Page 1

2.5 V/3.3 V, Four LVPECL Outputs,

V

FEATURES FEATURES

Operating frequency: 7.0 GHz Operating frequency: 7.0 GHz

Broadband random jitter: 50 fs rms Broadband random jitter: 50 fs rms

On-chip input terminations On-chip input terminations

Power supply (V

APPLICATIONS APPLICATIONS

Low jitter clock distribution Low jitter clock distribution

Clock and data signal restoration Clock and data signal restoration

Level translation Level translation

Wireless communications Wireless communications

Wired communications Wired communications

Medical and industrial imaging Medical and industrial imaging

ATE and high performance instrumentation ATE and high performance instrumentation

GENERAL DESCRIPTION

The ADCLK944 is an ultrafast clock fanout buffer fabricated on

the Analog Devices, Inc., proprietary XFCB3 silicon germanium

(SiGe) bipolar process. This device is designed for high speed

applications requiring low jitter.

The device has a differential input equipped with center-tapped,

differential, 100 Ω on-chip termination resistors. The input can

accept dc-coupled LVPECL, CML, 3.3 V CMOS (single-ended),

and ac-coupled 1.8 V CMOS, LVDS, and LVPECL inputs. A V

pin is available for biasing ac-coupled inputs.

− VEE): 2.5 V to 3.3 V Power supply (VCC − VEE): 2.5 V to 3.3 V

CC

REF

SiGe Clock Fanout Buffer

ADCLK944

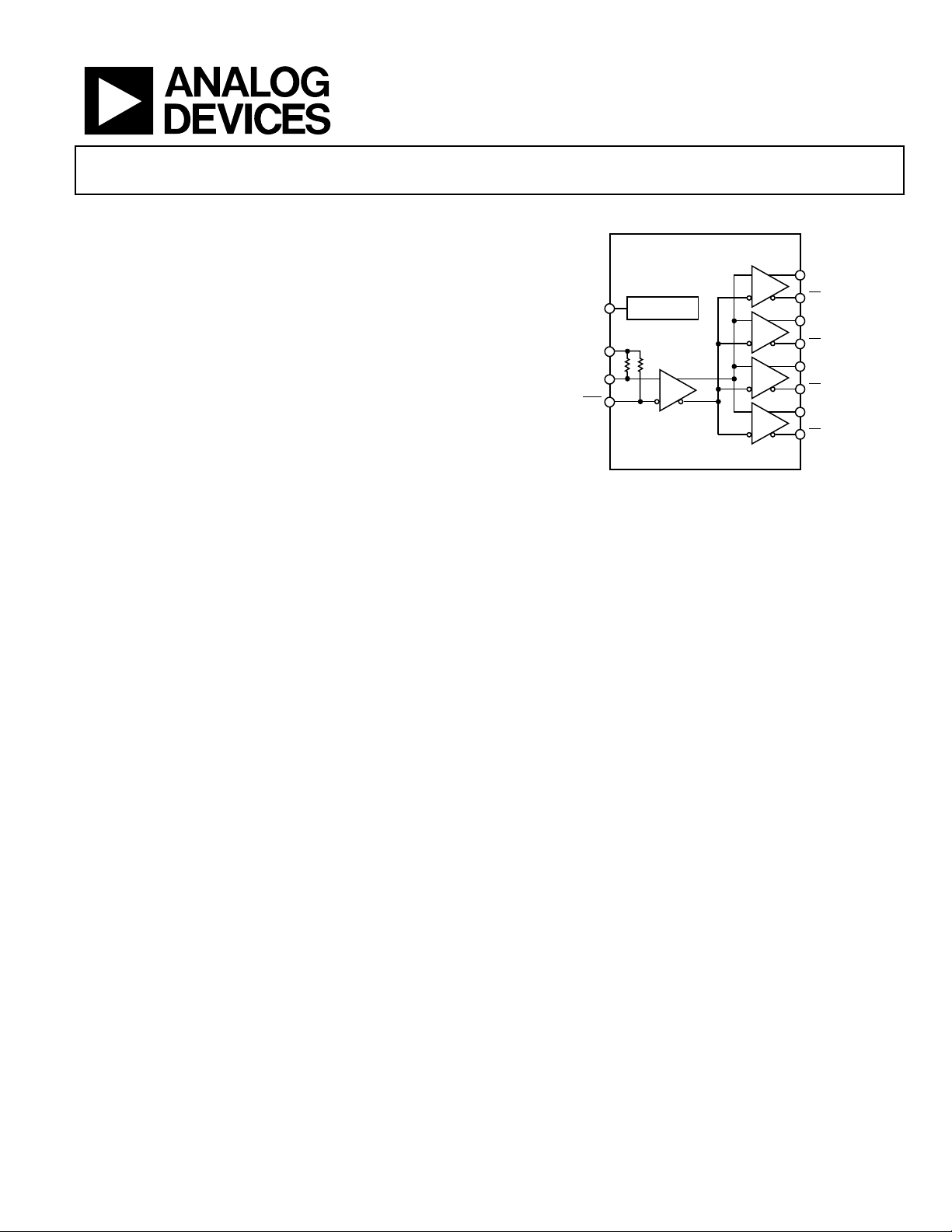

FUNCTIONAL BLOCK DIAGRAM FUNCTIONAL BLOCK DIAGRAM

ADCLK944

REF

CLK

CLK

V

REFERENCE

T

Figure 1.

The ADCLK944 features four full-swing emitter-coupled logic

(ECL) output drivers. For LVPECL (positive ECL) operation,

bias V

operation, bias V

to the positive supply and VEE to ground. For ECL

CC

to ground and VEE to the negative supply.

CC

The ECL output stages are designed to directly drive 800 mV

each side into 50 Ω terminated to V

tial output swing of 1.6 V.

The ADCLK944 is available in a 16-lead LFCSP and is specified

for operation over the standard industrial temperature range of

−40°C to +85°C.

LVPECL

Q0

Q0

Q1

Q1

Q2

Q2

Q3

Q3

8770-001

− 2 V for a total differen-

CC

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010 Analog Devices, Inc. All rights reserved.

Page 2

ADCLK944

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Clock Inputs and Outputs ........................................................... 3

Timing Characteristics ................................................................ 3

Power .............................................................................................. 4

Absolute Maximum Ratings ............................................................ 5

Determining Junction Temperature .......................................... 5

REVISION HISTORY

3/10—Revision 0: Initial Version

ESD Caution...................................................................................5

Thermal Performance ...................................................................5

Pin Configuration and Function Descriptions ..............................6

Typical Performance Characteristics ..............................................7

Theory of Operation .........................................................................9

Clock Inputs ...................................................................................9

Clock Outputs ................................................................................9

PCB Layout Considerations ...................................................... 10

Input Termination Options ....................................................... 11

Outline Dimensions ....................................................................... 12

Ordering Guide .......................................................................... 12

Rev. 0 | Page 2 of 12

Page 3

ADCLK944

SPECIFICATIONS

Typical values are given for VCC − VEE = 3.3 V and TA = 25°C, unless otherwise noted. Minimum and maximum values are given for the

full V

− VEE = 3.3 V + 10% to 2.5 V − 5% and TA = −40°C to +85°C variation, unless otherwise noted.

CC

CLOCK INPUTS AND OUTPUTS

Table 1.

Parameter Symbol Min Typ Max Unit Test Conditions/Comments

DC INPUT CHARACTERISTICS

Input Common-Mode Voltage V

Input Differential Voltage VID 0.4 3.4 V p-p ±1.7 V between input pins

Input Capacitance CIN 0.4 pF

Input Resistance RIN

Single-Ended Mode 50 Ω

Differential Mode 100 Ω

Common Mode 50 kΩ VT open

Input Bias Current 20 μA

DC OUTPUT CHARACTERISTICS

Output Voltage High Level VOH V

Output Voltage Low Level VOL V

Output Voltage, Single-Ended VO 600 960 mV VOH − VOL, output static

Voltage Reference V

Output Voltage (VCC + 1)/2 V −500 μA to +500 μA

Output Resistance 250 Ω

V

ICM

REF

+ 1.35 VCC − 0.1 V

EE

− 1.26 VCC − 0.76 V Load = 50 Ω to (VCC − 2.0 V)

CC

− 1.99 VCC − 1.54 V Load = 50 Ω to (VCC − 2.0 V)

CC

TIMING CHARACTERISTICS

Table 2.

Parameter Symbol Min Typ Max Unit Test Conditions/Comments

AC PERFORMANCE

Maximum Output Frequency 6.2 7.0 GHz

Output Rise/Fall Time tR 35 50 75 ps 20% to 80%, measured differentially

Propagation Delay tPD 70 100 130 ps VID = 1.6 V p-p

Temperature Coefficient 75 fs/°C

Output-to-Output Skew

1

15 ps

Part-to-Part Skew 35 ps VID = 1.6 V p-p

Additive Time Jitter

Integrated Random Jitter 26 fs rms BW = 12 kHz to 20 MHz, CLK = 1 GHz

Broadband Random Jitter2 50 fs rms VID = 1.6 V p-p, 8 V/ns, V

CLOCK OUTPUT PHASE NOISE

Absolute Phase Noise Input slew rate > 1 V/ns (see Figure 11)

fIN = 1 GHz −118 dBc/Hz 100 Hz offset

−135 dBc/Hz 1 kHz offset

−144 dBc/Hz 10 kHz offset

−150 dBc/Hz 100 kHz offset

−150 dBc/Hz >1 MHz offset

1

The output-to-output skew is the difference between any two similar delay paths while operating at the same voltage and temperature.

2

Measured at the rising edge of the clock signal; calculated using the SNR of the ADC method.

Differential output voltage swing > 0.8 V

(see Figure 4)

= 2 V

ICM

Rev. 0 | Page 3 of 12

Page 4

ADCLK944

POWER

Table 3.

Parameter Symbol Min Typ Max Unit Test Conditions/Comments

POWER SUPPLY

Supply Voltage Requirement VCC − VEE 2.375 3.63 V 3.3 V + 10% to 2.5 V − 5%

Power Supply Current Static

Negative Supply Current I

I

Positive Supply Current I

I

Power Supply Rejection

Output Swing Supply Rejection

1

Change in tPD per change in VCC.

2

Change in output swing per change in VCC.

1

2

35 mA VCC − VEE = 2.5 V ± 5%

VEE

37 49 mA VCC − VEE = 3.3 V ± 10%

VEE

139 mA VCC − VEE = 2.5 V ± 5%

VCC

138 165 mA VCC − VEE = 3.3 V ± 10%

VCC

PSR

−3 ps/V

VCC

PSR

28 dB

VCC

Rev. 0 | Page 4 of 12

Page 5

ADCLK944

ABSOLUTE MAXIMUM RATINGS

Table 4.

Parameter Rating

Supply Voltage

VCC − VEE 6.0 V

Input Voltage

CLK, CLK

CLK to CLK

Input Termination, VT to CLK, CLK

Input Current, CLK, CLK to VT Pin

VEE − 0.5 V to VCC + 0.5 V

±1.8 V

±2 V

±40 mA

(CML, LVPECL Termination)

Maximum Voltage on Output Pins VCC + 0.5 V

Maximum Output Current 35 mA

Voltage Reference (V

) VCC to VEE

REF

Operating Temperature

Ambient Range −40°C to +85°C

Junction 150°C

Storage Temperature Range −65°C to +150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

DETERMINING JUNCTION TEMPERATURE

To determine the junction temperature on the application

printed circuit board (PCB), use the following equation:

T

= T

J

+ (ΨJT × PD)

CASE

where:

T

is the junction temperature (°C).

J

is the case temperature (°C) measured by the customer at

T

CASE

the top center of the package.

Ψ

is as indicated in Tabl e 5.

JT

is the power dissipation.

P

D

Val u es o f θ

design considerations. θ

imation of T

where T

Val u es o f θ

are provided for package comparison and PCB

JA

can be used for a first-order approx-

JA

using the following equation:

J

= TA + (θJA × PD)

T

J

is the ambient temperature (°C).

A

are provided in Tab l e 5 for package comparison

JB

and PCB design considerations.

ESD CAUTION

THERMAL PERFORMANCE

Table 5.

Parameter Symbol Description Value

Junction-to-Ambient Thermal Resistance

Still Air θJA Per JEDEC JESD51-2

0.0 m/sec Airflow 78 °C/W

Moving Air θ

Per JEDEC JESD51-6

JMA

1.0 m/sec Airflow 68 °C/W

2.5 m/sec Airflow 61 °C/W

Junction-to-Board Thermal Resistance θJB Per JEDEC JESD51-8

Moving Air

1.0 m/sec Airflow 49 °C/W

Junction-to-Case Thermal Resistance (Die-to-Heat Sink) θJC Per MIL-STD-883, Method 1012.1

Still Air

0.0 m/sec Airflow 1.5 °C/W

Junction-to-Top-of-Package Characterization Parameter ΨJT

Still Air Per JEDEC JESD51-2

0.0 m/sec Airflow 2.0 °C/W

1

Results are from simulations. The PCB is a JEDEC multilayer type. Thermal performance for actual applications requires careful inspection of the conditions in the

application to determine whether they are similar to those assumed in these calculations.

1

Unit

Rev. 0 | Page 5 of 12

Page 6

ADCLK944

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

EE

V

Q0

16

15

CC

Q0

V

13

14

1

CLK

2

V

T

3

V

REF

4

CLK

NOTES

1. EXPOSED PAD MUST BE CONNECTED

TO V

EE

.

ADCLK944

TOP VIEW

(Not to Scale)

6

5

EE

Q3

V

8

7

Q3

V

Figure 2. Pin Configuration

Table 6. Pin Function Descriptions

Pin No. Mnemonic Description

1 CLK Differential Input (Positive).

2 VT

3 V

4

CLK

REF

Center Tap. This pin provides the center tap of a 100 Ω input resistor for the CLK and CLK

Reference Voltage. This pin provides the reference voltage for biasing ac-coupled CLK and CLK

Differential Input (Negative).

5, 16 VEE Negative Supply Pin.

6, 7

Q3

, Q3

Differential LVPECL Outputs.

8, 13 VCC Positive Supply Pin.

9, 10

11, 12

14, 15

Q2

Q1

Q0

, Q2

, Q1

, Q0

Differential LVPECL Outputs.

Differential LVPECL Outputs.

Differential LVPECL Outputs.

EPAD The exposed pad must be connected to VEE.

12

Q1

11

Q1

10

Q2

9

Q2

CC

2

08770-00

inputs.

inputs.

Rev. 0 | Page 6 of 12

Page 7

ADCLK944

TYPICAL PERFORMANCE CHARACTERISTICS

VCC = 3.3 V, VEE = 0.0 V, V

ICM

= V

, TA = 25°C, clock outputs terminated at 50 Ω to VCC − 2 V, unless otherwise noted.

REF

1

CH1 300mV M 1.25ns 20. 0GS/s

A CH1 36.0mV

IT 25.0ps/pt

Figure 3. LVPECL Differential Output Waveform at 200 MHz

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

DIFFERENTIAL OUTPUT VOLTAGE SWING (V)

0

0 1000 2000 3000 4000 5000 6000 7000 8000

FREQUENCY (MHz )

3.3V

2.5V

Figure 4. Differential Output Voltage Swing vs. Frequency

1

08770-003

CH1 300mV M 250ps 20.0GS/s

A CH1 36.0mV

IT 5.0ps/pt

08770-006

Figure 6. LVPECL Differential Output Waveform at 1000 MHz

1.55

1.50

1.45

1.40

1.35

DIFFERENTIAL OUTPUT VOLTAGE SWING (V)

1.30

2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8

08770-004

POWER SUPPLY VOLTAGE (V)

+25°C

+85°C

–40°C

08770-009

Figure 7. Differential Output Voltage Swing vs. Power Supply Voltage

and Temperature, V

= 1.6 V p-p

ID

80

85

90

95

100

105

PROPAGATI ON DELAY (ps)

110

115

0.1 0.3 0.5 0.7 0.9 1.1

DIFFERENTIAL INPUT VOLTAGE SWING (V)

DELAY 3.3V

DELAY 2.5V

Figure 5. Propagation Delay vs. Differential Input Voltage Swing

08770-005

Rev. 0 | Page 7 of 12

140

130

120

110

100

PROPAGATION DELAY (ps)

90

80

1.0 1.5 2.0 2.5 3.0 3.5

2.5V

3.3V

DC COMMON-MODE VOLTAGE (V

ICM

– VEE)

Figure 8. Propagation Delay vs. DC Common-Mode Voltage

0-008

0877

Page 8

ADCLK944

–

160

300

140

I

120

100

80

60

CURRENT (mA)

40

20

0

2.375 2.500 2.625 2.970 3.300 3.630

VCC

I

VEE

POWER SUPPLY VOLTAGE (V)

–40°C

+25°C

+85°C

08770-010

Figure 9. Power Supply Current vs. Power Supply Voltage and Temperature,

− 2 V)

CC

ADCLK944

PHASE NOISE (d Bc/Hz)

All Outputs Loaded (50 Ω to V

90

–100

–110

–120

–130

–140

–150

250

200

s rms)

f

150

100

RANDOM JITT E R (

50

0

02015105

Figure 11. Random Jitter vs. Input Slew Rate, V

INPUT SLEW RATE (V/ns)

Method

ID

08770-012

–160

–170

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY O F FSET (Hz)

CLOCK SOURCE

Figure 10. Absolute Phase Noise Measured at 1 GHz with Agilent E5052B

08770-011

Rev. 0 | Page 8 of 12

Page 9

ADCLK944

A

V

V

V

V

A

A

THEORY OF OPERATION

CLOCK INPUTS

The ADCLK944 accepts a differential clock input and distributes it to all four LVPECL outputs. The maximum specified

frequency is the point at which the output voltage swing is 50%

of the standard LVPECL swing (see Figure 4).

The device has a differential input equipped with center-tapped,

differential, 100 Ω on-chip termination resistors. The input can

accept dc-coupled LVPECL, CML, 3.3 V CMOS (single-ended,

3.3 V operation only), and ac-coupled 1.8 V CMOS, LVDS, and

LVPECL i n p u t s . A V

pin is available for biasing ac-coupled

REF

inputs (see Figure 20 and Figure 21).

Maintain the differential input voltage swing from approximately 400 mV p-p to no more than 3.4 V p-p. See Figure 18

through Figure 21 for various clock input termination schemes.

Output jitter performance is significantly degraded by an input

slew rate below 1 V/ns, as shown in Figure 11. The ADCLK944

is specifically designed to minimize added random jitter over a

wide input slew rate range. Whenever possible, clamp excessively

large input signals with fast Schottky diodes because attenuators

reduce the slew rate. Input signal runs of more than a few centimeters should be over low loss dielectrics or cables with good

high frequency characteristics.

CLOCK OUTPUTS

The specified performance necessitates using proper transmission line terminations. The LVPECL outputs of the ADCLK944

are designed to directly drive 800 mV into a 50 Ω cable or into

microstrip/stripline transmission lines terminated with 50 Ω

referenced to V

output stage is shown in Figure 12. The outputs are designed

for best transmission line matching. If high speed signals must

be routed more than a centimeter, either the microstrip or the

stripline technique is required to ensure proper transition times

and to prevent excessive output ringing and pulse-width-dependent

propagation delay dispersion.

− 2 V, as shown in Figure 13. The LVPECL

CC

V

CC

Q

Q

Figure 13 through Figure 16 depict various LVPECL output

termination schemes. When dc-coupled, V

of the receiving

CC

buffer should match VS_DRV.

S_DRV

DCLK944

Z0 = 50Ω

VCC – 2V

Z0 = 50Ω

Figure 13. DC-Coupled, 3.3 V LVPECL

50Ω

50Ω

CC

= VS_DR

LVPECL

08770-014

Thevenin-equivalent termination uses a resistor network to provide

50 Ω termination to a dc voltage that is below V

of the LVPECL

OL

driver. In this case, VS_DRV on the ADCLK944 should equal

V

of the receiving buffer. Although the resistor combination

CC

shown in Figure 14 results in a dc bias point of VS_DRV − 2 V,

the actual common-mode voltage is VS_DRV − 1.3 V because

there is additional current flowing from the ADCLK944 LVPECL

driver through the pull-down resistor.

S_DRV

VS_DRV

ADCLK944

SINGLE-ENDED

(NOT COUPLED)

50Ω

50Ω

127Ω 127Ω

83Ω 83Ω

V

CC

LVPECL

8770-015

Figure 14. DC-Coupled, 3.3 V LVPECL Far-End Thevenin Termination

LVPECL Y-termination (see Figure 15) is an elegant termination

scheme that uses the fewest components and offers both oddand even-mode impedance matching. Even-mode impedance

matching is an important consideration for closely coupled transmission lines at high frequencies. Its main drawback is that it offers

limited flexibility for varying the drive strength of the emitterfollower LVPECL driver. This can be an important consideration

when driving long trace lengths but is usually not an issue.

VS_DRV VCC = VS_DRV

VS_DRV

DCLK944

Z0 = 50Ω

Z0 = 50Ω

50Ω

50Ω

50Ω

LVPECL

Figure 15. DC-Coupled, 3.3 V LVPECL Y-Termination

DCLK944

0.1nF

0.1nF

100Ω DIFFERENTIAL

(COUPLED)

TRANSMISSION LINE

100Ω

V

CC

LVPECL

8770-016

V

EE

08770-013

Figure 12. Simplified Schematic Diagram

of the LVPECL Output Stage

Rev. 0 | Page 9 of 12

200Ω 200Ω

08770-017

Figure 16. AC-Coupled LVPECL with Parallel Transmission Line

Page 10

ADCLK944

PCB LAYOUT CONSIDERATIONS

The ADCLK944 buffer is designed for very high speed applications. Consequently, high speed design techniques must be used

to achieve the specified performance. It is critically important to

use low impedance supply planes for both the negative supply

(V

) and the positive supply (VCC) planes as part of a multilayer

EE

board. Providing the lowest inductance return path for switching

currents ensures the best possible performance in the target

application.

The following references to the ground plane assume that the V

power plane is grounded for LVPECL operation. Note that, for

ECL operation, the V

power plane becomes the ground plane.

CC

It is also important to adequately bypass the input and output

supplies. Place a 1 µF electrolytic bypass capacitor within several

inches of each V

power supply pin to the ground plane. In

CC

addition, place multiple high quality 0.001 F bypass capacitors

as close as possible to each V

supply pin, and connect the

CC

capacitors to the ground plane with redundant vias. Select high

frequency bypass capacitors for minimum inductance and ESR.

To improve the effectiveness of the bypass at high frequencies,

minimize parasitic layout inductance. Also, avoid discontinuities

along input and output transmission lines; such discontinuities

can affect jitter performance.

In a 50 Ω environment, input and output matching have a significant impact on performance. The buffer provides internal 50 Ω

termination resistors for both the CLK and

CLK

inputs. Normally,

the return side is connected to the reference pin that is provided.

Bypass the termination potential using ceramic capacitors to

prevent undesired aberrations on the input signal due to parasitic

inductance in the termination return path. If the inputs are dccoupled to a source, take care to ensure that the pins are within

the rated input differential and common-mode voltage ranges.

EE

If the return is floated, the device exhibits a 100 cross-termination, but the source must then control the common-mode

voltage and supply the input bias currents.

ESD/clamp diodes between the input pins prevent the application

from developing excessive offsets to the input transistors. ESD

diodes are not optimized for best ac performance. When a clamp

is required, it is recommended that appropriate external diodes

be used.

Exposed Metal Paddle

The exposed metal paddle on the ADCLK944 package is both an

electrical connection and a thermal enhancement. For the device

to function properly, the paddle must be properly attached to

pins.

the V

EE

When properly mounted, the ADCLK944 also dissipates heat

through its exposed paddle. The PCB acts as a heat sink for the

ADCLK944. The PCB attachment must provide a good thermal

path to a larger heat dissipation area. This requires a grid of vias

from the top layer of the PCB down to the V

power plane (see

EE

Figure 17). The ADCLK944 evaluation board (ADCLK944/PCBZ)

provides an example of how to attach the part to the PCB.

VIAS TO VEE POWER

PLANE

Figure 17. PCB Land for Attaching Exposed Paddle

08770-018

Rev. 0 | Page 10 of 12

Page 11

ADCLK944

V

C

G

A

C

R

INPUT TERMINATION OPTIONS

CC

CONNECT VTTO VCC.

V

T

CLK

CLK

V

REF

50Ω50Ω

Figure 18. Interfacing to CML Inputs

V

REF

V

T

V

– 2V

CC

CLK

CLK

CONNECT VTTO VCC − 2V.

50Ω50Ω

Figure 19. Interfacing to PECL Inputs

V

REF

V

T

REF

50Ω50Ω

.

08770-021

CLK

CLK

08770-019

CONNECT VTTO V

Figure 20. AC Coupling Differential Signal Inputs, Such as LVDS

V

REF

V

T

CLK

CLK

ONNECT VT, V

PLACE A BYPASS CAPACITOR FROM V

08770-020

ROUND.

LTERNATIV E LY, VT, V

ONNECTED TO GETHER, GIVING A CLE ANE

LAY

OUT AND A 180° PHASE S HIFT.

REF

50Ω50Ω

, AND CLK TOGETHER.

, AND CLK CAN BE

REF

TO

T

08770-022

Figure 21. Interfacing to AC-Coupled, Single-Ended Inputs

Rev. 0 | Page 11 of 12

Page 12

ADCLK944

OUTLINE DIMENSIONS

PIN 1

INDICATOR

0.80

0.75

0.70

SEATING

PLANE

3.10

3.00 SQ

2.90

0.50

BSC

0.45

0.40

0.35

0.05 MAX

0.02 NOM

0.20 REF

0.30

0.25

0.18

13

12

9

8

BOTTOM VIEWTOP VIEW

COPLANARITY

0.08

1

P

N

I

C

I

A

N

I

16

EXPOSED

PAD

5

FOR PROPER CONNECTION O F

THE EXPOSED PAD, REFER TO

THE PIN CONF IGURATIO N AND

FUNCTION DESCRI P T I O NS

SECTION O F THIS DATA SHEET.

D

1

1.60

1.50 SQ

1.40

4

0.25 MIN

R

O

T

COMPLIANTTOJEDEC STANDARDS MO-220- W E ED-6.

111808-A

Figure 22. 16-Lead Lead Frame Chip Scale Package [LFCSP_WQ]

3 mm × 3 mm Body, Very Very Thin Quad

(CP-16-18)

Dimensions shown in millimeters

ORDERING GUIDE

1

Model

ADCLK944BCPZ-R2 −40°C to +85°C 16-Lead LFCSP_WQ CP-16-18 Y2K

ADCLK944BCPZ-R7 −40°C to +85°C 16-Lead LFCSP_WQ CP-16-18 Y2K

ADCLK944BCPZ-WP −40°C to +85°C 16-Lead LFCSP_WQ CP-16-18 Y2K

ADCLK944/PCBZ Evaluation Board

1

Z = RoHS Compliant Part.

Temperature Range Package Description Package Option Branding Code

©2010 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D08770-0-3/10(0)

Rev. 0 | Page 12 of 12

Loading...

Loading...