Page 1

with 12-Bit DAC

AD9914

Rev. PrJ

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

Trad emarks and registered trademarks are the property of their respective owners.

Fax: 781.461.3113 ©2012 Analog Devices, Inc. All rights reserved.

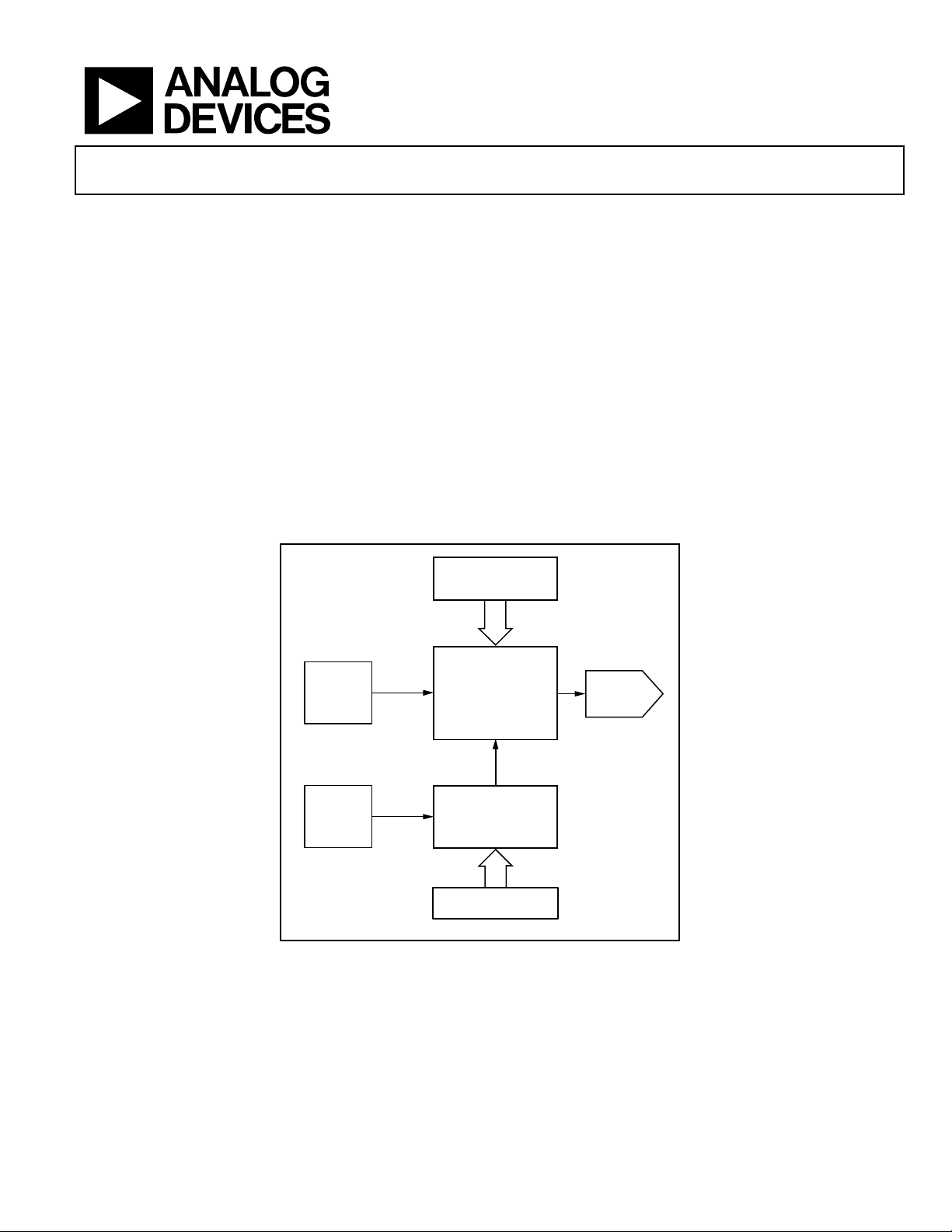

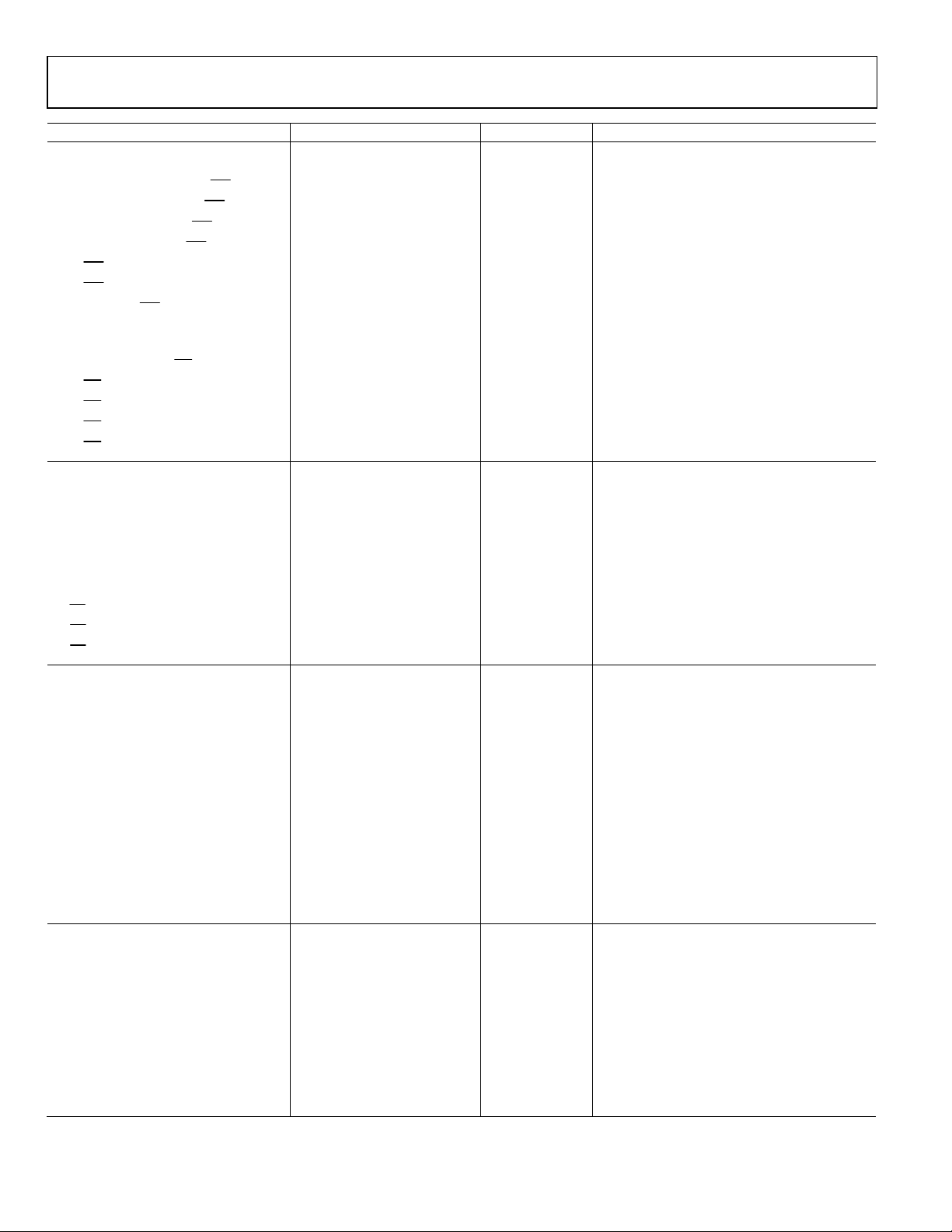

12-BIT DAC

3.5GSPS DDS CORE

TIMINGAND CONTROL

10836-001

AD9914

HIGH SPEE D P ARALLEL

MODULATION

PORT

LINEAR

SWEEP

BLOCK

SERIAL O R P ARALLEL

DATA PORT

REF CLK

MULTIPLIER

Preliminary Technical Data

FEATURES

3.5 GSPS internal clock speed

Integrated 12-bit DAC

Frequency tuning resolution to 271 pHz

16-bit phase tuning resolution

12-bit amplitude scaling

Programmable modulus

Automatic linear and nonlinear frequency sweeping

capability

32-bit parallel datapath interface

8 frequency/phase offset profiles

Phase noise −128 dBc/Hz (10 kHz offset at 1396 MHz)

Wide band SFDR <−50 dBc

Serial or parallel I/O control

1.8 V/3.3 V power supplies

FUNCTIONAL BLOCK DIAGRAM

3.5 GSPS Direct Digital Synthesizer

Software and hardware controlled power-down

88-lead LFCSP package

PLL REF CLK multiplier

Phase modulation capability

Amplitude modulation capability

Multichip synchronization

APPLICATIONS

Agile LO frequency synthesis

Programmable clock generator

FM chirp source for radar and scanning systems

Test and measurement equipment

Acousto-optic device drivers

Polar modulator

Fast frequency hopping

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Page 2

AD9914 Preliminary Technical Data

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 3

Specifications ..................................................................................... 4

DC Specifications ......................................................................... 4

AC Specifications .......................................................................... 5

Absolute Maximum Ratings ............................................................ 8

Thermal Performance .................................................................. 8

ESD Caution .................................................................................. 8

Pin Configuration and Function Descriptions ............................. 9

Typical Performance Characteristics ........................................... 12

Equivalent Circuits ......................................................................... 16

Theory of Operation ...................................................................... 17

Single Tone Mode ....................................................................... 17

Profile Modulation Mode .......................................................... 17

Digital Ramp Modulation Mode .............................................. 17

Parallel Data Port Modulation Mode ....................................... 17

Programmable Modulus Mode ................................................. 17

Functional Block Detail ................................................................. 19

DDS Core ..................................................................................... 19

12-Bit DAC Output .................................................................... 20

DAC Calibration Output ........................................................... 20

Reconstruction Filter ................................................................. 20

Clock Input (REF_CLK/

PLL Lock Indication .................................................................. 22

Output Shift Keying (OSK) ....................................................... 22

Digital Ramp Generator (DRG) ............................................... 23

Power-Down Control ................................................................ 27

Programming and Function pins ................................................. 28

Serial Programming ....................................................................... 29

Control Interface—Serial I/O ................................................... 29

General Serial I/O Operation ................................................... 29

Instruction Byte .......................................................................... 29

Serial I/O Port Pin Descriptions .............................................. 29

Serial I/O Timing Diagrams ..................................................... 30

MSB/LSB Transfers .................................................................... 30

Parallel Programming .................................................................... 31

Register Map and Bit Descriptions .............................................. 32

Outline Dimensions ....................................................................... 38

Ordering Guide .......................................................................... 38

REF_CLK

) ........................................ 21

Rev. PrJ | Page 2 of 38

Page 3

Preliminary Technical Data AD9914

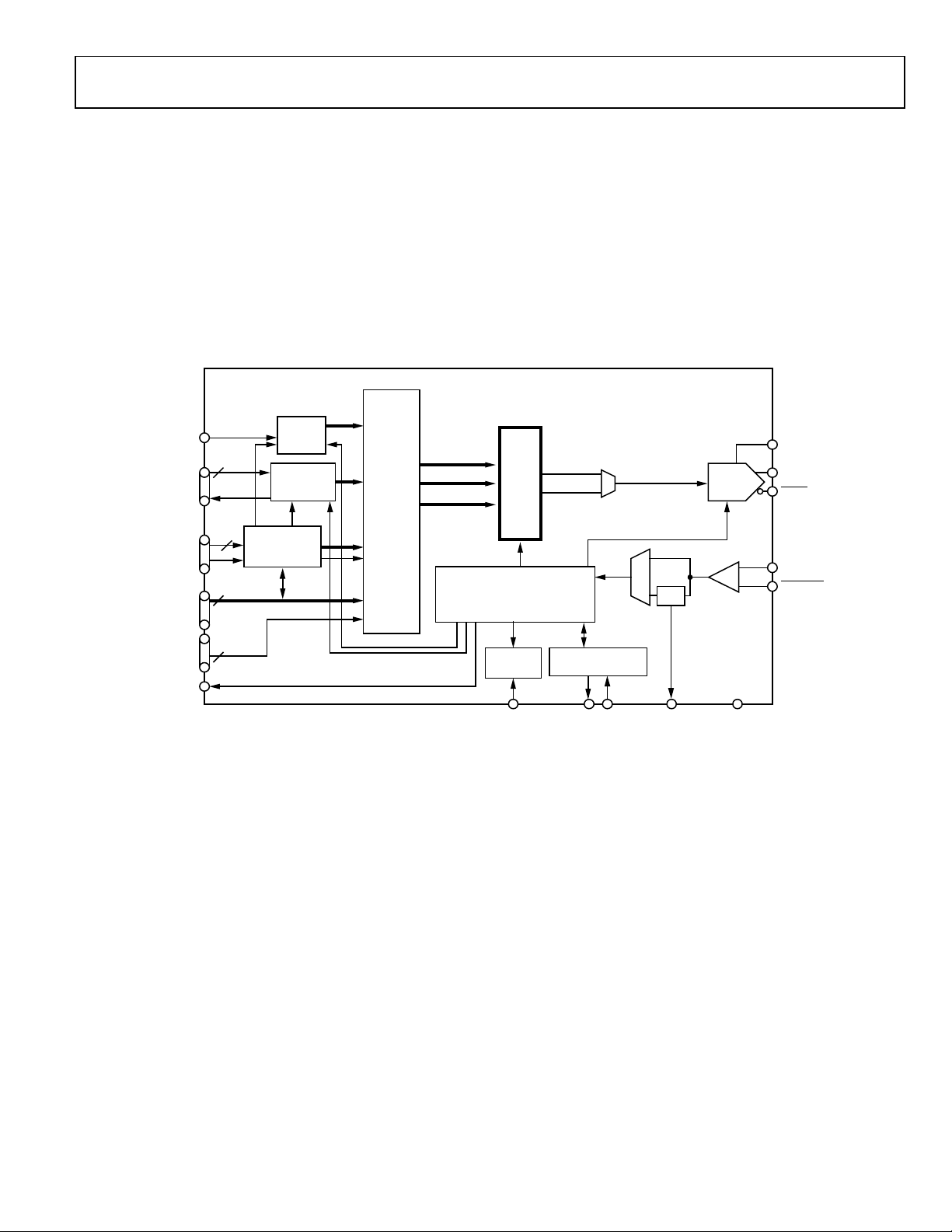

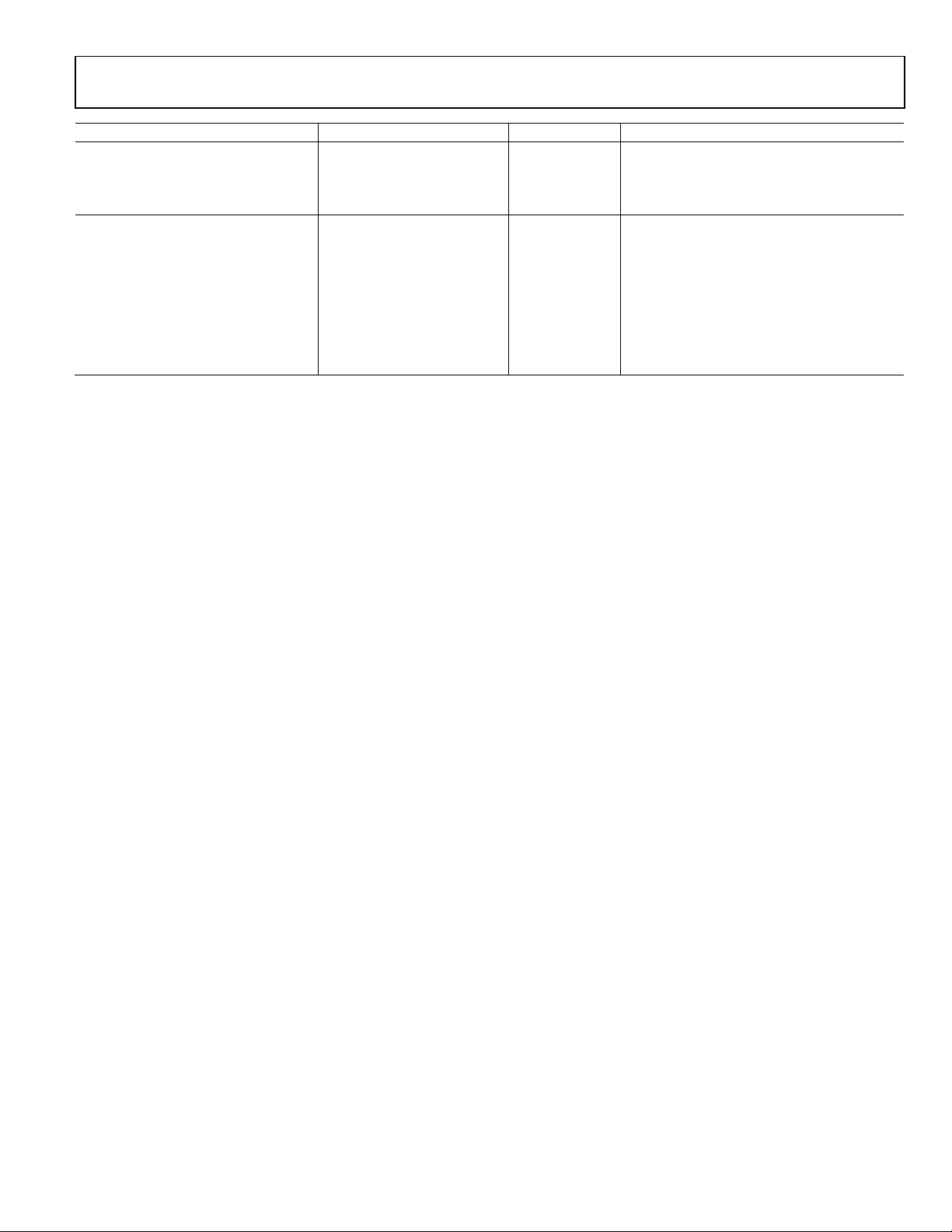

10836-002

32

F0 – F3

D0 – D31

PROFILES[2:0]

I/O_UPDATE

POWER-

DOWN

CONTROL

EXT_PWR_DWN

DAC_RSET

AOUT

AOUT

OSK

DROVER

DRCTL

DRHOLD

SYNC_CLK

A

θ

CLOCK

AMPLIT UDE ( A)

FREQUENCY (ω)

PHASE (θ)

DIGITAL

RAMP

GENERATOR

2

4

MULTICHIP

SYNCHRONIZATION

SYSCLK

PLL

REF_CLK

REF_CLK

AD9914

OUTPUT

SHIFT

KEYING

DATA

ROUTE

AND

PARTITION

CONTROL

3

INTERNAL CLOCK TIMI NG

AND CONTROL

ω

Acos (ωt + θ)

Asin (ωt + θ)

SYNC_OUT

SYNC_IN

LOOP_FILTER

MASTER_RESET

DAC

12-BIT

DDS

INTERNAL

PROGRAMMING

REGISTERS

GENERAL DESCRIPTION

The AD9914 is a direct digital synthesizer (DDS) featuring a

12-bit DAC. The AD9914 uses advanced DDS technology,

coupled with an internal high speed, high performance DAC

to form a digitally programmable, complete high frequency

synthesizer capable of generating a frequency-agile analog

output sinusoidal waveform at up to 1.4 GHz. The AD9914

enables fast frequency hopping and fine tuning resolution

(64-bit capable using programmable modulus mode). The

AD9914 also offers fast phase and amplitude hopping capability.

The frequency tuning and control words are loaded into the

AD9914 via a serial or parallel I/O port. The AD9914 also

supports a user defined linear sweep mode of operation for

generating linear swept waveforms of frequency, phase, or

amplitude. A high speed, 32-bit parallel data input port is

included enabling high data rates for polar modulation schemes

and fast reprogramming of the phase, frequency, and amplitude

tuning words.

The AD9914 is specified to operate over the extended industrial

temperature range (see Absolute Maximum Ratings section).

Figure 2. Detailed Block Diagram

Rev. PrJ | Page 3 of 38

Page 4

AD9914 Preliminary Technical Data

DVDD_I/O

I

DVDD

433

mA

Pin 6, Pin 23, Pin 73

AVDD (1.8V)

Input Low Voltage (VIL)

0.8 V

INH

INL

Input Resistance

1.4 kΩ

Differential

Internally Generated DC Bias

2 V

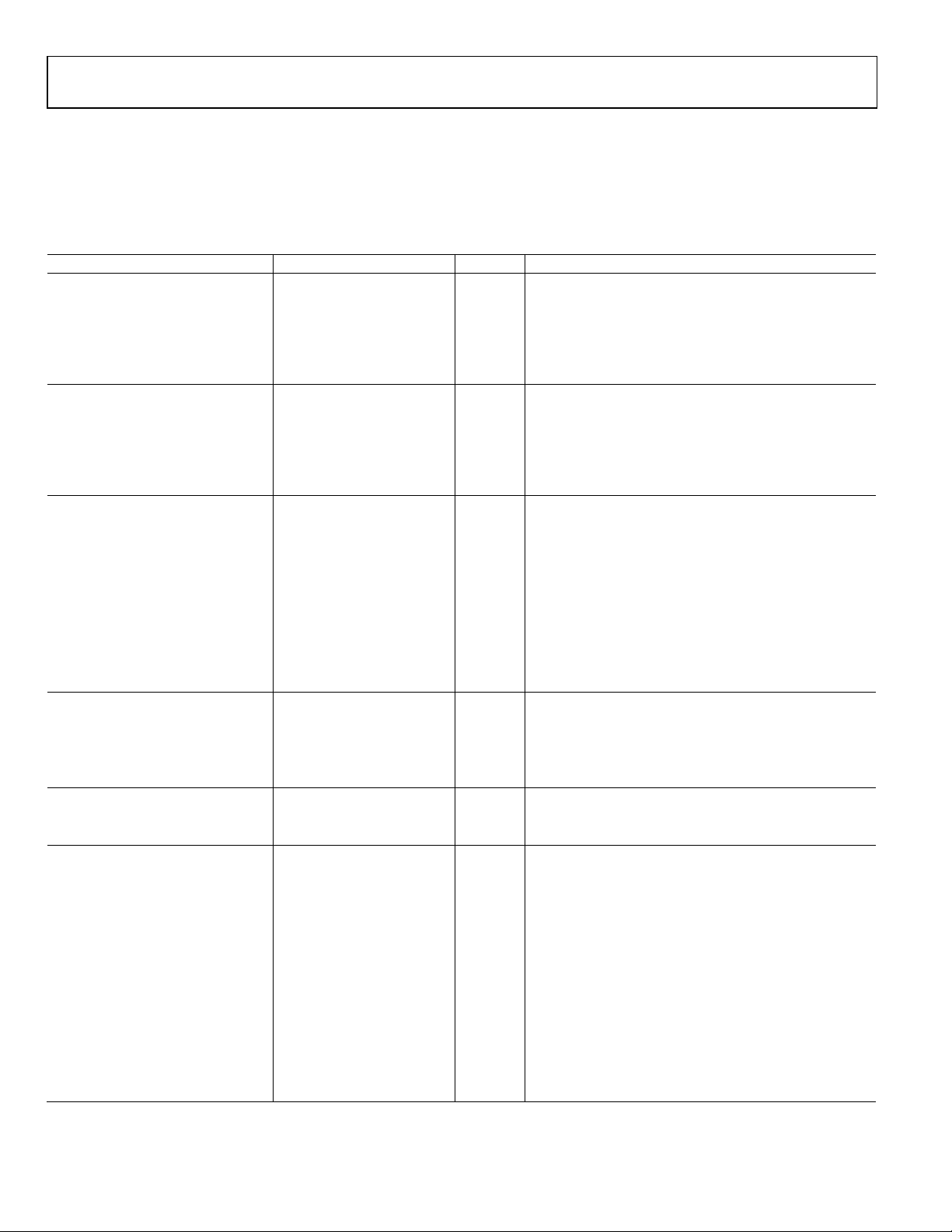

SPECIFICATIONS

DC SPECIFICATIONS

AVDD (1.8V) and DVDD (1.8V) = 1.8 V ± 5%, AVDD (3.3V) and DVDD_I/O (3.3V) = 3.3 V ± 5%, T = 25°C, R

I

= 20 mA, external reference clock frequency = 3.5 GHz with reference clock (REF CLK) multiplier bypassed, unless otherwise noted.

OUT

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments

SUPPLY VOLTAGE

DVDD_I/O 3.135 3.30 3.465 V Pin 16, Pin 83

DVDD 1.71 1.80 1.89 V Pin 6, Pin 23, Pin 73

AVDD(3.3V) 3.135 3.30 3.465 V Pin 34, Pin 36, Pin 39, Pin 40, Pin 43, Pin 47, Pin 50, Pin 52,

Pin 53, Pin 60

AVDD (1.8V) 1.71 1.80 1.89 V Pin 32, Pin 56, Pin 57

SUPPLY CURRENT See also the total power dissipation specifications

I

20 mA Pin 16, Pin 83

I

640 mA Pin 34, Pin 36, Pin 39, Pin 40, Pin 43, Pin 47, Pin 50, Pin 52,

AVDD (3.3V)

Pin 53, Pin 60

I

178 mA Pin 32, Pin 56, Pin 57

TOTAL POWER DISSIPATION

Base DDS Power, PLL Disabled 2392 3091 mW 3.5 GHz, single-tone mode, modules disabled, linear

sweep disabled, amplitude scaler disabled

Base DDS Power, PLL Enabled 2237 2627 mW 2.5 GHz, single-tone mode, modules disabled, linear

sweep disabled, amplitude scaler disabled

Linear Sweep Additional Power 28 mW

Modulus Additional Power 20 mW

Amplitude Scaler Additional

138 mW Manual or automatic

Power

Full Power-Down Mode 400 616 mW Using either the power-down and enable register or the

EXT_PWR_DWN pin

CMOS LOGIC INPUTS

Input High Voltage (VIH) 2.0 DVDD_I/O V

= 3.3 kΩ,

SET

Input Current (I

Maximum Input Capacitance (CIN) 3 pF

CMOS LOGIC OUTPUTS

Output High Voltage (VOH) 2.7 DVDD_I/O V IOH = 1 mA

Output High Voltage (VOL) 0.4 V IOL = 1 mA

REF CLK INPUT CHARACTERISTICS REF CLK inputs should always be ac-coupled (both single-

REF CLK Multiplier Bypassed

Input Capacitance 1 pF Single-ended, each pin

Voltage

Differential Input Voltage 0.8 1.5 mV p-p

REF CLK Multiplier Enabled

Input Capacitance 1 pF Single-ended, each pin

Input Resistance 1.4 kΩ Differential

Internally Generated DC Bias

Voltage

Differential Input Voltage 0.8 1.5 mV p-p

, I

) ±60 ±200 µA At VIN = 0 V and VIN = DVDD_I/O

ended and differential)

2 V

Rev. PrJ | Page 4 of 38

Page 5

Preliminary Technical Data AD9914

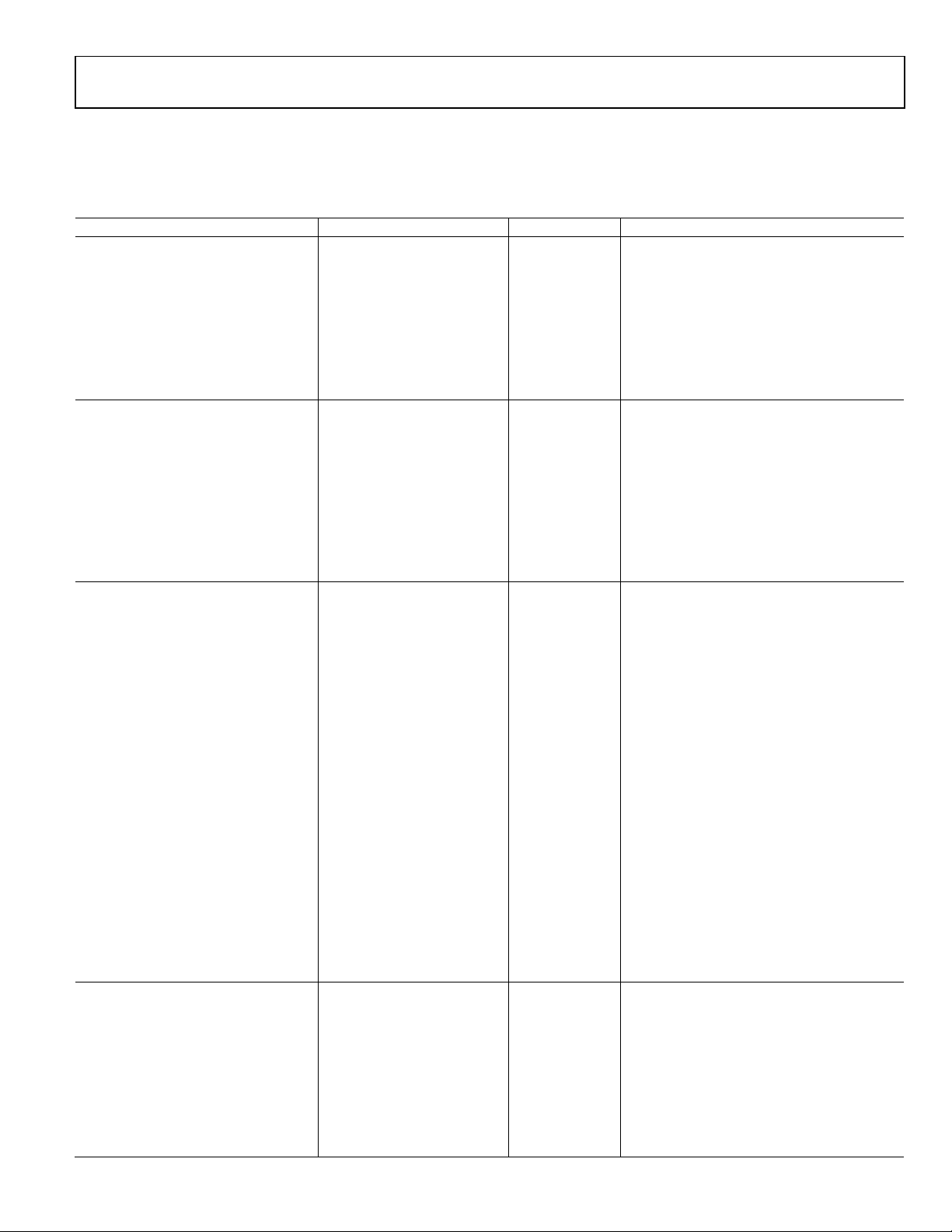

AC SPECIFICATIONS

AVDD (1.8V) and DVDD (1.8V) = 1.8 V ± 5%, AVDD3 (3.3V) = 3.3 V ± 5%, DVDD_I/O (3.3V) = 3.3 V ± 5%, T = 25°C, R

I

= 20 mA, external reference clock frequency = 3.5 GHz with reference clock (REF CLK) multiplier disabled, unless otherwise noted.

OUT

Table 2.

Parameter Min Typ Max Unit Test Conditions/Comments

REF CLK INPUT Input frequency range

REF CLK Multiplier Bypassed

Input Frequency Range 500 3500 MHz Maximum f

Duty Cycle 45 55 %

Minimum Differential Input Level 632 mV p-p Equivalent to 316 mV swing on each leg

System Clock (SYSCLK) PLL Enabled

VCO Frequency Range 2400 2500 MHz

VCO Gain (KV) 50 MHz/V

Maximum PFD Rate 125 MHz

CLOCK DRIVERS

SYNC_CLK Output Driver

Frequency Range 146 MHz

Duty Cycle 45 50 55 %

Rise Time/Fall Time (20% to 80%) 650 ps

SYNC_OUT Output Driver 10 pF load

Frequency Range 9.1 MHz

Duty Cycle 33 66 % CFR2 Bit 9 = 1

Rise Time (20% to 80%) 1350 ps 10 pF load

Fall Time (20% to 80%) 1670 ps 10 pF load

DAC OUTPUT CHARACTERISTICS

Output Frequency Range (1st Nyquist

0 1750 MHz

Zone)

Output Resistance 50 Ω Single-ended (each pin internally terminated to

AVDD (3.3V))

Output Capacitance 5 pF

Full-Scale Output Current 20.48 mA Range depends on DAC R

Gain Error −10 +10 % FS

Output Offset 0.6 A

Voltage Compliance Range AVDD −

0.50

AVDD +

V

0.50

Wideband SFDR See the Typical Performance Characteristics

section

101.1 MHz Output −66 dBc 0 MHz to 1750 MHz

427.5 MHz Output −65 dBc 0 MHz to 1750 MHz

696.5 MHz Output −57 dBc 0 MHz to 1750 MHz

1396.5 MHz Output −52 dBc 0 MHz to 1750 MHz

Narrow-Band SFDR See the Typical Performance Characteristics

section

100.5 MHz Output −95 dBc ±500 kHz

427.5 MHz Output −95 dBc ±500 kHz

696.5 MHz Output −95 dBc ±500 kHz

1396.5 MHz Output −92 dBc ±500 kHz

DIGITAL TIMING SPECIFICATIONS

Time Required to Enter Power-Down TBD µs Power-down mode loses DAC/PLL calibration

settings

Time Required to Leave Power-Down TBD µs Must recalibrate DAC/PLL

Minimum Master Reset time TBD TBD

Maximum DAC Calibration Time (t

Maximum PLL Calibration Time (t

) TBD TBD f

CAL

) TBD TBD

REF_CLK

CAL

= f

Synchronization Time 16 SYNC_IN cycles

Maximum Profile Toggle Rate 1 SYNC_CLK

period

Rev. PrJ | Page 5 of 38

is 0.4 × f

OUT

/384 USR 0 register, Bit 6 = 0

SYSCLK

SYSCLK

SET

SET

resistor

= 3.3 kΩ,

Page 6

AD9914 Preliminary Technical Data

Parameter Min Typ Max Unit Test Conditions/Comments

PARALLEL PORT TIMING

Write Timing

Address Setup Time to WR Active

Address Hold Time to WR Inactive

Data Setup Time to WR Inactive

Data Hold Time to WR Inactive

WR Minimum Low Time

WR Minimum High Time

Minimum WR Time

Read Timing

Address to Data Valid 92 ns

Address Hold to RD Inactive

RD Active to Data Valid

RD Inactive to Data Tristate

RD Minimum Low Time

RD Minimum High Time

SERIAL PORT TIMING

SCLK Clock Rate (1/t

SCLK Pulse Width High, t

SCLK Pulse Width Low, t

) 80 MHz SCLK duty cycle = 50%

CLK

1.5 ns

HIGH

5.1 ns

LOW

SDIO to SCLK Setup Time, tDS 4.9 ns

SDIO to SCLK Hold Time, tDH 0 ns

SCLK Falling Edge to Valid Data on

SDIO/SDO, t

CS to SCLK Setup Time, t

CS to SCLK Hold Time, t

CS Minimum Pulse Width High, t

DV

S

H

PWH

DATA PORT TIMING

D[31:0] Setup Time to SYNC_CLK 2 ns

D[31:0] Hold Time to SYNC_CLK 0 ns

F[3:0] Setup Time to SYNC_CLK 2 ns

F[3:0] Hold Time to SYNC_CLK 0 ns

IO_UPDATE Pin Setup Time to

SYNC_CLK

IO_UPDATE Pin Hold Time to

SYNC_CLK

Profile Pin Setup Time to SYNC_CLK ns

Profile Pin Hold Time to SYNC_CLK 2 ns

DR_CTL/DR_HOLD Setup Time to

SYNC_CLK

DR_CTL/DR_HOLD Hold Time to

SYNC_CLK

DATA LATENCY (PIPELINE DELAY)

Single Tone Mode (Matched Latency

Disabled)

Frequency 320 SYSCLK cycles

Phase 296 SYSCLK cycles

Amplitude 104 SYSCLK cycles

Single Tone Mode (Matched Latency

Enabled)

Frequency 320 SYSCLK cycles

Phase 320

Amplitude 320 SYSCLK cycles

1 ns

0 ns

3.8 ns

0 ns

2.1 ns

3.8 ns

10.5 ns

0 ns

69 ns

50 ns

69 ns

50 ns

78 ns

4 ns

0 ns

4 ns

2 ns

0 ns

2 0 ns

0 ns

SYSCLK cycles = fS = system clock frequency

in GHz

Rev. PrJ | Page 6 of 38

Page 7

Preliminary Technical Data AD9914

Parameter Min Typ Max Unit Test Conditions/Comments

Profile Pin Selection Mode

Frequency 320 SYSCLK cycles

Phase 296 SYSCLK cycles

Amplitude 104 SYSCLK cycles

Modulation Mode with 32-Bit Parallel

Port

Frequency 296 SYSCLK cycles

Phase 272 SYSCLK cycles

Amplitude 80 SYSCLK cycles

Sweep Mode

Frequency 392 SYSCLK cycles

Phase 368 SYSCLK cycles

Amplitude 176 SYSCLK cycles

Rev. PrJ | Page 7 of 38

Page 8

AD9914 Preliminary Technical Data

per JEDEC JESD51-6

θ

Junction-to-board thermal

13.3

°C/W

ABSOLUTE MAXIMUM RATINGS

Table 3.

Parameter Rating

AVDD (1.8V), DVDD (1.8V) Supplies 2 V

AVDD (3.3V), DVDD_I/O (3.3V) Supplies 4 V

Digital Input Voltage −0.7 V to +4 V

Digital Output Current 5 mA

Storage Temperature Range −65°C to +150°C

Operating Temperature Range −40°C to +85°C

Maximum Junction Temperature 150°C

Lead Temperature (10 sec Soldering) 300°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL PERFORMANCE

Table 4.

Symbol Description Value1 Unit

θJA

θ

JMA

θ

JMA

JB

ΨJB

θJC

ΨJT

1

Results are from simulations. PCB is JEDEC multilayer. Thermal performance

for actual applications requires careful inspection of the conditions in the

application to determine if they are similar to those assumed in these

calculations.

Junction-to-ambient thermal

resistance (Still Air) per JEDEC

JESD51-2

Junction-to-ambient thermal

resistance (1.0 m/sec airflow)

per JEDEC JESD51-6

Junction-to-ambient thermal

resistance (2.0 m/sec air flow)

resistance (still air) per JEDEC

JESD51-8

Junction-to-board characterization

parameter (still air) per JEDEC

JESD51-6

Junction-to-case thermal resistance 2.21 °C/W

Junction-to-top-of-package

characterization parameter (still air)

per JEDEC JESD51-2

24.1 °C/W

21.3 °C/W

20.0 °C/W

12.8 °C/W

0.23 °C/W

ESD CAUTION

Rev. PrJ | Page 8 of 38

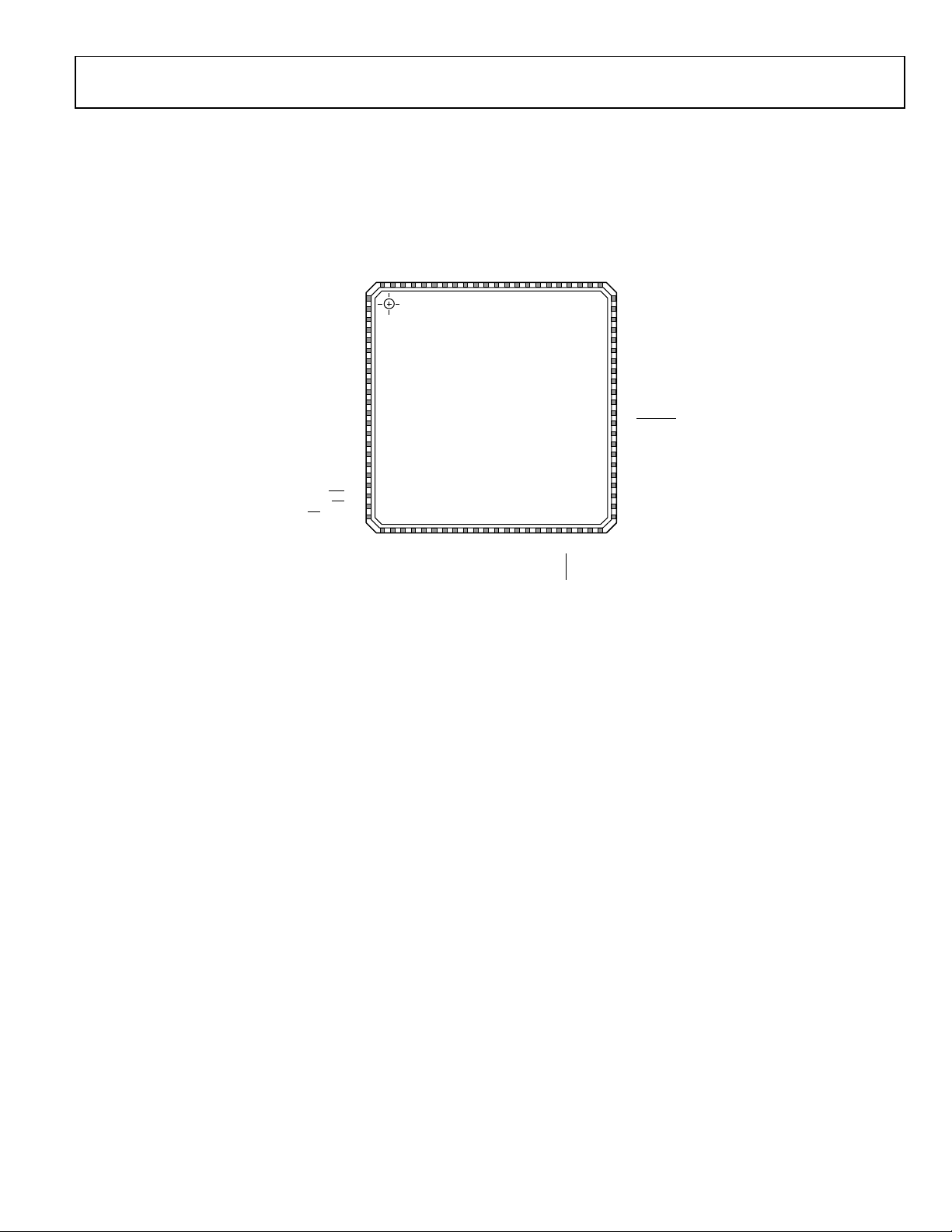

Page 9

Preliminary Technical Data AD9914

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

D17

D16

D15/A7

D14/A6

D13/A5

DVDD (1.8V)

DGND

D12/A4

D11/A3

D10/A2

D9/A1

D8/A0

D7

D6

D5

DVDD_I/O ( 3.3V)

17DGND

18D4/SYNCIO

19D3/SDO

20D2/SDIO/WR

23242526272829303132333436

37

DVDD (1.8V)

DGND

PS0

PS1

PS2

F0F1F2

F3

AVDD (1.8V)

AGND

AVDD (3.3V)

35AGND

AVDD (3.3V)

AGND

38AGND

39AVDD (3.3V)

40AVDD (3.3V)

41

AOUT

58

57

56

55

54

53

52

51

50

49

48

47

46

45

LOOP_FILTER

59 REF

60 AVDD (3.3V)

61 SYNC_OUT

62 SYNC_IN

63 DRCTL

64 DRHOLD

65 DROVER

66 OSK

AVDD (1.8V)

AVDD (1.8V)

REF CLK

REF CLK

AVDD (3.3V)

AVDD (3.3V)

AGND

AVDD (3.3V)

AGND

DAC_RSET

AVDD (3.3V)

AGND

DAC_BP

7877767574737271706968

67

D23

79 D22

80 D21

81 D20

82 SYNC_CLK

83 DVDD_I/O ( 3.3V)

84 DGND

85 MASTER_RESET

86 I/O_UPDATE

87 D19

88 D18

D24

D25

D26

DGND

DVDD (1.8V)

D27

D28

D29

D30

D31

EXT_PWR_DWN

NOTES

1. THE EPAD M US T BE SOLDERED TO GROUND.

10836-003

21D1/SCLK/RD

22D0/CS/PWD

42AOUT

43AVDD (3.3V)

44AGND

AD9914

TOP VIEW

(Not to S cale)

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

Figure 3. Pin Configuration

Rev. PrJ | Page 9 of 38

Page 10

AD9914 Preliminary Technical Data

Table 5. Pin Function Descriptions

Pin No. Mnemonic I/O1 Description

1, 2, 13 to 15, 68

to 72, 75 to 81,

87, 88

3 D15/A7 I/O Parallel Port Pin/Address Line. Multipurpose pin depending on the state of the function pins

4 D14/A6 I/O Parallel Port Pin/Address Line. Multipurpose pin depending on the state of the function pins

5 D13/A5 I/O Parallel Port Pin/Address Line. Multipurpose pin depending on the state of the function pins

8 D12/A4 I/O Parallel Port Pin/Address Line. Multipurpose pin depending on the state of the function pins

9 D11/A3 I/O Parallel Port Pin/Address Line. The state of the F0 to F3 function pins determines if this acts as

10 D10/A2 I/O Parallel Port Pin/Address Line. Multipurpose pin depending on the state of the function pins

11 D9/A1 I/O Parallel Port Pin/Address Line. Multipurpose pin depending on the state of the function pins

12 D8/A0 I/O Parallel Port Pin/Address Line. Multipurpose pin depending on the state of the function pins

18 D4/SYNCIO I Parallel Port Pin/Serial Port Synchronization Pin. Multipurpose pin depending on the state of

19 D3/SDO I/O Parallel Port Pin/Serial Data Output. Multipurpose pin depending on the state of the function

20 D2/SDIO/WR I/O Parallel Port Pin/Serial Data Input and Output/Write Input. Multipurpose pin depending on

21 D1/SCLK/RD I Parallel Port Pin/Serial Clock/Read Input. Multipurpose pin depending on the state of the

22 D0/CS/PWD I Parallel Port Pin/Chip Select/Parallel Width. Multipurpose pin depending on the state of the

6, 23, 73 DVDD (1.8V) I Digital Core Supplies (1.8 V).

7, 17, 24, 74, 84 DGND I Digital Ground.

16, 83 DVDD_I/O (3.3V) I Digital Input/Output Supplies (3.3 V).

32, 56, 57 AVDD (1.8V) I Analog Core Supplies (1.8 V).

33, 35, 37, 38,

44, 46, 49, 51

34, 36, 39, 40,

43, 47, 50, 52,

53, 60

D5 to D7, D16 to

D31, D27 to D31

AGND I Analog Ground.

AVDD (3.3V) I Analog DAC Supplies (3.3 V).

I/O Parallel Port Pins. The 32-bit parallel port offers the option for serial or parallel programming

of the internal registers. In addition, the parallel port can be configured to provide direct FSK,

PSK, or ASK (or combinations thereof ) modulation data. The 32-bit parallel port configuration

is set by the state of the four function pins (F0 to F3).

(F0 to F3). The state of the F0 to F3 function pins determines if this acts as a line for direct

FSK, PSK, or ASK data or as an address line for programming the internal registers.

(F0 to F3). The state of the F0 to F3 function pins determines if this acts as a line for direct

FSK, PSK, or ASK data or as an address line for programming the internal registers.

(F0 to F3). The state of the F0 to F3 function pins determines if this acts as a line for direct

FSK, PSK, or ASK data or as an address line for programming the internal registers.

(F0 to F3). The state of the F0 to F3 function pins determines if this acts as a line for direct

FSK, PSK, or ASK data or as an address line for programming the internal registers.

a line for direct FSK, PSK, or ASK data or as an address line for programming the internal

registers.

(F0 to F3). The state of the F0 to F3 function pins determines if this acts as a line for direct

FSK, PSK, or ASK data or as an address line for programming the internal registers.

(F0 to F3). The state of the F0 to F3 function pins determines if this acts as a line for direct

FSK, PSK, or ASK data or as an address line for programming the internal registers.

(F0 to F3). The state of the F0 to F3 function pins determines if this acts as a line for direct

FSK, PSK, or ASK data or as an address line for programming the internal registers.

the function pins (F0 to F3). This pin is D4 for direct FSK, PSK, or ASK data. If serial mode is

invoked via F0 to F3, this pin is used to reset the serial port.

pins (F0 to F3). This pin is D3 for direct FSK, PSK, or ASK data. If serial mode is invoked via (F0F3), this pin is used for readback mode for serial operation.

the state of the function pins (F0 to F3). This pin is D2 for direct FSK, PSK, or ASK data. If serial

mode is invoked via F0 to F3, this pin is used for the SDIO for serial operation. If parallel mode

is enabled, this pin is used to write to change the values of the internal registers.

function pins (F0 to F3). This pin is D1 for direct FSK, PSK, or ASK data. If serial mode is

invoked via F0 to F3, this pin is used for SCLK for serial operation. If parallel mode is enabled,

this pin is used to read back the value of the internal registers.

function pins (F0 to F3). This pin is D0 for direct FSK, PSK, or ASK data. If serial mode is

invoked via F0 to F3, this pin is used for the chip select for serial operation. If parallel mode is

enabled, this pin is used to set either 8-bit data or 16-bit data.

Rev. PrJ | Page 10 of 38

Page 11

Preliminary Technical Data AD9914

up on the SYNC_CLK pin.

28, 29, 30, 31

F0 to F3

I

Function Pins. Digital Inputs. The state of these pins determine if a serial or parallel interface

63

DRCTL

I

Ramp Control. Digital input (active high). This pin controls the sweep direction (up/down).

64

DRHOLD

I

Ramp Hold. Digital input (active high). Pauses the sweep when active.

Pin No. Mnemonic I/O1 Description

25, 26, 27 PROFILE[0:2] I Profile Select Pins. Digital inputs (active high). Use these pins to select one of eight

phase/frequency profiles for the DDS. Changing the state of one of these pins transfers the

current contents of all I/O buffers to the corresponding registers. State changes should be set

is used. In addition, the function pins determine how the 32-bit parallel data-word is

partitioned for FSK, PSK, or ASK modulation mode.

41

42 AOUT O DAC Output Source. Analog output (voltage mode). Internally connected through a 50 Ω

45 DAC_BP I DAC Bypass Pin.

48 DAC_RSET O Analog Reference. This pin programs the DAC output full-scale reference current. Connect a

54

55 REF_CLK I Reference Clock Input. Analog input.

58 LOOP_FILTER O External PLL Loop Filter Node.

59 REF O Local PLL Reference Supply. Typically at 2.05 V.

61 SYNC_OUT O Digital Synchronization Output. Used to synchronize multiple chips together.

62 SYNC_IN I Digital Synchronization Input. Used to synchronize multiple chips together.

O DAC Complementary Output Source. Analog output (voltage mode). Internally connected

AOUT

through a 50 Ω resistor to AVDD (3.3V).

resistor to AVDD (3.3V).

3.3 kΩ resistor to AGND.

REF_CLK

I Complementary Reference Clock Input. Analog input.

65 DROVER O Ramp Over. Digital output (active high). This pin switches to Logic 1 whenever the digital

ramp generator reaches its programmed upper or lower limit.

66 OSK I Output Shift Keying. Digital input (active high). When the OSK features are placed in either

manual or automatic mode, this pin controls the OSK function. In manual mode, it toggles

the multiplier between 0 (low) and the programmed amplitude scale factor (high). In

automatic mode, a low sweeps the amplitude down to zero and a high sweeps the

amplitude up to the amplitude scale factor.

67 EXT_PWR_DWN I External Power-Down. Digital input (active high). A high level on this pin initiates the

currently programmed power-down mode.

82 SYNC_CLK O Clock Output. Digital output. Many of the digital inputs on the chip, such as I/O_UPDATE,

PROFILE[2:0], and the parallel data port (D0 to D31), must be set up on the rising edge of this

signal.

85 MASTER_RESET I Master Reset. Digital input (active high). Clears all memory elements and sets registers to

default values.

86 I/O_UPDATE I Input/Output Update. Digital input (active high). A high on this pin transfers the contents of

the I/O buffers to the corresponding internal registers.

EPAD Exposed Pad. The EPAD must be soldered to ground.

1

I = input, O = output.

Rev. PrJ | Page 11 of 38

Page 12

AD9914 Preliminary Technical Data

START 0Hz

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

0

175MHz/DIV STOP 1.75GHz

SFDR (dBc)

10836-004

START 0Hz

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

0

175MHz/DIV STOP 1.75GHz

SFDR (dBc)

10836-005

START 0Hz

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

0

175MHz/DIV STOP 1.75GHz

SFDR (dBc)

10836-006

CENTER 171.5MHz

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

0

50kHz/DIV SPAN 500kHz

SFDR (dBc)

10836-007

CENTER 427.5MHz

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

0

50kHz/DIV SPAN 500kHz

SFDR (dBc)

10836-008

CENTER 696.5MHz

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

0

50kHz/DIV SPAN 500kHz

SFDR (dBc)

10836-009

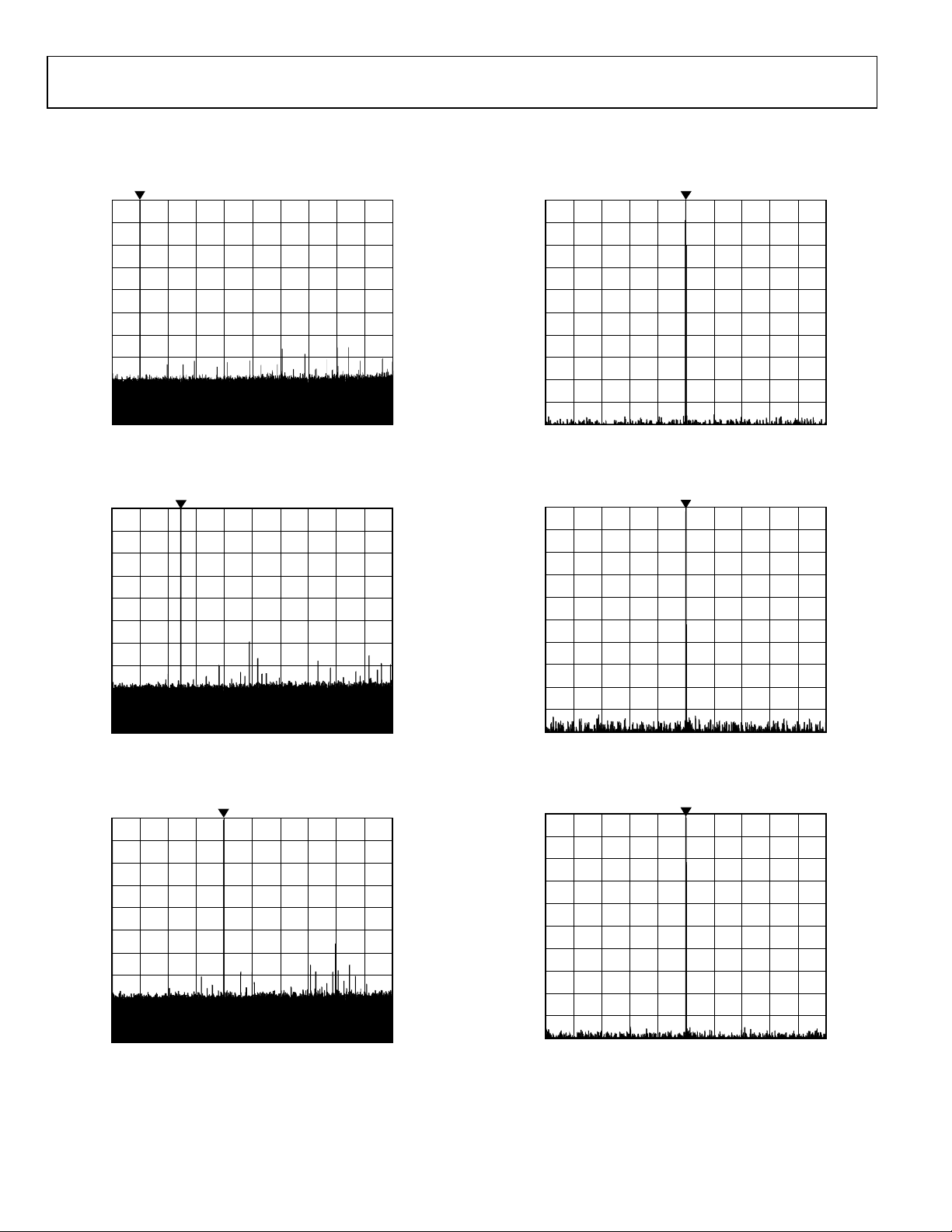

TYPICAL PERFORMANCE CHARACTERISTICS

Nominal supply voltage; DAC R

= 3.3 kΩ, 25°C, unless otherwise noted.

SET

Figure 4. Wideband SFDR at 171.5 MHz

SYSCLK = 3.5 GHz (SYSCLK PLL Bypassed)

Figure 5. Wideband SFDR at 427.5 MHz

SYSCLK = 3.5 GHz (SYSCLK PLL Bypassed)

Figure 7. Narrow-Band SFDR at 171.5 MHz,

SYSCLK = 3.5 GHz (SYSCLK PLL Bypassed)

Figure 8. Narrow-Band SFDR at 427.5 MHz,

SYSCLK = 3.5 GHz (SYSCLK PLL Bypassed)

Figure 6. Wideband SFDR at 696.5 MHz,

SYSCLK = 3.5 GHz (SYSCLK PLL Bypassed)

Rev. PrJ | Page 12 of 38

Figure 9. Narrow-Band SFDR at 696.5 MHz,

SYSCLK = 3.5 GHz (SYSCLK PLL Bypassed)

Page 13

Preliminary Technical Data AD9914

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

0

SFDR (dBc)

START 0Hz 175MHz/DIV STOP 1.75GHz

10836-010

0

–80

0 0.05 0.10 0.15 0.400.350.300.250.20

SFDR (dBc)

f

C

/

f

S

–70

–60

–50

–40

–30

–20

–10

10836-011

0

–80

0 0.05 0.10 0.15 0.400.350.300.250.20

SFDR (dBc)

f

C

/

f

S

–70

–60

–50

–40

–30

–20

–10

10836-012

SYSCLK = 2. 7GHz

SYSCLK = 2. 8GHz

SYSCLK = 2. 9GHz

SYSCLK = 3. 0GHz

SYSCLK = 3. 1GHz

SYSCLK = 3. 2GHz

SYSCLK = 3. 3GHz

SYSCLK = 3. 4GHz

SYSCLK = 3. 5GHz

SYSCLK = 1. 5GHz

SYSCLK = 1. 6GHz

SYSCLK = 1. 7GHz

SYSCLK = 1. 8GHz

SYSCLK = 1. 9GHz

SYSCLK = 2. 0GHz

SYSCLK = 2. 1GHz

SYSCLK = 2. 2GHz

SYSCLK = 2. 3GHz

SYSCLK = 2. 4GHz

SYSCLK = 2. 5GHz

SYSCLK = 2. 6GHz

CENTER 1.3965MHz

–100

–90

–80

–70

–60

–50

–40

–30

–20

–10

0

50kHz/DIV SPAN 500kHz

SFDR (dBc)

10836-013

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY OFFSET (Hz)

–70

–90

–80

–100

–110

–120

–130

–140

–150

–160

–170

PHASE NOISE (dBc/Hz)

SMA

SMA AND

ADCLK925

10836-014

10 100 1k 10k 100k 1M 10M 100M

FREQUENCY OFFSET (Hz)

–70

–90

–80

–100

–110

–120

–130

–140

–150

–160

–170

PHASE NOISE (dBc/Hz)

1396MHz

696MHz

427MHz

171MHz

10836-015

Figure 10. Wideband SFDR at 1396.5 MHz,

SYSCLK = 3.5 GHz (SYSCLK PLL Bypassed)

Figure 11. Wideband SFDR vs. Normalized f

SYSCLK = 3.5 GHz

OUT

Figure 13. Narrow-Band SFDR at 1396.5 MHz,

SYSCLK = 3.5 GHz (SYSCLK PLL B ypassed)

Figure 14. Absolute Phase Noise of REF CLK Source Driving AD9914

Rohde & Schwarz SMA100 Signal Generator at 3.5 GHz Buffered by Series

ADCLK925

Figure 12. Wideband SFDR vs. Normalized f

SYSCLK = 2.5 GHz to 3.5 GHz

OUT

,

Figure 15. Absolute Phase Noise Curves of DDS Output at 3.5 GHz Operation

Rev. PrJ | Page 13 of 38

Page 14

AD9914 Preliminary Technical Data

10 1k 100k 10M

FREQUENCY OFFSET (Hz)

–70

–90

–80

–100

–110

–120

–130

–140

–150

–160

–170

PHASE NOISE (dBc/Hz)

1396MHz

NORMALIZED

REF CLK SO URCE

10836-016

10 1k 100k 10M

FREQUENCY OFFSET (Hz)

–60

–90

–80

–70

–100

–110

–120

–130

–140

–150

–160

–170

–180

PHASE NOISE (dBc/Hz)

1396MHz

696MHz

427MHz

171MHz

10836-017

0.5

0.4

0.3

0.2

0.1

0

500 1000 400035003000250020001500

SUPPLY CURRENT (A)

SYSTEM CLOCK (MHz)

10836-018

3.3V ANALOG

3.3V DIGITAL

1.8V ANALOG

1.8V DIGITAL

10

FREQUENCY OFFSET (Hz)

–70

–90

–80

–100

–110

–120

–130

–140

–150

–160

–170

PHASE NOISE (dBc/Hz)

978MHz

305MHz

123MHz

1k 100k 10M

497MHz

10836-019

10 1k 100k 10M

FREQUENCY OFFSET (Hz)

–60

–90

–80

–70

–100

–110

–120

–130

–140

–150

–160

PHASE NOISE (dBc/Hz)

1396MHz ABSOLUTE

1396MHz RESIDUAL

10836-020

–60

–90

–80

–70

–100

–110

–120

–130

–140

–150

–160

–170

–180

10 1k 100k 10M

FREQUENCY OFFSET (Hz)

PHASE NOISE (dBc/Hz)

1396MHz ABSOLUTE

1396MHz RESIDUAL

10836-021

Figure 16. Absolute Phase Noise Curves of Normalized REF CLK Source to

DDS Output at 1396 MHz (SYSCLK = 3.5 GHz)

Figure 17. Residual Phase Noise Curves

Figure 19. Absolute Phase Noise Curves of DDS Output Using Internal PLL at

2.5 GHz Operation

Figure 20. Residual PN vs. Absolute PN Measurement Curves at 1396 MHz

Figure 18. Power Supply Current vs. SYSCLK

Figure 21. Residual Phase Noise

Rev. PrJ | Page 14 of 38

Page 15

Preliminary Technical Data AD9914

10836-022

CH2 1.0V Ω M20.00ms IT 40.0ps/pt

A CH2 1.64V

1

10

9

1

2

3

4

5

6

7

8

0

100 4100

TIME (ms)

SYSTEM CLOCK RATE (MHz)

600 1100 1600 2100 2600 3100 3600

10836-023

930

870

880

890

900

910

920

–6 –2–4 6420

FREQUENCY ( Hz )

TIME (ms)

10836-024

930

870

880

890

900

910

920

–6 –2–4 6420

FREQUENCY ( Hz )

TIME (ms)

10836-025

Figure 22. SYNC_OUT (SYSCLK/384)

Figure 24. Measured Rising Linear Frequency Sweep

Figure 23. DAC Calibration Time vs. SYSCLK Rate

Figure 25. Measured Falling Linear Frequency Sweep

Rev. PrJ | Page 15 of 38

Page 16

AD9914 Preliminary Technical Data

10836-044

SWITCH

CONTROL

CODE

IFS/2 IFS/2

AVDD (3.3V)

AGND

CURRENT

SWITCH

ARRAY

CURRENT

SWITCH

ARRAY

AOUT

AOUT

INTERNAL

50Ω

INTERNAL

50Ω

IFS/2 + I

CODE

I

FS

/2 – I

CODE

I

FS

41

42

TBD

TBD

DVDD (3.3V)

10836-043

EQUIVALENT CIRCUITS

Figure 26. DAC Output

Figure 28. CMOS Input

Figure 27. REF CLK input

Figure 29. CMOS Output

Rev. PrJ | Page 16 of 38

Page 17

Preliminary Technical Data AD9914

THEORY OF OPERATION

The AD9914 has five modes of operation.

• Single tone

• Profile modulation

• Digital ramp modulation (linear sweep)

• Parallel data port modulation

• Programmable modulus mode

The modes define the data source used to supply the DDS with

its signal control parameters: frequency, phase, or amplitude.

The partitioning of the data into different combinations

of frequency, phase, and amplitude is established based on the

mode and/or specific control bits and function pins.

Although the various modes are described independently, they

can be enabled simultaneously. This provides an unprecedented

level of flexibility for generating complex modulation schemes.

However, to avoid multiple data sources from driving the same

DDS signal control parameter, the device has a built-in priority

protocol.

In single tone mode, the DDS signal control parameters come

directly from the profile programming registers. In digital ramp

modulation mode, the DDS signal control parameters are

delivered by a digital ramp generator. In parallel data port

modulation mode, the DDS signal control parameters are driven

directly into the parallel port.

The various modulation modes generally operate on only one of

the DDS signal control parameters (two in the case of the polar

modulation format via the parallel data port). The unmodulated

DDS signal control parameters are stored in programming

registers and automatically routed to the DDS based on the

selected mode.

A separate output shift keying (OSK) function is also available.

This function employs a separate digital linear ramp generator

that only affects the amplitude parameter of the DDS. The OSK

function has priority over the other data sources that can drive

the DDS amplitude parameter. As such, no other data source

can drive the DDS amplitude when the OSK function is enabled.

SINGLE TONE MODE

In single tone mode, the DDS signal control parameters are

supplied directly from the profile programming registers. A

profile is an independent register that contains the DDS signal

control parameters. Eight profile registers are available. Note

that the profile pins must be used to select the desired register.

PROFILE MODULATION MODE

Each profile is independently accessible. For FSK, PSK, or ASK

modulation, use the three external profile pins (PROFILE[2:0])

to select the desired profile. A change in the state of the profile

pins with the next rising edge on SYNC_CLK updates the DDS

with the parameters specified by the selected profile. Therefore,

the profile change must meet the setup and hold times to the

SYNC_CLK rising edge. Note that amplitude control must also

Rev. PrJ | Page 17 of 38

be enabled using the OSK enable bit in Register

CFR1(0x000[8]).

DIGITAL RAMP MODULATION MODE

In digital ramp modulation mode, the modulated DDS signal

control parameter is supplied directly from the digital ramp

generator (DRG). The ramp generation parameters are

controlled through the serial or parallel I/O port.

The ramp generation parameters allow the user to control both

the rising and falling slopes of the ramp. The upper and lower

boundaries of the ramp, the step size and step rate of the rising

portion of the ramp, and the step size and step rate of the falling

portion of the ramp are all programmable.

The ramp is digitally generated with 32-bit output resolution.

The 32-bit output of the DRG can be programmed to affect

frequency, phase, or amplitude. When programmed for frequency,

all 32 bits are used. However, when programmed for phase or

amplitude, only the 16 MSBs or 12 MSBs, respectively, are used.

The ramp direction (rising or falling) is externally controlled by

the DRCTL pin. An additional pin (DRHOLD) allows the user

to suspend the ramp generator in its present state. Note that

amplitude control must also be enabled using the OSK enable

bit in Register CFR1.

PARALLEL DATA PORT MODULATION MODE

In parallel data port modulation mode, the modulated DDS

signal control parameter(s) are supplied directly from the 32-bit

parallel data port. The function pins define how the 32-bit dataword is applied to the DDS signal control parameters. Formatting of the 32-bit data-word is unsigned binary, regardless of the

destination.

Parallel Data Clock (SYNC_CLK)

The AD9914 generates a clock signal on the SYNC_CLK pin

that runs at 1/24 of the DAC sample rate (the sample rate of the

parallel data port). SYNC_CLK serves as a data clock for the

parallel port.

PROGRAMMABLE MODULUS MODE

In programmable modulus mode, the DRG is used as an

auxiliary accumulator to alter the frequency equation of the

DDS core, making it possible to implement fractions that are

not restricted to a power of 2 in the denominator. A standard

DDS is restricted to powers of 2 as a denominator because the

phase accumulator is a set of bits as wide as the frequency

tuning word (FTW).

When in programmable modulus mode, however, the

frequency equation is:

f

= (fS)(FTW + A/B)/232

0

where f

This equation implies a modulus of B × 2

the case of a standard DDS). Furthermore, because B is

< ½, 0 ≤ FTW < 2

0/fS

31

, 2 ≤ B ≤ 232 – 1, and A < B.

32

(rather than 232, in

Page 18

AD9914 Preliminary Technical Data

programmable, the result is a DDS with a programmable

modulus.

When in programmable modulus mode, the 32-bit auxiliary

accumulator operates in a way that allows it to roll over at a

value other than its full capacity of 2

32

. That is, it operates with a

modified modulus based on the programmable value of B. With

each roll over of the auxiliary accumulator, a value of 1 LSB

adds to the current accumulated value of the 32-bit phase

accumulator. This behavior changes the modulus of the phase

accumulator to B × 2

the desired f

.

0

32

(instead of 232) allowing it to synthesize

To determine the programmable modulus mode register values

for FTW, A, and B the user must first define f

relatively prime integers, M/N. That is, having converted f

f

to integers, M and N, reduce the fraction, M/N, to lowest

S

terms. Then, divide M × 2

32

by N. The integer part of this

as a ratio of

0/fS

and

0

division operation is the value of FTW (Register 0x04[31:0]).

The remainder, Y, of this division operation is

32

Y = (2

×M) – (FTW×N)

The value of Y facilitates the determination of A and B by

taking the fraction, Y/N, and reducing it to lowest terms. Then,

the numerator of the reduced fraction is A (Register 0x06[31:0])

and the denominator is the B (Register 0x05[31:0]).

For example, synthesizing precisely 300 MHz with a 1 GHz

system clock is not possible with a standard DDS. It is possible,

however, using programmable modulus as follows.

First, express f

as a ratio of integers:

0/fS

300,000,000/1,000,000,000

Reducing this fraction to lowest terms yields 3/10; therefore, M

= 3 and N = 10. FTW is the integer part of (M × 2

32

2

)/10, which is 1,288,490,188 (0x4CCCCCCC in 32-bit

hexadecimal notation). The remainder, Y, of (3 × 2

32

)/N, or (3 ×

32

)/10, is (232

× 3) − (1,288,490,188 × 10), which is 8. Therefore, Y/N is 8/10,

which reduces to 4/5. Therefore, A = 4 and B = 5 (0x00000004

and 0x00000005 in 32-bit hexadecimal notation, respectively).

Programming the AD9914 with these values of FTW, A, and B

results in an output frequency that is exactly 3/10 of the system

clock frequency.

Rev. PrJ | Page 18 of 38

Page 19

Preliminary Technical Data AD9914

SYSCLK

OUT

f

FTW

f

=

32

2

=

SYSCLK

OUT

f

f

FTW

32

2round

SYSCLK

OUT

f

FTW

f

−=

32

2

1

=∆

14

14

2

360

2

2

POW

POW

π

θ

=

12

12

2

log20

2

ASF

ASF

ScaleAmplitude

DDS_CLK

32 17

FREQUENCY

CONTROL

ANGLE-TOAMPLITUDE

CONVERSION

(SINE OR

COSINE)

PHASE

OFFSET

CONTROL

TO DAC

(MSBs)

D Q

R

ACCUMULATOR

RESET

32

14

MSB ALIGNED

AMPLITUDE

CONTROL

12

DDS SIGNAL CONTROL PARAMETERS

14

12

17

32

32

12

12

32-BIT

ACCUMULATOR

10836-026

FUNCTIONAL BLOCK DETAIL

DDS CORE

The direct digital synthesizer (DDS) block generates a reference

signal (sine or cosine based on CFR1[16], the enable sine output

bit). The parameters of the reference signal (frequency, phase,

and amplitude) are applied to the DDS at its frequency, phase

offset, and amplitude control inputs, as shown in Figure 30.

The output frequency (f

) of the AD9914 is controlled by the

OUT

frequency tuning word (FTW) at the frequency control input to

the DDS. The relationship among f

, FTW, and f

OUT

SYSCLK

is given by

(1)

where FTW is a 32-bit integer ranging in value from 0 to

2,147,483,647 (2

31

− 1), which represents the lower half of the

full 32-bit range. This range constitutes frequencies from dc to

Nyquist (that is, ½ f

The FTW required to generate a desired value of f

SYSCLK

).

is found

OUT

by solving Equation 1 for FTW, as given in Equation 2.

where the upper quantity is for the phase offset expressed as

radian units and the lower quantity as degrees.

To find the POW value necessary to develop an arbitrary Δθ,

solve the preceding equation for POW and round the result (in

a manner similar to that described previously for finding an

arbitrary FTW).

The relative amplitude of the DDS signal can be digitally scaled

(relative to full scale) by means of a 12-bit amplitude scale

factor (ASF). The amplitude scale value is applied at the output

of the angle-to-amplitude conversion block internal to the DDS

core. The amplitude scale is given by

(3)

(2)

where the round(x) function rounds the argument (the value of

x) to the nearest integer. This is required because the FTW is

constrained to be an integer value. For example, for f

41 MHz and f

= 122.88 MHz, FTW = 1,433,053,867

SYSCLK

OUT

=

(0x556AAAAB).

Programming an FTW greater than 2

31

produces an aliased

image that appears at a frequency given by

(for FTW ≥ 231)

The relative phase of the DDS signal can be digitally controlled

by means of a 16-bit phase offset word (POW). The phase offset

is applied prior to the angle-to-amplitude conversion block

internal to the DDS core. The relative phase offset (Δθ) is given by

where the upper quantity is amplitude expressed as a fraction of

full scale and the lower quantity is expressed in decibels relative

to full scale.

To find the ASF value necessary for a particular scale factor, solve

Equation 3 for ASF and round the result (in a manner similar

to that described previously for finding an arbitrary FTW).

When the AD9914 is programmed to modulate any of the DDS

signal control parameters, the maximum modulation sample

rate is ¼ f

images at multiples of ¼ f

. This means that the modulation signal exhibits

SYSCLK

. The impact of these images

SYSCLK

must be considered when using the device as a modulator.

Figure 30. DDS Block Diagram

Rev. PrJ | Page 19 of 38

Page 20

AD9914 Preliminary Technical Data

PRIMARY

SIGNAL

FILTER

RESPONSE

SIN(x)/x

ENVELOPE

SPURS

IMAGE 0 IMAGE 1 I MAGE 2 IMAGE 3 IMAGE 4

0

–20

–40

–60

–80

–100

MAGNITUDE

(dB)

f

s

/2

f

s

3

f

s

/2 2

f

s

5

f

s

/2

f

BASE BAND

10836-027

12-BIT DAC OUTPUT

The AD9914 incorporates an integrated 12-bit, current output

DAC. The output current is delivered as a balanced signal using

two outputs. The use of balanced outputs reduces the potential

amount of common-mode noise present at the DAC output,

offering the advantage of an increased signal-to-noise ratio. An

external resistor (R

) connected between the DAC_RSET pin

SET

and AGND establishes the reference current. The recommended

value of R

is 3.3 kΩ.

SET

Attention should be paid to the load termination to keep the

output voltage within the specified compliance range; voltages

developed beyond this range cause excessive distortion and can

damage the DAC output circuitry.

DAC CALIBRATION OUTPUT

The DAC CAL enable bit in the DAC control register (0x03[24])

must be manually set and then cleared after each power-up and

every time the REF CLK or internal system clock is changed.

This initiates an internal calibration routine to optimize the

setup and hold times for internal DAC timing. Failure to

calibrate degrades ac performance.

RECONSTRUCTION FILTER

The DAC output signal appears as a sinusoid sampled at fS. The

frequency of the sinusoid is determined by the frequency tuning

word (FTW) that appears at the input to the DDS. The DAC

output is typically passed through an external reconstruction

filter that serves to remove the artifacts of the sampling process

and other spurs outside the filter bandwidth.

Because the DAC constitutes a sampled system, its output must

be filtered so that the analog waveform accurately represents the

digital samples supplied to the DAC input. The unfiltered DAC

output contains the desired baseband signal, which extends

from dc to the Nyquist frequency (f

/2). It also contains images

S

of the baseband signal that theoretically extend to infinity. Notice

that the odd numbered images (shown in Figure 31) are mirror

images of the baseband signal. Furthermore, the entire DAC

output spectrum is affected by a sin(x)/x response, which is

caused by the sample-and-hold nature of the DAC output signal.

For applications using the fundamental frequency of the DAC

output, the response of the reconstruction filter should preserve

the baseband signal (Image 0), while completely rejecting all

other images. However, a practical filter implementation

typically exhibits a relatively flat pass band that covers the

desired output frequency plus 20%, rolls off as steeply as

possible, and then maintains significant (though not complete)

rejection of the remaining images. Depending on how close

unwanted spurs are to the desired signal, a third-, fifth-, or

seventh-order elliptic low-pass filter is common.

Some applications operate from an image above the Nyquist

frequency, and those applications use a band-pass filter instead

of a low-pass filter. The design of the reconstruction filter has a

significant impact on the overall signal performance. Therefore,

good filter design and implementation techniques are important

for obtaining the best possible jitter results.

Figure 31. DAC Spectrum vs. Reconstruction Filter Response

Rev. PrJ | Page 20 of 38

Page 21

Preliminary Technical Data AD9914

111

1000

REF_CLK

REF_CLK

2 7

2

LOOP FILTER

58

DOUBLER ENABLE

CFR3[19]

55

54

DOUBLER

CLOCK EDGE

CFR3[16]

×2

÷ 1, 2, 4, 8

ENABLE

IN

PLL ENABLE

CFR3[18]

LOOP

FILTER

PLL OUT

0

1

0

1

SYSCLK

INPUT DIVIDER

RESET CFR3[22]

INPUT DIVIDER RATIO

CFR3[21:20]

CHARGE

PUMP

DIVIDE

N

CFR3[15:8]

ICP

CFR3[5:3]

10836-028

TERMINATION

REF_CLK

DIFFERENTIAL SOURCE,

DIFFERENTIAL INPUT

SINGLE - E NDE D S OURCE,

DIFFERENTIAL INPUT

SINGLE - E NDE D S OURCE,

SINGLE - E NDE D INPUT

55

54

0.1µF

0.1µF

PECL,

LVPECL,

OR

LVDS

DRIVER

REF_CLK

55

54

50Ω

0.1µF

0.1µF

BALUN

(1:1)

REF_CLK

REF_CLK

REF_CLK

REF_CLK

55

54

0.1µF

0.1µF

50Ω

10836-029

CLOCK INPUT (REF_CLK/

REF_CLK/

REF_CLK

Overview

REF_CLK

The AD9914 supports a number of options for producing the

internal SYSCLK signal (that is, the DAC sample clock) via the

REF_CLK/

REF_CLK

input pins. The REF_CLK input can be

driven directly from a differential or single-ended source. There

is also an internal phase-locked loop (PLL) multiplier that can

be independently enabled. However, the PLL limits the SYSCLK

signal between 2.4 GHz and 2.5 GHz operation. A block

diagram of the REF_CLK functionality is shown in Figure 32.

Figure 32 also shows how the CFR3 control bits are associated

with specific functional blocks.

)

The PLL enable bit is used to choose between the PLL path or

the direct input path. When the direct input path is selected,

the REF_CLK/

signal source (single-ended or differential). Input frequencies

up to 3.5 GHz are supported.

Direct Driven REF_CLK/

With a differential signal source, the REF_CLK/

are driven with complementary signals and ac-coupled with 0.1 µF

capacitors. With a single-ended signal source, either a singleended-to-differential conversion can be employed or the

REF_CLK input can be driven single-ended directly. In either

case, 0.1 µF capacitors are used to ac couple both

REF_CLK/

bias voltage of ~1.35 V. See

The REF_CLK/

(~1.2 kΩ single-ended). Most signal sources have relatively low

output impedances. The REF_CLK/

is relatively high; therefore, its effect on the termination impedance

is negligible and can usually be chosen to be the same as the

output impedance of the signal source. The bottom two examples

in

Figure 33 assume a signal source with a 50 Ω output impedance.

REF_CLK

REF_CLK

REF_CLK

Figure 32. REF_CLK Block Diagram

pins must be driven by an external

REF_CLK

REF_CLK

pins to avoid disturbing the internal dc

Figure 33 for more details.

input resistance is ~2.5 kΩ differential

REF_CLK

input resistance

Phase-Locked Loop (PLL) Multiplier

An internal phase-locked loop (PLL) provides the option to use

a reference clock frequency that is significantly lower than the

system clock frequency. The PLL supports a wide range of

programmable frequency multiplication factors (8× to 255×) as

well as a programmable charge pump current and external loop

filter components (connected via the PLL LOOP_FILTER pin).

These features add an extra layer of flexibility to the PLL,

allowing optimization of phase noise performance and

flexibility in frequency plan development. The PLL is also

equipped with a PLL lock bit indicator (0x1B[24]).

The PLL output frequency range (f

range of 2.GHz ≤ f

PLL Calibration

TBD

pins

PLL Charge Pump

The charge pump current (ICP) is programmable to provide the

user with additional flexibility to optimize the PLL performance.

Tabl e 6 lists the bit settings vs. the nominal charge pump current.

Table 6. PLL Charge Pump Current

ICP Bits (CFR3[5:3]) Charge Pump Current, ICP (μA)

000 125

001 250

010 375

011 500 (default)

100 625

101 750

110 875

Rev. PrJ | Page 21 of 38

Figure 33. Direct Connection Diagram

) is constrained to the

SYSCLK

≤ 2.5 GHz by the internal VCO.

SYSCLK

Page 22

AD9914 Preliminary Technical Data

( )

+=

φKK

Nfπ

R1

VD

OL

sin

1

1

( )

( )

2

2

tan

OL

VD

fπN

φKK

C1 =

( )

( )

( )

−

=

φ

φ

fπN

KK

C2

OL

VD

cos

sin1

2

2

PFD CP

LOOP_FILTER

VCO

÷N

PLL OUT

PLL IN

REFCLK PLL

R1

C1

C2

59 58

10836-030

REF

OSK ENABLE

EXTERNAL

OSK ENABLE

12

OSK

DDS CLOCK

12

PS0 PS1 PS2

25

26 27

66

TO DDS

AMPLITUDE

CONTROL

PARAMETER

OSK

CONTROLLER

AMPLIT UDE S CALE

FACTOR (1 OF 8

SELECTED PROFILE

REGISTERS [27:16])

10836-031

External PLL Loop Filter Components

The PLL LOOP_FILTER pin provides a connection interface to

attach the external loop filter components. The ability to use

custom loop filter components gives the user more flexibility to

optimize the PLL performance. The PLL and external loop filter

components are shown in Figure 34.

Figure 34. REF CLK PLL External Loop Filter

In the prevailing literature, this configuration yields a thirdorder, Type II PLL. To calculate the loop filter component

values, begin with the feedback divider value (N), the gain of

the phase detector (K

the programmed VCO SEL bit settings (see Tabl e 2 for K

), and the gain of the VCO (KV) based on

D

). The

V

loop filter component values depend on the desired open-loop

bandwidth (f

) and phase margin (φ), as follows:

OL

(4)

PLL LOCK INDICATION

When the PLL is in use, the PLL lock bit (0x1B[24])provides an

active high indication that the PLL has locked to the REF CLK

input signal.

OUTPUT SHIFT KEYING (OSK)

The OSK function (see Figure 35) allows the user to control the

output signal amplitude of the DDS. The amplitude data

generated by the OSK block has priority over any other

functional block that is programmed to deliver amplitude data

to the DDS. Therefore, the OSK data source, when enabled,

overrides all other amplitude data sources.

The operation of the OSK function is governed by two CFR1

register bits, OSK enable (0x00[8]) and external OSK enable

(0x08[9]), the external OSK pin, the profile pins, and the 12 bits

of amplitude scale factor found in one of eight profile registers.

The profile pins are used to select the profile register containing

the desired amplitude scale factor.

The primary control for the OSK block is the OSK enable bit

(0x00[8]). When the OSK function is disabled , the OSK input

controls and OSK pin are ignored.

The OSK pin functionality depends on the state of the external

OSK enable bit and the OSK enable bit. When both bits are set

to Logic 1 and the OSK pin is Logic 0, the output amplitude is

forced to 0; otherwise, if the OSK pin is Logic 1, the output

amplitude is set by the amplitude scale factor value in one of

eight profile registers depending on the profile pin selection.

(5)

(6)

where:

K

is equal to the programmed value of ICP.

D

K

is taken from Table 2

V

Ensure that proper units are used for the variables in Equation 4

through Equation 6. I

as appears in Table 6; K

must be in amps, not microamps (μA)

CP

must be in hertz per volts (Hz/V), not

V

megahertz per volts (MHz/V) as listed in Tab l e 2; the loop

bandwidth (f

) must be in hertz (Hz); and the phase margin

OL

(φ) must be in radians.

For example, suppose the PLL is programmed such that I

287 μA, K

= 625 MHz/V, and N = 25. If the desired loop

V

=

CP

bandwidth and phase margin are 50 kHz and 45°, respectively,

Rev. PrJ | Page 22 of 38

then the loop filter component values are R1 = 52.85 Ω, C1 =

145.4 nF, and C2 = 30.11 nF.

Figure 35. OSK Block Diagram

Page 23

Preliminary Technical Data AD9914

00

Frequency

31:0

DRCTL

DDS CLOCK

DRHOLD

DROVER

DIGITAL RAMP ENABLE

LOAD LRR AT I/O_UPDATE

CLEAR DIGI TAL

RAMP ACCUMULATOR

AUTOCLEAR DIGITAL

RAMP ACCUMULATOR

32

32

DIGITAL RAMP DESTINATION

2

DIGITAL RAMP NO-DWELL

2

32

32

63 64 65

32

32

TO DDS

SIGNAL

CONTROL

PARAMETER

DIGITAL

RAMP

GENERATOR

DIGITAL RAMP LOWER LIMIT REGISTER

RISING DIGITAL STEP SIZE REGISTER

DIGITAL RAMP UPPER LIMIT REGISTER

FALLING DIGITAL STEP SIZE REGISTER

DIGITAL RAMP RATE REGISTER

10836-032

DDS CLOCK

D Q

R

LOWER

LIMIT

0

1

DECREMENT STEP SIZE

PRESET

Q

DRCTL

LOAD

CLEAR DIGITAL RAMPACCUMULATOR

AUTOCLEAR DIGITAL RAMPACC

.

NO DWELL

LIMIT CONTROL

DIGITAL RAMPACCUMULATOR

INCREMENT S TEP SIZE

32

32

0

1

NEGATIVE SLOPE RATE

POSITIVE SLOPE RATE

16

16

32

16

62

DRHOLD

63

32

32

LOAD

CONTROL

LOGIC

LOAD LRR AT I/O_UPDATE

DIGITAL

RAMP

TIMER

ACCUMULATOR

RESET

CONTROL

LOGIC

NO-DWELL

CONTROL

2

3232

TO DDS

SIGNAL

CONTROL

PARAMETER

UPPER

LIMIT

32

10836-033

DIGITAL RAMP GENERATOR (DRG)

DRG Overview

To sweep phase, frequency, or amplitude from a defined start

point to a defined endpoint, a completely digital ramp generator

is included in the AD9914. The DRG makes use of eight control

register bits, three external pins, and five 32-bit registers (see

Figure 36).

Figure 36. Digital Ramp Block Diagram

The primary control for the DRG is the digital ramp enable bit.

When disabled, the other DRG input controls are ignored and the

internal clocks are shut down to conserve power.

The output of the DRG is a 32-bit unsigned data bus that can be

routed to any one of the three DDS signal control parameters, as

controlled by the two digital ramp destination bits in Control

Function Register 2 according to Table 7. The 32-bit output bus

is MSB-aligned with the 32-bit frequency parameter, the 14-bit

phase parameter, or the 12-bit amplitude parameter, as defined

by the destination bits. When the destination is phase or

amplitude, the unused LSBs are ignored.

Table 7. Digital Ramp Destination

Digital Ramp

Destination Bits

(CFR2[21:20])

DDS Signal

Control

Parameter

Bits Assigned to

DDS Parameter

01 Phase 31:18

1x1 Amplitude 31:20

1

x = don’t care.

The ramp characteristics of the DRG are fully programmable. This

includes the upper and lower ramp limits, and independent control

of the step size and step rate for both the positive and negative slope

characteristics of the ramp. A detailed block diagram of the DRG is

shown in Figure 37.

The direction of the ramping function is controlled by the

DRCTL pin. A Logic 0 on this pin causes the DRG to ramp

with a negative slope, whereas a Logic 1 causes the DRG to

ramp with a positive slope.

The DRG also supports a hold feature controlled via the DRHOLD

pin. When this pin is set to Logic 1, the DRG is stalled at its last

state; otherwise, the DRG operates normally. The DDS signal

control parameters that are not the destination of the DRG are

taken from the active profile.

Figure 37. Digital Ramp Generator Detail

Rev. PrJ | Page 23 of 38

Page 24

AD9914 Preliminary Technical Data

SYSCLK

f

Pt24

=∆+

SYSCLK

f

Nt24

=∆−

SYSCLK

f

M

StepFrequency

=

32

2

31

2

M

StepPhase

π

=

29

2

45M

StepPhase =

FS

I

M

StepAmplitude

=

32

2

DRG Slope Control

The core of the DRG is a 32-bit accumulator clocked by a

programmable timer. The time base for the timer is the DDS

clock, which operates at 1/24 f

. The timer establishes the

SYSCLK

interval between successive updates of the accumulator. The

positive (+Δt) and negative (−Δt) slope step intervals are

independently programmable as given by

where P and N are the two 16-bit values stored in the 32-bit digital

ramp rate register and control the step interval. N defines the step

interval of the negative slope portion of the ramp. P defines the step

interval of the positive slope portion of the ramp.

The step size of the positive (STEP

) and negative (STEPN) slope

P

portions of the ramp are 32-bit values programmed into the 32bit rising and falling digital ramp step size registers (0x06 and

0x07). Program each of the step sizes as an unsigned integer

(the hardware automatically interprets STEP

as a negative

N

value). The relationship between the 32-bit step size values and

actual units of frequency, phase, or amplitude depend on the digital

ramp destination bits. Calculate the actual frequency, phase, or

amplitude step size by substituting STEP

or STEPP for M in the

N

following equations as required:

(radians)

(degrees)

Note that the frequency units are the same as those used to

represent f

the same as those used to represent I

(MHz, for example). The amplitude units are

SYSCLK

, the full-scale output

FS

current of the DAC (mA, for example).

The phase and amplitude step size equations yield the average

step size. Although the step size accumulates with 32-bit precision,

the phase or amplitude destination exhibits only 14 bits or

12 bits, respectively. Therefore, at the destination, the actual

phase or amplitude step is the accumulated 32-bit value

truncated to 14 bits or 12 bits, respectively.

As described previously, the step interval is controlled by a

16-bit programmable timer. There are three events that can

cause this timer to be reloaded prior to its expiration. One event

occurs when the digital ramp enable bit transitions from cleared

to set, followed by an I/O update. A second event is a change of

state in the DRCTL pin. The third event is enabled using the load

LRR at I/O update bit (see the Register Map and Bit Descriptions

section for details).

DRG Limit Control

The ramp accumulator is followed by limit control logic that

enforces an upper and lower boundary on the output of the

ramp generator. Under no circumstances does the output of the

DRG exceed the programmed limit values while the DRG is

enabled. The limits are set through the 64-bit digital ramp limit

register. Note that the upper limit value must be greater than the

lower limit value to ensure normal operation.

DRG Accumulator Clear

The ramp accumulator can be cleared (that is, reset to 0) under

program control. When the ramp accumulator is cleared, it forces

the DRG output to the lower limit programmed into the digital

ramp limit register.

With the limit control block embedded in the feedback path of the

accumulator, resetting the accumulator is equivalent to presetting it

to the lower limit value.

Normal Ramp Generation

Normal ramp generation implies that both no-dwell bits are

cleared (see the No-Dwell Ramp Generation section for details).

In Figure 38, a sample ramp waveform is depicted with the

required control signals. The top trace is the DRG output.

The next trace down is the status of the DROVER output pin

(assuming that the DROVER pin active bit is set). The remaining

traces are control bits and control pins. The pertinent ramp

parameters are also identified (upper and lower limits plus step

size and Δt for the positive and negative slopes). Along the

bottom, circled numbers identify specific events. These events

are referred to by number (Event 1 and so on) in the following

paragraphs.

Rev. PrJ | Page 24 of 38

Page 25

Preliminary Technical Data AD9914

DRG OUTPUT

LOWER LIMIT

UPPER LIMIT

DRCTL

DRHOLD

AUTOCLEAR DIGITAL

RAMP ACCUMULATOR

CLEAR DIGI TAL

RAMP ACCUMULATOR

I/O_UPDATE

POSITIVE

STEP SIZE

NEGATIVE

STEP SIZE

P DDS CLOCK CYCLES

N DDS CLOCK CYCL E S

1 DDS CLOCK CYCL E

DIGITAL RAMP ENABLE

DROVER

CLEAR

RELEASE

AUTO

CLEAR

–Δ

t

+Δ

t

1

2 3 4

5 6 7

8 9

10

11

12

13

10836-034

In this particular example, the positive and negative slopes of

the ramp are different to demonstrate the flexibility of the DRG.

The parameters of both slopes can be programmed to make the

positive and negative slopes the same.

Event 1—The digital ramp enable bit is set, which has no effect

on the DRG output because the bit is not effective until an I/O

update.

Event 2—An I/O update registers the digital ramp enable bit. If

DRCTL = 1 is in effect at this time (the gray portion of the

DRCTL trace), the DRG output immediately begins a positive

slope (the gray portion of the DRG output trace). Otherwise, if

DRCTL = 0, the DRG output is initialized to the lower limit.

Event 3—DRCTL transitions to a Logic 1 to initiate a positive

slope at the DRG output. In this example, the DRCTL pin is

held long enough to cause the DRG to reach its programmed

upper limit. The DRG remains at the upper limit until the ramp

accumulator is cleared, DRCTL = 0, or the upper limit is

reprogrammed to a higher value. In the last case, the DRG

immediately resumes its previous positive slope profile.

Event 4—DRCTL transitions to a Logic 0 to initiate a negative

slope at the DRG output. In this example, the DRCTL pin is

held long enough to cause the DRG to reach its programmed

lower limit. The DRG remains at the lower limit until DRCTL = 1,

or until the lower limit is reprogrammed to a lower value. In the

latter case, the DRG immediately resumes its previous negative

slope profile.

Event 5—DRCTL transitions to a Logic 1 for the second time,

initiating a second positive slope.

Event 6—The positive slope profile is interrupted by DRHOLD

transitioning to a Logic 1. This stalls the ramp accumulator and

freezes the DRG output at its last value.

Figure 38. Normal Ramp Generation

Event 7—DRHOLD transitions to a Logic 0, releasing the ramp

accumulator and reinstating the previous positive slope profile.

Event 8—The clear digital ramp accumulator bit is set, which

has no effect on the DRG because the bit is not effective until an

I/O update is issued.

Event 9—An I/O update registers that the clear digital ramp

accumulator bit is set, resetting the ramp accumulator and

forcing the DRG output to the programmed lower limit. The

DRG output remains at the lower limit until the clear condition

is removed.

Event 10—The clear digital ramp accumulator bit is cleared,

which has no effect on the DRG output because the bit is not

effective until an I/O update is issued.

Event 11—An I/O update registers that the clear digital ramp

accumulator bit is cleared, releasing the ramp accumulator, and

the previous positive slope profile restarts.

Event 12—The autoclear digital ramp accumulator bit is set,

which has no effect on the DRG output because the bit is not

effective until an I/O update is issued.

Event 13—An I/O update registers that the autoclear digital

ramp accumulator bit is set, resetting the ramp accumulator.

However, with an automatic clear, the ramp accumulator is only

held reset for a single DDS clock cycle. This forces the DRG

output to the lower limit, but the ramp accumulator is immediately made available for normal operation. In this example, the

DRCTL pin remains a Logic 1; therefore, the DRG output

restarts the previous positive ramp profile.

Rev. PrJ | Page 25 of 38

Page 26

AD9914 Preliminary Technical Data

UPPER LIMIT

P DDS CLOCK CYCLES

1 2 3 4 5 6 7 8

DRG OUTPUT

LOWER LIMIT

DRCTL

POSITIVE

STEP SIZE

DROVER

+Δ

t

10836-035

No-Dwell Ramp Generation

The two no-dwell high and no-dwell low bits in Control Function

Register 2 (0x01[18:17]) add to the flexibility of the DRG

capabilities. During normal ramp generation, when the DRG

output reaches the programmed upper or lower limit, it simply

remains at the limit until the operating parameters dictate

otherwise. However, during no-dwell operation, the DRG output

does not necessarily remain at the limit. For example, if the digital

ramp no-dwell high bit is set when the DRG reaches the upper

limit, it automatically (and immediately) snaps to the lower limit

(that is, it does not ramp back to the lower limit; it jumps to the

lower limit). Likewise, when the digital ramp no-dwell low bit is set,

and the DRG reaches the lower limit, it automatically (and

immediately) snaps to the upper limit.

During no-dwell operation, the DRCTL pin is monitored for state

transitions only; that is, the static logic level is immaterial.

During no-dwell high operation, a positive transition of the

DRCTL pin initiates a positive slope ramp, which continues

uninterrupted (regardless of any further activity on the DRCTL

pin) until the upper limit is reached.

During no-dwell low operation, a negative transition of the DRCTL

pin initiates a negative slope ramp, which continues uninterrupted

(regardless of any further activity on the DRCTL pin) until the

lower limit is reached.

Setting both no-dwell bits invokes a continuous ramping mode

of operation; that is, the DRG output automatically oscillates

between the two limits using the programmed slope parameters.

Furthermore, the function of the DRCTL pin is slightly different.

Instead of controlling the initiation of the ramp sequence, it

only serves to change the direction of the ramp; that is, if the

DRG output is in the midst of a positive slope and the DRCTL

pin transitions from Logic 1 to Logic 0, the DRG immediately

switches to the negative slope parameters and resumes oscillation between the limits. Likewise, if the DRG output is in the

midst of a negative slope and the DRCTL pin transitions from

Logic 0 to Logic 1, the DRG immediately switches to the positive

slope parameters and resumes oscillation between the limits.

When both no-dwell bits are set, the DROVER signal produces a

positive pulse (two cycles of the DDS clock) each time the DRG

output reaches either of the programmed limits (assuming that the

DROVER pin active bit is set).

A no-dwell high DRG output waveform is shown in Figure 39.

The waveform diagram assumes that the digital ramp no-dwell

high bit is set and has been registered by an I/O update. The