Page 1

High-Accuracy, Dual-Axis

Digital Inclinometer and Accelerometer

FEATURES

Dual-mode inclinometer system

Dual-axis, horizontal operation, ±90°

Single-axis, vertical operation, ±180°

High accuracy, 0.1°

14-bit digital inclination data, 0.025° resolution

14-bit digital acceleration data, 0.244 mg resolution

±1.7 g accelerometer measurement range

12-bit digital temperature sensor output

Digitally controlled bias calibration

Digitally controlled sample rate

Digitally controlled frequency response

Dual alarm settings with rate/threshold limits

Auxiliary digital I/O

Digitally activated self-test

Digitally activated low power mode

SPI-compatible serial interface

Auxiliary 12-bit ADC input and DAC output

Single-supply operation: 3.0 V to 3.6 V

3500 g powered shock survivability

VDD

GND

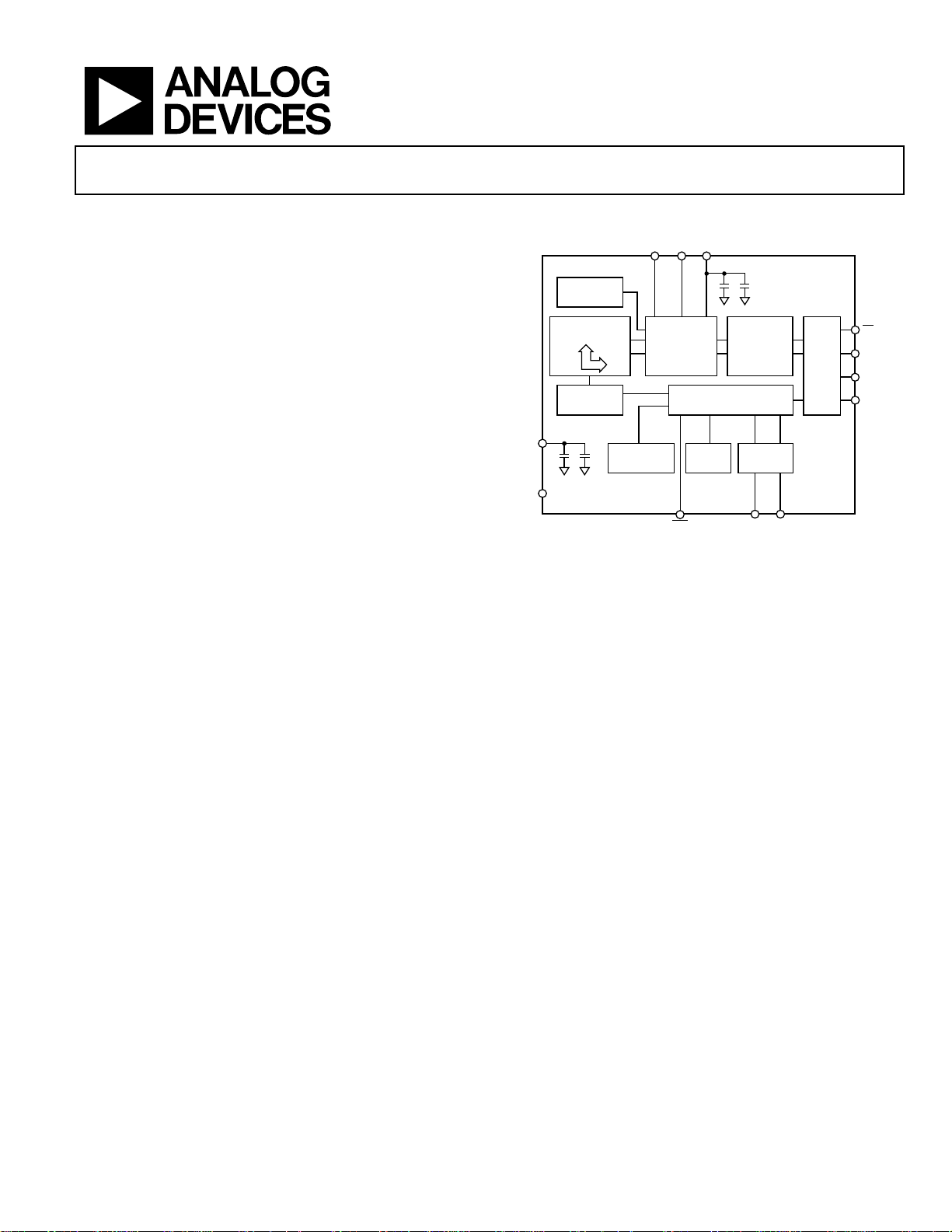

FUNCTIONAL BLOCK DIAGRAM

AUX

AUX

TEMPERATURE

SENSOR

DUAL-AXIS

ACCELEROMETER

SELF-TEST

MANAGEMENT

ADC

POWER

VREF

DAC

SIGNAL

CONDITIONI NG

AND

CONVERSION

RST DIO1 DIO2

Figure 1.

ALARMS

CALIBRATION

PROCESSING

DIGITAL

CONTROL

DIGIT AL

AUXILIARY

ADIS16209

ADIS16209

AND

SPI

PORT

I/O

CS

SCLK

DIN

DOUT

07096-001

APPLICATIONS

Platform control, stabilization, and alignment

Tilt sensing, inclinometers, leveling

Motion/position measurement

Monitor/alarm devices (security, medical, safety)

Navigation

GENERAL DESCRIPTION

The ADIS16209 is a high-accuracy, digital inclinometer that

accommodates both single axis (±180°) and dual-axis (±

peration. The standard supply voltage (3.3 V) and serial

o

peripheral interface (SPI) serial interface enable simple

integration into most industrial system designs. A simple

internal register structure handles all output data and

configuration features. This includes access to the following

output data: calibrated acceleration, accurate incline angles,

power supply, internal temperature, auxiliary analog and digital

input signals, diagnostic error flags, and programmable alarm

conditions.

90°)

Configurable operating parameters include sample rate,

power management, digital filtering, auxiliary analog and

digital output, offset/null adjustment, and self-test for sensor

mechanical structure.

The ADIS16209 is available in a 9.2 mm × 9.2 mm × 3.9 mm

LGA package that operates over a temperature range of −40°C

to +125°C. It can be attached using standard RoHS-compliant

solder reflow processes.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

Page 2

ADIS16209

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Timing Specifications .................................................................. 5

Timing Diagrams .......................................................................... 5

Absolute Maximum Ratings ............................................................ 6

Thermal Resistance ...................................................................... 6

ESD Caution .................................................................................. 6

REVISION HISTORY

3/08—Revison 0: Initial Version

Pin Configuration and Function Descriptions ..............................7

Recommended Pad Geometry ....................................................7

Typical Performance Characteristics ..............................................8

Theory of Operation ...................................................................... 10

Basic Operation .............................................................................. 11

Output Data Registers ............................................................... 12

Operation Control Registers ..................................................... 12

Calibration Registers .................................................................. 14

Alarm Registers .......................................................................... 14

Outline Dimensions ....................................................................... 16

Ordering Guide .......................................................................... 16

Rev. 0 | Page 2 of 16

Page 3

ADIS16209

SPECIFICATIONS

TA = 25°C, VDD = 3.3 V, tilt = 0°, unless otherwise noted.

Table 1.

Parameter Conditions Min Typ Max Unit

HORIZONTAL INCLINE Each axis

Input Range ±90 Degrees

Relative Accuracy ±30° from horizon, AVG_CNT = 0x08 ±0.1 Degrees

Sensitivity ±30° from horizon 0.025 °/LSB

VERTICAL ROTATION Rotational plane within ±30 degrees of vertical

Input Range −180 +180 Degrees

Relative Accuracy 360° of rotation ±0.25 Degrees

Sensitivity −40°C to +85°C 0.025 °/LSB

ACCELEROMETER Each axis

Input Range

Nonlinearity

Alignment Error X sensor to Y sensor ±0.1 Degrees

Cross Axis Sensitivity ±2 %

Sensitivity −40°C to +85°C, VDD = 3.0 V to 3.6 V 0.243 0.244 0.245 mg/LSB

ACCELEROMETER NOISE PERFORMANCE

Output Noise AVG_CNT = 0x00 1.7 mg rms

Noise Density AVG_CNT = 0x00 0.19 mg/√Hz rms

ACCELEROMETER FREQUENCY RESPONSE

Sensor Bandwidth 50 Hz

Sensor Resonant Frequency 5.5 kHz

ACCELEROMETER SELF-TEST STATE

Output Change When Active At 25°C 706 1343 1973 LSB

TEMPERATURE SENSOR

Output at 25°C 1278 LSB

Scale Factor −0.47 °C/LSB

ADC INPUT

Resolution 12 Bits

Integral Nonlinearity (INL) ±2 LSB

Differential Nonlinearity (DNL) ±1 LSB

Offset Error ±4 LSB

Gain Error ±2 LSB

Input Range 0 2.5 V

Input Capacitance During acquisition 20 pF

ON-CHIP VOLTAGE REFERENCE 2.5 V

Accuracy At 25°C −10 +10 mV

Reference Temperature Coefficient ±40 ppm/oC

Output Impedance 70 Ω

DAC OUTPUT 5 kΩ/100 pF to GND

Resolution 12 Bits

Relative Accuracy For Code 101 to Code 4095 4 LSB

Differential Nonlinearity 1 LSB

Offset Error ±5 mV

Gain Error ±0.5 %

Output Range 0 to 2.5 V

Output Impedance 2 Ω

Output Settling Time 10 µs

1

1

2

25°C ±1.7

% of full scale ±0.1 ±0.2 %

g

Rev. 0 | Page 3 of 16

Page 4

ADIS16209

Parameter Conditions Min Typ Max Unit

LOGIC INPUTS

Input High Voltage, V

Input Low Voltage, V

Logic 1 Input High Current, I

Logic 0 Input Low Current, I

All except

RST

RST

3

Input Capacitance, CIN 10 pF

DIGITAL OUTPUTS

Output High Voltage, VOH I

Output Low Voltage, VOL I

SLEEP TIMER

Timeout Period

START-UP TIME

5

Power-On Fast mode, SMPL_PRD ≤ 0x07 150 ms

Normal mode, SMPL_PRD ≥ 0x08 190 ms

Reset Recovery Fast mode, SMPL_PRD ≤ 0x07 30 ms

Normal mode, SMPL_PRD ≥ 0x08 70 ms

Sleep Mode Recovery 2.5 ms

FLASH MEMORY

Endurance

6

Data Retention

CONVERSION RATE SETTING 1.04 2731 SPS

POWER SUPPLY

Operating Voltage Range 3.0 3.3 3.6 V

Power Supply Current Normal mode, SMPL_PRD ≥ 0x08 11 14 mA

Fast mode, SMPL_PRD ≤ 0x07 36 42 mA

Sleep mode, −40°C to +85°C 140 350 µA

1

Guaranteed by iMEMS® packaged part testing, design, and/or characterization.

2

Self-test response changes as the square of VDD.

3

RST

The

pin has an internal pull-up.

4

Guaranteed by design.

5

The times presented in this section do not include the sensor’s transient response time, which is associated with a 50 Hz single-pole system. System accuracy goals

should be given consideration when determining the amount of time it takes to start acquiring accurate readings. These times do not include the time it takes to

arrive at thermal stability, which can also introduce transient errors.

6

Endurance is qualified as per JEDEC Standard 22 Method A117 and measured at −40°C, +25°C, +85°C, and +125°C.

7

Retention lifetime equivalent at junction temperature (TJ) 55°C as per JEDEC Standard 22 Method A117. Retention lifetime decreases with junction temperature.

2.0 V

INH

0.8 V

INL

CS

For

signal when used to wake up from sleep mode

VIH = 3.3 V ±0.2 ±10 µA

INH

V

INL

= 0 V

IL

−40 −60 A

0.55 V

−1 mA

= 1.6 mA 2.4 V

SOURCE

= 1.6 mA 0.4 V

SINK

4

0.5 128 Seconds

Time until data is available

20,000 Cycles

7

TJ = 85°C 20 Years

Rev. 0 | Page 4 of 16

Page 5

ADIS16209

K

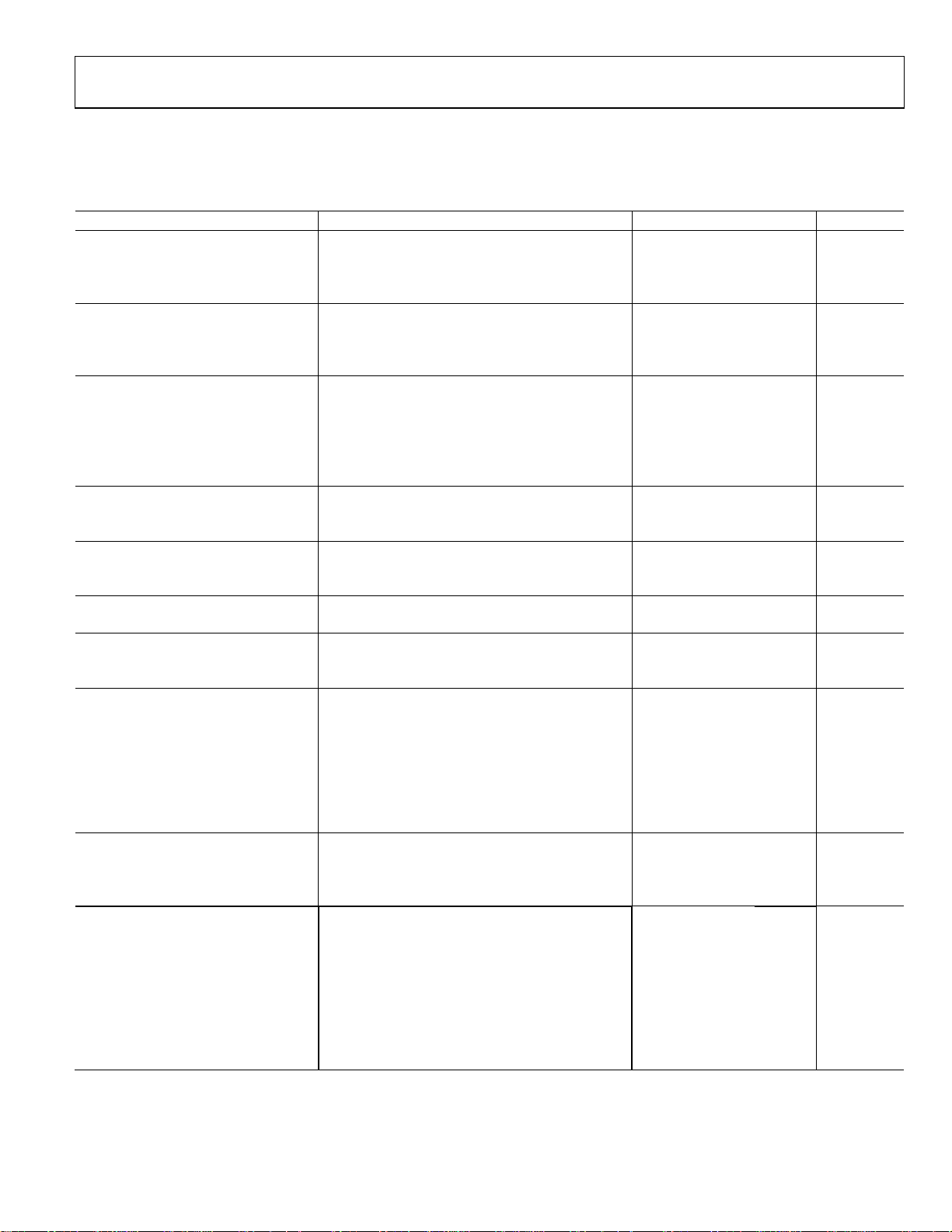

TIMING SPECIFICATIONS

TA = 25°C, VDD = 3.3 V, tilt = 0°, unless otherwise noted.

Table 2.

Parameter Description Min1 Typ Max Unit

f

Fast mode, SMPL_PRD ≤ 0x07 (fS ≥ 546 Hz)2 0.01 2.5 MHz

SCLK

Normal mode, SMPL_PRD ≥ 0x08 (fS ≤ 482 Hz)2 0.01 1.0 MHz

t

Chip select period, fast mode, SMPL_PRD ≤ 0x07 (fS ≥ 546 Hz)2 40 s

DATARATE

tCS Chip select to clock edge 48.8 ns

t

Data output valid after SCLK edge 100 ns

DAV

t

Data input setup time before SCLK rising edge 24.4 ns

DSU

t

Data input hold time after SCLK rising edge 48.8 ns

DHD

tDF Data output fall time 5 12.5 ns

tDR Data output rise time 5 12.5 ns

t

SFS

1

Guaranteed by design, not tested.

2

Note that fS means internal sample rate.

TIMING DIAGRAMS

Chip select period, normal mode, SMPL_PRD ≥ 0x08 (fS ≤ 482 Hz)2 100 s

high after SCLK edge

CS

t

DATARATE

t

STALL

5 ns

CS

SCLK

t

=

t

– 16/

STALL

DATARATE

f

SCLK

07096-002

Figure 2. SPI Chip Select Timing

CS

SCLK

DOUT

DIN

t

CS

1 2 3 4 5 6 15 16

t

DAV

MSB DB14

W/R A5 A4 A3 A2

DB13 DB12 DB10DB11 DB2 LSBDB1

t

DSU

t

DHD

D2

D1 L SB

t

SFS

07096-003

Figure 3. SPI Timing

(Utilizing SPI Settings Typically Identified as Phase = 1, Polarity = 1)

CS

SCL

DATA FRAME

DIN

W/R A5 A4 A3 A2 A1 A0 DC7 DC6 DC5 DC4 DC3 DC2 DC1 DC0

WRITE = 1

READ = 0

REGISTER ADDRESS DATA FOR WRITE COMMANDS

DON’T CARE FO R READ COMMANDS

07096-004

Figure 4. DIN Bit Sequence

Rev. 0 | Page 5 of 16

Page 6

ADIS16209

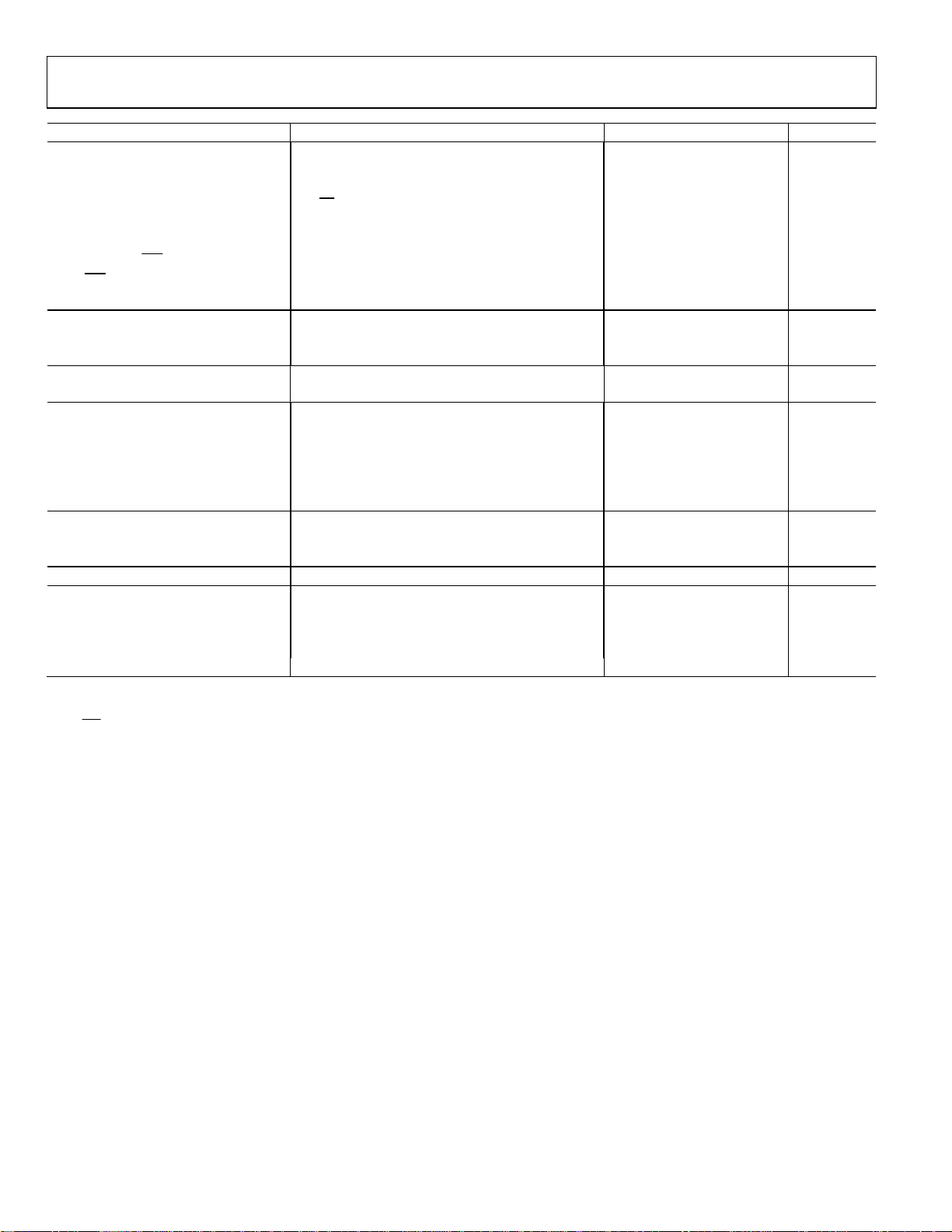

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Acceleration (Any Axis, Unpowered) 3500 g

Acceleration (Any Axis, Powered) 3500 g

VDD to GND −0.3 V to +7.0 V

Digital Input/Output Voltage to GND −0.3 V to +5.5 V

Analog Inputs to GND −0.3 to VDD + 0.3 V

Analog Inputs to GND −0.3 to VDD + 0.3 V

Operating Temperature Range −40°C to +125°C

Storage Temperature Range −65°C to +150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

Table 4. Package Characteristics

Package Type θJA θ

16-Terminal LGA 250°C/W 25°C/W 0.6 grams

Device Weight

JC

ESD CAUTION

Rev. 0 | Page 6 of 16

Page 7

ADIS16209

2

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

F

AUX ADC

VRE

GND

16 15 14 13

A

SCLK

DOUT

DIN

CS

NOTES

1. NC = NO CONNECT.

. THIS IS NOT AN ACTUAL TO P VIEW, BECAUSE THE PINS ARE NOT VIS IBLE FROM THE TOP. THIS IS

A LAYOUT VI EW, WHI CH REPRESENTS T HE PIN CONFI GURATIO N, IF THE PACKAGE IS LOOKED

THROUGH FRO M THE TOP . THIS CO NFIGURATI ON IS PRO VIDED FOR PCB L AYOUT PURPO SES.

Y

A

X

PIN 1

INDICATO R

ADIS16209

TOP

LOOK THRO UGH

VIEW

(Not to Scale)

4 3 2 1

5 6 7 8

DIO2

DIO1

Figure 5. Pin Configuration

VDD

AUX DAC

NC

NC

9 10 11 12

RST

NC

NC

07096-005

Table 5. Pin Function Descriptions

Pin No. Mnemonic Type

1

Description

1 SCLK I SPI, Serial Clock.

2 DOUT O SPI, Data Output.

3 DIN I SPI, Data Input.

4

CS

I SPI, Chip Select.

5, 6 DIO1, DIO2 I/O Digital Input/Output Pins.

7, 8, 10, 11 NC N/A No Connect.

9

RST

I Reset, Active Low.

12 AUX DAC O Auxiliary DAC Output.

13 VDD S Power Supply, 3.3 V.

14 AUX ADC I Auxiliary ADC Input.

15 VREF O Precision Reference.

16 GND S Ground.

1

S = supply; O = output; I = input.

RECOMMENDED PAD GEOMETRY

4.1865

8×

0.670

12×

8.373

2×

5.391

4×

2.6955

8×

0.500

1.127

16×

9.2mm × 9.2mm S TACKED LGA PACKAGE

16×

07096-006

Figure 6. Example of a Pad Layout

Rev. 0 | Page 7 of 16

Page 8

ADIS16209

TYPICAL PERFORMANCE CHARACTERISTICS

0.20

0.15

0.10

0.05

0

–0.05

ERROR (Degrees)

–0.10

–0.15

–0.20

–40 –30 –20 –10 0 10 20 30 40

INCLINATI ON ANGLE (Degrees)

MAXIMUM

INCLINE

ERROR

Figure 7. Horizontal Inclination Error (8 Parts), Autonull at Horizontal

Position, Stable Temperature, 3.3 V

0.3

07096-018

0.25

0.20

0.15

0.10

0.05

0

–0.05

ERROR (Degrees)

–0.10

–0.15

–0.20

–0.25

0 100 200 300 400

ROTATIO NAL ANGLE (Degrees)

Figure 10. Vertical Mode Rotational Error (8 parts), 25°C, 3.3 V

0.3

07096-021

0.2

0.1

0

–0.1

ERROR (Degrees)

–0.2

–0.3

–60 –4 0 – 20 0 20 40 60 80 100

TEMPERATURE (°C)

07096-019

Figure 8. Maximum Incline Error over a ±30° Incline Range (8 Parts) over

Temperature, Autonull at Horizontal Position, 25°C, 3.3 V

0.15

0.10

0.05

0

–0.05

ERROR (Degrees)

–0.10

–0.15

0.2

0.1

0

–0.1

–0.2

ERROR (Degrees)

–0.3

–0.4

–0.5

–60 –40 –20 0 20 40 60 80 100

TEMPERATURE ( °C)

Figure 11. Vertical Mode Error (8 Parts) vs. Temperature, 0° to 360°, 3.3 V

0.3

0.2

0.1

0

–0.1

–0.2

ERROR (Degrees)

–0.3

–0.4

07096-022

–0.20

3.0 3.3 3.6

SUPPLY VOLTAGE (V)

Figure 9. Maximum Incline Error over a ±30° Incline Range (8 Parts) over

Supply Voltage, Autonull Horizontal Position, 25°C, 3.3 V

07096-020

Rev. 0 | Page 8 of 16

–0.5

3.0 3.3 3.6

SUPPLY VOLTAGE (V)

07096-023

Figure 12. Vertical Mode Error (8 Parts) vs. Supply Voltage, 0° to 360°, 25°C

Page 9

ADIS16209

30

25

VDD = 3.0V, 3. 3V, 3.6V

TEMP = –40°C, +25°C, +85°C

3.5

3.0

20

15

10

5

PERCENTAGE O F POPULAT ION (%)

0

–0.50 –0. 38 –0.26 –0.14 –0. 02 0.10 0.22 0.34 0.46

SENSITIV ITY ERROR (%)

Figure 13. Accelerometer Output Sensitivity Error Distribution

20

18

16

14

12

10

8

6

4

PERCENTAGE O F POPULAT ION (%)

2

0

–6.0 –4.4 –2.8 –1.2 0.4 2.0 3.6 5.2

BIAS ERROR (mg)

VDD = 3.0V, 3. 3V, 3.6V

TEMP = –40 °C, +25°C, +85°C

Figure 14. Accelerometer Output Bias Error Distribution

2.5

2.0

1.5

ERROR (Degrees)

1.0

0.5

0

0 102030405060708090

07096-013

OFF-VE RTICAL T ILT (Deg rees)

7096-015

Figure 15. Error vs. Off-Vertical Tilt, 25°C, 3.3 V

07096-014

Rev. 0 | Page 9 of 16

Page 10

ADIS16209

G

G

THEORY OF OPERATION

The ADIS16209 tilt sensing system uses gravity as its only

stimulus, and a MEMS accelerometer as its sensing element.

MEMS accelerometers typically employ a tiny, spring-loaded

structure that is interlaced with a fixed pick-off finger structure.

The spring constant of the floating structure determines how

far it moves when subjected to a force. This structure responds

to dynamic forces associated with acceleration and to static

forces, such as gravity.

Figure 16 and Figure 17 illustrate how the accelerometer

responds to gravity, according to its orientation, with respect

to gravity. Figure 16 displays the configuration for the incline

angle outputs, and Figure 17 displays the configuration used

for the rotational angle position. This configuration provides

greater measurement range than a single axis. The ADIS16209

incorporates the signal processing circuit that converts acceleration into an incline angle, and corrects for several known error

sources that would otherwise degrade the accuracy level.

0° TIL T

LEVEL PLANE

POSITIVE

X AXIS TILT

DIRECTION

58

4

Y AXIS Y AXIS

POSITIVE

Y AXIS TILT

DIRECTION

4

16

1

XINCL_OUT = 0°

YINCL_OUT = 0°

13

12

9

85

Figure 18. Horizontal Incline Angle Orientation

POSITIVE DIRECTION

1

9

1316

0° ≤ XINCL_OUT ≤ 90°

YINCL_OUT = 0°

RAVITY = 1g

Figure 16. Single-Axis Tilt Theory Diagram

RAVITY = 1g

Figure 17. Dual-Axis Tilt Theory Diagram

12

4

θ

x

a

x

θ

x

HORIZON

a

y

θ

x

a

x

θ

x

HORIZON

16

1

5

13

12

9

8

XINCL_OUT = 0°

0° ≤ YINCL_OUT ≤ 90°

07096-007

07096-008

X AXISX AXIS

07096-011

1

6

2

0

9

1

6

2

0

16209

ROT_OUT = 0°

9

90° ≤ ROT_OUT ≤ 180°

–180° ≤ ROT_OUT ≤ –90°

07096-012

Figure 19. Vertical Angle Orientation

Rev. 0 | Page 10 of 16

Page 11

ADIS16209

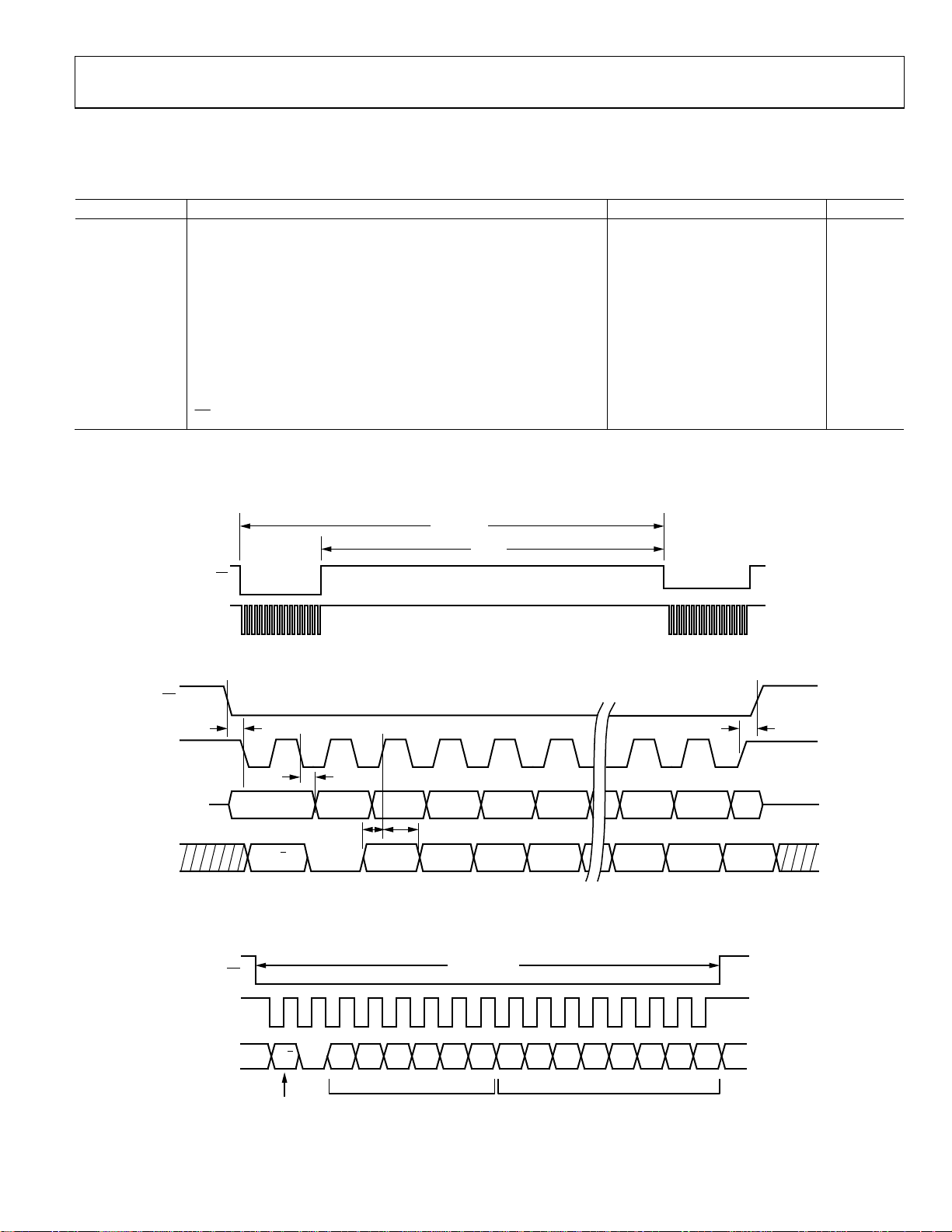

BASIC OPERATION

The ADIS16209 requires only power/ground and SPI connections. The SPI is simple to hook up and is supported by many

common digital hardware platforms. Figure 20 provides a

simple hook-up diagram, while Table 2, Figure 2, and Figure 3

provide timing and bit assignments. Figure 4 provides the bit

sequence for accessing the register memory structure. Each

function within the ADIS16209 has its own 16-bit, 2-byte register. Each byte has its own unique, 6-bit address. Note that

all 16 SCLK cycles are required for the DIN bit sequence to

configure the output for the next data frame. The ADIS16209

supports full duplex mode operation. Table 6 provides the

entire user register map for the ADIS16209. For each register,

the lower bytes address is given. For those registers that have

two bytes, the upper bytes address is simply the lower bytes

Many of the configuration registers have also been assigned

mirror locations in the flash memory, which effectively provides

them with a backup storage function. To assure the backup of

these registers, the COMMAND register provides an initiation

bit for manual flash updates. The ENDURANCE register

provides a running count of these events.

ADIS16209

CS

SCLK

DIN

DOUT

Figure 20. Typical SPI Hook-up

address, incremented by 0x01.

Table 6. User Register Map

Name R/W Flash Backup Address Size (Bytes) Function Reference

ENDURANCE R Yes 0x00 2 Diagnostics, flash write counter (16-bit binary)

SUPPLY_OUT R No 0x02 2 Output, power supply Table 7

XACCL_OUT R No 0x04 2 Output, x-axis acceleration Table 7

YACCL_OUT R No 0x06 2 Output, y-axis acceleration Table 7

AUX_ADC R No 0x08 2 Output, auxiliary ADC Table 7

TEMP_OUT R No 0x0A 2 Output, temperature Table 7

XINCL_OUT R No 0x0C 2 Output, ±90° x-axis inclination Table 7

YINCL_OUT R No 0x0E 2 Output, ±90° y-axis inclination Table 7

ROT_OUT R No 0x10 2 Output, ±180° vertical rotational position Table 7

XACCL_NULL R/W Yes 0x12 2 Calibration, x-axis acceleration offset null Table 16

YACCL_NULL R/W Yes 0x14 2 Calibration, y-axis acceleration offset null Table 16

XINCL_NULL R/W Yes 0x16 2 Calibration, x-axis inclination offset null Table 17

YINCL_NULL R/W Yes 0x18 2 Calibration, y-axis inclination offset null Table 17

ROT_NULL R/W Yes 0x1A 2 Calibration, vertical rotation offset null Table 17

0x1C to 0x1F 4 Reserved, do not write to these locations

ALM_MAG1 R/W Yes 0x20 2 Alarm 1, amplitude threshold Table 18

ALM_MAG2 R/W Yes 0x22 2 Alarm 2, amplitude threshold Table 18

ALM_SMPL1 R/W Yes 0x24 2 Alarm 1, sample period Table 19

ALM_SMPL2 R/W Yes 0x26 2 Alarm 2, sample period Table 19

ALM_CTRL R/W Yes 0x28 2 Alarm, source control register Table 20

No 0x2A to 0x2F 6 Reserved

AUX_DAC R/W No 0x30 2 Auxiliary DAC data Table 14

GPIO_CTRL R/W No 0x32 2 Operation, digital I/O configuration and data Table 13

MSC_CTRL R/W No 0x34 2 Operation, data-ready and self-test control Table 12

SMPL_PRD R/W Yes 0x36 2 Operation, sample rate configuration Table 8

AVG_CNT R/W Yes 0x38 2 Operation, filter configuration Table 10

SLP_CNT W Yes 0x3A 2 Operation, sleep mode control Table 9

STATUS R No 0x3C 2 Diagnostics, system status register Table 21

COMMAND W No 0x3E 2 Operation, system command register Table 15

EMBEDDED

PROCESSOR/

DSP/FPGA

PF

SCK

MOSI

MISO

07096-009

Rev. 0 | Page 11 of 16

Page 12

ADIS16209

OUTPUT DATA REGISTERS

Tabl e 7 provides the data configuration for each output data

register in the ADIS16209. Starting with the MSB of the upper

byte, each output data register has the following bit sequence:

new data (ND) flag, error/alarm (EA) flag, followed by 14 data

bits. The data bits are LSB-justified and, in the case of the 12-bit

data formats, the remaining two bits are not used. The ND flag

indicates that unread data resides in the output data registers.

This flag clears and returns to 0 during an output register read

sequence. It returns to 1 after the next internal sample update

cycle completes. The EA flag indicates an error condition. The

STATUS register contains all of the error flags and provides the

ability to investigate root cause.

Table 7. Output Data Register Formats

Register Bits Format Scale1

SUPPLY_OUT 14 Binary, 3.3 V = 0x2A3D 0.30518 mV

XACCL_OUT 14 Twos complement 0.24414 mg

YACCL_OUT 14 Twos complement 0.24414 mg

AUX_ADC 12 Binary, 2 V = 0x0CCC 0.6105 mV

TEMP_OUT 12 Binary, 25°C = 0x04FE −0.47°C

XINCL_OUT2 14 Twos complement 0.025°

YINCL_OUT2 14 Twos complement 0.025°

ROT_OUT3 14 Twos complement 0.025°

1

Scale denotes quantity per LSB.

2

Range is −90° to +90°.

3

Range is −180° to +179.975°.

of 68%. The two different modes of operation offer a systemlevel trade-off between performance (sample rate, serial transfer

rate) and power dissipation.

Power Management

In addition to offering two different performance modes for

power optimization, the ADIS16209 offers a programmable

shutdown period that the SLP_CNT register controls.

Table 9. SLP_CNT Bit Descriptions

Bit Description (Default = 0x0000)

15:8 Not used

7:0 Data bits, 0.5 seconds/LSB

For example, writing 0x08 to the SLP_CNT register places the

ADIS16209 into sleep mode for 4 seconds. The only way to stop

this process is to remove power or reset the device.

Digital Filtering

The AVG_CNT register controls the moving average digital filter,

which determines the size of the moving average filter, in eight

power-of-two step sizes (that is, 2

M

= 1, 2, 4, 16, 32, 64, 128, and

256). Filter setup requires one simple step: write the appropriate

M factor to the assigned bits in the AVG_CNT register.

Table 10. AVG_CNT Bit Descriptions

Bit Description (Default = 0x0004)

15:4 Not used

3:0 Power-of-two step size, maximum binary value = 1000

OPERATION CONTROL REGISTERS

Internal Sample Rate

The SMPL_PRD register controls the ADIS16209 internal sample

rate and has two parts: a selectable time base and a multiplier. The

following relationship produces the sample rate:

= tB × NS + 122.07μs

t

S

Table 8. SMPL_PRD Bit Descriptions

Bit Description (Default = 0x0004)

15:8 Not used

7 Time base (tB)

0 = 244.14 µs, 1 = 7.568 ms

6:0 Increment setting (NS)

An example calculation of the default sample period follows:

SMPL_PRD = 0x01, B7 − B0 = 00000001

B7 = 0 → t

t

= tB × NS + 122.07μs = 244.14 × 1 + 122.07 = 366.21 μs

S

f

= 1∕tS = 2731 SPS

S

The sample rate setting has a direct impact on the SPI data

rate capability. For sample rates ≥546 SPS, the SPI SCLK can

run at a rate up to 2.5 MHz. For sample rates <546 SPS, the SPI

SCLK can run at a rate up to 1 MHz. The sample rate setting

also affects power dissipation. When the sample rate is set to

<546 SPS, power dissipation typically reduces by a factor

= 244.14 μs, B6…B0 = 000000001 → NS = 1

B

The following equation offers a frequency response relationship

for this filter:

)sin(

tfN

×××π

S

)(

fH

=

A

20

0

–20

–40

MAGNITUDE (d B)

–60

–80

–100

0.001 0. 01 0.1

Figure 21. Frequency Response—Moving Average Filter

××π×

tfN

S

N = 128

)sin(

N = 4

N = 16

f/f

S

07096-010

Rev. 0 | Page 12 of 16

Page 13

ADIS16209

Digital I/O Lines

The ADIS16209 provides two, general purpose, digital

input/output lines that have several configuration options.

Table 11. Digital I/O Line Configuration Registers

Function [Priority] Register

Data-Ready I/O Indicator [1] MSC_CTRL

Alarm Indicator [2] ALM_CTRL

General-Purpose I/O Configuration [3] GPIO_CTRL

General-Purpose I/O Line Communication GPIO_CTRL

Table 13. GPIO_CTRL Bit Descriptions

Bit Description (Default = 0x0000)

15:10 Not used

9 General-Purpose I/O Line 2 data

8 General-Purpose I/O Line 1 data

7:2 Not used

1 General-Purpose I/O Line 2, data direction control

1 = output, 0 = input

0 General-Purpose I/O Line 1, data direction control

1 = output, 0 = input

Data-Ready I/O Indicator

The MSC_CTRL register provides controls for a data-ready

function. For example, writing 0x05 to this register enables this

function and establishes DIO2 as an active-low, data-ready line.

The duty cycle is 25% (±10% tolerance).

Table 12. MSC_CTRL Bit Descriptions

Bit Description (Default = 0x0000)

15:11 Not used

10 Self-test at power-on: 1 = disabled, 0 = enabled

9 Not used

8 Self-test enable (temporary, bit is volatile)

1 = enabled, 0 = disabled

7:3 Not used

2 Data-ready enable: 1 = enabled, 0 = disabled

1 Data-ready polarity: 1 = active high, 0 = active low

0 Data-ready line select: 1 = DIO2, 0 = DIO1

Self-Test

Self-test exercises the mechanical structure of the sensor and

provides a simple method for verifying the operation of the

entire sensor signal conditioning circuit. There are two different

self-test options: startup and manual. If either of these self-tests

results in a failure, the self-test error flag, located in the STATUS

register, sets to 1. The manual self-test option results in a

repeating pattern, until the bit is set back to 0. While in the

manual self-test loop, SMPL_PRD and AVG_CNT cannot be

changed. See Ta ble 1 2 for the appropriate MSC_CTRL bit

designations.

General Purpose I/O

The GPIO_CTRL register controls the direction and data of the

general-purpose digital lines, DIO1 and DIO2. For example,

writing a 0x02 to the GPIO_CTRL register sets DIO2 as an

output line and DIO1 as an input line. Reading the data bits in

GPIO_CTRL reveals the line logic level.

Auxiliary DAC

The auxiliary DAC provides a 12-bit level adjustment function.

The AUX_DAC register controls the operation of the auxiliary

DAC function, which is useful for systems that require analog

level controls. It offers a rail-to-rail buffered output that has a

range of 0 V to 2.5 V. The DAC can drive its output to within

5 mV of the ground reference when it is not sinking current.

As the output approaches ground, the linearity begins to degrade

(100 LSB beginning point). As the sink current increases, the

nonlinear range increases. The DAC output latch function,

contained in the COMMAND register, provides continuous

operation while writing to each byte of this register. The

contents of this register are volatile, which means that the

desired output level must be set after every reset and power

cycle event.

Table 14. AUX_DAC Bit Descriptions

Bit Description (Default = 0x0000)

15:12 Not used

11:0 Data bits, scale factor = 0.6105 mV/code

Offset binary format, 0 V = 0 codes

Global Commands

The COMMAND register provides initiation bits for several

commands that simplify many common operations. Writing a 1

to the assigned COMMAND bit exercises its function.

Table 15. COMMAND Bit Descriptions

Bit Description (Default = 0x0000)

15:8 Not used

7 Software reset

6:5 Not used

4 Clear status register (reset all bits to 0)

3 Flash update; backs up all registers, see Table 6

2 DAC data latch

1 Factory calibration restore

0 Autonull

The software reset command restarts the internal processor,

which loads all registers with the contents in their flash memory

locations.

Rev. 0 | Page 13 of 16

Page 14

ADIS16209

The flash update copies the contents of all the flash backup

registers into their assigned, nonvolatile, flash memory locations. This process takes approximately 50 ms and requires a

power supply that is within the specified operating range. After

waiting the appropriate time for the flash update to complete,

verify successful completion by reading the STATUS register (if

successful, the flash update error is 0). If the flash update was

not successful, reading this error bit accomplishes two things:

(1) alerting the system processor to try again, and (2) clearing

the error flag, which is required for flash memory access.

The DAC data latch command loads the contents of AUX_DAC

into the DAC latches. Because the AUX_DAC contents must be

updated one byte at a time, this command ensures a stable DAC

output voltage during updates.

The autonull command provides a simple method for removing

offset from the sensor outputs. This command takes the

contents of the output data registers and loads the equal but

opposite number into the offset calibration registers. The

accuracy of this operation depends on zero force, zero motion,

and optimal noise management during the measurement (see

the Digital Filtering section). The factory calibration restore sets

the offset null registers (XACCL_NULL, for example) back to

their default values.

CALIBRATION REGISTERS

The ADIS16209 incorporates an extensive factory calibration

and provides precision acceleration, incline, and rotational

position data. For systems that require on-site calibration,

user-programmable offset adjustment registers are available.

Tabl e 16 provides the bit assignments for the following userprogrammable calibration registers: XACCL_NULL and

YACCL_NULL. Ta b le 1 7 provides the bit assignments for

the following user-programmable calibration registers:

XINCL_NULL, YINCL_NULL, and ROT_NULL.

Table 16. Acceleration Offset Register Bit Designations

Bit Description (Default = 0x0000)

15:14 Not used

13:0 Data bits, twos complement, sensitivity = 0.24414 mg/LSB

Table 17. Incline/Rotation Offset Register Bit Designations

Bit Description (Default = 0x0000)

15:14 Not used

13:0 Data bits, twos complement, sensitivity = 0.025°/LSB

ALARM REGISTERS

The alarm function provides monitoring for two independent

conditions. The ALM_CTRL register provides control inputs

for data source, data filtering (prior to comparison), static/

dynamic, and output indicator configurations. The ALM_MAGx

registers establish the trigger threshold and polarity configurations. The ALM_SMPLx registers provide the numbers of

samples to use in the dynamic, rate-of-change configuration.

The rate-of-change calculation is

N

DS

1

Y <>⇒⇒−+=

C

∑

N

DS

=1

n

where:

N

is the number of samples in ALM_SMPLx.

DS

y(n) is the sampled output data.

M

is the magnitude for comparison in ALM_MAGx.

C

> or < is determined by the MSB in ALM_MAGx.

Table 18. ALM_MAG1/ALM_MAG2 Bit Designations

Bit Description (Default = 0x0000)

15 Comparison polarity: 1 = greater than, 0 = less than

14 Not used

13:0 Data bits, matches format of trigger source selection

Table 19. ALM_SMPL1/ALM_SMPL2 Bit Designations

Bit Description (Default = 0x0001)

15:8 Not used

7:0 Data bits: number of samples (both 0x00 and 0x01 = 1)

Table 20. ALM_CTRL Bit Descriptions

Bit Value Description (Default = 0x0000)

15:12 Trigger source, Alarm 2

0000 Disabled

0001

0010

0011

0100

0101

0110

0111

1000

11:8

7

6 Alarm 2 rate of change control: 1 = enabled

5

4

3

2

1

0 Alarm indicator line select: 1 = DIO2, 0 = DIO1

1

Incline and vertical angles always use filtered data in this comparison.

Power supply

X-acceleration

Y-acceleration

Auxiliary ADC

Temperature sensor

X-axis incline angle

Y-axis incline angle

Rotational position

Trigger source, Alarm 1, same as Bits [15:12]

Not used

Alarm 1 rate of change control: 1 = enabled

Alarm 2 filter: 1 = filtered data, 0 = no filter1

Alarm 1 filter: 1 = filtered data, 0 = no filter1

Alarm indicator, using DIO1/DIO2: 1 = enabled

Alarm indicator polarity: 1 = active high

?oris)()1(

MYAlarmnyny

CC

Rev. 0 | Page 14 of 16

Page 15

ADIS16209

Status

The STATUS register provides a series of error flags that

provide indicator functions for common system-level issues.

All of the flags clear (set to 0) after each STATUS register read

cycle. If an error condition remains, the error flag returns to 1

during the next sample cycle.

Table 21. STATUS Bit Descriptions

Bit Description (Default = 0x0000)

15:10 Not used

9 Alarm 2 status:

1 = active, 0 = inactive

8 Alarm 1 status

1 = active, 0 = inactive

7:6 Not used

5 Self-test diagnostic error flag

1 = error condition, 0 = normal operation

4 Not used

3 SPI communications failure

1 = error condition, 0 = normal operation

2 Flash update failed

1 = error condition, 0 = normal operation

1 Power supply above 3.625 V

1 ≥ 3.625 V, 0 ≤ 3.625 V (normal)

0 Power supply below 2.975 V

1 ≤ 2.975 V, 0 ≥ 2.975 V (normal)

Rev. 0 | Page 15 of 16

Page 16

ADIS16209

OUTLINE DIMENSIONS

5.391

BSC

9.35

MAX

TOP VIEW

5.00

TYP

9.20

TYP

3.90

MAX

8.373

BSC

(2×)

0.200

MIN

(ALL SIDES)

2.6955

BSC

(8×)

13 16

12

9

(4×)

BOTTOM VIEW

1

4

58

PIN 1

INDICATOR

1.000 BSC

(16×)

0.797 BSC

(12×)

0.373 BSC

(16×)

SIDE VIEW

022007-B

Figure 22. 16-Terminal Land Grid Array [LGA]

(CC-16-2)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADIS16209CCCZ

ADIS16209/PCBZ1 Evaluation Board

1

Z = RoHS Compliant Part.

1

−40°C to +125°C 16-Terminal Land Grid Array [LGA] CC-16-2

©2008 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D07096-0-3/08(0)

Rev. 0 | Page 16 of 16

Loading...

Loading...