Page 1

FEATURES

Pin-compatible family

Excellent dynamic performance

AD9736: SFDR = 82 dBc at f

AD9736: SFDR = 69 dBc at f

AD9736: IMD = 87 dBc at f

AD9736: IMD = 82 dBc at f

LVDS data interface with on-chip 100 Ω terminations

Built-in self test

LVDS sampling integrity

LVDS-to-DAC data transfer integrity

Low power: 380 mW (I

= 20 mA; f

FS

1.8/3.3 V dual-supply operation

Adjustable analog output

8.66 mA to 31.66 mA (RL = 25 Ω to 50 Ω)

On-chip 1.2 V reference

160-lead chip scale ball grid array (CSP_BGA) package

APPLICATIONS

Broadband communications systems

Cellular infrastructure (digital predistortion)

Point-to-point wireless

CMTS/VOD

Instrumentation, automatic test equipment

Radar, avionics

PRODUCT DESCRIPTION

= 30 MHz

OUT

= 130 MHz

OUT

= 30 MHz

OUT

= 130 MHz

OUT

OUT

= 330 MHz)

10-, 12-, 14-Bit, 1200 MSPS DACS

AD9734/AD9735/AD9736

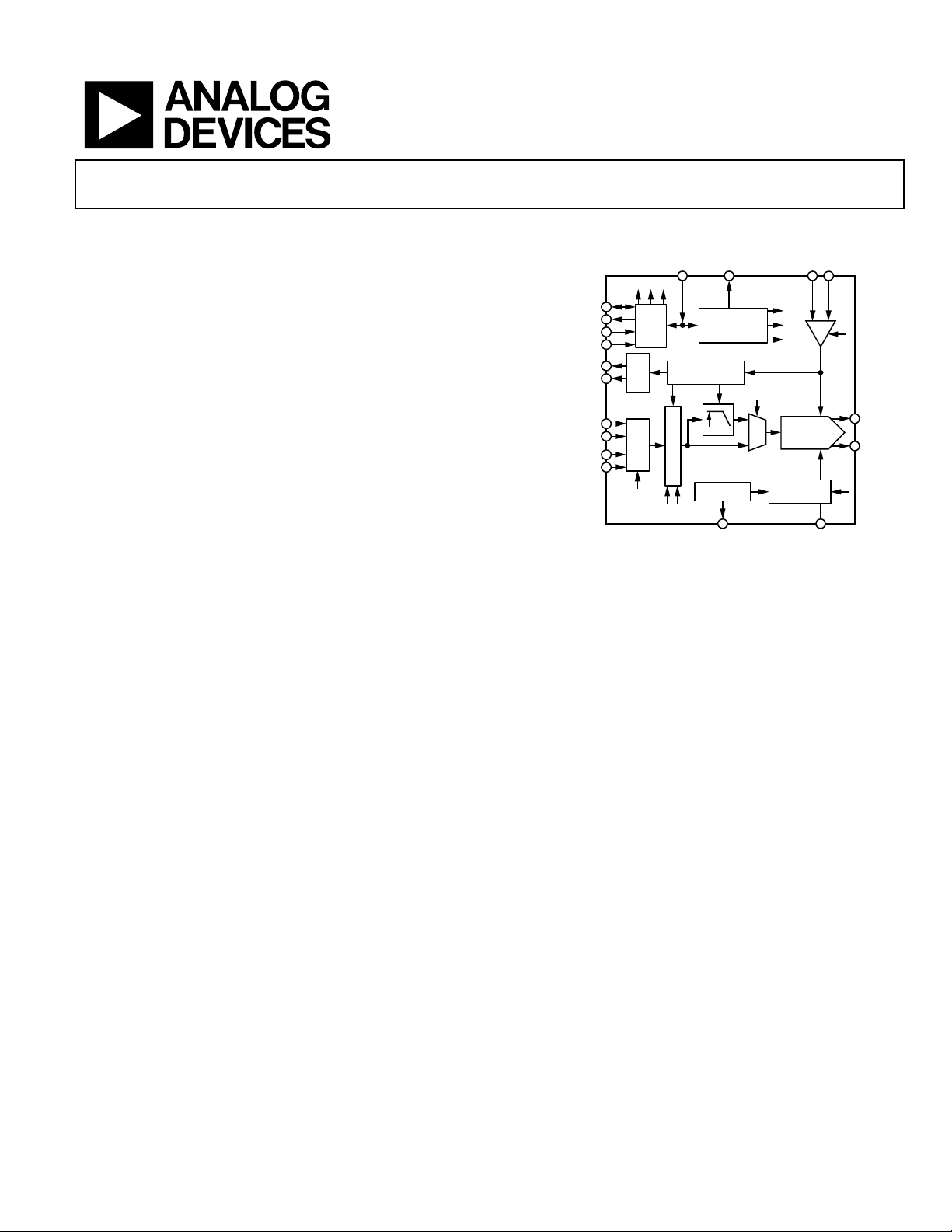

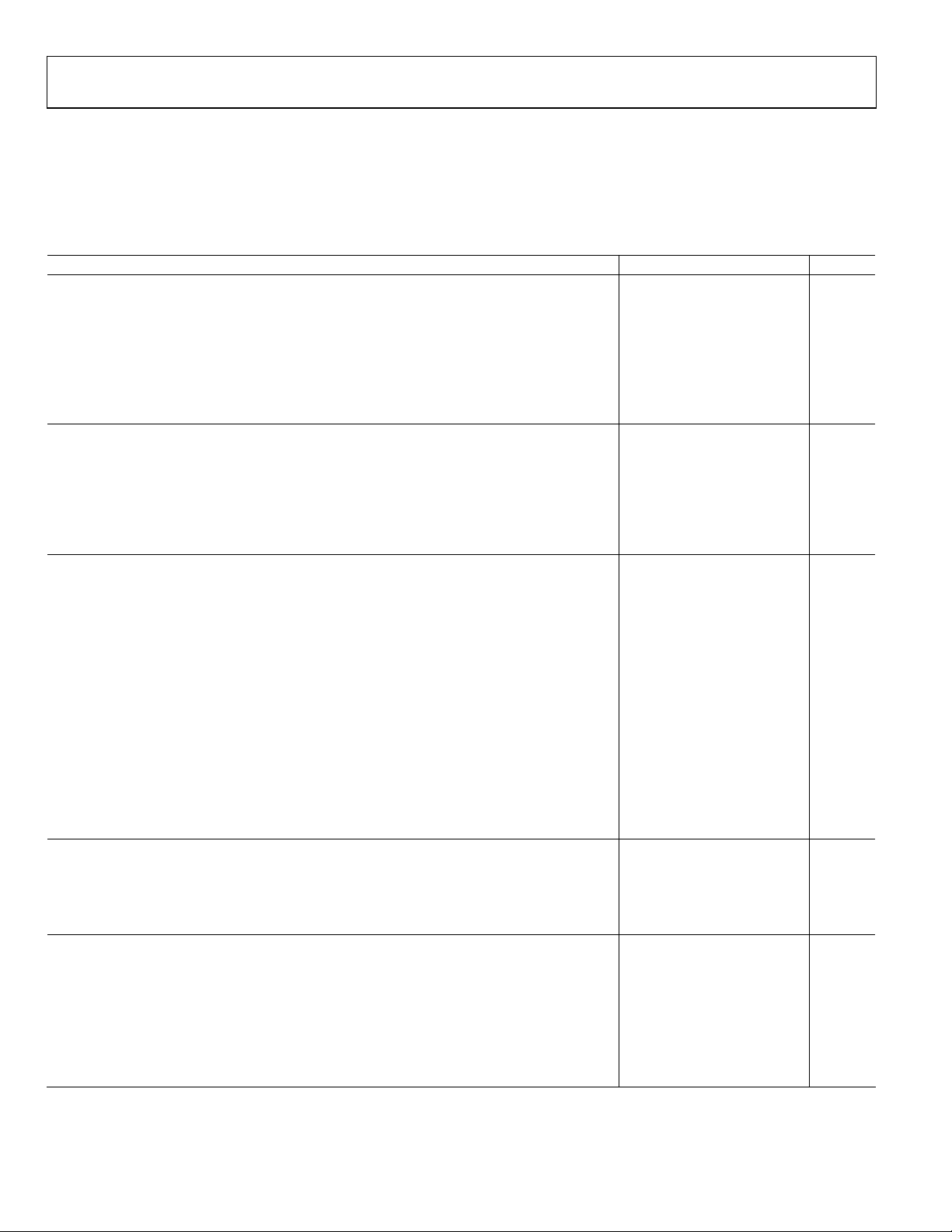

FUNCTIONAL BLOCK DIAGRAM

DACCLK–

S3

REFERENCE

CURRENT

SDI

SDO

CSB

SCLK

DATACLK_OUT+

DATACLK_OUT–

DATACLK_IN+

DATACLK_IN–

DB[13:0]+

DB[13:0]–

S1S2S3

SPI

LVDS

DRIVER

LVDS

RECEIVER

C2

RESET

CONTROLLER

CLOCK

DISTRIBUTION

SYNCHRONIZER

BAND GAP

C1S1

Figure 1.

IRQ

2×

PRODUCT HIGHLIGHTS

1. Low noise and intermodulation distortion (IMD) features

enable high quality synthesis of wideband signals at

intermediate frequencies up to 600 MHz.

2. Double data rate (DDR) LVDS data receivers support the

maximum conversion rate of 1200 MSPS.

3. Direct pin programmability of basic functions or SPI port

access for complete control of all AD973x family functions.

C1

C2

C3

14-, 12-,

10-BIT DAC

CORE

I120VREF

DACCLK+

C3

S2

IOUTA

IOUTB

04862-001

The AD9736, AD9735, and AD9734 are high performance, high

frequency DACs that provide sample rates of up to 1200 MSPS,

permitting multicarrier generation up to their Nyquist

frequency. The AD9736 is the 14-bit member of the family,

while the AD9735 and the AD9734 are the 12-bit and 10-bit

members, respectively. They include a serial peripheral interface

(SPI) port that provides for programming of many internal

parameters and also enables readback of status registers. A

reduced-specification LVDS interface is utilized to achieve the

high sample rate. The output current can be programmed

over a range of 8.66 mA to 31.66 mA. The AD973x family is

manufactured on a 0.18 µm CMOS process and operates from

1.8 V and 3.3 V supplies for a total power consumption of

380 mW in bypass mode. It is supplied in a 160-lead chip scale

ball grid array for reduced package parasitics.

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable.

However, no responsibility is assumed by Analog Devices for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications subject to change without notice. No license is granted by implication

or otherwise under any patent or patent rights of Analog Devices. Trademarks and

registered trademarks are the property of their respective owners.

4. Manufactured on a CMOS process, the AD973x family

uses a proprietary switching technique that enhances

dynamic performance.

5. The current output(s) of the AD9736 family are easily con-

figured for single-ended or differential circuit topologies.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.461.3113 © 2005 Analog Devices, Inc. All rights reserved.

www.analog.com

Page 2

AD9734/AD9735/AD9736

TABLE OF CONTENTS

DC Specifications ............................................................................. 4

Digital Specifications........................................................................ 6

AC Specifications.............................................................................. 8

Absolute Maximum Ratings............................................................ 9

ESD Caution.................................................................................. 9

Pin Configuration and Function Descriptions........................... 10

Te r mi n ol o g y .................................................................................... 13

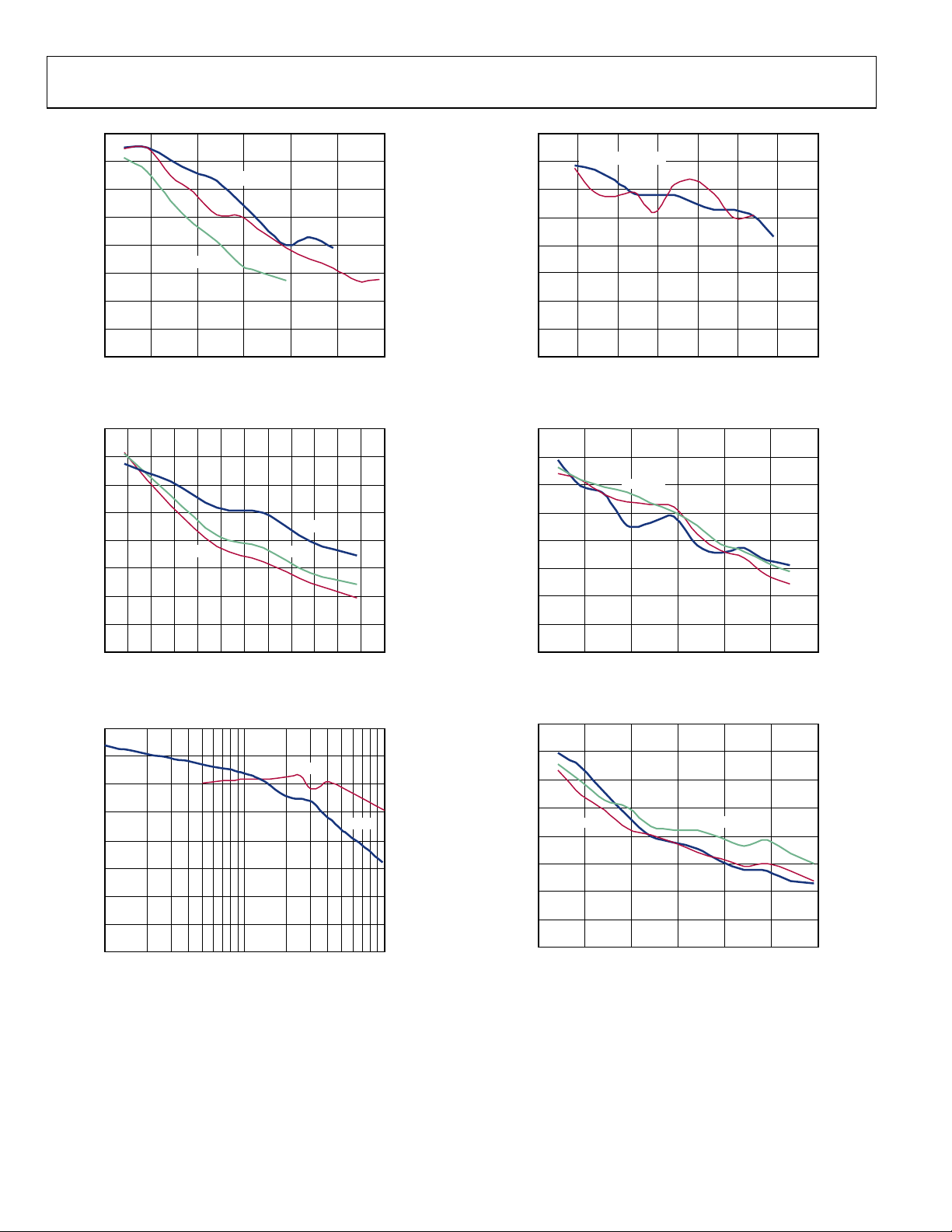

Typical Performance Characteristics........................................... 14

AD9736 Static Linearity, 10 mA Full Scale............................. 14

AD9736 Static Linearity, 20 mA Full Scale............................. 15

AD9736 Static Linearity, 30 mA Full Scale............................. 16

AD9735 Static Linearity, 10 mA, 20 mA, 30 mA Full Scale .17

AD9734 Static Linearity, 10 mA, 20 mA, 30 mA Full Scale .18

AD9736 Power Consumption, 20 mA Full Scale................... 19

AD9736 Dynamic Performance, 20 mA Full Scale................ 19

Theory of Operation ...................................................................... 31

Serial Peripheral Interface............................................................. 32

General Operation of the Serial Interface............................... 32

Short Instruction Mode (8-Bit Instruction) ........................... 32

Long Instruction Mode (16-Bit Instruction).......................... 32

Serial Interface Port Pin Descriptions..................................... 32

MSB/LSB Transfers .................................................................... 33

Notes on Serial Port Operation ................................................ 33

Pin Mode Operation .................................................................. 34

Reset Operation.......................................................................... 34

Programming Sequence ............................................................ 34

Interpolation Filter ..................................................................... 35

Data Interface Controllers......................................................... 35

LVDS Samp l e Logic .................................................................... 36

LVDS Samp l e Logic C a l ibr ation ............................................... 36

AD9736 Dynamic Performance, 20 mA Full Scale................ 21

AD9736, AD9735, AD9734 WCDMA ACLR, 20 mA Full

.............................................................................................. 22

Scale

AD9735, AD9734 Dynamic Performance, 20 mA Full Scale24

SPI Register Map............................................................................. 25

SPI Register Descriptions.............................................................. 26

MODE Register (REG 00)......................................................... 26

Interrupt Request Register (IRQ) (Reg 01)............................. 26

Full Scale Current (FSC) Register (Regs 02, 03)..................... 27

LVDS Controller (LVDS_CNT) Register (Regs 04, 05, 06).. 27

SYNC Controller (SYNC_CNT) Register (Regs 07, 08) .......28

Cross Controller (CROS_CNT) Register (Regs 10, 11)........ 28

Analog Control (ANA_CNT) Register (Regs 14, 15)............ 29

Built-in Self Test Control (BIST_CNT) Registers (Regs 17, 18,

19, 20, 21)

Controller Clock Predivider (CCLK_DIV) Reading Register

(Reg 22)

.................................................................................... 29

........................................................................................ 30

Operating the LVDS Controller In Manual Mode via the SPI

............................................................................................... 37

Port

Operating the LVDS Controller in Surveillance and Auto

............................................................................................ 37

Mode

SYNC Logic and Controller.......................................................... 38

SYNC Logic and Controller Operation................................... 38

Operating in Manual Mode ...................................................... 38

Operation in Surveillance and Auto Modes ........................... 38

FIFO Bypass................................................................................ 38

Digital Built-In Self Test (BIST) ................................................... 40

Overview ..................................................................................... 40

AD973x BIST Procedure........................................................... 41

AD973x Expected BIST Signatures.......................................... 41

Generating Expected Signatures .............................................. 42

Cross Controller Registers............................................................. 43

Rev. 0 | Page 2 of 68

Page 3

AD9734/AD9735/AD9736

Analog Control Registers...............................................................44

DAC Data Sources ..........................................................................49

Band Gap Temperature Characteristic Trim Bits ...................44

Mirror Roll-Off Frequency Control .........................................44

Headroom Bits.............................................................................44

Volt a ge R e fere n ce ........................................................................45

Applications Information...............................................................46

Driving the DACCLK Input......................................................46

DAC Output Distortion Sources ...................................................47

DC-Coupled DAC Outputs ...........................................................48

REVISION HISTORY

4/05—Revision 0: Initial Version

Input Data Timing ..........................................................................50

Synchronization Timing.................................................................51

Power Supply Sequencing ..............................................................52

AD973X Evaluation Board Schematics ........................................53

AD973X Evaluation Board PCB Layout .......................................58

Outline Dimensions........................................................................65

Ordering Guide...........................................................................65

Rev. 0 | Page 3 of 68

Page 4

AD9734/AD9735/AD9736

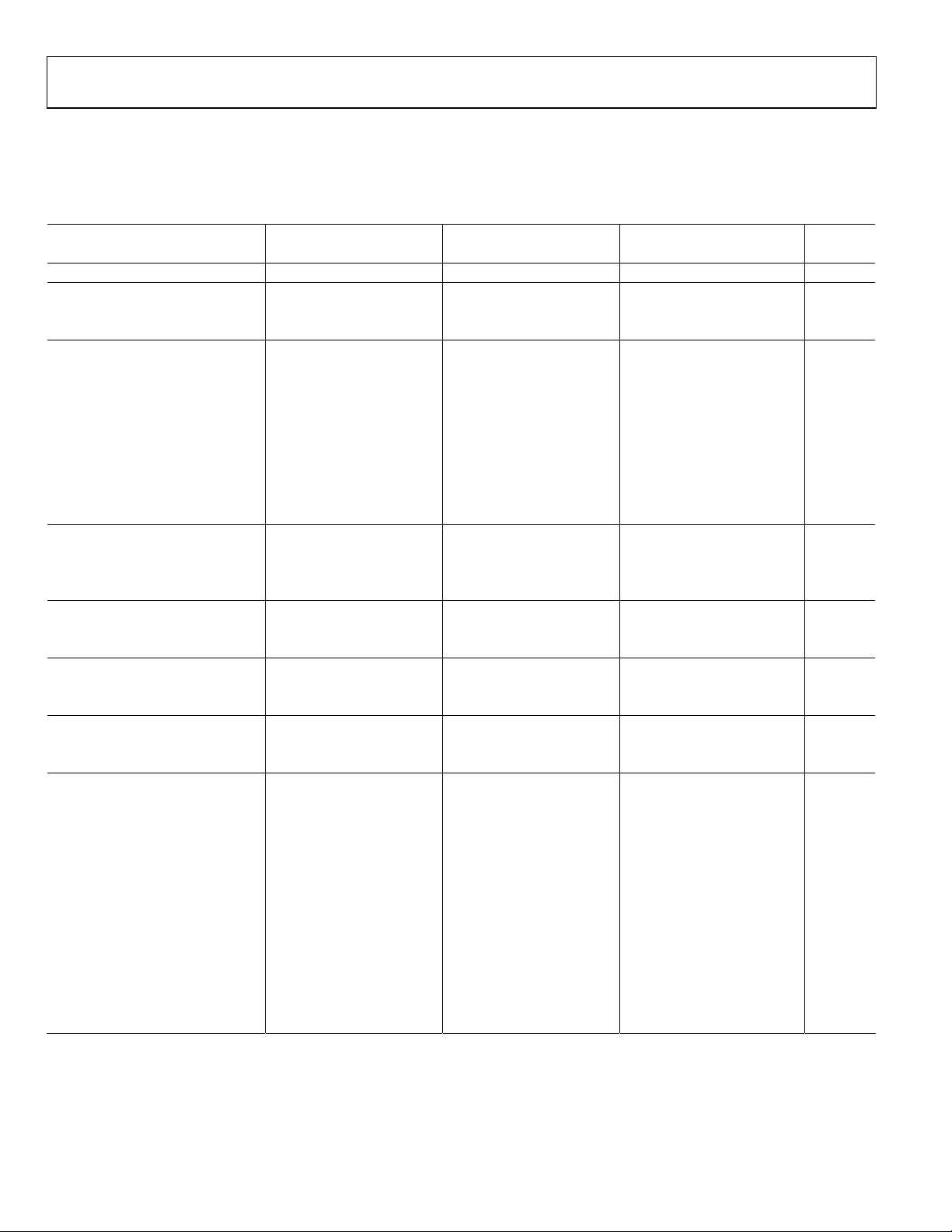

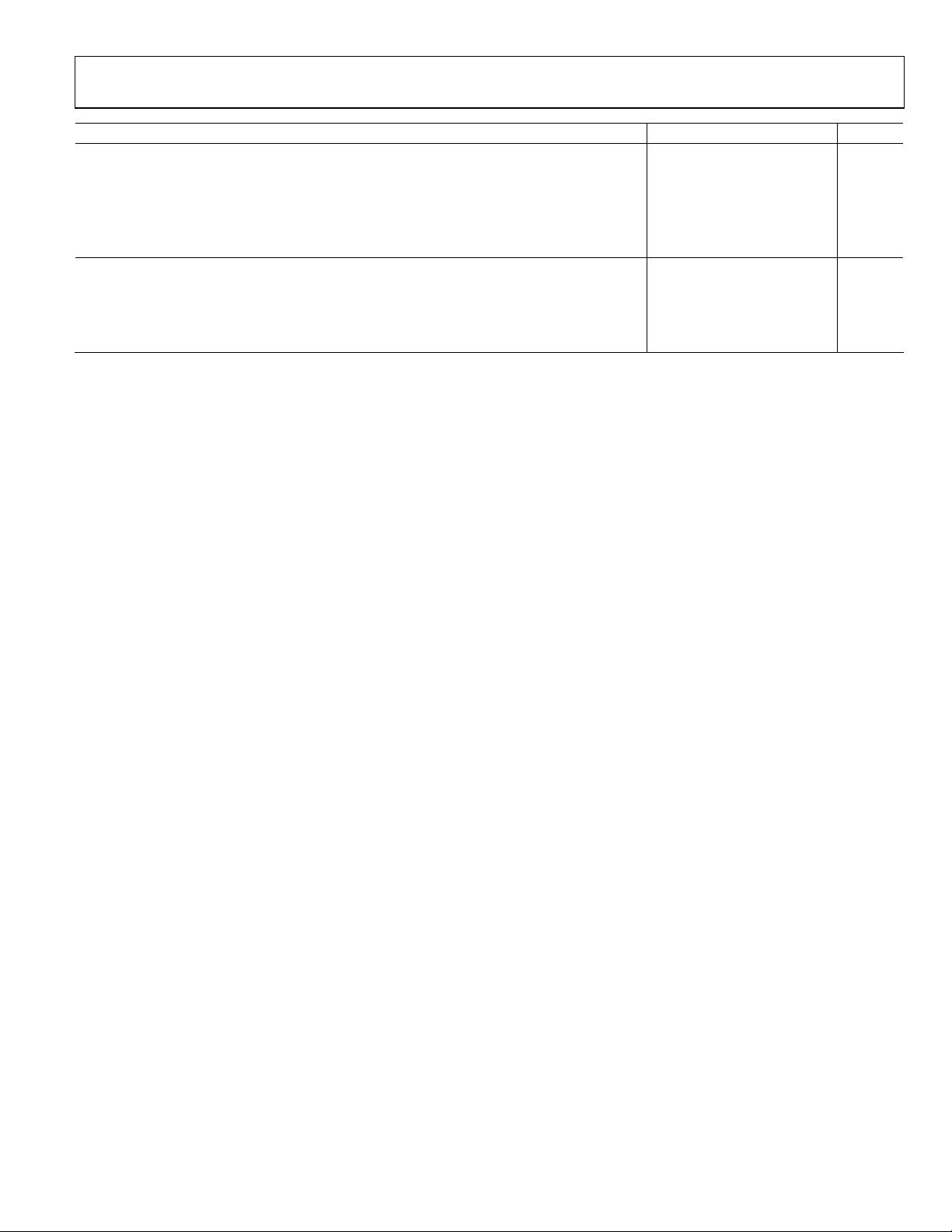

DC SPECIFICATIONS

AVDD33 = DVDD33 = 3.3 V, CVDD18 = DVDD18 = 1.8 V, maximum sample rate, IFS = 20 mA, 1× mode, 25 Ω 1% balanced load,

unless otherwise noted.

Table 1.

AD9736 AD9735 AD9734

Parameter Min Typ Max Min Typ Max Min Typ Max Unit

RESOLUTION 14 12 10 Bits

ACCURACY

Integral Nonlinearity (INL) −5.6 ±1.0 +5.6 −1.5 ±0.50 +1.5 −0.5 ±0.12 +0.5 LSB

Differential Nonlinearity (DNL) −2.1 ±0.6 +2.1 −0.5 ±0.25 +0.5 −0.1 ±0.06 +0.1 LSB

ANALOG OUTPUTS

Offset Error −0.01 ±0.005 +0.01 −0.01 ±0.005 +0.01 −0.01 ±0.005 +0.01 % FSR

Gain Error (With Internal

Reference)

Gain Error (Without Internal

Reference)

Full-Scale Output Current 8.66 20.2 31.66 8.66 20.2 31.66 8.66 20.2 31.66 mA

Output Compliance Range −1.0 +1.0 −1.0 1.0 −1.0 +1.0 V

Output Resistance 10 10 10 MΩ

Output Capacitance 1 1 1 pF

TEMPERATURE DRIFT

Offset 0 0 0 ppm/°C

Gain 80 80 80 ppm/°C

Reference Voltage

1

REFERENCE

Internal Reference Voltage1 1.14 1.2 1.26 1.14 1.2 1.26 1.14 1.2 1.26 V

Output Resistance

2

ANALOG SUPPLY VOLTAGES

AVDD33 3.13 3.3 3.47 3.13 3.3 3.47 3.13 3.3 3.47 V

CVDD18 1.70 1.8 1.90 1.70 1.8 1.90 1.70 1.8 1.90 V

DIGITAL SUPPLY VOLTAGES

DVDD33 3.13 3.3 3.47 3.13 3.3 3.47 3.13 3.3 3.47 V

DVDD18 1.70 1.8 1.90 1.70 1.8 1.90 1.70 1.8 1.90 V

SUPPLY CURRENTS

1× Mode, 1.2 GSPS

I

AVDD33

I

CVDD18

I

DVDD33

I

DVDD18

FIR Bypass (1×) Mode 380 380 380 mW

2× Mode, 1.2 GSPS

I

AVDD33

I

CVDD18

I

DVDD33

I

DVDD18

FIR 2× Interpolation Filter

Enabled

±1.0 ±1.0 ±1.0 % FSR

±1.0 ±1.0 ±1.0 % FSR

40 40 40 ppm/°C

5 5 5 kΩ

25 25 25 mA

47 47 47 mA

10 10 10 mA

122 122 122 mA

25 25 25 mA

47 47 47 mA

10 10 10 mA

234 234 234 mA

550 550 550 mW

Rev. 0 | Page 4 of 68

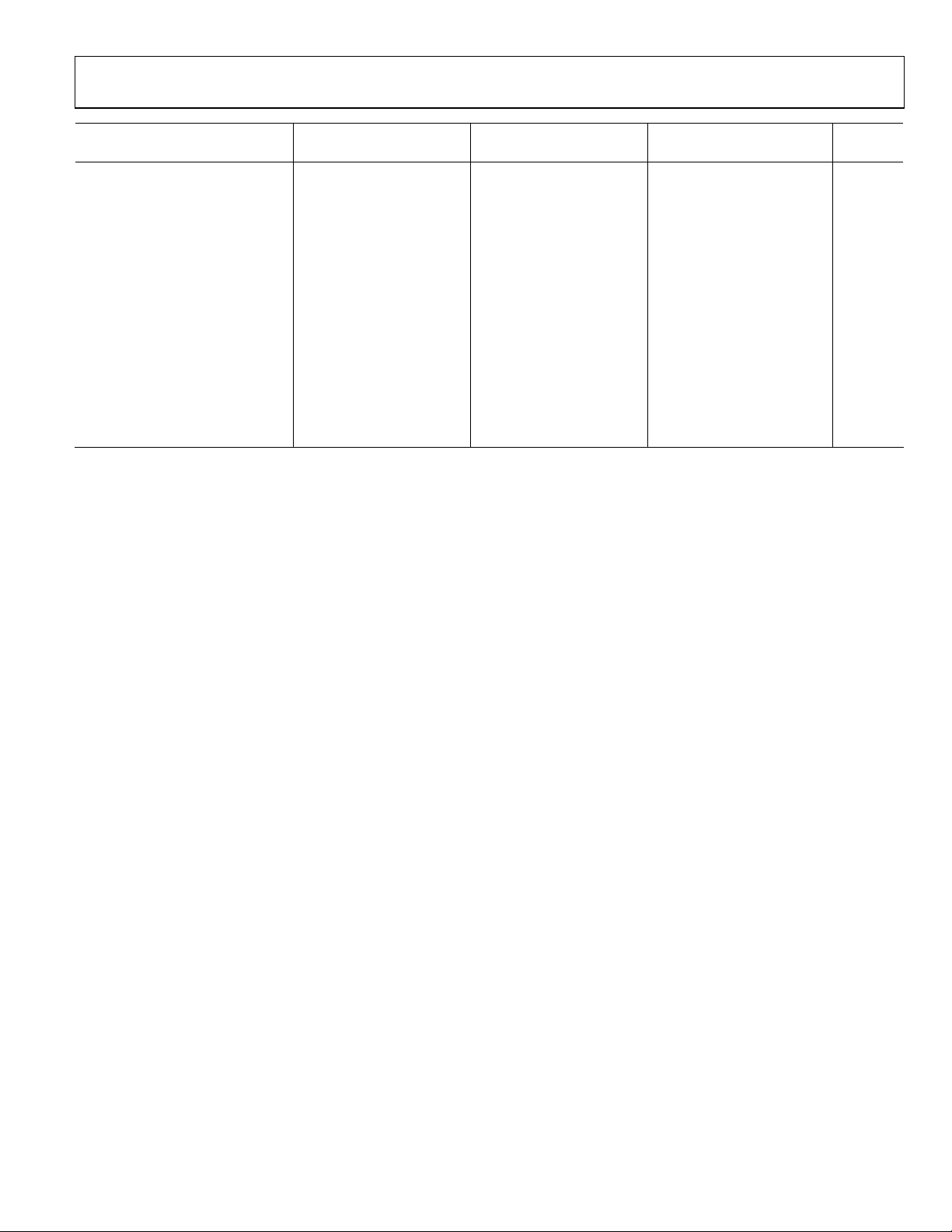

Page 5

AD9734/AD9735/AD9736

AD9736 AD9735 AD9734

Parameter Min Typ Max Min Typ Max Min Typ Max Unit

Static, No Clock

I

AVDD33

I

CVDD18

I

DVDD33

I

DVDD18

FIR Bypass (1×) Mode 133 133 133 mW

Sleep Mode, No Clock

I

AVDD33

FIR Bypass (1×) Mode 59 65 59 65 59 65 mW

Power-Down Mode

I

AVDD33

I

CVDD18

I

DVDD33

I

DVDD18

FIR Bypass (1×) Mode 0.12 1.24 0.12 1.24 0.12 1.24 mW

1

Default band gap adjustment (Reg0E<2:0> = 0h).

2

Use an external amplifier to drive any external load.

25 25 25 mA

8 8 8 mA

10 10 10 mA

2 2 2 mA

2.5 3.15 2.5 3.15 2.5 3.15 mA

0.01 0.13 0.01 0.13 0.01 0.13 mA

0.02 0.12 0.02 0.12 0.02 0.12 mA

0.01 0.12 0.01 0.12 0.01 0.12 mA

0.01 0.11 0.01 0.11 0.01 0.11 mA

Rev. 0 | Page 5 of 68

Page 6

AD9734/AD9735/AD9736

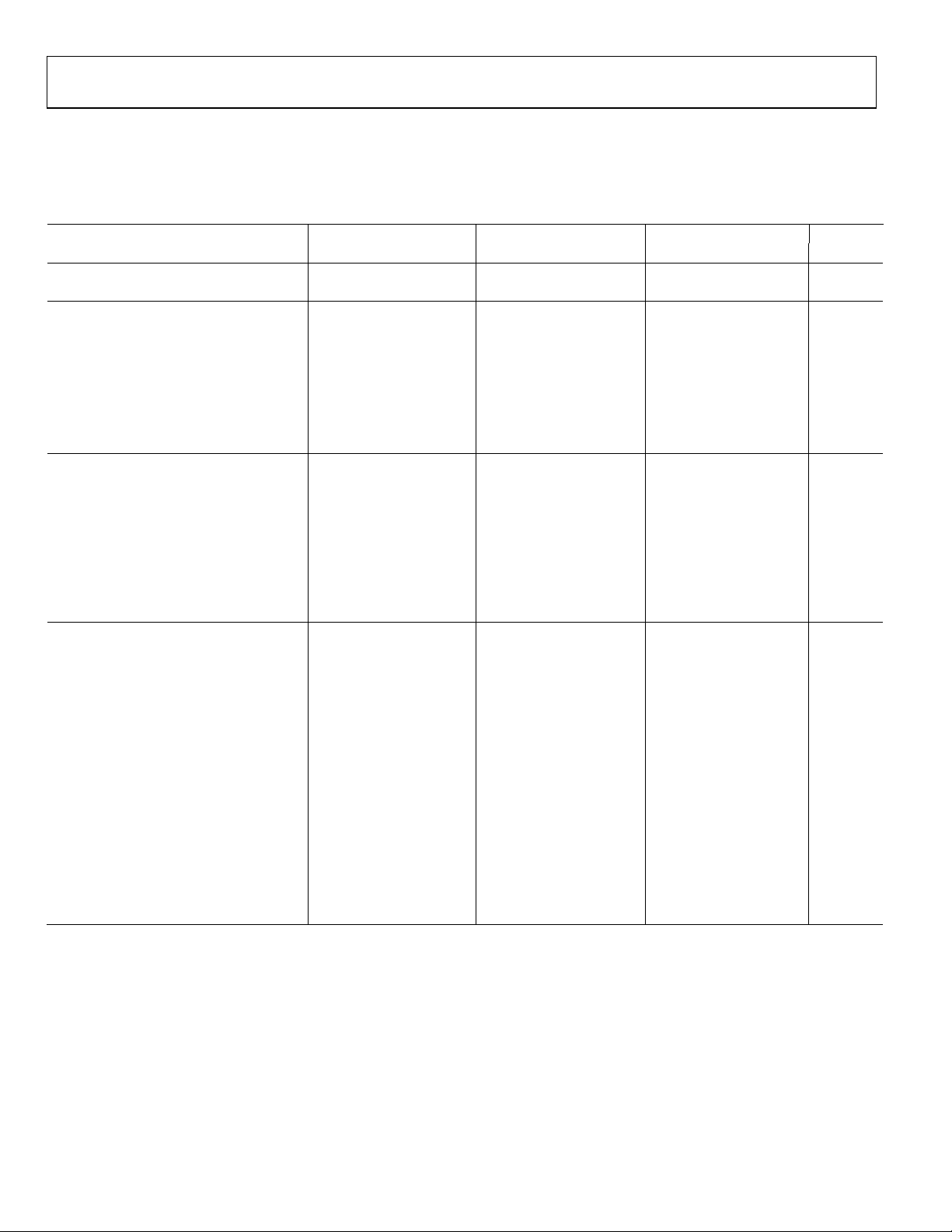

DIGITAL SPECIFICATIONS

AVDD33 = DVDD33 = 3.3 V, CVDD18 = DVDD18 = 1.8 V, maximum sample rate, IFS = 20 mA, 1× mode, 25 Ω 1% balanced load,

unless otherwise noted.

LVDS drivers and receivers are compliant to the IEEE-1596 reduced range link, unless otherwise noted.

Table 2.

Parameter Min Typ Max Unit

LVDS DATA INPUTS

(DB[13:0]+, DB[13:0]−) DB+ = V

Input Voltage Range, Via or Vib 825 1575 mV

Input Differential Threshold, V

Input Differential Hysteresis, V

Receiver Differential Input Impedance, R

LVDS Input Rate 1200 MSPS

LVDS Minimum Data Valid Period (t

LVDS CLOCK INPUT

(DATACLK_IN+, DATACLK_IN−) DATACLK_IN+ = V

Input Voltage Range, Via or V

Input Differential Threshold1, V

Input Differential Hysteresis, V

Receiver Differential Input Impedance, R

Maximum Clock Rate 600 MHz

LVDS CLOCK OUTPUT

(DATACLK_OUT+, DATACLK_ OUT−) DATACLK_OUT+ = V

Termination

Output Voltage High, Voa or V

Output Voltage Low, Voa or V

Output Differential Voltage, |Vod| 150 200 250 mV

Output Offset Voltage, V

Output Impedance, Single-Ended, R

Ro Mismatch Between A and B, ∆R

Change in |Vod| Between 0 and 1, |∆Vod|

Change in Vos Between 0 and 1, ∆V

Output Current—Driver Shorted to Ground, Isa, I

Output Current—Drivers Shorted Together, I

Power-Off Output Leakage, |Ixa|, |Ixb| 10 mA

Maximum Clock Rate 600 MHz

DAC CLOCK INPUT (CLK+, CLK−)

Input Voltage Range, CLK– or CLK+ 0 800

Differential Peak-to-Peak Voltage 400 800 1600 mV

Common-Mode Voltage 300 400 500 mV

Maximum Clock Rate 1200 MHz

SERIAL PERIPHERAL INTERFACE

Maximum Clock Rate (f

Minimum Pulse Width High, t

Minimum Pulse Width Low, t

Minimum SDIO and CSB to SCLK Setup, t

Minimum SCLK to SDIO Hold, t

Maximum SCLK to Valid SDIO and SDO, t

Minimum SCLK to Invalid SDIO and SDO, t

, DB- = Vib

ia

idth

– V

idthh

idthl

in

) 344 ps

MDE

, DATACLK_IN− = V

ia

ib

idth

- V

idthh

idthl

in

, DATACLK_OUT− = Vob 100 Ω

oa

ib

−100 +100 mV

20 mV

80 120 Ω

825 1575 mV

−100 +100 mV

20 mV

80 120 Ω

ob

ob

os

o

o

1375 mV

1025 mV

1150 1250 mV

80 100 120 Ω

10 %

25 mV

SCLK

os

sb

sab

, 1/t

) 20 MHz

SCLK

PWH

PWL

DS

DH

DV

DNV

25 mV

20 mA

4 mA

20 ns

20 ns

10 ns

5 ns

20 ns

5 ns

Rev. 0 | Page 6 of 68

Page 7

AD9734/AD9735/AD9736

Parameter Min Typ Max Unit

INPUTS (SDI, SDIO, SCLK, CSB)

Voltage in High, V

Voltage in Low, V

Current in High, I

Current in Low, I

ih

il

ih

il

Input Capacitance pF

SDIO OUTPUT

Voltage out High, V

Voltage out Low, V

Current out High, I

Current out Low, I

1

Refer to the section for recommended LVDS differential drive levels. Input Data Timing

oh

ol

oh

ol

2.0 3.3 V

0 0.8 V

−10 +10 µA

−10 +10 µA

2.4 3.6 V

0 0.4 V

4 mA

4 mA

Rev. 0 | Page 7 of 68

Page 8

AD9734/AD9735/AD9736

AC SPECIFICATIONS

AVDD33 = DVDD33 = 3.3 V, CVDD18 = DVDD18 = 1.8 V, maximum sample rate, IFS = 20 mA, 1× mode, 25 Ω 1% balanced load,

unless otherwise noted.

Table 3.

AD9736 AD9735 AD9734

Parameter Min Typ Max Min Typ Max Min Typ Max Unit

DYNAMIC PERFORMANCE

Maximum Update Rate 1200 1200 1200 MSPS

SPURIOUS-FREE DYNAMIC RANGE (SFDR)

f

= 800 MSPS

DAC

f

= 20 MHz 75 75 75 dBc

OUT

f

= 1200 MSPS

DAC

f

= 50 MHz 80 76 76 dBc

OUT

f

= 100 MHz 77 74 71 dBc

OUT

f

= 316 MHz 63 63 60 dBc

OUT

f

= 550 MHz 55 54 53 dBc

OUT

TWO-TONE INTERMODULATION

DISTORTION (IMD)

f

= 1200 MSPS

DAC

f

= f

OUT2

+ 1.25 MHz

OUT

f

= 40 MHz 88 84 83 dBc

OUT

f

= 50 MHz 85 84 83 dBc

OUT

f

= 100 MHz 84 81 79 dBc

OUT

f

= 315 MHz 70.5 67 66 dBc

OUT

f

= 550 MHz 65 60 60 dBc

OUT

NOISE SPECTRAL DENSITY (NSD)

Single Tone

f

= 1200 MSPS

DAC

f

= 50 MHz −165

OUT

f

= 100 MHz −164 −161 −154 dBm/Hz

OUT

f

= 241MHz −158.5 −160.5 −159.5 −155 dBm/Hz

OUT

f

= 316 MHz −158 −157 −152 dBm/Hz

OUT

f

= 550 MHz −155 −155 −149 dBm/Hz

OUT

Eight-Tone

f

= 1200 MSPS, 500 kHz Tone

DAC

Spacing

f

= 50 MHz −166.5 −163 −154 dBm/Hz

OUT

f

= 100 MHz −166 −163 −152 dBm/Hz

OUT

f

= 241MHz −163.3 −165 −161.5 −150.5 dBm/Hz

OUT

f

= 316 MHz −164 −162 −151 dBm/Hz

OUT

f

= 550 MHz −162 −160 −150 dBm/Hz

OUT

−162

−154 dBm/Hz

Rev. 0 | Page 8 of 68

Page 9

AD9734/AD9735/AD9736

ABSOLUTE MAXIMUM RATINGS

Table 4.

With

Parameter

AVDD33 AVSS −0.3 V +3.6 V

DVDD33 DVSS −0.3 V +3.6 V

DVDD18 DVSS −0.3 V +1.98 V

CVDD18 CVSS −0.3 V +1.98 V

AVSS DVSS −0.3 V +0.3 V

AVSS CVSS −0.3 V +0.3 V

DVSS CVSS −0.3 V +0.3 V

CLK+, CLK− CVSS −0.3 V CVDD18 + 0.18 V

PIN_MODE DVSS −0.3 V DVDD33 + 0.3 V

DATACLK_IN,

DATACLK_OUT

LVDS Data Inputs DVSS −0.3 V DVDD33 + 0.3 V

IOUTA, IOUTB AVSS −1.0 V AVDD33 + 0.3 V

I120, VREF, IPTAT AVSS −0.3 V AVDD33 + 0.3 V

IRQ, CSB, SCLK,

SDO, SDIO, RESET DVSS −0.3 V DVDD33 + 0.3 V

Junction Temp. 150°C

Storage Temp. −65°C +150°C

Respect to

DVSS −0.3 V DVDD33 + 0.3 V

Min Max

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

sections of this specification is not implied. Exposure to

absolute maximum ratings for extended periods may effect

device reliability.

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on

the human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance

degradation or loss of functionality.

Note that this device in its current form does not meet Analog Devices’ standard requirements for ESD as measured against the charged

device model (CDM). As such, special care should be used when handling this product, especially in a manufacturing environment. Analog

Devices will provide a more ESD-hardy product in the near future at which time this warning will be removed from this datasheet.

Rev. 0 | Page 9 of 68

Page 10

AD9734/AD9735/AD9736

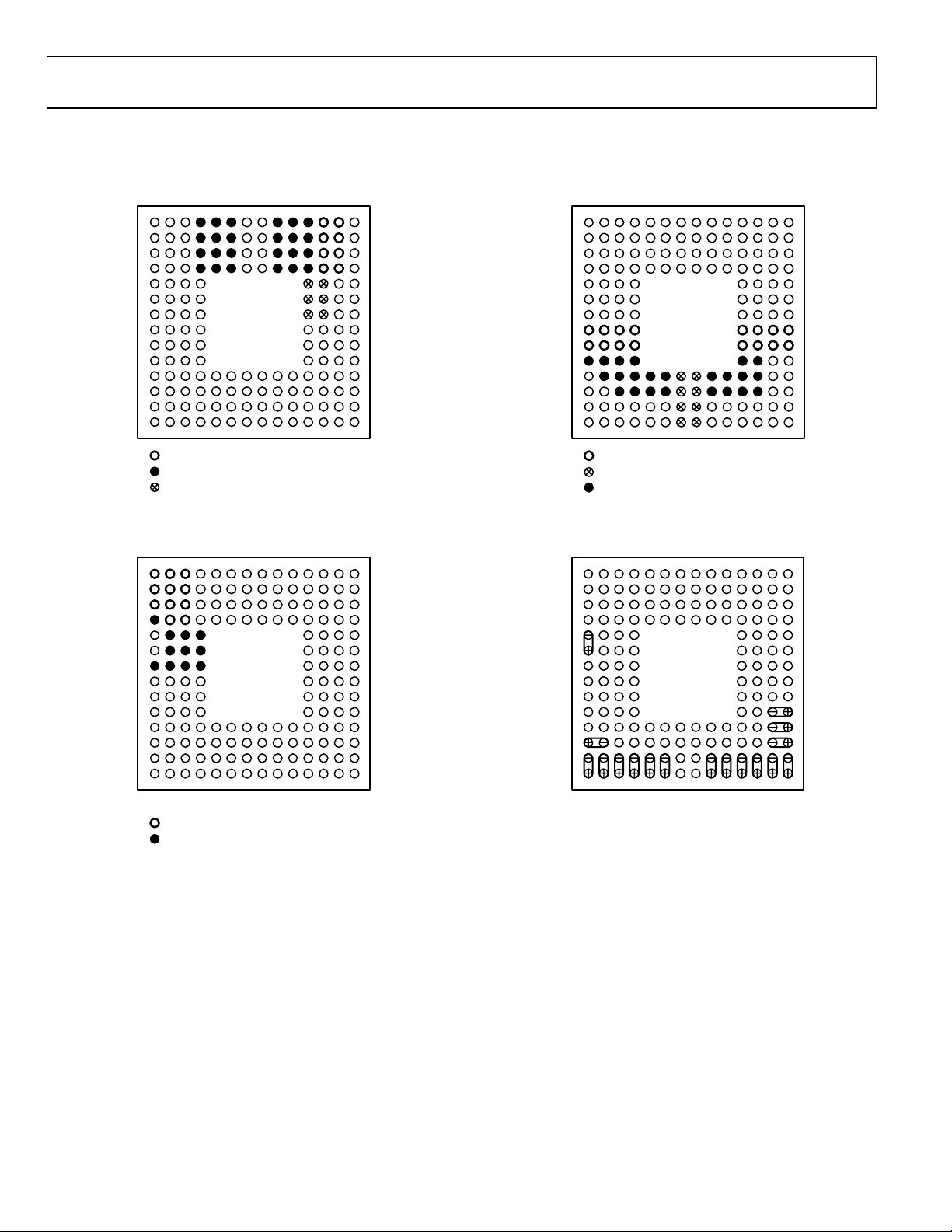

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

1413121110876321954

1413121110876321954

A

B

C

D

E

F

G

H

J

K

L

M

N

P

AVDD33, 3.3V, ANALOG SUPPLY

AVSS, ANALOG SUPPLY GROUND

AVSS, ANALOG SUPPLY GROUND SHIELD

Figure 2. AD9736 Analog Supply Pins ( Top View)

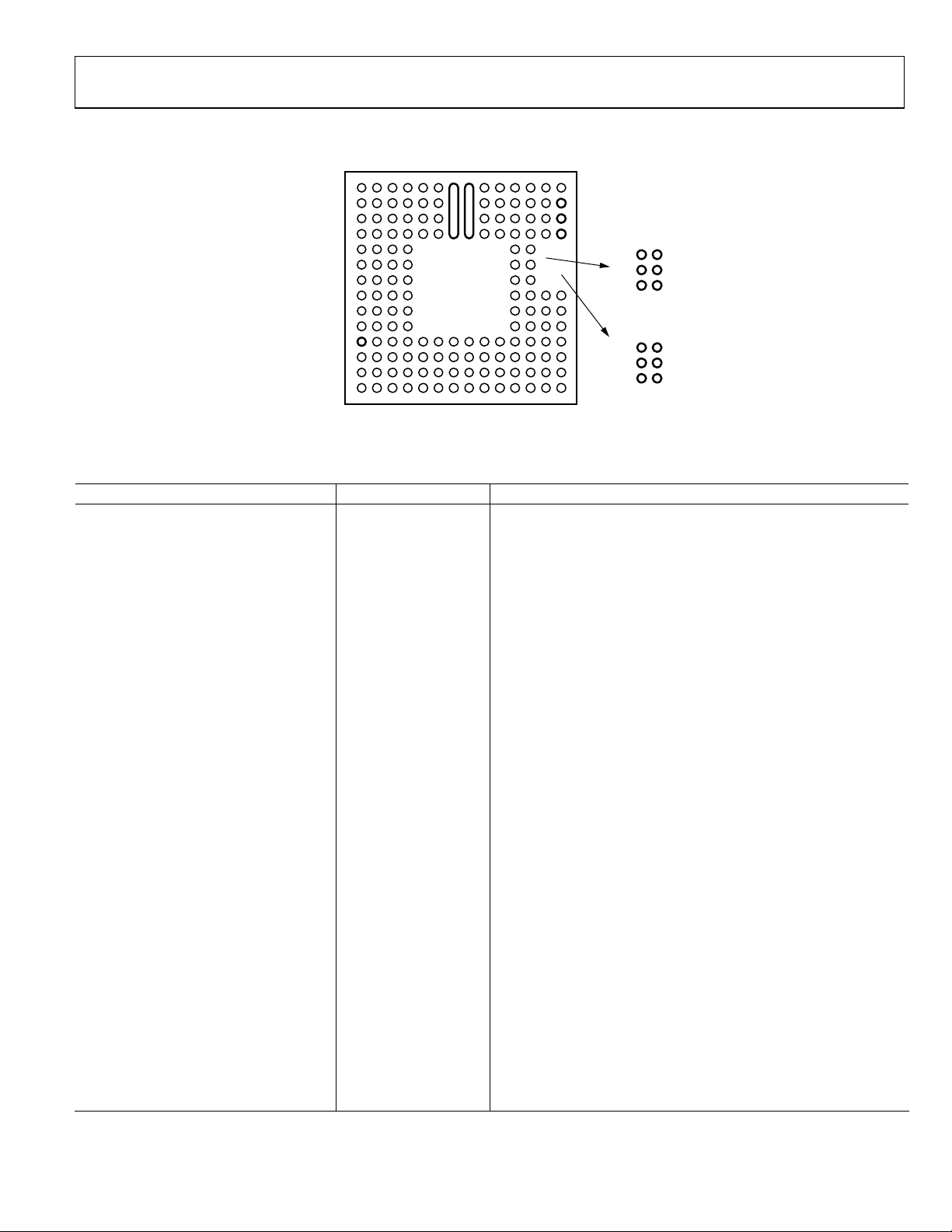

A

B

C

D

E

F

G

H

J

K

L

M

N

P

A

B

C

D

E

F

G

H

J

K

L

M

N

P

DVDD18, 1.8V DIGITAL SUPPLY

DVDD33, 3.3V DIGITAL SUPPLY

04862-002

DVSS DIGITAL SUPPLY GROUND

04862-004

Figure 4. AD9736 Digital Supply Pins ( Top View)

1413121110876321954

A

B

C

D

E

CLK–

F

CLK+

G

H

J

K

L

MDB0 (LSB)

N

P

1413121110876321954

DB13 (MSB)

DB12

DB11

CVDD18, 1.8V CLOCK SUPPLY

CVSS, CLOCK SUPPLY GROUND

Figure 3. AD9736 Clock Supply Pins ( Top View)

04862-003

DB1

DATACLK_OUT

DB6

DATACLK_IN

Figure 5. AD9736 Digital LVDS Inputs, Clock I/O (Top View)

DB7

DB8

DB9

DB10

04862-005

DB5

DB4

DB3

DB2

Rev. 0 | Page 10 of 68

Page 11

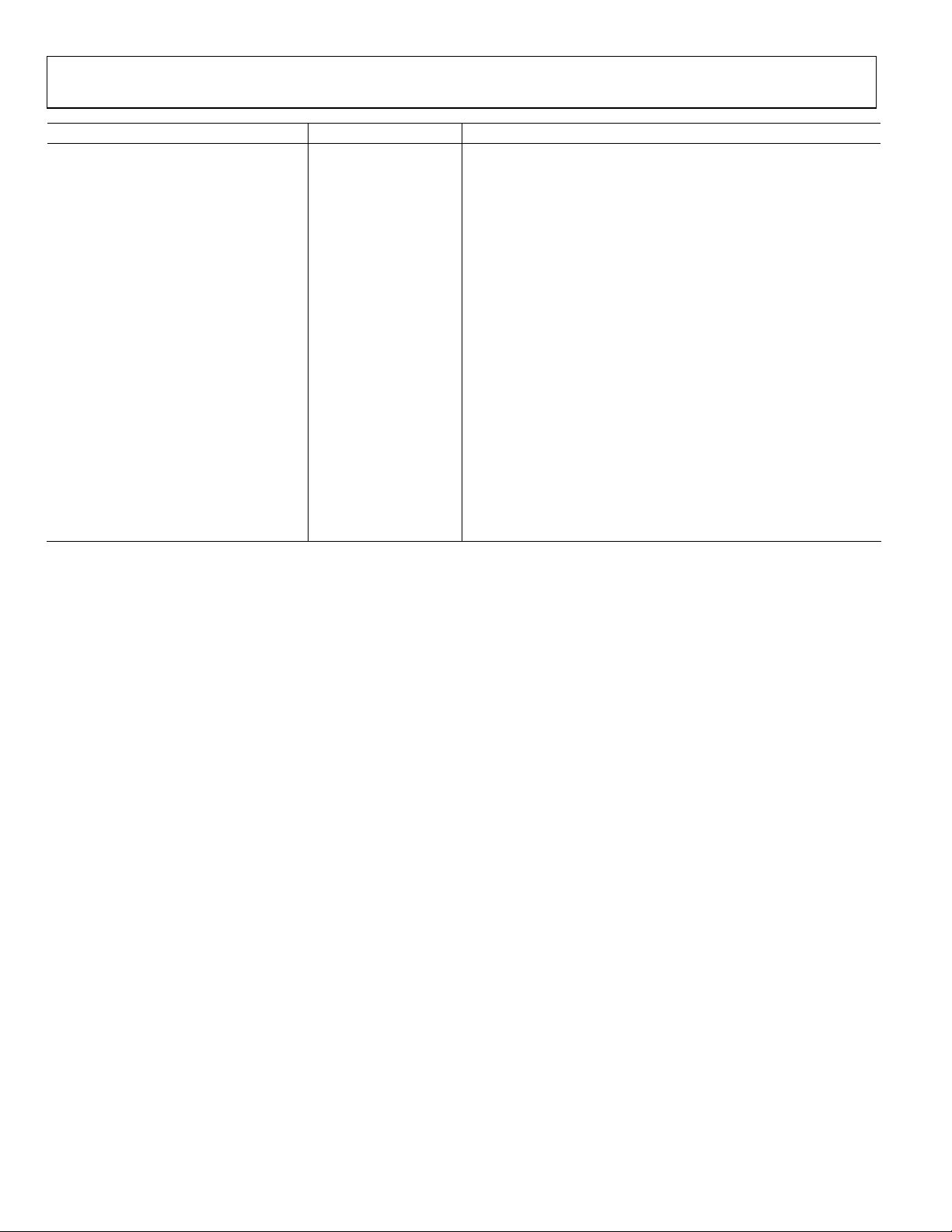

AD9734/AD9735/AD9736

IOUTB

IOUTA

1413121110876321954

PIN_MODE

A

B

C

D

E

F

G

H

J

K

L

M

N

P

I120

VREF

IPTAT

CSB

SCLK

UNSIGNED

FSC0

PIN_MODE = 0,

SPI ENABLED

IRQ

PIN_MODE = 1,

SPI DISABLED

2×

RESET

SDIO

SDO

PD

FIFO

FSC1

04862-006

Figure 6. AD9736 Analog I/O and SPI Control Pins ( Top View)

Table 5. Pin Function Descriptions

Pin No. Mnemonic Description

A1, A2, A3, B1, B2, B3, C1, C2, C3, D2, D3 CVDD18 1.8 V Clock Supply.

A4, A5, A6, A9, A10, A11, B4, B5, B6, B9,

AVSS Analog Supply Ground.

B10, B11, C4, C5, C6, C9, C10, C11, D4, D5,

D6, D9, D10, D11

A7, B7, C7, D7 IOUTB DAC Negative Output; 10 mA to 30 mA full-scale output current.

A8, B8, C8, D8 IOUTA DAC Positive Output; 10 mA to 30 mA full-scale output current.

A12, A13, B12, B13, C12, C13, D12, D13 AVDD33 3.3 V Analog Supply.

A14 DNC Do Not Connect.

B14 I120

Nominal 1.2 V Reference; tie to analog ground via 10 kΩ resistor to

generate a 120 µA reference current.

C14 VREF

Band Gap Voltage Reference I/O; tie to analog ground via 1 nF

capacitor, output impedance approximately 5 kΩ.

D1, E2, E3, E4, F2, F3, F4, G1, G2, G3, G4 CVSS Clock Supply Ground.

D14 IPTAT

Factory Test Pin; output current proportional to absolute

temperature, approximately 10 µA at 25°C with approximately

20 nA/°C slope.

E1, F1 DACCLK−/DACCLK+ Negative/Positive DAC Clock Input (DACCLK).

E11, E12, F11, F12, G11, G12 AVSS Analog Supply Ground Shield; tie to AVSS at the DAC.

E13 IRQ/UNSIGNED

If PIN_MODE = 0, IRQ: Active low open-drain interrupt request

output, pull up to DVDD33 with 10 kΩ resistor.

If PIN_MODE = 1, UNSIGNED: Digital input pin where 0 = twos

complement input data format, 1 = unsigned.

E14 RESET/PD If PIN_MODE = 0, RESET: 1 resets the AD9736.

If PIN_MODE = 1, PD: 1 puts the AD9736 in the power-down state.

F13 CSB/2×

See Serial Peripheral Interface and Pin Mode Operation sections for

pin description.

F14 SDIO/FIFO See the Pin Mode Operation section for pin description.

G13 SCLK/FSC0 See the Pin Mode Operation section for pin description.

G14 SDO/FSC1 See the Pin Mode Operation section for pin description.

H1, H2, H3, H4, H11, H12, H13, H14, J1, J2,

DVDD18 1.8 V Digital Supply.

J3, J4, J11, J12, J13, J14

K1, K2, K3, K4, K11, K12, L2, L3, L4, L5, L6,

DVSS Digital Supply Ground.

L9, L10, L11, L12, M3, M4, M5, M6, M9,

M10, M11, M12

Rev. 0 | Page 11 of 68

Page 12

AD9734/AD9735/AD9736

Pin No. Mnemonic Description

K13, K14 DB<13>−/DB<13>+ Negative/Positive Data Input Bit 13 (MSB); reduced swing LVDS.

L1 PIN_MODE 0 = SPI Mode; SPI enabled.

1 = PIN Mode; SPI disabled, direct pin control.

L7, L8, M7, M8, N7, N8, P7, P8 DVDD33 3.3 V Digital Supply.

L13, L14 DB<12>−/DB<12>+ Negative/Positive Data Input Bit 12; reduced swing LVDS.

M2, M1 DB<0>−/DB<0>+ Negative/Positive Data Input Bit 0 (LSB); reduced swing LVDS.

M13, M14 DB<11>−/DB<11>+ Negative/Positive Data Input Bit 11; reduced swing LVDS.

N1, P1 DB<1>−/DB<1>+ Negative/Positive Data Input Bit 1; reduced swing LVDS.

N2, P2 DB<2>−/DB<2>+ Negative/Positive Data Input Bit 2; reduced swing LVDS.

N3, P3 DB<3>−/DB<3>+ Negative/Positive Data Input Bit 3; reduced swing LVDS.

N4, P4 DB<4>−/DB<4>+ Negative/Positive Data Input Bit 4; reduced swing LVDS..

N5, P5 DB<5>−/DB<5>+ Negative/Positive Data Input Bit 5; reduced swing LVDS.

N6, P6 DATACLK_OUT−/

DATACLK_OUT+

N9, P9 DATACLK_IN−/

DATACLK_IN+

N10, P10 DB<6>−/DB<6>+ Negative/Positive Data Input Bit 6; reduced swing LVDS.

N11, P11 DB<7>−/DB<7>+ Negative/Positive Data Input Bit 7; reduced swing LVDS.

N12, P12 DB<8>−/DB<8>+ Negative/Positive Data Input Bit 8; reduced swing LVDS.

N13, P13 DB<9>−/DB<9>+ Negative/Positive Data Input Bit 9; reduced swing LVDS.

N14, P14 DB<10>−/DB<10>+ Negative/Positive Data Input Bit 10; reduced swing LVDS.

Negative/Positive Data Output Clock; reduced swing LVDS.

Negative/Positive Data Input Clock; reduced swing LVDS

Rev. 0 | Page 12 of 68

Page 13

AD9734/AD9735/AD9736

TERMINOLOGY

Linearity Error (Integral Nonlinearity or INL)

The maximum deviation of the actual analog output from the

ideal output, determined by a straight line drawn from zero to

full scale.

Power Supply Rejection

The maximum change in the full-scale output as the supplies

are varied from nominal to minimum and maximum specified

voltages.

Differential Nonlinearity (DNL)

The measure of the variation in analog value, normalized to full

scale, associated with a 1 LSB change in digital input code.

Monotonicity

A DAC is monotonic if the output either increases or remains

constant as the digital input increases.

Offset Error

The deviation of the output current from the ideal of zero is

called the offset error. For IOUTA, 0 mA output is expected

when the inputs are all 0s. For IOUTB, 0 mA output is expected

when all inputs are set to 1s.

Gain Error

The difference between the actual and ideal output span. The

actual span is determined by the output when all inputs are set

to 1s minus the output when all inputs are set to 0s.

Output Compliance Range

The range of allowable voltage at the output of a current output

DAC. Operation beyond the maximum compliance limits may

cause either output stage saturation or breakdown, resulting in

nonlinear performance.

Temp er at u re D ri ft

Specified as the maximum change from the ambient (25°C)

value to the value at either T

drift, the drift is reported in ppm of full-scale range (FSR)

per °C. For reference drift, the drift is reported in ppm per °C.

MIN

or T

. For offset and gain

MAX

Settling Time

The time required for the output to reach and remain within a

specified error band about its final value, measured from the

start of the output transition.

Glitch Impulse

Asymmetrical switching times in a DAC give rise to undesired

output transients that are quantified by a glitch impulse. It is

specified as the net area of the glitch in pV-s.

Spurious-Free Dynamic Range

The difference, in dB, between the rms amplitude of the output

signal and the peak spurious signal over the specified bandwidth.

Total Harmonic Distortion (THD)

THD is the ratio of the rms sum of the first six harmonic

components to the rms value of the measured input signal. It is

expressed as a percentage or in decibels (dB).

Multitone Power Ratio

The spurious-free dynamic range containing multiple carrier

tones of equal amplitude. It is measured as the difference

between the rms amplitude of a carrier tone to the peak

spurious signal in the region of a removed tone.

Rev. 0 | Page 13 of 68

Page 14

AD9734/AD9735/AD9736

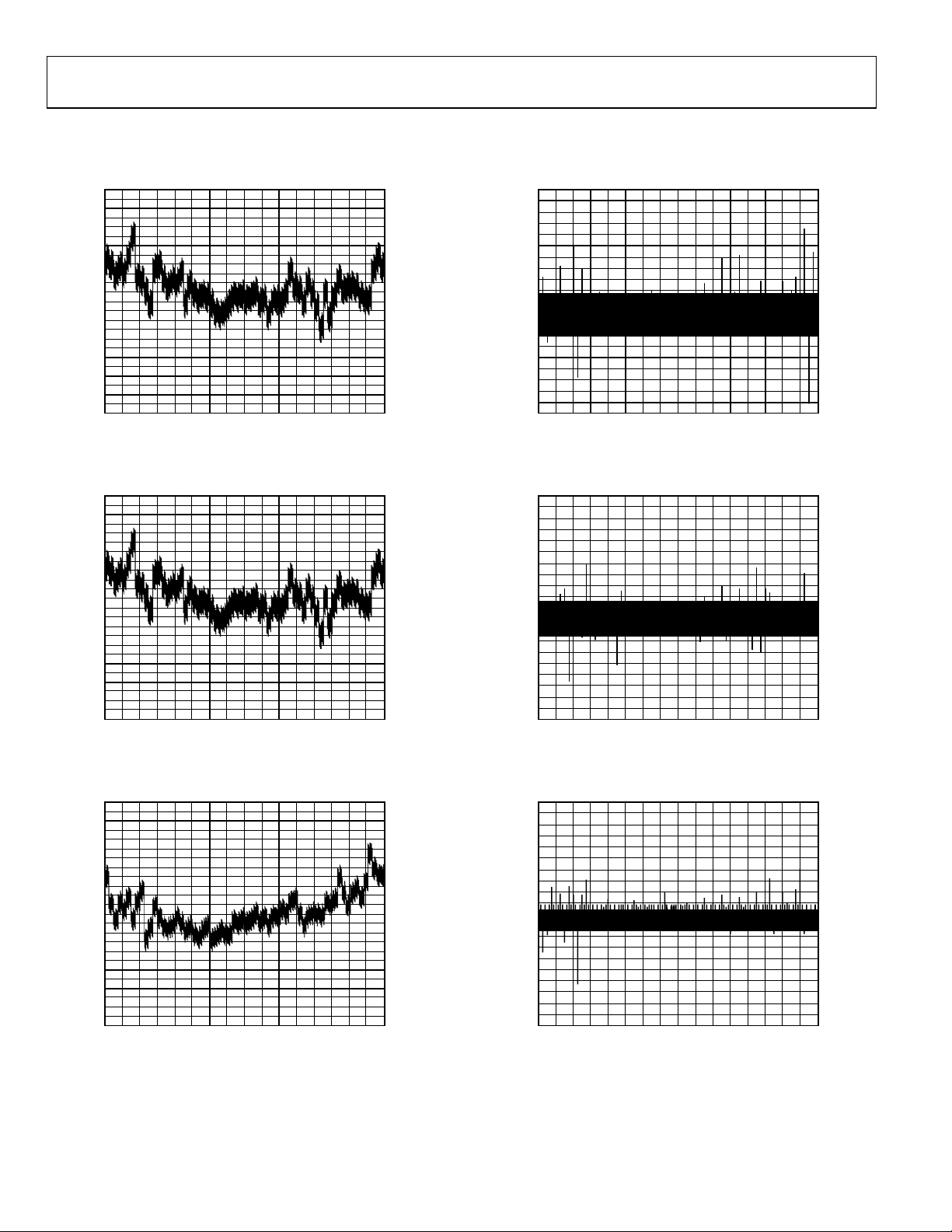

TYPICAL PERFORMANCE CHARACTERISTICS

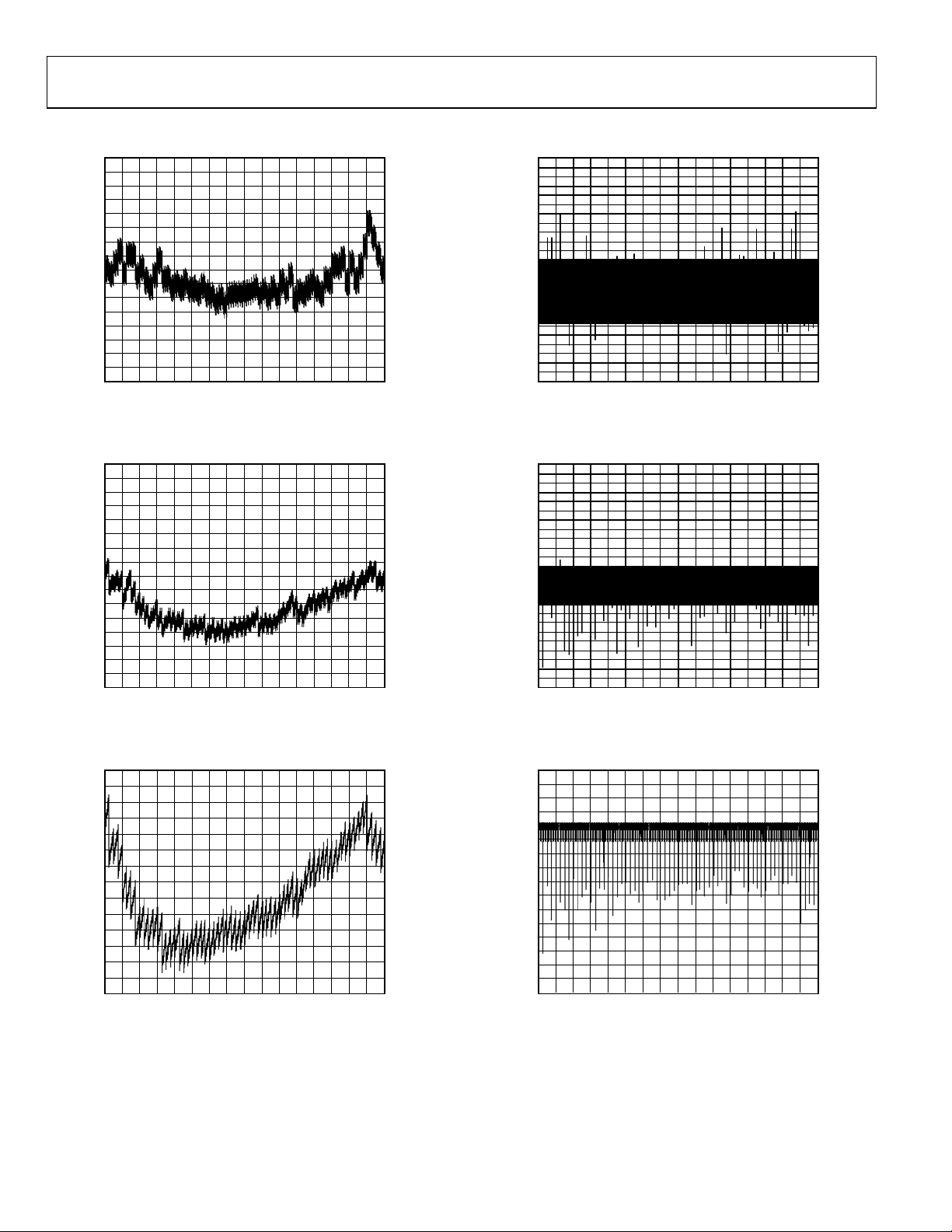

AD9736 STATIC LINEARITY, 10 mA FULL SCALE

1.00

0.75

0.50

0.25

0

–0.25

–0.50

–0.75

ERROR (LSB)

–1.00

–1.25

–1.50

–1.75

–2.00

–0.25

–0.50

–0.75

ERROR (LSB)

–1.00

–1.25

–1.50

–1.75

–2.00

–0.25

–0.50

–0.75

ERROR (LSB)

–1.00

–1.25

–1.50

–1.75

–2.00

CODE

Figure 7. AD9736 INL, −40°C, 10 mA FS

1.00

0.75

0.50

0.25

0

CODE

Figure 8. AD9736 INL, 25°C, 10 mA FS

1.00

0.75

0.50

0.25

0

CODE

Figure 9. AD9736 INL, 85°C, 10 mA FS

163840 2048 4096 6144 8192 10240 12288 14336

04862-008

163840 2048 4096 6144 8192 10240 12288 14336

04862-008

163840 2048 4096 6144 8192 10240 12288 14336

04862-009

1.0

0.8

0.6

0.4

0.2

0

–0.2

ERROR (LSB)

–0.4

–0.6

–0.8

–1.0

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-010

Figure 10. AD9736 DNL, −40°C, 10 mA FS

1.0

0.8

0.6

0.4

0.2

0

–0.2

ERROR (LSB)

–0.4

–0.6

–0.8

–1.0

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-011

Figure 11. AD976 DNL, 25°C, 10 mA FS

1.0

0.8

0.6

0.4

0.2

0

–0.2

ERROR (LSB)

–0.4

–0.6

–0.8

–1.0

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-012

Figure 12. AD9736 DNL, 85°C, 10 mA FS

Rev. 0 | Page 14 of 68

Page 15

AD9734/AD9735/AD9736

AD9736 STATIC LINEARITY, 20 mA FULL SCALE

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

ERROR (LSB)

–0.6

–0.8

–1.0

–1.2

–1.4

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-013

Figure 13. AD9736 INL, −40°C, 20 mA FS

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

ERROR (LSB)

–0.6

–0.8

–1.0

–1.2

–1.4

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-014

Figure 14. AD9736 INL, 25°C, 20 mA FS

1.0

0.8

0.6

0.4

0.2

0

–0.2

–0.4

ERROR (LSB)

–0.6

–0.8

–1.0

–1.2

–1.4

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-015

Figure 15. AD9736 INL, 85°C, 20 mA FS

0.6

0.5

0.4

0.3

0.2

0.1

0

–0.1

ERROR (LSB)

–0.2

–0.3

–0.4

–0.5

–0.6

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-016

Figure 16. AD9736 DNL, −40°C, 20 mA FS

0.6

0.5

0.4

0.3

0.2

0.1

0

–0.1

ERROR (LSB)

–0.2

–0.3

–0.4

–0.5

–0.6

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-017

Figure 17. AD9736 DNL, 25°C, 20 mA FS

0.6

0.5

0.4

0.3

0.2

0.1

0

–0.1

ERROR (LSB)

–0.2

–0.3

–0.4

–0.5

–0.6

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-018

Figure 18. AD9736 DNL, 85°C, 20 mA FS

Rev. 0 | Page 15 of 68

Page 16

AD9734/AD9735/AD9736

AD9736 STATIC LINEARITY, 30 mA FULL SCALE

2.0

1.5

1.0

0.5

0

–0.5

ERROR (LSB)

–1.0

–1.5

–2.0

CODE

Figure 19. AD9736 INL, −40°C, 30 mA FS

2.0

1.5

1.0

0.5

0

–0.5

ERROR (LSB)

–1.0

–1.5

–2.0

CODE

Figure 20. AD9736 INL, 25°C, 30 mA FS

2.0

1.5

1.0

0.5

0

0

0

0

–0.5

–0.5

ERROR (LSB)

–1.0

–1.0

–1.5

–1.5

–2.0

CODE

Figure 21. AD9736 INL, 85°C, 30 mA FS

163840 2048 4096 6144 8192 10240 12288 14336

163840 2048 4096 6144 8192 10240 12288 14336

163840 2048 4096 6144 8192 10240 12288 14336

04862-019

04862-020

04862-021

0.6

0.5

0.4

0.3

0.2

0.1

0

–0.1

ERROR (LSB)

–0.2

–0.3

–0.4

–0.5

–0.6

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-022

Figure 22. AD9736 DNL, −40°C, 30 mA FS

0.6

0.5

0.4

0.3

0.2

0.1

0

–0.1

ERROR (LSB)

–0.2

–0.3

–0.4

–0.5

–0.6

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-023

Figure 23. AD9736 DNL, 25°C, 30 mA FS

1.0

0.5

0

–0.5

–1.0

–1.5

ERROR (LSB)

–2.0

–2.5

–3.0

CODE

163840 2048 4096 6144 8192 10240 12288 14336

04862-024

Figure 24. AD9736 DNL, 85°C, 30 mA FS

Rev. 0 | Page 16 of 68

Page 17

AD9734/AD9735/AD9736

–

–

–

–

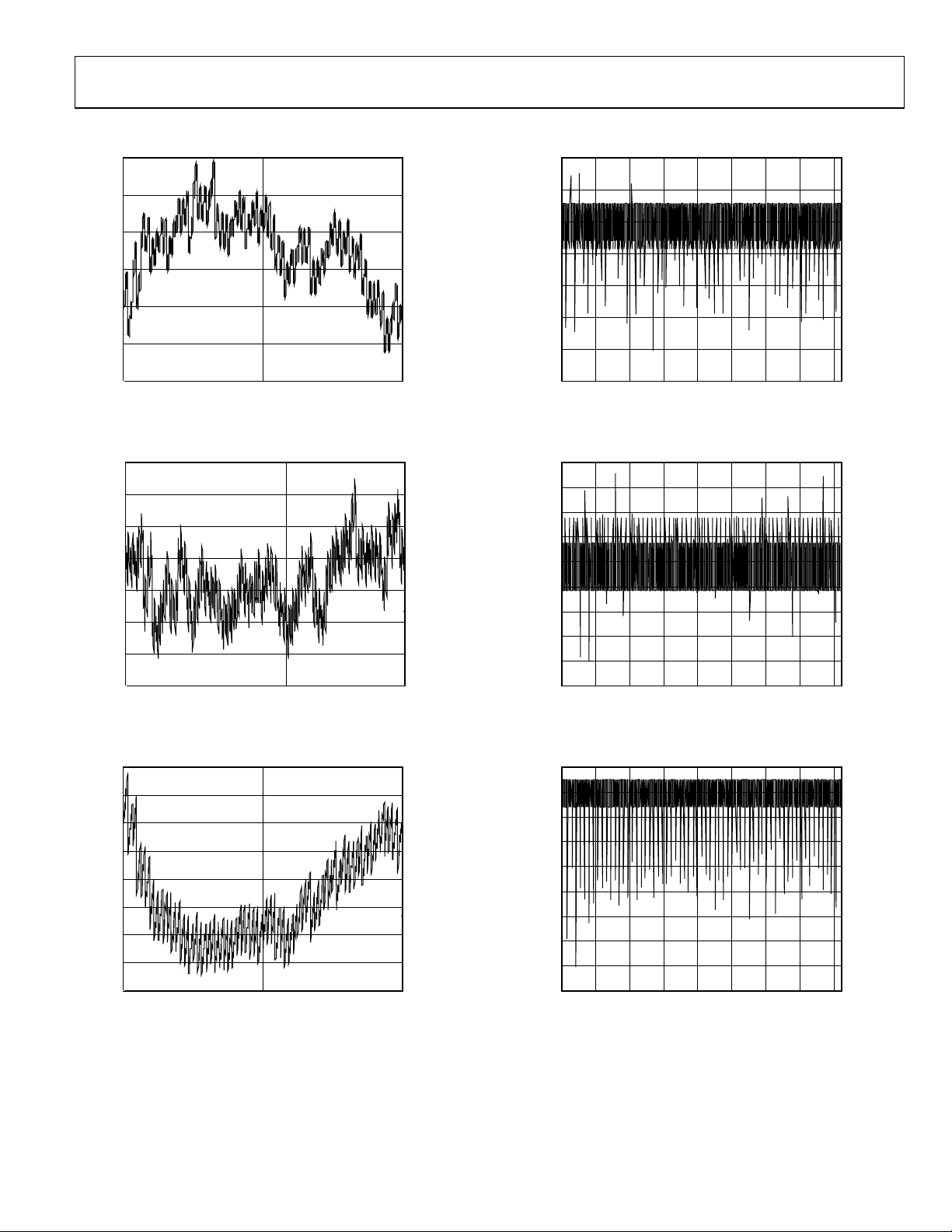

AD9735 STATIC LINEARITY, 10 mA, 20 mA, 30 mA FULL SCALE

0.4

0.100

0.3

0.2

0.1

–0.1

–0.2

0.15

0.10

0.05

0.05

0.10

0.15

0.20

0.2

0.1

–0.1

–0.2

–0.3

–0.4

–0.5

–0.6

0.050

0

–0.050

–0.100

0

40950 2341

04862-025

Figure 25. AD9735 INL, 25°C, 10 mA FS

0

40950 2341

04862-026

Figure 26. AD9735 INL, 25°C, 20 mA FS

0

40950 2341

04862-027

Figure 27. AD9735 INL, 25°C, 30 mA FS

–0.150

–0.200

–0.250

0.100

0.075

0.050

0.025

–0.025

–0.050

–0.075

–0.100

–0.125

0.050

–0.050

–1.000

–1.150

–0.200

–0.250

–0.300

–0.350

–0.400

40950 500 1000 1500 2000 2500 3000 3500

04862-028

Figure 28. AD9735 DNL, 25°C, 10 mA FS

0

40950 500 1000 1500 2000 2500 3000 3500

04862-029

Figure 29. AD9735 DNL, 25°C, 20 mA FS

0

40950 500 1000 1500 2000 2500 3000 3500

04862-030

Figure 30. AD9735 DNL, 25°C, 30 mA FS

Rev. 0 | Page 17 of 68

Page 18

AD9734/AD9735/AD9736

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

AD9734 STATIC LINEARITY, 10 mA, 20 mA, 30 mA FULL SCALE

0.06

0.04

0.04

0.02

0.02

0.04

0.06

0.03

0.02

0.01

0.01

0.02

0.03

0.04

0.05

0.06

0.06

0.04

0.02

0.02

0.04

0.06

0.08

0.10

0.12

0.03

0.02

0

10230 100 200 300 400 500 600 800 900700

04862-031

Figure 31. AD9734 INL, 25°C, 10 mA FS

0

10230 100 200 300 400 500 600 800 900700

04862-032

Figure 32. AD9734 INL, 25°C, 20 mA FS

0

10230 100 200 300 400 500 600 800 900700

04862-033

Figure 33. AD9734 INL, 25°C, 30 mA FS

0.01

0.01

0.02

0.03

0.02

0.01

0.01

0.02

0.03

0.01

0.01

0.02

0.03

0.04

0.05

0.06

0

10230 100 200 300 400 500 600 800 900700

04862-034

Figure 34. AD9734 DNL, 25°C, 10 mA FS

0

10230 100 200 300 400 500 600 800 900700

04862-035

Figure 35. AD9734 DNL, 25°C, 20 mA FS

0

10230 100 200 300 400 500 600 800 900700

04862-036

Figure 36. AD9734 DNL, 25°C, 30 mA FS

Rev. 0 | Page 18 of 68

Page 19

AD9734/AD9735/AD9736

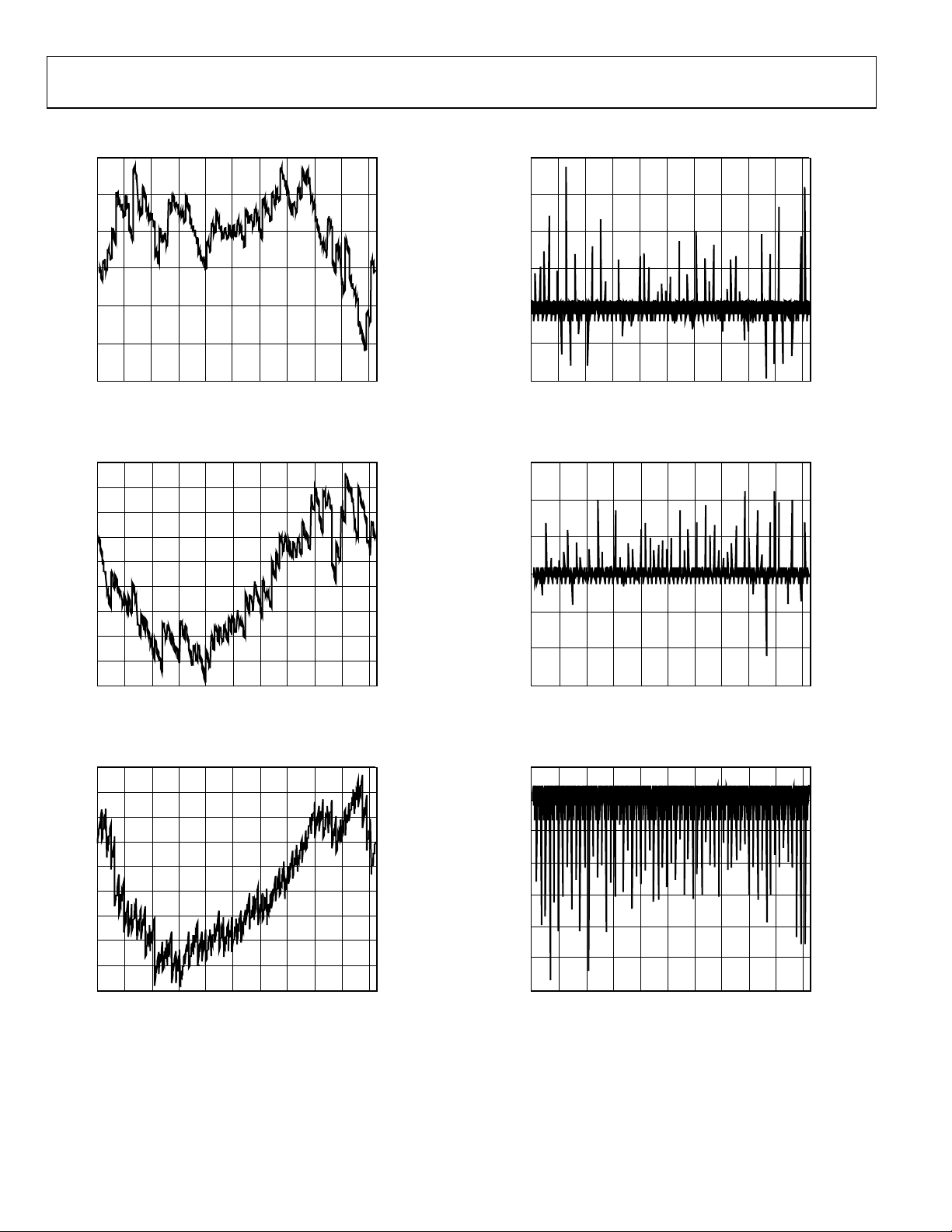

AD9736 POWER CONSUMPTION, 20 mA FULL SCALE

0.50

0.45

0.40

0.35

0.30

0.25

0.20

POWER (W)

0.15

0.10

0.05

0

f

DAC

Figure 37. AD9736 1× Mode Power vs. f

(MHz)

TOTAL

AVDD33

DVDD18

CVDD18

DVDD33

at 25°C

DAC

15000 250 500 750 1000 1250

04862-037

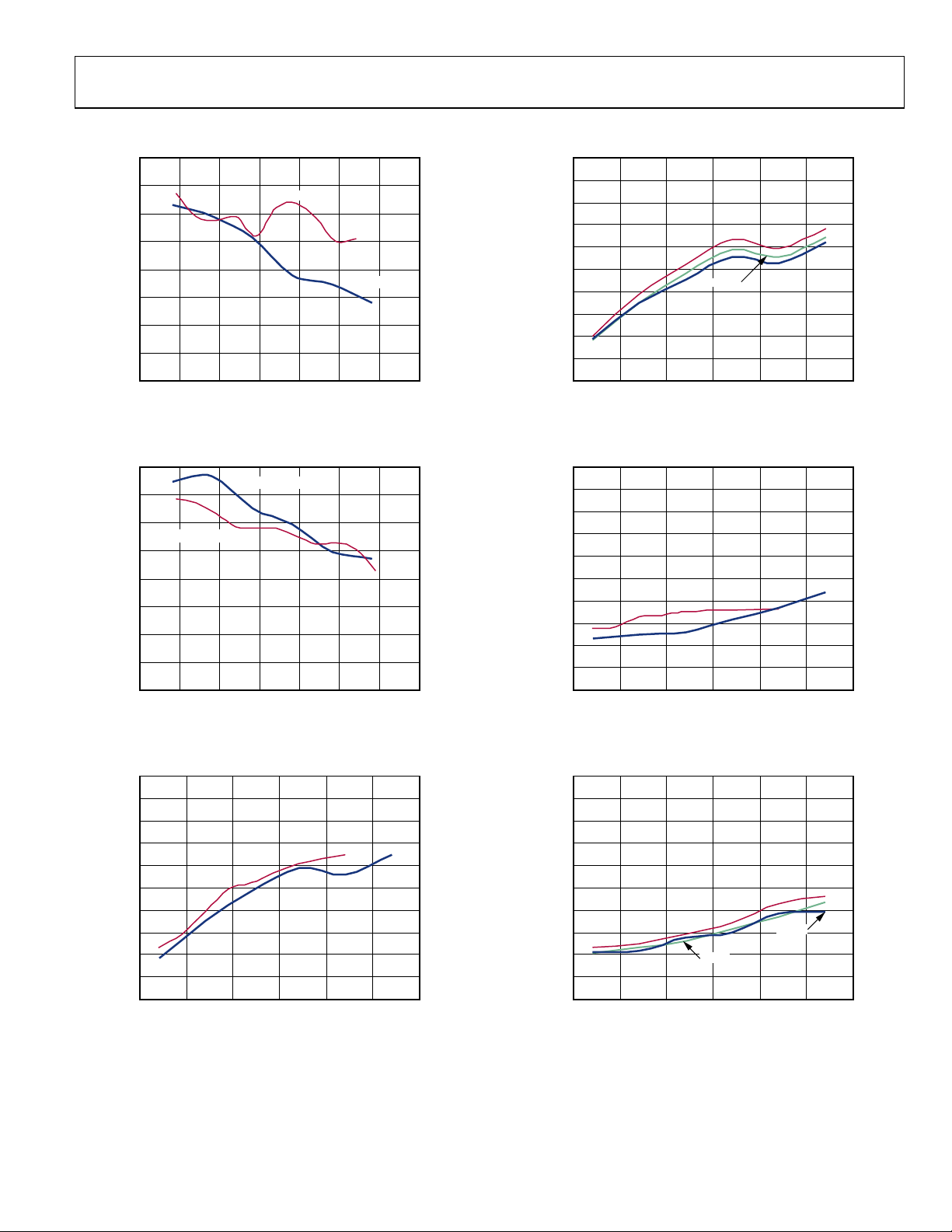

AD9736 DYNAMIC PERFORMANCE, 20 mA FULL SCALE

80

0.7

0.6

0.5

0.4

0.3

POWER (W)

0.2

0.1

0

AVDD33

f

DAC

(MHz)

TOTAL

Figure 38. AD9736, 2× Interpolation Mode Power vs. f

80

DVDD18

VCDD18

DVDD33

DAC

15000 250 500 750 1000 1250

04862-038

at 25°C

75

70

65

SFDR (dBc)

60

55

50

Figure 39. AD9736 SFDR vs. f

78

76

74

72

70

68

66

64

SFDR (dBc)

62

60

58

56

54

52

Figure 41. AD9736 SFDR vs. f

800MSPS

1.2GSPS

1GSPS

f

(MHz)

OUT

over f

OUT

DAC

f

(MHz)

OUT

over 50 parts, 25°C, 1.2 GSPS

OUT

at 25°C

75

70

65

SFDR (dBc)

60

55

6000 50 100 150 200 250 300 350 400 450 500 550

04862-039

50

Figure 40. AD9736 SFDR vs. f

92

90

88

86

84

82

80

78

76

74

IMD (dBc)

72

70

68

66

64

62

60

5500 50 100 150 200 250 300 350 400 450 500

04862-041

58

f

Figure 42. AD9736 IMD vs. f

+85°C

+25°C

f

(MHz)

OUT

over Temperature

OUT

(MHz)

OUT

over 50 parts, 25°C,1.2 GSPS

OUT

–40°C

6000 50 100 150 200 250 300 350 400 450 500 550

04862-040

5500 50 100 150 200 250 300 350 400 450 500

04862-042

Rev. 0 | Page 19 of 68

Page 20

AD9734/AD9735/AD9736

90

85

80

1GSPS

90

85

80

THIRD-ORDER IMD

SFDR

75

70

IMD (dBc)

65

60

55

50

Figure 43. AD9736 IMD vs. f

90

85

80

75

70

IMD (dBc)

65

60

55

50

Figure 44. AD9736 IMD vs. f

95

90

85

80

75

70

IMD AND SFDR (dBc)

65

60

55

800MSPS

+85°C

f

(MHz)

OUT

over f

OUT

DAC

–40°C

+25°C

f

(MHz)

OUT

over Temperature, 1.2 GSPS

OUT

IMD

f

(MHz)

OUT

Figure 45. AD9736 Low Frequency IMD and SFDR vs. f

1.2GSPS

at 25°C

SFDR

, 25°C, 1.2 GSPS

OUT

75

70

65

SFDR, IMID (dBc)

60

55

6000 100 200 300 400 500

04862-043

6000 100 200 300 400 500

04862-044

100010

04862-045

50

f

OUT

Figure 46. AD9736 IMD and SFDR vs. f

80

75

70

65

60

55

SFDR (dBc)

50

45

40

0dBFS

–12dBFS

f

OUT

Figure 47. AD9736 SFDR vs. f

90

85

80

75

70

IMD (dBc)

65

60

55

50

0dBFS

–6dBFS

f

OUT

Figure 48. AD9736 IMD vs. f

(MHz)

, 25°C, 1.2 GSPS, 2× Interpolation

OUT

–6dBFS

(MHz)

OUT

(MHz)

OUT

over A

over A

–12dBFS

, 25°C, 1.2 GSPS

OUT

, 25°C, 1.2 GSPS

OUT

3500 50 100 150 200 250 300

04862-046

6000 100 200 300 400 500

04862-047

6000 100 200 300 400 500

04862-048

Rev. 0 | Page 20 of 68

Page 21

AD9734/AD9735/AD9736

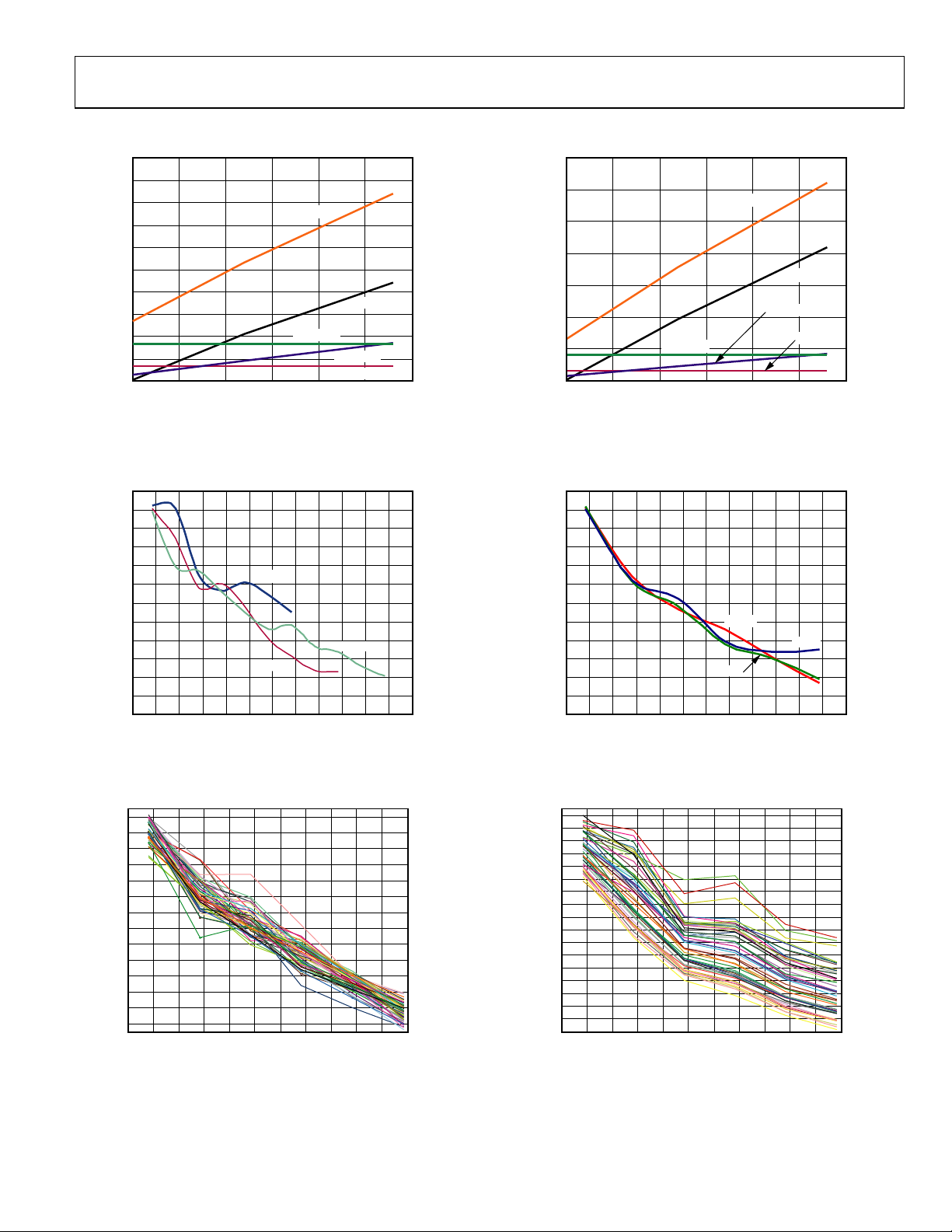

AD9736 DYNAMIC PERFORMANCE, 20 mA FULL SCALE

90

85

80

75

70

65

SFDR, IMD (dBc)

60

55

50

Figure 49. AD9736 SFDR vs. f

90

85

80

THIRD-ORDER IMD_2×

75

70

65

SFDR, IMD (dBc)

60

55

50

Figure 50. AD9736 IMD vs. f

–150

–152

–154

–156

–158

–160

–162

NSD (dBm/Hz)

–164

–166

–168

–170

Figure 51. AD9736 1-Tone NSD vs. f

SFDR_2×

SFDR_1×

f

(MHz)

OUT

, 25°C, 1.2 GSPS, 1× and 2× Interpolation

OUT

THIRD-ORDER IMD_1×

f

(MHz)

OUT

, 25°C, 1.2 GSPS, 1× and 2× Interpolation

OUT

1GSPS

1.2GSPS

f

(MHz)

OUT

over f

DAC

, 25°C

OUT

3500 50 100 150 200 250 300

04862-049

3500 50 100 150 200 250 300

04862-050

6000 100 200 300 400 500

04862-051

–150

–152

–154

–156

–158

–160

–162

NSD (dBm/Hz)

–164

–166

–168

–170

Figure 52. AD9736 1-Tone NSD vs. f

–150

–152

–154

–156

–158

–160

–162

NSD (dBm/Hz)

–164

–166

–168

–170

1GSPS

Figure 53. AD9736 8-Tone NSD vs. f

–150

–152

–154

–156

–158

–160

–162

NSD (dBm/Hz)

–164

–166

–168

–170

Figure 54. AD9736 8-Tone NSD vs. f

f

f

f

+85°C

+25°C

(MHz)

OUT

over Temperature, 1.2 GSPS

OUT

1.2GSPS

(MHz)

OUT

over f

OUT

+85°C

+25°C

(MHz)

OUT

over Temperature, 1.2 GSPS

OUT

–40°C

DAC

–40°C

6000 100 200 300 400 500

04862-052

6000 100 200 300 400 500

04862-053

, 25°C

6000 100 200 300 400 500

04862-054

Rev. 0 | Page 21 of 68

Page 22

AD9734/AD9735/AD9736

–157

–158

–159

–160

–161

–162

NSD (dBm/Hz)

–163

–164

–165

–166

f

OUT

Figure 55. AD9736 1-Tone NSD vs. f

(MHz)

over 50 Parts, 1.2 GSPS, 25°C

OUT

5500 50 100 150 200 250 300 350 400 450 500

04862-055

AD9736, AD9735, AD9734 WCDMA ACLR, 20 mA FULL SCALE

REF –22.75dBm

#AVG

LOG 10dB/

#ATTEN 6dB

–161

–162

–163

–164

NSD (dBm/Hz)

–165

–166

–167

Figure 56. AD9736 1-Tone NSD vs. f

f

(MHz)

OUT

over 50 Parts, 1.2 GSPS, 25°C

OUT

5500 50 100 150 200 250 300 350 400 450 500

04862-056

PAVG

10

W1 S2

CENTER 134.83MHz

#RES BW 30kHz

RMS RESULTS OFFSET FREQ REF BW dBc dBm dBc dBm

CARRIER POWER 5.00MHz 3.840MHz –81.65 –92.37 –81.39 –92.11

–10.72dBm/ 10.0MHz 3.840MHz –82.06 –92.78 –82.43 –93.16

3.84000MHz 15.0MHz 3.884MHz –82.11 –92.83 –82.39 –93.11

Figure 57. AD9736 WCDMA Carrier at 134.83 MHz, f

VBW 300kHz SPAN 33.88MHz

LOWER UPPER

= 491.52 MSPS

DAC

SWEEP 109.9ms (601pts)

04862-057

Rev. 0 | Page 22 of 68

Page 23

AD9734/AD9735/AD9736

REF –22.75dBm

#AVG

LOG 10dB/

#ATTEN 6dB

PAVG

10 S2

CENTER 134.83MHz

#RES BW 30kHz

RMS RESULTS OFFSET FREQ REF BW dBc dBm dBc dBm

CARRIER POWER 5.00MHz 3.840MHz –80.32 –91.10 –80.60 –91.38

–10.72dBm/ 10.0MHz 3.840MHz –81.13 –91.91 –80.75 –91.53

3.84000MHz 15.0MHz 3.884MHz –80.43 –91.21 –81.36 –92.13

Figure 58. AD9735 WCDMA Carrier at 134.83 MHz, f

VBW 300kHz

SWEEP 109.9ms (601pts)

LOWER UPPER

= 491.52 MSPS

DAC

REF –22.75dBm

#AVG

LOG 10dB/

PAVG

10 S2

CENTER 134.83MHz

#RES BW 30kHz

RMS RESULTS OFFSET FREQ REF BW dBc dBm dBc dBm

CARRIER POWER 5.00MHz 3.840MHz –71.07 –81.83 –71.23 –81.99

–10.76dBm/ 10.0MHz 3.840MHz –70.55 –81.31 –71.42 –82.19

3.84000MHz 15.0MHz 3.884MHz –70.79 –81.56 –71.25 –82.01

#ATTEN 6dB

VBW 300kHz

LOWER UPPER

Figure 59. AD9734 WCDMA Carrier at 134.83 MHz, f

= 491.52 MSPS

DAC

SWEEP 109.9ms (601pts)

SPAN 33.88MHz

04862-058

04862-059

SPAN 33.88MHz

Rev. 0 | Page 23 of 68

Page 24

AD9734/AD9735/AD9736

AD9735, AD9734 DYNAMIC PERFORMANCE, 20 mA FULL SCALE

80

90

IMD (dBc)

NSD (dBc/Hz)

NSD (dBc/Hz)

–150

–152

–154

–156

–158

–160

–162

–164

–166

–168

–170

–145

–147

–149

–151

–153

–155

–157

–159

–161

–163

–165

85

80

75

70

65

60

55

50

Figure 63. AD9734 IMD vs. f

Figure 64. AD9735 NSD vs. f

Figure 65. AD9734 NSD vs. f

1GSPS

8 TONES

f

OUT

8 TONES

f

OUT

f

OUT

(MHz)

(MHz)

(MHz)

OUT

1 TONE

over f

800MSPS

DAC

, 1.2 GSPS

OUT

, 1.2 GSPS

OUT

1.2GSPS

, 1.2 GSPS

1 TONE

6000 50 100 150 200 250 300 350 400 450 500 550

04862-063

6000 50 100 150 200 250 300 350 400 450 500 550

04862-064

6000 50 100 150 200 250 300 350 400 450 500 550

04862-065

75

70

65

SFDR (dBc)

60

55

50

Figure 60. AD9735 SFDR vs. f

800MSPS

1GSPS

f

OUT

(MHz)

OUT

over f

, 1.2 GSPS

DAC

1.2GSPS

6000 50 100 150 200 250 300 350 400 450 500 550

04862-060

80

75

70

65

SFDR (dBc)

60

55

50

Figure 61. AD9734 SFDR vs. f

800MSPS

1GSPS

f

OUT

(MHz)

OUT

over f

, 1.2 GSPS

DAC

1.2GSPS

6000 50 100 150 200 250 300 350 400 450 500 550

04862-061

90

85

80

800MSPS

75

70

IMD (dBc)

65

60

55

50

Figure 62. AD9735 IMD vs. f

1GSPS

f

OUT

(MHz)

1.2GSPS

OUT

over f

, 1.2 GSPS

DAC

6000 50 100 150 200 250 300 350 400 450 500 550

04862-062

Rev. 0 | Page 24 of 68

Page 25

AD9734/AD9735/AD9736

SPI REGISTER MAP

Write 0 to unspecified or reserved bit locations. Reading these bits returns unknown values.

Table 6. SPI Register Map

ADR

ADR

Hex

Register

Name

Dec

0 00 MODE SDIO_DIR LSBFIRST RESET LONG_INS 2X MODE FIFO MODE DATAFRMT PD 00 00

1 01 IRQ LVDS SYNC CROSS RESV’D IE_LVDS IE_SYNC IE_CROSS RESV’D 00 00

2 02 FSC_1 SLEEP FSC<9> FSC<8> 02 02

3 03 FSC_2 FSC<7> FSC<6> FSC<5> FSC<4> FSC<3> FSC<2> FSC<1> FSC<0> 00 00

4 04 LVDS_CNT1 MSD<3> MSD<2> MSD<1> MSD<0> MHD<3> MHD<2> MHD<1> MHD<0> 00 00

5 05 LVDS_CNT2 SD<3> SD<2> SD<1> SD<0> LCHANGE ERR_HI ERR_LO CHECK 00 00

6 06 LVDS_CNT3 LSURV LAUTO LFLT<3> LFLT<2> LFLT<1> LFLT<0> LTRH<1> LTRH<0> 00 00

7 07 SYNC_CNT1 FIFOSTAT3 FIFOSTAT2 FIFOSTAT1 FIFOSTAT0 VALID SCHANGE PHOF<1> PHOF<0> 00 00

8 08 SYNC_CNT2 SSURV SAUTO SFLT<3> SFLT<2> SFLT<1> SFLT<0> RESV’D STRH<0> 00 00

9 09 RESERVED

10 0A CROS_CNT1 UPDEL<5> UPDEL<4> UPDEL<3> UPDEL<2> UPDEL<1> UPDEL<0> 00 00

11 0B CROS_CNT2 DNDEL<5> DNDEL<4> DNDEL<3> DNDEL<2> DNDEL<1> DNDEL<0> 00 00

12 0C RESERVED

13 0D RESERVED

14 0E ANA_CNT1 MSEL<1> MSEL<0> TRMBG<2> TRMBG<1> TRMBG<0> C0 C0

15 0F ANA_CNT2 HDRM<7> HDRM<6> HDRM<5> HDRM<4> HDRM<3> HDRM<2> HDRM<1> HDRM<0> CA CA

16 10 RESERVED

17 11 BIST_CNT SEL<1> SEL<0> SIG_READ LVDS_EN SYNC_EN CLEAR 00 00

18 12 BIST<7:0>

19 13 BIST<15:8>

20 14 BIST<23:16>

21 15 BIST<31:24>

22 16 CCLK_DIV RESV’D RESV’D RESV’D RESV’D CCD<3> CCD<2> CCD<1> CCD<0> 00 00

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Default

Hex

Pin Mode

Hex

Rev. 0 | Page 25 of 68

Page 26

AD9734/AD9735/AD9736

SPI REGISTER DESCRIPTIONS

Reading these registers returns previously written values for all defined register bits, unless otherwise noted. Reset value for write registers

in bold text.

MODE REGISTER (REG 00)

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x00 MODE SDIO_DIR LSB/MSB RESET LONG_INS 2× MODE FIFO MODE DATAFRMT PD

Table 7. MODE Register Bit Descriptions

Bit Name Read/Write Description

SDIO_DIR : WRITE ->

LSBFIRST : WRITE ->

RESET : WRITE->

LONG_INS : WRITE ->

2×_MODE : WRITE ->

FIFO_MODE : WRITE ->

DATAFRMT : WRITE ->

PD : WRITE ->

0, Input only per SPI standard

1, Bidirectional per SPI standard

0, MSB first per SPI standard

1, LSB first per SPI standard

NOTE: Only change LSB/MSB order in single-byte instructions to avoid erratic behavior due to bit order

errors.

0, Execute software reset of SPI and controllers, reload default register values except registers 0x00 and

0x04

1, Set software reset, write 0 on the next (or any following) cycle to release the reset

0, Short (single-byte) instruction word

1, Long (two-byte) instruction word, not necessary since the maximum internal address is REG31 (0x1F)

0, Disable 2× interpolation filter

1, Enable 2× interpolation filter

0, Disable FIFO synchronization

1, Enable FIFO synchronization

0, Signed input DATA with midscale = 0x0000

1, Unsigned input DATA with midscale = 0x2000

0, Enable LVDS Receiver, DAC, and clock circuitry

1, Power down LVDS Receiver, DAC, and clock circuitry

INTERRUPT REQUEST REGISTER (IRQ) (REG 01)

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x01 IRQ LVDS SYNC CROSS RESV’D IE_LVDS IE_SYNC IE_CROSS RESV’D

Table 8. Interrupt Register Bit Descriptions

Bit Name Read/Write Description

LVDS : WRITE -> Don’t Care

: READ ->

SYNC : WRITE -> Don’t Care

: READ ->

CROSS : WRITE -> Don’t Care

: READ ->

IE_LVDS : WRITE ->

IE_SYNC : WRITE ->

IE_CROSS : WRITE ->

0, No active LVDS receiver interrupt

1, Interrupt in LVDS receiver occurred

0, No active SYNC logic interrupt

1, Interrupt in SYNC logic occurred

0, No active CROSS logic interrupt

1, Interrupt in CROSS logic occurred

0, Reset LVDS receiver interrupt and disable future LVDS receiver interrupts

1, Enable LVDS receiver interrupt to activate IRQ pin

0, Reset SYNC logic interrupt and disable future SYNC logic interrupts

1, Enable SYNC logic interrupt to activate IRQ pin

0, Reset CROSS logic interrupt and disable future CROSS logic interrupts

1, Enable CROSS logic interrupt to activate IRQ pin

Rev. 0 | Page 26 of 68

Page 27

AD9734/AD9735/AD9736

FULL SCALE CURRENT (FSC) REGISTER (REGS 02, 03)

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x02 FSC_1 SLEEP FSC<9> FSC<8>

0x03 FSC_2 FSC<7> FSC<6> FSC<5> FSC<4> FSC<3> FSC<2> FSC<1> FSC<0>

Table 9. Full Scale Output Register Bit Descriptions

Bit Name Read/Write Description

SLEEP : WRITE ->

FSC<9:0> : WRITE ->

LVDS CONTROLLER (LVDS_CNT) REGISTER (REGS 04, 05, 06)

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x04 LVDS_CNT1 MSD<3> MSD<2> MSD<1> MSD<0> MHD<3> MHD<2> MHD<1> MHD<0>

0x05 LVDS_CNT2 SD<3> SD<2> SD<1> SD<0> LCHANGE ERR_HI ERR_LO CHECK

0x06 LVDS_CNT3 LSURV LAUTO LFLT<3> LFLT<2> LFLT<1> LFLT<0> LTRH<1> LTRH<0>

Table 10. LVDS Controller Register Bit Descriptions

Bit Name Read/Write Description

MSD<3:0> : WRITE ->

: READ ->

MHD<3:0> : WRITE ->

: READ ->

SD<3:0> : WRITE->

: READ ->

LCHANGE : READ ->

ERR_HI : READ -> One of the 15 LVDS inputs is above the input voltage limits of the IEEE reduce link specification.

ERR_LO : READ -> One of the 15 LVDS inputs is below the input voltage limits of the IEEE reduced link specification.

CHECK : READ ->

LSURV : WRITE ->

LAUTO : WRITE ->

LFLT<3:0> : WRITE ->

LTRH<2:0> : : WRITE ->

0x0, Set setup delay for the measurement system

If ( LAUTO = 1) the latest measured value for the setup delay

If ( LAUTO = 0) read back of the last SPI write to this bit

0x0, Set hold delay for the measurement system

If ( LAUTO = 1) the latest measured value for the hold delay

If ( LAUTO = 0) read back of the last SPI write to this bit

0x0, Set sample delay

If ( LAUTO = 1) the result of a measurement cycle is stored in this register

If ( LAUTO = 0) read back of the last SPI write to this bit

0, No change from previous measurement

1, Change in value from the previous measurement

NOTE: The average filter and the threshold detection are not applied to this bit

0, Phase measurement—sampling in the previous or following DATA cycle

1, Phase measurement—sampling in the correct DATA cycle

0, The controller stops after completion of the current measurement cycle

1, Continuous measurements are taken and an interrupt is issued if the clock alignment drifts beyond the

threshold value

0, Sample delay is not automatically updated

1, Continuously starts measurement cycles and updates the sample delay according to the measurement

NOTE: LSURV (Reg 06, Bit 7) must be set to 1 and the LVDS IRQ (Reg 01 Bit 3) must be set to 0 for AUTO mode

0x0, Average filter length, Delay = Delay + Delta Delay / 2^ LFLT<3:0>, values greater than 12 (0x0C) are

clipped to 12

000, Set auto update threshold values

0, Enable DAC output

1, Set DAC output current to 0 mA

0x000, 10 mA full-scale output current

0x200, 20 mA full-scale output current

0x3FF, 30 mA full-scale output current

Rev. 0 | Page 27 of 68

Page 28

AD9734/AD9735/AD9736

SYNC CONTROLLER (SYNC_CNT) REGISTER (REGS 07, 08)

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x07 SYNC_CNT1 FIFOSTAT3 FIFOSTAT2 FIFOSTAT1 FIFOSTAT0 VALID SCHANGE PHOF<1> PHOF<0>

0x08 SYNC_CNT2 SSURV SAUTO SFLT<3> SFLT<2> SFLT<1> SFLT<0> RESV’D STRH<0>

Table 11. SYNC Controller Register Bit Descriptions

Bit Name Read/Write Description

FIFOSTAT<2:0> : READ -> Position of FIFO read counter, range from 0 to 7

FIFOSTAT<3> : READ ->

VALID : READ ->

SCHANGE : READ ->

PHOF<1:0> : WRITE ->

: READ ->

SSURV : WRITE ->

SAUTO : WRITE ->

SFLT<3:0> : WRITE ->

STRH<0> : WRITE ->

0, SYNC logic OK

1, Error in SYNC logic

0, FIFOSTAT<3:0> is not valid yet

1, FIFOSTAT<3:0> is valid after a reset

0, No change in FIFOSTAT<3:0>

1, FIFOSTAT<3:0> has changed since the previous measurement cycle when SSURV =

1 (surveillance mode active)

00, Change the readout counter

Current setting of the readout counter (PHOF<1:0>) in surveillance mode (SSURV = 1)

after an interrupt

Current calculated optimal readout counter value in AUTO mode (SAUTO = 1)

0, The controller stops after completion of the current measurement cycle

1, Continuous measurements are taken and an interrupt is issued if the readout

counter drifts beyond the threshold value

0, Readout counter (PHOF<3:0>) is not automatically updated

1, Continuously starts measurement cycles and updates the readout counter

according to the measurement

NOTE: SSURV (Reg 08 Bit 7) must be set to 1 and the SYNC IRQ (Reg 01 Bit 2) must be

set to 0 for AUTO mode

0x0, Average filter length, FIFOSTAT = FIFOSTAT + Delta FIFOSTAT/2 ^ SFLT<3:0>,

values greater than 12 (0x0C) are clipped to 12

0, If FIFOSTAT<2:0> = 0 | 7, generate a SYNC interrupt

1, If FIFOSTAT<2:0> = 0 | 1 | 6 | 7, generate a SYNC interrupt

CROSS CONTROLLER (CROS_CNT) REGISTER (REGS 10, 11)

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x0A CROS_CNT1 – – UPDEL<5> UPDEL<4> UPDEL<3> UPDEL<2> UPDEL<1> UPDEL<0>

0x0B CROS_CNT2 – – DNDEL<5> DNDEL<4> DNDEL<3> DNDEL<2> DNDEL<1> DNDEL<0>

Table 12. Cross Controller Register Description

Bit Name Read/Write Description

UPDEL<5:0> : WRITE ->

DNDEL<5:0> : WRITE ->

0x00, Move the differential output stage switching point up, set to 0 if DNDEL is non-zero

0x00, Move the differential output stage switching point down, set to 0 if UPDEL is non-zero

Rev. 0 | Page 28 of 68

Page 29

AD9734/AD9735/AD9736

ANALOG CONTROL (ANA_CNT) REGISTER (REGS 14, 15)

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x0E ANA_CNT1 MSEL<1> MSEL<0> – – – TRMBG<2> TRMBG<1> TRMBG<0>

0x0F ANA_CNT2 HDRM<7> HDRM<6> HDRM<5> HDRM<4> HDRM<3> HDRM<2> HDRM<1> HDRM<0>

Table 13. Analog Control Register Bit Descriptions

Bit Name Read/Write Description

MSEL<1:0> : WRITE ->

TRMBG<2:0> : WRITE ->

HDRM<7:0> : WRITE ->

BUILT-IN SELF TEST CONTROL (BIST_CNT) REGISTERS (REGS 17, 18, 19, 20, 21)

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x11 BIST_CNT SEL<1> SEL<0> SIG_READ LVDS_EN SYNC_EN CLEAR

0x12 BIST<7:0> BIST<7> BIST<6> BIST<5> BIST<4> BIST<3> BIST<2> BIST<1> BIST<0>

0x13 BIST<15:8> BIST<15> BIST<14> BIST<13> BIST<12> BIST<11> BIST<10> BIST<9> BIST<8>

0x14 BIST<23:16> BIST<23> BIST<22> BIST<21> BIST<20> BIST<19> BIST<18> BIST<17> BIST<16>

0x15 BIST<31:24> BIST<31> BIST<30> BIST<29> BIST<28> BIST<27> BIST<26> BIST<25> BIST<24>

Table 14. BIST Register Bit Descriptions

Bit Name Read/Write Description

SEL<1:0> : WRITE ->

SIG_READ : WRITE ->

LVDS_EN WRITE->

SYNC_EN : WRITE ->

CLEAR : WRITE ->

BIST<31:0> : READ -> Results of the built-in self test

00, Write result of the LVDS Phase 1 BIST to BIST<31:0>

01, Write result of the LVDS Phase 2 BIST to BIST<31:0>

10, Write result of the SYNC Phase 1 BIST to BIST<31:0>

11, Write result of the SYNC Phase 2 BIST to BIST<31:0>

0, No action

1, Enable BIST signature readback

0, No action

1, Enable LVDS BIST

0, No action

1, Enable SYNC BIST

0, No action

1, Clear all BIST registers

00, Mirror roll off frequency control = bypass

01, Mirror roll off frequency control = narrowest bandwidth

10, Mirror roll off frequency control = medium bandwidth

11, Mirror roll off frequency control = widest bandwidth

NOTE: See plot in the Analog Control Registers section.

000, Band gap temperature characteristic trim

NOTE: See the plot in the Analog Control Registers section.

0xCA, Output stack headroom control

HDRM<7:4> set reference offset from AVDD33 (VCAS centering)

HDRM<3:0> set overdrive (current density) trim (temperature tracking)

Note: Set to 0xCA for optimum performance

Rev. 0 | Page 29 of 68

Page 30

AD9734/AD9735/AD9736

CONTROLLER CLOCK PREDIVIDER (CCLK_DIV) READING REGISTER (REG 22)

ADR Name Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x16 CCLK_DIV RESV’D RESV’D RESV’D RESV’D CCD<3> CCD<2> CCD<1> CCD<0>

Table 15. Clock Predivider Register Bit Descriptions

Bit Name Read/Write Description

CCD<3:0> : WRITE ->

0x0, Controller clock = DACCLK/16

0x1, Controller clock = DACCLK/32

0x2, Controller clock = DACCLK/64 …

0xF, Controller clock = DACCLK/524288

NOTE: The 100 MHz to 1.2 GHz DACCLK must be divided to less than 10 MHz for correct operation.

CCD<3:0> must be programmed to divide the DACCLK so that this relationship is not violated.

Controller Clock = DACCLK/(2 ^ ( CCD<3:0> + 4 ))

Rev. 0 | Page 30 of 68

Page 31

AD9734/AD9735/AD9736

THEORY OF OPERATION

The AD9736, AD9735, and AD9734 are 14-, 12-, and 10-bit

DACs that run at an update rate up to 1.2 GSPS. Input data can

be accepted up to the full 1.2 GSPS rate, or a 2× interpolation

filter may be enabled (2× mode) allowing full speed operation

with a 600 MSPS input data rate. DATA and DATACLK_IN

inputs are parallel LVDS, meeting the IEEE reduced swing

LVDS specifications with the exception of input hysteresis. The

DATACLK_IN input runs at one-half the input DATA rate in a

double data rate (DDR) format. Each edge of DATACLK_IN is

used to transfer DATA into the AD9736, as shown in Figure 77.

The DACCLK−/DACCLK+ inputs (Pins E1, F1) directly

drive the DAC core to minimize clock jitter. The DACCLK

signal is also divided by 2 (1× and 2× mode), then output as the

DATACLK_OUT. The DATACLK_OUT signal is used to clock

the data source. The DAC expects DDR LVDS data (DB<13:0>)

aligned with the DDR input clock (DATACLK_IN) from a

circuit similar to the one shown in Figure 94. Table 16 shows

the clock relationships.

Table 16. AD973x Clock Relationship

MODE DACCLK DATACLK_OUT DATACLK_IN DATA

1× 1.2 GHz 600 MHz 600 MHz 1.2 GSPS

2× 1.2 GHz 600 MHz 300 MHz 600 MSPS

Maintaining correct alignment of data and clock is a common

challenge with high speed DACs, complicated by changes in

temperature and other operating conditions. Use of the

DATACLK_OUT signal to generate the data allows most of the

internal process, temperature, and voltage delay variation to be

cancelled. The AD973x further simplifies this high speed data

capture problem with two adaptive closed-loop timing

controllers.

One timing controller manages the LVDS data and data clock

alignment (LVDS controller), and the other manages the LVDS

data and DACCLK alignment (SYNC controller). The LVDS

controller locates the data transitions and delays the

DATACLK_IN so that its transition is in the center of the valid

data window. The SYNC controller manages the FIFO that

moves data from the LVDS DATACLK_IN domain to the

DACCLK domain. Both controllers can be operated in manual

mode under external processor control, surveillance mode

where error conditions generate external interrupts, or

automatic mode where errors are automatically corrected.

The LVDS and SYNC controllers include moving average

filtering for noise immunity and variable thresholds to control

their activity. Normally the controllers can be set to run in

automatic mode, and they make any necessary adjustments

without dropping or duplicating samples sent to the DAC. Both

controllers require initial calibration prior to entering automatic

update mode.

The AD973x analog output changes 35 DACCLK cycles after

the input data changes in 1× mode with the FIFO disabled. The

FIFO can add up to eight additional cycles of delay. This delay

can be read from the SPI port. Internal clock delay variation is

less than a single DACCLK cycle at 1.2 GHz (833 ps).

Stopping the AD973x DATACLK_IN while the DACCLK is still

running can lead to unpredictable output signals. This occurs

because the internal digital signal path is interleaved. The last

two samples clocked into the DAC continue to be clocked out

by DACCLK even after DATACLK_IN has been stopped. The

resulting output signal is at a frequency of one-half f

the amplitude depends on the difference between the last two

samples.

Control of the AD973x functions is via the serially programmed

registers listed in Table 6. Optionally, a limited number of

functions may be directly set by external pins in pin mode.

DAC,

and

Rev. 0 | Page 31 of 68

Page 32

AD9734/AD9735/AD9736

S

SERIAL PERIPHERAL INTERFACE

The AD973x serial port is a flexible, synchronous serial

communications port, allowing easy interface to many

industry-standard microcontrollers and microprocessors. The

serial I/O is compatible with most synchronous transfer

formats, including both the Motorola SPI® and Intel® SSR

protocols. The interface allows read/write access to all registers

that configure the AD973x. Single- or multiple-byte transfers

are supported, as well as most significant bit first (MSB-first) or

least significant bit first (LSB-first) transfer formats. The

AD973x serial interface port can be configured as a single pin

I/O (SDIO) or two unidirectional pins for in/out (SDIO/SDO).

SDO (PIN G14)

SDIO (PIN F14)

CLK (PIN G13)

CSB (PIN F13)

Figure 66. AD973x SPI Port

The AD973x can optionally be configured via external pins

rather than the serial interface. When the PIN_MODE input

(Pin L1) is high, the serial interface is disabled and its pins are

reassigned for direct control of the DAC. Specific functionality

is described in the Pin Mode Operation section.

GENERAL OPERATION OF THE SERIAL INTERFACE

There are two phases to a communication cycle with the

AD973x. Phase 1 is the instruction cycle, which is the writing of

an instruction byte into the AD973x, coincident with the first

eight SCLK rising edges. The instruction byte provides the

AD973x serial port controller with information regarding the

data transfer cycle, which is Phase 2 of the communication

cycle. The Phase 1 instruction byte defines whether the

upcoming data transfer is read or write, the number of bytes in

the data transfer, and the starting register address for the first

byte of the data transfer. The first eight SCLK rising edges of

each communication cycle are used to write the instruction byte

into the AD973x.

The remaining SCLK edges are for Phase 2 of the communication cycle. Phase 2 is the actual data transfer between the

AD973x and the system controller. Phase 2 of the communication cycle is a transfer of 1, 2, 3, or 4 data bytes as determined

by the instruction byte. Using one multibyte transfer is the

preferred method. Single-byte data transfers are useful to

reduce CPU overhead when register access requires one byte

only. Registers change immediately upon writing to the last bit

of each transfer byte.

CSB (Chip Select) can be raised after each sequence of 8 bits

(except the last byte) to stall the bus. The serial transfer resumes

when CSB is lowered. Stalling on nonbyte boundaries resets the

SPI.

AD9736

SPI PORT

04862-066

SHORT INSTRUCTION MODE (8-BIT INSTRUCTION)

The short instruction byte is shown in Table 17.

Table 17. SPI Instruction Byte

MSB LSB

I7 I6 I5 I4 I3 I2 I1 I0

R/W N1 N0 A4 A3 A2 A1 A0

R/W, Bit 7 of the instruction byte, determines whether a read or

a write data transfer occurs after the instruction byte write.

Logic high indicates read operation. Logic 0 indicates a write

operation. N1, N0, Bits 6 and 5 of the instruction byte,

determine the number of bytes to be transferred during the data

transfer cycle. The bit decodes are shown in Table 18.

A4, A3, A2, A1, A0, Bits 4, 3, 2, 1, 0 of the instruction byte,

determine which register is accessed during the data transfer

portion of the communications cycle. For multibyte transfers,

this address is the starting byte address. The remaining register

addresses are generated by the AD973x, based on the LSBFIRST

bit (Reg 00, Bit 6).

Table 18. Byte Transfer Count

N1 N2 Description

0 0 Transfer 1 byte

0 1 Transfer 2 bytes

1 0 Transfer 3 bytes

1 1 Transfer 4 bytes

LONG INSTRUCTION MODE (16-BIT INSTRUCTION)

The long instruction bytes are shown in Table 19.

Table 19. SPI Instruction Byte

MSB LSB

I15 I14 I13 I12 I11 I10 I9 I8

R/W N1 N0 A12 A11 A10 A9 A8

I7 I6 I5 I4 I3 I2 I1 I0

A7 A6 A5 A4 A3 A2 A1 A0

If LONG_INS = 1 (Reg 00, Bit 4), the instruction byte is

extended to 2 bytes where the second byte provides an

additional 8 bits of address information. Addresses 0x00 to 0x1F

are equivalent in short and long instruction modes. The

AD973x does not use any addresses greater than 31 (0x1F), so

always set LONG_INS = 0.

SERIAL INTERFACE PORT PIN DESCRIPTIONS

SCLK—Serial Clock. The serial clock pin is used to

synchronize data to and from the AD973x and to run the

internal state machines. The maximum frequency of SCLK is

20 MHz. All data input to the AD973x is registered on the rising

edge of SCLK. All data is driven out of the AD973x on the

rising edge of SCLK.

Rev. 0 | Page 32 of 68

Page 33

AD9734/AD9735/AD9736

CSB—Chip Select. Active low input starts and gates a

communication cycle. It allows more than one device to be used

on the same serial communications lines. The SDO and SDIO

pins goes to a high impedance state when this input is high.

Chip select should stay low during the entire communication

cycle.

SDIO—Serial Data I/O. Data is always written into the

AD973x on this pin. However, this pin can be used as a bidirectional data line. The configuration of this pin is controlled by

SDIO_DIR at Reg 00, Bit 7. The default is Logic 0, which

configures the SDIO pin as unidirectional.

SDO—Serial Data Out. Data is read from this pin for protocols

that use separate lines for transmitting and receiving data. In

the case where the AD973x operates in a single bidirectional

I/O mode, this pin does not output data and is set to a high

impedance state.

MSB/LSB TRANSFERS

The AD973x serial port can support both MSB-first or LSB-first

data formats. This functionality is controlled by LSBFIRST at

Reg 00, Bit 6. The default is MSB first (LSBFIRST = 0).

When LSBFIRST = 0 (MSB first), the instruction and data bytes

must be written from the most significant bit to the least

significant bit. Multibyte data transfers in MSB-first format start

with an instruction byte that includes the register address of the

most significant data byte. Subsequent data bytes should follow

in order from high address to low address. In MSB-first mode,

the serial port internal byte address generator decrements for

each data byte of the multibyte communication cycle.

When LSBFIRST = 1 (LSB first), the instruction and data bytes

must be written from least significant bit to most significant bit.

Multibyte data transfers in LSB-first format start with an

instruction byte that includes the register address of the least

significant data byte followed by multiple data bytes. The serial

port internal byte address generator increments for each byte of

the multibyte communication cycle.

The AD973x serial port controller data address decrements

from the data address written toward 0x00 for multibyte I/O

operations if the MSB-first mode is active. The serial port

controller address increments from the data address written

toward 0x1F for multibyte I/O operations if the LSB-first mode

is active.

NOTES ON SERIAL PORT OPERATION

The AD973x serial port configuration is controlled by Reg 00,

Bits 4, 5, 6, and 7. Note that the configuration changes

immediately upon writing to the last bit of the register. For

multibyte transfers, writing to this register may occur during

the middle of communication cycle. Care must be taken to

compensate for this new configuration for the remaining bytes

of the current communication cycle. The same considerations

apply to setting the software reset, RESET (Reg 00, Bit 5). All

registers are set to their default values except Reg 00 and Reg 04

which remain unchanged.

Use of only single-byte transfers when changing serial port

configurations or initiating a software reset is highly

recommended. In the event of unexpected programming

sequences, the AD973x SPI may become inaccessible. For

example, if user code inadvertently changes the LONG_INS bit

or the LSBFIRST bit, the following bits may have unexpected

results. The SPI can be returned to a known state by writing an

incomplete byte (1 to 7 bits) of all 0s followed by 3 bytes of

0x00. This returns to MSB-first short instructions (Reg 00 =

0x00) so the device may be reinitialized.

INSTRUCTION CYCLE DATA TRANSFER CYCLE

CSB

SCLK

SDIO

R/W N1 N0 A4 A3 A2 A1 A0 D7ND6ND5

Figure 67. Serial Register Interface Timing, MSB-First Write

INSTRUCTION CYCLE DATA TRANSFER CYCLE

CSB

SCLK

SDIO

SDO

R/W N1 N0 A4 A3 A2 A1 A0D7D6ND5

D6ND5

D7

Figure 68. Serial Register Interface Timing, MSB-First Read

INSTRUCTION CYCLE DATA TRANSFER CYCLE

CSB

SCLK

SDIO

A0 A1 A2 A3 A4 N0 N1 R/W D00D10D2

Figure 69. Serial Register Interface Timing, LSB-First Write

INSTRUCTION CYCLE DATA TRANSFER CYCLE

CSB

SCLK

SDIO

SDO

A0 A1 A2 A3 A4 N0 N1 R/W D10D2

D0

D10D2

D0

Figure 70. Serial Register Interface Timing, LSB-First Read

N

N

0

N

0

0

N

0

N

0

N

D00D10D20D3

0

D00D10D20D3

D00D10D20D3

D7ND6ND5ND4

D7ND6ND5ND4

D7ND6ND5ND4

04862-069

04862-067

04862-068

04862-070

Rev. 0 | Page 33 of 68

Page 34

AD9734/AD9735/AD9736

S

S

CSB

SCLK

SDIO

CSB

CLK

DIO

t

DS

t

DS

Figure 71. Timing Diagram for SPI Register Write

I1 I0 D7 D6 D5

Figure 72. Timing Diagram for SPI Register Read

t

PWH

t

t

SCLK

t

PWL

DH

INSTRUCTION BIT 6INSTRUCTION BIT 7

t

DNV

t

DV

After the last instruction bit is written to the SDIO pin, the

driving signal must be set to a high impedance in time for the

bus to turn around. The serial output data from the AD973x is

enabled by the falling edge of SCLK. This causes the first output

data bit to be shorter than the remaining data bits, as shown in

Figure 72.

To assure proper reading of data, read the SDIO or SDO pin

prior to changing the SCLK from low to high.

Due to the more complex multibyte protocol, multiple AD973x

devices cannot be daisy-chained on the SPI bus. Multiple DACs

should be controlled by independent CSB signals.

PIN MODE OPERATION

When the PIN_MODE input (Pin L1) is set high, the SPI port is