Page 1

TL/H/9287

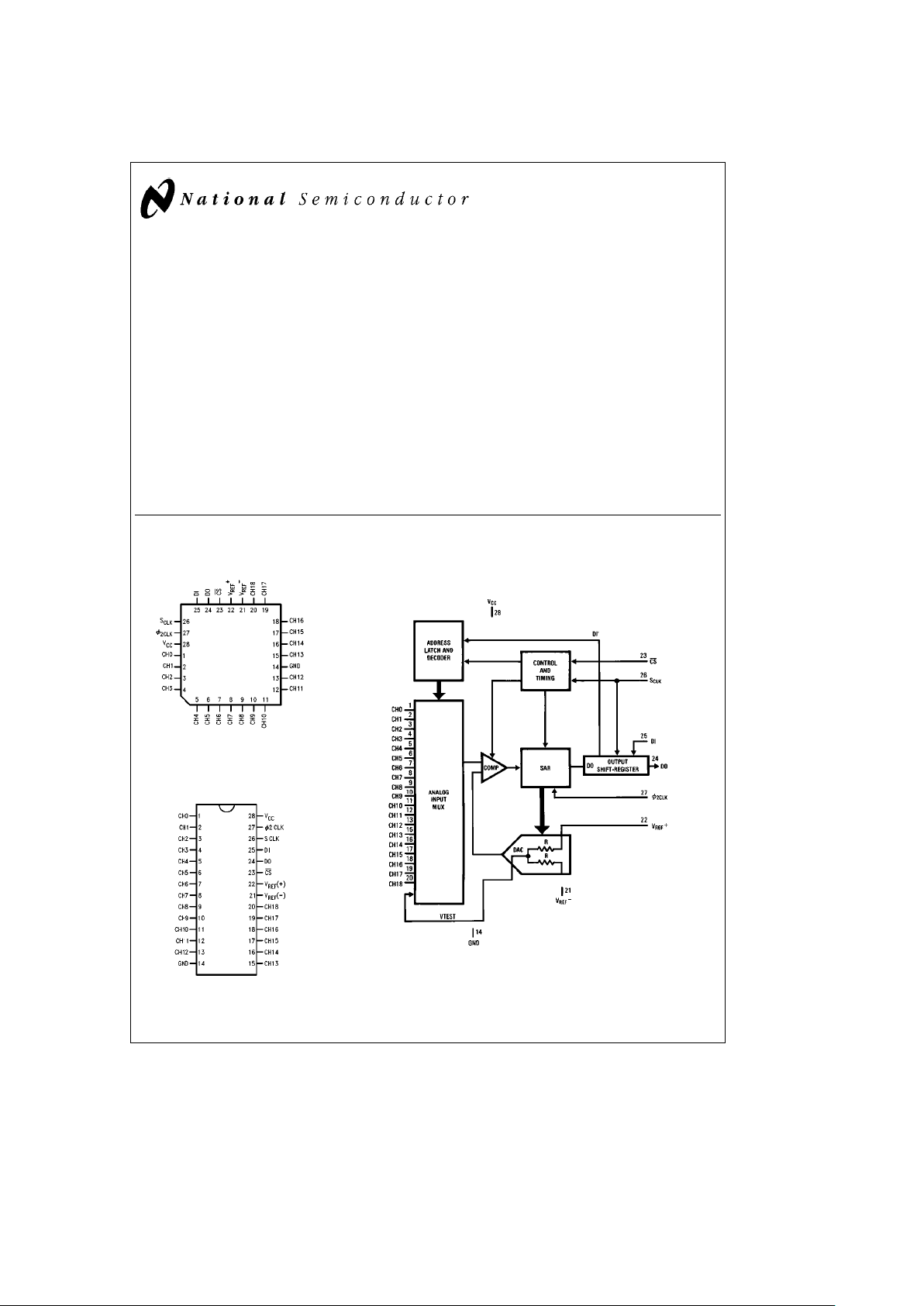

ADC0819 8-Bit Serial I/O A/D Converter with 19-Channel Multiplexer

December 1994

ADC0819 8-Bit Serial I/O A/D Converter

with 19-Channel Multiplexer

General Description

The ADC0819 is an 8-Bit successive approximation A/D

converter with simultaneous serial I/O. The serial input controls an analog multiplexer which selects from 19 input

channels or an internal half scale test voltage.

An input sample-and-hold is implemented by a capacitive

reference ladder and sampled data comparator. This allows

the input signal to vary during the conversion cycle.

Separate serial I/O and conversion clock inputs are provided to facilitate the interface to various microprocessors.

Features

Y

Separate asynchronous converter clock and serial data

I/O clock.

Y

19-Channel multiplexer with 5-Bit serial address logic.

Y

Built-in sample and hold function.

Y

Ratiometric or absolute voltage referencing.

Y

No zero or full-scale adjust required.

Y

Internally addressable test voltage.

Y

0V to 5V input range with single 5V power supply.

Y

TTL/MOS input/output compatible.

Y

28-pin molded chip carrier or 28-pin molded DIP

Key Specifications

Y

Resolution 8-Bits

Y

Total unadjusted error

g

(/2LSB andg1LSB

Y

Single supply 5V

DC

Y

Low Power 15 mW

Y

Conversion Time 16 ms

Connection Diagrams

Molded Chip Carrier (PCC) Package

TL/H/9287– 1

Top View

Order Number ADC0819BCV, CCV

See NS Package Number V28A

Dual-In-Line Package

TL/H/9287– 20

Top View

Order Number ADC0819BCN, CIN

See NS Package Number N28B

Functional Diagram

TL/H/9287– 2

C

1995 National Semiconductor Corporation RRD-B30M115/Printed in U. S. A.

Page 2

Absolute Maximum Ratings (Notes1&2)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales

Office/Distributors for availability and specifications.

Supply Voltage (V

CC

) 6.5V

Voltage

Inputs and Outputs

b

0.3V to V

CC

a

0.3V

Input Current Per Pin (Note 3)

g

5mA

Total Package Input Current (Note 3)

g

20mA

Storage Temperature

b

65§Ctoa150§C

Package Dissipation at T

A

e

25§C 875 mW

Lead Temperature (Soldering, 10 sec.)

Dual-In-Line Package (Plastic) 260

§

C

Surface Mount Package

Vapor Phase (60 sec.) 215

§

C

Infrared (15 sec.) 220

§

C

ESD Susceptibility (Note 11) 2000V

Operating Ratings (Notes1&2)

Supply Voltage (VCC) 4.5 VDCto 6.0 V

DC

Temperature Range T

MIN

s

T

A

s

T

MAX

ADC0819BCV, ADC0819CCV

b

40§CsT

A

s

a

85§C

ADC0819BCN 0§CsT

A

s

a

70§C

ADC0819CIN

b

40§CsT

A

s

a

85§C

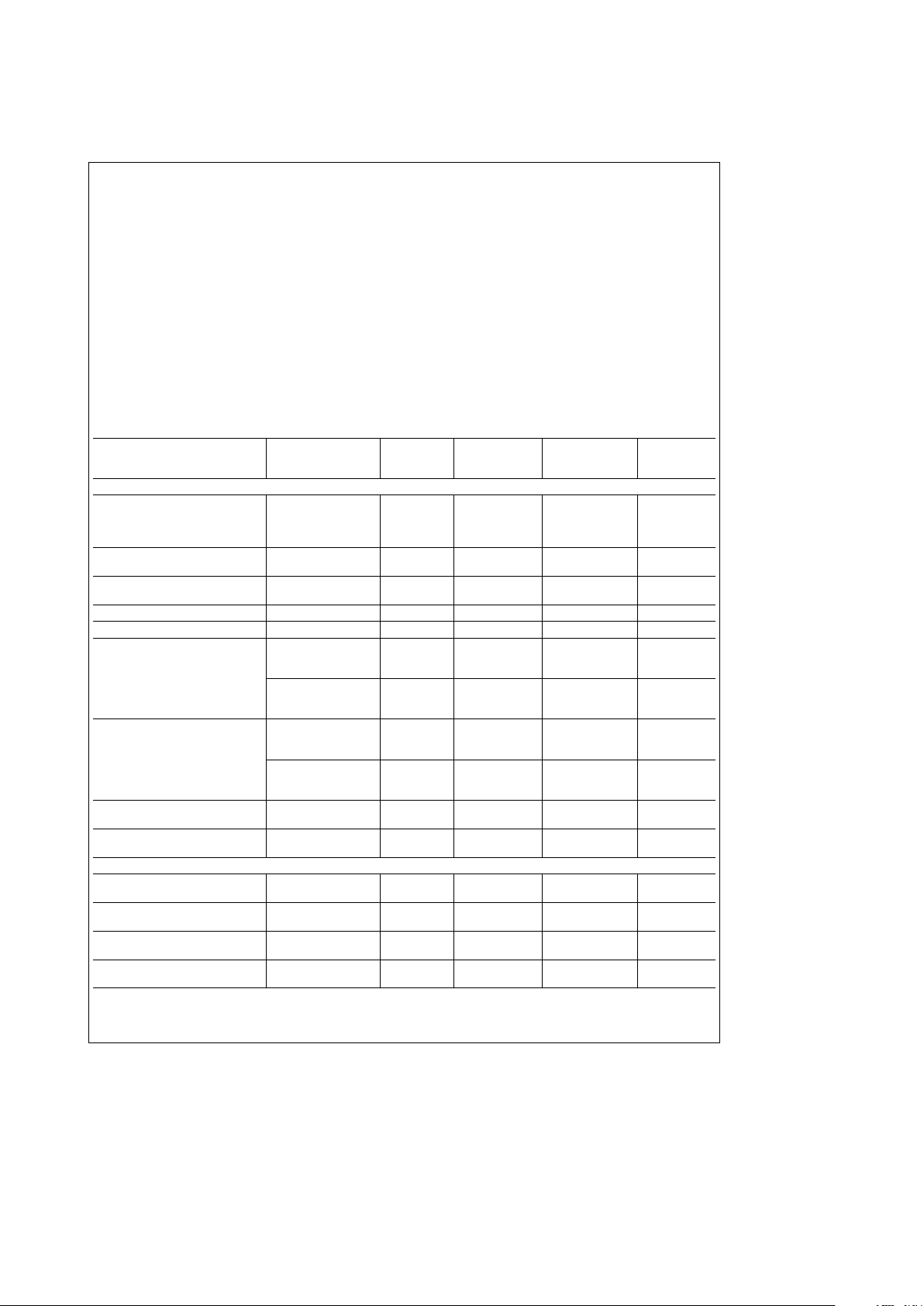

Electrical Characteristics

The following specifications apply for V

CC

e

5V, V

REF

e

5V, w

2 CLK

e

2.097 MHz unless otherwise specified. Boldface limits

apply from T

MIN

to T

MAX

; all other limits T

A

e

T

J

e

25§C.

Typical

Tested Design

Parameter Conditions

(Note 6)

Limit Limit Units

(Note 7) (Note 8)

CONVERTER AND MULTIPLEXER CHARACTERISTICS

Maximum Total V

REF

e

5.00 V

DC

Unadjusted Error (Note 4)

ADC0819BCV, BCN

g

(/2

g

(/2 LSB

ADC0819CCV, CIN

g

1

g

1 LSB

Minimum Reference

8 5 kX

Input Resistance

Maximum Reference

811 11 kX

Input Resistance

Maximum Analog Input Range (Note 5) V

CC

a

0.05 V

CC

a

0.05 V

Minimum Analog Input Range GNDb0.05 GNDb0.05 V

On Channel Leakage Current (Note 9)

On Channel

e

5V 400 1000 nA

Off Channel

e

0V

On Channele0V

b

400

b

1000 nA

Off Channel

e

5V

(Note 9)

Off Channel Leakage Current (Note 9)

On Channel

e

5V

b

400

b

1000 nA

Off Channel

e

0V

On Channele0V 400 1000 nA

Off Channel

e

5V

(Note 9)

Minimum V

TEST

V

REF

e

VCC, (Note 10)

Internal Test Voltage CH 19 Selected 125 125 Counts

Maximum V

TEST

V

REF

e

VCC, (Note 10)

Internal Test Voltage CH 19 Selected 130 130 Counts

DIGITAL AND DC CHARACTERISTICS

V

IN(1)

, Logical ‘‘1’’ Input V

CC

e

5.25V

2.0 2.0 V

Voltage (Min)

V

IN(0)

, Logical ‘‘0’’ Input V

CC

e

4.75V

0.8 0.8 V

Voltage (Max)

I

IN(1)

, Logical ‘‘1’’ Input V

IN

e

5.0V 0.005

2.5 2.5 mA

Current (Max)

I

IN(0)

, Logical ‘‘0’’ Input V

IN

e

0V

b

0.005

b

2.5

b

2.5 mA

Current (Max)

2

Page 3

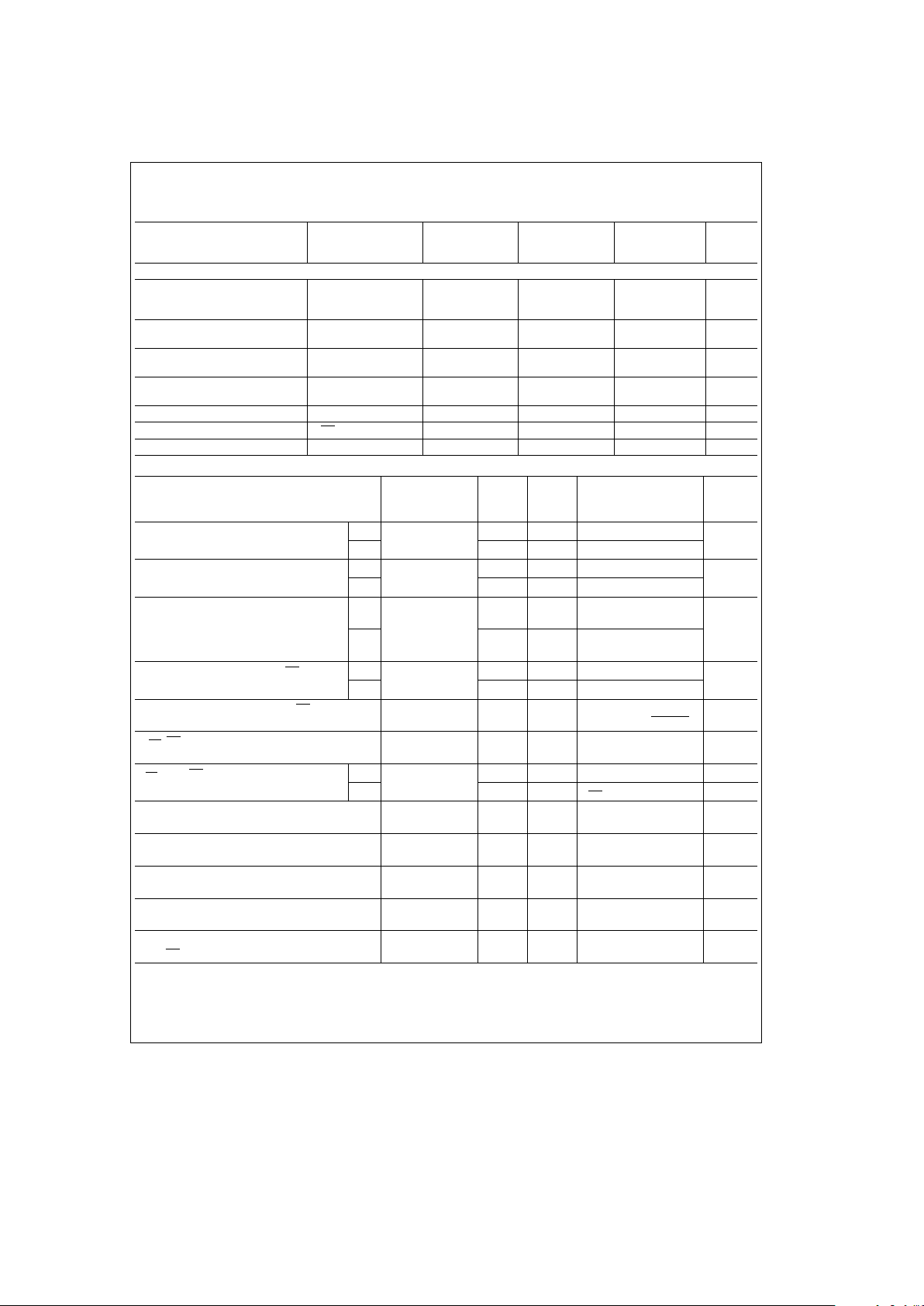

Electrical Characteristics (Continued)

The following specifications apply for V

CC

e

5V, V

REF

e

5V, w

2 CLK

e

2.097 MHz unless otherwise specified. Boldface limits

apply from T

MIN

to T

MAX

; all other limits T

A

e

T

J

e

25§C.

Typical

Tested Design

Parameter Conditions

(Note 6)

Limit Limit Units

(Note 7) (Note 8)

DIGITAL AND DC CHARACTERISTICS (Continued)

V

OUT(1)

, Logical ‘‘1’’ V

CC

e

4.75V

Output Voltage (Min) I

OUT

eb

360 mA 2.4 2.4 V

I

OUT

eb

10 mA 4.5 4.5 V

V

OUT(0)

, Logical ‘‘0’’ V

CC

e

5.25V

0.4 0.4 V

Output Voltage (Max) I

OUT

e

1.6 mA

I

OUT

, TRI-STATE Output V

OUT

e

0V

b

0.01

b

3

b

3 mA

Current (Max) V

OUT

e

5V 0.01 3 3 mA

I

SOURCE

, Output Source V

OUT

e

0V

b

14

b

6.5

b

6.5 mA

Current (Min)

I

SINK

, Output Sink Current (Min) V

OUT

e

V

CC

16 8.0 8.0 mA

ICC, Supply Current (Max) CSe1, V

REF

Open 1 2.5 2.5 mA

I

REF

(Max) V

REF

e

5V 0.7 1 1 mA

AC CHARACTERISTICS

Tested Design

Parameter Conditions Typical Limit Limit Units

(Note 6) (Note 7) (Note 8)

w

2 CLK

, w2Clock Frequency MIN 0.70 1.0

MHz

MAX 4.0 2.0 2.1

S

CLK

, Serial Data Clock MIN 5.0

KHz

Frequency

MAX 1000 525 525

TC, Conversion Process Time MIN Not Including MUX 26 26 w2cycles

Addressing and

MAX

Analog Input

32 32

Sampling Times

t

ACC

, Access Time Delay From CS MIN 1 w2cycles

Falling Edge to DO Data Valid MAX 3

t

SET-UP

, Minimum Set-up Time of CS Falling

4/w

2CLK

a

1

2S

CLK

sec

Edge to S

CLK

Rising Edge

t

HCS

,CSHold Time After the Falling

0 ns

Edge of S

CLK

tCS, Total CS Low Time MIN t

set-up

a

8/S

CLK

sec

MAX tCS(min)a26/w

2CLK

sec

t

HDI

, Minimum DI Hold Time from

0 0 ns

S

CLK

Rising Edge

t

HDO

, Minimum DO Hold Time from S

CLK

R

L

e

30k,

10 ns

Falling Edge C

L

e

100 pF

t

SDI

, Minimum DI Set-up Time to S

CLK

200 400 ns

Rising Edge

t

DDO

, Maximum Delay From S

CLK

R

L

e

30k,

180 200 250 ns

Falling Edge to DO Data Valid C

L

e

100 pF

t

TRI

, Maximum DO Hold Time, R

L

e

3k,

90 150 150 ns

(CS

Rising edge to DO TRI-STATE) C

L

e

100 pF

3

Page 4

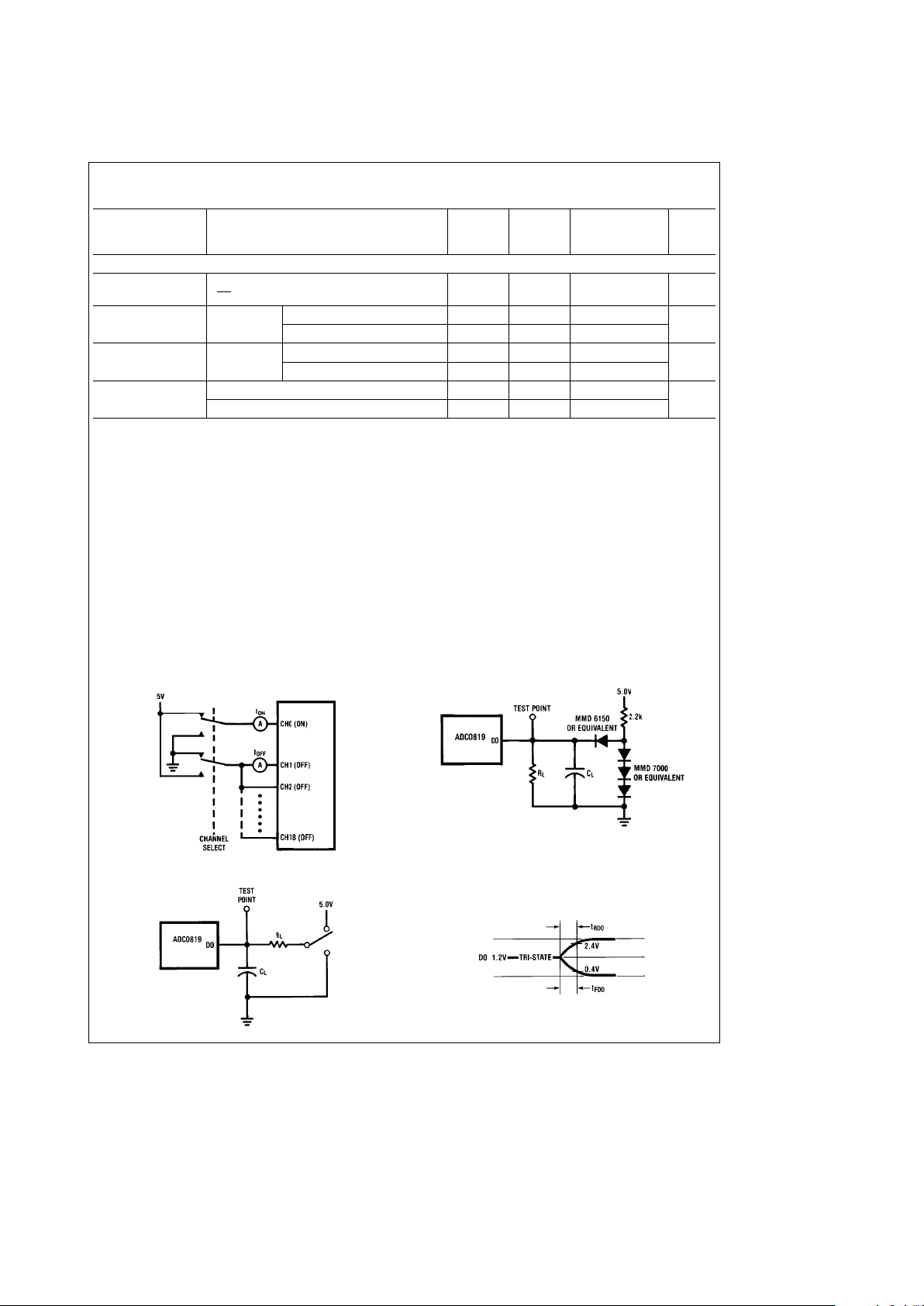

Electrical Characteristics The following specifications apply for V

CC

e

5V, t

r

e

t

f

e

20 ns, V

REF

e

5V, unless

otherwise specified. Boldface limits apply from T

MIN

to T

MAX

; all other limits T

A

e

T

J

e

25§C.

Typical

Tested Design

Parameter Conditions

(Note 6)

Limit Limit Units

(Note 7) (Note 8)

AC CHARACTERISTICS (Continued)

tCA, Analog After Address Is Latched

3/S

CLK

a

1 ms sec

Sampling Time CS

e

Low

t

RDO

, Maximum DO R

L

e

30 kX, ‘‘TRI-STATE’’ to ‘‘HIGH’’ State 75 150 150

ns

Rise Time C

L

e

100 pf ‘‘LOW’’ to ‘‘HIGH’’ State 150 300 300

t

FDO

, Maximum DO R

L

e

30 kX, ‘‘TRI-STATE’’ to ‘‘LOW’’ State 75 150 150

ns

Fall Time C

L

e

100 pf ‘‘HIGH’’ to ‘‘LOW’’ State 150 300 300

CIN, Maximum Input Analog Inputs, ANO–AN10 and V

REF

11 55

pF

Capacitance All Others 5 15

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. DC and AC electrical specifications do not apply when operating

the device beyond its specified operating conditions.

Note 2: All voltages are measured with respect to ground.

Note 3: Under over voltage conditions (V

IN

k

0V and V

IN

l

VCC) the maximum input current at any one pin isg5 mA. If the voltage at more than one pin exceeds

V

CC

a

.3V the total package current must be limited to 20 mA. For example the maximum number of pins that can be over driven at the maximum current level of

g

5 mA is four.

Note 4: Total unadjusted error includes offset, full-scale, linearity, multiplexer, and hold step errors.

Note 5: Two on-chip diodes are tied to each analog input, which will forward-conduct for analog input voltages one diode drop below ground or one diode drop

greater than V

CC

supply. Be careful during testing at low VCClevels (4.5V), as high level analog inputs (5V) can cause this input diode to conduct, especially at

elevated temperatures, and cause errors for analog inputs near full-scale. The spec allows 50 mV forward bias of either diode. This means that as long as the

analog V

IN

does not exceed the supply voltage by more than 50 mV, the output code will be correct. To achieve an absolute 0 VDCto5VDCinput voltage range will

therefore require a minimum supply voltage of 4.950 V

DC

over temperature variations, initial tolerance and loading.

Note 6: Typicals are at 25

§

C and represent most likely parametric norm.

Note 7: Tested Limits are guaranteed to National’s AOQL (Average Outgoing Quality Level).

Note 8: Design Limits are guaranteed, but not 100% production tested. These limits are not used to calculate outgoing quality levels.

Note 9: Channel leakage current is measured after the channel selection.

Note 10: 1 count

e

V

REF

/256.

Note 11: Human body model; 100 pF discharged through a 1.5 kX resistor.

Test Circuits

Leakage Current

TL/H/9287– 3

D0 Except ‘‘TRI-STATE’’

TL/H/9287– 4

t

TRI

‘‘TRI-STATE’’

TL/H/9287– 5

Timing Diagrams

D0 ‘‘TRI-STATE’’ Rise & Fall Times

TL/H/9287– 6

4

Page 5

Timing Diagrams (Continued)

D0 Low to High State

TL/H/9287– 7

D0 High to Low State

TL/H/9287– 8

Data Input and Output Timing

TL/H/9287– 9

Timing with a continuous S

CLK

TL/H/9287– 10

*Strobing CS High and Low will abort the present conversion and initiate a new serial I/O exchange.

Timing with a gated S

CLK

and CS Continuously Low

TL/H/9287– 11

Using CS To TRI-STATE D0

TL/H/9287– 12

Note: Strobing CS Low during this time interval will abort the conversion in process.

5

Page 6

Timing Diagrams (Continued)

CS

High During Conversion

TL/H/9287– 13

CS Low During Conversion

TL/H/9287– 14

Channel Addressing Table

TABLE I. ADC 0819 Channel Addressing

MUX ADDRESS

ANALOG

CHANNEL

A7A6A5A4A3A2A1A

0

SELECTED

00000XXX CH0

00001XXX CH1

00010XXX CH2

00011XXX CH3

00100XXX CH4

00101XXX CH5

00110XXX CH6

00111XXX CH7

01000XXX CH8

01001XXX CH9

0 1 0 1 0 X X X CH10

0 1 0 1 1 X X X CH11

0 1 1 0 0 X X X CH12

0 1 1 0 1 X X X CH13

0 1 1 1 0 X X X CH14

0 1 1 1 1 X X X CH15

1 0 0 0 0 X X X CH16

1 0 0 0 1 X X X CH17

1 0 0 1 0 X X X CH18

10011XXX V

TEST

1 0 1 0 0 X X X No Channel Select

1 0 1 0 1 X X X No Channel Select

1 0 1 1 0 X X X No Channel Select

1 0 1 1 1 X X X No Channel Select

1 1 X X X X X X Logic Test Mode*

*Analog channel inputs CH0 thru CH4 are logic outputs

6

Page 7

Functional Block Diagram

TL/H/9287– 15

7

Page 8

Functional Description

1.0 DIGITAL INTERFACE

The ADC0819 uses five input/output pins to implement the

serial interface. Taking chip select (CS

) low enables the I/O

data lines (DO and DI) and the serial clock input (S

CLK

). The

result of the last conversion is transmitted by the A/D on the

DO line, while simultaneously the DI line receives the address data that selects the mux channel for the next conversion. The mux address is shifted in on the rising edge of

S

CLK

and the conversion data is shifted out on the falling

edge. It takes eight S

CLK

cycles to complete the serial I/O.

A second clock (w

2

) controls the SAR during the conversion

process and must be continuously enabled.

1.1 CONTINUOUS S

CLK

With a continuous S

CLK

input CS must be used to synchro-

nize the serial data exchange (see

Figure 1

). The ADC0819

recognizes a valid CS

one to three w2clock periods after

the actual falling edge of CS

. This is implemented to ensure

noise immunity of the CS

signal. Any spikes on CS less than

one w

2

clock period will be ignored. CS must remain low

during the complete I/O exchange which takes eight S

CLK

cycles. Although CS is not immediately acknowledged for

the purpose of starting a new conversion, the falling edge of

CS

immediately enables DO to output the MSB (D7) of the

previous conversion.

The first S

CLK

rising edge will be acknowledged after a set-

up time (t

set-up

) has elapsed from the falling edge of CS.

This and the following seven S

CLK

rising edges will shift in

thechanneladdress for the analog multiplexer.Sincethere are

19 channels only five address bits are utilized. The first five

S

CLK

cycles clock in the mux address, during the next three

S

CLK

cycles the analog input is selected and sampled. During

this mux address/sample cycle, data from the last conversion is also clocked out on DO. Since D7 was clocked out

on the falling edge of CS

only data bits D6 – D0 remain to be

received. The following seven falling edges of S

CLK

shift out

this data on DO.

The 8th S

CLK

falling edge initiates the beginning of the A/D’s

actual conversion process which takes between 26 and 32

w

2

cycles (TC). During this time CS can go high to TRI-

STATE DO and disable the S

CLK

input or it can remain low.

If CS

is held low a new I/O exchange will not start until the

conversion sequence has been completed, however once

the conversion ends serial I/O will immediately begin. Since

there is an ambiguity in the conversion time (T

C

) synchroniz-

ing the data exchange is impossible. Therefore CS

should

go high before the 26th w

2

clock has elasped and return low

after the 32nd w

2

to synchronize serial communication.

A conversion or I/O operation can be aborted at any time by

strobing CS

.IfCSis high or low less than one w2clock it will

be ignored by the A/D. If the CS

is strobed high or low

between 1 to 3 w

2

clocks the A/D may or may not respond.

Therefore CS

must be strobed high or low greater than 3 w

2

clocks to ensure recognition. If a conversion or I/O exchange is aborted while in process the consequent data

output will be erroneous until a complete conversion sequence has been implemented.

1.2 DISCONTINUOUS S

CLK

Another way to accomplish synchronous serial communication is to tie CS

low continuously and disable S

CLK

after its

8th falling edge (see

Figure 2

). S

CLK

must remain low for

TL/H/9287– 16

FIGURE 1

TL/H/9287– 17

FIGURE 2

8

Page 9

Functional Description (Continued)

at least 32 w

2

clocks to ensure that the A/D has completed

its conversion. If S

CLK

is enabled sooner, synchronizing to

the data output on DO is not possible since an end of conversion signal from the A/D is not available and the actual

conversion time is not known. With CS

low during the con-

version time (32 w

2

max) DO will go high or low after the

eighth falling edge of S

CLK

until the conversion is completed. Once the conversion is through DO will transmit the

MSB. The rest of the data will be shifted out once S

CLK

is

enabled as discussed previously.

If CS

goes high during the conversion sequence DO is tri-

stated, and the result is not affected so long as CS

remains

high until the end of the conversion.

1.2 MULTIPLEXER ADDRESSING

The five bit mux address is shifted, MSB first, into DI. Input

data corresponds to the channel selected as shown in table

1. Care should be taken not to send an address greater than

or equal to twenty four (11XXX) as this puts the A/D in a

digital testing mode. In this mode the analog inputs CH0

thru CH4 become digital outputs, for our use in production

testing.

2.0 ANALOG INPUT

2.1 THE INPUT SAMPLE AND HOLD

The ADC0819’s sample/hold capacitor is implemented in its

capacitive ladder structure. After the channel address is received, the ladder is switched to sample the proper analog

input. This sampling mode is maintained for 1 msec after the

eighth S

CLK

falling edge. The hold mode is initiated with the

start of the conversion process. An acquisition window of

3t

S

CLK

a

1 msec is therefore available to allow the ladder

capacitance to settle to the analog input voltage. Any

change in the analog voltage before or after the acquisition

window will not effect the A/D conversion result.

In the most simple case, the ladder’s acquisition time is determined by the R

on

(3K) of the multiplexer switches and the

total ladder capacitance (90pf). These values yield an acquisition time of about 2 msec for a full scale reading. Therefore the analog input must be stable for at least 2 msec

before and 1 msec after the eighth S

CLK

falling edge to

ensure a proper conversion. External input source resistance and capacitance will lengthen the acquisition time and

should be accounted for.

Other conventional sample and hold error specifications are

included in the error and timing specs of the A/D. The hold

step and gain error sample/hold specs are taken into account in the ADC0819’s total unadjusted error, while the

hold settling time is included in the A/D’s max conversion

time of 32 w

2

clock periods. The hold droop rate can be

thought of as being zero since an unlimited amount of time

can pass between a conversion and the reading of data.

However, once the data is read it is lost and another conversion is started.

Typical Applications

ADC0819-INS8048 INTERFACE

TL/H/9287– 18

9

Page 10

ADC0819 FUNCTIONAL CIRCUIT

TL/H/9287– 19

Ordering Information

Temperature Range 0§Ctoa70§C

b

40§Ctoa85§C

Total Unadjustedg(/2 LSB ADC0819BCN ADC0819BCV

Error

g

1 LSB ADC0819CCV ADC0819CIN

Package Outline N28B V28A N28B

10

Page 11

Physical Dimensions inches (millimeters)

Molded Dual-In-Line Package (N)

Order Number ADC0819BCN or ADC0819CIN

NS Package Number N28B

11

Page 12

ADC0819 8-Bit Serial I/O A/D Converter with 19-Channel Multiplexer

Physical Dimensions inches (millimeters) (Continued)

Molded Chip Carrier (V)

Order Number ADC0819BCV, CCV

NS Package Number V28A

LIFE SUPPORT POLICY

NATIONAL’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT

DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF NATIONAL

SEMICONDUCTOR CORPORATION. As used herein:

1. Life support devices or systems are devices or 2. A critical component is any component of a life

systems which, (a) are intended for surgical implant support device or system whose failure to perform can

into the body, or (b) support or sustain life, and whose be reasonably expected to cause the failure of the life

failure to perform, when properly used in accordance support device or system, or to affect its safety or

with instructions for use provided in the labeling, can effectiveness.

be reasonably expected to result in a significant injury

to the user.

National Semiconductor National Semiconductor National Semiconductor National Semiconductor

Corporation Europe Hong Kong Ltd. Japan Ltd.

1111 West Bardin Road Fax: (

a

49) 0-180-530 85 86 13th Floor, Straight Block, Tel: 81-043-299-2309

Arlington, TX 76017 Email: cnjwge@tevm2.nsc.com Ocean Centre, 5 Canton Rd. Fax: 81-043-299-2408

Tel: 1(800) 272-9959 Deutsch Tel: (

a

49) 0-180-530 85 85 Tsimshatsui, Kowloon

Fax: 1(800) 737-7018 English Tel: (

a

49) 0-180-532 78 32 Hong Kong

Fran3ais Tel: (

a

49) 0-180-532 93 58 Tel: (852) 2737-1600

Italiano Tel: (

a

49) 0-180-534 16 80 Fax: (852) 2736-9960

National does not assume any responsibility for use of any circuitry described, no circuit patent licenses are implied and National reserves the right at any time without notice to change said circuitry and specifications.

Loading...

Loading...