Page 1

400 MSPS, 14-Bit, 1.8 V CMOS

FEATURES

400 MSPS internal clock speed

Integrated 14-bit DAC

32-bit tuning word

Phase noise ≤ –120 dBc/Hz @ 1 kHz offset (DAC output)

Excellent dynamic performance

>80 dB SFDR @ 160 MHz (±100 kHz offset) A

Serial I/O control

1.8 V power supply

Software and hardware controlled power-down

48-lead TQFP/EP package

Support for 5 V input levels on most digital inputs

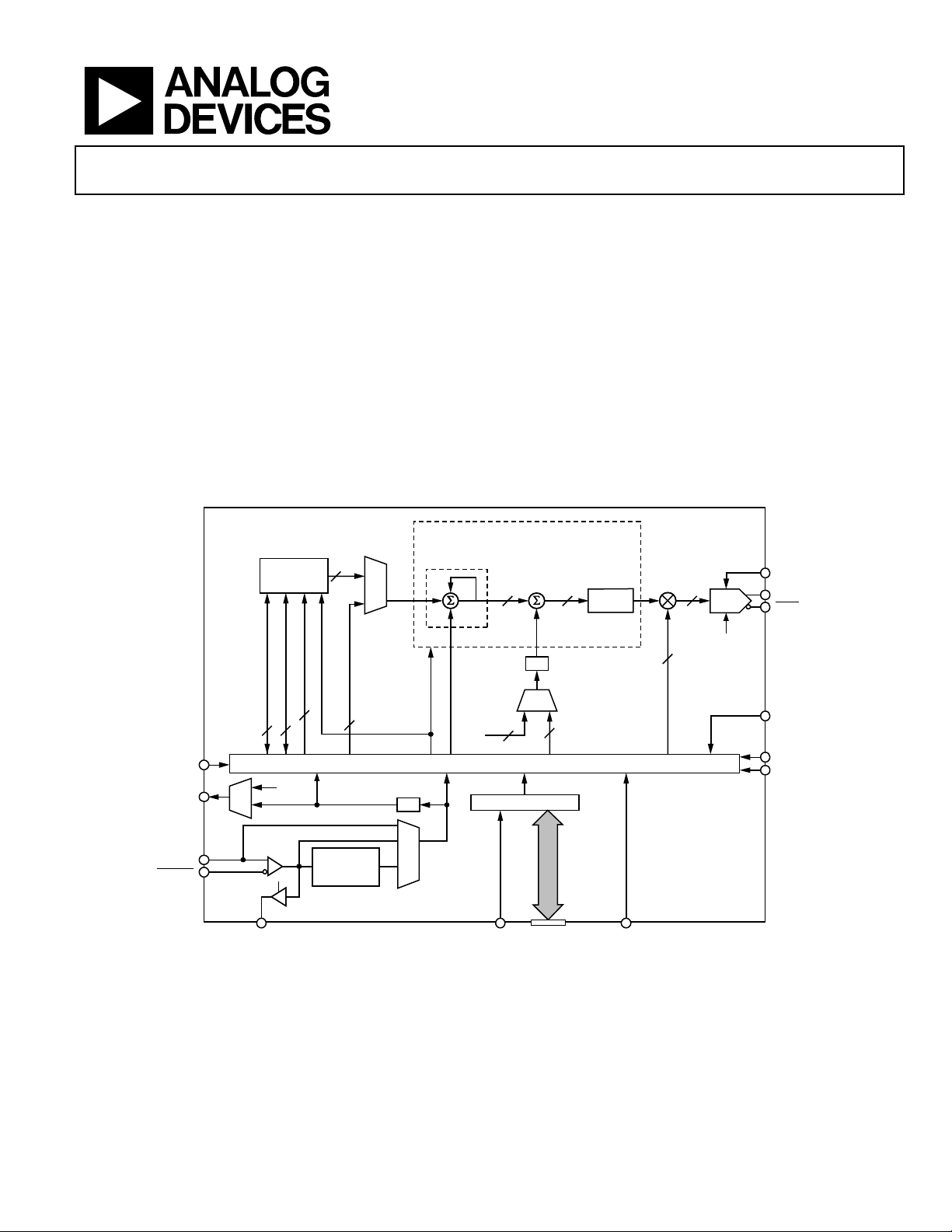

RAM

DDS CLOCK

RAM CONTROL

3

10

4×–20×

CLOCK

MULTIPLIER

DATA

32

32

I/O UPDATE

SYNC_CLK

REFCLK

REFCLK

1024 × 32

STATIC RAM

S

S

E

R

D

D

A

M

A

RAM DATA

R

32

0

M

U

X

OSCILLATOR/BUFFER

ENABLE

OUT

FUNCTIONAL BLOCK DIAGRAM

M

U

X

FREQUENCY

TUNING WORD

TIMING AND CONTROL LOGIC

SYNC

÷ 4

M

U

X

PHASE

ACCUMULATOR

–1

Z

RESET

PHASE

DDS CLOCK

ACCUMULATOR

RAM DATA <31:18>

CONTROL REGISTERS

SYSTEM

CLOCK

Direct Digital Synthesizer

PLL REFCLK multiplier (4× to 20×)

Internal oscillator, can be driven by a single crystal

Phase modulation capability

Multichip synchronization

APPLICATIONS

Agile VHF/UHF LO frequency synthesis

FM chirp source for radar and scanning systems

Nonlinear-shaped PSK/FSK modulator

Test and measurement equipment

DDS CORE

PHASE

OFFSET

Z

MUX

14

19 14

COS(X)

–1

PHASE

14

OFFSET

WORD

14

AD9953

SYSTEM

CLOCK

DAC

DAC_R

IOUT

IOUT

SYNC_IN

OSK

PWRDWNCTL

AD9953

SET

CRYSTAL OUT I/O PORTPS<1:0>

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

Figure 1.

03357-0-001

RESET

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

Page 2

AD9953

TABLE OF CONTENTS

General Description ......................................................................... 3

Programming AD9953 Features............................................... 22

Electrical Specifications ................................................................... 4

Absolute Maximum Ratings............................................................ 6

Pin Configuration............................................................................. 7

Pin Function Descriptions .............................................................. 8

Typical Performance Characteristics ............................................. 9

Theory of Operation ...................................................................... 12

Component Blocks..................................................................... 12

Modes of Operation ................................................................... 19

REVISION HISTORY

Revision 0: Initial Version

Serial Port Operation................................................................. 25

Instruction Byte.......................................................................... 27

Serial Interface Port Pin Description....................................... 27

MSB/LSB Transfers .................................................................... 27

Suggested Application Circuits ..................................................... 29

Outline Dimensions....................................................................... 30

ESD Caution................................................................................ 30

Ordering Guide .......................................................................... 30

Rev. 0 | Page 2 of 32

Page 3

AD9953

GENERAL DESCRIPTION

The AD9953 is a direct digital synthesizer (DDS) featuring a

14-bit DAC operating up to 400 MSPS. The AD9953 uses

advanced DDS technology, coupled with an internal high speed,

high performance DAC to form a digitally programmable,

complete high frequency synthesizer capable of generating a

frequency-agile analog output sinusoidal waveform at up to

200 MHz. The AD9953 includes an integrated 1024 × 32 static

RAM to support flexible frequency sweep capability in several

modes. The AD9953 is designed to provide fast frequency hopping and fine tuning resolution (32-bit frequency tuning word).

The frequency tuning and control words are loaded into the

AD9953 via a serial I/O port.

The AD9953 is specified to operate over the extended industrial

temperature range of –40°C to +105°C.

Rev. 0 | Page 3 of 32

Page 4

AD9953

ELECTRICAL SPECIFICATIONS

Table 1. Unless otherwise noted, AVDD, DVDD = 1.8 V ± 5%, DVDD_I/O = 3.3 V ± 5%, R

Frequency = 20 MHz with REFCLK Multiplier Enabled at 20×. DAC Output Must Be Referenced to AVDD, Not AGND.

Parameter Temp Min Typ Max Unit

REF CLOCK INPUT CHARACTERISTICS

Frequency Range

REFCLK Multiplier Disabled FULL 1 400 MHz

REFCLK Multiplier Enabled at 4× FULL 20 100 MHz

REFCLK Multiplier Enabled at 20× FULL 4 20 MHz

Input Capacitance 25°C 3 pF

Input Impedance 25°C 1.5 kΩ

Duty Cycle 25°C 50 %

Duty Cycle with REFCLK Multiplier Enabled 25°C 35 65 %

REFCLK Input Power1 FULL –15 0 +3 dBm

DAC OUTPUT CHARACTERISTICS

Resolution 14 Bits

Full-Scale Output Current 25°C 5 10 15 mA

Gain Error 25°C –10 +10 %FS

Output Offset 25°C 0.6 µA

Differential Nonlinearity 25°C 1 LSB

Integral Nonlinearity 25°C 2 LSB

Output Capacitance 25°C 5 pF

Residual Phase Noise @ 1 kHz Offset, 40 MHz A

REFCLK Multiplier Enabled @ 20× 25°C –105 dBc/Hz

REFCLK Multiplier Enabled @ 4× 25°C –115 dBc/Hz

REFCLK Multiplier Disabled 25°C –132 dBc/Hz

Voltage Compliance Range 25°C AVDD – 0.5 AVDD + 0.5 V

Wideband SFDR

1 MHz to 10 MHz Analog Out 25°C 73 dBc

10 MHz to 40 MHz Analog Out 25°C 67 dBc

40 MHz to 80 MHz Analog Out 25°C 62 dBc

80 MHz to 120 MHz Analog Out 25°C 58 dBc

120 MHz to 160 MHz Analog Out 25°C 52 dBc

Narrow-Band SFDR

40 MHz Analog Out (±1 MHz) 25°C 87 dBc

40 MHz Analog Out (±250 kHz) 25°C 89 dBc

40 MHz Analog Out (±50 kHz) 25°C 91 dBc

40 MHz Analog Out (±10 kHz) 25°C 93 dBc

80 MHz Analog Out (±1 MHz) 25°C 85 dBc

80 MHz Analog Out (±250 kHz) 25°C 87 dBc

80 MHz Analog Out (±50 kHz) 25°C 89 dBc

80 MHz Analog Out (±10 kHz) 25°C 91 dBc

120 MHz Analog Out (±1 MHz) 25°C 83 dBc

120 MHz Analog Out (±250 kHz) 25°C 85 dBc

120 MHz Analog Out (±50 kHz) 25°C 87 dBc

120 MHz Analog Out (±10 kHz) 25°C 89 dBc

160 MHz Analog Out (±1 MHz) 25°C 81 dBc

160 MHz Analog Out (±250 kHz) 25°C 83 dBc

160 MHz Analog Out (±50 kHz) 25°C 85 dBc

160 MHz Analog Out (±10 kHz) 25°C 87 dBc

OUT

= 3.92 kΩ, External Reference Clock

SET

Rev. 0 | Page 4 of 32

Page 5

AD9953

Parameter Temp Min Typ Max Unit

TIMING CHARACTERISTICS

Serial Control Bus

Maximum Frequency FULL 25 Mbps

Minimum Clock Pulse Width Low FULL 7 ns

Minimum Clock Pulse Width High FULL 7 ns

Maximum Clock Rise/Fall Time FULL 2 ns

Minimum Data Setup Time DVDD_I/O = 3.3 V FULL 3 ns

Minimum Data Setup Time DVDD_I/O = 1.8 V FULL 5 ns

Minimum Data Hold Time FULL 0 ns

Maximum Data Valid Time FULL 25 ns

Wake-Up Time2 FULL 1 ms

Minimum Reset Pulse Width High FULL 5 SYSCLK Cycles3

I/O UPDATE (PS0/PS1) to SYNC_CLK Setup Time DVDD_I/O = 3.3 V FULL 4 ns

I/O UPDATE (PS0/PS1) to SYNC_CLK Setup Time DVDD_I/O = 1.8 V FULL 6 ns

I/O UPDATE (PS0/PS1), SYNC_CLK Hold Time FULL 0 ns

Latency

I/O UPDATE (PS0/PS1) to Frequency Change Prop Delay 25°C 24 SYSCLK Cycles

I/O UPDATE (PS0/PS1) to Phase Offset Change Prop Delay 25°C 24 SYSCLK Cycles

I/O UPDATE (PS0/PS1) to Amplitude Change Prop Delay 25°C 16 SYSCLK Cycles

CMOS LOGIC INPUTS

Logic 1 Voltage @ DVDD_I/O (Pin 43) = 1.8 V 25°C 1.25 V

Logic 0 Voltage @ DVDD_I/O (Pin 43) = 1.8 V 25°C 0.6 V

Logic 1 Voltage @ DVDD_I/O (Pin 43) = 3.3 V 25°C 2.2 V

Logic 0 Voltage @ DVDD_I/O (Pin 43) = 3.3 V 25°C 0.8 V

Logic 1 Current 25°C 3 12 µA

Logic 0 Current 25°C 12 µA

Input Capacitance 25°C 2 pF

CMOS LOGIC OUTPUTS (1 mA Load) DVDD_I/O = 1.8 V

Logic 1 Voltage 25°C 1.35 V

Logic 0 Voltage 25°C 0.4 V

CMOS LOGIC OUTPUTS (1 mA Load) DVDD_I/O = 3.3 V

Logic 1 Voltage 25°C 2.8 V

Logic 0 Voltage 25°C 0.4 V

POWER CONSUMPTION (AVDD = DVDD = 1.8 V)

Single-Tone Mode 25°C 162 171 mW

Rapid Power-Down Mode 25°C 150 160 mW

Full-Sleep Mode 25°C 20 27 mW

SYNCHRONIZATION FUNCTION4

Maximum SYNC Clock Rate (DVDD_I/O = 1.8 V) 25°C 62.5 MHz

Maximum SYNC Clock Rate (DVDD_I/O = 3.3 V) 25°C 100 MHz

SYNC_CLK Alignment Resolution5 25°C ±1 SYSCLK Cycles

1

To achieve the best possible phase noise, the largest amplitude clock possible should be used. Reducing the clock input amplitude will reduce the phase noise

performance of the device.

2

Wake-up time refers to the recovery from analog power-down modes (see the Power-Down Functions of the AD9953 section). The longest time required is for the

reference clock multiplier PLL to relock to the reference. The wake-up time assumes there is no capacitor on DACBP and that the recommended PLL loop filter values

are used.

3

SYSCLK cycle refers to the actual clock frequency used on-chip by the DDS. If the reference clock multiplier is used to multiply the external reference clock frequency,

the SYSCLK frequency is the external frequency multiplied by the reference clock multiplication factor. If the reference clock multiplier is not used, the SYSCLK

frequency is the same as the external reference clock frequency.

4

SYNC_CLK = ¼ SYSCLK rate. For SYNC_CLK rates ≥ 50 MHz, the high speed sync enable bit, CFR2<11>, should be set.

5

This parameter indicates that the digital synchronization feature cannot overcome phase delays (timing skew) between system clock rising edges. If the system clock

edges are aligned, the synchronization function should not increase the skew between the two edges.

Rev. 0 | Page 5 of 32

Page 6

AD9953

ABSOLUTE MAXIMUM RATINGS

Table 2.

Parameter Rating

Maximum Junction Temperature 150°C

DVDD_I/O (Pin 43) 4 V

AVDD, DVDD 2 V

Digital Input Voltage (DVDD_I/O = 3.3 V) –0.7 V to +5.25 V

Digital Input Voltage (DVDD_I/O = 1.8 V) –0.7 V to +2.2 V

Digital Output Current 5 mA

Storage Temperature –65°C to +150°C

Operating Temperature –40°C to +105°C

Lead Temperature (10 sec Soldering) 300°C

θJA 38°C/W

θJC 15°C/W

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only and functional operation of the device at these or

any other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

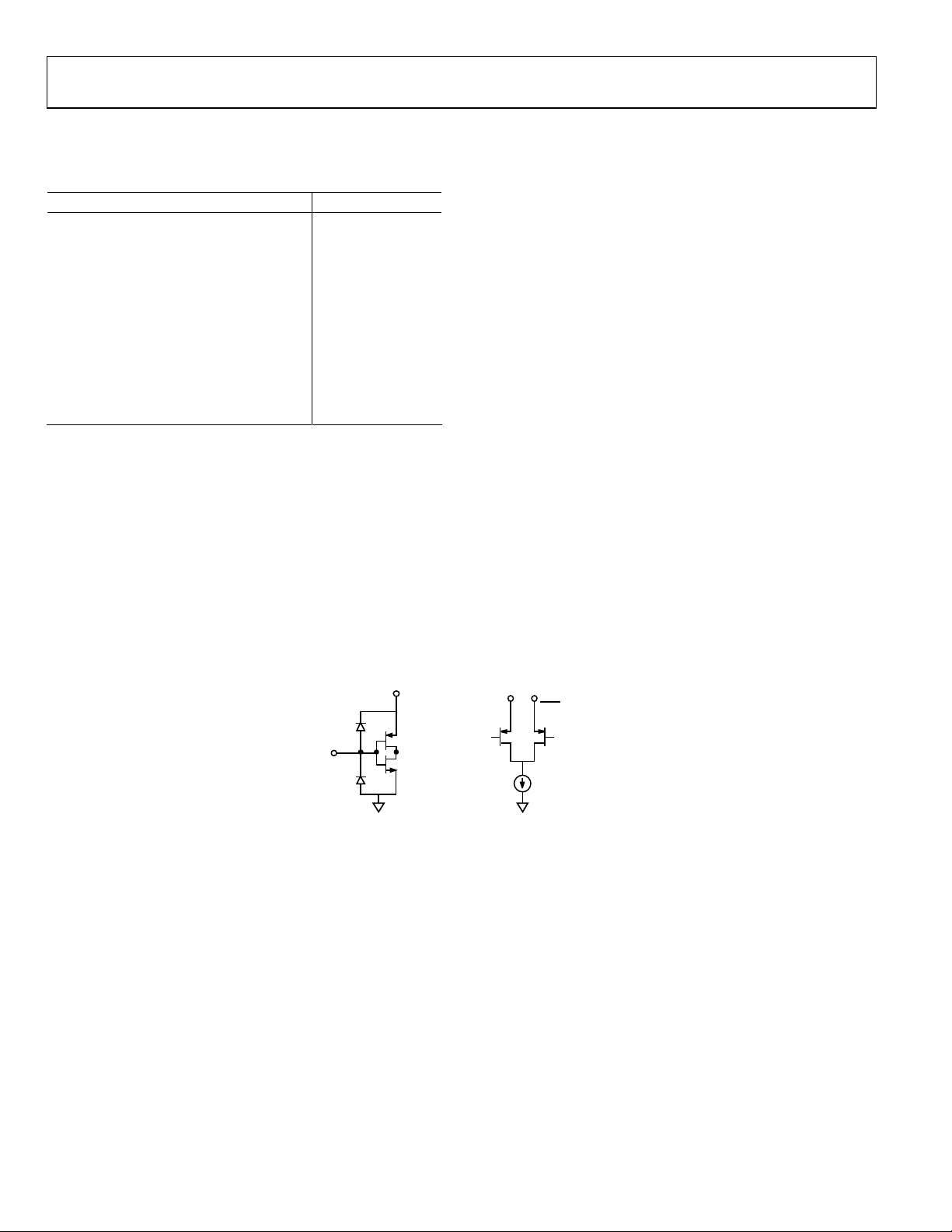

DIGITAL

INPUTS

DVDD_I/O

INPUT

AVOID OVERDRIVING

DIGITAL INPUTS.

FORWARD BIASING

ESD DIODES MAY

COUPLE DIGITAL NOISE

ONTO POWER PINS.

Figure 2. Equivalent Input and Output Circuits

DAC OUT PUTS

IOUT

MUST TERMINATE

OUTPUTS TO AVDD. DO

NOT EXCEED THE

OUTPUT VOLTAGE

COMPLIANCE RATING.

IOUT

03374-0-032

Rev. 0 | Page 6 of 32

Page 7

AD9953

PIN CONFIGURATION

OSK

PS1

PS0

SYNC_CLK

SYNC_IN

48 47 464544

DVDD_I/O

43

SCLK

DGND

SDIO

4241403938 37

SDOCSIOSYNC

I/O UPDATE

DVDD

DGND

AVDD

AGND

AVDD

AGND

OSC/REFCLK

OSC/REFCLK

CRYSTAL OUT

CLKMODESELECT

LOOP_FILTER

1

2

3

4

5

6

7

8

9

10

11

12

13 15 16 17 18 19 20 21 22 23 24

14

AVDD

AGND

AGND

AD9953

TOP VIEW

(Not to Scale)

AVDD

AGND

AVDD

AVDD

IOUT

IOUT

AGND

DACBP

SET

DAC_R

RESET

36

PWRDWNCTL

35

DVDD

34

DGND

33

AGND

32

AGND

31

AGND

30

AVDD

29

AGND

28

AVDD

27

AGND

26

AVDD

25

03357-0-002

Figure 3. 48-Lead TQFP/EP

Note that the exposed paddle on the bottom of the package forms an electrical connection for the DAC and must be attached to

analog ground. Note that Pin 43, DVDD_I/O, can be powered to 1.8 V or 3.3 V; however, the DVDD pins (Pin 2 and Pin 34) can only

be powered to 1.8 V.

Rev. 0 | Page 7 of 32

Page 8

AD9953

PIN FUNCTION DESCRIPTIONS

Table 3. 48-Lead TQFP/EP

Pin No. Mnemonic I/O Description

1 I/O UPDATE I

2, 34 DVDD I Digital Power Supply Pins (1.8 V).

3, 33, 42 DGND I Digital Power Ground Pins.

4, 6, 13,

16, 18, 19,

25, 27, 29

5, 7, 14,

15, 17, 22,

26, 32

8

9 OSC/REFCLK I

10 CRYSTAL OUT O Output of the Oscillator Section.

11 CLKMODESELECT I

12 LOOP_FILTER I

20

21 IOUT O DAC Output. Should be biased through a resistor to AVDD, not AGND.

23 DACBP I DAC Biasline Decoupling Pin.

24 DAC_R

35 PWRDWNCTL I Input Pin Used as an External Power-Down Control (see Table 10 for details).

36 RESET I

37 IOSYNC I

38 SDO O

39

40 SCLK I This pin functions as the serial data clock for I/O operations.

41 SDIO I/O

43 DVDD_I/O I Digital Power Supply (for I/O Cells Only, 3.3 V).

44 SYNC_IN I

45 SYNC_CLK O Clock Output Pin that Serves as a Synchronizer for External Hardware.

46 OSK I

47, 48 PS0, PS1 I

<49> AGND I

AVDD I Analog Power Supply Pins (1.8 V).

AGND I Analog Power Ground Pins.

/REFCLK

OSC

IOUT

I

SET

CS

The rising edge transfers the contents of the internal buffer memory to the I/O registers. This pin

must be set up and held around the SYNC_CLK output signal.

I

Complementary Reference Clock/Oscillator Input. When the REFCLK port is operated in singleended mode, REFCLK

Reference Clock/Oscillator Input. See Clock Input section for details on the OSCILLATOR/REFCLK

operation.

Control Pin for the Oscillator Section. When high, the oscillator section is enabled. When low, the

oscillator section is bypassed.

This pin provides the connection for the external zero compensation network of the REFCLK

multiplier’s PLL loop filter. The network consists of a 1 kΩ resistor in series with a 0.1 µF capacitor

tied to AVDD.

O Complementary DAC Output. Should be biased through a resistor to AVDD, not AGND.

A resistor (3.92 kΩ nominal) connected from AGND to DAC_R

for the DAC.

Active High Hardware Reset Pin. Assertion of the RESET pin forces the AD9953 to the initial state,

as described in the I/O port register map.

Asynchronous Active High Reset of the Serial Port Controller. When high, the current I/O

operation is immediately terminated, enabling a new I/O operation to commence once IOSYNC is

returned low. If unused, ground this pin; do not allow this pin to float.

When operating the I/O port as a 3-wire serial port, this pin serves as the serial data output. When

operated as a 2-wire serial port, this pin is unused and can be left unconnected.

I This pin functions as an active low chip select that allows multiple devices to share the I/O bus.

When operating the I/O port as a 3-wire serial port, this pin serves as the serial data input only.

When operated as a 2-wire serial port, this pin is the bidirectional serial data pin.

Input Signal Used to Synchronize Multiple AD9953s. This input is connected to the SYNC_CLK

output of a master AD9953.

Input Pin Used to Control the Direction of the Shaped On-Off Keying Function when

Programmed for Operation. OSK is synchronous to the SYNC_CLK pin. When OSK is not

programmed, this pin should be tied to DGND.

Input pin used to select one of the four internal profiles. Profile <1:0> are synchronous to the

SYNC_CLK pin. Any change in these inputs transfers the contents of the internal buffer memory

to the I/O registers (sends an internal I/O UPDATE).

The exposed paddle on the bottom of the package is a ground connection for the DAC and must

be attached to AGND in any board layout.

should be decoupled to AVDD with a 0.1 µF capacitor.

establishes the reference current

SET

Rev. 0 | Page 8 of 32

Page 9

AD9953

K

K

K

K

K

K

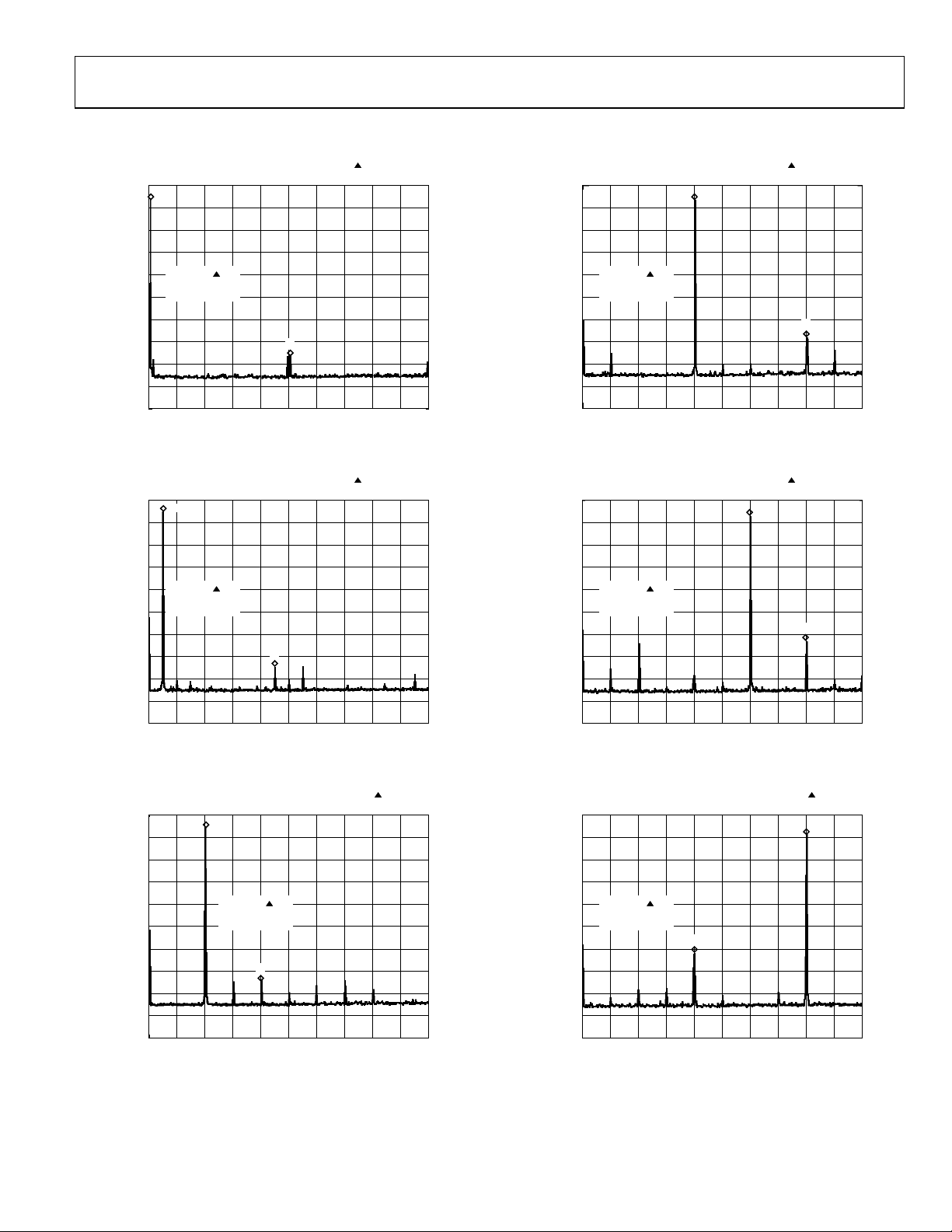

TYPICAL PERFORMANCE CHARACTERISTICS

PEA

LOG

10dB/

W1 S2

S3 FC

AA

PEA

LOG

10dB/

W1 S2

S3 FC

AA

PEA

LOG

10dB/

W1 S2

S3 FC

AA

REF 0dBm

0

1R

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

CENTER 100MHz

#RES BW 3kHz

Figure 4. F

REF 0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

CENTER 100MHz

#RES BW 3kHz

Figure 5. F

REF 0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

CENTER 100MHz

#RES BW 3kHz

Figure 6. F

ATTEN 10dB

MARKER

100.000000MHz

–70.68dB

1

VBW 3kHz

= 1 MHz FCLK = 400 MSPS, WBSFDR

OUT

ATTEN 10dB

1R

MARKER

80.000000MHz

–69.12dB

1

VBW 3kHz

= 10 MHz, FCLK = 400 MSPS, WBSFDR

OUT

ATTEN 10dB

1R

MARKER

40.000000MHz

–68.44dB

1

VBW 3kHz

= 40 MHz, FCLK = 400 MSPS, WBSFDR

OUT

MKR1 98.0MHz

–70.68dB

SWEEP 55.56 s (401 PTS)

SWEEP 55.56 s (401 PTS)

SWEEP 55.56 s (401 PTS)

SPAN 200MHz

MKR1 80.0MHz

–69.12dB

SPAN 200MHz

MKR1 0Hz

–68.44dB

SPAN 200MHz

03374-0-016

03374-0-017

03374-0-018

PEA

LOG

10dB/

W1 S2

S3 FC

AA

PEA

LOG

10dB/

W1 S2

S3 FC

AA

PEA

LOG

10dB/

W1 S2

S3 FC

AA

REF 0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

CENTER 100MHz

#RES BW 3kHz

Figure 7. F

REF 0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

CENTER 100MHz

#RES BW 3kHz

Figure 8. F

REF 0dBm

0

–10

–20

–30

–40

–50

–60

–70

–80

–90

–100

CENTER 100MHz

#RES BW 3kHz

Figure 9. F

ATTEN 10dB

1R

MARKER

80.000000MHz

–61.55dB

VBW 3kHz

= 80 MHz FCLK = 400 MSPS, WBSFDR

OUT

ATTEN 10dB

MARKER

40.000000MHz

–56.2dB

VBW 3kHz

= 120 MHz, FCLK = 400 MSPS, WBSFDR

OUT

ATTEN 10dB

MARKER

80.000000MHz

–53.17dB

= 160 MHz, FCLK = 400 MSPS, WBSFDR

OUT

1

VBW 3kHz

MKR1 80.0MHz

–61.55dB

1

1R

SPAN 200MHz

MKR1 40.0MHz

–56.2dB

1

SPAN 200MHz

MKR1 0Hz

–53.17dB

1R

SPAN 200MHz

SWEEP 55.56 s (401 PTS)

SWEEP 55.56 s (401 PTS)

SWEEP 55.56 s (401 PTS)

03374-0-019

03374-0-020

03374-0-021

Rev. 0 | Page 9 of 32

Page 10

AD9953

K

K

K

K

K

K

REF –4dBm

0

PEA

LOG

–10

10dB/

–20

–30

–40

–50

–60

W1 S2

–70

S3 FC

AA

–80

–90

ST

–100

CENTER 1.105MHz

#RES BW 30Hz

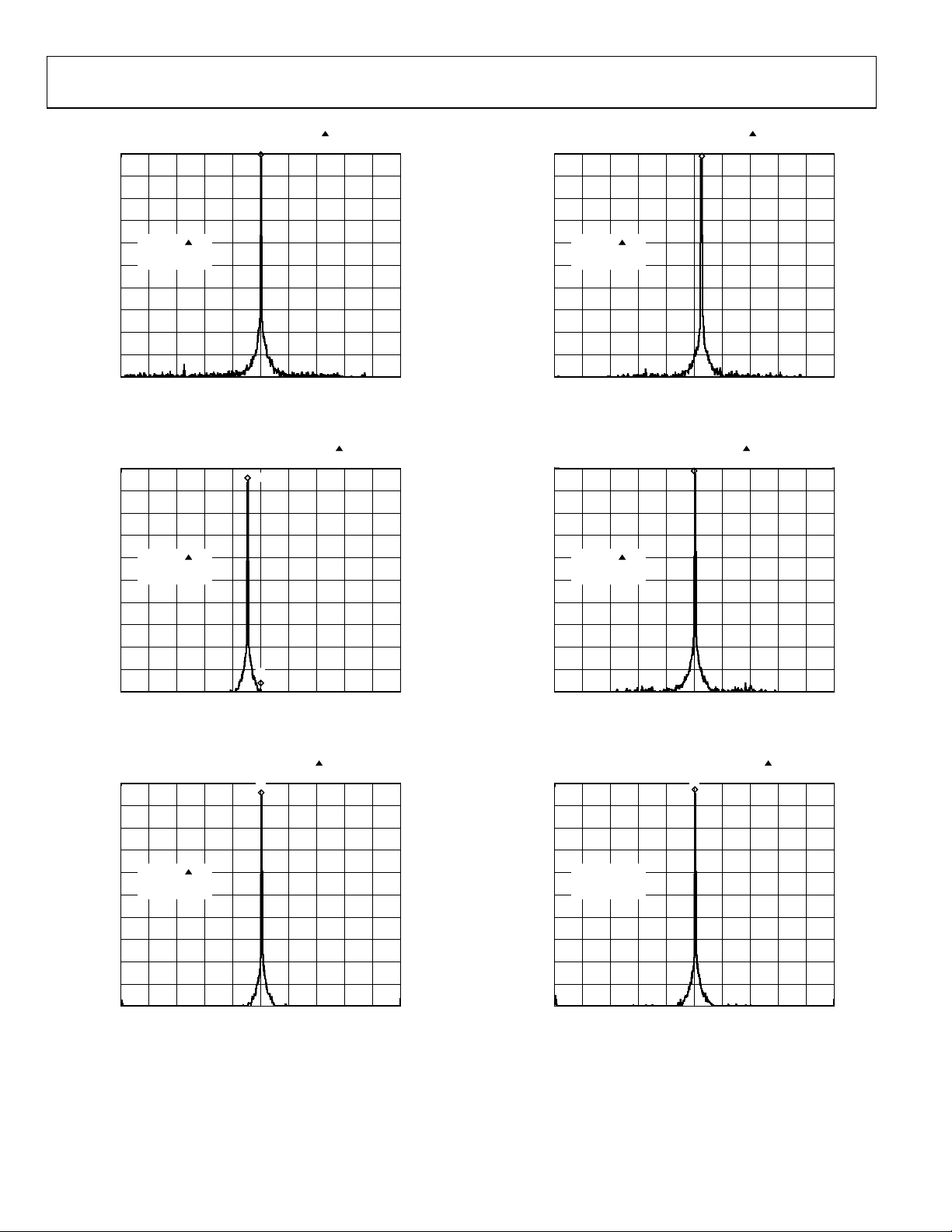

Figure 10. F

REF 0dBm

0

PEA

LOG

–10

10dB/

–20

–30

–40

–50

–60

W1 S2

–70

S3 FC

AA

–80

–90

–100

CENTER 10MHz

#RES BW 30Hz

Figure 11. F

REF 0dBm

0

PEA

LOG

–10

10dB/

–20

–30

–40

–50

–60

W1 S2

–70

S3 FC

AA

–80

–90

–100

CENTER 39.9MHz

#RES BW 30Hz

Figure 12. F

ATTEN 10dB

MARKER

1.105000MHz

–5.679dBm

= 1.1 MHz, FCLK = 400 MSPS, NBSFDR, ±1 MHz

OUT

ATTEN 10dB

MARKER

40.000000MHz

–56.2dB

= 10 MHz, FCLK = 400 MSPS, NBSFDR, ±1 MHz

OUT

ATTEN 10dB

MARKER

39.905000MHz

–5.347dBm

= 39.9 MHz, FCLK = 400 MSPS, NBSFDR, ±1 MHz

OUT

1

VBW 30Hz

1R

1

VBW 30Hz

1

VBW 30Hz

MKR1 1.105MHz

SWEEP 199.2 s (401 PTS)

MKR1 85kHz

SWEEP 199.2 s (401 PTS)

MKR1 39.905MHz

SWEEP 199.2 s (401 PTS)

–5.679dBm

SPAN 2MHz

–93.01dB

SPAN 2MHz

–5.347dBm

SPAN 2MHz

03374-0-022

03374-0-023

03374-0-024

REF –4dBm

PEA

LOG

10dB/

W1 S2

S3 FC

AA

ST

Figure 13. F

REF –4dBm

PEA

LOG

10dB/

W1 S2

S3 FC

AA

ST

Figure 14. F

REF –4dBm

PEA

LOG

10dB/

W1 S2

S3 FC

AA

ST

Figure 15. F

0

–10

–20

–30

MARKER

–40

80.301000MHz

–6.318dBm

–50

–60

–70

–80

–90

–100

CENTER 80.25MHz

#RES BW 30Hz

0

–10

–20

–30

MARKER

–40

120.205000MHz

–6.825dBm

–50

–60

–70

–80

–90

–100

CENTER 120.2MHz

#RES BW 30Hz

0

–10

–20

–30

CENTER

–40

160.5000000MHz

–50

–60

–70

–80

–90

–100

CENTER 160.5MHz

#RES BW 30Hz

MKR1 80.301MHz

ATTEN 10dB

= 80.3 MHz, FCLK = 400 MSPS, NBSFDR, ±1 MHz

OUT

ATTEN 10dB

= 120.2 MHz, FCLK = 400 MSPS, NBSFDR, ±1 MHz

OUT

ATTEN 10dB

= 160 MHz, FCLK = 400 MSPS, NBSFDR, ±1 MHz

OUT

VBW 30Hz

VBW 30Hz

VBW 30Hz

1

SWEEP 199.2 s (401 PTS)

1

SWEEP 199.2 s (401 PTS)

1

SWEEP 199.2 s (401 PTS)

–6.318dBm

SPAN 2MHz

MKR1 120.205MHz

–6.825dBm

SPAN 2MHz

MKR1 600kHz

–0.911dB

SPAN 2MHz

03374-0-025

03374-0-026

03374-0-027

Rev. 0 | Page 10 of 32

Page 11

AD9953

Figure 16. Residual Phase Noise with F

(Green), 4 × 100 MSPS (Red), and 20 × 20 MSPS (Blue)

1

CH1 200mVΩ

Figure 17. Residual Peak-to-Peak Jitter of DDS

and Comparator Operating Together at 160 MHz

= 159.5 MHz, F

OUT

A CH1 708mV

= 3.156ns

t

1

= 3.04ns

t

2

t =

–116.0PS

∆

1/∆

t =

IT 4.0PS/PT 3.1nsM 200PS 20.0GS/S

CLK

–8.621GHz

= 400 MSPS

03374-0-031

Figure 18. Residual Phase Noise with F

= 9.5 MHz, F

OUT

= 400 MSPS (Green),

CLK

4 ×100 MSPS (Red), and 20 × 20 MSPS (Blue)

FALL (R1) = 396.4PS

RISE(R2) = 464.3PS

R1

R2

REF2 200mV 500ns

A CH1 708mV

IT 10.0PS/PT –100PSM 500PS 20.0GS/S

03374-0-030

Figure 19. Comparator Rise and Fall Time at 160 MHz

Rev. 0 | Page 11 of 32

Page 12

AD9953

THEORY OF OPERATION

COMPONENT BLOCKS

DDS Core

The output frequency (fO) of the DDS is a function of the

frequency of the system clock (SYSCLK), the value of the

frequency tuning word (FTW), and the capacity of the accumu-

32

lator (2

with f

The value at the output of the phase accumulator is translated to

an amplitude value via the COS(x) functional block and routed

to the DAC.

In certain applications, it is desirable to force the output signal

to zero phase. Simply setting the FTW to 0 does not accomplish

this; it only results in the DDS core holding its current phase

value. Thus, a control bit is required to force the phase accumulator output to zero.

At power-up, the clear phase accumulator bit is set to Logic 1,

but the buffer memory for this bit is cleared (Logic 0). Therefore, upon power-up, the phase accumulator will remain clear

until the first I/O UPDATE is issued.

Phase-Locked Loop (PLL)

The PLL allows multiplication of the REFCLK frequency. Control of the PLL is accomplished by programming the 5-bit

REFCLK multiplier portion of Control Function Register No. 2,

Bits <7:3>.

When programmed for values ranging from 0x04 to 0x14

(4 decimal to 20 decimal), the PLL multiplies the REFCLK input

frequency by the corresponding decimal value. However, the

maximum output frequency of the PLL is restricted to

400 MHz. Whenever the PLL value is changed, the user should

be aware that time must be allocated to allow the PLL to lock

(approximately 1 ms).

, in this case). The exact relationship is given below

defined as the frequency of SYSCLK.

S

()

()

SO

()()

SO

3132

202/ ≤≤= FTWwithfFTWf

<<×= FTWwithFTWff

323132

1–222/–1

Clock Input

The AD9953 supports various clock methodologies. Support for

differential or single-ended input clocks and enabling of an

on-chip oscillator and/or a phase-locked loop (PLL) multiplier

is all controlled via user programmable bits. The AD9953 may

be configured in one of six operating modes to generate the

system clock. The modes are configured using the CLKMODESELECT pin, CFR1<4>, and CFR2<7:3>. Connecting the external pin CLKMODESELECT to Logic High enables the on-chip

crystal oscillator circuit. With the on-chip oscillator enabled,

users of the AD9953 connect an external crystal to the REFCLK

and REFCLKB inputs to produce a low frequency reference

clock in the range of 20 MHz to 30 MHz. The signal generated

by the oscillator is buffered before it is delivered to the rest of

the chip. This buffered signal is available via the CRYSTAL

OUT pin. Bit CFR1<4> can be used to enable or disable the

buffer, turning on or off the system clock. The oscillator itself is

not powered down in order to avoid long start-up times associated with turning on a crystal oscillator. Writing CFR2<9> to

Logic High enables the crystal oscillator output buffer. Logic

Low at CFR2<9> disables the oscillator output buffer.

Connecting CLKMODESELECT to Logic Low disables the

on-chip oscillator and the oscillator output buffer. With the

oscillator disabled, an external oscillator must provide the

REFCLK and/or REFCLKB signals. For differential operation,

these pins are driven with complementary signals. For singleended operation, a 0.1 µF capacitor should be connected

between the unused pin and the analog power supply. With the

capacitor in place, the clock input pin bias voltage is 1.35 V. In

addition, the PLL may be used to multiply the reference

frequency by an integer value in the range of 4 to 20. Table 4

summarizes the clock modes of operation. Note that the PLL

multiplier is controlled via the CFR2<7:3> bits, independent of

the CFR1<4> bit.

The PLL is bypassed by programming a value outside the range

of 4 to 20 (decimal). When bypassed, the PLL is shut down to

conserve power.

Table 4. Clock Input Modes of Operation

CFR1<4> CLKMODESELECT CFR2<7:3> Oscillator Enabled? System Clock Frequency Range (MHz)

Low High 3 < M < 21 Yes F

Low High M < 4 or M > 20 Yes F

Low Low 3 < M < 21 No F

Low Low M < 4 or M > 20 No F

High X X No F

Rev. 0 | Page 12 of 32

= F

CLK

CLK

CLK

CLK

CLK

× M 80 < F

OSC

= F

20 < F

OSC

= F

× M 80 < F

OSC

= F

10 < F

OSC

= 0 N/A

CLK

CLK

CLK

CLK

< 400

< 30

< 400

< 400

Page 13

AD9953

DAC Output

The AD9953 incorporates an integrated 14-bit current output

DAC.

Unlike most DACs, this output is referenced to AVDD,

not AGND.

Two complementary outputs provide a combined full-scale

output current (I

). Differential outputs reduce the amount of

OUT

common-mode noise that might be present at the DAC output,

offering the advantage of an increased signal-to-noise ratio. The

full-scale current is controlled by an external resistor (R

connected between the DAC_R

pin and the DAC ground

SET

SET

)

(AGND_DAC). The full-scale current is proportional to the

resistor value as follows:

IR /19.39=

OUTSET

The maximum full-scale output current of the combined DAC

outputs is 15 mA, but limiting the output to 10 mA provides the

best spurious-free dynamic range (SFDR) performance. The DAC

output compliance range is AVDD + 0.5 V to AVDD – 0.5 V.

Voltages developed beyond this range will cause excessive DAC

distortion and could potentially damage the DAC output circuitry.

Proper attention should be paid to the load termination to keep the

output voltage within this compliance range.

Serial IO Port

The AD9953 serial port is a flexible, synchronous serial communications port that allows easy interface to many industry-standard

microcontrollers and microprocessors. The serial I/O port is compatible with most synchronous transfer formats, including both the

Motorola 6905/11 SPI® and Intel® 8051 SSR protocols.

The interface allows read/write access to all registers that configure

the AD9953. MSB first or LSB first transfer formats are supported.

The AD9953’s serial interface port can be configured as a single pin

I/O (SDIO), which allows a 2-wire interface or two unidirectional

pins for in/out (SDIO/SDO), which in turn enables a 3-wire interface. Two optional pins, IOSYNC and

, enable greater flexibility

CS

for system design in the AD9953.

Register Map and Descriptions

The register map is listed in Table 5.

Rev. 0 | Page 13 of 32

Page 14

AD9953

Table 5. Register Map

Register

Name

(Serial

Address)

Control

Function

Register

No.1

(CFR1)

(0x00)

Control

Function

Register

No. 2 (CFR2)

(0x01)

Amplitude

Scale Factor

(ASF)

(0x02)

Amplitude

Ramp Rate

(ARR)

(0x03)

Frequency

Tuning

Word

(FTW0)

(0x04)

Phase

Offset Word

(POW0)

(0x05)

Frequency

Tuning

Word

(FTW1)

(0x06)

Bit

Range

<7:0>

<15:8>

<23:16>

<31:24>

<7:0>

<15:8> Not Used

<23:16> Not Used 0x00

<7:0> Amplitude Scale Factor Register <7:0> 0x00

<15:8>

<7:0> Amplitude Ramp Rate Register <7:0>

<7:0> Frequency Tuning Word No. 0 <7:0> 0x00

<15:8> Frequency Tuning Word No. 0 <15:8> 0x00

<23:16> Frequency Tuning Word No. 0 <23:16> 0x00

<31:24> Frequency Tuning Word No. 0 <31:24>

<7:0> Phase Offset Word No. 0 <7:0> 0x00

<15:8> Not Used<1:0> Phase Offset Word No. 0 <13:8>

<7:0> Frequency Tuning Word No. 1 <7:0> 0x00

<15:8> Frequency Tuning Word No. 1 <15:8> 0x00

<23:16> Frequency Tuning Word No. 1 <23:16> 0x00

<31:24>

(MSB)

Bit 7

Digital

Power-

Down

Load SRR

@ I/O UD

Automatic

Sync

Enable

RAM

Enable

Auto Ramp Rate Speed

Control <1:0>

Bit 6

Comp

Power-

Down

AutoClr

Freq.

Accum.

Software

Manual

Sync

RAM

Dest. Is

Phase

Word

0x00 or 0x01, or 0x02 or 0x03: Bypass Multiplier

0x04 to 0x14: 4× to 20× Multiplication

Bit 5

DAC

Power-

Down

AutoClr

Phase

Accum.

Linear

Sweep

Enable

Internal Profile Control <2:0>

REFCLK Multiplier

Frequency Tuning Word No. 1 <31:24> 0x00

Bit 4

Clock Input

Power-

Down

Enable

SINE

Output

Not Used Not Used Not Used Not Used

Amplitude Scale Factor Register <13:8>

Bit 3

External

Power-

Down

Mode

Clear

Freq.

Accum.

High

Speed

Sync

Enable

Bit 2

Linear

Sweep No

Dwell

Clear

Phase

Accum.

Load ARR

@ I/O UD

VCO Range

Hardware

Manual

Sync

Enable

Bit 1

SYNC_CLK

Out

Disable

SDIO

Input

Only

OSK

Enable

Charge Pump Current

CRYSTAL

OUT Pin

Active

<1:0>

(LSB)

Bit 0

Not

Used

LSB First

Not

Used

Auto

OSK

Keying

Not

Used

Default

Value

OR

Profile

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

0x00

Rev. 0 | Page 14 of 32

Page 15

AD9953

Register

Name

(Serial

Address)

RAM

Segment

Control

Word No. 0

(RSCW0)

(0x07)

RAM

Segment

Control

Word No. 1

(RSCW1)

(0x08)

RAM

Segment

Control

Word No. 2

(RSCW2)

(0x09)

RAM

Segment

Control

Word No. 3

(RSCW3)

(0x0A)

RAM (0x0B) RAM [1023:0] <31:0> (Read Instructions: Write Out RAM Register Data)

Bit

Range

<7:0>

<15:8>

<23:16>

<31:24>

<39:32>

<7:0>

<15:8>

<23:16>

<31:24>

<39:32>

<7:0>

<15:8>

<23:16>

<31:24>

<39:32>

<7:0>

<15:8>

<23:16>

<31:24>

<39:32>

(MSB)

Bit 7

RAM Segment 0 Mode Control <2:0>

RAM Segment 0 Beginning Address <5:0> RAM Segment 0 Final Address <9:8>

RAM Segment 1 Mode Control

RAM Segment 2 Mode Control

RAM Segment 2 Beginning Address <5:0> RAM Segment 2 Final Address <9:8>

RAM Segment 3 Mode Control

RAM Segment 3 Beginning Address <5:0> RAM Segment 3 Final Address <9:8>

Bit 6

<2:0>

RAM Segment 1 Beginning Address <5:0> RAM Segment 1 Final Address <9:8>

<2:0>

<2:0>

Bit 5

RAM Segment 0 Address Ramp Rate <15:8>

RAM Segment 0 Address Ramp Rate <7:0>

RAM Segment 1 Address Ramp Rate <15:8>

RAM Segment 1 Address Ramp Rate <7:0>

RAM Segment 2 Address Ramp Rate <15:8>

RAM Segment 2 Address Ramp Rate <7:0>

RAM Segment 3 Address Ramp Rate <15:8>

RAM Segment 3 Address Ramp Rate <7:0>

Bit 4

No Dwell

Active

RAM Segment 0 Final Address <7:0>

No Dwell

Active

RAM Segment 1 Final Address <7:0>

No Dwell Active

RAM Segment 2 Final Address <7:0>

No Dwell Active

RAM Segment 3 Final Address <7:0>

Bit 3

RAM Segment 0 Beginning Address <9:6>

RAM Segment 1 Beginning Address <9:6>

Bit 2

Bit 1

RAM Segment 2 Beginning

Address <9:6>

RAM Segment 3 Beginning

Address <9:6>

(LSB)

Bit 0

Default

Value

OR

Profile

PS0 = 0

PS1 = 0

PS0 = 0

PS1 = 0

PS0 = 0

PS1 = 0

PS0 = 0

PS1 = 0

PS0 = 0

PS1 = 0

PS0 = 0

PS1 = 1

PS0 = 0

PS1 = 1

PS0 = 0

PS1 = 1

PS0 = 0

PS1 = 1

PS0 = 0

PS1 = 1

PS0 = 1

PS1 = 0

PS0 = 1

PS1 = 0

PS0 = 1

PS1 = 0

PS0 = 1

PS1 = 0

PS0 = 1

PS1 = 0

PS0 = 1

PS1 = 1

PS0 = 1

PS1 = 1

PS0 = 1

PS1 = 1

PS0 = 1

PS1 = 1

PS0 = 1

PS1 = 1

Rev. 0 | Page 15 of 32

Page 16

AD9953

Control Register Bit Descriptions

Control Function Register. No. 1 (CFR1)

The CFR1 is used to control the various functions, features, and

modes of the AD9953. The functionality of each bit is below.

CFR1<31>: RAM Enable Bit

CFR1<31> = 0 (default). The RAM is powered down to conserve power. Single-tone mode of operation is active.

CFR1<31> = 1. If CFR1<31> is active, the RAM is enabled for

operation. Access control for normal operation is controlled via

the mode control bits of the RSCW for the current profile.

CFR1<30>: RAM Destination Bit

CFR1<30> = 0 (default). If CFR1<31> is active, a Logic 0 on the

RAM destination bit (CFR1<30> = 0) configures the AD9953

such that the RAM output drives the phase accumulator (i.e.,

the frequency tuning word). If CFR1<31> is inactive,

CFR1<30> is a Don’t Care.

CFR1<30> = 1. If CFR1<31> is active, a Logic 1 on the RAM

destination bit (CFR1<30> = 1) configures the AD9953 such

that the RAM output drives the phase-offset adder (i.e., sets the

phase offset of the DDS core).

CFR1<29:27>: Not Used

CFR1<26>: Amplitude Ramp Rate Load Control Bit

CFR1<26> = 0 (default). The amplitude ramp rate timer is

loaded only upon timeout (timer == 1) and is not loaded due to

an I/O UPDATE input signal.

CFR1<26> = 1. The amplitude ramp rate timer is loaded upon

timeout (timer == 1) or at the time of an I/O UPDATE input signal.

CFR1<25>: Shaped On-Off Keying Enable Bit

CFR1<25> = 0 (default). Shaped on-off keying is bypassed.

CFR1<25> = 1. Shaped on-off keying is enabled. When enabled,

CFR1<24> controls the mode of operation for this function.

CFR1<24>: Auto Shaped On-Off Keying Enable Bit (Only Valid

when CFR1<25> Is Active High)

CFR1<24> = 0 (default). When CFR1<25> is active, a Logic 0

on CFR1<24> enables the manual shaped on-off keying operation. Each amplitude sample sent to the DAC is multiplied by

the amplitude scale factor. See the Shaped On-Off Keying section for details.

will cause the output to ramp down from the amplitude scale

factor to zero scale at the amplitude ramp rate. See the Shaped

On-Off Keying section for details.

CFR1<23>: Automatic Synchronization Enable Bit

CFR1<23> = 0 (default). The automatic synchronization feature

of multiple AD9953s is inactive.

CFR1<23> = 1. The automatic synchronization feature of multiple AD9953s is active. The device will synchronize its internal

synchronization clock (SYNC_CLK) to align to the signal present on the SYNC_IN input. See the Synchronizing Multiple

AD9953s section for details.

CFR1<22>: Software Manual Synchronization of Multiple

AD9953s

CFR1<22> = 0 (default). The manual synchronization feature is

inactive.

CFR1<22> = 1. The software controlled manual synchronization feature is executed. The SYNC_CLK rising edge is

advanced by one SYNC_CLK cycle and this bit is cleared. To

advance the rising edge multiple times, this bit needs to be set

for each advance. See the Synchronizing Multiple AD9953s section for details.

CFR1<21:14>: Not Used

CFR1<13>: Auto-Clear Phase Accumulator Bit

CFR1<13> = 0 (default). The current state of the phase accumulator remains unchanged when the frequency tuning word is applied.

CFR1<13> = 1. This bit automatically synchronously clears

(loads 0s into) the phase accumulator for one cycle upon reception of an I/O UPDATE signal.

CFR1<12>: Sine/Cosine Select Bit

CFR1<12> = 0 (default). The angle-to-amplitude conversion

logic employs a COSINE function.

CFR1<12> = 1. The angle-to-amplitude conversion logic

employs a SINE function.

CFR1<11>: Not Used

CFR1<10>: Clear Phase Accumulator

CFR1<10> = 0 (default). The phase accumulator functions as

normal.

CFR1<24> = 1. When CFR1<25> is active, a Logic 1 on

CFR1<24> enables the auto shaped on-off keying operation.

Toggling the OSK pin high will cause the output scalar to ramp

up from zero scale to the amplitude scale factor at a rate determined by the amplitude ramp rate. Toggling the OSK pin low

Rev. 0 | Page 16 of 32

CFR1<10> = 1. The phase accumulator memory elements are

cleared and held clear until this bit is cleared.

CFR1<9>: SDIO Input Only

Page 17

AD9953

CFR1<9> = 0 (default). The SDIO pin has bidirectional operation (2-wire serial programming mode).

minimum. However, the synchronization circuitry remains active (internally) to maintain normal device timing.

CFR1<9> = 1. The serial data I/O pin (SDIO) is configured as

an input only pin (3-wire serial programming mode).

CFR1<8>: LSB First

CFR1<8> = 0 (default). MSB first format is active.

CFR1<8> = 1. The serial interface accepts serial data in LSB first

format.

CFR1<7>: Digital Power-Down Bit

CFR1<7> = 0 (default). All digital functions and clocks are active.

CFR1<7> = 1. All non-IO digital functionality is suspended,

lowering the power significantly.

CFR1<6>: Not Used

CFR1<5>: DAC Power-Down Bit

CFR1<5> = 0 (default). The DAC is enabled for operation.

CFR1<5> = 1. The DAC is disabled and is in its lowest power

dissipation state.

CFR1<4>: Clock Input Power-Down Bit

CFR1<4> = 0 (default). The clock input circuitry is enabled for

operation.

CFR1<4> = 1. The clock input circuitry is disabled and the

device is in its lowest power dissipation state.

CFR1<3>: External Power-Down Mode

CFR1<3> = 0 (default). The external power-down mode

selected is the rapid recovery power-down mode. In this mode,

when the PWRDWNCTL input pin is high, the digital logic

and the DAC digital logic are powered down. The DAC bias

circuitry, PLL, oscillator, and clock input circuitry are not

powered down.

CFR1<3> = 1. The external power-down mode selected is the

full power-down mode. In this mode, when the PWRDWNCTL

input pin is high, all functions are powered down. This includes

the DAC and PLL, which take a significant amount of time to

power up.

CFR1<2>: Not Used

CFR1<1>: SYNC_CLK Disable Bit

CFR1<1> = 0 (default). The SYNC_CLK pin is active.

CFR1<1> = 1. The SYNC_CLK pin assumes a static Logic 0

state to keep noise generated by the digital circuitry at a

CFR1<0>: Not Used, Leave at 0

Control Function Register No. 2 (CFR2)

The CFR2 is used to control the various functions, features, and

modes of the AD9953, primarily related to the analog sections

of the chip.

CFR2<23:12>: Not Used

CFR2<11>: High Speed Sync Enable Bit

CFR2<11> = 0 (default). The high speed sync enhancement is off.

CFR2<11> = 1. The high speed sync enhancement is on. This

bit should be set when attempting to use the autosynchronization feature for SYNC_CLK inputs beyond 50 MHz,

(200 MSPS SYSCLK). See the Synchronizing Multiple AD9953s

section for details.

CFR2<10>: Hardware Manual Sync Enable Bit

CFR2<10> = 0 (default). The hardware manual sync function is off.

CFR2<10> = 1. The hardware manual sync function is enabled.

While this bit is set, a rising edge on the SYNC_IN pin will

cause the device to advance the SYNC_CLK rising edge by one

REFCLK cycle. Unlike the software manual sync enable bit, this

bit does not self clear. Once the hardware manual sync mode is

enabled, it will stay enabled until this bit is cleared. See the

Synchronizing Multiple AD9953s section for details.

CFR2<9>: CRYSTAL OUT Enable Bit

CFR2<9> = 0 (default). The CRYSTAL OUT pin is inactive.

CFR2<9> = 1. The CRYSTAL OUT pin is active. When active,

the crystal oscillator circuitry output drives the CRYSTAL OUT

pin, which can be connected to other devices to produce a reference frequency. The oscillator will respond to crystals in the

range of 20 MHz to 30 MHz.

CFR2<8>: Not Used

CFR2<7:3>: Reference Clock Multiplier Control Bits

This 5-bit word controls the multiplier value out of the clockmultiplier (PLL) block. Valid values are decimal 4 to 20 (0x04 to

0x14). Values entered outside this range will bypass the clock

multiplier. See the Phase-Locked Loop (PLL) section for details.

CFR2<2>: VCO Range Control Bit

This bit is used to control the range setting on the VCO.

When CFR2<2> == 0 (default), the VCO operates in a range of

100 MHz to 250 MHz. When CFR2<2> == 1, the VCO operates

in a range of 250 MHz to 400 MHz.

Rev. 0 | Page 17 of 32

Page 18

AD9953

CFR2<1:0>: Charge Pump Current Control Bits

These bits are used to control the current setting on the charge

pump. The default setting, CFR2<1:0>, sets the charge pump

current to the default value of 75 µA. For each bit added (01, 10,

11), 25 µA of current is added to the charge pump current:

100 µA, 125 µA, and 150 µA.

Other Register Descriptions

Amplitude Scale Factor (ASF)

The ASF register stores the 2-bit auto ramp rate speed value

and the 14-bit amplitude scale factor used in the output shaped

keying (OSK) operation. In auto OSK operation, ASF <15:14>

tells the OSK block how many amplitude steps to take for each

increment or decrement. For ASF<15:14> = {00, 01, 10, 11}, the

increment/decrement is set to {1, 2, 4, 8}, respectively. ASF

<13:0> sets the maximum value achievable by the OSK internal

multiplier. In manual OSK mode, ASF<15:14> has no effect.

ASF <13:0> provides the output scale factor directly. If the OSK

enable bit is cleared, CFR1<25> = 0, this register has no effect

on device operation.

Amplitude Ramp Rate (ARR)

The ARR register stores the 8-bit amplitude ramp rate used in

the auto OSK mode. This register programs the rate at which

the amplitude scale factor counter increments or decrements. If

the OSK is set to manual mode, or if OSK enable is cleared, this

register has no effect on device operation.

Frequency Tuning Word 0 (FTW0)

The frequency tuning word is a 32-bit register that controls the

rate of accumulation in the phase accumulator of the DDS core.

Its specific role is dependent on the device mode of operation.

Phase Offset Word (POW)

The phase offset word is a 14-bit register that stores a phase

offset value. This offset value is added to the output of the phase

accumulator to offset the current phase of the output signal. The

exact value of phase offset is given by the following formula:

POW

⎛

=Φ 360

RAM Segment Control Words (RSCW0, RSCW1, RSCW2, and RSCW3)

When the linear sweep enable bit CFR1<21> is clear,

Registers 0x07, 0x08, 0x09, and 0x0A act as the RAM segment

control words for each of the RAM segments. Each of the RAM

segment control words is comprised of a RAM segment address

ramp rate, a final address value, a beginning address value, a

RAM segment mode control, and a no-dwell bit.

RAM Segment Address Ramp Rate, RSCW<39:24>

For RAM modes that step through address values, such as

⎞

⎜

⎟

14

2

⎝

⎠

°×

ramping, this 16-bit word defines the number of SYNC_CLK

cycles the RAM controller dwells at each address. A value of 0 is

invalid. Any other value from 1 to 65535 may be used.

RAM Segment Final Address RSCW<9:8>, RSCW<23:16>

This discontinuous 10-bit sequence defines the final address

value for the given RAM segment. The order in which the bits

are listed is the order in which the bits must be written.

RSCW<23>, even though during the write operation is more

significant than RSCW<9>, is only the third MSB of the final

address value. RSCW<9>, even though it comes later in the

RSCW than RSCW<23>, is the MSB of the final address value.

RAM Segment Beginning Address RSCW<3:0>, <15:10>

This discontinuous 10-bit sequence defines the final address

value for the given RAM segment. The order in which the bits

are listed is the order in which the bits must be written.

RSCW<15>, even though during the write operation is more

significant than RSCW<3>, is only the fifth MSB of the final

address value. RSCW<3>, even though it comes later in the

RSCW than RSCW<15>, is the MSB of the final address value.

RAM Segment Mode Control RSCW<7:5>

This 3-bit sequence determines the RAM segment’s mode of

operation. There are only five possible RAM modes, so only

values of 0 to 5 are valid. See Table 6 to determine the bit combination for various RAM modes.

RAM Segment No-Dwell Bit RSCW<4>

This bit sets the no-dwell feature of sweeping profiles. In profiles that sweep from a defined beginning to a defined end, the

RAM controller can either dwell at the final address until the

next profile is selected or, when this bit is set, the RAM controller will return to the beginning address and dwell there until the

next profile is selected.

RAM

The AD9953 incorporates a 1024 × 32 block of SRAM. The

RAM is a bidirectional single port. Both read and write operations from and to the RAM are valid, but they cannot occur

simultaneously. Write operations from the serial I/O port have

precedence, and if an attempt to write to RAM is made during a

read operation, the read operation will be halted. The RAM is

controlled in multiple ways, dictated by the modes of operation

described in the RAM Segment Control Word <7:5> as well as

data in the control function register. Read/write control for the

RAM will be described for each mode supported.

When the RAM enable bit (CFR1<31>) is set, the RAM output

optionally drives the input to the phase accumulator or the

phase offset adder, depending on the state of the RAM destination bit (CFR1<30>). If CFR1<30> is a Logic 1, the RAM output

is connected to the phase offset adder and supplies the phase

Rev. 0 | Page 18 of 32

Page 19

AD9953

offset control word(s) for the device. When CFR1<30> is

Logic 0 (default condition), the RAM output is connected to the

input of the phase accumulator and supplies the frequency tuning word(s) for the device. When the RAM output drives the

phase accumulator, the phase offset word (POW, Address 0x05)

drives the phase-offset adder. Similarly, when the RAM output

drives the phase offset adder, the frequency tuning word (FTW,

Address 0x04) drives the phase accumulator. When CFR1<31>

is Logic 0, the RAM is inactive unless being written to via the

serial port. The power-up state of the AD9953 is the single-tone

mode, in which the RAM enable bit is inactive. The RAM is

segmented into four unique slices controlled by the Profile<1:0>

input pins.

All RAM writes/reads, unless otherwise specified, are controlled

by the Profile<1:0> input pins and the respective RAM segment

control word. The RAM can be written to during normal operation, but any I/O operation that commands the RAM to be written immediately suspends read operation from the RAM, causing

the current mode of operation to be nonfunctional. This excludes

single-tone mode, as the RAM is not read in this mode.

Writing the RAM is accomplished as follows. After configuring

the desired RAM segment control words, the desired RAM

segment must be selected via the profile select pins PS<1:0>.

During the instruction byte, write the address for the RAM,

0x0B. The serial port and RAM controller will work in conjunction to determine the width of the profile and the serial port

will accept the defined number of 32-bit words sequentially

from the beginning address to the ending address. Consider the

following example:

• The RAM Segment Control Word 1 lists the beginning

RAM address at 256 and the ending address at 511.

• PS0 = 1 and PS1 = 0.

• The instruction byte is 10001001.

The RAM controller would configure the serial port to expect

256 32-bit words. The first 32 bits would be parsed as a word

and sent to RAM Address 256. The next 32 bits would be parsed

and sent to 257, and so forth, all the way through until the 256

word was sent (grand total of 8,192 data bits in this operation).

MODES OF OPERATION

Single-Tone Mode

In single-tone mode, the DDS core uses a single tuning word.

Whatever value is stored in FTW0 is supplied to the phase

accumulator. This value can only be changed manually, which is

done by writing a new value to FTW0 and by issuing an I/O

UPDATE. Phase adjustment is possible through the phase

offset register.

RAM Controlled Modes of Operation

Direct Switch Mode

Direct switch mode enables FSK or PSK modulation. The

AD9953 is programmed for direct switch mode by writing the

RAM enable bit true and programming the RAM segment

mode control bits of each desired profile to Logic 000(b). This

mode simply reads the RAM contents at the RAM segment

beginning address for the current profile. No address ramping is

enabled in direct switch mode.

To perform 4-tone FSK, the user programs each RAM segment

control word for direct switch mode and a unique beginning

address value. In addition, the RAM enable bit is written true,

which enables the RAM, and the RAM destination bit is written

false, setting the RAM output to be the frequency tuning word.

The Profile<1:0> inputs are the 4-tone FSK data inputs. When

the profile is changed, the frequency tuning word stored in the

new profile is loaded into the phase accumulator and is used to

increment the currently stored value in a phase continuous fashion. The phase offset word drives the phase-offset adder. Twotone FSK is accomplished by using only one profile pin for data.

Programming the AD9953 for PSK modulation is similar to

FSK except the RAM destination bit is set to a Logic 1, enabling

the RAM output to drive the phase offset adder. The FTW0

drives the input to the phase accumulator. Toggling the profile

pins changes (modulates) the current phase value. The upper

14 bits of the RAM drive the phase adder (<31:18>).

Bits <17:0> of the RAM output are unused when the RAM destination bit is set. The no-dwell bit is a Don’t Care in direct

switch mode.

Ramp-Up Mode

Ramp-up mode, in conjunction with the segmented RAM capability, allows up to four different sweep profiles to be programmed into the AD9953. The AD9953 is programmed for

ramp-up mode by writing the RAM enable bit true and programming the RAM mode control bits of each profile to be

used to Logic 001(b). As in all modes that enable the memory,

the RAM destination bit controls whether the RAM output

drives the phase accumulator or the phase offset adder.

Upon starting a sweep (via an I/O UPDATE or change in

profile bits), the RAM address generator loads the RAM

segment beginning address bits of the current RSCW, driving

the RAM output from this address, and the ramp rate timer

loads the RAM segment address ramp rate bits. When the

ramp rate timer finishes a cycle, the RAM address generator

increments to the next address and the timer reloads the ramp

rate bits and begins a new countdown cycle. This sequence continues until the RAM address generator has incremented to an

address equal to the RAM segment final address bits of the current RSCW.

Rev. 0 | Page 19 of 32

Page 20

AD9953

If the no-dwell bit is clear when the RAM address generator

equals the final address, the generator stops incrementing as the

terminal frequency has been reached. The sweep is complete

and does not restart until an I/O UPDATE or change in profile

is detected to enable another sweep from the beginning to the

final RAM address as described above.

If the no-dwell bit is set when the RAM address generator

equals the final address, after the next ramp rate timer cycle the

phase accumulator is cleared. The phase accumulator remains

cleared until another sweep is initiated via an I/O UPDATE

input or change in profile.

Another application for ramp-up mode is nonsymmetrical FSK

modulation. With the RAM configured for two segments, using

the Profile<0> bit as the data input allows nonsymmetrical

ramped FSK.

Bidirectional Ramp Mode

Bidirectional ramp mode allows the AD9953 to offer a symmetrical sweep between two frequencies using the Profile<0> signal

as the control input. The AD9953 is programmed for bidirectional ramp mode by writing the RAM enable bit true and the

RAM mode control bits of RSCW0 to Logic 010(b). In bidirectional ramp mode, the Profile<1> input is ignored and the

Profile<0> input is the ramp direction indicator. In this mode,

the memory is not segmented and uses only a single beginning

and final address. The address registers that affect the control of

the RAM are located in the RSCW associated with Profile 0.

Upon entering this mode (via an I/O UPDATE or changing

Profile<0>), the RAM address generator loads the RAM segment beginning address bits of RSCW0 and the ramp rate timer

loads the RAM segment address ramp rate bits. The RAM

drives data from the beginning address, and the ramp rate timer

begins to count down to 1. While operating in this mode, toggling the Profile<0> pin does not cause the device to generate

an internal I/O UPDATE. When the Profile<0> pin is acting as

the ramp direction indicator, any transfer of data from the I/O

buffers to the internal registers can only be initiated by a rising

edge on the I/O UPDATE pin.

RAM address control now is a function of the Profile<0> input.

When the Profile<0> bit is a Logic 1, the RAM address generator increments to the next address when the ramp rate timer

completes a cycle (and reloads to start the timer again). As in

the ramp-up mode, this sequence continues until the RAM

address generator has incremented to an address equal to the

final address as long as the Profile<0> input remains high. If the

Profile<0> input goes low, the RAM address generator immediately decrements and the ramp rate timer is reloaded. The RAM

address generator will continue to decrement at the ramp rate

period until the RAM address is equal to the beginning address

as long as the Profile<0> input remains low.

The sequence of ramping up and down is controlled via the

Profile<0> input signal for as long as the part is programmed

into this mode. The no-dwell bit is a Don’t Care in this mode as

is all data in the RAM segment control words associated with

Profiles 1, 2, and 3. Only the information in the RAM segment

control word for Profile 0 is used to control the RAM in the

bidirectional ramp mode.

Continuous Bidirectional Ramp Mode

Continuous bidirectional ramp mode allows the AD9953 to

offer an automatic symmetrical sweep between two frequencies.

The AD9953 is programmed for continuous bidirectional ramp

mode by writing the RAM enable bit true and the RAM mode

control bits of each profile to be used to Logic 011(b).

Upon entering this mode (via an I/O UPDATE or changing

Profile<1:0>), the RAM address generator loads the RAM segment beginning address bits of the current RSCW and the ramp

rate timer loads the RAM segment address ramp rate bits. The

RAM drives data from the beginning address, and the ramp rate

timer begins to count down to 1. When the ramp rate timer

completes a cycle, the RAM address generator increments to the

next address, and the timer reloads the ramp rate bits and continues counting down. This sequence continues until the RAM

address generator has incremented to an address equal to the

RAM segment final address bits of the current RSCW. Upon

reaching this terminal address, the RAM address generator will

decrement in value at the ramp rate until it reaches the RAM

segment beginning address. Upon reaching the beginning address, the entire sequence repeats.

The entire sequence repeats for as long as the part is programmed for this mode. The no-dwell bit is a Don’t Care in this

mode. In general, this mode is identical in control to the bidirectional ramp mode except the ramp up and down is automatic

(no external control via the Profile<0> input) and switching

profiles is valid. Once in this mode, the address generator ramps

from the beginning address to the final address, then back to

the beginning address at the rate programmed into the ramp

rate register. This mode enables generation of an automatic saw

tooth sweep characteristic.

Continuous Recirculate Mode

Continuous recirculate mode allows the AD9953 to offer

an automatic, continuous unidirectional sweep between two

frequencies. The AD9953 is programmed for continuous

recirculate mode by writing the RAM enable bit true and the RAM

mode control bits of each profile to be used to Logic 100(b).

Upon entering this mode (via an I/O UPDATE or changing

Profile<1:0>), the RAM address generator loads the RAM segment beginning address bits of the current RSCW and the ramp

rate timer loads the RAM segment address ramp rate bits. The

RAM drives data from the beginning address, and the ramp rate

timer begins to count down to 1. When the ramp rate timer

Rev. 0 | Page 20 of 32

Page 21

AD9953

completes a cycle, the RAM address generator increments to the

next address, and the timer reloads the ramp rate bits and continues counting down. This sequence continues until the RAM

address generator has incremented to an address equal to the

RAM segment final address bits of the current RSCW. Upon

reaching this terminal address, the RAM address generator

reloads the RAM segment beginning address bits and the

sequence repeats.

The sequence of circulating through the specified RAM

addresses repeats for as long as the part is programmed for this

mode. The no-dwell bit is a Don’t Care in this mode.

RAM Controlled Modes of Operation Notes and Summary

Notes:

1)

The user must ensure that the beginning address is lower

than the final address.

2)

Changing profiles or issuing an I/O UPDATE automatically

terminates the current sweep and starts the next sweep.

3)

Setting the RAM destination bit true such that the RAM

output drives the phase offset adder is valid. While the

above discussion describes a frequency sweep, a phase

sweep operation is also available.

The AD9953 offers five modes of RAM controlled operation

(see Table 6).

Table 6. RAM Modes of Operation

RSCW<7:5>

(Binary)

000 Direct Switch

001 Ramp Up

010

011

100

101, 110, 111 Open

Mode

Bidirectional

Ramp

Continuous

Bidirectional

Ramp

Continuous

Recirculate

Notes

No Sweeping, Profiles

Valid, No Dwell Invalid

Sweeping, Profiles Valid,

No Dwell Valid

Sweeping, Profile <0> Is a

Direction Control Bit, No

Dwell Invalid

Sweeping, Profiles Valid,

No Dwell Invalid

Sweeping, Profiles Valid,

No Dwell Invalid

Invalid Mode—Default To

Direct Switch

Internal Profile Control

The AD9953 offers a mode in which a composite frequency

sweep can be built, for which the timing control is software

programmable. The internal profile control capability disengages the Profile<1:0> pins and enables the AD9953 to take

control of switching between profiles. Modes are defined that

allow continuous or single burst profile switches for three

combinations of profile selection bits. These are listed in Table

7. When any of the CFR1<29:27> bits are active, the

Rev. 0 | Page 21 of 32

When any of the CFR1<29:27> bits are active, the

internal profile control mode is engaged. Internal profile control

is only valid when the device is operating in RAM mode. There

is no internal profile control for linear sweeping operations.

When the internal profile control mode is engaged, the RAM

segment mode control bits are Don’t Care and the device operates all profiles as if these mode control bits were programmed

for ramp-up mode. Switching between profiles occurs when the

RAM address generator has exhausted the memory contents for

the current profile.

Table 7. Internal Profile Control

CFR1<29:27>

(Binary)

000 Internal Control Inactive

001

010

011

100

101

110

111 Invalid

Mode Description

Internal Control Active, Single Burst, Activate

Profile 0, Then 1, Then Stop

Internal Control Active, Single Burst, Activate

Profile 0, Then 1, Then 2, Then Stop

Internal Control Active, Single Burst, Activate

Profile 0, Then 1, Then 2, Then 3, Then Stop

Internal Control Active, Continuous, Activate

Profile 0, Then 1, Then Loop Starting 0

Internal Control Active, Continuous, Activate

Profile 0, Then 1, Then 2, Then Loop Starting 0

Internal Control Active, Continuous, Activate

Profile 0, Then 1, Then 2, Then 3, Then Loop

Starting 0

A single burst mode is one in which the composite sweep is

executed once. For example, assume the device is programmed

for ramp-up mode and the CFR1<29:27> bits are written to

Logic 010(b). Upon receiving an I/O UPDATE, the internal

control logic signals the device to begin executing the ramp-up

mode sequence for Profile 0. Upon reaching the RAM segment

final address value for Profile 0, the device automatically

switches to Profile 1 and begins executing that ramp-up

sequence. Upon reaching the RAM segment final address value

for Profile 1, the device automatically switches to Profile 2 and

begins executing that ramp-up sequence. When the RAM segment final address value for Profile 2 is reached, the sequence is

over and the composite sweep has completed. Issuing another

I/O UPDATE restarts the burst process.

A continuous internal profile control mode is one in which the

composite sweep is continuously executed for as long as the

device is programmed into that mode. Using the example above,

except programming the CFR1<29:27> bits to Logic 101(b), the

operation would be identical until the RAM segment final

address value for Profile 2 is reached. At this point, instead of

stopping the sequence, it repeats, starting with Profile 0.

Page 22

AD9953

PROGRAMMING AD9953 FEATURES

Phase Offset Control

A 14-bit phase offset (θ) may be added to the output of the phase

accumulator by means of the control registers. This feature provides

the user with two different methods of phase control.

The first method is a static phase adjustment where a fixed

phase offset is loaded into the appropriate phase offset register

and left unchanged. The result is that the output signal is offset

by a constant angle relative to the nominal signal. This allows

the user to phase align the DDS output with some external

signal, if necessary.

The second method of phase control is where the user regularly

updates the phase offset register via the I/O port. By properly

modifying the phase offset as a function of time, the user can

implement a phase modulated output signal. However, both the

speed of the I/O port and the frequency of SYSCLK limit the

rate at which phase modulation can be performed.

The AD9953 allows for a programmable continuous zeroing of

the phase accumulator as well as a clear and release or automatic zeroing function. Each feature is individually controlled

via the CFR1 bits. CFR1<13> is the automatic clear phase

accumulator bit. CFR1<10> clears the phase accumulator and

holds the value to zero.

Continuous Clear Bit

The continuous clear bit is simply a static control signal that,

when active high, holds the phase accumulator at zero for the

entire time the bit is active. When the bit goes low, inactive, the

phase accumulator is allowed to operate.

Clear and Release Function

When set, the auto-clear phase accumulator clears and releases

the phase accumulator upon receiving an I/O UPDATE. The

automatic clearing function is repeated for every subsequent

I/O UPDATE until the appropriate auto-clear control bit is

cleared.

Shaped On-Off Keying

The shaped on-off keying function of the AD9953 allows the

user to control the ramp-up and ramp-down time of an on-off

emission from the DAC. This function is used in burst transmissions of digital data to reduce the adverse spectral impact of

short, abrupt bursts of data.

Auto and manual shaped on-off keying modes are supported.

The auto mode generates a linear scale factor at a rate determined by the amplitude ramp rate (ARR) register controlled by

an external pin (OSK). Manual mode allows the user to directly

control the output amplitude by writing the scale factor value

into the amplitude scale factor (ASF) register.

The shaped on-off keying function may be bypassed (disabled)

by clearing the OSK enable bit (CFR1<25> = 0).

The modes are controlled by two bits located in the most significant byte of the control function register (CFR). CFR1<25>

is the shaped on-off keying enable bit. When CFR1<25> is set,

the output scaling function is enabled and CFR1<25> bypasses

the function. CFR1<24> is the internal shaped on-off keying

active bit. When CFR1<24> is set, internal shaped on-off keying

mode is active; CFR1<24> is cleared, external shaped on-off

keying mode is active. CFR1<24> is a Don’t Care if the shaped

on-off keying enable bit (CFR1<25>) is cleared. The power-up

condition is shaped on-off keying disabled (CFR1<25> = 0).

Figure 20 shows the block diagram of the OSK circuitry.

AUTO Shaped On-Off Keying Mode Operation

The auto shaped on-off keying mode is active when CFR1<25>

and CFR1<24> are set. When auto shaped on-off keying mode

is enabled, a single scale factor is internally generated and

applied to the multiplier input for scaling the output of the DDS

core block (see Figure 20). The scale factor is the output of a

14-bit counter that increments/decrements at a rate determined

by the contents of the 8-bit output ramp rate register. The scale

factor increases if the OSK pin is high and decreases if the OSK

pin is low. The scale factor is an unsigned value such that all 0s

multiply the DDS core output by 0 (decimal) and 0x3FFF multiplies the DDS core output by 16383 (decimal).

For those users who use the full amplitude (14 bits) but need

fast ramp rates, the internally generated scale factor step size

is controlled via the ASF<15:14> bits. Table 8 describes the

increment/decrement step size of the internally generated scale

factor per the ASF<15:14> bits.

A special feature of this mode is that the maximum output

amplitude allowed is limited by the contents of the amplitude

scale factor register. This allows the user to ramp to a value less

than full scale.

Table 8. Auto-Scale Factor Internal Step Size

ASF<15:14> (Binary) Increment/Decrement Size

00 1

01 2

10 4

11 8

Rev. 0 | Page 22 of 32

Page 23

AD9953

OSK Ramp Rate Timer

The OSK ramp rate timer is a loadable down counter, which

generates the clock signal to the 14-bit counter that generates

the internal scale factor. The ramp rate timer is loaded with the

value of the ASFR every time the counter reaches 1 (decimal).

This load and countdown operation continues for as long as the

timer is enabled, unless the timer is forced to load before reaching a count of 1.

If the load OSK timer bit (CFR1<26>) is set, the ramp rate timer

is loaded upon an I/O UPDATE or upon reaching a value of 1.

The ramp timer can be loaded before reaching a count of 1 by

three methods.

DDS CORE

0

COS(X)

AMPLITUDE SCALE

FACTOR REGISTER

(ASF)

01

1 01

OSK ENABLE

CFR<25>

OSK PIN

0

The first method of loading is by changing the OSK input pin.

When the OSK input pin changes state, the ASFR value is

loaded into the ramp rate timer, which then proceeds to count

down as normal.

The second method in which the sweep ramp rate timer can be

loaded before reaching a count of 1 is if the load OSK timer bit

(CFR1<26>) is set and an I/O UPDATE is issued.

The third method in which the sweep ramp rate timer can be

loaded before reaching a count of 1 is when going from the

inactive auto shaped on-off keying mode to the active auto

shaped on-off keying mode; that is, when the sweep enable bit is

being set.

AUTO DESK

ENABLE

TO DAC

SYNC_CLK

CFR1<24>

LOAD OSK TIMER

CFR1<26>

AMPLITUDE RAMP

RATE REGISTER

(ASF)

OUT

INC/DEC ENABLE

FACTOR GENERATOR

Figure 20. On-Off Shaped Keying Block Diagram

HOLD

UP/DN

AUTO SCALE

DATALOAD

EN

CLOCK

RAMP RATE TIMER

03374-0-005

Rev. 0 | Page 23 of 32

Page 24

AD9953

External Shaped On-Off Keying Mode Operation

The external shaped on-off keying mode is enabled by writing

CFR1<25> to a Logic 1 and writing CFR1<24> to a Logic 0.

When configured for external shaped on-off keying, the

content of the ASFR becomes the scale factor for the data path.

The scale factors are synchronized to SYNC_CLK via the

I/O UPDATE functionality.

Synchronization; Register Updates (I/O UPDATE)

Functionality of the SYNC_CLK and I/O UPDATE

Data into the AD9953 is synchronous to the SYNC_CLK signal

(supplied externally to the user on the SYNC_CLK pin). The

I/O UPDATE pin is sampled on the rising edge of the

SYNC_CLK.

Internally, SYSCLK is fed to a divide-by-4 frequency divider to

produce the SYNC_CLK signal. The SYNC_CLK signal is provided to the user on the SYNC_CLK pin. This enables synchronization of external hardware with the device’s internal clocks.

This is accomplished by forcing any external hardware to obtain

its timing from SYNC_CLK. The I/O UPDATE signal coupled

with SYNC_CLK is used to transfer internal buffer contents

into the control registers of the device. The combination of the

SYNC_CLK and I/O UPDATE pins provides the user with

constant latency relative to SYSCLK, and also ensures phase

continuity of the analog output signal when a new tuning word

or phase offset value is asserted. Figure 21 demonstrates an I/O

UPDATE timing cycle and synchronization.

Notes for synchronization logic:

1)

The I/O UPDATE signal is edge detected to generate a