Page 1

June 1999

ADC10662/ADC10664

10-Bit 360 ns A/D Converter with Input Multiplexer and

Sample/Hold

ADC10662/ADC10664 10-Bit 360 ns A/D Converter with Input Multiplexer and Sample/Hold

General Description

Using an innovative, patented multistep*conversion technique, the 10-bit ADC10662 and ADC10664 are 2- and

4-input CMOS analog-to-digital converters offering

sub-microsecond conversion times yet dissipating a maximum of only 235 mW. The ADC10662 and ADC10664 perform a 10-bit conversion in two lower-resolution “flashes”,

thus yielding a fast A/D without the cost, power dissipation,

and other problems associated with true flash approaches.

In addition to standard static performance specifications

(Linearity,Full-Scale Error, etc.) dynamic performance (THD,

S/N) is guaranteed.

The analog input voltage to the ADC10662 andADC10664 is

sampled and held by an internal sampling circuit. Input signals at frequencies from dc to over 250 kHz can therefore be

digitized accurately without the need for an external

sample-and-hold circuit.

The ADC10662 and ADC10664 include a “speed-up” pin.

Connecting an external resistor between this pin and ground

reduces the typical conversion time to as little as 360 ns.

For ease of interface to microprocessors, the ADC10662 and

ADC10664 have been designed to appear as a memory location or I/O port without the need for external interface

logic.

Ordering Information

ADC10662

Industrial

(−40˚C ≤ T

ADC10662CIWM M24B Small Outline

≤ +85˚C)

A

Package

Features

n Built-in sample-and-hold

n Single +5V supply

n 2- or 4-input multiplexer options

n No external clock required

Key Specifications

n Conversion time to 10 bits: 360 ns typical, 466 ns

max over temperature

n Sampling Rate: 1.5 MHz (min)

n Low power dissipation: 235 mW (max)

n Total harmonic distortion (50 kHz): −60 dB (max)

n No missing codes over temperature

Applications

n Digital signal processor front ends

n Instrumentation

n Disk drives

n Mobile telecommunications

ADC10664

Industrial

(−40˚C ≤ T

ADC10664CIWM M28B Small Outline

≤ +85˚C)

A

Package

*

U.S. Patent Number 4918449

®

TRI-STATE

is a registered trademark of National Semiconductor Corporation.

© 1999 National Semiconductor Corporation DS011192 www.national.com

Page 2

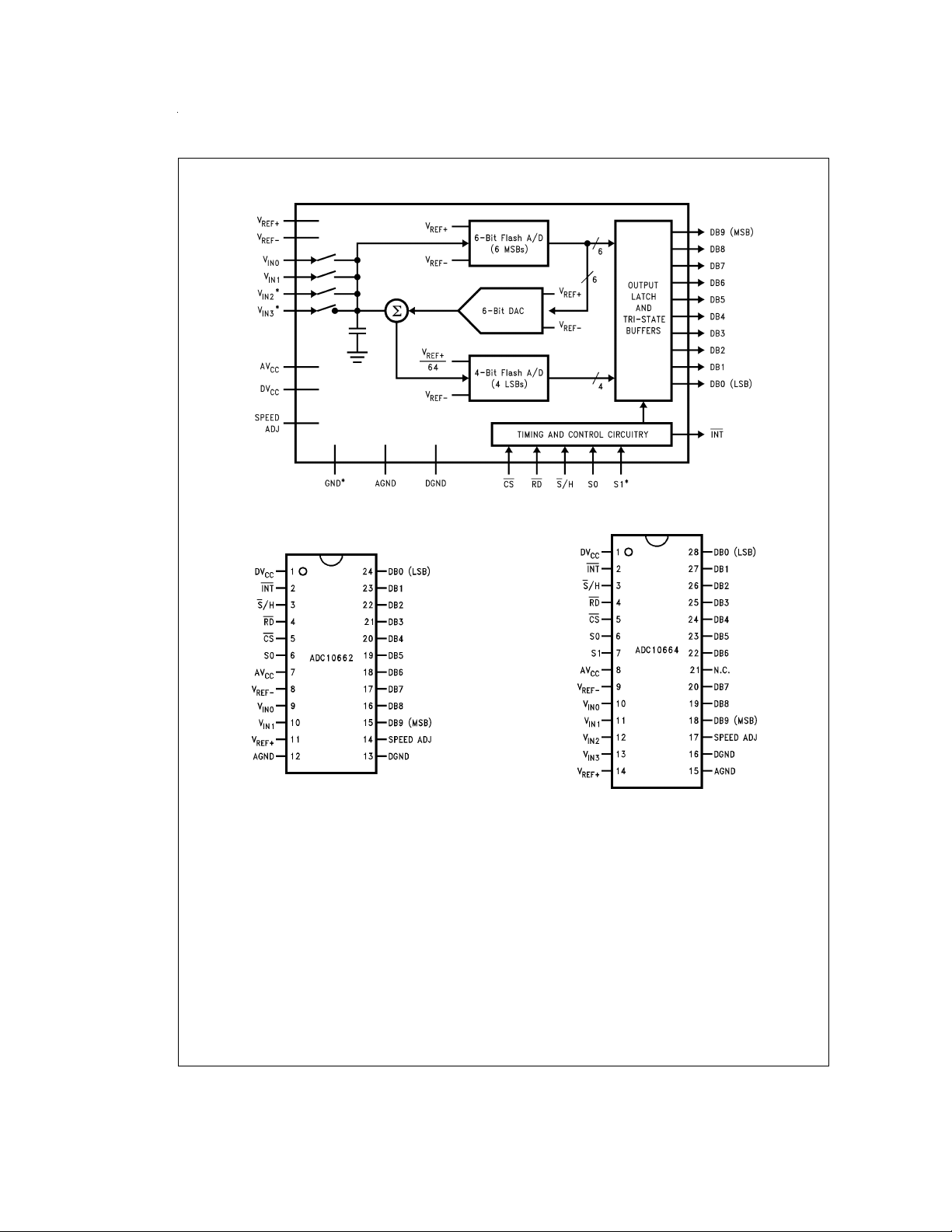

Simplified Block Diagram

*ADC10664 Only

Connection Diagrams

Top View

DS011192-9

DS011192-10

DS011192-11

Top View

www.national.com 2

Page 3

Pin Descriptions

DVCC,

AV

CC

INT

S/H This is the Sample/Hold control input. When

RD

CS

S0, S1 These pins select the analog input that will be

V

REF−

V

REF+

These are the digital and analog positive supply voltage inputs. They should always be connected to the same voltage source, but are

brought out separately to allow for separate

bypass capacitors. Each supply pin should be

bypassed with a 0.1 µF ceramic capacitor in

parallel with a 10 µF tantalum capacitor to

ground.

This is the active low interrupt output. INT

goes low at the end of each conversion, and

returns to a high state following the rising edge

of RD .

this pin is forced low (and CS is low), it causes

the analog input signal to be sampled and initiates a new conversion.

This is the active low Read control input.

When this RD and CS are low, any data

present in the output registers will be placed

on the data bus.

This is the active low Chip Select control input.

When low, this pin enables the RD and S /H

pins.

connected to the A/D during the conversion.

The input is selected based on the state of S0

and S1 when S /H makes its High-to-Low transition (See the Timing Diagrams). The

ADC10664 includes both S0 and S1. The

ADC10662 includes just S0.

,

These are the reference voltage inputs. They

may be placed at any voltage between GND

and V

, but V

CC

V

. An input voltage equal to V

REF−

duces an output code of 0, and an input voltage equal to (V

put code of 1023.

must be greater than

REF+

− 1 LSB) produces an out-

REF+

REF−

pro-

V

V

IN0,VIN1

IN2,VIN3

,

These are the analog input pins. The

ADC10662 has two inputs (V

the ADC10664 has four inputs (V

V

and V

IN2

should be less than 500Ω for best accuracy

). The impedance of the source

IN3

and V

IN0

and conversion speed. For accurate conversions, no input pin (even one that is not selected) should be driven more than 50 mV

GND, AGND,

DGND

above V

These are the power supply ground pins. The

ADC10662 and ADC10664 have separate

or 50 mV below ground.

CC

analog and digital ground pins (AGND and

DGND) for separate bypassing of the analog

and digital supplies. The ground pins should

be connected to a stable, noise-free system

ground. Both pins should be returned to the

same potential.

DB0–DB9 These are the TRI-STATE output pins.

SPEED

ADJ

By connecting a resistor between this pin and

ground, the conversion time can be reduced.

The specifications listed in the table of Electri-

cal Characteristics apply for a speed adjust re-

sistor (R

kΩ (Mode 2). See the Typical Performance

) equal to 14.0 kΩ (Mode 1) or 8.26

SA

Curves and the table of Electrical Characteris-

tics.

) and

IN1

IN0,VIN1

,

www.national.com3

Page 4

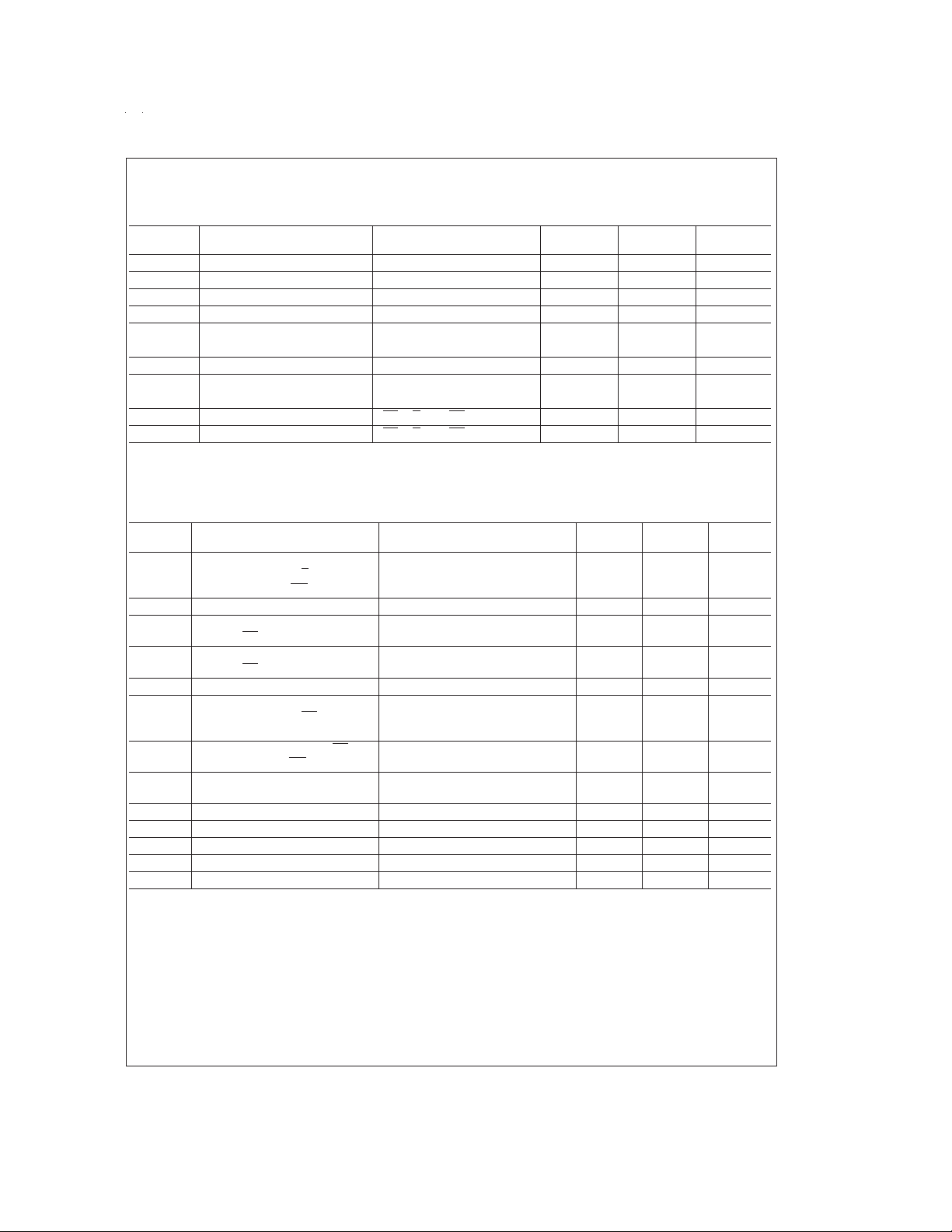

Absolute Maximum Ratings (Notes 1, 2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

+

=

Supply Voltage (V

Voltage at Any Input or Output −0.3V to V

Input Current at Any Pin (Note 3) 5 mA

Package Input Current (Note 3) 20 mA

Power Dissipation (Note 4) 875 mW

ESD Susceptability (Note 5) 2000V

Soldering Information (Note 6)

N Package (10 Sec) 260˚C

Converter Characteristics

The following specifications apply for V

through a 14.0 kΩ resistor (Mode 1) or an 8.26 kΩ resistor (Mode 2) unless otherwise specified. Boldface limits apply for T

=

=

T

to T

T

J

Min

Max

=

AV

DV

CC

CC

; all other limits T

) −0.3V to +6V

+

=

=

T

A

+5V, V

=

+25˚C.

J

REF(+)

+

+ 0.3V

=

+5V, V

SO Package:

Vapor Phase (60 Sec) 215˚C

Infrared (15 Sec) 220˚C

Storage Temperature Range −65˚C to +150˚C

Junction Temperature 150˚C

Operating Ratings (Notes 1, 2)

Temperature Range T

ADC10662CIN, ADC10662CIWM,

ADC10664CIN,

ADC10664CIWM −40˚C ≤ T

Supply Voltage Range 4.5V to 5.5V

=

GND, and Speed Adjust pin connected to ground

REF(−)

MIN

≤ TA≤ T

≤ +85˚C

A

Symbol Parameter Conditions Typical Limit Units

(Note 7) (Note 8) (Limit)

Resolution 10 Bits

Integral Linearity Error

Offset Error

Full-Scale Error

Total Unadjusted Error

±

0.5

±

0.5

±

1.0/±1.5 LSB

±

1 LSB (max)

±

1 LSB (max)

±

1.5/±2.0 LSB

Missing Codes 0 (max)

Power Supply Sensitivity V

THD Total Harmonic Distortion (Note 10) f

SNR Signal-to-Noise Ratio (Note 10) f

ENOB Effective Number of Bits (Note 10) f

R

REF

Reference Resistance 650 400 Ω (min)

=

5V

+

=

V

5V

=

1 kHz, 4.85 V

IN

=

f

50 kHz, 4.85 V

IN

=

f

100 kHz, 4.85 V

IN

=

f

240 kHz, 4.85 V

IN

=

1 kHz, 4.85 V

IN

=

f

50 kHz, 4.85 V

IN

=

f

100 kHz, 4.85 V

IN

=

1 kHz, 4.85 V

IN

=

f

50 kHz, 4.85 V

IN

±

5%,V

±

10%,V

REF

REF

=

4.5V

=

4.5V

P-P

P-P

P-P

P-P

P-P

P-P

P-P

P-P

P-P

±

1/16 LSB

1

±

⁄

8

LSB

−68 dB

−66 −60 dB (max)

−62 dB

−58 dB

61 dB

60 58 dB (min)

60 dB

9.6 Bits

9.5 9 Bits (min)

+

900 Ω (max)

V

V

V

V

V

V

REF(+)

REF(−)

REF(+)

REF(−)

IN

IN

V

Input Voltage V++ 0.05 V (max)

REF(+)

V

Input Voltage GND −

REF(−)

V

Input Voltage V

REF(+)

V

Input Voltage V

REF(−)

0.05

REF(−)

REF(+)

V (min)

V (min)

V (max)

Input Voltage V++ 0.05 V (max)

Input Voltage GND −

V (min)

0.05

OFF Channel Input Leakage Current CS=V

ON Channel Input Leakage Current CS=V

+

+

,V

,V

+

=

V

IN

+

=

V

IN

0.01 3 µA (max)

±

1 −3 µA (max)

MAX

A

www.national.com 4

Page 5

DC Electrical Characteristics

The following specifications apply for V

through a 14.0 kΩ resistor (Mode 1) or an 8.26 kΩ resistor (Mode 2) unless otherwise specified. Boldface limits apply for

=

=

to T

T

T

A

T

J

MIN

Symbol Parameter Conditions

V

V

I

I

V

V

I

DI

AI

IN(1)

IN(0)

OUT

IN(1)

IN(0)

OUT(1)

OUT(0)

CC

CC

Logical “1” Input Voltage V

Logical “0” Input Voltage V

Logical “1” Input Current V

Logical “0” Input Current V

Logical “1” Output Voltage V

Logical “0” Output Voltage V

TRI-STATE®Output Current V

DVCCSupply Current CS=S/H=RD=0 1.0 2 mA (max)

AVCCSupply Current CS=S/H=RD=0 30 45 mA (max)

; all other limits T

MAX

+

=

+5V, V

A

=

5V V

REF(+)

=

=

T

+25˚C.

J

+

=

5.5V 2.0 V (min)

+

=

4.5V 0.8 V (max)

=

5V 0.005 3.0 µA (max)

IN(1)

0V −0.005 −3.0 µA (max)

IN(0)

+

=

4.5V, I

+

=

V

4.5V, I

+

=

4.5V, I

=

5V 0.1 50 µA (max)

OUT

=

V

0V −0.1 −50 µA (max)

OUT

=

GND, and Speed Adjust pin connected to ground

REF(−)

Typical

(Note 7)

=

−360 µA 2.4 V (min)

OUT

=

−10 µA 4.25 V (min)

OUT

=

1.6 mA 0.4 V (max)

OUT

Limit

(Note 8)

(Limits)

Units

AC Electrical Characteristics

The following specifications apply for V

nected to ground through a 14.0 kΩ resistor (Mode 1) or an 8.26 kΩ resistor (Mode 2) unless otherwise specified. Boldface

limits apply for T

Symbol Parameter Conditions

=

=

T

A

T

J

MIN

to T

+

MAX

=

+5V, t

=

=

t

r

f

; all other limits T

20 ns, V

=

A

=

5V, V

REF(+)

=

T

+25˚C.

J

=

GND, and Speed Adjust pin con-

REF(−)

Typical

(Note 7)

Limit

(Note 8)

Units

(Limits)

Mode 1 Conversion Time

t

CONV

t

CRD

t

ACC1

t

ACC2

t

SH

t

1H,t0H

t

INTH

t

P

t

MS

t

MH

C

VIN

C

OUT

C

IN

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur.OperatingRatings indicate conditions for which the device is functional. These ratings do not guarantee specific performance limits, however.For guaranteed specifications and test conditions, see the Electrical Characteristics. The

guaranteed specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed

test conditons.

Note 2: All voltages are measured with respect to GND, unless otherwise specified.

Note 3: When the input voltage (V

to 5 mA or less. The 20 mA package input current limits the number of pins that can safely exceed the power supplies with an input current of 5 mA to four.

Note 4: The maximum power dissipation must be derated at elevated temperatures and is dictated by T

allowable power dissipation at any temperature is P

the maximum derated power dissipation will be reached only during fault conditions. For these devices, T

tables below:

from Rising Edge of S /H

to Falling Edge of INT

Mode 2 Conversion Time 470 610 ns (max)

=

1k, C

=

100 pF

L

=

100 pF

L

(Figure 1 )

=

10 pF

L

; (Note 9) 150 ns (max)

Access Time (Delay from Falling

Mode 1; C

Edge of RD to Output Valid)

Access Time (Delay from Falling

Mode 2; C

Edge of RD to Output Valid)

Minimum Sample Time Mode 1

TRI-STATE Control (Delay

from Rising Edge of RD

R

L

to High-Z State)

Delay from Rising Edge of RD

to Rising Edge of INT

=

C

100 pF

L

Delay from End of Conversion

to Next Conversion

Multiplexer Control Setup Time 10 75 ns (max)

Multiplexer Hold Time 10 40 ns (max)

Analog Input Capacitance 35 pF (max)

Logic Output Capacitance 5 pF (max)

Logic Input Capacitance 5 pF (max)

) at any pin exceeds the power supply rails (V

IN

=

(T

D

)/θJAor the number given in the Absolute Maximum Ratings, whichever is lower. In most cases,

JMAX−TA

IN

<

GND or V

>

V+) the absolute value of current at that pin should be limited

IN

JMAX

JMAX

360 466 ns (max)

30 50 ns (max)

475 616 ns (max)

30 60 ns (max)

25 50 ns (max)

50 ns (max)

, θJAand the ambient temperature, TA. The maximum

for a board-mounted device can be found from the

www.national.com5

Page 6

AC Electrical Characteristics (Continued)

Part θJA(˚C/W)

ADC10662CIWM 82

ADC10664CIWM 78

Note 5: Human body model, 100 pF discharged through a 1.5 kΩ resistor.

Note 6: See AN-450 “Surface Mounting Methods and Their Effect on Product Reliability” or the section titled “Surface Mount” found in a current National Semicon-

ductor Linear Data Book for other methods of soldering surface mount devices.

Note 7: Typicals represent most likely parametric norm.

Note 8: Tested limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 9: Accuracy may degrade if t

Note 10: THD, SNR, and ENOB are tested in Mode 1. Measuring these quantities in Mode 2 yields similar values.

is shorter than the value specified. See curves of Accuracy vs tSH.

SH

Typical Performance Characteristics

Zero (Offset) Error

vs Reference Voltage

Digital Supply Current

vs Temperature

Conversion Time vs

Speed-Up Resistor

DS011192-14

DS011192-17

Linearity Error

vs Reference Voltage

Conversion Time

vs Temperature

Conversion Time vs

Speed-Up Resistor

DS011192-15

DS011192-18

Analog Supply Current

vs Temperature

DS011192-16

Conversion Time

vs Temperature

DS011192-19

Spectral Response with

100 kHz Sine Wave Input

DS011192-20

www.national.com 6

DS011192-21

DS011192-22

Page 7

Typical Performance Characteristics (Continued)

Spectral Response with

100 kHz Sine Wave Input

DS011192-23

Linearity Change vs

Speed-Up Resistor

Signal-to-Noise + THD Ratio

vs Signal Frequency

Linearity Error Change

vs Sample Time

DS011192-26

TRI-STATE Test Circuits and Waveforms

DS011192-24

Linearity Change

vs Speed-Up Resistor

DS011192-25

DS011192-27

DS011192-3

DS011192-5

DS011192-4

DS011192-6

www.national.com7

Page 8

Timing Diagrams

FIGURE 1. Mode 1. The conversion time (t

) is set by the internal timer.

CONV

DS011192-7

FIGURE 2. Mode 2 (RD Mode). The conversion time (t

sampling time and is determined by the internal timer.

Functional Description

The ADC10662 and ADC10664 digitize an analog input signal to 10 bits accuracy by performing two lower-resolution

“flash” conversions. The first flash conversion provides the

six most significant bits (MSBs) of data, and the second flash

conversion provides the four least significant bits LSBs).

Figure 3

is a simplified block diagram of the converter. Near

the center of the diagram is a string of resistors. At the bottom of the string of resistors are 16 resistors, each of which

has a value 1/1024 the resistance of the whole resistor

www.national.com 8

DS011192-8

) includes the

CRD

string. These lower 16 resistors (the LSB Ladder) therefore

have a voltage drop of 16/1024, or 1/64 of the total reference

voltage (V

resistor string is made up of eight groups of eight resistors

REF+−VREF−

connected in series. These comprise the MSB Ladder. Each

section of the MSB Ladder has

) across them. The remainder of the

1

⁄8of the total reference voltage across it, and each of the LSB resistors has 1/64 of the

total reference voltage across it. Tap points across these resistors can be connected, in groups of sixteen, to the sixteen

comparators at the right of the diagram.

Page 9

Functional Description (Continued)

On the left side of the diagram is a string of seven resistors

connected between V

pare the input voltage with the tap voltages on this resistor

string to provide a low-resolution “estimate” of the input voltage. This estimate is then used to control the multiplexer that

connects the MSB Ladder to the sixteen comparators on the

right. Note that the comparators on the left needn’t be very

accurate; they simply provide an estimate of the input voltage. Only the sixteen comparators on the right and the six on

the left are necessary to perform the initial six-bit flash conversion, instead of the 64 comparators that would be required using conventional half-flash methods.

To perform a conversion, the estimator compares the input

voltage with the tap voltages on the seven resistors on the

left. The estimator decoder then determines which MSB Ladder tap points will be connected to the sixteen comparators

on the right. For example, assume that the estimator determines that V

timator decoder will instruct the comparator MUX to connect

is between 11/16 and 13/16 of V

IN

the 16 comparators to the taps on the MSB ladder between

10/16 and 14/16 of V

form the first flash conversion. Note that since the compara-

and V

REF+

. The 16 comparators will then per-

REF

. Six comparators com-

REF−

REF

. The es-

tors are connected to ladder voltages that extend beyond the

range indicated by the estimator circuit, errors in the estimator as large as 1/16 of the reference voltage (64 LSBs) will

be corrected. This first flash conversion produces the six

most significant bits of data — four bits in the flash itself, and

2 bits in the estimator.

The remaining four LSBs are now determined using the

same sixteen comparators that were used for the first flash

conversion. The MSB Ladder tap voltage just below the input

voltage (as determined by the first flash) is subtracted from

the input voltage and compared with the tap points on the

sixteen LSB Ladder resistors. The result of this second,

four-bit flash conversion is then decoded, and the full 10-bit

result is latched.

Note that the sixteen comparators used in the first flash conversion are reused for the second flash. Thus, the multistep

conversion technique used in theADC10662 andADC10664

needs only a small fraction of the number of comparators

that would be required for a traditional flash converter, and

far fewer than would be used in a conventional half-flash approach. This allows the ADC10662 and ADC10664 to perform high-speed conversions without excessive power drain.

FIGURE 3. Block Diagram of the Multistep Converter Architecture

Applications Information

1.0 MODES OF OPERATION

The ADC10662 and ADC10664 have two basic digital interface modes.

the two modes. The ADC10662 and ADC10664 have input

multiplexers that are controlled by the logic levels on pins S

and S1when S /H goes low.

how the input channnels are assigned.

Figure 1

and

Figure 2

are timing diagrams for

Table1

is a truth table showing

DS011192-12

Mode 1

In this mode, the S /H pin controls the start of conversion.

S/H is pulled low for a minimum of 150 ns. This causes the

comparators in the “coarse” flash converter to become active. When S /H goes high, the result of the coarse conver-

0

sion is latched and the “fine” conversion begins. After 360 ns

(typical), INT goes low, indicating that the conversion results

are latched and can be read by pulling RD low. Note that CS

must be low to enable S /H or RD. CS is internally “ANDed”

www.national.com9

Page 10

Applications Information (Continued)

with S /H and RD; the input voltage is sampled when CS and

S /H are low, and data is read when CS and RD are low.INT

is reset high on the rising edge of RD.

TABLE 1. Input Multiplexer Programming

S

1

00V

01V

10V

11V

TABLE 2. Input Multiplexer Programming

S

0

0V

1V

Mode 2

In Mode 2, also called “RD mode”, the S /H and RD pins are

tied together. A conversion is initiated by pulling both pins

low. The A/D converter samples the input voltage and

causes the coarse comparators to become active. An internal timer then terminates the coarse conversion and begins

the fine conversion. 470 ns (typical) after S /H and RD are

pulled low, INT goes low, indicating that the conversion is

completed. Approximately 20 ns later the data appearing on

the TRI-STATE output pins will be valid. Note that data will

appear on these pins throughout the conversion, but until

INT goes low the data at the output pins will be the result of

the previous conversion.

2.0 REFERENCE CONSIDERATIONS

The ADC10662 and ADC10664 each have two reference inputs. These inputs, V

and define the zero to full-scale range of the input signal.

The reference inputs can be connected to span the entire

supply voltage range (V

metric applications, or they can be connected to different

voltages (as long as they are between ground and V

when other input spans are required. Reducing the overall

V

span to less than 5V increases the sensitivity of the

REF

converter (e.g., if V

however, that linearity and offset errors become larger when

lower reference voltages are used. See the Typical Performance Curves for more information. For this reason, reference voltages less than 2V are not recommended.

ADC10664

S

0

Channel

IN0

IN1

IN2

IN3

ADC10662

Channel

IN0

IN1

and V

REF+

REF−

=

2V,then 1 LSB=1.953 mV). Note,

REF

, are fully differential

REF−

=

0V, V

REF+

=

V

CC

) for ratio-

CC

In most applications, V

ground, but it is often useful to have an input span that is off-

will simply be connected to

REF−

set from ground. This situation is easily accommodated by

the reference configuration used in the ADC10662 and

ADC10664. V

ground as long as the voltage source connected to this pin is

capable of sinking the converter’s reference current (12.5

@

mA Max

other than ground, bypass it with multiple capacitors.

can be connected to a voltage other than

REF−

=

V

5V). If V

REF

is connected to a voltage

REF−

Since the resistance between the two reference inputs can

be as low as 400Ω, the voltage source driving the reference

inputs should have low output impedance. Any noise on either reference input is a potential cause of conversion errors,

so each of these pins must be supplied with a clean, low

noise voltage source. Each reference pin should be bypassed with a 10 µF tantalum and a 0.1 µF ceramic.

3.0 THE ANALOG INPUT

The ADC10662 and ADC10664 sample the analog input

voltage once every conversion cycle. When this happens,

the input is briefly connected to an impedance approximately

equal to 600Ω in series with 35 pF. Short-duration current

spikes can therefore be observed at the analog input during

normal operation. These spikes are normal and do not degrade the converter’s performance.

Large source impedances can slow the charging of the sampling capacitors and degrade conversion accuracy. Therefore, only signal sources with output impedances less than

500Ω should be used if rated accuracy is to be achieved at

the minimum sample time (250 ns maximum). If the sampling time is increased, the source impedance can be larger.

If a signal source has a high output impedance, its output

should be buffered with an operational amplifier. The operational amplifier’s output should be well-behaved when driving

a switched 35 pF/600Ω load. Any ringing or voltage shifts at

the op amp’s output during the sampling period can result in

conversion errors.

Correct conversion results will be obtained for input voltages

greater than GND − 50 mV and less than V

allow the signal source to drive the analog input pin more

than 300 mV higher than AV

mV lower than GND. If an analog input pin is forced beyond

and DVCC, or more than 300

CC

these voltages, the current flowing through the pin should be

limited to 5 mA or less to avoid permanent damage to the IC.

The sum of all the overdrive currents into all pins must be

less than 20 mA. When the input signal is expected to extend

)

more than 300 mV beyond the power supply limits, some

sourt of protection scheme should be used.A simple network

using diodes and resistors is shown in

Figure 4

+

+ 50 mV. Do not

.

www.national.com 10

Page 11

Applications Information (Continued)

DS011192-13

FIGURE 4. Typical Connection. Note the multiple bypass capacitors on the reference and power supply pins. If V

is not grounded, it should also be bypassed to analog ground using multiple capacitors (see 5.0 “Power Supply

Considerations”). AGND and DGND should be at the same potential. V

4.0 INHERENT SAMPLE-AND-HOLD

Because the ADC10662 and ADC10664 sample the input

signal once during each conversion, they are capable of

measuring relatively fast input signals without the help of an

external sample-hold. In a non-sampling

successive-approximation A/D converter, regardless of

±

speed, the input signal must be stable to better than

1/2

LSB during each conversion cycle or significant errors will

result. Consequently, even for many relatively slow input signals, the signals must be externally sampled and held constant during each conversion if a SAR with no internal

sample-and-hold is used.

Because they incorporate a direct sample/hold control input,

the ADC10662 and ADC10664 are suitable for use in

DSP-based systems. The S /H input allows synchronization

of the A/D converter to the DSP system’s sampling rate and

to other ADC10662s, andADC10664s.

The ADC10662 and ADC10664 can perform accurate conversions of input signals with frequency components from

DC to over 250 kHz.

5.0 POWER SUPPLY CONSIDERATIONS

The ADC10662 and ADC10664 are designed to operate

from a +5V (nominal) power supply. There are two supply

pins, AV

bypass capacitors for the analog and digital portions of the

and DVCC. These pins allow separate external

CC

circuit. To guarantee accurate conversions, the two supply

pins should be connected to the same voltage source, and

each should be bypassed with a 0.1 µF ceramic capacitor in

parallel with a 10 µF tantalum capacitor. Depending on the

circuit board layout and other system considerations, more

bypassing may be necessary.

The ADC10662 and ADC10664 have separate analog and

digital ground pins for separate bypassing of the analog and

digital supplies. Their ground pins should be connected to

the same potential, and all grounds should be “clean” and

free of noise.

In systems with multiple power supplies, careful attention to

power supply sequencing may be necessary to avoid overdriving inputs. The A/D converter’s power supply pins should

be at the proper voltage before digital or analog signals are

applied to any of the other pins.

6.0 LAYOUT AND GROUNDING

In order to ensure fast, accurate conversions from the

ADC10662 and ADC10664, it is necessary to use appropriate circuit board layout techniques. The analog ground return path should be low-impedance and free of noise from

other parts of the system. Noise from digital circuitry can be

especially troublesome, so digital grounds should always be

separate from analog grounds. For best performance, separate ground planes should be provided for the digital and

analog parts of the system.

All bypass capacitors should be located as close to the converter as possible and should connect to the converter and

to ground with short traces. The analog input should be isolated from noisy signal traces to avoid having spurious signals couple to the input.Any external component (e.g., a filter capacitor) connected across the converter’s input should

be connected to a very clean ground return point. Grounding

the component at the wrong point will result in reduced conversion accuracy.

7.0 DYNAMIC PERFORMANCE

Many applications require the A/D converter to digitize AC

signals, but conventional DC integral and differential nonlinearity specifications don’t accurately predict theA/D converter’s performance with AC input signals. The important specifications for AC applications reflect the converter’s ability to

digitize AC signals without significant spectral errors and

without adding noise to the digitized signal. Dynamic characteristics such as signal-to-noise ratio (SNR) and total harmonic distortion (THD), are quantitative measures of this capability.

is shown with an input protection network.

IN0

REF−

www.national.com11

Page 12

Applications Information (Continued)

An A/D converter’s AC performance can be measured using

Fast Fourier Transform (FFT) methods. A sinusoidal waveform is applied to the A/D converter’s input, and the transform is then performed on the digitized waveform. The resulting spectral plot might look like the ones shown in the

typical performance curves. The large peak is the fundamental frequency, and the noise and distortion components (if

any are present) are visible above and below the fundamental frequency. Harmonic distortion components appear at

whole multiples of the input frequency. Their amplitudes are

combined as the square root of the sum of the squares and

compared to the fundamental amplitude to yield the THD

specification. Guaranteed limits for THD are given in the

table of Electrical Characteristics.

Signal-to-noise ratio is the ratio of the amplitude at the fundamental frequency to the rms value at all other frequencies,

excluding any harmonic distortion components. Guaranteed

limits are given in the Electrical Characteristics table. An alternative definition of signal-to-noise ratio includes the distortion components along with the random noise to yield a

signal-to-noise-plus-distortion ration, or S/(N + D).

The THD and noise performance of the A/D converter will

change with the frequency of the input signal, with more distortion and noise occurring at higher signal frequencies. One

way of describing the A/D’s performance as a function of signal frequency is to make a plot of “effective bits” versus frequency. An ideal A/D converter with no linearity errors or

self-generated noise will have a signal-to-noise ratio equal to

(6.02n + 1.76) dB, where n is the resolution in bits of the A/D

converter. A real A/D converter will have some amount of

noise and distortion, and the effective bits can be found by:

where S/(N + D) is the ratio of signal to noise and distortion,

which can vary with frequency.

As an example, an ADC10662 with a 4.85 V

sine wave input signal will typically have a

, 100 kHz

P-P

signal-to-noise-plus-distortion ratio of 59.2 dB, which is

equivalent to 9.54 effective bits. As the input frequency increases, noise and distortion gradually increase, yielding a

plot of effective bits or S/(N + D) as shown in the typical performance curves.

8.0 SPEED ADJUST

The speed adjust pin is connected to an on-chip current

source that determines the converter’s internal timing. By

connecting a resistor between the speed adjust pin and

ground as shown in

Figure 4

, the internal programming current is increased, which reduces the conversion time. The

ADC10662 andADC10664 are specified and guaranteed for

operation with R

(Mode 2). Smaller resistors will result in faster conversion

times, but linearity will begin to degrade as R

smaller (see curves).

=

14.0 kΩ (Mode 1) or R

SA

SA

SA

=

8.26k

becomes

www.national.com 12

Page 13

Physical Dimensions inches (millimeters) unless otherwise noted

Order Number ADC10662CIWM

NS Package Number M24B

Order Number ADC10664CIWM

NS Package Number M28B

www.national.com13

Page 14

Notes

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT AND GENERAL

COUNSEL OF NATIONAL SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or

systems which, (a) are intended for surgical implant

into the body, or (b) support or sustain life, and

whose failure to perform when properly used in

accordance with instructions for use provided in the

2. A critical component is any component of a life

support device or system whose failure to perform

can be reasonably expected to cause the failure of

the life support device or system, or to affect its

safety or effectiveness.

labeling, can be reasonably expected to result in a

significant injury to the user.

ADC10662/ADC10664 10-Bit 360 ns A/D Converter with Input Multiplexer and Sample/Hold

National Semiconductor

Corporation

Americas

Tel: 1-800-272-9959

Fax: 1-800-737-7018

Email: support@nsc.com

www.national.com

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

National Semiconductor

Europe

Fax: +49 (0) 1 80-530 85 86

Email: europe.support@nsc.com

Deutsch Tel: +49 (0) 1 80-530 85 85

English Tel: +49 (0) 1 80-532 78 32

Français Tel: +49 (0) 1 80-532 93 58

Italiano Tel: +49 (0) 1 80-534 16 80

National Semiconductor

Asia Pacific Customer

Response Group

Tel: 65-2544466

Fax: 65-2504466

Email: sea.support@nsc.com

National Semiconductor

Japan Ltd.

Tel: 81-3-5639-7560

Fax: 81-3-5639-7507

Loading...

Loading...