Page 1

ADC12L030/ADC12L032/ADC12L034/ADC12L038

3.3V Self-Calibrating 12-Bit Plus Sign Serial I/O A/D

Converters with MUX and Sample/Hold

June 1999

ADC12L030/ADC12L032/ADC12L034/ADC12L038 3.3V Self-Calibrating 12-Bit Plus Sign Serial I/O

A/D Converters with MUX and Sample/Hold

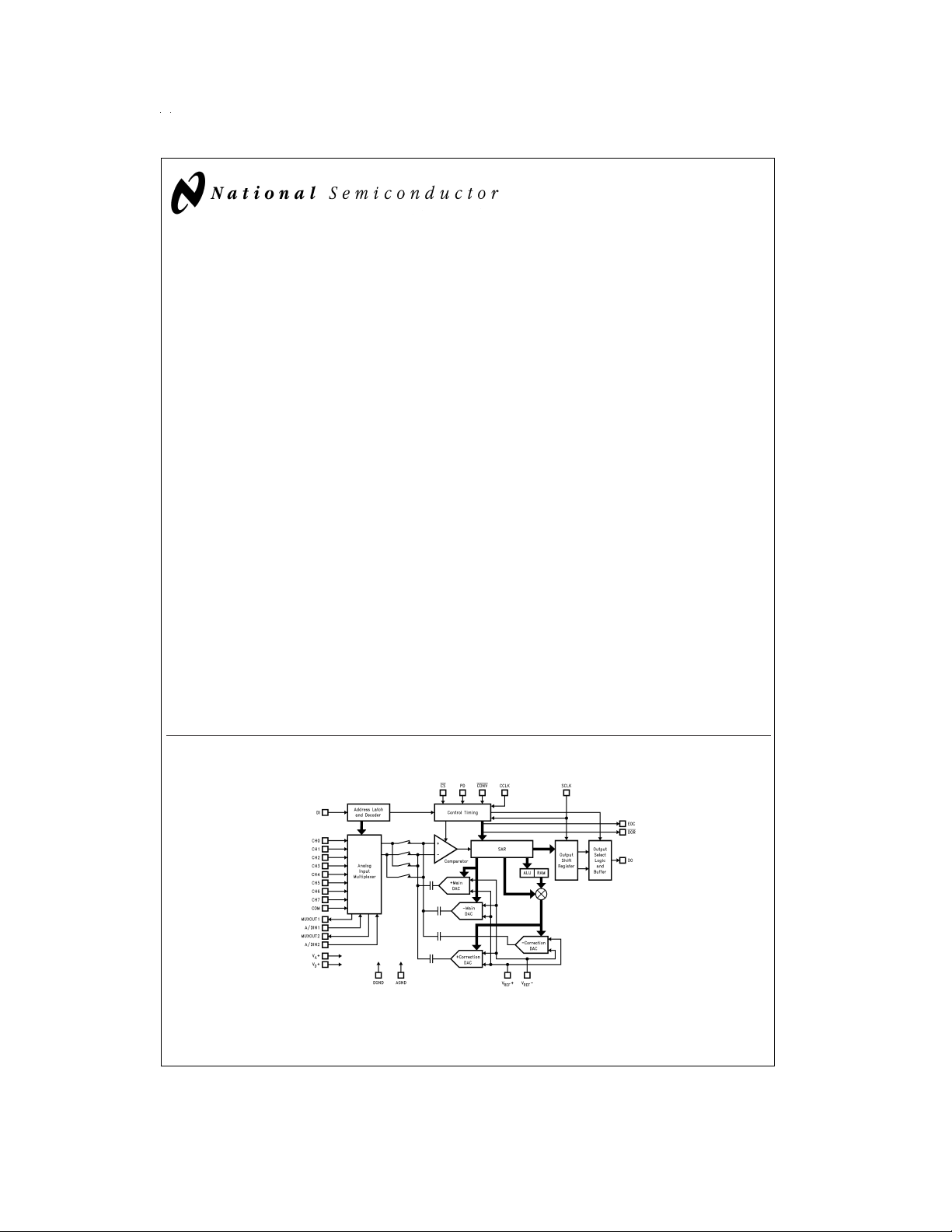

General Description

The ADC12L030 family is 12-bit plus sign successive approximation A/D converters with serial I/O and configurable

input multiplexers. These devices are fully tested with a

single 3.3Vpowersupply. TheADC12L032,ADC12L034 and

ADC12L038 have 2, 4 and 8 channel multiplexers, respectively. Differential multiplexer outputs and A/D inputs are

available on the MUXOUT1, MUXOUT2, A/DIN1 and A/DIN2

pins. The ADC12L030 has a two channel multiplexer withthe

multiplexer outputs and A/D inputs internally connected. On

request, these A/Ds go through a self calibration process

that adjusts linearity, zero and full-scale errors to less than

1

±

⁄2LSB each.

The analog inputs can be configured to operate in various

combinations of single-ended, differential, or

pseudo-differential modes.A fully differential unipolar analog

input range (0V to +3.3V) can be accommodated with a

single +3.3V supply. In the differential modes, valid outputs

are obtained even when the negative inputs are greater than

the positive because of the 12-bit plus sign two’s compliment

output data format.

The serial I/O is configured to comply with NSC’s

MICROWIRE

references, see the LM4040 or LM4041 data sheets.

™

and Motorola’s SPI standards. For voltage

ADC12L038 Simplified Block Diagram

Features

n 0V to 3.3V analog input range with single 3.3V power

supply

n Serial I/O ( MICROWIRE and SPI Compatible)

n 2, 4, or 8 channel differential or single-ended multiplexer

n Analog input sample/hold function

n Power down mode

n Variable resolution and conversion rate

n Programmable acquisition time

n Variable digital output word length and format

n No zero or full scale adjustment required

n Fully tested and guaranteed with a 2.5V reference

n No Missing Codes over temperature

Key Specifications

n Resolution 12-bit plus sign

n 12-bit plus sign conversion time 8.8 µs (min)

n 12-bit plus sign sampling rate 73 kHz (max)

n Integral linearity error

n Single supply 3.3V

n Power dissipation 15 mW (max)

n Power down 40 µW (typ)

±

1 LSB (max)

±

10

Applications

n Portable Medical instruments

n Portable computing

n Portable Test equipment

%

DS011830-1

TRI-STATE®is a registered trademark of National Semiconductor Corporation.

™

COPS

microcontrollers, HPC™and MICROWIRE™are trademarks of National Semiconductor Corporation.

™

Microsoft

is a trademark of Microsoft Corporation.

© 1999 National Semiconductor Corporation DS011830 www.national.com

Page 2

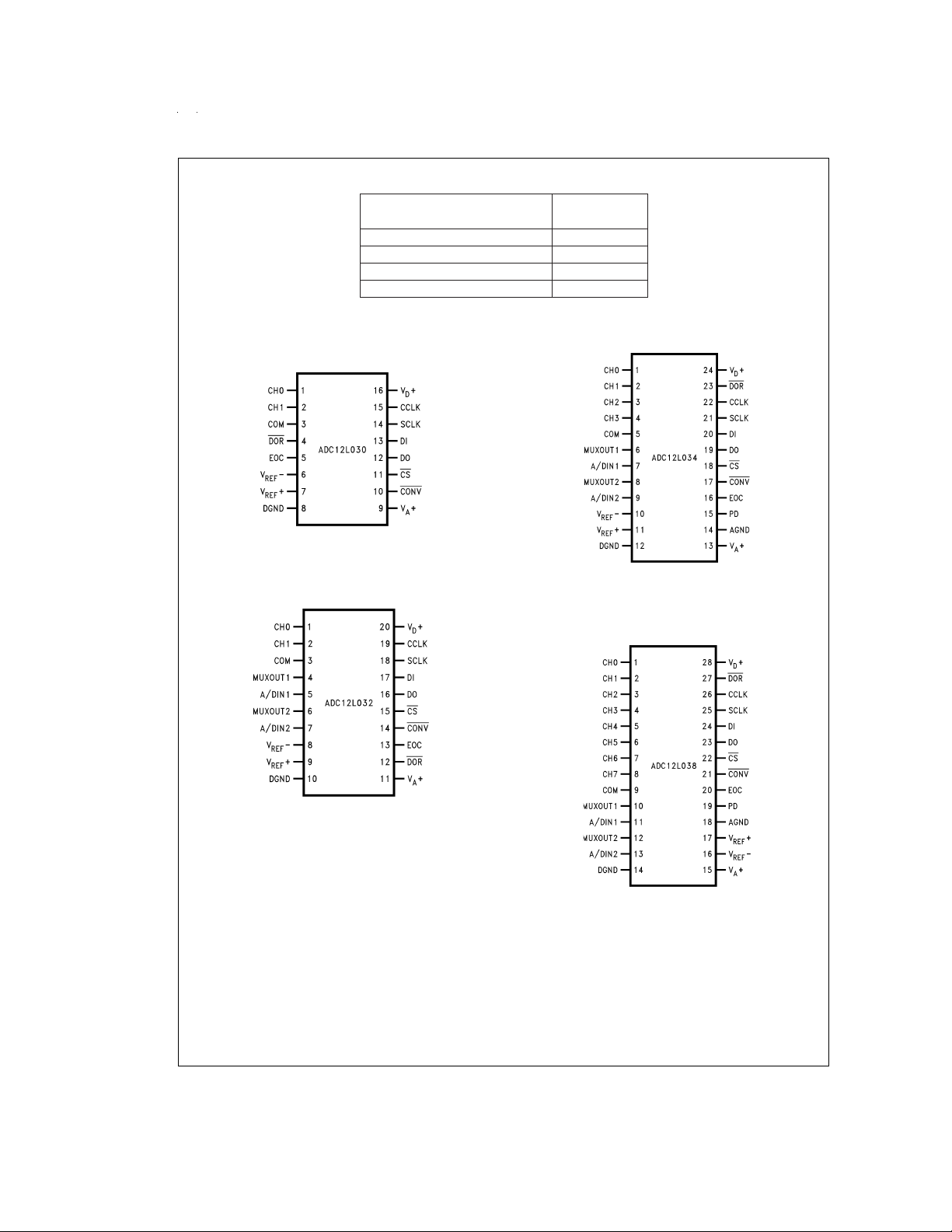

Ordering Information

Industrial Temperature Range NS Package

−40˚C ≤ T

≤ +85˚C Number

A

ADC12L030CIWM M16B

ADC12L032CIWM M20B

ADC12L034CIWM M24B

ADC12L038CIWM M28B

Connection Diagrams

16-Pin Wide Body

SO Packages

Top View

20-Pin Wide Body

SO Packages

24-Pin Wide Body

SO Packages

DS011830-2

DS011830-4

Top View

248-Pin Wide Body

SO Packages

DS011830-3

Top View

www.national.com 2

DS011830-5

Top View

Page 3

Pin Descriptions

CCLK The clock applied to this input controls the su-

SCLK This is the serial data clock input. The clock

DI This is the serial data input pin. The data ap-

DO The data output pin. This pin is an active push/

EOC This pin is an active push/pull output and indi-

CS

cessive approximation conversion time interval

and the acquisition time. The rise and fall times

of the clock edges should not exceed 1 µs.

applied to this input controls the rate at which

the serial data exchange occurs. The rising

edge loads the information on the DI pin into

the multiplexer address and mode select shift

register. This address controls which channel

of the analog input multiplexer (MUX) is selected and the mode of operation for the A/D.

With CS low the falling edge of SCLK shifts the

data resulting from the previous ADC conversion out on DO, with the exception of the first

bit of data. When CS is low continuously, the

first bit of the data is clocked out on the rising

edge of EOC (end of conversion). When CS is

toggled the falling edge of CS always clocks

out the first bit of data. CS should be brought

low when SCLK is low. The rise and fall times

of the clock edges should not exceed 1 µs.

plied to this pin is shifted by the rising edge of

SCLK into the multiplexer address and mode

select register.

Tables 2, 3, 4, 5

show the assignment of the multiplexer address and the

mode select data.

pull output when CS is Low. When CS is High

this output is in TRI-STATE. The A/D conversion result(D0–D12) and converter status data

are clocked out by the falling edge of SCLK on

this pin. The word length and format of this result can vary (see

Table 1

). The word length

and format are controlled by the data shifted

into the multiplexer address and mode select

register (see

Table 5

).

cates the status of the ADC12L030/2/4/8.

When low, it signals that the A/D is busy with a

conversion, auto-calibration, auto-zero or

power down cycle. The rising edge of EOC signals the end of one of these cycles.

This is the chip select pin. When a logic low is

applied to this pin, the rising edge of SCLK

shifts the data on DI into the address register.

This low also brings DO out of TRI-STATE.

With CS low the falling edge of SCLK shifts the

data resulting from the previous ADC conversion out on DO, with the exception of the first

bit of data. When CS is low continuously, the

first bit of the data is clocked out on the rising

edge of EOC (end of conversion). When CS is

toggled the falling edge of CS always clocks

out the first bit of data. CS should be brought

low when SCLK is low. The falling edge of CS

resets a conversion in progress and starts the

sequence for a new conversion. When CS is

brought back low during a conversion, that

conversion is prematurely ended. The data in

the output latches may be corrupted. Therefore, when CS is brought back low during a

conversion in progress the data output at that

time should be ignored. CS may also be left

continuously low. In this case it is imperative

that the correct number of SCLK pulses be applied to the ADC in order to remain synchronous. After theADC supply power is applied, it

expects to see 13 clock pulses for each I/O sequence. The number of clock pulses the ADC

expects is the same as the digital output word

length. This word length can be modified by

the data shifted in on the DO pin.

Table 5

de-

tails the data required.

DOR

This is the data output ready pin. This pin is an

active push/pull output. It is low when the conversion result is being shifted out and goes

high to signal that all the data has been shifted

out.

CONV

A logic low is required on this pin to program

any mode or change the ADC’s configuration

as listed in the Mode Programming Table

(

Table 5

) such as 12-bit conversion, 8-bit conversion,Auto Cal, Auto Zero etc. When this pin

is high the ADC is placed in the read data only

mode. While in the read data only mode, bringing CS low and pulsing SCLK will only clock

out on DO any data stored in the ADCs output

shift register. The data on DI will be neglected.

A new conversion will not be started and the

ADC will remain in the mode and/or configuration previously programmed. Read data only

cannot be performed while a conversion,

Auto-Cal or Auto-Zero are in progress.

PD This is the power down pin. When PD is high

the A/D is powered down; when PD is low the

A/D is powered up. The A/D takes a maximum

of 700 µs to power up after the command is

given.

CH0–CH7 These are the analog inputs of the MUX. A

channel input is selected by the address information at the DI pin, which is loaded on the rising edge of SCLK into the address register

(see

Tables 2, 3, 4

).

The voltage applied to these inputs should not

exceed V

range on an unselected channel will corrupt

+ or go below GND. Exceeding this

A

the reading of a selected channel.

COM This pin is another analog input pin. It is used

as a pseudo ground when the analog multiplexer is single-ended.

MUXOUT1,

MUXOUT2

A/DIN1,

A/DIN2

These are the multiplexer output

pins.

These are the converter input pins. MUXOUT1

is usually tied to A/DIN1. MUXOUT2 is usually

tied toA/DIN2. If external circuitry is placed between MUXOUT1 and A/DIN1, or MUXOUT2

and A/DIN2 it may be necessary to protect

these pins. The voltage at these pins should

not exceed V

5

).

+ This is the positive analog voltage reference

V

REF

input. In order to maintain accuracy the voltage

range of V

+

or go belowAGND (see

A

=

REF(VREF

V

REF

+−V

REF

Figure

−) is

www.national.com3

Page 4

Pin Descriptions (Continued)

1V

to 3.3 VDCand the voltage at V

DC

not exceed V

mended bypassing.

V

− The negative voltage reference input. In order

REF

to maintain accuracy the voltage at this pin

+. See

A

Figure 6

must not go below GND or exceed V

Figure 6

).

+, VD+ These are the analog and digital power supply

V

A

+

pins. V

A

on the chip. These pins should be tied to the

+

and V

are not connected together

D

same power supply and bypassed separately

(see

Figure 6

V

+ and VD+ is 3.0 VDCto 5.5 VDC.

A

). The operating voltage range of

DGND This is the digital ground pin (see

AGND This is the analog ground pin (see

REF

for recom-

A

Figure 6

Figure 6

+ can-

+. (See

).

).

www.national.com 4

Page 5

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Positive Supply Voltage

+

=

+=VD+) 6.5V

V

(V

Voltage at Inputs and Outputs

Voltage at Analog Inputs

|V

Input Current at Any Pin (Note 3)

Package Input Current (Note 3)

Package Dissipation at

A

+

except CH0–CH7 and COM −0.3V to V

CH0–CH7 and COM GND −5V to V

+−VD+| 300 mV

A

=

25˚C (Note 4) 500 mW

T

A

+0.3V

+

±

30 mA

±

120 mA

+5V

Operating Ratings (Notes 1, 2)

Operating Temperature Range T

ADC12L030CIWM,

ADC12L032CIWM,

ADC12L034CIWM,

ADC12L038CIWM −40˚C ≤ T

Supply Voltage

+

=

+=VD+) +3.0V to +5.5V

V

(V

A

+−VD+| ≤ 100 mV

|V

A

+ 0VtoVA+

V

REF

− 0VtoV

V

REF

V

REF(VREF

V

REF

+−V

−) 1V to VA+

REF

Common Mode Voltage Range

ESD Susceptability (Note 5)

Human Body Model 1500V

Soldering Information

N Packages (10 seconds) 260˚C

SO Package (Note 6):

A/DIN1, A/DIN2, MUXOUT1

and MUXOUT2 Voltage Range 0V to V

A/D IN Common Mode Voltage Range

Vapor Phase (60 seconds) 215˚C

Infrared (15 seconds) 220˚C

Storage Temperature −65˚C to +150˚C

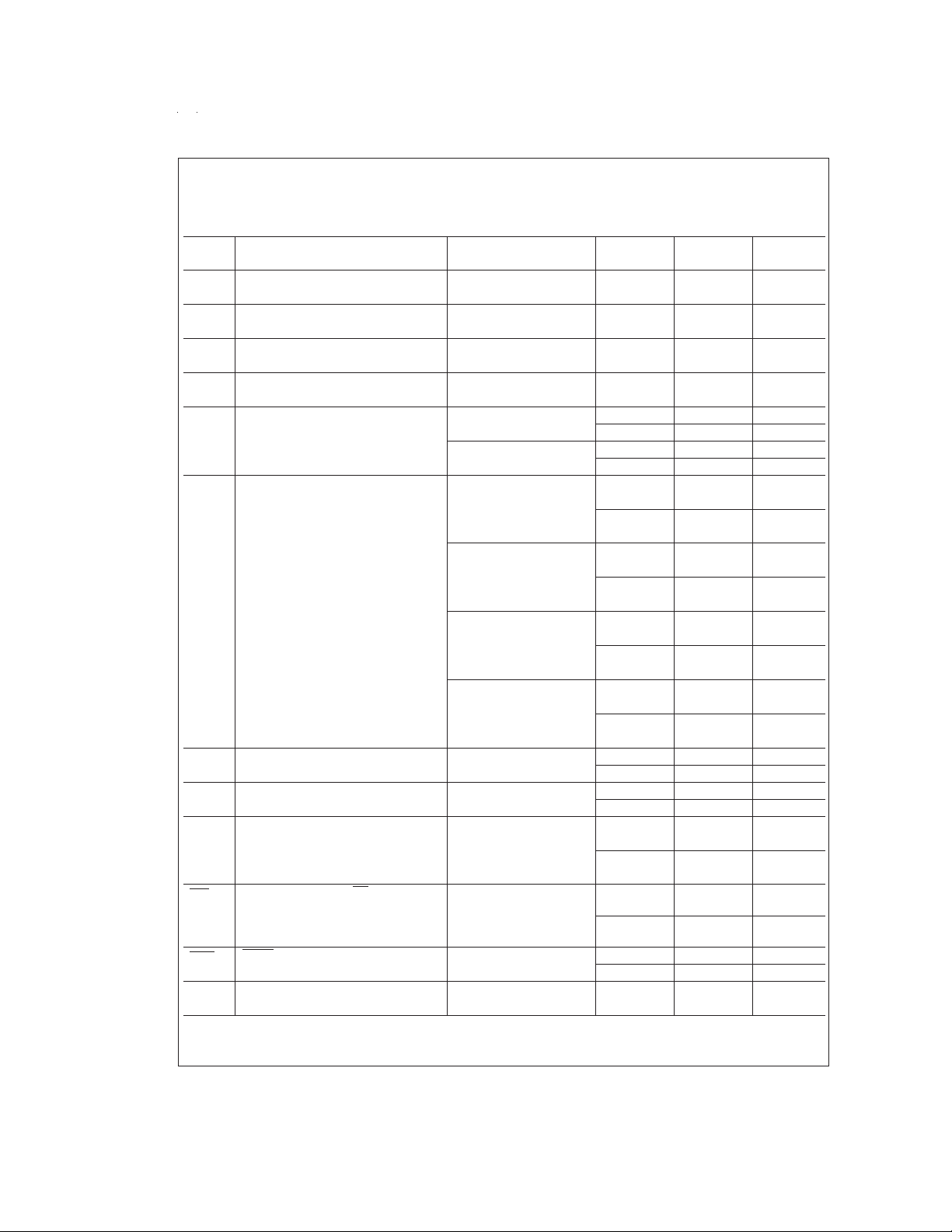

Converter Electrical Characteristics

The following specifications apply for V

sion mode, f

1.250V common-mode voltage, and 10(t

to T

T

MIN

Symbol Parameter Conditions Typical

=

f

CK

SK

; all other limits T

MAX

=

5 MHz, R

+

=

+=VD+=+3.3 VDC,V

V

A

=

25Ω, source impedance for V

S

) acquisition time unless otherwise specified. Boldface limits apply for T

CK

=

=

T

25˚C. (Notes 7, 8, 9)

A

J

+=+2.500 VDC,V

REF

+ and V

REF

REF

− ≤ 25Ω, fully-differential input with fixed

REF

(Note 10)

STATIC CONVERTER CHARACTERISTICS

Resolution with No Missing Codes 12 + sign Bits (min)

+ILE Positive Integral Linearity Error After Auto-Cal (Notes 12, 18)

−ILE Negative Integral Linearity Error After Auto-Cal (Notes 12, 18)

±

1/2

±

1/2

DNL Differential Non-Linearity After Auto-Cal

Positive Full-Scale Error After Auto-Cal (Notes 12, 18)

Negative Full-Scale Error After Auto-Cal (Notes 12, 18)

Offset Error After Auto-Cal (Notes 5, 18)

V

(+)=VIN(−)=1.250V

IN

DC Common Mode Error After Auto-Cal (Note 15)

TUE Total Unadjusted Error After Auto-Cal

±

1/2

±

1/2

±

1/2

±

2

±

1 LSB

(Notes 12, 13, 14)

Resolution with No Missing Codes 8-bit + sign mode 8 + sign Bits (min)

+INL Positive Integral Linearity Error 8-bit + sign mode (Note 12)

−INL Negative Integral Linearity Error 8-bit + sign mode (Note 12)

DNL Differential Non-Linearity 8-bit + sign mode

Positive Full-Scale Error 8-bit + sign mode (Note 12)

Negative Full-Scale Error 8-bit + sign mode (Note 12)

Offset Error 8-bit + sign mode,

after Auto-Zero (Note 13)

V

(+)=VIN(−)=+ 1.250V

IN

TUE Total Unadjusted Error 8-bit + sign mode

after Auto-Zero

(Notes 12, 13, 14)

≤ TA≤ T

MIN

≤ +85˚C

A

MAX

REF

−=0VDC, 12-bit + sign conver-

=

=

T

A

J

Limits Units

(Note 11)

±

1 LSB (max)

±

1 LSB (max)

±

1 LSB (max)

±

2 LSB (max)

±

2 LSB (max)

±

2 LSB (max)

±

3.5 LSB (max)

±

1/2 LSB (max)

±

1/2 LSB (max)

±

3/4 LSB (max)

±

1/2 LSB (max)

±

1/2 LSB (max)

±

1/2 LSB (max)

±

3/4 LSB (max)

(Limits)

+

+

A

www.national.com5

Page 6

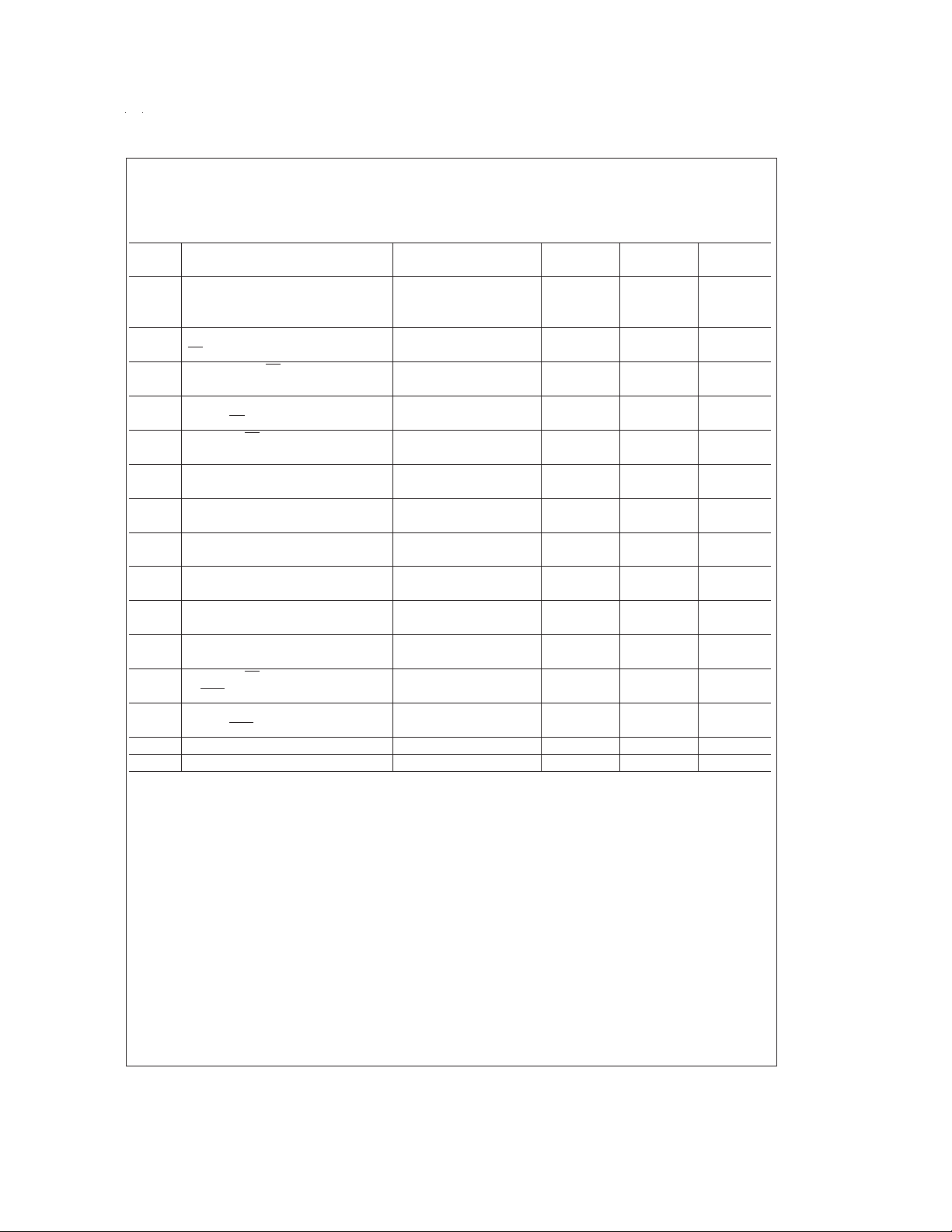

Converter Electrical Characteristics (Continued)

+

The following specifications apply for V

sion mode, f

1.250V common-mode voltage, and 10(t

to T

T

MIN

=

f

CK

SK

; all other limits T

MAX

=

5 MHz, R

A

Symbol Parameter Conditions Typical

STATIC CONVERTER CHARACTERISTICS

Multiplexer Channel to Channel

Matching

Power Supply Sensitivity V

+ Full-Scale Error

− Full-Scale Error

+ Integral Linearity Error

− Integral Linearity Error

Output Data from (Note 20) +10 LSB (max)

“12-Bit Conversion of Offset” −10 LSB (min)

(see

Table 5

)

Output Data from (Note 20) 4095 LSB (max)

“12-Bit Conversion of Full-Scale” 4093 LSB (min)

(see

Table 5

)

UNIPOLAR DYNAMIC CONVERTER CHARACTERISTICS

S/(N+D) Signal-to-Noise Plus f

Distortion Ratio f

−3 dB Full Power Bandwidth V

DIFFERENTIAL DYNAMIC CONVERTER CHARACTERISTICS

S/(N+D) Signal-to-Noise Plus f

Distortion Ratio f

−3 dB Full Power Bandwidth V

REFERENCE INPUT, ANALOG INPUTS AND MULTIPLEXER CHARACTERISTICS

C

REF

C

A/D

Reference Input Capacitance 85 pF

A/DIN1 and A/DIN2 Analog Input 75 pF

Capacitance

A/DIN1 and A/DIN2 Analog Input V

Leakage Current V

CH0–CH7 and COM Input Voltage GND − 0.05 V (min)

C

CH

C

MUXOUT

CH0–CH7 and COM Input

Capacitance

MUX Output Capacitance 20 pF

Off Channel Leakage (Note 16) On Channel=3.3V and −0.01 −0.3 µA (min)

CH0–CH7 and COM Pins Off Channel=0V

On Channel Leakage (Note 16) On Channel=3.3V and 0.01 0.3 µA (max)

CH0–CH7 and COM Pins Off Channel=0V

=

+=VD+=+3.3 VDC,V

V

A

=

25Ω, source impedance for V

S

) acquisition time unless otherwise specified. Boldface limits apply for T

CK

=

=

T

25˚C. (Notes 7, 8, 9)

J

+

=

Offset Error

=

IN

=

IN

=

f

IN

IN

drops 3 dB

=

IN

=

IN

=

f

IN

IN

drops 3 dB

IN

IN

On Channel=0V and 0.01 0.3 µA (max)

Off Channel=3.3V

On Channel=0V and −0.01 −0.3 µA (min)

Off Channel=3.3V

REF

REF

±

%

10

+3.3V

1 kHz, V

20 kHz, V

40 kHz, V

=

2.5 V

1 kHz, V

20 kHz, V

40 kHz, V

=

±

=

+3.3V or

=

0V

=

IN

=

IN

=

IN

, where S/(N+D)

PP

=

IN

=

IN

=

IN

2.5V, where S/(N+D)

+=+2.500 VDC,V

+ and V

− ≤ 25Ω, fully-differential input with fixed

REF

REF

(Note 10)

±

0.05 LSB

±

0.5

±

0.5

±

0.5

±

0.5 LSB

±

0.5 LSB

2.5 V

2.5 V

2.5 V

PP

PP

PP

69.4 dB

68.3 dB

65.7 dB

31 kHz

±

2.5V 77.0 dB

±

2.5V 73.9 dB

±

2.5V 67.0 dB

40 kHz

±

0.1

10 pF

−=0VDC, 12-bit + sign conver-

=

=

T

A

J

Limits Units

(Note 11)

±

1 LSB (max)

±

1.5 LSB (max)

±

1.5 LSB (max)

±

1.0 µA (max)

V

+ + 0.05 V (max)

A

(Limits)

www.national.com 6

Page 7

Converter Electrical Characteristics (Continued)

+

The following specifications apply for V

sion mode, f

1.250V common-mode voltage, and 10(t

to T

T

MIN

=

f

CK

SK

; all other limits T

MAX

=

5 MHz, R

A

Symbol Parameter Conditions Typical

REFERENCE INPUT, ANALOG INPUTS AND MULTIPLEXER CHARACTERISTICS

MUXOUT1 and MUXOUT2 V

Leakage Current V

R

ON

MUX On Resistance V

R

Matching Channel to Channel V

ON

Channel to Channel Crosstalk V

MUX Bandwidth 90 kHz

=

+=VD+=+3.3 VDC,V

V

A

=

25Ω, source impedance for V

S

) acquisition time unless otherwise specified. Boldface limits apply for T

CK

=

=

T

25˚C. (Notes 7, 8, 9)

J

MUXOUT

MUXOUT

IN

V

MUXOUT

IN

V

MUXOUT

IN

+=+2.500 VDC,V

REF

REF

+ and V

REF

REF

− ≤ 25Ω, fully-differential input with fixed

(Note 10)

=

3.3V or 0.01 0.3 µA (max)

=

0V

=

1.65V and 1300 1900 Ω (max)

=

1.55V

=

1.65V and 5

=

1.55V

=

3.3 V

=

40 kHz −72 dB

PP,fIN

−=0VDC, 12-bit + sign conver-

=

=

T

A

J

Limits Units

(Note 11)

(Limits)

%

DC and Logic Electrical Characteristics

The following specifications apply for V

sion mode, f

1.250V common-mode voltage, and 10(tCK) acquisition time unless otherwise specified. Boldface limits apply for T

to T

T

MIN

=

f

CK

SK

; all other limits T

MAX

=

5 MHz, R

+

=

+=VD+=+3.3 VDC,V

V

A

=

25Ω, source impedance for V

S

=

=

T

25˚C. (Notes 7, 8, 9)

A

J

+=+2.500 VDC,V

REF

+ and V

REF

−=0VDC, 12-bit + sign conver-

REF

− ≤ 25Ω, fully-differential input with fixed

REF

=

=

T

A

J

Symbol Parameter Conditions Typical Limits Units

(Note 10) (Note 11) (Limits)

CCLK, CS, CONV, DI, PD AND SCLK INPUT CHARACTERISTICS

+

V

V

I

I

IN(1)

IN(0)

Logical “1” Input Voltage V

IN(1)

Logical “0” Input Voltage V

IN(0)

Logical “1” Input Current V

Logical “0” Input Current V

=

3.6V 2.0 V (min)

+

=

3.0V 0.8 V (max)

=

3.3V 0.005 1.0 µA (max)

IN

=

0V −0.005 −1.0 µA (min)

IN

DO, EOC AND DOR DIGITAL OUTPUT CHARACTERISTICS

V

V

I

+I

−I

OUT

Logical “1” Output Voltage V

OUT(1)

Logical “0” Output Voltage V

OUT(0)

TRI-STATE®Output Current V

Output Short Circuit Source Current V

SC

Output Short Circuit Sink Current V

SC

=

3.0V, I

+

=

V

3.0V, I

+

=

3.0V, I

=

OUT

=

V

OUT

=

OUT

=

OUT

=

−360 µA 2.4 V (min)

OUT

=

−10µA 2.9 V (min)

OUT

=

1.6 mA 0.4 V (max)

OUT

0V −0.1 −3.0 µA (max)

3.3V 0.1 3.0 µA (max)

0V 14 6.5 mA (min)

+168.0 mA (min)

V

D

+

POWER SUPPLY CHARACTERISTICS

I

+ Digital Supply Current Awake 1.1 1.5 mA (max)

D

I

+ Positive Analog Supply Current Awake 2.2 3.0 mA (max)

A

I

REF

Reference Input Current Awake 70 µA

CS=HIGH, Powered Down, CCLK on

CS=HIGH, Powered Down, CCLK off

CS=HIGH, Powered Down, CCLK on

CS=HIGH, Powered Down, CCLK off

CS=HIGH, Powered Down

600 µA

12 µA

10 µA

0.1 µA

0.1 µA

www.national.com7

Page 8

AC Electrical Characteristics

The following specifications apply for V

sion mode, t

with fixed 1.250V common-mode voltage, and 10(t

=

T

J

=

=

t

3 ns, f

r

f

=

to T

T

MIN

CK

; all other limits T

MAX

+

=

=

5 MHz, R

=

A

A

=

25Ω, source impedance for V

S

) acquisition time unless otherwise specified. Boldface limits apply for T

CK

=

T

25˚C. (Note 17)

J

=

f

SK

+=VD+=+3.3 VDC,V

V

+=+2.500 VDC,V

REF

REF

+ and V

−=0VDC, 12-bit + sign conver-

REF

− ≤ 25Ω, fully-differential input

REF

Symbol Parameter Conditions Typical Limits Units

(Note 10) (Note 11) (Limits)

f

CK

Conversion Clock (CCLK) Frequency 10 5 MHz (max)

1 MHz (min)

f

SK

Serial Data Clock SCLK Frequency 10 5 MHz (max)

0 Hz (min)

Conversion Clock Duty Cycle 40

60

Serial Data Clock Duty Cycle 40

60

t

C

Conversion Time 12-Bit + Sign or 12-Bit 44(tCK) 44(tCK) (max)

%

%

%

%

(min)

(max)

(min)

(max)

8.8 µs (max)

8-Bit + Sign or 8-Bit 21(t

) 21(tCK) (max)

CK

4.2 µs (max)

t

A

Acquisition Time 6 Cycles Programmed 6(tCK) 6(tCK) (min)

(Note 19) 7(t

) (max)

CK

1.2 µs (min)

1.4 µs (max)

10 Cycles Programmed 10(t

) 10(tCK) (min)

CK

11(t

) (max)

CK

2.0 µs (min)

2.2 µs (max)

18 Cycles Programmed 18(t

) 18(tCK) (min)

CK

19(t

) (max)

CK

3.6 µs (min)

3.8 µs (max)

34 Cycles Programmed 34(t

) 34(tCK) (min)

CK

35(t

) (max)

CK

6.8 µs (min)

7.0 µs (max)

t

CAL

Self-Calibration Time 4944(tCK) 4944(tCK) (max)

988.8 µs (max)

t

AZ

Auto-Zero Time 76(tCK) 76(tCK) (max)

15.2 µs (max)

t

SYNC

Self-Calibration or Auto-Zero 2(tCK) 2(tCK) (min)

Synchronization Time 3(t

) (max)

CK

from DOR 0.40 µs (min)

0.60 µs (max)

t

DOR

DOR High Time when CS is Low

Continuously

for Read Data and Software Power

9(t

) 9(tSK) (max)

SK

1.8 µs (max)

Up/Down

t

CONV

CONV Valid Data Time 8(tSK) 8(tSK) (max)

1.6 µs (max)

t

HPU

Hardware Power-Up Time, Time from 250 700 µs (max)

PD Falling Edge to EOC Rising Edge

A

www.national.com 8

Page 9

AC Electrical Characteristics (Continued)

+

The following specifications apply for V

sion mode, t

with fixed 1.250V common-mode voltage, and 10(t

=

T

J

=

=

t

r

f

=

to T

T

MIN

MAX

=

3 ns, f

CK

; all other limits T

Symbol Parameter Conditions Typical Limits Units

t

SPU

Software Power-Up Time, Time from

EOC Rising Edge

t

ACC

Access Time Delay from 25 60 ns (max)

CS Falling Edge to DO Data Valid

t

SET-UP

Set-Up Time of CS Falling Edge to 50 ns (min)

Serial Data Clock Rising Edge

t

DELAY

Delay from SCLK Falling 0 5 ns (min)

Edge to CS Falling Edge

t1H,t0HDelay from CS Rising Edge to R

DO TRI-STATE

t

HDI

DI Hold Time from Serial Data 5 15 ns (min)

Clock Rising Edge

t

SDI

DI Set-Up Time from Serial Data 5 10 ns (min)

Clock Rising Edge

t

HDO

DO Hold Time from Serial Data R

Clock Falling Edge 5 ns (min)

t

DDO

Delay from Serial Data Clock 50 90 ns (max)

Falling Edge to DO Data Valid

t

RDO

DO Rise Time, TRI-STATE to High R

DO Rise Time, Low to High 10 40 ns (max)

t

FDO

DO Fall Time, TRI-STATE to Low R

DO Fall Time, High to Low 15 40 ns (max)

t

CD

Delay from CS Falling Edge 50 80 ns (max)

to DOR Falling Edge

t

SD

Delay from Serial Data Clock Falling 45 80 ns (max)

Edge to DOR Rising Edge

C

IN

C

OUT

Note 1: Absolute Maximum Ratingsindicate limits beyond which damageto the device may occur.Operating Ratings indicate conditions for which the deviceis functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test conditions.

Note 2: All voltages are measured with respect to GND, unless otherwise specified.

Note 3: When the input voltage (V

The 120 mA maximum package input current rating limits the number of pins that can safely exceed the power supplies with an input current of 20 mA to four.

Note 4: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

allowable power dissipation at any temperature is P

T

Capacitance of Logic Inputs 10 pF

Capacitance of Logic Outputs 20 pF

) at any pin exceeds the power supplies (V

IN

max=150˚C. The typical thermal resistance (θJA) of these parts when board mounted follow:

J

f

SK

=

5 MHz, R

A

D

=

+=VD+=+3.3 VDC,V

V

A

=

25Ω, source impedance for V

S

) acquisition time unless otherwise specified. Boldface limits apply for T

=

T

25˚C. (Note 17)

J

CK

=

+=+2.500 VDC,V

REF

REF

+ and V

−=0VDC, 12-bit + sign conver-

REF

− ≤ 25Ω, fully-differential input

REF

(Note 10) (Note 11) (Limits)

500 700 µs (max)Serial Data Clock Falling Edge to

=

=

3k, C

L

=

L

=

L

=

L

=

max − TA)/θJAor the number given in the Absolute Maximum Ratings, whichever is lower. For this device,

(T

J

100 pF 70 100 ns (max)

L

=

3k, C

100 pF 35 65 ns (max)

L

=

3k, C

100 pF 10 40 ns (max)

L

=

3k, C

100 pF 15 40 ns (max)

L

IN

<

GND or V

>

VA+orVD+), the current at that pin should be limited to 20 mA.

IN

max, θJAand the ambient temperature, TA. The maximum

J

A

www.national.com9

Page 10

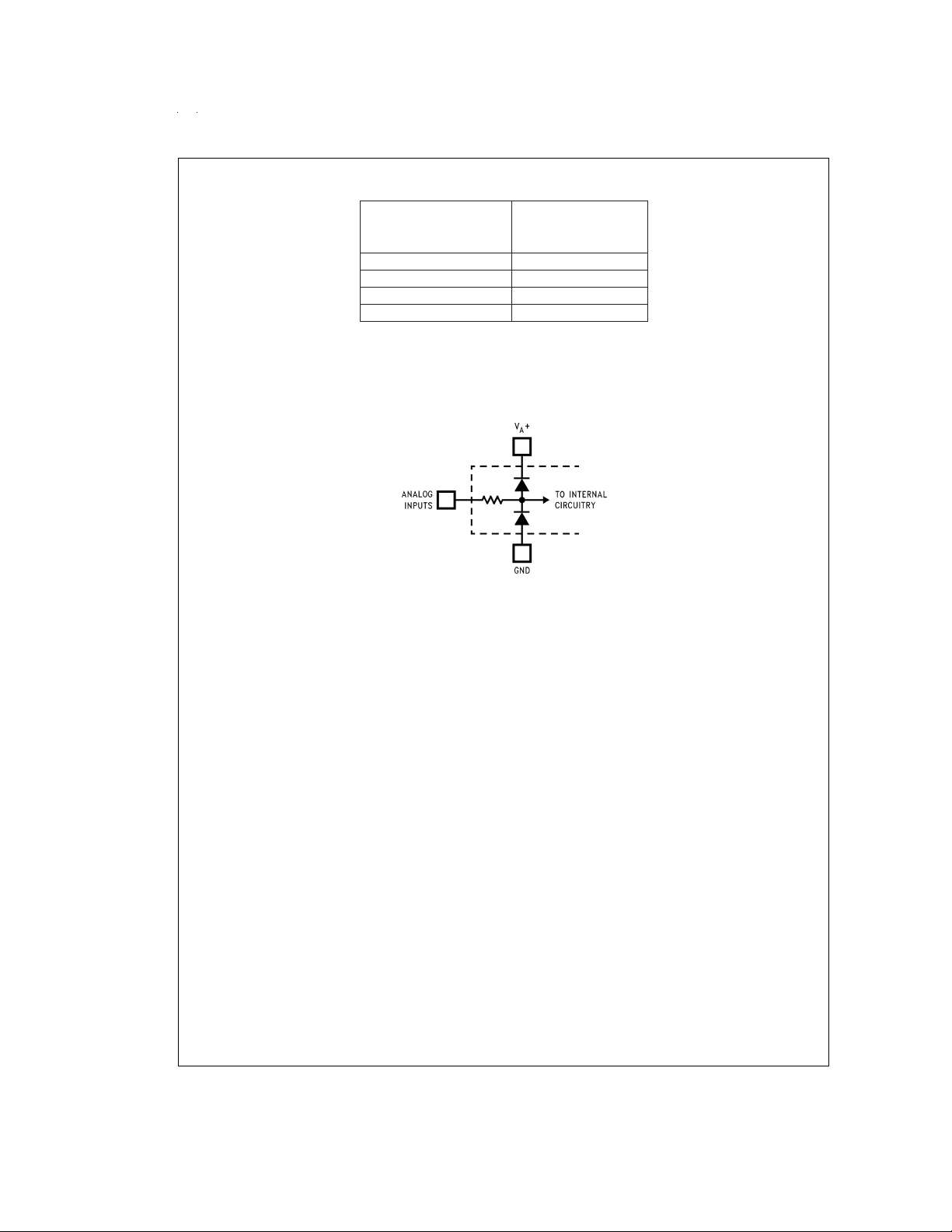

AC Electrical Characteristics (Continued)

Thermal

Part Number Resistance

θ

ADC12L030CIWM 70˚C/W

ADC12L032CIWM 64˚C/W

ADC12L034CIWM 57˚C/W

ADC12L038CIWM 50˚C/W

Note 5: The human body model is a 100 pF capacitor discharged through a 1.5 kΩ resistor into each pin.

Note 6: SeeAN450 “Surface Mounting Methods and Their Effect on Product Reliability” or the section titled “Surface Mount” found in any post 1986 National Semi-

conductor Linear Data Book for other methods of soldering surface mount devices.

Note 7: Twoon-chip diodes are tied to each analog input through a series resistor as shown below. Input voltage magnitude up to 5V above V

will not damage this device. However, errors in theA/D conversion can occur (if these diodes are forward biased by more than 50 mV) if the input voltage magnitude

of selected or unselected analog input go above V

to ensure accurate conversions.

V

DC

Note 8: Toguarantee accuracy, it is required that the V

pin.

Note 9: With the test condition for V

Note 10: Typicals are at T

Note 11: Tested limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

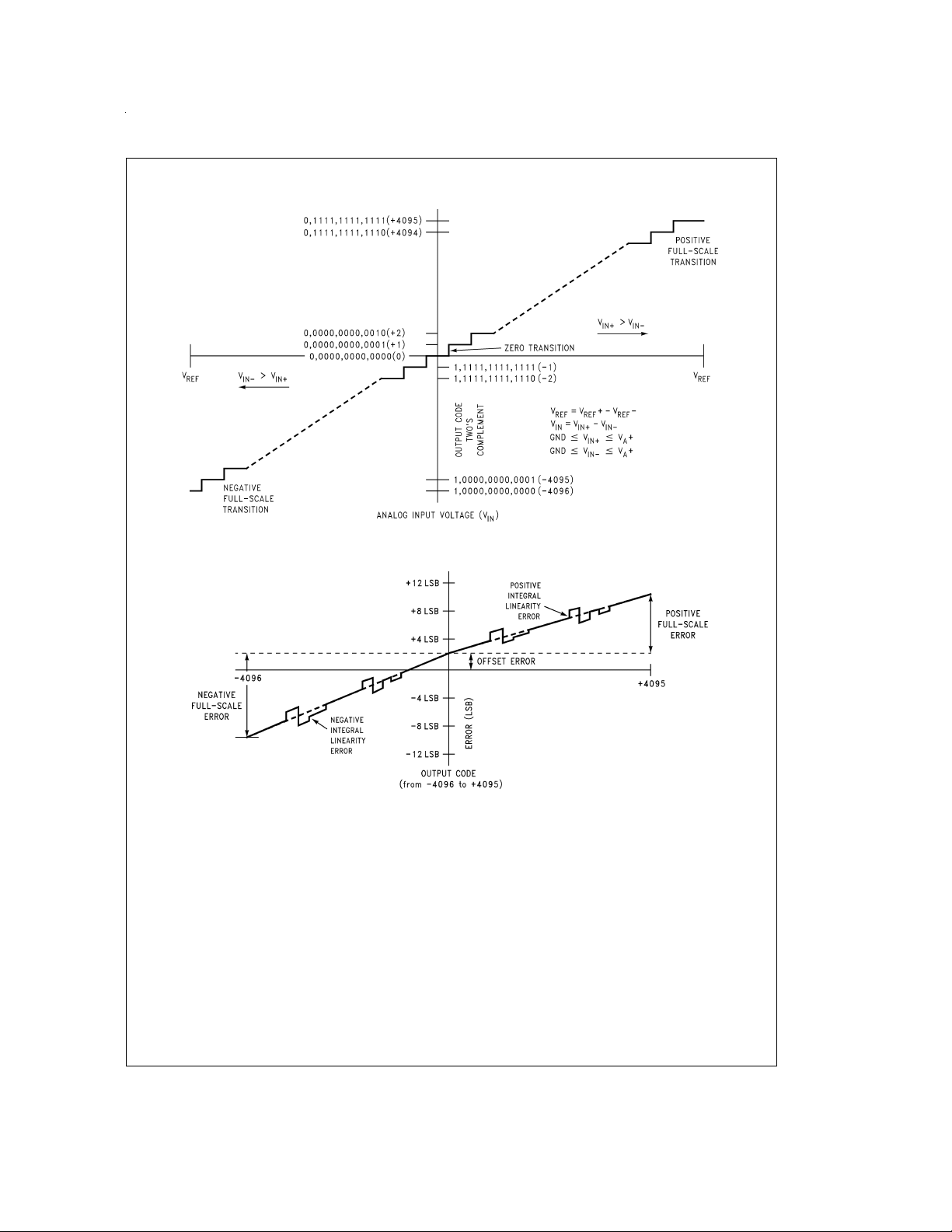

Note 12: Positive integral linearity error is defined as the deviation of the analog value, expressed in LSBs, from the straight line that passes through positive

full-scale and zero. For negative integral linearity error, the straight line passes through negative full-scale and zero (see

Note 13: Zero error is a measure of the deviation from the mid-scale voltage (a code of zero), expressed in LSB. It is the worst-case value of the code transitions

between 1 to 0 and 0 to +1 (see

Note 14: Total unadjusted error includes offset, full-scale, linearity and multiplexer errors.

Note 15: The DC common-mode error is measured in the differential multiplexer mode with the assigned positive and negative input channels shorted together.

Note 16: Channel leakage current is measured after the channel selection.

Note 17: Timing specifications are tested at the TTL logic levels, V

to 1.4V.

Note 18: TheADC12L030 family’s self-calibration technique ensures linearity and offseterrors as specified, but noise inherent in the self-calibration process will re-

sult in a maximum repeatability uncertainty of 0.2 LSB.

Note 19: If SCLK and CCLK are driven from the same clock source, then t

Note 20: The “12-Bit Conversion of Offset” and “12-Bit Conversion of Full-Scale” modes are intended to test the functionality of the device. Therefore, the output

data from these modes are not an indication of the accuracy of a conversion result.

REF(VREF

=

=

T

25˚C and represent most likely parametric norm.

J

A

Figure 4

+ or below GND by more than 50 mV. As an example, if VA+ is 3.0 VDC, full-scale input voltage must be ≤3.05

A

+ and VD+ be connected together to the same power supply with separate bypass capacitors at each V

A

+−V

−) given as +2.500V the 12-bit LSB is 610 µV and the 8-bit LSB is 9.8 mV.

REF

).

=

0.4V for a falling edge and V

IL

is 6, 10, 18 or 34 clock periods minimum and maximum.

A

JA

+ or 5V below GND

A

DS011830-6

Figure 2

and

Figure 3

).

=

2.4V for a rising edge. TRI-STATE output voltage is forced

IH

+

www.national.com 10

Page 11

AC Electrical Characteristics (Continued)

FIGURE 1. Transfer Characteristic

DS011830-7

DS011830-8

FIGURE 2. Simplified Error Curve vs Output Code without Auto-Calibration or Auto-Zero Cycles

www.national.com11

Page 12

AC Electrical Characteristics (Continued)

FIGURE 3. Simplified Error Curve vs Output Code after Auto-Calibration Cycle

DS011830-9

DS011830-10

FIGURE 4. Offset or Zero Error Voltage

Typical Performance Characteristics The following curves apply for 12-bit + sign mode after

auto-calibration unless otherwise specified. The performance for 8-bit + sign mode is equal to or better than shown. (Note 9)

Linearity Error Change

vs Temperature

DS011830-51

www.national.com 12

Full-Scale Error Change

vs Temperature

Full-Scale Error Change

vs Supply Voltage

DS011830-52

DS011830-53

Page 13

Typical Performance Characteristics The following curves apply for 12-bit + sign mode after

auto-calibration unless otherwise specified. The performance for 8-bit + sign mode is equal to or better than shown. (Note

9) (Continued)

Zero Error Change

vs Temperature

Digital Supply Current

vs Temperature

Test Circuits

DS011830-54

DS011830-57

Zero Error Change

vs Supply Voltage

DS011830-55

Analog Supply Current

vs Temperature

DS011830-56

DO “TRI-STATE” (t1H,t0H)

DO except “TRI-STATE”

DS011830-15

DS011830-16

www.national.com13

Page 14

Test Circuits (Continued)

Timing Diagrams

Leakage Current

DS011830-17

DO Falling and Rising Edge

DS011830-18

DO “TRI-STATE” Falling and Rising Edge

DS011830-19

DI Data Input Timing

DS011830-20

DO Data Output Timing Using CS

www.national.com 14

DS011830-21

Page 15

Timing Diagrams (Continued)

DO Data Output Timing with CS Continuously Low

DS011830-22

ADC12L038 Auto Cal or Auto Zero

Note: DO output data is not valid during this cycle.

DS011830-23

www.national.com15

Page 16

Timing Diagrams (Continued)

ADC12L038 Read Data without Starting a Conversion Using CS

ADC12L038 Read Data without Starting a Conversion with CS Continuously Low

DS011830-24

www.national.com 16

DS011830-25

Page 17

Timing Diagrams (Continued)

ADC12L038 Conversion Using CS with 8-Bit Digital Output Format

ADC12L038 Conversion Using CS with 16-Bit Digital Output Format

DS011830-26

DS011830-27

www.national.com17

Page 18

Timing Diagrams (Continued)

ADC12L038 Conversion with CS Continuously Low and 8-Bit Digital Output Format

ADC12L038 Conversion with CS Continuously Low and 16-Bit Digital Output Format

DS011830-28

www.national.com 18

DS011830-29

Page 19

Timing Diagrams (Continued)

ADC12L038 Software Power Up/Down Using CS with 16-Bit Digital Output Format

ADC12L038 Software Power Up/Down with CS Continuously Low and 16-Bit Digital Output Format

DS011830-30

DS011830-31

www.national.com19

Page 20

Timing Diagrams (Continued)

ADC12L038 Hardware Power Up/Down

Note: Hardware power up/down may occur at any time. If PD is high while a conversion is in progress that conversion will be corrupted and erroneous data will

be stored in the output shift register.

DS011830-32

ADC12L038 Configuration Modification— Example of a Status Read

Note: In order for all 9 bits of status information to be accessible the last conversion programmed before Cycle N needs to have a resolution of 8 bits plus sign,

12 bits, 12 bits plus sign, or greater.

DS011830-33

FIGURE 5. Protecting the MUXOUT1, MUXOUT2, A/DIN1 and A/DIN2 Analog Pins

www.national.com 20

DS011830-34

Page 21

Timing Diagrams (Continued)

*

Tantalum

**

Monolithic Ceramic or better

DS011830-35

FIGURE 6. Recommended Power Supply Bypassing and Grounding

Tables

TABLE 1. Data Out Formats

DO Formats DB0 DB1 DB2 DB3 DB4 DB5 DB6 DB7 DB8 DB9 DB10 DB11 DB12 DB13 DB14 DB15 DB16

with

Sign

17 X X X X Sign MSB 10 987654321LSB

Bits

MSB 13 Sign MSB 10 9 8 7 6 5432 1LSB

First Bits

9 Sign MSB 6 5 4 3 2 1 LSB

Bits

17 LSB 1 2 3 4 5 6 7 8 9 10 MSB Sign XXXX

Bits

LSB 13 LSB 1 2 3 4 5 6 7 8 9 10 MSB Sign

First Bits

9 LSB 1 2 3 4 5 6 MSB Sign

Bits

www.national.com21

Page 22

Tables (Continued)

TABLE 1. Data Out Formats (Continued)

DO Formats DB0 DB1 DB2 DB3 DB4 DB5 DB6 DB7 DB8 DB9 DB10 DB11 DB12 DB13 DB14 DB15 DB16

without

Sign

X=High or Low state.

Address with A/DIN1 tied to MUXOUT1 Assignment Channel

DI0 DI1 DI2 DI3 CH0 CH1 CH2 CH3 CH4 CH5 CH6 CH7 COM A/DIN1 A/DIN2 MUXOUT1 MUXOUT2

LLLL+− + − CH0 CH1

L L L H + − + − CH2 CH3

L L H L + − + − CH4 CH5

L L H H + − + − CH6 CH7 Differential

L H L L − + − + CH0 CH1

LHLH −+ − + CH2 CH3

L H H L − + − + CH4 CH5

L H H H − + − + CH6 CH7

H L L L + − + − CH0 COM

H L L H + − + − CH2 COM

HLHL + − + − CH4 COM

H L H H + − + − CH6 COM Single-Ended

H H L L + − + − CH1 COM

H H L H + − + − CH3 COM

H H H L + − + − CH5 COM

HHHH + − + − CH7 COM

160000MSB10987654321LSB

Bits

MSB12MSB10987654321LSB

First Bits

8 MSB 6 5 4 3 2 1 LSB

Bits

16LSB12345678910MSB0000

Bits

LSB 12 LSB 1 2 3 4 5 6 7 8 9 10 MSB

First Bits

8 LSB 1 2 3 4 5 6 MSB

Bits

TABLE 2. ADC12L038 Multiplexer Addressing

Analog Channel Addressed A/D Input Multiplexer Mode

MUX and Assignment Polarity Output

and A/DIN2 tied to MUXOUT2 Assignment

TABLE 3. ADC12L034 Multiplexer Addressing

Analog Channel Addressed A/D Input Multiplexer Mode

MUX and Assignment Polarity Output

Address with A/DIN1 tied to MUXOUT1 Assignment Channel

and A/DIN2 tied to MUXOUT2 Assignment

DI0 DI1 DI2 CH0 CH1 CH2 CH3 COM A/DIN1 A/DIN2 MUXOUT1 MUXOUT2

L L L + − + − CH0 CH1

L L H + − + − CH2 CH3 Differential

L H L − + − + CH0 CH1

L H H − + − + CH2 CH3

H L L + − + − CH0 COM

H L H + − + − CH2 COM Single-Ended

H H L + − + − CH1 COM

H H H + − + − CH3 COM

www.national.com 22

Page 23

Tables (Continued)

TABLE 4. ADC12L032 and ADC12L030 Multiplexer Addressing

Analog Channel Addressed A/D Input Multiplexer Mode

MUX and Assignment Polarity Output

Address with A/DIN1 tied to MUXOUT1 Assignment Channel

and A/DIN2 tied to MUXOUT2 Assignment

DI0 DI1 CH0 CH1 COM A/DIN1 A/DIN2 MUXOUT1 MUXOUT2

L L + − + − CH0 CH1 Differential

L H − + − + CH0 CH1

H L + − + − CH0 COM Single-Ended

H H + − + − CH1 COM

Note 21: ADC12L030 does not have A/DIN1, A/DIN2, MUXOUT1 and MUXOUT2 pins.

TABLE 5. Mode Programming

ADC12L038 DI0 DI1 DI2 DI3 DI4 DI5 DI6 DI7 Mode Selected

ADC12L034 DI0 DI1 DI2 DI3 DI4 DI5 DI6

(Current)

ADC12L030

and DI0 DI1 DI2 DI3 DI4 DI5

ADC12L032

See

Tables 2, 3, 4

See

Tables 2, 3, 4

See

Tables 2, 3, 4

LLLL 12BitConversion 12 or 13 Bit MSB First

L L L H 12 Bit Conversion 16 or 17 Bit MSB First

L L H L 8 Bit Conversion 8 or 9 Bit MSB First

L L L L L L H H 12 Bit Conversion of Full-Scale 12 or 13 Bit MSB First

See

Tables 2, 3, 4

See

Tables 2, 3, 4

See

Tables 2, 3, 4

L H L L 12 Bit Conversion 12 or 13 Bit LSB First

L H L H 12 Bit Conversion 16 or 17 Bit LSB First

L H H L 8 Bit Conversion 8 or 9 Bit LSB First

L L L L L H H H 12 Bit Conversion of Offset 12 or 13 Bit LSB First

L L L L H L L L Auto Cal No Change

L L L L H L L H Auto Zero No Change

L L L L H L H L Power Up No Change

L L L L H L H H Power Down No Change

L L L L H H L L Read Status Register No Change

L L L L H H L H Data Out without Sign No Change

H L L L H H L H Data Out with Sign No Change

L L L L H H H L Acquisition Time— 6 CCLK

Cycles

L H L L H H H L Acquisition Time — 10 CCLK

Cycles

H L L L H H H L Acquisition Time— 18 CCLK

Cycles

H H L L H H H L Acquisition Time— 34 CCLK

Cycles

L L L LHHHH User Mode No Change

HX X XHHHH Test Mode No Change

(CH1–CH7 become Active

Outputs)

X=Don’t Care

Note 22: The A/D powers up with no Auto Cal, no Auto Zero, 10 CCLK acquisition time, 12-bit + sign conversion, power up, 12- or 13-bit MSB first and user mode.

DO Format

(next Conversion

Cycle)

No Change

No Change

No Change

No Change

www.national.com23

Page 24

Tables (Continued)

Status

Bit

Location

Status

Bit

DB0 DB1 DB2 DB3 DB4 DB5 DB6 DB7 DB8

PU PD Cal 8 or 9 12 or 13 16 or 17 Sign Justification Test

TABLE 6. Conversion/Read Data Only Mode Programming

CS CONV PD Mode

LLL See

L H L Read Only (Previous DO Format)

H X L Idle

X X H Power Down

X=Don’t Care

TABLE 7. Status Register

Device Status DO Output Format Status

Table 5

for Mode

No Conversion

Mode

Function

“High”

indicates

a Power

Up

Sequence

is in

progress

“High”

indicates

a Power

Down

Sequence

is in

progress

“High”

indicates

an

Auto-Cal

Sequence

is in

progress

“High”

indicates

an8or9

bit format

Application Hints

1.0 DIGITAL INTERFACE

1.1 Interface Concepts

Figure 7

The example in

after the power is applied to the ADC12L030/2/4/8:

FIGURE 7. Typical Power Supply Power Up Sequence

The first instruction input to the A/D via DI initiates Auto Cal.

The data output on DO at that time is meaningless and is

completely random. To determine whether the Auto Cal has

been completed, a read status instruction is issued to the

A/D. Again the data output at that time has no significance

since the Auto Cal procedure modifies the data in the output

shift register.To retrieve the status information, an additional

read status instruction is issued to the A/D. At this time the

status data is available on DO. If the Cal signal in the status

word is low Auto Cal has been completed. Therefore, the

next instruction issued can start a conversion. The data output at this time is again status information. To keep noise

from corrupting the A/D conversion, the status can not be

read during a conversion. If CS is strobed and is brought low

during a conversion, that conversion is prematurely ended.

www.national.com 24

shows a typical sequence of events

DS011830-36

“High”

indicates

a12or

13 bit

format

“High”

indicates

a16or

17 bit

format

EOC can be used to determine the end of a conversion or

theA/D controller can keep track in software of when it would

be appropriate to communicate to the A/D again. Once it has

been determined that the A/D has completed a conversion

another instruction can be transmitted to the A/D. The data

from this conversion can be accessed when the next instruction is issued to the A/D.

Note, when CS is low continuously it is important to transmit

the exact number of SCLK cycles, as shown in the timing

diagrams. Not doing so will desynchronize theserial communication to the A/D (see Section 1.3).

1.2 Changing Configuration

The configuration of the ADC12L030/2/4/8 on power up defaults to 12-bit plus sign resolution, 12- or 13-bit MSB First,

10 CCLK acquisition time, user mode, no Auto Cal, no Auto

Zero, and power up mode. Changing the acquisition time

and turning the sign bit on and off requires an 8-bit instruction to be issued to the ADC. This instruction will not start a

conversion. The instructions that select a multiplexer address and format the output data do start a conversion.

ure 8

describes an example of changing the configuration of

the ADC12L030/2/4/8.

During I/O sequence 1 the instruction on DI configures the

ADC12L030/2/4/8 to do a conversion with 12-bit +sign resolution. Notice that when the 6 CCLK Acquisition and Data

Out without Sign instructions are issued to the ADC, I/O sequences 2 and 3, a new conversion is not started. The data

“High”

indicates

that the

sign bit is

included.

When

“Low” the

sign bit is

not

included.

When “High”

the conversion

result will be

output MSB

first. When

“Low” the

result will be

output LSB

first.

When

“High”

the

device is

in test

mode.

When

“Low” the

device is

in user

mode.

Fig-

Page 25

Application Hints (Continued)

output during these instructions is from conversion N which

was started during I/O sequence 1. The Configuration Modification timing diagram describes in detail the sequence of

events necessary for a Data Out without Sign, Data Out with

Sign, or 6/10/18/34 CCLK Acquisition time mode selection.

FIGURE 8. Changing the ADC’s Conversion Configuration

Table 5

describes the actual data necessary to be input to

the ADC to accomplish this configuration modification. The

next instruction, shown in

Figure 8

, issued to the A/D starts

conversion N+1 with 8 bits of resolution formatted MSB first.

Again the data output during this I/O cycle is the data from

conversion N.

DS011830-37

The number of SCLKs applied to the A/D during any conversion I/O sequence should vary in accord with the data out

word format chosen during the previous conversion I/O sequence. The various formats and resolutions available are

shown in

Table 1

.In

Figure 8

, since 8-bit without sign MSB

first format was chosen during I/O sequence 4, the number

of SCLKs required during I/O sequence 5 is 8. In the following I/O sequence the format changes to 12-bit without sine

MSB first; therefore the number of SCLKs required during

I/O sequence 6 changes accordingly to 12.

1.3 CS Low Continuously Considerations

When CS is continuously low, it is important to transmit the

exact number of SCLK pulses that theADC expects. Not doing so will desynchronize the serial communications to the

ADC. When the supply power is first applied to the ADC, it

will expect to see 13 SCLK pulses for each I/O transmission.

The number of SCLK pulses that the ADC expects to see is

the same as the digital output word length. The digital output

word length is controlled by the Data Out (DO) format. The

DO format maybe changed any time a conversion is started

or when the sign bit is turned on or off. The table below details out the number of clock periods required for different

DO formats:

Number of

DO Format SCLKs

Expected

8-Bit MSB or LSB First SIGN OFF 8

SIGN ON 9

12-Bit MSB or LSB First SIGN OFF 12

SIGN ON 13

16-Bit MSB or LSB first SIGN OFF 16

SIGN ON 17

If erroneous SCLK pulses desynchronize the communications, the simplest way to recover is by cycling the power

supply to the device. Not being able to easily resynchronize

the device is a shortcoming of leaving CS low continuously.

The number of clock pulses required for an I/O exchange

may be different for the case when CS is left low continuously vs. the case when CS is cycled. Take the I/O sequence

detailed in

Figure 7

(Typical Power Supply Sequence) as an

example. The table below lists the number of SCLK pulses

required for each instruction:

Instruction CS Low CS Strobed

Continuously

Auto Cal 13 SCLKs 8 SCLKs

Read Status 13 SCLKs 8 SCLKs

Read Status 13 SCLKs 8 SCLKs

12-Bit + Sign Conv 1 13 SCLKs 8 SCLKs

12-Bit + Sign Conv 2 13 SCLKs 13 SCLKs

1.4 Analog Input Channel Selection

The data input on DI also selects the channel configuration

for a particularA/D conversion (See

ure 8

the only times when the channel configuration could be

Tables2, 3, 4, 5

). In

Fig-

modified would be during I/O sequences 1, 4, 5 and 6. Input

channels are reselected before the start of eachnew conversion. Shown below is the data bit stream required on DI, during I/O sequence number 4 in

Figure 8

, to set CH1 as the

positive input and CH0 as the negative input for the different

versions of ADCs:

Part

Number

ADC12L030 LHLLHLXX

ADC12L032 LHLLHLXX

ADC12L034 LHLLLHLX

ADC12L038 LHLLLLHL

Where X can be a logic high (H) or low (L).

DI0 DI1 DI2 DI3 DI4 DI5 DI6 DI7

DI Data

1.5 Power Up/Down

The ADC may be powered down at any time by taking the

PD pin HIGH or by the instruction input on DI (see

6

, and the Power Up/Down timing diagrams). When the ADC

Tables5,

is powered down in this way the circuitry necessary for an

A/D conversion is deactivated. The circuitry necessary for

digital I/O is kept active. Hardware power up/down is controlled by the state of the PD pin. Software power up/down is

controlled by the instruction issued to the ADC. If a software

power up instruction is issued to the ADC while a hardware

power down is in effect (PD pin high) the device will remain

www.national.com25

Page 26

Application Hints (Continued)

in the power-down state. If a software power down instruction is issued to the ADC while a hardware power up is in effect (PD pin low), the device will power down. When the device is powered down by software, it may be powered up by

either issuing a software power up instruction or by taking

PD pin high and then low. If the power down command is issued during an A/D conversion, that conversion is disrupted.

Therefore, the data output after power up cannot be relied

on.

1.6 User Mode and Test Mode

An instruction may be issued to the ADC to put it into test

mode. Test mode is used by the manufacturer to verify complete functionality of the device. During test mode CH0–CH7

become active outputs. If the device is inadvertently put into

the test mode with CS low continuously, the serial communications may be desynchronized. Synchronization may be regained by cycling the power supply voltage to the device.

Cycling the power supply voltage will also set the device into

user mode. If CS is used in the serial interface, theADC may

be queried to see what mode it is in. This is done by issuing

a “read STATUS register” instruction to the ADC. When bit 9

of the status register is high the ADC is in test mode; when

bit 9 is low theADC is in user mode. As an alternative to cycling the power supply, an instruction sequence may beused

to return the device to user mode. This instruction sequence

must be issued to the ADC using CS.

The followingtable lists the instructions required to return the

device to user mode:

Instruction

TEST MODE HXXXHHHH

RESET LLLLHHHL

TEST MODE LLLLHLHL

INSTRUCTIONS LLLLHLHH

USER MODE LLLLHHHH

Power Up LLLLHLHL

Set DO with H

or without or L L L H H L H

Sign L

Set H H

Acquisition or or L L H H H L

Time L L

Start HHHH HHH

a ororororLororor

Conversion LLLL LLL

X=Don’t Care

DI0 DI1 DI2 DI3 DI4 DI5 DI6 DI7

After returning to user mode with the user mode instruction

the power up, data with or without sign, and acquisition time

instructions need to be resent to ensure that the ADC is in

the required state before a conversion is started.

DI Data

1.7 Reading the Data Without Starting a Conversion

The data from a particular conversion may be accessed

without starting a new conversion by ensuring that the

CONV line is taken high during the I/O sequence. See the

Read Data timing diagrams.

Table6

describes the operation

of the CONV pin.

2.0 DESCRIPTION OF THE ANALOG MULTIPLEXER

For the ADC12L038, the analog input multiplexer can be

configured with 4 differential channels or 8 single ended

channels with the COM input as the zero reference or any

combination thereof (see

the voltages on the V

put voltage span (V

+

to V

. Negative digital output codes result when V

A

+

V

. The actual voltage at V

IN

AGND.

Figure 9

+

REF

). The analog input voltage range is 0

REF

). The difference between

−

and V

pins determines the in-

REF

−

+

or V

IN

IN

cannot go below

−

IN

4 Differential

Channels

DS011830-38

8 Single-Ended Channels

with COM

as Zero Reference

DS011830-39

FIGURE 9.

CH0, CH2, CH4, and CH6 can be assigned to the MUXOUT1 pin in the differential configuration, while CH1, CH3,

CH5, and CH7 can be assigned to the MUXOUT2 pin. In the

differential configuration, the analog inputs are paired as follows: CH0 with CH1, CH2 with CH3, CH4 with CH5 and CH6

with CH7. The A/DIN1 and A/DIN2 pins can be assigned

positive or negative polarity.

With the single-ended multiplexer configuration CH0 through

CH7 can be assigned to the MUXOUT1 pin. The COM pin is

always assigned to the MUXOUT2 pin. A/DIN1 is assigned

as the positive input; A/DIN2 is assigned as the negative input. (See

Figure 10

).

The Multiplexer assignment tables for the ADC12L030,2,4,8

(

Tables2, 3, 4

) summarize the aforementioned functions for

the different versions of A/Ds.

>

www.national.com 26

Page 27

Application Hints (Continued)

Differential

Configuration

DS011830-40

A/DIN1 and A/DIN2 can be assigned as the + or − input

A/DIN1 is + input

A/DIN2 is − input

FIGURE 10.

Single-Ended

Configuration

DS011830-41

FIGURE 11. Single-Ended Biasing

2.1 Biasing for Various Multiplexer Configurations

Figure 11

is an example of biasing the device for

single-ended operation. The sign bit is always low.The digital output range is 0 0000 0000 0000 to 0 1111 1111 1111.

One LSB is equal to 610 µV (2.5V/4096 LSBs).

For pseudo-differential signed operation the biasing circuit

shown in

Figure 12

shows a signal AC coupled to the ADC.

This gives a digital output range of −4096 to +4095. With a

1.25V reference, as shown, 1 LSB is equal to 305 µV. Although the ADC is not production tested with a 1.25V reference linearity error typically will not change more than 0.3

LSB. With the ADC set to an acquisition time of 10 clock periods the input biasing resistor needs to be 600Ω or less. Notice though that the input coupling capacitor needs to be

DS011830-46

made fairly large to bring down the high pass corner. Increasing the acquisition time to 34 clock periods (with a

5 MHz CCLK frequency) would allow the 600Ω to increase to

6k, which with a 1 µF coupling capacitor would set the high

pass corner at 26 Hz. The value of R1 will depend on the

value of R2.

An alternative method for biasing pseudo-differential operation is to use the +1.25V from the LM4040 to bias any amplifier circuits driving the ADC as shown in

Figure 13

. The value

of the resistor pull-up biasing the LM4040-2.5 will depend

upon the current required by the op amp biasing circuitry.

Fully differential operation is shown in

Figure 14

. One LSB

for this case is equal to (2.5V/4096)=610 mV.

www.national.com27

Page 28

Application Hints (Continued)

FIGURE 12. Pseudo-Differential Biasing with the Signal Source AC Coupled Directly into the ADC

DS011830-47

FIGURE 13. Alternative Pseudo-Differential Biasing

www.national.com 28

DS011830-48

Page 29

Application Hints (Continued)

FIGURE 14. Fully Differential Biasing

3.0 REFERENCE VOLTAGE

The difference in the voltages applied to the V

−

V

defines the analog input span (the difference between

REF

the voltage applied between two multiplexer inputs or the

voltage applied to one of the multiplexer inputs and analog

ground), over which 4095 positive and 4096 negative codes

exist. The voltage sources driving V

very low output impedance and noise.

REF

+

or V

The ADC12L030/2/4/8 can be used in either ratiometric or

absolute reference applications. In ratiometric systems, the

analog input voltage is proportional to the voltage used for

the ADC’s reference voltage. When this voltage is the system power supply, the V

−

V

is connected to ground. This technique relaxes the

REF

system reference stability requirements because the analog

+

pin is connected to V

REF

input voltage and the ADC reference voltage move together.

This maintains the same output code for given input conditions. For absolute accuracy, where the analog input voltage

varies between very specific voltage limits, a time and temperature stable voltage source can be connected to the reference inputs. Typically, the reference voltage’s magnitude

will require an initial adjustment to null reference voltage induced full-scale errors.

Below are recommended references along with some key

specifications.

Output Temperature

Part Number Voltage Coefficient

Tolerance (max)

LM4041CIM3-Adj

LM4040AIM3-2.5

±

%

0.5

±

%

0.1

±

±

The reference voltage inputs are not fully differential. The

ADC12L030/2/4/8 will not generate correct conversions or

comparisons if V

sions result when V

at all times, between ground and V

mode range, (V

+

(0.6 x V

). Therefore, with V

A

+

is taken below V

REF

REF

+

+V

REF

+

and V

−

)/2, is restricted to (0.1 x V

REF

REF

−

differ by 1V and remain,

REF

+

. The V

A

+

=

3.3V the center of the ref-

A

−

. Correct conver-

REF

−

must have

REF

100ppm/˚C

100ppm/˚C

common

REF

+

and

+

and

A

+

)to

A

DS011830-50

erence ladder should not go below 0.33V or above 1.98V.

Figure 15

tions on V

is a graphic representation of the voltage restric-

+

and V

REF

FIGURE 15. V

REF

−

.

REF

DS011830-43

Operating Range

www.national.com29

Page 30

Application Hints (Continued)

4.0 ANALOG INPUT VOLTAGE RANGE

The ADC12L030/2/4/8’s fully differential ADC generate a

two’s complement output that is found by using the equations shown below:

for (12-bit) resolution the Output Code

for (8-bit) resolution the Output Code

Round off to the nearest integer value between −4096 to

4095 for 12-bit resolution and between −256 to 255 for 8-bit

resolution if the result of the above equation is not a whole

number.

Examples are shown in the table below:

+

−

V

V

REF

REF

+2.5V +1V +1.5V 0V 0,1111,1111,1111

+2.500V 0V +2V 0V 0,1100,1100,1101

+2.500V 0V +2.499V +2.500V 1,1111,1111,1111

+2.500V 0V 0V +2.500V 1,0000,0000,0000

+

V

IN

5.0 INPUT CURRENT

At the start of the acquisition window (t

flows into or out of the analog input pins (A/DIN1 and

A/DIN2) depending on the input voltage polarity. The analog

input pins are CH0–CH7 and COM when A/DIN1 is tied to

MUXOUT1 andA/DIN2 is tied to MUXOUT2. The peak value

of this input current will depend on the actual input voltage

applied, the source impedance and the internal multiplexer

switch on resistance. With MUXOUT1 tied to A/DIN1 and

MUXOUT2 tied to A/DIN2 the internal multiplexer switch on

resistance is typically 1.6 kΩ. The A/DIN1 and A/DIN2 mux

on resistance is typically 750Ω.

6.0 INPUT SOURCE RESISTANCE

For low impedance voltage sources (

charging current will decay, before the end of the S/H’s acquisition time of 2 µs (10 CCLK periods with f

a valuethat will not introduceany conversion errors. For high

source impedances, the S/H’s acquisition time can be increased to 18 or 34 CCLK periods. For less ADC resolution

and/or slower CCLK frequencies the S/H’s acquisition time

may be decreased to 6 CCLK periods. To determine the

number of clock periods (N

with a specific source impedance for the various resolutions

) required for the acquisition time

c

the following equations can be used:

12 Bit + Sign

8 Bit + Sign

=

N

R

+ 2.3] x

[

C

S

=

N

R

+ 2.3] x

[

C

S

Where fCis the conversion clock (CCLK) frequency in MHz

and R

is the external source resistance in kΩ.Asanex-

S

ample, operating with a resolution of 12 Bits+sign,a5MHz

clock frequency and maximum acquistion time of 34 conversion clock periods the ADC’s analog inputs can handle a

source impedanceas high as 6 kΩ. The acquisition time may

=

−

V

IN

) a charging current

A

<

fCx 0.824

fCx 0.57

=

Digital

Output

Code

600Ω), the input

=

5 MHz), to

C

also be extended to compensate for the settling or response

time of external circuitry connected between the MUXOUT

and A/DIN pins.

The acquisition time (t

and ended by a rising edge of CCLK (see Timing Diagrams).

) is started by a falling edge of SCLK

A

If SCLK and CCLK are asynchronous one extra CCLK clock

period may be inserted into the programmed acquisition time

for synchronization. Therefore with asnychronous SCLK and

CCLK the acquisition time will change from conversion to

conversion.

7.0 INPUT BYPASS CAPACITANCE

External capacitors (0.01 µF–0.1 µF) can be connected between the analog input pins, CH0–CH7, and analog ground

to filter any noise caused by inductive pickupassociated with

long input leads. These capacitors will not degrade the conversion accuracy.

8.0 NOISE

The leads to each of the analog multiplexer input pins should

be kept as short as possible. This will minimize input noise

and clock frequency coupling that can cause conversion errors. Input filtering can be used to reduce the effects of the

noise sources.

9.0 POWER SUPPLIES

Noise spikes on the V

conversion errors; the comparator will respond to the noise.

A

+

+

and V

supply lines can cause

D

The ADC is especially sensitive to any power supply spikes

that occur during the auto-zero or linearity correction. The

minimum power supply bypassing capacitors recommended

are low inductance tantalum capacitors of 10 µF or greater

paralleled with 0.1 µF monolithic ceramic capacitors.More or

different bypassing may be necessary depending on the

overall system requirements. Separate bypass capacitors

should be used for the V

close as possible to these pins.

A

+

+

and V

supplies and placed as

D

10.0 GROUNDING

The ADC12L030/2/4/8’s performance can be maximized

through proper grounding techniques. These include the use

of separate analog and digital ground planes. The digital

ground plane is placed under all components that handle

digital signals,while the analog ground plane is placed under

all components that handle analog signals. The digital and

analog ground planes are connected together at only one

point, either the power supply ground or at the pins of the

ADC. This greatly reduces the occurence of ground loops

and noise.

Shown in

Figure 16

is the ideal ground plane layout for the

ADC12L038 along with ideal placement of the bypass capacitors. The circuit board layout shown in

Figure 16

uses

three bypass capacitors: 0.01 µF (C1) and 0.1 µF (C2) surface mount capacitors and 10 µF (C3) tantalum capacitor.

11.0 CLOCK SIGNAL LINE ISOLATION

TheADC12L030/2/4/8’s performance is optimized by routing

the analog input/output and reference signal conductors as

far as possible from the conductors that carry the clock signals to the CCLK and SCLK pins. Ground traces parallel to

the clock signal traces can be used on printed circuit boards

to reduce clock signal interference on the analog input/

output pins.

www.national.com 30

Page 31

Application Hints (Continued)

FIGURE 16. Ideal Ground Plane for the ADC12L038

12.0 THE CALIBRATION CYCLE

A calibration cycle needs to be started after the power supplies, reference, and clock have been given enough time to

stabilize after initial turn on. During the calibration cycle, correction values are determined for the offset voltage of the

sampled data comparator and any linearity and gain errors.

These values are stored in internal RAM and used during an

analog-to-digital conversion to bring the overall full-scale,

offset, and linearity errors down to the specified limits.

Full-scale error typically changes

ture and linearity error changes even less; thereforeit should

be necessary to go through the calibration cycle only once

after power up if the Power Supply Voltage and the ambient

temperature do not change significantly (see the curves in

the Typical Performance Characteristics).

13.0 THE AUTO-ZERO CYCLE

To correct for any change in the zero (offset) error of the A/D,

the auto-zero cycle can be used. It may be necessary to do

an auto-zero cycle whenever the ambient temperature or the

power supply voltage change significantly. (See the curves

titled “Zero Error Change vs Ambient Temperature” and

“Zero Error Change vs Supply Voltage” in the Typical Performance Characteristics.)

14.0 DYNAMIC PERFORMANCE

Many applications require the A/D converter to digitize AC

signals, but the standard DC integral and differential nonlinearity specifications will not accurately predict the A/D converter’s performance with AC input signals. The important

specifications for AC applications reflect the converter’s ability to digitize AC signals without significant spectral errors

and without adding noise to the digitized signal. Dynamic

characteristics such as signal-to-noise (S/N), signal-to-noise

+ distortion ratio (S/(N + D)), effective bits, full power bandwidth, aperture time and aperture jitter are quantitative measures of the A/D converter’s capability.

±

0.4 LSB over tempera-

DS011830-44

An A/D converter’s AC performance can be measured using

Fast Fourier Transform (FFT) methods. A sinusoidal waveform is applied to the A/D converter’s input, and the transform is then performed on the digitized waveform. S/(N + D)

and S/N are calculated from the resulting FFT data, and a

spectral plot may also be obtained.

The A/D converter’s noise and distortion levels will change

with the frequency of the input signal, with more distortion

and noise occurring at higher signal frequencies.This can be

seen inthe S/(N + D)versus frequency curves. These curves

will also give an indication of the full power bandwidth (the

frequency at which the S/(N + D) or S/N drops 3 dB).

Effective number of bits can also be useful in describing the

A/D’s noise performance. An ideal A/D converter will have

some amount of quantization noise, determined by its resolution, which will yield an optimum S/N ratio given by the following equation:

S/N=(6.02xn+1.76) dB

where n is the A/D’s resolution in bits.

The effective bits of a real A/D converter, therefore, can be

found by:

As an example, this device with a±2.5V, 10 kHz sine wave

input signal will typically have a S/N of 78 dB, which is

equivalent to 12.6 effective bits.

15.0 AN RS232 SERIAL INTERFACE

Shown below is a schematic for an RS232 interface to any

IBM and compatible PCs. The DTR, RTS, and CTS RS232

signal lines are buffered via level translators and connected

to the ADC12L038’s DI, SCLK, and DO pins, respectively.

The D flip flop drive the CS control line.

www.national.com31

Page 32

Application Hints (Continued)

+

Note: V

caps. The DS14C335 has an internal DC-DC converter that generates the necessary TIA/EIA-232-E output levels from a 3.3V supply. There are four 0.47 µF

capacitors required for the DC-DC converter that are not shown in the above schematic.

+

,V

A

D

, and V

+

on the ADC12L038 each have 0.01 µF and 0.1 µF chip caps, and 10 µF tantalum caps. All logic devices are bypassed with 0.1 µF

REF

DS011830-45

The assignment of the RS232 port is shown below

B7 B6 B5 B4 B3 B2 B1 B0

COM1 Input Address 3FE X X X CTS X X X X

Output Address 3FC X X X 0 X X RTS DTR

A sample program, written in Microsoft

™

QuickBasic, is

shown on the next page. The program prompts for data

mode select instruction to be sent to the A/D. This can be

found from the Mode Programming table shown earlier. The

data should be entered in “1”s and “0”s as shown in the table

with DI0 first. Next the program prompts for the number of

SCLKs requiredfor the programmed mode select instruction.

For instance, to send all “0”s to the A/D, selects CH0 as the

+input, CH1as the −input, 12-bit conversion, and 13-bit MSB

first data output format (if the sign bit was not turned off by a

previous instruction). This would require 13 SCLK periods

since the output data format is 13 bits. The part powers up

with No Auto Cal, No Auto Zero, 10 CCLK Acquisition Time,

12-bit conversion, data out with sign, 12- or 13-bit MSB First,

power up, and user mode. Auto Cal, Auto Zero, Power UP

and Power Down instructions do not change these default

settings. The following power up sequence should be followed:

1. Run the program

2. Priorto responding to the prompt apply the power to the

ADC12L038

3. Respond to the program prompts

It is recommended that the first instruction issued to the

ADC12L038 be Auto Cal (see Section 1.1).

www.national.com 32

Page 33

Application Hints (Continued)

DS011830-63

www.national.com33

Page 34

Physical Dimensions inches (millimeters) unless otherwise noted

Order Number ADC12L030CIWM

NS Package Number M16B

Order Number ADC12L032CIWM

NS Package Number M20B

www.national.com 34

Page 35

Physical Dimensions inches (millimeters) unless otherwise noted (Continued)

Order Number ADC12L034CIWM

NS Package Number M24B

Order Number ADC12L038CIWM

NS Package Number M28B

www.national.com35

Page 36

A/D Converters with MUX and Sample/Hold

Notes

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

ADC12L030/ADC12L032/ADC12L034/ADC12L038 3.3V Self-Calibrating 12-Bit Plus Sign Serial I/O

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...