Page 1

CMOS 200 MSPS 14-Bit

FEATURES

200 MHz internal clock rate

14-bit data path

Excellent dynamic performance:

80 dB SFDR @ 65 MHz (±100 kHz) A

4× to 20× programmable reference clock multiplier

Reference clock multiplier PLL lock detect indicator

Internal 32-bit quadrature DDS

FSK capability

8-bit output amplitude control

Single-pin power-down function

Four programmable, pin-selectable signal profiles

SIN(x)/x correction (inverse SINC function)

Simplified control interface

10 MHz serial, 2-wire or 3-wire SPI®-compatible

INVERSE

CIC FILTER

I

PARALLEL

DATA IN

(14-BIT)

14

14

DEMUX

Q

DATA CLOCK

INV

CIC

INVERSE CIC CLOCK

OUT

POLATOR

MUX

INVERSE CIC CONTROL

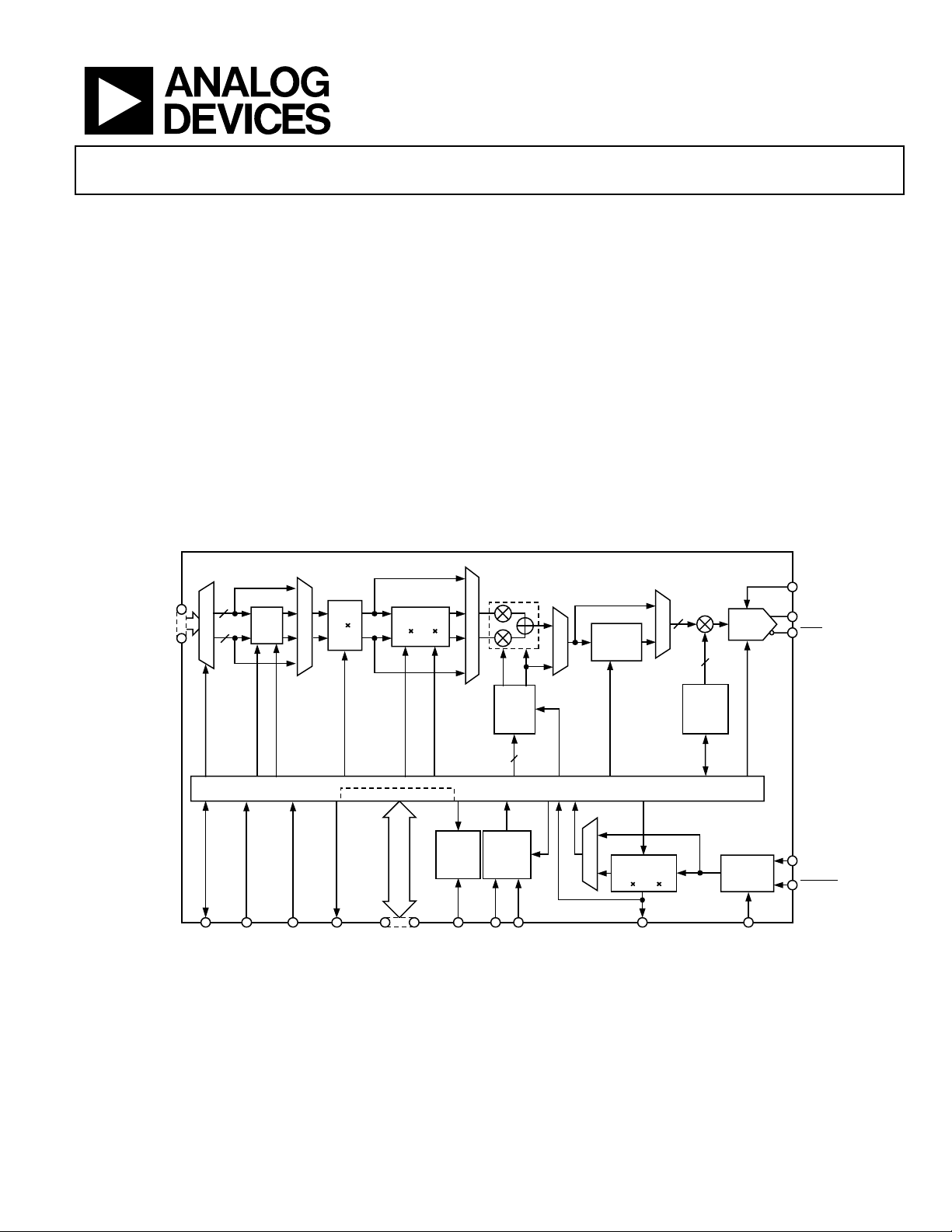

FUNCTIONAL BLOCK DIAGRAM

FIXED

INTER-

PROGRAMMABLE

INTERPOLATOR

(4 )

HALF-BAND CLOCKS

CONTROL REGISTERS

CIC

- 63 )

(2

INTERP CLOCK

INTERP CONTROL

Quadrature Digital Upconverter

AD9857

3.3 V single supply

Single-ended or differential input reference clock

80-lead LQFP surface-mount packaging

Three modes of operation:

Quadrature modulator mode

Single-tone mode

Interpolating DAC mode

APPLICATIONS

HFC data, telephony, and video modems

Wireless base station

Agile, LO frequency synthesis

Broadband communications

QUADRATURE

MODULATOR

MUX

SIN

COS

DDS

CORE

TUNING

32

WORD

TIMING AND CONTROL

MUX

CLOCK

INVERSE

SINC

FILTER

INVERSE

SINC CLOCK

AD9857

14

MUX

8

OUTPUT

SCALE

VALUE

14-BIT

DAC

DAC CLOCK

DAC_RSET

IOUT

IOUT

POWER-

DOWN

LOGIC

PDCLK/

TxENABLE

FUD

Rev. C

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

RESET CIC

OVERFLOW

SERIAL

PORT

DIGITAL

POWER-

DOWN

PROFILE

SELECT

LOGIC

Figure 1.

SYNCH

SYSCLK

MUX

CLOCK

MULTIPLIER

(4 – 20 )

PS0PS1

PLL

LOCK

MODE

CONTROL

CLOCK

INPUT

MODE

REFCLK

REFCLK

01018-C-001

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

www.analog.com

Fax: 781.326.8703 © 2004 Analog Devices, Inc. All rights reserved.

Page 2

AD9857

TABLE OF CONTENTS

Revision History ............................................................................... 3

General Description......................................................................... 4

Specifications..................................................................................... 5

Absolute Maximum Ratings............................................................ 8

Explanation of Test Levels........................................................... 8

ESD Caution.................................................................................. 8

Pin Configuration and Function Descriptions............................. 9

Typical Performance Characteristics ........................................... 11

Modulated Output Spectral Plots............................................. 11

Single-Tone Output Spectral Plots ........................................... 12

Narrow-band SFDR Spectral Plots........................................... 13

Output Constellations................................................................ 14

Modes Of Operation ...................................................................... 15

Quadrature Modulation Mode .................................................15

Single-Tone Mode ...................................................................... 16

Interpolating DAC Mode .......................................................... 17

Signal Processing Path ...................................................................18

Input Data Assembler ................................................................ 18

Inverse CIC Filter....................................................................... 19

Programmable (2× to 63×) CIC Interpolating Filter............. 21

Quadrature Modulator .............................................................. 21

DDS Core..................................................................................... 21

Inverse SINC Filter .....................................................................22

Output Scale Multiplier .............................................................22

14-Bit D/A Converter ................................................................ 22

Reference Clock Multiplier .......................................................23

Input Data Programming.............................................................. 24

Control Interface—Serial I/O................................................... 24

General Operation of the Serial Interface............................... 24

Instruction Byte.......................................................................... 26

Serial Interface Port Pin Descriptions..................................... 26

Control Register Descriptions.................................................. 27

Profile #0...................................................................................... 27

Profile #1...................................................................................... 28

Profile #2...................................................................................... 28

Profile #3...................................................................................... 28

Latency......................................................................................... 30

Ease of Use Features....................................................................... 32

Profile Select................................................................................ 32

Setting the Phase of the DDS.................................................... 32

Reference Clock Multiplier....................................................... 32

PLL Lock...................................................................................... 32

Single or Differential Clock ...................................................... 33

CIC Overflow Pin....................................................................... 33

Clearing the CIC Filter ..............................................................33

Digital Power-Down.................................................................. 33

Hardware-Controlled Digital Power-Down ........................... 34

Software-Controlled Digital Power-Down............................. 34

Full Sleep Mode .......................................................................... 34

Power Management Considerations........................................ 34

Support ........................................................................................ 35

Outline Dimensions....................................................................... 38

Ordering Guide .......................................................................... 39

Rev. C | Page 2 of 40

Page 3

AD9857

REVISION HISTORY

5/04−Data Sheet Changed from Rev. B to Rev. C

Changes to 14-Bit D/A Converter Section ..................................22

Changes to Register Address 0Ch, Bit 1 Equation ......................28

Changes to Register Address 12h, Bit 1 Equation.......................28

Changes to Register Address 18h, Bit 1 Equation.......................28

Added Support Section...................................................................35

Updated Figure 38...........................................................................38

Updated Ordering Guide ...............................................................39

4/02—Changed from Rev. A to Rev. B

Edit to Functional Block Diagram..................................................1

Edits to Specifications.......................................................................3

Edits to Figure 5 ................................................................................6

Edits to Figure 18 ............................................................................11

Edits to Figure 19 ............................................................................12

Edits to Figure 20 ............................................................................13

Edits to Figure 25 ........................................................................... 16

Edits to Figure 26 ............................................................................16

Edit to Equation 1 ...........................................................................16

Edit to Figure 28..............................................................................19

Edit to Notes on Serial Port Operation section...........................21

Edit to Figure 37..............................................................................31

Rev. C| Page 3 of 40

Page 4

AD9857

GENERAL DESCRIPTION

The AD9857 integrates a high speed direct digital synthesizer

(DDS), a high performance, high speed, 14-bit digital-to-analog

converter (DAC), clock multiplier circuitry, digital filters, and

other DSP functions onto a single chip, to form a complete

quadrature digital upconverter device. The AD9857 is intended

to function as a universal I/Q modulator and agile upconverter,

single-tone DDS, or interpolating DAC for communications

applications, where cost, size, power dissipation, and dynamic

performance are critical attributes.

The AD9857 offers enhanced performance over the industrystandard AD9856, as well as providing additional features.

The AD9857 is available in a space-saving, surface-mount

package and is specified to operate over the extended industrial

temperature range of −40°C to +85°C.

Rev. C | Page 4 of 40

Page 5

AD9857

SPECIFICATIONS

VS = 3.3 V ± 5%, R

Table 1.

Parameter Temp Test Level Min Typ Max Unit

REF CLOCK INPUT CHARACTERISTICS

Frequency Range

REFCLK Multiplier Disabled Full VI 1 200 MHz

REFCLK Multiplier Enabled at 4× Full VI 1 50 MHz

REFCLK Multiplier Enabled at 20× Full VI 1 10 MHz

Input Capacitance 25°C V 3 pF

Input Impedance 25°C V 100 MΩ

Duty Cycle 25°C V 50 %

Duty Cycle with REFCLK Multiplier Enabled 25°C V 35 65 %

Differential Input (VDD/2) ±200 mV 25°C V 1.45 1.85 V

DAC OUTPUT CHARACTERISTICS

Resolution 14 Bits

Full-Scale Output Current 5 10 20 mA

Gain Error 25°C I 8.5 0 % FS

Output Offset 25°C I 2 µA

Differential Nonlinearity 25°C V 1.6 LSB

Integral Nonlinearity 25°C V 2 LSB

Output Capacitance 25°C V 5 pF

Residual Phase Noise @ 1 kHz Offset, 40 MHz A

REFCLK Multiplier Enabled at 20× 25°C V −107 dBc/Hz

REFCLK Multiplier at 4× 25°C V −123 dBc/Hz

REFCLK Multiplier Disabled 25°C V −145 dBc/Hz

Voltage Compliance Range 25°C I −0.5 +1.0 V

Wideband SFDR

1 MHz to 20 MHz Analog Out 25°C V −75 dBc

20 MHz to 40 MHz Analog Out 25°C V −65 dBc

40 MHz to 60 MHz Analog Out 25°C V −62 dBc

60 MHz to 80 MHz Analog Out 25°C V −60 dBc

Narrowband SFDR

10 MHz Analog Out (±1 MHz) 25°C V −87 dBc

10 MHz Analog Out (±250 kHz) 25°C V −88 dBc

10 MHz Analog Out (±50 kHz) 25°C V −92 dBc

10 MHz Analog Out (±10 kHz) 25°C V −94 dBc

65 MHz Analog Out (±1 MHz) 25°C V −86 dBc

65 MHz Analog Out (±250 kHz) 25°C V −86 dBc

65 MHz Analog Out (±50 kHz) 25°C V −86 dBc

65 MHz Analog Out (±10 kHz) 25°C V −88 dBc

80 MHz Analog Out (±1 MHz) 25°C V −85 dBc

80 MHz Analog Out (±250 kHz) 25°C V −85 dBc

80 MHz Analog Out (±50 kHz) 25°C V −85 dBc

80 MHz Analog Out (±0 kHz) 25°C V −86 dBc

= 1.96 kΩ, external reference clock frequency = 10 MHz with REFCLK multiplier enabled at 20×.

SET

OUT

Rev. C| Page 5 of 40

Page 6

AD9857

Parameter Temp Test Level Min Typ Max Unit

MODULATOR CHARACTERISTICS (65 MHz A

(Input data: 2.5 MS/s, QPSK, 4× oversampled, inverse SINC

filter ON, inverse CIC ON)

I/Q Offset 25°C IV 55 65 dB

Error Vector Magnitude 25°C IV 0.4 1 %

INVERSE SINC FILTER (variation in gain from DC to 80 MHz,

inverse SINC filter ON)

SPURIOUS POWER (off channel, measured in equivalent

bandwidth), Full-Scale Output

6.4 MHz Bandwidth 25°C IV −65 dBc

3.2 MHz Bandwidth 25°C IV −67 dBc

1.6 MHz Bandwidth 25°C IV −69 dBc

0.8 MHz Bandwidth 25°C IV −69 dBc

0.4 MHz Bandwidth 25°C IV −70 dBc

0.2 MHz Bandwidth 25°C IV −72 dBc

SPURIOUS POWER (Off channel, measured in equivalent

bandwidth), Output Attenuated 18 dB

Relative to Full Scale

6.4 MHz Bandwidth 25°C IV −51 dBc

3.2 MHz Bandwidth 25°C IV −54 dBc

1.6 MHz Bandwidth 25°C IV −56 dBc

0.8 MHz Bandwidth 25°C IV −59 dBc

0.4 MHz Bandwidth 25°C IV −62 dBc

0.2 MHz Bandwidth 25°C IV −63 dBc

TIMING CHARACTERISTICS

Serial Control Bus

Maximum Frequency 25°C I 10 MHz

Minimum Clock Pulse Width Low (t

Minimum Clock Pulse Width High (t

Maximum Clock Rise/Fall Time 25°C I 1 ms

Minimum Data Setup Time (tDS) 25°C I 30 ns

Minimum Data Hold Time (tDH) 25°C I 0 ns

Maximum Data Valid Time (tDV) 25°C I 35 ns

Wake-Up Time1 25°C I 1 ms

Minimum RESET Pulse Width High (tRH) 25°C I 5 SYSCLK22Cycles

Minimum CS Setup Time

CMOS LOGIC INPUTS

Logic 1 Voltage 25°C IV 2.0 V

Logic 0 Voltage 25°C IV 0.8 V

Logic 1 Current 25°C I 5 µA

Logic 0 Current 25°C I 5 µA

Input Capacitance 25°C V 3 pF

CMOS LOGIC OUTPUTS (1 mA LOAD)

Logic 1 Voltage 25°C I 2.7 V

Logic 0 Voltage 25°C I 0.4 V

OUT

)

25°C V ±0.1 dB

) 25°C I 30 ns

PWL

) 25°C I 30 ns

PWH

25°C I 40 ns

Rev. C | Page 6 of 40

Page 7

AD9857

Parameter Temp Test Level Min Typ Max Unit

POWER SUPPLY VSCURRENT3 (all power specifications at

= 3.3 V, 25°C, REFCLK = 200 MHz)

V

DD

Full Operating Conditions 25°C I 540 615 mA

160 MHz Clock (×16) 25°C I 445 515 mA

120 MHz Clock (×12) 25°C I 345 400 mA

Burst Operation (25%) 25°C I 395 450 mA

Single-Tone Mode 25°C I 265 310 mA

Power-Down Mode 25°C I 71 80 mA

Full-Sleep Mode 25°C I 8 13.5 mA

1

Wake-up time refers to recovery from full-sleep mode. The longest time required is for the reference clock multiplier PLL to lock up (if it is being used). The wake-up

time assumes that there is no capacitor on DAC_BP, and that the recommended PLL loop filter values are used. The state of the reference clock multiplier lock can be

determined by observing the signal on the PLL_LOCK pin.

2

SYSCLK refers to the actual clock frequency used on-chip by the AD9857. If the reference clock multiplier is used to multiply the external reference frequency, the

SYSCLK frequency is the external frequency multiplied by the reference clock multiplier multiplication factor. If the reference clock multiplier is not used, the SYSCLK

frequency is the same as the external REFCLK frequency.

3

CIC = 2, INV SINC ON, FTW = 40%, PLL OFF, auto power-down between burst On, TxENABLE duty cycle = 25%.

Rev. C| Page 7 of 40

Page 8

AD9857

ABSOLUTE MAXIMUM RATINGS

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

Table 2.

Parameter Rating

Maximum Junction Temperature 150°C

V

S

Digital Input Voltage −0.7 V to +V

Digital Output Current 5 mA

Storage Temperature −65°C to +150°C

Operating Temperature −40°C to +85°C

Lead Temperature (Soldering 10 s) 300°C

θ

JA

θ

JC

4 V

S

35°C/W

16°C/W

EXPLANATION OF TEST LEVELS

Table 3.

Test Level

1 100% production tested.

2

3 Sample tested only.

4

5 Parameter is a typical value only.

6

100% production tested at 25°C and sample tested at

specific temperatures.

Parameter is guaranteed by design and

characterization testing.

Devices are 100% production tested at 25°C and

guaranteed by design and characterization testing for

industrial operating temperature range.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Rev. C | Page 8 of 40

Page 9

AD9857

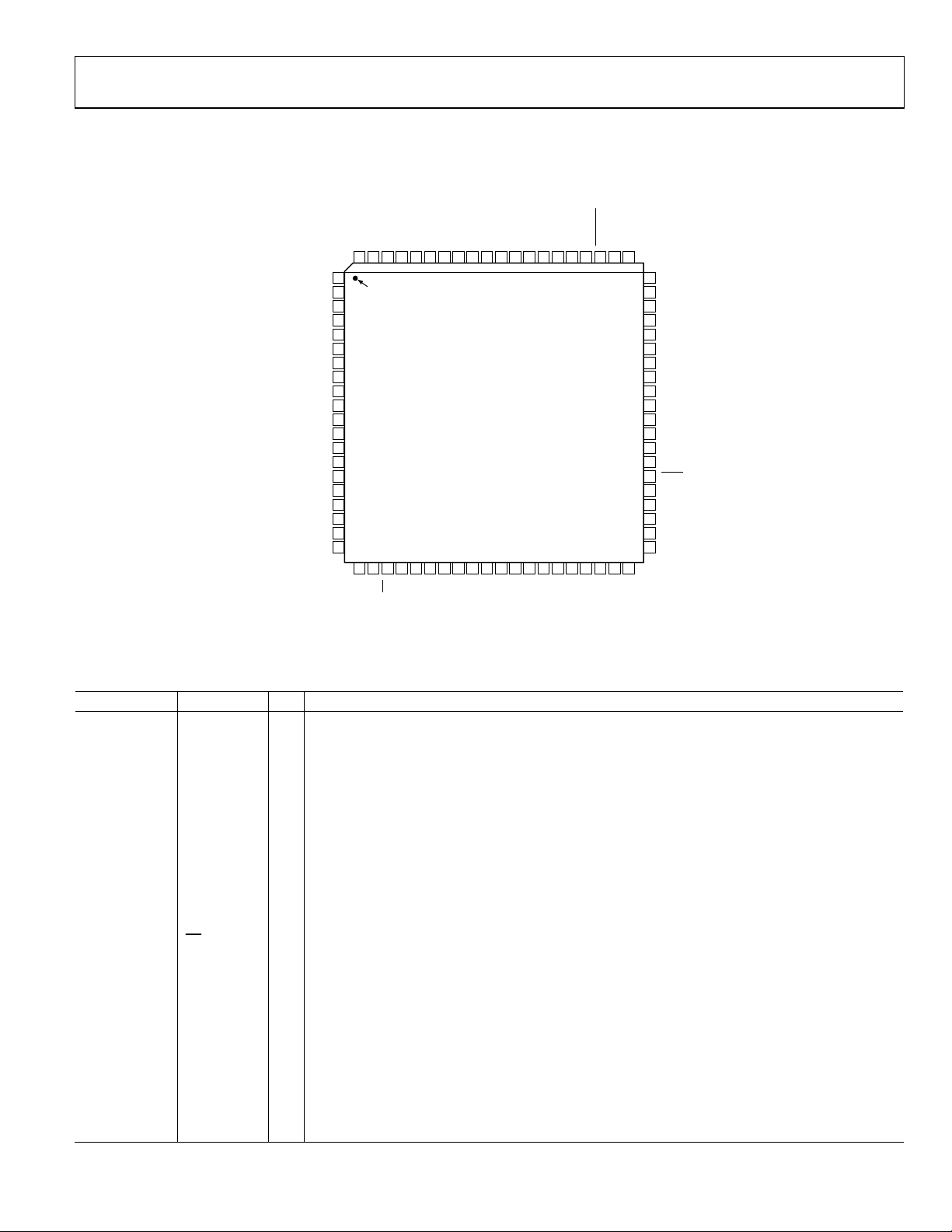

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

RESET

DPD

AGND

AVDD

REFCLK

REFCLK

AVDD

AVDD

AGND

AGND

AGND

60

DIFFCLKEN

59

AGND

58

AVDD

57

NC

56

AGND

55

PLL_FILTER

54

AVDD

53

AGND

52

NC

51

NC

50

DAC_RSET

49

DAC_BP

48

AVDD

47

AGND

46

IOUT

45

IOUT

44

AGND

43

AVDD

42

AGND

41

NC

01018-C-000

TxENABLE

PDCLK/FUD

DGND

DGND

DGND

DVDD

DVDD

DVDD

DGND

DGND

DGND

CIC_OVRFL

DVDD

DGND

PLL_LOCK

34 35 36 37 38 39 40

NC

AVDD

DVDD

DVDD

AGND

64 63 62 6167 66 65

D13

D12

D11

D10

D9

D8

D7

DVDD

DVDD

DVDD

DGND

DGND

DGND

D6

D5

D4

D3

D2

D1

D0

NC = NO CONNECT

80 79 78 77 76 71 70 69 6875 74 73 72

1

PIN 1

2

INDICATOR

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21 22 23 24 25 26 27 28 29 30 31 32 33

CS

PS1

PS0

SDIO

SCLK

SDO

SYNCIO

AD9857

TOP VIEW

(Not to Scale)

DGND

DGND

Figure 2. Pin Configuration

Table 4. Pin Function Descriptions

Pin Number Mnemonic I/O Function

20–14, 7–1

D0–D6, D7–

D13

I

14-Bit Parallel Data Bus for I and Q Data. The required numeric format is twos complement with D13

as the sign bit and D12–D0 as the magnitude bits. Alternating 14-bit words are demultiplexed onto

the I and Q data pathways (except when operating in the interpolating DAC mode, in which case

every word is routed onto the I data path). When the TxENABLE pin is asserted high, the next

accepted word is presumed to be I data, the next Q data, and so forth.

8–10, 31–33,

DVDD 3.3 V Digital Power pin(s).

73–75

11–13, 28–30,

DGND Digital Ground pin(s).

70–72, 76–78

21 PS1 I

Profile Select Pin 1. The LSB of the two profile select pins. In conjunction with PS0, selects one of four

profile configurations.

22 PS0 I

Profile Select Pin 0. The MSB of the two profile select pins. In conjunction with P1, selects one of four

profile configurations.

23

CS

I

Serial Port Chip Select pin. An active low signal that allows multiple devices to operate on a single

serial bus.

24 SCLK I Serial Port Data Clock pin. The serial data CLOCK for the serial port.

25 SDIO I/O

Serial Port Input/Output Data pin. Bidirectional serial DATA pin for the serial port. This pin can be

programmed to operate as a serial input only pin, via the control register bit 00h<7>. The default

state is bidirectional.

26 SDO O

Serial Port Output Data pin. This pin serves as the serial data output pin when the SDIO pin is

configured for serial input only mode. The default state is three-state.

27 SYNCIO I

Serial Port Synchronization pin. Synchronizes the serial port without affecting the programmable

register contents. This is an active high input that aborts the current serial communication cycle.

34, 41, 51, 52,

NC No connect.

57

Rev. C| Page 9 of 40

Page 10

AD9857

Pin Number Mnemonic I/O Function

35, 37, 38, 43,

48, 54, 58, 64

36, 39, 40, 42,

44, 47, 53, 56,

59, 61, 65

45 IOUT O DAC Output pin. Normal DAC output current (analog).

46

49 DAC_BP DAC Reference Bypass. Typically not used.

50 DAC_RSET I DAC Current Set pin. Sets DAC reference current.

55 PLL_FILTER O PLL Filter. R-C network for PLL filter.

60 DIFFCLKEN I

62 REFCLK I

63

66 DPD I

67 RESET I Hardware RESET pin. An active high input that forces the device into a predefined state.

68 PLL_LOCK O PLL Lock pin. Active high output signifying, in real time, when PLL is in lock state.

69 CIC_OVRFL O

79 PDCLK/FUD I/O

80 TxENABLE I

AVDD 3.3 V Analog Power pin(s).

AGND Analog Ground pin(s).

IOUT

REFCLK

O DAC Complementary Output pin. Complementary DAC output current (analog).

Clock Mode Select pin. A logic high on this pin selects DIFFERENTIAL REFCLK input mode. A logic

low selects the SINGLE-ENDED REFCLK input mode.

Reference Clock pin. In single-ended clock mode, this pin is the Reference Clock input. In differential

clock mode, this pin is the positive clock input.

I Inverted Reference Clock pin. In differential clock mode, this pin is the negative clock input.

Digital Power-Down pin. Assertion of this pin shuts down the digital sections of the device to

conserve power. However, if selected, the PLL remains operational.

CIC Overflow pin. Activity on this pin indicates that the CIC Filters are in “overflow” state. This pin is

typically low unless a CIC overflow occurs.

Parallel Data Clock/Frequency Update pin. When not in single-tone mode, this pin is an output

signal that should be used as a clock to synchronize the acceptance of the 14-bit parallel

data-words on Pins D13–D0. In single-tone mode, this pin is an input signal that synchronizes the

transfer of a changed frequency tuning word (FTW) in the active profile (PSx) to the accumulator

(FUD = frequency update signal). When profiles are changed by means of the PS–PS1 pins, the FUD

does not have to be asserted to make the FTW active.

When TxENABLE is asserted, the device processes the data through the I and Q data pathways;

otherwise 0s are internally substituted for the I and Q data entering the signal path. The first data

word accepted when the TxENABLE is asserted high is treated as I data, the next data word is Q data,

and so forth.

Rev. C | Page 10 of 40

Page 11

AD9857

TYPICAL PERFORMANCE CHARACTERISTICS

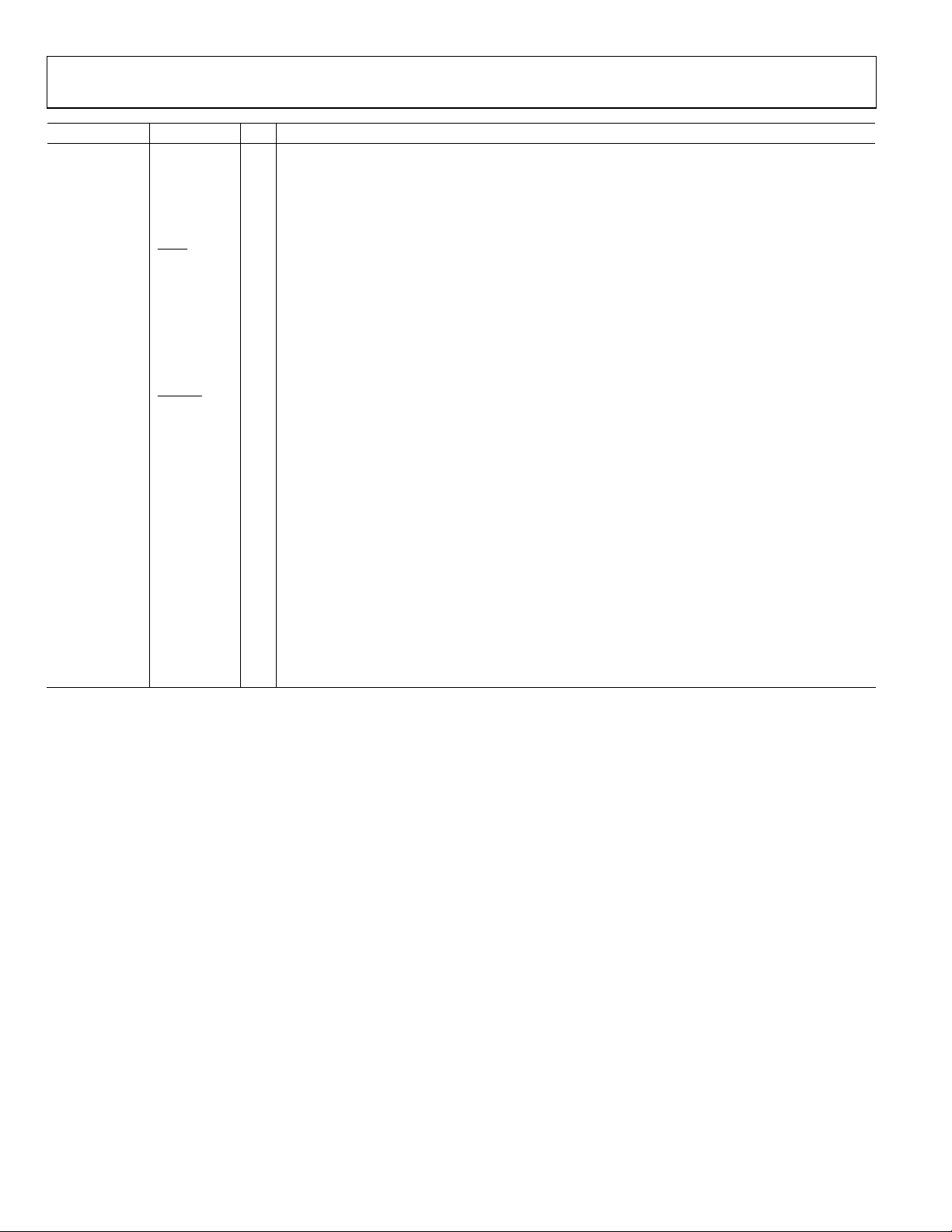

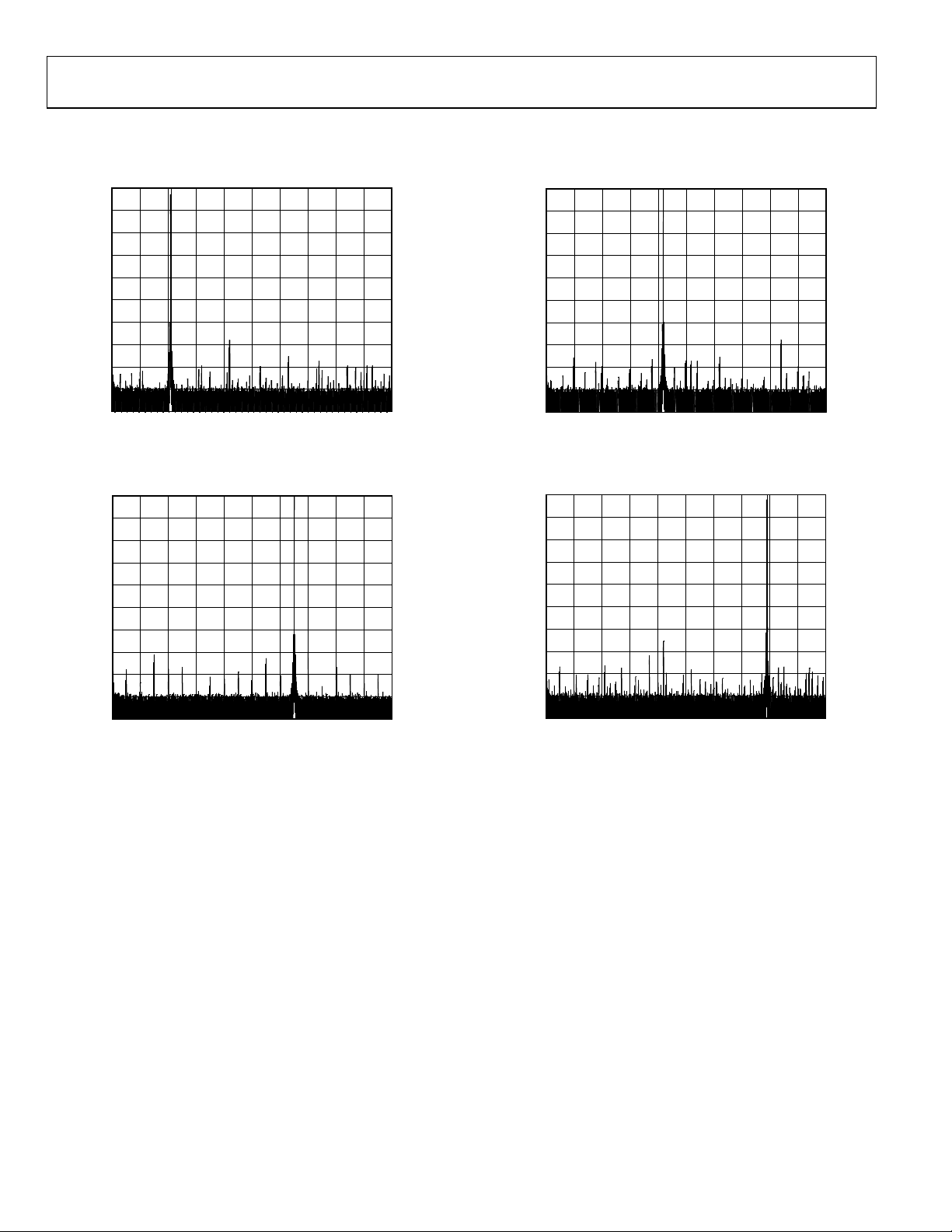

MODULATED OUTPUT SPECTRAL PLOTS

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

START 0Hz 5MHz/ STOP 50MHz

Figure 3. QPSK at 42 MHz and 2.56 MS/s; 10.24 MHz External Clock

with REFCLK Multiplier = 12, CIC Interpolation Rate = 3,

4× Oversampled Data

0

–8

–16

–24

–32

–40

dB

–48

–56

–64

–72

–80

START 0Hz 4MHz/ STOP 40MHz

Figure 4. 64-QAM at 28 MHz and 6 MS/s; 36 MHz External Clock

with REFCLK Multiplier = 4, CIC Interpolation Rate = 2,

3× Oversampled Data

01018-C-003

01018-C-004

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

START 0Hz 8MHz/ STOP 80MHz

01018-C-005

Figure 5. 16-QAM at 65 MHz and 1.28 MS/s; 10.24 MHz External Clock

with REFCLK Multiplier = 18, CIC Interpolation Rate = 9,

4× Oversampled Data

0

–8

–16

–24

–32

–40

dB

–48

–56

–64

–72

–80

START 0HzSTART 0Hz 5MHz/ STOP 50MHz

Figure 6. 256-QAM at 38 MHz and 6 MS/s; 48 MHz External Clock

with REFCLK Multiplier = 4, CIC Interpolation Rate = 2,

4× Oversampled Data

01018-C-006

Rev. C| Page 11 of 40

Page 12

AD9857

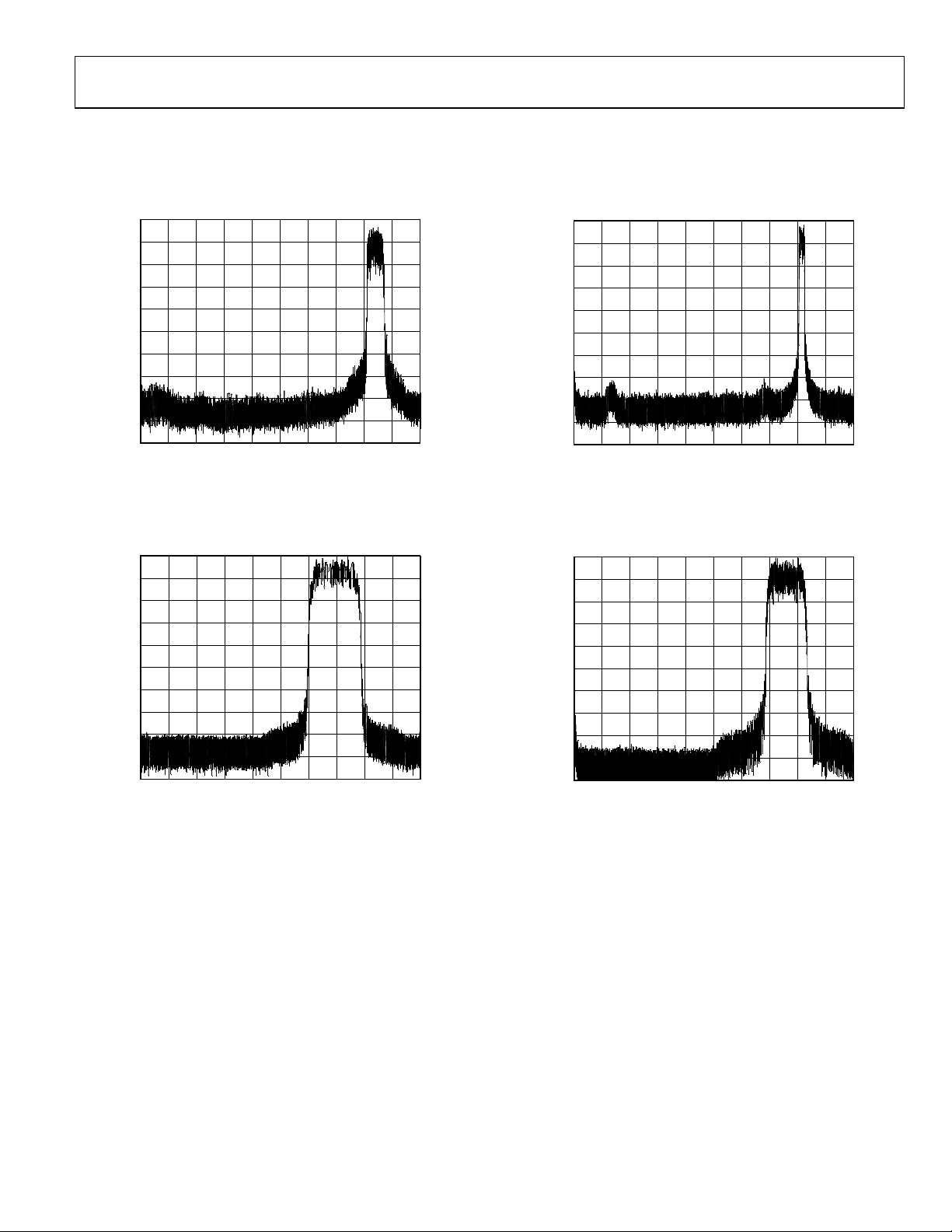

SINGLE-TONE OUTPUT SPECTRAL PLOTS

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

START 0Hz 10MHz/ STOP 100MHz

Figure 7. 21 MHz Single-Tone Output

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

START 0Hz

Figure 8. 65 MHz Single-Tone Output

10MHz/ STOP 100MHz

01018-C-007

01018-C-008

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

START 0Hz 10MHz/ STOP 100MHz

Figure 9. 42 MHz Single-Tone Output

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

START 0Hz 10MHz/ STOP 100MHz

Figure 10. 79 MHz Single-Tone Output

01018-C-009

01018-C-010

Rev. C | Page 12 of 40

Page 13

AD9857

NARROW-BAND SFDR SPECTRAL PLOTS

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

CENTER 70.1MHz

10kHz/ SPAN 100kHz

Figure 11. 70.1 MHz Narrow-Band SFDR, 10 MHz External Clock

with REFCLK Multiplier = 20

01018-C-011

0

–10

–20

–30

–40

–50

dB

–60

–70

–80

–90

–100

CENTER 70.1MHz

10kHz/ SPAN 100kHz

Figure 12. 70.1 MHz Narrow-Band SFDR, 200 MHz External Clock

with REFCLK Multiplier Disabled

01018-C-012

Rev. C| Page 13 of 40

Page 14

AD9857

2

2

2

OUTPUT CONSTELLATIONS

1

1

CONST

200m/DIV

–1

–1.3071895838 1.30718958378

Figure 13. QPSK, 65 MHz, 2.56 MS/s

1

CONST

00m/DIV

–1

–1.3071895838 1.30718958378

Figure 14. 64-QAM, 42 MHz, 6 MS/s

1

01018-C-013

01018-C-014

CONST

200m/DIV

–1

–1.3071895838 1.30718958378

Figure 16. 16-QAM, 65 MHz, 2.56 MS/s

1

CONST

00m/DIV

–1

–1.3071895838 1.30718958378

Figure 17. 256-QAM, 42 MHz, 6 MS/s

01018-C-016

01018-C-017

CONST

00m/DIV

–1

–1.3071895838 1.30718958378

01018-C-015

Figure 15. GMSK Modulation, 13 MS/s

Rev. C | Page 14 of 40

Page 15

AD9857

MODES OF OPERATION

The AD9857 has three operating modes:

• Quadrature modulation mode (default)

• Single-tone mode

• Interpolating DAC mode

Mode selection is accomplished by programming a control

register via the serial port. The inverse SINC filter and output

scale multiplier are available in all three modes.

QUADRATURE MODULATION MODE

In quadrature modulation mode, both the I and Q data paths

are active. A block diagram of the AD9857 operating in the

quadrature modulation mode is shown in Figure 18.

In quadrature modulation mode, the PDCLK/FUD pin is an

output and functions as the parallel data clock (PDCLK), which

serves to synchronize the input of data to the AD9857. In this

mode, the input data must be synchronized with the rising edge

of PDCLK. The PDCLK operates at twice the rate of either the I

or Q data path. This is due to the fact that the I and Q data must

be presented to the parallel port as two 14-bit words

multiplexed in time. One I word and one Q word together

comprise one internal sample. Each sample is propagated along

the internal data pathway in parallel fashion.

The DDS core provides a quadrature (sin and cos) local

oscillator signal to the quadrature modulator, where the I and Q

data are multiplied by the respective phase of the carrier and

summed together, to produce a quadrature-modulated data

stream.

All of this occurs in the digital domain, and only then is the

digital data stream applied to the 14-bit DAC to become the

quadrature-modulated analog output signal.

PARALLEL

DATA IN

(14-BIT)

DATA CLOCK

PDCLK/

FUD

I

14

14

DEMUX

Q

TxENABLE

INVERSE

CIC FILTER

INV

CIC

INVERSE CIC CLOCK

INVERSE CIC CONTROL

FIXED

INTER-

POLATOR

MUX

RESET CIC

OVERFLOW

PROGRAMMABLE

INTERPOLATOR

(4 )

HALF-BAND CLOCKS

CONTROL REGISTERS

(2

INTERP CONTROL

SERIAL

PORT

CIC

- 63 )

Figure 18. Quadrature Modulation Mode

INTERP CLOCK

POWER-

DOWN

LOGIC

DIGITAL

POWER-

DOWN

QUADRATURE

MODULATOR

MUX

SIN

COS

DDS

CORE

TUNING

32

WORD

TIMING AND CONTROL

PROFILE

SELECT

LOGIC

SYNCH

PS0PS1

MUX

CLOCK

SYSCLK

INVERSE

SINC

FILTER

INVERSE

SINC CLOCK

MUX

MULTIPLIER

CLOCK

(4

PLL

LOCK

– 20 )

AD9857

14

MUX

8

OUTPUT

SCALE

VALUE

14-BIT

DAC

DAC CLOCK

MODE

CONTROL

CLOCK

INPUT

MODE

DAC_RSET

IOUT

IOUT

REFCLK

REFCLK

01018-C-018

Rev. C| Page 15 of 40

Page 16

AD9857

SINGLE-TONE MODE

A block diagram of the AD9857 operating in the single-tone

mode is shown in Figure 19. In the single-tone mode, both the

I and Q data paths are disabled from the 14-bit parallel data

port up to and including the modulator. The PDCLK/ FUD pin

is an input and functions as a frequency update (FUD) control

signal. This is necessary because the frequency tuning word is

programmed via the asynchronous serial port. The FUD signal

causes the new frequency tuning word to become active.

In single-tone mode, the cosine portion of the DDS serves as

the signal source. The output signal consists of a single

frequency as determined by the tuning word stored in the

appropriate control register, per each profile.

In the single-tone mode, no 14-bit parallel data is applied to the

AD9857. The internal DDS core is used to produce a single

frequency signal according to the tuning word. The single-tone

signal then moves toward the output, where the inverse SINC

filter and the output scaling can be applied. Finally, the digital

single-tone signal is converted to the analog domain by the

14-bit DAC.

AD9857

PDCLK/

FUD

CONTROL REGISTERS

RESET SERIAL

PORT

DDS

CORE

TUNING

WORD

TIMING AND CONTROL

POWER-

DOWN

LOGIC

DIGITAL

POWER-

DOWN

PROFILE

SELECT

LOGIC

PS0PS1

Figure 19. Single-Tone Mode

COS

DAC_RSET

14

CLOCK

(4

PLL

LOCK

MUX

OUTPUT

– 20 )

INVERSE

SINC

FILTER

INVERSE

SYSCLK

SINC CLOCK

MUX

MULTIPLIER

CLOCK

32

SYNCH

8

SCALE

VALUE

14-BIT

DAC

DAC CLOCK

MODE

CONTROL

CLOCK

INPUT

MODE

IOUT

IOUT

REFCLK

REFCLK

01018-C-001

Rev. C | Page 16 of 40

Page 17

AD9857

INTERPOLATING DAC MODE

A block diagram of the AD9857 operating in the interpolating

DAC mode is shown in Figure 20. In this mode, the DDS and

modulator are both disabled and only the I data path is active.

The Q data path is disabled from the 14-bit parallel data port up

to and including the modulator.

As in the quadrature modulation mode, the PDCLK pin is an

output and functions as a clock which serves to synchronize the

input of data to the AD9857. Unlike the quadrature modulation

mode, however, the PDCLK operates at the rate of the I data

path. This is because only I data is being presented to the

parallel port as opposed to the interleaved I/Q format of the

quadrature modulation mode.

In the Interpolating DAC mode, the baseband data supplied at

the parallel port remains at baseband at the output; that is, no

modulation takes place. However, a sample rate conversion

takes place based on the programmed interpolation rate. The

interpolation hardware performs the necessary signal

processing required to eliminate the aliased images at baseband

that would otherwise result from a sample rate conversion. The

interpolating DAC function is effectively an oversampling

operation with the original input spectrum intact but sampled

at a higher rate.

PARALLEL

DATA IN

(14-BIT)

I

14

DEMUX

DATA CLOCK

PDCLK/

FUD

INVERSE

CIC FILTER

INV

CIC

INVERSE CIC CLOCK

TxENABLE

INVERSE CIC CONTROL

FIXED

INTER-

POLATOR

(4 )

MUX

HALF-BAND CLOCKS

RESET CIC

OVERFLOW

PROGRAMMABLE

INTERPOLATOR

CIC

(2

- 63 )

INTERP CLOCK

INTERP CONTROL

CONTROL REGISTERS

POWER-

SERIAL

PORT

DIGITAL

POWER-

MUX

TIMING AND CONTROL

PROFILE

DOWN

SELECT

LOGIC

DOWN

LOGIC

AD9857

DAC_RSET

14

INVERSE

SINC

FILTER

INVERSE

SINC CLOCK

SYNCH

SYSCLK

MUX

PS0PS1

MUX

CLOCK

MULTIPLIER

(4

– 20 )

PLL

LOCK

OUTPUT

SCALE

VALUE

14-BIT

DAC

8

DAC CLOCK

MODE

CONTROL

CLOCK

INPUT

MODE

IOUT

IOUT

REFCLK

REFCLK

01018-C-001

Figure 20. Interpolating DAC Mode

Rev. C| Page 17 of 40

Page 18

AD9857

SIGNAL PROCESSING PATH

To better understand the operation of the AD9857 it is helpful

to follow the signal path from input, through the device, to the

output, examining the function of each block (refer to Figure 1).

The input to the AD9857 is a 14-bit parallel data path. This

assumes that the user is supplying the data as interleaved I and

Q values. Any encoding, interpolation, and pulse shaping of the

data stream should occur before the data is presented to the

AD9857 for upsampling.

The AD9857 demultiplexes the interleaved I and Q data into

two separate data paths inside the part. This means that the

input sample rate (f

presented to the AD9857, must be 2× the internal I/Q Sample

Rate (f

words, f

), the rate at which the I/Q pairs are processed. In other

IQ

= 2 × fIQ.

DATA

From the input demultiplexer to the quadrature modulator, the

data path of the AD9857 is a dual I/Q path.

All timing within the AD9857 is provided by the internal

system clock (SYSCLK) signal. The externally provided

reference clock signal may be used as is (1×), or multiplied by

the internal clock multiplier (4×−20×) to generate the SYSCLK.

All other internal clocks and timing are derived from the

SYSCLK.

INPUT DATA ASSEMBLER

In the quadrature modulation or interpolating DAC modes, the

device accepts 14-bit, twos complement data at its parallel data

port. The timing of the data supplied to the parallel port may be

easily facilitated with the PDCLK/FUD pin of the AD9857,

which is an output in the quadrature modulation mode and the

interpolating DAC mode. In the single-tone mode, the same pin

becomes an input to the device and serves as a frequency

update (FUD) strobe.

Frequency control words are programmed into the AD9857 via

the serial port (see the Control Register description). Because

the serial port is an asynchronous interface, when programming

new frequency tuning words into the on-chip profile registers,

the AD9857’s internal frequency synthesizer must be

synchronized with external events. The purpose of the FUD

input pin is to synchronize the start of the frequency

synthesizer to the external timing requirements of the user. The

rising edge of the FUD signal causes the frequency tuning word

of the selected profile (see the Profile section) to be transferred

), the rate at which 14-bit words are

DATA

to the accumulator of the DDS, thus starting the frequency

synthesis process.

After loading the frequency tuning word to a profile, a FUD

signal is not needed when switching between profiles using the

two profile select pins (PS0, PS1). When switching between

profiles, the frequency tuning word in the profile register

becomes effective.

In the quadrature modulation mode, the PDCLK rate is twice

the rate of the I (or Q) data rate. The AD9857 expects

interleaved I and Q data words at the parallel port with one

word per PDCLK rising edge. One I word and one Q word

together comprise one internal sample. Each sample is

propagated along the internal data pathway in parallel.

In the interpolating DAC mode, however, the PDCLK rate is the

same as the I data rate because the Q data path is inactive. In

this mode, each PDCLK rising edge latches a data word into the

I data path.

The PDCLK is provided as a continuous clock (i.e., always

active). However, the assertion of PDCLK may be optionally

qualified internally by the PLL lock indicator if the user elects

to set the PLL lock control bit in the appropriate control register.

Data supplied by the user to the 14-bit parallel port is latched

into the device coincident with the rising edge of the PDCLK.

In the quadrature modulation mode, the rising edge of the

TxENABLE signal is used to synchronize the device. While

TxENABLE is in the Logic 0 state, the device ignores the 14-bit

data applied to the parallel port and allows the internal data

path to be flushed by forcing 0s down the I and Q data pathway.

On the rising edge of TxENABLE, the device is ready for the

first I word. The first I word is latched into the device

coincident with the rising edge of PDCLK. The next rising edge

of PDCLK latches in a Q word, etc., until TxENABLE is set to a

Logic 0 state by the user.

When in the quadrature modulation mode, it is important that

the user ensure that an even number of PDCLK intervals are

observed during any given TxENABLE period. This is because

the device must capture both an I and a Q value before the data

can be processed along the internal data pathway.

The timing relationship between TxENABLE, PDCLK, and

DATA is shown in Figure 21 and Figure 22.

Rev. C | Page 18 of 40

Page 19

AD9857

TxENABLE

PDCLK

D<13:0>

t

DS

t

DS

I

0

t

DH

Q

0

Figure 21. 14-Bit Parallel Port Timing Diagram—Quadrature Modulation Mode

TxENABLE

PDCLK

D<13:0>

t

DS

t

DS

I

0

t

DH

I

1

Figure 22. 14-Bit Parallel Port Timing Diagram—Interpolating DAC Mode

Table 5. Parallel Data Bus Timing

Symbol Definition Minimum

tDS Data Setup Time 4 ns

tDH Data Hold Time 0 ns

INVERSE CIC FILTER

The inverse cascaded integrator comb (CIC) filter precompensates the data to offset the slight attenuation gradient imposed

by the CIC filter. See the Programmable (2× to 63×) CIC

Interpolating Filter section. The I (or Q) data entering the first

half-band filter occupies a maximum bandwidth of one-half

as defined by Nyquist (where f

f

DATA

input of the first half-band filter). This is shown graphically in

Figure 23.

INBAND

ATTENUATION

GRADIENT

is the sample rate at the

DATA

t

DH

I

1

I

2

Q

1

I

3

I

I

K– 1

N

t

DH

Q

N

01018-C-021

I

K

01018-C-022

If the CIC filter is employed, the inband attenuation gradient

could pose a problem for those applications requiring an

extremely flat pass band. For example, if the spectrum of the

data as supplied to the AD9857 I or Q path occupies a

significant portion of the one-half f

region, the higher

DATA

frequencies of the data spectrum receives slightly more

attenuation than the lower frequencies (the worst-case overall

droop from f = 0 to one-half f

is < 0.8 dB). This may not be

DATA

acceptable in certain applications. The inverse CIC filter has a

response characteristic that is the inverse of the CIC filter

response over the one-half f

DATA

region.

The net result is that the product of the two responses yields in

an extremely flat pass band, thereby eliminating the inband

attenuation gradient introduced by the CIC filter. The price

to be paid is a slight attenuation of the input signal of approximately 0.5 dB for a CIC interpolation rate of 2 and 0.8 dB for

interpolation rates of 3 to 63.

f

DATA

CIC FILTER RESPONSE

f

DATA

/2

Figure 23. CIC Filter Response

The inverse CIC filter is implemented as a digital FIR filter

with a response characteristic that is the inverse of the

programmable CIC interpolator. The product of the two

responses yields a nearly flat response over the baseband

Nyquist bandwidth. The inverse CIC filter provides frequency

compensation that yields a response flatness of ±0.05 dB over

the baseband Nyquist bandwidth, allowing the AD9857 to

provide excellent SNR over its performance range.

f

4f

DATA

01018-C-023

The inverse CIC filter can be bypassed by setting Control

Register 06h<0>. It is automatically bypassed if the CIC

interpolation rate is 1×. Whenever this stage is bypassed, power

to the stage is shutoff, thereby reducing power dissipation.

Rev. C| Page 19 of 40

Page 20

AD9857

Fixed Interpolator (4×)

This block is a fixed 4× interpolator. It is implemented as two

half-band filters. The output of this stage is the original data

upsampled by 4×.

Before presenting a detailed description of the half-band filters,

recall that in the case of the quadrature modulation mode the

input data stream is representative of complex data; i.e., two

input samples are required to produce one I/Q data pair. The

I/Q sample rate is one-half the input data rate. The I/Q sample

rate (the rate at which I or Q samples are presented to the input

of the first half-band filter) is referred to as f

AD9857 is a quadrature modulator, f

IQ

. Because the

IQ

represents the baseband

of the internal I/Q sample pairs. It should be emphasized here

is not the same as the baseband of the user’s symbol rate

that f

IQ

data, which must be upsampled before presentation to the

AD9857 (as explained later). The I/Q sample rate (f

limit on the minimum bandwidth necessary to transmit the f

) puts a

IQ

IQ

spectrum. This is the familiar Nyquist limit and is equal to one-

, hereafter referred to as f

half f

IQ

NYQ

.

Together, the two half-band filters provide a factor-of-four

increase in the sampling rate (4 × f

or 8 × f

IQ

NYQ

). Their

combined insertion loss is 0.01 dB, so virtually no loss of signal

level occurs through the two half-band filters. Both half-band

filters are linear phase filters, so that virtually no phase

distortion is introduced within the pass band of the filters. This

is an important feature as phase distortion is generally

intolerable in a data transmission system.

The half-band filters are designed so that their composite

performance yields a usable pass band of 80% of the baseband

Nyquist frequency (0.2 on the frequency scale below). Within

that pass band, the ripple does not exceed 0.002 dB. The stop

band extends from 120% to 400% of the baseband Nyquist

frequency (0.3 to 1.0 on the frequency scale) and offers a

minimum of 85 dB attenuation. Figure 24 and Figure 25 show

the composite response of the two half-band filters together.

10

0

0.2

–10

–20

–30

–40

–50

–60

–70

–80

SAMPLE RATE

–90

–100

–110

–120

–130

–140

0 0.2 0.4

Figure 24. Half-Band 1 and 2 Frequency Response; Frequency

0.3

0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0

FREQUENCY

Relative to HB1 Output Sample Rate

–85

01018-C-024

0.010

0.008

0.006

0.004

0.002

0

GAIN (dB)

–0.002

–0.004

–0.006

–0.008

–0.010

0

Figure 25. Combined Half-Band 1 and 2 Pass Band Detail;

The usable bandwidth of the filter chain puts a limit on the

maximum data rate that can be propagated through the

0.05 0.10 0.15 0.20 0.25

RELATIVE FREQUENCY (HB1 OUTPUT SAMPLE RATE = 1)

Frequency Relative to HB1 Output Sample Rate

01018-C-025

AD9857. A look at the pass band detail of the half-band filter

response (Figure 25) indicates that in order to maintain an

amplitude error of no more than 1 dB, signals are restricted to

having a bandwidth of no more than about 90% of f

. Thus, to

NYQ

keep the bandwidth of the data in the flat portion of the filter

pass band, the user must oversample the baseband data by at

least a factor of two prior to presenting it to the AD9857. Note

that without oversampling, the Nyquist bandwidth of the

baseband data corresponds to the f

. Because of this, the

NYQ

upper end of the data bandwidth suffers 6 dB or more of

attenuation due to the frequency response of the half-band

filters. Furthermore, if the baseband data applied to the AD9857

has been pulse shaped, there is an additional concern.

Typically, pulse shaping is applied to the baseband data via a

filter having a raised cosine response. In such cases, an α value is

used to modify the bandwidth of the data where the value of α

is such that ≤ α ≤ 1. A value of 0 causes the data bandwidth to

correspond to the Nyquist bandwidth. A value of 1 causes the

data bandwidth to be extended to twice the Nyquist bandwidth.

Thus, with 2× oversampling of the baseband data and α = 1, the

Nyquist bandwidth of the data corresponds with the I/Q

Nyquist bandwidth. As stated earlier, this results in problems

near the upper edge of the data bandwidth due to the roll-off

attenuation of the half-band filters. Figure 26 illustrates the

relationship between α and the bandwidth of raised cosine

shaped pulses. The problem area is indicated by the shading in

the tail of the pulse with α = 1 which extends into the roll-off

region of the half-band filter.

The effect of raised cosine filtering on baseband pulse

bandwidth, and the relationship to the half-band filter response

are shown in Figure 26.

Rev. C | Page 20 of 40

Page 21

AD9857

()(

ω×+ω×

()(

ω×−ω×

A)

The transfer function of the CIC interpolating filter is

BANDWIDTH

OF I OR Q

DATA

f

NYQ

B)

f

NYQ

C)

NYQ

1 SAMPLE RATE

(@1 ) f

(@1 ) f

(@1 )

IQ

= 0

= 0.5

= 1

(@2 )

NYQ

HALF-BAND FILTER RESPONSE

f

(@2 )f

NYQ

Figure 26. Effect of Alpha

f

: DATA VECTOR RATE

IQ

AT INPUT TO AD9857

2× OVERSAMPLE RATE

f

IQ

2 OVERSAMPLE RATE

f

IQ

f

f

f

01018-C-026

PROGRAMMABLE (2× TO 63×) CIC INTERPOLATING FILTER

The programmable interpolator is implemented as a CIC filter.

It is programmable by a 6-bit control word, giving a range of

2× to 63× interpolation. This interpolator has a low-pass

frequency characteristic that is compensated by the inverse CIC

filter.

The programmable interpolator can be bypassed to yield a 1×

(no interpolation) configuration by setting the bit in the

appropriate control register, per each profile. Whenever the

programmable interpolator is bypassed (1× CIC rate), power to

the stage is removed. If the programmable interpolator is

bypassed, the inverse CIC filter (see above) is automatically

bypassed, because its compensation is not needed in this case.

The output of the programmable interpolator is the data from

the 4× interpolator upsampled by an additional 2× to 63×,

according to the rate chosen by the user. This results in the

input data being upsampled by a factor of 8× to 252×.

1

−

R

⎛

)(

=

efH

⎜

∑

0

=

k

⎝

5

⎞

)2(

π−

fkj

(1)

⎟

⎠

where R is the interpolation rate, and f is the frequency relative

to SYSCLK.

QUADRATURE MODULATOR

The digital quadrature modulator stage is used to frequency

shift the baseband spectrum of the incoming data stream up to

the desired carrier frequency (this process is known as

upconversion).

At this point the incoming data has been converted from an

incoming sampling rate of f

to an I/Q sampling rate equal to

IN

SYSCLK. The purpose of the upsampling process is to make the

data sampling rate equal to the sampling rate of the carrier

signal.

The carrier frequency is controlled numerically by a Direct

Digital Synthesizer (DDS). The DDS uses the internal reference

clock (SYSCLK) to generate the desired carrier frequency with a

high degree of precision. The carrier is applied to the I and Q

multipliers in quadrature fashion (90° phase offset) and

summed to yield a data stream that represents the quadrature

modulated carrier.

The modulation is done digitally which eliminates the phase

and gain imbalance and crosstalk issues typically associated

with analog modulators. Note that the modulated “signal” is

actually a number stream sampled at the rate of SYSCLK, the

same rate at which the output D/A converter is clocked.

The quadrature modulator operation is also controlled by

spectral invert bits in each of the four profiles. The quadrature

modulation takes the form:

)

sincos QI

when the spectral invert bit is set to a Logic 1.

)

sincos QI

when the spectral invert bit is set to a Logic 0.

DDS CORE

The direct digital synthesizer (DDS) block generates the sin/cos

carrier reference signals that digitally modulate the I/Q data

paths. The DDS frequency is tuned via the serial control port

with a 32-bit tuning word (per profile). This allows the

AD9857’s output carrier frequency to be very precisely tuned

while still providing output frequency agility.

Rev. C| Page 21 of 40

Page 22

AD9857

=

The equation relating output frequency (f

digital modulator to the frequency tuning word (FTWORD)

and the system clock (SYSCLK) is

) of the AD9857

OUT

Because the AD9857 defaults to the Modulation mode, the

default value for the multiplier is B5h (which corresponds

2

).

to √

32

(2)

)

2/SYSCLKFTWORDf

31

−1).

= 41 MHz and

OUT

where f

(

OUT

and SYSCLK frequencies are in Hz and FTWORD is

OUT

×=

a decimal number from 0 to 2,147,483,647 (2

For example, find the FTWORD for f

SYSCLK = 122.88 MHz

= 41 MHz and SYSCLK = 122.88 MHz, then

If f

OUT

hexFTWORD AAAAB556= (3)

Loading 556AAAABh into Control Bus Registers 08h–0Bh

(for Profile 1) programs the AD9857 for f

= 41 MHz, given a

OUT

SYSCLK frequency of 122.88 MHz.

INVERSE SINC FILTER

The sampled carrier data stream is the input to the digital-toanalog converter (DAC) integrated onto the AD9857. The

DAC output spectrum is shaped by the characteristic sin(x)/x

(or SINC) envelope, due to the intrinsic zero-order hold effect

associated with DAC-generated signals. Because the shape of

the SINC envelope is well known, it can be compensated for.

This envelope restoration function is provided by the optional

inverse SINC filter preceding the DAC. This function is

implemented as an FIR filter, which has a transfer function that

is the exact inverse of the SINC response. When the inverse

SINC filter is selected, it modifies the incoming data stream so

that the desired carrier envelope, which would otherwise be

shaped by the SINC envelope, is restored. However, this

correction is only complete for carrier frequencies up to

approximately 45% of SYSCLK.

Programming the output scale multiplier to unity gain (80h)

bypasses the stage, reducing power dissipation.

14-BIT D/A CONVERTER

A 14-bit digital-to-analog converter (DAC) is used to convert

the digitally processed waveform into an analog signal. The

worst-case spurious signals due to the DAC are the harmonics

of the fundamental signal and their aliases (please see the

Analog Devices DDS Technical Tutorial, accessible from the

DDS Technical Library at

explanation of aliases). The wideband 14-bit DAC in the

AD9857 maintains spurious-free dynamic range (SFDR)

performance of −60 dBc up to A

= 65 MHz.

to A

OUT

The conversion process produces aliased components of the

fundamental signal at n × SYSCLK ± FCARRIER (n = 1, 2, 3).

These are typically filtered with an external RLC filter at the

DAC output. It is important for this analog filter to have a

sufficiently flat gain and linear phase response across the

bandwidth of interest to avoid modulation impairments.

The AD9857 provides true and complemented current outputs

on A

OUT

and A

, respectively. The full-scale output current is

OUT

set by the RSET resistor at DAC_RSET. The value of RSET for a

particular IOUT is determined using the following equation:

For example, if a full-scale output current of 20 mA is desired,

then RSET = (39.93/0.02), or approximately 2 kΩ. Every

doubling of the RSET value halves the output current.

www.analog.com/dds for a detailed

= 42 MHz and −55 dBc up

OUT

(4)

IOUTRSET /93.39

Note also that the inverse SINC filter introduces about a 3.5 dB

loss at low frequencies as compared to the gain with the inverse

SINC filter turned off. This is done to flatten the overall gain

from dc to 45% of SYSCLK.

The full-scale output current range of the AD9857 is 5 mA−20

mA. Full-scale output currents outside of this range degrade

SFDR performance. SFDR is also slightly affected by output

matching; the two outputs should be terminated equally for best

SFDR performance.

The inverse SINC filter can be bypassed if it is not needed. If the

inverse SINC filter is bypassed, its clock is stopped, thus

reducing the power dissipation of the part.

The output load should be located as close as possible to the

AD9857 package to minimize stray capacitance and inductance.

The load may be a simple resistor to ground, an op amp

OUTPUT SCALE MULTIPLIER

An 8-bit multiplier (output scale value in the block diagram)

preceding the DAC provides the user with a means of adjusting

the final output level. The multiplier value is programmed via

the appropriate control registers, per each profile. The LSB

weight is 2

or nearly 2×. Because the quadrature modulator has an intrinsic

loss of 3 dB (1/√

2

) restores the data to the full-scale range of the DAC when

√

the device is operating in the quadrature modulation mode.

–7

, which yields a multiplier range of 0 to 1.9921875,

2

), programming the multiplier for a value of

Rev. C | Page 22 of 40

current-to- voltage converter, or a transformer-coupled circuit.

Driving an LC filter without a transformer requires that the

filter be doubly terminated for best performance. Therefore, the

filter input and output should both be resistively terminated

with the appropriate values. The parallel combination of the

two terminations determines the load that the AD9857 sees

for signals within the filter pass band. For example, a

50 Ω terminated input/ output low-pass filter looks like a

25 Ω load to the AD9857.

Page 23

AD9857

The output compliance voltage of the AD9857 is −0.5 V to

+1.0 V. Any signal developed at the DAC output should not

exceed 1.0 V, otherwise, signal distortion results. Furthermore,

the signal may extend below ground as much as 0.5 V without

damage or signal distortion. The use of a transformer with a

grounded center tap for common-mode rejection results in

signals at the AD9857 DAC output pins that are symmetrical

about ground.

As previously mentioned, by differentially combining the two

signals, the user can provide some degree of common-mode

signal rejection. A differential combiner might consist of a

transformer or an op amp. The object is to combine or amplify

only the difference between two signals and to reject any

common, usually undesirable, characteristic, such as 60 Hz

hum or clock feed-through that is equally present on both input

signals. The AD9857 true and complement outputs can be

differentially combined using a broadband 1:1 transformer with

a grounded, center-tapped primary to perform differential

combining of the two DAC outputs.

REFERENCE CLOCK MULTIPLIER

It is often difficult to provide a high quality oscillator with an

output in the frequency range of 100 MHz – 200 MHz. The

AD9857 allows the use of a lower-frequency oscillator that can

be multiplied to a higher frequency by the on-board reference

clock multiplier, implemented with a phase locked loop

architecture. See the Ease of Use Features section for a more

thorough discussion of the reference clock multiplier feature.

Rev. C| Page 23 of 40

Page 24

AD9857

INPUT DATA PROGRAMMING

CONTROL INTERFACE—SERIAL I/O

The AD9857 serial port is a flexible, synchronous, serial

communications port allowing easy interface to many industrystandard microcontrollers and microprocessors. The serial I/O

is compatible with most synchronous transfer formats,

including both the Motorola 6905/11 SPI and Intel 8051 SSR

protocols.

The interface allows read/write access to all registers that

configure the AD9857. Single or multiple byte transfers are

supported as well as MSB first or LSB first transfer formats. The

AD9857’s serial interface port can be configured as a single pin

I/O (SDIO) or two unidirectional pins for in/out (SDIO/SDO).

GENERAL OPERATION OF THE SERIAL INTERFACE

There are two phases to a communication cycle with the

AD9857. Phase 1 is the instruction cycle, which is the writing of

an instruction byte into the AD9857, coincident with the first

eight SCLK rising edges. The instruction byte provides the

AD9857 serial port controller with information regarding the

data transfer cycle, which is Phase 2 of the communication

cycle. The Phase 1 instruction byte defines whether the

upcoming data transfer is read or write, the number of bytes in

the data transfer (1-4), and the starting register address for the

first byte of the data transfer.

The first eight SCLK rising edges of each communication cycle

are used to write the instruction byte into the AD9857. The

remaining SCLK edges are for Phase 2 of the communication

cycle. Phase 2 is the actual data transfer between the AD9857

and the system controller. Phase 2 of the communication cycle

is a transfer of 1, 2, 3, or 4 data bytes as determined by the

instruction byte. Typically, using one communication cycle in a

multibyte transfer is the preferred method. However, single-byte

communication cycles are useful to reduce CPU overhead when

register access requires one byte only. An example of this may

be to write the AD9857 SLEEP bit.

At the completion of any communication cycle, the AD9857

serial port controller expects the next eight rising SCLK edges

to be the instruction byte of the next communication cycle.

All data input to the AD9857 is registered on the rising edge of

SCLK. All data is driven out of the AD9857 on the falling edge

of SCLK.

Figure 27 and Figure 28 illustrate the data write and data read

operations on the AD9857 serial port. Figure 29 through

Figure 32 show the general operation of the AD9857 serial port.

CS

SCLK

SDIO

t

PRE

t

DSU

t

SCLKPWH

SYMBOL DEFINITION MIN

t

PRE

t

SCLK

t

DSU

t

SCLKPWH

t

SCLKPWL

t

DHLD

Figure 27. Timing Diagram for Data Write to AD9857

t

SCLK

t

SCLKPWL

t

DHLD

1ST BIT

CS SETUP TIME

PERIOD OF SERIAL DATA CLOCK

SERIAL DATA SETUP TIME

SERIAL DATA CLOCK PULSE WIDTH HIGH

SERIAL DATA CLOCK PULSE WIDTH LOW

SERIAL DATA HOLD TIME

2ND BIT

40ns

100ns

30ns

40ns

40ns

0ns

01018-C-027

Rev. C | Page 24 of 40

Page 25

AD9857

S

CS

SCLK

SDIO

SDO

SYMBOL DEFINITION MAX

t

DV

1ST BIT

DATA VALID TIME

2ND BIT

t

DV

30ns

01018-C-028

Figure 28. Timing Diagram for Data Read from AD9857

CS

SCLK

SDIO

I

7

INSTRUCTION CYCLE DATA TRANSFER CYCLE

I

6I5I4I3I2I1I0

D7D6D5D4D3D2D1D

Figure 29. Serial Port Writing Timing—Clock Stall Low

0

01018-C-029

CS

CLK

SDIO

I

7

INSTRUCTION CYCLE DATA TRANSFER CYCLE

I6I5I4I3I2I1I

0

DON'T CARE

SDO

D

O7

O6DO5DO4DO3DO2DO1

D

O0

01018-C-030

D

Figure 30. 3-Wire Serial Port Read Timing—Clock Stall Low

CS

SCLK

SDIO

INSTRUCTION CYCLE DATA TRANSFER CYCLE

I

I

7

6I5I4I3I2I1I0

D

D6D5D4D3D2D1D

7

Figure 31. Serial Port Write Timing—Clock Stall High

0

01018-C-031

CS

SCLK

SDIO

INSTRUCTION CYCLE DATA TRANSFER CYCLE

I

I

7

6I5I4I3I2I1I0

DO7DO6DO5DO4DO3DO2DO1D

Figure 32. 2-Wire Serial Port Read Timing—Clock Stall High

O0

01018-C-032

Rev. C| Page 25 of 40

Page 26

AD9857

INSTRUCTION BYTE

The instruction byte contains the information shown in Table 6.

Table 6. Instruction Byte Information

MSB D6 D5 D4 D3 D2 D1 LSB

R/W

R/W

Bit 7 of the instruction byte determines whether a read or write

data transfer occurs after the instruction byte write. Logic high

indicates a read operation. Logic 0 indicates a write operation.

N1, N0

Bits 6 and 5 of the instruction byte determine the number of

bytes to be transferred during the data transfer cycle of the

communications cycle. The bit decodes are shown in Table 7.

Table 7. N1, N0 Decode Bits

N1 N0 Transfer

0 0 1 byte

0 1 2 bytes

1 0 3 bytes

1 1 4 bytes

A4, A3, A2, A1, A0

Bits 4, 3, 2, 1, and 0 of the instruction byte determine which

register is accessed during the data transfer portion of the

communications cycle. For multibyte transfers, this address is

the starting byte address. The remaining register addresses are

generated by the AD9857.

SERIAL INTERFACE PORT PIN DESCRIPTIONS

SCLK

Serial Clock. The serial clock pin is used to synchronize data to

and from the AD9857 and to run the internal state machines.

SCLK maximum frequency is 10 MHz.

CS

Chip Select. Active low input that allows more than one device

on the same serial communications lines. The SDO and SDIO

pins go to a high impedance state when this input is high. If

driven high during any communications cycle, that cycle is

suspended until

low in systems that maintain control of SCLK.

SDIO

Serial Data I/O. Data is always written into the AD9857 on this

pin. However, this pin can be used as a bidirectional data line.

The configuration of this pin is controlled by Bit 7 of register

address 00h. The default is logic zero, which configures the

SDIO pin as bidirectional.

SDO

Serial Data Out. Data is read from this pin for protocols that use

separate lines for transmitting and receiving data. When the

AD9857 operates in a single bidirectional I/O mode, this pin

does not output data and is set to a high impedance state.

N1 N0 A4 A3 A2 A1 A0

CS

is reactivated low. Chip Select can be tied

SYNCIO

Synchronizes the I/O port state machines without affecting the

addressable registers contents. An active high input on the

SYNC I/O pin causes the current communication cycle to abort.

After SYNC I/O returns low (Logic 0) another communication

cycle may begin, starting with the instruction byte write.

MSB/LSB Transfers

The AD9857 Serial Port can support both most significant bit

(MSB) first or least significant bit (LSB) first data formats. This

functionality is controlled by the Control Register 00h<6>bit.

The default value of Control Register 00h<6> is low (MSB first).

When Control Register 00h<6> is set high, the AD9857 serial

port is in LSB first format. The instruction byte must be written

in the format indicated by Control Register 00h<6>. That is, if

the AD9857 is in LSB first mode, the instruction byte must be

written from least significant bit to most significant bit.

Multibyte data transfers in MSB format can be completed by

writing an instruction byte that includes the register address of

the most significant byte. In MSB first mode, the serial port

internal byte address generator decrements for each byte

required of the multibyte communication cycle. Multibyte data

transfers in LSB first format can be completed by writing an

instruction byte that includes the register address of the least

significant byte. In LSB First mode, the serial port internal byte

address generator increments for each byte required of the

multibyte communication cycle.

Notes on Serial Port Operation

The AD9857 serial port configuration bits reside in Bits 6 and 7

of register address 0h. It is important to note that the

configuration changes immediately upon writing to this register.

For multibyte transfers, writing to this register may occur

during the middle of a communication cycle. Care must be

taken to compensate for this new configuration for the

remainder of the current communication cycle.

The AD9857 serial port controller address rolls from 19h to 0h

for multibyte I/O operations if the MSB first mode is active. The

serial port controller address rolls from 0h to 19h for multibyte

I/O operations if the LSB first mode is active.

The system must maintain synchronization with the AD9857 or

the internal control logic is not able to recognize further

instructions. For example, if the system sends an instruction

byte for a 2-byte write, then pulses the SCLK pin for a 3-byte

write (8 additional SCLK rising edges), communication

synchronization is lost. In this case, the first 16 SCLK rising

edges after the instruction cycle properly writes the first two

data bytes into the AD9857, but the next eight rising SCLK

edges are interpreted as the next instruction byte, not the final

byte of the previous communication cycle.

Rev. C | Page 26 of 40

Page 27

AD9857

When synchronization is lost between the system and the

AD9857, the SYNC I/O pin provides a means to re-establish

synchronization without reinitializing the entire chip. The

SYNC I/O pin enables the user to reset the AD9857 state

machine to accept the next eight SCLK rising edges to be

coincident with the instruction phase of a new communication

cycle. By applying and removing a “high” signal to the SYNC

I/O pin, the AD9857 is set to once again begin performing the

communication cycle in synchronization with the system. Any

information that had been written to the AD9857 registers

during a valid communication cycle prior to loss of

synchronization remains intact.

CONTROL REGISTER DESCRIPTIONS

Reference Clock (REFCLK) Multiplier—Register Address 00h,

Bits 0, 1, 2, 3, 4

A 5-bit number (M), the value of which determines the

multiplication factor for the internal PLL (Bit 4 is the MSB). The

system clock (SYSCLK) is M times the frequency of the

REFCLK input signal. If M = 01h, the PLL circuit is bypassed

and f

REFCLK frequency by M (4–20 decimal). Any other value of M

is considered an invalid entry.

PLL Lock Control—Register Address 00h, Bit 5

When set to a Logic 0, the device uses the status of the PLL lock

indicator pin to internally control the operation of the 14-bit

parallel data path. When set to a Logic 1, the internal control

logic ignores the status of the PLL lock indicator pin.

LSB First—Register Address 00h, Bit 6

When set to a Logic 1, the serial interface accepts serial data in

LSB first format. When set to a Logic 0, MSB first format is

assumed.

SDIO Input Only—Register Address 00h, Bit 7

When set to a Logic 1, the serial data I/O pin (SDIO) is

configured as an input only pin. When set to a Logic 0, the

SDIO pin has bidirectional operation.

Operating Mode—Register Address 01h, Bits 0, 1

00h: Selects the quadrature modulation mode of operation. 01h:

Selects the single-tone Mode of operation. 02h: Selects the

interpolating DAC mode of operation. 03h: Invalid entry.

Auto Power-Down—Register Address 01h, Bit 2

When set to a Logic 1, the device automatically switches into its

low power mode whenever TxENABLE is deasserted for a sufficiently long period of time. When set to a Logic 0, the device

only powers down in response to the digital power-down pin.

SYSCLK

=f

. If 04h ≤ M ≤14h, the PLL multiplies the

REFCLK

Full Sleep Mode—Register Address 01h, Bit 3

When set to a Logic 1, the device completely shuts down.

Reserved—Register Address 01h, Bit 4

Reserved—Register Address 01h, Bit 5

This bit must always be set to 0.

Inverse SINC Bypass—Register Address 01h, Bit 6

When set to a Logic 1, the inverse Sinc filter is BYPASSED.

When set to a Logic 0, the inverse Sinc filter is active.

CIC Clear—Register Address 01h, Bit 7

When set to a Logic 1, the CIC filters are cleared. When set to a

Logic 0, the CIC filters operate normally.

PROFILE #0

Tuning Word—Register Address 02h, Bits 0, 1, 2, 3, 4, 5, 6, 7

The lower byte of the 32-bit frequency tuning word, Bits 0–7.

Tuning Word—Register Address 03h, Bits 0, 1, 2, 3, 4, 5, 6, 7

The second byte of the 32-bit frequency tuning word, Bits 8–15.

Tuning Word—Register Address 04h, Bits 0,1, 2, 3, 4, 5, 6, 7

The third byte of the 32-bit frequency tuning word, Bits 16–23.

Tuning Word—Register Address 05h, Bits 0, 1, 2, 3, 4, 5, 6, 7

The fourth byte of the 32-bit frequency tuning word, Bits 24–31.

Inverse CIC Bypass—Register Address 06h, Bit 0

When set to a Logic 1, the inverse CIC filter is BYPASSED.

When set to a Logic 0, the inverse CIC filter is active.

Spectral Invert—Register Address 06h, Bit 1

The quadrature modulator takes the form:

I × cos(ω) + Q × sin(ω) when set to a Logic 1.

I × cos(ω) − Q × sin(ω) when set to a Logic 0.

CIC Interpolation Rate—Register Address 06h, Bits 2, 3, 4, 5,

6, 7

00h: Invalid entry.

01h: CIC filters BYPASSED.

02h–3Fh: CIC interpolation rate (2–63, decimal).

Output Scale Factor—Register Address 07h, Bits 0, 1, 2, 3, 4,

5, 6, 7

An 8-bit number that serves as a multiplier for the data pathway

before the data is delivered the DAC. It has an LSB weight of 2

(0.0078125). This yields a multiplier range of 0 to 1.9921875.

–7

Rev. C| Page 27 of 40

Page 28

AD9857

PROFILE #1

Tuning Word—Register Address 08h, Bits 0, 1, 2, 3, 4, 5, 6, 7

The lower byte of the 32-bit frequency tuning word, Bits 0–7.

Tuning Word—Register Address 09h, Bits 0, 1, 2, 3, 4, 5, 6, 7

The second byte of the 32-bit frequency tuning word, Bits 8–15.

Tuning Word—Register Address 0Ah, Bits 0, 1, 2, 3, 4, 5, 6, 7

The third byte of the 32-bit frequency tuning word, Bits 16–23.

Tuning Word—Register Address 0Bh, Bits 0, 1, 2, 3, 4, 5, 6, 7

The fourth byte of the 32-bit frequency tuning word, Bits 24–31.

Inverse CIC Bypass—Register Address 0Ch, Bit 0

When set to a Logic 1, the inverse CIC filter is BYPASSED.

When set to a Logic 0, the inverse CIC filter is active.

Spectral Invert—Register Address 0Ch, Bit 1

The quadrature modulator takes the form:

I × cos(ω) + Q × sin(ω) when set to a Logic 1.

I × cos(ω)

CIC Interpolation Rate—Register Address 0Ch, Bits 2, 3, 4, 5,

6, 7

00h: Invalid entry.

01h: CIC filters BYPASSED.

02h–3Fh: CIC interpolation rate (2–63, decimal).

Output Scale Factor—Register Address 0Dh, Bits 0, 1, 2, 3, 4,

5, 6, 7

An 8-bit number that serves as a multiplier for the data pathway

before the data is delivered the DAC. It has an LSB weight of 2

(0.0078125). This yields a multiplier range of 0 to 1.9921875.

PROFILE #2

Tuning Word—Register Address 0Eh, Bits 0, 1, 2, 3, 4, 5, 6, 7

The lower byte of the 32-bit frequency tuning word, Bits 0–7.

Tuning Word—Register Address 0Fh, Bits 0, 1, 2, 3, 4, 5, 6, 7

The second byte of the 32-bit frequency tuning word, Bits 8–15.

Tuning Word—Register Address 10h, Bits 0, 1, 2, 3, 4, 5, 6, 7

The third byte of the 32-bit frequency tuning word, Bits 16–23.