Page 1

Digital Output, High Precision

www.BDTIC.com/ADI

FEATURES

Low noise density: 0.0125o/sec/√Hz

Industry-standard serial peripheral interface (SPI)

24-bit digital resolution

Dynamic range: ±250

Z-axis, yaw rate response

Bandwidth, adjustable: 300 Hz

Turn-on time: 35 ms

Digital self-test

High vibration rejection

High shock survivability

Embedded temperature sensor output

Precision voltage reference output

5 V single-supply operation

−40°C to +85°C

APPLICATIONS

Guidance and control

Instrumentation

Inertial measurement units (IMU)

Platform stabilization

Navigation

o

/sec

Angular Rate Sensor

ADIS16130

GENERAL DESCRIPTION

The ADIS16130 is a low noise, digital output angular rate sensor

(gyroscope) that provides an output response over the complete

dynamic range of ±250

Its industry-standard serial interface and register structure provide

ple interface that is supported by most MCU, DSP, and FPGA

a sim

platforms.

By implementing a unique design, the device provides superior

ability over variations in temperature, voltage, linear acceleration,

st

vibration, and next-level assembly. In addition, the surface-micromachining technology used to manufacture the device is the

same high volume BiMOS process used by Analog Devices, Inc.,

for its high reliability automotive sensor products.

Features include a temperature output that provides critical

info

rmation for system-level calibrations and a digital self-test

feature that exercises the mechanical structure of the sensor and

enables system-level diagnostics.

The package configuration is a 36 mm × 44 mm × 16 mm

mo

dule with a standard 24-lead connector interface.

o

/sec.

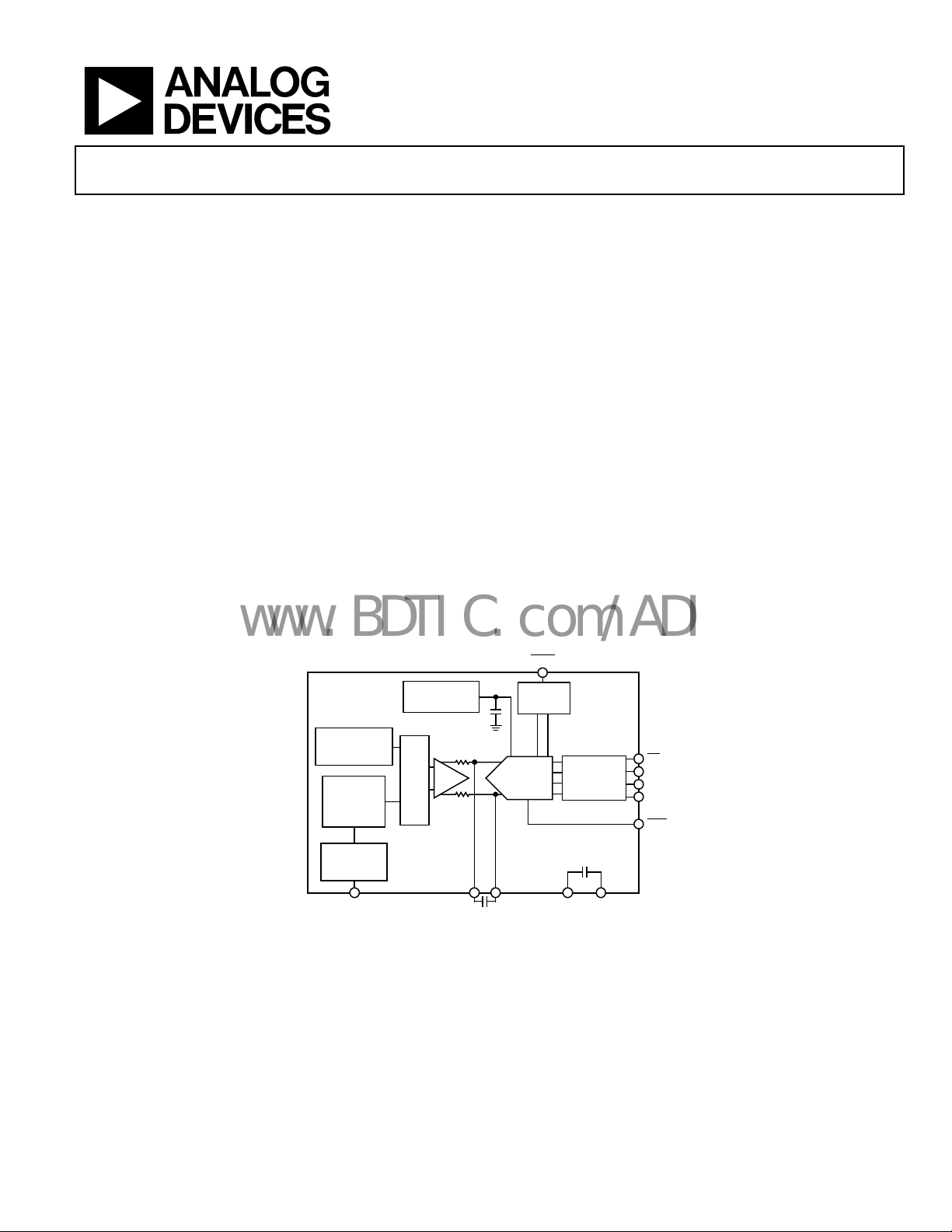

FUNCTIONAL BLOCK DIAGRAM

SYNC

ADIS16130

TEMPERATURE

SENSOR

MEMS

ANGULAR

RATE

SENSOR

SELF-TEST

ST ROA1 ROA2 VCC GND

REFERENCE

2:1

MUX

Figure 1.

SYNC

24-BIT

Σ-Δ ADC

SERIAL

INTERFACE

CS

SCLK

SDI

SDO

RDY

07238-001

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

Page 2

ADIS16130

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

Timing Specifications .................................................................. 4

Absolute Maximum Ratings............................................................ 6

Thermal Resistance ...................................................................... 6

ESD Caution.................................................................................. 6

Pin Configuration and Function Descriptions............................. 7

REVISION HISTORY

3/08—Rev. 0 to Rev. A

Changes to Figure 15...................................................................... 10

Changes to Ordering Guide.......................................................... 13

1/08—Revision 0: Initial Version

Typical Perf or m an c e Chara c t e risti c s ..............................................8

Basic Operation .................................................................................9

Quick Start .....................................................................................9

Configuration Options .............................................................. 10

Control Registers............................................................................ 11

Control Register Details ............................................................ 11

Applications Information.............................................................. 12

Achieving Optimal Noise Performance .................................. 12

Second-Level Assembly ............................................................. 12

Outline Dimensions ....................................................................... 13

Ordering Guide .......................................................................... 13

Rev. A | Page 2 of 16

Page 3

ADIS16130

www.BDTIC.com/ADI

SPECIFICATIONS

TA = 25°C, VCC = 5 V, angular rate = 0°/sec, C

= 0 μF, ±1 g, unless otherwise noted.

OUT

Table 1.

Parameter Conditions Min

1

Typ Max

1

Unit

SENSITIVITY Clockwise rotation is positive output (see Figure 5)

Dynamic Range

2

Full-scale range over specified operating conditions ±250 °/sec

Initial 22,548 23,488 24,428 LSB/°/sec

Nonlinearity Best-fit straight line 0.04 % of FS

NULL

Initial Null ±1σ ±3 °/sec

In-Run Bias Stability 1σ 0.0016 °/sec

Angle Random Walk 1σ 0.56 °/√Hr

Turn-On Time Power on to ±0.5°/sec of final value, 80 Hz bandwidth 35 ms

Linear Acceleration Effect Any axis 0.05 °/sec/g

Voltage Sensitivity VCC = 4.75 V to 5.25 V 0.2 °/sec/V

NOISE PERFORMANCE

Rate Noise Density

3

0.0125 °/sec/√Hz

FREQUENCY RESPONSE

Bandwidth −3 dB frequency with no external capacitance 300 Hz

Sensor Resonant Frequency 14 kHz

SELF-TEST INPUTS

ST RATEOUT Response

4

ST pins from Logic 0 to Logic 1 65 75 85 °/sec

Logic 1 Input Voltage Standard high logic level definition 3.3 V

Logic 0 Input Voltage Standard low logic level definition 1.7 V

Input Impedance To GND 3.13 kΩ

TEMPERATURE SENSOR

Output at 298 K (25°C) 8,388,608 LSB

Scale Factor 14,093 LSB/°C

DIGITAL OUTPUTS

Output Low Voltage (VOL) 0.4 V

Output High Voltage (VOH) 4 V

DIGITAL INPUTS

Input Current

CS

10 μA

All others 1 μA

Input Capacitance 5 pF

VT+ 1.4 2 V

VT− 0.8 1.4 V

(VT+) – (VT−) 0.3 0.85 V

POWER SUPPLY

Operating Voltage Range 4.75 5.00 5.25 V

Quiescent Supply Current I

= 0 mA, 5 V 73 85 mA

OUT

TEMPERATURE RANGE

Operating Range –40 +85 °C

1

All minimum and maximum specifications are guaranteed. Typical specifications are not tested or guaranteed.

2

Dynamic range is the maximum full-scale measurement range possible, including output swing range, initial offset, sensitivity, offset drift, and sensitivity drift at 4.75 V

to 5.25 V supplies.

3

Resulting bias stability is <0.01°/sec.

4

Self-test response varies with temperature, see Figure 12.

Rev. A | Page 3 of 16

Page 4

ADIS16130

www.BDTIC.com/ADI

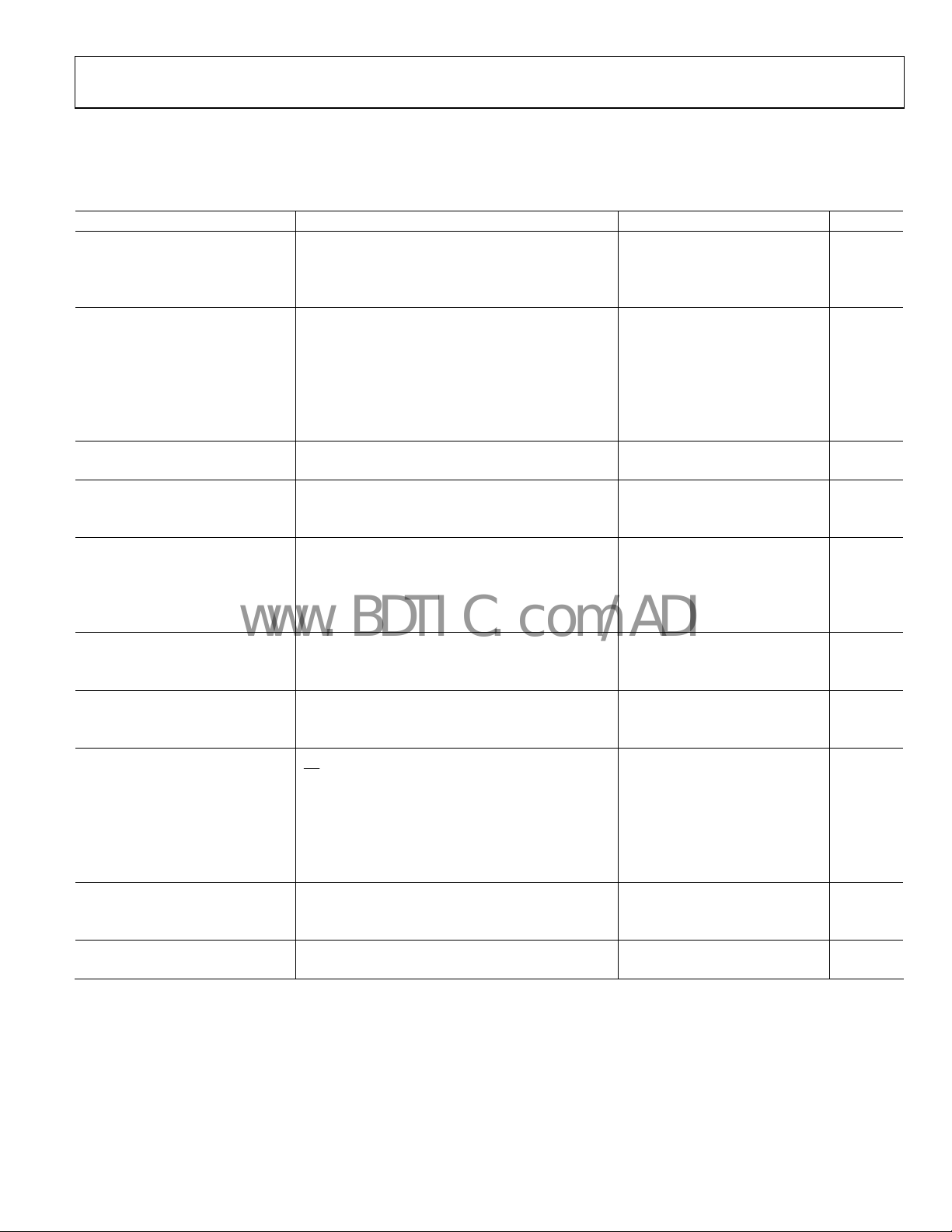

TIMING SPECIFICATIONS

All input signals are specified with 10% to 90% rise and fall times of less than 5 ns.

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

t

1

Read Operation

t

4

1

t

SCLK falling edge to data valid delay

5

0 60 ns DVDD of 4.75 V to 5.25 V

1, 2

t

5A

0 60 ns DVDD of 4.75 V to 5.25 V

t

6

t

7

t

8

3

t

9

Write Operation

t

11

t

12

t

13

t

14

t

15

t

16

1

These numbers are measured with the load circuit shown in Figure 4 and defined as the time required for the output to cross the VOL or VOH limits.

2

This specification is relevant only if CS goes low while SCLK is low.

3

These numbers are derived from the measured time taken by the data output to change 0.5 V when loaded with the circuit shown in Figure 4. The measured number

is then extrapolated back to remove effects of charging or discharging the 50 pF capacitor. Therefore, the times quoted are the true bus relinquish times of the part

and as such are independent of external bus loading capacitances.

50 ns

0 ns

pulse width

SYNC

falling edge to SCLK falling edge setup time

CS

falling edge to data valid delay

CS

50 ns SCLK high pulse width

50 ns SCLK low pulse width

0 ns

rising edge after SCLK rising edge hold time

CS

10 80 ns Bus relinquish time after SCLK rising edge

0 ns

falling edge to SCLK falling edge setup

CS

30 ns Data valid to SCLK rising edge setup time

25 ns Data valid after SCLK rising edge hold time

50 ns SCLK high pulse width

50 ns SCLK low pulse width

0 ns

rising edge after SCLK rising edge hold time

CS

Rev. A | Page 4 of 16

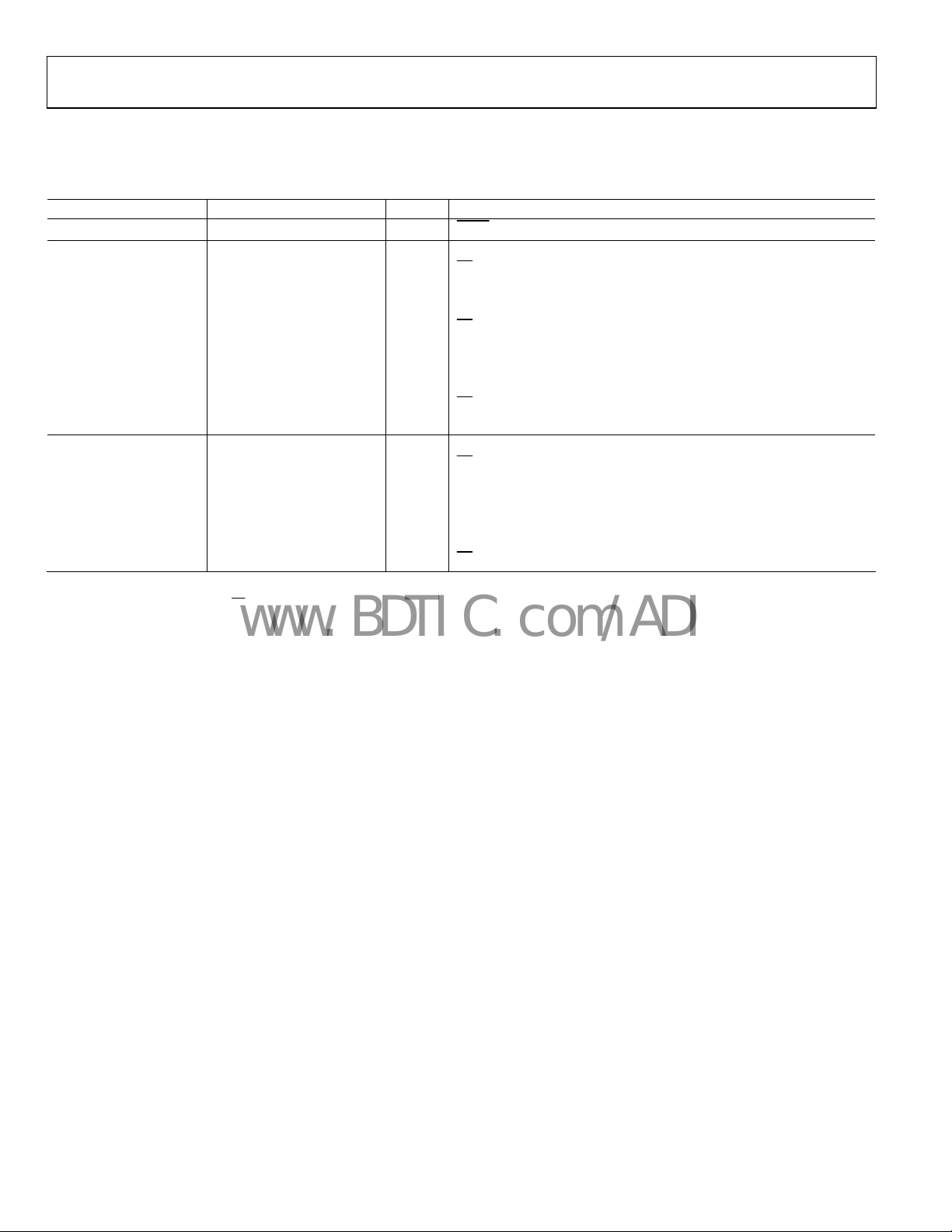

Page 5

ADIS16130

SCLK

www.BDTIC.com/ADI

CS

t

11

SCLK

t

12

t

13

SDI MSB LSB

t

14

t

15

t

16

07238-002

Figure 2. Input Timing for Write Operation

CS

t

8

t

9

07238-003

SDO

t

4

t

5

t

5A

MSB LSB

t

6

t

7

Figure 3. Output Timing for Read Operation

(800µA AT DVDD = 5V

I

SINK

100µA AT DV

DD

= 3V)

TO OUTPUT

PIN

50pF

I

SOURCE

1.6V

(200µA AT DVDD = 5V

100µA AT DV

DD

= 3V)

07328-024

Figure 4. Load Circuit for Access Time and Bus Relinquish Time

Rev. A | Page 5 of 16

Page 6

ADIS16130

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

Acceleration (Any Axis, Unpowered, 0.5 ms) 2000 g

Acceleration (Any Axis, Powered, 0.5 ms) 2000 g

+V

S

Output Short-Circuit Duration

(Any Pin to Common)

Operating Temperature Range −40°C to +85°C

Storage Temperature Range −65°C to +150°C

−0.3 V to +6.0 V

Indefinite

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Dropping the device onto a hard surface may cause a shock of

reater than 2000 g and exceed the absolute maximum rating of

g

the device. Care should be exercised when handling the device

to avoid damage.

THERMAL RESISTANCE

The ADIS16130 provides a temperature output that is

representative of the junction temperature. This can be used

for system-level monitoring and power management/thermal

characterization.

Table 4. Thermal Characteristics

Package Type

24-Lead Module 15.7 1.48 °C/W

1

Weight = 28.5 g typical.

1

θ

RATE

AXIS

+

JA

θ

JC

POSITIVE

ROTATIO N

DIRECTIO N

Unit

07238-026

Figure 5. Rotational Measurement Orientation

ESD CAUTION

Rev. A | Page 6 of 16

Page 7

ADIS16130

www.BDTIC.com/ADI

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

ADIS16130

TOP VIEW

(Not to Scale)

STSTST

23456789101112131415161718192021222324

1

STSTSTSTST

CS

RDY

SDO

SDI

VCC

VCC

Figure 6. Pin Configuration

Table 5. Pin Function Descriptions

Pin No. Mnemonic Description

1 to 7, 9 ST Self-Test (see the Self-Test Function section)

8

10

CS

RDY

Chip Select of the SPI

Data Ready

11, 13, 15 VCC Power Supply

12 SDO Data Output of the SPI

14 SDI Data Input of the SPI

16 SCLK Serial Clock of the SPI

17, 19 to 22 GND Power Supply Ground

18

SYNC

Synchronization Input

23 ROA1 Analog Filter Node 1

24 ROA2 Analog Filter Node 2

SCLK

SYNC

GND

GND

ROA2

VCC

GND

GND

GND

07328-004

ROA1

Rev. A | Page 7 of 16

Page 8

ADIS16130

www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

2.5

2.0

1.5

1.0

0.5

0

–0.5

BIAS SHIFT (°/sec)

–1.0

–1.5

–2.0

–2.5

–60 –40 –20 0 20 40 60 80 100 120

TEMPERATURE ( °C)

σ

µ

σ

Figure 7. Bias Shift vs. Temperature, VCC = 5 V

07328-018

0.01

µ+ σ

ROOT ALL EN VARIANCE (° /sec)

0.001

1 10010 1000

INTEGRAT ION TI ME, (sec)

µ

µ – σ

Figure 10. Root Allen Variance, VCC = 5 V, 25°C

07328-021

1.00

0.75

0.50

0.25

0

–0.25

SENSITIV ITY ERROR (%)

–0.50

–0.75

–1.00

–60 –40 –20 0 20 40 60 80 100 120

TEMPERATURE ( °C)

Figure 8. Sensitivity Error vs. Temperature, VCC = 5 V

0.05

0

–0.05

2

1

0

SENSITIV ITY ERROR (%)

–1

07328-019

–2

0 50 100 150 200 250 300 350 400

ANGULAR RATE (° /sec)

07328-022

Figure 11. Sensitivity Error vs. Angular Rate, VCC = 5 V, 25°C

90

85

80

75

SENSITIV ITY ERROR (%)

–0.10

–0.15

4.75 5.0 5.25

POWER SUPPLY (V)

07328-020

Figure 9. Sensitivity Error vs. Power Supply, 25°C

Rev. A | Page 8 of 16

70

SELF-TEST RESPONSE (°/sec)

65

60

–60 –40 –20 0 20 40 80

TEMPERATURE (°C)

60 100 120

Figure 12. Self-Test Response vs. Temperature, VCC = 5 V

07328-023

Page 9

ADIS16130

www.BDTIC.com/ADI

BASIC OPERATION

The ADIS16130 produces digital angular rate (RATE) and

temperature (TEMP) data. The digital communication employs

a simple 4-wire SPI that provides access to output data and

several configuration features. A set of communication and

configuration registers govern the operation in the ADIS16130.

See

Tabl e 8 for a summary of these registers.

QUICK START

The ADIS16130 SPI operates in 8-bit segments. The first byte of

a SPI sequence goes into the COM register, which contains the

read/write control bit and the address of the target register. When

writing information into control registers, the next byte contains

the configuration information. When reading output data, the

next one to three bytes contain the contents of the register selected.

Configuration Sequence

The sequence in Table 6 provides the recommended configuration

sequence. Tabl e 2 and Figure 2 provide the timing information

r each segment of this configuration sequence.

fo

Table 6. Configuration Sequence

Step SDI1Register Purpose

1 0x01 COM Start a write sequence for IOP.

2 0x38 IOP

3 0x28 COM

4 0x0A RATECS

5 0x30 COM

6 0x05 RATECONV Initialize the RATE conversion.

7 0x2A COM

8 0x0A TEMPCS

9 0x32 COM

10 0x05 TEMPCONV Initialize the TEMP conversion.

11 0x38 COM

12 0x22 MODE

1

The SDI column lists the hexadecimal code representation of the SDI bit

input sequence.

Configure the data-ready signal to

w when the RATEDATA and

pulse lo

TEMPDATA output registers

contain new data. The data-ready

signal goes high after reading

either of these registers.

Start a write sequence for the

TECS register.

RA

Enable and configure the

oscope data channel.

gyr

Start a write sequence for

TECONV register.

RA

Start a write sequence for the

register.

TEMPCS

Enable and configure the

emperature data channel.

t

Start a write sequence for

ONV.

TEMPC

Start a write sequence for the

egister.

MODE r

Establish the data output

esolution to 24 bits and start the

r

conversion process with the

RATEDATA channel.

Reading RATE Output Data

After the configuration sequence in Tab le 6 is complete, reading the

output data is very simple. The ADIS16130 converts the RATE

and TEMP data continuously. To better understand this process,

Figure 13 provides an example read sequence, and Tab l e 2 and

Figure 3 provide critical timing details for the output signal.

The first byte of the sequence uses SDI to establish a read of the

ATE output register. This is accomplished by writing 0x48 to the

R

COM register.

The most significant byte is first in the SDO sequence, followed

y the next significant, and then the least significant. When 16-bit

b

resolution is in use, only two bytes are output from the SDO during

the read sequence.

CS

SCLK

SDO

SDI

RDY

0x48

Figure 13. Read Sequence Example

The data-ready signal,

DATA

RDY

, indicates that unread data is

DATA DATA

07328-005

available on both RATE and TEMP output registers. After the

RATE or TEMP channel is read, the signal returns high, as

shown in

s

equentially, and each has a sample rate of 5.7 kSPS. The

Figure 13. The RATE and TEMP channels update

internal sample rate is not dependent on the SPI signals or read

rates. Using the data-ready signal to drive data collection helps

avoid losing data due to data collision, which is when a userdriven read cycle coincides with the internal update time. In

this case, the old data remains and the new data is lost.

If a lower sample rate meets system-level requirements, the

ta-ready signal can still be useful in facilitating SPI read

da

sequences. In this case, the data-ready signal pulses high for

approximately 26 μs before returning low and then repeats this

pattern at two times the internal sample rate. This signal can

feed a counter circuit (or firmware), which drives a processor

interrupt routine at a reduced sample rate.

Reading TEMP Output Data

Reading TEMP data requires a sequence that is very similar to

that of Figure 13, except that the initial SDI sequence must be

hanged from 0x48 to 0x4A. If the TEMP data is not used, Step 7

c

to Step 10 of the configuration sequence are not required.

Rev. A | Page 9 of 16

Page 10

ADIS16130

www.BDTIC.com/ADI

CONFIGURATION OPTIONS

Synchronization Input

SYNC

The

other devices in the system. When the

register (IOP) is set and the

does not process any conversions. Instead, it waits until the

SYNC

the conversion to start from a known point in time (for example,

the rising edge of the

Self-Test Function

The self-test function enables system-level diagnostic checks for the

entire ADIS16130 sensor/signal conditioning circuit. To activate

the self-test function, there must be a logic high signal on all

ST pins (see

in a r

with the limits specified in this data sheet, users can determine

the pass/fail criteria for system-level diagnostic routines.

For normal gyroscope operation, place a logic low input on

all S

ST pins to GND.

Analog Bandwidth

The typical −3 dB cutoff frequency for the ADIS16130 is

300 Hz, which is the combined response of two single-pole

filters, as shown in Figure 14. Pin ROA1 and Pin ROA2 provide

he opportunity for further bandwidth reduction in the first

t

filter stage, as shown in the following relationship:

where:

R = 25 kΩ.

C = 6800 pF

C

ext

The relationship between the −3 dB cutoff frequency and the

exter

Tabl e 7 .

pin can be used to synchronize the ADIS16130 with

SYNC

bit in the I/O port

SYNC

pin is low, the ADIS16130

pin goes high, and then starts the operation. This allows

SYNC

pin).

Tabl e 5). When activated, the self-test function results

ate measurement shift. By comparing the observed shift

T pins. For systems that do not require this feature, tie all

=

dB

−

3

2

1

()

CCRf+××π×

ext

.

is as defined in Figure 15 and Ta bl e 7.

nal capacitance of the ADIS16130 is shown in Figure 15 and

0

–1

–2

–3

–4

–5

–6

AMPLITUDE (dB)

–7

–8

–9

–10

1 10 100 1k 10k

Figure 15. Frequency Response: C

C

ext

= 0.15µF

FREQUENCY (Hz)

C

ext

= 0 μF vs. C

ext

= 0µF

= 0.15 μF

ext

07328-007

Table 7. Nominal Bandwidth for Standard Capacitor Values

C

(pF) BW (Hz) C

ext

(pF) BW (Hz) C

ext

(pF) BW (Hz)

ext

1000 276.8 10,000 198.9 100,000 52.2

1200 274.4 12,000 187.2 120,000 44.8

1500 270.9 15,000 172.1 150,000 37.0

1800 267.5 18,000 159.2 180,000

31.5

2200 263.1 22,000 144.7 220,000 26.3

2700 257.7 27,000 129.9 270,000

21.8

3300 251.6 33,000 115.7 330,000 18.1

3900 245.8 39,000 104.4 390,000

15.5

4300 242.1 43,000 97.9 430,000 14.1

4700 238.4 47,000 92.3 470,000

12.9

5100 234.9 51,000 87.2 510,000 12.0

5600 230.7 56,000 81.6 560,000

10.9

6200 225.8 62,000 75.8 620,000 9.9

7500 215.8 75,000 65.6 750,000

8200 210.8 82,000 61.2 820,000

8.2

7.6

9100 204.7 91,000 56.3 910,000 6.8

327Hz 1kHz

Figure 14. Frequency Response Block Diagram

ADC

07328-006

Rev. A | Page 10 of 16

Page 11

ADIS16130

www.BDTIC.com/ADI

CONTROL REGISTERS

Table 8. Register Descriptions

Name Address Type Purpose

COM 0x00 W Facilitate communications in the SPI port (see Table 9)

IOP 0x01 R/W Data-ready and synchronization controls (see Table 10)

0x02 to 0x07 Reserved

RATEDATA 0x08 R Gyroscope output, rate of rotation

TEMPDATA 0x0A R Temperature output

0x10 to 0x22 Reserved

RATECS 0x28 R/W Gyroscope channel setup (see Table 11)

TEMPCS 0x2A R/W Temperature channel setup (see Table 12)

RATECONV 0x30 R/W Gyroscope conversion time control (see Table 13)

TEMPCONV 0x32 R/W Temperature conversion time control (see Table 13)

0x33 to 0x37 Reserved

MODE 0x38 R/W Resolution mode control (see Table 14)

CONTROL REGISTER DETAILS

Table 9. COM Register Bit Assignments

Bit Description

[7] 0

[6]

1 = read;

ite

0 = wr

[5:0] Register address

Table 10. IOP Register Bit Assignments

Bit Description

[7:4] 0011

[3]

1 = data-ready signal low when unread data on all channels;

data-ready signal low when unread data on one channel

0 =

[2:1] 00

[0]

0 = synchronization disabled;

1 = synchr

Table 11. RATECS Register Bit Assignments

Bit Description

[7:4] 0000

[3]

1 = channel enable;

0 = channe

[2:0] 010

onization enabled

l disable

Table 12. TEMPCS Register Bit Assignments

Bit Description

[7:4] 0000

[3]

1 = channel enable;

0 = channe

[2:0] 010

Table 13. RATECONV/TEMPCONV Bit Assignments

Bit Description

[7:0] 00000101

Table 14. MODE Register Bit Assignments

Bit Description

[7:2] 001000

[1]

1 = 24-bit resolution;

0 = 16-bit r

[0] 0

l disable

esolution

Rev. A | Page 11 of 16

Page 12

ADIS16130

C

0

www.BDTIC.com/ADI

APPLICATIONS INFORMATION

ACHIEVING OPTIMAL NOISE PERFORMANCE

Several system-level considerations can have an impact on the

noise and accuracy of the ADIS16130. Understanding and

managing these factors can influence the behavior of any high

performance system.

Supply and Common Considerations

The ADIS16130 provides approximately 1.8 μF of decoupling

capacitance. This capacitance is distributed throughout the

device and should be taken into account when considering

potential noise threats on the power supply lines.

Bandwidth Setting

If C

is applied to reduce the bandwidth of the ADIS16130

OUT

response, it should be placed close to the device. Long cable

leads and PCB traces increase the risk of introducing noise into

the system.

SECOND-LEVEL ASSEMBLY

The ADIS16130 package supports two mounting approaches:

a bulkhead mount, where the interface is separate from the

attachment surface, and a PCB mount that provides the

mechanical and electrical connections on the same surface.

Figure 16 provides a suggested design for the ADIS16130’s

echanical attachment. The hole pattern shown in Figure 16

m

ca

n support either mounting approach and enables the integration

of the mating socket layout that is illustrated in

The mating socket layout uses the Samtec CLM-112-02 family of

co

nnectors. The 24 holes that are inside the pad accommodate the

pins on the ADIS16130, which can extend beyond the package

body. The stress relief provided by these holes is important for

maintaining reliability and optimal bias stability performance.

Figure 17.

15.600 BSC

39.60 BSC

19.800 BSC

4x 2.500 BSC

0.019685

[0.5000]

(TYP)

.054 [1.37]

0.022± DIA (T YP)

NONPLATED

THRU HOLE 2×

Figure 17. Mating Socket Recommended Pad Layout with

31.200 BS

2x 0.560 BSC

ALIGNMENT HOLES

17.520

2.280

5.00 BSC

Figure 16. Suggested Hole Pattern for Mounting

0.4334 [11.0]

0.022 DIA THRU HO LE (TYP)

NONPLATED T HRU HOLE

Dim

ensions Shown in Inches and (Millimeters)

FOR MATING SOCKET

5.00 BSC

0.0240 [0.610]

0.0394 [1.00]

0.0394 [1.00]

0.1800

[4.57]

07238-025

7328-017

Rev. A | Page 12 of 16

Page 13

ADIS16130

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

35.854

35.600

35.346

31.350

31.200

31.050

15.700

2.200

TYP

15.600

15.500

2.400 THRU HOL E

(4 PLACES)

39.750

39.600

39.450

2.200 TYP

3.27

3.07

2.87

44.254

44.000

43.746

010908-A

14.054

13.800

13.546

17.670

17.520

17.370

19.900

19.800

19.700

1.00 BSC

(LEAD PITCH)

5.50 BSC

TOP VIEW

END VIEW

0.30 BSC SQ

(PIN SIZE)

Figure 18. PCB Module with Connector Interface

(M

L-24-3)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADIS16130AMLZ

1

Z = RoHS Compliant Part.

1

−40°C to +85°C PCB Module with Connector Interface ML-24-3

Rev. A | Page 13 of 16

Page 14

ADIS16130

www.BDTIC.com/ADI

NOTES

Rev. A | Page 14 of 16

Page 15

ADIS16130

www.BDTIC.com/ADI

NOTES

Rev. A | Page 15 of 16

Page 16

ADIS16130

www.BDTIC.com/ADI

NOTES

©2008 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D07238-0-3/08(A)

Rev. A | Page 16 of 16

Loading...

Loading...