Page 1

ADC0851 and ADC0858 8-Bit Analog Data

Acquisition and Monitoring Systems

ADC0851 and ADC0858 8-Bit Analog Data Acquisition and Monitoring Systems

January 1995

General Description

The ADC0851 and ADC0858 are 2 and 8 input analog data

acquisition systems. They can function as conventional multiple input A/D converters, automatic scanning A/D converters or programmable analog ‘‘watchdog’’ systems. In

‘‘watchdog’’ mode they monitor analog inputs and determine whether these inputs are inside or outside user programmed window limits. This monitoring process takes

place independent of the host processor. When any input

falls outside of its programmed window limits, an interrupt is

automatically generated which flags the processor; the chip

can then be interrogated as to exactly which channels

crossed which limits.

The advantage of this approach is that its frees the processor from having to frequently monitor analog variables. It

can consequently save having to insert many A/D subroutine calls throughout real time application code. In control

systems where many variables are continually being monitored this can significantly free up the processor, especially

if the variables are DC or slow varying signals.

The Auto A/D conversion feature allows the device to scan

through selected input channels, performing an A/D conversion on each channel without the need to select a new

channel after each conversion.

Applications

Y

Instrumentation monitoring and process control

Y

Digitizing automotive sensor signals

Y

Embedded diagnostics

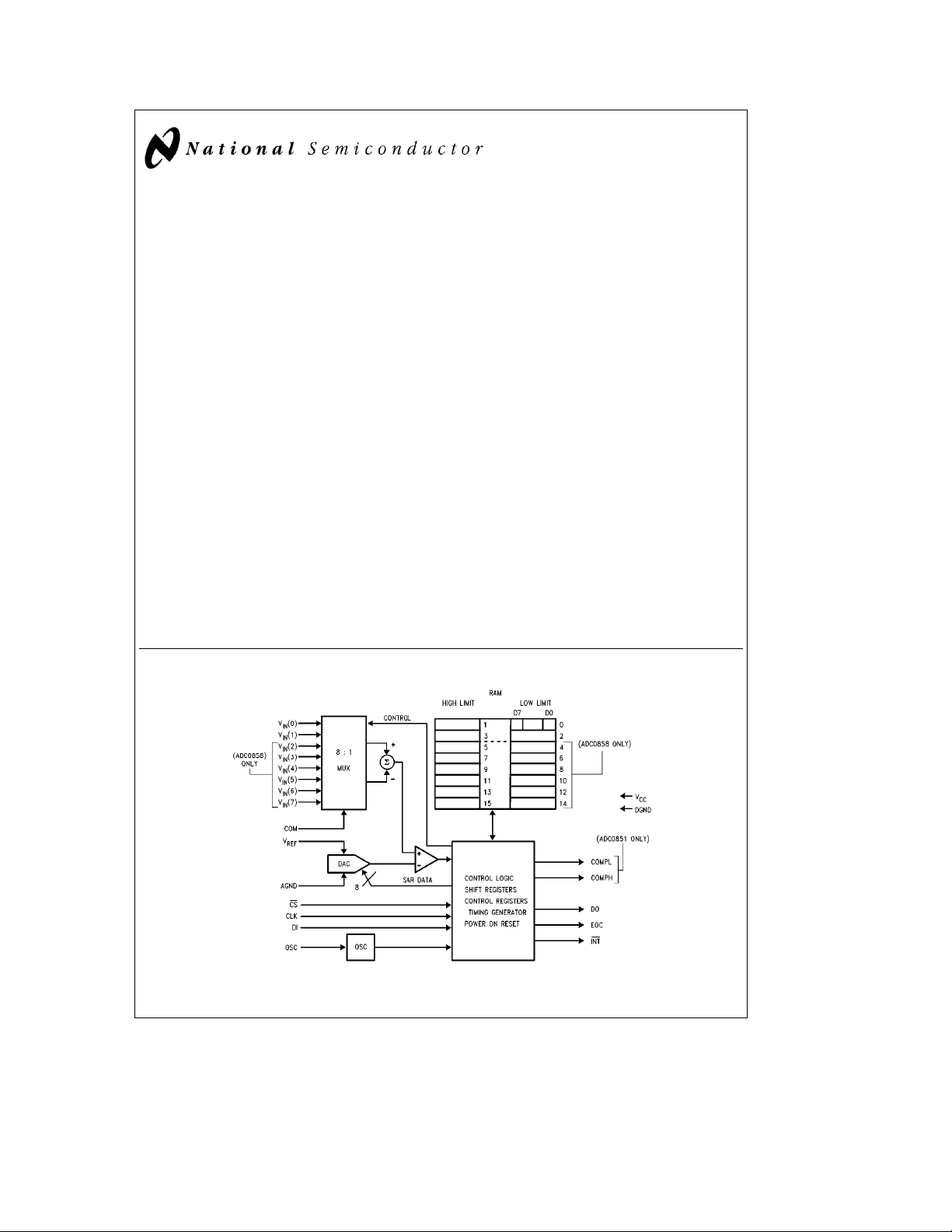

Simplified Block Diagram

Key Specifications

Y

Resolution 8 Bits

Y

Total error

Y

Low power 50 mW

Y

Conversion time 18 ms/Channel

Y

Limit comparison time 2 ms/Limit

g

(/2 LSB org1 LSB

Features

Y

Watchdog operation signals processor when any

channel is outside user programmed window limits

Y

Frees microprocessor from continually monitoring

analog signals and simplifies applications software

Y

2 (ADC0851) or 8 (ADC0858) analog input channels

Y

Single ended or differential input pairs

Y

COM input for DC offsetting of input voltage

Y

4 (ADC0851) and 16 (ADC0858), 8-bit programmable

limits

Y

NSC MICROWIRETMinterface

Y

Power fail detection

Y

Auto A/D conversion feature

Y

Single 5V supply

Y

Window limits are user programmable via serial interface

FIGURE 1

TL/H/11021– 22

TRI-STATEÉis a registered trademark of National Semiconductor Corporation.

TM

MICROWIRE

C

1995 National Semiconductor Corporation RRD-B30M75/Printed in U. S. A.

is a trademark of National Semiconductor Corporation.

TL/H/11021

Page 2

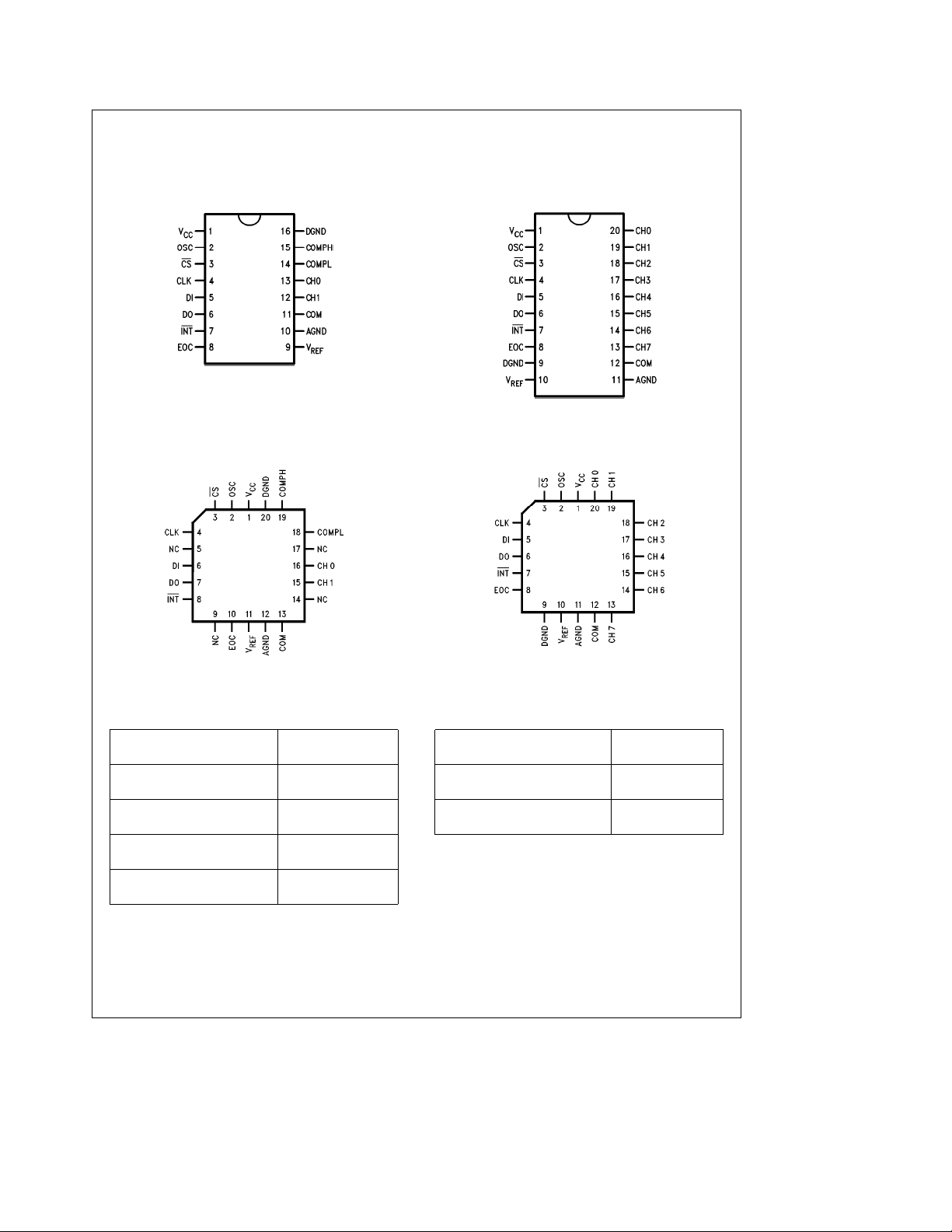

Connection Diagrams

ADC0851

2-Channel MUX

Dual-In-Line Package

Top View

ADC0851 PLCC Package

ADC0858

8-Channel MUX

Dual-In-Line Package

TL/H/11021– 1

TL/H/11021– 2

Top View

ADC0858 PLCC Package

Top View

Ordering Information

Industrial

b

(

40§CsT

s

a

85§C)

A

ADC0851BIN, N16E, 16-Pin

ADC0851CIN Plastic DIP

ADC0858BIN, N20A, 20-Pin

ADC0858CIN Plastic DIP

ADC0851BIV, V20A, 20-Lead

ADC0851CIV PLCC

ADC0858BIV, V20A, 20-Lead

ADC0858CIV PLCC

TL/H/11021– 3

Package

Top View

TL/H/11021– 4

b

(

55§CsT

Military

s

A

a

125§C)

Package

ADC0851CMJ/883 J16A, 16-Pin

Ceramic DIP

ADC0858CMJ/883 J20A, 20-Pin

Ceramic DIP

2

Page 3

Absolute Maximum Ratings (Notes1&2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage, V

Voltage at Logic and Analog

Inputs (Note 3)

CC

b

0.3V to V

Input Current per Pin

Input Current per Package

Storage Temperature

Package Dissipation 500 mW

ea

at T

25§C (Board Mount) 800 mW

A

b

65§Ctoa150§C

Lead Temperature (Soldering, 10 Sec.)

Dual-In-Line (Plastic)

Dual-In-Line (Ceramic)

ESD Susceptibility (Note 4) 2000V

CC

a

g

g

a

a

6.5V

0.3V

5mA

20 mA

260§C

300§C

Operating Ratings (Notes1&2)

Supply Voltage, V

Temperature Range T

ADC0858CMJ/883

ADC0851CMJ/883

ADC0858BIN, ADC0858CIN

ADC0851BIN, ADC0851CIN

ADC0858BIV, ADC0858CIV

ADC0851BIV, ADC0851CIV

CC

b

55§CsT

b

55§CsT

b

40§CsT

b

40§CsT

b

40§CsT

b

40§CsT

MIN

4.5V to 5.5V

s

s

T

A

s

a

A

s

a

A

s

a

A

s

a

A

s

a

A

s

a

A

T

MAX

125§C

125§C

85§C

85§C

85§C

85§C

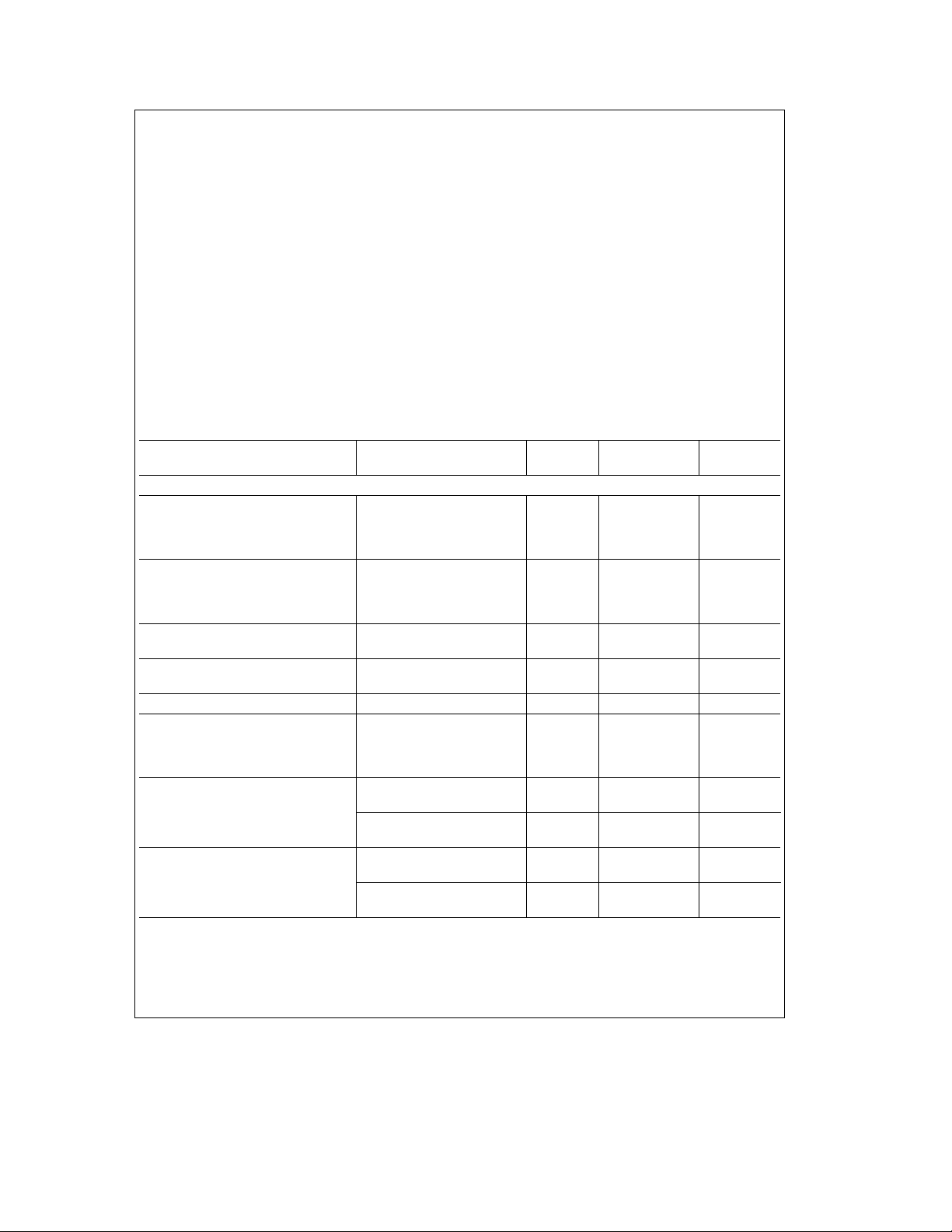

DC Electrical Characteristics

The following specifications apply for V

3.16 kX,C

at T

A

e

170 pF) unless otherwise specified. Boldface limits apply for T

ext

e

ea

T

25§C.

J

Parameter Conditions

CC

ea

5VDC,V

REF

ea

4.5 VDC, AGNDeDGNDe0V and f

e

e

T

A

J

Typical Limit Units

(Note 5) (Note 6) (Limits)

e

1 MHz (R

T

MIN

OSC

to T

; all other limits apply

MAX

CONVERTER AND MULTIPLEXER CHARACTERISTICS

Total Unadjusted Error (Note 7)

ADC0851/8/BIN, ADC0851/8/BIV

ADC0851/8/CIN, ADC0851/8/CMJ,

ADC0851/8/CIV

g

(/2 LSB (Max)

g

1 LSB (Max)

g

1 LSB (Max)

Comparator Offset

ADC0851/8/BIN, ADC0858BIV

ADC0851/8/CIN, ADC0851/8/CMJ,

ADC0858CIV

V

Input Resistance 6 3.5 kX (Min)

REF

g

2.5

g

2.5

g

2.5

g

10 mV (Max)

g

20 mV (Max)

g

20 mV (Max)

10 kX (Max)

Common Mode Input Voltage All MUX Inputs GNDb0.05 V (Min)

(Note 8) and COM Input V

DC Common Mode Error DV

Power Supply Sensitivity V

I

, On Channele5V

OFF

Off Channel Off Channel

Leakage Current

(Note 9)

eb

0.05V toa5.05V

CM

e

4.75V

REF

e

V

5Vg5%

CC

e

V

4.5V

REF

e

5Vg10%

V

CC

e

0V

On Channele0V

e

Off Channel

5V

ION, On Channele5V

e

On Channel Off Channel

Leakage Current

(Note 9)

On Channele0V

Off Channel

0V

e

5V

g

g

g

b

a

a

b

1/16

1/16

1/16

0.01

0.01

0.01

0.01

a

0.05 V (Max)

CC

g

1/4 LSB (Max)

g

1/4 LSB (Max)

g

1/2

b

3 mA (Max)

a

3 mA (Max)

a

3 mA (Max)

b

3 mA (Max)

ext

e

3

Page 4

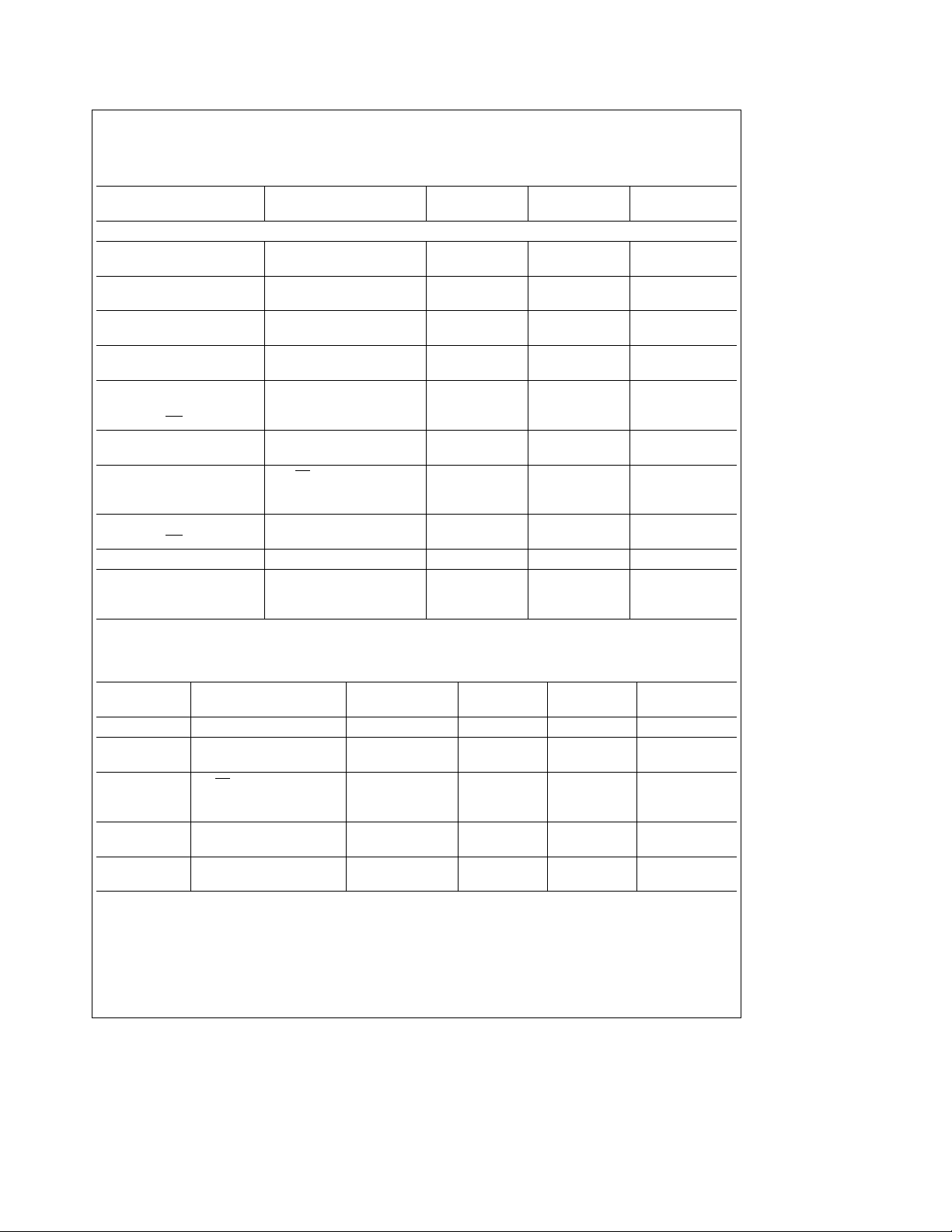

DC Electrical Characteristics (Continued)

The following specifications apply for V

3.16 kX,C

at T

A

e

170 pF) unless otherwise specified. Boldface limits apply for T

ext

e

ea

T

25§C.

J

CC

ea

5VDC,V

Parameter Conditions

DIGITAL CHARACTERISTICS

I

OUT

OUT

OUT

V

e

5.5V

CC

e

4.5V

CC

e

V

IN

CC

e

0V

IN

e

4.5V

CC

eb

360 mA 2.4 V (Min)

eb

10 mA 4.2 V (Min)

e

1.6 mA

e

4.5V

CC

Logic ‘‘1’’ Input V

Voltage, V

IH

Logic ‘‘0’’ Input V

Voltage, V

IL

Logic ‘‘1’’ Input V

Current, I

IH

Logic ‘‘0’’ Input V

Current, I

IL

Logic ‘‘1’’ Output V

Voltage, V

(Except INT

OH

)I

Logic ‘‘0’’ Output I

Voltage, V

OL

TRI-STATEÉOutput CSeLogic ‘‘1’’ (5V)

Current (DO) V

I

SOURCE

(Except INT

I

SINK

Supply Current, I

ADC0851 or ADC0858 f

)

CC

e

0.4V

OUT

e

V

5V 0.1 3 mA (Max)

OUT

V

Short to GND

OUT

V

Short to V

OUT

e

f

1 MHz 7 10 mA (Max)

CLK

e

2 MHz 7.2 mA

CLK

(Note 10)

CC

REF

ea

4.5 VDC, AGNDeDGNDe0V and f

e

e

T

A

J

Typical Limit Units

(Note 5) (Note 6) (Limits)

0.005 3 mA (Max)

b

0.005

b

0.1

b

14

16 8 mA (Min)

e

1 MHz (R

T

MIN

OSC

to T

; all other limits apply

MAX

2.2 V (Min)

0.8 V(Max)

b

3 mA (Max)

0.4 V (Max)

b

3 mA (Max)

b

6.5 mA (Min)

ext

e

AC Electrical Characteristics

The following specifications apply for V

5 ns unless otherwise specified. Boldface limits apply for T

CC

ea

5VDC,V

REF

Symbol Parameter Conditions

f

CLK

Data Clock Frequency 1 2 MHz (Max)

Clock Duty Cycle 40 % (Min)

(Note 11) 60 % (Max)

t

SET-UP

CS Falling Edge or

Data Input Valid to 30 70 ns (Min)

CLK Rising Edge

t

HOLD

t

PD1,tPD0

Data Input Valid after

CLK Rising Edge

CLK Rising Edge to C

Output Data Valid

e

L

ea

4.5 VDC, AGNDeDGNDe0V, f

e

e

T

T

A

J

MIN

to T

MAX

Typical Limit Units

(Note 5) (Note 6) (Limits)

5 30 ns (Min)

100 pF

80 200 ns (Max)

4

e

; all other limits apply at T

CLK

1 MHz, t

e

A

e

e

t

r

f

e

T

25§C.

J

Page 5

AC Electrical Characteristics (Continued)

The following specifications apply for V

5 ns unless otherwise specified. Boldface limits apply for T

Symbol Parameter Conditions

t1H,t

0H

Rising Edge of CS to Ce100 pF, Re2k

Data Output Hi-Z (See TRI-STATE 90 200 ns (Max)

CC

ea

5VDC,V

REF

ea

4.5 VDC, AGNDeDGNDe0V, f

e

e

T

T

to T

A

J

MIN

; all other limits apply at T

MAX

Typical Limit Units

(Note 5) (Note 6) (Limits)

CLK

e

1 MHz, t

e

T

A

e

t

r

f

e

25§C.

J

Test Circuits)

f

t

OSC

EOC

Oscillator Clock Freq. R

(Analog Timing) C

CS to End of OSC Clock

Conversion Delay Periods

e

3.16 kX

ext

e

170 pF 0.6 MHz (Min)

ext

1

1.4 MHz (Max)

1 Min

2 Max

t

Conv

Conversion Time OSC Clock

Periods

17 (Min)

18 (Max)

t

CS-INT

C

IN

C

OUT

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

functional, but do not guarantee specific performance limits. For guaranteed specifications and test conditions, see the Electrical Characteristics. The guaranteed

specifications apply only for the test conditions listed. Some performance characteristics may degrade when the device is not operated under the listed test

conditions.

Note 2: All voltages are measured with respect to ground (AGND

Note 3: All of the analog and digital input pins are internally diode clamped to the supply pins. Should the applied voltage at any pin exceed the power supply

voltage, the additional absolute value of current at that pin (caused by the forward biasing of the internal diodes) should be limited to 5 mA or less.

Note 4: Human body model, 100 pF discharged through a 1.5 kX resistor.

Note 5: Typical specifications are at

Note 6: Tested limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 7: Total unadjusted error includes comparator offset, ADC linearity and multiplexer error, and, is expressed in LSBs.

Note 8: Two on-chip diodes are tied to each analog input. The diodes will forward conduct for analog input voltages one diode drop below ground or one diode drop

above V

. Care should be exercised when operating the device at low supply voltages (e.g., V

CC

diodes to conduct, especially at elevated temperatures. This will cause errors for analog inputs near full scale. The specification allows 50 mV forward bias of either

clamp diode. Thus as long as V

to5VDCinput voltage range will therefore require a minimum supply voltage of 4.950 VDC.

Note 9: Leakage current is measured with the oscillator clock disabled.

Note 10: Measured supply current does not include the DAC ladder current.

Note 11: A 40% to 60% clock duty cycle range ensures proper operation at all clock frequencies.

CS to Interrupt Delay 60 120 ns (Max)

Capacitance of

Logic Input

Capacitance of

Logic Output

a

25§C and represent the most likely parametric norm.

or V

IN

REF

e

DGNDe0V).

does not exceed the supply voltage by more than 50 mV, the output code will be correct. To achieve an absolute 0 V

5pF

5pF

e

4.5V) because high analog inputs (5V) can cause the input

CC

e

DC

5

Page 6

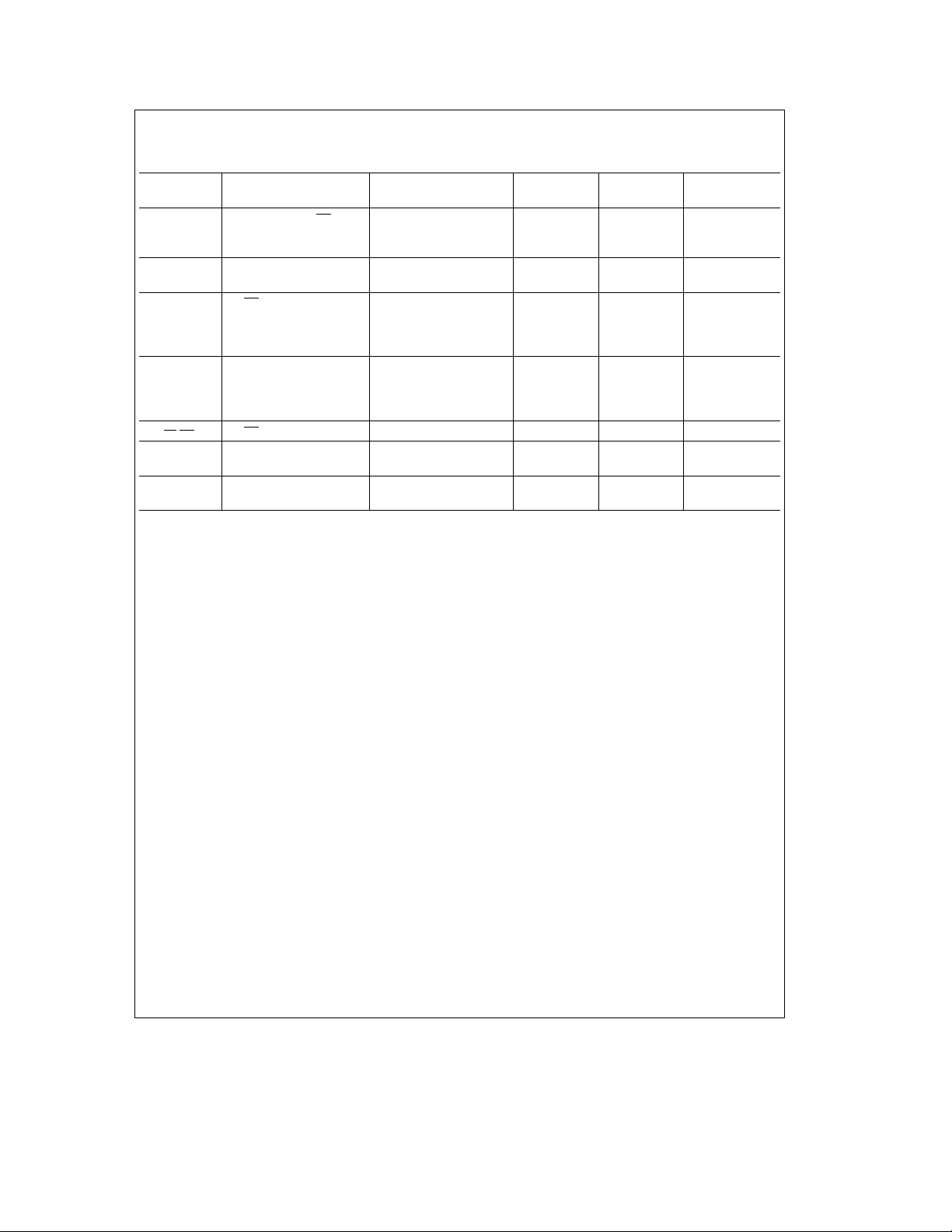

Typical Performance Characteristics

Offset Error vs

Reference Voltage Reference Voltage

OSC Frequency

vs Temperature

Linearity Error vs

OSC Frequency vs

and C

R

ext

ext

Total Unadjusted Error

vs Temperature

TL/H/11021– 5

6

Page 7

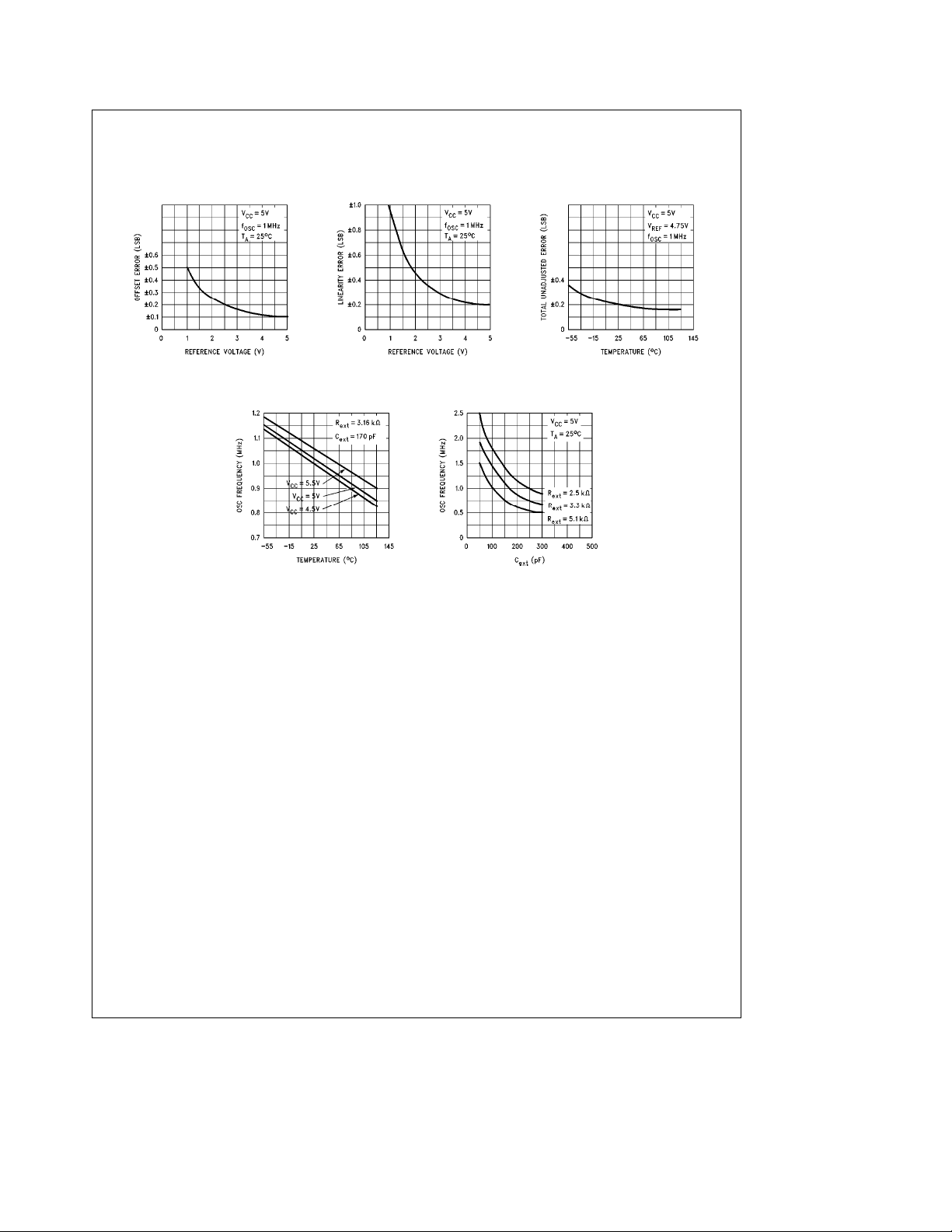

Test Circuits and Waveforms

Timing Diagrams

t

1H

TL/H/11021– 6

t

0H

TL/H/11021– 7

t1H,C

t1H,C

e

10 pF

L

TL/H/11021– 8

e

10 pF

L

TL/H/11021– 9

Data Input Timing

Data Output Timing

TL/H/11021– 11

TL/H/11021– 10

7

Page 8

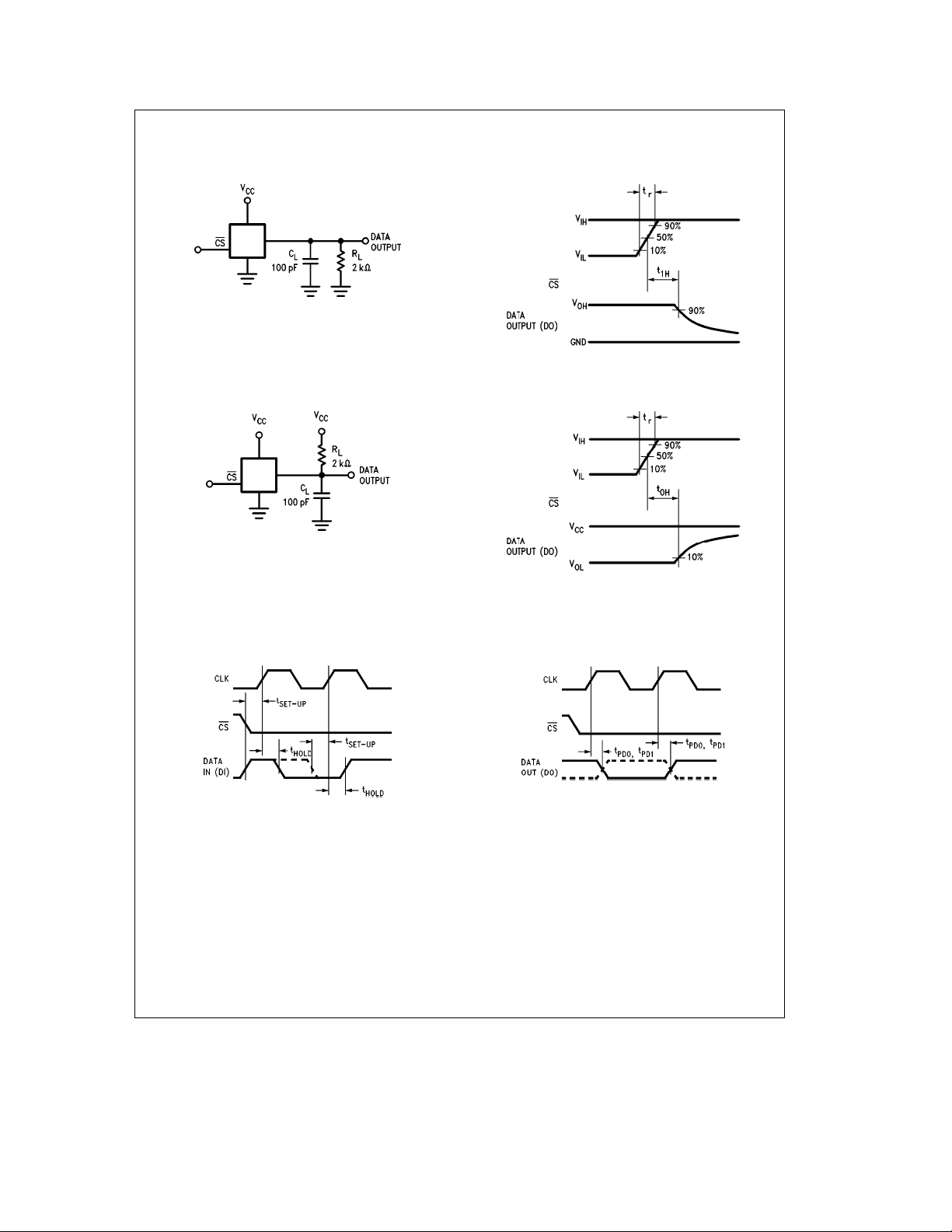

Timing Diagrams (Continued)

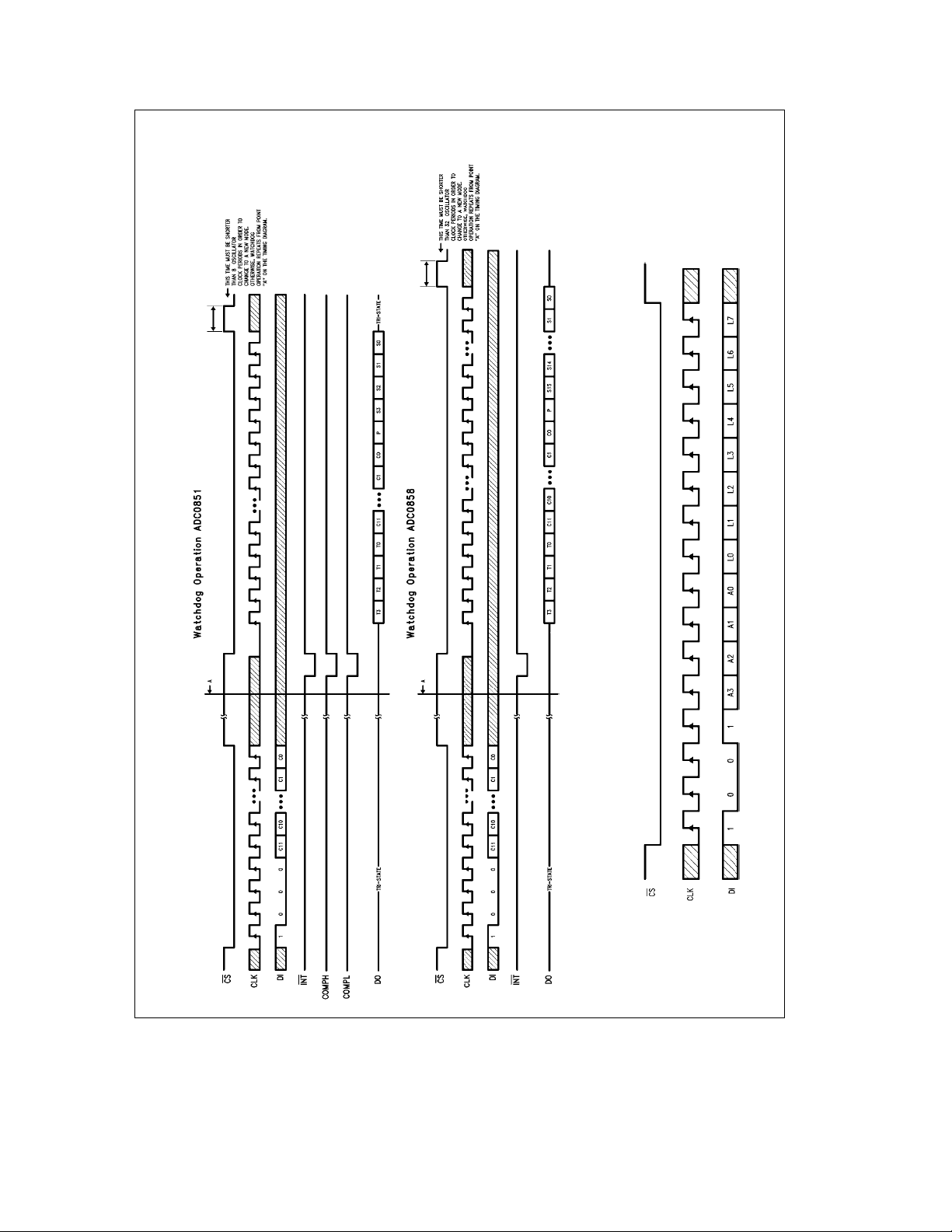

Watchdog Timing

A/D Conversion Timing

Timing Diagrams for ADC0851 and ADC0858

Read Power Flag after Power Up ADC0851/ADC0858

TL/H/11021– 12

TL/H/11021– 13

TL/H/11021– 14

8

Page 9

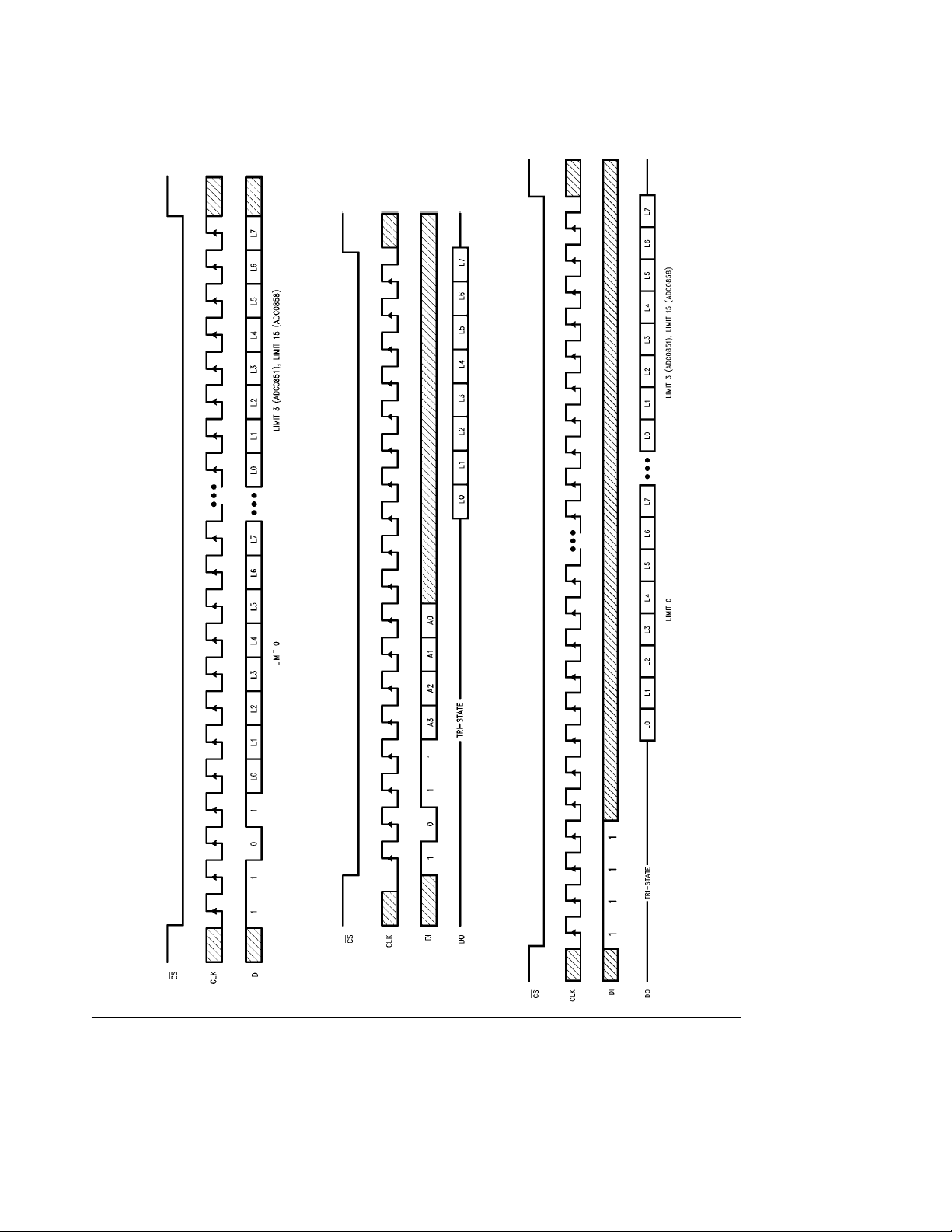

Timing Diagrams for ADC0851 and ADC0858 (Continued)

TL/H/11021– 15

TL/H/11021– 16

Write 1 Limit to ADC0851/ADC0858

9

Page 10

Timing Diagrams for ADC0851 and ADC0858 (Continued)

Write all Limits to ADC0851/ADC0858

TL/H/11021– 17

Read 1 Limit from ADC0851/ADC0858

TL/H/11021– 18

TL/H/11021– 19

Read all Limits from ADC0851/ADC0858

10

Page 11

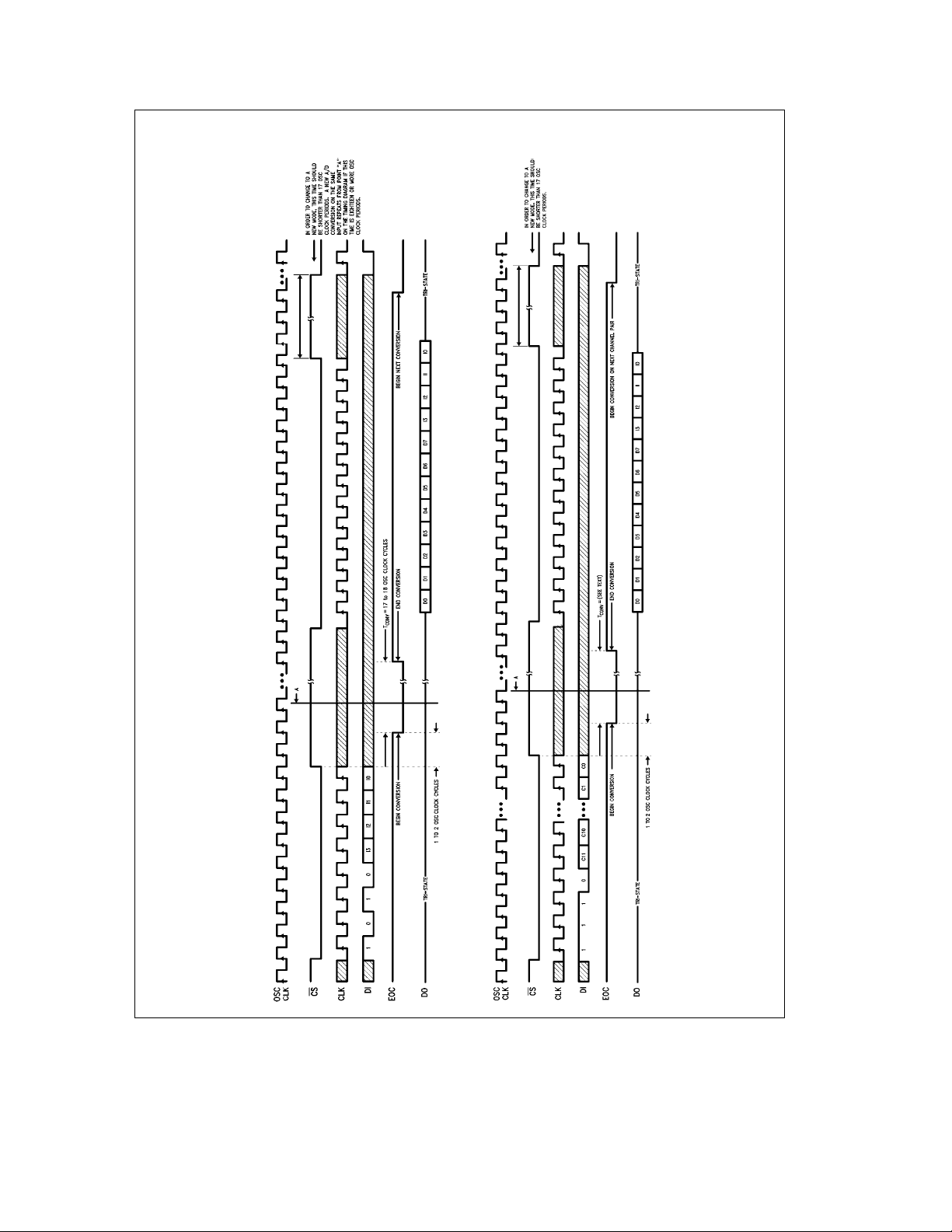

Timing Diagrams for ADC0851 and ADC0858 (Continued)

TL/H/11021– 20

TL/H/11021– 21

1 A/D Conversion ADC0851/ADC0858

Auto A/D Conversion ADC0851/ADC0858

11

Page 12

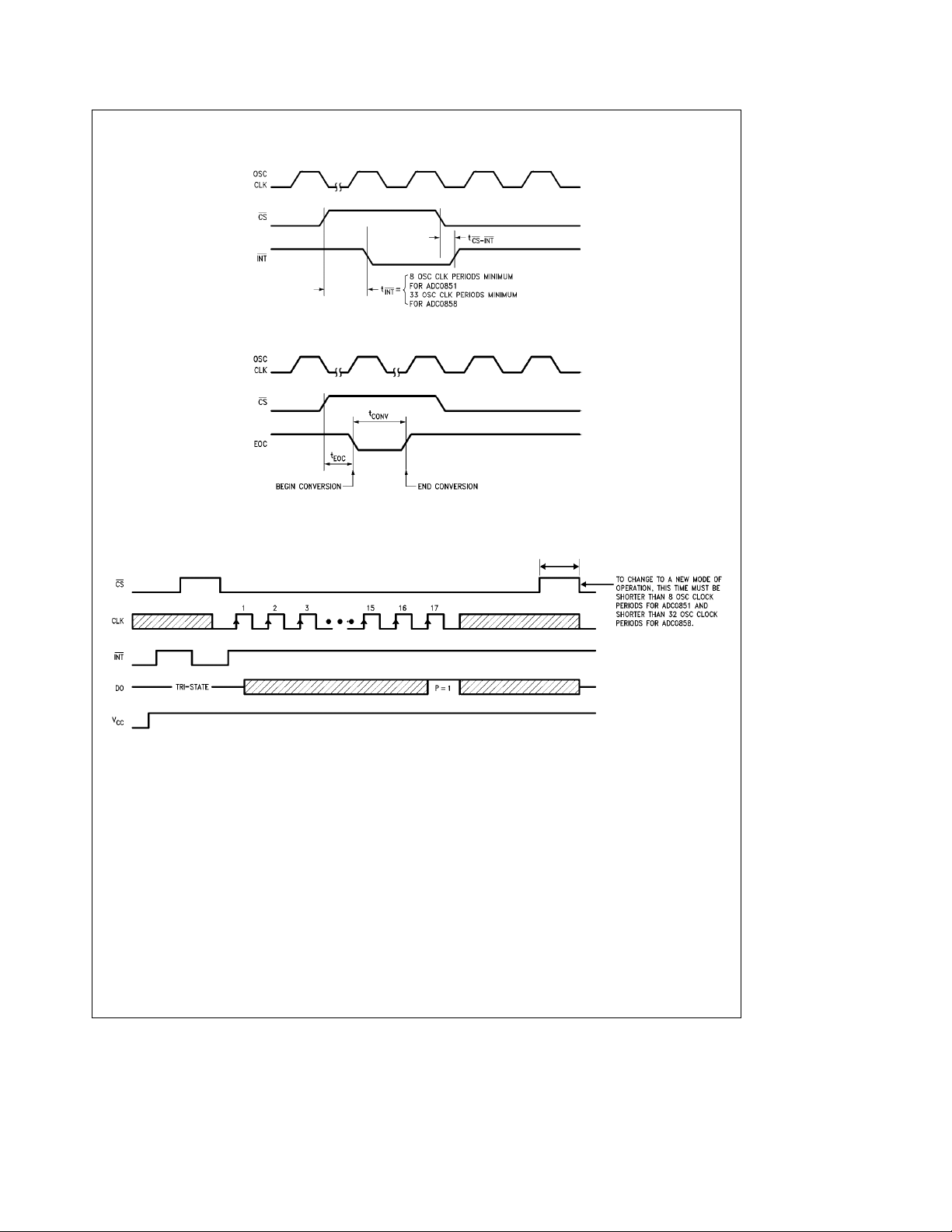

ADC0851 Programming Chart

Function

Watchdog 1000 C11...C0 T3...T0,C11...C0,P,S3...S0 Send Data after INT

Write 1 Limit 1001 A3...A0,L0...L7 Write Limit to RAM

1 A/D Conversion 1010 I3...I0 D0...D7,I3...I0 Send Data after Conversion

Read 1 Limit 1011 A3...A0 L0...L7 Send Limit from RAM

Test 1100 Do Not Use (See Text)

Write all Limits 1101 4 Bytes, L0 First Write All Limits to RAM

Auto A/D Convert 1110 C11...C0 D0...D7,I3...I0 Continuous Conversion

Read all Limits 1111 4 Bytes, L0 First Send all Limits from RAM

Receive (DI) Transmit

Mode

(DO)

Comments

ADC0858 Programming Chart

Function

Watchdog 1000 C11...C0 T3...T0,C11...C0,P,S15...S0 Send Data after INT

Write 1 Limit 1001 A3...A0,L0...L7 Write Limit to RAM

1 A/D Conversion 1010 I3...I0 D0...D7,I3...I0 Send Data after Conversion

Read 1 Limit 1011 A3...A0 L0...L7 Send Limit from RAM

Test 1100 Do Not Use (See Text)

Write all Limits 1101 16 Bytes, L0 First Write all Limits to RAM

Auto A/D Convert 1110 C11...C0 D0...D7,I3...I0 Continuous Conversion

Read all Limits 1111 16 Bytes, L0 First Send all Limits from RAM

Receive (DI) Transmit

Mode

(DO)

Comments

Serial Communication Bit Order

Bit Order

Information Type ADC0851 ADC0858

First Last First Last

Limit Data L0 . . . L7 L0 . . . L7

A/D Conversion Data D0 . . . D7 D0 . . . D7

Limit Address A3 . . . A0 A3 . . . A0

Status S3 . . . S0 S15 . . . S0

Channel Tag T3 . . . T0 T3 . . . T0

Channel Configuration C11 . . . C0 C11 . . . C0

Channel Information I3 . . . I0 I3 . . . I0

Mode M3 . . . M0 M3 . . . M0

Power Fail P (One Bit) P (One Bit)

12

Page 13

Pin Descriptions

V

CC

OSC Input/Output pin used to generate internal

CS This is the chip select input pin. It must be

CLK The serial clock input pin is used to clock

DI Serial data digital input pin.

DO TRI-STATE data output pin.

INT

EOC End of conversion output pin. The low state

Positive power supply pin. Bypass to analog

ground with a 0.1 mF ceramic capacitor in

parallel with a 10 mF tantalum capacitor.

timing for A/D conversion. This pin is connected to an external resistor and capacitor

to set the oscillation frequency for analog

timing (see

held low while data is transferred to or from

the ADC0851/8 (see Timing Diagram).

serial data either into the data input pin (DI)

or out of the data output pin (DO). Input data

is loaded on the rising edge of CLK and the

output data is valid at the falling edge of

CLK.

This is the active low interrupt pin that indicates that at least one analog input channel

voltage level has exceeded the programmed window limits. Since this pin has

an open drain output, an external pull up resistor is required. This allows many devices

to be wire-ORed together using a single

pull-up resistor.

indicates that an A/D conversion is in progress. The EOC pin goes high when the conversion is completed.

Figure 12

).

AGND Analog ground reference.

DGND Digital ground reference for the logic inputs.

V

REF

COM The COM pin functions as an inverting dif-

CH0–CH1 CH0– CH7 are analog input channels which

(ADC0851) can be configured as single ended inputs or

CH0–CH7

(ADC0858)

COMPL, These output pins are available only on the

COMPH ADC0851. During ‘‘Watchdog’’ operation, if

Both AGND and DGND should be at same

potential.

This is the analog reference pin. The voltage applied to this pin sets the full scale

A/D conversion range. Recommended voltages applied to this pin range from 1V to

V

. Bypass to analog ground with a 0.1 mF

CC

ceramic capacitor in parallel with a 10mF

tantalum capacitor.

ferential input common to all analog inputs

when each channel is configured as a single-ended channel. If the input channels are

programmed as differential pairs then the

COM input has no effect.

as differential pairs. The analog input voltage should stay within the power supply

range.

either of the inputs exceeds the window limits, not only is an interrupt generated but

also the COMPL and COMPH pins go low to

indicate whether the upper or lower boundary was exceeded (See applications section

for more information.)

13

Page 14

General Overview

The ADC0851/58 is a versatile microprocessor-compatible

data acquisition system with an on-board watchdog capability. The device is capable of synchronous serial interface

with most microprocessors and includes a multiplexer, a

RAM and a successive approximation register. The

ADC0851 and the ADC0858 have two and eight input channels respectively.

1.0 Modes of Operation

The device can be used in any one of the eight modes of

operation listed below. A mode is selected by taking CS

and providing the IC with an input word whose first four bits

specify the desired mode (see the ‘‘Programming Charts’’

for the mode selection codes):

1.1 WATCHDOG MODE

This mode of operation allows the device to operate as a

digitally-programmable window comparator. The analog input voltage at each channel is compared against the upper

and lower boundary limits stored in an internal RAM. When

an input falls outside of its programmed window limits, an

interrupt is generated. The microprocessor can then pull CS

low which causes the device to produce a bit stream that

indicates which channel(s) crossed which limit(s).

The watchdog mode is selected by taking CS

low and shifting in the four bit word (1000) followed by a twelve bit

word that configures the analog inputs to operate either as

single-ended or as differential pairs (CH0 –CH1, CH2 –CH3,

etc.). When a channel is operating single-ended, its input

voltage is compared to the upper and lower limits stored in

RAM for that input. When two inputs are configured as a

differential pair, the limits stored in the RAM for the channel

with the lower number will be compared against the differential input voltage. For example, the differential voltage

CH0–CH1 will be compared with the lower and upper limits

for CH0. The limits are programmed using the ‘‘write one

limit to RAM’’ or ‘‘write all limits to RAM’’ mode.

Data Input (DI) WordÐADC0851 or ADC0858

1.2 WRITE ONE LIMIT TO RAM

This mode allows the user to update a single limit for one of

the input channels. This is accomplished by using a 16-bit

stream of input data (see ‘‘Programming Chart’’). The first

four bits (1001)select the mode, the next four bits select

low

TL/H/11021– 23

the input channel and the limit (upper or lower) that will be

preset, and the last eight bits set the limit (or comparator

threshold).

The limit data representing the input voltage limit (or comparator threshold) is expressed as per the following equation:

e

V

V

LIM

((/2 L7a(/4 L6a...a1/256 L0)

REF

where L7 is the MSB.

Data Input (DI) WordÐADC0851 or ADC0858

TL/H/11021– 24

1.3 WRITE ALL LIMITS TO RAM

This mode is used to update each pair of lower and upper

limits for all channels. This is accomplished by a stream of

input data whose first four bits select the mode of operation

followed by four bytes of limit data for the ADC0851 and

sixteen bytes of limit data for the ADC0858.

The limit data representing the input voltage limit (or comparator threshold) is expressed as per the following equation:

e

V

V

LIM

((/2 L7a(/4 L6a...a1/256 L0)

REF

where L7 is the MSB.

Data Input (DI) WordÐADC0851 or ADC0858

TL/H/11021– 25

1.4 READ ONE LIMIT FROM RAM

When the ADC0851/8 is configured in this mode, the user

can read back an 8-bit limit word from the RAM memory

location pointed to by the limit address. An 8-bit input word

selects the mode (1011) and thememory location to be

read.

Data Input (DI)ÐADC0851 or ADC0858

TL/H/11021– 26

14

Page 15

1.0 Modes of Operation (Continued)

1.5 READ ALL LIMITS FROM RAM

This mode of operation allows the device to serially output

8-bit limit data from each memory location in succession

starting with CH0-lower limit (see Section 2.4 under interface considerations).

Data Input (DI) WordÐADC0851 or ADC0858

TL/H/11021– 27

1.6 INITIATE ONE A/D CONVERSION

At any time, the user can initiate an A/D conversion on any

input channel. Note that the input channels may be configured as single ended or differential inputs. The first four bits

of the input word select the mode of operation and the next

four bits assign the multiplexer configuration.

Data Input (DI) WordÐADC0851 or ADC0858

TL/H/11021– 28

1.7 INITIATE AUTO A/D CONVERSION

When configured in this mode, an A/D conversion is done

on a channel or channel pair and after the output data is

transmitted, conversion begins on the next subsequent

channel or channel pair. In this mode the device continually

scans through the input channels making A/D conversions

unless the device’s mode of operation is changed. The first

four bits of the input word select the mode of operation and

the next twelve bits assign the multiplexer configuration.

Data Input (DI) WordÐADC0851 or ADC0858

TL/H/11021– 29

1.8 TEST MODE

This mode is used to test the ADC0851/8 at the factory and

is not intended for normal use. If this mode is accidentally

selected, the supply voltage must be disconnected and then

reconnected to reset the device.

2.0 Conversion Timing vs

Serial Interface Timing

Note that the ADC0851/8 uses two clock signals for proper

operation. Connecting an external resister (R

OSC pin (pin 2) to V

and an external capacitor (C

CC

) from the

ext

ext

) from

the OSC pin to ground causes the device’s internal oscillator to generate the OSC clock signal for A/D conversion

and watchdog timing. With R

170 pF, the OSC clock frequency is approximately 1 MHz.

Note that internally, ADC0851/8 divides the OSC clock frequency by two. An A/D conversion is completed in eighteen

OSC clock periods maximum. It should be noted that the

OSC pin of the ADC0851/8 should not be driven by an external clock.

An external clock signal is applied to the CLK pin (pin 4) of

the ADC0851/8. The CLK signal is used to clock serial data

either into the data input pin (DI) or out of the data output

pin (DO).

Note that input data is loaded at the rising edge of CLK

while the output data is valid at the falling edge of CLK. All

digital timing such as data set-up and hold times and delays

are measured with respect to the CLK signal. The OSC

clock and CLK frequencies need not be the same.

ext

e

3.16 kX and C

ext

3.0 Programming Information

The ADC0851 and ADC0858 communicate data serially

over the DI (data input) and DO (data output) lines. The data

format for the input and output words for various modes of

operation are shown in the ‘‘programming charts.’’

There are nine types of data as shown in the ‘‘serial communication bit order’’ table. The order in which data is communicated is MSB first in all but two cases: Limit data and

A/D conversion data. The various data types are described

below.

3.1 LIMIT DATA (L0, L1,...L7)

Limits on the ADC0851/8 are 8 bits in width and can either

represent an upper or lower boundary limit. Limit data can

either be written (in the ‘‘write one limit’’ or ‘‘write all limits’’

mode) to or read (in the ‘‘read one limit’’ or ‘‘read all limits’’

mode) from the limit RAM. Being able to read back the limit

data allows system testability, and it also allows independent software routines to see what window limits were previously written to the chip. During watchdog operation, a programmed limit must be crossed in order to cause an interrupt.

3.2 A/D CONVERSION DATA (D0, D1,...D7)

There are two A/D conversion modes (One A/D conversion

and Auto A/D conversion) that produce 8-bit conversion

data. During either type of A/D conversion, a single-ended

analog input or a differential analog input pair is digitized to

produce this conversion data.

3.3 LIMIT ADDRESS (A3, A2,...A0)

The limit address points to the location, within the limit

RAM, to which limit data is sent or from which it is received.

Limit address is used in the ‘‘write one limit to RAM’’, ‘‘write

all limits to RAM’’, ‘‘read one limit from RAM’’ or ‘‘read all

limits from RAM’’ mode. There are two addresses for each

analog input; the even addresses correspond to the lower

e

15

Page 16

3.0 Programming Information

(Continued)

limits while the odd addresses correspond to the upper limits. The ADC0851 and ADC0858 both use four bits (A3– A0)

to address the limit RAM but the ADC0851 only decodes

the two LSBs while ignoring the two MSBs. The ADC0858

decodes all four bits thus yielding sixteen limit addresses.

3.4 STATUS AND CHANNEL TAG DATA

(S3, S2, . . . , S0, ADC0851; S15, S14, . . . , S0, ADC0858)

(T3, T2, . . . , T0)

During watchdog mode, immediately after one analog input

is determined to be outside of its programmed window limit,

its channel number is stored in the channel tag register and

the remaining inputs are checked one more time and the

pass/fail status of each input is stored in the status register.

When the microprocessor receives the interrupt signal, it

can read the status and channel tag data by pulling CS

and clocking out the data.

3.5 CHANNEL CONFIGURATION DATA

(C11, C10,...C0)

The channel configuration data assigns the configuration of

the multiplexer. The data is comprised of twelve bits with

each group of three bits addressing an analog input channel

pair. Each channel pair can be configured for single-ended

operation, differential operation, one single ended channel

and one disabled channel, or both channels disabled. The

channel configuration data is required when the device is in

the watchdog or Auto A/D conversion mode.

3.6 CHANNEL INFORMATION DATA

(I3, I2,...I0)

This data is used by the ADC0851/8 only when the device is

configured in the ‘‘One A/D conversion’’ mode. The channel information data assigns the configuration of the multiplexer.

3.7 MODE ADDRESS (M3, M2,...M0)

The input word (DI) configures the ADC0851/8 for various

modes of operation. The first four bits of the input word

constitute the mode address which specifies the mode of

operation.

3.8 POWER FAIL BIT (P)

The ADC0851/8 is automatically configured to the watchdog mode upon power-up and an interrupt is immediately

generated after CS

17-bit data stream. The seventeenth bit of the output word

DO in the watchdog mode is the power fail bit, P. If the

output data is read after power-up then P will be at logical

‘‘1’’. Changing the mode of operation resets P to logical

‘‘0’’. Any subsequent power failure will cause the device to

configure in the watchdog mode upon power-up with P at

logical ‘‘1’’.

is pulled high. Pulling CS low produces a

low

4.0 Initialization after Power-Up

The ADC0851/8 is automatically configured in the watchdog mode upon power-up. After reading the power fail bit

CS

is pulled high. To exit the watchdog mode and to change

to a new mode of operation, CS

eight oscillator clock periods for the ADC0851 and less than

should be high less than

thirty two oscillator clock periods for the ADC0858 respectively (see the Timing Diagram, ‘‘Read Power Flag after

Power Up ADC0851/8’’). When changing to a new mode of

operation, the device readies itself to read a new input word

clocked in at the data input (DI) pin. The input word configures the new mode of operation.

Functional Description

The simplified block diagram (

the various functional blocks. The ADC0851 and ADC0858

include 2- and 8-channel analog input multiplexers respectively. Using the appropriate serial input word at the Data

Input (DI) pin, the analog channels can be configured for

either single-ended operation or differential mode operation.

The COM input pin provides additional flexibility since the

COM pin functions as an inverting differential input common

to all analog inputs when each channel is configured as a

single ended channel. Applying an external DC voltage at

the COM pin allows offsetting the single ended analog input

voltages from ground (pseudo-differential mode). Input

channels that are configured as differential pairs will be unaffected by the voltage at COM pin.

The ADC0851/8 includes an 8-bit DAC, a comparator and

an 8-bit successive approximation register. An analog-todigital conversion can be initiated at any time on any one of

the input channels. The 8-bit digital word corresponding to

the analog input voltage is serially clocked out at the Data

Output (DO) pin. In addition to its use as a multiplexed A/D

converter, the ADC0851/8 may also be used as a window

comparator in the watchdog mode. An upper and lower

boundary limit corresponding to each analog input voltage

may be stored in an internal RAM. The RAM consists of

sixteen memory locations, each 8 bit wide; however, for the

ADC0851 only four memory locations are used. Limit data

can either be written into or read back from the RAM. The

read/write capability allows independent software routines

to read back previously programmed window limits. Furthermore, currently programmed limits may also be read back to

ensure system testability. An address register holds the addresses of the RAM’s memory locations where data may

either be stored or retrieved from.

When the device is operated in the watchdog mode (as described in the ‘‘general overview’’ section), the analog inputs are continually polled and compared against their respective window limits. Once an input signal that has exceeded either boundary limit is detected, a ‘‘1’’ is stored in

the MSB position in a 16-bit status register, indicating a limit

crossing. Note that the ADC0851 uses only four locations of

the status register because it has only four limits. In addition, the tag register is updated so that the register holds the

address which indicates the channel and the corresponding

upper or lower limit that was crossed. After the first limit

crossing is detected, the device cycles through the remaining limits and compares them against their respective input

signals. If any additional limit crossing is or are detected

then a ‘‘1’’ is stored in the appropriate locations of the

status register. After the completion of this operation, the

interrupt pin (INT

essor. The microprocessor can then cause the serial status

data to be shifted out by bringing the CS

with the status and tag bits, the microprocessor can determine which channel exceeded which limit. If desired the mi-

) goes low, providing a flag to a microproc-

Figure 1

, front page) shows

line low. Together

16

Page 17

Functional Description (Continued)

croprocessor can then initiate an A/D conversion on any

channel(s). The ADC0851 includes two additional output

pins, COMPL and COMPH. During watchdog operation, if

either of the inputs exceeds its respective window bounds

then not only is an interrupt generated but a logic low at

COMPL or COMPH indicates whether the lower or upper

boundary was crossed.

A mode register within the ADC0851/8 allows the device to

be used in any one of the eight modes of operation as described in the ‘‘general overview’’ section.

The features described make the ADC0851/8 ideal for use

in microprocessor-based automotive, instrumentation and

control applications. Such applications often require monitoring of various transducer signals and comparison against

pre-programmed window limits. With its watchdog operation, the ADC0851/8 frees up the microprocessor from having to continually monitor the analog variables; the microprocessor is interrupted only when the input signal crosses

the preset bounds. Furthermore, the window limits can easily be changed with simple software control.

Applications Information

I. Digital Interface Considerations

The ADC0851 and ADC0858 communicate data serially

over the DI (Data Input) and DO (Data Output) pins. The

data transfer is synchronous with the external clock (CLK)

signal and is clocked in or out of the device at the rising

edge of clock. Note that although the output data is clocked

out starting at the rising edge of CLK, the data is valid at the

falling edge of CLK.

All internal timing in the device is with respect to the oscillator clock. The oscillator frequency is set by connecting a

resistor from the OSC pin (pin 2 for ADC0851 or ADC0858)

to V

and a capacitor from the OSC pin to ground. The

CC

period of the oscillator clock will determine the A/D conversion time and chip select (CS

cussed in the following sections.

) high duration as will be dis-

1.0 Modes of Operation

To initiate the operation of the device in any one of the eight

modes, the chip select (CS

is detected, serial input data at the DI pin is clocked in starting at the first rising edge of the serial clock. The first four

bits of the input word are reserved for specifying the mode

) line must go low. After a CS low

of operation, with the first bit of the input word always being

a logic ‘‘1’’. Table I shows the mode addresses for selecting

the different modes of operation.

TABLE I. Modes of Operation

Mode Address

M3 M2 M1 M0

1 0 0 0 Watchdog

1 0 0 1 Write One Limit

1 0 1 0 One A/D Conversion

1 0 1 1 Read One Limit

1 1 0 0 Test (for Factory Use Only)

1 1 0 1 Write All Limits

1 1 1 0 Auto A/D Conversion

1 1 1 1 Read All Limits

1.1 POWER FAILURE DETECTION/

INITIALIZATION AFTER POWER-UP

Upon power up, the device is automatically configured in the

watchdog mode. The status of the power flag bit, P, provides power failure indication to the microprocessor. The

timing diagram of

First consider the case of initial power up. After power is

applied, CS

es the INT

that a failure has occurred. The microprocessor can then

interrogate the device as to the type of failure by bringing

CS

low. When CS goes low, it resets the INT pin to high and

the output data is read starting at the first rising edge of

clock (CLK) after CS

read cycle after power up, the power flag bit, P, is set high

and appears at the rising edge of the seventeenth clock

cycle after CS

flag is read by the microprocessor, CS

that the duration for which CS

flag is read) must be less than eight oscillator clock periods

for ADC0851 and less than thirty-two oscillator clock periods for ADC0858. This is required to interrupt the device

from watchdog mode so that when CS

reads a valid data input (DI) word and configures to a new

mode.

During normal operation, the power flag bit is reset to zero

after the first ‘‘read’’ cycle and will be updated to a ‘‘1’’ only

if a power interruption occurs.

Figure 2

shows the sequence of events.

should be brought high. Bringing CS high caus-

pin to go low, which signals the microprocessor

has gone low. Since this is the first

low is detected

remains high (after the power

Mode

(Figure 2)

. After the power

is taken high. Note

goes low, the device

FIGURE 2. Read Power Flag after

Power Up ADC0851/ADC0858

17

TL/H/11021– 30

Page 18

2.0 Memory Access Modes

The ADC0851/8 has an internal RAM with sixteen memory

locations (one location for the upper limit and one for the

lower limit for each of the 8 input channels). Each memory

location is 8 bits wide. An 8-bit limit word representing an

upper or lower limit boundary can either be written to or read

from the RAM. The ADC0851 uses only four memory locations for the four boundary limits corresponding to the two

inputs. The eight channel ADC0858, however, makes use of

all sixteen memory locations.

Each memory location is accessed by a specific address as

shown by Table II(a) and (b). Note that even addresses correspond to the lower limits while the odd addresses correspond to the upper limits. The ADC0851 and ADC0858 both

use 4 bits (A3, . . . A0) to address the RAM, however,

ADC0851 decodes only the two LSBs of the address data

while ignoring the two MSBs.

TABLE IIa. RAM Address and

Limit Data for ADC0851

RAM Address

A3 A2 A1 A0

X X 0 0 CH0 –Lower Limit

X X 0 1 CH0 –Upper Limit

X X 1 0 CH1 –Lower Limit

X X 1 1 CH1 –Upper Limit

Limit Data (ADC0851)

L0 L1 L2 L3 L4 L5 L6 L7

TABLE IIb. RAM Address and

Limit Data for ADC0858

RAM Address

A3 A2 A1 A0

0 0 0 0 CH0– Lower Limit

0 0 0 1 CH0– Upper Limit

0 0 1 0 CH1– Lower Limit

0 0 1 1 CH1– Upper Limit

0 1 0 0 CH2– Lower Limit

0 1 0 1 CH2– Upper Limit

0 1 1 0 CH3– Lower Limit

0 1 1 1 CH3– Upper Limit

1 0 0 0 CH4– Lower Limit

1 0 0 1 CH4– Upper Limit

1 0 1 0 CH5– Lower Limit

1 0 1 1 CH5– Upper Limit

1 1 0 0 CH6– Lower Limit

1 1 0 1 CH6– Upper Limit

1 1 1 0 CH7– Lower Limit

1 1 1 1 CH7– Upper Limit

Limit Data (ADC0858)

L0 L1 L2 L3 L4 L5 L6 L7

Corresponding

Channel and Limit

Corresponding

Channel and Limit

2.1 WRITE ONE LIMIT

This mode is used to update a single memory location in the

limit RAM. An 8-bit limit word is written to the location pointed to by the limit address. From Table I we can see that to

initiate the operation of the device in the ‘‘write one limit’’

mode, the mode address has to be1001.Thedata format

for the input word is as shown below.

Data Input (DI) WordÐADC0851 or ADC0858

TL/H/11021– 31

18

Page 19

2.0 Memory Access Modes (Continued)

Note that the memory address is clocked in with the MSB

(bit A3) first whereas the limit data is clocked in with the LSB

(bit L0) first.

Figure 3

shows the timing diagram for writing one limit. After

CS

is brought low, the input word (DI) is clocked in starting

at the first rising edge of CLK. Taking CS

(bit L7) of the limit data is loaded completes the write operation.

2.2 WRITE ALL LIMITS MODE

This mode is used to update all memory locations in the limit

RAM. An 8-bit limit word is written to each memory location.

Note that there are four limit words for the ADC0851 and

sixteen limit words for the ADC0858. To initiate the operation of the device in the ‘‘write all limits’’ mode, the mode

address has to be1101(see Table I). The data format for

the input word is as shown below.

Data Input (DI) WordÐADC0851 or ADC0858

high after the MSB

When writing all limits, memory address is not required. The

limit data is sequentially written into the RAM starting at the

location for CH0 – Lower Limit and ending at; CH1 –Upper

Limit for the ADC0851 (see Table IIa), CH7–Upper Limit for

ADC0858 (see Table IIb). Note that L0 corresponds to the

LSB of the limit data.

Figure 4

shows the timing diagram. After CS is brought low,

the input word (DI) is clocked in starting at the first rising

edge of CLK. The first four bits of D1 configure the device in

the ‘‘write all limits’’ mode. Next, the limit data is serially

clocked in. To complete the operation, CS

should be

brought high after the data is loaded.

2.3 READ ONE LIMIT MODE

When the mode address is1011,thedevice is configured

in the ‘‘read one limit’’ mode. One 8-bit limit word can be

read from the RAM memory location pointed to by the limit

address. The data format for the input word is as shown

below.

Data Input (DI)ÐADC0851 or ADC0858

TL/H/11021– 32

FIGURE 3. Timing Diagram for Write One Limit

FIGURE 4. Timing Diagram for Write All Limits

TL/H/11021– 33

TL/H/11021– 34

TL/H/11021– 35

19

Page 20

2.0 Memory Access Modes (Continued)

The address bits access specific memory locations as per

Table II(a) and (b) for the ADC0851 and ADC0858 respectively. The address data is clocked in with the MSB (bit A3)

first.

The timing diagram in

low, the first four bits of the input word configure the device

to ‘‘read one limit’’ mode. Next, the address bits select the

desired memory location. Third clock rising edge after the

address data’s LSB is loaded, the limit data is output with

the LSB (bit L0) first.

2.4 READ ALL LIMITS MODE

With a mode address of1111,thedevice is configured in

the ‘‘read all limits mode’’. When in this mode, 8-bit limit

data from each memory location is serially transmitted out.

The data format for the input word is as follows:

Data Input (DI) WordÐADC0851 or ADC0858

Figure 5

shows that after CS goes

TL/H/11021– 36

Note that no memory address data is required. The limit

data is sequentially transmitted out starting from the memory location for CH0–Lower Limit and ending at; CH1 – Upper

Limit for the ADC0851 (see Table II(a)), CH7–Upper Limit

for the ADC0858 (see Table II(b)).

The timing diagram of

loaded starting at the first rising edge of CLK after CS

Figure 6

shows that the input data is

goes

low. Third clock rising edge after the last bit of the input data

is loaded, the limit data is serially transmitted out. Four limit

words are transmitted for the ADC0851; sixteen for the

ADC0858. Each limit word is output with the LSB (bit L0)

first. Taking CS

high after the MSB of the last limit data is

transmitted completes the operation.

FIGURE 5. Timing Diagram for Read One Limit ADC0851/ADC0858

FIGURE 6. Timing Diagram for Read All Limits ADC0851/ADC0858

TL/H/11021– 38

TL/H/11021– 39

20

Page 21

3.0 Watchdog Mode

This is the primary real time operating mode. During watchdog operation, the upper and lower limits stored in the RAM

are applied sequentially to the DAC’s digital inputs. The

DAC’s analog output is applied to the comparator input and

compared against the voltage at the enabled analog input

pin. The data format for the input word is as shown below.

Data Input (DI) WordÐADC0851 or ADC0858

TL/H/11021– 37

The last twelve bits of the input word assign the multiplexer

channel configuration.

3.1 SELECTING THE CHANNEL CONFIGURATION

When the device is either in the watchdog or automatic A/D

conversion mode, each pair of analog input channels must

be programmed to determine which channel(s) will be active, and whether they will be operating single-ended or differentially. Table III(a) and (b) show the channel addresses

for the ADC0851 and the ADC0858 in various channel configurations. When the channels are configured as singleended inputs, the input voltages are measured with respect

to the voltage at the COM pin. Applying a DC voltage at the

TABLE IIIa. Multiplexer Channel Configuration (ADC0851)

COM pin will cause the device to measure the difference

between the input signal and the voltage at the COM pin.

The voltage at the COM pin has no effect on an input channel that is configured as a differential pair. When the channel pairs are configured as differential inputs (i.e., CH0 –

CH1, CH2 –CH3, etc.) the differential voltage is compared

with the limits for the lower numbered channel. For example, the differential voltage CH0– CH1 will be compared with

the limits for CH0. Note that the channel pairs are programmed in groups of three bits. The channel address is

input to the A/D converter with the MSB (bit C11) first.

The timing diagrams for ADC0851 and ADC0858 watchdog

operation are shown in

Figure 7

. After a CS low is detected,

the input word (DI) is clocked in starting at the first rising

edge of the serial clock (CLK). Once the least significant bit

of the channel address is loaded, CS

CS

high after the proper input word is loaded initiates the

should go high. Taking

operation of the device in the watchdog mode. To keep the

device in continuous watchdog mode, CS

should remain

high for eight or more OSC clock periods for the ADC0851

and thirty-three or more OSC clock periods for the

ADC0858. If the input signals are within the boundary limits,

the interrupt pin (INT) remains at logic ‘‘1’’ and the Data

Ouptut (DO) pin is in TRI-STATE. In addition, in the case of

the ADC0851, the COMPL and COMPH pins remain at logic

‘‘1’’.

TABLE IIIb. Multiplexer Channel Configuration (ADC0858)

21

TL/H/11021– 40

TL/H/11021– 41

Page 22

3.0 Watchdog Mode (Continued)

TL/H/11021– 42

FIGURE 7. Timing Diagrams for Watchdog Operation

22

Page 23

3.0 Watchdog Mode (Continued)

The device will read the new input word and configure to a

different mode if CS

clock periods for the ADC0851 and less than thirty-two oscillator clock periods for the ADC0858.

Once a boundary limit is crossed, INT

for ADC0851, COMPL goes low if a lower limit is crossed,

whereas COMPH goes low if an upper limit is crossed. If the

input signals exceed both the upper and lower boundary

limits then both COMPL and COMPH would go low.

To output data after a limit crossing occurs (i.e., after INT

goes low), CS should be brought low. Note that INT,

COMPL and COMPH would remain low as long as CS

doesn’t go low. After CS

COMPH go high and one clock cycle later output data is

transmitted starting at the first rising edge of CLK, however,

the data is valid at the falling edge of CLK (

3.2 LIMIT CROSSING DETECTION

When the ADC0851/8 is configured in the watchdog mode,

the device operates as a window comparator. First the lower window limit (stored in the RAM) for CH0 is compared

against the input voltage at CH0. If the input voltage is

greater than the lower limit, then no interrupt is generated.

Next the upper window limit for CH0 is compared against

CH0 input voltage. If the input voltage is less than the upper

window limit then no interrupt is generated for CH0 and the

device starts a similar comparison cycle for the next channel (CH1). Note that the lower limit can be greater than the

upper limit; in this case the device will flag the microprocessor if the input signal falls inside a window.

TABLE IVa. Channel Tag Address

Tag Tag Address Corresponding Limit

Ý

T3 T2 T1 T0

0 0000Lower LimitÐCH0

1 0001Upper LimitÐCH0

2 0010Lower LimitÐCH1

3 0011Upper LimitÐCH1

is high for less than eight oscillator

goes low. Moreover,

goes low INT, COMPL and

Figure 7

and Status (ADC0851)

and Channel

TL/H/11021– 43

).

TABLE IVb. Channel Tag Address

and Status (ADC0858)

Tag Tag Address Corresponding Limit

Ý

T3 T2 T1 T0

and Channel

0 0000Lower LimitÐCH0

1 0001Upper LimitÐCH0

2 0010Lower LimitÐCH1

3 0011Upper LimitÐCH1

4 0100Lower LimitÐCH2

5 0101Upper LimitÐCH2

6 0110Lower LimitÐCH3

7 0111Upper LimitÐCH3

8 1000Lower LimitÐCH4

9 1001Upper LimitÐCH4

101010Lower LimitÐCH5

111011Upper LimitÐCH5

121100Lower LimitÐCH6

131101Upper LimitÐCH6

141110Lower LimitÐCH7

151111Upper LimitÐCH7

TL/H/11021– 44

Each comparison takes 2 ms; thus a total of 4 ms is required

per channel.

When in watchdog mode, the device will continuously cycle

through the input channels until an input that has crossed its

preset window limit is detected. When this occurs, a logical

‘‘1’’ is stored in the MSB (bit S3 for ADC0851 and S15 for

ADC0858) position of the status register. In addition the tag

register is updated with the channel’s address (see Tables

IV(a) and (b) for ADC0851 and ADC0858 respectively). Note

that the tag address indicates which channel crossed which

limit. Once the tag register is updated after the first limit is

crossed, the device will once more cycle through the remaining channels and compare the input voltages against

23

Page 24

3.0 Watchdog Mode (Continued)

their respective window limits. A logical ‘‘1’’ will be placed in

the appropriate location of the status register for each limit

that is crossed as the device cycles through the remaining

channels. Note that the tag register is updated only once

i.e., when the first limit is exceeded. After the last limit comparison is made subsequent to the first limit crossing, the

device will cease any further limit comparisons and will

cause the interrupt pin to go low. Taking CS

data in the status and tag registers to be transmitted along

with the programmed channel configuration information. In

addition, an extra bit, P, is inserted between the channel

and status information. This bit is updated to a logic ‘‘1’’ in

case of a power interruption.

The format for the output data is as shown below.

Data Output (DO) WordÐADC0851

low causes the

ter is only updated once when the first limit crossing is detected thus indicating which channel first exceeded its lower

or upper limit.

Data Output (DO) WordÐADC0858

TL/H/11021– 46

TL/H/11021– 47

The order in which data is transmitted is as follows

(ADC0851 or ADC0858):

Tags (4 bits)ÐMSB (T3) first

#

Channel configuration (12 bits)ÐMSB (C11) first

#

Power interrupt (1 bit)

#

Status (4 bits for ADC0851, 16 bits for ADC0858)ÐMSB

#

(S3/S15) first

It is important to note that any channel that is disabled will

not cause an interrupt. Furthermore, when operated in the

differential mode, the arithmetic difference of the two voltages will be compared with the lower and upper limits for

the lower numbered channel. For example, with CH0 and

CH1 operating as a differential input pair, the CH0 limits will

apply.

Consider an example where the lower limit of CH1 is

crossed first and while the remaining limits are being

checked, the upper limit of CH0 is crossed.

Figure 8

illustrates the sequence of events for the ADC0851. During

watchdog operation, CH0’s lower limit stored in the RAM is

compared against the input voltage at CH0. Since no limit

crossing is detected, the upper limit is compared against

CH0 input voltage. Again no limit crossing is detected and

so CH1’s lower limit is next compared against the CH1 input

voltage. This time a limit crossing is detected and a logic

‘‘1’’ is now stored in the MSB (S3) position of the status

register (see Table IV(a)). Also the Tag register is updated

with the corresponding address (0010)from Table IV(a).

The device now cycles through the remaining channels

once more. Since no limit crossing is detected for the upper

limit of CH1, a logic ‘‘0’’ is stored for S2 of the status register. Similarly a logic ‘‘0’’ is stored for S1 of the status register. Finally to complete the cycle, the last limit (upper limit of

CH0) is checked and a limit crossing is detected. Consequently, a logic ‘‘1’’ is stored for S0. Note that the Tag regis-

(Example: Lower limit of CH1 is crossed first. During cycle through, upper

limit of CH0 is crossed)

TL/H/11021– 45

FIGURE 8. Example of Limit Crossing

Detection (ADC0851)

Assuming that there is no power interruption and that the

ADC0851 was configured for single ended operation, the

output word for our example would be:

(Example of ADC0851 Data Output. Single ended input.

Lower limit of CH1 fails first. During cycle through, upper

limitÐCH0 failure is detected).

0010 X X XXX...0 001001

T3 T2 T1 T0 C11 C10 C9 C8 C7 C1 C0 P S3 S2 S1 S0

XeDon’t care, whatever bit was initially programmed (ADC0851 only).

The ADC0858 operates similar to the ADC0851 except that

the ADC0858 has a 16-bit status word for the sixteen limits

and sixteen tag addresses (See Table IV(b)). The output

word transmitted to the microprocessor not only contains

information as to how the channels are configured but also

which input crossed which limit. If desired, the microprocessor can go through a status bit normalization routine to normalize the status information with the tag number as will be

discussed next.

3.3 STATUS BIT NORMALIZATION

Figure 9

shows the procedure for normalizing the status information. Let’s consider the example cited earlier for the

ADC0851. In our example, the lower limit of CH1 was

crossed first and during cycle-through, upper limitÐCH0

crossing was detected. The serial status data is thus1001

andthetagdata0010corresponds to tag

Ý

2 (see Table

IVa). Since the most significant bit (S3) of the status data is

transmitted first, the data stored in the microprocessor’s

memory is1001.Themicroprocessor next computes the

tag number from the tag data and rotates the status bits left

‘‘TAG’’ places as in

Figure 9

. For our example, the status

bits are rotated by shifting left 2 places. The status information in the microprocessor’s memory is now normalized i.e.,

U0 corresponds to tag 0, U1 corresponds to tag 1 and so

on. From the example in

Figure 9

we can see that the status

register in the microprocessor’s memory shows that tag 2

and tag 1 failed. The ADC0858 uses a 16-bit status word

and operates similar to the ADC0851. An example shown in

Figure 9

for the ADC0858 demonstrates how status bit nor-

malization is carried out.

24

Page 25

3.0 Watchdog Mode (Continued)

FIGURE 9. Status Bit Normalization

4.0 A/D Conversion Modes

The ADC0851/8 can be used in two A/D conversion

modes. In ‘‘One A/D conversion’’ mode, the device operates as a multiplexed A/D converter and a conversion may

be initiated on any channel or channel pair configured in the

differential mode. In the ‘‘Automatic A/D conversion’’ mode,

an A/D conversion is done on a channel or channel pair and

after the output data is transmitted, conversion begins on

the next subsequent channel or channel pair. This process

will continue unless the device’s mode of operation is

changed.

Note that the A/D conversion time is determined by the

oscillator clock period and has no relation with the digital

clock signal, CLK. The oscillator clock’s frequency is set by

connecting a resistor from the OSC pin (pin 2 for ADC0851

or ADC0858) to V

ground. The conversion time of the A/D converter is eighteen OSC clock periods maximum. Assuming that the oscillation clock frequency is set at 1 MHz (with R

and C

18 ms maximum.

ext

e

4.1 ONE A/D CONVERSION MODE

This mode is used to initiate one A/D conversion on a single

channel or channel pair configured in the differential mode.

The necessary mode address as per Table I is1010.The

format for the input word is as follows:

Data Input (DI) wordÐADC0851 or ADC0858.

and a capacitor from the OSC pin to

CC

e

3.16 kX

170 pF) then the conversion time would be

ext

TL/H/11021– 48

The 4-bit data following the mode address is the channel

information address. These four bits assign the MUX configuration for the single A/D conversion. The channel information addresses and the corresonding MUX configurations

are shown in Table V(a) and (b) for ADC0851 and ADC0858

respectively. Note that the ADC0851 only decodes the two

LSBs of the channel information data while ignoring the two

MSBs (I3 and I2). When a channel pair is configured in the

differential mode, it is important to note that the arithmetic

difference of the channel voltages should not be negative.

Negative difference voltage would result in all zeroes at the

output.

TABLE V(a). Channel Information for

One A/D Conversion (ADC0851)

Channel Information

I3 I2 I1 I0

Channels Enabled

X X 0 0 CH0

X X 0 1 CH0– CH1

X X 1 0 CH1

X X 1 1 Invalid

(Table V(a) for ADC0851, Table V(b) for ADC0858)

TL/H/11021– 49

25

Page 26

4.0 A/D Conversion Modes (Continued)

TABLE V(b). Channel Information

for One A/D Conversion (ADC0858)

Channel Information

I3 I2 I1 I0

0000CH0

0 0 0 1 CH0– CH1

0010CH1

0 0 1 1 Invalid

0100CH2

0 1 0 1 CH2– CH3

0110CH3

0 1 1 1 Invalid

1000CH4

1 0 0 1 CH4– CH5

1010CH5

1 0 1 1 Invalid

1100CH6

1 1 0 1 CH6– CH7

1110CH7

1 1 1 1 Invalid

The timing diagram for one A/D conversion is shown in

ure 10

. After CS goes low, the input word (DI) is clocked in

starting at the first rising edge of the digital clock signal,

CLK. The first four bits of the input word configure the device for ‘‘one A/D conversion’’ mode while the following

four bits (channel information address) assign the configuration of the MUX as per Table V(a) and (b) for the ADC0851

and the ADC0858 respectively. Any input data following the

channel information address is ignored until the device’s

mode of operation is changed.

Taking CS

address loads the input word. Had CS

the following bits of the input word would have been ignored. The device takes one to two OSC clock periods after

CS

EOC output goes low, thus signalling the start of the conversion process. After a maximum of eighteen OSC clock periods, conversion is completed and EOC output goes high,

thus signalling the end of conversion. The output data is

now available and will be transmitted only if CS

low. The output data is transmitted starting at the first rising

edge of CLK after CS

high after the last bit of the channel information

goes high to initiate the start of A/D conversion. The

goes low.

Channels Enabled

Fig-

been kept low longer,

is brought

The format for the output word is as shown below.

Data Output (DO)ÐADC0851 or ADC0858

TL/H/11021– 50

The first eight bits of the output word represent the digital

equivalent of the input voltage. Bits I3 through I0 provide the

channel configuration information as per Table V(a) and (b)

for ADC0851 and ADC0858 respectively. Note that this information is the same as the channel information in the input word. The order in which the output data is transmitted

is as follows:

DataÐLSB (D0) first

#

Channel informationÐMSB (I3) first

#

Note that the output will be TRI-STATE if CS remains low

after I0 is transmitted. Taking CS

is transmitted causes the device to initiate the start of the

next A/D conversion on the same input while ignoring the

data input word (DI). If the duration for which CS

less than seventeen OSC clock periods, the conversion process will be interrupted and the device will look for the mode

address at the falling edge of CS

mode of operation. However, if CS

more OSC clock periods then the conversion operation will

continue from point A on the timing diagram

To ensure repetitive A/D conversion on the same input, CS

going low should be synchronized with EOC going high.

Thus after EOC goes high, the conversion is completed and

CS

can go low to transmit the output data. Meanwhile, if CS

goes low while EOC is low then the conversion process is

interrupted and the device is readied for a new mode of

operation.

4.2 AUTO A/D CONVERSION MODE

When used in this mode, the ADC0851/8 offers added flexibility that many multiplexed A/D converters don’t. In the

auto A/D conversion mode, the ADC0851/8 scans through

the selected input channels, performing A/D conversion on

each channel without the need for reloading a new data

input word each time. From Table I, the mode address for

the ‘‘Auto A/D Conversion’’ mode is1110.

The format for the input word is as follows:

Data Input (DI) WordÐADC0851 or ADC0858

high after the output data

is high is

so as to configure to a new

is high for eighteen or

(Figure 10)

.

TL/H/11021– 51

26

Page 27

4.0 A/D Conversion Modes (Continued)

The 12-bit channel address following the mode address assigns the MUX configuration as per Table III(a) and (b) for

ADC0851 and ADC0858 respectively. Note that the

ADC0851 only decodes the three LSBs (C0, C1 and C2) of

the channel address.

The timing diagram for ‘‘Auto A/D Conversion’’ mode is

shown in

Figure 11

first rising edge of the CLK after CS

bits configure the device for the ‘‘Auto A/D Conversion’’

mode while the 12-bit channel address assigns the configuration of each channel pair. If CS

loaded then any subsequent input data is ignored. Taking

CS

high after the input word is loaded initiates the start of

A/D conversion. A/D conversion starts one to two OSC

clock periods after CS

to signal the start of an A/D conversion. The conversion

time may range from 17 msto74ms depending on how

. The input word is loaded starting at the

goes low. The first four

remains low after C0 is

goes high. The EOC output goes low

the channel pairs are configured. The EOC output goes high

at the end of conversion thus signalling that the result of the

A/D conversion can now be retrieved. The output data will

be transmitted only if CS

ing at the first rising edge of CLK signal after CS

The format for the output word is as follows:

Data Output (DO)ÐADC0851 or ADC0858

goes low and is transmitted start-

goes low.

TL/H/11021– 52

27

Page 28

4.0 A/D Conversion Modes (Continued)

TL/H/11021– 53

TL/H/11021– 54

FIGURE 10. Timing Diagram for One A/D Conversion ADC0851/ADC0858

28

FIGURE 11. Timing Diagram for Auto A/D Conversion ADC0851/ADC0858

Page 29

4.0 A/D Conversion Modes (Continued)

The first eight bits of the output word represents the digital

equivalent of the analog input voltage. Status bits I3 through

I0 provide the channel configuration information as per Table V(a) and (b) for ADC0851 and ADC0858 respectively.

Keeping CS

be TRI-STATE. Once the output data is transmitted, CS

low after I0 is transmitted causes the output to

may

go high to initiate the start of the next A/D conversion. The

subsequent A/D conversion starts on the next channel pair

that is configured as per the initially loaded input word

ure 11)

. Any data on the data input (DI) line is ignored. Note

that if the duration for which CS

is high is less than seven-

(Fig-

teen OSC clock periods then the conversion process would

be interrupted and the device would look for the mode address at the falling edge of CS

so that a new mode of opera-

tion can be configured.

To ensure proper operation in the ‘‘Auto A/D Conversion’’

mode, CS

going low should be synchronized with EOC going high. Thus after EOC goes high, the conversion is completed and CS

the output data is transmitted, CS

can go low to transmit the output data. After

should go high to initiate

automatic A/D conversion on the next channel pair and remain high until the conversion is completed and EOC goes

high. Meanwhile, if CS

goes low while EOC is low then the

conversion process is interrupted and the device is readied

for a new mode of operation.

5.0 Test Mode

A mode address of1100configures the device in the test

mode. This mode is used to test the internal operation of the

device at the factory and is not recommended for normal

use. If the device is accidentally configured in the test mode

then the power supply must be disconnected and reconnected again to reset the device.

6.0 Bidirectional I/O

If the microprocessor has bidirectional Input/Output capability then ADC0851/8’s input and output pins can be tied

together and a single wire can be used to serially input data

to or output data from ADC0851/8. This capability is made

possible because when the input word is clocked in, the

output pin is in TRI-STATE and when the output word is

clocked out, the data at the input pin is ignored.

II. Analog Considerations

1.0 A/D Conversion Time

The A/D conversion time is a function of the OSC clock

frequency. The oscillator frequency is set by connecting an

external resistor, R

V

and an external capacitor, C

CC

ground. With R

frequency is 1 MHz at V

5.5V.

The OSC frequency will vary as the ambient temperature

varies, this is shown by the Typical Performance Characteristics curve, ‘‘OSC Frequency vs Temperature’’. For a specified external resistor, the OSC frequency can be changed

by varying the external capacitor as is shown by the Typical

Performance Characteristics curve, ‘‘OSC Frequency vs

R

and C

ext

should not be driven by an external clock as this might

ext

from the ADC0851/8’s OSC pin to

ext

ext

e

3.16 kX and C

e

CC

from the OSC pin to

ext

e

170 pF, the OSC

ext

4.5V and 1.05 MHz at V

CC

’’. Note that the OSC pin of the ADC0851/8

cause improper operation. The A/D converter’s conversion

time is a minimum of seventeen OSC clock periods and a

maximum of eighteen.

Figure 12

shows a typical connection

for the ADC0851 and ADC0858.

2.0 The Reference

The magnitude of the reference voltage (V

the A/D converter determines the analog input voltage span

(i.e., the difference between V

which the 256 possible output codes apply. The reference

voltage source connected to the V

must be capable of driving a minimum load of 4 kX.

IN(max)

REF

The ADC0851/8 can be used in either ratiometric applications or in systems requiring absolute accuracy. In a ratiometric system, the analog input voltage is proportional to

the voltage used for the A/D’s reference. This voltage is

usually the system power supply, so the V

tied to V

CC

.

For absolute accuracy, where the analog input varies between very specific voltage limits, the reference pin must be

connected to a voltage source that is stable over time and

temperature. The LM385 and LM336 micropower references are good low current devices for use with these A/D

converters.

The maximum value of the reference voltage is limited by

the A/D converter’s power supply voltage, V

mum value, however, can be as low as 1V while maintaining

a typical Integral Linearity of

g

1 LSB (see Typical Performance Characteristics curve, ‘‘Linearity Error vs Reference

voltage’’). This allows direct conversion of transducer outputs that provide less than a 5V output span. Due to the

increased sensitivity of the A/D converter at low reference

voltages (e.g., 1 LSB

e

3.9 mV for a 1V full scale range),

care must be exercised with regard to noise pickup, circuit

layout, and system error voltage sources.

) applied to

REF

and V

IN(Min)

) over

pin of ADC0851/8

pin can be

REF

. The mini-

CC

3.0 The Analog Inputs

3.1 REDUCING COMMON MODE ERROR

Rejection of common mode noise can be achieved by configuring the ADC0851/8’s inputs in the differential mode

since the offending common mode signal is common to

both the selected ‘‘

between sampling the ‘‘

oscillator clock period. A change in the common-mode voltage during this short time interval can cause conversion errors. For a sinusoidal common-mode signal this error is:

where fCMis the frequency of the common-mode signal,

V

is the signal’s peak voltage and f

PEAK

converter’s OSC clock frequency.

For a 60 Hz common-mode signal to generate a (/4 LSB

e

error (&5 mV for a 5V full scale range) with the converter

running at f

be 3.3V.

3.2 SOURCE RESISTANCE

For a source resistance under 2 kX, the ADC0851/8’s total

unadjusted error is typically

s

f

1 MHz (see Typical Performance Characteristics

OSC

curves, ‘‘Total Unadjusted Error vs Source Impedance’’).

One source of error is the multiplexer’s leakage current of

3 mA which contributesa3mVdrop acrossa1kXsource

a

’’ and ‘‘b’’ inputs. The time interval

a

’’ input and the ‘‘b’’ input is one

V

OSC

e

V

error(Max)

e

250 kHz, its peak voltage would have to

(2qfCM) (1/f

PEAK

g

0.2 LSB at V

OSC

OSC

REF

)

is the A/D

e

4.75V and

29

Page 30

3.0 The Analog Inputs (Continued)

resistance. Another source of error is the sampling nature of

the A/D converter. Short spikes of current enter the ‘‘

input and exit the ‘‘

b

’’ input at the rising and falling transition of the OSC clock . These currents decay rapidly and

generally do not cause errors since the internal comparator

is strobed at the end of a clock period. If large source resistances are used however, then the transients caused by the

current spikes may not settle completely before conversion

begins. If a capacitor is used at the input of the A/D converter for input filtering then the input signal source resistance

should be kept at 1 kX or less.

3.3 ANALOG INPUT PROTECTION

Often the analog inputs of A/D converters are driven from

voltage sources that can swing higher than V

than GND. Analog inputs often come from op amps which

g

use

15V supplies. While during normal operation the input

voltages stay within the 0V–5V A/D converter supply voltage range, at power up the input voltage may actually rise

above or fall below the A/D converter’s supply voltages. If

the input voltage to any A/D converter input pin does fall

outside the supply voltage by more than 0.3V (worst case)

and the input draws more than 5 mA then there is a good

possibility that the converter may latch up and provide a low

impedance short between V

Figure 13

shows the overvoltage protection circuit for the

and GND.

CC

analog input. If, for instance, the amplifier’s output saturates

to its positive supply rail, then the junction of R1 and R2

would be clamped to V

limits the op amp’s output current and R2 limits the current

plus a diode drop. Resistor R1

CC

flowing into the input of the A/D converter. Likewise, the

junction of R1 and R2 would be clamped to a diode drop

below ground if the op amp’s output saturates to the negative rail.

CC

a

or lower

4.0 Zero Scale and Full Scale

Adjustment

4.1 ZERO SCALE ERROR

The zero scale error of the A/D converter does not require

adjustment. If the minimum analog input voltage value,

V

, is not at ground potential then a zero offset can be

IN(Min)

done. The converter can be made to output 0000 0000 digital code for this minimum input voltage by biasing the V

IN(b)

input of a differential input pair at this V

utilizes the differential mode operation of the A/D converter.

The zero scale error of the A/D converter relates to the

’’

location of the first riser of the transfer function and can be