Page 1

SigmaDSP 28-/56-Bit Audio Processor

A

G

FEATURES

28-/56-bit, 50 MIPS digital audio processor

2 ADCs: SNR of 100 dB, THD + N of −83 dB

4 DACs: SNR of 104 dB, THD + N of −90 dB

Complete standalone operation

Self-boot from serial EEPROM

Auxiliary ADC with 4-input mux for analog control

GPIOs for digital controls and outputs

Fully programmable with SigmaStudio graphical tool

28-bit × 28-bit multiplier with 56-bit accumulator for full

double-precision processing

Clock oscillator for generating master clock from crystal

PLL for generating master clock from 64 × f

384 × f

, or 512 × fS clocks

S

Flexible serial data input/output ports with I

left-justified, right-justified, and TDM modes

Sampling rates of up to 192 kHz supported

On-chip voltage regulator for compatibility with 3.3 V systems

48-lead, plastic LQFP

Qualified for automotive applications

APPLICATIONS

Multimedia speaker systems

MP3 player speaker docks

Automotive head units

Minicomponent stereos

Digital televisions

Studio monitors

Speaker crossovers

Musical instrument effects processors

In-seat sound systems (aircraft/motor coaches)

, 256 × fS,

S

2

S-compatible,

with Two ADCs and Four DACs

ADAU1401A

GENERAL DESCRIPTION

The ADAU1401A is a complete, single-chip audio system with

28-/56-bit audio DSP, ADCs, DACs, and microcontroller-like

control interfaces. Signal processing includes equalization, crossover, bass enhancement, multiband dynamics processing, delay

compensation, speaker compensation, and stereo image widening.

This processing can be used to compensate for real-world limitations of speakers, amplifiers, and listening environments, providing

dramatic improvements in perceived audio quality.

The signal processing of the ADAU1401A is comparable to that

found in high end studio equipment. Most processing is done in

full 56-bit, double-precision mode, resulting in very good low

level signal performance. The ADAU1401A is a fully programmable DSP. The easy to use SigmaStudio™ software allows the

user to graphically configure a custom signal processing flow

using blocks such as biquad filters, dynamics processors, level

controls, and GPIO interface controls.

The ADAU1401A programs can be loaded on power-up either

from a serial EEPROM through its own self-boot mechanism or

from an external microcontroller. On power-down, the current

state of the parameters can be written back to the EEPROM from

the ADAU1401A to be recalled the next time the program is run.

Two Σ- ADCs and four Σ- DACs provide a 98.5 dB analog

input to analog output dynamic. Each ADC has a THD + N of

−83 dB, and each DAC has a THD + N of −90 dB. Digital input

and output ports allow a glueless connection to additional ADCs

and DACs. The ADAU1401A communicates through an I

or a 4-wire SPI port.

2

C® bus

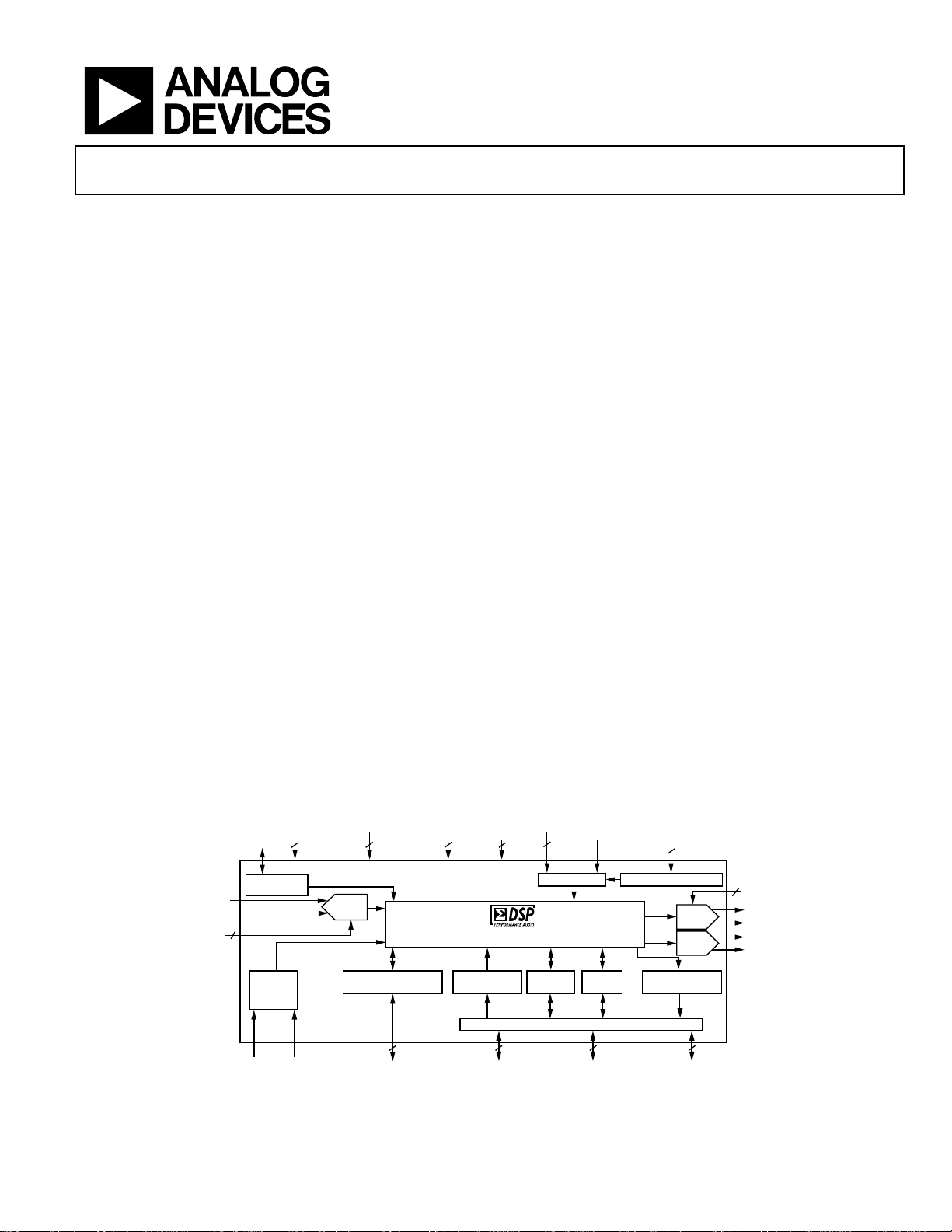

FUNCTIONAL BLOCK DIAGRAM

DIGITAL VDD DIGITAL GROUNDANALOG VDD

3.3V

3 3 3

1.8V

2-CHANNEL

ANALOG

INPUT

FILTA/

ADC_RES

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

REGULATOR

2

RESET/

MODE

SELECT

RESET SEL F-BOOT DIGITAL IN OR GPIO AUX ADC OR GPIO DIGITAL OUT OR GP IO

STEREO

ADC

CONTROL I NTERFACE

AND SELF-BOOT

2

C/SPI AND WRITEBACK

I

ADAU1401A

AUDIO PROCESSOR CORE, 40ms DELAY MEMORY

NALO

GROUND

28-/56-BIT, 50MIPS

8-CHANNEL

DIGITAL INPUT

Figure 1.

PLL MODE

2

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2010 Analog Devices, Inc. All rights reserved.

PLL LOOP

FILTER

3

PLL CLOCK OS CILLATO R

8-BIT AUX

ADC

GPIO

INPUT/OUTPUT MATRIX

CRYSTAL

2

DAC

DAC

8-CHANNEL

DIGITAL OUTPUT

3335

FILTD/CM

2

4-CHANNEL

ANALOG

OUTPUT

08506-001

Page 2

ADAU1401A

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 3

Specifications..................................................................................... 4

Analog Performance .................................................................... 4

Digital Input/Output.................................................................... 5

Power.............................................................................................. 6

Temperature Range ...................................................................... 6

PLL and Oscillator........................................................................ 6

Regulator........................................................................................ 6

Digital Timing Specifications ..................................................... 7

Absolute Maximum Ratings.......................................................... 10

Thermal Resistance .................................................................... 10

ESD Caution................................................................................ 10

Pin Configuration and Function Descriptions........................... 11

Typical Performance Characteristics ........................................... 14

System Block Diagram................................................................... 15

Theory of Operation ...................................................................... 16

Initialization .................................................................................... 17

Power-Up Sequence ................................................................... 17

Control Registers Setup............................................................. 17

Recommended Program/Parameter Loading Procedure .....17

Power Reduction Modes............................................................ 17

Using the Oscillator.................................................................... 18

Setting Master Clock/PLL Mode.............................................. 18

Voltage Regulator ....................................................................... 19

Audio ADCs.................................................................................... 20

Audio DACs ....................................................................................21

Control Ports................................................................................... 22

I2C Port ........................................................................................ 23

SPI Port........................................................................................ 26

Self-Boot ...................................................................................... 27

Signal Processing ............................................................................ 29

Numeric Formats........................................................................ 29

Programming.............................................................................. 29

RAMs and Registers ....................................................................... 30

Address Maps.............................................................................. 30

Parameter RAM.......................................................................... 30

Data RAM ................................................................................... 30

Read/Write Data Formats ......................................................... 30

Control Register Map..................................................................... 32

Control Register Details ................................................................ 34

Address 2048 to Address 2055 (0x0800 to 0x0807)—Interface

Registers....................................................................................... 34

Address 2056 (0x0808)—GPIO Pin Setting Register............ 35

Address 2057 to Address 2060 (0x0809 to 0x080C)—

Auxiliary ADC Data Registers.................................................. 36

Address 2064 to Address 2068 (0x0810 to 0x0814)—Safeload

Data Registers ............................................................................. 37

Address 2069 to Address 2073 (0x0815 to 0x0819)—Safeload

Address Registers ....................................................................... 37

Address 2074 and Address 2075 (0x081A and 0x081B)—Data

Capture Registers........................................................................ 38

Address 2076 (0x081C)—DSP Core Control Register.......... 39

Address 2078 (0x081E)—Serial Output Control Register.... 40

Address 2079 (0x081F)—Serial Input Control Register ....... 41

Address 2080 and Address 2081 (0x0820 and 0x0821)—

Multipurpose Pin Configuration Registers............................. 42

Address 2082 (0x0822)—Auxiliary ADC and Power Control

Register ........................................................................................ 43

Address 2084 (0x0824)—Auxiliary ADC Enable Register ... 43

Address 2086 (0x0826)—Oscillator Power-Down Register . 43

Address 2087 (0x0827)—DAC Setup Register....................... 43

Multipurpose Pins.......................................................................... 44

Auxiliary ADC............................................................................ 44

General-Purpose Input/Output Pins....................................... 44

Serial Data Input/Output Ports ................................................ 44

Layout Recommendations............................................................. 47

Parts Placement .......................................................................... 47

Grounding................................................................................... 47

Typical Application Schematics.................................................... 48

Self-Boot Mode........................................................................... 48

I2C Control.................................................................................. 49

SPI Control.................................................................................. 50

Outline Dimensions....................................................................... 51

Ordering Guide .......................................................................... 51

Rev. A | Page 2 of 52

Page 3

ADAU1401A

REVISION HISTORY

11/10—Rev. 0 to Rev. A

Changes to Figure 7 and Table 11 .................................................11

Changes to Figure 37 ......................................................................48

Changes to Figure 38 ......................................................................49

Changes to Figure 39 ......................................................................50

4/10—Revision 0: Initial Version

Rev. A | Page 3 of 52

Page 4

ADAU1401A

SPECIFICATIONS

AVDD = 3.3 V, DVDD = 1.8 V, PVDD = 3.3 V, IOVDD = 3.3 V, master clock input = 12.288 MHz, unless otherwise noted.

ANALOG PERFORMANCE

Specifications are guaranteed at 25°C (ambient).

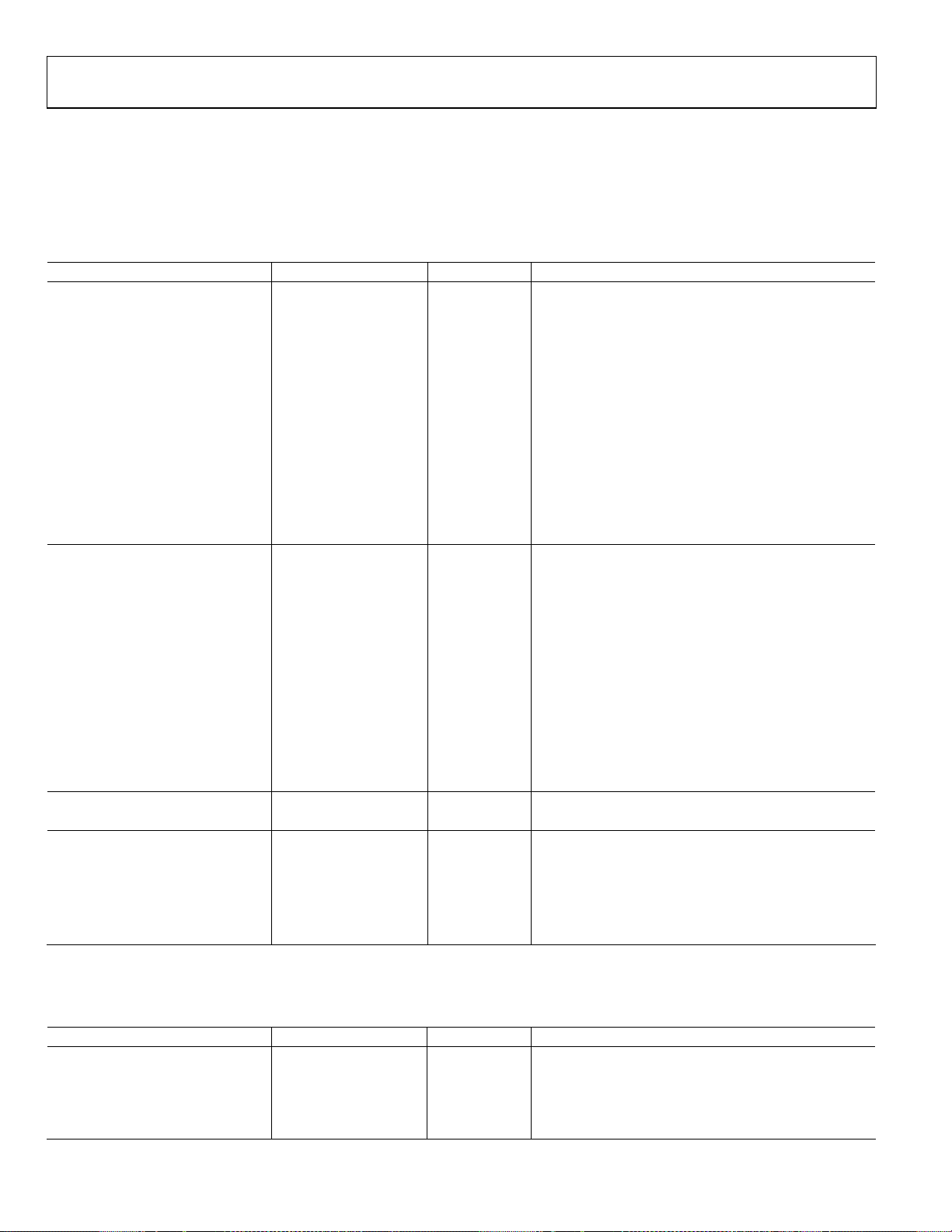

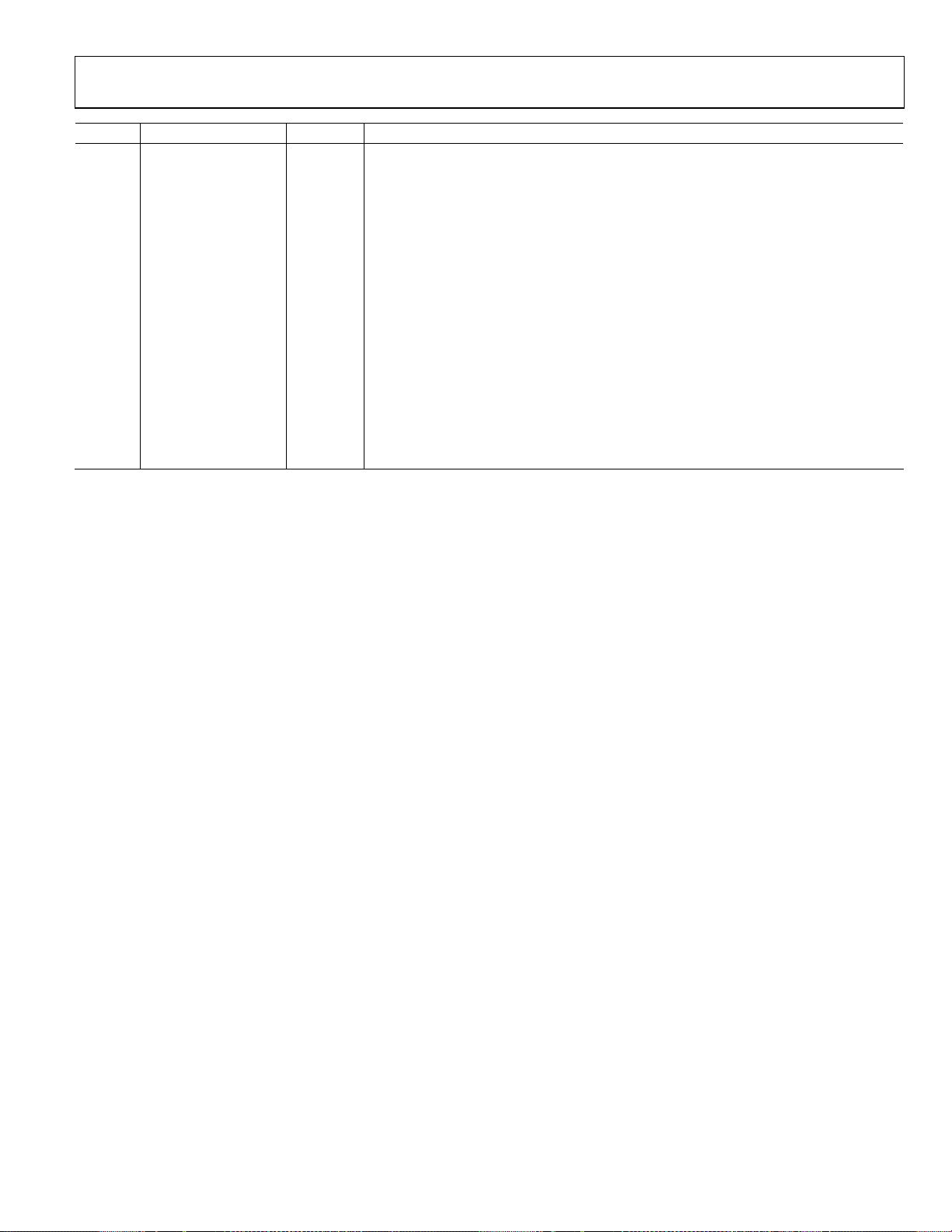

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

ADC INPUTS

Number of Channels 2 Stereo input

Resolution 24 Bits

Full-Scale Input 100 (283) µA rms (µA p-p)

Signal-to-Noise Ratio

Dynamic Range −60 dB with respect to full-scale analog input

Total Harmonic Distortion + Noise −83 dB −3 dB with respect to full-scale analog input

Interchannel Gain Mismatch 25 300 mdB

Crosstalk −82 dB Analog channel-to-channel crosstalk

DC Bias 1.4 1.5 1.6 V

Gain Error −11 +11 %

DAC OUTPUTS

Number of Channels 4 Two stereo output channels

Resolution 24 Bits

Full-Scale Analog Output 0.9 (2.5) V rms (V p-p) Sine wave

Signal-to-Noise Ratio

Dynamic Range −60 dB with respect to full-scale analog output

Total Harmonic Distortion + Noise −90 dB −1 dB with respect to full-scale analog output

Crosstalk −100 dB Analog channel-to-channel crosstalk

Interchannel Gain Mismatch 25 250 mdB

Gain Error −10 +10 %

DC Bias 1.4 1.5 1.6 V

VOLTAGE REFERENCE

Absolute Voltage, CM Pin 1.4 1.5 1.6 V

AUXILIARY ADC

Full-Scale Analog Input 2.8 2.95 3.1 V

INL 0.5 LSB

DNL 0.5 LSB

Offset 15 mV

Input Impedance 17.8 30 42 kΩ

Specifications are guaranteed at 130°C (ambient).

A-Weighted 100 dB

A-Weighted 95 100 dB

A-Weighted 104 dB

A-Weighted 99 104 dB

2 V rms input with 20 kΩ (18 kΩ external + 2 kΩ internal)

series resistor

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

ADC INPUTS

Number of Channels 2 Stereo input

Resolution 24 Bits

Full-Scale Input 100 (283) µA rms (µA p-p)

2 V rms input with 20 kΩ (18 kΩ external + 2 kΩ internal)

series resistor

Rev. A | Page 4 of 52

Page 5

ADAU1401A

Parameter Min Typ Max Unit Test Conditions/Comments

Signal-to-Noise Ratio

A-Weighted 100 dB

Dynamic Range −60 dB with respect to full-scale analog input

A-Weighted 92 100 dB

Total Harmonic Distortion + Noise −83 dB −3 dB with respect to full-scale analog input

Interchannel Gain Mismatch 25 250 mdB

Crosstalk −82 dB Analog channel-to-channel crosstalk

DC Bias 1.4 1.5 1.6 V

Gain Error −11 +11 %

DAC OUTPUTS

Number of Channels 4 Two stereo output channels

Resolution 24 Bits

Full-Scale Analog Output 0.85 (2.4) V rms (V p-p) Sine wave

Signal-to-Noise Ratio

A-Weighted 104 dB

Dynamic Range −60 dB with respect to full-scale analog output

A-Weighted 98 104 dB

Total Harmonic Distortion + Noise −90 dB −1 dB with respect to full-scale analog output

Crosstalk −100 dB Analog channel-to-channel crosstalk

Interchannel Gain Mismatch 25 250 mdB

Gain Error −10 +10 %

DC Bias 1.4 1.5 1.6 V

VOLTAGE REFERENCE

Absolute Voltage, CM Pin 1.4 1.5 1.6 V

AUXILIARY ADC

Full-Scale Analog Input 2.8 2.95 3.1 V

INL 0.5 LSB

DNL 0.5 LSB

Offset 15 mV

Input Impedance 17.8 30 42 kΩ

DIGITAL INPUT/OUTPUT

Table 3.

Parameter Min Typ Max1 Unit Test Conditions/Comments

Input Voltage, High (VIH) 2.0 IOVDD V

Input Voltage, Low (VIL) 0.8 V

Input Leakage, High (IIH) 1 µA Excluding MCLKI

Input Leakage, Low (IIL) 1 µA Excluding MCLKI and bidirectional pins

Bidirectional Pin Pull-Up Current, Low 150 µA

MCLKI Input Leakage, High (IIH) 3 µA

MCLKI Input Leakage, Low (IIL) 3 µA

Output Voltage, High (VOH) 2.0 V IOH = 2 mA

Output Voltage, Low (VOL) 0.8 V IOL = 2 mA

Input Capacitance 5 pF

GPIO Output Drive 2 mA

1

Maximum specifications are measured across a temperature range of −40°C to +130°C (case), a DVDD range of 1.62 V to 1.98 V, and an AVDD range of 2.97 V to 3.63 V.

Rev. A | Page 5 of 52

Page 6

ADAU1401A

POWER

Table 4.

Parameter Min Typ Max1 Unit

SUPPLY VOLTAGE

Analog Voltage 3.3 V

Digital Voltage 1.8 V

PLL Voltage 3.3 V

IOVDD Voltage 3.3 V

SUPPLY CURRENT

Analog Current (AVDD and PVDD) 50 85 mA

Digital Current (DVDD) 25 40 mA

Analog Current, Reset 35 55 mA

Digital Current, Reset 1.5 4.5 mA

DISSIPATION

Operation (AVDD, DVDD, PVDD)2 259.5 mW

Reset, All Supplies 118 mW

POWER SUPPLY REJECTION RATIO (PSRR)

1 kHz, 200 mV p-p Signal at AVDD 50 dB

1

Maximum specifications are measured across a temperature range of −40°C to +130°C (case), a DVDD range of 1.62 V to 1.98 V, and an AVDD range of 2.97 V to 3.63 V.

2

Power dissipation does not include IOVDD power because the current drawn from this supply is dependent on the loads at the digital output pins.

TEMPERATURE RANGE

Table 5.

Parameter Min Typ Max Unit

Functionality Guaranteed −40 +105 °C ambient

PLL AND OSCILLATOR

Table 6.

Parameter1 Min Typ Max Unit

PLL Operating Range MCLK_Nom − 20% MCLK_Nom + 20% MHz

PLL Lock Time 20 ms

Crystal Oscillator Transconductance (gm) 78 mmho

1

Maximum specifications are measured across a temperature range of −40°C to +130°C (case), a DVDD range of 1.62 V to 1.98 V, and an AVDD range of 2.97 V to 3.63 V.

REGULATOR

Table 7.

Parameter1 Min Typ Max Unit

DVDD Voltage 1.7 1.8 1.84 V

1

Regulator specifications are calculated using a Zetex Semiconductors FZT953 transistor in the circuit.

Rev. A | Page 6 of 52

Page 7

ADAU1401A

DIGITAL TIMING SPECIFICATIONS

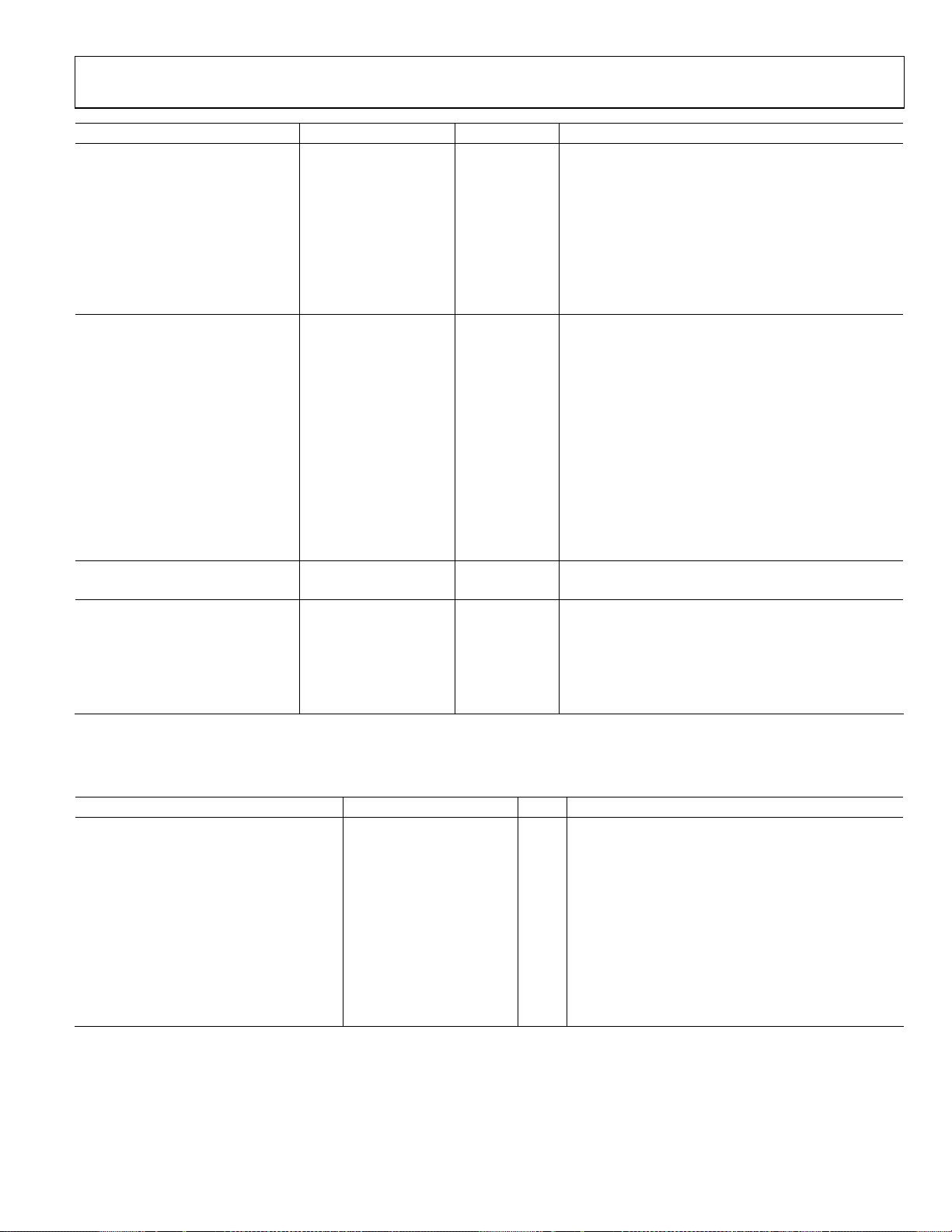

Table 8.

Limit

Parameter1 t

MASTER CLOCK

tMP 36 244 ns MCLKI period, 512 × fS mode.

tMP 48 366 ns MCLKI period, 384 × fS mode.

tMP 73 488 ns MCLKI period, 256 × fS mode.

tMP 291 1953 ns MCLKI period, 64 × fS mode.

SERIAL PORT

t

40 ns INPUT_BCLK low pulse width.

BIL

t

40 ns INPUT_BCLK high pulse width.

BIH

t

10 ns INPUT_LRCLK setup; time to INPUT_BCLK rising.

LIS

t

10 ns INPUT_LRCLK hold; time from INPUT_BCLK rising.

LIH

t

10 ns SDATA_INx setup; time to INPUT_BCLK rising.

SIS

t

10 ns SDATA_INx hold; time from INPUT_BCLK rising.

SIH

t

10 ns OUTPUT_LRCLK setup in slave mode.

LOS

t

10 ns OUTPUT_LRCLK hold in slave mode.

LOH

tTS 5 ns OUTPUT_BCLK falling to OUTPUT_LRCLK timing skew.

t

40 ns SDATA_OUTx delay in slave mode; time from OUTPUT_BCLK falling.

SODS

t

40 ns SDATA_OUTx delay in master mode; time from OUTPUT_BCLK falling.

SODM

SPI PORT

f

CCLK

t

80 ns CCLK pulse width low.

CCPL

t

80 ns CCLK pulse width high.

CCPH

t

0 ns CLATCH setup; time to CCLK rising.

CLS

t

100 ns CLATCH hold; time from CCLK rising.

CLH

t

80 ns CLATCH pulse width high.

CLPH

t

0 ns CDATA setup; time to CCLK rising.

CDS

t

80 ns CDATA hold; time from CCLK rising.

CDH

t

101 ns COUT delay; time from CCLK falling.

COD

I2C PORT

f

SCL

t

0.6 µs SCL high.

SCLH

t

1.3 µs SCL low.

SCLL

t

0.6 µs SCL setup time, relevant for repeated start condition.

SCS

t

0.6 µs SCL hold time. After this period, the first clock is generated.

SCH

tDS 100 ns Data setup time.

t

300 ns SCL rise time.

SCR

t

300 ns SCL fall time.

SCF

t

300 ns SDA rise time.

SDR

t

300 ns SDA fall time.

SDF

t

0.6 Bus-free time; time between stop and start.

BFT

MULTIPURPOSE PINS AND RESET

t

50 ns GPIO rise time.

GRT

t

50 ns GPIO fall time.

GFT

t

1.5 × 1/fS µs GPIO input latency; time until high/low value is read by core.

GIL

t

20 ns

RLPW

1

All timing specifications are given for the default (I2S) states of the serial input port and the serial output port (see Table 66).

t

MIN

Unit Description

MAX

6.25 MHz CCLK frequency.

400 kHz SCL frequency.

RESET

low pulse width.

Rev. A | Page 7 of 52

Page 8

ADAU1401A

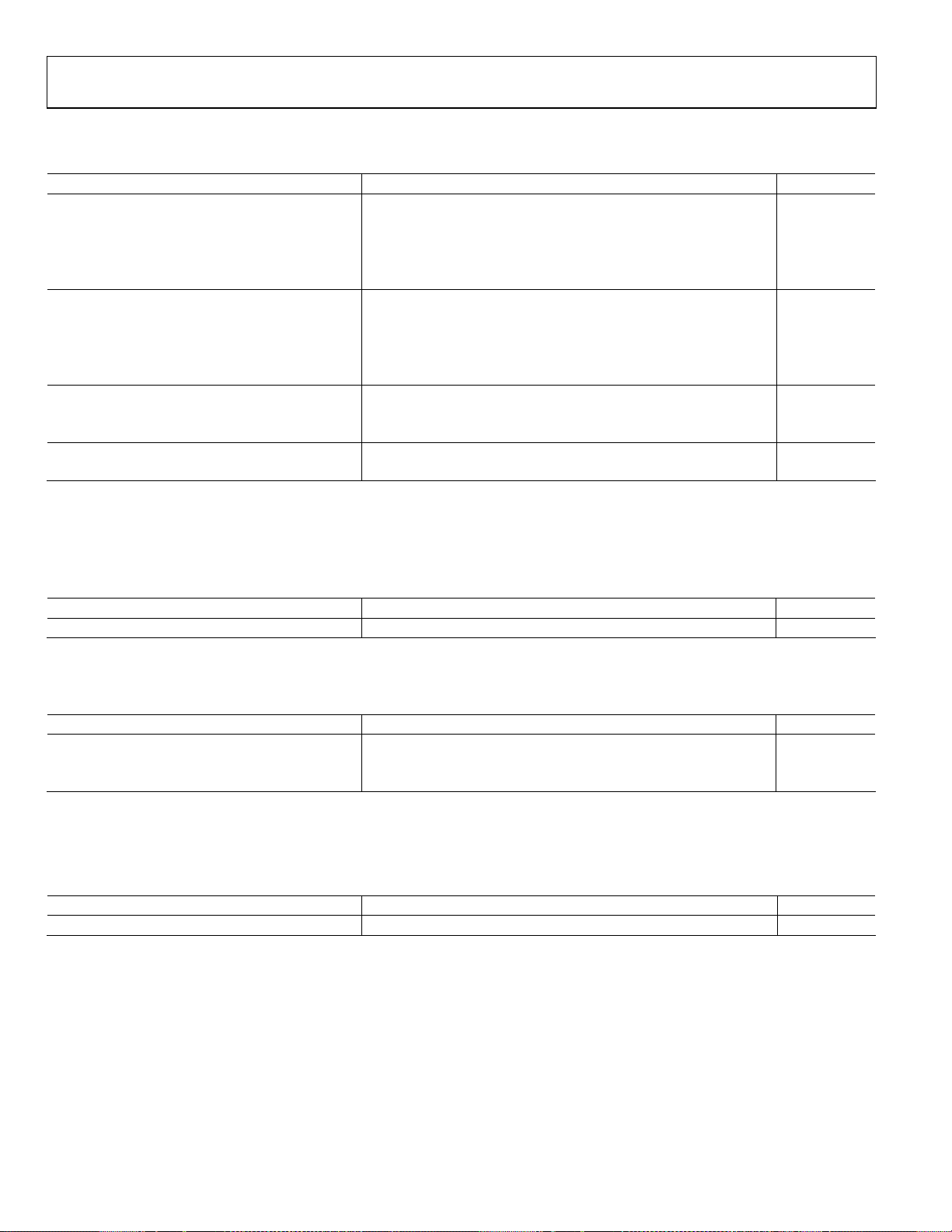

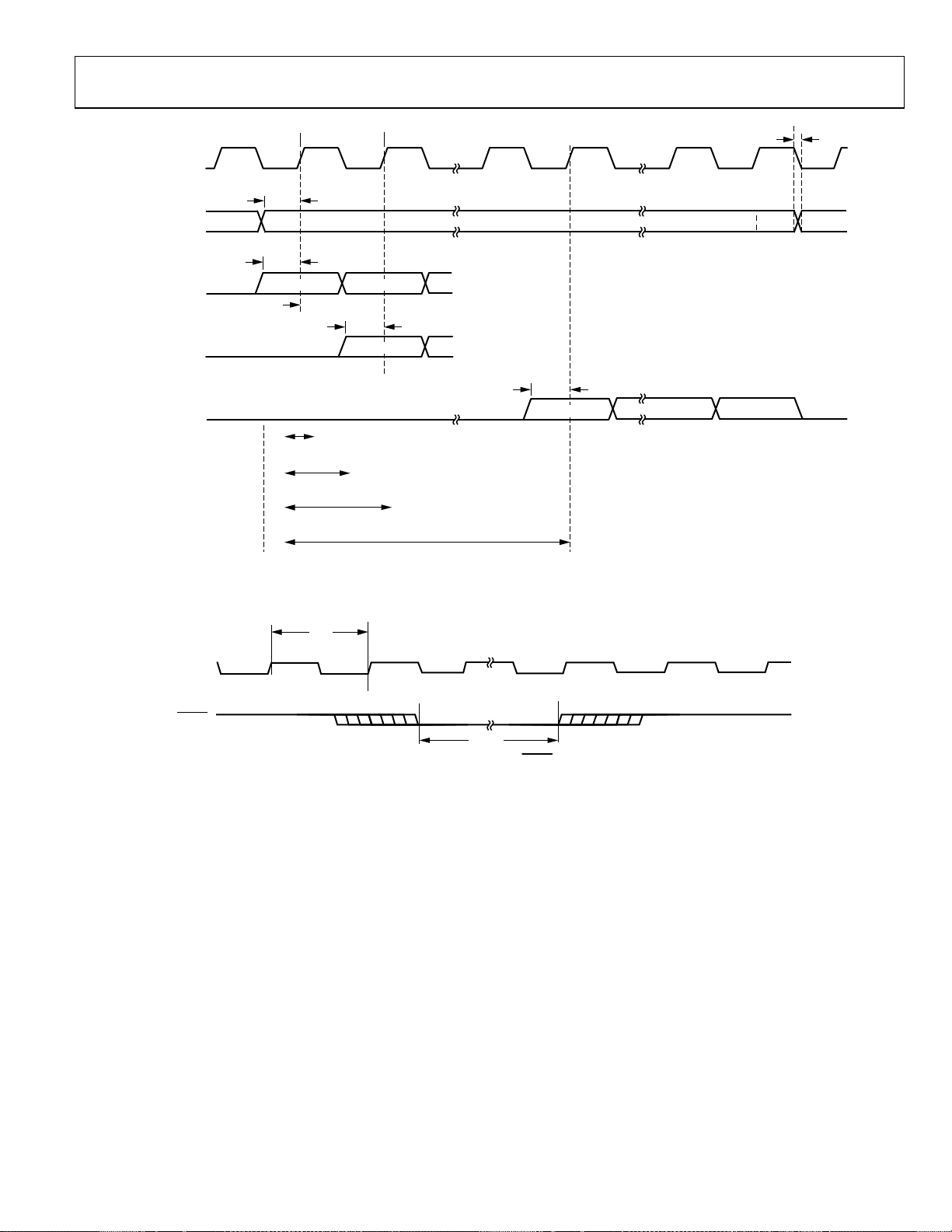

Digital Timing Diagrams

t

LIH

t

SIS

LSB

t

SIH

8506-002

t

CLPH

INPUT_BCLK

INPUT_LRCLK

SDATA_INx

LEFT-JUSTIFIED

RIGHT-JUSTIFIED

SDATA_INx

SDATA_INx

CLATCH

MODE

I2S MODE

MODE

t

BIH

t

BIL

t

LIS

t

SIS

MSB

t

SIH

8-BIT CLOCKS

(24-BIT DATA)

12-BIT CLOCKS

(20-BIT DATA)

14-BIT CLOCKS

(18-BIT DATA)

16-BIT CLOCKS

(16-BIT DATA)

MSB – 1

t

SIS

MSB

t

SIH

t

SIS

MSB

t

SIH

Figure 2. Serial Input Port Timing

t

CLS

t

t

CCPH

CCPL

t

CLH

CCLK

CDATA

t

CDH

t

COD

08506-004

COUT

t

CDS

Figure 3. SPI Port Timing

t

t

SCLH

t

SCF

Figure 4. I

DS

2

C Port Timing

t

SCH

t

SCS

t

BFT

08506-005

SDA

SCL

t

SCH

t

SCR

t

SCLL

Rev. A | Page 8 of 52

Page 9

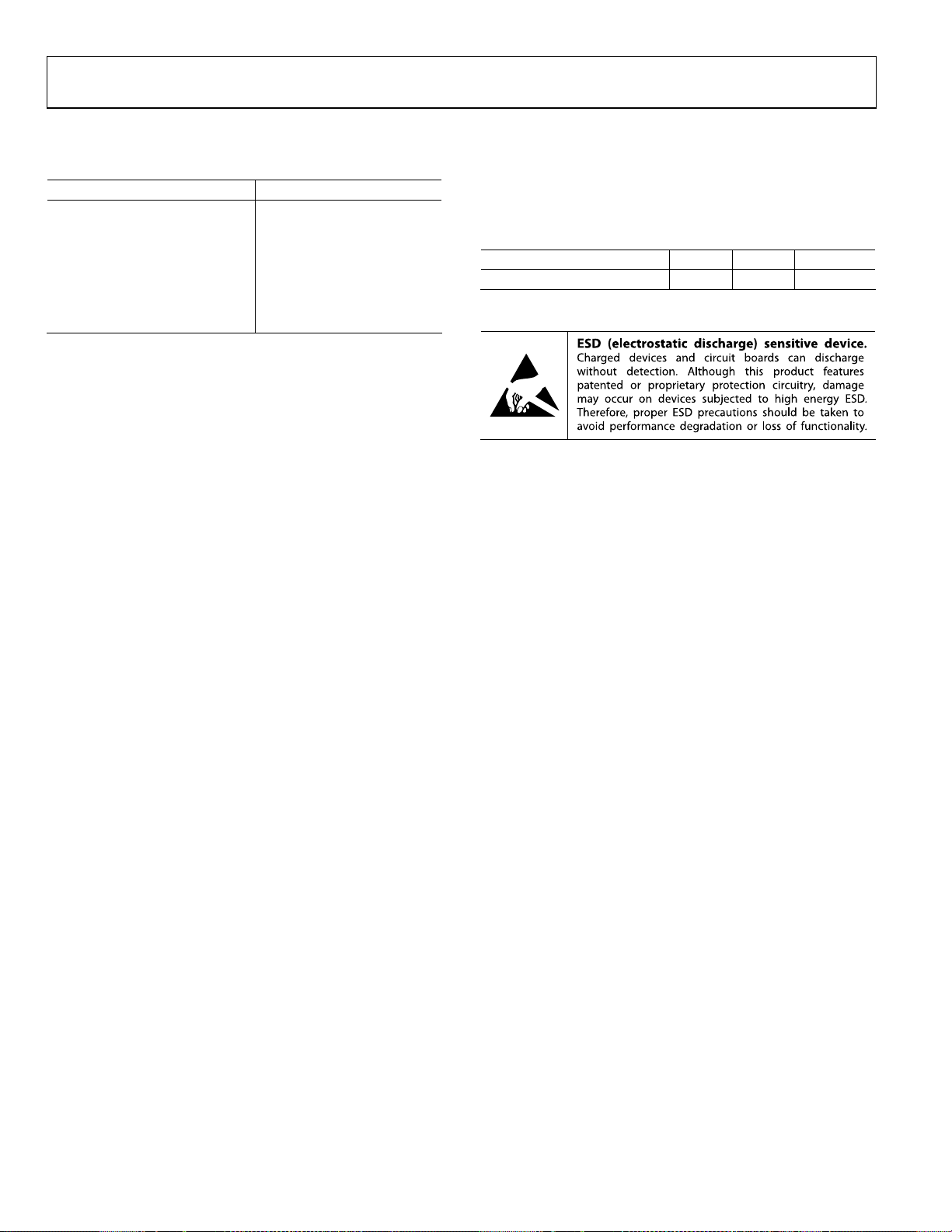

ADAU1401A

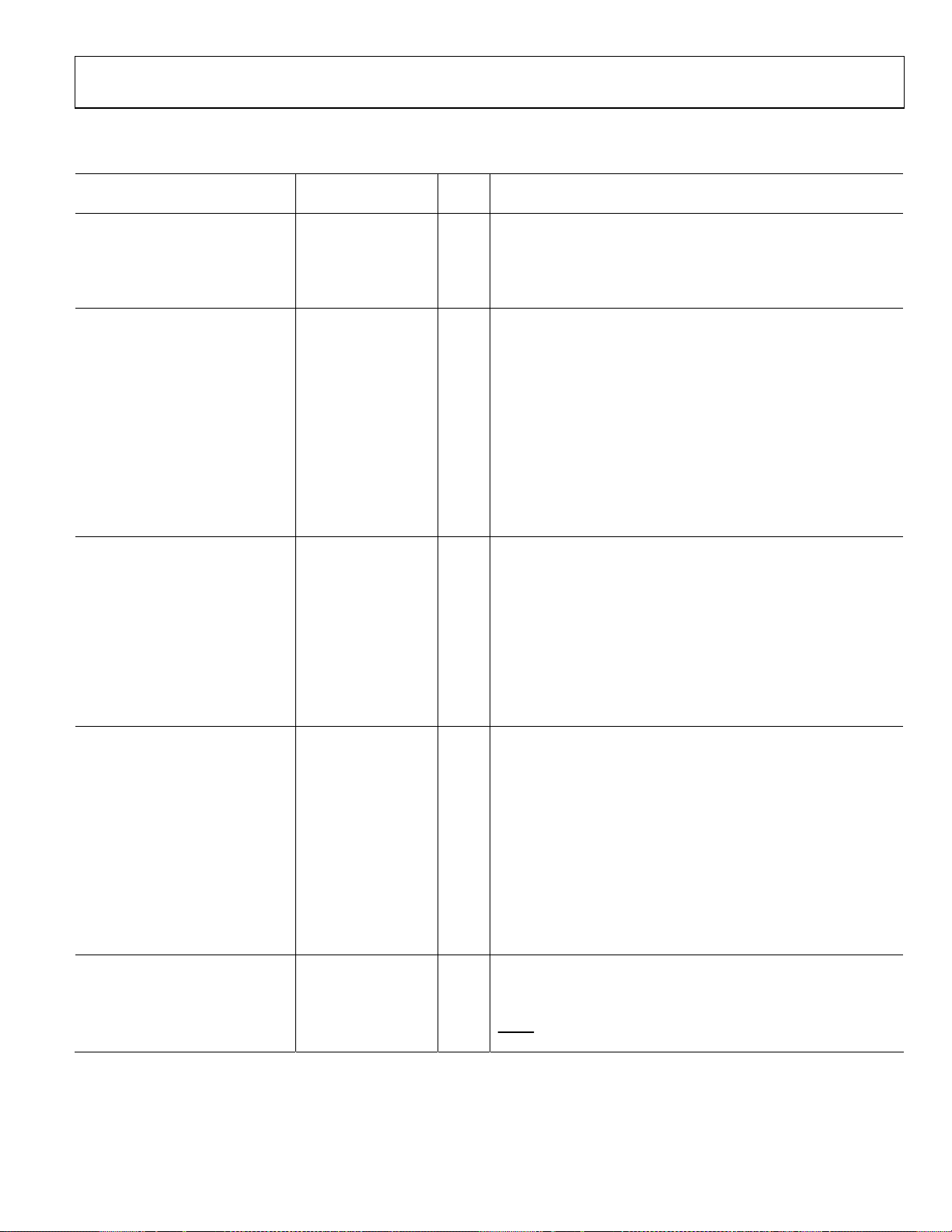

t

TS

OUTPUT_BCLK

t

LOS

OUTPUT_L RCLK

t

SODS

t

SODM

MSB

8-BIT CLOCKS

(24-BIT DATA)

12-BIT CLO CKS

(20-BIT DATA)

14-BIT CLO CKS

(18-BIT DATA)

16-BIT CLO CKS

(16-BIT DATA)

t

MSB – 1

t

SODS

t

SODM

MSB

t

SODS

t

SODM

MSB

LSB

08506-003

Figure 5. Serial Output Port Timing

MP

SDATA_OUTx

LEFT-JUSTIFIED

RIGHT -JUSTI FIED

MODE

SDATA_OUTx

2

I

S MODE

SDATA_OUTx

MODE

MCLKI

RESET

t

RLPW

Figure 6. Master Clock and

RESET

Timing

08506-006

Rev. A | Page 9 of 52

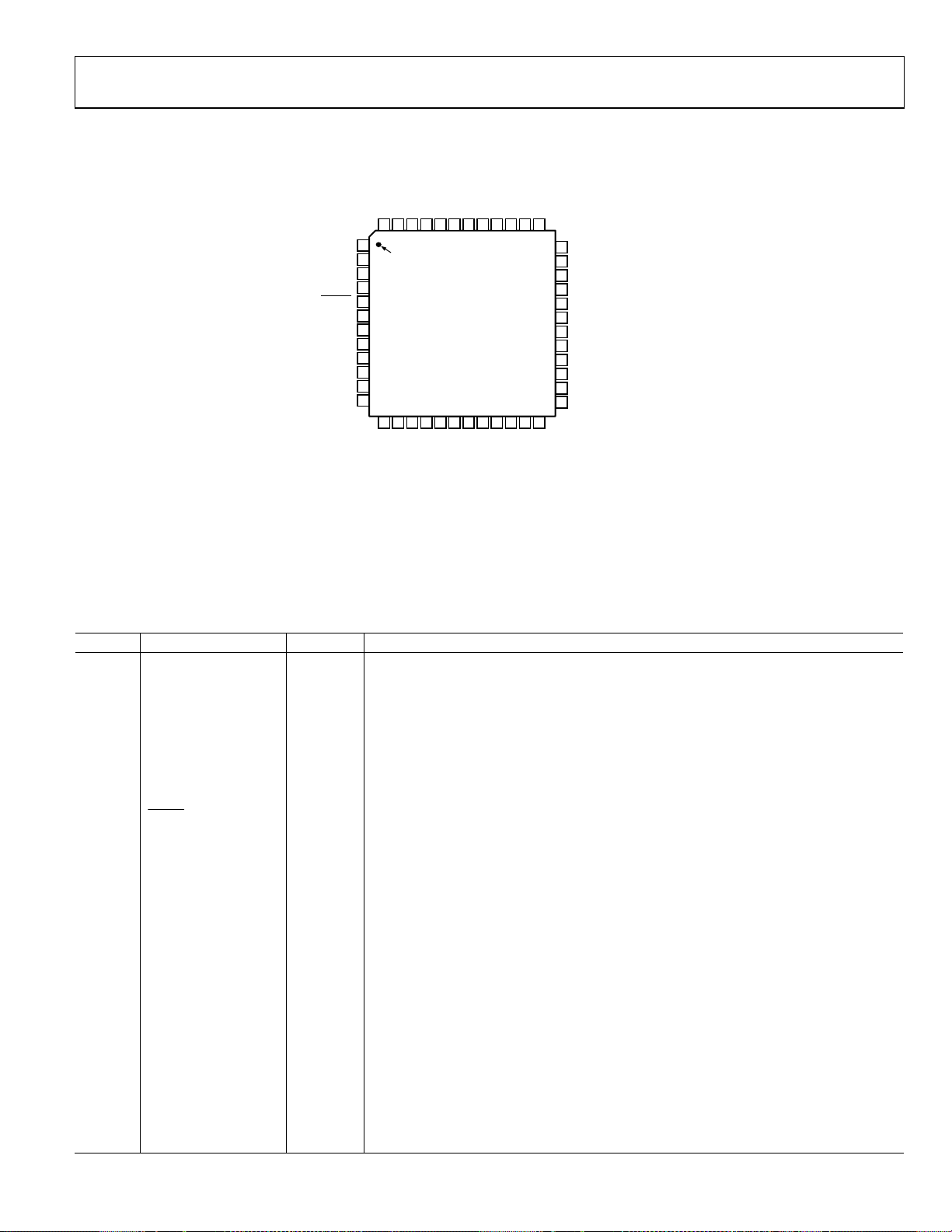

Page 10

ADAU1401A

ABSOLUTE MAXIMUM RATINGS

Table 9.

Parameter Rating

DVDD to Ground 0 V to 2.2 V

AVDD to Ground 0 V to 4.0 V

IOVDD to Ground 0 V to 4.0 V

Digital Inputs DGND − 0.3 V, IOVDD + 0.3 V

Maximum Junction Temperature 135°C

Storage Temperature Range −65°C to +150°C

Soldering (10 sec) 300°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 10. Thermal Resistance

Package Type θJA θ

48-Lead LQFP 72 19.5 °C/W

Unit

JC

ESD CAUTION

Rev. A | Page 10 of 52

Page 11

ADAU1401A

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

AVDD

FILTA

VOUT0

VOUT1

VOUT2

VOUT3

AGND

FILTDCMPLL_MODE1

PLL_MODE0

AGND

36

AVDD

35

PLL_LF

34

PVDD

33

PGND

32

MCLKI

31

OSCO

30

RSVD

29

MP2/SDATA_I N2/AUX_ADC1

28

MP3/SDATA_I N3/AUX_ADC2

27

MP8/SDATA_O UT2/AUX_ADC3

26

MP9/SDATA_O UT3/AUX_ADC0

25

DGND

AGND

ADC0

ADC_RES

ADC1

RESET

SELFBOOT

ADDR0

MP4/INPUT_LRCLK

MP5/INPUT_BCLK

MP1/SDATA_I N1

MP0/SDATA_I N0

DGND

48 47 46 45 44 43 42 41 40 39 38 37

1

PIN 1

INDICATOR

2

3

4

5

6

7

8

9

10

11

12

ADAU1401A

TOP VIEW

(Not to Scale)

13 14 15 16 17 18 19 20 21 22 23 24

DVDD

MP7/SDATA_OUT1

MP6/SDATA_O UT0/TDM_I N

MP11

IOVDD

VDRIVE

ADDR1/CDATA/WB

MP10/OUTPUT_LRCLK

DVDD

SCL/CCLK

SDA/COUT

CLATCH/WP

08506-007

Figure 7. 48-Lead LQFP Pin Configuration

Table 11. Pin Function Descriptions

Pin No. Mnemonic Typ e1 Description

1, 37, 42 AGND PWR

Analog Ground Pin. The AGND, DGND, and PGND pins can be tied directly together in a

common ground plane. AGND should be decoupled to an AVDD pin with a 100 nF capacitor.

2 ADC0 A_IN

Analog Audio Input 0. Full-scale 100 A rms input. The current input allows the input voltage

level to be scaled with an external resistor. An 18 kΩ resistor results in a 2 V rms full-scale input.

See the Audio ADCS section for details.

3 ADC_RES A_IN

ADC Reference Current. The full-scale current of the ADCs can be set with an external 18 kΩ

resistor connected between this pin and ground. See the Audio ADCS section for details.

4 ADC1 A_IN

Analog Audio Input 1. Full-scale 100 A rms input. The current input allows the input voltage

level to be scaled with an external resistor. An 18 kΩ resistor results in a 2 V rms full-scale input.

5

RESET

D_IN

Active Low Reset Input. Reset is triggered on a high-to-low edge, and the ADAU1401A exits

reset on a low-to-high edge. For more information about initialization, see the Power-Up

Sequence section for details.

6 SELFBOOT D_IN

Enable/Disable Self-Boot. SELFBOOT selects control port (low) or self-boot (high). Setting

this pin high initiates a self-boot operation when the ADAU1401A is brought out of a reset.

This pin can be tied directly to the control voltage or pulled up/down with a resistor. See

the Self-Boot section.

7 ADDR0 D_IN

8 MP4/INPUT_LRCLK D_IO

2

C and SPI Address 0. In combination with ADDR1, this pin allows up to four ADAU1401A

I

devices to be used on the same I

CLATCH signal. See the I

2

2

C bus or up to two ICs to be used with a common SPI

C Port section for details.

Multipurpose GPIO/Serial Input Port LRCLK. See the Multipurpose Pins section for more

details.

9 MP5/INPUT_BCLK D_IO Multipurpose GPIO/Serial Input Port BCLK. See the Multipurpose Pins section for more details.

10 MP1/SDATA_IN1 D_IO

Multipurpose GPIO/Serial Input Port Data 1. See the Multipurpose Pins section for more

details.

11 MP0/SDATA_IN0 D_IO

Multipurpose GPIO/Serial Input Port Data 0. See the Multipurpose Pins section for more

details.

12, 25 DGND PWR

Digital Ground Pin. The AGND, DGND, and PGND pins can be tied directly together in a

common ground plane. DGND should be decoupled to a DVDD pin with a 100 nF capacitor.

13, 24 DVDD PWR

1.8 V Digital Supply. The input for this pin can be supplied either externally or generated

Rev. A | Page 11 of 52

Page 12

ADAU1401A

Pin No. Mnemonic Typ e1 Description

from a 3.3 V supply with the on-board 1.8 V regulator. DVDD should be decoupled to DGND

with a 100 nF capacitor.

14 MP7/SDATA_OUT1 D_IO

15

MP6/SDATA_OUT0/

D_IO

TDM_IN

16 MP10/OUTPUT_LRCLK D_IO

17 VDRIVE A_OUT

18 IOVDD PWR

19 MP11 D_IO

20 ADDR1/CDATA/WB D_IN

21 CLATCH/WP D_IO

22 SDA/COUT D_IO

23 SCL/CCLK D_IO

26

MP9/SDATA_OUT3/

D_IO/A_IO

AUX_ADC0

27

MP8/SDATA_OUT2/

D_IO/A_IO

AUX_ADC3

28

MP3/SDATA_IN3/

D_IO/A_IO

AUX_ADC2

29

MP2/SDATA_IN2/

D_IO/A_IO

AUX_ADC1

30 RSVD Reserved. Tie this pin to ground, either directly or through a pull-down resistor.

31 OSCO D_OUT

32 MCLKI D_IN

33 PGND PWR

34 PVDD PWR

35 PLL_LF A_OUT

36, 48 AVDD PWR 3.3 V Analog Supply. This pin should be decoupled to AGND with a 100 nF capacitor.

Multipurpose GPIO/Serial Output Port Data 1. See the Multipurpose Pins section for

more details.

Multipurpose GPIO/Serial Output Port Data 0/TDM Data Input. See the Multipurpose Pins

section for more details.

Multipurpose GPIO/Serial Output Port LRCLK. See the Multipurpose Pins section for

more details.

Drive for 1.8 V Regulator. The base of the voltage regulator external PNP transistor is

driven from VDRIVE. See the Voltage Regulator section for details.

Supply for Input and Output Pins. The voltage on this pin sets the highest input voltage that

should be seen on the digital input pins. This pin is also the supply for the digital output signals

on the control port and MPx pins. IOVDD should always be set to 3.3 V. The current draw of this

pin is variable because it is dependent on the loads of the digital outputs.

Multipurpose GPIO or Serial Output Port BCLK (OUTPUT_BCLK). See the Multipurpose Pins

section for more details.

2

C Address 1/SPI Data Input/EEPROM Writeback Trigger. ADDR1 in combination with ADDR0

I

sets the I

bus (see the I

2

C address of the IC so that four ADAU1401A devices can be used on the same I2C

2

C Port section for details). For more information about the CDATA function of this

pin, see the SPI Port section. A rising (default) or falling (if set by EEPROM messages) edge

on the WB pin triggers a writeback of the interface registers to the external EEPROM. This

function can be used to save parameter data on power-down (see the Self-Boot section

for details).

SPI Latch Signal/Self-Boot EEPROM Write Protect. CLATCH must go low at the beginning of an

SPI transaction and high at the end of a transaction. Each SPI transaction can take a different

number of cycles on the CCLK pin to complete, depending on the address and read/write

bit that are sent at the beginning of the SPI transaction (see the SPI Port section for details). The

WP pin is an open-collector output when the device is in self-boot mode. The ADAU1401A

pulls WP low to enable writes to an external EEPROM. This pin should be pulled high to

3.3 V (see the Self-Boot section for details).

2

C Data/SPI Data Output. SDA is a bidirectional open collector. The line connected to SDA

I

should have a 2.2 kΩ pull-up resistor (see the I

2

C Port section for details). COUT is used for

reading back registers and memory locations. It is three-stated when an SPI read is not

active (see the SPI Port section for details).

2

C Clock/SPI Clock. SCL is always an open-collector input when in I2C control mode. In

I

self-boot mode, SCL is an open-collector output (I

should have a 2.2 kΩ pull-up resistor (see the I

2

C master). The line connected to SCL

2

C Port section for details). CCLK can either

run continuously or be gated off between SPI transactions (see the SPI Port section for details).

Multipurpose GPIO/Serial Output Port Data 3/Auxiliary ADC Input 0. See the Multipurpose

Pins section for more details.

Multipurpose GPIO/Serial Output Port Data 2/Auxiliary ADC Input 3. See the Multipurpose

Pins section for more details.

Multipurpose GPIO/Serial Input Port Data 3/Auxiliary ADC Input 2. See the Multipurpose

Pins section for more details.

Multipurpose GPIO/Serial Input Port Data 2/Auxiliary ADC Input 1. See the Multipurpose

Pins section for more details.

Crystal Oscillator Circuit Output. A 100 Ω damping resistor should be connected between

this pin and the crystal. This output should not be used to directly drive a clock to another

IC. If the crystal oscillator is not used, this pin can be left unconnected. See the Using the

Oscillator section for details.

Master Clock Input. This pin can either be connected to a 3.3 V clock signal or be the input

from the crystal oscillator circuit. See the Setting Master Clock/PLL Mode section for details.

PLL Ground Pin. The AGND, DGND, and PGND pins can be tied directly together in a

common ground plane. PGND should be decoupled to PVDD with a 100 nF capacitor.

3.3 V Power Supply for the PLL and the Auxiliary ADC Analog Section. This pin should be

decoupled to PGND with a 100 nF capacitor.

PLL Loop Filter Connection. Two capacitors and a resistor must be connected to this pin, as

shown in Figure 15. See the Setting Master Clock/PLL Mode section for more details.

Rev. A | Page 12 of 52

Page 13

ADAU1401A

Pin No. Mnemonic Typ e1 Description

38, 39

PLL_MODE0,

PLL_MODE1

40 CM A_OUT

41 FILTD A_OUT

43 VOUT3 A_OUT

44 VOUT2 A_OUT

45 VOUT1 A_OUT

46 VOUT0 A_OUT

47 FILTA A_OUT

1

PWR = power/ground, A_IN = analog input, D_IN = digital input, A_OUT = analog output, D_IO = digital input/output, D_IO/A_IO = digital input/output or analog

input/output.

D_IN

PLL Mode Setting. These pins set the output frequency of the master clock PLL. See the

Setting Master Clock/PLL Mode section for more details.

1.5 V Common-Mode Reference. A 47 F decoupling capacitor should be connected

between this pin and ground to reduce crosstalk between the ADCs and DACs. The material of

the capacitors is not critical. This pin can be used to bias external analog circuits, as long as

those circuits are not drawing current from the pin (such as when the CM pin is connected

to the noninverting input of an op amp).

DAC Filter Decoupling Pin. A 10 F capacitor should be connected between this pin and

ground. The capacitor material is not critical. The voltage on this pin is 1.5 V.

VOUT3 DAC Output. The full-scale output voltage is 0.9 V rms. This output can be used with

an active or passive output reconstruction filter. See the Audio DACS section for details.

VOUT2 DAC Output. The full-scale output voltage is 0.9 V rms. This output can be used with

an active or passive output reconstruction filter. See the Audio DACS section for details.

VOUT1 DAC Output. The full-scale output voltage is 0.9 V rms. This output can be used with

an active or passive output reconstruction filter. See the Audio DACS section for details.

VOUT0 DAC Output. The full-scale output voltage is 0.9 V rms. This output can be used with

an active or passive output reconstruction filter. See the Audio DACS section for details.

ADC Filter Decoupling Pin. A 10 F capacitor should be connected between this pin and

ground. The capacitor material is not critical. The voltage on this pin is 1.5 V.

Rev. A | Page 13 of 52

Page 14

ADAU1401A

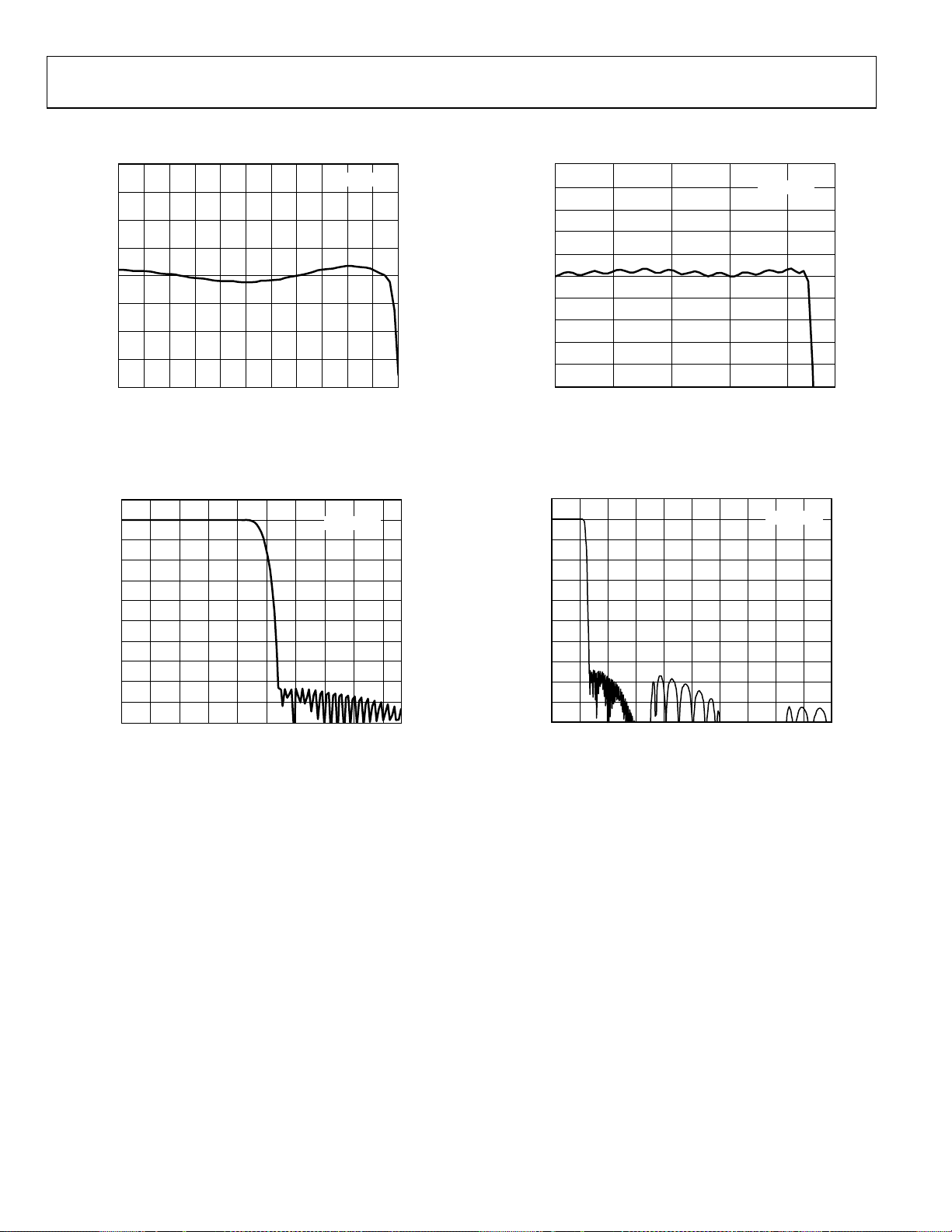

TYPICAL PERFORMANCE CHARACTERISTICS

0.20

0.15

0.10

0.05

0

GAIN (dB)

–0.05

–0.10

–0.15

–0.20

0 2 4 6 8 10 12 14 16 18 20 22

FREQUENCY (kHz)

Figure 8. ADC Pass-Band Filter Response

f

= 48kHz

S

08506-008

0.10

0.08

0.06

0.04

0.02

0

GAIN (dB)

–0.02

–0.04

–0.06

–0.08

–0.10

0 5 10 15 20

FREQUENCY (kHz)

Figure 10. DAC Pass-Band Filter Response

f

= 48kHz

S

8506-010

10

0

–10

–20

–30

–40

–50

GAIN (dB)

–60

–70

–80

–90

–100

0 2530354020151054

FREQUENCY (kHz)

f

= 48kHz

S

5

8506-009

Figure 9. ADC Stop-Band Filter Response

10

0

–10

–20

–30

–40

–50

GAIN (dB)

–60

–70

–80

–90

–100

0 2 4 6 8 10 12 14 16 18 20

FREQUENCY (kHz)

Figure 11. DAC Stop-Band Filter Response

f

= 48kHz

S

8506-011

Rev. A | Page 14 of 52

Page 15

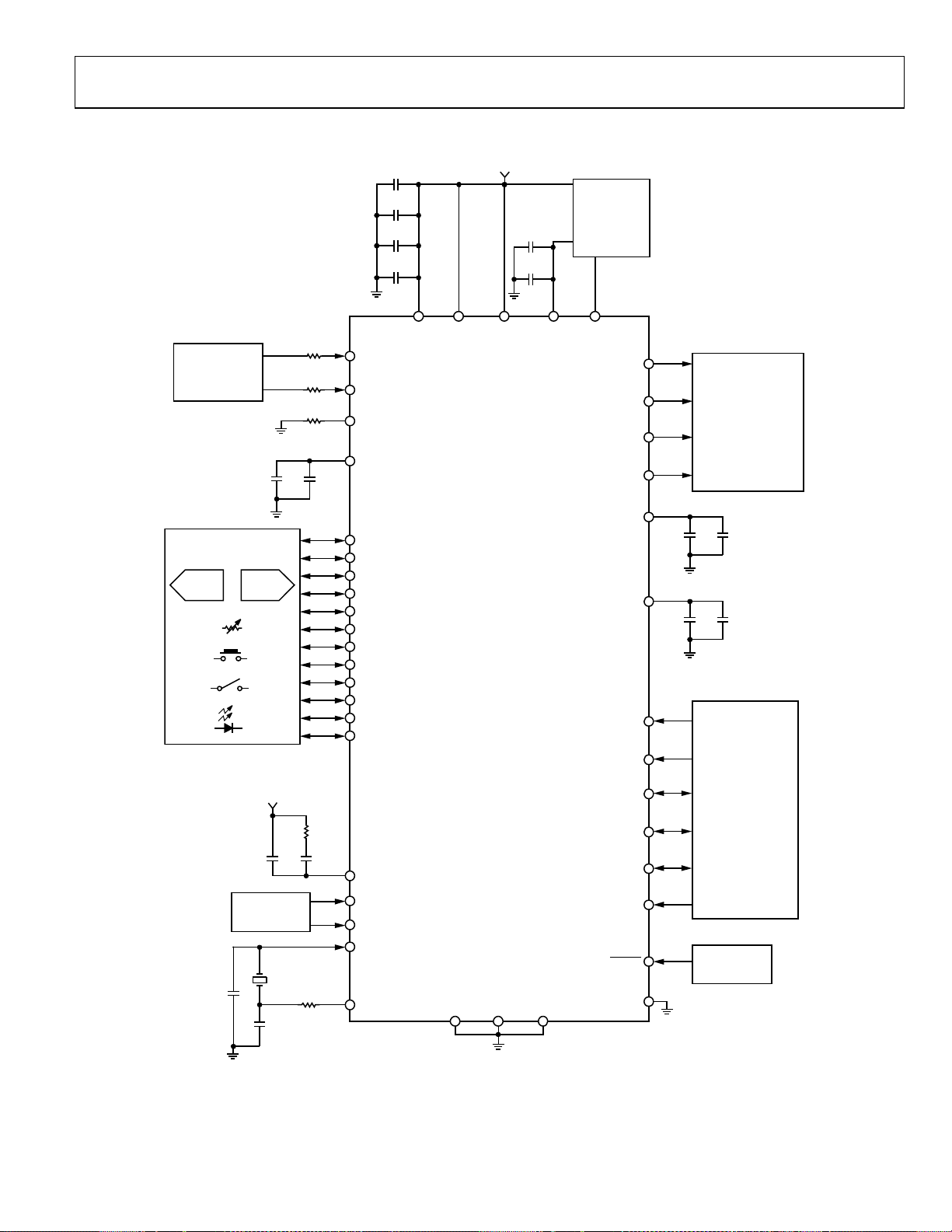

ADAU1401A

V

SYSTEM BLOCK DIAGRAM

100nF

3.3

AUDIO ADC

INPUT SIGNALS

10µF

MULTIPURPOSE

PIN INTERF ACES

ADCs DACs

100nF

100nF

10µF

+

IOVDD PVDD AVDD DVDD VDRIVE

18k

18k

18k

+

100nF

ADC0

ADC1

ADC_RES

FILTA

MP0

MP1

MP2

MP3

MP4

MP5

MP6

MP7

MP8

MP9

MP10

MP11

ADAU1401A

100nF

10µF

+

3.3V TO 1. 8V

REGULATOR

CIRCUIT

VOUT0

VOUT1

VOUT2

VOUT3

FILTD

CM

ADDR0

ADDR1/CDATA/WB

DAC OUTPUT FILTERS

(ACTIVE OR PASSIVE)

+

+

47µF

100nF10µ F

100nF

EEPROM,

MICROCONTRO LLER,

AND/OR SELF-BOOT

LOGIC

RESET LOGIC

08506-012

22pF

3.3V

PLL

SETTINGS

3MHz TO 25MHz

22pF

100

475

56nF3.3nF

PLL_LF

PLL_MODE0

PLL_MODE1

MCLKI

OSCO

AGND DGND PGND

CLATCH/WP

SDA/COUT

SCL/CCLK

SELFBOOT

RESET

RSVD

Figure 12. System Block Diagram

Rev. A | Page 15 of 52

Page 16

ADAU1401A

THEORY OF OPERATION

The core of the ADAU1401A is a 28-bit DSP (56-bit with doubleprecision processing) optimized for audio processing. The

program and parameter RAMs can be loaded with a custom

audio processing signal flow built using the SigmaStudio graphical

programming software from Analog Devices, Inc. The values

stored in the parameter RAM control individual signal processing

blocks, such as equalization filters, dynamics processors, audio

delays, and mixer levels. A safeload feature allows transparent

parameter updates and prevents clicks in the output signals.

The program RAM, parameter RAM, and register contents can

be saved in an external EEPROM, from which the ADAU1401A

can self-boot on startup. In this standalone mode, parameters

can be controlled through the on-board multipurpose pins. The

ADAU1401A can accept controls from switches, potentiometers,

rotary encoders, and IR receivers. Parameters such as volume

and tone settings can be saved to the EEPROM on power-down

and recalled again on power-up.

The ADAU1401A can operate with digital or analog inputs and

outputs, or a mix of both. The stereo ADC and four DACs each

have an SNR of at least +100 dB and a THD + N of at least

−83 dB. The 8-channel, flexible serial data input/output ports

allow glueless interconnection to a variety of ADCs, DACs,

general-purpose DSPs, S/PDIF receivers and transmitters, and

sample rate converters. The serial ports of the ADAU1401A can

be configured in I

2

S, left-justified, right-justified, or TDM serial

port compatible modes.

Twelve multipurpose pins (MP0 to MP11) allow the ADAU1401A

to receive external control signals as input and to output flags or

controls to other devices in the system. The MPx pins can be

configured as digital I/Os, inputs to the 4-channel auxiliary

ADC, or serial data I/O ports. As inputs, these pins can be

connected to buttons, switches, rotary encoders, potentiometers,

IR receivers, or other external circuitry to control the internal

signal processing program. When configured as outputs, these

pins can be used to drive LEDs, control other ICs, or connect to

other external circuitry in an application.

The ADAU1401A has a sophisticated control port that supports

complete read/write capability of all memory locations. Control

registers are provided to offer complete control of the configuration and serial modes of the chip. The ADAU1401A can be

configured for either SPI or I

2

C control, or it can self-boot from

an external EEPROM.

An on-board oscillator can be connected to an external crystal

to generate the master clock. In addition, a master clock phase-

locked loop (PLL) allows the ADAU1401A to be clocked from

various clock speeds. The PLL can accept inputs of 64 × f

384 × f

, or 512 × fS to generate the internal master clock of the core.

S

, 256 × fS,

S

The SigmaStudio software is used to program and control the

SigmaDSP® through the control port. Along with designing and

tuning a signal flow, SigmaStudio tools can be used to configure

all of the DSP registers and burn a new program into the external

EEPROM. The SigmaStudio graphical interface allows anyone

with digital or analog audio processing knowledge to easily design

a DSP signal flow and port it to a target application. In addition,

the interface provides enough flexibility and programmability

for an experienced DSP programmer to have in-depth control

of the design. In SigmaStudio, the user can connect graphical

blocks (such as biquad filters, dynamics processors, mixers, and

delays), compile the design, and load the program and parameter

files into the ADAU1401A memory through the control port.

Signal processing blocks available in the provided libraries include

• Single- and double-precision biquad filters

• Processors with peak or rms detection for monochannel

and multichannel dynamics

• Mixers and splitters

• Tone and noise generators

• Fixed and variable gain

• Loudness

• Delay

• Stereo enhancement

• Dynamic bass boost

• Noise and tone sources

• FIR filters

• Level detectors

• GPIO control and conditioning

Additional processing blocks are always being developed.

Analog Devices also provides proprietary and third-party

algorithms for applications such as matrix decoding, bass

enhancement, and surround virtualizers. Contact Analog

Devices for information about licensing these algorithms.

The ADAU1401A operates from a 1.8 V digital power supply

and a 3.3 V analog supply. An on-board voltage regulator can

be used to operate the chip from a single 3.3 V supply. The

ADAU1401A is fabricated on a single monolithic, integrated

circuit and is packaged in a 48-lead LQFP for operation over the

−40°C to +105°C temperature range.

Rev. A | Page 16 of 52

Page 17

ADAU1401A

INITIALIZATION

This section describes the procedure for properly setting up the

ADAU1401A. The following five-step sequence provides an

overview of how to initialize the IC:

1. Apply power to the ADAU1401A.

2. Wai t fo r t h e P L L t o l o ck .

3. Load the SigmaDSP program and parameters.

4. Set up registers (including multipurpose pins and digital

interfaces).

5. Turn off the default muting of the converters, clear the

data registers, and initialize the DAC setup register (see

the Control Registers Setup section for specific settings).

To only test analog audio pass-through (ADCs to DACs), skip

Step 3 and Step 4 and use the default internal program.

POWER-UP SEQUENCE

The ADAU1401A has a built-in power-up sequence that initializes

the contents of all internal RAMs on power-up or when the device

is brought out of a reset. On the rising edge of

of the internal program boot ROM are copied to the internal

program RAM memory, the parameter RAM is filled with values

(all 0s) from its associated boot ROM, and all registers are

initialized to 0s. The default boot ROM program copies audio

from the inputs to the outputs without processing it (see

13

). In this program, SDATA_IN0 and SDATA_IN1 are output

on DAC0 and DAC1 and on SDATA_OUT0 and

SDATA_OUT1. ADC0 and ADC1 are output on DAC2 and

DAC3. The data memories are also zeroed at power-up. New

values should not be written to the control port until the

initialization is complete.

Table 12. Power-Up Time

Maximum Program/

MCLKI Input

Frequency

3.072 MHz (64 × fS) 85 ms 175 ms 260 ms

11.2896 MHz (256 × fS) 23 ms 175 ms 198 ms

12.288 MHz (256 × fS) 21 ms 175 ms 196 ms

18.432 MHz (384 × fS) 16 ms 175 ms 191 ms

24.576 MHz (512 × fS) 11 ms 175 ms 186 ms

Init.

Time

Parame ter/Regis ter

Boot Time (I

The PLL start-up time lasts for 218 cycles of the clock on the

MCLKI pin. This time ranges from 10.7 ms for a 24.576 MHz

(512 × f

) input clock to 85.3 ms for a 3.072 MHz (64 × fS) input

S

clock and is measured from the rising edge of

the PLL startup, the duration of the ADAU1401A boot cycle is

about 42 s for a f

of 48 kHz. The user should avoid writing to or

S

reading from the ADAU1401A during this start-up time. For an

MCLKI input signal of 12.288 MHz, the full initialization sequence

(PLL startup plus boot cycle) is approximately 21 ms. As the device

comes out of a reset, the clock mode is immediately set by the

PLL_MODE0 and PLL_MODE1 pins. The reset is synchronized

to the falling edge of the internal clock.

RESET

2

C)

RESET

, the contents

Figure

To ta l

Time

. Following

Tabl e 12 lists typical times to boot the ADAU1401A into an

operational state for an application, assuming a 400 kHz I

2

C

clock loading a full program, parameter set, and all registers

(about 8.5 kB). In reality, most applications do not fill the RAMs

and, therefore, boot time is less than the value listed in Column 3

of Tab l e 1 2 .

CONTROL REGISTERS SETUP

The following registers must be set as described in this section

to initialize the ADAU1401A. These settings are the basic

minimum settings needed to operate the IC with an analog

input/output of 48 kHz. More registers may need to be set,

depending on the application. See the RAMs and Registers

section for additional settings.

DSP Core Control Register (Address 2076)

Set Bits[4:2] (ADM, DAM, and CR) each to 111.

DAC Setup Register (Address 2087)

Set Bits[1:0] (DS[1:0]) to 01.

RECOMMENDED PROGRAM/PARAMETER LOADING PROCEDURE

When writing large amounts of data to the program or parameter RAM in direct write mode, the processor core should

be disabled to prevent unpleasant noises from appearing in

the audio output. To disable the processor core,

1. Set Bits[4:3] (active low) of the DSP core control register

(Address 2076) to 1 to mute the ADCs and DACs. This

begins a volume ramp-down.

2. Set Bit 2 (active low) of the DSP core control register to 1.

This zeroes the SigmaDSP accumulators, the data output

registers, and the data input registers.

3. Fill the program RAM using burst mode writes.

4. Fill the parameter RAM using burst mode writes.

5. Set Bits[4:2] of the DSP core control register to 111.

DAC0

DAC1

DAC2

DAC3

SDATA_OUT0

08506-013

SDATA_IN0

ADC0

ADC1

Figure 13. Default Program Signal Flow

POWER REDUCTION MODES

Sections of the ADAU1401A chip can be turned on and off as

needed to reduce power consumption. These include the ADCs,

DACs, and voltage reference.

The individual analog sections can be turned off by writing to

the auxiliary ADC and power control register (Address 2082).

By default, the ADCs, DACs, and reference are enabled (all bits

Rev. A | Page 17 of 52

Page 18

ADAU1401A

V

3

F

set to 0). Each of these can be turned off by writing a 1 to the

appropriate bits in this register. The ADC power-down mode

powers down both ADCs, and each DAC can be powered down

individually. The current savings is about 15 mA when the ADCs

are powered down and about 4 mA for each DAC that is powered

down. The voltage reference, which is supplied to both the ADCs

and DACs, should only be powered down if all ADCs and DACs

are powered down. The voltage reference is powered down by

setting both Bit 6 and Bit 7 of the auxiliary ADC and power

control register.

USING THE OSCILLATOR

The ADAU1401A can use an on-board oscillator to generate its

master clock. The oscillator is designed to work with a 256 × f

master clock, which is 12.288 MHz for a f

11.2896 MHz for a f

of 44.1 kHz. The crystal in the oscillator

S

of 48 kHz and

S

circuit should be an AT-cut, parallel resonator operating at its

fundamental frequency. Figure 14 shows the external circuit

recommended for proper operation.

ADAU1401A

C1

100

OSCO

C2

Figure 14. Crystal Oscillator Circuit

MCLKI

08506-014

The 100 damping resistor on OSCO gives the oscillator a

voltage swing of approximately 2.2 V. The crystal shunt capacitance should be 7 pF. Its load capacitance should be about 18 pF,

although the circuit supports values of up to 25 pF. The necessary

values of the C1 and C2 load capacitors can be calculated from

the crystal load capacitance as follows:

C +

L

where C

×

=

C2C1

+

is the stray capacitance in the circuit and is usually

STRAY

C

STRAY

C2C1

assumed to be approximately 2 pF to 5 pF.

OSCO should not be used to drive the crystal signal directly to

another IC. This signal is an analog sine wave, and it is not appropriate to use it to drive a digital input. There are two options for

using the ADAU1401A to provide a master clock to other ICs in

the system. The first, and less recommended, method is to use a

high impedance input digital buffer on the OSCO signal. If this

approach is used, minimize the trace length to the buffer input.

The second method is to use a clock from the serial output port.

Pin 19 (MP11) can be set as an output (master) clock divided down

from the internal core clock. If this pin is set to serial output port

(OUTPUT_BCLK) mode in the multipurpose pin configuration

register (Address 2081) and the port is set to master in the serial

output control register (Address 2078), the desired output frequency can also be set in the serial output control register with

the OBF[1:0] bits (see Tab le 4 9).

S

If the oscillator is not used in the design and a system master clock

is already available in the system, the oscillator can be powered

down to save power. By default, the oscillator is powered on. The

oscillator powers down when a 1 is written to the OPD bit of

the oscillator power-down register (Address 2086; see Tabl e 60 ).

SETTING MASTER CLOCK/PLL MODE

The MCLKI input of the ADAU1401A feeds a PLL, which

generates the 50 MIPS SigmaDSP core clock. In normal operation,

the input to MCLKI must be one of the following: 64 × f

384 × f

, or 512 × fS, where fS is the input sampling rate. The mode

S

is set by configuring PLL_MODE0 and PLL_MODE1 as described

in Tabl e 1 3 . If the ADAU1401A is set to receive double-rate signals

(by reducing the number of program steps per sample by a factor

of 2 using the core control register), the master clock frequency

must be 32 × f

, 128 × fS, 192 × fS, or 256 × fS. If the ADAU1401A

S

is set to receive quad-rate signals (by reducing the number of

program steps per sample by a factor of 4 using the DSP core

control register), the master clock frequency must be 16 × f

, 96 × fS, or 128 × fS. On power-up, a clock signal must be

64 × f

S

present on the MCLKI pin so that the ADAU1401A can complete

its initialization routine.

Table 13. PLL Modes

MCLKI Input

Frequency

PLL_MODE0 PLL_MODE1

64 × fS 0 0

256 × fS 0 1

384 × f

1 0

S

512 × f

1 1

S

The clock mode should not be changed without also resetting

the ADAU1401A. If the mode is changed during operation, a

click or pop may result in the output signals. The state of the

PLL_MODEx pins should be changed while

RESET

The PLL loop filter should be connected to the PLL_LF pin. This

filter, shown in Figure 15, includes three passive components—

two capacitors and a resistor. The values of these components

do not need to be exact; the tolerance can be up to 10% for the

resistor and up to 20% for the capacitors. The 3.3 V signal shown in

Figure 15 can be connected to the AVDD supply of the chip.

3.3

475

.3n

PLL_LF

Figure 15. PLL Loop Filter

56nF

ADAU1401A

08506-015

, 256 × fS,

S

,

S

is held low.

Rev. A | Page 18 of 52

Page 19

ADAU1401A

V

VOLTAGE REGULATOR

The digital voltage of the ADAU1401A must be set to 1.8 V. The

chip includes an on-board voltage regulator that allows the

device to be used in systems without an available 1.8 V supply

but with an available 3.3 V supply. The only external components

needed in such instances are a PNP transistor, a resistor, and a

few bypass capacitors. Only one pin, VDRIVE, is necessary to

support the regulator.

The recommended design for the voltage regulator is shown

in Figure 16. The 10 µF and 100 nF capacitors shown in this

configuration are recommended for bypassing, but are not

necessary for operation. Each DVDD pin should have its own

100 nF bypass capacitor, but only one bulk capacitor (10 µF to

47 µF) is needed for both DVDD pins. With this configuration,

3.3 V is the main system voltage; 1.8 V is generated at the

transistor’s collector, which is connected to the DVDD pins.

VDRIVE is connected to the base of the PNP transistor. If the

regulator is not used in the design, VDRIVE can be tied to ground.

Two specifications must be considered when choosing a regulator transistor: the transistor’s current amplification factor

(h

or beta) should be at least 100, and the transistor’s collector

FE

must be able to dissipate the heat generated when regulating

from 3.3 V to 1.8 V. The maximum digital current drawn from

the ADAU1401A is 40 mA. The equation to determine the

minimum power dissipation of the transistor is as follows:

(3.3 V − 1.8 V) × 60 mA = 90 mW

There are many transistors with these specifications available in

small SOT-23 or SOT-223 packages.

10µF

+

100nF

DVDD

VDRIVE

Figure 16. Voltage Regulator Configuration

3.3

1k

ADAU1401A

08506-016

Rev. A | Page 19 of 52

Page 20

ADAU1401A

AUDIO ADCs

The ADAU1401A has two Σ- ADCs. The signal-to-noise ratio

(SNR) of the ADCs is 100 dB, and the THD + N is −83 dB.

The stereo audio ADCs are current input; therefore, a voltageto-current resistor is required on the inputs. This means that

the voltage level of the input signals to the system can be set to

any level; only the input resistors need to be scaled to provide

the proper full-scale current input. The ADC0 and ADC1 input

pins, as well as the ADC_RES pin, have an internal 2 kΩ resistor

for ESD protection. The voltage seen directly on the ADC input

pins is the 1.5 V common-mode voltage.

The external resistor connected to ADC_RES sets the full-scale

current input of the ADCs. The full range of the ADC inputs is

100 µA rms with an external 18 kΩ resistor on ADC_RES (20 kΩ

total, because it is in series with the internal 2 kΩ). The only

reason to change the ADC_RES resistor is if a sampling rate

other than 48 kHz is used.

The voltage-to-current resistors connected to ADC0 and ADC1 set

the full-scale voltage input of the ADCs. With a full-scale current

input of 100 µA rms, a 2.0 V rms signal with an external 18 kΩ

resistor (in series with the 2 kΩ internal resistor) results in an

input using the full range of the ADC. The matching of these

resistors to the ADC_RES resistor is important to the operation of

the ADCs. For these three resistors, a 1% tolerance is recommended.

The ADC0 input pin and/or the ADC1 input pin can be left

unconnected if the corresponding channel of the ADC is unused.

The calculations of resistor values assume a 48 kHz sample rate.

The recommended input and current setting resistors scale linearly

with the sample rate because the ADCs have a switched-capacitor

input. The total value (2 kΩ internal plus external resistor) of the

ADC_RES resistor with sample rate f

can be calculated as

S_NEW

follows:

R

TOTAL

k20 ×=

000,48

f

NEWS

_

The values of the resistors (internal plus external) in series with

the ADC0 and ADC1 pins can be calculated as follows:

TOTALINPUT

VoltageInputrmsR

k10)( ××=

000,48

f

NEWS

_

Tabl e 14 lists the external and total resistor values for common

signal input levels at a 48 kHz sampling rate. A full-scale rms

input voltage of 0.9 V is shown in the table because a full-scale

signal at this input level is equal to a full-scale output on the DACs.

Table 14. ADC Input Resistor Values

Total ADC0/ADC1

Full-Scale

RMS Input

Voltage (V)

ADC_RES

Value (kΩ)

ADC0/ADC1

Resistor

Value (kΩ)

Input Resistance

(External +

Internal) (kΩ)

0.9 18 7 9

1.0 18 8 10

2.0 18 18 20

Figure 17 shows a typical configuration of the ADC inputs for

a 2.0 V rms input signal for a f

of 48 kHz. The 47 F capacitors are

S

used to ac-couple the signals so that the inputs are biased at 1.5 V.

47µF

47µF

Figure 17. Audio ADC Input Configuration

ADAU1401A

18k

18k

18k

ADC0

ADC1

ADC_RES

08506-017

Rev. A | Page 20 of 52

Page 21

ADAU1401A

AUDIO DACs

The ADAU1401A includes four Σ- DACs. The SNR of the

DACs is 104 dB, and the THD + N is −90 dB. A full-scale

output on the DACs is 0.9 V rms (2.5 V p-p).

The DACs are in an inverting configuration. If a signal inversion

from input to output is undesirable, it can be reversed either by

using an inverting configuration for the output filter or by simply

inverting the signal in the SigmaDSP program flow.

The DAC outputs can be filtered with either an active or passive

reconstruction filter. A single-pole, passive, low-pass filter with

a 50 kHz corner frequency, as shown in Figure 18, is sufficient

to filter the DAC out-of-band noise, although an active filter may

provide better audio performance. Figure 19 shows a triple-pole,

470µF

AD8608

Figure 19. Active DAC Output Filter

DAC_OUT

4.75k4.75k

150pF

C8

+

active, low-pass filter that provides a steeper roll-off and better

stop-band attenuation than the passive filter. In this configuration,

the V+ and V− pins of the AD8606 op amp are set to VDD and

ground, respectively.

To properly initialize the DACs, the DS[1:0] bits in the DAC

setup register (Address 2087) should be set to 01.

47µF

DAC_OUT

Figure 18. Passive DAC Output Filter

47µF

604

+

3.3nF

49.9k

560

+

5.6nF

FILTER_OUT

08506-019

FILTER_OUT

08506-018

Rev. A | Page 21 of 52

Page 22

ADAU1401A

CONTROL PORTS

The ADAU1401A can operate in one of three control modes:

2

C control, SPI control, or self-boot (no external controller).

I

The ADAU1401A has both a 4-wire SPI control port and a

2

2-wire I

C bus control port. Either port can be used to set the

RAMs and registers. When the SELFBOOT pin is low at power-

2

up, the part defaults to I

C mode but can be put into SPI control

mode by pulling the CLATCH/WP pin low three times. When

the SELFBOOT pin is set high at power-up, the ADAU1401A

loads its program, parameters, and register settings from an

external EEPROM on startup.

The control port is capable of full read/write operation for all

addressable memory locations and registers. Most signal processing

parameters are controlled by writing new values to the parameter

RAM using the control port. Other functions, such as mute and

input/output mode control, are programmed by writing to the

registers.

All addresses can be accessed in a single-address mode or a

burst mode. The first byte (Byte 0) of a control port write

W

contains the 7-bit chip address plus the R/

bit. The next two

bytes (Byte 1 and Byte 2) together form the subaddress of the

memory or register location within the ADAU1401A. This

subaddress must be two bytes because the memory locations

within the ADAU1401A are directly addressable and their sizes

exceed the range of single-byte addressing. All subsequent bytes

(starting with Byte 3) contain the data, such as control port data,

program data, or parameter data. The number of bytes per word

depends on the type of data that is being written. The exact formats

for specific types of writes are shown in to . Tabl e 22 Ta bl e 31

The ADAU1401A has several mechanisms for updating signal

processing parameters in real time without causing pops or

clicks. If large blocks of data need to be downloaded, the output

of the DSP core can be halted (using the CR bit in the DSP core

control register (Address 2076)), new data can be loaded, and

then the device can be restarted. This is typically done during

the booting sequence at startup or when loading a new program

into RAM. In cases where only a few parameters need to be

changed, they can be loaded without halting the program. To

avoid unwanted side effects while loading parameters on-the-fly,

the SigmaDSP provides the safeload registers. The safeload

registers can be used to buffer a full set of parameters (for

example, the five coefficients of a biquad) and then transfer

these parameters into the active program within one audio

frame. The safeload mode uses internal logic to prevent

contention between the DSP core and the control port.

The control port pins are multifunctional, depending on the

mode in which the part is operating. Ta b le 1 5 details these

multiple functions.

Table 15. Control Port Pins and SELFBOOT Pin Functions

Pin I2C Mode SPI Mode Self-Boot

SCL/CCLK SCL—input CCLK—input SCL—output

SDA/COUT SDA—open-collector output and input COUT—output SDA—open-collector output and input

ADDR1/CDATA/WB ADDR1—input CDATA—input WB—writeback trigger

CLATCH/WP Unused input—tie to ground or IOVDD CLATCH—input WP—EEPROM write protect, open-collector output

ADDR0 ADDR0—input ADDR0—input Unused input—tie to ground or IOVDD

Rev. A | Page 22 of 52

Page 23

ADAU1401A

I2C PORT

The ADAU1401A supports a 2-wire serial (I2C-compatible)

microprocessor bus driving multiple peripherals. Two pins—

serial data (SDA) and serial clock (SCL)—carry information

between the ADAU1401A and the system I

2

In I

C mode, the ADAU1401A is always a slave on the bus,

meaning it cannot initiate a data transfer. Each slave device is

recognized by a unique address. The address byte format is

shown in Tab l e 1 6 . The ADAU1401A slave addresses are set

with the ADDR0 and ADDR1 pins. The address resides in the

2

first seven bits of the I

C write. The LSB of this byte sets either a

read or write operation. Logic Level 1 corresponds to a read

operation, and Logic Level 0 corresponds to a write operation.

Bit 5 and Bit 6 of the address are set by tying the ADDRx pins of

the ADAU1401A to Logic Level 0 or Logic Level 1. The full byte

addresses, including the pin settings and read/

are shown in . Tabl e 17

Burst mode addressing, where the subaddresses are automatically incremented at word boundaries, can be used for writing

large amounts of data to contiguous memory locations. This

increment happens automatically after a single-word write unless a

stop condition is encountered. The registers and RAMs in the

ADAU1401A range in width from one to five bytes; therefore, the

auto-increment feature knows the mapping between subaddresses

and the word length of the destination register (or memory

location). A data transfer is always terminated by a stop condition.

Both SDA and SCL should have 2.2 kΩ pull-up resistors on the

lines connected to them. The voltage on these signal lines should

not be more than IOVDD (3.3 V).

Table 16. ADAU1401A I2C Address Byte Format

Bit 0 Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7

0 1 1 0 1 ADDR1 ADDR0

Table 17. ADAU1401A I2C Addresses

R/

ADDR1 ADDR0

0 0 0 0x68

0 0 1 0x69

0 1 0 0x6A

0 1 1 0x6B

1 0 0 0x6C

1 0 1 0x6D

1 1 0 0x6E

1 1 1 0x6F

W

2

C master controller.

write

(R/W) bit,

R/W

Slave Address

Addressing

Initially, each device on the I2C bus is in an idle state monitoring

the SDA and SCL lines for a start condition and the proper address.

2

The I

C master initiates a data transfer by establishing a start

condition, defined by a high-to-low transition on SDA while

SCL remains high. This indicates that an address or an address

and a data stream follow. All devices on the bus respond to the

start condition and shift the next eight bits (the 7-bit address

W

plus the R/

bit) MSB first. The device that recognizes the

transmitted address responds by pulling the data line low

during the ninth clock pulse. This ninth bit is known as an

acknowledge bit. All other devices withdraw from the bus at

W

this point and return to the idle condition. The R/

bit

determines the direction of the data. A Logic 0 on the LSB of

the first byte means that the master writes information to the

peripheral, whereas a Logic 1 means that the master reads

information from the peripheral after writing the subaddress

and repeating the start address. A data transfer takes place until

a stop condition is encountered. A stop condition occurs when

SDA transitions from low to high while SCL is held high.

2

shows the timing of an I

2

C read.

of an I

C write, and shows the timing

Figure 21

Figure 20

Stop and start conditions can be detected at any stage during the

data transfer. If these conditions are asserted out of sequence

with normal read and write operations, the ADAU1401A

immediately jumps to the idle condition. During a given SCL

high period, the user should only issue one start condition, one

stop condition, or a single stop condition followed by a single

start condition. If an invalid subaddress is issued by the user,

the ADAU1401A does not issue an acknowledge and returns to

the idle condition. If the user exceeds the highest subaddress

while in auto-increment mode, one of two actions is taken. In

read mode, the ADAU1401A outputs the highest subaddress

register contents until the master device issues a no acknowledge,

indicating the end of a read. A no-acknowledge condition is

where the SDA line is not pulled low on the ninth clock pulse

on SCL. On the other hand, if the highest subaddress location is

reached while in write mode, the data for the invalid byte is not

loaded into any subaddress register, a no acknowledge is issued

by the ADAU1401A, and the part returns to the idle condition.

Rev. A | Page 23 of 52

Page 24

ADAU1401A

SCL

110

SDA

START BY

MASTER

SCL

(CONTINUED)

SDA

(CONTINUED)

SCL

SDA 0 0 011 1

START BY

MASTER

SCL

(CONTINUED)

SDA

(CONTINUED)

0

CHIP ADDRESS BYTE

CHIP ADDRESS BYTE

SUBADDRESS BYTE 2

10

FRAME 1

FRAME 3

SUBADDRESS BYTE 2

Figure 20. I

ADDR

SEL

FRAME 1

FRAME 3

ADDR

R/W

SEL

R/W

ACK BY

ADAU1401A

ACK BY

ADAU1401A

2

C Write to ADAU1401A Clocking

ACK BY

ADAU1401A

ACK BY

ADAU1401A

REPEATED

START BY MAST ER

FRAME 2

SUBADDRESS BYTE 1

FRAME 4

DATA BYTE 1

FRAME 2

SUBADDRESS BYTE 1

FRAME 4

CHIP ADDRESS BYTE

ADAU1401A

ADAU1401A

ACK BY

ADAU1401A

ADR

SEL

ACK BY

ACK BY

R/W

ACK BY

ADAU1401A

STOP BY

MASTER

08506-020

SCL

(CONTINUED)

SDA

(CONTINUED)

FRAME 5

READ DATA BYTE 1

Figure 21. I

ACK BY

MASTER

2

C Read from ADAU1401A Clocking

READ DATA BYTE 2

FRAME 6

ACK BY

MASTER

STOP BY

MASTER

08506-021

Rev. A | Page 24 of 52

Page 25

ADAU1401A

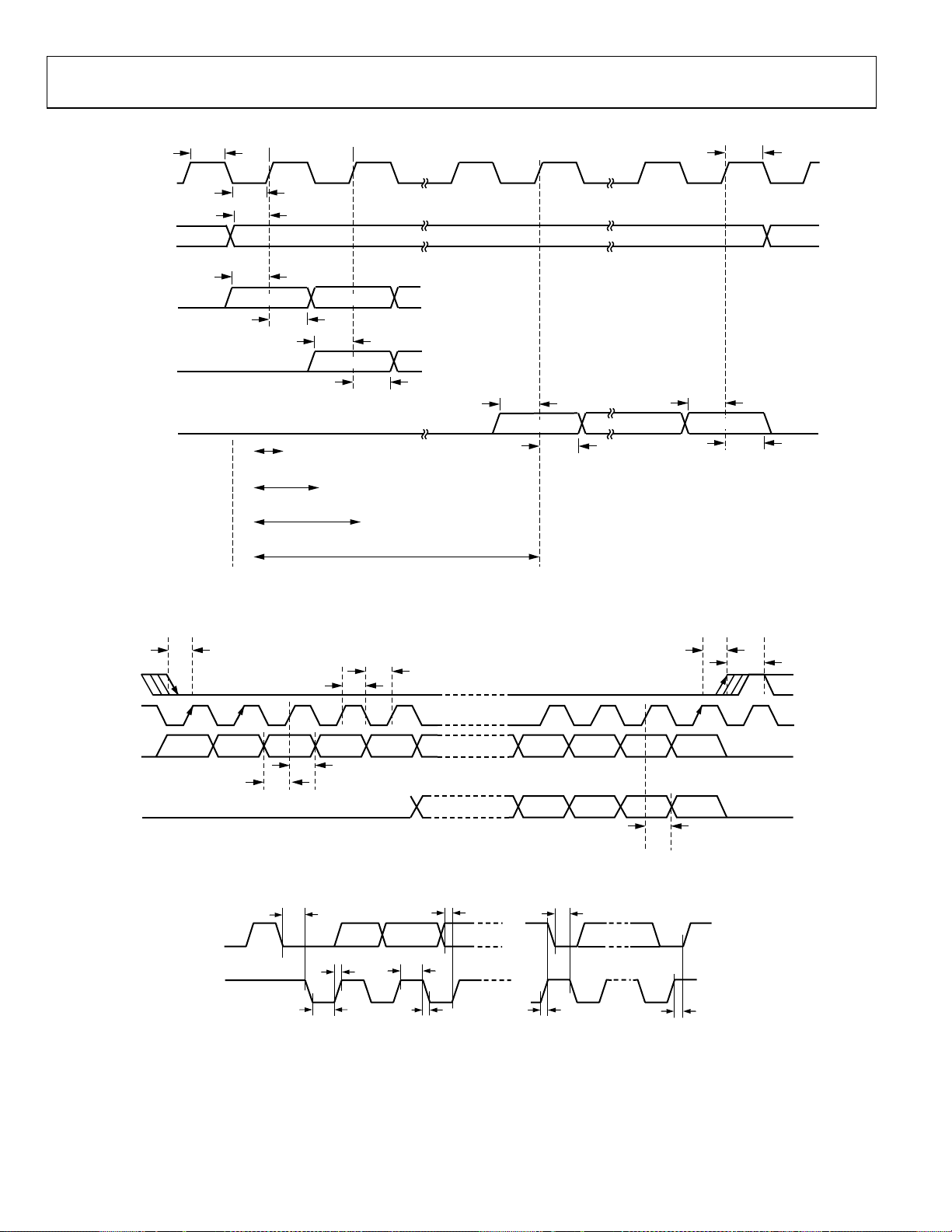

I2C Read and Write Operations

Figure 22 shows the timing of a single-word write operation. On

every ninth clock, the ADAU1401A issues an acknowledge by

pulling SDA low.

Figure 23 shows the timing of a burst mode write sequence.

This figure shows an example where the target destination

registers are two bytes. The ADAU1401A knows to increment

its subaddress register every two bytes because the requested

subaddress corresponds to a register or memory area with a

word length of two bytes.

The timing of a single-word read operation is shown in

W

Figure 24. Note that the first R/

bit is 0, indicating a write

operation. This is because the subaddress still needs to be

written to set up the internal address. After the ADAU1401A

acknowledges the receipt of the subaddress, the master must

CHIP ADDRESS,

S

R/W = 0

S = START BIT, P = STOP BIT, AS = ACKNOWLEDGE BY SLAVE.

SHOWS A ONE- WORD WRIT E, WHERE EACH WORD HAS N BYTES.

AS

SUBADDRESS,

HIGH BYTE

SUBADDRESS,

AS AS AS AS ... AS P

LOW BYTE

Figure 22. Single-Word I

CHIP

S AS AS ASASASASAS ASAS

ADDRESS,

R/W = 0

SUBADDRESS,

HIGH BYTE

SUBADDRESS,

LOW BYTE

issue a repeated start command followed by the chip address

W

byte with the R/

bit set to 1 (read). This causes the ADAU1401A

SDA to reverse and begin driving data back to the master. The

master then responds every ninth pulse with an acknowledge

pulse to the ADAU1401A.

Figure 25 shows the timing of a burst mode read sequence. This

figure shows an example where the target read registers are two

bytes. The ADAU1401A increments its subaddress register every

two bytes because the requested subaddress corresponds to a

register or memory area with word lengths of two bytes. Other

addresses may have word lengths ranging from one to five bytes.

The ADAU1401A always decodes the subaddress and sets the

auto-increment circuit so that the address increments after the

appropriate number of bytes.

DATA

BYTE 1

2

C Write Format

DATA

BYTE 2

DATA

BYTE N

08506-022

...

P

DATA-WORD 1,

BYTE 1

S = START BIT, P = STOP BIT, AS = ACKNOWLEDG E BY SLAVE.

SHOWS AN N-WORD WRITE, WHERE EACH WORD HAS TWO BYTES. (OTHER WORD LENGTHS ARE POSSIBLE, RANGING FROM ONE TO FIVE BYTES.)

Figure 23. Burst Mode I

DATA-WORD 1,

BYTE 2

2

DATA-WO RD 2,

BYTE 1

C Write Format

DATA-WORD 2,

BYTE 2

DATA-WO RD N,

BYTE 1

DATA-WO RD N,

BYTE 2

08506-023

CHIP ADDRESS,

S

R/W = 0

S = START BIT, P = STOP BIT, AM = ACKNOWLEDG E BY MASTER, AS = ACKNOWLEDGE BY SLAVE.

SHOWS A ONE- WORD READ, W HERE EACH WORD HAS N BYT ES.

SUBADDRESS,

HIGH BYTE

SUBADDRESS,

LOW BYTE

Figure 24. Single-Word I

CHIP ADDRESS,

R/W = 1

2

C Read Format

DATA

BYTE 1

DATA

BYTE 2

DATA

...

AMAMAS AMAS SASAS

BYTE N

P

08506-024

CHIP

SAS AS AS AS AMAM AMAM

ADDRESS,

R/W = 0

S = START BIT, P = STOP BIT, AM = ACKNOWLEDG E BY MASTER, AS = ACKNOWLEDGE BY SLAVE.

SHOWS AN N-WO RD READ, WHERE E ACH WORD HAS TWO BYTES. (OTHER WO RD LENGTHS ARE POSSIBLE , RANGING F ROM ONE T O FIVE BY TES.)

SUBADDRESS,

HIGH BYTE

SUBADDRESS,

LOW BYTE

Figure 25. Burst Mode I

S

CHIP

ADDRESS,

R/W = 1

DATA-WORD 1,

BYTE 1

2

C Read Format

DATA-WORD 1,

BYTE 2

...

DATA-WO RD N,

BYTE 1

DATA-WO RD N,

BYTE 2

P

08506-025

Rev. A | Page 25 of 52

Page 26

ADAU1401A

SPI PORT

By default, the ADAU1401A is in I2C mode, but it can be put into

SPI control mode by pulling CLATCH/WP low three times. The

SPI port uses a 4-wire interface, consisting of the CLATCH, CCLK,

CDATA, and COUT signals, and is always a slave port. The

CLATCH signal should go low at the beginning of a transaction

and high at the end of a transaction. The CCLK signal latches

CDATA during a low-to-high transition. COUT data is shifted

out of the ADAU1401A on the falling edge of CCLK and should

be clocked into a receiving device, such as a microcontroller, on

the CCLK rising edge. The CDATA signal carries the serial input

data, and the COUT signal is the serial output data. The COUT

signal remains three-stated until a read operation is requested.

This allows other SPI-compatible peripherals to share the same

readback line. All SPI transactions have the same basic format

shown in Tabl e 19 . A timing diagram is shown in Figure 3. All

data should be written MSB first. The ADAU1401A cannot be

taken out of SPI mode without a full reset.

Chip Address, R/W

The first byte of an SPI transaction includes the 7-bit chip address

and an R/

allows two ADAU1401A devices to share a CLATCH signal, yet

still operate independently. When ADDR0 is low, the chip address

is 0000000; when ADDR0 is high, the address is 0000001 (see

Tabl e 18

transaction is a read (Logic Level 1) or a write (Logic Level 0).

W

bit. The chip address is set by the ADDR0 pin. This

). The LSB of this first byte determines whether the SPI

Table 18. ADAU1401A SPI Address Byte Format

Bit 0 Bit 1 Bit 2 Bit 3 Bit 4 Bit 5 Bit 6 Bit 7

0 0 0 0 0 0 ADDR0

R/W

Subaddress

The 12-bit subaddress word is decoded into a location in one of

the memory areas or registers. This subaddress is the location of the

appropriate RAM location or register. The MSBs of the subaddress

are zero-padded to bring the word to a full 2-byte length.

Data Bytes

The number of data bytes varies according to the register or

memory location being accessed. During a burst mode write, an

initial subaddress is written followed by a continuous sequence

of data for consecutive memory/register locations. The detailed

data format for continuous mode operation is shown in Ta bl e

23 and Tabl e 25 in the Read/Write Data Formats section.

A sample timing diagram of a single-write SPI operation to the

parameter RAM is shown in Figure 26. A sample timing diagram

of a single-read SPI operation is shown in Figure 27. In Figure 27,

the COUT pin goes from three-state to being driven at the

beginning of Byte 3. In this example, Byte 0 to Byte 2 contain the

W

addresses and the R/