Page 1

Ultrafast, SiGe, Open-Collector

V

www.BDTIC.com/ADI

FEATURES FEATURES

7.5 GHz operating frequency 7.5 GHz operating frequency

160 ps propagation delay 160 ps propagation delay

100 ps output rise/fall 100 ps output rise/fall

110 fs random jitter 110 fs random jitter

On-chip input terminations On-chip input terminations

Extended industrial temperature range: −40°C to +125°C Extended industrial temperature range: −40°C to +125°C

3.3 V power supply (V

APPLICATIONS APPLICATIONS

Clock and data signal restoration Clock and data signal restoration

High speed converter clocking High speed converter clocking

Broadband communications Broadband communications

Cellular infrastructure Cellular infrastructure

High speed line receivers High speed line receivers

ATE and high performance instrumentation ATE and high performance instrumentation

Level shifting Level shifting

Threshold detection Threshold detection

GENERAL DESCRIPTION

The ADCLK914 is an ultrafast clock/data buffer fabricated on

the Analog Devices, Inc., proprietary, complementary bipolar

(XFCB-3) silicon-germanium (SiGe) process. The ADCLK914

features high voltage differential signaling (HVDS) outputs

suitable for driving the latest Analog Devices high speed digitalto-analog converters (DACs). The ADCLK914 has a single,

differential open-collector output.

The ADCLK914 buffer operates up to 7.5 GHz with a 160 ps

propagation delay and adds only 110 fs random jitter (RJ).

− VEE) 3.3 V power supply (VCC − VEE)

CC

HVDS Clock/Data Buffer

ADCLK914

FUNCTIONAL BLOCK DIAGRAM FUNCTIONAL BLOCK DIAGRAM

V

V

CC

REF

V

V

T

T

50Ω 50Ω

D

D

D

D

The input has a center tapped, 100 Ω, on-chip termination

resistor and accepts LVPECL, CML, CMOS, LVTTL, or LVDS

(ac-coupled only). A V

inputs.

The HVDS output stage is designed to directly drive 1.9 V each

side into 50 Ω terminated to V

swing of 3.8 V.

The ADCLK914 is available in a 16-lead LFCSP. It is specified

for operation over the extended industrial temperature range of

−40°C to +125°C.

CC

ADCLK914

50Ω 50Ω

Q

Q

Q

Q

V

V

EE

EE

Figure 1.

pin is available for biasing ac-coupled

REF

for a total differential output

CC

06561-001

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2008 Analog Devices, Inc. All rights reserved.

Page 2

ADCLK914

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

Electrical Characteristics ............................................................. 3

Absolute Maximum Ratings ............................................................ 5

Thermal Resistance ...................................................................... 5

ESD Caution .................................................................................. 5

Pin Configuration and Function Descriptions ............................. 6

REVISION HISTORY

10/08—Rev. 0 to Rev. A

Changes to Input Low Voltage Parameter, Table 1 ....................... 3

Changes to Output High Voltage Parameter, Table 1 ................ 3

Changes to Output Low Voltage Parameter, Table 1 .................. 3

Output Differential Range Parameter, Table 1 ............................ 3

Changes to Absolute Maximum Ratings Section ........................ 5

7/08—Revision 0: Initial Version

Typical Performance Characteristics ..............................................7

Applications Information .................................................................9

Power/Ground Layout and Bypassing ........................................9

HVDS Output Stage ......................................................................9

Interfacing to High Speed DACs .................................................9

Optimizing High Speed Performance ........................................9

Random Jitter .................................................................................9

Typical Application Circuits ..................................................... 10

Outline Dimensions ....................................................................... 11

Ordering Guide .......................................................................... 11

Rev. A | Page 2 of 12

Page 3

ADCLK914

www.BDTIC.com/ADI

SPECIFICATIONS

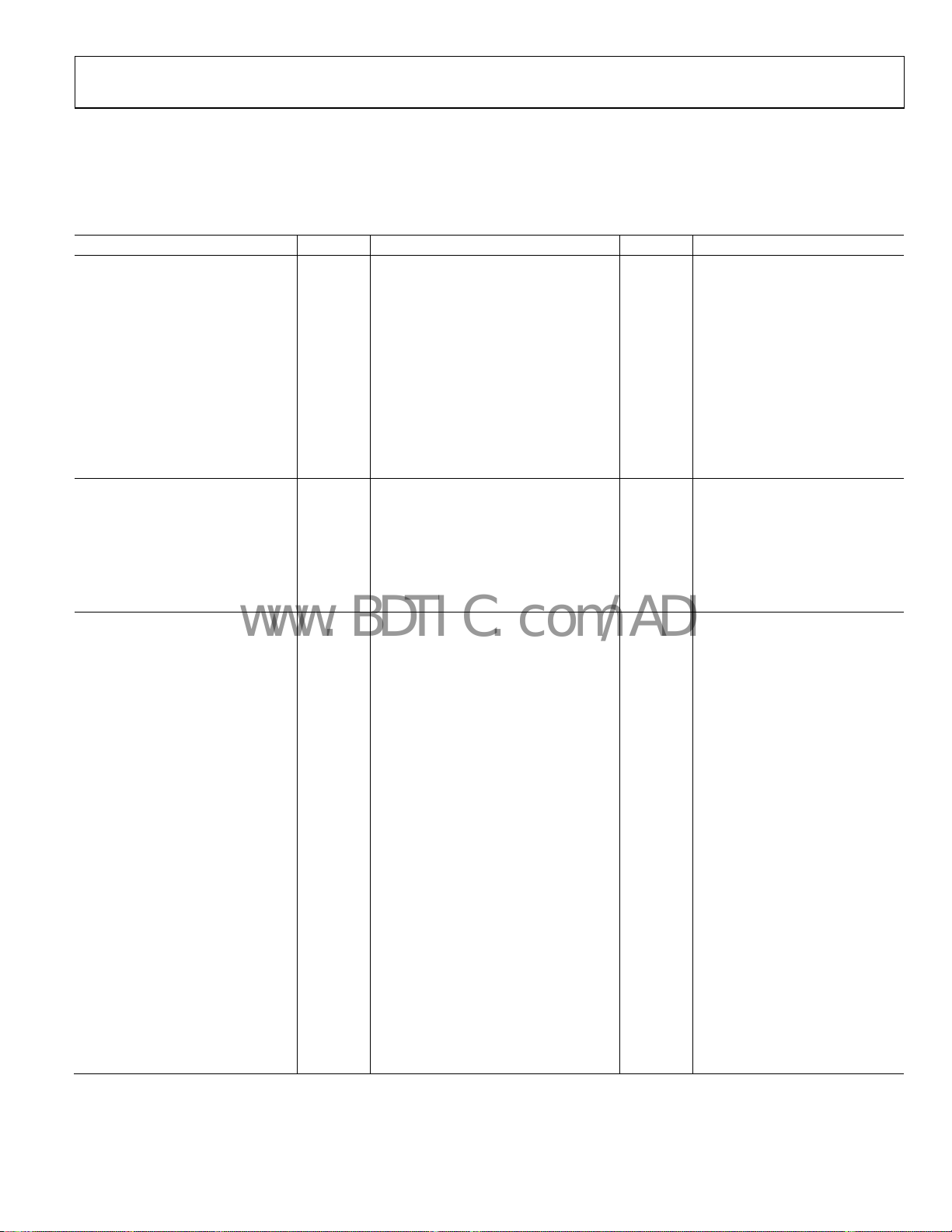

ELECTRICAL CHARACTERISTICS

VCC = 3.3 V, VEE = 0 V, TA = −40°C to +125°C. All outputs terminated through 50 Ω to VCC, unless otherwise noted.

Table 1.

Parameter Symbol Min Typ Max Unit Test Conditions/Comments

DC INPUT CHARACTERISTICS

Input High Voltage VIH V

Input Low Voltage VIL V

Input Differential Range VID 0.2 3.4 V p-p

0.2 2.8 V p-p

Input Capacitance CIN 0.4 pF

Input Resistance 50 Ω

Differential Mode 100 Ω

Common Mode 50 kΩ Open termination

Input Bias Current 20 µA

DC OUTPUT CHARACTERISTICS

Output High Voltage VOH V

Output Low Voltage VOL V

Output Differential Range VOD 1.54 1.95 2.22 V

Reference Voltage V

REF

Output Voltage (VCC + 1)/2 V −500 A to +500 A

Output Resistance 250 Ω

AC PERFORMANCE

Operating Frequency 7.5 GHz

Propagation Delay tPD 127 158 202 ps

Propagation Delay Temperature

140 fs/°C

Coefficient

Propagation Delay Skew (Device

65 ps V

to Device)

Output Rise Time tR 100 125 ps 20%/80%

Output Fall Time tF 80 95 ps 80%/20%

Wideband Random Jitter

1

RJ 110 fs rms VID = 1.6 V p-p, 6 V/ns, V

Additive Phase Noise

622.08 MHz −132 dBc/Hz @10 Hz offset

−143 dBc/Hz @100 Hz offset

−151 dBc/Hz @1 kHz offset

−156 dBc/Hz @10 kHz offset

−157 dBc/Hz @100 kHz offset

−156 dBc/Hz >1 MHz offset

245.76 MHz −133 dBc/Hz @10 Hz offset

−143 dBc/Hz @100 Hz offset

−153 dBc/Hz @1 kHz offset

−158 dBc/Hz @10 kHz offset

−159 dBc/Hz @100 kHz offset

−158 dBc/Hz >1 MHz offset

+ 1.65 VCC V

EE

V

EE

− 0.2 V

CC

= −40°C to +85°C

T

A

(±1.7 V between input pins)

= 85°C to 125°C

T

A

(±1.4 V between input pins)

− 0.55 VCC − 0.40 VCC − 0.25 V

CC

− 2.75 VCC − 2.35 VCC − 1.9 V

CC

>1.1 V differential output swing,

= 3.3 V ± 10%

V

CC

= 3.3 V ± 10%,V

V

CC

V

= 1.6 V p-p

ID

= 1.6 V p-p

ID

ICM

= V

ICM

,

REF

= 1.85 V

Rev. A | Page 3 of 12

Page 4

ADCLK914

www.BDTIC.com/ADI

Parameter Symbol Min Typ Max Unit Test Conditions/Comments

122.88 MHz −150 dBc/Hz @10 Hz offset

−156 dBc/Hz @100 Hz offset

−160 dBc/Hz @1 kHz offset

−161 dBc/Hz @10 kHz offset

−161 dBc/Hz @100 kHz offset

−160 dBc/Hz >1 MHz offset

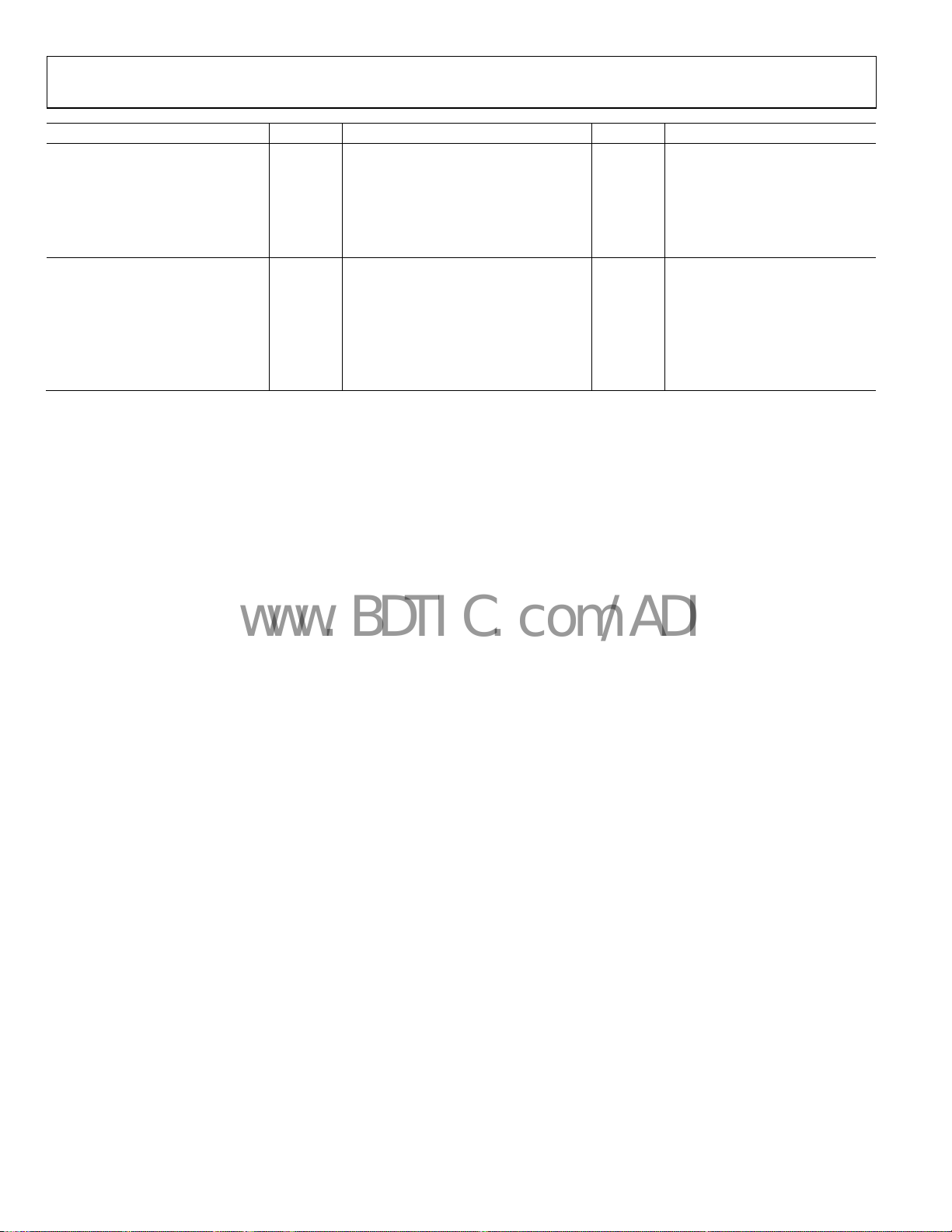

POWER SUPPLY

Supply Voltage Requirement VCC 2.97 3.63 V

Power Supply Current

Negative Supply Current I

Positive Supply Current I

Power Supply Rejection

2

Output Swing Supply Rejection3 −15 dB VCC = 3.3 V ± 10%

1

Calculated from SNR of ADC method. See Figure 8 for rms jitter vs. input slew rate.

2

Change in tPD per change in VCC.

3

Change in output swing per change in VCC.

66 111 150 mA Includes output current

VEE

34 55 73 mA

VCC

PSR

13 ps/V VCC = 3.3 V ± 10%

VCC

Rev. A | Page 4 of 12

Page 5

ADCLK914

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Supply Voltage (VCC to GND) 6.0 V

Input Voltage −0.5 V to VCC + 0.5 V

Maximum Output Voltage VCC + 0.5 V

Minimum Output Voltage VEE − 0.5 V

Input Termination ±2 V

Voltage Reference VCC − VEE

Operating Temperature Range, Ambient −40°C to +125°C

Operating Temperature, Junction 150°C

Storage Temperature Range −65°C to +150°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL PERFORMANCE

The ADCLK914 is specified for a case temperature (T

ensure that T

is not exceeded, use an airflow source.

CASE

To determine the junction temperature on the application PCB

T

= T

+ (ΨJT × PD)

J

CASE

where:

T

is the junction temperature (°C).

J

T

is the case temperature (°C) measured by the customer at

CASE

top center of package.

is determined by the values listed in Table 3 .

Ψ

JT

PD is the power dissipation.

CASE

). To

Val u es o f θ

design considerations. θ

approximation of T

where T

Values of θ

are provided for package comparison and PCB

JA

can be used for a first-order

JA

by the equation

J

T

= TA + (θJA × PD)

J

is the ambient temperature (°C).

A

are provided for package comparison and PCB

JB

design considerations.

Table 3. Thermal Parameters for ADCLK914 16-Lead LFCSP

Symbol Description1 Value Units

θJA

θ

JMA

θ

JMA

θJB

θJC

ΨJT

1

Descriptions based on using a 2s2p test board.

Junction-to-ambient thermal

resistance, 0.0 meters per sec air

flow per JEDEC JESD51-2 (still air)

Junction-to-ambient thermal

resistance, 1.0 meter per sec air flow

per JEDEC JESD51-6 (moving air)

Junction-to-ambient thermal

resistance, 2.5 m/s air flow per

JEDEC JESD51-6 (moving air)

Junction-to-board thermal

resistance, 1.0 meter per sec air flow

per JEDEC JESD51-8 (moving air)

Junction-to-case thermal resistance

(die-to-heatsink) per MIL-Std 883,

Method 1012.1

Junction-to-top-of-package

characterization parameter, 0

meters per sec air flow per JEDEC

JESD51-2 (still air)

78.4 °C/W

68.5 °C/W

61.4 °C/W

48.8 °C/W

1.5 °C/W

2.0 °C/W

ESD CAUTION

Rev. A | Page 5 of 12

Page 6

ADCLK914

www.BDTIC.com/ADI

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

REF

T

EE

CC

V

V

V

V

14

13

15

16

PIN 1

1D

2D

ADCLK914

3NC

(Not to Scale)

4NC

INDICAT OR

TOP VIEW

Q

12

Q

11

NC

10

NC

9

NC = NO CONNECT

8

7

5

6

EE

CC

NC

NC

V

V

Figure 2. Pin Configuration

Table 4. Pin Function Descriptions

Pin No. Mnemonic Description

1 D Noninverting Input.

2

D

Inverting Input.

3, 4, 5, 6, 9, 10 NC No Connect. No physical connection to the die.

7, 14 VEE Negative Supply Voltage.

8, 13 VCC Positive Supply Voltage.

11

Q

Inverting Output.

12 Q Noninverting Output.

15 V

Reference Voltage. Reference voltage for biasing ac-coupled inputs.

REF

16 VT Center Tap. Center tap of 100 Ω input resistor.

Heat Sink/

Exposed Pad

NC

No Connect. The metallic back surface of the package is not electrically connected to any part of the circuit.

It can be left floating for optimal electrical isolation between the package handle and the substrate of the

die. It can also be soldered to ground on the application board if improved thermal and/or mechanical

stability is needed. Exposed metal at the corners of the package is connected to this back surface. Allow

sufficient clearance for vias and other components.

06561-002

Rev. A | Page 6 of 12

Page 7

ADCLK914

V

–

–

V

–

www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

VCC = 3.3 V, VEE = 0 V, TA = 25°C. All outputs terminated through 50 to VCC, unless otherwise noted.

Q

250mV/DI

Q

62.5ps/DI V

Figure 3. Output Waveform at 1 GHz, VCC = 3.3 V

120

–130

–140

–150

PHASE NOISE (dBc/Hz)

–160

Q

250mV/DI

Q

06561-003

100ps/DIV

06561-006

Figure 6. Output Waveform at 1 GHz, VCC = 3.3 V

120

–130

–140

–150

PHASE NOISE (dBc/Hz)

–160

–170

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY (Hz)

Figure 4. Phase Noise at 122.88 MHz

120

–130

–140

–150

PHASE NOISE (dBc/Hz)

–160

–170

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY (Hz)

Figure 5. Phase Noise at 245.76 MHz

–170

10 100 1k 10k 100k 1M 10M 100M

06561-004

FREQUENCY (Hz)

06561-007

Figure 7. Phase Noise at 622.08 MHz

350

300

250

200

150

RMS JITT ER (fs)

100

50

0

06561-005

012345678

INPUT SLEW RATE (V/ns)

TA = 25°C

06561-008

Figure 8. RMS Jitter vs. Input Slew Rate

Rev. A | Page 7 of 12

Page 8

ADCLK914

www.BDTIC.com/ADI

3.80

162

3.75

3.70

3.65

3.60

3.55

DIFFERENTIAL OUTP UT SWING (V)

3.50

2.97 3.13 3.30 3. 46 3.63

POWER SUPPLY VOLTAGE (V)

Figure 9. Differential Output Swing vs. Power Supply Voltage

115

114

113

112

111

110

109

108

107

POWER SUPPL Y CURRENT (mA)

106

105

2.97 3.13 3.30 3.46 3.63

POWER SUPPLY VOLTAGE (V)

Figure 10. Power Supply Current vs. Power Supply Voltage

200

180

160

140

120

100

80

60

PROPAGATI ON DELAY (ps)

40

20

0

0.5 1.0 1.5 2.0 2.5

Figure 11. Propagation Delay vs. V

INPUT COMMON MODE (V)

; VID = 1.6 V p-p

ICM

160

158

156

154

152

150

PROPAGATI ON DELAY (p s)

148

146

0.4 0.8 1.2 1.6 2.0

06561-009

Figure 12. Propagation Delay vs. VID; V

INPUT DIFFERENTIAL (V p-p)

= 2.15 V

ICM

06561-012

4.0

3.5

3.0

2.5

2.0

1.5

1.0

DIFFERENTIAL OUTPUT SWING (V)

0.5

0

0.5 1.5 2.5 3.5 4.5 5. 5 6.5 7.5 8.5 9.5 10.5 11.5 12. 5

06561-010

FREQUENCY (G Hz)

06561-013

Figure 13. Toggle Rate, Differential Output Swing vs. Frequency

06561-011

Rev. A | Page 8 of 12

Page 9

ADCLK914

www.BDTIC.com/ADI

APPLICATIONS INFORMATION

POWER/GROUND LAYOUT AND BYPASSING

The ADCLK914 buffer is designed for very high speed applications. Consequently, high speed design techniques must be used

to achieve the specified performance. It is critically important to

use low impedance supply planes for both the negative supply

(V

) and the positive supply (VCC) planes as part of a multilayer

EE

board. Providing the lowest inductance return path for switching

currents ensures the best possible performance in the target

application.

It is also important to adequately bypass the input and output

supplies. Place a 1 µF electrolytic bypass capacitor within several

inches of each power supply pin to ground. In addition, place

multiple high quality 0.001 µF bypass capacitors as close as

possible to each V

and VCC supply pin and connect these cap-

EE

acitors to the GND plane with redundant vias. Carefully select

high frequency bypass capacitors for minimum inductance and

ESR. To maximize the effectiveness of the bypass capacitors at

high frequencies, strictly avoid parasitic layout inductance.

Slew currents may also appear at the V

and VSS pins of the

DD

device being driven by the ADCLK914.

HVDS OUTPUT STAGE

The ADCLK914 has been developed to provide a bipolar interface

to any CMOS device that requires extremely low jitter, high

amplitude clocks. It is intended to be placed as close as possible

to the receiving device and allows the rest of the clock distribution to run at standard CML or PECL levels.

Interconnects must be short and very carefully designed

because the single terminated design provides much less

margin for error than lower voltage, double terminated

transmission techniques.

Q

Q

40mA

Figure 14. Simplified Schematic Diagram

of the ADCLK914 HVDS Output Stage

7mA

7mA

V

V

EE

V

EE

EE

06561-015

INTERFACING TO HIGH SPEED DACs

The ADCLK914 is designed to drive high amplitude, low jitter

clock signals into high speed, multi-GSPS DACs. The ADCLK914

should be placed as close as possible to the clock input of the

DAC so that the high slew rate and high amplitude clock signal

that these devices require do not cause routing difficulties,

generate EMI, or become degraded by dielectric and other

losses. The ADCLK914, in turn, may be driven directly by

standard or low swing PECL, CML, CMOS, or LVTTL sources,

or by LVDS with simple ac coupling, as illustrated in Figure 15

through Figure 19.

OPTIMIZING HIGH SPEED PERFORMANCE

As with any high speed circuit, proper design and layout techniques are essential to obtaining the specified performance.

Stray capacitance, inductance, inductive power, and ground

impedances, as well as other layout issues, can severely limit

performance and can cause oscillation. Discontinuities along

input and output transmission lines can also severely limit the

specified jitter performance by reducing the effective input

slew rate.

Input and output matching have a significant impact on

performance. The ADCLK914 buffer provides internal 50 Ω

termination resistors for both D and

D

inputs. The return side

can be connected to the reference pin provided or to a current

sink at V

direct coupled CML. The V

− 2 V for use with differential PECL, or to VCC for

CC

pin should be left floating any

REF

time that it is not used to minimize power consumption.

Note that the ADCLK914 V

damage from momentary shorts to V

charging currents; for this reason, the V

source is current-limited to resist

REF

or VCC and from capacitor

EE

source cannot be

REF

used as a PECL termination supply.

Carefully bypass the termination potential using ceramic capacitors to prevent undesired aberrations on the input signal due

to parasitic inductance in the termination return path. If the

inputs are directly coupled to a source, care must be taken to

ensure that the pins remain within the rated input differential

and common-mode ranges.

If the return is floated, the device exhibits 100 Ω cross-termination, but the source must then control the common-mode

voltage and supply the input bias currents.

ESD/clamp diodes between the input pins prevent the application of excessive offsets to the input transistors. ESD diodes

are not optimized for best ac performance. If a clamp is needed,

it is recommended that appropriate external diodes be used.

RANDOM JITTER

The ADCLK914 buffer has been specifically designed to

minimize random jitter over a wide input range. Provided

that sufficient voltage swing is present, random jitter is affected

most by the slew rate of the input signal. Whenever possible,

clamp excessively large input signals with fast Schottky diodes

because attenuators reduce the slew rate. Input signal runs of

more than a few centimeters should be over low loss dielectrics

or cables with good high frequency characteristics.

Rev. A | Page 9 of 12

Page 10

ADCLK914

V

V

www.BDTIC.com/ADI

TYPICAL APPLICATION CIRCUITS

V

CC

V

REF

V

T

– 2V

D

D

CC

V

REF

V

T

D

D

CONNECT VT TO VCC.

06561-017

Figure 15. Interfacing to CML Inputs

V

REF

V

T

D

D

TO V

CONNECT V

NOTES

1. PLACI NG A BYPA SS CAPACI TOR

FROM V

THE NOISE PERFORMANCE.

TO GROUND CAN IMPROVE

T

.

T

REF

Figure 16. AC Coupling Differential Signals

CC

Q

Q

CONNECT VT TO VCC – 2V.

06561-018

Figure 18. Interfacing to ECL Inputs

V

REF

V

T

D

D

CONNECT VT, V

CAPACITOR FRO M V

ALTERNATIVELY, V

06561-019

CONNECTED, G IVING A CLEANER LAYOUT AND

A 180º PHASE SHIFT.

, AND D. PLACE A BYPAS S

REF

TO GROUND.

T

, V

, AND D CAN BE

T

REF

06561-020

Figure 19. Interfacing to AC-Coupled, Single-Ended Inputs

40mA

7mA

7mA

V

V

EE

V

EE

EE

06561-021

Figure 17. Interfacing to High Speed DAC

Rev. A | Page 10 of 12

Page 11

ADCLK914

www.BDTIC.com/ADI

OUTLINE DIMENSIONS

0.50

EXPOSED

PAD

0.40

0.30

16

1

4

5

P

N

I

N

I

D

*

1.65

1.50 SQ

1.35

0.25 MIN

1

A

R

O

T

C

I

071708-A

0.45

0.50

BSC

1.50 REF

0.60 MAX

BOTTOM VIE W

13

12

9

8

FOR PROPER CONNECTION OF

THE EXPOSED PAD, REFER TO

THE PIN CONF IGURATIO N AND

FUNCTION DES CRIPTIONS

SECTION O F THIS DAT A SHEET.

PIN 1

INDICATOR

0.90

0.85

0.80

SEATING

PLANE

12° MAX

3.00

BSC SQ

2.75

BSC SQ

0.80 MAX

0.65 TYP

0.05 MAX

0.02 NOM

0.20 REF

*

COMPLIANT

EXCEPT FO R EXPOSED PAD DI MENSION.

TO

JEDEC STANDARDS MO-220-VEED-2

0.30

0.23

0.18

TOP

VIEW

Figure 20. 16-Lead Lead Frame Chip Scale Package [LFCSP_VQ]

3 mm × 3 mm Body, Very Thin Quad

(CP-16-3)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option

ADCLK914BCPZ-WP

ADCLK914BCPZ-R71 −40°C to +125°C 16-Lead Lead Frame Chip Scale Package [LFCSP_VQ] CP-16-3

ADCLK914BCPZ-R21 −40°C to +125°C 16-Lead Lead Frame Chip Scale Package [LFCSP_VQ] CP-16-3

ADCLK914/PCBZ1 Evaluation Board

1

Z = RoHS Compliant Part.

1

−40°C to +125°C 16-Lead Lead Frame Chip Scale Package [LFCSP_VQ] CP-16-3

Rev. A | Page 11 of 12

Page 12

ADCLK914

www.BDTIC.com/ADI

NOTES

©2008 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D06561-0-10/08(A)

Rev. A | Page 12 of 12

Loading...

Loading...