Page 1

ADC150

Programmable

Integrating A/D Converter

THALER CORPORATION • 2015 N. FORBES BOULEVARD • TUCSON, AZ. 85745 • (520) 882-4000

FEATURES

• 24 BIT RESOLUTION

• SOFTWARE SELECTABLE FEATURES

• 0.5ppm/°C MAX. SCALE FACTOR ERROR

• 2 ppm MAX. LINEARITY ERROR

• AUTO ZERO

• BUS COMPATIBLE

• INTERNAL CLOCK and REFERENCE

• LOW POWER CONSUMPTION (0.450 WATTS)

APPLICATIONS

• TEST EQUIPMENT

• DATA ACQUISITION

• SCIENTIFIC INSTRUMENTS

• MEDICAL INSTRUMENTS

• SEISMOLOGICAL EQUIPMENT

• ROBOTIC SYSTEMS

• WEIGHING SYSTEMS

DESCRIPTION

ADC150 is a high performance programmable 24bit integrating A/D converter based on a patented

architecture. The integration time and resolution

along with the power line cycle selection can be

easily programmed through the Mode Control

Byte.

ADC150 offers 2 ppm max. linearity error and

1 ppm/°C max. scale factor error over the military temperature range. It also has excellent offset stability at

2 ppm max. which the user can auto zero if desired.

ADC150's compatibility with popular microcomputer buses increases its ease of application in smart

systems. An on-board microprocessor controls all internal functions of the ADC150. Thaler designers

have minimized external connections to greatly reduce the problem often encountered when applying

ADC's.

Operating from ±15VDC and a +5VDC power supply, ADC150 is packaged in a hermetically sealed 40-pin

ceramic DIP package. Precision test equipment, scientific and medical instruments, and data acquisition

systems are primary application areas for the unusually high resolution and accuracy of this ADC.

Type Operating Range Factor Deviation

ADC150C -25°C to +85°C 60ppm

ADC150CA -25°C to +85°C 30ppm

ADC150M -55°C to +125°C 100ppm

Temperature Max. Scale

ADC150DS REV. F MAR 00

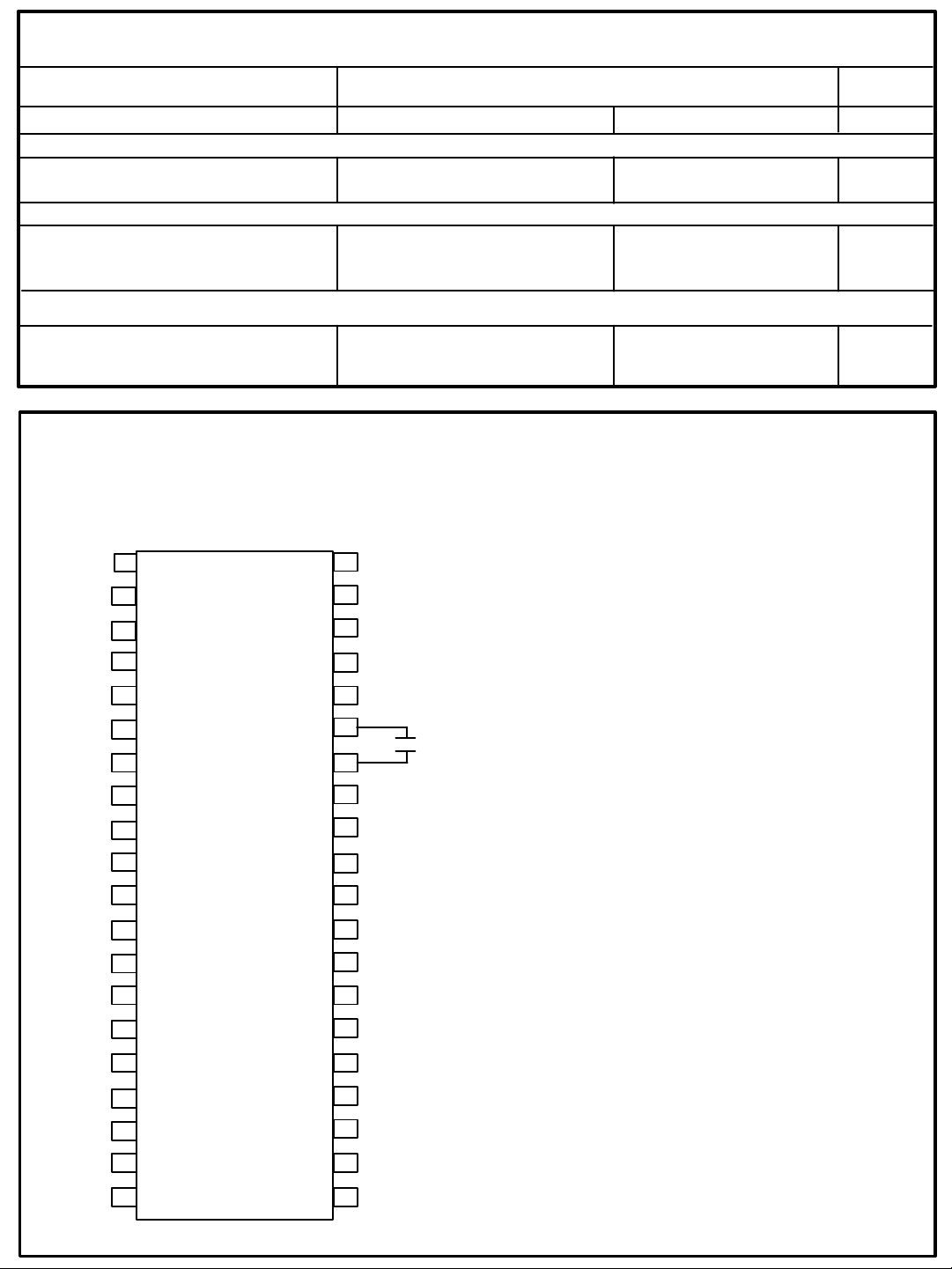

Page 2

MAXIMUM RATING SPECIFICATIONS ADC150

MODEL

PARAMETER

TEMPERATURE

Operating

Storage

POWER SUPPLY

V

CC

V

EE

V

DD

INPUTS

Analog Inputs

Digital Inputs

EXTERNAL CONNECTIONS

N.C.

N.C.

N.C.

Vee (-15V)

Vee (+15V)

Vdd (+5V)

GND

N.C.

N.C.

N.C.

1

2

3

4

5

6

7

8

9

10

(TOP VIEW)

ADC150

40

ANALOG LOW

39

ANALOG HIGH

38

ALTERNATE INPUT

37

N.C.

36

N.C.

35

34

33

N.C.

N.C.

32

31

N.C.

MIN

-55

0

+14

-14

+4

V

EE

0

INTEGRATION

CAPACITOR

ADC150

MAX

125

160

+16

-16

+6

V

CC

V

DD

NOTES:

1. Power Supply Decoupling

The ADC150 has internal 0.1µF decoupling

capacitors for all power supply inputs. The

internal decoupling capacitors are adequate

for applications with relatively short power

supply leads (approx. 5") or if additional

capacitors are located on a circuit board.

For applications with long power supply

leads an external capacitor of 10 µF on the

+/- 15V inputs and 33 µF on the +5V input is

recommended.

2. Ground

The ground connection (pin 7) should be

made as solid as possible since ground

noise can result in a loss of accuracy. Use

of a ground plane is a good approach to

maintain the full accuracy of the ADC150.

UNITS

°C

°C

VDC

VDC

VDC

N.C.

N.C.

D0

D1

D2

D3

D4

D5

D6

D7

11

12

13

14

15

16

17

18

19

20

30

N.C.

AUTO ZERO

29

RESET

N.C.

28

N.C.

27

N.C.

26

25

MODE CONTROL

24

STATUS 1

23

STATUS 0

CONVERT

22

21

OUTPUT ENABLE

3. External Components

A .68 µF polystyrene integration capacitor

must be connected to pins 34 and 35 with a

lead length not exceeding 2".

4. Analog Inputs

In order to avoid differential noise pickup it is

recommended to use parallel adjacent lines

for the analog inputs (pins 39, 40) on PC

boards and shielded lines outside of the PC

connections.

ADC150DS REV. F MAR 00

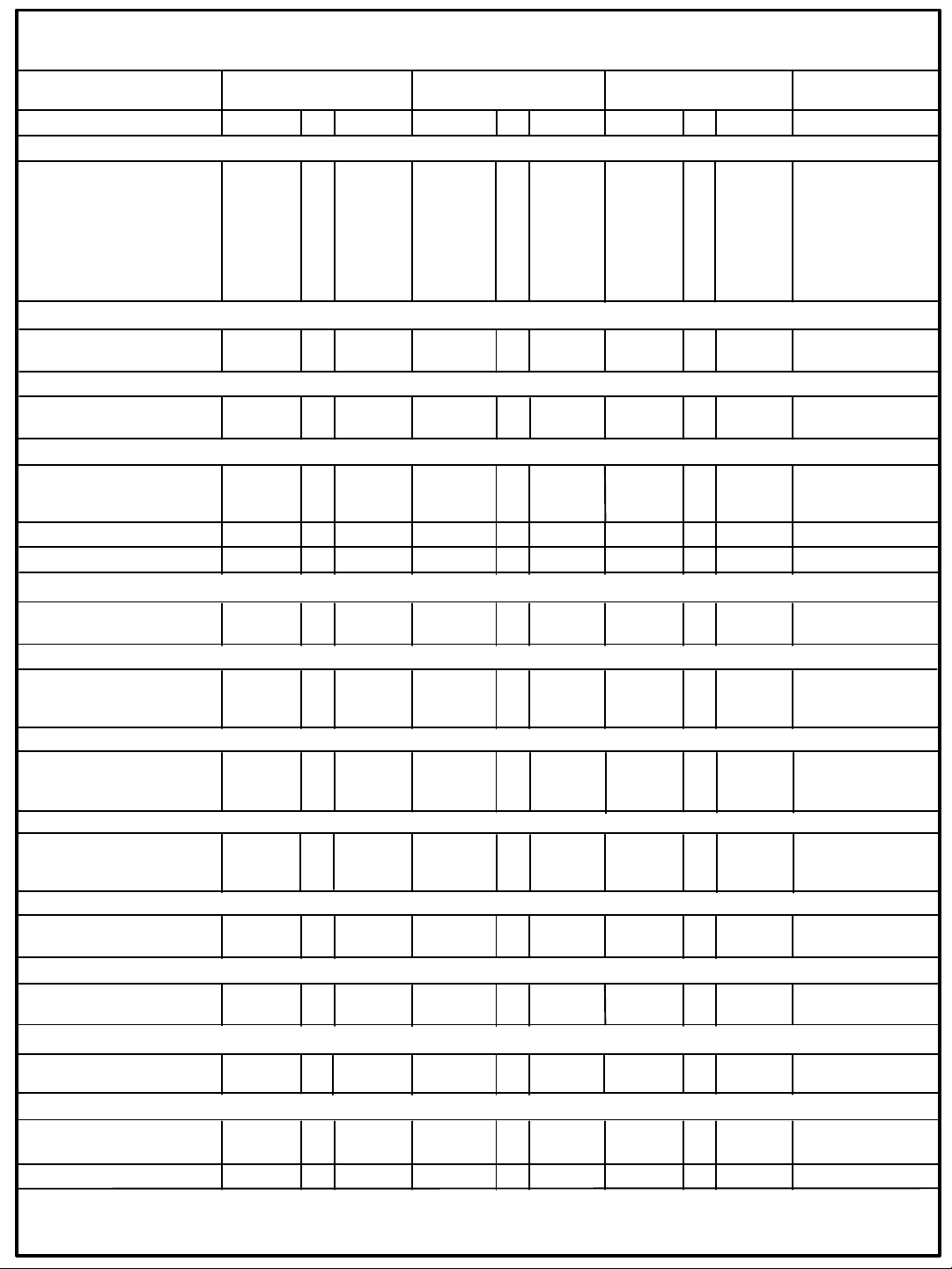

Page 3

ELECTRICAL SPECIFICATIONS

(Vps = +/- 15V, + 5V, T = 25 Deg. C.)

ADC150

MODEL

PARAMETER

ACCURACY

Resolution

Input Equivalent Noise

Offset without Auto Zero

Offset with Auto Zero

Full Scale

Noise (.1-10Hz) @ 10V

Nonlinearity

Normal Mode Rejection

TEMPERATURE STABILITY

Offset

Full Scale

TIME STABILITY

Offset

Full Scale

ERROR ALL SOURCES

24 hrs, +/- 1 Deg. C Amb.

90 days, +/- 5 Deg. C Amb.

1 year, +/- 5 Deg. C Amb.

CONVERSION TIME

WARM-UP TIME

POWER SUPPLY REJECTION

+/- 15 VDC

5 VDC

ANALOG INPUT CHARACTERISTICS

Input Range -10.485760

Bias Current 1.2

Input Impedance 200

POWER SUPPLY VOLTAGES

+15 V

-15 V

POWER SUPPLY CURRENTS

+15 V

-15 V

DIGITAL INPUTS

Low

High

DIGITAL OUTPUTS

Low

High

AUTO ZERO INPUT

Low

High

CONVERT INPUT

Low

High

TEMPERATURE RANGE

* Same as ADC150C

Note: 1) 60 Cycle

2

5 v

5 v

2) ( Max-Min Value) - Noise(.1-10Hz)

MIN MAXTYP MIN MAXTYP MIN MAXTYP

1

60

80

80

14.5 15 15.5 * * * * * * V

14.5

4.0

4.0

ADC150C

18

4.5

4.0 * *

4.0 *

-25

24

1

4

1

100

6

1

2

0.2 0.1

1.0 0.5

.1

2

.0005, 2 .0003, 2 %, +/- Counts

.0010, 2 .0008, 2

.0015, 2

1067 ms

5

10.485755

3

15 15.5

5

5.5

23

24

42

0.8

0.8

0.8

0.8

85 *

ADC150CA ADC150M

*

*

2

0.5

50

*

*

*

* * dB

* * dB

* * * *

* * * * * *

* * * * * *

* * mA

* *

* *

* *

* *

*

*

*

*

.0013, 2

*

* *

* *

* *

*

* *

* *

*

*

-55

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

125

ADC150DS REV. F MAR 00

Bits

µV

ppm

ppm

ppm

µVpp

ppm

dB

ppm/oC

ppm/oC

ppm/month

ppm/24 hrs.

%, +/- Counts

%, +/- Counts

minutes

V

nA

GΩ

V

V

mA

mA

V

V

V

V

V

V

V

V

o

C

Page 4

THEORY OF OPERATION

In the ADC150 block diagram (see Figure 1), V

and V

into a differential, voltage controlled, single output

current source. This current is added to the

reference current at the input of the op amp

integrator. The output of the integrator is fed into

a Schmitt trigger, which in turn, is fed into the

ADC's timing control circuitry. When the

integrator output actuates the Schmitt trigger, the

timing circuit changes the direction of the

reference current source and the integrator

begins integrating in the opposite direction. This

continues until the Schmitt trigger is actuated

again by the integrator and reverses the direction

of the reference current.

The equation for integration times are:

Resolving these equations produces:

are the inputs. Both are buffered and fed

low

V X C

Tp=

I ref + I inp

V = Voltage

C= Integration Capacitor Value

I ref = Reference Current

I inp = Input Current

I inp = I ref

Tp = Time Positive

Tm = Time Negative

Tp - Tm

Tp + Tm

Tm=

V X C

-I ref + I inp

hi

The timing control circuitry governs the counters that

measure the integration time in both directions.

The ADC150's on-board microprocessor is used to

calculate the results of the integration equation and

perform error corrections. Note that the µP

automatically performs an auto zero function at startup, but it is recommended to achieve maximum

accuracy, that an auto zero be performed again after

the ADC150 is fully warmed up.

When the µP detects a convert signal, it lowers the

status lines to indicate that the ADC is involved in a

conversion. When it detects a change in slope

direction, the µP will collect the counts for the

integration time. When sufficient counts have been

collected, the µP performs the calculations described

above.

When the calculations are complete, the µP places

the most significant byte in the output buffer and

raises the S0flag. When another pulse is placed on

the convert line, the middle byte is placed on the

output, the S0flag is lowered and the S1flag raised.

When the last pulse is placed in the convert line, the

least significant byte is placed in the output buffer and

both status flags are high indicating that the ADC150

is ready for another conversion.

Status line summary:

S1S

0 0

0 1

1 0

1 1

0

Conversion in progress.

Conversion complete. MSB in output.

Middle byte in output register.

LSB in output. Ready for next conversion.

V

hi

Auto

Zero

Switch

V

low

Data

Output

FIGURE 1. BLOCK DIAGRAM

Output

Buffer

Output Enable

Differential

Voltage Controlled

Current Source

Microprocessor

ïï

Auto

Zero

Bidirectional

Reference

Current Source

Convert

Status

Lines

ï

Current

Directional

Switch

Timing

Control

and

Counter

Schmitt

Trigger

+15V

-15V

Clock

ADC150DS REV. F MAR 00

Page 5

CONNECTING THE ADC150

POWER SUPPLIES

The power supply lines are connected to pins 4-7.

Pin 4 is -15V, pin 5 is +15V, pin 6 is +5V and pin 7

is GND.

OUTPUT DATA LINES

The output data is available in byte form on pins

13-20. Pin 20 is the Most Significant Bit and pin 13

the Least Significant Bit. The data lines go to a high

impedance state when the Output Enable line is at a

logic one level.

OUTPUT ENABLE (PIN 21)

Data is placed on the Output Data Lines by a logic

zero on this line. See figure 2 for data output

format.

CONVERT (Pin22)

This line is used to initiate a conversion cycle and

to retrieve the output data. The status lines indicate

which function will be executed. The first pulse

(transition from logic one to logic zero) starts the

conversion cycle. Two subsequent pulses are used

to place the lower two bytes on the Output Data

Lines. See figure 4 for timing diagram.

STATUS LINES (Pins 23, 24)

These lines indicate the present state of the ADC.

When the Convert line receives the first pulse in a

conversion cycle the Status Lines go to logic zero,

indicating that a conversion cycle is in progress.

When the conversion is complete the

microprocessor places the MSB of the output data

in the output buffer and then raises S0to a logic

one, indicating that the MSB at the output data is

available in the output buffer. When the Convert

Line is pulsed again the middle byte of the output

data is placed in that output buffer and S1changes

to logic one and S0to logic zero. The third pulse

places the LSB of the output data in the buffer and

both status lines go to the logic one. The converter

is now ready for the next conversion cycle. See

figure 5 for timing diagrams.

The table below shows a summary of the status

code.

S1S

0 0

0 1

1 0

1 1

0

Conversion in process.

Conversion complete. MSB in output.

Middle byte in output register.

LSB in output. Ready for next conversion.

MODE CONTROL (Pin 25)

This line is used to program the ADC150. The

mode control byte (8 bit) is placed on the data bus.

Pin 25 is then set to logic high, pin 21 is pulsed low

to accept the control byte. Pin 22 is then pulsed low

and held low until the status lines return high

(~2ms). Pin 21 is then pulsed high and pin 25 is

then returned to logic low. The ADC150 has now

been reset to the new parameters. See figure 6 for

timing diagrams.

The mode control byte is defined as follows:

Bits 7 and 6 - unused

Bits 5 and 4 - 00 Pin 39 signal input, autozero*

01 Pin 38 signal input

Bit 3 - 0 60 Hz.*

1 50 Hz.

Bits 2,1, 0 - 001 18 Bit

010 20 Bit

011 22 Bit*

100 24 Bit

* Factory default settings

AUTO-ZERO / RESET (Pin 29)

A logic zero on this input will autozero the ADC150

by internally connecting the analog high to analog

low. Since the µP is reset, the ADC150 reverts to

the factory default settings in the EPROM (ie.

22bits, 60Hz, pin 39 analog high). To select a

mode different than the default settings, the mode

control must be set after auto zero. See figure 3 for

timing diagrams.

INTEGRATION CAPACITOR (Pin 34, 35)

A 0.68 µF polystyrene or Mylar must be connected

to these pins. Lead length should be as short as

possible and not exceed 2".

ANALOG INPUTS (Pin 39, 40)

Both analog inputs are buffered by op-amps and

have a common mode rejection of approximately

80dB minimum. To maintain the full accuracy at the

ADC it is recommended to keep the input to analog

low to less than 0.1VDC.

ADC150DS REV. F MAR 00

Page 6

OUTPUT DATA REPRESENTATION

The output data is represented in BOB (Bipolar Offset Binary)

format. The table below shows the output data codes for zero

and plus-minus full scale input voltage for the programmable

resolution of the converter.

24 Bits

1 LSB = 1.24 µV

22 Bits

1 LSB = 5 µV

20 Bits

1 LSB = 20 µV

Input Voltage

-10.485760 V

0.0 V

+10.485755 V

Input Voltage

-10.485760 V

0.0 V

+10.485755 V

Input Voltage

-10.485760 V

0.0 V

+10.485755 V

Output Data

High Byte Middle Byte Low Byte

00

80

FF

High Byte Middle Byte Low Byte

00

20

3F

High Byte Middle Byte Low Byte

00

08

10

00

00

FF

Output Data

00

00

FF

Output Data

00

00

FF

00

00

FF

00

00

FF

00

00

FF

18 Bits

1 LSB = 80 µV

FIGURE 2

Input Voltage

-10.485760 V

0.0 V

+10.485755 V

Output Data

High Byte Middle Byte Low Byte

00

02

04

00

00

FF

00

00

FF

ADC150DS REV. F MAR 00

Page 7

TIMING DIAGRAMS

CONVERT

AZ

S1

S0

t

TRST

Symbol Parameter Min. Typ. Max. Unit

t

AZD

t

TRST

t

AZ

FIGURE 3. AUTO ZERO

→

→

→

t

AZD

→

t

AZ

AZ Pulse Width 0.2 µs

Tristate Time 30 ms

AZ Time 400 ms

→

→

t

CONZ

CONVERT

S1

t

→

SZ

→

S0

Symbol Parameter Min. Typ. Max. Unit

t

CONZ

t

SZ

t

CONV

Convert Pulse 5.0 µs

Status Delay 8.0 µs

Convert Time 320 ms

FIGURE 4. CONVERSION (22 Bits)

t

CONV

ADC150DS REV. F MAR 00

Page 8

OE

TIMING DIAGRAMS

D0 - D7

CONVERT

t

→

OEDV

S1

S0

Symbol Parameter Min. Typ. Max. Unit

t

OEDV

t

SIR

FIGURE 5. DATA OUTPUT

OE

MSB

MIB

LSB

→

t

SIR

OE Delay 45 ns

Status Delay 3.0 µs

→

→

→

→

t

SIR

CNVRT

t

S1

OEDV

S0

MODE

Symbol Parameter Min. Typ. Max. Unit

t

SIR

t

SL

t

OEDV

FIGURE 6. MODE CHANGE

→

→

→

t

→

SL

→

t

→

SIR

Status Delay 8.0 µs

Status Low 100 ms

OE Delay 45 ns

ADC150DS REV. F MAR 00

Page 9

RESOLUTION

LINE CYCLES

CONV. / SEC (60/50 Hz)

18 BITS

20 BITS

22 BITS

24 BITS

Line Cycle at 60 Hz = 16.667 ms; 50 Hz = 20 ms

FIGURE 7. INTEGRATION TIMES

16

64

1

4

60 / 50

15 / 12

3.7 / 3.1

1.2 / .93

40-PIN HYBRID PACKAGE

INCHES

DIM

E

D

A

L

B2

B

MIN

1.080

2.075

0.155

0.220

.100 typ

.018 typ

MAX

1.100

2.115

0.185

0.240

FIGURE 8. MECHANICAL SPECIFICATIONS

Q

C

P

G1

B1

NOTES:

1. GOLD PLATING 60 MICRO INCHES MINIMUM

THICKNESS OVER 100 MICRO INCHES NOMINAL

THICKNESS OF NICKEL

.015

.009

.012

.890

.040 typ

.035

.012

.018

.910

ADC150DS REV. F MAR 00

Loading...

Loading...