Page 1

Dual 12-/14-/16-Bit,1 GSPS,

FEATURES

Low power: 1.0 W @ 1 GSPS, 600 mW @ 500 MSPS,

full operating conditions

Single carrier W-CDMA ACLR = 7 dBc @ 80 MHz IF

Analog output: adjustable 8.7 mA to 31.7 mA,

R

= 25 Ω to 50 Ω

L

Novel 2×, 4×, and 8× interpolator/coarse complex modulator

allows carrier placement anywhere in DAC bandwidth

Auxiliary DACs allow control of external VGA and offset control

Multiple chip synchronization interface

High performance, low noise PLL clock multiplier

Digital inverse sinc filter

100-lead, exposed paddle TQFP

APPLICATIONS

Wireless infrastructure

W-CDMA, CDMA2000, TD-SCDMA, WiMax, GSM

Digital high or low IF synthesis

Internal digital upconversion capability

Transmit diversity

Wideband communications: LMDS/MMDS, point-to-point

Digital-to-Analog Converters

AD9776A/AD9778A/AD9779A

GENERAL DESCRIPTION

The AD9776A/AD9778A/AD9779A are dual, 12-/14-/16-bit,

high dynamic range, digital-to-analog converters (DACs) that

provide a sample rate of 1 GSPS, permitting a multicarrier

generation up to the Nyquist frequency. They include features

optimized for direct conversion transmit applications, including

complex digital modulation, and gain and offset compensation.

The DAC outputs are optimized to interface seamlessly with

analog quadrature modulators such as the ADL537x FMOD

series from Analog Devices, Inc. A serial peripheral interface

(SPI) provides for programming/readback of many internal

parameters. Full-scale output current can be programmed over

a range of 10 mA to 30 mA. The devices are manufactured on

an advanced 0.18 m CMOS process and operate on 1.8 V and

3.3 V supplies for a total power consumption of 1.0 W. They are

enclosed in a 100-lead TQFP.

PRODUCT HIGHLIGHTS

1. Ultralow noise and intermodulation distortion (IMD)

enable high quality synthesis of wideband signals from

baseband to high intermediate frequencies.

2. A proprietary DAC output switching technique enhances

dynamic performance.

3. The current outputs are easily configured for various

single-ended or differential circuit topologies.

4. CMOS data input interface with adjustable setup and hold.

5. Novel 2×, 4×, and 8× interpolator/coarse complex

modulator allows carrier placement anywhere in DAC

bandwidth.

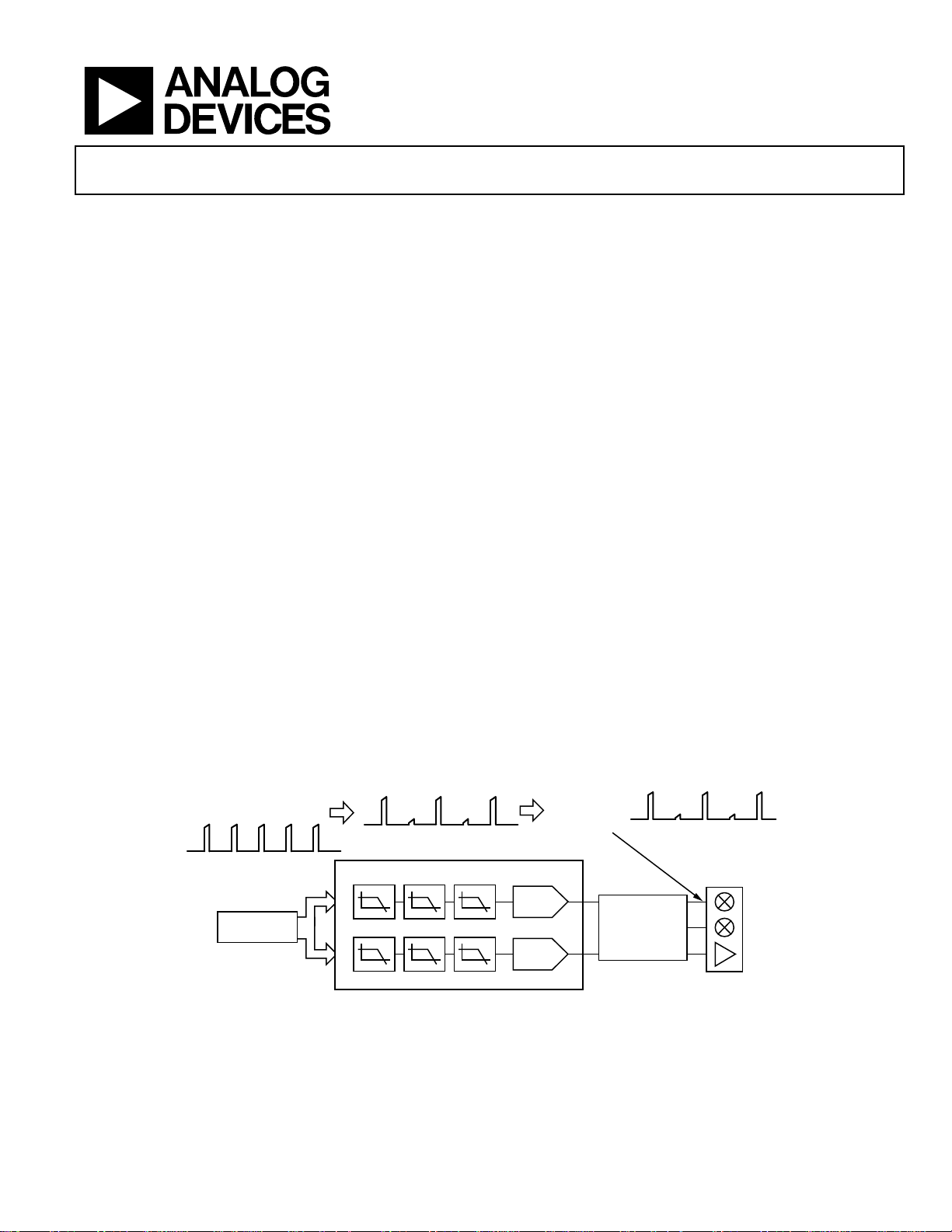

TYPICAL SIGNAL CHAIN

COMPLEX I AND Q

DC

DC

FPGA/ASI C/DSP

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

DIGITAL INTERPOL ATION FILTERS

AD9776A/AD9778A/AD9779A

QUADRATURE

MODULATOR/

MIXER/

AMPLIFIER

I DAC

POST DAC

ANALOG FILTER

Q DAC

Figure 1.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007–2008 Analog Devices, Inc. All rights reserved.

LO

A

6452-114

Page 2

AD9776A/AD9778A/AD9779A

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

General Description ......................................................................... 1

Product Highlights ........................................................................... 1

Typical Signal Chain ......................................................................... 1

Revision History ............................................................................... 2

Functional Block Diagram .............................................................. 3

Specifications ..................................................................................... 4

DC Specifications ......................................................................... 4

Digital Specifications ................................................................... 5

Digital Input Data Timing Specifications ................................. 6

AC Specifications .......................................................................... 6

Absolute Maximum Ratings ............................................................ 7

Thermal Resistance ...................................................................... 7

ESD Caution .................................................................................. 7

Pin Configurations and Function Descriptions ........................... 8

Typical Performance Characteristics ........................................... 14

Terminolog y .................................................................................... 22

Theory of Operation ...................................................................... 23

Differences Between AD9776/AD9778/ AD9779 and

AD9776A/AD9778A/AD9779A............................................... 23

Serial Peripheral Interface ............................................................. 24

General Operation of the Serial Interface ............................... 24

Instruction Byte .......................................................................... 24

Serial Interface Port Pin Descriptions ..................................... 25

MSB/LSB Transfers..................................................................... 25

SPI Register Map ............................................................................. 26

Interpolation Filter Architecture .................................................. 31

Interpolation Filter Bandwidth Limits .................................... 35

Sourcing the DAC Sample Clock ................................................. 36

Direct Clocking .......................................................................... 36

Clock Multiplication .................................................................. 36

Driving the REFCLK Input ....................................................... 38

Full-Scale Current Generation ..................................................... 39

Internal Reference ...................................................................... 39

Transmit Path Gain and Offset Correction................................. 40

I/Q Channel Gain Matching ..................................................... 40

Auxiliary DAC Operation ......................................................... 40

LO Feedthrough Compensation .............................................. 41

Results of Gain and Offset Correction .................................... 41

Input Data Ports ............................................................................. 42

Single Port Mode ........................................................................ 42

Dual Port Mode .......................................................................... 42

Input Data Referenced to DATACLK ...................................... 42

Input Data Referenced to REFCLK ......................................... 43

Optimizing the Data Input Timing .......................................... 44

Device Synchronization ................................................................. 45

Synchronization Logic Overview ............................................. 45

Synchronizing Devices to a System Clock .............................. 46

Interrupt Request Operation .................................................... 46

Power Dissipation ........................................................................... 47

Power-Down and Sleep Modes................................................. 48

Evaluation Board Operation ......................................................... 49

Using the ADL5372 Quadrature Modulator .......................... 51

Evaluation Board Schematics ................................................... 52

Outline Dimensions ....................................................................... 60

Ordering Guide .......................................................................... 60

REVISION HISTORY

3/08—Rev. 0 to Rev. A

Changes to Features .......................................................................... 1

Added Note 2 .................................................................................... 4

Changes to Table 2 ............................................................................ 5

Changes to Table 3 ............................................................................ 6

Changes to Thermal Resistance Section ........................................ 7

Inserted Table 6 ................................................................................. 8

Changes to Pin 39 Description, Table 7 ......................................... 9

Changes to Pin 39 Description, Table 8 ....................................... 10

Changes to Pin 39 Description, Table 9 ....................................... 12

Changes to Theory of Operation Section .................................... 23

Rev. A | Page 2 of 60

Changes to Table 10 ....................................................................... 23

Changes to Table 13 ....................................................................... 26

Changes to Table 14 ....................................................................... 27

Changes to Interpolation Filter Architecture Section ............... 33

Replaced Sourcing the DAC Sample Clock Section .................. 36

Replaced Transmit Path Gain and Offset Correction Section . 40

Replaced Input Data Ports Section .............................................. 42

Replaced Device Synchronization Section .................................. 45

Deleted Figure 112 to Figure 117 ................................................. 58

8/07—Revision 0: Initial Version

Page 3

AD9776A/AD9778A/AD9779A

K

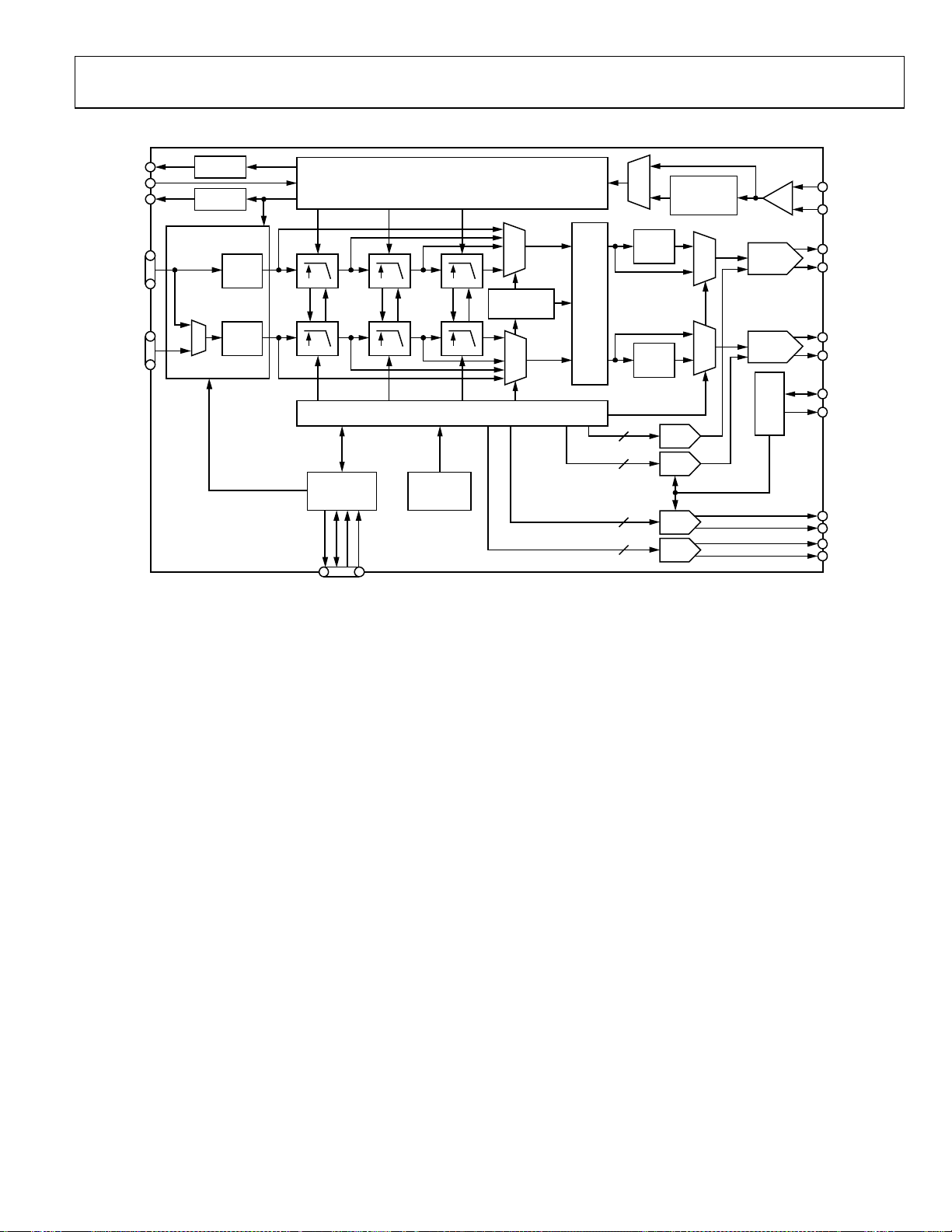

FUNCTIONAL BLOCK DIAGRAM

SYNC_O

SYNC_I

DATACLK

P1D<15:0>

P2D<15:0>

DELAY

LINE

DELAY

LINE

DATA

ASSEMBLER

LATCH

LATCH

AD9779A

CLOCK GENERAT ION/DISTRIBUTIO N

I

Q

2× 2×

2× 2× 2×

DIGITAL CONTROLL ER

SERIAL

PERIPHERAL

INTERFACE

SDO

SDIO

SCL

CSB

POWER-ON

RESET

2×

n × f

/8

DAC

n = 0, 1, 2 ... 7

COMPLEX

MODULATOR

10

10

10

10

SYNC

SYNC

CLOCK

MULTIPLIER

2×/4×/8×

GAIN

GAIN

GAIN

GAIN

16-BIT

I DAC

16-BIT

Q DAC

REFERENCE

AND BIAS

REFCLK+

REFCLK–

OUT1_P

OUT1_N

OUT2_P

OUT2_N

VREF

I120

AUX1_P

AUX1_N

AUX2_P

AUX2_N

6452-001

Figure 2. AD9779A Functional Block Diagram

Rev. A | Page 3 of 60

Page 4

AD9776A/AD9778A/AD9779A

SPECIFICATIONS

DC SPECIFICATIONS

T

to T

MIN

otherwise noted.

Table 1.

AD9776A AD9778A AD9779A

Parameter Min Typ Max Min Typ Max Min Typ Max Unit

RESOLUTION 12 14 16 Bits

ACCURACY

Differential Nonlinearity (DNL) ±0.1 ±0.65 ±2.1 LSB

Integral Nonlinearity (INL) ±0.6 ±1 ±3.7 LSB

MAIN DAC OUTPUTS

Offset Error −0.001 0 +0.001 −0.001 0 +0.001 −0.001 0 +0.001 % FSR

Gain Error (With Internal Reference) ±2 ±2 ±2 % FSR

Full-Scale Output Current

Output Compliance Range −1.0 +1.0 −1.0 +1.0 −1.0 +1.0 V

Output Resistance 10 10 10 MΩ

Gain DAC Monotonicity Guaranteed Guaranteed Guaranteed

MAIN DAC TEMPERATURE DRIFT

Offset 0.04 0.04 0.04 ppm/°C

Gain 100 100 100 ppm/°C

Reference Voltage 30 30 30 ppm/°C

AUX DAC OUTPUTS

Resolution 10 10 10 Bits

Full-Scale Output Current

Output Compliance Range (Source) 0 1.6 0 1.6 0 1.6 V

Output Compliance Range (Sink) 0.8 1.6 0.8 1.6 0.8 1.6 V

Output Resistance 1 1 1 MΩ

AUX DAC Monotonicity Guaranteed Guaranteed Guaranteed

REFERENCE

Internal Reference Voltage 1.2 1.2 1.2 V

Output Resistance 5 5 5 kΩ

ANALOG SUPPLY VOLTAGES

AVDD33 3.13 3.3 3.47 3.13 3.3 3.47 3.13 3.3 3.47 V

CVDD18 1.70 1.8 2.05 1.70 1.8 2.05 1.70 1.8 2.05 V

DIGITAL SUPPLY VOLTAGES

DVDD33 3.13 3.3 3.47 3.13 3.3 3.47 3.13 3.3 3.47 V

DVDD18 1.70 1.8 2.05 1.70 1.8 2.05 1.70 1.8 2.05 V

POWER CONSUMPTION

1× Mode, f

2× Mode, f

2× Mode, f

4× Mode, f

8× Mode, f

Power-Down Mode 2.5 9.8 2.5 9.8 2.5 9.8 mW

Power Supply Rejection Ratio, AVDD33 −0.3 +0.3 −0.3 +0.3 −0.3 +0.3 % FSR/V

OPERATING RANGE −40 +25 +85 −40 +25 +85 −40 +25 +85 °C

1

Based on a 10 kΩ external resistor.

2

See the Power Dissipation section for more details.

, AVDD33 = 3.3 V, DVDD33 = 3.3 V, DVDD18 = 1.8 V, CVDD18 = 1.8 V, I

MAX

1

1

2

= 100 MSPS, IF = 1 MHz 250 300 250 300 250 300 mW

DAC

= 320 MSPS, IF = 16 MHz, PLL Off 498 498 498 mW

DAC

= 320 MSPS, IF = 16 MHz, PLL On 588 588 588 mW

DAC

/4 Modulation, f

DAC

= 500 MSPS,

DAC

8.66 20.2 31.66 8.66 20.2 31.66 8.66 20.2 31.66 mA

−1.998 +1.998 −1.998 +1.998 −1.998 +1.998 mA

572 572 572 mW

IF = 137.5 MHz, Q DAC Off

/4 Modulation, f

DAC

= 1 GSPS,

DAC

980 980 980 mW

IF = 262.5 MHz

= 20 mA, maximum sample rate, unless

OUTFs

Rev. A | Page 4 of 60

Page 5

AD9776A/AD9778A/AD9779A

DIGITAL SPECIFICATIONS

T

to T

MIN

, AVDD33 = 3.3 V, DVDD33 = 3.3 V, DVDD18 = 1.8 V, CVDD18 = 1.8 V, I

MAX

otherwise noted. LVDS driver and receiver are compliant to the IEEE-1596 reduced range link, unless otherwise noted.

Table 2.

Parameter Conditions Min Typ Max Unit

CMOS INPUT LOGIC LEVEL

Input VIN Logic High 2.0 V

Input VIN Logic Low 0.8 V

Maximum Input Data Rate at Interpolation

1× 300 MSPS

2× 250 MSPS

4× 200 MSPS

8× DVDD18, CVDD18 = 1.8 V ± 5% 112.5 MSPS

DVDD18, CVDD18 = 1.9 V ± 5% 125 MSPS

DVDD18, CVDD18 = 2.0 V ± 2% 137.5 MSPS

CMOS OUTPUT LOGIC LEVEL (DATACLK, PIN 37)

Output V

Output V

Logic High 2.4 V

OUT

Logic Low 0.4 V

OUT

1

DATACLK Output Duty Cycle At 250 MHz, into 5 pF load 40 50 60 %

LVDS RECEIVER INPUTS (SYNC_I+, SYNC_I−) SYNC_I+ = VIA, SYNC_I− = VIB

Input Voltage Range, VIA or VIB 825 1575 mV

Input Differential Threshold, V

Input Differential Hysteresis, V

−100 +100 mV

IDTH

− V

IDTHH

20 mV

IDTHL

Receiver Differential Input Impedance, RIN 80 120 Ω

LVDS Input Rate

Additional limits on f

apply; see description of

SYNC_I

Register 5, Bits<3:1> in Tab le 14

Setup Time, SYNC_I to REFCLK 0.4 ns

Hold Time, SYNC_I to REFCLK 0.55 ns

LVDS DRIVER OUTPUTS (SYNC_O+, SYNC_O−) SYNC_O+ = VOA, SYNC_O− = VOB, 100 Ω termination

Output Voltage High, VOA or VOB 1375 mV

Output Voltage Low, VOA or VOB 1025 mV

Output Differential Voltage, |VOD| 150 200 250 mV

Output Offset Voltage, VOS 1150 1250 mV

Output Impedance, RO Single-ended 80 100 120 Ω

DAC CLOCK INPUT (REFCLK+, REFCLK−)

Differential Peak-to-Peak Voltage 400 800 2000 mV

Common-Mode Voltage 300 400 500 mV

Maximum Clock Rate DVDD18, CVDD18 = 1.8 V ± 5% 900 MSPS

DVDD18, CVDD18 = 1.9 V ± 5% 1000 MSPS

DVDD18, CVDD18 = 2.0 V ± 2% 1100 MSPS

SERIAL PERIPHERAL INTERFACE

Maximum Clock Rate (SCLK) 40 MHz

Minimum Pulse Width High 12.5 ns

Minimum Pulse Width Low 12.5 ns

Setup Time, SDI to SCLK 1.6 ns

Hold Time, SDI to SCLK 0.0 ns

Data Valid, SDO to SCLK 2.0 ns

1

Specification is at a DATACLK frequency of 100 MHz into a 1 kΩ load, maximum drive capability of 8 mA. At higher speeds or greater loads, best practice suggests

using an external buffer for this signal.

= 20 mA, maximum sample rate, unless

OUTFs

250 MSPS

Rev. A | Page 5 of 60

Page 6

AD9776A/AD9778A/AD9779A

DIGITAL INPUT DATA TIMING SPECIFICATIONS

All modes, −40°C to +85°C.

Table 3.

Parameter Conditions Min Typ Max Unit

Input Data1

Setup Time Input data to DATACLK 3.0 ns

Hold Time Input data to DATACLK 0.0 ns

Setup Time Input data to REFCLK −0.8 ns

Hold Time Input data to REFCLK 3.7 ns

Latency

1× Interpolation With or without modulation 25 DACCLK Cycles

2× Interpolation With or without modulation 70 DACCLK Cycles

4× Interpolation With or without modulation 146 DACCLK Cycles

8× Interpolation With or without modulation 297 DACCLK Cycles

Inverse Sync 18 DACCLK Cycles

Power-Up Time

1

Timing vs. temperature and data valid keep out windows are delineated in Table 25.

2

Measured from CSB rising edge on Register 0x00, Bit 4 write from 0 to 1. VREF decoupling capacitor equal to 0.1 μF.

AC SPECIFICATIONS

T

to T

MIN

otherwise noted.

2

, AVDD33 = 3.3 V, DVDD33 = 3.3 V, DVDD18 = 1.8 V, CVDD18 = 1.8 V, I

MAX

260 ms

= 20 mA, maximum sample rate, unless

OUTFs

Table 4.

AD9776A AD9778A AD9779A

Parameter Min Typ Max Min Typ Max Min Typ Max Unit

SPURIOUS FREE DYNAMIC RANGE (SFDR)

f

= 100 MSPS, f

DAC

f

= 200 MSPS, f

DAC

f

= 400 MSPS, f

DAC

f

= 800 MSPS, f

DAC

= 20 MHz 82 82 82 dBc

OUT

= 50 MHz 81 81 82 dBc

OUT

= 70 MHz 80 80 80 dBc

OUT

= 70 MHz 85 85 87 dBc

OUT

TWO-TONE INTERMODULATION DISTORTION (IMD)

f

= 200 MSPS, f

DAC

f

= 400 MSPS, f

DAC

f

= 400 MSPS, f

DAC

f

= 800 MSPS, f

DAC

NOISE SPECTRAL DENSITY (NSD) EIGHT-TONE, 500 kHz

= 50 MHz 87 87 91 dBc

OUT

= 60 MHz 80 85 85 dBc

OUT

= 80 MHz 75 81 81 dBc

OUT

= 100 MHz 75 80 81 dBc

OUT

TONE SPACING

f

= 200 MSPS, f

DAC

f

= 400 MSPS, f

DAC

f

= 800 MSPS, f

DAC

W-CDMA ADJACENT CHANNEL LEAKAGE RATIO (ACLR),

= 80 MHz −152 −155 −158 dBm/Hz

OUT

= 80 MHz −155 −159 −160 dBm/Hz

OUT

= 80 MHz −157.5 −160 −161 dBm/Hz

OUT

SINGLE CARRIER

f

= 491.52 MSPS, f

DAC

f

= 491.52 MSPS, f

DAC

W-CDMA SECOND ADJACENT CHANNEL LEAKAGE RATIO

= 100 MHz 76 78 79 dBc

OUT

= 200 MHz 69 73 74 dBc

OUT

(ACLR), SINGLE CARRIER

f

= 491.52 MSPS, f

DAC

f

= 491.52 MSPS, f

DAC

= 100 MHz 77.5 80 81 dBc

OUT

= 200 MHz 76 78 78 dBc

OUT

Rev. A | Page 6 of 60

Page 7

AD9776A/AD9778A/AD9779A

ABSOLUTE MAXIMUM RATINGS

Table 5.

Parameter With Respect To Rating

AVDD33, DVDD33

DVDD18, CVDD18

AGND DGND, CGND −0.3 V to +0.3 V

DGND AGND, CGND −0.3 V to +0.3 V

CGND AGND, DGND −0.3 V to +0.3 V

I120, VREF, IPTAT AGND

OUT1_P, OUT1_N,

OUT2_P, OUT2_N,

AUX1_P, AUX1_N,

AUX2_P, AUX2_N

P1D<15> to P1D<0>,

P2D<15> to P2D<0>

DATACLK, TXENABLE DGND

REFCLK+, REFCLK− CGND

RESET, IRQ, PLL_LOCK,

SYNC_O+, SYNC_O−,

SYNC_I+, SYNC_I−,

CSB, SCLK, SDIO, SDO

Junction Temperature +125°C

Storage Temperature

Range

AGND, DGND,

CGND

AGND, DGND,

CGND

AGND

DGND

DGND

−65°C to +150°C

−0.3 V to +3.6 V

−0.3 V to +2.1 V

−0.3 V to

AVDD33 + 0.3 V

−1.0 V to

AVDD33 + 0.3 V

−0.3 V to

DVDD33 + 0.3 V

−0.3 V to

DVDD33 + 0.3 V

−0.3 V to

CVDD18 + 0.3 V

−0.3 V to

DVDD33 + 0.3 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

For optimal thermal performance, the exposed paddle (EPAD)

should be soldered to the ground plane for the 100-lead,

thermally enhanced TQFP_EP package.

Typical θ

Airflow increases heat dissipation effectively reducing θ

and θJC are specified for a 4-layer board in still air.

JA

JA

.

Table 6. Thermal Resistance

Package Type θJA θJB θJC Unit

100-Lead TQFP_EP

EPAD Soldered 19.1 12.4 7.1 °C/W

EPAD Not Soldered 27.4 °C/W

ESD CAUTION

Rev. A | Page 7 of 60

Page 8

AD9776A/AD9778A/AD9779A

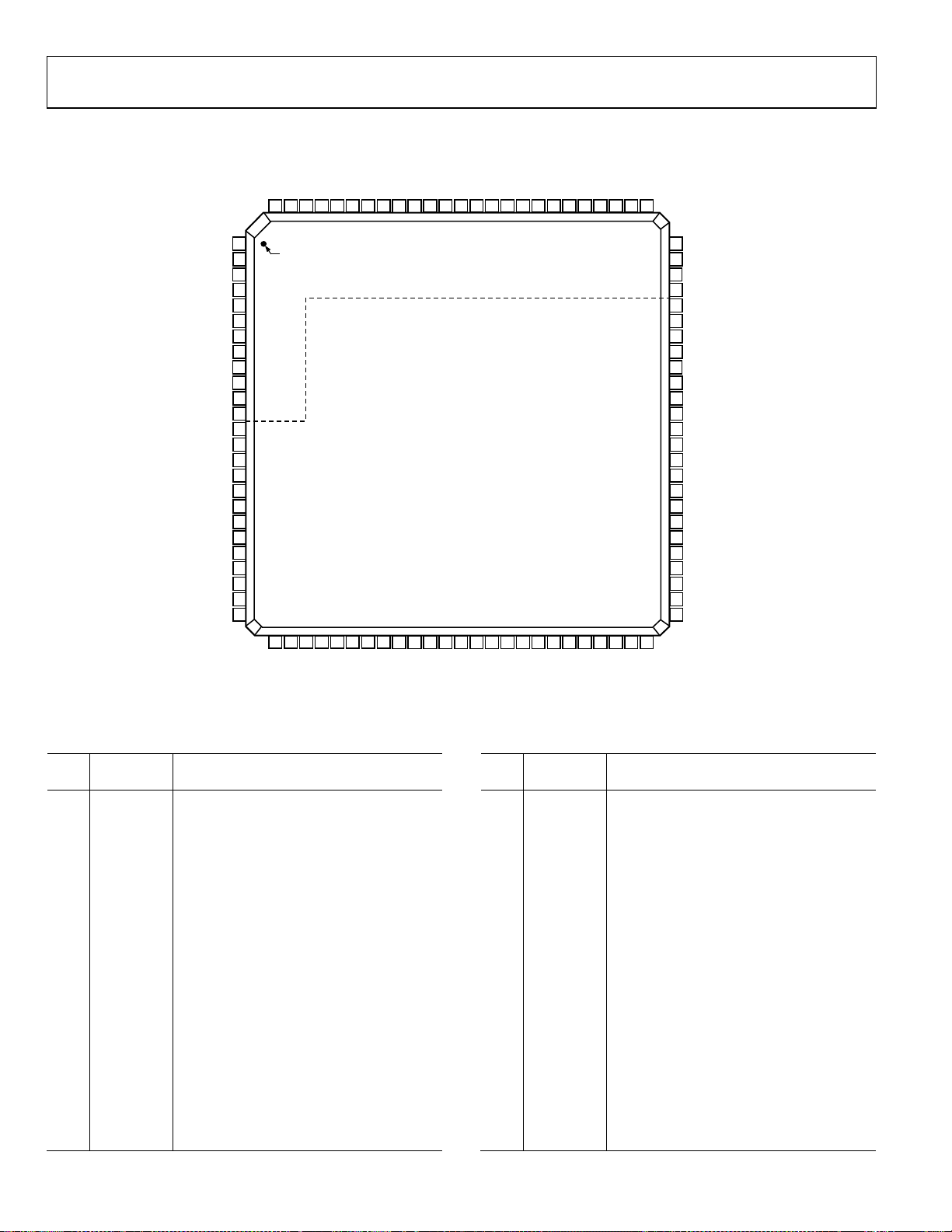

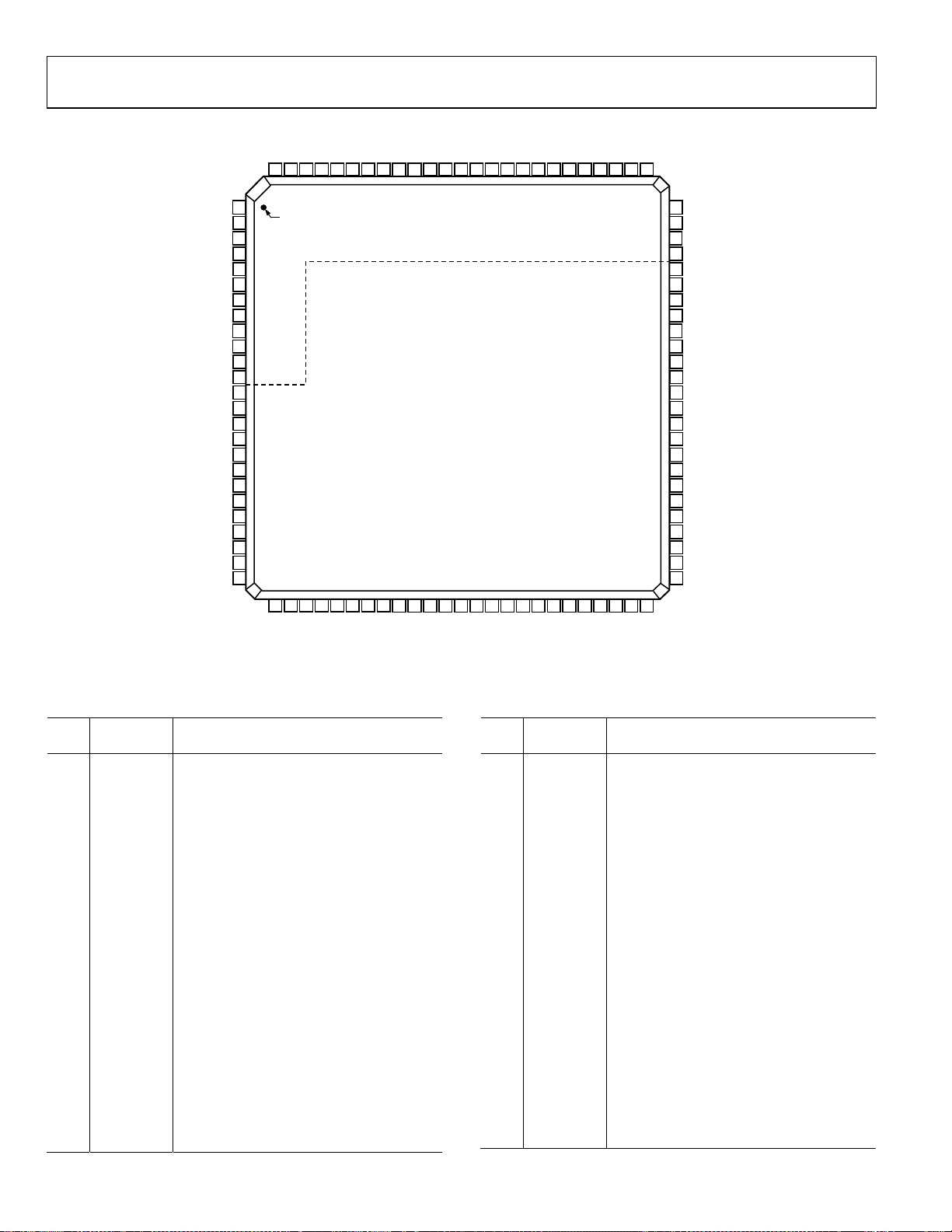

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

AVDD3399AGND98AVDD3397AGND96AVDD3395AGND94AGND93OUT1_P92OUT1_N91AGND90AUX1_P89AUX1_N88AGND87AUX2_N86AUX2_P85AGND84OUT2_N83OUT2_P82AGND81AGND80AVDD3379AGND78AVDD3377AGND76AVDD33

100

CGND

CGND

CGND

CGND

CGND

AGND

DGND

P1D<9>

P1D<8>

P1D<7>

DGND

P1D<6>

P1D<5>

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

CVDD18

CVDD18

REFCLK+

REFCLK–

CVDD18

CVDD18

SYNC_I+

SYNC_I–

DVDD18

P1D<11>

P1D<10>

DVDD18

NC = NO CONNECT

PIN 1

26

P1D<4>27P1D<3>28P1D<2>29P1D<1>30P1D<0>

ANALOG DOMAIN

DIGITAL DO MAIN

AD9776A

TOP VIEW

(Not to Scale)

31NC32

33

DGND

DVDD18

34NC35NC36NC37

38

39

40

DVDD33

P2D<11>41P2D<10>

DATACLK

TXENABLE

Figure 3. AD9776A Pin Configuration

75

I120

74

VREF

73

IPTAT

72

AGND

71

IRQ

70

RESET

69

CSB

68

SCLK

67

SDIO

66

SDO

65

PLL_LOCK

64

DGND

63

SYNC_O+

62

SYNC_O–

61

DVDD33

60

DVDD18

59

NC

58

NC

57

NC

56

NC

55

P2D<0>

54

DGND

53

DVDD18

52

P2D<1>

51

P2D<2>

42

43

44

45

DGND

P2D<9>

P2D<8>46P2D<7>47P2D<6>48P2D<5>49P2D<4>50P2D<3>

DVDD18

06452-002

Table 7. AD9776A Pin Function Descriptions

Pin

No. Mnemonic Description

Pin

No. Mnemonic Description

1 CVDD18 1.8 V Clock Supply. 20 P1D<8> Port 1, Data Input D8.

2 CVDD18 1.8 V Clock Supply. 21 P1D<7> Port 1, Data Input D7.

3 CGND

4 CGND

5 REFCLK+

6 REFCLK−

7 CGND

8 CGND

9 CVDD18

10 CVDD18

11 CGND

12 AGND

13 SYNC_I+

14 SYNC_I−

15 DGND

16 DVDD18

17 P1D<11>

18 P1D<10>

19 P1D<9> Port 1, Data Input D9.

Clock Ground. 22 DGND Digital Ground.

Clock Ground. 23 DVDD18 1.8 V Digital Supply.

Differential Clock Input. 24 P1D<6> Port 1, Data Input D6.

Differential Clock Input. 25 P1D<5> Port 1, Data Input D5.

Clock Ground. 26 P1D<4> Port 1, Data Input D4.

Clock Ground. 27 P1D<3> Port 1, Data Input D3.

1.8 V Clock Supply. 28 P1D<2> Port 1, Data Input D2.

1.8 V Clock Supply. 29 P1D<1> Port 1, Data Input D1.

Clock Ground. 30 P1D<0> Port 1, Data Input D0 (LSB).

Analog Ground. 31 NC No Connect.

Differential Synchronization Input. 32 DGND Digital Ground.

Differential Synchronization Input. 33 DVDD18 1.8 V Digital Supply.

Digital Ground. 34 NC No Connect.

1.8 V Digital Supply. 35 NC No Connect.

Port 1, Data Input D11 (MSB). 36 NC No Connect.

Port 1, Data Input D10. 37

DATACLK

Data Clock Output.

38 DVDD33 3.3 V Digital Supply.

Rev. A | Page 8 of 60

Page 9

AD9776A/AD9778A/AD9779A

Pin

No. Mnemonic Description

39 TXENABLE

40 P2D<11> Port 2, Data Input D11 (MSB).

41 P2D<10> Port 2, Data Input D10.

42 P2D<9> Port 2, Data Input D9.

43 DVDD18 1.8 V Digital Supply.

44 DGND Digital Ground.

45 P2D<8> Port 2, Data Input D8.

46 P2D<7> Port 2, Data Input D7.

47 P2D<6> Port 2, Data Input D6.

48 P2D<5> Port 2, Data Input D5.

49 P2D<4> Port 2, Data Input D4.

50 P2D<3> Port 2, Data Input D3.

51 P2D<2> Port 2, Data Input D2.

52 P2D<1> Port 2, Data Input D1.

53 DVDD18 1.8 V Digital Supply.

54 DGND Digital Ground.

55 P2D<0> Port 2, Data Input D0 (LSB).

56 NC No Connect.

57 NC No Connect.

58 NC No Connect.

59 NC No Connect.

60 DVDD18 1.8 V Digital Supply.

61 DVDD33 3.3 V Digital Supply.

62 SYNC_O− Differential Synchronization Output.

63 SYNC_O+ Differential Synchronization Output.

64 DGND Digital Ground.

65 PLL_LOCK PLL Lock Indicator.

66 SDO SPI Port Data Output.

67 SDIO SPI Port Data Input/Output.

68 SCLK SPI Port Clock.

69 CSB SPI Port Chip Select Bar.

70 RESET Reset, Active High.

71 IRQ Interrupt Request.

Transmit Enable. In single port mode, this

pin also functions as IQSELECT.

Pin

No. Mnemonic Description

72 AGND Analog Ground.

73 IPTAT

74 VREF Voltage Reference Output.

75 I120 120 μA Reference Current.

76 AVDD33 3.3 V Analog Supply.

77 AGND Analog Ground.

78 AVDD33 3.3 V Analog Supply.

79 AGND Analog Ground.

80 AVDD33 3.3 V Analog Supply.

81 AGND Analog Ground.

82 AGND Analog Ground.

83 OUT2_P Differential DAC Current Output, Channel 2.

84 OUT2_N Differential DAC Current Output, Channel 2.

85 AGND Analog Ground.

86 AUX2_P Auxiliary DAC Current Output, Channel 2.

87 AUX2_N Auxiliary DAC Current Output, Channel 2.

88 AGND Analog Ground.

89 AUX1_N Auxiliary DAC Current Output, Channel 1.

90 AUX1_P Auxiliary DAC Current Output, Channel 1.

91 AGND Analog Ground.

92 OUT1_N Differential DAC Current Output, Channel 1.

93 OUT1_P Differential DAC Current Output, Channel 1.

94 AGND Analog Ground.

95 AGND Analog Ground.

96 AVDD33 3.3 V Analog Supply.

97 AGND Analog Ground.

98 AVDD33 3.3 V Analog Supply.

99 AGND Analog Ground.

100 AVDD33 3.3 V Analog Supply.

Factory Test Pin. Output current is

proportional to absolute temperature,

approximately 14 μA at 25°C with

approximately 20 nA/°C slope. This pin

should remain floating.

Rev. A | Page 9 of 60

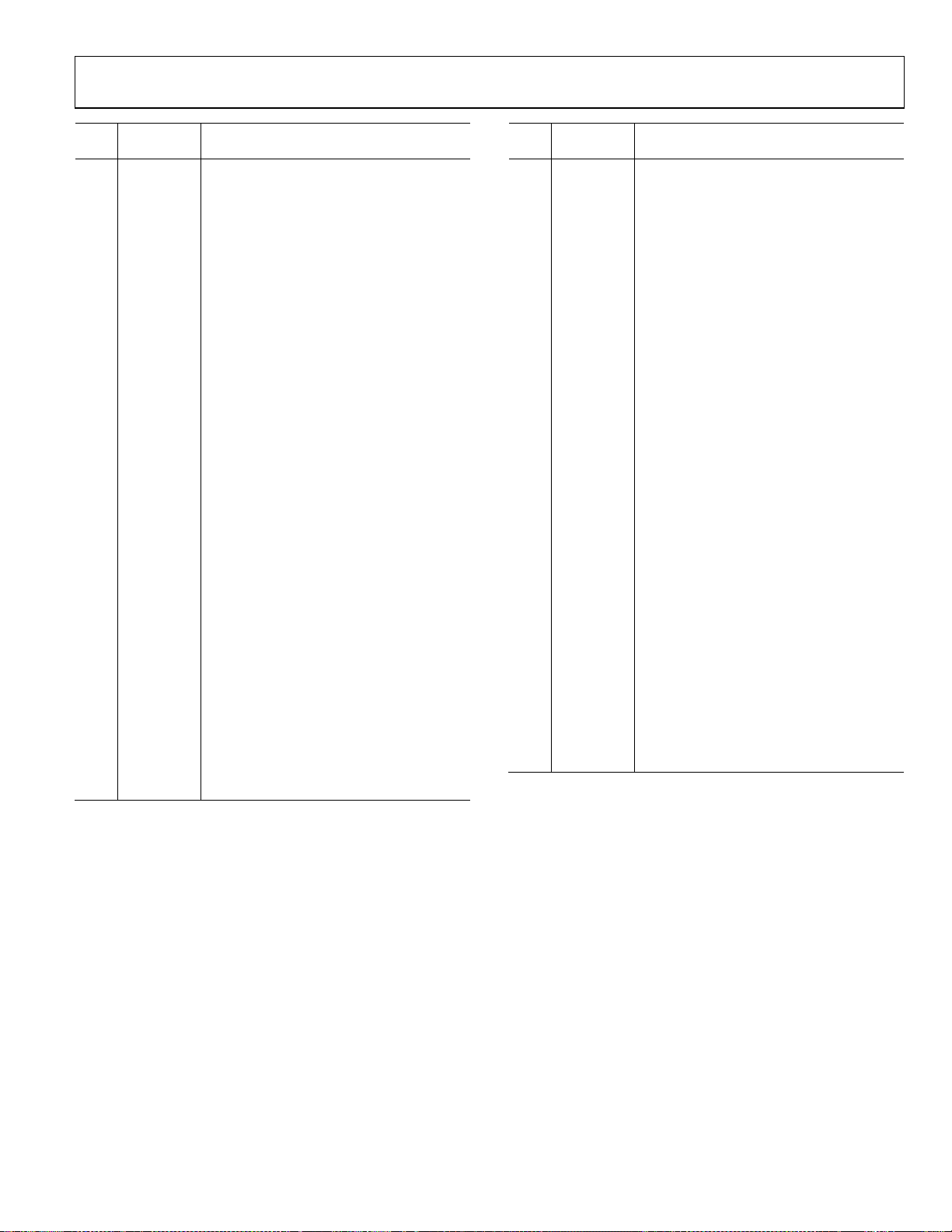

Page 10

AD9776A/AD9778A/AD9779A

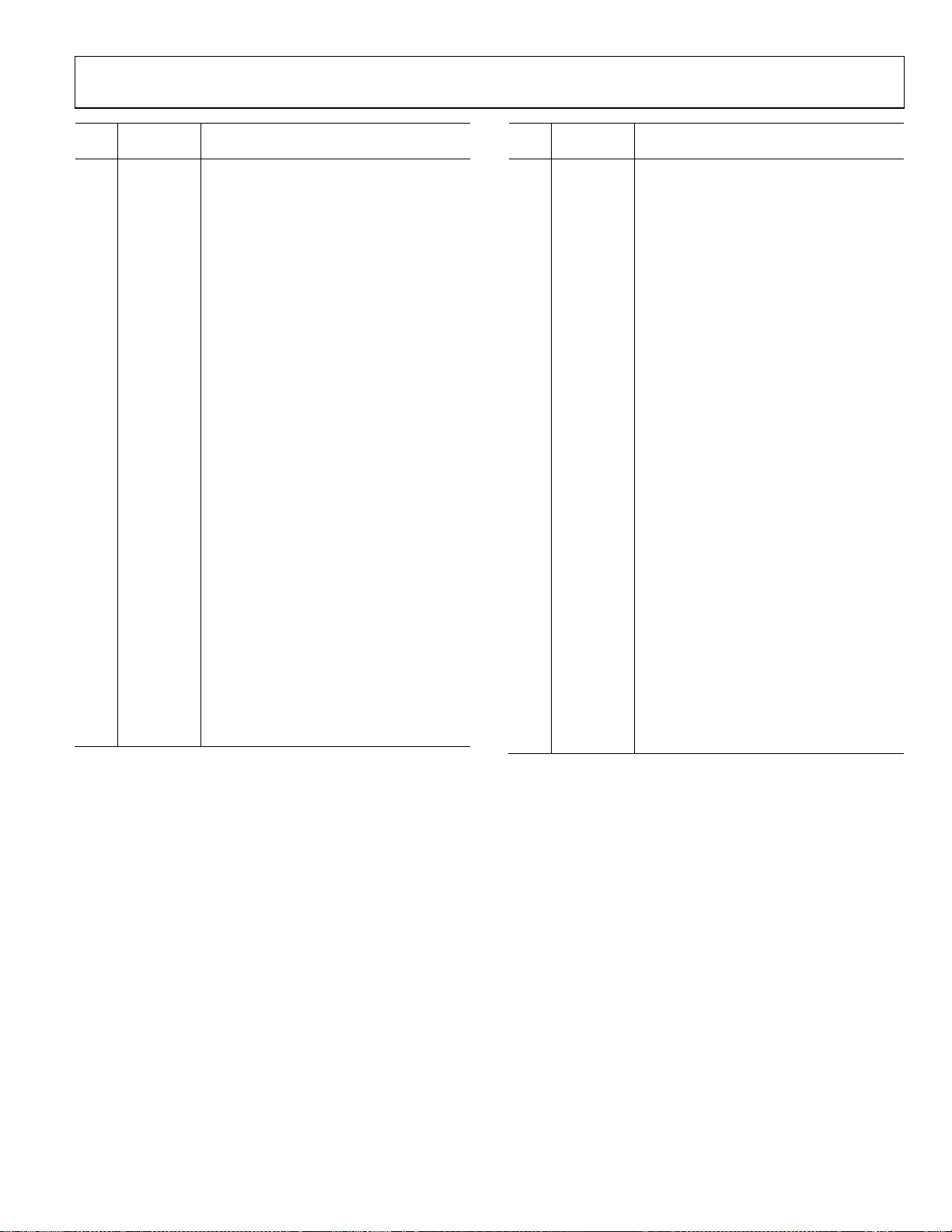

AVDD3399AGND98AVDD3397AGND96AVDD3395AGND94AGND93OUT1_P92OUT1_N91AGND90AUX1_P89AUX1_N88AGND87AUX2_N86AUX2_P85AGND84OUT2_N83OUT2_P82AGND81AGND80AVDD3379AGND78AVDD3377AGND76AVDD33

100

CGND

CGND

CGND

CGND

CGND

AGND

DGND

P1D<9>

DGND

P1D<8>

P1D<7>

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

CVDD18

CVDD18

REFCLK+

REFCLK–

CVDD18

CVDD18

SYNC_I+

SYNC_I–

DVDD18

P1D<13>

P1D<12>

P1D<11>

P1D<10>

DVDD18

NC = NO CONNECT

PIN 1

26

P1D<6>27P1D<5>28P1D<4>29P1D<3>30P1D<2>31P1D<1>

ANALOG DOMAIN

DIGITAL DO MAIN

AD9778A

TOP VIEW

(Not to Scale)

32

33

34

DGND

DVDD18

35NC36NC37

P1D<0>

38

39

40

DVDD33

P2D<13>41P2D<12>42P2D<11>

DATACLK

TXENABLE

Figure 4. AD9778A Pin Configuration

75

I120

74

VREF

73

IPTAT

72

AGND

71

IRQ

70

RESET

69

CSB

68

SCLK

67

SDIO

66

SDO

65

PLL_LOCK

64

DGND

63

SYNC_O+

62

SYNC_O–

61

DVDD33

60

DVDD18

59

NC

58

NC

57

P2D<0>

56

P2D<1>

55

P2D<2>

54

DGND

53

DVDD18

52

P2D<3>

51

P2D<4>

43

44

45

46

DGND

P2D<9>47P2D<8>48P2D<7>49P2D<6>50P2D<5>

DVDD18

P2D<10>

06452-003

Table 8. AD9778A Pin Function Descriptions

Pin

No. Mnemonic Description

1 CVDD18 1.8 V Clock Supply.

2 CVDD18 1.8 V Clock Supply.

3 CGND Clock Ground.

4 CGND Clock Common.

5 REFCLK+ Differential Clock Input.

6 REFCLK− Differential Clock Input.

7 CGND Clock Ground.

8 CGND Clock Ground.

9 CVDD18 1.8 V Clock Supply.

10 CVDD18 1.8 V Clock Supply.

11 CGND Clock Ground.

12 AGND Analog Ground.

13 SYNC_I+ Differential Synchronization Input.

14 SYNC_I− Differential Synchronization Input.

15 DGND Digital Ground.

16 DVDD18 1.8 V Digital Supply.

17 P1D<13> Port 1, Data Input D13 (MSB).

18 P1D<12> Port 1, Data Input D12.

19 P1D<11> Port 1, Data Input D11.

20 P1D<10> Port 1, Data Input D10.

21 P1D<9> Port 1, Data Input D9.

Pin

No. Mnemonic Description

22 DGND Digital Ground.

23 DVDD18 1.8 V Digital Supply.

24 P1D<8> Port 1, Data Input D8.

25 P1D<7> Port 1, Data Input D7.

26 P1D<6> Port 1, Data Input D6.

27 P1D<5> Port 1, Data Input D5.

28 P1D<4> Port 1, Data Input D4.

29 P1D<3> Port 1, Data Input D3.

30 P1D<2> Port 1, Data Input D2.

31 P1D<1> Port 1, Data Input D1.

32 DGND Digital Ground.

33 DVDD18 1.8 V Digital Supply.

34 P1D<0> Port 1, Data Input D0 (LSB).

35 NC No Connect.

36 NC No Connect.

37

38 DVDD33 3.3 V Digital Supply.

39 TXENABLE

40 P2D<13> Port 2, Data Input D13 (MSB).

41 P2D<12> Port 2, Data Input D12.

Rev. A | Page 10 of 60

DATACLK

Data Clock Output.

Transmit Enable. In single port mode, this

pin also functions as IQSELECT.

Page 11

AD9776A/AD9778A/AD9779A

Pin

No. Mnemonic Description

42 P2D<11> Port 2, Data Input D11.

43 DVDD18 1.8 V Digital Supply.

44 DGND Digital Ground.

45 P2D<10> Port 2, Data Input D10.

46 P2D<9> Port 2, Data Input D9.

47 P2D<8> Port 2, Data Input D8.

48 P2D<7> Port 2, Data Input D7.

49 P2D<6> Port 2, Data Input D6.

50 P2D<5> Port 2, Data Input D5.

51 P2D<4> Port 2, Data Input D4.

52 P2D<3> Port 2, Data Input D3.

53 DVDD18 1.8 V Digital Supply.

54 DGND Digital Ground.

55 P2D<2> Port 2, Data Input D2.

56 P2D<1> Port 2, Data Input D1.

57 P2D<0> Port 2, Data Input D0 (LSB).

58 NC No Connect.

59 NC No Connect.

60 DVDD18 1.8 V Digital Supply.

61 DVDD33 3.3 V Digital Supply.

62 SYNC_O− Differential Synchronization Output.

63 SYNC_O+ Differential Synchronization Output.

64 DGND Digital Ground.

65 PLL_LOCK PLL Lock Indicator.

66 SDO SPI Port Data Output.

67 SDIO SPI Port Data Input/Output.

68 SCLK SPI Port Clock.

69 CSB SPI Port Chip Select Bar.

70 RESET Reset, Active High.

71 IRQ Interrupt Request.

72 AGND Analog Ground.

Pin

No. Mnemonic Description

73 IPTAT

74 VREF Voltage Reference Output.

75 I120 120 μA Reference Current.

76 AVDD33 3.3 V Analog Supply.

77 AGND Analog Ground.

78 AVDD33 3.3 V Analog Supply.

79 AGND Analog Ground.

80 AVDD33 3.3 V Analog Supply.

81 AGND Analog Ground.

82 AGND Analog Ground.

83 OUT2_P Differential DAC Current Output, Channel 2.

84 OUT2_N Differential DAC Current Output, Channel 2.

85 AGND Analog Ground.

86 AUX2_P Auxiliary DAC Current Output, Channel 2.

87 AUX2_N Auxiliary DAC Current Output, Channel 2.

88 AGND Analog Ground.

89 AUX1_N Auxiliary DAC Current Output, Channel 1.

90 AUX1_P Auxiliary DAC Current Output, Channel 1.

91 AGND Analog Ground.

92 OUT1_N Differential DAC Current Output, Channel 1.

93 OUT1_P Differential DAC Current Output, Channel 1.

94 AGND Analog Ground.

95 AGND Analog Ground.

96 AVDD33 3.3 V Analog Supply.

97 AGND Analog Ground.

98 AVDD33 3.3 V Analog Supply.

99 AGND Analog Ground.

100 AVDD33 3.3 V Analog Supply.

Factory Test Pin. Output current is

proportional to absolute temperature,

approximately 14 μA at 25°C with

approximately 20 nA/°C slope. This pin

should remain floating.

Rev. A | Page 11 of 60

Page 12

AD9776A/AD9778A/AD9779A

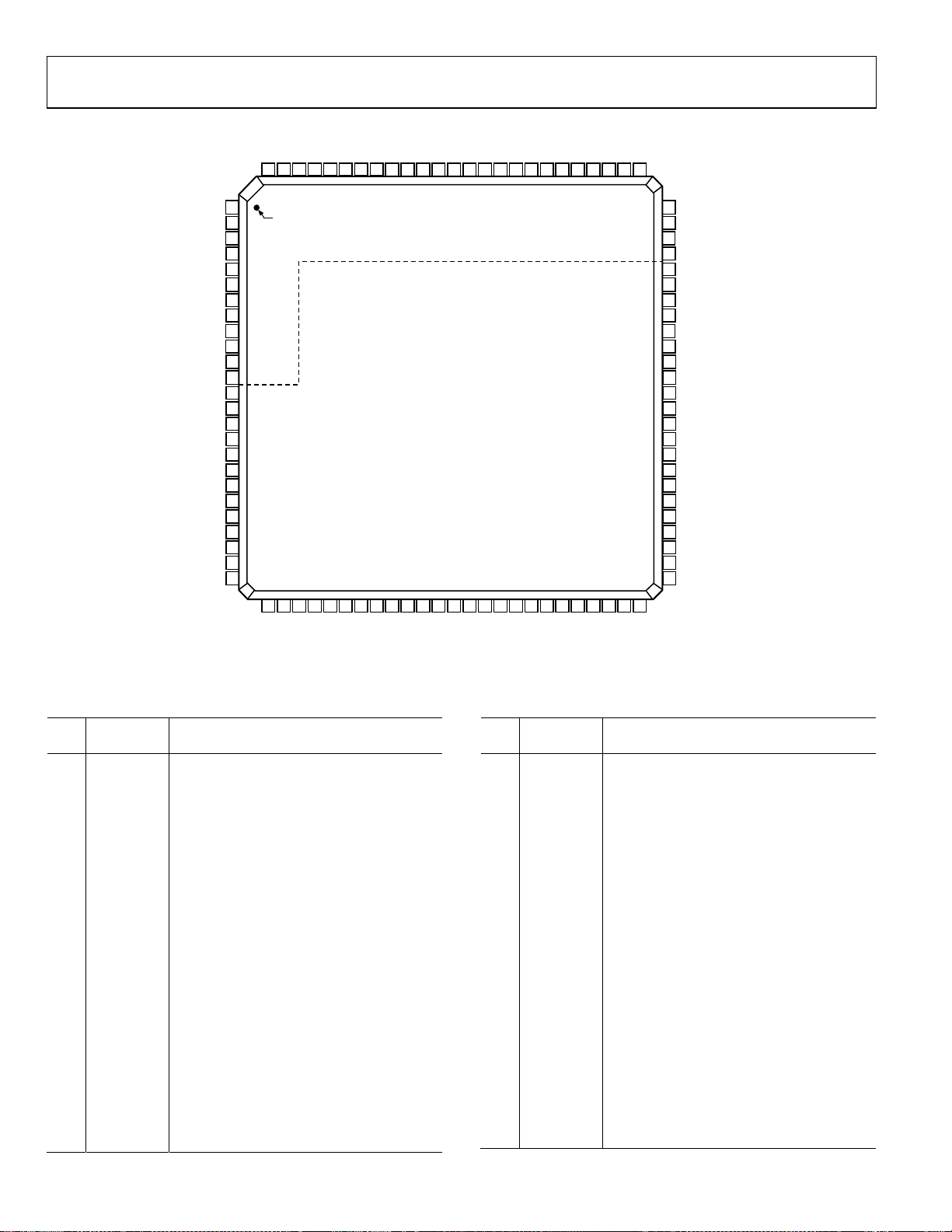

AVDD3399AGND98AVDD3397AGND96AVDD3395AGND94AGND93OUT1_P92OUT1_N91AGND90AUX1_P89AUX1_N88AGND87AUX2_N86AUX2_P85AGND84OUT2_N83OUT2_P82AGND81AGND80AVDD3379AGND78AVDD3377AGND76AVDD33

100

CVDD18

CVDD18

CGND

CGND

REFCLK+

REFCLK–

CGND

CGND

CVDD18

CVDD18

CGND

AGND

SYNC_I+

SYNC_I–

DGND

DVDD18

P1D<15>

P1D<14>

P1D<13>

P1D<12>

P1D<11>

DGND

DVDD18

P1D<10>

P1D<9>

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

PIN 1

26

P1D<8>27P1D<7>28P1D<6>29P1D<5>30P1D<4>31P1D<3>

ANALOG DOMAIN

DIGITAL DO MAIN

AD9779A

TOP VIEW

(Not to Scale)

32

33

DGND

34

DVDD18

P1D<2>35P1D<1>36P1D<0>

37

38

39

40

DVDD33

P2D<15>41P2D<14>42P2D<13>

XENABLE

DATACLK

Figure 5. AD9779A Pin Configuration

75

I120

74

VREF

73

IPTAT

72

AGND

71

IRQ

70

RESET

69

CSB

68

SCLK

67

SDIO

66

SDO

65

PLL_LOCK

64

DGND

63

SYNC_O+

62

SYNC_O–

61

DVDD33

60

DVDD18

59

P2D<0>

58

P2D<1>

57

P2D<2>

56

P2D<3>

55

P2D<4>

54

DGND

53

DVDD18

52

P2D<5>

51

P2D<6>

43

44

45

48

DGND

DVDD18

P2D<12>46P2D<11>47P2D<10>

P2D<9>49P2D<8>50P2D<7>

6452-004

Table 9. AD9779A Pin Function Descriptions

Pin

No. Mnemonic Description

Pin

No. Mnemonic Description

1 CVDD18 1.8 V Clock Supply. 22 DGND Digital Ground.

2 CVDD18 1.8 V Clock Supply.

3 CGND Clock Ground.

4 CGND Clock Ground.

5 REFCLK+ Differential Clock Input.

6 REFCLK− Differential Clock Input.

7 CGND Clock Ground.

8 CGND Clock Ground.

9 CVDD18 1.8 V Clock Supply.

10 CVDD18 1.8 V Clock Supply.

11 CGND Clock Ground.

12 AGND Analog Ground.

13 SYNC_I+ Differential Synchronization Input.

14 SYNC_I− Differential Synchronization Input.

15 DGND Digital Ground.

16 DVDD18 1.8 V Digital Supply.

17 P1D<15> Port 1, Data Input D15 (MSB).

18 P1D<14> Port 1, Data Input D14.

19 P1D<13> Port 1, Data Input D13.

20 P1D<12> Port 1, Data Input D12.

21 P1D<11> Port 1, Data Input D11.

Rev. A | Page 12 of 60

23 DVDD18 1.8 V Digital Supply.

24 P1D<10> Port 1, Data Input D10.

25 P1D<9> Port 1, Data Input D9.

26 P1D<8> Port 1, Data Input D8.

27 P1D<7> Port 1, Data Input D7.

28 P1D<6> Port 1, Data Input D6.

29 P1D<5> Port 1, Data Input D5.

30 P1D<4> Port 1, Data Input D4.

31 P1D<3> Port 1, Data Input D3.

32 DGND Digital Ground.

33 DVDD18 1.8 V Digital Supply.

34 P1D<2> Port 1, Data Input D2.

35 P1D<1> Port 1, Data Input D1.

36 P1D<0> Port 1, Data Input D0 (LSB).

DATACLK

37

Data Clock Output.

38 DVDD33 3.3 V Digital Supply.

39 TXENABLE

Transmit Enable. In single port mode, this

pin also functions as IQSELECT.

40 P2D<15> Port 2, Data Input D15 (MSB).

41 P2D<14> Port 2, Data Input D14.

Page 13

AD9776A/AD9778A/AD9779A

Pin

No. Mnemonic Description

42 P2D<13> Port 2, Data Input D13.

43 DVDD18 1.8 V Digital Supply.

44 DGND Digital Ground.

45 P2D<12> Port 2, Data Input D12.

46 P2D<11> Port 2, Data Input D11.

47 P2D<10> Port 2, Data Input D10.

48 P2D<9> Port 2, Data Input D9.

49 P2D<8> Port 2, Data Input D8.

50 P2D<7> Port 2, Data Input D7.

51 P2D<6> Port 2, Data Input D6.

52 P2D<5> Port 2, Data Input D5.

53 DVDD18 1.8 V Digital Supply.

54 DGND Digital Ground.

55 P2D<4> Port 2, Data Input D4.

56 P2D<3> Port 2, Data Input D3.

57 P2D<2> Port 2, Data Input D2.

58 P2D<1> Port 2, Data Input D1.

59 P2D<0> Port 2, Data Input D0 (LSB).

60 DVDD18 1.8 V Digital Supply.

61 DVDD33 3.3 V Digital Supply.

62 SYNC_O− Differential Synchronization Output.

63 SYNC_O+ Differential Synchronization Output.

64 DGND Digital Ground.

65 PLL_LOCK PLL Lock Indicator.

66 SDO SPI Port Data Output.

67 SDIO SPI Port Data Input/Output.

68 SCLK SPI Port Clock.

69 CSB SPI Port Chip Select Bar.

70 RESET Reset, Active High.

71 IRQ Interrupt Request.

72 AGND Analog Ground.

Pin

No. Mnemonic Description

73 IPTAT

74 VREF Voltage Reference Output.

75 I120 120 μA Reference Current.

76 AVDD33 3.3 V Analog Supply.

77 AGND Analog Ground.

78 AVDD33 3.3 V Analog Supply.

79 AGND Analog Ground.

80 AVDD33 3.3 V Analog Supply.

81 AGND Analog Ground.

82 AGND Analog Ground.

83 OUT2_P Differential DAC Current Output, Channel 2.

84 OUT2_N Differential DAC Current Output, Channel 2.

85 AGND Analog Ground.

86 AUX2_P Auxiliary DAC Current Output, Channel 2.

87 AUX2_N Auxiliary DAC Current Output, Channel 2.

88 AGND Analog Ground.

89 AUX1_N Auxiliary DAC Current Output, Channel 1.

90 AUX1_P Auxiliary DAC Current Output, Channel 1.

91 AGND Analog Ground.

92 OUT1_N Differential DAC Current Output, Channel 1.

93 OUT1_P Differential DAC Current Output, Channel 1.

94 AGND Analog Ground.

95 AGND Analog Ground.

96 AVDD33 3.3 V Analog Supply.

97 AGND Analog Ground.

98 AVDD33 3.3 V Analog Supply.

99 AGND Analog Ground.

100 AVDD33 3.3 V Analog Supply.

Factory Test Pin. Output current is

proportional to absolute temperature,

approximately 14 μA at 25°C with

approximately 20 nA/°C slope. This pin

should remain floating.

Rev. A | Page 13 of 60

Page 14

AD9776A/AD9778A/AD9779A

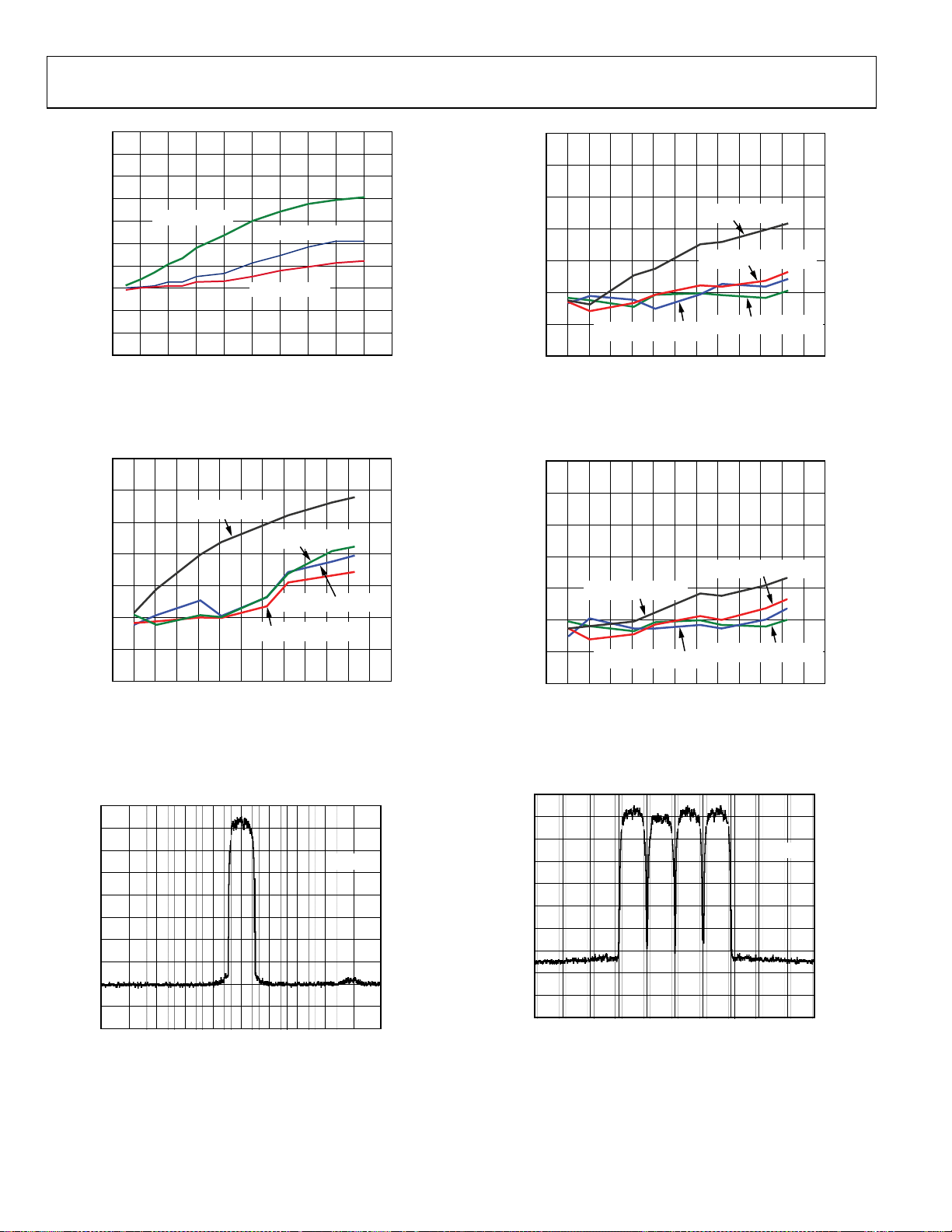

TYPICAL PERFORMANCE CHARACTERISTICS

4

3

2

1

0

–1

–2

INL (16-BIT LSB)

–3

–4

–5

–6

10k 20k 30k 60k50k

0

CODE

40k

06452-005

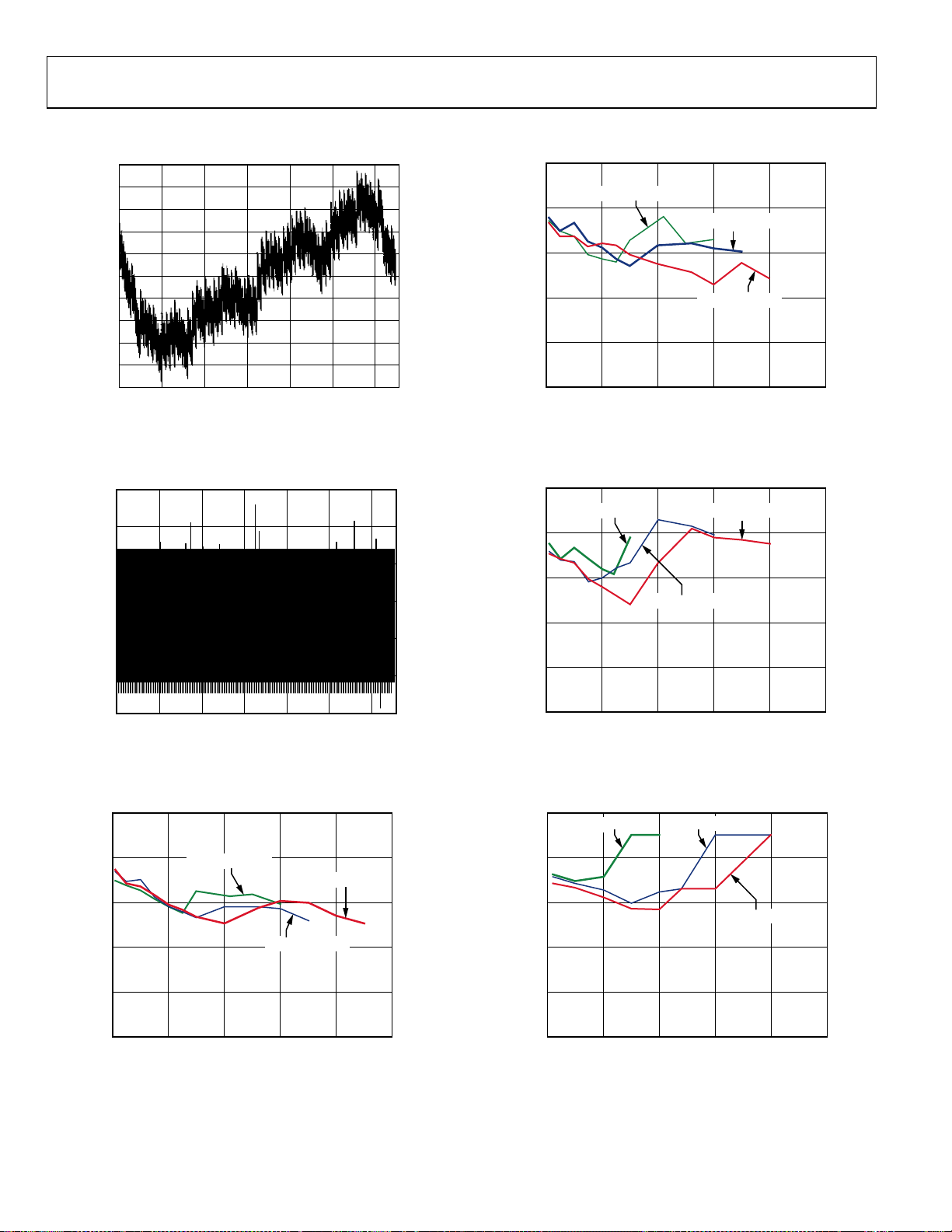

Figure 6. AD9779A Typical INL

100

f

= 160MSPS

90

80

70

SFDR (dBc)

60

50

0

DATA

f

= 200MSPS

DATA

f

= 250MSPS

DATA

20 40 60 80

f

(MHz)

OUT

Figure 9. AD9779A In-Band SFDR vs. f

OUT

100

06452-008

,

2× Interpolation

DNL (16-BIT L SB)

100

SFDR (dBc)

1.5

1.0

0.5

0

–0.5

–1.0

–1.5

–2.0

0 60k50k40k30k20k10k

90

80

70

CODE

Figure 7. AD9779A Typical DNL

f

= 160MSPS

DATA

f

DATA

f

= 200MSPS

DATA

= 250MSPS

100

f

f

= 100MSPS

DATA

90

80

f

= 150MSPS

DATA

70

SFDR (dBc)

60

50

0

6452-006

20 40 60 80

f

(MHz)

OUT

Figure 10. AD9779A In-Band SFDR vs. f

DATA

= 200MSPS

OUT

100

06452-009

,

4× Interpolation

100

f

= 50MSPS

DATA

90

80

70

SFDR (dBc)

f

DATA

= 100MSPS

f

DATA

= 125MSPS

60

50

0

20 40 60 80

f

OUT

Figure 8. AD9779A In-Band SFDR vs. f

(MHz)

OUT

100

06452-007

,

1× Interpolation

60

50

0

10 20 30 40

Figure 11. AD9779A In-Band SFDR vs. f

8× Interpolation

f

OUT

(MHz)

OUT

50

06452-010

,

Rev. A | Page 14 of 60

Page 15

AD9776A/AD9778A/AD9779A

100

100

90

f

= 160MSPS

DATA

80

70

SFDR (dBc)

60

50

0

20 40 60 80

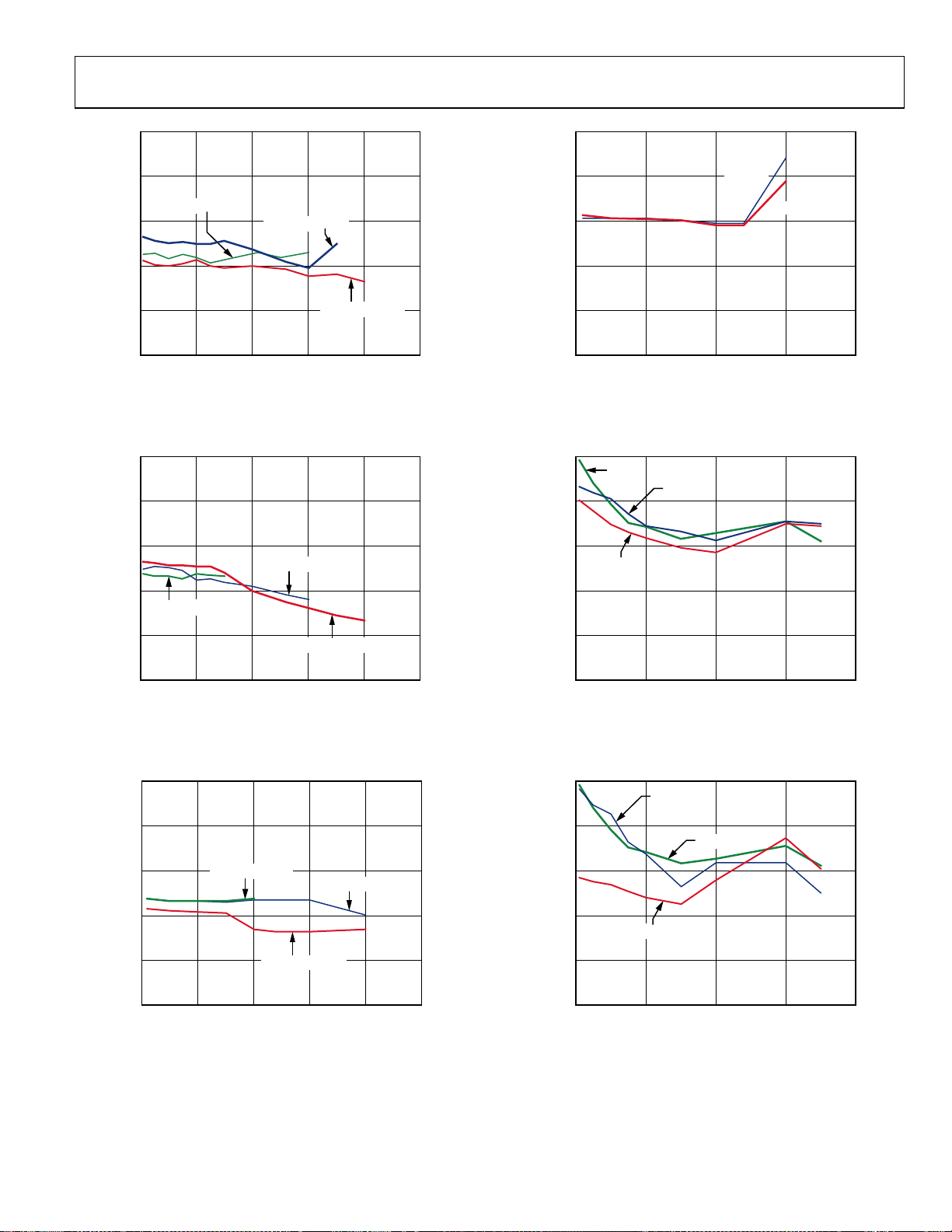

Figure 12. AD9779A Out-of-Band SFDR vs. f

f

OUT

f

DATA

(MHz)

= 200MSPS

f

DATA

= 250MSPS

,

OUT

100

06452-011

2× Interpolation

100

90

80

f

= 150MSPS

DATA

70

SFDR (dBc)

f

= 100MSPS

DATA

90

80

70

SFDR (dBc)

60

50

0

10 20 30

f

OUT

PLL OFF

(MHz)

Figure 15. AD9779A In-Band SFDR, 4× Interpolation,

= 100 MSPS, PLL On/Off

f

DATA

100

90

80

70

SFDR (dBc)

0dBFS

–3dBFS

–6dBFS

PLL ON

40

06452-014

60

50

0

20 40 60 80

Figure 13. AD9779A Out-of-Band SFDR vs. f

f

OUT

(MHz)

f

DATA

= 200MSPS

OUT

100

06452-012

,

4× Interpolation

100

90

f

80

70

SFDR (dBc)

60

50

0

10 20 30 40

Figure 14. AD9779A Out-of-Band SFDR vs. f

DATA

= 50MSPS

f

DATA

f

OUT

= 125MSPS

(MHz)

f

DATA

= 100MSPS

,

OUT

50

06452-013

8× Interpolation

60

50

0

20 40 60

f

(MHz)

OUT

Figure 16. AD9779A In-Band SFDR vs. f

OUT

80

06452-015

,

Digital Full Scale

100

90

80

70

SFDR (dBc)

60

50

0

Figure 17. AD9779A In-Band SFDR vs. f

10mA

20mA

30mA

20 40 60

f

(MHz)

OUT

OUT

80

06452-016

,

Output Full-Scale Current

Rev. A | Page 15 of 60

Page 16

AD9776A/AD9778A/AD9779A

IMD (dBc)

100

90

f

80

70

60

50

0

= 250MSPS

DATA

20 40 60 80 100

f

OUT

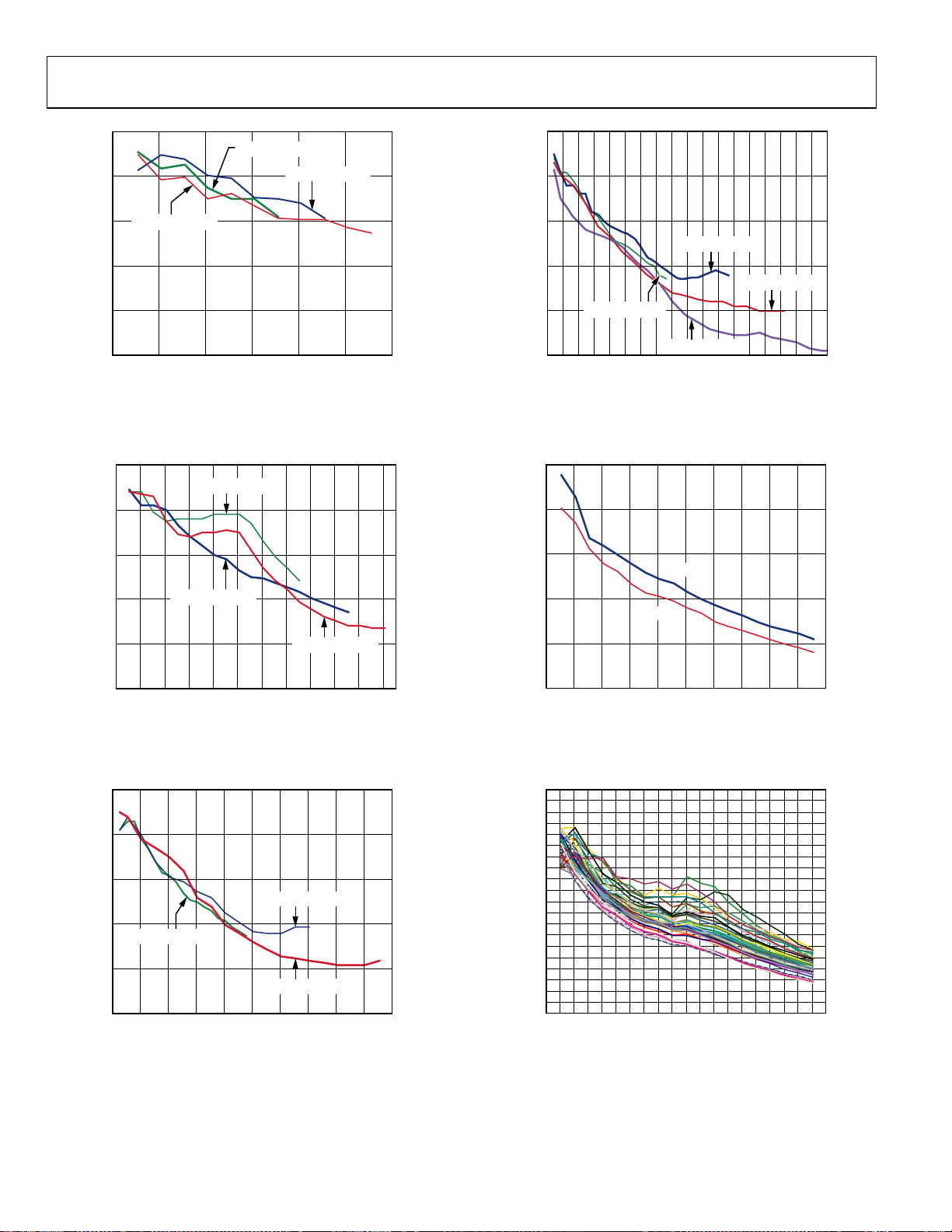

Figure 18. AD9779A Third-Order IMD vs. f

1× Interpolation

f

DATA

(MHz)

= 160MSPS

f

DATA

= 200MSPS

,

OUT

120

06452-017

IMD (dBc)

100

90

80

70

f

50

DATA

75

= 50MSPS

150

125

100

175

f

DATA

f

OUT

200

60

50

0

25

Figure 21. AD9779A Third-Order IMD vs. f

8× Interpolation

f

= 75MSPS

DATA

= 125MSPS

250

225

(MHz)

275

f

300

DATA

= 100MSPS

350

325

OUT

375

,

400

425

450

06452-020

100

f

= 160MSPS

DATA

90

80

IMD (dBc)

70

60

50

0 20 40 60 80 100 120 140 160 180 200

f

DATA

= 200MSPS

f

OUT

(MHz)

Figure 19. AD9779A Third-Order IMD vs. f

2× Interpolation

100

90

80

f

= 150MSPS

DATA

IMD (dBc)

70

f

= 100MSPS

DATA

60

f

= 200MSPS

DATA

50

0

40 80 120 160 200 240 280 320 360

f

(MHz)

OUT

Figure 20. AD9779A Third-Order IMD vs. f

4× Interpolation

f

DATA

= 250MSPS

,

OUT

,

OUT

220

400

100

90

80

PLL OFF

IMD (dBc)

70

60

50

0

20 40 60 80 120 140 160 180

06452-018

Figure 22. AD9779A Third-Order IMD vs. f

4× Interpolation, f

100

95

90

85

80

75

IMD (dBc)

70

65

60

55

50

0

40 80 120 160 200 240 280 320

06452-019

Figure 23. AD9779A Third-Order IMD vs. f

50 Parts, 4× Interpolation, f

PLL ON

100

f

(MHz)

OUT

= 100 MSPS, PLL On vs. PLL Off

DATA

f

(MHz)

OUT

OUT

= 200 MSPS

DATA

,

OUT

, over

200

06452-021

400360

06452-022

Rev. A | Page 16 of 60

Page 17

AD9776A/AD9778A/AD9779A

–

100

95

90

85

80

75

IMD (dBc)

70

65

60

55

50

0 400

0dBFS

–3dBFS

–6dBFS

80 160 240 36032040 120 200 280

f

(MHz)

OUT

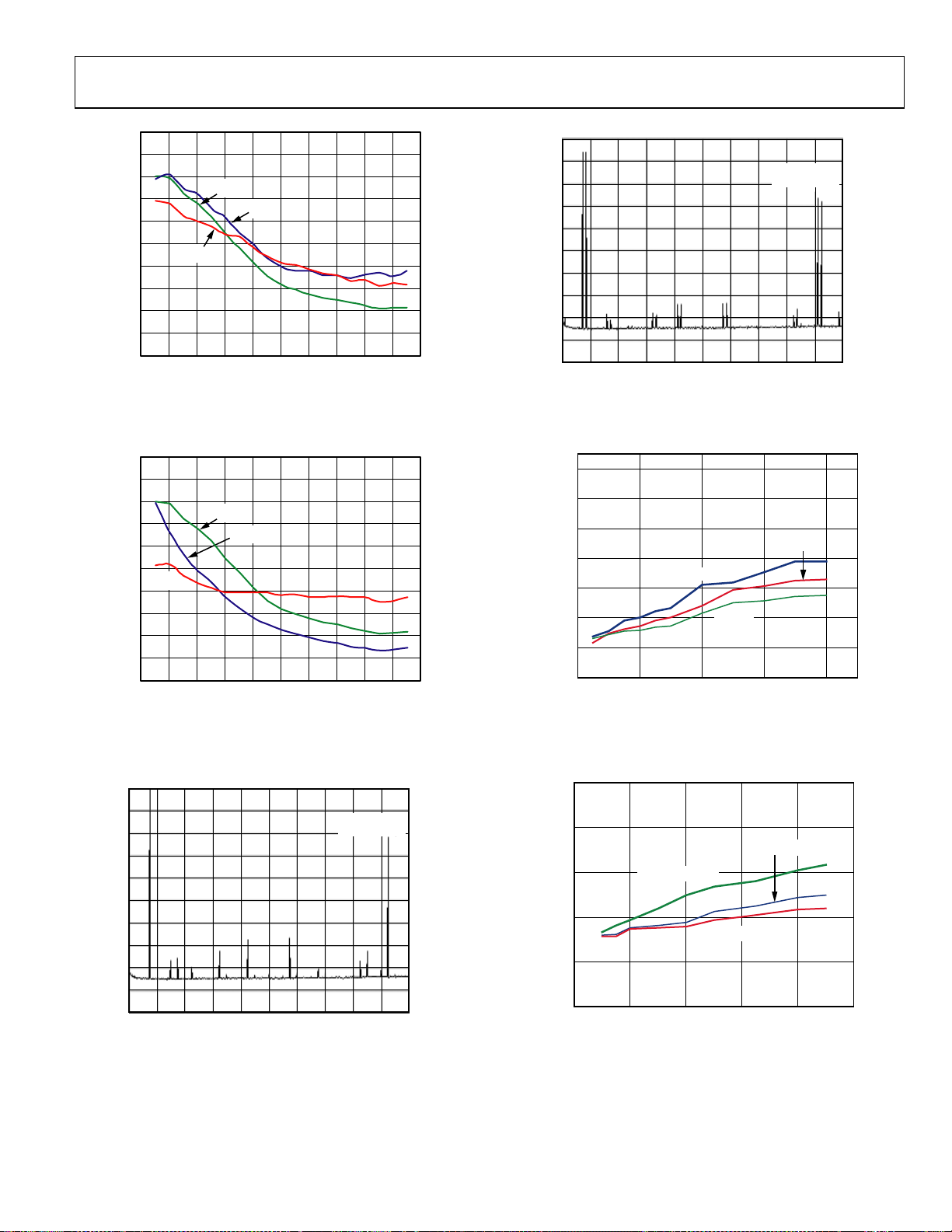

Figure 24. AD9779A IMD Performance vs. Digital Full-Scale Input over

Output Frequency, 4× Interpolation, f

= 200 MSPS

DATA

REF 0dBm

*PEAK

Log

10dB

LGAV

51

S2

W1

FC

S3

AA

£(f):

FTUN

SWP

START 1.0MHz

06452-117

*RES BW 20kHz

4× Interpolation, f

*ATTEN 20dB

EXT REF

DC-COUPLED

VBW 20kHz

STOP 400.0M Hz

SWEEP 1.203s (601 pts)

Figure 27. AD9779A Two-Tone Spectrum,

= 100 MSPS, f

DATA

= 30 MHz, 35 MHz

OUT

06452-024

100

95

90

85

80

75

30mA

IMD (dBc)

70

65

60

55

50

0 400

20mA

10mA

80 160 240 36032040 120 200 280

f

(MHz)

OUT

Figure 25. AD9779A IMD Performance vs. Full-Scale Output Current over

Output Frequency, 4× Interpolation, f

REF 0dBm

*PEAK

Log

10dB

LGAV

51

S2

W1

FC

S3

AA

£(f):

FTUN

SWP

START 1.0MHz

*RES BW 20kHz

*ATTEN 20dB

VBW 20kHz

= 200 MSPS

DATA

EXT REF

DC-COUPLED

STOP 400.0M Hz

SWEEP 1.203s (601 pts)

06452-023

Figure 26. AD9779A Single Tone, 4× Interpolation,

f

= 100 MSPS, f

DATA

= 30 MHz

OUT

–142

–146

–150

–154

–158

NSD (dBm/Hz)

–162

–166

–170

0

06452-118

20 40 60 80

0dBFS

f

OUT

–6dBFS

(MHz)

–3dBFS

06452-025

Figure 28. AD9779A Noise Spectral Density vs. Digital Full-Scale over Output

Frequency of Single Tone Input, f

= 200 MSPS,

DATA

2× Interpolation

150

–154

f

= 400MSPS

DAC

f

–158

–162

NSD (dBm/Hz)

–166

–170

0

Figure 29. AD9779A Noise Spectral Density vs. f

Eight-Tone Input with 500 kHz Spacing, f

= 200MSPS

DAC

f

= 800MSPS

DAC

20 40 60 80

f

(MHz)

OUT

over Output Frequency for

DAC

= 200 MSPS

DATA

100

06452-026

Rev. A | Page 17 of 60

Page 18

AD9776A/AD9778A/AD9779A

–

–

–

–

150

55

–154

f

= 200MSPS

DAC

f

f

DAC

= 400MSPS

DAC

= 800MSPS

NSD (dBm/Hz)

–158

–162

–166

–170

0

20 40 60 80

f

(MHz)

OUT

Figure 30. AD9779A Noise Spectral Density vs. f

over Output Frequency

DAC

100

06452-027

with a Single Tone Input at −6 dBFS

55

–60

–65

0dBFS, PLL ENABLED

0dBFS, PL L DISABLED

–70

–75

ACLR (dBc)

–3dBFS, PLL DISABLED

–80

–6dBFS, PL L DISABLED

–85

–90

0

f

(MHz)

OUT

26024022020018016014012010080604020

06452-300

Figure 31. AD9779A ACLR for First Adjacent Band W-CDMA, 4× Interpolation,

= 122.88 MSPS, On-Chip Modulation Translates Baseband Signal to IF

f

DATA

REF –25.28dBm

*AVG

Log

10dB

*ATTEN 4dB

EXT REF

–60

–65

0dBFS, PLL ENABLED

–70

ACLR (dBc)

–75

–6dBFS, PLL DISABLED

–80

–85

–90

–3dBFS , PLL DISABL ED

0

f

OUT

0dBFS, PLL DISABLED

(MHz)

Figure 33. AD9779A ACLR for Second Adjacent Band W-CDMA,

4× Interpolation, f

= 122.88 MSPS;

DATA

On-Chip Modulation Translates Baseband Signal to IF

55

–60

–65

ACLR (dBc)

–70

–75

0dBFS, PL L ENABLED

–6dBFS, PL L DISABLE D

–80

–85

–90

–3dBFS , PLL DISABL ED

0

f

OUT

0dBFS, PLL DISABLED

(MHz)

Figure 34. AD9779A ACLR for Third Adjacent Band W-CDMA, 4×

Interpolation, f

= 122.88 MSPS, On-Chip Modulation Translates

DATA

Baseband Signal to IF

REF –30.28dBm

*AVG

Log

10dB

*ATTEN 4dB

EXT REF

26024022020018016014012010080604020

06452-301

26024022020018016014012010080604020

06452-302

PAVG

PAVG

10

W1 S2

CENTER 143.88MHz

*RES BW 30kHz

RMS RESULTS

CARRIER POW ER

–12.49dBm/

3.84000MHz

FREQ OFFSET

5.000MHz

10.00MHz

15.00MHz

VBW 300kHz

REF BW

3.840MHz

3.840MHz

3.840MHz

SWEEP 162. 2ms (601 pts)

LOWER

dBm

dBc

–89.23

–76.75

–93.43

–80.94

–92.44

–79.95

Figure 32. AD9779A W-CDMA Signal, 4× Interpolation,

= 122.88 MSPS, f

f

DATA

/4 Modulation

DAC

SPAN 50MHz

UPPER

dBc

–77.42

–80.47

–78.96

dBm

–89.91

–92.96

–91.45

06452-031

10

W1 S2

CENTER 151.38MHz

*RES BW 30kHz

TOTAL CARRIER POWER –12.61dBm/15.3600MHz

REF CARRIER PO WER –17.87dBm/3.84000MHz

1 –17.87dBm

2 –20.65dBm

3 –18.26dBm

4 –18.23dBm

VBW 300kHz

FREQ OFFSET

5.000MHz

10.00MHz

15.00MHz

INTEG BW

3.840MHz

3.840MHz

3.840MHz

Figure 35. AD9779A Multicarrier W-CDMA Signal,

4× Interpolation, f

= 122.88 MSPS, f

DAC

dBc

dBm

–67.70

–85.57

–69.32

–97.87

–71.00

–99.52

/4 Modulation

DAC

SPAN 50MHz

UPPER

SWEEP 162. 2ms (601 pts)

LOWER

dBc

–67.70

–70.00

–71.65

dBm

–85.57

–87.19

–88.88

06452-032

Rev. A | Page 18 of 60

Page 19

AD9776A/AD9778A/AD9779A

1.5

1.0

0.5

0

INL (14-BIT LSB)

–0.5

–1.0

–1.5

0

2k 4k 6k 8k

CODE

10k

6452-033

Figure 36. AD9778A Typical INL

0.6

0.4

0.2

0

–0.2

–0.4

DNL (14-BIT L SB)

–0.6

–0.8

–1.0

0

CODE

16k14k12k10k8k6k4k2k

06452-034

Figure 37. AD9778A Typical DNL

100

90

f

= 160MSPS

DATA

f

DATA

= 200MSPS

80

f

= 250MSPS

70

SFDR (dBc)

DATA

60

50

0

20 40 60 80

f

(MHz)

OUT

Figure 39. AD9778A In-Band SFDR vs. f

, 2× Interpolation

OUT

100

–60

ACLR (dBc)

–70

3RD ADJ CHAN

1ST ADJ CHAN

–80

2ND ADJ CHAN

–90

0

25 50 75 100 125 150 175 200 225

f

(MHz)

OUT

250

Figure 40. AD9778A ACLR, Single Carrier W-CDMA, 4× Interpolation,

f

= 122.88 MSPS, Amplitude = −3 dBFS

DATA

06452-036

06452-037

100

90

80

IMD (dBc)

70

4× 100MSPS

60

50

0

40 80 120 160 200 240 280 320 360

Figure 38. AD9778A IMD vs. f

4× 150MSPS

f

(MHz)

OUT

4× 200MSPS

, 4× Interpolation

OUT

400

06452-035

Rev. A | Page 19 of 60

REF –25.39dBm

*AVG

Log

10dB

PAVG

10

W1 S2

CENTER 143.88MHz

*RES BW 30kHz

RMS RESULTS

CARRIER POW ER

–12.74dBm/

3.84000MHz

FREQ OFFSET

5.000MHz

10.00MHz

15.00MHz

Figure 41. AD9778A ACLR, f

*ATTEN 4dB

VBW 300kHz

REF BW

3.884MHz

3.840MHz

3.840MHz

/4 Modulation

f

DAC

dBm

–89.23

–92.87

–93.64

SPAN 50MHz

UPPER

dBc

–76.89

–80.02

–79.53

dBm

–89.63

–92.76

–92.27

SWEEP 162. 2ms (601 pts)

LOWER

dBc

–76.49

–80.13

–80.90

= 122.88 MSPS, 4× Interpolation,

DATA

06452-038

Page 20

AD9776A/AD9778A/AD9779A

–

–

NSD (dBm/Hz)

150

–154

–158

–162

–166

f

DAC

= 200MSPS

f

f

DAC

= 400MSPS

DAC

= 800MSPS

DNL (12-BIT LSB)

0.20

0.15

0.10

0.05

0

–0.05

–0.10

–0.15

–170

0

20 40 60 80

f

(MHz)

OUT

Figure 42. AD9778A Noise Spectral Density vs. f

DATA

(MHz)

= 200 MSPS

f

DAC

NSD (dBm/Hz)

150

–154

–158

–162

–166

–170

with 500 kHz Spacing, f

f

= 200MSPS

DAC

0

20 40 60 80

f

DAC

= 800MSPS

f

OUT

Figure 43. AD9778A Noise Spectral Density vs. f

at −6 dBFS, f

0.4

= 200 MSPS

DATA

for Eight-Tone Input

OUT

= 400MSPS

with Single Tone Input

OUT

100

100

–0.20

0

512 1024 1536 2560 3072 3584

06452-039

2048

CODE

4096

06452-042

Figure 45. AD9776A Typical DNL

100

95

90

85

80

75

IMD (dBc)

70

65

60

55

50

0

40 80 120 160 200 240 280 320 360

06452-040

Figure 46. AD9776A IMD vs. f

100

4× 100MSPS

4× 150MSPS

f

(MHz)

OUT

4× 200MSPS

, 4× Interpolation

OUT

400

06452-043

0.3

0.2

0.1

0

–0.1

INL (12-BIT LSB)

–0.2

–0.3

–0.4

0

512 1024 256020481536 3072 3584

CODE

4096

06452-041

Figure 44. AD9776A Typical INL

90

f

= 160MSPS

DATA

80

70

SFDR (dBc)

60

50

f

= 200MSPS

DATA

0

20 40 60 80

f

OUT

Figure 47. AD9776A In-Band SFDR vs. f

(MHz)

f

= 250MSPS

DATA

, 2× Interpolation

OUT

100

06452-044

Rev. A | Page 20 of 60

Page 21

AD9776A/AD9778A/AD9779A

–

–

–

55

–60

–65

–70

–75

ACLR (d Bc)

–80

–85

3RD ADJ CHAN

1ST ADJ CHAN

2ND ADJ CHAN

NSD (dBm/Hz)

150

–154

–158

–162

–166

f

DAC

= 200MSPS

f

= 800MSPS

DAC

f

= 400MSPS

DAC

–90

0 250

25 50 75 100 125 150 175 200 225

(MHz)

F

OUT

Figure 48. AD9776A ACLR, f

REF –25.29dBm

*AVG

Log

10dB

PAVG

10

W1 S2

CENTER 143.88MHz

*RES BW 30kHz

RMS RESULTS

CARRIER POW ER

–12.67dBm/

3.84000MHz

FREQ OFFSET

5.000MHz

10.00MHz

15.00MHz

*ATTEN 4dB

VBW 300kHz

= 122.88 MSPS, 4× Interpolation,

DATA

/4 Modulation

f

DAC

SWEEP 162. 2ms (601 pts)

REF BW

3.884MHz

3.840MHz

3.840MHz

LOWER

dBc

–75.00

–78.05

–77.73

dBm

–87.67

–90.73

–90.41

dBc

–75.30

–77.99

–77.50

SPAN 50MHz

UPPER

dBm

–87.97

–90.66

–90.17

Figure 49. AD9776A, Single Carrier W-CDMA, 4× Interpolation,

= 122.88 MSPS, Amplitude = −3 dBFS

f

DATA

–170

0

10 30 50 70 90

20 40 60 80

f

(MHz)

= 200MSPS

f

= 800MSPS

DAC

f

OUT

OUT

DATA

f

(MHz)

OUT

= 200 MSPS

= 400MSPS

DAC

, Eight-Tone Input

06452-045

Figure 50. AD9776A Noise Spectral Density vs. f

with 500 kHz Spacing, f

150

f

DAC

–154

–158

–162

NSD (dBm/Hz)

–166

–170

0

10 30 50 70 90

20 40 60 80

06452-046

Figure 51. AD9776A Noise Spectral Density vs. f

Single Tone Input at −6 dBFS, f

= 200 MSPS

DATA

OUT

100

06452-047

100

06452-048

,

Rev. A | Page 21 of 60

Page 22

AD9776A/AD9778A/AD9779A

TERMINOLOGY

Integral Nonlinearity (INL)

INL is defined as the maximum deviation of the actual analog

output from the ideal output, determined by a straight line

drawn from zero scale to full scale.

Differential Nonlinearity (DNL)

DNL is the measure of the variation in analog value, normalized

to full scale, associated with a 1 LSB change in digital input code.

Monotonicity

A DAC is monotonic if the output either increases or remains

constant as the digital input increases.

Offset Error

The deviation of the output current at Code 0 from the ideal

of zero is called offset error. For I

when the inputs are all 0s. For I

, 0 mA output is expected

OUTA

, 0 mA output is expected

OUTB

when all inputs are set to 1s.

Gain Error

Gain error is difference between the actual and ideal output

span. The actual span is determined by the difference between

the full-scale output and bottom-scale output.

Output Compliance Range

Output compliance range is the range of allowable voltage at

the output of a current-output DAC. Operation beyond the

maximum compliance limits can cause either output stage

saturation or breakdown, resulting in nonlinear performance.

Temp er at u re D ri ft

Temperature drift is specified as the maximum change from

the ambient (25°C) value to the value at either T

MIN

or T

MAX

.

For offset and gain drift, the drift is reported in ppm of fullscale range (FSR) per degree Celsius. For reference drift, the

drift is reported in ppm per degree Celsius.

Power Supply Rejection (PSR)

PSR is the maximum change in the full-scale output as the

supplies are varied from minimum to maximum specified

voltages.

Settling Time

Settling time is the time required for the output to reach and

remain within a specified error band around its final value,

measured from the start of the output transition.

In-Band Spurious Free Dynamic Range (SFDR)

In-band SFDR is the difference, in decibels, between the peak

amplitude of the output signal and the peak spurious signal

between dc and the frequency equal to half the input data rate.

Out-of-Band Spurious Free Dynamic Range (SFDR)

Out-of-band SFDR is the difference, in decibels, between the

peak amplitude of the output signal and the peak spurious signal

within the band that starts at the frequency of the input data

rate and ends at the Nyquist frequency of the DAC output sample

rate. Normally, energy in this band is rejected by the interpolation

filters. This specification, therefore, defines how well the interpolation filters work and the effect of other parasitic coupling

paths to the DAC output.

Total Harmonic Distortion (THD)

THD is the ratio of the rms sum of the first six harmonic components to the rms value of the measured fundamental. It is

expressed as a percentage or in decibels.

Signal-to-Noise Ratio (SNR)

SNR is the ratio of the rms value of the measured output signal

to the rms sum of all other spectral components below the

Nyquist frequency, excluding the first six harmonics and dc.

The value for SNR is expressed in decibels.

Interpolation Filter

If the digital inputs to the DAC are sampled at a multiple rate of

f

(interpolation rate), a digital filter can be constructed that

DATA

has a sharp transition band near f

appear around f

(output data rate) can be greatly suppressed.

DAC

/2. Images that typically

DATA

Adjacent Channel Leakage Ratio (ACLR)

ACLR is the ratio in dBc between the measured power within a

channel relative to its adjacent channel.

Complex Image Rejection

In a traditional two part upconversion, two images are created

around the second IF frequency. These images have the effect of

wasting transmitter power and system bandwidth. By placing

the real part of a second complex modulator in series with the

first complex modulator, either the upper or lower frequency

image near the second IF can be rejected.

Rev. A | Page 22 of 60

Page 23

AD9776A/AD9778A/AD9779A

THEORY OF OPERATION

The AD9776A/AD9778A/AD9779A have many features that

make them highly suited for wired and wireless communications

systems. The dual digital signal path and dual DAC structure

allow an easy interface with common quadrature modulators

when designing single sideband transmitters. The speed and

performance of the parts allow wider bandwidths and more

carriers to be synthesized than in previously available DACs.

The digital engine uses an innovative filter architecture that

combines the interpolation with a digital quadrature modulator.

This allows the parts to perform digital quadrature frequency

upconversions. The on-chip synchronization circuitry enables

multiple devices to be synchronized to each other, or to a

system clock.

DIFFERENCES BETWEEN AD9776/AD9778/ AD9779 AND AD9776A/AD9778A/AD9779A

REFCLK Maximum Frequency vs. Supply

With some restrictions on the DVDD18 and CVDD18 power

supplies, the AD9776A/AD9778A/AD9779A support a maximum sample rate of 1100 MHz. Tabl e 2 lists the valid operating

frequencies vs. power supply voltage.

REFCLK Amplitude

With a differential sinusoidal clock applied to REFCLK, the

PLL on the AD9776/AD9778/AD9779 does not achieve optimal

noise performance unless the REFCLK differential amplitude is

increased to 2 V p-p. Note that if an LVPECL driver is used on the

AD9776/AD9778/AD9779, the PLL gives optimal performance if

the REFCLK amplitude is well within LVPECL specifications

(<1.6 V p-p differential). The design of the PLL on the AD9779A

has been improved so that even with a sinusoidal clock, the PLL

still achieves optimal amplitude with the swing = 1.6 V p-p.

PLL Lock Ranges

The individual lock ranges for the AD9776A/AD9778A/AD9779A

PLL are wider than those for the AD9776/AD9778/AD9779.

Table 10.

BW Adjustment,

Register 0x0A

Part No.

AD9776/AD9778/AD9779 11111 111 010 00

AD9776A/AD9778A/AD9779A 01111 011 011 11

Bits<4:0>

PLL Bias Setting,

Register 0x09

Bits<2:0>

This means that the AD9776A/AD9778A/AD9779A PLL

remains in lock in a given range over a wider temperature range

than the AD9776/ AD9778/AD9779. See Tab l e 21 for PLL lock

ranges for the AD9776A/AD9778A/AD9779A.

PLL Optimal Settings

The optimal settings for the AD9776/AD9778/AD9779 differ

from the AD9776A/AD9778A/AD9779A. Refer to the PLL Bias

Settings section for complete details.

Input Data Delay Line, Manual and Automatic Correction Modes

The AD9776A/AD9778A/AD9779A can be programmed to

sense when the timing margin on the input data falls below

a preset threshold and to take action. The device can be

programmed to either set the IRQ (pin and register) or

automatically reoptimize the timing input data timing.

Input Data Timing

See Tab le 2 5 for timing specifications vs. temperature. The

input data timing specifications (setup and hold) have changed

in the AD9776A/AD9778A/AD9779A. They are not the same

as the timing specifications in the AD9776/AD9778/AD9779.

DATACLK D elay R ange

In the AD9776/AD9778/AD9779, the input data delay was

controlled by Register 4, Bits<7:4>. At 25°C, the delay was

stepped by approximately 180 ps/increment. In the AD9779A,

an extra bit has been added, which effectively doubles the delay

range. This bit is now located at Register 1, Bit 1. The increment/

step on the AD9776A/AD9778A/AD9779A remains at ~180 ps.

Versi on Regi st e r

The version register (Register 0x1F) of the AD9776A/AD9778A/

AD9779A reads a value of 0x03. The version register of the

AD9776/AD9778/AD9779 reads a value of 0x02.

Optimal PLL Value,

Register 0x0A

Bits<7:5>

PLL VCO AGC,

Register 0x08

Bits<1:0>

Rev. A | Page 23 of 60

Page 24

AD9776A/AD9778A/AD9779A

S

SERIAL PERIPHERAL INTERFACE

The SPI port is a flexible, synchronous serial communications

port allowing easy interface to many industry-standard microcontrollers and microprocessors. The port is compatible with

most synchronous transfer formats including both the Motorola

SPI and Intel® SSR protocols.

The interface allows read and write access to all registers

that configure the AD9776A/AD9778A/AD9779A. Single

or multiple byte transfers are supported as well as MSB first

or LSB first transfer formats. Serial data input/output can be

accomplished through a single bidirectional pin (SDIO) or

through two unidirectional pins (SDIO/SDO).

The serial port configuration is controlled by Register 0x00,

Bits<7:6>. It is important to note that any change made to the

serial port configuration occurs immediately upon writing to

the last bit of this byte. Therefore, it is possible with a multibyte

transfer to write to this register and change the configuration in

the middle of a communication cycle. Care must be taken to

compensate for the new configuration within the remaining

bytes of the current communication cycle.

Use of a single byte transfer when changing the serial port

configuration is recommended to prevent unexpected device

behavior.

As described in this section, all serial port data is transferred

to/from the device in synchronization to the SCLK pin. If

synchronization is lost, the device has the ability to asynchronously terminate an I/O operation, putting the serial port

controller into a known state and, thereby, regaining synchronization.

66

SDO

67

SDIO

CLK

CSB

Figure 52. SPI Port

SPI

PORT

68

69

6452-049

GENERAL OPERATION OF THE SERIAL INTERFACE

There are two phases to a communication cycle with the

AD9776A/AD9778A/AD9779A. Phase 1 is the instruction cycle

(the writing of an instruction byte into the device), coinciding

with the first eight SCLK rising edges. The instruction byte

provides the serial port controller with information regarding

the data transfer cycle, Phase 2 of the communication cycle.

The Phase 1 instruction byte defines whether the upcoming

data transfer is a read or write, the number of bytes in the data

transfer, and the starting register address for the first byte of the

data transfer. The first eight SCLK rising edges of each communication cycle are used to write the instruction byte into the device.

A logic high on the CSB pin followed by a logic low resets the

SPI port timing to the initial state of the instruction cycle.

From this state, the next eight rising SCLK edges represent the

instruction bits of the current I/O operation, regardless of the

state of the internal registers or the other signal levels at the

inputs to the SPI port. If the SPI port is in an instruction cycle

or a data transfer cycle, none of the present data is written.

The remaining SCLK edges are for Phase 2 of the communication cycle. Phase 2 is the actual data transfer between the device

and the system controller. Phase 2 of the communication cycle

is a transfer of one, two, three, or four data bytes as determined

by the instruction byte. Using one multibyte transfer is preferred.

Single byte data transfers are useful in reducing CPU overhead

when register access requires only one byte. Registers change

immediately upon writing to the last bit of each transfer byte.

INSTRUCTION BYTE

See Tab le 1 1 for information contained in the instruction byte.

Table 11. SPI Instruction Byte

MSB LSB

I7 I6 I5 I4 I3 I2 I1 I0

R/W

R/W, Bit 7 of the instruction byte, determines whether a read

or a write data transfer occurs after the instruction byte write.

Logic 1 indicates a read operation. Logic 0 indicates a write

operation.

N1 and N0, Bit 6 and Bit 5 of the instruction byte, determine

the number of bytes to be transferred during the data transfer

cycle. The translation for the number of bytes to be transferred

is listed in Tabl e 12.

A4, A3, A2, A1, and A0—Bit 4, Bit 3, Bit 2, Bit 1, and Bit 0,

respectively—of the instruction byte determine the register that

is accessed during the data transfer portion of the communication

cycle. For multibyte transfers, this address is the starting byte

address. The remaining register addresses are generated by the

device based on the LSB First bit (Register 0x00, Bit 6).

Table 12. Byte Transfer Count

N1 N0 Description

0 0 Transfer one byte

0 1 Transfer three bytes

1 0 Transfer two bytes

1 1 Transfer four bytes

N1 N0 A4 A3 A2 A1 A0

Rev. A | Page 24 of 60

Page 25

AD9776A/AD9778A/AD9779A

SERIAL INTERFACE PORT PIN DESCRIPTIONS

Serial Clock (SCLK)

The serial clock pin synchronizes data to and from the device

as well as running the internal state machines. The maximum

frequency of SCLK is 40 MHz. All data input is registered on

the rising edge of SCLK. All data is driven out on the falling

edge of SCLK.

Chip Select (CSB)

Active low input starts and gates a communication cycle. It

allows more than one device to be used on the same serial

communications lines. The SDO and SDIO pins go to a high

impedance state when this input is high. Chip select should

stay low during the entire communication cycle.

Serial Data I/O (SDIO)

Data is always written into the device on this pin. However, this

pin can be used as a bidirectional data line. The configuration

of this pin is controlled by Register 0x00, Bit 7. The default is

Logic 0, configuring the SDIO pin as unidirectional.

Serial Data Out (SDO)

Data is read from this pin for protocols that use separate lines

for transmitting and receiving data. In the case where the device

operates in a single bidirectional I/O mode, this pin does not

output data and is set to a high impedance state.

MSB/LSB TRANSFERS

The serial port can support both MSB first and LSB first data

formats. This functionality is controlled by Register Bit LSB/MSB

First (Register 0x00, Bit 6). The default is MSB first (LSB/MSB

First = 0).

When LSB/MSB first = 0 (MSB first) the instruction and

data bit must be written from MSB to LSB. Multibyte data

transfers in MSB first format start with an instruction byte

that includes the register address of the most significant data

byte. Subsequent data bytes should follow from high address to

low address. In MSB first mode, the serial port internal byte address

generator decrements for each data byte of the multibyte

communication cycle.

When LSB/MSB First = 1 (LSB first) the instruction and data

bit must be written from LSB to MSB. Multibyte data transfers

in LSB first format start with an instruction byte that includes

the register address of the least significant data byte followed by

multiple data bytes. The serial port internal byte address generator increments for each byte of the multibyte communication cycle.

The serial port controller data address decrements from the data

address written toward 0x00 for multibyte I/O operations if the

MSB first mode is active. The serial port controller address increments from the data address written toward 0x1F for multibyte

I/O operations if the LSB first mode is active.

INSTRUCTIO N CYCLE DATA TRANSFER CYCL E

CSB

SCLK

SDIO

SDO

R/W N1 N0 A4 A3 A2 A1 A0 D7 D6ND5

D7 D6ND5

N

N

D00D10D20D3

0

D00D10D20D3

0

Figure 53. Serial Register Interface Timing, MSB First

INSTRUCTIO N CYCLE DATA TRANSFER CYCL E

CSB

SCLK

SDIO

SDO

A0 A1 A2 A3 A4 N0 N1 R/W D00D10D2

D00D10D2

0

0

D7ND6ND5ND4

N

D7ND6ND5ND4

N

Figure 54. Serial Register Interface Timing, LSB First

t

CSB

SCLK

SDIO

DS

t

DS

t

PWH

t

t

SCLK

t

PWL

DH

INSTRUCTIO N BIT 6INSTRUCTIO N BIT 7

Figure 55. Timing Diagram for SPI Register Write

CSB

SCLK

t

SDIO

SDO

Figure 56. Timing Diagram for SPI Register Read

DV

DATA BIT n –1DATA BIT n

06452-050

06452-051

06452-052

6452-053

Rev. A | Page 25 of 60

Page 26

AD9776A/AD9778A/AD9779A

SPI REGISTER MAP

Note that all unused register bits should be kept at the device default values.

Table 13.

Register

Name

Comm 0x00 00 SDIO

Digital

Control

Sync

Control

PLL

Control

Misc.

Control

I DAC

Control

AUX

DAC1

Control

Q DAC

Control

AUX

DAC2

Control

Interrupt 0x19 25 Data Timing

Version 0x1F 31 Version<7:0> 0x03

Address

Hex Decimal

0x01 01 Interpolation Factor<1:0> Filter Modulation Mode<3:0> DATACLK

0x02 02 Data Format Interleaved

0x03 03 DATACLK

0x04 04 DATACLK Delay<3:0> SYNC_O Divide<2:0> SYNC_O

0x05 05 SYNC_O Delay<3:0> SYNC_I Ratio<2:0> SYNC_I

0x06 06 SYNC_I Delay<3:0> SYNC_I Timing Margin<3:0> 0x00

0x07 07 SYNC_I

0x08 08 PLL Band Select<5:0> PLL VCO Drive<1:0> 0xE7

0x09 09 PLL Enable PLL VCO Divide