Page 1

February 2007

ADC12C170

12-Bit, 170 MSPS, 1.1 GHz Bandwidth A/D Converter with

CMOS outputs

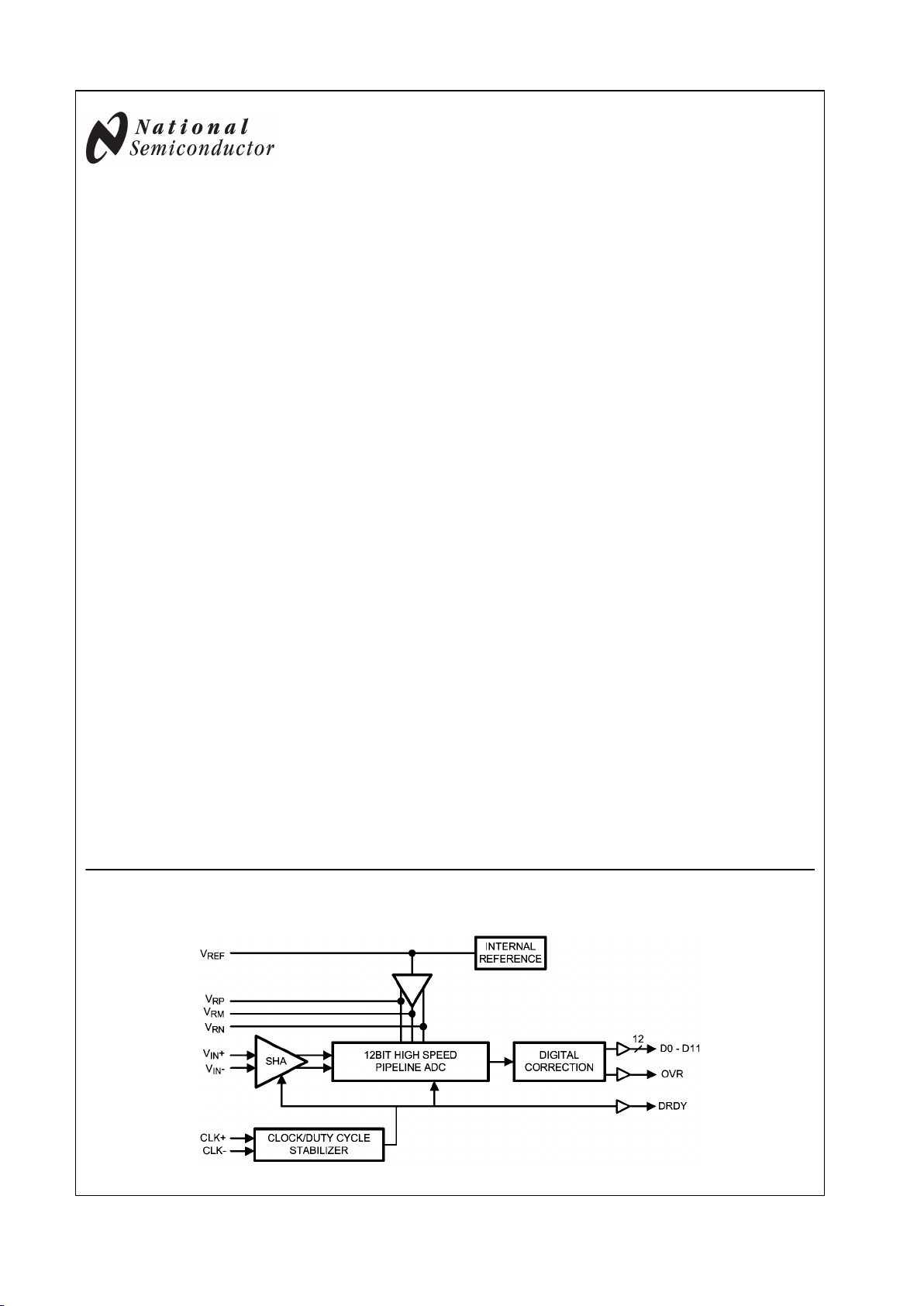

General Description

The ADC12C170 is a high-performance CMOS analog-todigital converter capable of converting analog input signals

into 12-Bit digital words at rates up to 170 Mega Samples Per

Second (MSPS). This converter uses a differential, pipelined

architecture with digital error correction and an on-chip sample-and-hold circuit to minimize power consumption and the

external component count, while providing excellent dynamic

performance. A unique sample-and-hold stage yields a fullpower bandwidth of 1.1 GHz. The ADC12C170 operates from

dual +3.3V and +1.8V power supplies and consumes 715 mW

of power at 170 MSPS.

The separate +1.8V supply for the digital output interface allows lower power operation with reduced noise. A powerdown feature reduces the power consumption to 5 mW while

still allowing fast wake-up time to full operation. In addition

there is a sleep feature which consumes 50 mW of power and

has a faster wake-up time.

The differential inputs provide a full scale differential input

swing equal to 2 times the reference voltage. A stable 1.0V

internal voltage reference is provided, or the ADC12C170 can

be operated with an external reference.

Clock mode (differential versus single-ended) and output data

format (offset binary versus 2's complement) are pin-selectable. A duty cycle stabilizer maintains performance over

a wide range of input clock duty cycles.

The ADC12C170 is pin compatible with the ADC14155.

It is available in a 48-lead LLP package and operates over the

industrial temperature range of −40°C to +85°C.

Features

■

1.1 GHz Full Power Bandwidth

■

Internal sample-and-hold circuit

■

Low power consumption

■

Internal precision 1.0V reference

■

Single-ended or Differential clock modes

■

Clock Duty Cycle Stabilizer

■

Dual +3.3V and +1.8V supply operation (+/- 10%)

■

Power-down and Sleep modes

■

Offset binary or 2's complement output data format

■

Pin-compatible with: ADC14155

■

48-pin LLP package, (7x7x0.8mm, 0.5mm pin-pitch)

Key Specifications

■

Resolution 12 Bits

■

Conversion Rate 170 MSPS

■

SNR (fIN = 70 MHz) 67.2 dBFS (typ)

■

SFDR (fIN = 70 MHz) 85.4 dBFS (typ)

■

ENOB (fIN = 70 MHz) 10.8 bits (typ)

■

Full Power Bandwidth 1.1 GHz (typ)

■

Power Consumption 715 mW (typ)

Applications

■

High IF Sampling Receivers

■

Wireless Base Station Receivers

■

Power Amplifier Linearization

■

Multi-carrier, Multi-mode Receivers

■

Test and Measurement Equipment

■

Communications Instrumentation

■

Radar Systems

Block Diagram

20209202

© 2007 National Semiconductor Corporation 202092 www.national.com

ADC12C170 12-Bit, 170 MSPS, 1.1 GHz Bandwidth A/D Converter

Page 2

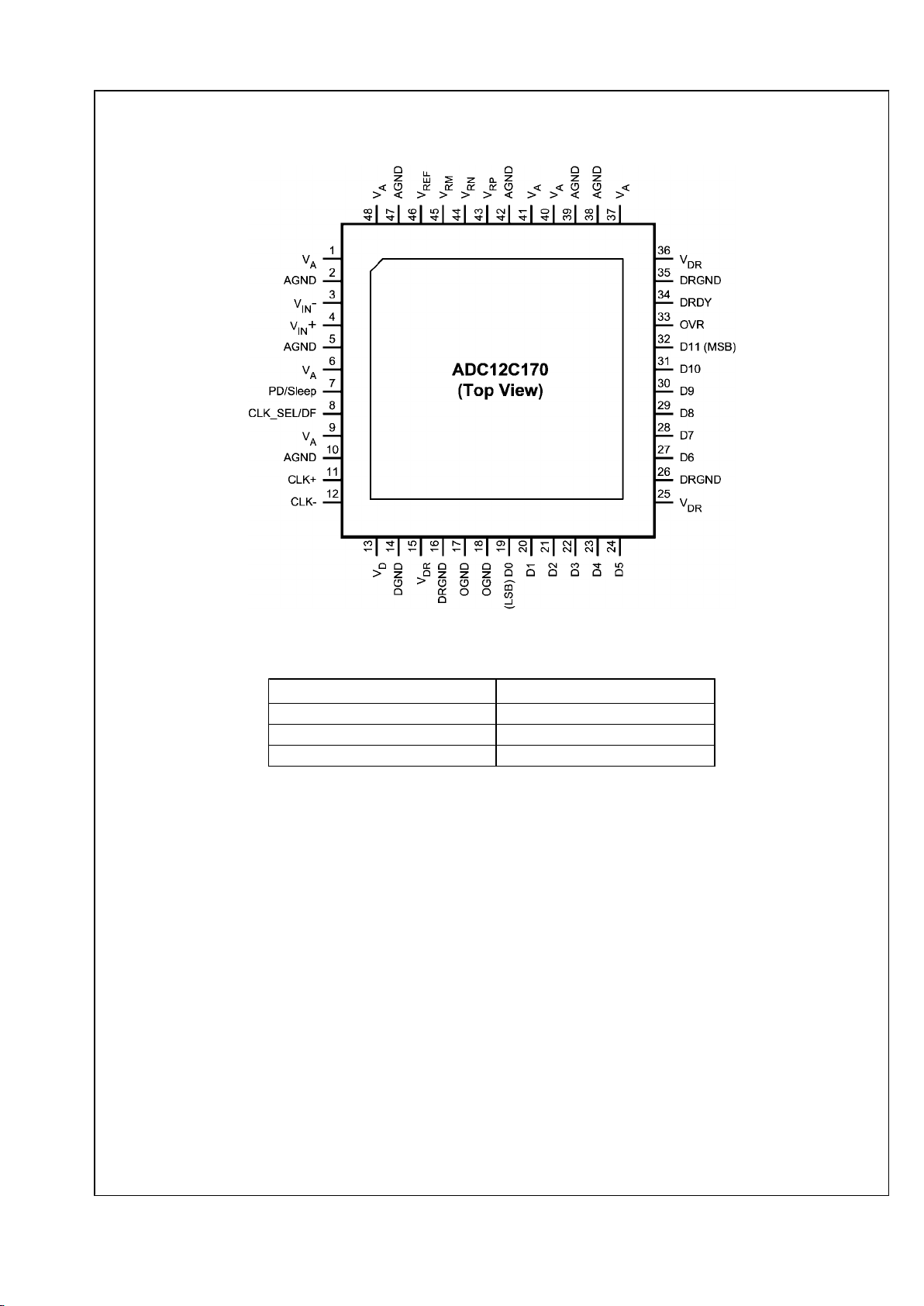

Connection Diagram

20209201

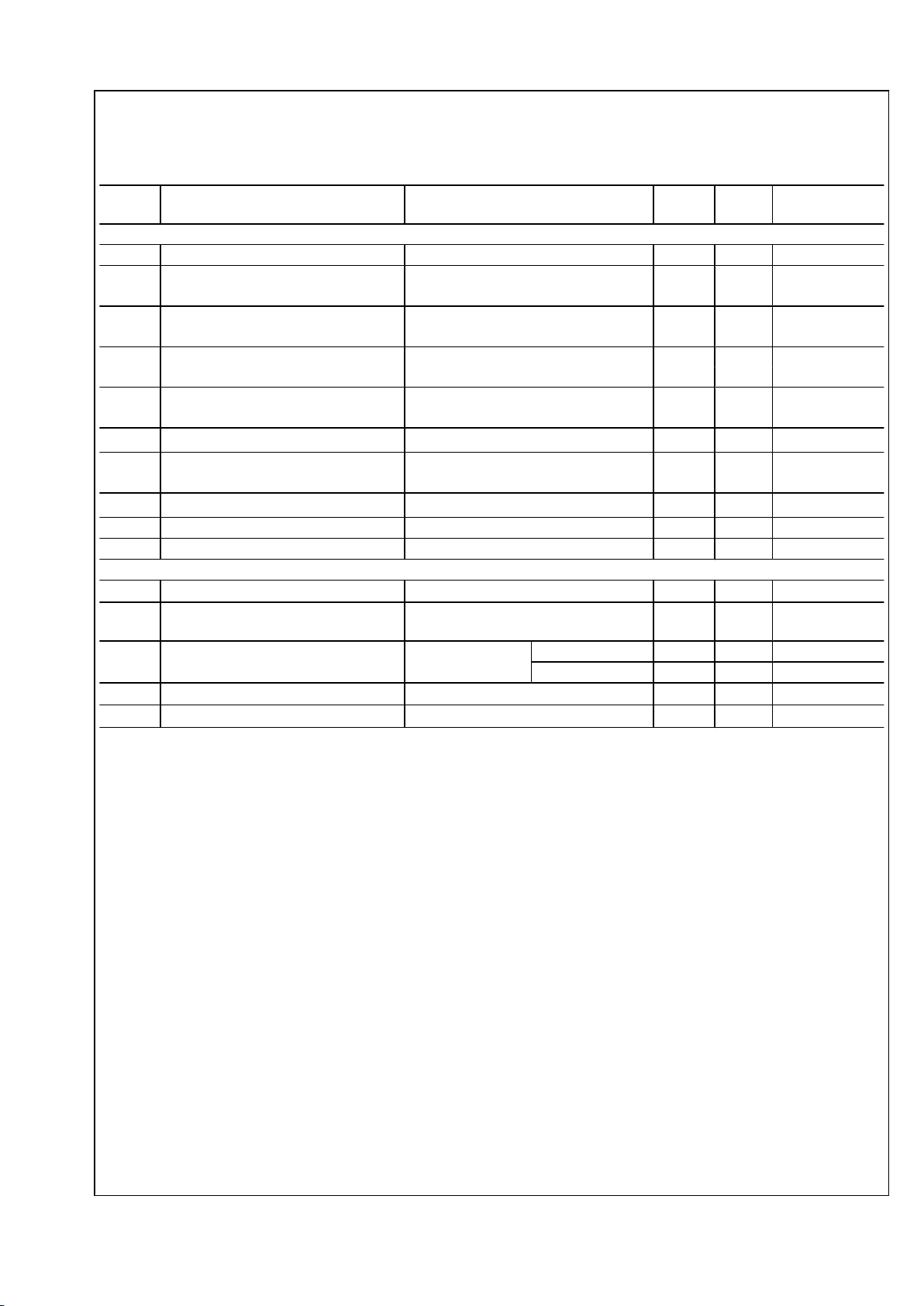

Ordering Information

Industrial (−40°C ≤ TA ≤ +85°C)

Package

ADC12C170CISQ 48 Pin LLP

ADC12C170LFEB Evaluation Board

ADC12C170HFEB Evaluation Board

www.national.com 2

ADC12C170

Page 3

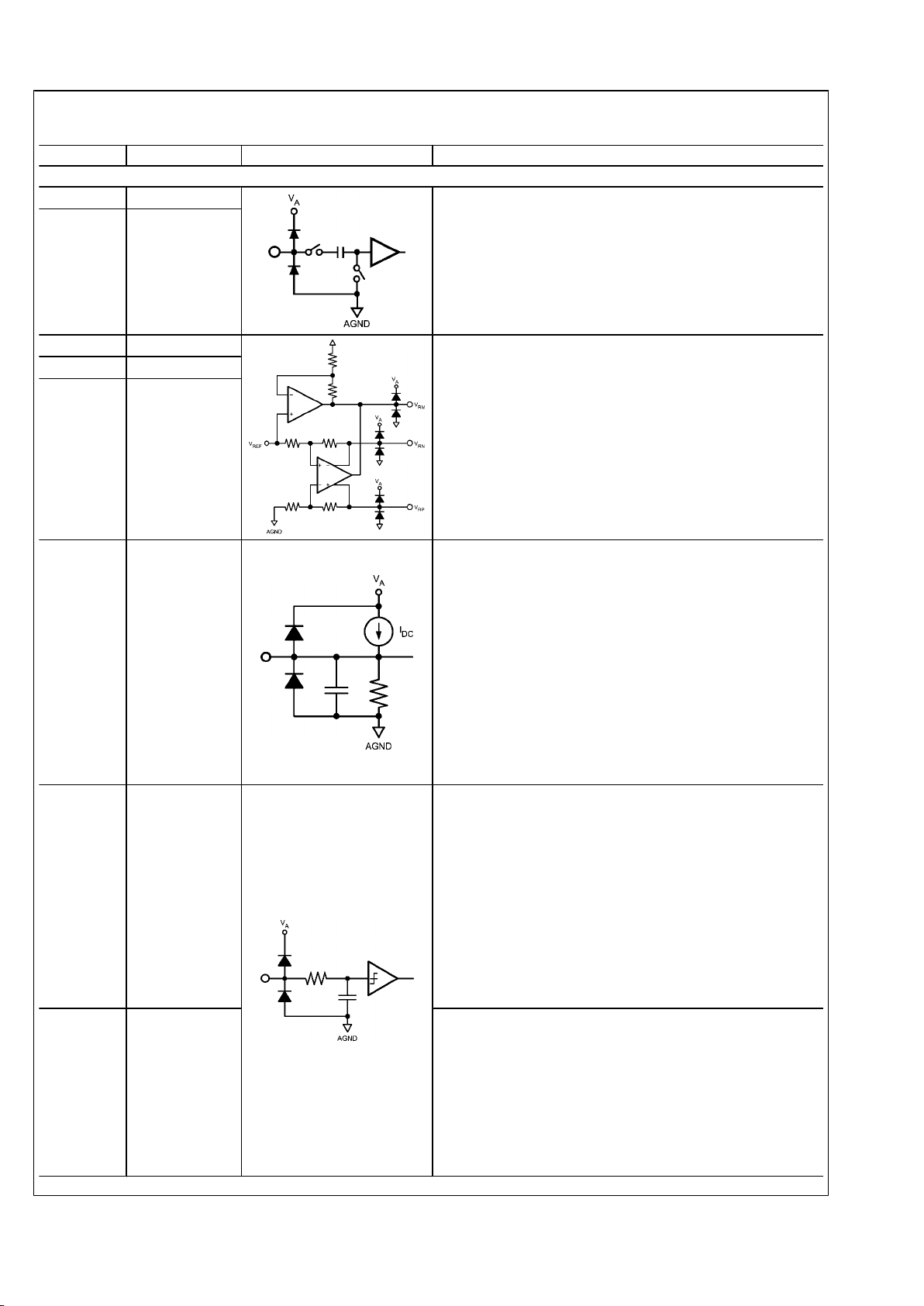

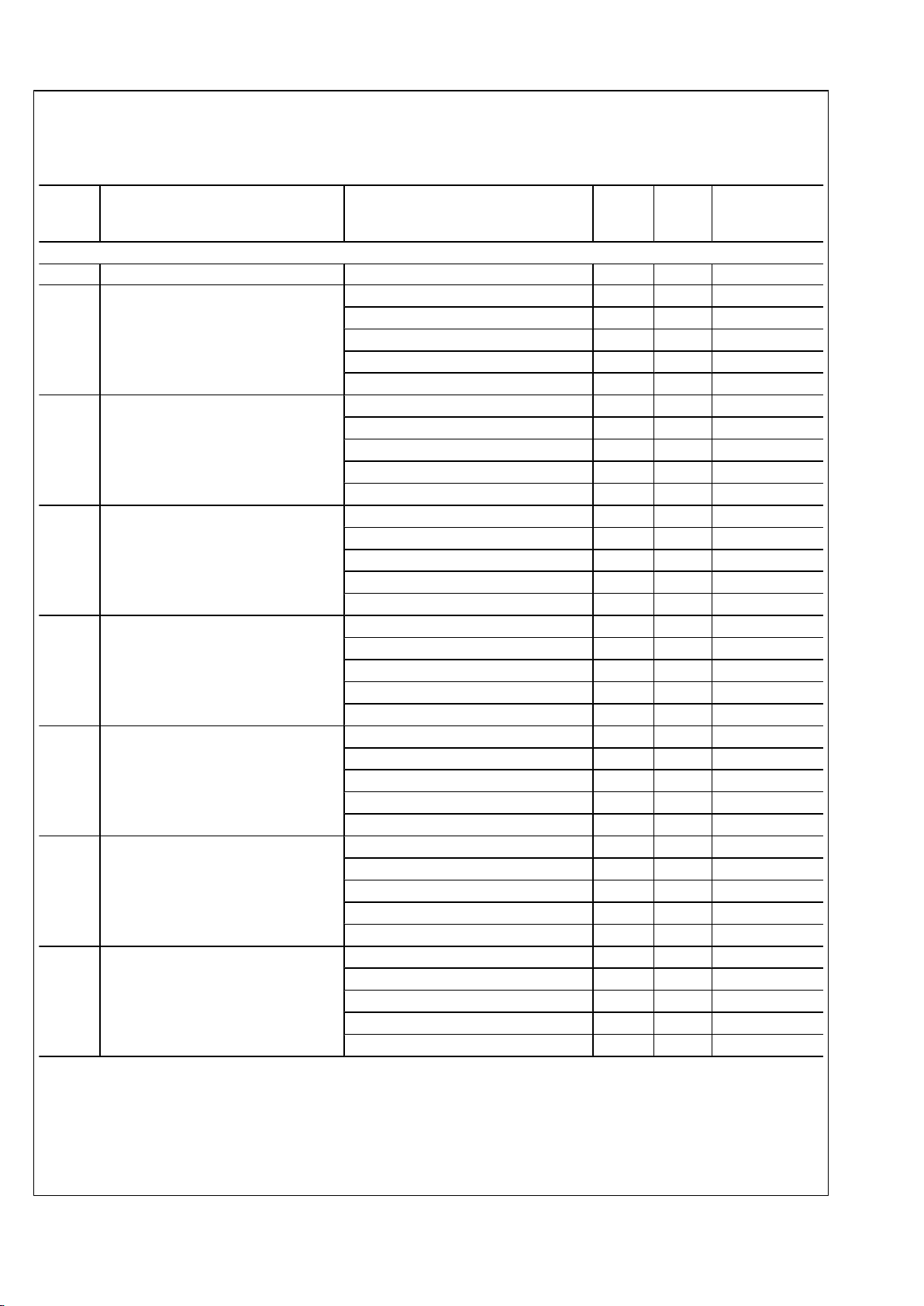

Pin Descriptions and Equivalent Circuits

Pin No. Symbol Equivalent Circuit Description

ANALOG I/O

3

VIN− Differential analog input pins. The differential full-scale input signal

level is two times the reference voltage with each input pin signal

centered on a common mode voltage, VCM.

4

VIN+

43

V

RP

These pins should each be bypassed to AGND with a low ESL

(equivalent series inductance) 0.1 µF capacitor placed very close

to the pin to minimize stray inductance. A 0.1 µF capacitor should

be placed between VRP and VRN as close to the pins as possible,

and a 10 µF capacitor should be placed in parallel.

VRP and VRN should not be loaded. VRM may be loaded to 1mA for

use as a temperature stable 1.5V reference.

It is recommended to use VRM to provide the common mode

voltage, VCM, for the differential analog inputs, VIN+ and VIN−.

45

V

RM

44

V

RN

46

V

REF

This pin can be used as either the +1.0V internal reference voltage

output (internal reference operation) or as the external reference

voltage input (external reference operation).

To use the internal reference, V

REF

should be decoupled to AGND

with a 0.1 µF, low equivalent series inductance (ESL) capacitor. In

this mode, V

REF

defaults as the output for the internal 1.0V

reference.

To use an external reference, overdrive this pin with a low noise

external reference voltage. The input impedance looking into this

pin is 9kΩ. Therefore, to overdrive this pin, the output impedance

of the external reference source should be << 9kΩ.

This pin should not be used to source or sink current.

The full scale differential input voltage range is 2 * V

REF

.

8 CLK_SEL/DF

This is a four-state pin controlling the input clock mode and output

data format.

CLK_SEL/DF = VA, CLK+ and CLK− are configured as a

differential clock input. The output data format is 2's complement.

CLK_SEL/DF = (2/3)*VA, CLK+ and CLK− are configured as a

differential clock input. The output data format is offset binary.

CLK_SEL/DF = (1/3)*VA, CLK+ is configured as a single-ended

clock input and CLK− should be tied to AGND. The output data

format is 2's complement.

CLK_SEL/DF = AGND, CLK+ is configured as a single-ended clock

input and CLK− should be tied to AGND. The output data format is

offset binary.

7 PD/Sleep

This is a three-state input controlling Power Down and Sleep

modes.

PD = VA, Power Down is enabled. In the Power Down state only

the reference voltage circuitry remains active and power

dissipation is reduced.

PD = VA/2, Sleep mode is enabled. Sleep mode is similar to Power

Down mode - it consumes more power but has a faster recovery

time.

PD = AGND, Normal operation.

3 www.national.com

ADC12C170

Page 4

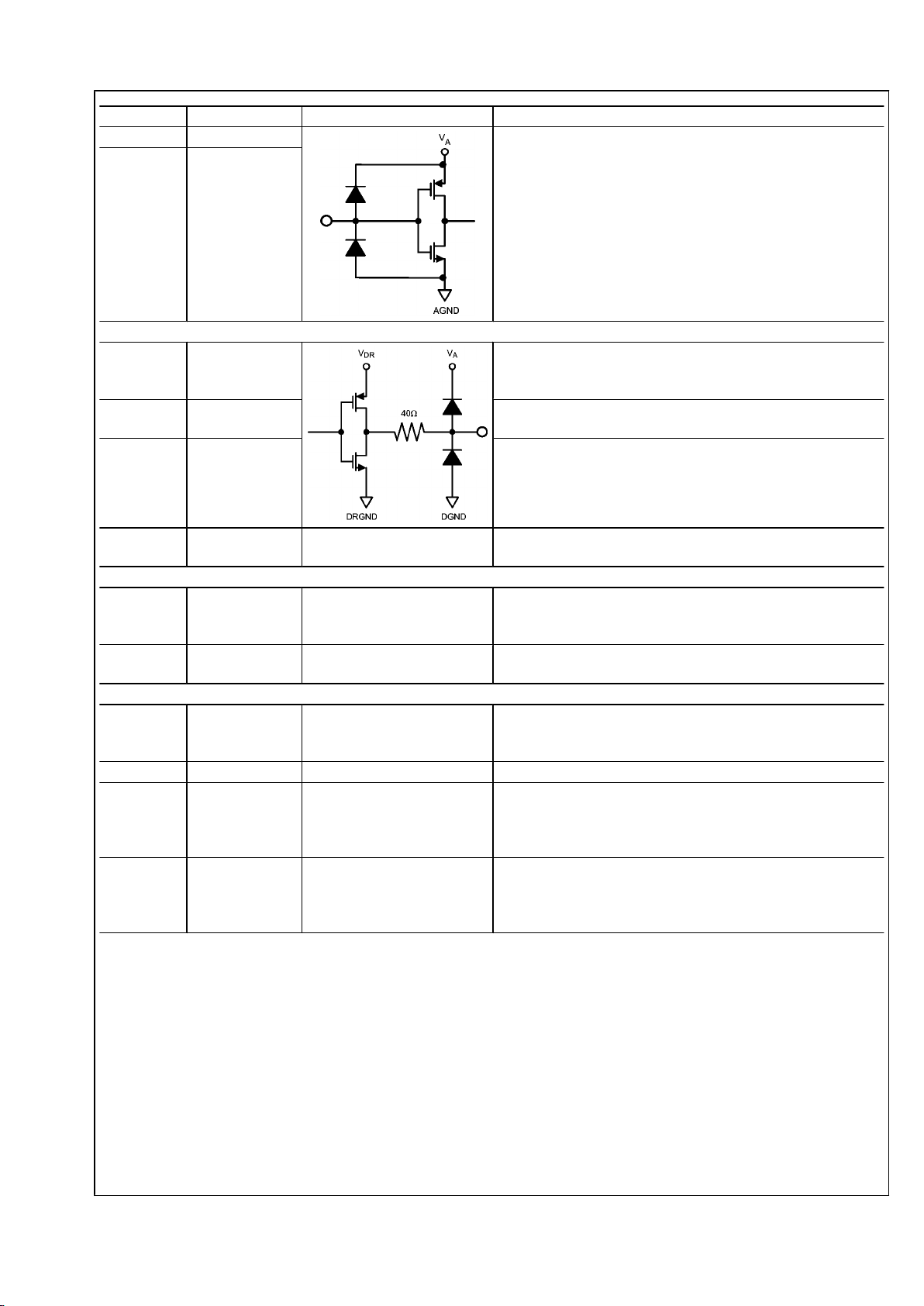

Pin No. Symbol Equivalent Circuit Description

11 CLK+ The clock input pins can be configured to accept either a single-

ended or a differential clock input signal.

When the single-ended clock mode is selected through CLK_SEL/

DF (pin 8), connect the clock input signal to the CLK+ pin and

connect the CLK− pin to AGND.

When the differential clock mode is selected through CLK_SEL/DF

(pin 8), connect the positive and negative clock inputs to the CLK

+ and CLK− pins, respectively.

The analog input is sampled on the falling edge of the clock input.

12 CLK−

DIGITAL I/O

19-24,

27-32

D0–D11

Digital data output pins that make up the 12-Bit conversion result.

D0 (pin 19) is the LSB, while D11 (pin 32) is the MSB of the output

word. Output levels are CMOS compatible.

33 OVR

Over-Range Indicator. This output is set HIGH when the input

amplitude exceeds the 12-Bit conversion range (0 to 4095).

34 DRDY

Data Ready Strobe. This pin is used to clock the output data. It has

the same frequency as the sampling clock. One word of data is

output in each cycle of this signal. The rising edge of this signal

should be used to capture the output data.

17-18 OGND

Output GND, internally tied to GND through 5k ohm resistor to

provide pin compatibility with 14 bit ADCs.

ANALOG POWER

1, 6, 9, 37, 40,

41, 48

V

A

Positive analog supply pins. These pins should be connected to a

quiet +3.3V source and be bypassed to AGND with 0.01 µF and

0.1 µF capacitors located close to the power pins.

2, 5, 10, 38,

39, 42, 47

AGND The ground return for the analog supply.

DIGITAL POWER

13

V

D

Positive digital supply pin. This pin should be connected to a quiet

+3.3V source and be bypassed to DGND with a 0.01 µF and 0.1

µF capacitor located close to the power pin.

14 DGND The ground return for the digital supply.

15, 25, 36

V

DR

Positive driver supply pin for the output drivers. This pin should be

connected to a quiet voltage source of +1.8V and be bypassed to

DRGND with 0.01 µF and 0.1 µF capacitors located close to the

power pins.

16, 26, 35 DRGND

The ground return for the digital output driver supply. These pins

should be connected to the system digital ground, but not be

connected in close proximity to the ADC's DGND or AGND pins.

See Section 6.0 (Layout and Grounding) for more details.

www.national.com 4

ADC12C170

Page 5

Absolute Maximum Ratings

(Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Supply Voltage (VA, VD) −0.3V to 4.2V

Supply Voltage (VDR) −0.3V to 2.35V

|VA–VD|

≤ 100 mV

Voltage on Any Input Pin

(Not to exceed 4.2V)

−0.3V to (VA +0.3V)

Voltage on Any Output Pin

(Not to exceed 2.35V)

-0.3V to (VDR +0.2V)

Input Current at Any Pin other

than Supply Pins (Note 3)

±5 mA

Package Input Current (Note 3) ±50 mA

Max Junction Temp (TJ) +150°C

Thermal Resistance (θJA)

24°C/W

Package Dissipation at TA = 25°

C (Note 4)

5.2W

ESD Rating

Human Body Model (Note 5) 2000 V

Machine Model (Note 5) 200 V

Charge Device Model 1000 V

Storage Temperature −65°C to +150°C

Soldering process must comply with National

Semiconductor's Reflow Temperature Profile

specifications. Refer to www.national.com/packaging.

(Note 6)

Operating Ratings (Notes 1, 2)

Operating Temperature

−40°C ≤ TA ≤ +85°C

Supply Voltage (VA, VD) +3.0V to +3.6V

Output Driver Supply (VDR)

+1.6V to +2.0V

CLK −0.05V to (VA + 0.05V)

Clock Duty Cycle 30/70 %

Analog Input Pins 0V to 2.6V

V

CM

1.4V to 1.6V

|AGND-DGND|

≤100mV

5 www.national.com

ADC12C170

Page 6

Converter Electrical Characteristics

Unless otherwise specified, the following specifications apply: VIN = -1dBFS, AGND = DGND = DRGND = 0V, VA = VD = +3.3V,

VDR = +1.8V, Internal V

REF

= +1.0V, f

CLK

= 170 MHz, VCM = VRM, CL = 5 pF/pin, Single-Ended Clock Mode, Offset Binary Format.

Typical values are for TA = 25°C. Boldface limits apply for T

MIN

≤ TA ≤ T

MAX

. All other limits apply for TA = 25°C (Notes 7, 8, 9)

Symbol Parameter Conditions

Typical

(Note 10)

Limits

Units

(Limits)

STATIC CONVERTER CHARACTERISTICS

Resolution with No Missing Codes 12 Bits (min)

INL Integral Non Linearity (Note 11)

±0.85

2.95 LSB (max)

-3.29 LSB (min)

DNL Differential Non Linearity

±0.54

1.3 LSB (max)

-0.92 LSB (min)

PGE Positive Gain Error +0.85

3.38 %FS (max)

-2.10 %FS (min)

NGE Negative Gain Error -0.31

3.00 %FS (max)

-3.57 %FS (min)

TC GE Gain Error Tempco

−40°C ≤ TA ≤ +85°C

+8.0 ppm/°C

V

OFF

Offset Error (VIN+ = VIN−)

−0.13

0.89 %FS (max)

-1.14 %FS (min)

TC V

OFF

Offset Error Tempco

−40°C ≤ TA ≤ +85°C

+0.5 ppm/°C

Under Range Output Code 0 0

Over Range Output Code 4095 4095

REFERENCE AND ANALOG INPUT CHARACTERISTICS

V

CM

Common Mode Input Voltage 1.5 V

V

RM

Reference Ladder Midpoint Output

Voltage

Output load = 1 mA 1.5 V

C

IN

VIN Input Capacitance (each pin to GND)

(Note 12)

VIN = 1.5 Vdc

± 0.5 V

(CLK LOW) 9 pF

(CLK HIGH) 6 pF

V

REF

Reference Voltage (Note 13) 1.00 V

Reference Input Resistance 9

kΩ

www.national.com 6

ADC12C170

Page 7

Dynamic Converter Electrical Characteristics

Unless otherwise specified, the following specifications apply: VIN = -1dBFS, AGND = DGND = DRGND = 0V, VA = VD = +3.3V,

VDR = +1.8V, Internal V

REF

= +1.0V, f

CLK

= 170 MHz, VCM = VRM, CL = 5 pF/pin, Single-Ended Clock Mode, Offset Binary Format.

Typical values are for TA = 25°C. Boldface limits apply for T

MIN

≤ TA ≤ T

MAX

. All other limits apply for TA = 25°C (Notes 7, 8, 9)

Symbol Parameter Conditions

Typical

(Note

10)

Limits

Units

(Limits)

DYNAMIC CONVERTER CHARACTERISTICS, AIN = -1dBFS

FPBW Full Power Bandwidth -1 dBFS Input, −3 dB Corner 1.1 GHz

SNR Signal-to-Noise Ratio

fIN = 10 MHz

67.5 dBFS

fIN = 70 MHz

67.2 66.0 dBFS

fIN = 150 MHz

67.1 dBFS

fIN = 250 MHz

66.8 dBFS

fIN = 400 MHz

66.0 dBFS

SFDR Spurious Free Dynamic Range

fIN = 10 MHz

86.6 dBFS

fIN = 70 MHz

85.4 74.0 dBFS

fIN = 150 MHz

83.4 dBFS

fIN = 250 MHz

84.1 dBFS

fIN = 400 MHz

72.9 dBFS

ENOB Effective Number of Bits

fIN = 10 MHz

10.9 Bits

fIN = 70 MHz

10.8 10.5 Bits

fIN = 150 MHz

10.8 Bits

fIN = 250 MHz

10.8 Bits

fIN = 400 MHz

10.5 Bits

THD Total Harmonic Disortion

fIN = 10 MHz

-82.6 dBFS

fIN = 70 MHz

−82.6 -72.0 dBFS

fIN = 150 MHz

-81.1 dBFS

fIN = 250 MHz

-80.3 dBFS

fIN = 400 MHz

-70.7 dBFS

H2 Second Harmonic Distortion

fIN = 10 MHz

-89.7 dBFS

fIN = 70 MHz

−88.4 -77.0 dBFS

fIN = 150 MHz

-93.5 dBFS

fIN = 250 MHz

-91.0 dBFS

fIN = 400 MHz

-72.9 dBFS

H3 Third Harmonic Distortion

fIN = 10 MHz

-86.7 dBFS

fIN = 70 MHz

−85.4 -74 dBFS

fIN = 150 MHz

-84.6 dBFS

fIN = 250 MHz

-84.1 dBFS

fIN = 400 MHz

-77.6 dBFS

SINAD Signal-to-Noise and Distortion Ratio

fIN = 10 MHz

67.3 dBFS

fIN = 70 MHz

67.1 65.2 dBFS

fIN = 150 MHz

67.0 dBFS

fIN = 250 MHz

66.6 dBFS

fIN = 400 MHz

64.7 dBFS

7 www.national.com

ADC12C170

Page 8

Logic and Power Supply Electrical Characteristics

Unless otherwise specified, the following specifications apply: VIN = -1 dBFS, AGND = DGND = DRGND = 0V, VA = VD = +3.3V,

VDR = +1.8V, Internal V

REF

= +1.0V, f

CLK

= 170 MHz, VCM = VRM, CL = 5 pF/pin, Single-Ended Clock Mode, Offset Binary Format.

Typical values are for TA = 25°C. Boldface limits apply for T

MIN

≤ TA ≤ T

MAX

. All other limits apply for TA = 25°C (Notes 7, 8, 9)

Symbol Parameter Conditions

Typical

(Note 10)

Limits

Units

(Limits)

CLK INPUT CHARACTERISTICS

V

IN(1)

Logical “1” Input Voltage

VD = 3.6V

2.0 V (min)

V

IN(0)

Logical “0” Input Voltage

VD = 3.0V

0.8 V (max)

I

IN(1)

Logical “1” Input Current

VIN = 3.3V

10

µA

I

IN(0)

Logical “0” Input Current VIN = 0V

−10 µA

C

IN

Input Capacitance 5 pF

DIGITAL OUTPUT CHARACTERISTICS (D0–D11, DRDY, OVR)

V

OUT(1)

Logical “1” Output Voltage

I

OUT

= −0.5 mA , VDR = 1.8V

1.2 V (min)

V

OUT(0)

Logical “0” Output Voltage

I

OUT

= 1.6 mA, VDR = 1.8V

0.4 V (max)

+I

SC

Output Short Circuit Source Current V

OUT

= 0V

−10

mA

−I

SC

Output Short Circuit Sink Current

V

OUT

= V

DR

10 mA

C

OUT

Digital Output Capacitance 5 pF

POWER SUPPLY CHARACTERISTICS

I

A

Analog Supply Current

Full Operation 207 259 mA (max)

I

D

Digital Supply Current

Full Operation 9.8 10.7 mA (max)

I

DR

Digital Output Supply Current

Full Operation (Note 14) 13 mA

Power Consumption

Excludes IDR (Note 14) 715 mW

Power Down Power Consumption 5 mW

Sleep Power Consumption 50 mW

www.national.com 8

ADC12C170

Page 9

Timing and AC Characteristics

Unless otherwise specified, the following specifications apply: VIN = -1dBFS, AGND = DGND = DRGND = 0V, VA = VD = +3.3V,

VDR = +1.8V, Internal V

REF

= +1.0V, f

CLK

= 170 MHz, VCM = VRM, CL = 5 pF/pin, Single-Ended Clock Mode, Offset Binary Format.

Typical values are for TA = 25°C. Timing measurements are taken at 50% of the signal amplitude. Boldface limits apply for

T

MIN

≤ TA ≤ T

MAX

. All other limits apply for TA = 25°C (Notes 7, 8, 9)

Symbol Parameter Conditions

Typical

(Note 10)

Limits

Units

(Limits)

Maximum Clock Frequency 170 MHz (max)

Minimum Clock Frequency 5 MHz (min)

t

CH

Clock High Time 2.7

ns

t

CL

Clock Low Time

2.7 ns

Conversion Latency 7 Clock Cycles

t

OD

Output Delay of CLK to DATA Relative to falling edge of CLK 2.0 ns

t

DV

Data Output Setup Time

Time output data is valid before the

output edge of DRDY (Note 15)

1.9 1.35 ns (min)

t

DNV

Data Output Hold Time

Time till output data is not valid after the

output edge of DRDY (Note 15)

1.9 1.35 ns (min)

t

AD

Aperture Delay 0.5 ns

Aperture Jitter 0.08 ps rms

Power Down Recovery Time

0.1 µF on pins 43, 44; 10 µF and 0.1 µF

between pins 43, 44; 0.1 µF and 10 µF

on pins 45, 46

3.0 ms

Sleep Recovery Time

0.1 µF on pins 43, 44; 10 µF and 0.1 µF

between pins 43, 44; 0.1 µF and 10 µF

on pins 45, 46

100 µs

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

guaranteed to be functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics.

The guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under

the listed test conditions. Operation of the device beyond the maximum Operating Ratings is not recommended.

Note 2: All voltages are measured with respect to GND = AGND = DGND = DRGND = 0V, unless otherwise specified.

Note 3: When the input voltage at any pin exceeds the power supplies (that is, VIN < AGND, or VIN > VA), the current at that pin should be limited to ±5 mA. The

±50 mA maximum package input current rating limits the number of pins that can safely exceed the power supplies with an input current of ±5 mA to 10.

Note 4: The maximum allowable power dissipation is dictated by T

J,max

, the junction-to-ambient thermal resistance, (θJA), and the ambient temperature, (TA), and

can be calculated using the formula P

D,max

= (T

J,max

- TA )/θJA. The values for maximum power dissipation listed above will be reached only when the device is

operated in a severe fault condition (e.g. when input or output pins are driven beyond the power supply voltages, or the power supply polarity is reversed). Such

conditions should always be avoided.

Note 5: Human Body Model is 100 pF discharged through a 1.5 kΩ resistor. Machine Model is 220 pF discharged through 0 Ω

Note 6: Reflow temperature profiles are different for lead-free and non-lead-free packages.

Note 7: The inputs are protected as shown below. Input voltage magnitudes above VA or below GND will not damage this device, provided current is limited per

(Note 3). However, errors in the A/D conversion can occur if the input goes above 2.6V or below GND as described in the Operating Ratings section.

20209211

Note 8: To guarantee accuracy, it is required that |VA–VD| ≤ 100 mV and separate bypass capacitors are used at each power supply pin.

Note 9: With the test condition for V

REF

= +1.0V (2V

P-P

differential input), the 12-Bit LSB is 488.3 µV.

Note 10: Typical figures are at TA = 25°C and represent most likely parametric norms at the time of product characterization. The typical specifications are not

guaranteed.

Note 11: Integral Non Linearity is defined as the deviation of the analog value, expressed in LSBs, from the straight line that passes through positive and negative

full-scale.

Note 12: The input capacitance is the sum of the package/pin capacitance and the sample and hold circuit capacitance.

Note 13: Optimum performance will be obtained by keeping the reference input in the 0.9V to 1.1V range. The LM4051CIM3-ADJ (SOT-23 package) is

recommended for external reference applications.

Note 14: IDR is the current consumed by the switching of the output drivers and is primarily determined by load capacitance on the output pins, the supply voltage,

VDR, and the rate at which the outputs are switching (which is signal dependent). IDR=VDR(C0 x f0 + C1 x f1 +....C11 x f11) where VDR is the output driver power

supply voltage, Cn is total capacitance on the output pin, and fn is the average frequency at which that pin is toggling.

Note 15: This test parameter is guaranteed by design and characterization.

9 www.national.com

ADC12C170

Page 10

Specification Definitions

APERTURE DELAY is the time after the falling edge of the

clock to when the input signal is acquired or held for conversion.

APERTURE JITTER (APERTURE UNCERTAINTY) is the

variation in aperture delay from sample to sample. Aperture

jitter manifests itself as noise in the output.

CLOCK DUTY CYCLE is the ratio of the time during one cycle

that a repetitive digital waveform is high to the total time of

one period. The specification here refers to the ADC clock

input signal.

COMMON MODE VOLTAGE (VCM) is the common DC voltage applied to both input terminals of the ADC.

CONVERSION LATENCY is the number of clock cycles between initiation of conversion and when that data is presented

to the output driver stage. Data for any given sample is available at the output pins the Pipeline Delay plus the Output

Delay after the sample is taken. New data is available at every

clock cycle, but the data lags the conversion by the pipeline

delay.

DIFFERENTIAL NON-LINEARITY (DNL) is the measure of

the maximum deviation from the ideal step size of 1 LSB.

EFFECTIVE NUMBER OF BITS (ENOB, or EFFECTIVE

BITS) is another method of specifying Signal-to-Noise and

Distortion Ratio or SINAD. ENOB is defined as (SINAD -

1.76) / 6.02 and says that the converter is equivalent to a

perfect ADC of this (ENOB) number of bits.

FULL POWER BANDWIDTH is a measure of the frequency

at which the reconstructed output fundamental drops 3 dB

below its low frequency value for a full scale input.

GAIN ERROR is the deviation from the ideal slope of the

transfer function. It can be calculated as:

Gain Error = Positive Full Scale Error − Negative Full Scale

Error

It can also be expressed as Positive Gain Error and Negative

Gain Error, which are calculated as:

PGE = Positive Full Scale Error - Offset Error

NGE = Offset Error - Negative Full Scale Error

INTEGRAL NON LINEARITY (INL) is a measure of the deviation of each individual code from a line drawn from negative

full scale (½ LSB below the first code transition) through positive full scale (½ LSB above the last code transition). The

deviation of any given code from this straight line is measured

from the center of that code value.

INTERMODULATION DISTORTION (IMD) is the creation of

additional spectral components as a result of two sinusoidal

frequencies being applied to the ADC input at the same time.

It is defined as the ratio of the power in the intermodulation

products to the total power in the original frequencies. IMD is

usually expressed in dBFS.

LSB (LEAST SIGNIFICANT BIT) is the bit that has the smallest value or weight of all bits. This value is VFS/2n, where

“VFS” is the full scale input voltage and “n” is the ADC resolution in bits.

MISSING CODES are those output codes that will never appear at the ADC outputs. The ADC12C170 is guaranteed not

to have any missing codes.

MSB (MOST SIGNIFICANT BIT) is the bit that has the largest

value or weight. Its value is one half of full scale.

NEGATIVE FULL SCALE ERROR is the difference between

the actual first code transition and its ideal value of ½ LSB

above negative full scale.

OFFSET ERROR is the difference between the two input

voltages [(VIN+) – (VIN-)] required to cause a transition from

code 2047 to 2048.

OUTPUT DELAY is the time delay after the falling edge of the

clock before the data update is presented at the output pins.

PIPELINE DELAY (LATENCY) See CONVERSION LATENCY.

POSITIVE FULL SCALE ERROR is the difference between

the actual last code transition and its ideal value of 1½ LSB

below positive full scale.

POWER SUPPLY REJECTION RATIO (PSRR) is a measure

of how well the ADC rejects a change in the power supply

voltage. PSRR is the ratio of the Full-Scale output of the ADC

with the supply at the minimum DC supply limit to the FullScale output of the ADC with the supply at the maximum DC

supply limit, expressed in dB.

SIGNAL TO NOISE RATIO (SNR) is the ratio, expressed in

dB, of the rms value of the input signal to the rms value of the

sum of all other spectral components below one-half the sampling frequency, not including harmonics or DC.

SIGNAL TO NOISE PLUS DISTORTION (S/N+D or

SINAD) Is the ratio, expressed in dB, of the rms value of the

input signal to the rms value of all of the other spectral components below half the clock frequency, including harmonics

but excluding d.c.

SPURIOUS FREE DYNAMIC RANGE (SFDR) is the difference, expressed in dB, between the rms values of the input

signal and the peak spurious signal, where a spurious signal

is any signal present in the output spectrum that is not present

at the input.

TOTAL HARMONIC DISTORTION (THD) is the ratio, expressed in dB, of the rms total of the first nine harmonic levels

at the output to the level of the fundamental at the output. THD

is calculated as

where f1 is the RMS power of the fundamental (output) frequency and f2 through f10 are the RMS power of the first 9

harmonic frequencies in the output spectrum.

SECOND HARMONIC DISTORTION (2ND HARM) is the difference expressed in dB, between the RMS power in the input

frequency at the output and the power in its 2nd harmonic

level at the output.

THIRD HARMONIC DISTORTION (3RD HARM) is the difference, expressed in dB, between the RMS power in the

input frequency at the output and the power in its 3rd harmonic

level at the output.

www.national.com 10

ADC12C170

Page 11

Timing Diagram

20209209

Output Timing

Transfer Characteristic

20209210

FIGURE 1. Transfer Characteristic (Offset Binary Format)

11 www.national.com

ADC12C170

Page 12

Typical Performance Characteristics, DNL, INL

Unless otherwise specified, the following specifications apply: VIN = -1dBFS, AGND = DGND = DRGND = 0V, VA = VD = +3.3V,

VDR = +1.8V, Internal V

REF

= +1.0V, f

CLK

= 170 MHz, VCM = VRM, CL = 5 pF/pin, Single-Ended Clock Mode, Offset Binary Format.

Typical values are for TA = 25°C. (Notes 7, 8, 9)

DNL

20209261

INL

20209262

www.national.com 12

ADC12C170

Page 13

Typical Performance Characteristics, Dynamic Performance

Unless otherwise specified, the following specifications apply: VIN = -1dBFS, AGND = DGND = DRGND = 0V, VA = VD = +3.3V,

VDR = +1.8V, Internal V

REF

= +1.0V, f

CLK

= 170 MHz, fIN = 70 MHz, VCM = VRM, CL = 5 pF/pin, Single-Ended Clock Mode, Offset

Binary Format. Typical values are for TA = 25°C.

SNR, SINAD, SFDR vs. f

IN

20209295

DISTORTION vs. f

IN

20209283

SNR, SINAD, SFDR vs. V

A

20209273

DISTORTION vs. V

A

20209274

SNR, SINAD, SFDR vs. V

DR

20209275

DISTORTION vs. V

DR

20209276

13 www.national.com

ADC12C170

Page 14

Typical Performance Characteristics, Dynamic Performance

Unless otherwise specified, the following specifications apply: VIN = -1dBFS, AGND = DGND = DRGND = 0V, VA = VD = +3.3V,

VDR = +1.8V, Internal V

REF

= +1.0V, f

CLK

= 170 MHz, fIN = 70 MHz, VCM = VRM, CL = 5 pF/pin, Single-Ended Clock Mode, Offset

Binary Format. Typical values are for TA = 25°C.

SNR, SINAD, SFDR vs. V

REF

20209277

DISTORTION vs. V

REF

20209278

SNR, SINAD, SFDR vs. Temperature

20209281

DISTORTION vs. Temperature

20209282

www.national.com 14

ADC12C170

Page 15

Typical Performance Characteristics, Dynamic Performance

Unless otherwise specified, the following specifications apply: VIN = -1dBFS, AGND = DGND = DRGND = 0V, VA = VD = +3.3V,

VDR = +1.8V, Internal V

REF

= +1.0V, f

CLK

= 170 MHz, fIN = 70 MHz, VCM = VRM, CL = 5 pF/pin, Single-Ended Clock Mode, Offset

Binary Format. Typical values are for TA = 25°C.

Spectral Response @ 70 MHz Input

20209292

Spectral Response @ 150 MHz Input

20209293

Spectral Response @ 220 MHz Input

20209294

Spectral Response @ 250 MHz Input

20209296

Spectral Response @ 350 MHz Input

20209297

Spectral Response @ 400 MHz Input

20209298

15 www.national.com

ADC12C170

Page 16

Functional Description

Operating on dual +3.3V and +1.8V supplies, the ADC12C170 digitizes a differential analog input signal to 12 bits,

using a differential pipelined architecture with error correction

circuitry and an on-chip sample-and-hold circuit to ensure

maximum performance.

The user has the choice of using an internal 1.0V stable reference, or using an external reference. The ADC12C170 will

accept an external reference between 0.9V and 1.1V (1.0V

recommended) which is buffered on-chip to ease the task of

driving that pin. The +1.8V output driver supply reduces power consumption and decreases the noise at the output of the

converter.

The quad state function pin CLK_SEL/DF (pin 8) allows the

user to choose between using a single-ended or a differential

clock input and between offset binary or 2's complement output data format. The digital outputs are CMOS compatible

signals that are clocked by a synchronous data ready output

signal (DRDY, pin 34) at the same rate as the clock input. For

the ADC12C170 the clock frequency can be between 5 MSPS

and 170 MSPS (typical) with fully specified performance at

170 MSPS. The analog input is acquired at the falling edge of

the clock and the digital data for a given sample is output on

the falling edge of the DRDY signal and is delayed by the

pipeline for 7 clock cycles. The data should be captured on

the rising edge of the DRDY signal.

Power-down is selectable using the PD/Sleep pin (pin 7). A

logic high on the PD/Sleep pin disables everything except the

voltage reference circuitry and reduces the converter power

consumption to 5 mW. When PD/Sleep is biased to VA/2 the

the chip enters sleep mode. In sleep mode everything except

the voltage reference circuitry and its accompanying on chip

buffer is disabled; power consumption is reduced to 50 mW.

For normal operation, the PD/Sleep pin should be connected

to the analog ground (AGND). A duty cycle stabilizer maintains performance over a wide range of clock duty cycles.

Applications Information

1.0 OPERATING CONDITIONS

We recommend that the following conditions be observed for

operation of the ADC12C170:

3.0V ≤ VA ≤ 3.6V

VD = V

A

VDR = 1.8V

5 MHz ≤ f

CLK

≤ 170 MHz

1.0V internal reference

0.9V ≤ V

REF

≤ 1.1V (for an external reference)

VCM = 1.5V (from VRM)

Single Ended Clock Mode

2.0 ANALOG INPUTS

2.1 Signal Inputs

2.1.1 Differential Analog Input Pins

The ADC12C170 has one pair of analog signal input pins,

VIN+ and VIN−, which form a differential input pair. The input

signal, VIN, is defined as

VIN = (VIN+) – (VIN−)

Figure 2 shows the expected input signal range. Note that the

common mode input voltage, VCM, should be 1.5V. Using

VRM (pin 45) for VCM will ensure the proper input common

mode level for the analog input signal. The peaks of the individual input signals should each never exceed 2.6V. Each

analog input pin of the differential pair should have a peak-topeak voltage equal to the reference voltage, V

REF

, be 180°

out of phase with each other and be centered around

VCM.The peak-to-peak voltage swing at each analog input pin

should not exceed the value of the reference voltage or the

output data will be clipped.

20209214

FIGURE 2. Expected Input Signal Range

For single frequency sine waves the full scale error in LSB

can be described as approximately

EFS = 4096 ( 1 - sin (90° + dev))

Where dev is the angular difference in degrees between the

two signals having a 180° relative phase relationship to each

other (see Figure 3). For single frequency inputs, angular errors result in a reduction of the effective full scale input. For

complex waveforms, however, angular errors will result in

distortion.

20209216

FIGURE 3. Angular Errors Between the Two Input Signals

Will Reduce the Output Level or Cause Distortion

It is recommended to drive the analog inputs with a source

impedance less than 100Ω. Matching the source impedance

for the differential inputs will improve even ordered harmonic

performance (particularly second harmonic).

Table 1 indicates the input to output relationship of the ADC12C170.

www.national.com 16

ADC12C170

Page 17

TABLE 1. Input to Output Relationship

V

IN

+

V

IN

−

Binary Output 2’s Complement Output

VCM − V

REF

/2 VCM + V

REF

/2

0000 0000 0000 1000 0000 0000 Negative Full-Scale

VCM − V

REF

/4 VCM + V

REF

/4

0100 0000 0000 1100 0000 0000

V

CM

V

CM

1000 0000 0000 0000 0000 0000 Mid-Scale

VCM + V

REF

/4 VCM − V

REF

/4

1100 0000 0000 0100 0000 0000

VCM + V

REF

/2 VCM − V

REF

/2

1111 1111 1111 0111 1111 1111 Positive Full-Scale

2.1.2 Driving the Analog Inputs

The VIN+ and the VIN− inputs of the ADC12C170 have an internal sample-and-hold circuit which consists of an analog

switch followed by a switched-capacitor amplifier. The analog

inputs are connected to the sampling capacitors through

NMOS switches, and each analog input has parasitic capacitances associated with it.

When the clock is high, the converter is in the sample phase.

The analog inputs are connected to the sampling capacitor

through the NMOS switches, which causes the capacitance

at the analog input pins to appear as the pin capacitance plus

the internal sample and hold circuit capacitance (approximately 9 pF). While the clock level remains high, the sampling

capacitor will track the changing analog input voltage. When

the clock transitions from high to low, the converter enters the

hold phase, during which the analog inputs are disconnected

from the sampling capacitor. The last voltage that appeared

at the analog input before the clock transition will be held on

the sampling capacitor and will be sent to the ADC core. The

capacitance seen at the analog input during the hold phase

appears as the sum of the pin capacitance and the parasitic

capacitances associated with the sample and hold circuit of

each analog input (approximately 6 pF). Once the clock signal

transitions from low to high, the analog inputs will be reconnected to the sampling capacitor to capture the next sample.

Usually, there will be a difference between the held voltage

on the sampling capacitor and the new voltage at the analog

input. This will cause a charging glitch that is proportional to

the voltage difference between the two samples to appear at

the analog input pin. The input circuitry must be fast enough

to allow the sampling capacitor to settle before the clock signal goes low again, as incomplete settling can degrade the

SFDR performance.

A single-ended to differential conversion circuit is shown in

Figure 4. A transformer is preferred for high frequency input

signals. Terminating the transformer on the secondary side

provides two advantages. First, it presents a real broadband

impedance to the ADC inputs and second, it provides a common path for the charging glitches from each side of the

differential sample-and-hold circuit.

One short-coming of using a transformer to achieve the single-ended to differential conversion is that most RF transformers have poor low frequency performance. A differential

amplifier can be used to drive the analog inputs for low frequency applications. The amplifier must be fast enough to

settle from the charging glitches on the analog input resulting

from the sample-and-hold operation before the clock goes

high and the sample is passed to the ADC core.

The SFDR performance of the converter depends on the external signal conditioning circuity used, as this affects how

quickly the sample-and-hold charging glitch will settle. An external resistor and capacitor network as shown in Figure 4

should be used to isolate the charging glitches at the ADC

input from the external driving circuit and to filter the wideband

noise at the converter input. These components should be

placed close to the ADC inputs because the analog input of

the ADC is the most sensitive part of the system, and this is

the last opportunity to filter that input. For Nyquist applications

the RC pole should be at the ADC sample rate. The ADC input

capacitance in the sample mode should be considered when

setting the RC pole. For wideband undersampling applications, the RC pole should be set at about 1.5 to 2 times the

maximum input frequency to maintain a linear delay response.

2.1.3 Input Common Mode Voltage

The input common mode voltage, VCM, should be in the range

of 1.4V to 1.6V and be a value such that the peak excursions

of the analog signal do not go more negative than ground or

more positive than 2.6V. It is recommended to use VRM (pin

45) as the input common mode voltage.

2.2 Reference Pins

The ADC12C170 is designed to operate with an internal 1.0V

reference, or an external 1.0V reference, but performs well

with external reference voltages in the range of 0.9V to 1.1V.

The internal 1.0 Volt reference is the default condition when

no external reference input is applied to the V

REF

pin. If a volt-

age in the range of 0.9V to 1.1V is applied to the V

REF

pin,

then that voltage is used for the reference. The V

REF

pin

should always be bypassed to ground with a 0.1 µF capacitor

close to the reference input pin. Lower reference voltages will

decrease the signal-to-noise ratio (SNR) of the ADC12C170.

Increasing the reference voltage (and the input signal swing)

beyond 1.1V may degrade THD for a full-scale input, especially at higher input frequencies.

It is important that all grounds associated with the reference

voltage and the analog input signal make connection to the

ground plane at a single, quiet point to minimize the effects of

noise currents in the ground path.

The Reference Bypass Pins (VRP, VRM, and VRN) are made

available for bypass purposes. All these pins should each be

bypassed to ground with a 0.1 µF capacitor. A 0.1 µF and a

10 µF capacitor should be placed between the VRP and V

RN

pins, as shown in Figure 4. This configuration is necessary to

avoid reference oscillation, which could result in reduced SFDR and/or SNR. VRM may be loaded to 1mA for use as a

temperature stable 1.5V reference. The remaining pins

should not be loaded.

Smaller capacitor values than those specified will allow faster

recovery from the power down and sleep modes, but may result in degraded noise performance. Loading any of these

pins, other than VRM, may result in performance degradation.

The nominal voltages for the reference bypass pins are as

follows:

VRM = 1.5 V

VRP = VRM + V

REF

/ 2

VRN = VRM − V

REF

/ 2

17 www.national.com

ADC12C170

Page 18

2.3 Control Inputs

2.3.1 Power-Down & Sleep (PD/Sleep)

The power-down and sleep modes can be enabled through

this three-state input pin. Table 2 shows how to utilize these

options.

TABLE 2. Power Down/Sleep Selection Table

PD Input Voltage Power State

V

A

Power-down

VA/2

Sleep

AGND On

The power-down and sleep modes allows the user to conserve power when the converter is not being used. In the

power-down state all bias currents of the analog circuitry, excluding the reference are shut down which reduces the power

consumption to 5 mW with no clock running. In sleep mode

some additional buffer circuitry is left on to allow an even

faster wake time; power consumption in the sleep mode is 50

mW with no clock running. In both of these modes the output

data pins are undefined and the data in the pipeline is corrupted.

The Exit Cycle time for both the sleep and power-down mode

is determined by the value of the capacitors on the VRP, V

RM

and VRN reference bypass pins (pins 43, 44 and 45). These

capacitors lose their charge when the ADC is not operating

and must be recharged by on-chip circuitry before conversions can be accurate. For power-down mode the Exit Cycle

time is about 3 ms with the recommended component values.

The Exit Cycle time is faster for sleep mode. Smaller capacitor

values allow slightly faster recovery from the power down and

sleep mode, but can result in a reduction in SNR, SINAD and

ENOB performance.

2.3.2 Clock Mode Select/Data Format (CLK_SEL/DF)

Single-ended versus differential clock mode and output data

format are selectable using this quad-state function pin. Table

3 shows how to select between the clock modes and the output data formats.

TABLE 3. Clock Mode and Data Format Selection Table

CLK_SEL/DF

Input Voltage

Clock Mode

Output Data

Format

V

A

Differential 2's Complement

(2/3) * V

A

Differential Offset Binary

(1/3) * V

A

Single-Ended 2's Complement

AGND Single-Ended Offset Binary

3.0 CLOCK INPUTS

The CLK+ and CLK− signals control the timing of the sampling

process. The CLK_SEL/DF pin (pin 8) allows the user to configure the ADC for either differential or single-ended clock

mode (see Section 3.3). In differential clock mode, the two

clock signals should be exactly 180° out of phase from each

other and of the same amplitude. In the single-ended clock

mode, the clock signal should be routed to the CLK+ input and

the CLK− input should be tied to AGND in combination with

the correct setting from Table 3.

To achieve the optimum noise performance, the clock inputs

should be driven with a stable, low jitter clock signal in the

range indicated in the Electrical Table. The clock input signal

should also have a short transition region. This can be

achieved by passing a low-jitter sinusoidal clock source

through a high speed buffer gate. This configuration is shown

in Figure 4. The trace carrying the clock signal should be as

short as possible and should not cross any other signal line,

analog or digital, not even at 90°. Figure 4 shows the recom-

mended clock input circuit.

The clock signal also drives an internal state machine. If the

clock is interrupted, or its frequency is too low, the charge on

the internal capacitors can dissipate to the point where the

accuracy of the output data will degrade. This is what limits

the minimum sample rate.

The clock line should be terminated at its source in the characteristic impedance of that line. Take care to maintain a

constant clock line impedance throughout the length of the

line. Refer to Application Note AN-905 for information on setting characteristic impedance.

It is highly desirable that the the source driving the ADC clock

pins only drive that pin. However, if that source is used to drive

other devices, then each driven pin should be AC terminated

with a series RC to ground, such that the resistor value is

equal to the characteristic impedance of the clock line and the

capacitor value is

where tPD is the signal propagation rate down the clock line,

"L" is the line length and ZO is the characteristic impedance

of the clock line. This termination should be as close as possible to the ADC clock pin but beyond it as seen from the clock

source. Typical tPD is about 150 ps/inch (60 ps/cm) on FR-4

board material. The units of "L" and tPD should be the same

(inches or centimeters).

The duty cycle of the clock signal can affect the performance

of the A/D Converter. Because achieving a precise duty cycle

is difficult, the ADC12C170 has a Duty Cycle Stabilizer. It is

designed to maintain performance over a clock duty cycle

range of 30% to 70%.

4.0 DIGITAL OUTPUTS

Digital outputs consist of the 1.8V CMOS signals D0-D11,

DRDY, OVR and OGND.

The ADC12C170 has 16 CMOS compatible data output pins:

12 data output bits corresponding to the converted input value, a data ready (DRDY) signal that should be used to capture

the output data, an over-range indicator (OVR) which is set

high when the sample amplitude exceeds the 12-Bit conversion range and two output ground pins (OGND) which should

be ignored except when used for compatibility with a 14 bit

part. Valid data is present at these outputs while the PD/Sleep

pin is low.

Data should be captured and latched with the rising edge of

the DRDY signal. Depending on the setup and hold time requirements of the receiving circuit (ASIC), either the rising

edge or the falling edge of the DRDY signal can be used to

latch the data. Generally, rising-edge capture would maximize setup time with minimal hold time; while falling-edgecapture would maximize hold time with minimal setup time.

However, actual timing for the falling-edge case depends

greatly on the CLK frequency and both cases also depend on

the delays inside the ASIC. Refer to the AC Electrical Characterisitics table.

Be very careful when driving a high capacitance bus. The

more capacitance the output drivers must charge for each

conversion, the more instantaneous digital current flows

through VDR and DRGND. These large charging current

www.national.com 18

ADC12C170

Page 19

spikes can cause on-chip ground noise and couple into the

analog circuitry, degrading dynamic performance. Adequate

bypassing, limiting output capacitance and careful attention

to the ground plane will reduce this problem. Additionally, bus

capacitance beyond the specified 5 pF/pin will cause tOD to

increase, reducing the setup and hold time of the ADC output

data. The result could be an apparent reduction in dynamic

performance.

To minimize noise due to output switching, the load currents

at the digital outputs should be minimized. This can be done

by using a programmable logic device (PLD) such as the

LC4032V-25TN48C to level translate the ADC output data

from 1.8V to 3.3V for use by any other circuitry. Only one load

should be connected to each output pin. The outputs of the

ADC14155 have 40Ω on-chip series resistors to limit the output currents at the digital outputs. Additionally, inserting series resistors of about 22Ω at the digital outputs, close to the

ADC pins, will isolate the outputs from trace and other circuit

capacitances and limit the output currents, which could otherwise result in performance degradation. See Figure 4.

20209213

FIGURE 4. Application Circuit using Transformer Drive Circuit (If 14-bit compatibility is not required do not connect pins

17 and 18)

5.0 POWER SUPPLY CONSIDERATIONS

The power supply pins should be bypassed with a 0.1 µF capacitor and with a 0.01 µF ceramic chip capacitor close to

each power pin. Leadless chip capacitors are preferred because they have low series inductance.

As is the case with all high-speed converters, the ADC12C170 is sensitive to power supply noise. Accordingly, the

noise on the analog supply pin should be kept below 100

mV

P-P

.

No pin should ever have a voltage on it that is in excess of the

supply voltages, not even on a transient basis. Be especially

careful of this during power turn on and turn off.

The VDR pin provides power for the output drivers and may be

operated from a supply in the range of 1.6V to 2.0V. This enables lower power operation, reduces the noise coupling

effects from the digital outputs to the analog circuitry and simplifies interfacing to lower voltage devices and systems. Note,

however, that tOD increases with reduced VDR. A level translator may be required to interface the digital output signals of

the ADC12C170 to non-1.8V CMOS devices.

6.0 LAYOUT AND GROUNDING

Proper grounding and proper routing of all signals are essential to ensure accurate conversion. Maintaining separate analog and digital areas of the board, with the ADC12C170

between these areas, is required to achieve specified performance.

The ground return for the data outputs (DRGND) carries the

ground current for the output drivers. The output current can

exhibit high transients that could add noise to the conversion

process. To prevent this from happening, the DRGND pins

should NOT be connected to system ground in close proximity

to any of the ADC12C170's other ground pins.

Capacitive coupling between the typically noisy digital circuitry and the sensitive analog circuitry can lead to poor performance. The solution is to keep the analog circuitry separated

from the digital circuitry, and to keep the clock line as short as

possible.

The effects of the noise generated from the ADC output

switching can be minimized through the use of 22Ω resistors

in series with each data output line. Locate these resistors as

close to the ADC output pins as possible.

Since digital switching transients are composed largely of

high frequency components, total ground plane copper

weight will have little effect upon the logic-generated noise.

This is because of the skin effect. Total surface area is more

important than is total ground plane area.

Generally, analog and digital lines should cross each other at

90° to avoid crosstalk. To maximize accuracy in high speed,

high resolution systems, however, avoid crossing analog and

digital lines altogether. It is important to keep clock lines as

19 www.national.com

ADC12C170

Page 20

short as possible and isolated from ALL other lines, including

other digital lines. Even the generally accepted 90° crossing

should be avoided with the clock line as even a little coupling

can cause problems at high frequencies. This is because other lines can introduce jitter into the clock line, which can lead

to degradation of SNR. Also, the high speed clock can introduce noise into the analog chain.

Best performance at high frequencies and at high resolution

is obtained with a straight signal path. That is, the signal path

through all components should form a straight line wherever

possible.

Be especially careful with the layout of inductors and transformers. Mutual inductance can change the characteristics of

the circuit in which they are used. Inductors and transformers

should not be placed side by side, even with just a small part

of their bodies beside each other. For instance, place transformers for the analog input and the clock input at 90° to one

another to avoid magnetic coupling.

The analog input should be isolated from noisy signal traces

to avoid coupling of spurious signals into the input. Any external component (e.g., a filter capacitor) connected between

the converter's input pins and ground or to the reference input

pin and ground should be connected to a very clean point in

the ground plane.

All analog circuitry (input amplifiers, filters, reference components, etc.) should be placed in the analog area of the board.

All digital circuitry and dynamic I/O lines should be placed in

the digital area of the board. The ADC12C170 should be between these two areas. Furthermore, all components in the

reference circuitry and the input signal chain that are connected to ground should be connected together with short

traces and enter the ground plane at a single, quiet point. All

ground connections should have a low inductance path to

ground.

7.0 DYNAMIC PERFORMANCE

To achieve the best dynamic performance, the clock source

driving the CLK input must have a sharp transition region and

be free of jitter. Isolate the ADC clock from any digital circuitry

with buffers, as with the clock tree shown in Figure 5 . The

gates used in the clock tree must be capable of operating at

frequencies much higher than those used if added jitter is to

be prevented. Best performance will be obtained with a single-ended drive input drive, compared with a differential clock.

As mentioned in Section 6.0, it is good practice to keep the

ADC clock line as short as possible and to keep it well away

from any other signals. Other signals can introduce jitter into

the clock signal, which can lead to reduced SNR performance, and the clock can introduce noise into other lines.

Even lines with 90° crossings have capacitive coupling, so try

to avoid even these 90° crossings of the clock line.

20209217

FIGURE 5. Isolating the ADC Clock from other Circuitry

with a Clock Tree

www.national.com 20

ADC12C170

Page 21

Physical Dimensions inches (millimeters) unless otherwise noted

48-Lead LLP Package

Ordering Number ADC12C170CISQ

NS Package Number SQA48A

21 www.national.com

ADC12C170

Page 22

Notes

ADC12C170 12-Bit, 170 MSPS, 1.1 GHz Bandwidth A/D Converter

THE CONTENTS OF THIS DOCUMENT ARE PROVIDED IN CONNECTION WITH NATIONAL SEMICONDUCTOR CORPORATION

(“NATIONAL”) PRODUCTS. NATIONAL MAKES NO REPRESENTATIONS OR WARRANTIES WITH RESPECT TO THE ACCURACY

OR COMPLETENESS OF THE CONTENTS OF THIS PUBLICATION AND RESERVES THE RIGHT TO MAKE CHANGES TO

SPECIFICATIONS AND PRODUCT DESCRIPTIONS AT ANY TIME WITHOUT NOTICE. NO LICENSE, WHETHER EXPRESS,

IMPLIED, ARISING BY ESTOPPEL OR OTHERWISE, TO ANY INTELLECTUAL PROPERTY RIGHTS IS GRANTED BY THIS

DOCUMENT.

TESTING AND OTHER QUALITY CONTROLS ARE USED TO THE EXTENT NATIONAL DEEMS NECESSARY TO SUPPORT

NATIONAL’S PRODUCT WARRANTY. EXCEPT WHERE MANDATED BY GOVERNMENT REQUIREMENTS, TESTING OF ALL

PARAMETERS OF EACH PRODUCT IS NOT NECESSARILY PERFORMED. NATIONAL ASSUMES NO LIABILITY FOR

APPLICATIONS ASSISTANCE OR BUYER PRODUCT DESIGN. BUYERS ARE RESPONSIBLE FOR THEIR PRODUCTS AND

APPLICATIONS USING NATIONAL COMPONENTS. PRIOR TO USING OR DISTRIBUTING ANY PRODUCTS THAT INCLUDE

NATIONAL COMPONENTS, BUYERS SHOULD PROVIDE ADEQUATE DESIGN, TESTING AND OPERATING SAFEGUARDS.

EXCEPT AS PROVIDED IN NATIONAL’S TERMS AND CONDITIONS OF SALE FOR SUCH PRODUCTS, NATIONAL ASSUMES NO

LIABILITY WHATSOEVER, AND NATIONAL DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY RELATING TO THE SALE

AND/OR USE OF NATIONAL PRODUCTS INCLUDING LIABILITY OR WARRANTIES RELATING TO FITNESS FOR A PARTICULAR

PURPOSE, MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR

SYSTEMS WITHOUT THE EXPRESS PRIOR WRITTEN APPROVAL OF THE CHIEF EXECUTIVE OFFICER AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

Life support devices or systems are devices which (a) are intended for surgical implant into the body, or (b) support or sustain life and

whose failure to perform when properly used in accordance with instructions for use provided in the labeling can be reasonably expected

to result in a significant injury to the user. A critical component is any component in a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system or to affect its safety or effectiveness.

National Semiconductor and the National Semiconductor logo are registered trademarks of National Semiconductor Corporation. All other

brand or product names may be trademarks or registered trademarks of their respective holders.

Copyright© 2007 National Semiconductor Corporation

For the most current product information visit us at www.national.com

National Semiconductor

Americas Customer

Support Center

Email:

new.feedback@nsc.com

Tel: 1-800-272-9959

National Semiconductor Europe

Customer Support Center

Fax: +49 (0) 180-530-85-86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 69 9508 6208

English Tel: +49 (0) 870 24 0 2171

Français Tel: +33 (0) 1 41 91 8790

National Semiconductor Asia

Pacific Customer Support Center

Email: ap.support@nsc.com

National Semiconductor Japan

Customer Support Center

Fax: 81-3-5639-7507

Email: jpn.feedback@nsc.com

Tel: 81-3-5639-7560

www.national.com

Loading...

Loading...