Page 1

TL/H/5676

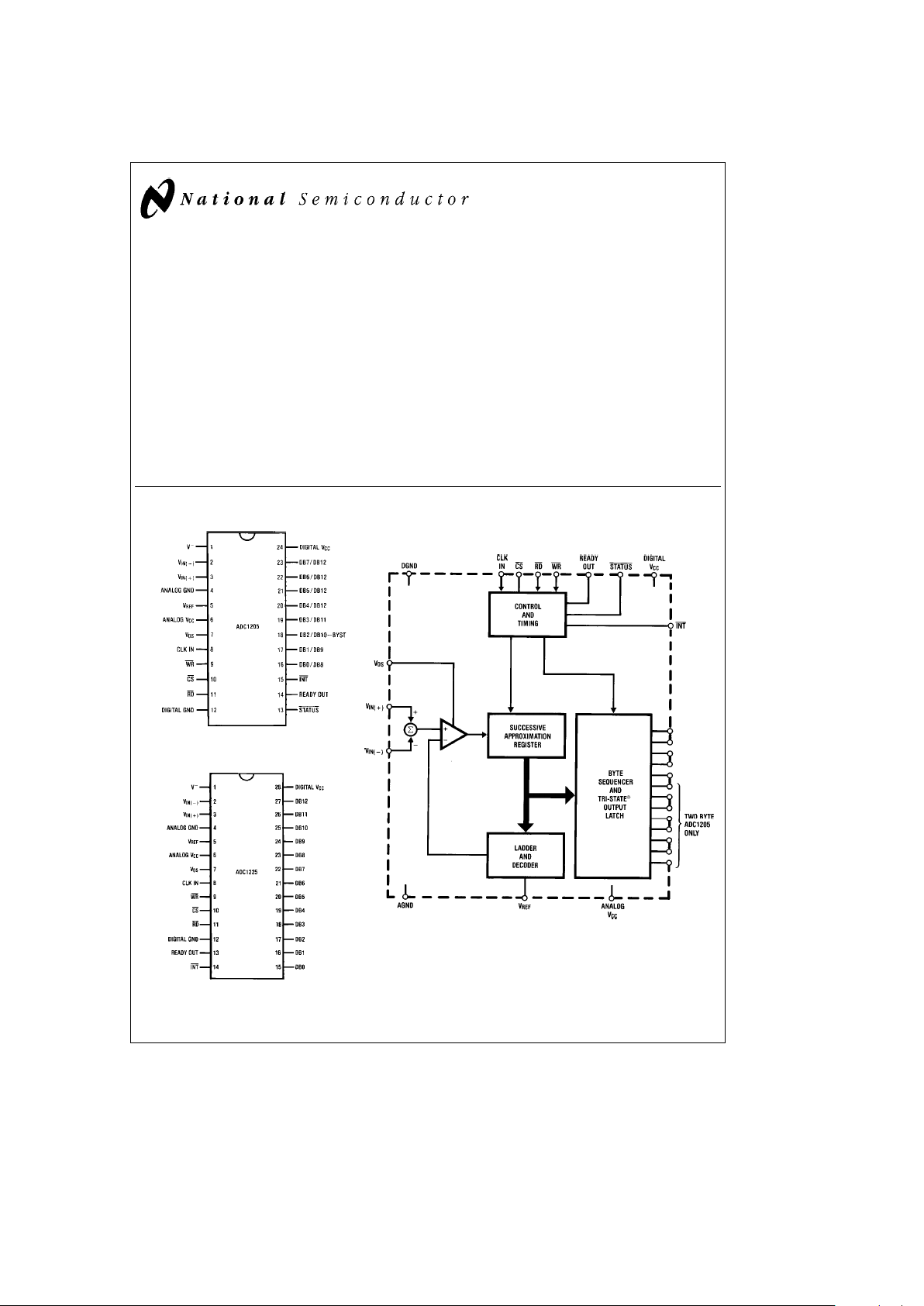

ADC1205/ADC1225 12-Bit Plus Sign mP Compatible A/D Converters

June 1994

ADC1205/ADC1225 12-Bit Plus Sign

mP Compatible A/D Converters

General Description

The ADC1205 and ADC1225 are CMOS, 12-bit plus sign

successive approximation A/D converters. The 24-pin

ADC1205 outputs the 13-bit data result in two 8-bit bytes,

formatted high-byte first with sign extended. The 28-pin

ADC1225 outputs a 13-bit word in parallel for direct interface to a 16-bit data bus.

Negative numbers are represented in 2’s complement data

format. All digital signals are fully TTL and MOS compatible.

A unipolar input (0V to 5V) can be accommodated with a

single 5V supply, while a bipolar input (

b

5V toa5V) re-

quires the addition of a 5V negative supply.

The ADC1205C and ADC1225C have a maximum non-linearity of 0.0224% of Full Scale.

Key Specifications

Y

ResolutionÐ12 bits plus sign

Y

Linearity ErrorÐg1 LSB

Y

Conversion TimeÐ100 ms

Features

Y

Compatible with all mPs

Y

True differential analog voltage inputs

Y

0V to 5V analog voltage range with single 5V supply

Y

TTL/MOS input/output compatible

Y

Low powerÐ25 mW max

Y

Standard 24-pin or 28-pin DIP

Connection and Functional Diagrams

Dual-In-Line Package

TL/H/5676– 1

Top View

Dual-In-Line Package

TL/H/5676– 2

Top View

TL/H/5676– 3

See Ordering Information

TRI-STATEÉis a registered trademark of National Semiconductor Corporation.

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

Page 2

Absolute Maximum Ratings (Notes1&2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage (DV

CC

and AVCC) 6.5V

Negative Supply Voltage (V

b

)

b

15V to GND

Logic Control Inputs

b

0.3V toa15V

Voltage at Analog Inputs

[

V

IN(a),VIN(b)

]

(V

b

)b0.3V to V

CC

a

0.3V

Voltage at All Outputs, V

REF,VOS

b

0.3V to (V

CC

a

0.3)V

Input Current per Pin

g

5mA

Input Current per Package

g

20mA

Storage Temperature Range

b

65§Ctoa150§C

Package Dissipation at T

A

e

25§C 875 mW

Lead Temp. (Soldering, 10 seconds) 300

§

C

ESD Susceptibility (Note 12) 800V

Operating Conditions (Notes1&2)

Temperature Range T

MIN

s

T

A

s

T

MAX

ADC1205CCJ, ADC1225CCD

b

40§CsT

A

s

a

85§C

ADC1205CCJ-1, ADC1225CCD-1 0

§

CsT

A

s

70§C

Supply Voltage (DV

CC

and AVCC) 4.5 VDCto 6.0 V

DC

Negative Supply Voltage (Vb)

b

15V to GND

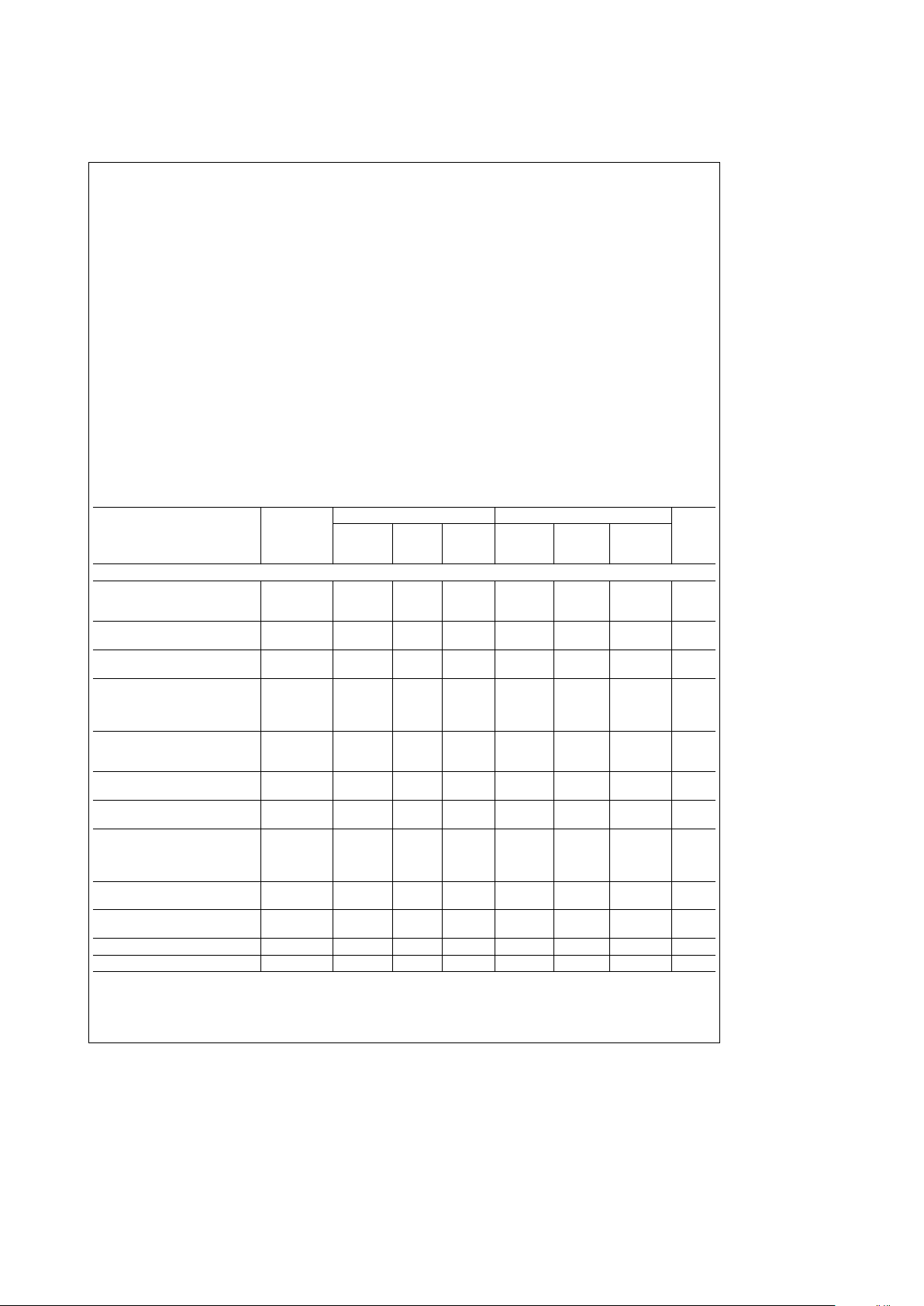

Electrical Characteristics

The following specifications apply for DV

CC

e

AV

CC

e

5V, V

REF

e

5V, f

CLK

e

1.0 MHz, V

b

eb

5V for bipolar input range, or

V

b

e

GND for unipolar input range unless otherwise specified. Bipolar input range is defined asb5.05VsV

IN(a)

s

5.05V;

b

5.05VsV

IN(b)

s

5.05V andlV

IN(a)

b

V

IN(b)

l

s

5.05V. Unipolar input range is defined asb0.05VsV

IN(a)

s

5.05V;

b

0.05VsV

IN(b)

s

5.05V andlV

IN(a)

b

V

IN(b)

l

s

5.05V. Boldface limits apply from T

MIN

to T

MAX

; all other limits T

A

e

T

J

e

25§C (Notes 3, 4, 5, 6, 7).

Parameter Conditions

ADC1205CCJ, ADC1225CCD ADC1205CCJ-1, ADC1225CCD-1

Units

Limit

Typ

Tested Design

Typ

Tested Design

(Note 8)

Limit Limit

(Note 8)

Limit Limit

(Note 9) (Note 10) (Note 9) (Note 10)

CONVERTER CHARACTERISTICS

Linearity Error Unipolar Input

ADC1205CCJ, ADC1225CCD Range

g

1 LSB

ADC1205CCJ-1, ADC1225CCD-1 (Note 11)

g

1

g

1 LSB

Unadjusted Zero Error Unipolar Input

g

2

g

2

g

2 LSB

Range

Unadjusted Positive and Negative Unipolar Input

g

30

g

30

g

30 LSB

Full-Scale Error Range

Negative Full-Scale Error Unipolar Input

g

(/2

g

(/2 LSB

Range, Full

Scale Adj. to

Zero

Linearity Error Bipolar Input

ADC1205CCJ, ADC1225CCD Range

g

2 LSB

ADC1205CCJ-1, ADC1225CCD-1 (Note 11)

g

2

g

2 LSB

Unadjusted Zero Error Bipolar Input

g

2

g

2

g

2 LSB

Range

Unadjusted Positive and Negative Bipolar Input

g

30

g

30

g

30 LSB

Full-Scale Error Range

Negative Full-Scale Error Bipolar Input

g

2

g

2

g

2 LSB

Range, Full

Scale Adj. to

Zero

Maximum Gain Temperature 6 15 6 15 ppm/§C

Coefficient

Maximum Offset Temperature 0.5 1.5 0.5 1.5 ppm/§C

Coefficient

Minimum V

REF

Input Resistance 4.0 2 4.0 2 2 kX

Maximum V

REF

Input Resistance 4.0 8 4.0 8 8 kX

2

Page 3

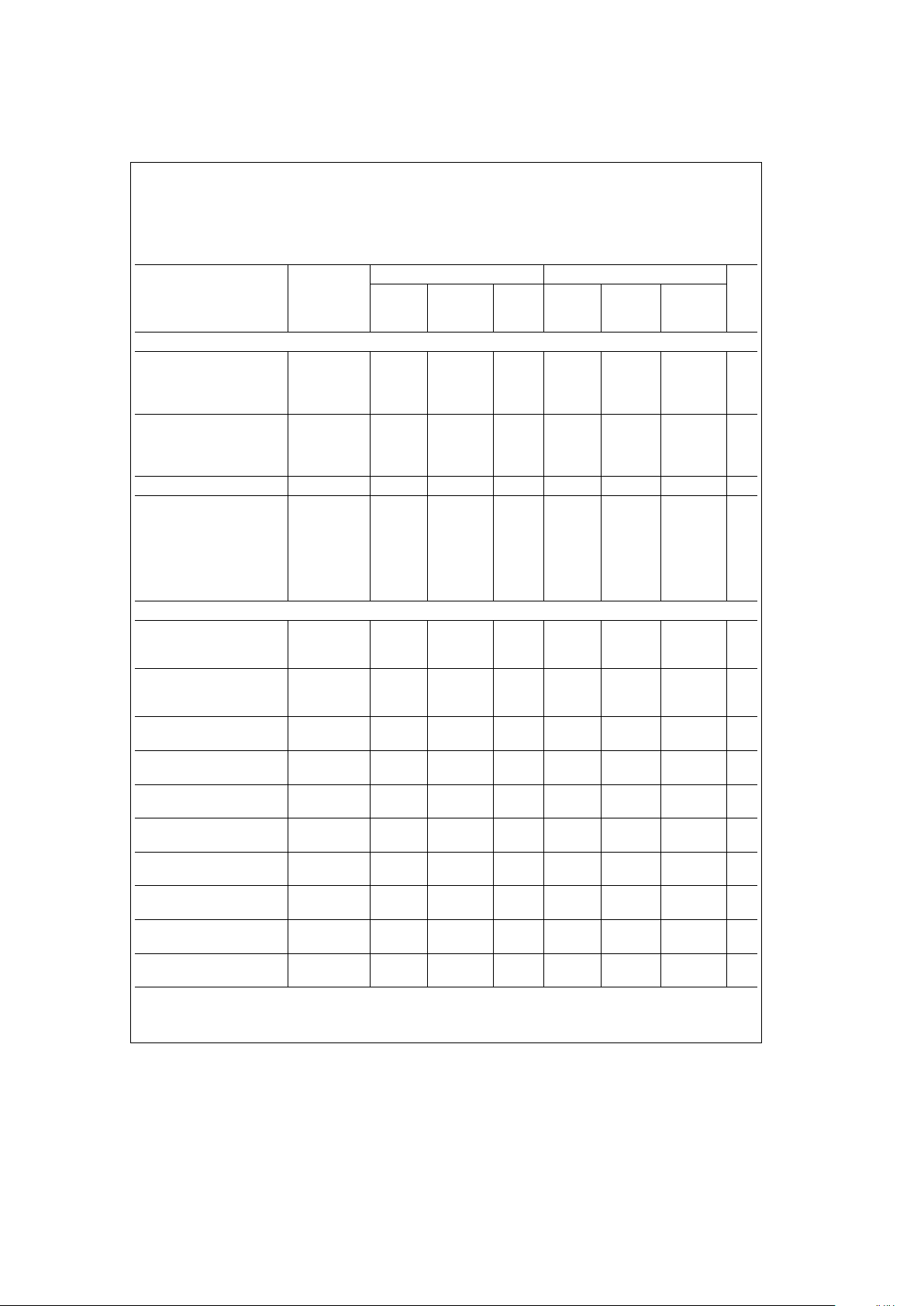

Electrical Characteristics (Continued)

The following specifications apply for DV

CC

e

AV

CC

e

5V, V

REF

e

5V, f

CLK

e

1.0 MHz, V

b

eb

5V for bipolar input range, or

V

b

e

GND for unipolar input range unless otherwise specified. Bipolar input range is defined asb5.05VsV

IN(a)

s

5.05V;

b

5.05VsV

IN(b)

s

5.05V andlV

IN(a)

b

V

IN(b)

l

s

5.05V. Unipolar input range is defined asb0.05VsV

IN(a)

s

5.05V;

b

0.05VsV

IN(b)

s

5.05V andlV

IN(a)

b

V

IN(b)

l

s

5.05V. Boldface limits apply from T

MIN

to T

MAX

; all other limits T

A

e

T

J

e

25§C (Notes 3, 4, 5, 6, 7).

Parameter Conditions

ADC1205CCJ, ADC1225CCD ADC1205CCJ-1, ADC1225CCD-1

Units

Limit

Typ

Tested Design

Typ

Tested Design

(Note 8)

Limit Limit

(Note 8)

Limit Limit

(Note 9) (Note 10) (Note 9) (Note 10)

CONVERTER CHARACTERISTICS (Continued)

Minimum Analog Input Unipolar Input GND-0.05 GND-0.05 GND-0.05 V

Voltage Range

Bipolar Input

b

V

CC

b

0.05

b

V

C

b

0.05bV

CC

b

0.05 V

Range

Maximum Analog Input Unipolar Input V

CC

a

0.05 V

CC

a

0.05 V

CC

a

0.05 V

Voltage Range

Bipolar Input V

CC

a

0.05 V

CC

a

0.05 V

CC

a

0.05 V

Range

DC Common-Mode Error

g

(/8

g

(/2

g

(/8

g

(/2

g

(/2 LSB

Power Supply Sensitivity AV

CC

e

DV

CC

e

5Vg5%,

V

b

eb

5Vg5%

Zero Error

g

*/4

g

*/4

g

*/4 LSB

Positive and Negative

g

*/4

g

*/4

g

*/4 LSB

Full-Scale Error

Linearity Error

g

(/4

g

(/4

g

(/4 LSB

DIGITAL AND DC CHARACTERISTICS

V

IN(1)

, Logical ‘‘1’’ Input V

CC

e

5.25V, 2.0 2.0 2.0 V

Voltage (Min) All Inputs except

CLK IN

V

IN(0)

, Logical ‘‘0’’ Input V

CC

e

4.75V, 0.8 0.8 0.8 V

Voltage (Max) All Inputs except

CLK IN

I

IN(1)

, Logical ‘‘1’’ Input V

IN

e

5V 0.005 1 0.005 1 mA

Current (Max)

I

IN(0)

, Logical ‘‘0’’ Input V

IN

e

0V

b

0.005

b

1

b

0.005

b

1 mA

Current (Max)

V

T

a

(Min), Minimum Positive- CLK IN 3.1 2.7 3.1 2.7 2.7 V

Going Threshold Voltage

V

T

a

(Max), Maximum Positive- CLK IN 3.1 3.5 3.1 3.5 3.5 V

Going Threshold Voltage

V

T

b

(Min), Minimum Negative- CLK IN 1.8 1.4 1.8 1.4 1.4 V

Going Threshold Voltage

V

T

b

(Max), Maximum Negative- CLK IN 1.8 2.1 1.8 2.1 2.1 V

Going Threshold Voltage

VH(Min), Minimum Hysteresis CLK IN 1.3 0.6 1.3 0.6 0.6 V

[

V

T

a

(Min)bV

T

b

(Max)

]

VH(Max), Maximum Hysteresis CLK IN 1.3 2.1 1.3 2.1 2.1 V

[

V

T

a

(Max)bV

T

b

(Min)

]

3

Page 4

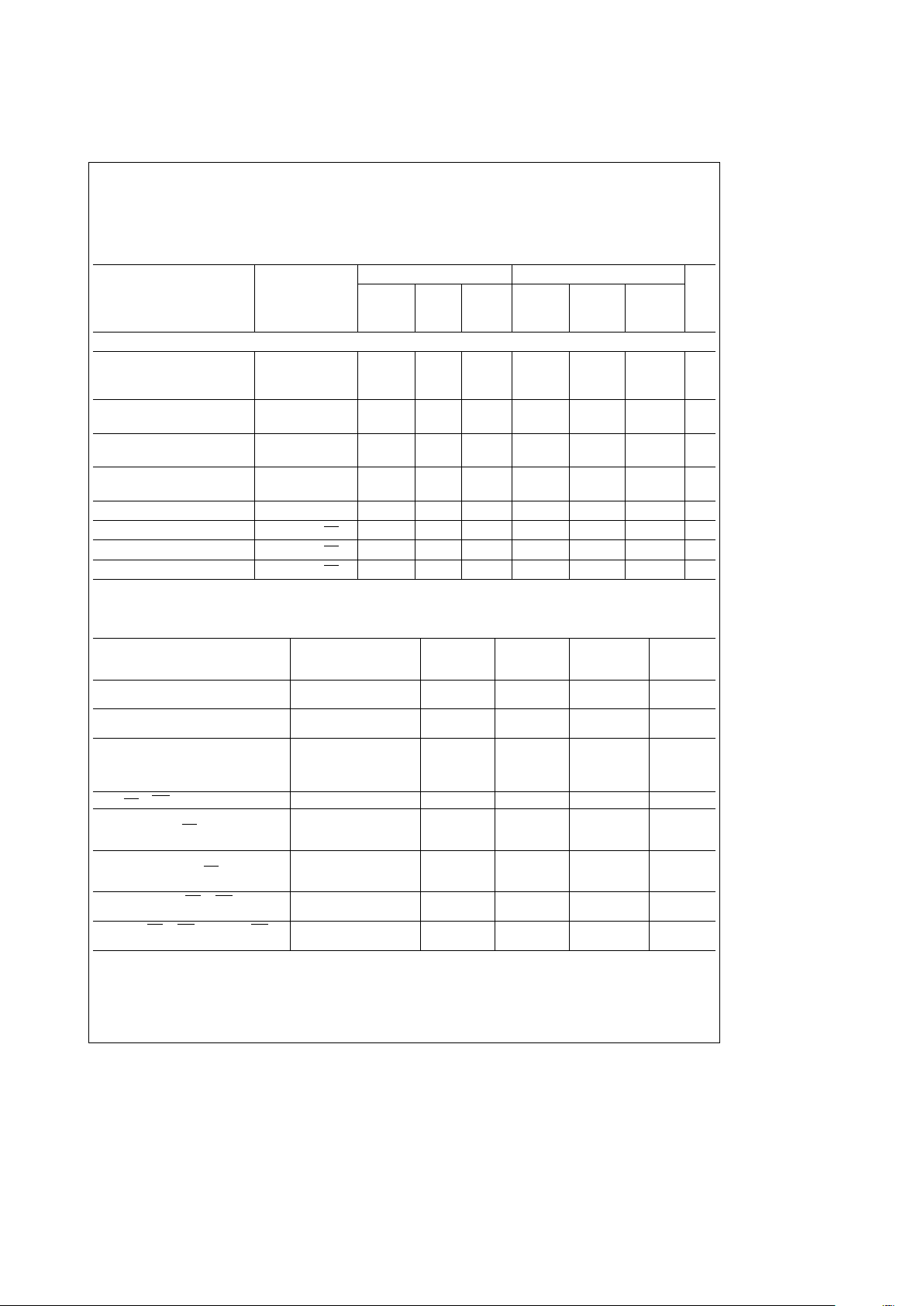

Electrical Characteristics (Continued)

The following specifications apply for DV

CC

e

AV

CC

e

5V, V

REF

e

5V, f

CLK

e

1.0 MHz, V

b

eb

5V for bipolar input range, or

V

b

e

GND for unipolar input range unless otherwise specified. Bipolar input range is defined asb5.05VsV

IN(a)

s

5.05V;

b

5.05VsV

IN(b)

s

5.05V andlV

IN(a)

b

V

IN(b)

l

s

5.05V. Unipolar input range is defined asb0.05VsV

IN(a)

s

5.05V;

b

0.05VsV

IN(b)

s

5.05V andlV

IN(a)

b

V

IN(b)

l

s

5.05V. Boldface limits apply from T

MIN

to T

MAX

; all other limits T

A

e

T

J

e

25§C (Notes 3, 4, 5, 6, 7).

Parameter Conditions

ADC1205CCJ, ADC1225CCD ADC1205CCJ-1, ADC1225CCD-1

Units

Limit

Typ

Tested Design

Typ

Tested Design

(Note 8)

Limit Limit

(Note 8)

Limit Limit

(Note 9) (Note 10) (Note 9) (Note 10)

DIGITAL AND DC CHARACTERISTICS (Continued)

V

OUT(1)

, Logical ‘‘1’’ Output V

CC

e

4.75V

Voltage (Min) I

OUT

eb

360 mA 2.4 2.4 2.4 V

I

OUT

eb

10 mA 4.5 4.5 4.5 V

V

OUT(0)

, Logical ‘‘0’’ Output V

CC

e

4.75V 0.4 0.4 0.4 V

Voltage (Max) I

OUT

e

1.6 mA

I

OUT

, TRI-STATE Output Leakage V

OUT

e

0V

b

0.01

b

3

b

0.01

b

0.3

b

3 mA

Current (Max) V

OUT

e

5V 0.01 3 0.01 0.3 3 mA

I

SOURCE

, Output Source Current V

OUT

e

0V

b

12

b

6.0

b

12

b

7.0

b

6.0 mA

(Min)

I

SINK

, Output Sink Current (Min) V

OUT

e

5V 16 8.0 16 9.0 8.0 mA

DICC,DVCCSupply Current (Max) f

CLK

e

1 MHz, CSe11 3 1 2.5 3 mA

AICC,AVCCSupply Current (Max) f

CLK

e

1 MHz, CSe11 3 1 2.5 3 mA

Ib,VbSupply Current (Max) f

CLK

e

1 MHz, CSe110 100 10 100 100 mA

AC Electrical Characteristics

The following specifications apply for DV

CC

e

AV

CC

e

5.0V, t

r

e

t

f

e

20 ns and T

A

e

25§C unless otherwise specified.

Typ

Tested Design

Limit

Parameter Conditions

(Note 8)

Limit Limit

Units

(Note 9) (Note 10)

f

CLK

, Clock Frequency MIN 1.0 0.3 MHz

MAX 1.0 1.5 MHz

Clock Duty Cycle MIN 40 %

MAX 60 %

TC, Conversion Time MIN 108 1/f

CLK

MAX 109 1/f

CLK

MIN f

CLK

e

1.0 MHz 108 ms

MAX f

CLK

e

1.0 MHz 109 ms

t

W(WR)L

,WRPulse Width MAX 220 350 ns

t

ACC

, Access Time (Delay from C

L

e

100 pF 210 340 ns

Falling Edge of RD

to

Output Data Valid) (Max)

t1H,t0H, TRI-STATE Control (Delay R

L

e

2k, C

L

e

100 pF 170 290 ns

from Rising Edge of RD

to

Hi-Z State) (Max)

t

PD(READYOUT)

,RDor WR to 250 400 ns

READYOUT Delay (Max)

t

PD(INT),

RD or WR to Reset of INT 250 400 ns

(Max)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. DC and AC electrical specifications do not apply when operating

the device beyond its specified operating ratings.

Note 2: All voltages are measured with respect to ground, unless otherwise specified.

Note 3: A parasitic zener diode exists internally from AV

CC

and DVCCto ground. This parasitic zener has a typical breakdown voltage of 7 VDC.

4

Page 5

AC Electrical Characteristics (Continued)

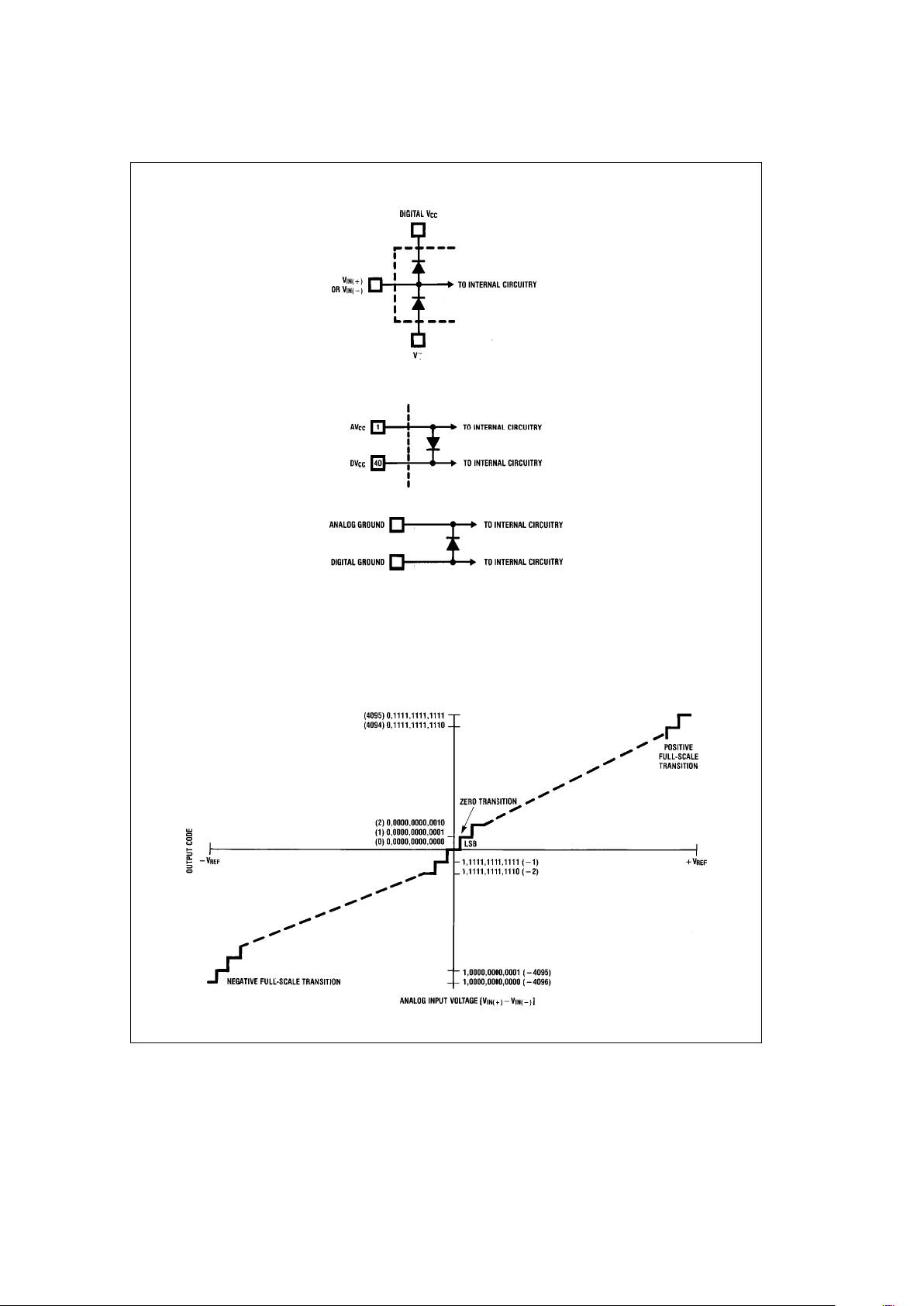

Note 4: Two on-chip diodes are tied to each analog input as shown below.

TL/H/5676– 4

Errors in the A/D conversion can occur if these diodes are forward biased more than 50 mV. This means that if AVCCand DVCCare minimum (4.75 VDC) and Vbis

minimum (

b

4.75VDC), full-scale must bes4.8VDC.

Note 5: A diode exists between analog V

CC

and digital VC.

TL/H/5676– 20

To guarantee accuracy, it is required that the AVCCand DVCCbe connected together to a power supply with separate bypass filters at each VCCpin.

Note 6: A diode exists between analog ground and digital ground.

TL/H/5676– 21

To guarantee accuracy, it is required that the analog ground and digital ground be connected together externally.

Note 7: Accuracy is guaranteed at f

CLK

e

1.0 MHz. At higher clock frequencies accuracy may degrade.

Note 8: Typicals are at 25

§

C and represent most likely parametric norm.

Note 9: Tested and guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 10: Guaranteed, but not 100% production tested. These limits are not used to calculate outgoing quality levels.

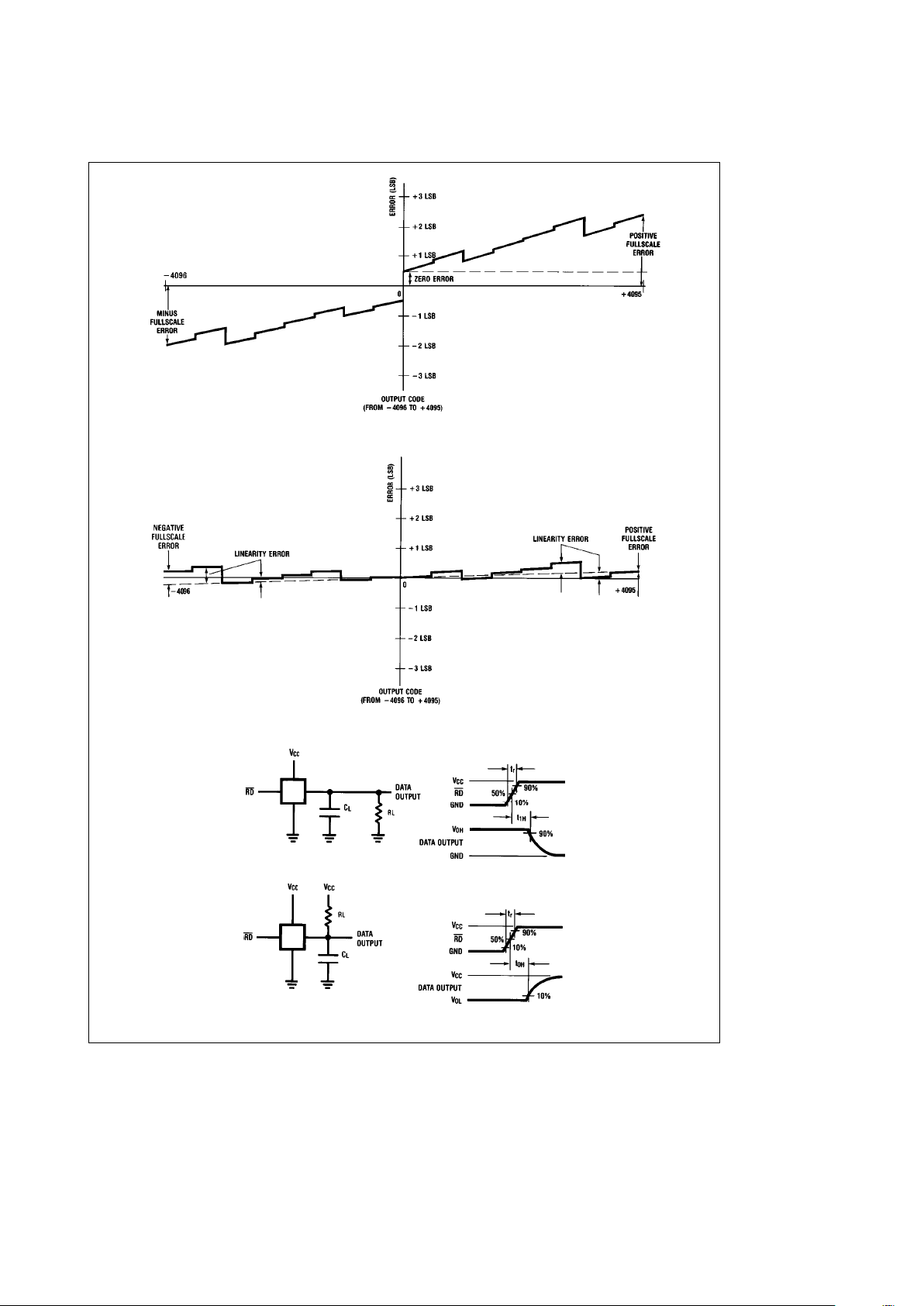

Note 11: Linearity error is defined as the deviation of the analog value, expressed in LSBs, from the straight line which passes through positive full scale and zero,

after adjusting zero error. (See

Figures 1b

and1c).

Note 12: Human body model; 100 pF discharged through a 1.5 kX resistor.

TL/H/5676– 8

FIGURE 1a. Transfer Characteristic

5

Page 6

TL/H/5676– 22

FIGURE 1b. Simplified Error Curve vs. Output Code Without Zero and Fullscale Adjustment

TL/H/5676– 23

FIGURE 1c. Simplified Error Curve vs. Output Code after Zero/Fullscale Adjustment

TL/H/5676– 7

FIGURE 2. TRI-STATE Test Circuits and Waveforms

6

Page 7

Timing Diagrams

TL/H/5676– 15

FIGURE 3. Timing Diagram

TL/H/5676– 13

FIGURE 4. Ready Out

TL/H/5676– 14

FIGURE 5. Data Out

7

Page 8

TL/H/5676– 5

FIGURE 6. Functional Block Diagram

8

Page 9

Functional Description

1.0 THE A/D CONVERSION

1.1 STARTING A CONVERSION

When using the ADC1225 or ADC1205 with a microprocessor, starting an A-to-D conversion is like writing to an external memory location. The WR

and CS lines are used to start

the conversion. The simplified logic (

Figure 6

) shows that

the falling edge of WR

with CS low clocks the D-type flipflop and initiates the conversion sequence. A new conversion can therefore be restarted before the end of the previous sequence. INT

going low indicates the conversion’s

end.

1.2 THE CONVERSION PROCESS (Numbers designated

by[]refer to portions of

Figure 6

.)

The SARS LOGIC[2]controls the A-to-D conversion process. When ‘sars’ goes high the clock (clk) is gated to the

TIMING GENERATOR[9]. One of the outputs of the TIMING GENERATOR, T

z

, provides the clock for the Succes-

sive Approximation Register, SAR LOGIC[5]. The T

z

clock

rate is (/8 of the CLK IN frequency.

Inputs to the 12-BIT DAC[11]and control of the SAMPLED

DATA COMPARATOR[10]sign logic are provided by the

SAR LOGIC. The first step in the conversion process is to

set the sign to positive (logic ‘0’) and the input of the DAC to

000 (HEX notation). If the differential input, V

IN(a)

b

V

IN(b)

,

is positive the sign bit will remain low. If it is negative the

sign bit will be set high. Differential inputs of only a few

hundred microvolts are enough to provide full logic swings

at the output of the SAMPLED DATA COMPARATOR.

The sign bit indicates the polarity of the differential input. If it

is set high, the negative input must have been greater than

the positive input. By reversing the polarity of the differential

input, V

IN(a)

and V

IN(b)

are interchanged and the DAC

sees the negative input as positive. The input polarity reversal is done digitally by changing the timing on the input sampling switches of the SAMPLED DATA COMPARATOR.

Thus, with almost no additional circuitry, the A/D is extended from a unipolar 12-bit to a bipolar 12-bit (12-bit plus sign)

device.

After determining the input polarity, the conversion proceeds with the successive approximation process. The SAR

LOGIC successively tries each bit of the 12-BIT DAC. The

most significant bit (MSB), B11, has a weight of (/2 of V

REF

.

The next bit, B10, has a weight of (/4 V

REF

. Each successive

bit is reduced in weight by a factor of 2 which gives the least

significant bit (LSB) a weight of 1/4096 V

REF

.

When the MSB is tried, the comparator compares the DAC

output, V

REF

/2, to the analog input. If the analog input is

greater than V

REF

/2 the comparator tells the SAR LOGIC to

set the MSB. If the analog input is less than V

REF

/2 the

comparator tells the SAR LOGIC to reset the MSB. On the

next bit-test the DAC output will either be */4 V

REF

or (/4

V

REF

depending on whether the MSB was set or not. Following this sequence through for each successive bit will

approximate the analog input to within 1-bit (one part in

4096).

On completion of the LSB bit-test the conversion-complete

flip-flop (CC) is set, signifying that the conversion is finished.

The end-of-conversion (EOC) and interrupt (INT

) lines are

not changed at this time. Some internal housekeeping tasks

must be completed before the outside world is notified that

the conversion is finished.

Setting CC enables the UPDATE LOGIC[12]. This logic

controls the transfer of data from the SAR LOGIC to the

OUTPUT LATCH[6]and resets the internal logic in preparation for a new conversion. This means that when EOC

goes high, a new conversion can be immediately started

since the internal logic has already been reset. In the same

way, data is transferred to the OUTPUT LATCH prior to issuing an interrupt. This assures that data can be read immediately after INT

goes low.

2.0 READING THE A/D

The ADC 1225 makes all thirteen bits of the conversion

result available in parallel. Taking CS

and RD low enables

the TRI-STATE

É

output buffers. The conversion result is

represented in 2’s complement format.

The ADC1205 makes the conversion result available in two

eight-bit bytes. The output format is 2’s complement with

extended sign. Data is right justified and presented high

byte first. With CS

low and STATUS high, the high byte

(DB12–DB8) will be enabled on the output buffers the first

time RD

goes low. When RD goes low a second time, the

low byte (DB7– DB0) will be enabled. On each read operation, the ‘byst’ flip-flop is toggled so that on successive

reads alternate bytes will be available on the outputs. The

‘byst’ flip-flop is always reset to the high byte at the end of a

conversion. Table 1 below shows the data bit locations on

the ADC1205.

The ADC1205’s STATUS

pin makes it possible to read the

conversion status and the state of the ‘byst’ flip-flop. With

RD

, STATUS and CS low, this information appears on the

data bus. The ‘byst’ status appears on pin 18 (DB2/DB10).

A low output on pin 18 indicates that the next data read will

be the high byte. A high output indicates that the next data

read will be the low byte. A high status bit on pin 22 (DB6/

DB12) indicates that the conversion is in progress. A high

output appears on pin 17 (DB1/DB9) when the conversion

is completed and the data has been transferred to the output latch. A high output on pin 16 (DB0/DB8) indicates that

the conversion has been completed and the data is ready to

read. This status bit is reset when a new conversion is initiated, data is read, or status is read. When reading status or a

conversion result, STATUS

should always change states at

least 600 ns before RD

goes low. If the conversion status

information is not needed, the STATUS

pin should be hard-

wired to V

a

. Table 2 summarizes the meanings of the four

status bits.

TABLE I. Data Bit Locations, ADC1205

HIGH BYTE DB12 DB12 DB12 DB12 DB11 DB10 DB9 DB8

LOW BYTE DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

TABLE II. Status Bit Locations and Meanings

Status

Status

Condition to

Bit

Bit

Meaning Clear Status

Location Bit

DB6 SARS ‘‘High’’ indicates that

the conversion is in

progress

DB2 BYST ‘‘Low’’ indicates that Status write

the next data read is or toggle it

the high byte. with data

‘‘High’’ indicates that read

the next data read is

the low byte

9

Page 10

Functional Description (Continued)

TABLE II. Status Bit Locations and Meanings

(Continued)

Status Status Condition to

Bit Bit Meaning Clear Status

Location Bit

DB1 EOC ‘‘High’’ indicates that

the conversion is

completed and data is

transferred to the

output latch.

DB0 INT ‘‘High’’ indicates that Data read or

it is the end of the status read

conversion and the or status

data is ready to read write

3.0 INTERFACE

3.1 RESET OF INTERRUPT

INT

goes low at the end of the conversion and indicates that

data is transferred to the output latch. By reading data, INT

will be reset to high on the leading edge of the first read (RD

going low). INT is also reset on the leading (falling) edge of

WR

when starting a conversion.

3.2 READY OUT

To simplify the hardware connection to high speed microprocessors, a READY OUT line is provided. This allows the

A-to-D to insert a wait state in the mP’s read cycle. The

equivalent circuit and the timing diagram for READY OUT is

shown in

Figures 7

and8.

TL/H/5676– 9

FIGURE 7. READY OUT Equivalent Circuit

TL/H/5676– 10

FIGURE 8. READY OUT Timing Diagram

3.3 RESETTING THE A/D

All the internal logic can be reset, which will abort any conversion in process and reset the status bits. The reset function is achieved by performing a status write (CS

,WRand

STATUS

are low).

3.4 ADDITIONAL TIMING AND INTERFACE OPTIONS

ADC1225

1. WR

and RD can be tied together with CS low continuously or strobed. The previous conversion’s data will be

available when the WR

and RD are low as shown below.

One drawback is that, since the conversion is started on the

falling edge and the data read on the rising edge of WR

/RD,

the first data access will have erroneous information depending on the power-up state of the internal output latches.

If the WR

/RD strobe is longer than the conversion time,

INTR

will never go low to signal the end of a conversion.

The conversion will be completed and the output latches will

be updated. In this case the READY OUT signal can be

used to sense the end of the conversion since it will go low

when the output latches are being updated.

TL/H/5676– 24

FIGURE 9

10

Page 11

Functional Description (Continued)

TL/H/5676– 25

FIGURE 10

TL/H/5676– 26

FIGURE 11

TL/H/5676– 27

FIGURE 12

11

Page 12

Functional Description (Continued)

TL/H/5676– 28

TL/H/5676– 29

FIGURE 13

When using this method of conversion only one strobe is

necessary and the rising edge of WR

/RD can be used to

read the current conversion results. These methods reduce

the throughput time of the conversion since the RD

and WR

cycles are combined.

2. With the standard timing WR pulse width longer than the

conversion time a conversion is completed but the INTR

will

never go low to signal the end of a conversion. The output

latches will be updated and valid information will be available when the RD

cycle is accomplished.

3. Tying CS

and RD low continuously and strobing WR to

initiate a conversion will also yield valid data. The INTR

will

never go low to signal the end of a conversion and the

digital outputs will always be enabled, so using INTR

to

strobe the WR

line for a continuous conversion cannot be

done with this part.

A simple stand-alone circuit can be accomplished by driving

WR

with the inverse of the READY OUT signal using a sim-

ple inverter as shown below.

TL/H/5676– 30

FIGURE 14

12

Page 13

Functional Description (Continued)

ADC1205

Case 1 would be the only one that would appy to the

ADC1205 since two RD

strobes are necessary to retrieve

the 13 bits of information on the 8 bit data bus. Simultaneously strobing WR

and RD low will enable the most significant byte on DB0 – DB7 and start a conversion. Pulsing

WR

/RD low before the end of this conversion will enable

the least significant byte of data on the outputs and restart a

conversion.

4.0 REFERENCE VOLTAGE

The voltage applied to the reference input of the converter

defines the voltage span of the analog inputs (the difference

between V

IN(a)

and V

IN(b)

, over which 4096 positive output codes and 4096 negative output codes exist. The

A-to-D can be used in either ratiometric or absolute reference applications. V

REF

must be connected to a voltage

source capable of driving the reference input resistance

(typically 4 kX).

In a ratiometric system, the analog input voltage is proportional to the voltage used for the A/D reference. When this

voltage is the system power supply, the V

REF

pin can be

tied to V

CC

. This technique relaxes the stability requirement

of the system reference as the analog input and A/D reference move together maintaining the same output code for a

given input condition.

For absolute accuracy, where the analog input varies between very specific voltage limits, the reference pin can be

biased with a time and temperature stable voltage source.

In general, the magnitude of the reference voltage will require an initial adjustment to null out full-scale errors.

5.0 THE ANALOG INPUTS

5.1 DIFFERENTIAL VOLTAGE INPUTS AND COMMON

MODE REJECTION

The differential inputs of the ADC1225 and ADC1205 actually reduce the effects of common-mode input noise, i.e.,

signals common to both V

IN(a)

and V

IN(b)

inputs (60 Hz is

most typical). The time interval between sampling the ‘‘

a

’’

and ‘‘

b

‘‘ input is 4 clock periods. Therefore, a change in the

common-mode voltage during this short time interval may

cause conversion errors. For a sinusoidal common-mode

signal the error would be:

V

ERROR(MAX)

e

V

PEAK

(2q fCM)

4

f

CLK

where fCMis the frequency of the common-mode signal,

V

PEAK

is its peak voltage value and f

CLK

is the converter’s

clock frequency. In most cases V

ERROR

will not be significant. For a 60 Hz common-mode signal to generate a (/4

LSB error (300 mV) with the converter running at 1 MHz its

peak value would have to be 200mV.

5.2 INPUT CURRENT

Due to the sampling nature of the analog inputs, short duration spikes of current enter the ‘‘

a

’’ input and exit the ‘‘b’’

input at the leading clock edges during the actual conversion. These currents decay rapidly and do not cause errors

as the internal comparator is strobed at the end of a clock

period.

5.3 INPUT BYPASS CAPACITORS

Bypass capacitors at the inputs will average the current

spikes mentioned in 5.2 and cause a DC current to flow

through the output resistance of the analog signal source.

This charge pumping action is worse for continuous conversions with the V

IN(a)

input voltage at full-scale. For continuous conversions with a 1 MHz clock frequency and the

V

IN(a)

input at 5V, the average input current is approximately 5 mA. For this reason bypass capacitors should not be

used at the analog inputs for high resistance sources

(R

SOURCE

100 X).

If input bypass capacitors are necessary for noise filtering

and high source resistance is desirable to minimize capacitor

size, the detrimental effects of the voltage drop across this

input resistance, due to the average value of the input current, can be minimized with a full-scale adjustment while the

given source resistance and input bypass capacitor are both

in place. This is effective because the average value of the

input current is a linear function of the differential input voltage.

5.4 INPUT SOURCE RESISTANCE

Large values of source resistance where an input bypass

capacitor is not used, will not cause errors as the input currents settle out prior to the comparison time. If a low pass

filter is required in the system, use a low valued series resistor (R

s

100 X) for a passive RC section or add an op amp

RC active low pass filter. For low source resistance applications, (R

SOURCE

s

100 X) a 0.001 mF bypass capacitor at

the inputs will prevent pickup due to series lead inductance

of a long wire. A 100 X series resistor can be used to isolate

this capacitor – both the R and C are placed outside the

feedback loop – from the output of an op amp, if used.

5.5 NOISE

The leads to the analog inputs should be kept as short as

possible to minimize input noise coupling. Both noise and

undesired digital clock coupling to these inputs can cause

errors. Input filtering can be used to reduce the effects of

these sources, but careful note should be taken of sections

5.3 and 5.4 if this route is taken.

6.0 POWER SUPPLIES

Noise spikes on the V

CC

supply line can cause conversion

errors as the comparator will respond to this noise. Low

inductance tantalum capacitors of 1 mF or greater are recommended for supply bypassing. Separate bypass caps

should be placed close to the DV

CC

and AVCCpins. If an

unregulated voltage source is available in the system, a separate LM340LAZ-5.0 voltage regulator for the A-to-D’s V

CC

(and other analog circuitry) will greatly reduce digital noise

on the supply line.

7.0 ERRORS AND REFERENCE VOLTAGE

ADJUSTMENTS

7.1 ZERO ADJUST

The zero error of the A/D converter relates to the location

of the first riser of the transfer function and can be measured by grounding the V

IN(b)

input and applying a small

magnitude positive voltage to the V

IN(a)

input. Zero error is

the difference between the actual DC input voltage necessary to just cause an output digital code transition from all

zeroes to 0,0000,0000,0001 and the ideal (/2 LSB value ((/2

LSB

e

0.61 mV for V

REF

e

5VDC). Zero error can be adjust-

ed as shown in

Figure 15

.V

IN(a)

is forced to 0.61 mV, and

V

IN(b)

is forced to 0V. The potentiometer is adjusted until

the digital output code changes from all zeroes to

0,000,0000,0001.

13

Page 14

Functional Description (Continued)

A simpler, although slightly less accurate, approach is to

ground V

IN(a)

and V

IN(b)

, and adjust for all zeros at the

output. Error will be well under (/2 LSB if the adjustment is

done so that the potentiometer is ‘‘centered’’ within the

0,000,000 range. A positive voltage at the V

OS

input will

reduce the output code. The adjustment range is

a

4to

b

30 LSB.

TL/H/5676– 11

FIGURE 15. Zero Adjust Circuit

7.2 POSITIVE AND NEGATIVE FULL-SCALE

ADJUSTMENT

Unipolar Inputs

Apply a differential input voltage which is 1.5 LSB below the

desired analog full-scale voltage (V

F

) and adjust the magni-

tude of the V

REF

input so that the output code is just chang-

ing from 0,1111,1111,1110 to 0,1111,1111,1111.

Bipolar Inputs

Do the same procedure outlined above for the unipolar case

and then change the differential input voltage so that the

digital output code is just changing from 1,0000,0000,0001

to 1,0000,0000,0000. Record the differential input voltage,

V

X

. the ideal differential input voltage for that transition

should be;

#

b

V

F

a

V

F

8192

J

Calculate the difference between Vx and the ideal voltage;

D

e

V

X

b#b

V

F

a

V

F

8192

J

Then apply a differential input voltage of;

#

V

X

b

D

2

J

and adjust the magnitude of V

REF

so the digital output

code is just changing from 1,0000,0000,0001 to

1,0000,0000,0000. That will obtain the positive and negative

full-scale transition with symmetrical minimum error.

Typical Applications

*Input must have some

current return path to

signal ground

TL/H/5676– 12

14

Page 15

Typical Applications (Continued)

Protecting the Input

TL/H/5676– 16

Diodes are 1N914

Operating with Ratiometric Transducers

*VIN(b)e0.15 V

CC

15% of V

CC

s

V

XDR

s

85% of V

CC

TL/H/5676– 17

15

Page 16

Typical Applications (Continued)

Bipolar Input Temperature Converter

TL/H/5676– 18

a

150 tob55§C with 0.04§C resolution

Note: * resistors are 1% metal film types

Strain Gauge Converter with .025% Resolution and Single Power Supply

TL/H/5676– 19

Note: 1)* resistors are 1% metal film types

2) LF412 power

a

10V and ground

16

Page 17

Ordering Information

Temperature Range 0§Cto70§C

b

40§Ctoa85§C

Non-Linearity 0.024% ADC1205CCJ-1 ADC1225CCD-1 ADC1205CCJ ADC1225CCD

Package Outline J24A D28D J24A D28D

Physical Dimensions inches (millimeters)

Ceramic Dual-In Line Package (J)

Order Number ADC1205CCJ-1 or ADC1205CCJ

NS Package Number J24A

17

Page 18

ADC1205/ADC1225 12-Bit Plus Sign mP Compatible A/D Converters

Physical Dimensions inches (millimeters) (Continued)

Ceramic Dual-In-Line Package (D)

Order Number ADC1225CCD-1 or ADC1225CCD

NS Package Number D28D

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

Fax: 1(800) 737-7018 English Tel: (

a

49) 0-180-532 78 32 Hong Kong

Fran3ais Tel: (

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

Italiano Tel: (

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...