Page 1

APPLICATIONS

• INERTIAL GUIDANCE

• TEST EQUIPMENT

• DATA ACQUISITION

• SCIENTIFIC INSTRUMENTS

• MEDICAL INSTRUMENTS

• WEIGHT SCALES

FEATURES

• 26 BIT RESOLUTION

• UP TO 2.5kHz CONVERSION RATES

• AUTO ZERO FUNCTION

• ±10.48 V INPUT RANGE

• 0.5ppm/°C MAX. SCALE FACTOR ERROR

AND 2 ppm MAX. LINEARITY ERROR

(-55°C to +125°C).

• 8 BIT PARALLEL DATA BUS

• INTERNAL CRYSTAL CLOCK and

PRECISION REFERENCE

• LOW POWER CONSUMPTION: 0.4 WATTS

DESCRIPTION

The ADC180 is a 26 bit, charge balanced A/D

converter. Continuous sampling of 20 MHz and

conversion rates of up to 2.5 kHz make the converter

ideal for low frequency signal measurement. The

integration time is user selectable through an

external capacitor.

The ADC180 will continuously collect and average

integrations until the user requests data. Converter

resolution is dependent on the number of integration

cycles completed before the data is requested.

Converter resolution ranges from 13 - 26 bits.

In order to retain accuracy, internal calculations are

made at a 32 bit level. The output of the result is

also made at the 32 bit level. This makes it possible

to use a relatively high conversion rate and average

the data external to the converter without loss of

accuracy due to computation roundoff errors. For

inertial guidance systems, velocity information can

be obtained at a high rate without loss of position

accuracy.

The use of hybrid technology allows for separation

of sensitive analog circuitry from digital circuit

noise. This produces far superior accuracy over

monolithic A/D convertors.

The converter uses a proprietary, patented charge

balance modulator. It has an internal crystal clock,

microcontroller, precision reference, and patented

nonlinear temperature compensation network which

provides excellent electrical performance over

temperature.

The maximum scale factor drift is 0.5ppm/oC,

maximum offset drift of 0.1ppm/oC, and a maximum

nonlinearity over the mil. temp. range of 2 ppm.

The ADC180 is packaged in a 40 pin hermetic

TDIP and requires ±15V and +5V supplies. The

converter dissipates 450 mW and is available in

commercial and military grades.

ADC180DS REV H MAR 00

ADC180

Programmable

Integrating A/D Converter

THALER CORPORATION • 2015 N. FORBES BOULEVARD • TUCSON, AZ. 85745 • (520) 882-4000

Page 2

ELECTRICAL SPECIFICATIONS

MODEL

PARAMETER

ACCURACY

TEMPERATURE STABILITY

TIME STABILITY

ERROR ALL SOURCES

CONVERSION TIME

WARM-UP TIME

TEMPERATURE RANGE

DIGITAL OUTPUTS

DIGITAL INPUTS

POWER SUPPLY CURRENTS

POWER SUPPLY VOLTAGES

ANALOG INPUT CHARACTERISTICS

POWER SUPPLY REJECTION

Resolution

Input Equivalent Noise

Offset without Auto Zero

Offset with Auto Zero

Scale Factor Error

Noise (.1-10Hz) @ 10V

Nonlinearity

Normal Mode Rejection

Common Mode Rejection

Offset

Full Scale

Offset

Full Scale

MIN MAXTYP MIN MAXTYP MIN MAXTYP

ADC180C

ADC180CA ADC180M

bits

µV

ppm FS

ppm FS

ppm FS

µVpp

ppm FS

dB

dB

.25

6

1

*

*

*

*

*

*

*

*

*

*

60

80

*

*

*

*

0.2 0.1

*

1.0 0.5

*

ppm/oC

ppm/oC

0.1

2

ppm/24 hrs.

ppm/month

.0005, 2 .0003, 2 %, +/- counts

24 hrs, +/- 1 Deg. C Amb.

90 days, +/- 5 Deg. C Amb.

1 year, +/- 5 Deg. C Amb.

.0010, 2 .0008, 2

*

.0015, 2

.0013, 2

%, +/- counts

%, +/- counts

*

*

ms

*

5

*

* *

minutes

+Vcc, -Vee

5 VDC

80

80

* * dB

* * dB

Low

High

Low

High

-25

85 *

*

-55

125

V

V

V

V

0.8

*

*

4.0

* *

4.0

* *

0.8

* *

+Vcc

23

* * mA

-Vee

24

* *

mA

+Vdd

42

* *

mA

+Vcc

-Vee

+Vdd

+14.5 +15 +15.5

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

V

-14.5

-15 -15.5 V

+4.5

+5

+5.5

V

Input Range -10.485760

+10.485755

3

*

*

*

*

*

*

*

*

V

Bias Current 1.2

* *

nA

Input Impedance

Max. Input Voltage

200

* *

GO

2

0.5

50

*

* Same as ADC180C

Notes: 1) 60 Cycle 2) ( Max-Min Value) - Noise(0.1-10Hz)

ADC180

(Vcc = +15V, Vee = -15V, Vdd= + 5V, TA = +25oC)

*

*

*

*

4

1

100

2

(1)

o

C

(2)

26

*

*

32000.250

*

*

13

*

*

ADC180DS REV H MAR 00

V

-Vee +Vcc

Page 3

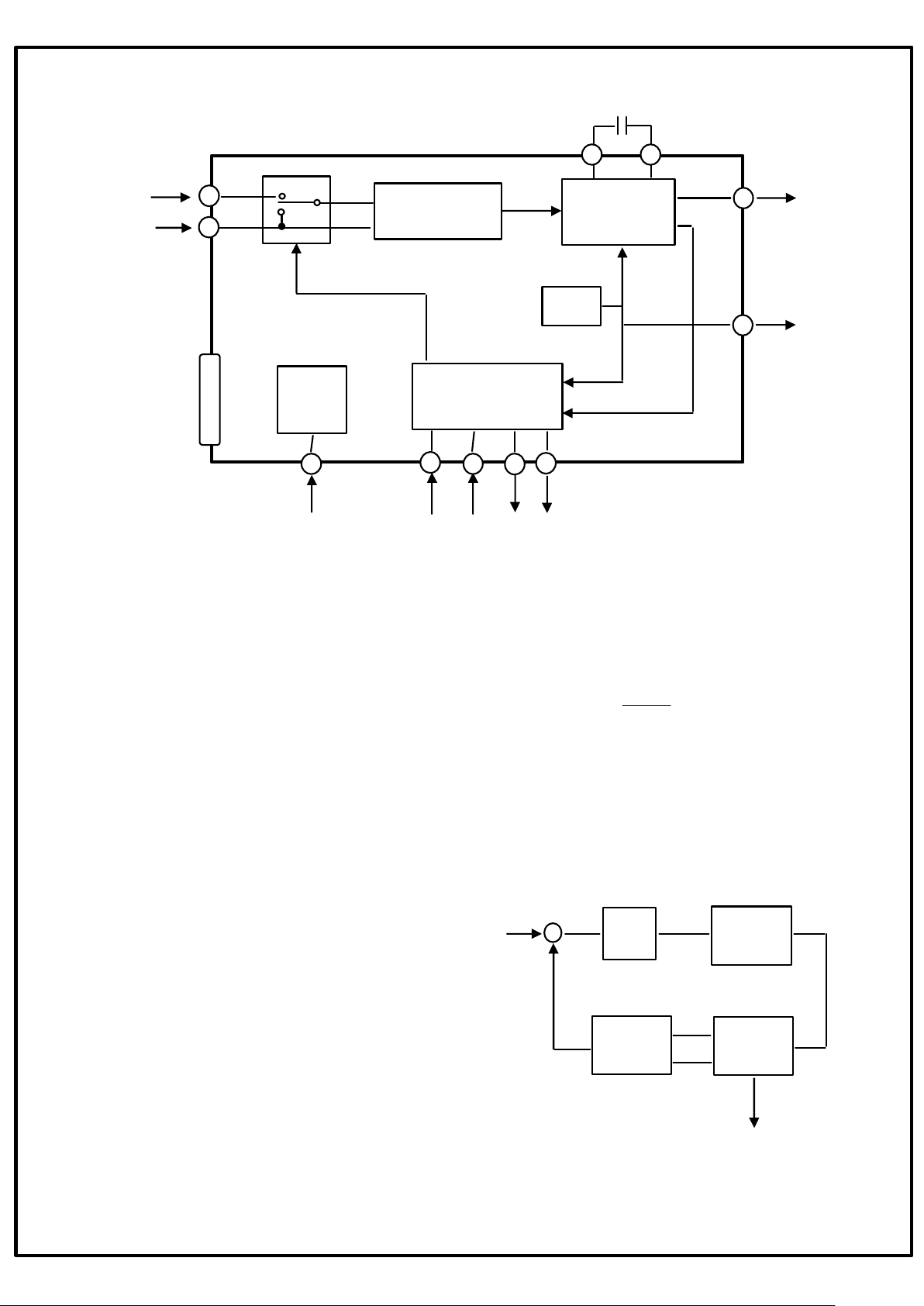

THEORY OF OPERATION

The ADC180 uses a differential input to improve

accuracy. To measure single source voltages,

V

low

should be connected to the ground point of the

source voltage to be measured. In figure 1, the

switch is shown in the normal operating mode

connecting V

hi

and V

low

to the differential input of

the transadmittance amplifier. For an autozero

cycle, V

hi

is disconnected and the input to the

amplifier is shorted.

The charge balance modulator (figure 2) uses a

proprietary patented architecture to achieve the

high accuracy of the ADC180 without any error

correction method other than autozero. This

enables the converter to sample the output of the

transadmittance amplifier continuously at a

sampling rate of 20 MHz. This is important for

applications like inertial guidance systems where

Auto Zero Switch

Charge Balance

Modulator

Microprocessor

Output

Buffer

Crystal

Clock

Transadmittance

Amplifier

V

hi

V

low

Auto

Zero

Data

Request

Status

Lines

Output Enable

Data

Output

ï

ï

13

.

.

.

20

21

29

22

23

24

34 35

39

40

FIGURE 1. BLOCK DIAGRAM

Bidirectional

Curent

Source

∫

Direction

Switch

Bilevel

Comparator

Figure 2. Patented Charge Balance Modulator

The conversion result between two consecutive

data request inputs at times t1and t2is

mathematically represented by the equation

Data

Output

I

IN

ADC180DS REV H MAR 00

Duty Cycle

Test Point

3

20MHz clock output

26

The converter provides two 32 bit data words with

the first word containing t2-t1and the second word

containing

∫

⋅

−

=

2

1

12

1

t

t

inpiav

dtV

tt

V

dtV

t

t

inp

⋅

∫

2

1

dtV

t

t

inp

⋅

∫

2

1

must be measured without any loss of time

increments. The output of the charge balance

modulator is in the form of a pulse width

modulation signal. The internal microprocessor

provides all control functions and digital signal

processing.

The converter also has an internal crystal clock to

avoid phase jitter errors and a tristate output

buffer for easy interface with bus based systems.

For the data output timing see figures 5 and 6.

Page 4

CONNECTING THE ADC180

DUTY CYCLE OUTPUT (pin 3)

This logic level output allows monitoring of the

integration cycle and is usually used for timing

purposes.

POWER SUPPLIES (pins 4-7)

The ADC180 has internal 0.1µF decoupling

capacitors for all power supply inputs. This is

sufficient for applications with relatively short power

supply leads (approx. 5") or if additional capacitors

are located on the circuit board. External capacitors

of 10 µF on the ±15V inputs and 33 µF on the +5V

input is recommended for applications with longer

power supply leads.

GROUND (pin7)

Since ground noise can result in a loss of accuracy,

the ground connection should be made as solid as

possible. Use of a ground plane is a good approach

to maintain the full accuracy of the ADC180.

OUTPUT DATA LINES (pins 13-20)

The parallel output data is available on pins 13-20.

Pin 20 is the Most Significant Bit and pin 13 the

Least Significant Bit. The data lines go to a high

impedance state when the Output Enable line is at a

logic 1 level.

ANALOG INPUTS (pins 39,40)

The differential analog inputs are buffered by

op amps and have a common mode rejection of

approximately 80dB minimum. To maintain the full

accuracy of the ADC180 it is recommended to

maintain the input to analog low to less than

0.1VDC. To avoid differential noise pickup, parallel

adjacent lines should be used for the analog inputs

on PC boards and shielded lines outside of the PC

connections.

CAPACITOR (pin 34, 35)

The only external component required to operate

the ADC180 is a capacitor which sets the

integration time. A 0.082 µF capacitor results in an

integration time of approximately 250 µs. For 2,000

µs a 0.68µF capacitor is required. The relationship

is linear for intermediate capacitor values.

The main parameter affected by shorter conversion

times is bias stability over temperature.

Polystyrene, mylar, or polycarbonate capacitors are

recommended.

AUTO ZERO / RESET (pin 29)

A logic 0 on this input will autozero the ADC180 by

internally connecting the analog high to analog low.

Since the internal microprocessor is reset, the

ADC180 is not functional during this time

(approximately 1s). S1will go to logic 1 indicating

that no data is available. After completing the

autozero function, S1will return to logic 0 and the

ADC will begin collecting data.

20MHz CLOCK OUTPUT (pin 26)

Output of the internal crystal oscillator.

STATUS LINES (pins 23, 24)

These lines indicate the present state of the ADC.

After a data request has been received and the

current integration cycle is complete, the ADC will

output the data collected subsequent to the

previous data request. S1will go to logic 1 to

acknowledge the data request. The 8 bytes of data

will be placed on the data bus sequentially. A logic

1 on S0indicates valid data on the data bus. After

the data has been transmitted, S1will return to

logic 0.

DATA REQUEST (pin 22)

A logic 0 on this line initiates a data transfer

sequence.

OUTPUT ENABLE (pin 21)

A logic 0 on this line enables outputs D0 - D7.

NC= Factory test points, do not connect to these pins.

Vee (-15V)

Vcc (+15V)

Vdd (+5V)

(TOP VIEW)

ADC180

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

N.C.

Duty Cycle Output

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

20MHz CLOCK OUTPUT

N.C.

N.C.

N.C.

D0

D1

D2

D5

D4

D3

D6

D7

GND

ANALOG LOW

ANALOG HIGH

/AUTO ZERO / RESET

S1

S0

/DATA REQUEST

/OUTPUT ENABLE

CAPACITOR

FIGURE 3. EXTERNAL CONNECTIONS

ADC180DS REV H MAR 00

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

Page 5

TIMING DIAGRAMS

FIGURE 4. AUTO ZERO TIMING

FIGURE 5. DATA REQUEST CYCLE TIMING

S1

S0

AutoZero

*

*

t

AZ

t

TS

t

AC

* Data Request at logic 1, output enable (don’t care)

/DR

t

DD

t

DRA

t

NDR

FIGURE 6. TIMING TABLE

AutoZero request

Autozero Cycle

port TriState time

Data Request Acknowledge

S1 Response after duty cycle

Data Delay

time before Next Data Request

Data Valid

Data Cycle

t

AZ

t

AC

t

TS

t

DRA

t

S1R

t

DD

t

NDR

t

DV

t

DC

100

*

27

0

30

50

1

2

1.3

*

34

ns

s

ms

µs

µs

µs

µs

µs

* T

DRA

must be either 1 integration cycle minimum or until S1 goes high.

SIGNAL SYMBOL MIN TYP MAX UNITS

ADC180DS REV H MAR 00

t

S1R

duty cycle

S1

S0

S0

D0 - D7

t

DV

t

DC

enlarged detail

data on D0 - D7

valid upon rising

edge of S0

Page 6

Sampling Time

(ms) approx.

3200

1600

800

400

200

100

50

25

12.5

6.25

3.12

1.56

0.78

0.39

SPECIFICATIONS

MAXIMUM RATINGS ADC180

MODEL

ADC180

PARAMETER

TEMPERATURE

POWER SUPPLY

INPUTS

MIN

MAX

Operating

Storage

125

150

UNITS

° C

° C

analog inputs

digital inputs

VDC

VDC

VDC

+16

-16

+6

Vcc

Vee

Vdd

Vee

0

Vcc

Vdd

RESOLUTION

(bits)

26

25

24

23

22

21

20

19

18

17

16

15

14

13

FIGURE 7 APPROXIMATE SAMPLING TIME VS. RESOLUTION

Note: 0.082µF external capacitor provides ~250µs integration cycle

0.68µF external capacitor provides ~2000µs integration cycle

ADC180DS REV H MAR 00

-55

0

+14

-14

+4

cycles w/0.082µF

capacitor

12800

6400

3200

1600

800

400

200

100

50

25

13

6

3

1

cycles w/ 0.68µF

capacitor

1600

800

400

200

100

50

25

13

6

3

1

-

-

-

FIGURE 8 OUTPUT DATA REPRESENTATION

input voltage

+10.485775 V

0 V

-10.485760 V

output

2^28

(2^28)/2

0

output (hex)

10 00 00 00

08 00 00 00

00 00 00 00

LSB weighting

(µV)

0.31

0.62

1.25

2.5

5

10

20

40

80

160

320

640

1280

2560

Conversions

Per Second

0.31

0.62

1.25

2.5

5

10

20

40

80

160

320

640

1280

2560

Page 7

DIM

INCHES

MIN

MAX

E

D

A

L

B

Q

C

P

G1

1.080

1.100

2.075

2.115

0.155

.100 typ

.018 typ

.015

.009

.012

.890

0.185

.035

.012

.018

.910

40-PIN HYBRID PACKAGE

B1

.040 typ

B2

0.220

0.240

NOTES:

1. GOLD PLATING 60 MICRO INCHES MINIMUM

THICKNESS OVER 100 MICRO INCHES NOMINAL

THICKNESS OF NICKEL

ADC180DS REV H MAR 00

FIGURE 9 OUTPUT CALCULATION PSEUDO-CODE

FIGURE 10 MECHANICAL SPECIFICATIONS

outputword1 = (byte1 * 2^24) + (byte2 * 2^16) + (byte3 * 2^8) + byte4

outputword2 = ((byte5 - 8) * 2^24) + (byte6 * 2^16) + (byte7 * 2^8) + byte8

Vout = (outputword2 / outputword1) * 20

scales to ±10V

scales to 0V

Loading...

Loading...