Page 1

14-Bit, 2.5 GSPS,

SCLK

FEATURES

Direct RF synthesis at 2.5 GSPS update rate

DC to 1.25 GHz in baseband mode

1.25 GHz to 3.0 GHz in mix mode

Industry leading single/multicarrier IF or RF synthesis

Dual-port LVDS data interface

Up to 1.25 GSPS operation

Source synchronous DDR clocking

Pin-compatible with the AD9739

Programmable output current: 8.7 mA to 31.7 mA

Low power: 1.1 W at 2.5 GSPS

APPLICATIONS

Broadband communications systems

DOCSIS CMTS systems

Military jammers

Instrumentation, automatic test equipment

Radar, avionics

RF Digital-to-Analog Converter

AD9739A

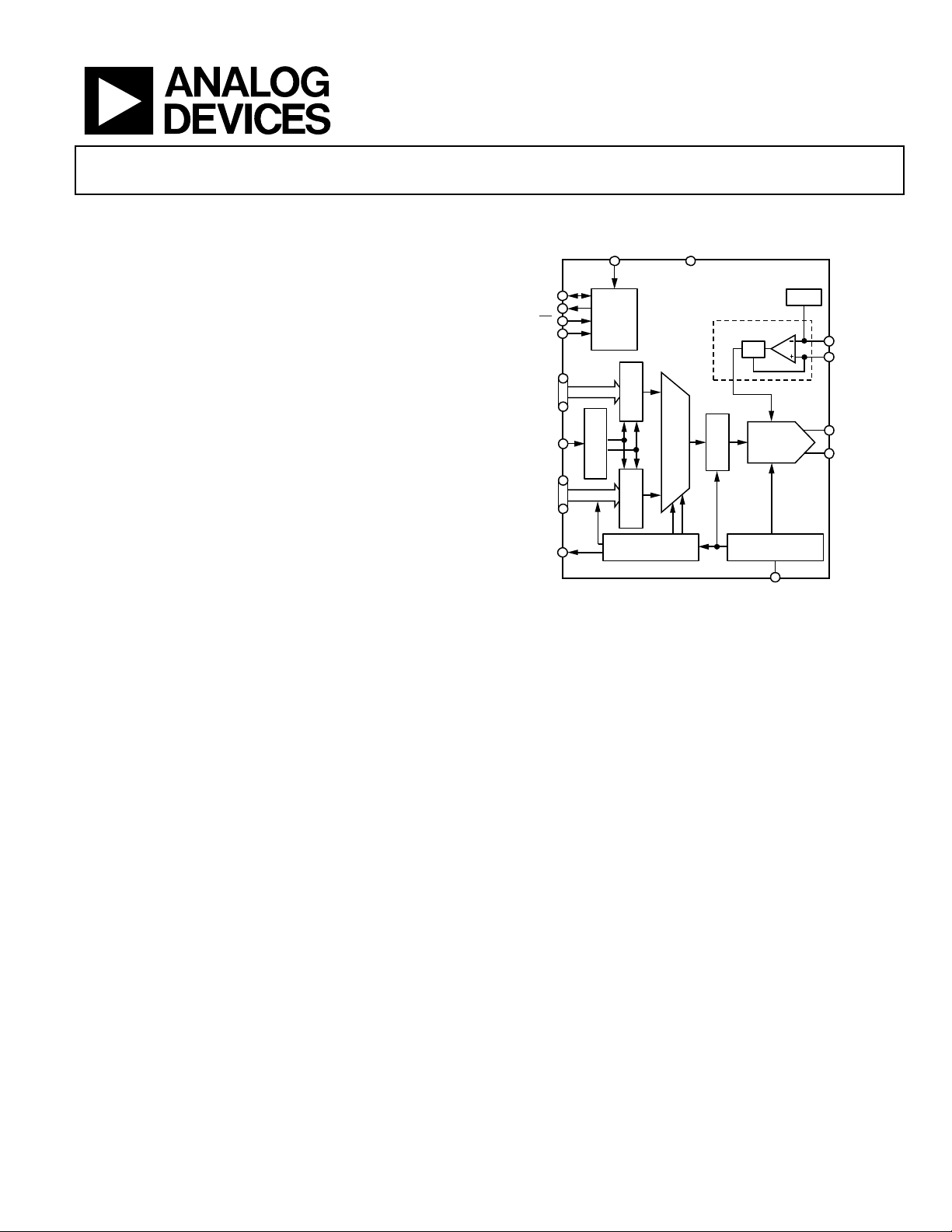

FUNCTIONAL BLOCK DIAGRAM

SDIO

SDO

CS

DCI

DCO

RESET

SPI

DB0[13:0]DB1[13:0]

LVDS DDR

DATA

CONTROLLER

LVDS DDR

(DIV-BY-4)

IRQ

AD9739A

1.2V

DAC BIAS

RECEIVER

TxDAC

DATA

4-TO-1

DATA ASSEMBLER

RECEIVER

CLK DISTRIBUTION

CORE

LATCH

DLL

(MU CONTROL LER)

VREF

I120

IOUTN

IOUTP

GENERAL DESCRIPTION

The AD9739A is a 14-bit, 2.5 GSPS high performance RF DAC

capable of synthesizing wideband signals from dc up to 3 GHz.

The AD9739A is pin and functionally compatible with the AD9739

with the exception that the AD9739A does not support

synchronization and is specified to operate between 1.6 GSPS

and 2.5 GSPS. By elimination of the synchronization circuitry,

some nonideal artifacts such as images and discrete clock spurs

remain stationary on the AD9739A between power-up cycles,

thus allowing for possible system calibration. AC linearity and

noise performance remain the same between the AD9739 and

AD9739A.

The inclusion of on-chip controllers simplifies system integration. A dual-port, source synchronous, LVDS interface

simplifies the digital interface with existing FGPA/ASIC

technology. On-chip controllers are used to manage external

and internal clock domain variations over temperature to

ensure reliable data transfer from the host to the DAC core. A

serial peripheral interface (SPI) is used for device configuration

as well as readback of status registers.

The AD9739A is manufactured on a 0.18 μm CMOS process

and operates from 1.8 V and 3.3 V supplies. It is supplied in a

160-ball chip scale ball grid array for reduced package parasitics.

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Analog Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

DACCLK

Figure 1.

PRODUCT HIGHLIGHTS

1. Ability to synthesize high quality wideband signals with

bandwidths of up to 1.25 GHz in the first or second

Nyquist zone.

2. A proprietary quad-switch DAC architecture provides

exceptional ac linearity performance while enabling mixmode operation.

3. A dual-port, double data rate, LVDS interface supports the

maximum conversion rate of 2500 MSPS.

4. On-chip controllers manage external and internal clock

domain skews.

5. Programmable differential current output with a 8.66 mA

to 31.66 mA range.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2011 Analog Devices, Inc. All rights reserved.

09616-001

Page 2

AD9739A

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications ....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description ......................................................................... 1

Product Highlights ........................................................................... 1

Revision History ............................................................................... 2

Specifications ..................................................................................... 3

DC Specifications ......................................................................... 3

LVDS Digital Specifications ........................................................ 4

Serial Port Specifications ............................................................. 5

AC Specifications .......................................................................... 6

Absolute Maximum Ratings ............................................................ 7

Thermal Resistance ...................................................................... 7

ESD Caution .................................................................................. 7

Pin Configurations and Function Descriptions ........................... 8

Typical Performance Characteristics ........................................... 11

AC (Normal Mode) .................................................................... 11

AC (Mix Mode) .......................................................................... 14

One-Carrier DOCSIS Performance (Normal Mode) ............ 16

Four-Carrier DOCSIS Performance (Normal Mode) ........... 17

Eight-Carrier DOCSIS Performance (Normal Mode) .......... 18

16-Carrier DOCSIS Performance (Normal Mode) ............... 19

32-Carrier DOCSIS Performance (Normal Mode) ............... 20

64- and 128-Carrier DOCSIS Performance (Normal Mode)21

Terminolog y .................................................................................... 22

Serial Port Interface (SPI) Register .............................................. 23

SPI Register Map Description .................................................. 23

SPI Operation ............................................................................. 23

SPI Register Map ........................................................................ 25

Theory of Operation ...................................................................... 28

LVDS Data Port Interface .......................................................... 29

Mu Controller ............................................................................. 32

Interrupt Requests ...................................................................... 33

Analog Interface Considerations .................................................. 35

Analog Modes of Operation ..................................................... 35

Clock Input Considerations ...................................................... 36

Voltage Reference ....................................................................... 37

Analog Outputs .......................................................................... 37

Nonideal Spectral Artifacts ....................................................... 39

Lab Evaluation of the AD9739A .............................................. 40

Recommended Start-Up Sequence .......................................... 41

Outline Dimensions ....................................................................... 43

Ordering Guide .......................................................................... 43

REVISION HISTORY

7/11—Rev 0 to Rev. A

Changed Maximum Update Rate (DACCLK Input) Parameter

to DAC Clock Rate Parameter in Table 4 ...................................... 6

Added Adjusted DAC Update Rate Parameter and Endnote 1 in

Table 4 ................................................................................................ 6

Updated Outline Dimensions ....................................................... 43

1/11—Revision 0: Initial Version

Rev. A | Page 2 of 44

Page 3

AD9739A

SPECIFICATIONS

DC SPECIFICATIONS

VDDA = VDD33 = 3.3 V ± 6%, VDDC = VDD = 1.8 V ± 6%, I

Table 1.

Parameter Min Typ Max Unit

RESOLUTION 14 Bits

ACCURACY

Integral Nonlinearity (INL) ±2.5 LSB

Differential Nonlinearity (DNL) ±2.0 LSB

ANALOG OUTPUTS

Gain Error (with Internal Reference) 5.5 %

Full-Scale Output Current 8.66 20.2 31.66 mA

Output Compliance Range −1.0 +1.0 V

Common-Mode Output Resistance 10 MΩ

Differential Output Resistance 70 Ω

Output Capacitance 1 pF

DAC CLOCK INPUT (DACCLK_P, DACCLK_N)

Differential Peak-to-Peak Voltage 1.2 1.6 2.0 V

Common-Mode Voltage 900 mV

Clock Rate 1.6 2.5 GHz

TEMPERATURE DRIFT

Gain 60 ppm/°C

Reference Voltage 20 ppm/°C

REFERENCE

Internal Reference Voltage 1.15 1.2 1.25 V

Output Resistance 5 kΩ

ANALOG SUPPLY VOLTAGES

VDDA 3.1 3.3 3.5 V

VDDC 1.70 1.8 1.90 V

DIGITAL SUPPLY VOLTAGES

VDD33 3.10 3.3 3.5 V

VDD 1.70 1.8 1.90 V

SUPPLY CURRENTS AND POWER DISSIPATION, 2.0 GSPS

I

37 38 mA

VDDA

I

158 167 mA

VDDC

I

14.5 16 mA

VDD33

I

173 183 mA

VDD

Power Dissipation 0.770 W

Sleep Mode, I

2.5 2.75 mA

VDDA

Power-Down Mode (All Power-Down Bits Set in Register 0x01 and

Register 0x02)

I

0.02 mA

VDDA

I

6 mA

VDDC

I

0.6 mA

VDD33

I

0.1 mA

VDD

SUPPLY CURRENTS AND POWER DISSIPATION, 2.5 GSPS

I

37 mA

VDDA

I

223 mA

VDDC

I

14.5 mA

VDD33

I

215 mA

VDD

Power Dissipation 0.960 W

OUTFS

= 20 mA.

Rev. A | Page 3 of 44

Page 4

AD9739A

LVDS DIGITAL SPECIFICATIONS

VDDA = VDD33 = 3.3 V ± 6%, VDDC = VDD = 1.8 V ± 6%, I

Standard 1596.3-1996 reduced range link, unless otherwise noted.

Table 2.

Parameter Min Typ Max Unit

LVDS DATA INPUTS (DB0[13:0], DB1[13:0])1

Input Common-Mode Voltage Range, V

Logic High Differential Input Threshold, V

Logic Low Differential Input Threshold, V

825 1575 mV

COM

175 400 mV

IH_DTH

−175 −400 mV

IL_DTH

Receiver Differential Input Impedance, RIN 80 120 Ω

Input Capacitance 1.2 pF

LVDS Input Rate 1250 MSPS

LVDS Minimum Data Valid Period (t

) (See Figure 76) 344 ps

MDE

LVDS CLOCK INPUT (DCI)2

Input Common-Mode Voltage Range, V

Logic High Differential Input Threshold, V

Logic Low Differential Input Threshold, V

825 1575 mV

COM

175 400 mV

IH_DTH

−175 −400 mV

IL_DTH

Receiver Differential Input Impedance, RIN 80 120 Ω

Input Capacitance 1.2 pF

Maximum Clock Rate 625 MHz

LVDS CLOCK OUTPUT (DCO)3

Output Voltage High (DCO_P or DCO_N) 1375 mV

Output Voltage Low (DCO_P or DCO_N) 1025 mV

Output Differential Voltage, |VOD| 150 200 250 mV

Output Offset Voltage, VOS 1150 1250 mV

Output Impedance, Single-Ended, RO 80 100 120 Ω

RO Single-Ended Mismatch 10 %

Maximum Clock Rate 625 MHz

1

DB0[x]P, DB0[x]N, DB1[x]P, and DB1[x]N pins.

2

DCI_P and DCI_N pins.

3

DCO_P and DCO_N pins with 100 Ω differential termination.

= 20 mA. LVDS drivers and receivers are compliant to the IEEE

OUTFS

Rev. A | Page 4 of 44

Page 5

AD9739A

SERIAL PORT SPECIFICATIONS

VDDA = VDD33 = 3.3 V ± 6%, VDDC = VDD = 1.8 V ± 6%.

Tabl e 3

.

Parameter Min Typ Max Unit

WRITE OPERATION (See Figure 71)

SCLK Clock Rate, f

SCLK Clock High, tHI 18 ns

SCLK Clock Low, t

SDIO to SCLK Setup Time, tDS 2 ns

SCLK to SDIO Hold Time, tDH 1 ns

CS to SCLK Setup Time, tS

SCLK to CS Hold Time, tH

READ OPERATION (See Figure 72 and Figure 73)

SCLK Clock Rate, f

SCLK Clock High, tHI 18 ns

SCLK Clock Low, t

SDIO to SCLK Setup Time, tDS 2 ns

SCLK to SDIO Hold Time, tDH 1 ns

CS to SCLK Setup Time, tS

SCLK to SDIO (or SDO) Data Valid Time, tDV 15 ns

CS to SDIO (or SDO) Output Valid to High-Z, tEZ

INPUTS (SDI, SDIO, SCLK, CS)

Voltage in High, VIH 2.0 3.3 V

Voltage in Low, VIL 0 0.8 V

Current in High, IIH −10 +10 μA

Current in Low, IIL −10 +10 μA

OUTPUT (SDIO)

Voltage Out High, VOH 2.4 3.5 V

Voltage Out Low, VOL 0 0.4 V

Current Out High, IOH 4 mA

Current Out Low, IOL 4 mA

, 1/t

SCLK

LOW

20 MHz

SCLK

18 ns

3 ns

2 ns

, 1/t

SCLK

LOW

20 MHz

SCLK

18 ns

3 ns

2 ns

Rev. A | Page 5 of 44

Page 6

AD9739A

AC SPECIFICATIONS

VDDA = VDD33 = 3.3 V ± 6%, VDDC = VDD = 1.8 V ± 6%, I

Table 4.

Parameter Min Typ Max Unit

DYNAMIC PERFORMANCE

DAC Clock Rate 800 2500 MSPS

Adjusted DAC Update Rate1 800 2500 MSPS

Output Settling Time to 0.1% 13 ns

SPURIOUS-FREE DYNAMIC RANGE (SFDR)

f

= 100 MHz 69.5 dBc

OUT

f

= 350 MHz 58.5 dBc

OUT

f

= 550 MHz 54 dBc

OUT

f

= 950 MHz 60 dBc

OUT

TWO-TONE INTERMODULATION DISTORTION (IMD), f

f

= 100 MHz 94 dBc

OUT

f

= 350 MHz 78 dBc

OUT

f

= 550 MHz 72 dBc

OUT

f

= 950 MHz 68 dBc

OUT

OUT2

= f

OUT1

NOISE SPECTRAL DENSITY (NSD), 0 dBFS SINGLE TONE

f

= 100 MHz −166 dBm/Hz

OUT

f

= 350 MHz −161 dBm/Hz

OUT

f

= 550 MHz −160 dBm/Hz

OUT

f

= 850 MHz −160 dBm/Hz

OUT

WCDMA ACLR (SINGLE CARRIER), ADJACENT/ALTERNATE ADJACENT CHANNEL

f

= 2457.6 MSPS f

DAC

f

= 2457.6 MSPS, f

DAC

f

= 2457.6 MSPS, f

DAC

f

= 2457.6 MSPS, f

DAC

1

Adjusted DAC updated rate is calculated as f

with f

= 2500 MSPS, f

DAC

= 350 MHz 80/80 dBc

OUT

= 950 MHz 78/79 dBc

OUT

= 1700 MHz (Mix Mode) 74/74 dBc

OUT

= 2100 MHz (Mix Mode) 69/72 dBc

OUT

divided by the minimum required interpolation factor. For the AD9739A, the minimum interpolation factor is 1. Thus,

, adjusted, = 2500 MSPS.

DAC

DAC

= 20 mA.

OUTFS

+ 1.25 MHz

Rev. A | Page 6 of 44

Page 7

AD9739A

ABSOLUTE MAXIMUM RATINGS

Table 5.

With

Parameter

VDDA VSSA −0.3 V to +3.6 V

VDD33 VSS −0.3 V to +3.6 V

VDD VSS −0.3 V to +1.98 V

VDDC VSSC −0.3 V to +1.98 V

VSSA VSS −0.3 V to +0.3 V

VSSA VSSC −0.3 V to +0.3 V

VSS VSSC −0.3 V to +0.3 V

DACCLK_P,

DACCLK_N

DCI, DCO VSS −0.3 V to VDD33 + 0.3 V

LVDS Data Inputs VSS −0.3 V to VDD33 + 0.3 V

IOUTP, IOUTN VSSA −1.0 V to VDDA + 0.3 V

I120, VREF VSSA −0.3 V to VDDA + 0.3 V

IRQ, CS, SCLK, SDO,

SDIO, RESET

Junction

Temperature

Storage Temperature −65°C to +150°C

Respect To

VSSC −0.3 V to VDDC + 0.18 V

VSS −0.3 V to VDD33 + 0.3 V

150°C

Rating

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

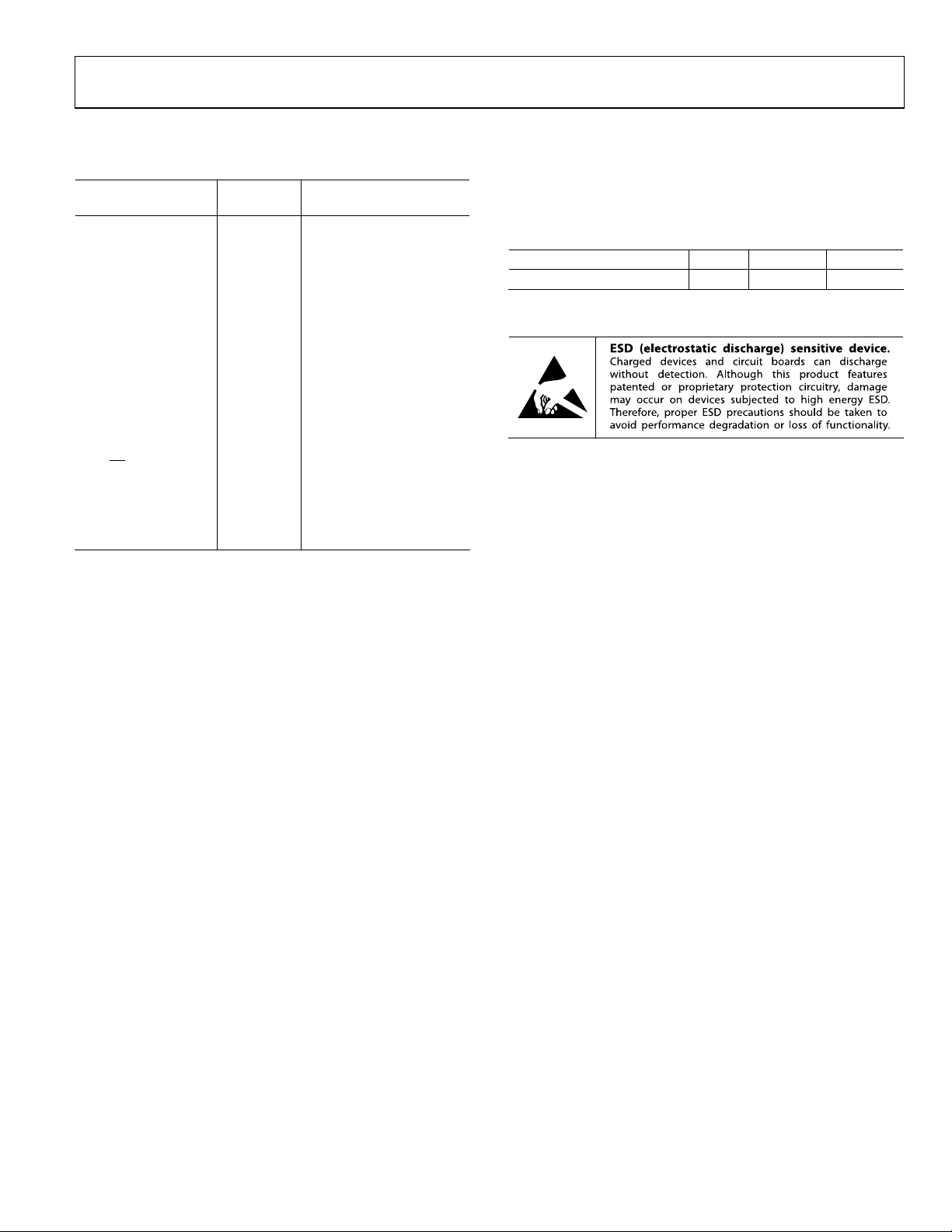

THERMAL RESISTANCE

θJA is specified for the worst-case conditions, that is, a device

soldered in a circuit board for surface-mount packages.

Table 6. Thermal Resistance

Package Type θJA θ

160-Ball CSP_BGA 31.2 7.0 °C/W1

1

With no airflow movement.

Unit

JC

ESD CAUTION

Rev. A | Page 7 of 44

Page 8

AD9739A

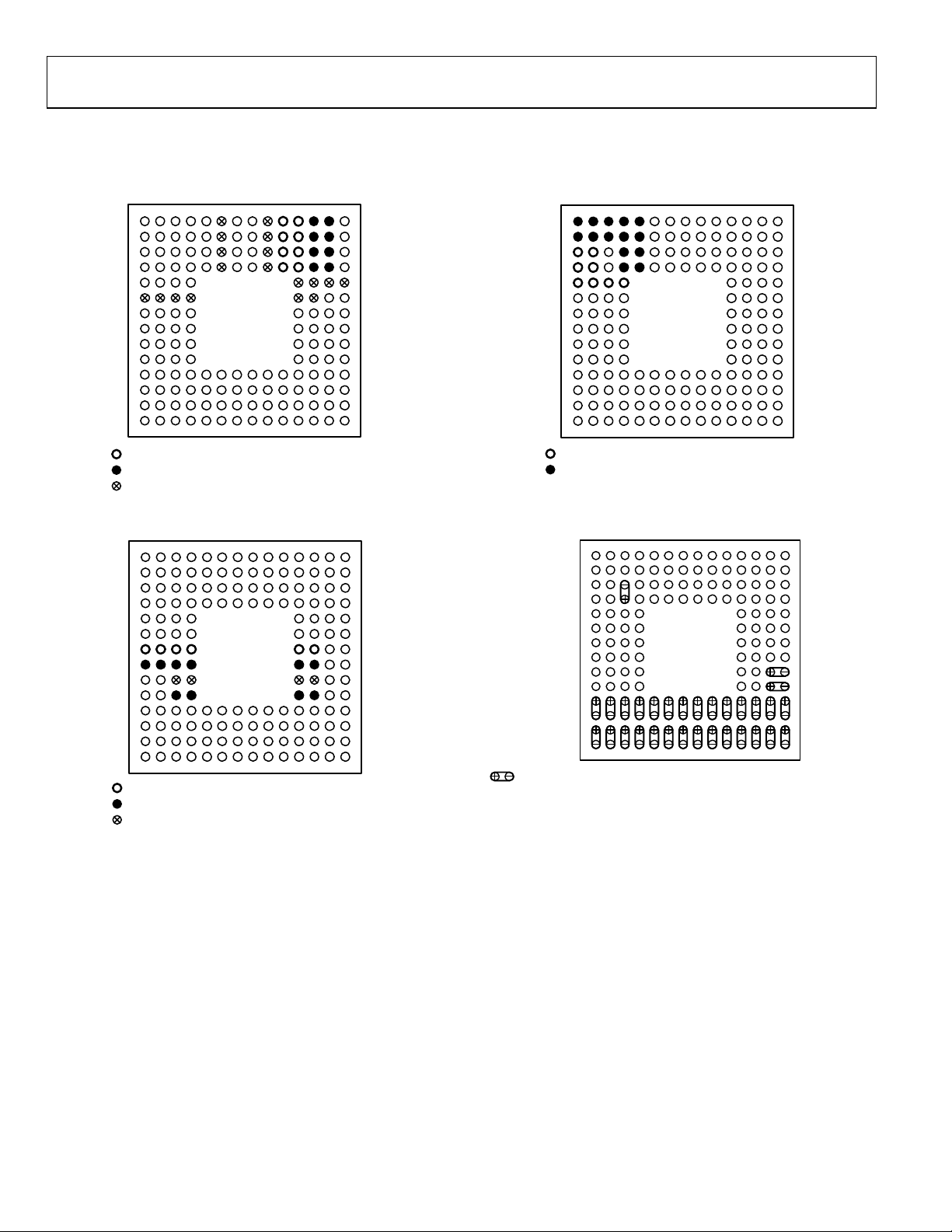

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

1413121110876321954

1413121110876321954

A

B

C

D

E

F

G

H

J

K

L

M

N

P

VDDA, 3.3V, ANALOG SUPPLY

VSSA, ANALOG SUPPLY GROUND

VSSA SHIELD, ANALOG SUPPLY GROUND SHIELD

Figure 2. Analog Supply Pins (Top View)

A

B

C

D

E

F

G

H

J

K

L

M

N

P

VDD, 1.8V, DIGITAL SUPPLY

VSS DIGITAL SUPPLY GROUND

VDD33, 3.3V DI GITAL SUPPLY

Figure 3. Digital Supply Pins (Top View)

A

B

C

D

E

F

G

H

J

K

L

M

N

P

VDDC, 1.8V, CLOCK SUPPLY

VSSC, CLOCK SUPPLY GROUND

09616-002

09616-004

Figure 4. Digital LVDS Clock Supply Pins (Top View)

1413121110876321954

A

B

DACCLK_N

DACCLK_P

DB1[0:13] P

DB1[0:13]N

DB0[0:13] P

DB0[0:13]N

09616-003

C

D

E

F

G

H

J

K

L

M

N

P

DIFFERE NTIAL INPUT SIGNAL (CL OCK OR DATA)

1413121110876321954

DCO_P/_N

DCI_P/_N

09616-005

Figure 5. Digital LVDS Input, Clock I/O (Top View)

Rev. A | Page 8 of 44

Page 9

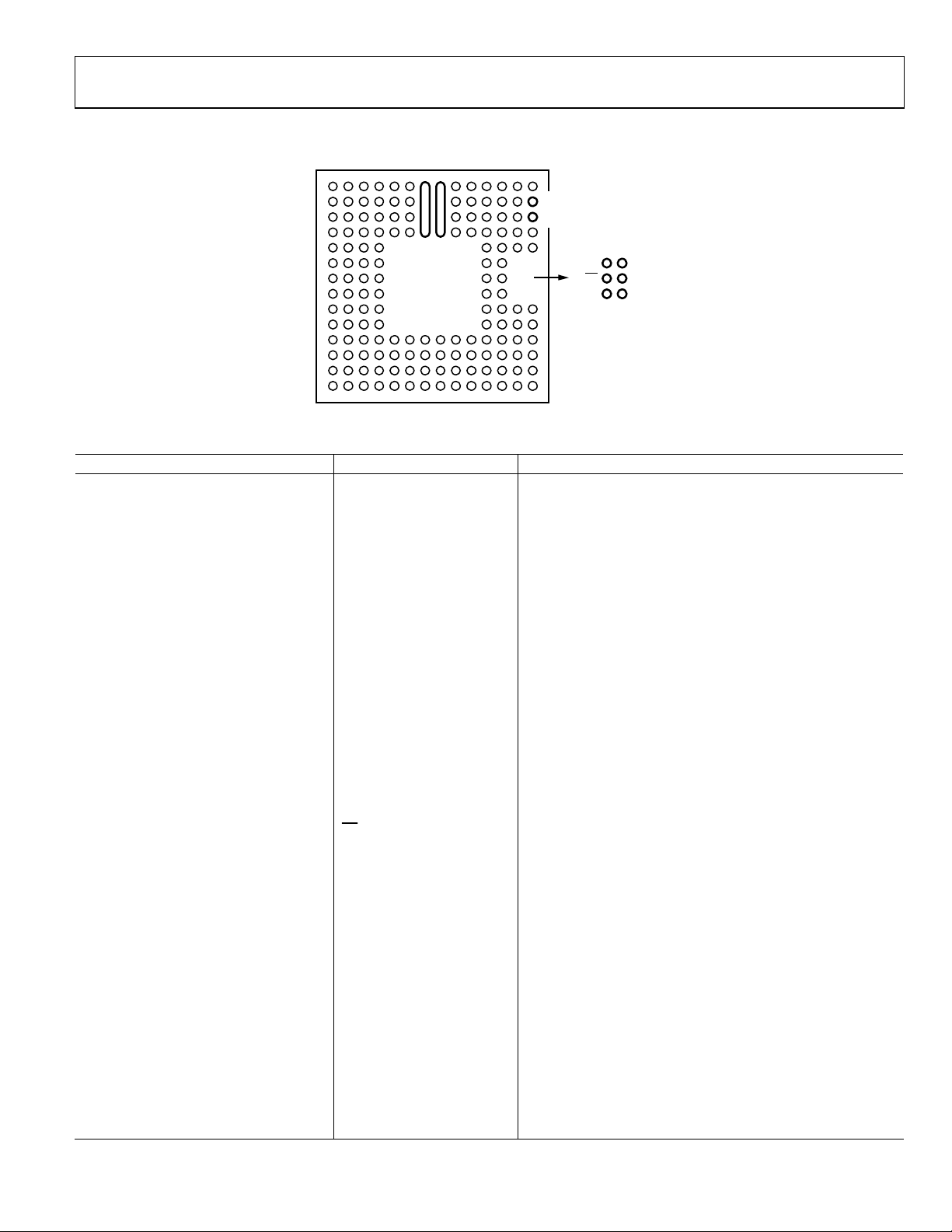

AD9739A

IOUTN

IOUTP

1413121110876321954

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Figure 6. Analog I/O and SPI Control Pins (Top View)

I120

VREF

IRQ

CS

SCLK

RESET

SDIO

SDO

09616-006

Table 7. AD9739A Pin Function Descriptions

Pin No. Mnemonic Description

C1, C2, D1, D2, E1, E2, E3, E4 VDDC 1.8 V Clock Supply Input.

A1, A2, A3, A4, A5, B1, B2, B3, B4, B5, C4,

VSSC

Clock Supply Return.

C5, D4, D5

A10, A11, B10, B11, C10, C11, D10, D11 VDDA

A12, A13, B12, B13, C12, C13, D12, D13, VSSA

A6, A9, B6, B9, C6, C9, D6, D9, F1, F2, F3,

VSSA Shield Analog Supply Return Shield.

F4, E11, E12, E13, E14, F11, F12

A14 NC

A7, B7, C7, D7 IOUTN

A8, B8, C8, D8 IOUTP

B14 I120

3.3 V Analog Supply Input.

Analog Supply Return.

Tie to VSSA at the DAC.

Do not connect to this pin.

DAC Negative Current Output Source.

DAC Positive Current Output Source.

Nominal 1.2 V Reference. Tie to analog ground via a 10 kΩ

resistor to generate a 120 μA reference current.

C14 VREF Voltage Reference Input/Output.

Decouple to VSSA with a 1 nF capacitor.

D14 NC

C3, D3 DACCLK_N/DACCLK_P

F13 IRQ

Factory Test Pin. Do not connect to this pin.

Negative/Positive DAC Clock Input (DACCLK).

Interrupt Request Open Drain Output. Active high. Pull up to

VDD33 with a 10 kΩ resistor.

F14 RESET

G13

CS

G14 SDIO

H13 SCLK

H14 SDO

J3, J4, J11, J12 VDD33

G1, G2, G3, G4, G11, G12 VDD

H1, H2, H3, H4, H11, H12, K3, K4, K11, K12 VSS

J1, J2 NC

Reset Input. Active high. Tie to VSS if unused.

Serial Port Enable Input.

Serial Port Data Input/Output.

Serial Port Clock Input.

Serial Port Data Output.

3.3 V Digital Supply Input.

1.8 V Digital Supply. Input.

Digital Supply Return.

Differential resistor of 200 Ω exists between J1 and J2. Do not

connect to this pin.

K1, K2 NC

Differential resistor of 100 Ω exists between J1 and J2. Do not

connect to this pin.

J13, J14 DCO_P/DCO_N

K13, K14 DCI_P/DCI_N

L1, M1 DB1[0]P/DB1[0]N

L2, M2 DB1[1]P/DB1[1]N

L3, M3 DB1[2]P/DB1[2]N

Positive/Negative Data Clock Output (DCO).

Positive/Negative Data Clock Input (DCI).

Port 1 Positive/Negative Data Input Bit 0.

Port 1 Positive/Negative Data Input Bit 1.

Port 1 Positive/Negative Data Input Bit 2.

L4, M4 DB1[3]P/DB1[3]N Port 1 Positive/Negative Data Input Bit 3.

Rev. A | Page 9 of 44

Page 10

AD9739A

Pin No. Mnemonic Description

L5, M5 DB1[4]P/DB1[4]N Port 1 Positive/Negative Data Input Bit 4.

L6, M6 DB1[5]P/DB1[5]N Port 1 Positive/Negative Data Input Bit 5.

L7, M7 DB1[6]P/DB1[6]N Port 1 Positive/Negative Data Input Bit 6.

L8, M8 DB1[7]P/DB1[7]N Port 1 Positive/Negative Data Input Bit 7.

L9, M9 DB1[8]P/DB1[8]N Port 1 Positive/Negative Data Input Bit 8.

L10, M10 DB1[9]P/DB1[9]N Port 1 Positive/Negative Data Input Bit 9.

L11, M11 DB1[10]P/DB1[10]N Port 1 Positive/Negative Data Input Bit 10.

L12, M12 DB1[11]P/DB1[11]N Port 1 Positive/Negative Data Input Bit 11.

L13, M13 DB1[12]P/DB1[12]N Port 1 Positive/Negative Data Input Bit 12.

L14, M14 DB1[13]P/DB1[13]N Port 1 Positive/Negative Data Input Bit 13.

N1, P1 DB0[0]P/DB0[0]N Port 0 Positive/Negative Data Input Bit 0.

N2, P2 DB0[1]P/DB0[1]N Port 0 Positive/Negative Data Input Bit 1.

N3, P3 DB0[2]P/DB0[2]N Port 0 Positive/Negative Data Input Bit 2.

N4, P4 DB0[3]P/DB0[3]N Port 0 Positive/Negative Data Input Bit 3.

N5, P5 DB0[4]P/DB0[4]N Port 0 Positive/Negative Data Input Bit 4.

N6, P6 DB0[5]P/DB0[5]N Port 0 Positive/Negative Data Input Bit 5.

N7, P7 DB0[6]P/DB0[6]N Port 0 Positive/Negative Data Input Bit 6.

N8, P8 DB0[7]P/DB0[7]N Port 0 Positive/Negative Data Input Bit 7.

N9, P9 DB0[8]P/DB0[8]N Port 0 Positive/Negative Data Input Bit 8.

N10, P10 DB0[9]P/DB0[9]N Port 0 Positive/Negative Data Input Bit 9.

N11, P11 DB0[10]P/DB0[10]N Port 0 Positive/Negative Data Input Bit 10.

N12, P12 DB0[11]P/DB0[11]N Port 0 Positive/Negative Data Input Bit 11.

N13, P13 DB0[12]P/DB0[12]N Port 0 Positive/Negative Data Input Bit 12.

N14, P14 DB0[13]P/DB0[13]N Port 0 Positive/Negative Data Input Bit 13.

Rev. A | Page 10 of 44

Page 11

AD9739A

–

–

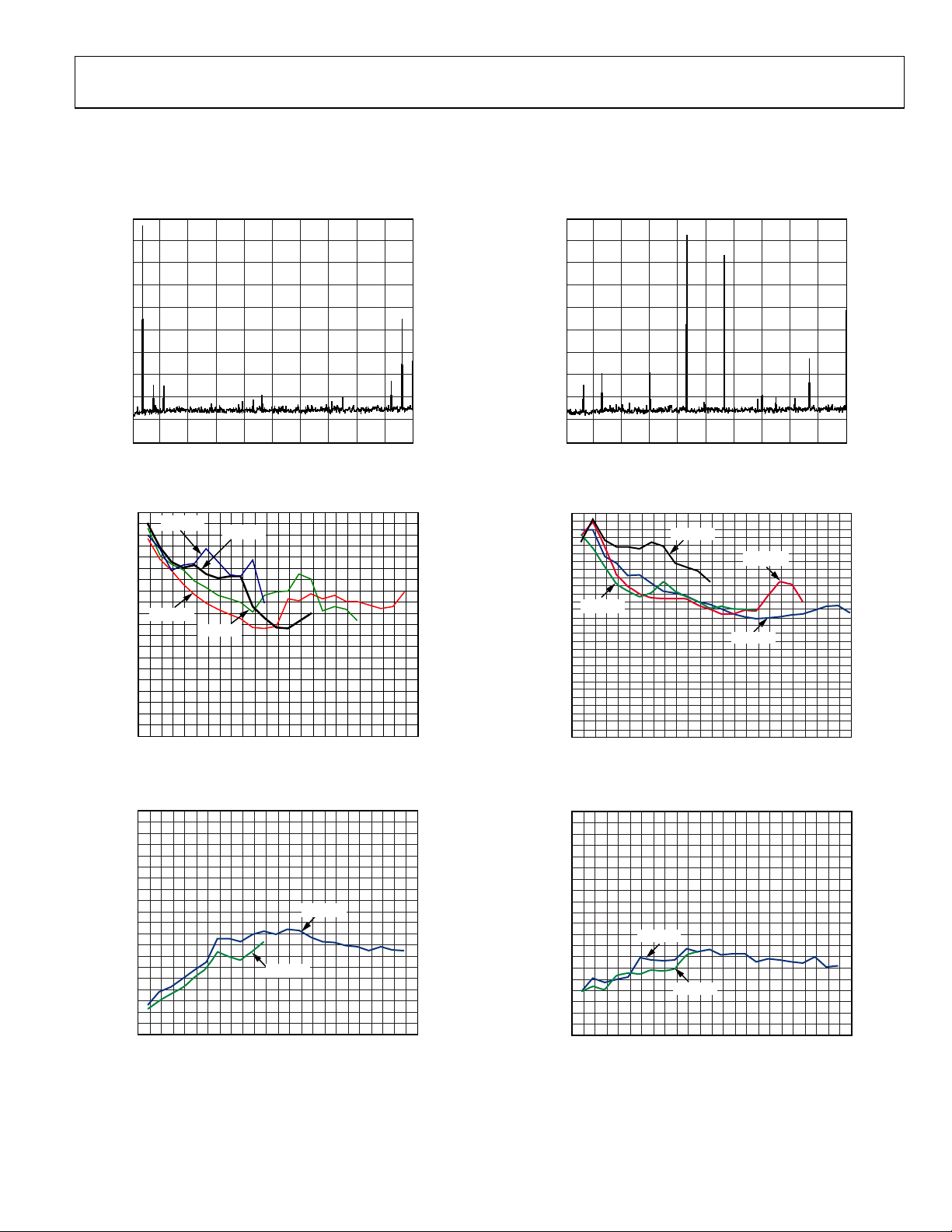

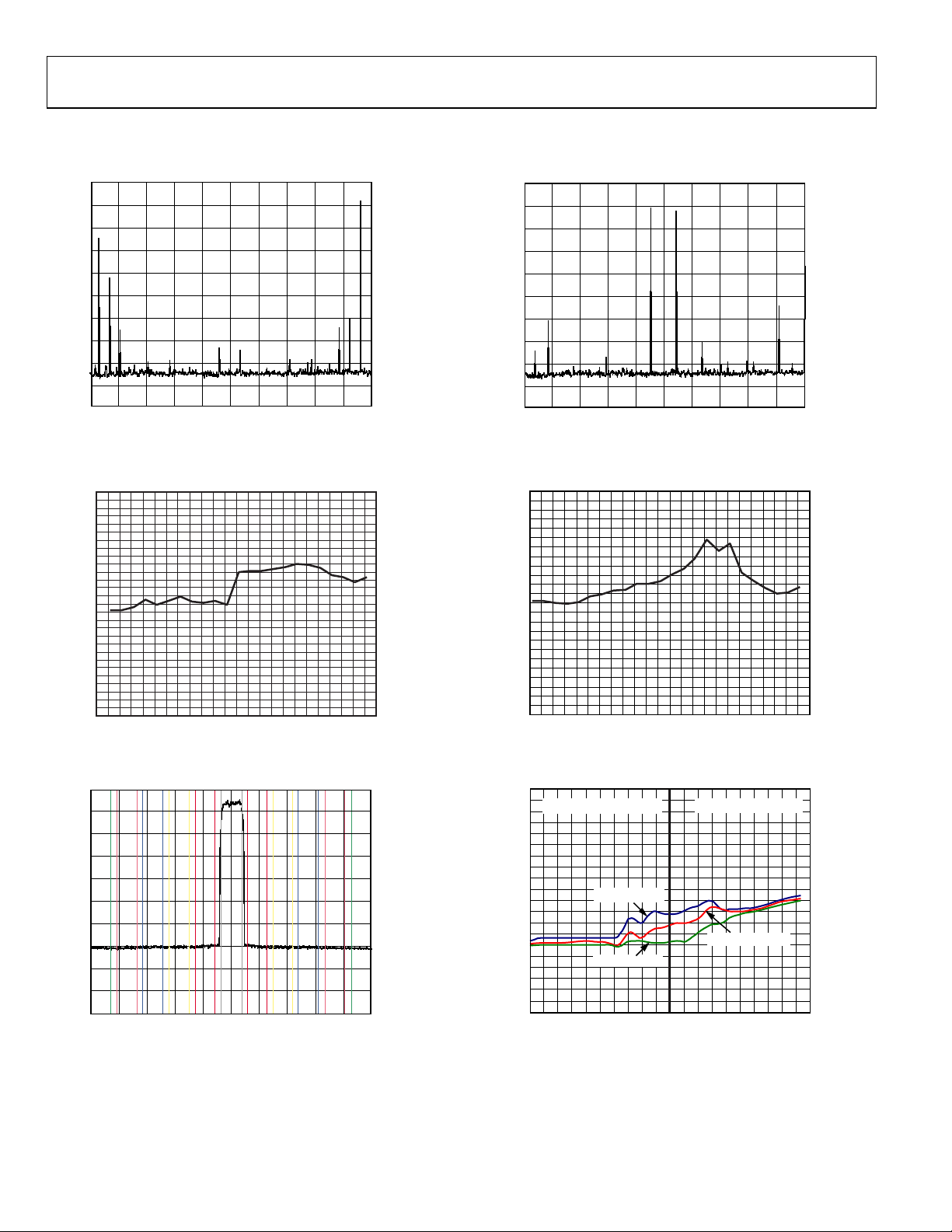

TYPICAL PERFORMANCE CHARACTERISTICS

AC (NORMAL MODE)

I

= 20 mA, nominal supplies, 25°C, unless otherwise noted.

OUTFS

10dB/DIV

Figure 7. Single-Tone Spectrum at f

80

1.2GSPS

75

70

65

60

2.4GSPS

55

50

SFDR (dBc)

45

40

35

30

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

2.0GSPS

Figure 8. SFDR vs. f

150

–152

–154

–156

–158

–160

–162

NSD (dBm/Hz)

–164

–166

–168

–170

0 100 200 300 400 500 600 700 800 900 1000 110 0 1200

Figure 9. Single-Tone NSD over f

VBW 10kHz

1.6GSPS

f

f

OUT

OUT

OUT

(MHz)

OUT

1.2GSPS

(MHz)

= 91 MHz, f

over f

DAC

2.4GSPS

OUT

STOP 2.4GHzSTART 20MHz

DAC

= 2.4 GSPS

10dB/DIV

STOP 2.4GHzSTART 20MHz

2.4GSPS

VBW 10kHz

1.2GSPS

f

OUT

1.2GSPS

f

OUT

= 1091 MHz, f

OUT

2.4GSPS

(MHz)

over f

OUT

(MHz)

2.0GSPS

DAC

OUT

DAC

= 2.4 GSPS

1100 1200

09616-010

09616-011

09616-012

09616-007

Figure 10. Single-Tone Spectrum at f

100

95

90

85

80

75

1.6GSPS

70

65

60

IMD (dBc)

55

50

45

40

35

30

0 100 200 300 400 500 600 700 800 90 0 1000

09616-008

Figure 11. IMD vs. f

160

–161

–162

–163

–164

–165

–166

NSD (dBm/Hz)

–167

–168

–169

–170

0 100 200 300 400 500 600 700 800 900 1000 1100 1200

09616-009

Figure 12. Eight-Tone NSD over f

Rev. A | Page 11 of 44

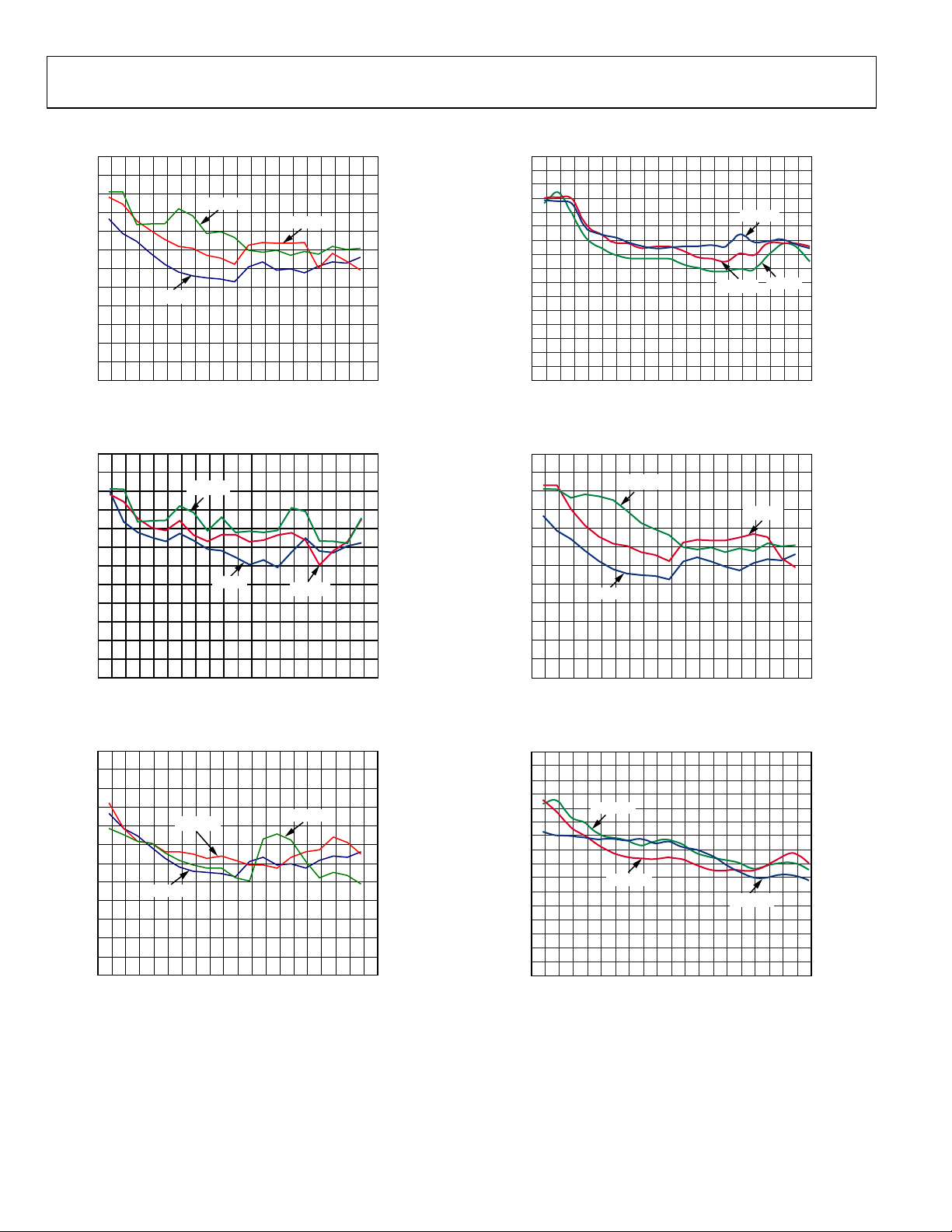

Page 12

AD9739A

f

= 2 GSPS, I

DAC

90

= 20 mA, nominal supplies, 25°C, unless otherwise noted.

OUTFS

110

80

70

60

SFDR (dBc)

50

40

30

0 100 200 300 400 500 600 700 800 900 1000

Figure 13. SFDR vs. f

90

80

70

60

SFDR (dB)

50

0dBFS

–6dBFS

f

(MHz)

OUT

over Digital Full Scale

OUT

–6dBFS

0dBFS

–3dBFS

–3dBFS

100

90

80

70

IMD (dBc)

60

50

40

30

0 100 200 300 400 500 600 700 800 900 1000

f

(MHz)

09616-013

Figure 16. IMD vs. f

90

80

70

60

SFDR (dB)

50

0dBFS

OUT

over Digital Full Scale

OUT

–6dBFS

–3dBFS

–6dBFS

–3dBFS

0dBFS

09616-016

40

30

0 100 200 300 400 500 600 700 800 900 1000

f

(MHz)

OUT

Figure 14. SFDR for Second Harmonic over f

90

80

70

60

SFDR (dBc)

50

40

30

0 100 200 300 400 500 600 700 800 900 1000

10mA FS

20mA FS

f

OUT

Figure 15. SFDR vs. f

(MHz)

OUT

OUT

30mA FS

over DAC I

vs. Digital Full Scale

OUTFS

40

30

0 100 200 300 400 500 600 700 800 900 1000

f

(MHz)

10mA FS

f

OUT

OUT

(MHz)

over DAC I

OUT

vs. Digital Full Scale

OUT

30mA FS

OUTFS

09616-014

Figure 17. SFDR for Third Harmonic over f

110

100

90

80

70

IMD (dBc)

60

50

40

30

0 100 200 300 400 500 600 700 800 900 1000

09616-015

20mA FS

Figure 18. IMD vs. f

9616-017

09616-018

Rev. A | Page 12 of 44

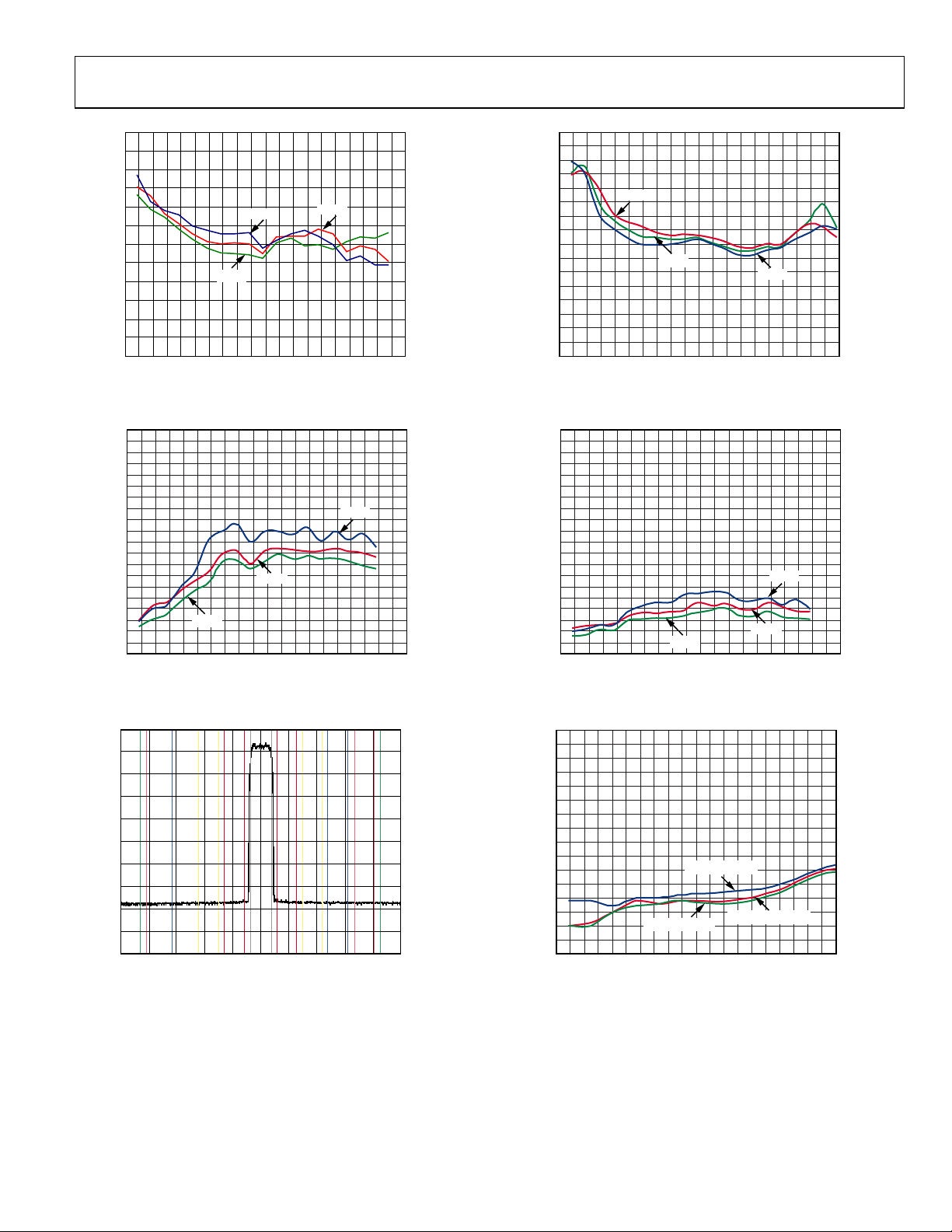

Page 13

AD9739A

–

–

–

90

110

80

70

–40°C

+85°C

60

SFDR (dBc)

50

+25°C

40

30

0 100 200 300 400 500 600 700 800 900 1000

f

(MHz)

OUT

Figure 19. SFDR vs. f

over Temperature

OUT

150

–152

–154

–156

–158

–40°C

–160

–162

NSD (dBm/Hz)

–164

–166

–168

–170

0 200 400 600 800 1000100 300 500 700 900

+25°C

Figure 20. Single-Tone NSD vs. f

f

OUT

+85°C

(MHz)

OUT

over Temperature

100

90

+85°C

80

70

IMD (dBc)

60

+25°C

–40°C

50

40

30

0 100 200 300 400 500 600 700 800 900 1000

f

(MHz)

09616-019

Figure 22. IMD vs. f

OUT

over Temperature

OUT

09616-022

150

–152

–154

–156

–158

–160

–162

NSD (dBm/Hz)

–164

–40°C

–166

–168

–170

0 200 400 600 800 1000100300500700900

09616-020

+25°C

f

OUT

(MHz)

Figure 23. Eight-Tone NSD vs. f

+85°C

over Temperature

OUT

09616-023

50

10dB/DIV

CENTER 350.27MHz

#RES BW 30kHz

RMS RESULTS

CARRIER POW ER

–14.54dBm/

3.84MHz

FREQ

OFFSET

(MHz)

5

10

15

20

25

VBW 300kHz

REF

BW

(dBc)

(MHz)

–79.90

3.84

–80.60

3.84

–80.90

3.84

–80.62

3.84

–80.76

3.84

LOWER

(dBm)

–94.44

–95.14

–95.45

–95.16

–95.30

Figure 21. Single-Carrier WCDMA at 350 MHz, f

SPAN 53.84MHz

SWEEP 174.6ms (601p ts)

UPPER

(dBm)

(dBc)

–93.57

–79.03

–94.40

–79.36

–95.27

–80.73

–95.51

–80.97

–95.49

–80.95

= 2457.6 MSPS

DAC

09616-021

Rev. A | Page 13 of 44

–55

–60

–65

–70

ACLR (dBc)

–75

FIRST ADJ CH

–80

–85

–90

0

122.88

245.76

FIFTH ADJ CH

491.52

368.64

f

OUT

614.40

(MHz)

737.28

Figure 24. Four-Carrier WCDMA at 350 MHz, f

SECOND ADJ CH

983.04

860.16

1105.90

= 2457.6 MSPS

DAC

1228.80

09616-108

Page 14

AD9739A

–

AC (MIX MODE)

f

= 2.4 GSPS, I

DAC

OUTFS

= 20 mA, nominal supplies, 25°C, unless otherwise noted.

10dB/DIV

START 20MHz

#RES BW 10kHz

Figure 25. Single-Tone Spectrum at f

80

75

70

65

60

55

50

45

40

SFDR (dBc)

35

30

25

20

15

10

1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400

VBW 10kHz

f

(MHz)

OUT

= 2.31 GHz, f

OUT

Figure 26. SFDR in Mix Mode vs. f

10dB/DIV

CENTER 2.10706MHz

#RES VW 30kHz

RMS RESULTS

CARRIER PO WER

–21.43dBm/

3.84MHz

FREQ

OFFSET

(MHz)

5

10

15

20

25

VBW 300kHz

REF

BW

(MHz)

3.84

3.84

3.84

3.84

3.84

SWEEP 174.6ms ( 601pts)

LOWER

(dBc)

(dBm)

–68.99

–90.43

–72.09

–93.52

–72.86

–94.30

–74.34

–95.77

–74.77

–96.20

STOP 2.4GHz

SWEEP 28.7s (601p ts)

= 2.4 GSPS

DAC

at 2.4 GSPS

OUT

SPAN 53.84MHz

UPPER

(dBc)

(dBm)

–63.94

–90.37

–71.07

–92.50

–71.34

–92.77

–72.60

–94.03

–73.26

–94.70

09616-026

09616-032

Figure 27. Typical Single-Carrier WCDMA ACLR Performance at 2.1 GHz,

= 2457.6 MSPS (Second Nyquist Zone)

f

DAC

10dB/DIV

START 20MHz

#RES BW 10kHz

VBW 10kHz

Figure 28. Single-Tone Spectrum in Mix Mode at f

f

= 2.4 GSPS

DAC

90

85

80

75

70

65

60

55

IMD (dBc)

50

45

40

35

30

1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400

f

(MHz)

09616-027

OUT

Figure 29. IMD in Mix Mode vs. f

40

SECOND NYQUIS T ZONE THIRD NYQUIST ZONE

–45

–50

–55

–60

–65

–70

ACLR (dBc)

–75

–80

–85

–90

1229 1475 1720 1966 2212 2458 2703 2949 3195 3441 3686

FIRST ADJ CH

FIFTH ADJ CH

f

OUT

(MHz)

Figure 30. Single-Carrier WCDMA ACLR vs. f

STOP 2.4GHz

STOP 2.4GHzSTART 20MHz

SWEEP 28.7s ( 601pts)

= 1.31 GHz,

OUT

at 2.4 GSPS

OUT

SECOND ADJ CH

at 2457.6 MSPS

OUT

09616-030

09616-031

09616-025

Rev. A | Page 14 of 44

Page 15

AD9739A

10dB/DIV

CENTER 2.807GHz

#RES BW 30kHz

RMS RESULTS

CARRIER PO WER

–24.4dBm/

3.84MHz

FREQ

OFFSET

(MHz)

5

10

15

20

25

VBW 300kHz

REF

BW

(dBc)

(MHz)

–64.90

3.84

–66.27

3.84

–68.44

3.84

–70.20

3.84

–70.85

3.84

LOWER

(dBm)

–89.30

–90.67

–92.84

–94.60

–95.25

SPAN 53.84MHz

SWEEP 174.6ms (601pts)

UPPER

(dBm)

(dBc)

–88.22

–63.82

–90.10

–65.70

–90.95

–66.55

–93.35

–68.95

–94.85

–70.45

09616-033

Figure 31. Typical Single-Carrier WCDMA ACLR Performance at 2.8 GHz,

= 2457.6 MSPS (Third Nyquist Zone)

f

DAC

10dB/DIV

10dB/DIV

CENTER 2.81271GHz

#RES BW 30kHz

RMS RESULTS

CARRIER PO WER

–27.98dBm/

3.84MHz

FREQ

OFFSET

(MHz)

5

10

15

20

25

30

VBW 300kHz

REF

BW

(dBc)

(MHz)

–0.42

3.84

–64.32

3.84

–66.03

3.84

–66.27

3.84

–66.82

3.84

–67.16

3.84

LOWER

(dBm)

–28.40

–92.30

–94.01

–94.24

–94.79

–95.13

SPAN 63.84MHz

SWEEP 207ms (601p ts)

UPPER

(dBm)

(dBc)

–28.07

–0.10

–28.06

–0.08

–93.34

–65.37

–94.03

–66.06

–93.34

–63.36

–94.51

–66.54

09616-035

Figure 33. Typical Four-Carrier WCDMA ACLR Performance at 2.8 GHz,

= 2457.6 MSPS (Third Nyquist Zone)

f

DAC

CENTER 2.09758GHz

#RES BW 30kHz

RMS RESU LTS

CARRIER POW ER

–25.53dBm/

3.84MHz

FREQ

OFFSET

(MHz)

5

10

15

20

25

30

VBW 300kHz

REF

LOWER

BW

(dBc)

(MHz)

0.22

3.84

–66.68

3.84

–68.01

3.84

–68.61

3.84

–68.87

3.84

–69.21

3.84

–25.31

–92.21

–93.53

–94.14

–94.40

–94.74

SPAN 63.84MHz

SWEEP 207ms (601p ts)

UPPER

(dBm)

(dBc)

(dBm)

0.24

0.14

–66.82

–67.83

–67.64

–68.50

–25.29

–25.38

–92.35

–93.36

–93.17

–94.03

09616-034

Figure 32. Typical Four-Carrier WCDMA ACLR Performance at 2.1 GHz,

= 2457.6 MSPS (Second Nyquist Zone)

f

DAC

Rev. A | Page 15 of 44

Page 16

AD9739A

V

V

V

ONE-CARRIER DOCSIS PERFORMANCE (NORMAL MODE)

f

= 20 mA, f

DAC

–31

–42

–53

–64

–75

11dB/DIV

–86

–97

–108

–119

–31

–42

–53

–64

–75

11dB/DI V

–86

–97

–108

–119

–31

–42

–53

–64

–75

11dB/DI V

–86

–97

–108

–119

START 50MHz

#RES BW 20kHz

1

2

3

4

5

2∆1

START 50MHz

#RES BW 20kHz

1

2

3

4

5

6

= 2.4576 GSPS, nominal supplies, 25°C, unless otherwise noted.

DAC

1

4∆1

5∆1

3∆1

2∆1

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

FUNCTION

VALU E

–11.475dBm

(∆)

–77.042dB

(∆)

–76.238dB

(∆)

–74.526dB

(∆)

–75.919dB

09616-036

MODEMKR S CLTRC

N

∆1

∆1

∆1

∆1

VBW 2kHz

X

200MHz

1

f

199.60MHz

1

f

(∆)

400.05MHz

1

f

(∆)

597.65MHz

1

f

(∆)

413.35MHz

1

f

(∆)

Y

–11.476dBm

–77.042dB

(∆)

–76.238dB

(∆)

–74.526dB

(∆)

–75.919dB

(∆)

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

Figure 34. Low Band Wideband ACLR

1

4∆1

5∆1

MODEMKR SCLTRC

N

∆1

∆1

∆1

∆1

∆1

3∆1

VBW 2kHz

X

549.60MHz

f

1

–485.35MHz

f

1

(∆)

127.40MHz

f

1

(∆)

254.70MHz

f

1

(∆)

63.75MHz

f

1

(∆)

293.65MHz

f

1

(∆)

(∆)

(∆)

(∆)

(∆)

(∆)

Y

–10.231dBm

–76.444dB

–75.649dB

–70.658dB

–75.836dB

–78.054dB

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

6∆1

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

6MHz

FUNCTION

VAL UE

–10.231dBm

–76.425dB

(∆)

–75.626dB

(∆)

–70.658dB

(∆)

–75.824dB

(∆)

–78.118dB

(∆)

09616-037

Figure 35. Mid Band Wideband ACLR

1

4∆1

2∆1

5∆1

3∆1

–80.7dBc –80.7dBc –80.7dBc –81.2dBc –10.2dBm –81.3dBc –80.7dBc –80.8dBc–80.8dBc

–35

–45

–55

–65

–75

10dB/DI

–85

–95

–105

–115

CENTER 200MHz

#RES BW 30kHz

CARRIER POWER –10.190dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

18.00MHz

24.00MHz

INTEG B W

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–59.38

–81.23

–80.71

–80.72

–80.73

dBc

LOWER

VBW 3kHz

dBm

–69.57

–60.16

–91.42

–81.26

–90.90

–80.72

–90.91

–80.76

–90.92

–80.78

dBc

UPPER

Figure 37. Low Band Narrow-Band ACLR

–78.5dBc –77.6dBc – 76.3dBc – 75.1dBc –10.4dBm –74.4dBc –75 .6dBc –77.7dBc–76 .7dBc

–35

–45

–55

–65

–75

10dB/DI

–85

–95

–105

–115

CENTER 550MHz

#RES BW 30kHz

CARRIER POWER –10.368dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

18.00MHz

24.00MHz

INTE G BW

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–57.91

–75.09

–76.29

–77.63

–78.51

dBc

LOWER

VBW 3kHz

dBm

–68.28

–58.53

–85.46

–74.41

–86.65

–75.55

–88.00

–76.69

–88.88

–77.67

dBc

UPPER

Figure 38. Mid Band Narrow-Band ACLR

–69.9dBc

–68.7dBc – 12.6dBm –67.9dBc –68.6dBc –70.6dBc –72.3dBc

10dB/DI

–72.6dBc –71.1dBc

–35

–45

–55

–65

–75

–85

–95

–105

–115

–70.35

–91.45

–90.91

–90.95

–90.97

dBm

–68.90

–84.78

–85.92

–87.06

–88.03

dBm

FILTER

OFF

OFF

OFF

OFF

OFF

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

SPAN 54MHz

SWEEP 1.49s

09616-039

09616-040

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-041

START 50MHz

#RES BW 20kHz

MODEMKR SCLTRC

N

1

1

∆1

2

1

∆1

3

1

∆1

4

1

∆1

5

1

Figure 36. High Band Wideband ACLR

f

f

f

f

f

(∆)

(∆)

(∆)

(∆)

X

979.00MHz

–484.40MHz

–118.65MH z

–613.60MHz

–365.65MHz

VBW 2kHz

Y

–13.703dBm

–65.548dB

(∆)

–66.990dB

(∆)

–69.044dB

(∆)

–72.789dB

(∆)

SWEEP 24.1s (1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

FUNCTION

VALU E

–13.658dBm

(∆)

–65.548dB

(∆)

–66.990dB

(∆)

–69.049dB

(∆)

–72.789dB

CENTER 980MHz

#RES BW 30kHz

CARRIER POWER –12.778dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

09616-038

18.00MHz

24.00MHz

INTEG B W

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–60.38

–68.67

–69.90

–71.12

–72.61

dBc

LOWER

VBW 3kHz

dBm

–73.15

–59.15

–81.44

–67.94

–82.68

–68.58

–83.90

–70.64

–85.39

–72.35

dBc

UPPER

dBm

–71.93

–80.72

–81.35

–83.42

–85.13

Figure 39. High Band Narrow-Band ACLR

Rev. A | Page 16 of 44

Page 17

AD9739A

V

V

V

FOUR-CARRIER DOCSIS PERFORMANCE (NORMAL MODE)

I

= 20 mA, f

OUTFS

–38

–48

–58

–68

–78

10dB/DI V

–88

–98

–108

–118

5∆1

= 2.4576 GSPS, nominal supplies, 25°C, unless otherwise noted.

DAC

1

2∆1

6∆1

3∆1

4∆1

–53.4dBc –0.1dBc –0.1dBc –0.5dBc –17.6dBm –73.6dBc –75.4dBc –79.1dBc–78.1dBc

–37

–47

–57

–67

–77

10dB/DI

–87

–97

–107

–117

FILTER

OFF

OFF

OFF

OFF

OFF

FILTER

OFF

OFF

OFF

OFF

OFF

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

SPAN 54MHz

SWEEP 1.49s

SPAN 54MHz

SWEEP 1.49s

09616-045

09616-046

09616-047

START 50MHz

#RES BW 20kHz

MODEMKR S CLTRC

N

1

1

∆1

2

1

∆1

3

1

∆1

4

1

∆1

5

1

∆1

6

1

f

f

f

f

f

f

(∆)

(∆)

(∆)

(∆)

(∆)

X

217.50MHz

201.10MHz

417.70MHz

608.65MHz

–124.75MHz

395.85MHz

VBW 2kHz

Y

–18.065dBm

–72.097dB

(∆)

–72.882dB

(∆)

–72.292dB

(∆)

–76.776dB

(∆)

–71.133dB

(∆)

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

6MHz

FUNCTION

VAL UE

–18.064dBm

(∆)

–72.097dB

(∆)

–72.882dB

(∆)

–72.292dB

(∆)

–76.776dB

(∆)

–71.133dB

09616-042

Figure 40. Low Band Wideband ACLR

–38

–48

–58

–68

–78

10dB/DI V

–88

–98

–108

4∆1

–118

START 50MHz

#RES BW 20kHz

1

2

3

4

5

6

5∆1

MODEMKR S CLTRC

N

∆1

∆1

∆1

∆1

∆1

2∆1

VBW 2kHz

X

f

1

667.80MHz

(∆)

f

1

–192.20MHz

(∆)

f

1

–98.15MHz

(∆)

f

1

–614.00MHz

(∆)

f

1

–567.45MHz

(∆)

f

1

–55.40MHz

Y

–18.760dBm

(∆)

–69.536dB

(∆)

–71.601dB

(∆)

–72.824dB

(∆)

–75.786dB

(∆)

–71.997dB

1

6∆1

3∆1

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

6MHz

FUNCTION

VAL UE

–18.760dBm

–69.536dB

(∆)

–71.601dB

(∆)

–72.833dB

(∆)

–75.320dB

(∆)

–71.997dB

(∆)

09616-043

Figure 41. Mid Band Wideband ACLR

–38

–48

–58

–68

–78

10dB/DIV

–88

–98

–108

–118

START 50MHz

#RES BW 20kHz

1

2

3

4

5

6

MODEMKR S CLTRC

N

∆1

∆1

∆1

∆

1

∆1

2∆1

VBW 2kHz

Y

–21.040dBm

–60.683dB

(∆)

–69.390dB

(∆)

–71.954dB

(∆)

–66.954dB

(∆)

–68.889dB

(∆)

6∆1

SWEEP 24.1s (1 001pts)

FUNCTION

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

6MHz

3∆1

4∆1

X

987.95MHz

1

f

–490.50MHz

1

f

(∆)

–624.45MHz

1

f

(∆)

–738.45MHz

1

f

(∆)

–130.46MHz

1

f

(∆)

–374.60MHz

1

f

(∆)

5∆1

STOP 1GHz

FUNCTION

VALU E

–21.029dBm

(∆)

(∆)

(∆)

(∆)

(∆)

1

–60.683dB

–69.390dB

–71.847dB

–66.954dB

–68.889dB

09616-044

Figure 42. High Band Wideband ACLR

CENTER 210MHz

#RES BW 30kHz

CARRIER POWER –17.556dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

18.00MHz

24.00MHz

INTEG B W

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–11.15

–0.454

–0.065

–0.091

–53.44

dBc

LOWER

VBW 3kHz

dBm

–28.70

–58.78

–18.01

–73.56

–17.62

–75.42

–17.65

–78.08

–70.99

–79.06

dBc

UPPER

dBm

–76.34

–91.12

–92.98

–95.64

–96.62

Figure 43. Low Band Narrow-Band ACLR (Worst Side)

–76.6dBc –76.4dBc –75.0dBc –72.9dBc –19.5dBm –0.3dBc –0.1dBc –50.2dBc–0.1dBc

–37

–47

–57

–67

–77

10dB/DI

–87

–97

–107

–117

CENTER 650MHz

#RES BW 30kHz

CARRIER POWER –19.503dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

18.00MHz

24.00MHz

INTE G BW

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–61.84

–72.95

–74.99

–76.38

–76.59

dBc

LOWER

VBW 3kHz

dBm

–81.35

–11.18

–92.45

–0.294

–94.49

–0.075

–95.89

–0.145

–96.10

–50.21

dBc

UPPER

dBm

–30.68

–19.80

–19.58

–19.65

–69.71

Figure 44. Mid Band Narrow-Band ACLR (Worst Side)

–74.2dBc –73.0dBc –70.7dBc –68.7dBc –20.7dBm –0.5dBc 0.1dBc –52.3dBc–0.5dBc

–37

–47

–57

–67

–77

10dB/DI

–87

–97

–107

–117

CENTER 970MHz

#RES BW 30kHz

CARRIER POWER –20.666dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

18.00MHz

24.00MHz

INTEG B W

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–60.65

–68.68

–70.67

–72.96

–74.22

dBc

LOWER

VBW 3kHz

dBm

dBc

–81.32

–10.77

–89.34

–0.522

–91.33

–0.140

–93.63

–0.511

–94.89

–52.31

UPPER

dBm

–31.44

–21.19

–20.81

–21.18

–72.98

Figure 45. High Band Narrow-Band ACLR (Worst Side)

Rev. A | Page 17 of 44

Page 18

AD9739A

V

V

V

EIGHT-CARRIER DOCSIS PERFORMANCE (NORMAL MODE)

I

= 20 mA, f

OUTFS

–38

–48

–58

–68

–78

10dB/DIV

–88

–98

–108

–118

3∆1

= 2.4576 GSPS, nominal supplies, 25°C, unless otherwise noted.

DAC

1

6∆1

5∆1

2∆1

4∆1

0dBc 0dBc 0.1dBc –0.3dBc –21.9dBm –70.0dBc –69.9dBc –70.1dBc–69.7dBc

–37

–47

–57

–67

–77

10dB/DI

–87

–97

–107

–117

START 50MHz

#RES BW 20kHz

1

2

3

4

5

6

–38

–48

–58

–68

–78

10dB/DIV

–88

–98

–108

4∆1

–118

START 50MHz

#RES BW 20kHz

1

2

3

4

5

6

–38

–48

–58

–68

–78

10dB/DIV

–88

–98

–108

–118

VBW 2kHz

MODEMKR S CLTRC

N

∆1

∆1

∆1

∆1

∆1

X

241.25MHz

1

f

198.25MHz

1

f

(∆)

–135.20MHz

1

f

(∆)

746.40MHz

1

f

(∆)

20.60MH z

1

f

(∆)

371.15MHz

1

f

(∆)

(∆)

(∆)

(∆)

(∆)

(∆)

Y

–23.278dBm

–67.453dB

–72.684dB

–68.278dB

–69.581dB

–66.474dB

Figure 46. Low Band Wideband ACLR

5∆1

MODEMKR S CLTRC

N

∆1

∆1

∆1

∆1

∆1

X

667.80MHz

1

f

–171.30MHz

1

f

(∆)

–98.15MHz

1

f

(∆)

–614.00MHz

1

f

(∆)

–567.45MHz

1

f

(∆)

–55.40MHz

1

f

(∆)

2∆1

VBW 2kHz

Y

–23.977dBm

–69.185dB

(∆)

–68.551dB

(∆)

–69.923dB

(∆)

–72.145dB

(∆)

–65.009dB

(∆)

Figure 47. Mid Band Wideband ACLR

2∆1

3∆1

4∆1

SWEEP 24.1s (1 001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

1

6∆1

3∆1

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

6∆1

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

6MHz

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

6MHz

5∆1

FUNCTION

VALU E

–23.279dBm

(∆)

–67.448dB

(∆)

–72.764dB

(∆)

–68.258dB

(∆)

–69.581dB

(∆)

–66.457dB

FUNCTION

VAL UE

–23.977dBm

(∆)

–69.185dB

(∆)

–68.551dB

(∆)

–69.938dB

(∆)

–72.083dB

(∆)

–65.009dB

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-051

CENTER 222MHz

#RES BW 30kHz

CARRIER POWER –21.874dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

18.00MHz

09616-048

24.00MHz

INTE G BW

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–10.98

–0.334

–0.087

–0.034

–0.031

dBc

LOWER

VBW 3kHz

dBm

dBc

–32.85

–59.41

–22.21

–69.96

–21.79

–69.91

–21.91

–69.74

–21.84

–70.08

UPPER

dBm

–81.28

–91.83

–91.78

–91.62

–91.95

Figure 49. Low Band Narrow-Band ACLR (Worst Side)

–37

0dBc –0.1dBc –0.1dBc –0.3dBc –22.7dBm –69.2dBc –68.6dBc –69.2dBc–69.3dBc

–47

–57

–67

–77

10dB/DI

–87

–97

–107

–117

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-052

CENTER 622MHz

#RES BW 30kHz

CARRIER POWER –22.691dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

18.00MHz

09616-049

24.00MHz

INTE G BW

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–11.01

–0.339

–0.135

–0.089

–0.049

dBc

LOWER

VBW 3kHz

dBc

–61.38

–33.70

–69.17

–23.03

–68.64

–22.83

–69.33

–22.78

–69.18

–22.74

dBc

UPPER

–84.07

–91.86

–91.33

–92.02

–91.88

dBc

Figure 50. Mid Band Narrow-Band ACLR (Worst Side)

–37

1

–67.7dBc –67.7dBc –67.3dBc –67.4dBc

–47

–57

–67

–77

10dB/DI

–87

–97

–107

–117

–25.3dBm –0.5dBc –0.2dBc 0dBc0dBc

START 50MHz

#RES BW 20kHz

MODEMKR S CLTRC

1

1

N

1

2

∆1

1

3

∆1

1

4

∆1

1

5

∆1

1

6

∆1

Figure 48. High Band Wideband ACLR

f

f

f

f

f

f

(∆)

(∆)

(∆)

(∆)

(∆)

X

990.80MHz

–481.00MHz

–633.95MHz

–734.65MHz

–128.55MHz

–378.40MHz

VBW 2kHz

Y

–25.435dBm

(∆)

–61.947dB

(∆)

–67.517dB

(∆)

–69.583dB

(∆)

–65.237dB

(∆)

–64.615dB

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

6MHz

FUNCTION

VAL UE

–25.435dBm

–61.947dB

(∆)

–67.532dB

(∆)

–69.602dB

(∆)

–65.237dB

(∆)

–64.615dB

(∆)

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-053

CENTER 950MHz

#RES BW 30kHz

CARRIER POWER –25.344dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

09616-050

18.00MHz

24.00MHz

INTE G BW

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–60.39

–67.44

–67.29

–67.65

–67.65

dBc

LOWER

VBW 3kHz

dBm

dBc

–85.73

–10.93

–92.78

–0.487

–92.63

–0.205

–93.00

–0.047

–93.00

0.016

UPPER

dBm

–36.27

–25.83

–25.55

–25.39

–25.33

Figure 51. High Band Narrow-Band ACLR (Worst Side)

Rev. A | Page 18 of 44

Page 19

AD9739A

V

V

V

16-CARRIER DOCSIS PERFORMANCE (NORMAL MODE)

I

= 20 mA, f

OUTFS

= 2.4576 GSPS, nominal supplies, 25°C, unless otherwise noted.

DAC

–38

–48

–58

–68

–78

10dB/DI V

–88

–98

–108

–118

START 50MHz

#RES BW 20kHz

1

2

3

4

5

6

–38

–48

–58

–68

–78

10dB/DIV

–88

–98

–108

–118

1

3∆1

5∆1

VBW 2kHz

MODEMKR S CLTRC

N

∆1

∆1

∆1

∆1

∆1

X

f

1

289.70MHz

(∆)

f

1

202.05MHz

(∆)

f

1

–183.65MHz

(∆)

f

1

697.95MHz

(∆)

f

1

18.70MHz

(∆)

f

1

322.70MHz

Y

–25.335dBm

(∆)

–66.838dB

(∆)

–70.421dB

(∆)

–65.880dB

(∆)

–67.033dB

(∆)

–64.481dB

Figure 52. Low Band Wideband ACLR

3∆1

6∆1

2∆1

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

2∆1

–67.4dBc –67.3dBc –67.4dBc –68.5dBc –24.8dBm –0.4dBc –0.1dBc 0dBc0dBc

–44

–54

–64

–74

–84

10dB/DI

–94

–104

4∆1

–114

–124

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

6MHz

FUNCTION

VAL UE

–26.335dBm

–66.838dB

(∆)

–70.312dB

(∆)

–65.928dB

(∆)

–66.973dB

(∆)

–64.451dB

(∆)

CENTER 200MHz

#RES BW 30kHz

CARRIER POWER –24.819dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

18.00MHz

09616-054

24.00MHz

INTEG B W

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

dBc

–60.64

–68.49

–67.43

–67.32

–67.44

VBW 3kHz

LOWER

dBm

–85.46

–93.30

–92.24

–92.13

–92.26

–11.03

–0.368

0.137

0.010

0.035

dBc

UPPER

dBm

–35.85

–25.19

–24.68

–24.81

–24.78

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-057

Figure 55. Low Band Narrow-Band ACLR (Worst Side)

–66.7dBc –66.8dBc –67.1dBc –67.4dBc –26.1dBm –0.5dBc 0.1dBc 0dBc0.2dBc

–44

1

4∆1

10dB/DI

–54

–64

–74

–84

–94

–104

–114

–124

–38

–48

–58

–68

–78

10dB/DIV

–88

–98

–108

–118

START 50MHz

#RES BW 20kHz

MODEMKR S CLTRC

N

1

1

∆1

2

1

∆1

3

1

∆1

4

1

Figure 53. Mid Band Wideband ACLR

3∆1

START 50MHz

#RES BW 20kHz

MODEMKR S CLTRC

1

1

N

1

2

∆1

1

3

∆1

1

4

∆1

1

5

∆1

1

6

∆1

Figure 54. High Band Wideband ACLR

f

f

f

f

f

f

f

f

f

f

(∆)

(∆)

(∆)

4∆1

(∆)

(∆)

(∆)

(∆)

(∆)

X

690.60MHz

–141.85MHz

–623.50MHz

152.65MHz

X

989.85MHz

–422.10MHz

–922.75MHz

–668.15MHz

–137.10MHz

–377.45MHz

VBW 2kHz

Y

–28.317dBm

–64.672dB

(∆)

–65.202dB

(∆)

–64.574dB

(∆)

2∆1

VBW 2kHz

Y

–27.971dBm

(∆)

–61.110dB

(∆)

–63.327dB

(∆)

–65.509dB

(∆)

–62.779dB

(∆)

–59.828dB

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

6∆1

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

BAND POWER

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

5∆1

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

6MHz

6MHz

FUNCTION

VALU E

–28.317dBm

(∆)

–64.672dB

(∆)

–65.207dB

(∆)

–64.574dB

1

FUNCTION

VALU E

–27.960dBm

–61.110dB

(∆)

–63.332dB

(∆)

–65.483dB

(∆)

–62.779dB

(∆)

–59.828dB

(∆)

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-058

CENTER 600MHz

#RES BW 30kHz

CARRIER POWER –26.083dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

09616-055

12.00MHz

18.00MHz

24.00MHz

INTE G BW

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–61.77

–67.40

–67.09

–66.80

–66.67

dBc

LOWER

VBW 3kHz

dBm

dBc

–87.85

–10.38

–93.48

–0.494

–93.18

0.098

–92.88

0.180

–92.75

0.021

UPPER

dBm

–36.49

–26.58

–25.98

–25.90

–26.06

Figure 56. Mid Band Narrow-Band ACLR(Worst Side)

–64.9dBc –64.8dB c –64.6dBc –65.0dBc –28.4dBm –0.5dBc –0.1dBc 0.2dBc0dBc

–44

–54

–64

–74

–84

10dB/DI

–94

–104

–114

–124

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-059

CENTER 900MHz

#RES BW 30kHz

CARRIER POWER –28.435dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

09616-056

18.00MHz

24.00MHz

INTEG B W

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

dBc

–57.24

–65.03

–64.64

–64.80

–64.86

VBW 3kHz

LOWER

dBm

–85.68

–93.46

–93.08

–93.24

–93.29

dBc

–11.30

–0.490

–0.119

–0.016

0.153

UPPER

dBm

–39.73

–28.92

–28.55

–28.45

–28.28

Figure 57. High Band Narrow-Band ACLR (Worst Side)

Rev. A | Page 19 of 44

Page 20

AD9739A

V

V

V

32-CARRIER DOCSIS PERFORMANCE (NORMAL MODE)

I

= 20 mA, f

OUTFS

= 2.4576 GSPS, nominal supplies, 25°C, unless otherwise noted.

DAC

–52

–62

–72

–82

–92

10dB/DIV

–102

–112

–122

–132

START 50MHz

#RES BW 20kHz

1

2

3

4

–52

–62

–72

–82

–92

10dB/DI V

–102

–112

2∆1

–122

–132

1

2∆1

VBW 2kHz

MODEMKR S CLTRC

N

∆1

∆1

∆1

X

384.70MHz

1

f

–283.40MHz

1

f

(∆)

227.70MHz

1

f

(∆)

325.55MHz

1

f

(∆)

(∆)

(∆)

(∆)

Y

–29.646dBm

–64.175dB

–59.429dB

–62.750dB

Figure 58. Low Band Wideband ACLR

3∆1

3∆1

4∆1

SWEEP 24.1s (1001p ts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

1

4∆1

FUNCTION

VAL UE

–29.645dBm

(∆)

–64.167dB

(∆)

–59.423dB

(∆)

–62.750dB

–44

–63.5dBc –63.2dBc –63.1dBc –63.3dBc –29.3dBm –0.5dBc –0.2dBc –0.1dBc–0.2dBc

–54

–64

–74

–84

10dB/DI

–94

–104

–114

–124

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-063

CENTER 200MHz

#RES BW 30kHz

CARRIER POWER –29.311dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

09616-060

6.375MHz

12.00MHz

18.00MHz

24.00MHz

INTE G BW

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–58.76

–63.30

–63.05

–63.21

–63.46

dBc

LOWER

VBW 3kHz

dBm

dBc

–88.07

–10.78

–92.61

–0.487

–92.36

–0.175

–92.52

–0.151

–92.78

–0.061

UPPER

dBm

–40.09

–29.80

–29.49

–29.46

–29.37

Figure 61. Low Band Narrow-Band ACLR (Worst Side)

–44

–64.7dBc –64.7dBc –64.7dBc –65.3dBc

–54

–64

–74

–84

10dB/DI

–94

–104

–114

–124

–29.3dBm –0.5dBc –0.1dBc –0.2dBc–0.1dBc

START 50MHz

#RES BW 20kHz

1

2

3

4

–52

–62

–72

–82

–92

10dB/DIV

–102

–112

–122

–132

START 50MHz

#RES BW 20kHz

1

2

3

4

VBW 2kHz

MODEMKR S CLTRC

N

∆1

∆1

∆1

X

685.85MHz

1

f

–611.15MHz

1

f

(∆)

–243.50MHz

1

f

(∆)

162.15MHz

1

f

(∆)

(∆)

(∆)

(∆)

Y

–30.335dBm

–63.136dB

–63.860dB

–62.151dB

Figure 59. Mid Band Wideband ACLR

3∆1

VBW 2kHz

MODEMKR SCLTRC

N

∆1

∆1

∆1

X

f

1

985.10MHz

(∆)

f

1

–334.70MHz

(∆)

f

1

–909.45MHz

(∆)

f

1

–373.65MHz

(∆)

(∆)

(∆)

Y

–31.616dBm

–59.997dB

–60.458dB

–57.761dB

Figure 60. High Band Wideband ACLR

SWEEP 24.1s (1001p ts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

4∆1

2∆1

SWEEP 24.1s (1001pts)

BAND POWER

BAND POWER

BAND POWER

BAND POWER

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

6MHz

FUNCTION

VAL UE

–30.335dBm

(∆)

–63.112dB

(∆)

–63.860dB

(∆)

–62.151dB

FUNCTION

VALU E

–31.516dBm

–59.997dB

(∆)

–60.535dB

(∆)

–57.763dB

(∆)

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-064

CENTER 600MHz

#RES BW 30kHz

CARRIER POWER –29.255dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

09616-061

12.00MHz

18.00MHz

24.00MHz

INTE G BW

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–60.64

–65.26

–64.73

–64.65

–64.68

dBc

LOWER

VBW 3kHz

dBc

dBm

–10.40

–89.90

–0.515

–94.52

–0.178

–93.99

–0.069

–93.91

–0.197

–93.93

UPPER

dBm

–39.65

–29.77

–29.43

–29.32

–29.45

Figure 62. Mid Band Narrow-Band ACLR(Worst Side)

1

09616-062

–44

–62.8dBc –62.7dBc –62.8dBc

–54

–64

–74

–84

10dB/DI

–94

–104

–114

–124

CENTER 800MHz

#RES BW 30kHz

CARRIER POWER –30.746dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

6.375MHz

12.00MHz

18.00MHz

24.00MHz

INTEG B W

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

dBc

–60.75

–63.18

–62.76

–62.74

–62.84

–63.2dBc

LOWER

–91.49

–93.92

–93.50

–93.48

–93.59

VBW 3kHz

dBc

dBm

–10.84

–0.437

–0.354

–0.455

–0.410

UPPER

dBm

–41.59

–31.18

–31.10

–31.20

–31.16

–0.4dBc–30.7dBm –0.4dBc –0.4dBc–0.5dBc

SPAN 54MHz

SWEEP 1.49s

FILTER

OFF

OFF

OFF

OFF

OFF

09616-065

Figure 63. High Band Narrow-Band ACLR (Worst Side)

Rev. A | Page 20 of 44

Page 21

AD9739A

V

V

64- AND 128-CARRIER DOCSIS PERFORMANCE (NORMAL MODE)

I

= 20 mA, f

OUTFS

= 2.4576 GSPS, nominal supplies, 25°C, unless otherwise noted.

DAC

–52

–62

–72

–82

–92

10dB/DIV

–102

–112

–122

–132

START 50MHz

#RES BW 20kHz

1

2

3

–52

–62

–72

–82

–92

10dB/DIV

–102

–112

2∆1

–122

–132

1

VBW 2kHz

MODEMKR S CLTRC

N

∆1

∆1

X

478.75MHz

f

1

372.10MHz

f

1

(∆)

132.70MHz

f

1

(∆)

Y

–33.210dBm

–58.746dB

(∆)

–55.165dB

(∆)

Figure 64. Low Band Wideband ACLR

3∆1

3∆1

SWEEP 24.1s (1001pts)

BAND POWER

BAND POWER

BAND POWER

2∆1

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

FUNCTION

VAL UE

–33.209dBm

–58.804dB

(∆)

–55.165dB

(∆)

1

0.3dBc 0.2dBc 0.1dBc –0.3dBc –32.4dBm –62.3dBc –61.5dBc –61.4dBc–61.5dBc

–51

–61

–71

–81

–91

10dB/DI

–101

–111

–121

–131

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-069

CENTER 478MHz

#RES BW 30kHz

CARRIER POWER –32.409dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

09616-066

6.375MHz

12.00MHz

18.00MHz

24.00MHz

INTE G BW

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–10.83

–0.267

0.139

0.201

0.308

dBc

LOWER

VBW 3kHz

dBm

–43.24

–60.80

–32.68

–62.25

–32.27

–61.47

–32.21

–61.54

–32.10

–61.40

dBc

UPPER

dBm

–93.21

–94.66

–93.88

–93.95

–93.81

Figure 67. Low Band Narrow-Band ACLR (Worst Side)

–60.6dBc 33.6dBm 0.3dBc 0.1dBc 0.1dBc0.2dBc–60.6dBc –61.1dBc–60.6dBc

10dB/DI

–101

–111

–121

–131

–51

–61

–71

–81

–91

FILTER

OFF

OFF

OFF

OFF

OFF

SPAN 54MHz

SWEEP 1.49s

09616-070

START 50MHz

#RES BW 20kHz

1

2

3

–52

–62

–72

–82

–92

10dB/DIV

–102

–112

3∆1

–122

–132

START 50MHz

#RES BW 20kHz

1

2

3

VBW 2kHz

MODEMKR SCLTRC

N

∆1

∆1

X

f

1

978.45MHz

(∆)

f

1

–901.85MHz

(∆)

f

1

–561.75MHz

Y

–35.872dBm

(∆)

–58.581dB

(∆)

–59.214dB

Figure 65. Mid Band Wideband ACLR

2∆1

VBW 2kHz

MODEMKR SCLTRC

N

∆1

∆1

X

f

1

988.90MHz

(∆)

f

1

–481.95MHz

(∆)

f

1

–925.60MHz

Y

–37.954dBm

(∆)

–55.764dB

(∆)

–57.007dB

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

SWEEP 24.1s ( 1001pts)

BAND POWER

BAND POWER

BAND POWER

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

STOP 1GHz

FUNCTION

WIDTHFUNCTION

6MHz

6MHz

6MHz

FUNCTION

VAL UE

–35.873dBm

–58.625dB

(∆)

–59.286dB

(∆)

1

FUNCTION

VAL UE

–37.983dBm

–55.764dB

(∆)

–56.953dB

(∆)

CENTER 600MHz

#RES BW 30kHz

CARRIER POWER –33.558dBm/6MHz ACP-IBW

OFFSET FREQ

3.375MHz

09616-067

6.375MHz

12.00MHz

18.00MHz

24.00MHz

INTEG B W

750.0kHz

5.250MHz

6.000MHz

6.000MHz

6.000MHz

–60.02

–61.11

–60.57

–60.64

–60.58

dBc

LOWER

VBW 3kHz

dBm

dBc

–93.58

–11.84

–94.66

–0.284

–94.13

–0.099

–94.20

–0.221

–94.14

–0.060

UPPER

dBm

–45.04

–33.84

–33.46

–33.34

–33.50

Figure 68. Mid Band Narrow-Band ACLR(Worst Side)

09616-068

Figure 66. 128-Carrier High Band Wideband ACLR

Rev. A | Page 21 of 44

Page 22

AD9739A

TERMINOLOGY

Linearity Error (Integral Nonlinearity or INL)

The maximum deviation of the actual analog output from the

ideal output, determined by a straight line drawn from 0 to full

scale.

Differential Nonlinearity (DNL)

The measure of the variation in analog value, normalized to full

scale, associated with a 1 LSB change in digital input code.

Monotonicity

A DAC is monotonic if the output either increases or remains

constant as the digital input increases.

Offset Error

The deviation of the output current from the ideal of 0 is called

the offset error. For IOUTP, 0 mA output is expected when the

inputs are all 0s. For IOUTN, 0 mA output is expected when all

inputs are set to 1.

Gain Error

The difference between the actual and ideal output span. The

actual span is determined by the output when all inputs are set

to 1 minus the output when all inputs are set to 0.

Output Compliance Range

The range of allowable voltage at the output of a current output

DAC. Operation beyond the maximum compliance limits may

cause either output stage saturation or breakdown, resulting in

nonlinear performance.

Temp er at u re D ri ft

Specified as the maximum change from the ambient (25°C)

value to the value at either T

drift, the drift is reported in ppm of full-scale range (FSR)

per °C. For reference drift, the drift is reported in ppm per °C.

MIN

or T

. For offset and gain

MAX

Power Supply Rejection

The maximum change in the full-scale output as the supplies

are varied from nominal to minimum and maximum specified

voltages.

Spurious-Free Dynamic Range

The difference, in decibels (dB), between the rms amplitude of

the output signal and the peak spurious signal over the specified

bandwidth.

Total Harmonic Distortion (THD)

The ratio of the rms sum of the first six harmonic components

to the rms value of the measured input signal. It is expressed as

a percentage or in decibels (dB).

Noise Spectral Density (NSD)

NSD is the converter noise power per unit of bandwidth. This is

usually specified in dBm/Hz in the presence of a 0 dBm fullscale signal.

Adjacent Channel Leakage Ratio (ACLR)

The adjacent channel leakage (power) ratio is a ratio, in dBc, of

the measured power within a channel relative to its adjacent

channels.

Modulation Error Ratio (MER)

Modulated signals create a discrete set of output values referred

to as a constellation. Each symbol creates an output signal

corresponding to one point on the constellation. MER is a

measure of the discrepancy between the average output symbol

magnitude and the rms error magnitude of the individual

symbol.

Intermodulation Distortion (IMD)

IMD is the result of two or more signals at different frequencies

mixing together. Many products are created according to the

formula, aF1 ± bF2, where a and b are integer values.

Rev. A | Page 22 of 44

Page 23

AD9739A

SERIAL PORT INTERFACE (SPI) REGISTER

SPI REGISTER MAP DESCRIPTION

The AD9739A contains a set of programmable registers

described in Ta ble 9 that are used to configure and monitor

various internal parameters. Note the following points when

programming the AD9739A SPI registers:

• Registers pertaining to similar functions are grouped

together and assigned adjacent addresses.

• Bits that are undefined within a register should be assigned

a 0 when writing to that register.

• Registers that are undefined should not be written to.

• A hardware or software reset is recommended upon

power-up to place SPI registers in a known state.

• A SPI initialization routine is required as part of the boot

process. See Tab l e 12 for an example procedure.

Reset

Issuing a hardware or software reset places the AD9739A SPI

registers in a known state. All SPI registers (excluding 0x00) are

set to their default states as described in Tabl e 9 upon issuing a

reset. After issuing a reset, the SPI initialization process need

only write to registers that are required for the boot process as

well as any other register settings that must be modified,

depending on the target application.

Although the AD9739A does feature an internal power-on-reset

(POR), it is still recommended that a software or hardware reset

be implemented shortly after power-up. The internal reset

signal is derived from a logical OR operation from the internal

POR signal, the RESET pin, and the software reset state. A

software reset can be issued via the reset bit (Register 0x00,

Bit 5) by toggling the bit high then low. Note that, because the

MSB/LSB format may still be unknown upon initial power-up