP VIEW

END VIEW

DETAIL A

2.20 THRU HOLE

(2 PLACES)

9.13

8.88

8.63

6.55

6.30

6.05

0.64

CONNECTOR PITCH

1.27

1.27 BSC

7.82

15.24

DETAIL A

13.97

3.05

04-06-2010-A

Figure 21. 24-Lead Module with Connector Interface

(ML-24-4)

Dimensions shown in millimeters

ORDERING GUIDE

Model1 Temperature Range Package Description Package Option

ADIS16305AMLZ −40°C to +85°C 24-Lead Module with Connector Interface ML-24-4

ADIS16305/PCBZ Interface Board

1

Z = RoHS Compliant Part.

Rev. 0 | Page 19 of 20

Page 20

ADIS16305

NOTES

©2010 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D09020-0-7/10(0)

Rev. 0 | Page 20 of 20

Loading...

Loading...