Page 1

查询ADAU1701供应商

SigmaDSP® 28/56-Bit Audio

FEATURES

28/56-bit, 50 MHz digital audio processor

Stereo ADC: 102 dB dynamic range and -90 dB THD+N

4-channel DAC: 103 dB dynamic range and -90 dB THD+N

Complete stand-alone operation

Self-boot from serial EEPROM

Auxiliary ADC with four-input mux for analog control

GPIOs for digital controls and outputs

Fully programable with SigmaStudio’ gr aphical tool

Sampling rates up to 192 kHz supported

28-bit × 28-bit multiplier with 56-bit accumulator

Double precision mode for full 56-bit processing

Clock Oscillator for generating master clock from crystal

PLL for generating master clock from 64 × f

, or 512 × fS clocks

384 × f

S

Flexible serial data I/O ports with I

2

S compatible, left-

, 256 × fS,

S

justified, right-justified, and TDM modes

On-chip voltage regulator for compatibility with 3.3 V

systems

48-lead LQFP plastic package

GENERAL DESCRIPTION

The ADAU1701 is a stand-alone 28/56-bit audio DSP that

handles all system processing and control tasks. Processing

includes equalization, crossover, bass enhancement, multiband

dynamics processing, delay compensation, speaker

compensation, and stereo image widening. These algorithms

can be used to compensate for the real-world limitations of

speakers, amplifiers, and listening environments, resulting in a

dramatic improvement of perceived audio quality.

The signal processing used in the ADAU1701 is comparable to

that found in high end studio equipment. Most of the

processing is done in full 56-bit double-precision mode,

resulting in very good low level signal performance. The

ADAU1701 is a fully-programmable DSP. The easy-to-use

SigmaStudio software allows the user to graphically configure a

custom signal processing flow using blocks such as biquad

Processor with 2ADC/4DAC

ADAU1701

APPLICATIONS

Multimedia speaker systems

MP3 player speaker docks

Automotive head units

Mini-component stereos

Digital televisions

Studio monitors

Speaker crossovers

Musical instrument effects processors

In-seat sound systems (aircraft/motor coaches)

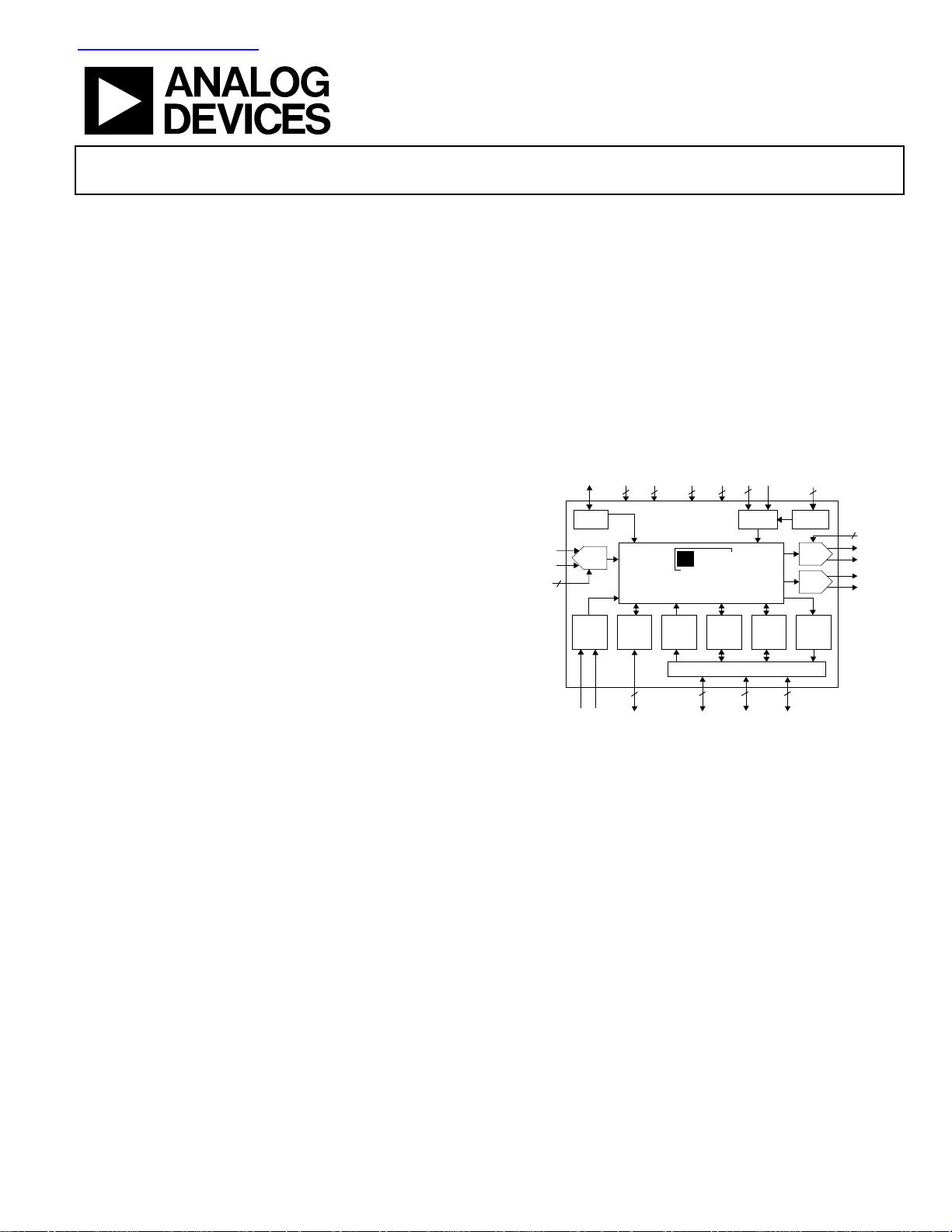

FUNCTIONAL BLOCK DIAGRAM

ANALOG

DIGITAL

2-CHANNEL

ANALOG

INPUT

FILTA/ IDAC

2

REGULATOR

RESET/

MODE

SELEC T

RESET

3.3 V

1.8 V

STEREO

ADC

SELF

BOOT

DIGITAL

VDD

CONTROL

INTER FACE

AND

SELFBO OT

I2C/SPI &

WRITEBACK

GROUND

3

3 3 3

5

ANALOG

VDD

GROUND

∑

∑

∑

DSP

PERFORMANCE AUDIO

AUDIO PRO CESSOR CORE

50 M Hz

40 ms DEL AY MEM OR Y

8-CH

DIGITAL

INPUT

8-BIT

AUX

ADC

INPUT/O UTPUT MATRIX

4 4 4

DIGITALIN

OR

GPIO

Figure 1.

filters, dynamics processors, level controls, and GPIO interface

controls.

ADAU1701 programs can be loaded on power-up either from a

serial EEPROM though its own self-boot mechanism or from

an external microcontroller. On power-down, the current state

of the parameters can be written back to the EEPROM from the

ADAU1701 to be recalled the next time the program is run.

The ADAU1701 s two ADCs and four DACs provide an analogin to analog-out dynamic range greater than 98 dB and THD+N

better than -92 dB. Digital input and output ports allow a

glueless connection to additional ADCs and DACs. The

ADAU1701 communicates through either an I

4-wire SPI port.

PLL

MODE

AUX ADC

OR

GPIO

2

PLL

GPIO

PLL

LOOP

FILTER

DIGITALOUT

GPIO

OR

CRYSTAL

2

CLOCK

OSCILLATOR

DAC

DAC

8-CH

DIGITAL

OUTPUT

2

C bus or a

FILTD/ CM

2

4-CHANNEL

ANALOG

OUTPUT

Rev. PrC

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2005 Analog Devices, Inc. All rights reserved.

Page 2

ADAU1701

TABLE OF CONTENTS

Features.............................................................................................. 1

Control Port Addressing ........................................................... 22

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Introduction ...................................................................................... 3

Specifications..................................................................................... 4

Analog Performance .................................................................... 4

Digital I/O ..................................................................................... 5

Power.............................................................................................. 5

Temperature Range ...................................................................... 5

Digital Timing............................................................................... 5

PLL ................................................................................................. 6

Regulator........................................................................................ 6

Absolute Maximum Ratings............................................................ 7

ESD Caution.................................................................................. 7

Digital Timing Diagrams................................................................. 8

Parameter RAM.......................................................................... 22

Recommended Program/Parameter Loading Procedure..... 23

Safeload Registers....................................................................... 23

Data Capture Registers.............................................................. 23

DSP Core Control Register....................................................... 24

Interface Registers...................................................................... 24

Control Port Read/Write Data Formats .................................. 24

Multipurpose Pins.......................................................................... 27

GPIO pin Setting Register......................................................... 27

Multi-Purpose pin Configuration Registers........................... 27

Auxiliary ADC............................................................................ 27

General Purpose Input/Outputs .............................................. 28

Serial Data Input/Output Ports ................................................ 28

Serial Output Control Registers ............................................... 30

Serial Input Control Register .................................................... 31

Pin Configuration and Function Descriptions........................... 11

Pin Functions .................................................................................. 13

Signal Processing ............................................................................ 15

Overview...................................................................................... 15

Numeric Formats........................................................................ 15

Programming.............................................................................. 15

Control Port.....................................................................................16

Overview...................................................................................... 16

SPI Port........................................................................................ 16

I2C Port ........................................................................................ 16

Self boot ....................................................................................... 19

RAMs and Registers ....................................................................... 22

REVISION HISTORY

9/05—Preliminary Version PrC1

Two-Channel Audio ADC ............................................................ 33

Four-Channel DAC ........................................................................ 34

Initialization.................................................................................... 35

Power-Up Sequence ................................................................... 35

Setting Master Clock/PLL Mode.............................................. 35

Voltage Regulator ....................................................................... 35

Layout Recommendations............................................................. 36

Parts Placement .......................................................................... 36

Grounding................................................................................... 36

Outline Dimensions....................................................................... 37

Ordering Guide .......................................................................... 37

Rev. PrC | Page 2 of 39

Page 3

INTRODUCTION

The core of the ADAU1701 is a 28-bit DSP (56-bit with double

precision) optimized for audio processing. The program and

parameter RAMs can be loaded with a custom audio processing

signal flow built with ADI’s SigmaStudio graphical

programming software. The values stored in the parameter

RAM control individual signal processing blocks, such as IIR

equalization filters, dynamics processors, audio delays, and

mixer levels. A safeload feature allows parameters to be

transparently updated without causing clicks on the output

signals.

The program RAM, parameter RAM, and register contents can

be saved in an external EEPROM, from which the ADAU1701

can self-boot on start-up. In this stand-alone mode, parameters

can be controlled through the on-board multipurpose pins.

The ADAU1701 can accept controls from switches,

potentiometers, rotary encoders, and IR receivers. Parameters

such as volume and tone settings can be saved to the EEPROM

on power-down and recalled when it is powered up again.

The ADAU1701 can operate with either digital I/Os, analog

I/Os, or a mix of both. The stereo ADC and four-channel DAC

have an analog-to-analog SNR of 97 dB. … The flexible serial

data input/output ports allow for glueless interconnection to a

variety of ADCs, DACs, general-purpose DSPs, S/PDIF

receivers & transmitters, and sample rate converters. The

ADAU1701 can be configured in I

justified, or TDM serial port compatible modes.

Twelve multi-purpose (MP) pins allow for the ADAU1701 to

input external control signals and output flags or controls to

other devices in the system. These MP pins can be configured

as digital I/Os, inputs to the 4-channel auxiliary ADC, or set up

as the serial data I/O ports. As inputs, they can be connected to

buttons, switches, rotary encoders, potentiometers, IR receivers,

or other external control circuitry to control the internal signal

processing program. When configured as outputs, these pins

can be used to drive LEDs (with a buffer), control other ICs, or

connect to other external circuitry in an application.

The ADAU1701 has a sophisticated control port that supports

complete read/write capability of all memory locations. Control

registers are provided to offer complete control of the chip’s

configuration and serial modes. Handshaking is included for

ease of memory uploads and downloads. The ADAU1701 can

be configured for either SPI or I

An on-board oscillator can be connected to an external crystal

to generate the master clock. Also, a master clock phase-locked

loop (PLL) allows the ADAU1701 to be clocked from a variety

of different clock speeds. The PLL can accept inputs of 64 × f

2

S, left-justified, right-

2

C control.

,

S

ADAU1701

256 × f

, 384 × fS, or 512 × fS to generate the core’s internal

S

master clock.

The SigmaStudio software is used to program and control the

SigmaDSP through the control port. Along with designing and

tuning a signal flow, the tools can configure the all registers and

burn a new program into the external EEPROM. SigmaStudio’s

graphical interface allows anyone with digital or analog audio

processing knowledge to easily design a DSP signal flow and

port it to a target application. It also provides enough flexibility

and programmability for an experienced DSP programmer to

have in-depth control of the design. In SigmaStudio, the user

can simply connect graphical blocks such as biquad filters,

dynamics processors, mixers, and delays, compile the design,

and load the program and parameter files into the ADAU1701’s

memory through the control port. Signal processing blocks

available in the provided libraries include

• Single- and double-precision biquad filters

• Mono and multichannel dynamics processors with peak or

RMS detection

• Mixers and splitters

• Tone and noise generators

• Fixed and variable gain

• Loudness

• Delay

• Stereo enhancement

• Dynamic bass boost

• Noise and tone sources

• Level detectors

• GPIO control & conditioning

More processing blocks are always in development. Analog

Devices also provides proprietary and third-party algorithms

for applications such as matrix decoding, bass enhancement,

and surround virtualizers. Please contact ADI for information

about licensing these algorithms.

The ADAU1701 operates from a 1.8 V digital power supply and

a 3.3 V analog supply. An on-board voltage regulator can be

used to operate the digital circuitry from a 3.3 V supply. It is

fabricated on a single monolithic integrated circuit and is

housed in a 48-lead LQFP package for operation over the –0°C

to +70°C temperature range.

Rev. PrC | Page 3 of 39

Page 4

ADAU1701

SPECIFICATIONS

Test conditions, unless otherwise noted.

Table 1.

Parameter Conditions

Analog Supply Voltage (AVDD)

Digital Supply Voltage (DVDD)

PLL Voltage (PVDD)

Output Voltage (IOVDD)

Ambient Temperature

Master Clock Input

Load Capacitance

Load Current

Input Voltage, HI

Input Voltage, LO

ANALOG PERFORMANCE

Table 2. Analog Performance

Parameter Min Typical Max Units Test Conditions/Comments

REFERENCE SECTION

Absolute Voltage V

V

Temperature Coefficient TBD ppm/°C

REF

AUX ANALOG INPUTS

Full Scale Analog Input 3.3 V

Step size 13 mV

ADC INPUTS

Number of channels 2 Stereo ADC

Resolution 24 Bits

Full Scale Analog Input

Signal-to-Noise Ratio

A-Weighted 100 dB

Dynamic Range -60dB with respect to full scale Analog input

A-Weighted TBD dB

Total Harmonic Distortion + Noise -95 dB -xxdB with respect to full scale Analog input

Interchannel Gain Mismatch TBD dB Left and Right channel Gain Mismatch

Crosstalk TBD dB Analog Channel Crosstalk

DC Bias TBD V

Gain Error TBD dB

Power Supply Rejection TBD dB 1kHz, 300mV

DAC OUTPUTS

Number of channels 4 2 stereo output channels

Resolution 24 Bits

Full Scale Analog Output 1 Vrms

Signal-to-Noise Ratio

A-Weighted 105 dB

Dynamic Range -60dB with respect to full scale Analog input

A-Weighted TBD dB

Total Harmonic Distortion + Noise -95 dB -xxdB with respect to full scale Analog input

Crosstalk TBD dB Analog Channel Crosstalk

Interchannel Gain Mismatch TBD dB Left and Right channel Gain Mismatch

DC Bias 1.5 V

Power Supply Rejection TBD dB 1kHz, 300mV

1.5 V

REF

100

μArms

2Vrms input with 20kΩ series resistor

Signal at AVDD

P-P

Signal at AVDD

P-P

Rev. PrC | Page 4 of 39

Page 5

ADAU1701

DIGITAL I/O

Table 3. Digital I/O

Parameter Min Max Unit

Input Voltage, HI (VIH) V

Input Voltage, LO (VIL) V

Input Leakage (IIH) μA

Input Leakage (IIL) μA

Low Level Output Voltage (VOL) IOVDD = x.x V, IOL = xx mA V

Low Level Output Voltage (VOL) IOVDD = x.x V, IOL = xx mA V

Input Capacitance pF

POWER

Table 4.

Parameter Comments Min Typ Max1 Unit

Supplies

Analog Voltage 3.3 V

Digital Voltage 1.8 V

PLL Voltage 3.3 V

Analog Current TBD mA

Digital Current TBD mA

PLL Current TBD mA

Analog Current, Reset TBD mA

Digital Current, Reset TBD mA

PLL Current, Reset TBD mA

Dissipation

Operation, all supplies TBD mW

Reset, all supplies TBD mW

1

Maximum specifications are measured across −xx°C to xx°C (case) and across VDD = xxx V to xxx V.

TEMPERATURE RANGE

Table 5.

Parameter Min Typ Max Unit

Functionality Guaranteed xx°C xx°C °C Ambient

xx°C xx°C °C Case

DIGITAL TIMING

Table 6 Digital Timing1

Parameter Comments Min Max Unit

tMP MCLK Period 512 fS mode ns

tMP MCLK Period 384 fS mode ns

tMP MCLK Period 256 fS mode ns

tMP MCLK Period 64 fS mode ns

tMP MCLK Period Bypass mode ns

t

MCLK Duty Cycle Bypass mode %

MDC

t

BCLK_IN LO Pulse Width ns

BIL

t

BCLK_IN HI Pulse Width ns

BIH

t

LRCLK_IN Setup To BCLK_IN rising ns

LIS

t

LRCLK_IN Hold From BCLK_IN rising ns

LIH

t

SDATA_INx Setup To BCLK_IN rising ns

SIS

t

SDATA_INx Hold From BCLK_IN rising ns

SIH

t

LRCLK_OUTx Setup Slave mode ns

LOS

t

LRCLK_OUTx Hold Slave mode ns

LOH

tTS

BCLK_OUTx Falling to

ns

Rev. PrC | Page 5 of 39

Page 6

ADAU1701

LRCLK_OUTx Timing Skew

t

SDATA_OUTx Delay Slave mode, from BCLK_OUTx falling ns

SODS

t

SDATA_OUTx Delay Master mode, from BCLK_OUTx falling ns

SODM

t

CCLK Pulse Width LO

CCPL

t

CCLK Pulse Width HI

CCPH

t

CLATCH Setup To CCLK rising ns

CLS

t

CLATCH Hold From CCLK rising

CLH

t

CLATCH Pulse Width HI

CLPH

t

CDATA Setup To CCLK rising ns

CDS

t

CDATA Hold From CCLK rising

CDH

t

COUT Delay From CCLK rising

COD

t

RESETB LO Pulse Width ns

RLPW

f

SCL Clock Frequency TBD kHz

SCL

t

SCL High TBD μS

SCLH

t

SCL Low TBD μS

SCLL

t

Setup Time Relevant for Repeated Start Condition TBD μS

SCS

t

Hold Time

SCH

After this period the 1st clock is

ns

ns

ns

ns

ns

ns

TBD μS

generated

tDS Data Setup Time TBD ns

t

SCL Rise Time TBD ns

SCR

t

SCL Fall Time TBD ns

SCF

t

SDA Rise Time TBD ns

SDR

t

SDA Fall Time TBD ns

SDF

1

All timing specifications are given for the default (I2S) states of the serial input control port and the serial output control ports. See

Table 40.

PLL

Table 7.

Parameter Min Typ Max Unit

Lock Time TBD ms

REGULATOR

Table 8.

Parameter Min Typ Max Unit

DVDD Voltage 1.8 V

Rev. PrC | Page 6 of 39

Page 7

ADAU1701

ABSOLUTE MAXIMUM RATINGS

Table 9.

Parameter Min Max Unit

DVDD to GND V

AVDD to GND V

IOVDD to GND V

Digital Inputs V

Maximum Junction Temperature 135 °C

Storage Temperature Range –65 +150 °C

Soldering (10 sec) 300 °C

Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only;

functional operation of the device at these or any other conditions above those indicated in the operational section of this specification is

not implied. Exposure to absolute maximum rating conditions for extended periods may affect device reliability.

Table 10. Package Characteristics

Parameter Min Typ Max Unit

θJA Thermal Resistance (Junction-to-Ambient) 72 °C/W

θJC Thermal Resistance (Junction-to-Case) 19.5 °C/W

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. PrC | Page 7 of 39

Page 8

ADAU1701

TYPICAL PERFORMANCE CHARACTERISTICS

Figure 2

Figure 3

Figure 5

Figure 6

Figure 4

Rev. PrC | Page 8 of 39

Page 9

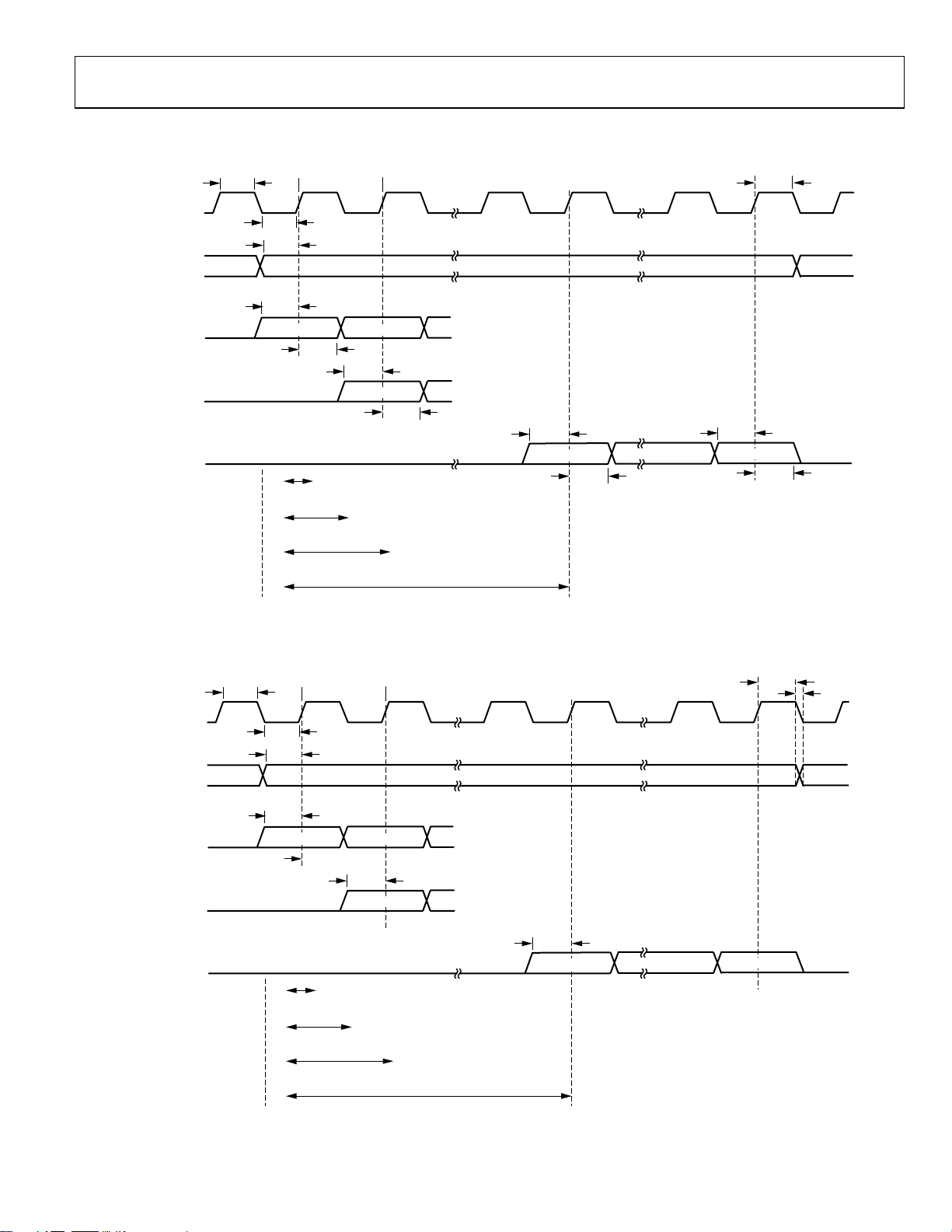

DIGITAL TIMING DIAGRAMS

t

BIH

BCLK_IN

t

BIL

t

LIS

LRCLK_IN

t

SDATA_INX

LEFT-JUSTIFIED

MODE

SDATA_INX

2

I

S-JUSTIFIED

MODE

SDATA_INX

RIGHT-JUSTIFIED

MODE

SIS

MSB

t

SIH

8-BIT CLOCKS

(24-BIT DATA)

12-BIT CLOCKS

(20-BIT DATA)

14-BIT CLOCKS

(18-BIT DATA)

16-BIT CLOCKS

(16-BIT DATA)

t

SIS

MSB-1

MSB

t

SIH

Figure 7. Serial Input Port Timing

ADAU1701

t

SIS

MSB

t

SIH

t

LIH

t

SIS

LSB

t

SIH

04607-0-013

BCLK_OUTX

LRCLK_OUTX

SDATA_OUTX

LEFT-JUSTIFIED

RIGHT-JUSTIFIED

MODE

SDATA_OUTX

2

I

S-JUSTIFIED

MODE

SDATA_OUTX

MODE

t

t

BIH

t

BIL

t

LOS

t

SDDS

t

SDDM

MSB

8-BIT CLOCKS

(24-BIT DATA)

12-BIT CLOCKS

(20-BIT DATA)

14-BIT CLOCKS

(18-BIT DATA)

16-BIT CLOCKS

(16-BIT DATA)

t

SDDS

t

SDDM

MSB-1

MSB

t

SDDS

t

SDDM

MSB

Figure 8. Serial Output Port Timing

LCH

LSB

t

TS

04607-0-014

Rev. PrC | Page 9 of 39

Page 10

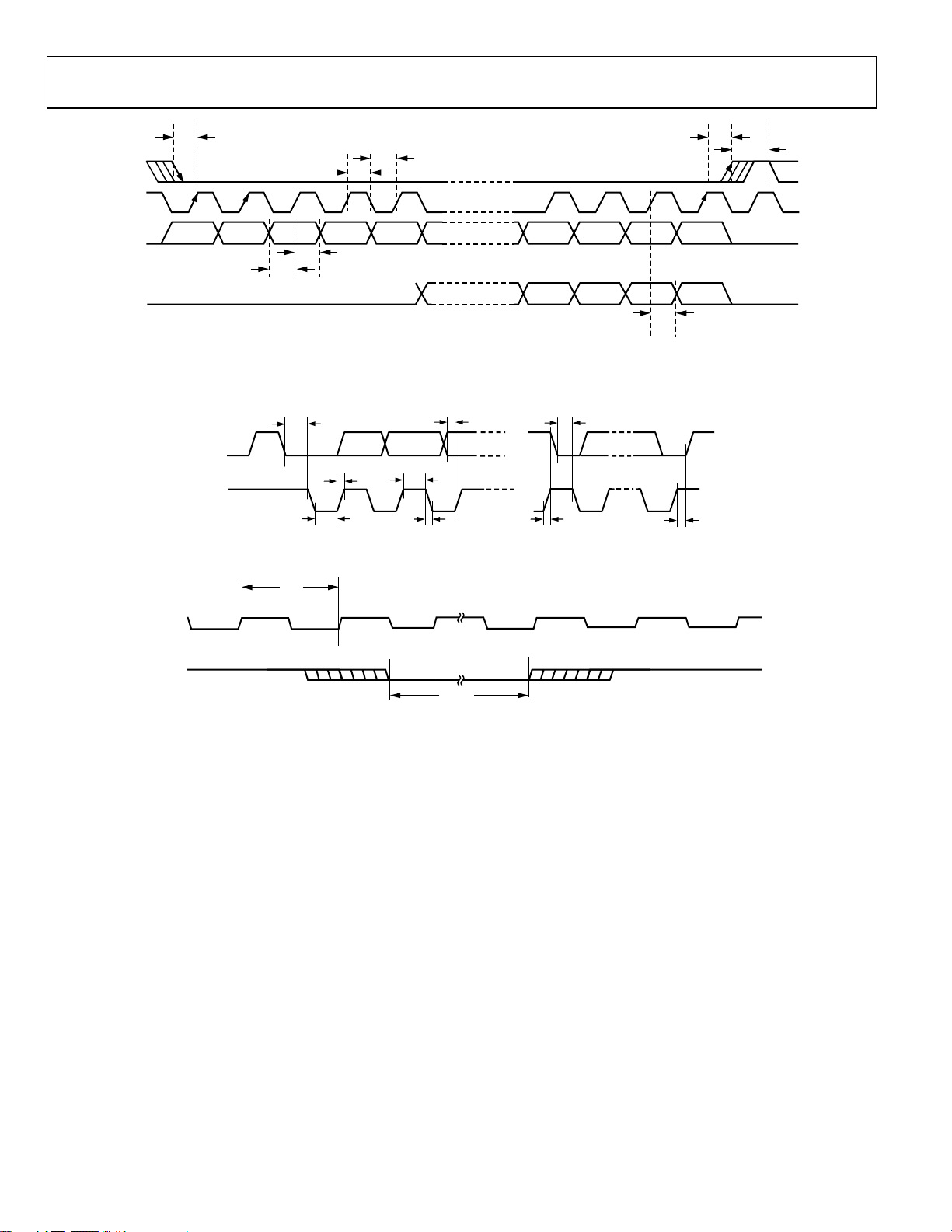

ADAU1701

CLATCH

CCLK

CDATA

COUT

t

CLS

t

CCPL

t

CDS

t

CCPH

t

CDH

Figure 9. SPI Port Timing

t

CLH

t

COD

t

CLPH

04607-0-015

t

DS

t

SCLH

t

ST

Figure 10. I

2

C Port Timing

t

TSCH

t

SCS

t

SSH

04607-026

SDA

SCLK

t

TSCH

t

SR

t

SCLL

t

MP

MCLK

RESETB

t

RLPW

Figure 11. Master Clock and Reset Timing

04607-0-016

Rev. PrC | Page 10 of 39

Page 11

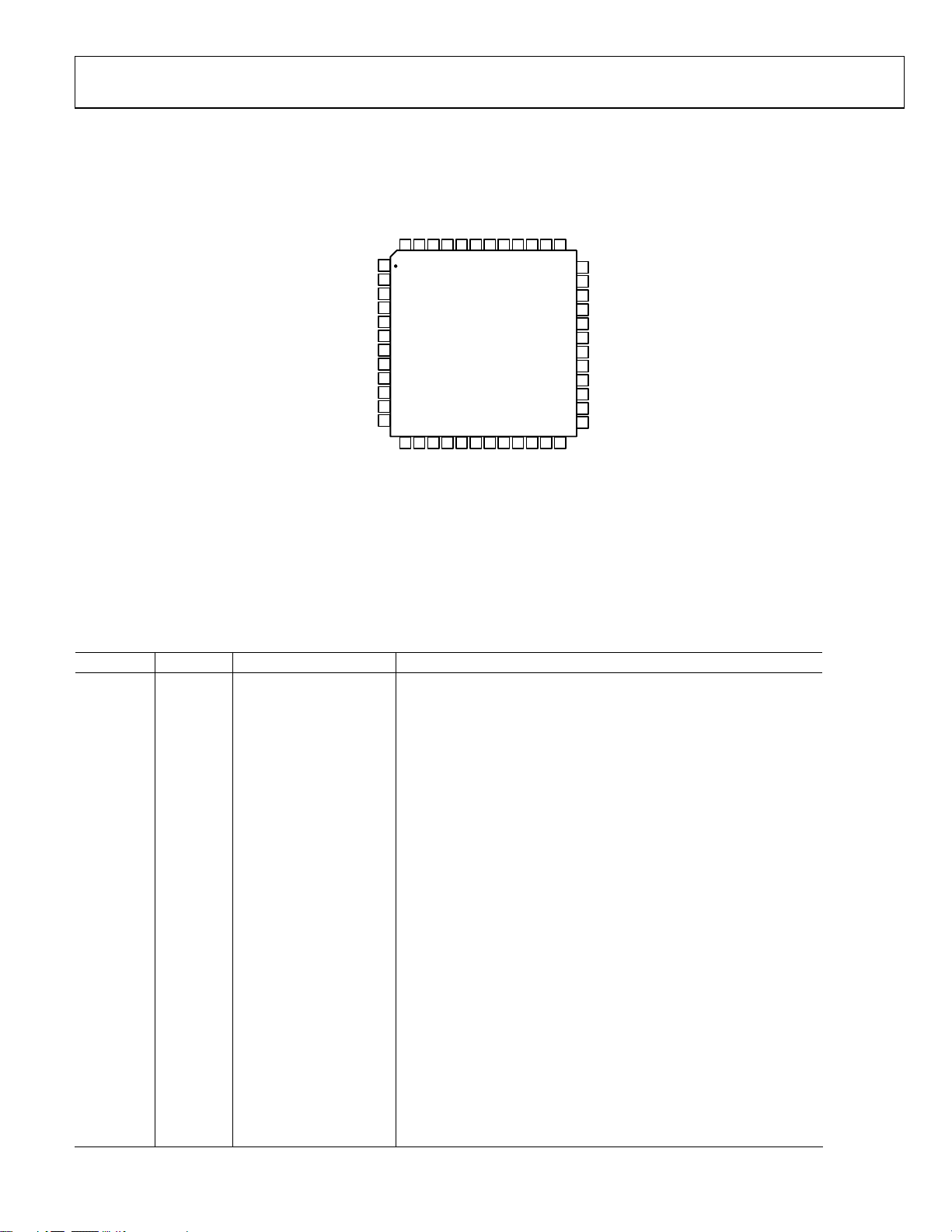

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

0

1

E

E

D

D

O

O

M

M

D

D

_

_

T

N

G

A

1

1

P

M

L

L

L

M

L

L

I

P

F

P

C

T

K

P

G

I

L

U

R

/W

C

O

T

H

C

/C

_

/

C

L

B

A

T

C

D

W

A

S

/

S

L

A

C

T

A

D

C

/

1

R

D

D

A

AGND

ADC1

ADC_RES

ADC0

RESETB

SELFBOOT

ADDR0

MP4

MP5

MP1

MP0

DGND

A

T

D

V

IL

A

F

48 47 46 45 44 39 38 3743 42 4 1 40

1

2

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

7

D

P

D

M

V

D

U

U

U

O

O

O

V

V

V

ADAU1701

TOP VIEW

(Not to Scale)

6

0

1

P

P

M

M

U

O

V

E

D

D

IV

V

R

D

IO

V

3

2

1

0

T

T

T

T

D

Figure 12. 48-Lead LQFP Pin Configuration

ADAU1701

D

N

G

A

36

AVDD

35

PLL_LF

34

PVDD

33

PGND

32

MCLKI

31

OSCO

30

RSVD

MP2

29

MP3

28

27

MP8

26

MP9

25

DGND

D

D

V

D

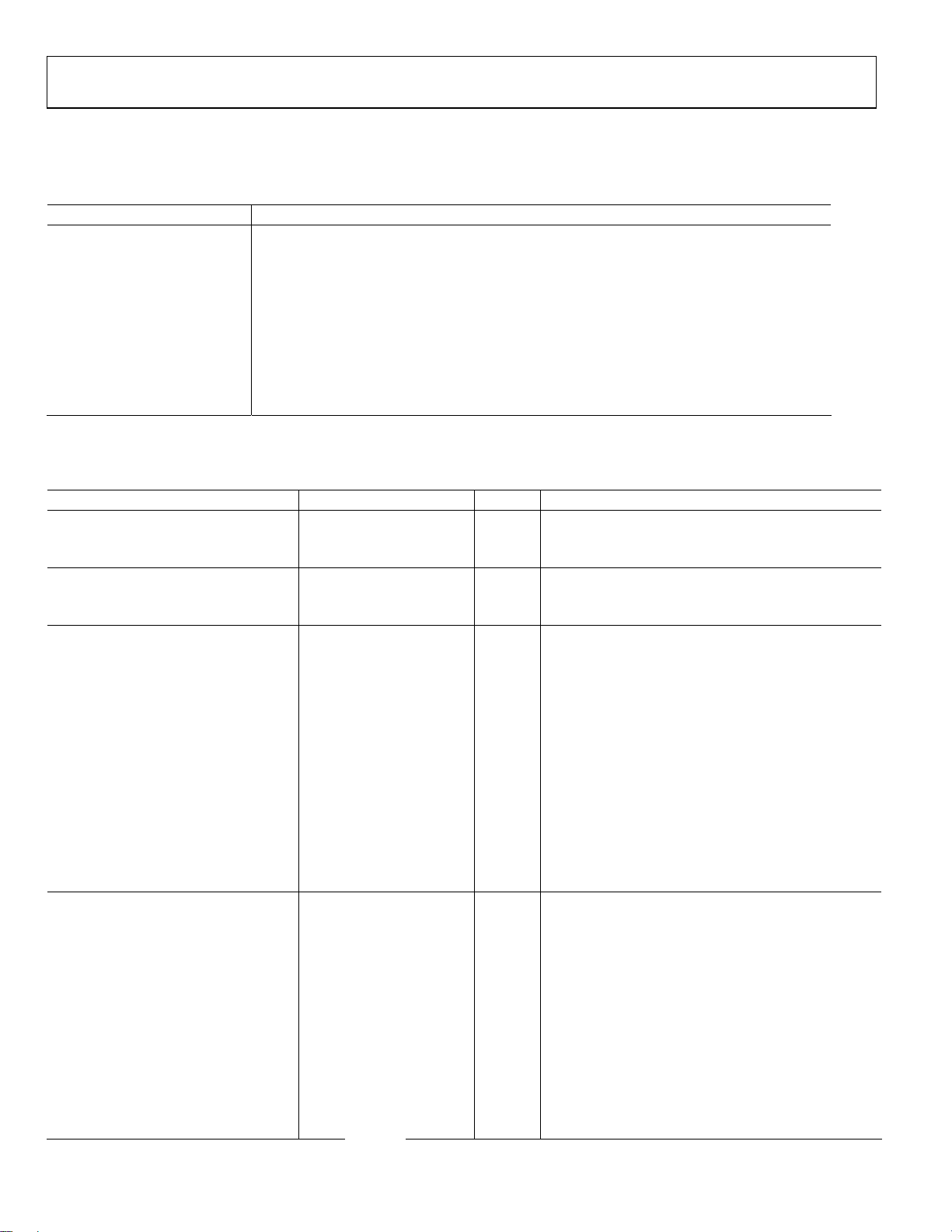

Table 11. Pin Function Descriptions

Pin No. I/O Mnemonic Description

1 AGND Analog Ground

2 IN ADC1 Analog input 1

3 ADC_RES Reference current – connect resistor

4 IN ADC0 Analog Input 0

5 IN RESETB Reset, Active Low

6 IN SELFBOOT Select Host or Self-boot mode

7 IN ADDR0 I2C and SPI Address 0

8 IN/OUT MP4 Multi-Purpose – GPIO or Serial input port LRCLK

9 IN/OUT MP5 Multi-Purpose – GPIO or Serial input port BCLK

10 IN/OUT MP1 Multi-Purpose – GPIO or Serial Input port data 1

11 IN/OUT MP0 Multi-Purpose – GPIO or Serial Input port data 0

12 DGND Digital Ground

13 DVDD 1.8 V Digital Supply

14 IN/OUT MP7 Multi-Purpose – GPIO or Serial output port data 1

15 IN/OUT MP6 Multi-Purpose – GPIO, Serial output port data 0, or TDM data output

16 IN/OUT MP10 Multi-Purpose – GPIO or Serial output port LRCLK

17 OUT VDRIVE Drive for external PNP Transistor for 1.8 V regulator

18 IOVDD Input and Output Pin Supply

19 IN/OUT MP11 Multi-Purpose – GPIO or Serial output port BCLK

20 IN ADDR1/CDATA/WB_TRIG I2C Address 1 / SPI Data Input / Self-boot Write-back trigger

21 IN/OUT CLATCH / WP SPI Latch / Self-boot EEPROM write protect

22 IN/OUT SDA/COUT I2C Data / SPI Data Out

23 IN/OUT SCL/CCLK I2C Clock / SPI Clock

24 DVDD 1.8 V Digital Supply

25 DGND Digital Ground

Rev. PrC | Page 11 of 39

Page 12

ADAU1701

26 IN/OUT MP9 Multi-Purpose – GPIO or Aux ADC input 0

27 IN/OUT MP8 Multi-Purpose – GPIO or Aux ADC input 3

28 IN/OUT MP3 Multi-Purpose – GPIO or Aux ADC input 2

29 IN/OUT MP2 Multi-Purpose – GPIO or Aux ADC input 1

30 RSVD Reserved, tie to ground

31 OUT OSCO Oscillator Output

32 IN MCLKI Master Clock or Crystal Input

33 PGND PLL Ground

34 PVDD 3.3 V PLL Power

35 PLL_LF PLL Loop Filter connection

36 AVDD 3.3 V Analog Supply

37 AGND Analog Ground

38 IN PLL_MODE0 PLL Mode select 0

39 IN PLL_MODE1 PLL Mode select 1

40 CM Common Mode Decoupling Capacitor

41 FILTD Decoupling Capacitor

42 AGND Analog Ground

43 OUT VOUT3 Channel 3 DAC output

44 OUT VOUT2 Channel 2 DAC output

45 OUT VOUT1 Channel 1 DAC output

46 OUT VOUT0 Channel 0 DAC output

47 FILTA Decoupling capacitor

48 AVDD 3.3 V Analog Supply

Rev. PrC | Page 12 of 39

Page 13

PIN FUNCTIONS

Table 11 shows the ADAU1701’s pin numbers, names, and

functions. Input pins have a logic threshold compatible with

TTL input levels and may be used in systems with 3.3 V logic.

ADAU1701

SDA

I2C Serial Data. The data line is bidirectional. The line

connected to this pin should have a 2 kΩ pull-up resistor on it.

ADC0

ADC1

Stereo ADC inputs.

IDAC

Bias current pin for ADC. A resistor with the same value as

those on the ADC0 & ADC1 should be connected between this

pin and ground.

FILTA

ADC decoupling pin. A 10 μF capacitor should be placed

between this pin and ground.

VOUT0

VOUT1

VOUT2

VOUT3

Four-channel DAC outputs

CM

Reference. A 47 μF capacitor should be placed between this pin

and ground to reduce crosstalk.

FILTD

DAC decoupling pin. A 10 μF capacitor should be placed

between this pin and ground.

PLL_MODE0

PLL_MODE1

PLL Mode Control Pins. The functionality of these pins is

described in the Setting Master Clock/PLL Mode section.

MCLKI

Master clock or crystal oscillator input.

OSCO

Crystal oscillator output.

PLL_LF

PLL loop filter connection.

SCL

I2C Clock. This pin is always an input when in I2C control

mode. In self-boot mode this pin will be an output (I

master). The line connected to this pin should have a 2 kΩ

pull-up resistor on it.

2

C

CDATA

Serial Data Input for the SPI Control Port.

COUT

Serial Data Output for the SPI Port. This is used for reading

back registers and memory locations. It is three-stated when an

SPI read is not active.

CCLK

SPI Bit Clock. This clock may either run continuously or be

gated off in between SPI transactions.

CLATCH

SPI Latch Signal. This must go low at the beginning of an SPI

transaction and high at the end of a transaction. Each SPI

transaction may take a different number of CCLKs to complete,

depending on the address and read/write bit that are sent at the

beginning of the SPI transaction.

ADDR0

ADDR1

Address Select. These pins select the address for the

ADAU1701’s communication with the control port. This allows

two ADAU1701s to be used on the same control port.

WP

EEPROM write protect.

WB_TRIG

EEPROM Writeback trigger.

RESETB

Active-Low Reset Signal. After RESETB goes high, the

ADAU1701 goes through an initialization sequence where the

program and parameter RAMs are initialized with the contents

of the on-board boot ROMs. All registers are set to 0, and the

data RAMs are also set to 0. The initialization is complete after

xxxx internal MCLK cycles (referenced to the rising edge of

RESETB), which corresponds to xxxx external MCLK cycles if

the part is in 256 × f

to the control port until the initialization is complete.

mode. New values should not be written

S

SELFBOOT

Selfboot or external program load select.

Rev. PrC | Page 13 of 39

Page 14

ADAU1701

MP0

MP1

MP2

MP3

MP4

MP5

MP6

MP7

MP8

MP9

MP10

MP11

Multi-purpose input/output pins. These pins can be configured

as serial data inputs/outputs, auxiliary ADC inputs, or general

purpose switch and button inputs/outputs.

DVDD

Digital VDD for Core. 1.8 V nominal.

DGND

Digital Ground.

IOVDD

Input and Output pins supply.

PVDD

PLL and aux ADC supply.

PGND

PLL and aux ADC ground.

VDRIVE

Drive for External Transistor. The base of the voltage regulator’s

external PNP transistor is driven from this pin.

AVDD

Analog VDD for Core. 3.3 V nominal.

AGND

Analog Ground.

RSVD

This pin should be tied to ground.

Rev. PrC | Page 14 of 39

Page 15

SIGNAL PROCESSING

OVERVIEW

The ADAU1701 is designed to provide all signal processing

functions commonly used in stereo or multichannel playback

systems. The signal processing flow is designed using the ADIsupplied SigmaStudio software, which allows graphical entry

and real-time control of all signal processing functions.

Many of the signal processing functions are coded using full,

56-bit double-precision arithmetic. The input and output word

lengths are 24 bits. Four extra headroom bits are used in the

processor to allow internal gains up to 24 dB without clipping.

Additional gains can be achieved by initially scaling down the

input signal in the signal flow.

The signal processing blocks can be arranged in a custom program that can be loaded to the ADAU1701’s RAM. The

available signal processing blocks are explained in the following

sections.

NUMERIC FORMATS

It is common in DSP systems to use a standardized method of

specifying numeric formats. Fractional number systems are

specified by an A.B format, where A is the number of bits to the

left of the decimal point and B is the number of bits to the right

of the decimal point.

The ADAU1701 uses the same numeric format for both the

coefficient values (stored in the parameter RAM) and the signal

data values. The format is as follows:

Numerical Format: 5.23

Range: –16.0 to (+16.0 − 1 LSB)

Examples:

1000 0000 0000 0000 0000 0000 0000 = –16.0

1110 0000 0000 0000 0000 0000 0000 = –4.0

1111 1000 0000 0000 0000 0000 0000 = –1.0

ADAU1701

1111 1110 0000 0000 0000 0000 0000 = –0.25

1111 1111 1111 1111 1111 1111 1111 = (1 LSB below 0.0)

0000 0000 0000 0000 0000 0000 0000 = 0.0

0000 0010 0000 0000 0000 0000 0000 = 0.25

0000 1000 0000 0000 0000 0000 0000 = 1.0

0010 0000 0000 0000 0000 0000 0000 = 4.0

0111 1111 1111 1111 1111 1111 1111 = (16.0 – 1 LSB).

The serial port accepts up to 24 bits on the input and is signextended to the full 28 bits of the core. This allows internal

gains of up to 24 dB without encountering internal clipping.

A digital clipper circuit is used between the output of the DSP

core and the outputs (see Figure 13). This clips the top four bits

of the signal to produce a 24-bit output with a range of 1.0

(minus 1 LSB) to –1.0.

4-BIT SIGN EXTENSION

DATA IN SERIAL PORT

1.23 5.23

Figure 13. Numeric Precision and Clipping Structure

SIGNAL PROCESSING

(5.23 FORMAT)

PROGRAMMING

On power-up, the ADAU1701’s default program passes the

unprocessed input signals to the outputs (Figure 27), but the

outputs are muted by default (see Power-Up Sequence section).

There are 1,024 instruction cycles per audio sample, resulting in

an internal clock rate of 49.152 MHz (for f

runs in a stream-oriented manner, meaning all 1,024

instructions are executed each sample period. The ADAU1701

may also be set up to accept double or quad-speed inputs by

reducing the number of instructions/sample, which can be set

in the core control register.

The part can be programmed easily using SigmaStudio, a

graphical tool provided by Analog Devices. No knowledge of

writing line-level DSP code is required.

s

DIGITAL

CLIPPER

5.23 1.23

= 48 kHz). This DSP

04607-0-005

Rev. PrC | Page 15 of 39

Page 16

ADAU1701

CONTROL PORT

OVERVIEW

The ADAU1701 has many different control options that can be

set through an SPI or I

4-wire SPI control port, and a 2-wire I

power-up, the part defaults to I

SPI control mode by pulling pin CLATCH/WP low three times.

The control port is capable of full read/write operation for all of

the memories and registers. Most signal processing parameters

are controlled by writing new values to the parameter RAM

using the control port. Other functions, such as mute and

input/output mode control, are programmed by writing to the

control registers.

All addresses may be accessed in both a single-address mode or

a burst mode. A control word consists of the chip address, the

register/RAM subaddress, and the data to be written. The

number of bytes per word depends on the type of data that is

written.

The first byte of a control word (Byte 0) contains the 7-bit chip

address plus the R/W bit. The next two bytes (Bytes 1 and 2)

together form the subaddress of the memory or register

location within the ADAU1701. This subaddress needs to be

two bytes because the memories within the ADAU1701 are

directly addressable, and their sizes exceed the range of singlebyte addressing. All subsequent bytes (Bytes 3, 4, etc.) contain

the data, such as control port data or program or parameter

data. The exact formats for specific types of writes are shown in

Table 22 to Table 30.

The ADAU1701 has several mechanisms for updating signal

processing parameters in real time without causing pops or

clicks. In cases where large blocks of data need to be downloaded, the output of the DSP core can be halted (using Bit x of

the core control register), new data loaded, and then restarted.

This is typically done during the booting sequence at start-up or

when loading a new program into RAM. In cases where only a

few parameters need to be changed, they can be loaded without

halting the program. To avoid unwanted side effects while

loading parameters on the fly, the SigmaDSP provides the

safeload registers. The safeload registers can be used to buffer a

full set of parameters (e.g. the five coefficients of a biquad) and

then transfer these parameters into the active program within

one audio frame. The safeload mode uses internal logic to

prevent contention between the DSP core and the control port.

SPI PORT

The SPI port uses a 4-wire interface, consisting of CLATCH,

CCLK, CDATA, and COUT signals. The CLATCH signal goes

low at the beginning of a transaction and high at the end of a

transaction. The CCLK signal latches CDATA on a low-to-high

transition. COUT data is shifted out of the ADAU1701 on the

2

C interface. The ADAU1701 has both a

2

C bus control port. At

2

C mode, but can be put into

falling edge of CCLK and should be clocked into the receiving

device, such as a microcontroller, on CCLK’s rising edge. The

CDATA signal carries the serial input data, and the COUT

signal is the serial output data. The COUT signal remains threestated until a read operation is requested. This allows other SPIcompatible peripherals to share the same readback line. All SPI

transactions follow the same basic format, shown in Table 12. A

timing diagram is shown in Figure 9. All data written should be

MSB-first.

Table 12. Generic Control Word Format

Byte 4,

Byte 0 Byte 1 Byte 2 Byte 3

chip_adr [6:0],

R/W

0000,

subadr

[11:8]

subadr[7:0] data data

etc.

Chip Address R/W

The first byte of an SPI transaction includes the 7-bit chip

address and a R/

bit. The chip address is set by the ADR_SEL

W

pin. This allows two ADAU1701s to share a CLATCH signal,

yet still operate independently. When ADR_SEL is low, the chip

address is 0000000; when it is high, the address is 0000001. The

LSB of this first byte determines whether the SPI transaction is

a read (Logic Level 1) or a write (Logic Level 0).

Subaddress

The 12-bit Subaddress word is decoded into a location in one of

the memories or registers. This subaddress is the location of the

appropriate RAM location or register.

Data Bytes

The number of data bytes varies according to the register or

memory being accessed. In burst write mode, an initial

subaddress is given followed by a continuous sequence of data

for consecutive memory/register locations. The detailed data

format diagram for continuous-mode operation is given in the

Control Port Read/Write Data Formats section.

A sample timing diagram for a single SPI write operation to the

parameter RAM is shown in Figure 14. A sample timing

diagram of a single SPI read operation is shown in Figure 15.

The COUT pin goes from three-state to driven at the beginning

of Byte 3. In this example, Bytes 0 to 2 contain the addresses and

R/W bit, and subsequent bytes carry the data.

I2C PORT

The ADAU1701 supports a 2-wire serial (I2C compatible)

micro-processor bus driving multiple peripherals. Two pins,

serial data (SDA) and serial clock (SCL), carry information

between the ADAU1701 and the system I

The ADAU1701 is always a slave on the I

that it will never initiate a data transfer. Each slave device is

2

C master controller.

2

C bus, which means

Rev. PrC | Page 16 of 39

Page 17

recognized by a unique address. The address byte format is

shown in Table 13. The ADAU1701 has four possible slave

addresses: two for writing operations and two for reading.

These are unique addresses for the device and are illustrated in

Table 14. The LSB of the byte sets either a read or write

operation; Logic Level 1 corresponds to a read operation, and

Logic Level 0 corresponds to a write operation. The sixth and

seventh bits of the address are set by tying the ADDRx pins of

the ADAU1701 to logic level 0 or logic level 1.

Table 13. ADAU1701 Address Byte Format

Bit 0 Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7

0 1 1 0 1 ADDR1 ADDR0

R/W

Table 14. ADAU1701 I2C Addresses

ADDR1 ADDR0

0 0 0 0x68

0 0 1 0x69

0 1 0 0x6A

0 1 1 0x6B

1 0 0 0x6C

1 0 1 0x6D

1 1 0 0x6E

1 1 1 0x6F

Read/

Write

Slave Address

Addressing

Initially, all devices on the I2C bus are in an idle state, which is

where the devices monitor the SDA and SCL lines for a start

condition and the proper address. The I

2

C master initiates a

data transfer by establishing a Start condition, defined by a

high-to-low transition on SDA while SCL remains high. This

indicates that an address/data stream will follow. All devices on

the bus respond to the start condition and shift the next eight

bits (7-bit address + R/

bit) MSB first. The device that

W

recognizes the transmitted address responds by pulling the data

line low during the ninth clock pulse. This ninth bit is known as

an acknowledge bit. All other devices withdraw from the bus at

this point and return to the idle condition. The R/

W

bit

determines the direction of the data. A logic 0 on the LSB of the

first byte means the master will write information to the

peripheral. A logic 1 on the LSB of the first byte means the

master will read information from the peripheral. A data

transfer takes place until a stop condition is encountered. A stop

condition occurs when SDA transitions from low to high while

2

SCL is held high. Figure 16 shows the timing of an I

C write.

Burst mode addressing, where the subaddresses are automatically incremented at word boundaries, can be used for writing

large amounts of data to contiguous memory locations. This

increment happens automatically if a stop condition is not

encountered after a single-word write. The registers and

memories in the ADAU1701 range in width from one to five

bytes, so the autoincrement feature knows the mapping between

ADAU1701

sub-addresses and the word length of the destination register

(or memory location). A data transfer is always terminated by a

stop condition.

Stop and start conditions can be detected at any stage during

the data transfer. If these conditions are asserted out of

sequence with normal read and write operations, these cause an

immediate jump to the idle condition. During a given SCL high

period, the user should only issue one start condition, one stop

condition, or a single stop condition followed by a single start

condition. If an invalid subaddress is issued by the user, the

ADAU1701 does not issue an acknowledge and returns to the

idle condition. If the user exceeds the highest subaddress while

in autoincrement mode, one of two actions will be taken. In

read mode, the ADAU1701 outputs the highest subaddress

register contents until the master device issues a noacknowledge, indicating the end of a read. A no-acknowledge

condition is where the SDA line is not pulled low on the ninth

clock pulse on SCL. If the highest subaddress location is

reached while in write mode, the data for the invalid byte is not

loaded into any subaddress register, a no-acknowledge is issued

by the ADAU1701, and the part returns to the idle condition.

I2C Read & Write Operations

Figure 18 shows the timing of a single-word write operation.

Every ninth clock, the ADAU1701 issues an acknowledge by

pulling SDA low.

Figure 19 shows the timing of a burst mode write sequence.

This figure shows an example where the target destination

registers are two bytes. The ADAU1701 knows to increment its

subaddress register every two bytes because the requested

subaddress corresponds to a register or memory area with a

2-byte word length.

The timing of a single word read operation is shown in

Figure 20. Note that the first R/

bit is still a 0, indicating a

W

write operation. This is because the subaddress still needs to be

written in order to set up the internal address. After the

ADAU1701 acknowledges the receipt of the subaddress, the

master must issue a repeated start command followed by the

chip address byte with the R/

set to 1 (read). This causes the

W

ADAU1701’s SDA to turn around and begin driving data back

to the master. The master then responds every ninth pulse with

an acknowledge pulse to the ADAU1701.

Figure 21 shows the timing of a burst-mode read sequence. This

figure shows an example where the target read registers are two

bytes. The ADAU1701 knows to increment its subaddress

register every two bytes because the requested subaddress

corresponds to a register or memory area with word lengths of

two bytes. Other address ranges may have a variety of word

lengths ranging from one to five bytes; the ADAU1701 always

decodes the subaddress and sets the autoincrement circuit so

Rev. PrC | Page 17 of 39

Page 18

ADAU1701

that the address increments after the appropriate number of

bytes.

CLATCH

CCLK

CDATA

BYTE 0 BYTE 1 BYTE 2 BYTE 3

04607-0-006

Figure 14. SPI Write format (Single-Write Mode)

CLATCH

CCLK

CDATA

COUT

BYTE 0

HI-Z

BYTE 1

DATA

DATA DATA

HI-Z

04607-0-007

Figure 15. SPI Read Format (Single-Read Mode)

SCK

SDA

START BY

MASTER

0

00 0

00

FRAME 1

CHIP ADDRESS BYTE

ADR

SEL

R/W

ADAU1421

ACK. BY

FRAME 2

SUBADDRESS BYTE 1

ACK. BY

ADAU1421

SCK

(CONTINUED)

SDA

(CONTINUED)

FRAME 2

SUBADDRESS BYTE 2

ACK. BY

ADAU1421

FRAME 3

DATA BYTE 1

ACK. BY

ADAU1421

STOP BY

MASTER

Figure 16. ADAU1701 I2C Write Format

Rev. PrC | Page 18 of 39

Page 19

ADAU1701

SCK

S

SDA

START BY

MASTER

SCK

(CONTINUED)

SDA

(CONTINUED)

SCK

(CONTINUED)

SDA

(CONTINUED)

Chip

Address,

= 0

R/W

AS

CHIP ADDRESS BYTE

SUBADDRESS BYTE 2

READ DATA BYTE 1

Subaddress

High

FRAME 1

FRAME 3

FRAME 5

AS

ADR

R/W

SEL

Figure 17. ADAU1701 I2C Read Format

Subaddress

Low

ACK. BY

ADAU1421

ACK. BY

ACK. BY

MASTER

REPEATED

START BY

MASTER

AS

Data Byte

ADAU1421

1

Figure 18. Single-Word I2C Write

FRAME 2

SUBADDRESS BYTE 1

FRAME 4

CHIP ADDRESS BYTE

FRAME 6

READ DATA BYTE 2

AS

Data Byte

2

ACK. BY

ADAU1421

ADR

SEL

ACK. BY

MASTER

… AS

R/W

ACK. BY

ADAU1421

STOP BY

MASTER

Data Byte

N

P

Chip

Address,

W

= 0

R/

Subaddress

High

Subaddress

Low

Figure 19. Burst Mode I2C Write

S

Chip

Address,

= 0

R/W

AS

Subaddress

High

AS

Subaddress

Low

AS S

Figure 20. Single Word I2C Read

S

Chip

Address,

= 0

R/W

S - Start Bit

P - Stop Bit

AM - Acknowledge by Master

AS - Acknowledge by Slave

AS

Subaddress

High

AS

Subaddress

Low

Figure 21. Burst Mode I2C Read

SELF BOOT

The ADAU1701 can load a set of program and parameters that

has been saved in an external EEPROM on power-up.

Data

Word

1,

Byte 1

Chip

Address,

R/W

AS S

Data

Word 1,

Byte 2

AS

Data

Byte 1

AM

Data

Word 2,

Byte 1

Data

Byte 2

Data

Word 2,

Byte 2

… AM

Data

Byte N

= 1

Chip

Address,

R/W = 1

AS

Data

Word 1,

Byte 1

AM

Data

Word 1,

Byte 2

AM … P

Combined with the auxiliary ADC and the GPIO pins, this

eliminates the need for a microcontroller in the system. The

self-booting is accomplished by the ADAU1701 acting as a

P

Rev. PrC | Page 19 of 39

Page 20

ADAU1701

master on the I2C bus on start-up, which occurs when the

Selfboot pin is set high. The ADAU1701 cannot self-boot in

SPI mode.

The maximum necessary EEPROM size is about 9 kB. This

much memory will only be needed if the program RAM (1024

× 5 bytes), parameter RAM (1024 × 4 bytes), and interface

registers (8 × 4 bytes) are each completely full. In most

applications, an 8 kB EEPROM will be sufficient.

2

Pin I

C Mode SPI Mode Selfboot

Mode

EEPROM format

The EEPROM contains a sequence of messages. Each message

may be one of:

Write bytes

Delay

Set write back multiple times

Set write back falling edge sensitive

End of messages

SCL/CCLK SCL - input CCLK -

SCL - output

input

SDA/COUT SDA – open

collector

output

ADDR1/CDAT

ADDR1 - input CDATA -

A/WB_TRIG

CLATCH/WP unused input –

tie to ground

or VDD

COUT –

output

input

CLATCH

- input

SDA – open

collector

output

trigger

writeback

EEPROM

Write Protect

- open

collector

output

Also used as

input. Attach

resistor to

3.3V VDD

ADDR0 ADDR0 - input ADDR0 -

input

unused input

– tie to

ground or

VDD

A selfboot operation is triggered on the rising edge of RESETB

when the SELFBOOT and WP pins are set high. The

ADAU1701 reads a program, parameters, and register settings

from the EEPROM. Once the ADAU1701 has finished

selfbooting, further messages may be sent to the ADAU1701 on

2

C bus, although this typically won’t be necessary in a

the I

selfbooting application. The I

write and 0x69 for a read in this mode. The ADDRx pins have

different functions if the chip is used in this mode, so the

settings on them are ignored.

The ADAU1701 will selfbooot only if WP is set low. This

allows the EEPROM to be programmed in-circuit. The WP

signal must be pulled low (it would normally have a resistor

pull-up) to enable writes to the EEPROM and this disables

selfboot until WP is taken high.

2

C device address is 0x68 for a

End of messages and wait for a writeback

No-op message

Each message consists of a sequence of one or more bytes. The

first byte determines the message type and must be one of the

following shown in Table 15. Bytes are written MSB-first.

Table 15. EEPROM Message Types

Message Byte Message Type Following Bytes

0x00 End none

0x01 Write 2 bytes for length

followed by data bytes

0x02 Delay 2 bytes for delay

0x03 No-Op none

0x04 Set multiple write

none

back

0x05 Set to falling edge

none

sensitive

0x06 End and wait for

none

writeback

Most messages will be block write (0x01) types.

The body of the message following the message type should

start with a 0x00 byte – this is the chip address. After this there

is always a 2-byte register/memory address field, as there is with

2

all other I

C or SPI transactions.

WriteBack

A writeback occurs when data is written to the EEPROM from

the ADAU1701. This function is typically used to save volume

and other parameter settings to the EEPROM just before power

is removed from the system. A writeback is triggered by a

rising edge on the WB_TRIG pin when the ADAU1701 is in

selfboot mode, unless a Set Falling To Edge Sensitive (0x05)

message was contained in the selfboot message sequence. Only

one write back will take place unless a Set Multiple Write Back

Rev. PrC | Page 20 of 39

Page 21

(0x04) message was contained in the selfboot message

sequence). The ADAU1701 is only capable of writing back the

contents of the interface registers to the EEPROM. These

registers can be controlled by the DSP program.

Writeback operated by writing a single page of the 8kB or 16kB

EEPROM. It is the second page that is written to – from

EEPROM location 32 to 63. The EEPROM should contain the

Message Byte (0x01), 2 length bytes, the chip address (0x00),

the 2-byte subaddress for the interface registers (0x08, 0x00)

immediately before EEPROM location 32 (i.e. starting at

EEPROM location 26). There must be a message to the DSP

core control register to enable port writing to the interface

registers prior to the interface register data in the EEPROM.

This should be stored in EEPROM address 0. No-op messages

(0x03) may be used in-between messages to ensure these

conditions are met.

Example – EEPROM starting at EEPROM location 0

Message Byte

No-Op Message Byte

Length Bytes

Device Address Byte (0x00)

ADAU1701

Write Back Data

0x01, 0x00, 0x05, 0x00, 0x08, 0x1c, 0x00, 0x40,

0x03, 0x03, 0x03, 0x03, 0x03, 0x03, 0x03, 0x03,

0x03, 0x03, 0x03, 0x03, 0x03, 0x03, 0x03, 0x03,

0x03, 0x03, 0x01, 0x00, 0x23, 0x00, 0x08, 0x00,

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00,

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00,

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00,

0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00, 0x00,

0x01, 0x01, 0x61, 0x00, 0x04, 0x00, 0x00, 0x00,

0x00, 0x00, 0x01, 0x00, 0x00, 0x00, 0xe8, 0x01,

0x00, 0x00, 0x00, 0x00, 0x01, 0x00, 0x08, 0x00,

Rev. PrC | Page 21 of 39

Page 22

ADAU1701

RAMS AND REGISTERS

Table 16. Control Port Addresses

SPI/ I2C Subaddress Register/RAM Name Read/Write Word Length

0–1023 (0x0000–0x03FF) Parameter RAM Write: 4 Bytes, Read: 4 Bytes

1024–2047 (0x0400-0x07FF) Program RAM Write: 5 Bytes, Read: 5 Bytes

2048-2055 (0x0800-0x0807) Interface Registers 0 - 7

2056 (0x0808) GPIO Pin Setting Register Read: 2 bytes, Write: 2 bytes

2057-2060 (0x0809-0x080C) Aux ADC Data Registers

2064–2068 (0x080D-0x0814) Safeload Data Registers 0 – 4 Write: 5 Bytes, Read: N/A

2069–2073 (0x0815-0x0819) Safeload Address Registers 0 - 4 Write: 2 Bytes, Read: N/A

2074-2075 (0x081A-0x081B) Data Capture Registers 0–1 Write: 2 Bytes, Read: 3 Bytes

2076 (0x081C) DSP Core Control Register Write: 2 Bytes, Read: 2 Bytes

2077 (0x081D) Reserved – do not write Write: 1 Byte, Read: 1 Byte

2078 (0x081E) Serial Output Control Register Write: 2 Bytes, Read: 2 Bytes

2079 (0x081F) Serial Input Control Register Write: 1 Byte, Read: 1 Byte

2080-2081 (0x0820-0x0821) Multi-Purpose Pin Configuration Registers 0 – 1 Write: 3 Bytes, Read: 3 Bytes

2082 (0x0822) Auxiliary ADC Control Register Write: 2 Bytes, Read: 2 Bytes

2083 (0x0823) Reserved – do not write Write: 2 Bytes, Read: 2 Bytes

2084 (0x0824) Auxiliary ADC Enable Register Write: 2 Bytes, Read: 2 Bytes

Table 17. RAM Read/Write Modes

Memory Size Address Range Read Write Write Modes

Parameter RAM 1024 × 28 0–1023 Yes Yes Direct Write1, Safeload Write

Program RAM 1024 × 40 1024–2047 Yes Yes Direct Write1

1

Internal registers should be cleared first to avoid clicks/pops.

CONTROL PORT ADDRESSING

Table 16 shows the addressing of the ADAU1701’s RAM and

register spaces. The address space encompasses a set of registers

and two RAMs: one each for holding signal processing

parameters and holding the program instructions. The

program and parameter RAMs are initialized on power-up from

on-board boot ROMs (see Power-Up Sequence section).

Table 17 shows the sizes and available writing modes of the

parameter and program RAMs.

All RAMs and registers have a default value of all zeros.

Direct Read/Write

This method allows direct access to the program and parameter

RAMs. This mode of operation is normally used during a

complete new load of the RAMs, using burst-mode addressing.

The clear registers bit in the core control register should be set

to 0 using this mode to avoid any clicks or pops in the outputs.

Note that it is also possible to use this mode during live

program execution, but since there is no handshaking between

the core and the control port, the parameter RAM will be

unavailable to the DSP core during control writes, resulting in

clicks and pops in the audio stream.

Read: 4 bytes, Write: 4 bytes

(set bit 6 in ccr first)

(set bit 7 in ccr first)

Read: 2 bytes (12-bits due to

filtering)

Write: 1 byte (no filtering, set

bit 8 in ccr first)

PARAMETER RAM

The parameter RAM is 28 bits wide and occupies Addresses 0 to

1023. The parameter RAM is initialized to all zeros on powerup. The data format of the parameter RAM is twos complement

5.23. This means that the coefficients may range from +16.0

(minus 1 LSB) to –16.0, with 1.0 represented by the binary word

0000 1000 0000 0000 0000 0000 0000.

The parameter RAM can be written and read using one of the

two following methods.

Rev. PrC | Page 22 of 39

Safeload Write

Up to five safeload registers can be loaded with parameter RAM

address/data. The data is then transferred to the requested

address when the RAM is not busy. This method can be used

for dynamic updates while live program material is playing

through the ADAU1701. For example, a complete update of one

biquad section can occur in one audio frame, while the RAM is

not busy. This method is not available for writing to the

program RAM or control registers.

Page 23

The following sections discuss these two options in more detail.

RECOMMENDED PROGRAM/PARAMETER

LOADING PROCEDURE

When writing large amounts of data to the program or

parameter RAM in direct write mode, the processor core should

be disabled to prevent unpleasant noises from appearing at the

audio output.

ADAU1701

Once the address and data registers are loaded, the initiate

safeload transfer bit in the core control register should be set to

initiate the loading into RAM. Program lengths should be

limited to 1,019 cycles (1,024 − 5) to ensure that the SigmaDSP

core has “free cycles” to perform the safeloads. It is guaranteed

that the safeload will have occurred within one LRCLK period

(21 μs at f

set.

= 48 kHz) of the initiate safeload transfer bit being

s

1. Assert bits 3 and 4 (active low) of the core control register

to mute the ADCs and DACs. This begins a volume rampdown.

2. Assert bit 2 (active low) of the core control register. This

zeroes the SigmaDSP’s accumulators, the data output

registers, and the data input registers.

3. Fill the program RAM using burst-mode writes.

4. Fill the parameter RAM using burst-mode writes.

5. Deassert bits 2-4 of the core control register.

SAFELOAD REGISTERS

Many applications require real-time microcontroller control of

signal processing parameters, such as filter coefficients, mixer

gains, multi-channel virtualizing parameters, or dynamics

processing curves. To prevent instability from occurring, all of

the parameters of a biquad filter must be updated at the same

time. Otherwise, the filter could execute for one or two audio

frames with a mix of old and new coefficients. This mix could

cause temporary instability, leading to transients that could take

a long time to decay. To eliminate this problem, the ADAU1701

can simultaneously load a set of five 28-bit values to the desired

parameter RAM address. Five registers are used because a

biquad filter uses five coefficients, and it is desirable to be able

to do a complete biquad update in one transaction.

The first step in performing a safeload is writing the parameter

address to one of the Safeload Address Registers (2069 – 2073).

The 10-bit data word that should be written is the address to

which the safeload is being performed. After the Safeload

Address Register is set, then the 28-bit data word can be written

to the corresponding Safeload Data Register (2064 – 2068). The

data formats for these writes are detailed in Table 30 and Table

31. Table 18 shows how each of the five Address Registers map

to their corresponding Data Registers.

Table 18. Safeload Address & Data Register Mapping

Safeload Register Safeload Address

Register

0 2069 2064

1 2070 2065

2 2071 2066

3 2072 2067

4 2073 2068

Safeload Data

Register

The safeload logic automatically sends only those safeload

registers that have been written to since the last safeload

operation. For example, if only two parameters are to be sent,

only two of the five safeload registers must be written. When

the initiate safeload transfer bit is asserted, only those two

registers are sent; the other three registers are not sent to the

RAM and can still hold old or invalid data.

DATA CAPTURE REGISTERS

The ADAU1701’s data capture feature allows the data at any

node in the signal processing flow to be sent to one of two

control port-readable registers. This can be used to monitor and

display information about internal signal levels or

compressor/limiter activity.

For each of the data capture registers, a capture count and a

register select must be set. The capture count is a number

between 0 and 1023 that corresponds to the program step

number where the capture will occur. The register select field

programs one of four registers in the DSP core that will be

transferred to the data capture register when the program

counter equals the capture count. The register select field

selections are shown in Table 19.

Table 19. Data Capture Control Registers (2074-2075)

Register Bits Function

12:2 11-Bit Program Counter Address

1:0 Register Select

Table 20. Data Capture Output Register Select

Setting Register

00 Multiplier X Input (Mult_X_input)

01 Multiplier Y Input (Mult_Y_input)

10 Multiplier-Accumulator Output (MAC_out)

11 Accumulator Feedback (Accum_fback)

The capture count and register select bits are set by writing to

one of the eight data capture registers at register addresses

2074: Control Port Data Capture Setup Register 0

2075: Control Port Data Capture Setup Register 1

The captured data is in 5.19 twos complement data format. The

four LSBs are truncated from the internal 5.23 data word.

The data that must be written to set up the data capture is a

concatenation of the 11-bit program count index with the 2-bit

Rev. PrC | Page 23 of 39

Page 24

ADAU1701

register select field. The capture count and register select values

that correspond to the desired point to be monitored in the

signal processing flow can be found in a file output from the

program compiler. The capture registers can be accessed by

reading from locations 2074 and 2075. The format for reading

and writing to the data capture registers can be seen in Table 28

and Table 29.

DSP CORE CONTROL REGISTER

The controls in this register set the operation of the

ADAU1701’s DSP core.

Table 21. DSP Core Control Register (2076)

Register Bits Function

15:14 Reserved

13:12 GPIO Debounce control

00 = 20ms

01 = 40ms

10 = 10ms

11 = 5ms

11:9 Reserved

8 Aux ADC Data registers control port write mode

7

6 Interface registers control port write mode

5 Initiate Safeload Transfer

4 Mute ADCs, active low

3 Mute DACs, active low

2 Clear Internal Registers to All Zeros, active low

1:0 Program Length

00 = 1024 (48 kHz)

01 = 512 (96 kHz)

10 = 256 (192 kHz)

00 = reserved

GPIO Debounce control (Bits 13:12)

Set debounce time of multipurpose pins set as GPIO inputs.

Aux ADC Data registers control port write mode (Bit 8)

When this bit is set, the Aux ADC Data registers (2057-2060)

can be written to directly from the control port. The Aux ADC

Data registers will no longer respond to settings on the multipurpose pins.

GPIO Pin Setting register control port write mode (Bit 7)

When this bit is set, the GPIO Pin Setting register (2056) can be

written to directly from the control port. The GPIO Pin Setting

register will no longer respond to input settings on the multipurpose pins.

Interface registers control port write mode (Bit 6)

When this bit is set, the Interface registers (2048-2055) can be

written to directly from the control port. The Interface registers

will not be set from the SigmaDSP program.

GPIO Pin Setting register control port write

mode

Initiate Safe Transfer to Parameter RAM (Bit 5)

Setting this bit to 1 initiates a safeload transfer to the parameter

RAM. This bit is automatically cleared when the operation is

completed. There are five safeload register pairs (address/data);

only those registers that have been written since the last

safeload event are transferred to the parameter RAM.

Mute ADCs (Bit 4)

This bit will mute the output of the ADCs. The bit defaults to 0

and is active-low, so it must be set to 1 in order to pass audio

from the ADCs.

Mute DACs (Bit 3)

This bit will mute the output of the DACs. The bit defaults to 0

and is active-low, so it must be set to 1 in order to pass audio

from the DACs.

Clear Internal Registers to All Zeros (Bit 2)

This bit defaults to 0 and is active low.

Program Length (Bits 1:0)

96 kHz and 192 kHz modes

These bits set the length of the internal program. The default

program length is 1,024 instructions for f

= 48 kHz, but the

s

program length can be shortened by factors of 2 to accommodate sample rates higher than 48 kHz. For f

= 96 kHz the

s

program length should be set to 512 (01), and the length should

be set at 256 steps (10) for f

= 192 kHz.

s

Low Power Mode

This setting can also be used to reduce the power consumption

of the ADAU1701. If the program length is set to 512 steps and

f

= 48 kHz, instead of 96 kHz, then the digital power

s

consumption of the part will be cut in approximately half.

Correspondingly, when the program length is set to 256 steps

with f

= 48 kHz the digital power consumption will be about ¼

s

of what it is in normal operation with 1,024 program steps and

f

= 48 kHz.

s

INTERFACE REGISTERS

See more information in the Self boot section.

CONTROL PORT READ/WRITE DATA FORMATS

The read/write formats of the control port are designed to be

byte-oriented. This allows for easy programming of common

microcontroller chips. In order to fit into a byte-oriented

format, 0s are appended to the data fields before the MSB in

order to extend the data word to the next multiple of eight bits.

For example, 28-bit words written to the parameter RAM are

appended with four leading 0s in order to reach 32 bits

(4 bytes); 40-bit words written to the program RAM are not

appended with any 0s because it is already a full 5 bytes. These

zero-extended data fields are appended to a 3-byte field

consisting of a 7-bit chip address, a read/write bit, and an 11-bit

Rev. PrC | Page 24 of 39

Page 25

ADAU1701

RAM/register address. The control port knows how many data

bytes to expect based on the address that is received in the first

three bytes.

The total number of bytes for a single-location write command

can vary from four bytes (for a control register write), to eight

bytes (for a program RAM write). Burst mode may be used to

fill contiguous register or RAM locations. A burst mode write is

transaction (by issuing a stop command in I

bringing the CLATCH signal high in SPI mode, after the data

word), as would be done in a single-address write, the next data

word can be written immediately without first writing its

specific address. The ADAU1701 control port auto-increments

the address of each write, even across the boundaries of the

different RAMs and registers. Table 23 and Table 25 show

examples of burst mode writes.

2

C mode or by

done by writing the address and data of the first RAM/register

location to be written. Rather than ending the control port

Table 22. Parameter RAM Read/Write Format (Single Address)

Byte 0 Byte 1 Byte 2 Byte 3 Bytes 4–6

chip_adr [6:0], W/R

00000, param_adr[10:8] param_adr[7:0] 0000, param[27:24] param [23:0]

Table 23. Parameter RAM Block Read/Write Format (Burst Mode)

Byte 0 Byte 1 Byte 2 Byte 3 Bytes 4–6 Byte 7 Byte 11

chip_adr [6:0], W/R 00000,

param_adr[7:0] 0000, param[27:24] param[23:0]

Byte 8 Byte 12

param_adr[10:8]

Byte 9 Byte 13

Byte 10 Byte 14

<—param_adr—> param_adr + 1 param_adr + 2

Table 24. Program RAM Read/Write Format (Single Address)

Byte 0 Byte 1 Byte 2 Bytes 3–7

chip_adr [6:0], W/R

0000, prog_adr[11:8] prog_adr[7:0] prog[39:0]

Table 25. Program RAM Block Read/Write Format (Burst Mode)

Byte 0 Byte 1 Byte 2 Byte 3-7 Byte 8 Byte 13

chip_adr [6:0], W/R

0000, prog_adr[11:8] prog_adr[7:0] prog[39:0]

Byte 9 Byte 14

Byte 10 Byte 15

Byte 11 Byte 16

Byte 12 Byte 17

<—prog_adr—> prog_adr +1 prog_adr +2

Table 26. Control Register Read/Write Format (Core, Serial Out 0, Serial Out 1)

Byte 0 Byte1 Byte 2 Byte 3 Byte 4

chip_adr [6:0], W/R

0000, reg_adr[11:8] reg_adr[7:0] data[15:8] data[7:0]

Table 27. Control Register Read/Write Format (RAM Configuration, Serial Input)

Byte 0 Byte1 Byte 2 Byte 3

chip_adr [6:0], W/R

0000, reg_adr[11:8] reg_adr[7:0] data[7:0]

Table 28. Data Capture Register Write Format

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4

chip_adr [6:0], W/R

1

ProgCount[10:0] = value of program counter where trap occurs (the table of values is generated by the program compiler).

2

RegSel[1:0] selects one of four registers (see Data Capture Registers section).

0000, data_capture_adr[11:8] data_capture_adr[7:0] 000, progCount[10:6]

1

progCount[5:0]1, regSel[1:0]2

Table 29. Data Capture (Control Port Readback) Register Read Format

Byte 0 Byte 1 Byte 2 Bytes 3–5

chip_adr [6:0], W/R

0000, data_capture_adr[11:8] data_capture_adr[7:0] data[23:0]

Rev. PrC | Page 25 of 39

Page 26

ADAU1701

Table 30. Safeload Address Register Write Format

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4

chip_adr [6:0], W/R

Table 31. Safeload Data Register Write Format

Byte 0 Byte 1 Byte 2 Byte 3 Byte 4 Bytes 5–7

chip_adr [6:0], W/R

0000, safeload_adr[11:8] safeload_adr[7:0] 000000, param_adr[9:8] param_adr[7:0]

0000, safeload_adr[11:8] safeload_adr[7:0] 00000000 0000, data[27:24] data[23:0]

Rev. PrC | Page 26 of 39

Page 27

ADAU1701

MULTIPURPOSE PINS

Table 32. Multi-Purpose Pin Configuration Registers

Register Bits[23:20] Bits[19:16] Bits[15:12] Bits[11:8] Bits[7:4] Bits[3:0]

MP_CFG0

(2080)

MP_CFG1

(2081)

MP5[3:0] MP4[3:0] MP3[3:0] MP2[3:0] MP1[3:0] MP0[3:0]

MP11[3:0] MP10[3:0] MP9[3:0] MP8[3:0] MP7[3:0] MP6[3:0]

The ADAU1701 has 12 multipurpose pins that can be

individually programmed to be used as serial data inputs, serial

data outputs, digital control inputs and outputs to and from the

SigmaDSP core, or as inputs to the four-channel auxiliary ADC.

GPIO PIN SETTING REGISTER

The GPIO pin settings can be directly written to or read from

this register after setting bit 7 of the Core Control Register.

Table 33. GPIO Pin Setting Register (2056)

Register Bits Function

15:12 Unused

11 MP11 setting

10 MP10 setting

9 MP9 setting

8 MP8 setting

7 MP7 setting

6 MP6 setting

5 MP5 setting

4 MP4 setting

3 MP3 setting

2 MP2 setting

1 MP1 setting

0 MP0 setting

MULTI-PURPOSE PIN CONFIGURATION

REGISTERS

Each multi-purpose pin can be set to its different functions

from this register. The MSB of each MP pin’s 4-bit

configuration inverts the input to or output from the pin.

Table 34. Multi-Purpose Pin Configuration Register Bit

Functions

MPx[3:0] Pin Function

1111 Aux ADC input (see Table 35)

1110 Reserved

1101 Reserved

1100

1011 Open Collector Output - inverted

1010 GPIO Output – inverted

1001 GPIO Input, no debounce – inverted

1000 GPIO Input, debounced – inverted

0111 N/A

Serial Data Port – inverted (see Table

38)

0110 Reserved

0101 Reserved

0100 Serial Data Port (see Table 38)

0011 Open Collector Output

0010 GPIO Output

0001 GPIO Input, no debounce

0000 GPIO Input, debounced

AUXILIARY ADC

The ADAU1701 has a four-channel auxiliary 8-bit ADC that

can be used to connect a potentiometer to control volume, tone,

or other parameter settings in the DSP program. Each of the

four channels is sampled at the sampling frequency (f

defaults to 48 kHz with a 12.288 MHz crystal connected to the

ADAU1701 oscillator. Full-scale input on this ADC is 3.3V, so

the step size is approximately 13mV (3.3V/256 steps).

The auxiliary ADC is turned on by writing a 1 to bit 15 of the

Aux ADC enable register (Table 37).

Noise on the ADC input could cause the digital output to be

constantly changing by a few LSBs. In cases where the aux

ADC is used as a volume control, this would cause small gain