Page 1

CCD Signal Processor

a

FEATURES

10-Bit, 18 MSPS A/D Converter

18 MSPS Full Speed Correlated Double Sampler (CDS)

Low Noise, Wideband PGA

Internal Voltage Reference

No Missing Codes Guaranteed

+3 V Single Supply Operation

Low Power CMOS: 185 mW

48-Terminal TQFP Package

PRODUCT DESCRIPTION

The AD9802 is a complete CCD signal processor developed

for electronic cameras. It is suitable for both camcorder and

consumer-level still camera applications.

The signal processing chain is comprised of a high speed CDS,

variable gain PGA and 10-bit ADC. Required clamping circuitry and an onboard voltage reference are provided as well as a

direct ADC input. The AD9802 operates from a single +3 V

supply with a typical power consumption of 185 mW.

The AD9802 is packaged in a space saving 48-terminal thin

quad flatpack (TQFP) and is specified over an operating temperature range of 0°C to +70°C.

For Electronic Cameras

AD9802

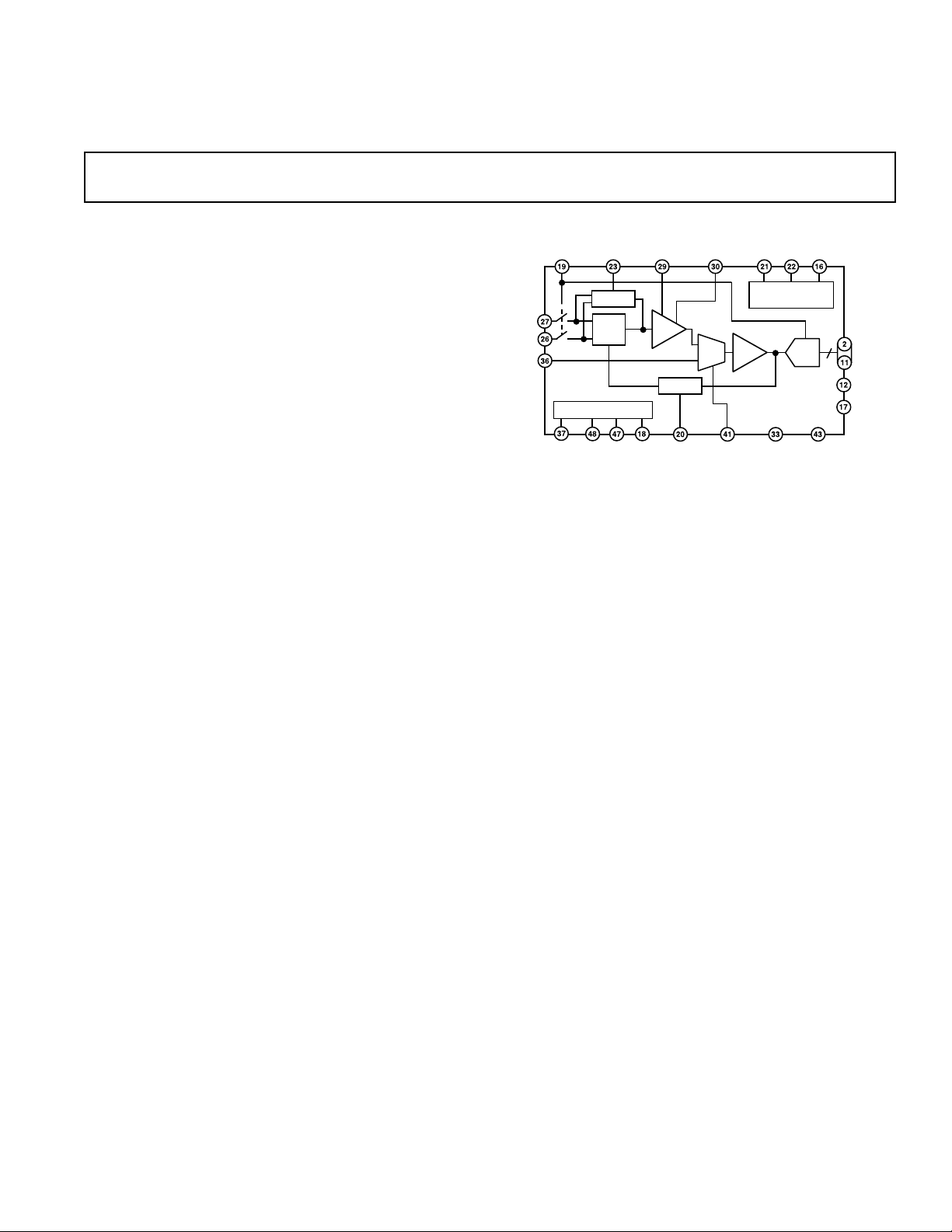

FUNCTIONAL BLOCK DIAGRAM

SHP

S/H

AD9802

ACVDD

SHD ADCCLK

TIMING

GENERATOR

A/D

ADVDD

10

DOUT

DRVDD

DVDD

PBLK

CLPDM

PGACONT1 PGACONT2

CLAMP

PIN

DIN

ADCIN

CMLEVEL VRT VRB STBY

PRODUCT HIGHLIGHTS

CDS

REFERENCE

PGA

CLAMP

CLPOB

MUX

ADCMODE

1. On-Chip Input Clamp and CDS

Clamp circuitry and high speed correlated double sampler

allow for simple ac-coupling to interface a CCD sensor at full

18 MSPS conversion rate.

2. On-Chip PGA

The AD9802 includes a low-noise, wideband amplifier with

analog variable gain from 0 dB to 31.5 dB (linear in dB).

3. Direct ADC Input

A direct input to the 10-bit A/D converter is provided for

digitizing video signals.

4. 10-Bit, High Speed A/D Converter

A linear 10-bit ADC is capable of digitizing CCD signals at

the full 18 MSPS conversion rate. Typical DNL is ± 0.5 LSB

and no missing code performance is guaranteed.

5. Low Power

At 185 mW, and 15 mW in power-down, the AD9802 consumes a fraction of the power of presently available multichip

solutions.

6. Digital I/O Functionality

The AD9802 offers three-state digital output control.

7. Small Package

Packaged in a 48-terminal, surface-mount thin quad flatpack,

the AD9802 is well suited to very compact, low headroom

designs.

REV. 0

Information furnished by Analog Devices is believed to be accurate and

reliable. However, no responsibility is assumed by Analog Devices for its

use, nor for any infringements of patents or other rights of third parties

which may result from its use. No license is granted by implication or

otherwise under any patent or patent rights of Analog Devices.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781/329-4700 World Wide Web Site: http://www.analog.com

Fax: 781/326-8703 © Analog Devices, Inc., 1997

Page 2

(T

to T

with ACVDD = 3.15 V, ADVDD = 3.15 V, DVDD = 3.15 V, DRVDD = 3.15 V

MAX

AD9802–SPECIFICA TIONS

MIN

unless otherwise noted)

Parameter Min Typ Max Units

TEMPERATURE RANGE

Operating 0 70 °C

Storage –65 150 °C

POWER SUPPLY VOLTAGE (For Functional Operation)

ACVDD 3.00 3.15 3.50 V

ADVDD 3.00 3.15 3.50 V

DVDD 3.00 3.15 3.50 V

DRVDD 3.00 3.15 3.50 V

POWER SUPPLY CURRENT

ACVDD 39.5 mA

ADVDD 14.6 mA

DVDD 4.7 mA

DRVDD 0.07 mA

POWER CONSUMPTION

Normal Operation 185 mW

Power-Down Mode 15 mW

MAXIMUM SHP, SHD, ADCCLK RATE 18 MHz

ADC

Resolution 10 Bits

Differential Nonlinearity ±0.5 LSBs

No Missing Codes GUARANTEED

ADCCLK Rate 18 MHz

Reference Top Voltage 1.75 V

Reference Bottom Voltage 1.25 V

Input Range 1.0 V p-p

CDS

Maximum Input Signal 500 mV p-p

Pixel Rate 18 MHz

1

PGA

Maximum Gain 31.5 dB

High Gain 14.5 19 23.5 dB

Medium Gain 1.0 4.0 7.0 dB

Minimum Gain –4.0 0 +4 dB

CLAMP (During CLPOB. Only Stable over PGA Range 0.3 V to 2.7 V)

Average Black Level 32 LSBs

Pixel-to-Pixel Offset (See Black Level Clamping for Description) 2 8 LSBs

NOTES

1

PGA test conditions: maximum gain PGACONT1 = 2.7 V, PGACONT2 = 1.5 V; high gain PGACONT1 = 2.0 V, PGACONT2 = 1.5 V; medium gain

0.5 V, PGACONT2 = 1.5 V; minimum gain PGACONT1 = 0.3 V, PGACONT2 = 1.5 V.

Specifications subject to change without notice.

PGACONT1 =

(T

to T

with ACVDD = 3.15 V, ADVDD = 3.15 V, DVDD = 3.15 V, DRVDD = 3.15 V unless otherwise

MAX

DIGITAL SPECIFICATIONS

MIN

noted)

Parameter Symbol Min Typ Max Units

LOGIC INPUTS

High Level Input Voltage V

Low Level Input Voltage V

High Level Input Current I

Low Level Input Current I

Input Capacitance C

IH

IL

IH

IL

IN

2.4 V

0.6 V

10 µA

10 µA

10 pF

LOGIC OUTPUTS

High Level Output Voltage V

Low Level Output Voltage V

OH

OL

I

OH

I

OL

2.4 V

0.6 V

50 µA

50 µA

–2–

REV. 0

Page 3

AD9802

WARNING!

ESD SENSITIVE DEVICE

(T

to T

TIMING SPECIFICATIONS

Parameter Min Typ Max Units

ADCCLK Clock Period 55.6 ns

ADCCLK Hi-Level Period 24.8 27.8 ns

ADCCLK Lo-Level Period 24.8 27.8 ns

SHP, SHD Clock Period 55.6 ns

SHP, SHD Minimum Pulse Width 12.5 ns

SHP Rising Edge to SHD Rising Edge 28 ns

Digital Output Delay 20 ns

PBLK MODE1 MODE2 Digital Output Data (D9–D0)

0 0 0 0000000000

1 0 0 Normal Operation

1 0 1 1010101010

1 1 0 0101010101

1 1 1 High Impedance

ABSOLUTE MAXIMUM RATINGS*

Parameter With Respect To Min Max Units

ADVDD ADVSS, SUBST –0.3 6.5 V

ACVDD ACVSS, SUBST –0.3 6.5 V

DVDD DVSS, DSUBT –0.3 6.5 V

DRVDD DRVSS, DSUBST –0.3 6.5 V

SHP, SHD DSUBST –0.3 DVDD + 2.0 V

ADCCLK, CLPOB, CLPDM DSUBST –0.3 DVDD + 0.3 V

PGACONT1, PGACONT2 SUBST –0.3 ACVDD + 0.3 V

PIN, DIN SUBST –0.3 ACVDD + 0.3 V

DOUT DSUBST –0.3 DRVDD + 0.3 V

VRT, VRB SUBST –0.3 ADVDD + 0.3 V

CLAMP_BIAS SUBST –0.3 ACVDD + 0.3 V

CCDBYP1, CCDBYP2 SUBST –0.3 ACVDD + 0.3 V

STBY DSUBST –0.3 DVDD + 0.3 V

MODE1, MODE2 SUBST –0.3 ADVDD + 0.3 V

DRVSS, DVSS, ACVSS, ADVSS SUBST, DSUBST –0.3 +0.3 V

Junction Temperature +150 °C

Storage Temperature –65 +150 °C

Lead Temperature (10 sec) +300 °C

*Stresses above those listed under Absolute Maximum Ratings may cause permanent damage to the device. This is a stress rating only; functional operation of the device

at these or other conditions above those indicated in the operational sections of this specification is not implied. Exposure to absolute maximum ratings for extended periods

may affect device reliability.

MIN

noted)

with ACVDD = 3.15 V, ADVDD = 3.15 V, DVDD = 3.15 V, DRVDD = 3.15 V unless otherwise

MAX

Digital Output Data Control

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD9802JST 0°C to +70°C 48-Terminal Plastic Thin Quad Flatpack ST-48

CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily

accumulate on the human body and test equipment and can discharge without detection.

Although the AD9802 features proprietary ESD protection circuitry, permanent damage may

occur on devices subjected to high energy electrostatic discharges. Therefore, proper ESD

precautions are recommended to avoid performance degradation or loss of functionality.

–3–REV. 0

Page 4

AD9802

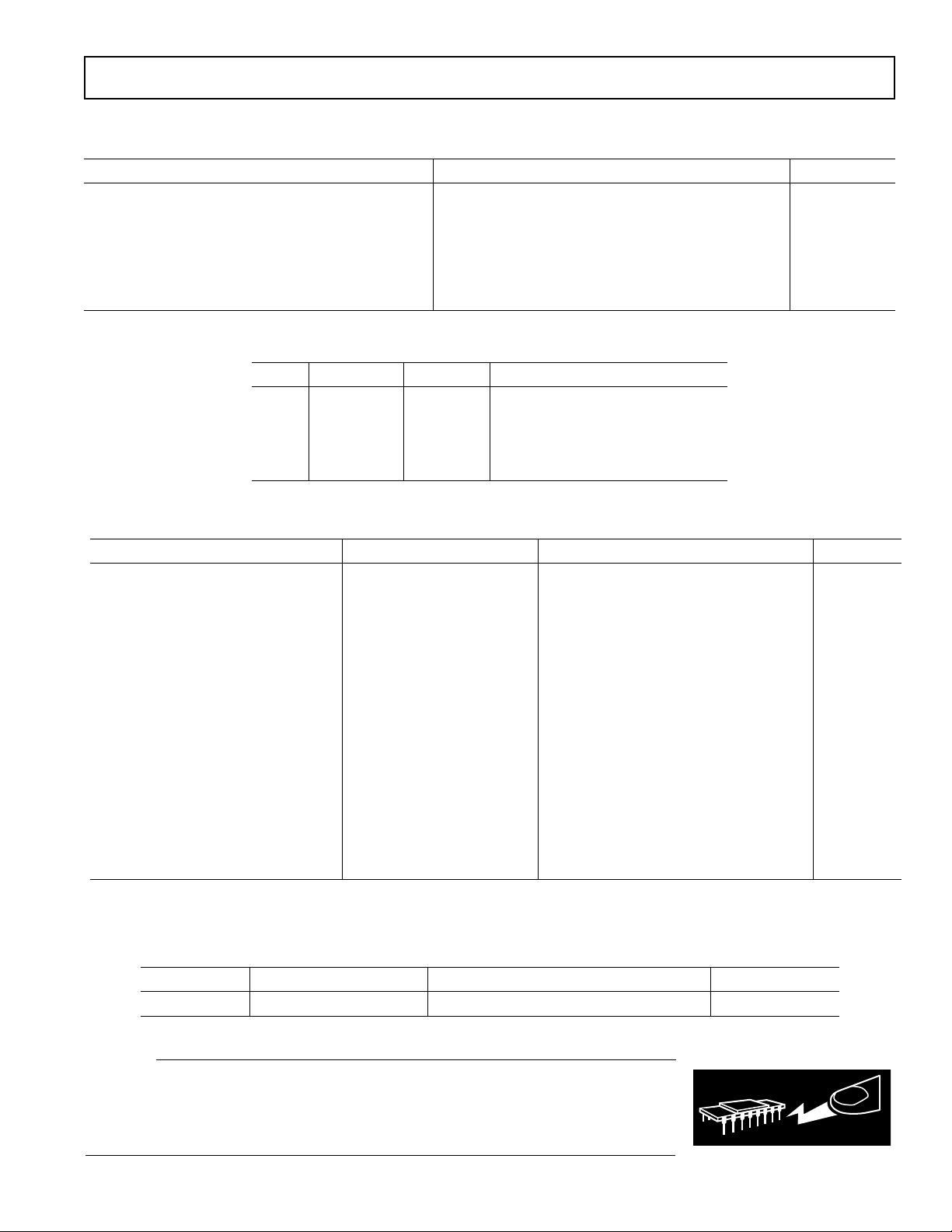

PIN CONFIGURATION

ADVSS

ADVDD

ADVSS

AD9802

TOP VIEW

(Not to Scale)

STBY

DVDD

ADCCLK

NC

ADCMODE

PBLK

CLPOB

MODE2

MODE1

SHP

SHD

CMLEVEL

SHABYP

DVSS

CLPDM

36

ADCIN

35

TEST2

34

TEST1

33

ACVDD

32

CLAMP_BIAS

31

ACVSS

30

PGACONT2

29

PGACONT1

28

CCDBYP1

27

PIN

26

DIN

25

CCDBYP2

ADVSS

(LSB) D0

D1

D2

D3

D4

D5

D6

D7

D8

(MSB) D9

DRVDD

NC = NO CONNECT

SUBST

VRB

VRT

48 47 46 45 44 39 38 3743 42 41 40

1

PIN 1

2

IDENTIFIER

3

4

5

6

7

8

9

10

11

12

13 14 15 16 17 18 19 20 21 22 23 24

DVSS

DRVSS

DSUBST

PIN FUNCTION DESCRIPTIONS

Pin # Pin Name Type Description

1 ADVSS P Analog Ground

2–11 D0–D9 DO Digital Data Outputs: D0 = LSB, D9 = MSB

12 DRVDD P +3 V Digital Driver Supply

13 DRVSS P Digital Driver Ground

14 DSUBST P Digital Substrate

15 DVSS P Digital Ground

16 ADCCLK DI ADC Sample Clock Input

17 DVDD P +3 V Digital Supply

18 STBY DI Power-Down (Active High)

19 PBLK DI Pixel Blanking (Active Low)

20 CLPOB DI Black Level Restore Clamp (Active Low)

21 SHP DI Reference Sample Clock Input

22 SHD DI Data Sample Clock Input

23 CLPDM DI Input Clamp (Active Low)

24 DVSS P Digital Ground

25 CCDBYP2 AO CCD Bypass. Decouple to analog ground through 0.1 µF.

26 DIN AI CDS Input. Tie to Pin 27 and AC-Couple to CCD output through 0.1µF.

27 PIN AI CDS Input. See above.

28 CCDBYP1 AO CCD Bypass. Decouple to analog ground through 0.1 µF.

29 PGACONT1 AI Coarse PGA Gain Control (0.3V–2.7 V). Decoupled to analog ground through 0.1 µF.

30 PGACONT2 AI Fine PGA Gain Control

31 ACVSS P Analog Ground

32 CLAMP_BIAS AO Clamp Bias Level. Decouple to analog ground through 0.1 µF.

33 ACVDD P +3 V Analog Supply

34, 35 TEST1, TEST2 AI Reserved Test Pins. Should be left NC or pulled high to ACVDD.

36 ADCIN AI Direct ADC Analog Input (See Driving the Direct ADC Input)

37 CMLEVEL AO Common-Mode Level. Decouple to analog ground through 0.1 µF.

38 SHABYP AO Internal Bias Level. Decouple to analog ground through 0.1µF.

39 MODE2 DI ADC Test Mode Control (See Digital Output Data Control.)

40 MODE1 DI ADC Test Mode Control (See Digital Output Data Control.)

41 ADCMODE DI ADC Input Control. Logic low for CDS/PGA, high for direct input.

42 NC No Connect

43 ADVDD P +3 V Analog Supply

44, 45 ADVSS P Analog Ground

46 SUBST P Substrate. Connect to analog ground.

47 VRB AO Bottom Reference Bypass. Decouple to analog ground through 0.1µF.

48 VRT AO Top Reference Bypass

NOTE

Type: AI = Analog Input, AO = Analog Output, DI = Digital Input, DO = Digital Output, P = Power.

–4–

REV. 0

Page 5

AD9802

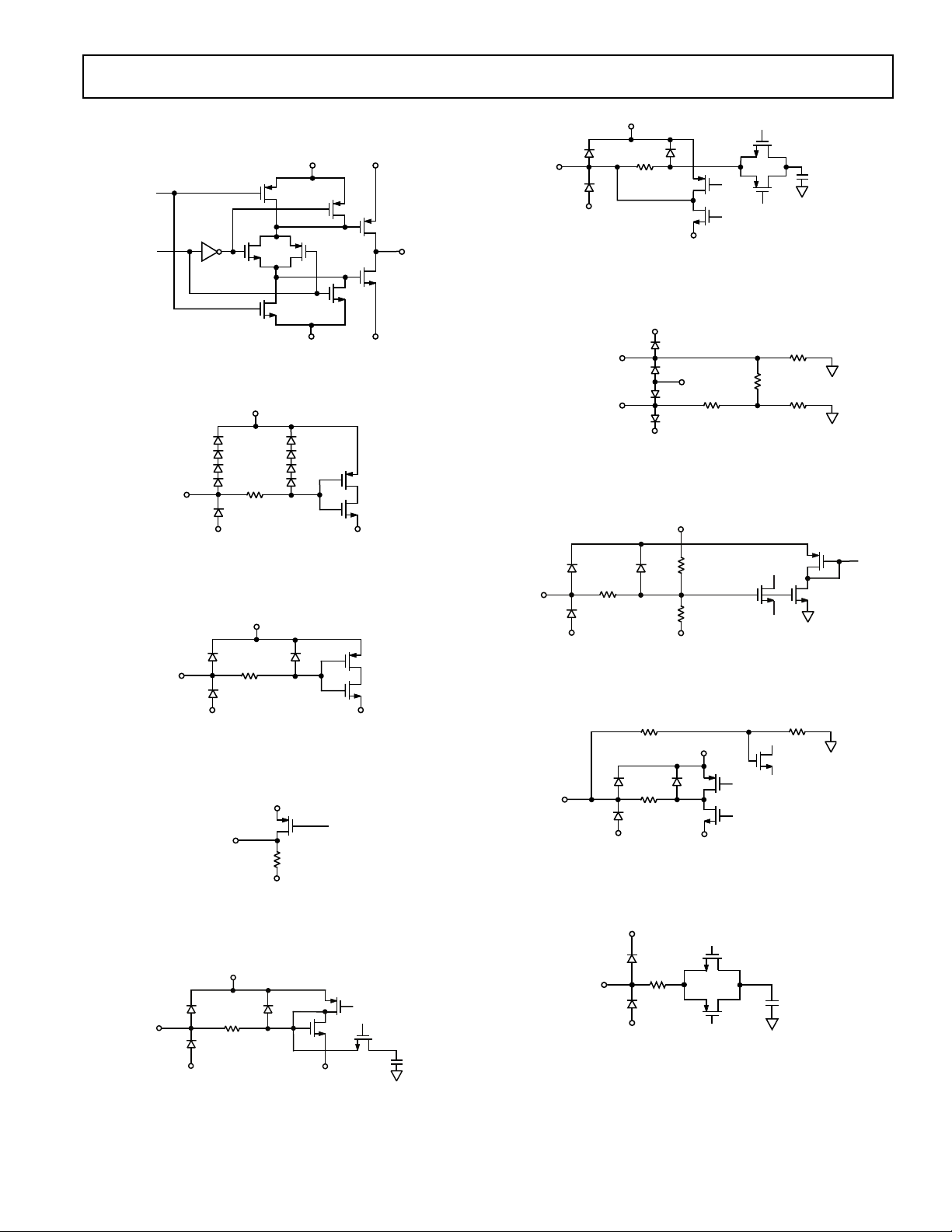

EQUIVALENT INPUT CIRCUITS

DVDD DRVDD

DVSS DRVSS

Figure 1. Pins 2–11 (DB0–DB9)

DVDD

200V

DSUBST

Figure 2. Pin 21 (SHP) and Pin 22 (SHD)

DVSS

ACVDD

50V

10pF

SUBST

ACVSS

Figure 6. Pin 26 (DIN) and Pin 27 (PIN)

ACVDD

PGACONT1

PGACONT2

SUBST

8kV 8kV

ACVDD

10kV

1kV

Figure 7. Pin 29 (PGACONT1) and Pin 30 (PGACONT2)

ACVDD

10kV

200V

DVDD

200V

DSUBST

DVSS

Figure 3. Pin 16 (ADCCLK)

ADVDD

9.3kV

ADVSS

Figure 4. Pin 37 (CMLEVEL)

ACVDD

50V

30kV

SUBST ACVSS

Figure 8. Pin 32 (CLAMP BIAS)

SUBST

3kV

ADVDD

200V

ADVSS

1.1kV

Figure 9. Pin 48 (VRT) and Pin 47 (VRB)

ACVDD

50V

1pF

SUBST

SUBST

ACVSS

Figure 5. Pin 25 (CCDBYP2) and Pin 28 (CCDBYP1)

REV. 0

Figure 10. Pin 36 (ADCIN) and Pin 38 (SHABYP)

–5–

Page 6

AD9802

CCD

SHP

SHD

CLPOB

PBLK

CLPDM

ADCCLK

EFFECTIVE

PIXEL

INTERVAL

BLACK

LEVEL

INTERVAL

BLANKING

INTERVAL

DUMMY

BLACK

INTERVAL

EFFECTIVE

PIXEL

INTERVAL

ADC DATA

NOTES:

CLPDM AND CLPOB OVERWRITE PBLK

CLAMP TIMING NEEDS TO BE ADJUSTED RELATIVE TO CCD'S BLACK PIXELS

RECOMMENDED PULSE WIDTH CLPDM = 1.5

s MIN

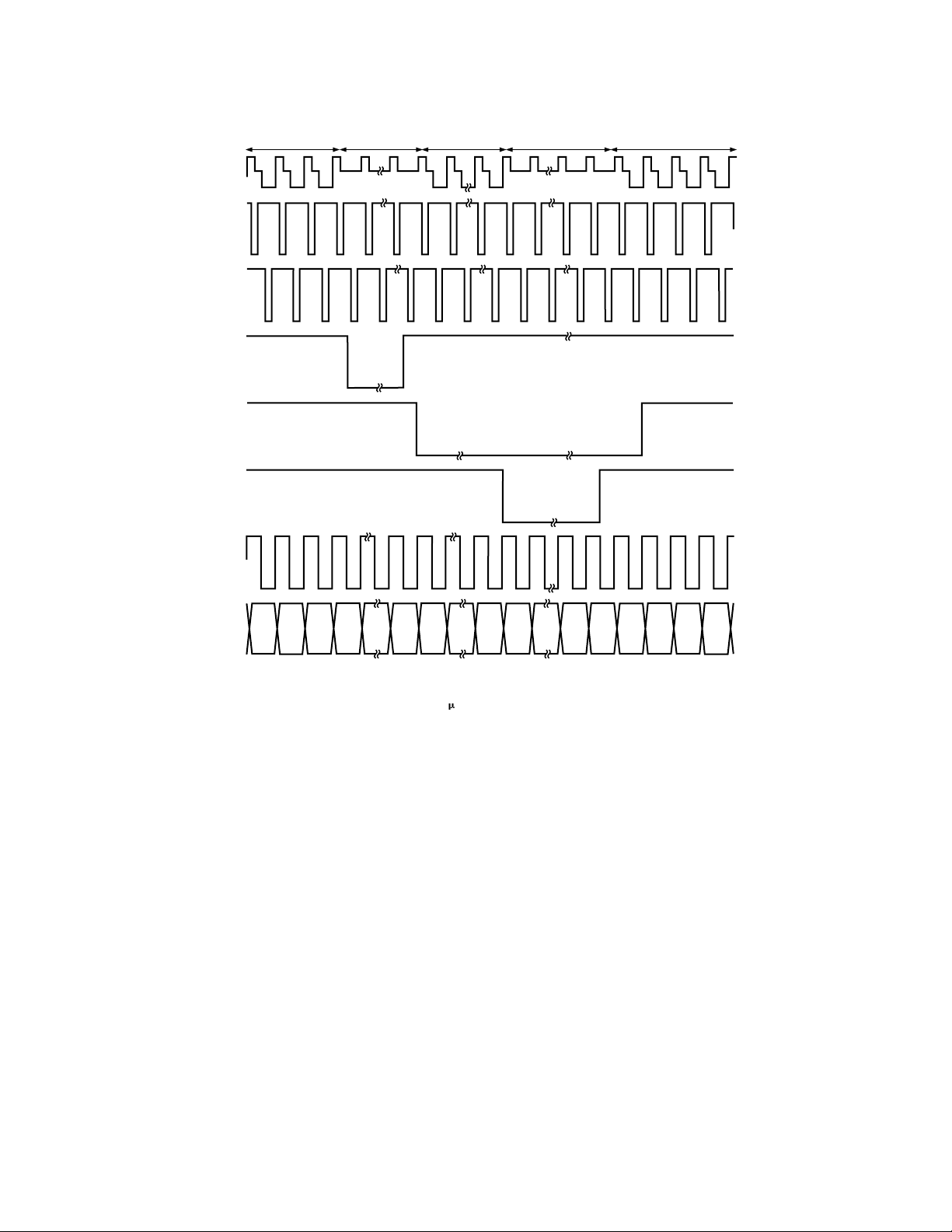

Figure 11. Typical Horizontal Interval Timing

–6–

REV. 0

Page 7

CCD SIGNAL

(DELAYED TO MATCH

ACTUAL SAMPLING

EDGE)

SHD

SHP

ACTUAL

SAMPLING

EDGE

ADCCLK

DIGITAL OUT

AD9802

1234567

N N+4

35ns35ns

N+1

t

ID

t

OD

N+2

N+3

t

H

DATA N–1 DATA N

OUTPUT LOAD C

SHP

SHD

PRE-ADC

OUTPUT LATCH

PRE-ADC

OUTPUT LATCH

DATA TRANSITION

ADCCLK

= 20pF OUTPUT DELAY

L

INTERNAL CLOCK DELAY

HOLD TIME

Figure 12. Timing Diagram

5ns

10ns

5ns

20ns

INHIBITED PERIOD

FOR ADCCLK

RISING EDGE

RISING EDGE

ANYWHERE IN

THIS PERIOD OK

t

= 15ns

OD

t

= 2ns

H

t

= 3ns

ID

LATENCY = 5 CYCLES

Figure 13. ADCCLK Timing Edge

–7–REV. 0

Page 8

AD9802

THEORY OF OPERATION

Introduction

The AD9802 is a 10-bit analog-to-digital interface for CCD

cameras. The block level diagram of the system is shown in

Figure 14. The device includes a correlated double sampler

(CDS), 0 dB–31 dB variable gain amplifier (PGA), black level

correction loop, input clamp and voltage reference. The only

external analog circuitry required at the system level is an emitter follower buffer between the CCD output and AD9802

inputs.

CDS

BLACK

LEVEL

PGA

GAIN

10-BIT

ADC

REF

OUT

CLAMP

IN

Figure 14.

Correlated Double Sampling (CDS)

CDS is important in high performance CCD systems as a method

for removing several types of noise. Basically, two samples of the

CCD output are taken: one with the signal present (data) and one

without (reference). Subtracting these two samples removes

any noise that is common to—or correlates with—both.

Figure 15 shows the block diagram of the AD9802’s CDS. The

S/H blocks are directly driven by the input and the sampling

function is performed passively, without the use of amplifiers.

This implementation relies on the off-chip emitter follower

buffer to drive the two 10 pF sampling capacitors. Only one

capacitor at a time is seen at the input pin.

The AD9802 actually uses two CDS circuits in a “ping-pong”

fashion to allow the system more acquisition time. In this way,

the output from one of the two CDS blocks will be valid for an

entire clock cycle. Thus, the bandwidth requirement of the

subsequent gain stage is reduced as compared to that for a

single CDS channel system. This lower bandwidth translates to

lower power and noise.

S/H

FROM

CCD

Q1

S/H

Q2

S

10pF

OUT

Figure 15.

Programmable Gain Amplifier (PGA)

The on-chip PGA provides a (linear in dB) gain range of 0dB–

31.5 dB. A typical gain characteristic plot is shown in Figure 16.

Only the range from 0.3 V to 2.7 V is intended for actual use.

35

30

25

20

15

10

GAIN – dB

5

0

–5

–10

–15

030.5 1 1.5 2 2.5

PGACONT1 – Volts

Figure 16.

As shown in Figure 17, PGA control is provided through the

PGACONT1 and PGACONT2 inputs. PGACONT1 provides

coarse, and PGACONT2 fine (1/16), gain control.

PGACONT1

PGACONT1 = COARSE CONTROL

PGACONT2 = FINE (1/16) CONTROL

PGACONT2

A

Figure 17.

Black Level Clamping

For correct processing, the CCD signal must be referenced to a

well established “black level” by the AD9802. At the edge of the

CCD, there is a collection of pixels covered with metal to prevent any light penetration. As the CCD is read out, these “black

pixels” provide a calibration signal that is used to establish the

black level.

The feedback loop shown in Figure 18 is closed around the

PGA during the calibration interval (CLPOB = LOW) to set the

black level. As the black pixels are being processed, an integrator block measures the difference between the input level and

the desired reference level. This difference, or error, signal is

amplified and passed to the CDS block where it is added to the

incoming pixel data. As a result of this process, the black pixels

are digitized at one end of the ADC range, taking maximum

advantage of the available linear range of the system.

–8–

CDS

IN

INTEGRATOR

PGA

ADC

CLPOB

NEG REF

Figure 18.

REV. 0

Page 9

AD9802

The actual implementation of this loop is slightly more complicated as shown in Figure 19. Because there are two separate

CDS blocks, two black level feedback loops are required and

two offset voltages are developed. Figure 19 also shows an additional PGA block in the feedback loop labeled “RPGA.” The

RPGA uses the same control inputs as the PGA, but has the

inverse gain. The RPGA functions to attenuate by the same

factor as the PGA amplifies, keeping the gain and bandwidth of

the loop constant.

There exists an unavoidable mismatch in the two offset voltages

used to correct both CDS blocks. This mismatch causes a slight

difference in the offset level for odd and even pixels, called

“pixel-to-pixel offset” (see Specifications). The pixel-to-pixel

offset is an output referred specification, because the black level

correction is done using the output of the PGA.

CDS1

IN

CDS2

PGA

RPGA2

RPGA1

CONTROL

INT2

INT1

ADC

CLPOB

NEG REF

Figure 19.

Input Bias Level Clamping

The buffered CCD output is connected to the AD9802 through

an external coupling capacitor. The dc bias point for this coupling capacitor is established during the clamping (CLPDM =

LOW) period using the “dummy clamp” loop shown in Figure

20. When closed around the CDS, this loop establishes the

desired dc bias point on the coupling capacitor.

CLPDM

INPUT

CLAMP

CCD

CDS

PGA

BLACK

LEVEL CLP

TO ADC

Figure 20.

Input Blanking

In some applications, the AD9802’s input may be exposed to

large signals from the CCD. These signals can be very large,

relative to the AD9802’s input range, and could thus saturate

on-chip circuit blocks. Recovery time from such saturation

conditions could be substantial.

To avoid problems associated with processing these transients,

the AD9802 includes an input blanking function. When active

(PBLK = LOW) this function stops the CDS operation and

allows the user to disconnect the CDS inputs from the CCD

buffer.

If the input voltage exceeds the supply rail by more than 0.3V,

then protection diodes will be turned on, increasing current flow

into the AD9802 (see Equivalent Input Circuits). Such voltage

levels should be externally clamped to prevent device damage or

reliability degradation.

10-Bit Analog-to-Digital Converter (ADC)

The ADC employs a multibit pipelined architecture that is

well suited for high throughput rates while being both area and

power efficient. The multistep pipeline presents a low input

capacitance resulting in lower on-chip drive requirements. A

fully differential implementation was used to overcome headroom constraints of the single +3 V power supply.

Direct ADC Input

The analog processing circuitry may be bypassed in the

AD9802. When ADCMODE (Pin 41) is taken high, the

ADCIN pin provides a direct input to the SHA. This feature

allows digitization of signals that do not require CDS and

gain adjustment. The PGA output is disconnected from the

SHA when ADCMODE is taken high.

Differential Reference

The AD9802 includes a 0.5 V reference based on a differential,

continuous-time bandgap cell. Use of an external bypass capacitor reduces the reference drive requirements, thus lowering the

power dissipation. The differential architecture was chosen for

its ability to reject supply and substrate noise. Recommended

decoupling shown in Figure 21.

0.1mF

1mF

0.1mF

REF

VRT

VRB

Figure 21.

Internal Timing

The AD9802’s on-chip timing circuitry generates all clocks

necessary for operation of the CDS and ADC blocks. The user

needs only to synchronize the SHP and SHD clocks with the

CCD waveform, as all other timing is handled internally. The

ADCCLK signal is used to strobe the output data, and can be

adjusted to accommodate desired timing.

–9–REV. 0

Page 10

AD9802

APPLICATIONS INFORMATION

Generating Clock Signals

For best performance, the AD9802 should be driven by 3 V

logic levels. As shown in the Equivalent Input Circuits, the use

of 5 V logic for ADCCLK will turn on the protection diode to

DVDD, increasing the current flow into this pin. As a result,

noise and power dissipation will increase. The CDS clock inputs, SHP and SHD, have a additional protection and can withstand direct 5 V levels.

External clamping diodes or resistor dividers can be used to

translate 5 V levels to 3 V levels, but the lowest power dissipation is achieved with a logic transceiver chip. National

Semiconductor’s 74LVX4245 provides a 5 V to 3 V level shift

for up to eight clock signals, has a three-state option, and

features low power consumption. Philips Semiconductor and

Quality also manufacture similar devices.

Driving the Direct ADC Input

The AD9802 can be used in a “direct ADC input” mode, in

which the input signal bypasses the input clamp, CDS and

PGA, and is sent directly to the sample and hold amplifier (SHA)

of the ADC. There are several methods that may be used to

drive the direct ADC input.

To enable the direct input mode of operation, ADCMODE (Pin

41) is taken to logic high. This will internally disconnect the

PGA output from the SHA input, and connect ADCIN (Pin 36)

to the SHA input.

The SHA has a differential input, consisting of ADCIN (Pin 36)

as the positive input, and SHABYP (Pin 38) as the negative

input. Both pins must be properly dc biased.

Figures 22 through 25 show four circuits for driving the direct

ADC input. Decoupling capacitors are not shown for CML,

VRT, VRB and SHABYP pins.

1V p-p

CML

+3V

ADCIN

CML

SHABYP

ADCMODE

SHA

1.5V

AD9802

Figure 22. DC-Coupled Input

Figure 22 is a single-ended, dc-coupled circuit. SHABYP is

connected to CML (1.5 V) to establish a midpoint bias. The

input signal of 1 V p-p should be centered around CML.

Figure 23 shows an ac-coupled configuration, where both inputs

are biased to CML. The input capacitor C

and bias resistors

IN

should be sized to set the appropriate high pass cutoff frequency

for the application. To minimize the differential offset voltage

due to the input bias currents, both resistors should be equal.

–10–

1V p-p

C

IN

+3V

ADCIN

R

BIAS

CML

R

BIAS

SHABYP

ADCMODE

SHA

1.5V

AD9802

Figure 23. AC-Coupled Input

Figure 24 shows an alternative ac-coupled configuration. By

connecting SHABYP to CML, the dc bias at Pin 36 (ADCIN)

will internally track to the same voltage, automatically setting

the input bias level. With a given input capacitor value, C

IN

, the

time constant in this configuration will be dependent on the

sampling frequency F

1V p-p

. Specifically:

S

τ = (C

IN/FS

C

IN

+3V

) × 2E +12

ADCIN

CML

SHABYP

ADCMODE

SHA

1.5V

AD9802

Figure 24. “Auto Bias” AC-Coupled Input

Figure 25 shows a true differential drive circuit. Each input

would be 500 mV p-p, to achieve the 1 V full-scale input to the

ADC. The common-mode input range for this configuration

extends from about 500 mV to 2.5 V. This circuit could also be

implemented with ac coupling, similar to Figure 23.

500mV p-p

500mV p-p

+3V

ADCIN

SHA

CML

SHABYP

AD9802

ADCMODE

Figure 25. Differential Input

Figure 26 shows a video clamp circuit which may be used with

the direct ADC mode of the AD9802 (supplies and decoupling

not shown). The circuit will clamp the reference black level of

an incoming video signal to 1.25 V dc. With SHABYP connected to 1.75 V (VRT), the ADCIN range spans from 1.25V

to 2.25 V. To accomplish this, the CLAMP pulse should be

asserted during the horizontal sync interval, when the video is at

its reference black level. A 5 V logic high applied to the gate of

the SD210 will turn on the device, and the input capacitor C

IN

will charge up to provide 1.25 V at the ADCIN pin of the

AD9802. Other appropriate NMOS devices may be substituted

for the SD210. The AD8047 op amp requires ± 5 V supplies;

appropriate single supply op amps may be substituted. The size

of capacitor C

should be set to meet the acquisition time and

IN

REV. 0

Page 11

AD9802

droop specifications needed. A capacitor value of 0.01µF will

result in a droop of less than 10 LSB across one video line, and

requires only a CLAMP pulse of 1 µs to charge up. A larger

capacitor may be used to reduce droop, but then a longer

CLAMP pulse may be necessary.

1V p-p

CLAMP

500V

C

IN

SD210

AD8047

500V

+3V

ADCIN

CML

SHABYP

VRT

VRB

ADCMODE

SHA

AD9802

Figure 26. Video Clamp Circuit

1.0

0.5

0

20.5

21.0

0 600100 200 300 400 500

700 800 900

1023

Figure 27. Direct ADC-Mode Typical INL

1.0

0.5

0

20.5

0

AMPLITUDE – dB

–100

0 9.0

FREQUENCY – MHz

Figure 29. Direct ADC Mode Typical FFT; FIN = 3.58 MHz,

= 18 MHz

F

S

Figures 27–29 show the typical linearity and distortion performance of the AD9802 in direct ADC mode.

Digitally Programmable Gain Control

The AD9802’s PGA is controlled by an analog input voltage of

0.3 V to 2.7 V. In some applications, digital gain control is

preferable. Figure 30 shows a circuit using Analog Devices’

AD8402 Digital Potentiometer to generate the PGA control

voltage. The AD8402 functions as two individual potentiometers, with a serial digital interface to program the position of

each wiper over 256 positions. The device will operate with 3V

or 5 V supplies, and features a power-down mode and a reset

function.

To keep external components to a minimum, the ends of the

“potentiometers” can be tied to ground and +3 V. One pot is

used for the coarse gain adjust, PGACONT1, with steps of

about 0.2 dB/LSB. The other pot is used for fine gain control,

PGACONT2, and is capable of around 0.01dB steps if all

eight bits are used. The two outputs should be filtered with

1 µF or larger capacitors to minimize noise into the PGACONT

pins of the AD9802.

PGACONT2

+3V

1mF

1

2

3

AD8402-10

4

5

6

7

14

13

12

11

10

9

8

+3V

PGACONT1

+3V

0.1mF1mF

21.0

0 600100 200 300 400 500

700 800 900

Figure 28. Direct ADC-Mode Typical DNL

1023

SHDN CS

SDI

RS

CLK

Figure 30. Digital Control of PGA

–11–REV. 0

Page 12

AD9802

The disadvantage of this circuit is that the control voltage will

be supply dependent. If additional precision is required, an

external op amp can be used to amplify the VREFT (1.75 V) or

VREFB (1.25 V) pins on the AD9802 to the desired voltage

level. These reference voltages are stable over the operating

supply range of the AD9802. Low power, low cost, rail-to-rail

output amplifiers like the AD820, OP150 and OP196 are specified for 3 V operation. Alternatively, a precision voltage reference may be used. The REF193 from Analog Devices features

low power, low dropout performance, maintaining a 3 V output

with a minimum 3.1 V supply when lightly loaded.

Power and Grounding Recommendations

The AD9802 should be treated as an analog component when

used in a system. The same power supply and ground plane

should be used for all of the pins. In a two-ground system, this

requires that the digital supply pins be decoupled to the analog

ground plane and the digital ground pins be connected to analog ground for best noise performance. If any pins on the

AD9802 are connected to the system digital ground, then noise

can capacitively couple inside the AD9802 (through package

and die parasitics) from the digital circuitry to the analog

circuitry. Separate digital supplies can be used, particularly if

slightly different driver supplies are needed, but the digital

power pins should still be decoupled to the same point as the

digital ground pins (analog ground plane). If the AD9802 digital outputs need to drive a bus or substantial load, a buffer

should be used at the AD9802’s outputs, with the buffer referenced to system digital ground. In some cases, when system

digital noise is not substantial, it is acceptable to split the

ground pins on the AD9802 to separate analog and digital

ground planes. If this is done, be sure to connect the ground

pins together at the AD9802.

To further improve performance, isolating the driver supply

DRVDD from DVDD with a ferrite bead can help reduce kickback effects during major code transitions. Alternatively, the use

of damping resistors on the digital outputs will reduce the output rise times, reducing the kickback effect.

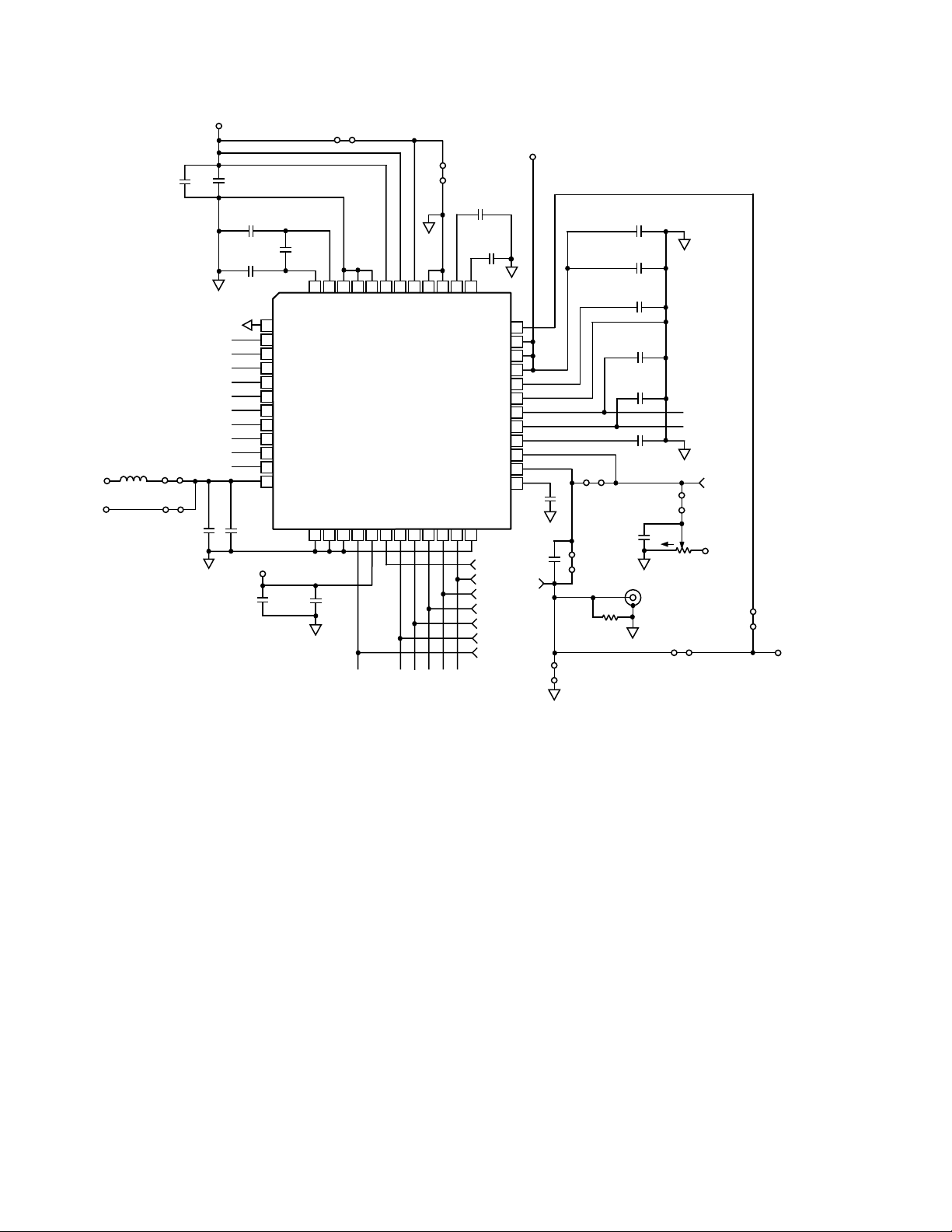

Evaluation Board

An evaluation board for the AD9802 is available. The board

includes circuitry for manual PGA gain adjustment, input signal

buffering, and logic level translation for 3 V or 5 V digital signals.

Documentation for the AD9802-EB is included, consisting of a

board description, schematic and layout information.

AD9801/AD9802 EVALUATION BOARD DESCRIPTION

Power Supply Connectors

J1 VDD: +3 V supply for the AD9801/AD9802. Data

sheet specifications are given for +3.15 V. Operational

range is from +3 V to +3.5 V.

J2 AVCC: +5 V supply for the AD8047 buffer, and for the

PGACONT and PIN potentiometers. If the buffer amplifier is not needed, AVCC may be connected to the

VDD supply.

J3 AVSS: –5 V supply for the AD8047 buffer. If the buffer

amplifier is not needed, AVSS may be connected to J4.

J4 AGND: This is the analog ground plane for the

AD9801/AD9802 and the buffer amplifier. The two

ground planes are already connected together in one

place on the evaluation board.

J5 DGND: This is the digital ground plane for the

LVXC3245 transceivers. The two ground planes are

already connected together in one place on the evalua-

tion board.

J6 +3D: +3 V digital supply for the LVXC3245 transceivers.

J7 +3/5D: +3 V or +5 V digital supply for the LVXC3245

transceivers. This voltage determines the logic compat-

ibility of the evaluation board. If 3 V clock levels and

3 V digital output levels are to be used, connect +3 V to

J7. If +5 V clock levels and +5 digital output levels are

to be used, connect +5 V to J7.

Input Connectors

J8 DIN: Unbuffered input to the AD9801/AD9802. This

input is 50 Ω terminated by R4, which may be removed

if no termination is required. See Input Configurations

for more information.

J9 VIN: Input to the AD8047 buffer amplifier. This

input is 50 Ω terminated by R5, which may be re-

moved if no termination is required. This op amp

can be used as a buffer to drive the DIN pin on the

AD9801/AD9802, or as a buffer for driving the direct

ADC input on the AD9802. See Input Configurations

and the AD9802 data sheet for more information.

Clock Connectors

J10 CLPDM

J11 SHD

J12 SHP

J13 CLPOB

J14 PBLK

J15 ADCCLK

All of the clock inputs are 50 Ω terminated and buffered by an

LVXC3245 transceiver. The supply level at J7 determines the

input clock level compatibility. The outputs of the LVXC3245

always send +3 V clock levels to the AD9801/AD9802.

–12–

REV. 0

Page 13

AD9802

Jumper Descriptions

JP1 Connect to bypass the input coupling capacitor C18.

JP2 Connect to short PIN and DIN (Pins 26 and 27 of the

AD9801) together.

JP3 Connects PIN to the dc level set by the wiper of R1.

JP4 Connect to short the input coupling capacitor to ground,

for test purposes.

JP5 Connects the output of the buffer amplifier to the

AD9801/AD9802 input.

JP6 Connects the AD9801/AD9802’s DRVDD pin to the

VDD supply through ferrite bead FB6.

JP7 Connects the AD9801/AD9802’s DRVDD pin to the

+3D supply.

JP8 Connects the output of the AD8047 op amp to the

direct ADC input of the AD9802. This jumper should

never be connected on the AD9801-EB.

JP9 Selects the regular camera mode of operation on the

AD9802. This jumper should always be in place on the

AD9801-EB.

JP10 Selects the direct ADC input mode on the AD9802.

This jumper should never be connected on the

AD9801-EB.

Input Configurations

Input JP1 JP2 JP3 JP4 JP5 JP8 JP9 JP10

Standard CCD Input J8 open short open open open open short open

Grounded Input Test none open short open short open open short open

Buffered Input* J9 open short open open short open short open

Direct ADC Input J9 [ ... don’t care... ] short open short

(9802 only)

*When using the buffer amplifier, ±5 V must be connected to AVCC and AVSS, and R4 should be removed.

Test Point Descriptions

TP1 Input signal at J8.

TP2 Input signal at PIN/DIN of AD9801/AD9802.

TP3 PGACONT1 voltage.

TP4 PGACONT2 voltage.

TP5 STANDBY pin, pull high to enable power-down mode.

TP6 CLPDM at AD9801/AD9802.

TP7 SHD at AD9801/AD9802.

TP8 SHP at AD9801/AD9802.

TP9 CLPOB at AD9801/AD9802.

TP10 PBLK at AD9801/AD9802.

TP11 ADCCLK at AD9801/AD9802.

TP12 VDD

TP13 AVCC

TP14 AVSS

TP15 AGND

TP16 DGND

TP17 +3D

TP18 +3/5D

Prototype Area

The top left hole in the prototyping area is connected to

AGND. The bottom right hole is connected to AVCC.

–13–REV. 0

Page 14

AD9802

VDD

+3D

FB6

C55

0.01mF

JP6

JP7

C17

0.01mF

VDD

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

C4

0.1mF

0.1mF

0.1mF

C16

0.1mF

JP10

VDD

JP9

C5

MODE1

MODE2

SHABYP

CLAMP_BIAS

PGACONT2

PGACONT1

CCDBYP1

CCDBYP2

SHD

CLPDM

SHP

0.1mF

C6

0.1mF

ADCIN

CMLEVEL

TEST2

TEST1

ACVDD

ACVSS

PIN

DIN

DVSS

TP5

TP6

TP7

TP8

TP9

TP10

TP11

36

35

34

33

32

31

30

29

28

27

26

25

0.1mF

0.1mF

TP1

C13

C18

JP1

JP2

R4

50V

C19

0.1mF

C56

0.1mF

C8

0.1mF

C9

0.1mF

C10

0.1mF

C11

0.1mF

C12

0.1mF

J8

DIN

JP3

CW

PGACONT2

PGACONT1

R1

1kV

JP5

TP2

AVCC

JP8

AMP_OUT

C2

1

2

3

4

5

6

7

8

9

10

11

12

C1

1mF

48 47 46 45 44 39 38 3743 42 41 40

VRT

VRB

SUBST

ADVSS

ADVSS

ADVSS

ADVDD

D0 (LSB)

D1

D2

D3

D4

D5

D6

U1

AD9802

D7

D8

D9 (MSB)

DRVDD

DRVSS

ADCCLK

DVDD

DVSS

STBY

DSUBST

13 14 15 16 17 18 19 20 21 22 23 24

ADVDD

ADCMODE

PBLK

CLPOB

C3

VDD

C15

0.01mF

C14

0.1mF

JP4

SHP

SHD

PBLK

CLPOB

ADCCLK

CLPDM

Figure 31. Evaluation Board

–14–

REV. 0

Page 15

AD9802

J1

J2

J3

J4

J5

J6

J7

+3V

+5V

–5V

GND

DGND

+3D

+3/5D

C34

0.1mF

C37

0.1mF

C40

0.1mF

C43

0.1mF

C46

0.1mF

FB1

FB2

FB3

FB4

FB5

TP15

TP16

TP12

TP13

TP14

TP17

TP18

C35

22mF

C38

22mF

C41

22mF

C44

22mF

C47

22mF

C36

0.1mF

C39

0.1mF

C42

0.1mF

C45

0.1mF

C48

0.1mF

VDD

AVCC

AVSS

+3D

+3/5D

AVCC

CW

R2

10kV

AVCC

CW

R3

10kV

AVCC

VIN

J9

R5

50V

R13

500V

U2

AD8047

AVSS

C31

0.1mF

C33

0.1mF

TP3

TP4

C21

0.01mF

C23

0.01mF

C30

10mF

16V

C32

10mF

16V

PGACONT1

PGACONT2

C20

1.0mF

C22

1.0mF

R6

20V

AMP_OUT

Figure 32. Evaluation Board

–15–REV. 0

Page 16

AD9802

C26

0.01mF

C28

0.01mF

C53

0.1mF

C52

0.1mF

ADCCLK

R7

50V

R9

50V

R11

50V

J10

J12

J14

CLPDM

R8

50V

SHP

R10

50V

PBLK

R12

50V

J11

SHD

J13

CLPOB

J15

ADCCLK

+3D

74LVXC3245

1

VCCA

2

T/R

B

3

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

+3D

A0

4

A1

5

A2

6

A3

7

A4

8

A5

9

A6

10

A6

11

GND

12

GND

1

VCCA

2

T/R

3

A0

4

A1

5

A2

6

A3

7

A4

8

A5

9

A6

10

A6

11

GND

12

GND

U4

74LVXC3245

B

U5

V

OE

GND

V

OE

GND

+3/5D

C27

C50

0.01mF

0.1mF

24

B

CC

23

NC

22

B

21

B0

B1

B2

B3

B4

B5

B6

B7

CC

NC

B0

B1

B2

B3

B4

B5

B6

B7

DB9

20

DB8

19

DB7

18

DB6

17

DB5

16

DB4

15

DB3

14

DB2

13

+3/5D

C29

C51

0.01mF

0.1mF

24

B

23

22

B

21

DB1

20

DB0

19

18

17

16

15

14

CLKOUT

13

C24

0.01mF

C54

0.1mF

CLPDM

SHD

SHP

CLPOB

PBLK

ADCCLK

+3D

1

VCCA

2

T/R

3

A0

4

A1

5

A2

6

A3

7

A4

8

A5

9

A6

10

A6

11

GND

12

GND

74LVXC3245

B

U3

40-PIN HEADER

+3/5D

C25

C49

24

V

B

CC

23

NC

22

OE

B

21

B0

20

B1

19

B2

18

B3

17

B4

16

B5

15

B6

14

B7

13

GND

2

1

3

5

7

10

9

11

13

15

J16

17

20

19

21

23

30

33

40

0.1mF

DB9 (MSB)

DB8

DB7

DB6

DB5

DB4

DB3

DB2

DB1

DB0 (LSB)

CLKOUT

0.01mF

Figure 33. Evaluation Board

–16–

REV. 0

Page 17

AD9802

Figure 34. Primary Side (Layer 1)

Figure 35. Ground Plane (Layer 2)

–17–REV. 0

Page 18

AD9802

Figure 36. Power Plane (Layer 3)

Figure 37. Secondary Layer (Layer 4)

–18–

REV. 0

Page 19

AD9802

Figure 38. Primary Side Assembly

Figure 39. Secondary Side Assembly

–19–REV. 0

Page 20

AD9802

OUTLINE DIMENSIONS

Dimensions shown in inches and (mm).

48-Terminal Plastic Thin Quad Flatpack (TQFP)

(ST-48)

0.030 (0.75)

0.018 (0.45)

SEATING

PLANE

0.076 MAX

0° – 7°

0.063 (1.60) MAX

0.030 (0.75)

0.057 (1.45)

0.018 (0.45)

0.053 (1.35)

0° MIN

0.007 (0.18)

0.004 (0.09)

0.354 (9.00) BSC

0.276 (7.0) BSC

48

1

TOP VIEW

(PINS DOWN)

12

13

0.019 (0.5)

BSC

37

36

25

24

0.011 (0.27)

0.006 (0.17)

0.276 (7.0) BSC

0.354 (9.00) BSC

C3102–3–10/97

–20–

PRINTED IN U.S.A.

REV. 0

Loading...

Loading...