Page 1

REV. B

a

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties that

may result from its use. No license is granted by implication or otherwise

under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 2002

AD ADC80

12-Bit Successive-Approximation

Integrated Circuit A/D Converter

FEATURES

True 12-Bit Operation: Max Nonlinearity ⴞ0.012%

Low Gain T.C.: ⴞ30 ppm/ⴗC Max

Low Power: 800 mW

Fast Conversion Time: 25 s

Precision 6.3 V Reference for External Application

Short-Cycle Capability

Parallel Data Output

Monolithic DAC with Scaling Resistors for Stability

Low Chip Count—High Reliability

Industry Standard Pinout

“Z“ Models for ⴞ12 V Supplies

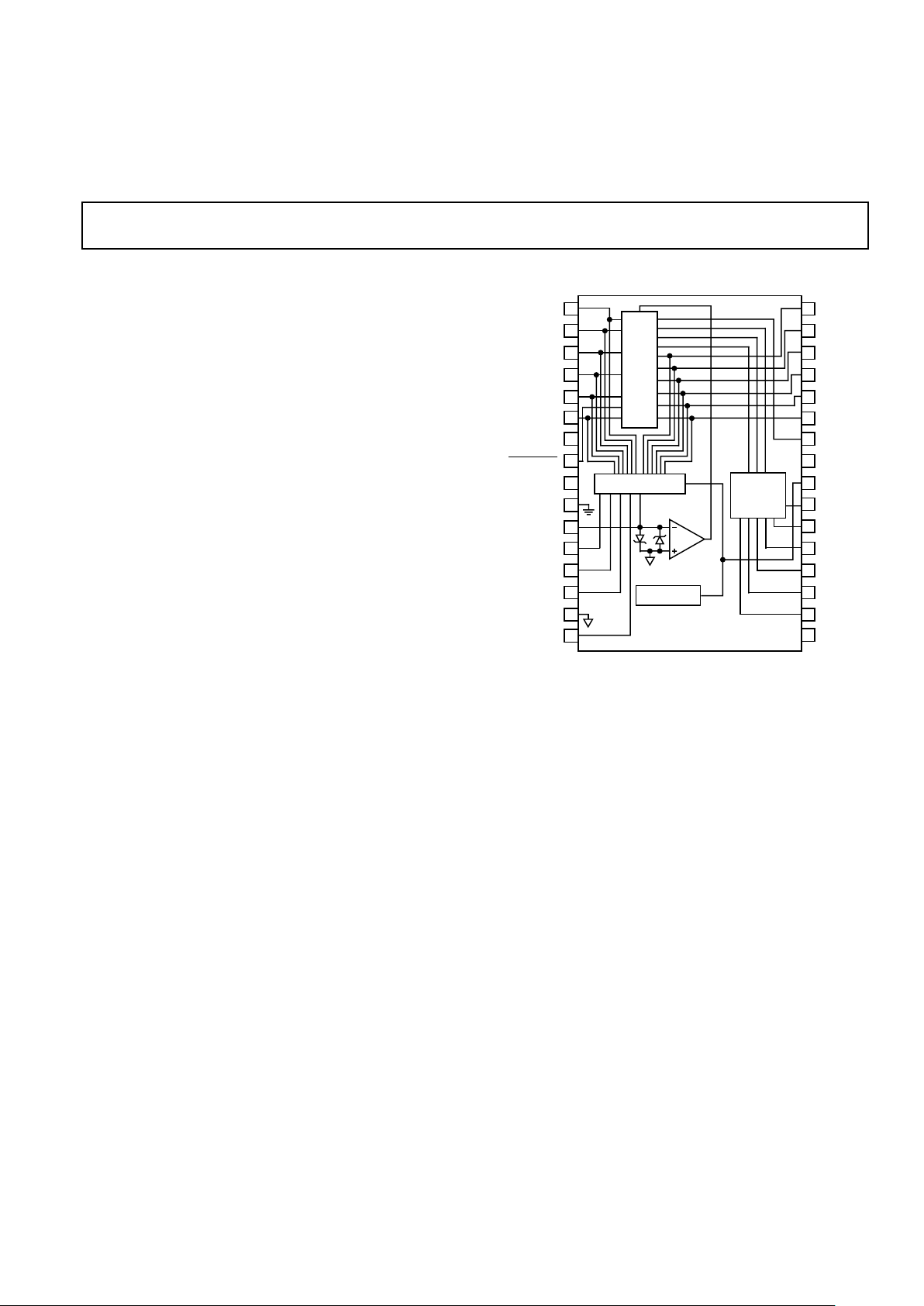

FUNCTIONAL BLOCK DIAGRAM

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

BIT 7

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

BIT 6

BIT 5

BIT 4

BIT 3

BIT 2

5V ANALOG

SUPPLY

DIGITAL GND

COMPARATOR

IN

BIPOLAR

OFFSET OUT

10V SPAN IN

20V SPAN IN

ANALOG GND

5V DIGITAL

SUPPLY

GAIN ADJUST

BIT 8

BIT 9

BIT 10

BIT 11

BIT 12

(LSB)

NC

–15V OR

–12V

REF OUT

(6.3V)

CLOCK

OUT

STATUS

SHORT

CYCLE

CLOCK

INHIBIT

EXTERNAL

CLOCK IN

CONVERT

START

15V OR

12V

COMP

12-BIT

SAR

REFERENCE

CLOCK

AND

CONTROL

CIRCUITS

AD ADC80

12-BIT DAC

NC = NO CONNECT

BIT 1 (MSB)

BIT 1 (MSB)

PRODUCT DESCRIPTION

The AD ADC80 is a complete 12-bit successive-approximation

analog-to-digital converter that includes an internal clock, reference, and comparator. Its hybrid IC design uses MSI digital and

linear monolithic chips in conjunction with a 12-bit monolithic

DAC to provide modular performance and versatility with IC

size, price, and reliability.

Important performance characteristics of the AD ADC80 include

a maximum linearity error at 25⬚C of ± 0.012%, max gain T.C. of

30 ppm/⬚C, typical power dissipation of 800 mW, and max conversion time of 25 s. Monotonic operation of the feedback D/A

converter guarantees no missing codes over the temperature

range of –25⬚C to +85⬚C.

The design of the AD ADC80 includes scaling resistors that

provide analog signal ranges of ± 2.5 V, ± 5.0 V, ± 10 V, 0 V to

5.0 V, or 0 V to 10.0 V. The 6.3 V precision reference may be

used for external applications. All digital signals are fully DTL

and TTL compatible; output data is in parallel form.

The AD ADC80 is available in grades specified for use over

the –25⬚C to +85⬚ C temperature range and is available in a

32-lead ceramic DIP.

PRODUCT HIGHLIGHTS

1. The AD ADC80 is a complete 12-bit A/D converter. No

external components are required to perform a conversion.

2. A monolithic 12-bit feedback DAC is used for reduced chip

count and higher reliability.

3. The internal buried Zener reference is laser trimmed to 6.3 V.

The reference voltage is available externally and can supply

up to 1.5 mA beyond that required for the reference and

bipolar offset current.

4. The scaling resistors are included on the monolithic DAC

for exceptional thermal tracking.

5. The AD ADC80 directly replaces other devices of this type

with significant increases in performance.

6. The fast conversion rate of the AD ADC80 makes it an

excellent choice for applications requiring high system

throughput rates.

7. The short cycle and external clock options are provided

for applications requiring faster conversion speeds or

lower resolutions.

Page 2

REV. B–2–

AD ADC80–SPECIFICATIONS

(Typical @ 25ⴗC, ⴞ15 V, and +5 V, unless otherwise noted.)

Model AD ADC80-12 Unit

RESOLUTION 12 Bits

ANALOG INPUTS

Voltage Ranges

Bipolar ± 2.5, ± 5, ± 10 V

Unipolar 0, +5, +10 V

Impedance (Direct Input) 0 to +5, ±2.5 V

0 to +10, ± 5V

± 10 V

DIGITAL INPUTS

1

Convert Command Positive Pulse 100 ns Wide (min)

(“0” to “1” Initiates Conversion)

Logic Loading 1 TTL Load

External Clock 1 TTL Load

TRANSFER CHARACTERISTICS ERROR

Gain Error

2

± 0.1 % of FSR

3

Offset

2

Unipolar ± 0.05 % of FSR

Bipolar ± 0.1 % of FSR

Linearity Error (max)

4

± 0.012 % of FSR

Inherent Quantization Error ± 1/2 LSB

Differential Linearity Error ± 1/2 LSB

No Missing Codes Temperature Range –25 to +85 ∞C

Power Supply Sensitivity

± 15 V ± 0.0030 % of FSR/% V

S

+5 V ± 0.0015 % of FSR/% V

S

DRIFT

Specification Temperature Range –25 to +85 ∞C

Gain (max) ± 30 ppm/∞C

Offset

Unipolar ± 3 ppm of FSR/∞C

Bipolar ± 15 ppm of FSR/∞C

Linearity (max) ± 3 ppm of FSR/∞C

Monotonicity GUARANTEED

CONVERSION SPEED

5

22, 25 ms min, ms max

DIGITAL OUTPUT (All Codes Complementary)

Parallel

Output Codes

6

Unipolar CSB

Bipolar COB, CTC

Output Drive 2 TTL Loads

Status Logic “1” During Conversion

Status Output Drive 2 TTL Loads

Internal Clock

Clock Output Drive 2 TTL Loads

Frequency

7

575 kHz

INTERNAL REFERENCE VOLTAGE +6.3, ± 10 V ± mV

Max External Current

(With No Degradation of Specifications) 1.5 mA

Tempco of Drift ± 10, ± 20 ppm/∞C typ, ppm/∞C max

Page 3

REV. B

AD ADC80

–3–

Model AD ADC80-12 Unit

POWER REQUIREMENTS

Rated Voltages ± 15, +5 V

Range for Rated Accuracy 4.75 to 5.25 and ± 14.0 to ± 16.0 V

Z Models

8

4.75 to 5.25 and ± 11.4 to ± 16.0 V

Supply Drain +15 V +10 mA

–15 V –20 mA

+5 V +70 mA

TEMPERATURE RANGE

Specification –25 to +85 ∞C

Operating (Derated Specifications) –55 to +100 ∞C

Storage –55 to +125 ∞C

PACKAGE OPTION

9

DH-32D AD ADC80-12

NOTES

1

DTL/TTL compatible, i.e., Logic “0” = 0.8 V max, Logic “1” = 2.0 V min for digital inputs, Logic “0” = 0.4 V max, and Logic “1” = 2.4 V min digital outputs.

2

Adjustable to zero with external trimpots.

3

FSR means Full-Scale Range, i.e., unit connected for ± 10 V range has 20 V FSR.

4

Error shown is the same as ± 1/2 LSB max for resolution of A/D converter.

5

Conversion time with internal clock.

6

See Table I. CSB—Complementary Straight Binary

COB—Complementary Offset Binary

CTC—Complementary Twos Complement

7

For conversion speeds specified.

8

For Z models order AD ADC80Z-12.

9

For package outline information see Package Information section.

Specifications subject to change without notice.

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection. Although the

AD ADC80 features proprietary ESD protection circuitry, permanent damage may occur on devices

subjected to high energy electrostatic discharges. Therefore, proper ESD precautions are recommended

to avoid performance degradation or loss of functionality.

WARNING!

ESD SENSITIVE DEVICE

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD ADC80-12 –25∞C to +85∞C 32-Lead Ceramic DIP DH-32D

AD ADC80-Z-12 –25∞C to +85∞C 32-Lead Ceramic DIP DH-32D

Page 4

REV. B–4–

AD ADC80

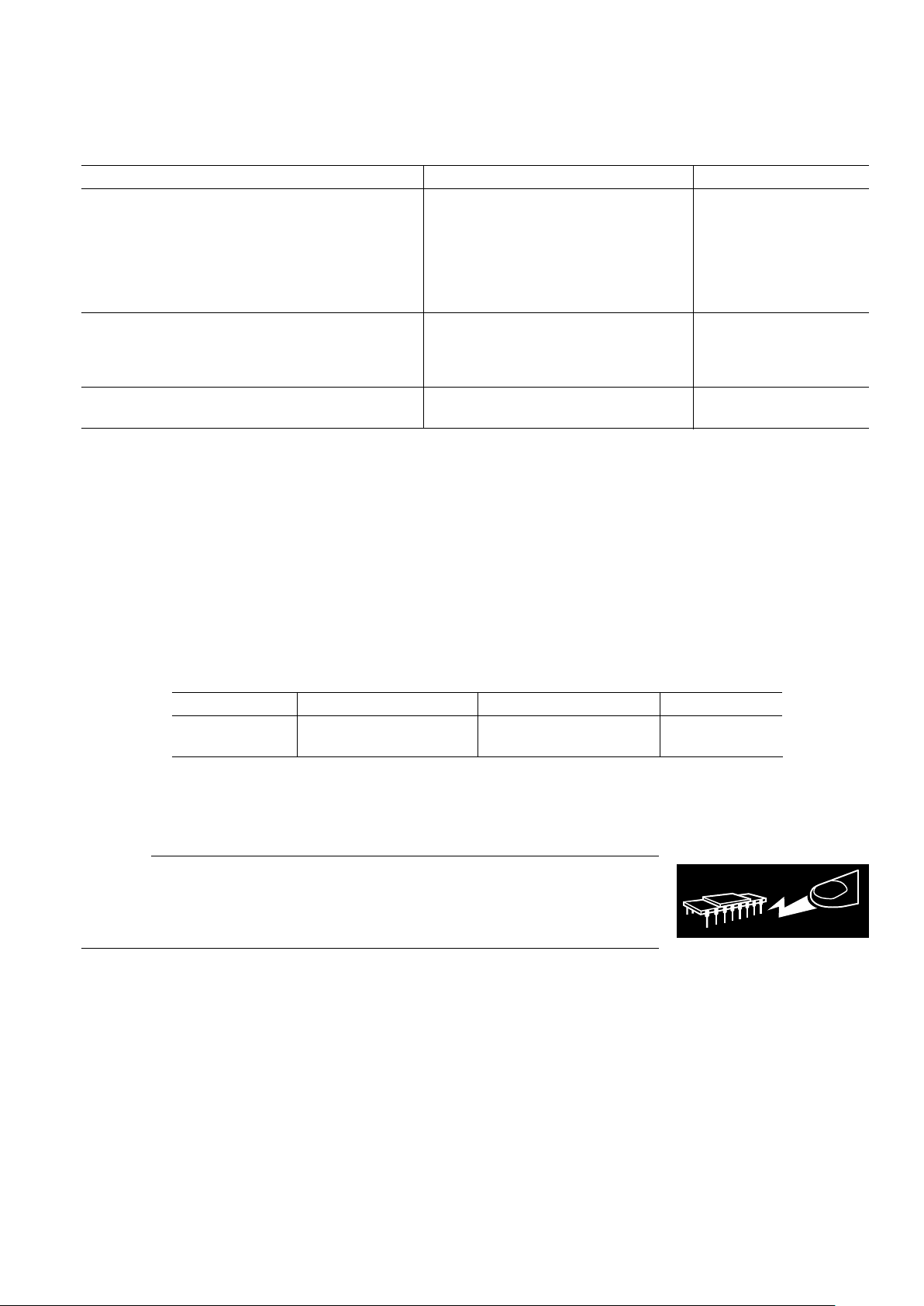

PIN CONFIGURATION

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

BIT 7

BIT 8

BIT 9

BIT 10

BIT 11

BIT 12 (LSB)

NC

–15V OR –12V

REF OUT (6.3V)

CLOCK OUT

STATUS

SHORT CYCLE

CLOCK INHIBIT

EXTERNAL CLOCK IN

CONVERT START

15V OR 12V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

BIT 6

BIT 5

BIT 4

BIT 3

BIT 2

5V ANALOG

SUPPLY

DIGITAL GND

COMPARATOR IN

BIPOLAR

OFFSET OUT

10V SPAN IN

20V SPAN IN

ANALOG GND

5V DIGITAL

SUPPLY

GAIN ADJUST

NC = NO CONNECT

BIT 1 (MSB)

BIT 1 (MSB)

PIN FUNCTION DESCRIPTIONS

Pin No. Mnemonic Function

1–6BIT 6–BIT 1 (MSB) Digital Outputs

75 V ANALOG SUPPLY Analog Positive Supply (nominally ± 0.25 V)

8BIT 1 (MSB) MSB Inverted Digital Output

95 V DIGITAL SUPPLY Digital Positive Supply (nominally ± 0.25 V)

10 DIGITAL GND Digital Ground

11 COMPARATOR IN Offset Adjust

12 BIPOLAR OFFSET OUT Bipolar Offset Output

13 10 V SPAN IN Analog Input 10 V Signal Range

14 20 V SPAN IN Analog Input 20 V Signal Range

15 ANALOG GND Analog Ground

16 GAIN ADJUST Gain Adjust

17 15 V OR 12 V Analog Positive Supply (nominally ± 1.0 V for 15 V or ± 0.6 V for 12 V)

18 CONVERT START Enables Conversion

19 EXTERNAL CLOCK IN External Clock Input

20 CLOCK INHIBIT Clock Inhibit

21 SHORT CYCLE Shortens Conversion Cycle to Desired Resolution

22 STATUS Logic High, ADC Converting/Logic Low, ADC Data Valid

23 CLOCK OUT Internal Clock Output

24 REF OUT (6.3 V) 6.3 V Reference Output

25 –15 V OR –12 V Analog Negative Supply (nominally ± 1.0 V for –15 V or ± 0.6 V for –12 V)

26 NC No Connection

27–32 BIT 12 (LSB)–BIT 7 Digital Outputs

Page 5

REV. B

Typical Performance Characteristics–AD ADC80

–5–

CONVERSION TIME – s

1.00

02

LINEARITY ERROR – LSB

468101214 16 18 20 24 26 28

0.50

0.25

8-BIT 10-BIT 12-BIT

TPC 1. Linearity Error vs. Conversion Time (Normalized)

CONVERSION TIME – s

1.00

02

DIFFERENTIAL LINEARITY ERROR – LSB

468101214161820242628

0.50

0.25

0.75

8-BIT 10-BIT 12-BIT

TPC 2. Differential Linearity Error vs. Conversion

Time (Normalized)

TEMPERATURE – ⴗC

0.3

–25

GAIN DRIFT ERROR – % of FSR

–0.3

–0.2

–0.1

0

0.1

0.2

025 7085

TPC 3. Maximum Gain Drift Error, % of FSR vs.

Temperature

TEMPERATURE – ⴗC

–25

REFERENCE DRIFT ERROR – %

–0.08

025 85–55 100

–0.06

–0.04

–0.02

0

0.02

0.04

0.06

0.08

TYPICAL

TPC 4. Reference Drift, % Error vs. Temperature

Page 6

REV. B–6–

AD ADC80

THEORY OF OPERATION

On receipt of a CONVERT START command, the AD ADC80

converts the voltage at its analog input into an equivalent 12-bit

binary number. This conversion is accomplished as follows: the

12-bit successive-approximation register (SAR) has its 12-bit

outputs connected both to the device bit output pins and to the

corresponding bit inputs of the feedback DAC. The analog input

is successively compared to the feedback DAC output, one bit

at a time (MSB first, LSB last). The decision to keep or reject

each bit is then made at the completion of each bit comparison

period, depending on the state of the comparator at that time.

TIMING

The timing diagram is shown in Figure 1. Receipt of a CONVERT

START signal sets the STATUS flag, indicating conversion in

progress. This, in turn, removes the inhibit applied to the gated

clock, permitting it to run through 13 cycles. All SAR parallel

bit and STATUS flip-flops are initialized on the leading edge, and

the gated clock inhibit signal is removed on the trailing edge of

the CONVERT START signal. At time t

0

, B1 is reset and B2–B

12

are set unconditionally. At t1, the Bit 1 decision is made (keep)

and Bit 2 is unconditionally reset. At t

2

, the Bit 2 decision is

made (keep) and Bit 3 is reset unconditionally. This sequence

continues until the Bit 12 (LSB) decision (keep) is made at t

12

.

After a 40 ns delay period, the STATUS flag is reset, indicating

that the conversion is complete and that the parallel output data

is valid. Resetting the STATUS flag restores the gated clock

inhibit signal, forcing the clock output to the Logic “0” state.

Parallel data bits become valid on the positive-going clock edge

(see Figure 1).

Incorporation of this 40 ns delay guarantees that the parallel

data is valid at the Logic “l” to “0” transition of the STATUS

flag, permitting parallel data transfer to be initiated by the trailing

edge of the STATUS signal.

t

0

t1 t

2

t

3

t4 t5 t6 t7 t8 t9t10t

11

t

12

CONVERT

1

START

INTERNAL

CLOCK

STATUS

MSB

BIT 2

BIT 3

BIT 4

BIT 5

BIT 6

BIT 7

BIT 8

BIT 9

BIT 10

BIT 11

LSB

“0”

“1”

“1”

“0”

“0”

“1”

“1”

“1”

“0”

“1”

“1”

“0”

NOTE

3

CONVERSION TIME

2

MAXIMUM THROUGHPUT TIME

NOTES

1

THE CONVERT START PULSEWIDTH IS 100ns MIN AND MUST REMAIN LOW DURING

A CONVERSION; THE CONVERSION IS INITIATED BY THE "RISING EDGE" OF THE

CONVERT COMMAND

2

25s FOR 12 BITS AND 21s FOR 10 BITS (MAX)

3

MSB DECISION

4

LSB DECISION 40ns PRIOR TO THE STATUS GOING LOW

BIT DECISIONS

NOTE

4

Figure 1. Timing Diagram (Binary Code 011001110110)

Page 7

REV. B

AD ADC80

–7–

DIGITAL OUTPUT DATA

Parallel data from TTL storage registers is in negative true

form. Parallel data output coding is complementary binary

for unipolar ranges and either complementary offset binary

or complementary twos complement binary, depending on

whether Bit 1 (Pin 6) or its logical inverse Bit 1 (Pin 8) is

used as the MSB. Parallel data becomes valid approximately 40 ns before the STATUS flag returns to Logic “0,”

permitting parallel data transfer to be clocked on the “1” to

“0” transition of the STATUS flag.

Parallel data outputs change state on positive-going clock edges.

There are 13 negative-going clock edges in the complete 12-bit

conversion cycle, as shown in Figure 1. The first edge shifts an

invalid bit into the register, which is shifted out on the 13th

negative-going clock edge.

Short Cycle Input

A Short Cycle Input, Pin 21, permits the timing cycle shown in

Figure 1 to be terminated after any number of desired bits has

been converted, permitting somewhat shorter conversion times

in applications not requiring full 12-bit resolution. When 10-bit

resolution is desired, Pin 21 is connected to Bit 11, output

Pin 28. The conversion cycle then terminates, and the STATUS

flag resets after the Bit 10 decision (t

10

+ 40 ns in timing dia-

gram of Figure 1). Short Cycle pin connections and associated

maximum 12-, 10-, and 8-bit conversion times are summarized

in Table I. When 12-bit resolution is required, Pin 21 is connected to 5 V (Pin 9).

INPUT SCALING

The AD ADC80 input should be scaled as close to the maximum

input signal range as possible to use the maximum signal

resolution of the A/D converter. Connect the input signal as shown

in Table II. See Figure 2 for circuit details.

COMPARATOR

R2, 5k⍀

TO SAR

FROM D/A

CONVERTER

10V RANGE 13

20V RANGE 14

COMP IN 11

6.3k⍀

V

REF

BIPOLAR

OFFSET

ANALOG

COMMON

12

15

R1, 5k⍀

Figure 2. Input Scaling Circuit

Table I. Short Cycle Connections

Connect Short Maximum Status

Cycle Pin 21 Resolution Conversion Flag

to Pin Bits (% FSR) Time (s) Reset

9120.024 25 t

12

+ 40 ns

28 10 0.100 21 t

10

+ 40 ns

30 8 0.390 17 t8 + 40 ns

Table II. Input Scaling Connections

Input Connect Connect Connect

Signal Output Pin 12 Pin 14 Input

Range Code to Pin to Signal to

± 10 V COB or CTC 11 Input Signal 14

± 5 V COB or CTC 11 Open 13

± 2.5 V COB or CTC 11 Pin 11 13

0 V to 5 V CSB 15 Pin 11 13

0 V to 10 V CSB 15 Open 13

Page 8

REV. B–8–

AD ADC80

OFFSET ADJUSTMENT

The zero adjust circuit consists of a potentiometer connected

across ± V

S

with its slider connected through a 1.8 MW resistor

to Comparator Input Pin 11 for all ranges. As shown in Figure 3

the tolerance of this fixed resistor is not critical, and a carbon

composition type is generally adequate. Using a carbon composition resistor having a –1200 ppm/∞C tempco contributes a

worst-case offset tempco of 8 ¥ 244 ¥ 10

–6

¥ 1200 ppm/∞C =

2.3 ppm/∞C of FSR, if the OFFSET ADJ potentiometer is set at

either end of its adjustment range. Since the maximum offset

adjustment required is typically no more than ± 4 LSB, use of a

carbon composition offset summing resistor typically contributes no more than 1 ppm/∞C of FSR offset tempco.

AD ADC80

1.8M⍀

11

10k⍀

TO

100k⍀

+15V

–15V

Figure 3. Offset Adjustment Circuit

An alternate offset adjust circuit, which contributes negligible

offset tempco if metal film resistors (tempco <100 ppm/∞C) are

used, is shown in Figure 4.

OFFSET

ADJUST

AD ADC80

180k⍀

MF

180k⍀

MF

11

10k⍀

TO

100k⍀

+15V

–15V

22k⍀

MF

Figure 4. Low Tempco Zero Adjustment Circuit

In either zero adjust circuit, the fixed resistor connected to

Pin 11 should be located close to this pin to keep the Pin 11

connection runs short. Comparator Input Pin 11 is quite sensitive to external noise pickup.

GAIN ADJUSTMENT

The gain adjust circuit consists of a potentiometer connected

across ± V

S

with its slider connected through a 10 MW resistor

to the gain adjust Pin 16 as shown in Figure 5.

GAIN

ADJUST

AD ADC80

10M⍀ 16

10k⍀

TO

100k⍀

+15V

–15V

0.01F

Figure 5. Gain Adjustment Circuit

An alternate gain adjust circuit, which contributes negligible

gain tempco if metal film resistors (tempco <100 ppm/∞C) are

used, is shown in Figure 6.

AD ADC80

16

10k⍀

TO

100k⍀

+15V

–15V

0.1F

270k⍀

MF

6.8k⍀

270k⍀

MF

Figure 6. Low Tempco Gain Adjustment Circuit

Table III. Input Voltages and Code Definitions

Binary (BIN)

Output

Analog Input

Voltage Range Defined As: ⴞ10 V ⴞ5 V ⴞ2.5 V 0 V to 10 V 0 V to 5 V

Code COB

1

COB

1

COB

1

Designation or CTC

2

or CTC

2

or CTC

2

CSB

3

CSB

3

One Least FSR 20 V 10 V 5 V 10 V 5 V

Significant 2

n

2

n

2

n

2

n

2

n

2

n

Bit (LSB) n = 8 78.13 mV 39.06 mV 19.53 mV 39.06 mV 19.53 mV

n = 10 19.53 mV 9.77 mV 4.88 mV 9.77 mV 4.88 mV

n = 12 4.88 mV 2.44 mV 1.22 mV 2.44 mV 1.22 mV

Transition Values

MSB LSB

000 . . . . 000

4

+Full Scale 10 V – 3/2 LSB 5 V – 3/2 LSB 2.5 V – 3/2 LSB 10 V – 3/2 LSB 5 V – 3/2 LSB

011 . . . . 111 Midscale 0 0 0 5 V 2.5 V

111 . . . . 110 –Full Scale –10 V + 1/2 LSB –5 V + 1/2 LSB –2.5 V + 1/2 LSB 0 V + 1/2 LSB 0 V + 1/2 LSB

NOTES

1

COB = Complementary Offset Binary

2

CTC = Complementary Twos Complement—obtained by using the complement of the most significant bit ( MSB). MSB is available on Pin 8.

3

CSB = Complementary Straight Binary

4

Voltages given are the nominal value for transition to the code specified.

Page 9

REV. B

AD ADC80

–9–

CALIBRATION

External ERO ADJ and GAIN ADJ potentiometers, connected

as shown in Figures 7 and 8, are used for device calibration.

To prevent interaction of these two adjustments, Zero is

always adjusted first and then Gain. Zero is adjusted with the

analog input near the most negative end of the analog range

(0 for unipolar and –FS for bipolar input ranges). Gain is

adjusted with the analog input near the most positive end of

the analog range.

0 to 10 V Range

Set analog input to +1 LSB = 0.0024 V. Adjust Zero for

digital output = 111111111110. Zero is now calibrated. Set

analog input to +FSR – 2 LSB = 9.9952 V. Adjust Gain for

000000000001 digital output code. Full-scale (Gain) is now

calibrated. For half-scale calibration check set analog input to

5.0000 V; digital output code should be 011111111111.

–10 V to +10 V Range

Set analog input to –9.9951 V, adjust Zero for 111111111110

digital output (complementary offset binary) code. Set analog input to +9.9902 V, adjust Gain for 000000000001

digital output (complementary offset binary) code. For

half-scale calibration check, set analog input to 0.0000 V;

digital output (complementary offset binary) code should be

011111111111.

Other Ranges

Representative digital coding for 0 V to 10 V and –10 V to +10 V

ranges is given above. Coding relationships and calibration

points for 0 V to 5 V, –2.5 V to +2.5 V, and –5 V to +5 V ranges

can be found by halving the corresponding code equivalents

listed for the 0 V to 10 V and –10 V to +10 V ranges, respectively.

Zero and full-scale calibration can be accomplished to a precision

of approximately ±1/4 LSB using the static adjustment procedure

described above. By summing a small sine- or triangular-wave

voltage with the signal applied to the analog input, the output

can be cycled through each of the calibration codes of interest to more accurately determine the center (or end points) of

each discrete quantization level. A detailed description of this

dynamic calibration technique is presented in “A/D Conversion

Notes,” D. Sheingold, Analog Devices, Inc., 1977, Part II,

Chapter 3.

COMP

AD ADC80

SAR

DAC

1.8M⍀

–15V

+15V

10k⍀

ANALOG

INPUT

+5V

+15V

–15V

–15V

+15V

10k⍀

10M⍀

0.01F

REF

24

17

15

25

79 10

16 12 14 13 11

Figure 7. Analog and Power Connections for

Unipolar 0 V–10 V Input Range

COMP

AD ADC80

SAR

DAC

1.8M⍀

–15V

+15V

10k⍀

ANALOG

INPUT

+5V

+15V

–15V

–15V

+15V

10k⍀

10M⍀

0.01F

REF

24

17

15

25

79 10

16 12 14 13 11

Figure 8. Analog and Power Connections for

Bipolar

±

10 V Input Range

Page 10

REV. B–10–

AD ADC80

GROUNDING

Many data-acquisition components have two or more ground

pins that are not connected together within the device. These

“grounds” are usually referred to as the Logic Power Return,

Analog Common (Analog Power Return), and Analog Signal

Ground. These grounds must be tied together at one point,

usually at the system power-supply ground. Ideally, a single

solid ground is desirable. However, since current flows through

the ground wires and etch stripes of the circuit cards, and since

these paths have resistance and inductance, hundreds of millivolts can be generated between the system ground point and the

ground pin of the AD ADC80. Therefore, separate ground

returns should be provided to minimize the current flow in the

path from sensitive points to the system ground point, and the

two device grounds should be tied together. In this way, supply

currents and logic-gate return currents are not summed into the

same return path as analog signals where they would cause

measurement errors.

Each of the AD ADC80’s supply terminals should be capacitively decoupled as close to the AD ADC80 as possible. A large

value capacitor such as 1 mF in parallel with a 0.1 mF capacitor

is usually sufficient. Analog supplies are bypassed to the Analog

Power Return pin and the logic supply is bypassed to the Logic

Power Return pin.

0.01

F

0.01

F

0.01

F

ANALOG

PS

+15V

–15VC

0.01

F

AD583

SAMPLE AND

HOLD

0.01

F

0.01

F

OUTPUT

REFERENCE

IF INDEPENDENT, OTHERWISE RETURN

AMPLIFIER REFERENCE TO MECCA AT

ANALOG PS COMMON

*

SIGNAL

GROUND

AD521

INST. AMP

DIGITAL

PS

5VC

DIG

COM

AD ADC80

0.01

F

17 15 25 10 9 7

ANALOG

GROUND

*

Figure 9. Basic Grounding Practice

CONTROL MODES

The timing sequence of the AD ADC80 allows the device to be

easily operated in a variety of systems with different control

modes. The most common control modes are illustrated in

Figures 10 through 12.

5V

AD ADC80

BIT 11

SHORT

CYCLE

CLOCK

INHIBIT

EXTERNAL

CLOCK

CONVERT

COMMAND

10-BIT

OPERATION

12-BIT

OPERATION

18

CONVERT

COMMAND

19

20

21

28

Figure 10. Internal Clock—Normal Operating

Mode. Conversion Initiated by the Rising Edge of

the Convert Command. The Internal Clock Runs

Only During Conversion.

5V

AD ADC80

BIT 11

SHORT

CYCLE

CLOCK

INHIBIT

EXTERNAL

CLOCK

CONVERT

COMMAND

10-BIT

OPERATION

19

18

DIGITAL

COMMON

DIGITAL

COMMON

EXTERNAL

CLOCK

21

20

28

12-BIT

OPERATION

Figure 11. Continuation Conversion with External

Clock. Conversion Is Initiated by 14th Clock Pulse.

Clock Runs Continuously.

AD ADC80

BIT 11

SHORT

CYCLE

CLOCK

INHIBIT

EXTERNAL

CLOCK

CONVERT

COMMAND

10-BIT

OPERATION

STATUS

19

22

18

EXTERNAL

CLOCK

5V

DIGITAL

COMMON

12-BIT

OPERATION

20

21

28

CONVERT

COMMAND

Figure 12. Continuous External Clock. Conversion

Initiated by Rising Edge of Convert Command.

The Convert Command Must Be Synchronized

with Clock.

Page 11

REV. B

AD ADC80

–11–

OUTLINE DIMENSIONS

32-Lead Side Brazed Ceramic DIP for Hybrid [Medium Cavity]

(DH-32D)

Dimensions shown in inches and (millimeters)

0.930 (23.62) MAX

0.890 (22.61) MIN

0.910 (23.11) MAX

0.870 (22.10) MIN

116

1732

1.616 (41.05)

MAX

0.280 (7.11) MAX

0.005 (0.13)

MIN

0.098 (2.49)

MAX

0.120 (3.05) MIN

0.020 (0.51) MAX

0.016 (0.41) MIN

0.100 (2.54)

BSC

0.055 (1.40) MAX

0.035 (0.89) MIN

0.060 (1.52) MAX

0.040 (1.02) MIN

0.180 (4.57)

MIN

0.012 (0.30) MAX

0.009 (0.23) MIN

PIN 1

NOTES

1. INDEX AREA; A NOTCH OR A LEAD ONE IDENTIFICATION MARK IS

LOCATED ADJACENT TO LEAD ONE

2. THE MINIMUM LIMIT FOR THE DIMENSION MAY BE 0.023" (0.58 MM) FOR

ALL FOUR CORNER LEADS ONLY

3. THE DIMENSION SHALL BE MEASURED FROM THE SEATING PLANE

TO THE BASE PLANE

4. THE BASIC PIN SPACING IS 0.100" (2.54 MM) BETWEEN

CENTER LINES

5. APPLIES TO ALL FOUR CORNERS

6. THE DIMENSION SHALL BE MEASURED AT THE CENTER LINE

OF THE LEADS

7. THIRTY SPACES

SEE NOTE 1

SEE NOTE 4,7

SEE NOTE 2 SEE NOTE 6

SEE NOTE 3

SEE NOTE 5SEE NOTE 5

Page 12

C01202–0–9/02(B)

PRINTED IN U.S.A.

–12–

AD ADC80

Revision History

Location Page

9/02—Data Sheet changed from REV. A to REV. B.

Edit to Figure 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OUTLINE DIMENSIONS Replaced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Loading...

Loading...