Page 1

6-5

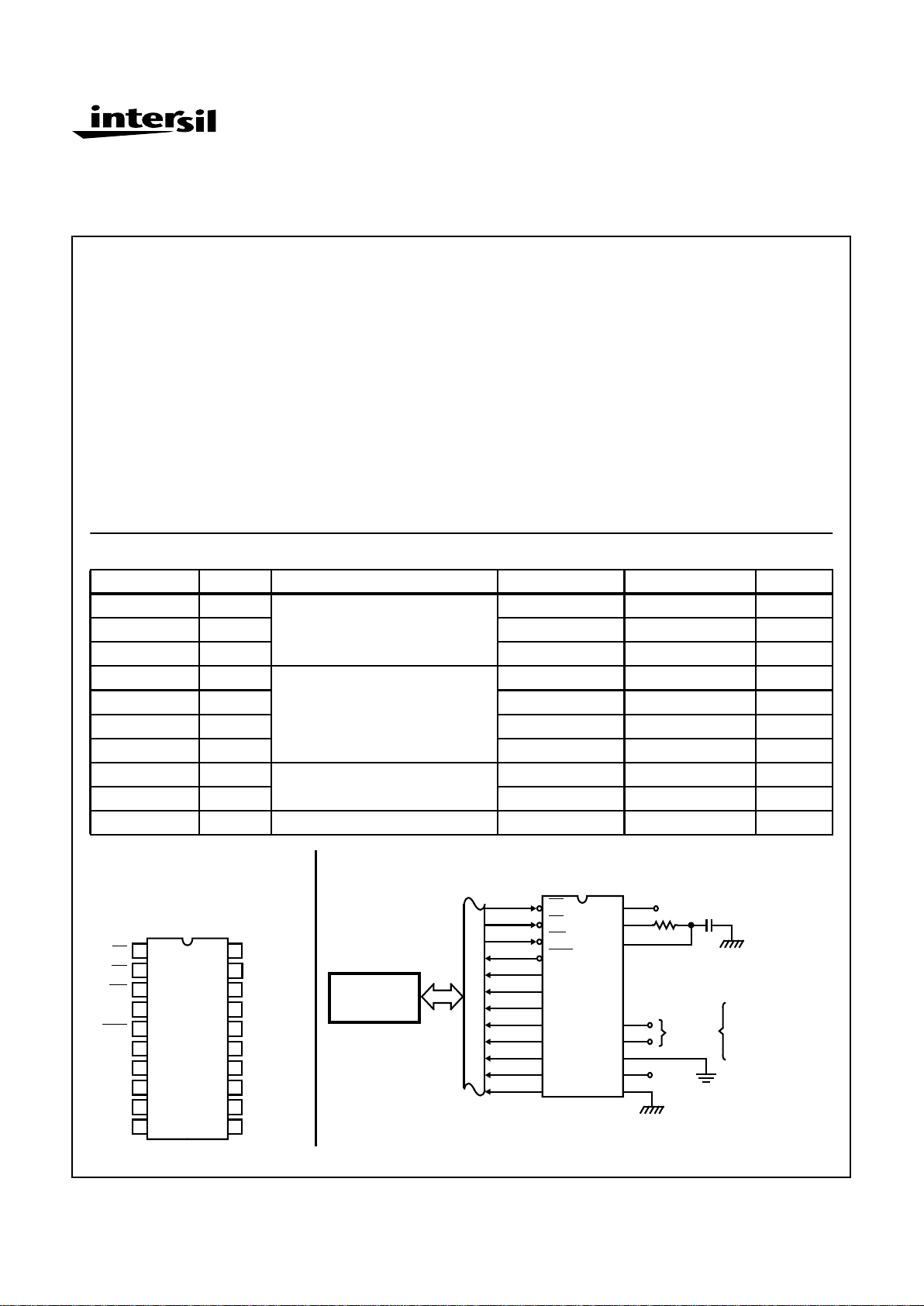

Features

• 80C48 and 80C80/85 Bus Compatible - No Interfacing

Logic Required

• Conversion Time < 100µs

• Easy Interface to Most Microprocessors

• Will Operate in a “Stand Alone” Mode

• Differential Analog Voltage Inputs

• Works with Bandgap Voltage References

• TTL Compatible Inputs and Outputs

• On-Chip Clock Generator

• 0V to 5V Analog Voltage Input Range (Single + 5V Supply)

• No Zero-Adjust Required

Description

The ADC0802 family are CMOS 8-Bit, successive-approximation A/D converters which use a modified potentiometric

ladder and are designed to operate with the 8080A control

bus via three-state outputs. These converters appear to the

processor as memory locations or I/O ports, and hence no

interfacing logic is required.

The differential analog voltage input has good commonmode-rejection and permits offsetting the analog zero-inputvoltage value. In addition, the voltage reference input can be

adjusted to allow encoding any smaller analog voltage span

to the full 8 bits of resolution.

Ordering Information

PART NUMBER ERROR EXTERNAL CONDITIONS TEMP. RANGE (oC) PACKAGE PKG. NO

ADC0802LCN ±1/2 LSB V

REF

/2 = 2.500VDC(No Adjustments) 0 to 70 20 Ld PDIP E20.3

ADC0802LCD ±3/4 LSB -40 to 85 20 Ld CERDIP F20.3

ADC0802LD ±1 LSB -55 to 125 20 Ld CERDIP F20.3

ADC0803LCN ±1/2 LSB V

REF

/2 Adjusted for Correct Full Scale

Reading

0 to 70 20 Ld PDIP E20.3

ADC0803LCD ±3/4 LSB -40 to 85 20 Ld CERDIP F20.3

ADC0803LCWM ±1 LSB -40 to 85 20 Ld SOIC M20.3

ADC0803LD ±1 LSB -55 to 125 20 Ld CERDIP F20.3

ADC0804LCN ±1 LSB V

REF

/2 = 2.500VDC(No Adjustments) 0 to 70 20 Ld PDIP E20.3

ADC0804LCD ±1 LSB -40 to 85 20 Ld CERDIP F20.3

ADC0804LCWM ±1 LSB -40 to 85 20 Ld SOIC M20.3

Pinout

ADC0802, ADC0803, ADC0804

(PDIP, CERDIP)

TOP VIEW

Typical Application Schematic

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1

WR

RD

CS

CLK IN

INTR

V

IN

(-)

VIN (+)

DGND

V

REF

/2

AGND

V+ OR V

REF

CLK R

DB

0 (LSB)

DB

1

DB

2

DB

3

DB

4

DB

5

DB

6

DB

7 (MSB)

3

2

1

12

11

5

15

14

13

18

17

16

7

6

10

9

8

4

19

20

WR

RD

CS

DB

6

DB

7

INTR

DB

3

DB

4

DB

5

DB

0

DB

1

DB

2

CLK IN

CLK R

V+

V

IN

(-)

V

IN

(+)

DGND

V

REF

/2

AGND

ANY

µPROCESSOR

8-BIT RESOLUTION

OVER ANY

DESIRED

ANALOG INPUT

VOLTAGE RANGE

DIFF

INPUTS

10K

150pF

V

REF

/2

µP BUS

+5V

August 1997

ADC0802, ADC0803

ADC0804

8-Bit, Microprocessor-

Compatible, A/D Converters

File Number 3094.1

CAUTION: These devices are sensitive to electrostatic discharge; follow proper IC Handling Procedures.

1-888-INTERSIL or 321-724-7143 | Copyright © Intersil Corporation 1999

Page 2

6-6

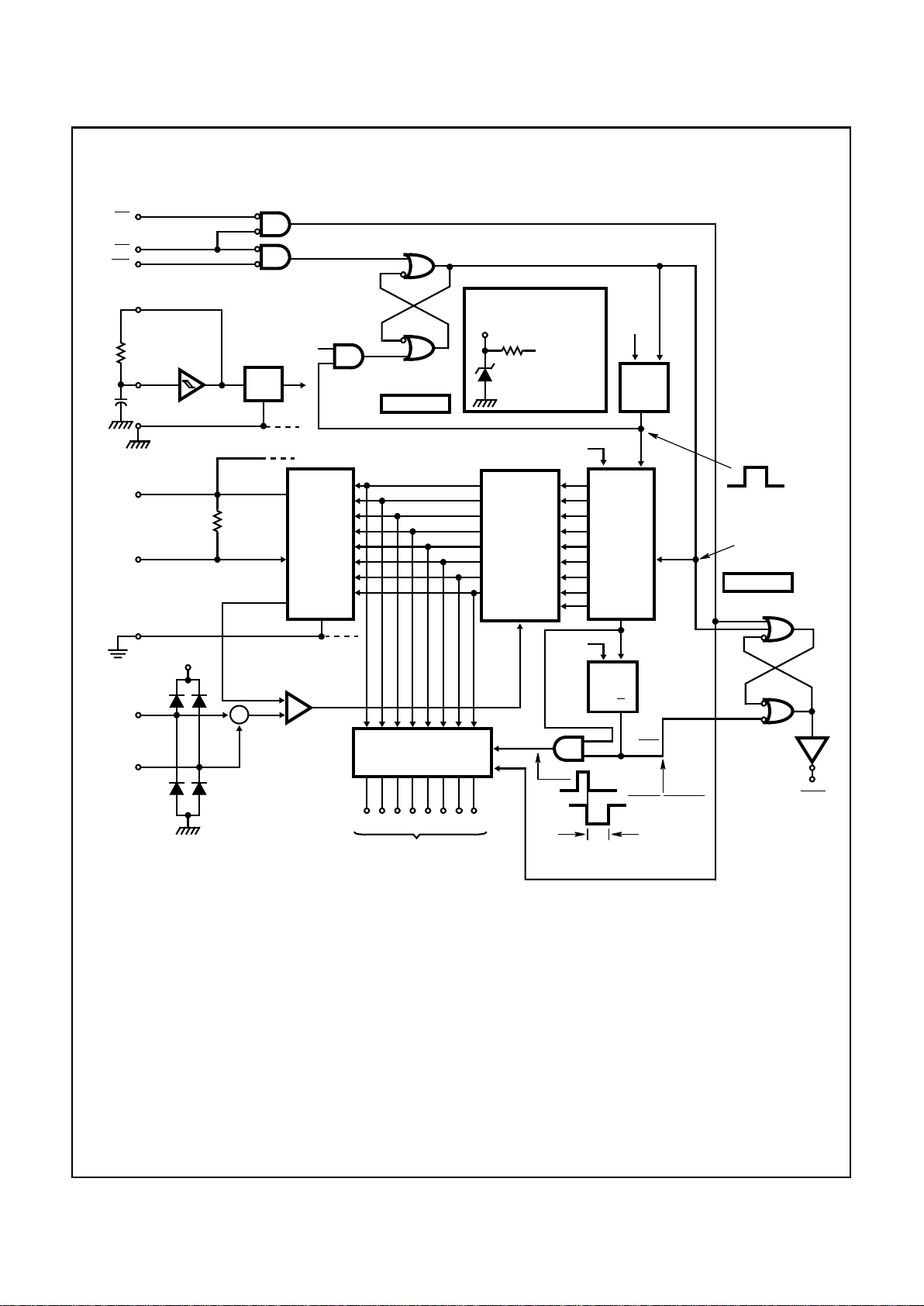

Functional Diagram

1211 151413 181716

WR

RD

CS

INTR

CLK OSC

CLK R

V+

V

IN

(-)

V

IN

(+)

DGND

V

REF

/2

AGND

(V

REF

)

DAC

V

OUT

COMP

CLK

GEN

CLKS

CLK A

RESET

START F/F

LADDER

AND

DECODER

SUCCESSIVE

APPROX.

REGISTER

AND LATCH

8-BIT

SHIFT

REGISTER

D

RESET

SET

CONV. COMPL.

THREE-STATE

OUTPUT LATCHES

DIGITAL OUTPUTS

THREE-STATE CONTROL

“1” = OUTPUT ENABLE

DFF2

CLK A

XFER

G2

Q

8 X 1/f

R

Q

INTR F/F

IF RESET = “0”

D

DFF1

Q

D

Q

CLK B

START

CONVERSION

MSB

LSB

Q

“1” = RESET SHIFT REGISTER

“0” = BUSY AND RESET STATE

RESET

READ

SET

3

2

1

5

7

6

10

9

8

4

19

20

CLK IN

MSB

G1

CLK

-

+

LSB

INPUT PROTECTION

FOR ALL LOGIC INPUTS

INPUT

TO INTERNAL

BV = 30V

CIRCUITS

∑

V+

+

-

ADC0802, ADC0803, ADC0804

Page 3

6-7

Absolute Maximum Ratings Thermal Information

Supply Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.5V

Voltage at Any Input . . . . . . . . . . . . . . . . . . . . . . -0.3V to (V+ +0.3V)

Operating Conditions

Temperature Range

ADC0802/03LD. . . . . . . . . . . . . . . . . . . . . . . . . . . -55oC to 125oC

ADC0802/03/04LCD. . . . . . . . . . . . . . . . . . . . . . . .-40oC to 85oC

ADC0802/03/04LCN. . . . . . . . . . . . . . . . . . . . . . . . . .0oC to 70oC

ADC0803/04LCWM . . . . . . . . . . . . . . . . . . . . . . . . -40oC to 85oC

Thermal Resistance (Typical, Note 1) θJA (oC/W) θJC (oC/W)

PDIP Package. . . . . . . . . . . . . . . . . . . . . 125 N/A

CERDIP Package . . . . . . . . . . . . . . . . . . 80 20

SOIC Package. . . . . . . . . . . . . . . . . . . . . 120 N/A

Maximum Junction Temperature

Hermetic Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175oC

Plastic Package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150oC

Maximum Storage Temperature Range . . . . . . . . . .-65oC to 150oC

Maximum Lead Temperature (Soldering, 10s) . . . . . . . . . . . . 300oC

(SOIC - Lead Tips Only)

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation

of the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

NOTE:

1. θJA is measured with the component mounted on an evaluation PC board in free air.

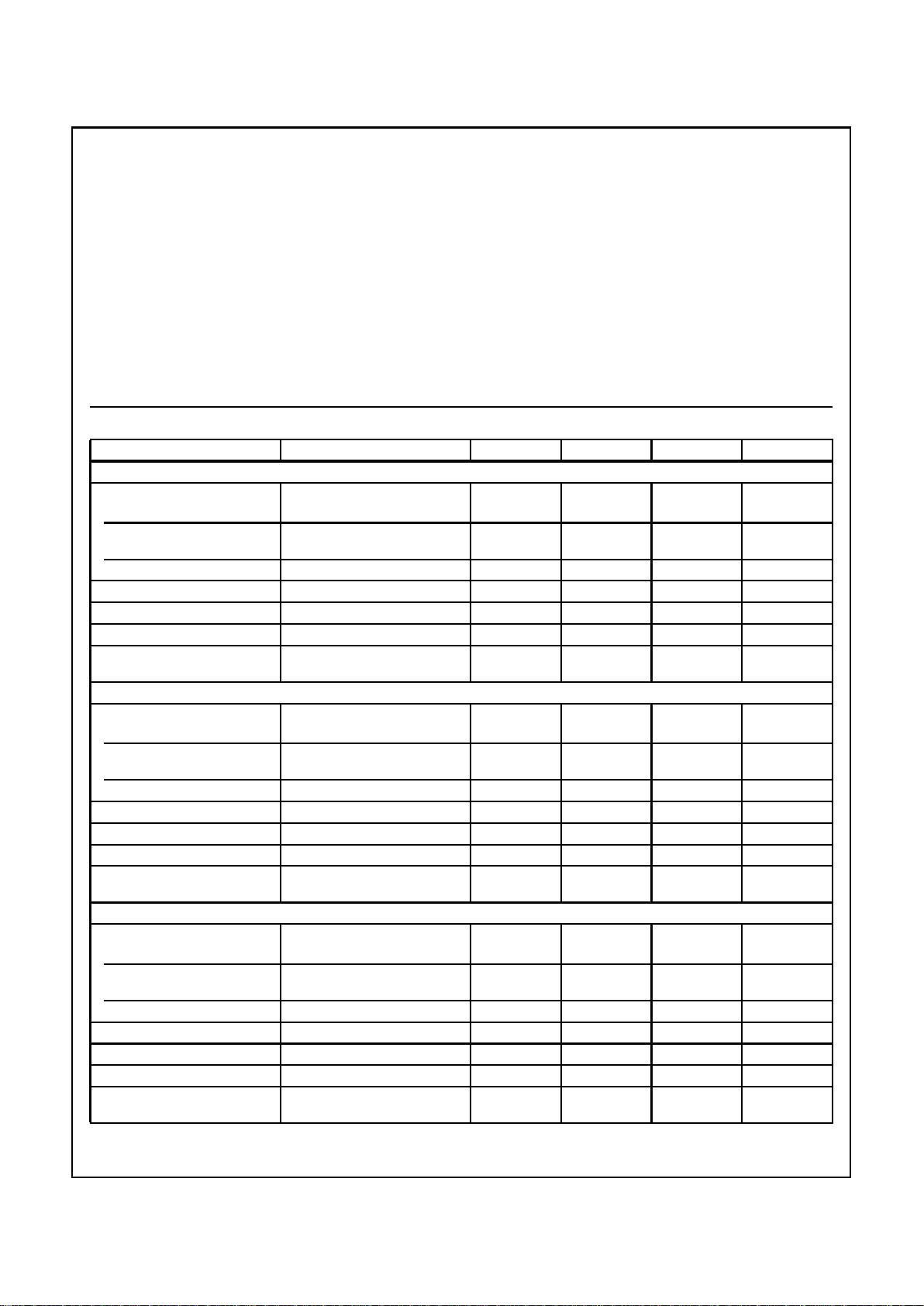

Electrical Specifications (Notes 1, 7)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

CONVERTER SPECIFICATIONS V+ = 5V, TA = 25oC and f

CLK

= 640kHz, Unless Otherwise Specified

Total Unadjusted Error

ADC0802 V

REF

/2 = 2.500V - - ±1/

2

LSB

ADC0803 V

REF

/2 Adjusted for Correct Full

Scale Reading

--±1/

2

LSB

ADC0804 V

REF

/2 = 2.500V - - ±1 LSB

V

REF

/2 Input Resistance Input Resistance at Pin 9 1.0 1.3 - kΩ

Analog Input Voltage Range (Note 2) GND-0.05 - (V+) + 0.05 V

DC Common-Mode Rejection Over Analog Input Voltage Range -

±

1

/

16

±

1

/

8

LSB

Power Supply Sensitivity V+ = 5V ±10% Over Allowed Input

Voltage Range

-

±

1

/

16

±

1

/

8

LSB

CONVERTER SPECIFICATIONS V+ = 5V, 0

o

C to 70oC and f

CLK

= 640kHz, Unless Otherwise Specified

Total Unadjusted Error

ADC0802 V

REF

/2 = 2.500V - - ±1/

2

LSB

ADC0803 V

REF

/2 Adjusted for Correct Full

Scale Reading

--±1/

2

LSB

ADC0804 V

REF

/2 = 2.500V - - ±1 LSB

V

REF

/2 Input Resistance Input Resistance at Pin 9 1.0 1.3 - kΩ

Analog Input Voltage Range (Note 2) GND-0.05 - (V+) + 0.05 V

DC Common-Mode Rejection Over Analog Input Voltage Range -

±

1

/

8

±

1

/

4

LSB

Power Supply Sensitivity V+ = 5V±10% Over Allowed Input

Voltage Range

-

±

1

/

16

±

1

/

8

LSB

CONVERTER SPECIFICATIONS V+ = 5V, -25

o

C to 85oC and f

CLK

= 640kHz, Unless Otherwise Specified

Total Unadjusted Error

ADC0802 V

REF

/2 = 2.500V - - ±3/

4

LSB

ADC0803 V

REF

/2 Adjusted for Correct Full

Scale Reading

--±3/

4

LSB

ADC0804 V

REF

/2 = 2.500V - - ±1 LSB

V

REF

/2 Input Resistance Input Resistance at Pin 9 1.0 1.3 - kΩ

Analog Input Voltage Range (Note 2) GND-0.05 - (V+) + 0.05 V

DC Common-Mode Rejection Over Analog Input Voltage Range -

±

1

/

8

±

1

/

4

LSB

Power Supply Sensitivity V+ = 5V±10% Over Allowed Input

Voltage Range

-

±

1

/

16

±

1

/

8

LSB

ADC0802, ADC0803, ADC0804

Page 4

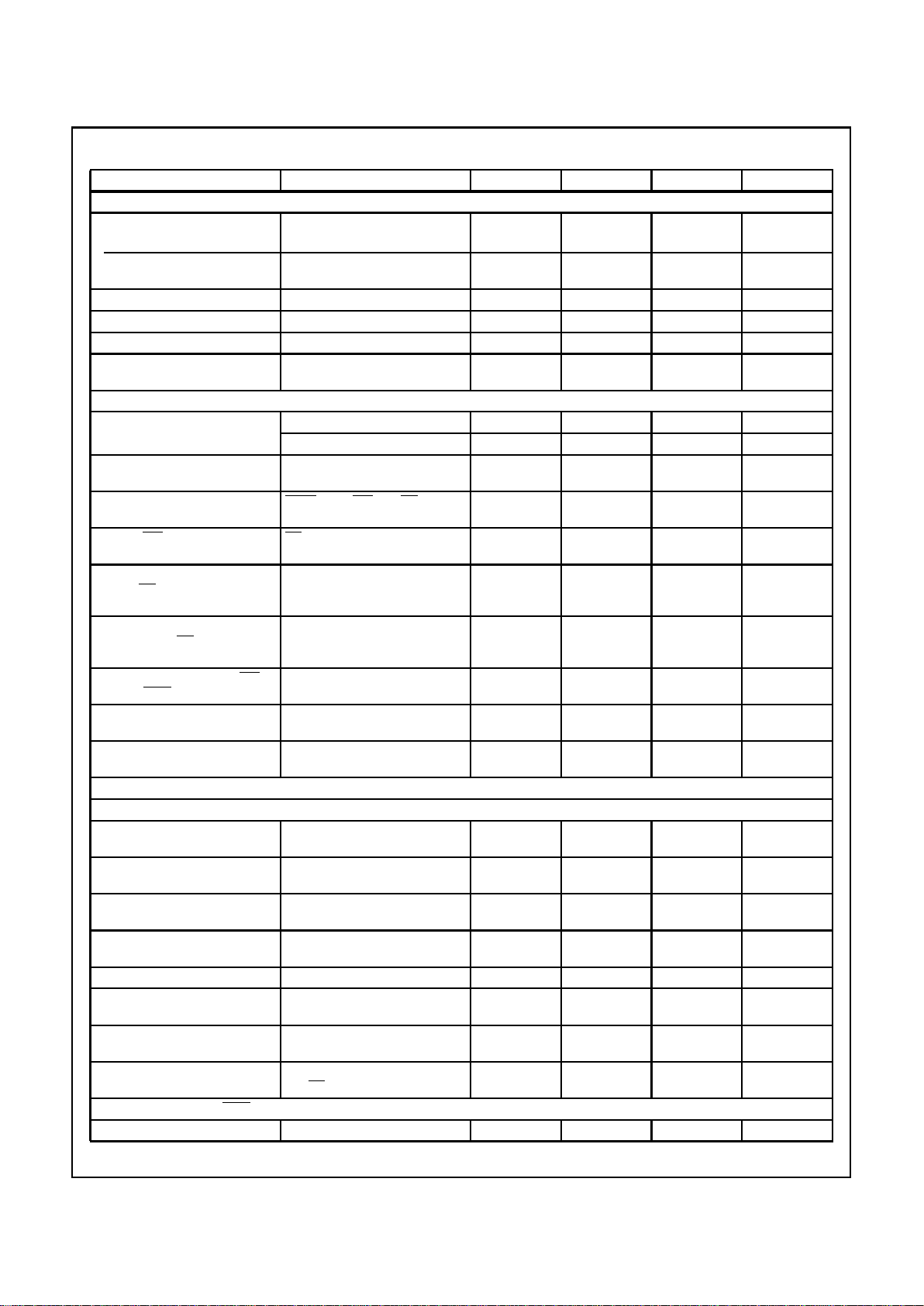

6-8

CONVERTER SPECIFICATIONS V+ = 5V, -55oC to 125oC and f

CLK

= 640kHz, Unless Otherwise Specified

Total Unadjusted Error

ADC0802 V

REF

/2 = 2.500V - - ±1 LSB

ADC0803 V

REF

/2 Adjusted for Correct Full

Scale Reading

--±1 LSB

V

REF

/2 Input Resistance Input Resistance at Pin 9 1.0 1.3 - kΩ

Analog Input Voltage Range (Note 2) GND-0.05 - (V+) + 0.05 V

DC Common-Mode Rejection Over Analog Input Voltage Range -

±

1

/

8

±

1

/

4

LSB

Power Supply Sensitivity V+ = 5V±10% Over Allowed Input

Voltage Range

-

±

1

/

8

±

1

/

4

LSB

AC TIMING SPECIFICATIONS V+ = 5V, and T

A

= 25oC, Unless Otherwise Specified

Clock Frequency, f

CLK

V+ = 6V (Note 3) 100 640 1280 kHz

V+ = 5V 100 640 800 kHz

Clock Periods per Conversion

(Note 4), t

CONV

62 - 73 Clocks/Conv

Conversion Rate In Free-Running

Mode, CR

INTR tied to WR with CS = 0V,

f

CLK

= 640kHz

- - 8888 Conv/s

Width of

WR Input (Start Pulse

Width), t

W(WR)I

CS = 0V (Note 5) 100 - - ns

Access Time (Delay from Falling

Edge of

RD to Output Data Valid),

t

ACC

CL = 100pF (Use Bus Driver IC for

Larger C

L)

- 135 200 ns

Three-State Control (Delay from

Rising Edge of

RD to Hl-Z State),

t1H, t

0H

CL = 10pF, RL= 10K

(See Three-State Test Circuits)

- 125 250 ns

Delay from Falling Edge of

WR to

Reset of INTR, tWI, t

RI

- 300 450 ns

Input Capacitance of Logic

Control Inputs, C

IN

-5-pF

Three-State Output Capacitance

(Data Buffers), C

OUT

-5-pF

DC DIGITAL LEVELS AND DC SPECIFICATIONS V+ = 5V, and T

MIN

to T

MAX

, Unless Otherwise Specified

CONTROL INPUTS (Note 6)

Logic “1“ Input Voltage (Except

Pin 4 CLK IN), V

INH

V+ = 5.25V 2.0 - V+ V

Logic “0“ Input Voltage (Except

Pin 4 CLK IN), V

INL

V+ = 4.75V - - 0.8 V

CLK IN (Pin 4) Positive Going

Threshold Voltage, V+

CLK

2.7 3.1 3.5 V

CLK IN (Pin 4) Negative Going

Threshold Voltage, V-

CLK

1.5 1.8 2.1 V

CLK IN (Pin 4) Hysteresis, V

H

0.6 1.3 2.0 V

Logic “1” Input Current

(All Inputs), I

INHI

VlN = 5V - 0.005 1 µΑ

Logic “0” Input Current

(All Inputs), I

INLO

VlN = 0V -1 -0.005 - µA

Supply Current (Includes Ladder

Current), I+

f

CLK

= 640kHz,TA = 25oC

and CS = Hl

- 1.3 2.5 mA

DATA OUTPUTS AND

INTR

Logic “0” Output Voltage, V

OL

lO= 1.6mA, V+ = 4.75V - - 0.4 V

Electrical Specifications (Notes 1, 7) (Continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

ADC0802, ADC0803, ADC0804

Page 5

6-9

Logic “1” Output Voltage, V

OH

lO= -360µA, V+ = 4.75V 2.4 - - V

Three-State Disabled Output

Leakage (All Data Buffers)

, I

LO

V

OUT

= 0V -3 - - µA

V

OUT

= 5V - - 3 µA

Output Short Circuit Current,

I

SOURCE

V

OUT

Short to Gnd TA = 25oC 4.5 6 - mA

Output Short Circuit Current,

I

SINK

V

OUT

Short to V+ TA = 25oC 9.0 16 - mA

NOTES:

1. All voltages are measured with respect to GND , unless otherwise specified. The separate AGND point should always be wired to the

DGND, being careful to avoid ground loops.

2. For V

IN(-)

≥ V

IN(+)

the digital output code will be 0000 0000. Two on-chip diodes are tied to each analog input (see Block Diagram) which

will forward conduct for analog input voltages one diode drop below ground or one diode drop greater than the V+ supply. Be careful,

during testing at low V+ levels (4.5V), as high level analog inputs (5V) can cause this input diode to conduct - especially at elevated temperatures, and cause errors for analog inputs near full scale. As long as the analog VIN does not exceed the supply voltage by more than

50mV, the output code will be correct. To achieve an absolute 0V to 5V input voltage range will therefore require a minimum supply voltage of 4.950V over temperature variations, initial tolerance and loading.

3. With V+ = 6V, the digital logic interfaces are no longer TTL compatible.

4. With an asynchronous start pulse, up to 8 clock periods may be required before the internal clock phases are proper to start the conversion

process.

5. The CS input is assumed to bracket the WR strobe input so that timing is dependent on the WR pulse width. An arbitrarily wide pulse

width will hold the converter in a reset mode and the start of conversion is initiated by the low to high transition of the WR pulse (see

Timing Diagrams).

6. CLK IN (pin 4) is the input of a Schmitt trigger circuit and is therefore specified separately.

7. None of these A/Ds requires a zero-adjust. Howe ver , if an all zero code is desired f or an analog input other than 0V, or if a narrow full scale span

exists (for e xample: 0.5V to 4V full scale) the V

IN(-)

input can be adjusted to achieve this. See the Zero Error description in this data sheet.

Electrical Specifications (Notes 1, 7) (Continued)

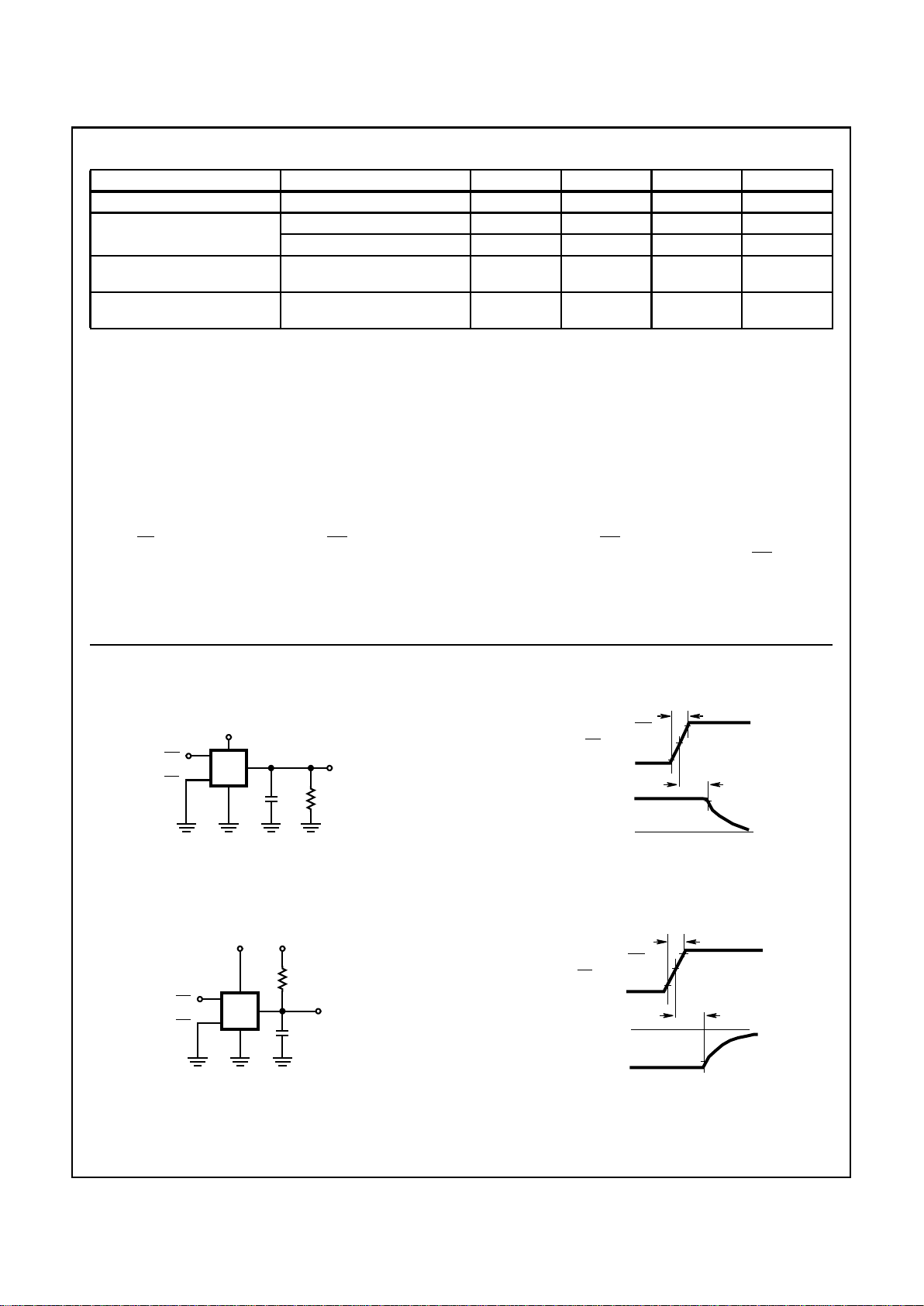

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Timing Waveforms

FIGURE 1A. t

1H

FIGURE 1B. t1H, CL = 10pF

FIGURE 1C. t

0H

FIGURE 1D. t0H, CL = 10pF

FIGURE 1. THREE-STATE CIRCUITS AND WAVEFORMS

10K

V+

RD

CS

C

L

DATA

OUTPUT

RD

2.4V

t

r

90%

50%

10%

t

1H

0.8V

DAT A

OUTPUTS

GND

t

r

= 20ns

V

OH

90%

10K

V+

RD

CS

C

L

DATA

OUTPUT

V+

RD

2.4V

t

r

90%

50%

10%

t

0H

0.8V

DAT A

OUTPUTS

V

OI

tr = 20ns

V+

10%

ADC0802, ADC0803, ADC0804

Page 6

6-10

Typical Performance Curves

FIGURE 2. LOGIC INPUT THRESHOLD VOLT AGE vs SUPPLY

VOLTAGE

FIGURE 3. DELA Y FR OM FALLING EDGE OF RD TO OUTPUT

DATA VALID vs LOAD CAPACITANCE

FIGURE 4. CLK IN SCHMITT TRIP LEVELS vs SUPPLY VOLTAGE FIGURE 5. f

CLK

vs CLOCK CAPACITOR

FIGURE 6. FULL SCALE ERROR vs f

CLK

FIGURE 7. EFFECT OF UNADJUSTED OFFSET ERROR

-55oC TO 125oC

1.8

1.7

1.6

1.5

1.4

1.3

4.754.50 5.00 5.25 5.50

V+ SUPPLY VOLTAGE (V)

LOGIC INPUT THRESHOLD VOLTAGE (V)

DELAY (ns)

500

400

300

200

100

0

LOAD CAPACITANCE (pF)

200 400 600 800 1000

CLK IN THRESHOLD VOLTAGE (V)

3.5

3.1

2.7

2.3

1.9

1.5

4.50

V+ SUPPLY VOLTAGE (V)

-55oC TO 125oC

V

T(-)

V

T(+)

4.75 5.00 5.25 5.50

1000

CLOCK CAPACITOR (pF)

f

CLK

(kHz)

100

10010 1000

R = 10K

R = 50K

R = 20K

FULL SCALE ERROR (LSBs)

7

6

5

4

3

2

1

0

f

CLK

(kHz)

0 400 800 1200 1600 2000

V+ = 4.5V

V+ = 5V

V+ = 6V

V

IN(+)

= V

IN(-)

= 0V

ASSUMES V

OS

= 2mV

THIS SHOWS THE NEED

FOR A ZERO ADJUSTMENT

IF THE SPAN IS REDUCED

OFFSET ERROR (LSBs)

16

14

12

10

8

6

4

2

V

REF

/2 (V)

0

0.01 0.1 1.0 5

ADC0802, ADC0803, ADC0804

Page 7

6-11

FIGURE 8. OUTPUT CURRENT vs TEMPERATURE FIGURE 9. POWER SUPPLY CURRENT vs TEMPERATURE

Timing Diagrams

FIGURE 10A. START CONVERSION

FIGURE 10B. OUTPUT ENABLE AND RESET

INTR

Typical Performance Curves (Continued)

OUTPUT CURRENT (mA)

8

7

6

5

4

3

2

-50

T

A

AMBIENT TEMPERATURE (oC)

-I

SINK

V

OUT

= 0.4V

I

SOURCE

V

OUT

= 2.4V

DATA OUTPUT

BUFFERS

V+ = 5V

-25 0 25 50 75 100 125

POWER SUPPLY CURRENT (mA)

TA AMBIENT TEMPERATURE (oC)

-50 -25 0 25 50 75 100 125

1.6

1.5

1.4

1.3

1.2

1.1

1.0

f

CLK

= 640kHz

V+ = 5.5V

V+ = 5.0V

V+ = 4.5V

t

WI

t

W(WR)I

1 TO 8 x 1/f

CLK

INTERNAL T

C

CS

WR

ACTUAL INTERNAL

STATUS OF THE

CONVERTER

INTR

(LAST DATA READ)

(LAST DATA NOT READ)

“NOT BUSY”

“BUSY”

DATA IS VALID IN

OUTPUT LATCHES

INTR

ASSERTED

t

VI

1

/2 f

CLK

VALID

DATA

VALID

DATA

INTR RESET

INTR

CS

RD

DAT A

OUTPUTS

THREE-STATE

(HI-Z)

t

RI

t

ACC

t1H, t

0H

ADC0802, ADC0803, ADC0804

Page 8

6-12

Understanding A/D Error Specs

A perfect A/D transfer characteristic (staircase wave-form) is

shown in Figure 11A. The horizontal scale is analog input voltage and the particular points labeled are in steps of 1 LSB

(19.53mV with 2.5V tied to the V

REF

/2 pin). The digital output

codes which correspond to these inputs are shown as D-1, D,

and D+1. For the perfect A/D, not only will center-value (A - 1,

A, A + 1, . . .) analog inputs produce the correct output digital

codes, but also each riser (the transitions between adjacent

output codes) will be located ±

1

/2 LSB away from each centervalue. As shown, the risers are ideal and hav e no width. Correct

digital output codes will be provided for a range of analog input

voltages which extend ±

1

/2 LSB from the ideal center-values.

Each tread (the range of analog input voltage which provides

the same digital output code) is therefore 1 LSB wide.

The error curve of Figure 11B shows the worst case transfer

function for the ADC0802. Here the specification guarantees

that if we apply an analog input equal to the LSB analog voltage center-value, the A/D will produce the correct digital code.

Next to each transfer function is shown the corresponding error

plot. Notice that the error includes the quantization uncertainty of

the A/D. For example, the error at point 1 of Figure 11A is

+

1

/2LSB because the digital code appeared1/2 LSB in advance

of the center-value of the tread. The error plots always have a

constant negative slope and the abrupt upside steps are always

1 LSB in magnitude, unless the device has missing codes.

Detailed Description

The functional diagram of the ADC0802 series of A/D

converters operates on the successive approximation principle (see Application Notes AN016 and AN020 for a more

detailed description of this principle). Analog switches are

closed sequentially by successive-approximation logic until

the analog differential input voltage [V

lN(+)

- V

lN(-)

] matches

a voltage derived from a tapped resistor string across the

reference voltage. The most significant bit is tested first and

after 8 comparisons (64 clock cycles), an 8-bit binary code

(1111 1111 = full scale) is transferred to an output latch.

The normal operation proceeds as follows. On the high-to-low

transition of the WR input, the internal SAR latches and the

shift-register stages are reset, and the INTR output will be set

high. As long as the CS input and WR input remain low, the

A/D will remain in a reset state. Conversion will start from 1 to

8 clock periods after at least one of these inputs makes a lowto-high transition. After the requisite number of clock pulses to

complete the conversion, the INTR pin will make a high-to-lo w

transition. This can be used to interrupt a processor, or

otherwise signal the availability of a new conversion. A RD

operation (with CS low) will clear the INTR line high again.

TRANSFER FUNCTION ERROR PLOT

FIGURE 11A. ACCURACY =±0 LSB; PERFECT A/D

TRANSFER FUNCTION ERROR PLOT

FIGURE 11B. ACCURACY =±1/2 LSB

FIGURE 11. CLARIFYING THE ERROR SPECS OF AN A/D CONVERTER

ANALOG INPUT (VIN)

DIGITAL OUTPUT CODE

D + 1

D

D - 1

A + 1

A

A - 1

3

21

56

4

3

2

15

64

ERROR

0

+1 LSB

-1 LSB

-

1

/2 LSB

+

1

/2 LSB

*

QUANTIZATION ERROR

A

ANALOG INPUT (V

IN

)

A + 1A - 1

ANALOG INPUT (VIN)

DIGITAL OUTPUT CODE

D + 1

D

D - 1

A + 1

A

A - 1

3

2

1

5

6

4

*

0

+1 LSB

-1 LSB

QUANTIZATION

ERROR

3

2

1

6

4

ANALOG INPUT (V

IN

)

A + 1AA - 1

ERROR

ADC0802, ADC0803, ADC0804

Page 9

6-13

The device may be operated in the free-running mode b y connecting INTR to the WR input with CS = 0. To ensure start-up

under all possible conditions, an external WR pulse is

required during the first power-up cycle. A conversion-in-process can be interrupted by issuing a second start command.

Digital Operation

The converter is started by having CS and WR simultaneously

low. This sets the start flip-flop (F/F) and the resulting “1” level

resets the 8-bit shift register, resets the Interrupt (INTR) F/F

and inputs a “1” to the D flip-flop, DFF1, which is at the input

end of the 8-bit shift register. Internal clock signals then transfer this “1” to the Q output of DFF1. The AND gate, G1, combines this “1” output with a clock signal to provide a reset

signal to the start F/F. If the set signal is no longer present

(either WR or CS is a “1”), the start F/F is reset and the 8-bit

shift register then can have the “1” clock ed in, which starts the

conversion process. If the set signal were to still be present,

this reset pulse would have no effect (both outputs of the start

F/F would be at a “1” level) and the 8-bit shift register would

continue to be held in the reset mode. This allows for asynchronous or wide CS and WR signals.

After the “1” is clocked through the 8-bit shift register (which

completes the SAR operation) it appears as the input to

DFF2. As soon as this “1” is output from the shift register, the

AND gate, G2, causes the new digital word to transfer to the

Three-State output latches. When DFF2 is subsequently

clocked, the

Q output makes a high-to-low transition which

causes the INTR F/F to set. An inverting buffer then supplies

the

INTR output signal.

When data is to be read, the combination of both

CS and RD

being low will cause the INTR F/F to be reset and the threestate output latches will be enabled to provide the 8-bit digital

outputs.

Digital Control Inputs

The digital control inputs (CS, RD, and WR) meet standard

TTL logic voltage lev els. These signals are essentially equivalent to the standard A/D Start and Output Enable control signals, and are active low to allow an easy interface to

microprocessor control busses. For non-microprocessor

based applications, the CS input (pin 1) can be grounded and

the standard A/D Start function obtained by an active low

pulse at the WR input (pin 3). The Output Enable function is

achieved by an active low pulse at the RD input (pin 2).

Analog Operation

The analog comparisons are performed by a capacitive

charge summing circuit. Three capacitors (with precise

ratioed values) share a common node with the input to an

auto-zeroed comparator. The input capacitor is switched

between V

lN(+)

and V

lN(-)

, while two ratioed reference capacitors are switched between taps on the reference voltage

divider string. The net charge corresponds to the weighted difference between the input and the current total value set by

the successive approximation register. A correction is made to

offset the comparison by

1

/2 LSB (see Figure 11A).

Analog Differential Voltage Inputs and Common-Mode

Rejection

This A/D gains considerable applications flexibility from the analog differential voltage input. The V

lN(-)

input (pin 7) can be used

to automatically subtract a fixed voltage value from the input

reading (tare correction). This is also useful in 4mA - 20mA current loop conversion. In addition, common-mode noise can be

reduced by use of the differential input.

The time interval between sampling V

IN(+)

and V

lN(-)

is 41/

2

clock periods. The maximum error voltage due to this slight

time difference between the input voltage samples is giv en b y:

where:

∆V

E

is the error voltage due to sampling delay,

V

PEAK

is the peak value of the common-mode voltage,

f

CM

is the common-mode frequency.

For example, with a 60Hz common-mode frequency, f

CM

,

and a 640kHz A/D clock, f

CLK

, keeping this error to1/4 LSB

(~5mV) would allow a common-mode voltage, V

PEAK

, given

by:

,

or

.

The allowed range of analog input voltage usually places

more severe restrictions on input common-mode voltage

levels than this.

An analog input voltage with a reduced span and a relatively

large zero offset can be easily handled by making use of the

differential input (see Reference Voltage Span Adjust).

Analog Input Current

The internal switching action causes displacement currents to

flow at the analog inputs. The voltage on the on-chip capacitance to ground is switched through the analog differential

input voltage, resulting in proportional currents entering the

V

IN(+)

input and leaving the V

IN(-)

input. These current transients occur at the leading edge of the internal clocks. They

rapidly decay and do not inherently cause errors as the onchip comparator is strobed at the end of the clock perIod.

Input Bypass Capacitors

Bypass capacitors at the inputs will average these charges

and cause a DC current to flow through the output resistances

of the analog signal sources. This charge pumping action is

worse for continuous conv ersions with the V

IN(+)

input voltage

at full scale. For a 640kHz clock frequency with the V

IN(+)

input at 5V, this DC current is at a maximum of approximately

5µA. Therefore, bypass capacitors should not be used at

the analog inputs or the V

REF

/2 pin for high resistance

sources (>1kΩ). If input bypass capacitors are necessary for

noise filtering and high source resistance is desirable to minimize capacitor size, the effects of the voltage drop across this

input resistance, due to the average value of the input current,

can be compensated by a full scale adjustment while the

given source resistor and input bypass capacitor are both in

place. This is possible because the average value of the input

current is a precise linear function of the differential input

voltage at a constant conversion r ate .

VEMAX()∆ V

PEAK

()2πfCM()

4.5

f

CLK

------------

=

V

PEAK

∆V

E MAX()f

CLK

()

2πfCM()4.5()

--------------------------------------------------=

V

PEAK

510

3–

×()640 103×()

6.28()60()4.5()

----------------------------------------------------------

1.9V≅=

ADC0802, ADC0803, ADC0804

Page 10

6-14

Input Source Resistance

Large values of source resistance where an input bypass

capacitor is not used will not cause errors since the input

currents settle out prior to the comparison time. If a lowpass filter is required in the system, use a low-value series

resistor (≤1kΩ) for a passive RC section or add an op amp

RC active low-pass filter. For low-source-resistance

applications (≤1kΩ), a 0.1µF bypass capacitor at the inputs

will minimize EMI due to the series lead inductance of a long

wire. A 100Ω series resistor can be used to isolate this

capacitor (both the R and C are placed outside the feedback

loop) from the output of an op amp, if used.

Stray Pickup

The leads to the analog inputs (pins 6 and 7) should be kept

as short as possible to minimize stray signal pickup (EMI).

Both EMI and undesired digital-clock coupling to these inputs

can cause system errors. The source resistance for these

inputs should, in general, be kept below 5kΩ. Larger values of

source resistance can cause undesired signal pickup. Input

bypass capacitors, placed from the analog inputs to ground,

will eliminate this pickup but can create analog scale errors as

these capacitors will average the transient input switching currents of the A/D (see Analog Input Current). This scale error

depends on both a large source resistance and the use of an

input bypass capacitor. This error can be compensated by a

full scale adjustment of the A/D (see Full Scale Adjustment)

with the source resistance and input bypass capacitor in

place, and the desired conversion rate .

Reference Voltage Span Adjust

For maximum application flexibility, these A/Ds have been

designed to accommodate a 5V, 2.5V or an adjusted voltage

reference. This has been achieved in the design of the IC as

shown in Figure 12.

Notice that the reference voltage f or the IC is either

1

/2 of the

voltage which is applied to the V+ supply pin, or is equal to

the voltage which is externally forced at the V

REF

/2 pin. This

allows for a pseudo-ratiometric voltage reference using, for

the V+ supply, a 5V reference voltage. Alternatively, a voltage less than 2.5V can be applied to the V

REF

/2 input. The

internal gain to the V

REF

/2 input is 2 to allow this factor of 2

reduction in the reference voltage.

Such an adjusted reference voltage can accommodate a

reduced span or dynamic voltage range of the analog input

voltage. If the analog input voltage w ere to r ange from 0.5V to

3.5V, instead of 0V to 5V, the span would be 3V. With 0.5V

applied to the V

lN(-)

pin to absorb the offset, the reference

voltage can be made equal to

1

/2 of the 3V span or 1.5V. The

A/D now will encode the V

lN(+)

signal from 0.5V to 3.5V with

the 0.5V input corresponding to zero and the 3.5V input corresponding to full scale. The full 8 bits of resolution are therefore

applied over this reduced analog input voltage r ange. The requisite connections are shown in Figure 13. For expanded

scale inputs, the circuits of Figures 14 and 15 can be used.

FIGURE 12. THE V

REFERENCE

DESIGN ON THE IC

FIGURE 13. OFFSETTING THE ZERO OF THE ADC0802 AND

PERFORMING AN INPUT RANGE (SPAN)

ADJUSTMENT

FIGURE 14. HANDLING ±10V ANALOG INPUT RANGE

V+

DGND

V

REF

/2

AGND

(V

REF

)

R

R

DIGITAL

CIRCUITS

ANALOG

CIRCUITS

9

810

20

DECODE

300

TO V

REF

/2

TO V

IN(-)

ZERO SHIFT VOLTAGE

0.1µF

5V

-

+

V

REF

(5V)

FS

ADJ.

“SPAN”/2

ICL7611

V

IN(-)

2R

5V

2R

V

IN

± 10V

R

V

IN(+)

(V

REF

)

V+

20

10µF

6

7

+

ADC0802-

ADC0804

ADC0802, ADC0803, ADC0804

Page 11

6-15

Reference Accuracy Requirements

The converter can be operated in a pseudo-ratiometric

mode or an absolute mode. In ratiometric converter applications, the magnitude of the reference voltage is a factor in

both the output of the source transducer and the output of

the A/D converter and therefore cancels out in the final digital output code. In absolute conversion applicatIons , both the

initial value and the temperature stability of the reference

voltage are important accuracy factors in the operation of the

A/D converter. For V

REF

/2 voltages of 2.5V nominal value,

initial errors of ±10mV will cause conversion errors of ±1

LSB due to the gain of 2 of the V

REF

/2 input. In reduced

span applications, the initial value and the stability of the

V

REF

/2 input voltage become even more important. For

example, if the span is reduced to 2.5V, the analog input LSB

voltage value is correspondingly reduced from 20mV (5V

span) to 10mV and 1 LSB at the V

REF

/2 input becomes

5mV. As can be seen, this reduces the allowed initial tolerance of the reference voltage and requires correspondingly

less absolute change with temperature variations. Note that

spans smaller than 2.5V place even tighter requirements on

the initial accuracy and stability of the reference source.

In general, the reference voltage will require an initial

adjustment. Errors due to an improper value of reference

voltage appear as full scale errors in the A/D transfer function. IC voltage regulators may be used for references if the

ambient temperature changes are not excessive.

Zero Error

The zero of the A/D does not require adjustment. If the

minimum analog input voltage value, V

lN(MlN)

, is not ground, a

zero offset can be done. The converter can be made to output

0000 0000 digital code for this minimum input voltage by biasing the A/D V

IN(-)

input at this V

lN(MlN)

value (see Applications

section). This utilizes the differential mode operation of the A/D.

The zero error of the A/D converter relates to the location of

the first riser of the transfer function and can be measured by

grounding the V

IN(-)

input and applying a small magnitude

positive voltage to the V

IN(+)

input. Zero error is the difference

between the actual DC input voltage which is necessary to

just cause an output digital code transition from 0000 0000 to

0000 0001 and the ideal

1

/2 LSB value (1/2 LSB = 9.8mV for

V

REF

/2 = 2.500V).

Full Scale Adjust

The full scale adjustment can be made by applying a

differential input voltage which is 1

1

/2 LSB down from the

desired analog full scale voltage range and then adjusting

the magnitude of the V

REF

/2 input (pin 9) for a digital output

code which is just changing from 1111 1110 to 1111 1111.

When offsetting the zero and using a span-adjusted V

REF

/2

voltage, the full scale adjustment is made by inputting V

MlN

to the V

IN(-)

input of the A/D and applying a voltage to the

V

IN(+)

input which is given by:

,

where:

V

MAX

= the high end of the analog input range,

and

V

MIN

= the low end (the offset zero) of the analog range.

(Both are ground referenced.)

Clocking Option

The clock for the A/D can be derived from an e xternal source

such as the CPU clock or an external RC network can be

added to provIde self-clocking. The CLK IN (pin 4) makes

use of a Schmitt trigger as shown in Figure 16.

Heavy capacitive or DC loading of the CLK R pin should be

avoided as this will disturb normal converter operation.

Loads less than 50pF, such as driving up to 7 A/D converter

clock inputs from a single CLK R pin of 1 converter, are

allowed. For larger clock line loading, a CMOS or low power

TTL buffer or PNP input logic should be used to minimize the

loading on the CLK R pin (do not use a standard TTL buffer).

Restart During a Conversion

If the A/D is restarted (

CS and WR go low and return high)

during a conversion, the converter is reset and a new conversion is started. The output data latch is not updated if the

conversion in progress is not completed. The data from the

previous conversion remain in this latch.

Continuous Conversions

In this application, the

CS input is grounded and the WR

input is tied to the

INTR output. This WR and INTR node

should be momentarily forced to logic low following a powerup cycle to insure circuit operation. See Figure 17 for details.

FIGURE 15. HANDLING ±5V ANALOG INPUT RANGE

V

IN(-)

R

5V

VIN±5V

R

V

IN(+)

(V

REF

)

V+

20

10µF

6

7

+

ADC0802-

ADC0804

V

IN +()fSADJVMAX

1.5

V

MAXVMIN

–()

256

-----------------------------------------

–=

CLK R

4

CLK IN

CLK

ADC0802-

ADC0804

f

CLK

≅

19

R

C

1

1.1 RC

R

≅10kΩ

FIGURE 16. SELF-CLOCKING THE A/D

ADC0802, ADC0803, ADC0804

Page 12

6-16

Driving the Data Bus

This CMOS A/D, like MOS microprocessors and memories,

will require a bus driver when the total capacitance of the

data bus gets large. Other circuItry, which is tied to the data

bus, will add to the total capacitive loading, even in threestate (high-impedance mode). Back plane busing also

greatly adds to the stray capacitance of the data bus.

There are some alternatives available to the designer to handle this problem. Basically, the capacitive loading of the data

bus slows down the response time, even though DC specifications are still met. For systems operating with a relatively

slow CPU clock frequency, more time is available in which to

establish proper logic levels on the bus and therefore higher

capacitive loads can be driven (see Typical Performance

Curves).

At higher CPU clock frequencies time can be extended for

I/O reads (and/or writes) by inserting wait states (8080) or

using clock-extending circuits (6800).

Finally, if time is short and capacitive loading is high,

external bus drivers must be used. These can be three-state

buffers (low power Schottky is recommended, such as the

74LS240 series) or special higher-drive-current products

which are designed as bus drivers. High-current bipolar bus

drivers with PNP inputs are recommended.

Power Supplies

Noise spikes on the V+ supply line can cause conversion

errors as the comparator will respond to this noise. A

low-inductance tantalum filter capacitor should be used

close to the converter V+ pin, and values of 1µF or greater

are recommended. If an unregulated voltage is available in

the system, a separate 5V voltage regulator for the con v erter

(and other analog circuitry) will greatly reduce digital noise

on the V+ supply. An lCL7663 can be used to regulate such

a supply from an input as low as 5.2V.

Wiring and Hook-Up Precautions

Standard digital wire-wrap sockets are not satisfactory for

breadboarding with this A/D converter. Sockets on PC

boards can be used. All logic signal wires and leads should

be grouped and kept as far a way as possible from the analog

signal leads. Exposed leads to the analog inputs can cause

undesired digital noise and hum pickup; therefore, shielded

leads may be necessary in many applications.

A single-point analog ground should be used which is separate

from the logic ground points. The power supply bypass capacitor and the self-clockIng capacitor (if used) should both be

returned to digital ground. Any V

REF

/2 bypass capacitors, analog input filter capacitors, or input signal shielding should be

returned to the analog ground point. A test for proper grounding

is to measure the zero error of the A/D converter. Zero errors in

excess of

1

/4 LSB can usually be traced to improper board

layout and wiring (see Zero Error for measurement). Further

information can be found in Application Note AN018.

Testing the A/D Converter

There are many degrees of complexity associated with testing

an A/D converter. One of the simplest tests is to apply a

known analog input voltage to the converter and use LEDs to

display the resulting digital output code as shown in Figure 18.

For ease of testing, the V

REF

/2 (pin 9) should be supplied

with 2.560V and a V+ supply voltage of 5.12V should be

used. This provides an LSB value of 20mV.

If a full scale adjustment is to be made, an analog input voltage of 5.090V (5.120 - 1

1

/2 LSB) should be applied to the

V

IN(+)

pin with the V

IN(-)

pin grounded. The value of the

V

REF

/2 input voltage should be adjusted until the digital output code is just changing from 1111 1110 to 1111 1111. This

value of V

REF

/2 should then be used for all the tests.

The digital-output LED display can be decoded by dividing the 8

bits into 2 hex characters, one with the 4 most-significant bits

(MS) and one with the 4 least-significant bits (LS). The output is

then interpreted as a sum of fractions times the full scale voltage:

.

For example, for an output LED display of 1011 0110, the

MS character is hex B (decimal 11) and the LS character is

hex (and decimal) 6, so:

.

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1

ADC0802 - ADC0804

WR

RD

CS

INTR

CLK IN

V

IN

(-)

V

IN

(+)

DGND

V

REF

/2

AGND

DB

1

DB

0

DB

4

DB

3

DB

2

DB

7

DB

6

DB

5

CLK R

V+

10K

5V (V

REF

)

10µF

+

DAT A

START

ANALOG

INPUTS

150pF

OUTPUTS

N.O.

MSB

LSB

FIGURE 17. FREE-RUNNING CONNECTION

V

OUT

MS

16

-------- -

LS

256

--------- -+

5.12()V=

START

VIN (+)

DGND

2.560V

AGND

10µF

150pF

N.O.

0.1µF

0.1µF

TANTALUM

5.120V

5V

1.3kΩ

LEDs

(8)

(8)

MSB

LSB

10kΩ

V

REF

/2

+

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1

ADC0802-

ADC0804

FIGURE 18. BASIC TESTER FOR THE A/D

V

OUT

11

16

------

6

256

--------- -+

5.12()3.64V==

ADC0802, ADC0803, ADC0804

Page 13

6-17

Figures 19 and 20 show more sophisticated test circuits.

Typical Applications

Interfacing 8080/85 or Z-80 Microprocessors

This converter has been designed to directly interface with

8080/85 or Z-80 Microprocessors. The three-state output

capability of the A/D eliminates the need for a peripheral

interface device, although address decoding is still required

to generate the appropriate

CS for the converter. The A/D

can be mapped into memory space (using standard memory-address decoding for

CS and the MEMR and MEMW

strobes) or it can be controlled as an I/O device by using the

I/OR and I/OW strobes and decoding the address bits A0 →

A7 (or address bits A8 → A15, since they will contain the

same 8-bit address information) to obtain the

CS input.

Using the I/O space provides 256 additional addresses and

may allow a simpler 8-bit address decoder, but the data can

only be input to the accumulator. To make use of the additional memory reference instructions, the A/D should be

mapped into memory space. See AN020 for more discussion of memory-mapped vs I/O-mapped interfaces. An

example of an A/D in I/O space is shown in Figure 21.

The standard control-bus signals of the 8080 (

CS, RD and

WR) can be directly wired to the digital control inputs of the

A/D, since the b us timing requirements , to allo w both starting

the converter, and outputting the data onto the data bus, are

met. A bus driver should be used for larger microprocessor

systems where the data bus leaves the PC board and/or

must drive capacitive loads larger than 100pF.

It is useful to note that in systems where the A/D converter is

1 of 8 or fewer I/O-mapped devices, no address-decoding

circuitry is necessary. Each of the 8 address bits (A0 to A7)

can be directly used as

CS inputs, one for each I/O device.

Interfacing the Z-80 and 8085

The Z-80 and 8085 control buses are slightly different from

that of the 8080. General

RD and WR strobes are provided

and separate memory request,

MREQ, and I/O request,

IORQ, signals have to be combined with the generalized

strobes to provide the appropriate signals. An advantage of

operating the A/D in I/O space with the Z-80 is that the CPU

will automatically insert one wait state (the

RD and WR

strobes are extended one clock period) to allow more time

for the I/O devices to respond. Logic to map the A/D in I/O

space is shown in Figure 22. By using

MREQ in place of

IORQ, a memory-mapped configuration results.

Additional I/O advantages exist as software DMA routines are

available and use can be made of the output data transfer

which exists on the upper 8 address lines (A8 to A15) during

I/O input instructions. For example, MUX channel selection for

the A/D can be accomplished with this operating mode.

The 8085 also provides a generalized

RD and WR strobe, with

an IO/

M line to distinguish I/O and memory requests. The cir-

cuit of Figure 22 can again be used, with IO/

M in place of IORQ

for a memory-mapped interface, and an extra inverter (or the

logic equivalent) to provide

IO/M for an I/O-mapped connection.

Interfacing 6800 Microprocessor Derivatives (6502, etc.)

The control bus for the 6800 microprocessor derivatives does

not use the RD and WR strobe signals. Instead it employs a

single R/W line and additional timing, if needed, can be derived

from the φ2 clock. All I/O devices are memory-mapped in the

6800 system, and a special signal, VMA, indicates that the current address is valid. Figure 23 shows an interface schematic

where the A/D is memory-mapped in the 6800 system. For simplicity, the CS decoding is shown using

1

/2 DM8092. Note that

in many 6800 systems, an already decoded

4/5 line is brought

out to the common bus at pin 21. This can be tied directly to the

CS pin of the A/D, provided that no other devices are

addressed at HEX ADDR: 4XXX or 5XXX.

In Figure 24 the ADC0802 series is interfaced to the MC6800

microprocessor through (the arbitrarily chosen) Port B of the

MC6820 or MC6821 Peripheral Interface Adapter (PlA). Here

the CS pin of the A/D is grounded since the PlA is already

memory-mapped in the MC6800 system and no CS decoding

is necessary. Also notice that the A/D output data lines are connected to the microprocessor bus under program control

through the PlA and therefore the A/D RD pin can be grounded.

Application Notes

ANALOG

INPUTS

“A”

R

“B”

R

R

R

“C”

100R

-

+

A2

8-BIT

A/D UNDER

TEST

10-BIT

DAC

V

ANALOG OUTPUT

100X ANALOG

-

+

A1

ERROR VOLTAGE

FIGURE 19. A/D TESTER WITH ANALOG ERROR OUTPUT . THIS

CIRCUIT CAN BE USED TO GENERATE “ERROR

PLOTS” OF FIGURE 11.

A/D UNDER

TEST

10-BIT

DAC

DIGITAL

V

ANALOG

INPUTS

DIGITAL

OUTPUTS

FIGURE 20. BASIC “DIGITAL” A/D TESTER

NOTE # DESCRIPTION

AnswerFAX

DOC. #

AN016 “Selecting A/D Converters” 9016

AN018 “Do’s and Don’ts of Applying A/D

Converters”

9018

AN020 “A Cookbook Approach to High Speed

Data Acquisition and Microprocessor

Interfacing”

9020

AN030 “The ICL7104 - A Binary Output A/D

Converter for Microprocessors”

9030

ADC0802, ADC0803, ADC0804

Page 14

6-18

NOTE: Pin numbers for 8228 System Controller: Others are 8080A.

FIGURE 21. ADC0802 TO 8080A CPU INTERFACE

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1

ADC0802 - ADC0804

WR

RD

CS

INTR

CLK IN

V

IN

(-)

V

IN

(+)

DGND

V

REF

/2

AGND

DB

1

DB

0

DB

4

DB

3

DB

2

DB

7

DB

6

DB

5

CLK R

V+

10K

5V

10µF

+

ANALOG

INPUTS

150pF

MSB

LSB

DB1(16) (NOTE)

DB0(13) (NOTE)

DB

4

(5) (NOTE)

DB

3

(9) (NOTE)

DB

2

(11) (NOTE)

DB

7

(7) (NOTE)

DB

6

(20) (NOTE)

DB

5

(18) (NOTE)

5V

AD15(36)

AD

14

(39)

AD

13

(38)

AD

12

(37)

AD

11

(40)

AD

10

(1)

8131

BUS

COMPARATOR

INT (14)

I/O RD (25) (NOTE)

I/O WR (27) (NOTE)

T

5

T

4

T

3

T

2

T

1

T

0

B

5

B

4

B

3

B

2

B

1

B

0

V+OUT

ADC0802, ADC0803, ADC0804

Page 15

6-19

FIGURE 22. MAPPING THE A/D AS AN

I/O DEVICE FOR USE

WITH THE Z-80 CPU

FIGURE 23. ADC0802 TO MC6800 CPU INTERFACE

FIGURE 24. ADC0802 TO MC6820 PIA INTERFACE

WR

RD

IORQ

RD

WR

74C32

ADC0802-

ADC0804

3

2

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1

ADC0802 - ADC0804

WR

RD

CS

INTR

CLK IN

V

IN

(-)

V

IN

(+)

DGND

V

REF

/2

AGND

DB

1

DB

0

DB

4

DB

3

DB

2

DB

7

DB

6

DB

5

CLK R

V+

10K

5V (8)

10µF

+

ANALOG

INPUTS

150pF

MSB

LSB

D1(32) [29]

D

0

(33) [31]

D

4

(29) [32]

D

3

(30) [H]

D

2

(31) [K]

D

7

(26) [J]

D6(27) [L]

D

5

(28) [30]

A12(22) [34]

A

13

(23) [N]

A

14

(24) [M]

A

15

(25) [33]

VMA (5) [F]

IRQ (4)† [D]††

R/W (34) [6]

1

2

3

4

5

6

1

/2 DM8092

A B C

1 2 3

† Numbers in parentheses refer to MC6800 CPU Pinout.

†† Numbers or letters in brackets refer to standard MC6800 System Common Bus Code.

11

12

13

14

15

16

17

18

20

19

10

9

8

7

6

5

4

3

2

1

ADC0802 - ADC0804

WR

RD

CS

INTR

CLK IN

V

IN

(-)

V

IN

(+)

DGND

V

REF

/2

AGND

DB

1

DB

0

DB

4

DB

3

DB

2

DB

7

DB

6

DB

5

CLK R

V+

10K

5V

ANALOG

INPUTS

150pF

MSB

LSB

11

10

14

13

12

17

16

15

PB

1

PB

0

PB

4

PB

3

PB

2

PB

7

PB

6

PB

5

MC6820

(MCS6520)

PIA

CB

2

CB

1

19

18

ADC0802, ADC0803, ADC0804

Page 16

6-20

Die Characteristics

DIE DIMENSIONS:

(101 mils x 93 mils) x 525µm x 25µm

METALLIZATION:

Type: Al

Thickness: 10k

Å ±1kÅ

PASSIVATION:

Type: Nitride over Silox

Nitride Thickness: 8k

Å

Silox Thickness: 7kÅ

Metallization Mask Layout

ADC0802, ADC0803, ADC0804

WR

RD

CS

CLK IN

INTRVIN (-) VIN (+)

DGND

V

REF

/2

AGND

V+ OR V

REF

CLK R

DB

0

DB

1

DB

2

DB

3

DB

4

DB

5

DB

6

DB

7 (MSB)

V+ OR V

REF

ADC0802, ADC0803, ADC0804

All Intersil semiconductor products are manufactured, assembled and tested under ISO9000 quality systems certification.

Intersil products are sold by description only. Intersil Corporation reserves the right to make changes in circuit design and/or specifications at any time without

notice. Accordingly, the reader is cautioned to verify that data sheets are current before placing orders. Information furnished by Intersil is believed to be accurate

and reliable. However, no responsibility is assumed by Intersil or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which

may result from its use. No license is granted by implication or otherwise under an y patent or patent rights of Intersil or its subsidiaries.

For information regarding Intersil Corporation and its products, see web site http://www.intersil.com

Loading...

Loading...