Page 1

16-Bit, 400 MSPS

FEATURES

Dynamic performance

SFDR ≥ 78 dBc @ f

IMD ≥ 82 dBc @ f

ACLR ≥ 76 dBc @ f

NSD ≤ –160 dB/Hz @ f

Precision calibrated linearity

DNL ≤ ±0.5 LSB @ +25°C

INL ≤ ±1.0 LSB @ +25°C

THD ≤ –95 dB @ f

LVDS inputs with internal 100 Ω terminations

Automatic data/clock timing synchronization

Single data rate or double data rate capable

Differential current outputs

Internal precision reference

Operates on 2.5 V and 3.3 V supplies

Extended industrial temperature range

Thermally enhanced, 80-lead, lead-free TQFP_EP package

APPLICATIONS

Instrumentation

Test equipment

Waveform synthesis

Communications systems

GENERAL DESCRIPTION

The AD9726 is a 16-bit digital-to-analog converter (DAC)

that offers leading edge performance at conversion rates up to

400 MSPS. The device uses low voltage differential signaling

(LVDS) inputs and includes internal 100 Ω terminations. The

analog output can be single-ended or differential current. An

internal precision reference is included.

The AD9726 also features synchronization logic to monitor and

optimizes the timing between incoming data and the sample clock.

This reduces system complexity and simplifies timing requirements. An LVDS clock output is also available to drive an external

data pump in either single data rate (SDR) or double data rate

(DDR) mode.

All device operation is fully programmable using the flexible

serial port interface (SPI). The AD9726 is also fully functional

in its default state for applications without a controller.

= 20 MHz

OUT

= 70 MHz

OUT

= 70 MHz

OUT

OUT

= 1 MHz

OUT

= 70 MHz

D/A Converter

AD9726

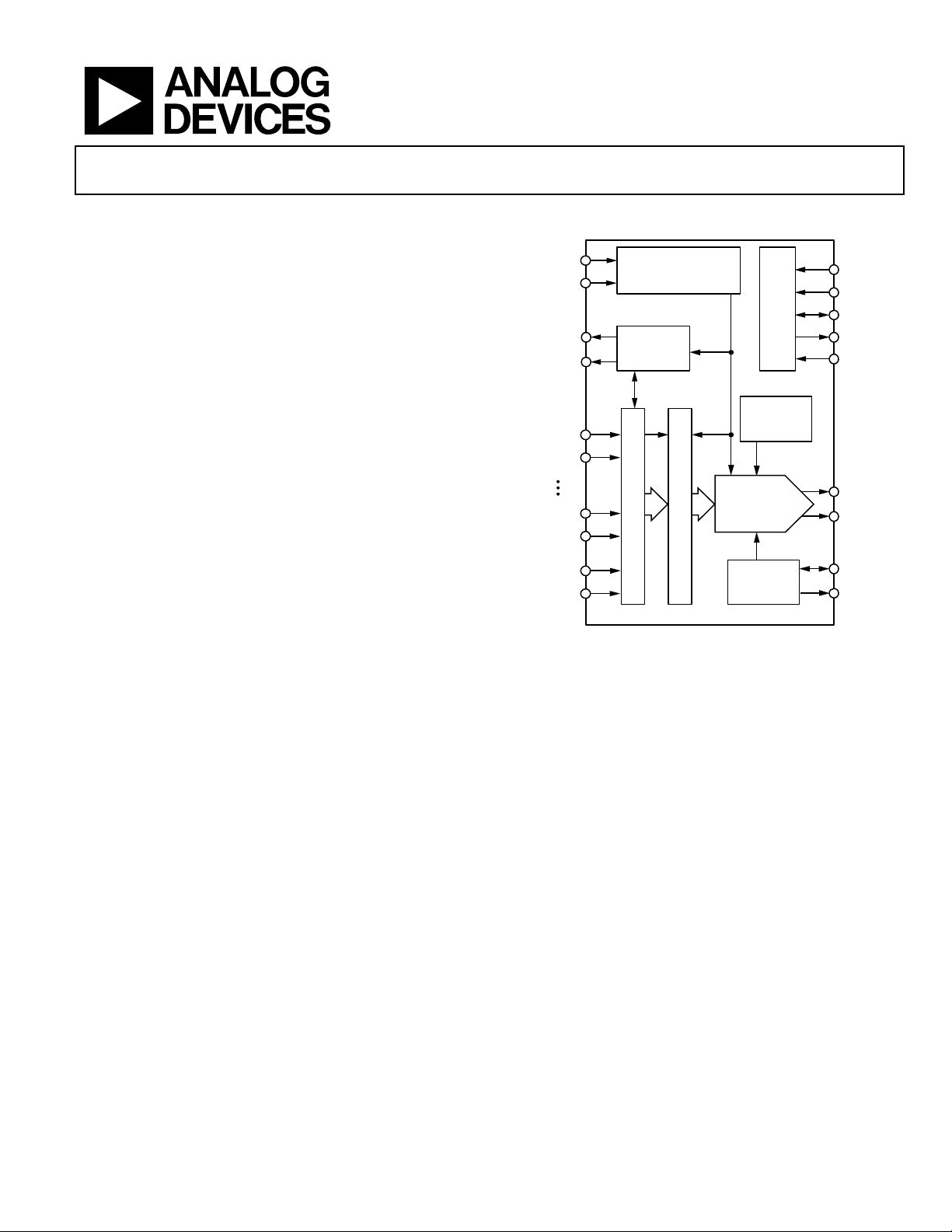

FUNCTIONAL BLOCK DIAGRAM

CLK+

CLK–

DCLK_OUT+

DCLK_OUT–

DB[15]+

DB[15]–

DB[0]+

DB[0]–

DCLK_IN+

DCLK_IN–

PRODUCT HIGHLIGHTS

1. A unique combination of precision and performance

makes the AD9726 equally suited to applications with

demanding frequency domain or demanding time domain

requirements.

2. Nonvolatile factory calibration assures a highly linear

transfer function. Internal logic offers on demand selfcalibration for linearity even at extended operating

temperatures.

3. Proprietary architecture minimizes data dependent,

discrete mixing spurs and offers enhanced dynamic

performance over a wide range of output frequencies.

High input data rates create a very high frequency

synthesis bandwidth.

4. The fully automatic, transparent synchronizer maintains

optimized timing between clock and data in real time and

offers programmable control options for added flexibility.

5. Full-scale output current is external resistor programmable.

CLOCK DISTRIBUTION

AND CONTROL

LVDS OUTPUT

DRIVER

LVDS INPUT DATA CAPTURE

DATA SYNCHRONIZATION

Figure 1.

.

SPI

CALIBRATION

MEMORY

16-BIT

DAC

INTERNAL

REFERENCE

CSB

SCLK

SDIO

SDO

RESET

I

OUTA

I

OUTB

REFIO

FSADJ

04540-001

Rev. A

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or other

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700

Fax: 781.461.3113 © 2005 Analog Devices, Inc. All rights reserved.

www.analog.com

Page 2

AD9726

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description......................................................................... 1

Product Highlights........................................................................... 1

Specifications..................................................................................... 3

DC Specifications ......................................................................... 3

AC Specifications.......................................................................... 4

Digital Signal Specifications........................................................ 5

Timing Specifications .................................................................. 5

Timing Diagrams.......................................................................... 6

Absolute Maximum Ratings............................................................ 7

Thermal Resistance ...................................................................... 7

ESD Caution.................................................................................. 7

Pin Configuration and Function Descriptions............................. 8

Serial Port Interface........................................................................ 13

Theory of Operation ...................................................................... 15

DAC Clock and Data Clock Output........................................ 15

Data Clock Input........................................................................ 15

Data Synchronization Circuitry............................................... 16

Analog Output............................................................................ 16

Internal Reference and Full-Scale Output .............................. 16

Reset ............................................................................................. 17

Serial Port Interface ................................................................... 17

SPI Pin Description.................................................................... 18

Calibration................................................................................... 18

Sync Logic Operation and Programming ............................... 20

Outline Dimensions ....................................................................... 22

Ordering Guide .......................................................................... 22

Te r mi n ol o g y .................................................................................... 10

Typical Performance Characteristics ........................................... 11

REVISION HISTORY

11/05—Rev. 0 to Rev. A

Changes to Features.......................................................................... 1

Changes to Table 3 and Table 4....................................................... 5

Changes to the Terminology Section........................................... 10

Changes to the Driving the DAC Clock Inputs Section............ 15

Changes to the Reset and Serial Port Interface Sections........... 17

Updated Outline Dimensions....................................................... 22

Changes to the Ordering Guide.................................................... 22

7/05—Revision 0: Initial Version

Rev. A | Page 2 of 24

Page 3

AD9726

SPECIFICATIONS

DC SPECIFICATIONS

DBVDD = AVDD1 = AVDD2 = 3.3 V, DVDD = CLKVDD = ADVDD = ACVDD = 2.5 V, I

to T

T

MIN

, unless otherwise specified.

MAX

Table 1.

Parameter Min Typ Max Unit

ACCURACY

1

DNL ±0.5 ±1.0 LSB

INL ±1.0 ±2.5 LSB

Offset Error 0.003 % FS

Gain Error 0.003 % FS

ANALOG OUTPUT

Full-Scale Current 20 mA

Compliance Voltage ±1 V

Output Impedance

10

INTERNAL REFERENCE

Output Voltage 1.18 1.22 1.27 V

Output Current

2

1 µA

EXTERNAL REFERENCE

Input Voltage 1.2 V

Input Resistance 10 MΩ

Small Signal Bandwidth 200 kHz

TEMPERATURE COEFFICIENTS

Gain Drift ±10 ppm of FS/ºC

Offset Drift ±10 ppm of FS/ºC

Reference Drift ±30 ppm/ºC

POWER SUPPLIES

3

AVDD1, AVDD2

Voltage Range 3.13 3.47 V

Supply Current (I

AVDD1

+ I

) 52 60 mA

AVDD2

ADVDD, ACVDD

Voltage Range 2.37 2.63 V

Supply Current (I

ACVDD

+ I

) 16 18 mA

ADVDD

CLKVDD

Voltage Range 2.37 2.63 V

Supply Current (I

) 45 50 mA

CLKVDD

DVDD

Voltage Range 2.37 2.63 V

Supply Current (I

) 80 90 mA

DVDD

DBVDD

Voltage Range 3.13 3.47 V

Supply Current (I

POWER DISSIPATION (P

) 16 18 mA

DBVDD

) 575 mW

DISS

Sleep Mode 465 mW

Power-Down Mode ≤10 mW

OPERATING TEMPERATURE RANGE –40 +85 °C

1

T

= 25°C.

AMB

2

Use buffer amplifier to drive external load.

3

Supply currents and power dissipation measured in SDR with f

= 400 MHz and f

DAC

= 1 MHz.

OUT

= 20 mA, internal reference,

OUT-FS

MΩ

Rev. A | Page 3 of 24

Page 4

AD9726

AC SPECIFICATIONS

DBVDD = AVDD1 = AVDD2 = 3.3 V, DVDD = CLKVDD = ADVDD = ACVDD = 2.5 V, I

to T

T

MIN

, unless otherwise specified.

MAX

Table 2.

Parameter Min Typ Max Unit

TOTAL HARMONIC DISTORTION (THD)

f

= 400 MHz, f

DAC

= 1 MHz, 0 dBFS –95 dB

OUT

SPURIOUS-FREE DYNAMIC RANGE (SFDR)

f

= 400 MHz, 0 dBFS

DAC

f

= 20 MHz 78 dBc

OUT

f

= 70 MHz 68 dBc

OUT

f

= 140 MHz 62 dBc

OUT

f

= 400 MHz, –3 dBFS

DAC

f

= 20 MHz 80 dBc

OUT

f

= 70 MHz 70 dBc

OUT

f

= 140 MHz 62 dBc

OUT

f

= 200 MHz, 0 dBFS

DAC

f

= 20 MHz 84 dBc

OUT

f

= 70 MHz 62 dBc

OUT

f

= 200 MHz, –3 dBFS

DAC

f

= 20 MHz 82 dBc

OUT

f

= 70 MHz 68 dBc

OUT

TWO-TONE INTERMODULATION DISTORTION (IMD)

f

= 400 MHz, 0 dBFS

DAC

f

= 20 MHz, f

OUT1

f

= 70 MHz, f

OUT1

f

= 140 MHz, f

OUT1

= 21 MHz 86 dBc

OUT2

= 71 MHz 82 dBc

OUT2

= 141 MHz 74 dBc

OUT2

ADJACENT CHANNEL LEAKAGE RATIO (ACLR)

f

= 245.76 MSPS, f

DATA

f

= 245.76 MSPS, f

DATA

f

= 245.76 MSPS, f

DATA

f

= 245.76 MSPS, f

DATA

= 70 MHz, 1-Carrier WCDMA 76 dBc

CARRIER

= 70 MHz, 2-Carrier WCDMA 70 dBc

CARRIER

= 70 MHz, 4-Carrier WCDMA 66 dBc

CARRIER1

= 70 MHz, 8-Carrier WCDMA 62 dBc

CARRIER1

NOISE SPECTRAL DENSITY (NSD)

f

= 400 MHz, f

DAC

f

= 400 MHz, f

DAC

f

= 400 MHz, f

DAC

= 70 MHz, 0 dBFS –160 dBm/Hz

OUT

= 70 MHz, –3 dBFS –163 dBm/Hz

OUT

= 70 MHz, –6 dBFS –165 dBm/Hz

OUT

UPDATE RATE 0 400 MSPS

= 20 mA, internal reference,

OUT-FS

Rev. A | Page 4 of 24

Page 5

AD9726

DIGITAL SIGNAL SPECIFICATIONS

DBVDD = AVDD1 = AVDD2 = 3.3 V, DVDD = CLKVDD = ADVDD = ACVDD = 2.5 V, I

to T

T

MIN

, unless otherwise specified.

MAX

Table 3.

Parameter Min Typ Max Unit

DAC CLOCK INPUTS (CLK+/–)

Differential Voltage 0.5 1.0 V

Common-Mode Voltage 1.0 1.25 V

LVDS INPUTS (DB[15:0]+/–, DCLK_IN+/–)

Input Voltage Range 825 1575 mV

Differential Threshold Voltage 100 mV

Differential Input Impedance 100 Ω

LVDS OUTPUT (DCLK_OUT+/–)

Differential Output Voltage

1

250 400 mV

Offset Voltage 1.0 1.2 V

Short-Circuit Output Current 20 mA

CMOS INPUTS (CSB, SCLK, SDIO, RESET)

Logic 0 Voltage 0.5 V

Logic 1 Voltage 2.5 V

Input Current 1 nA

CMOS OUTPUTS (SDO, SDIO)

Logic 0 Voltage 0.5 V

Logic 1 Voltage 3.0 V

Short-Circuit Output Current 10 mA

CONTROL INPUTS (SPI_DIS, SDR_EN)

Logic 0 Voltage 0.5 V

Logic 1 Voltage 2.0 V

Input Current 1 nA

1

With 100 Ω external load.

= 20 mA, internal reference,

OUT-FS

TIMING SPECIFICATIONS

DBVDD = AVDD1 = AVDD2 = 3.3 V, DVDD = CLKVDD = ADVDD = ACVDD = 2.5 V, I

to T

T

MIN

, unless otherwise specified.

MAX

Table 4.

Parameter Min Typ Max Unit

LVDS DATA BUS

DDR DCLK_OUT+/– Propagation Delay (t

DDR DB[15:0]+/– Set-Up Time (t

DDR DB[15:0]+/– Hold Time (t

) –100 ps

DSU-DDR

) 500 ps

DH-DDR

SDR DCLK_OUT+/– Propagation Delay (t

SDR DB[15:0]+/– Set-Up Time (t

SDR DB[15:0]+/– Hold Time (t

) –100 ps

DSU-SDR

) 500 ps

DH-SDR

) 2000 ps

DCPD-DDR

) 300 ps

DCPD-SDR

SERIAL PORT INTERFACE

SCLK Frequency (f

) 15 MHz

SCLK

SCLK Rise/Fall Time 1 ms

SCLK Pulse Width High (t

SCLK Pulse Width Low (t

SCLK Set-Up Time (t

SDIO Set-Up Time (t

CSU

DSU

) 30 ns

CPWH

) 30 ns

CPWL

) 30 ns

) 30 ns

SDIO Hold Time (tDH) 0 ns

SDIO/SDO Valid Time (tDV) 30 ns

RESET PULSE WIDTH 1.5 ns

Rev. A | Page 5 of 24

= 20 mA, internal reference,

OUT-FS

Page 6

AD9726

T

T

S

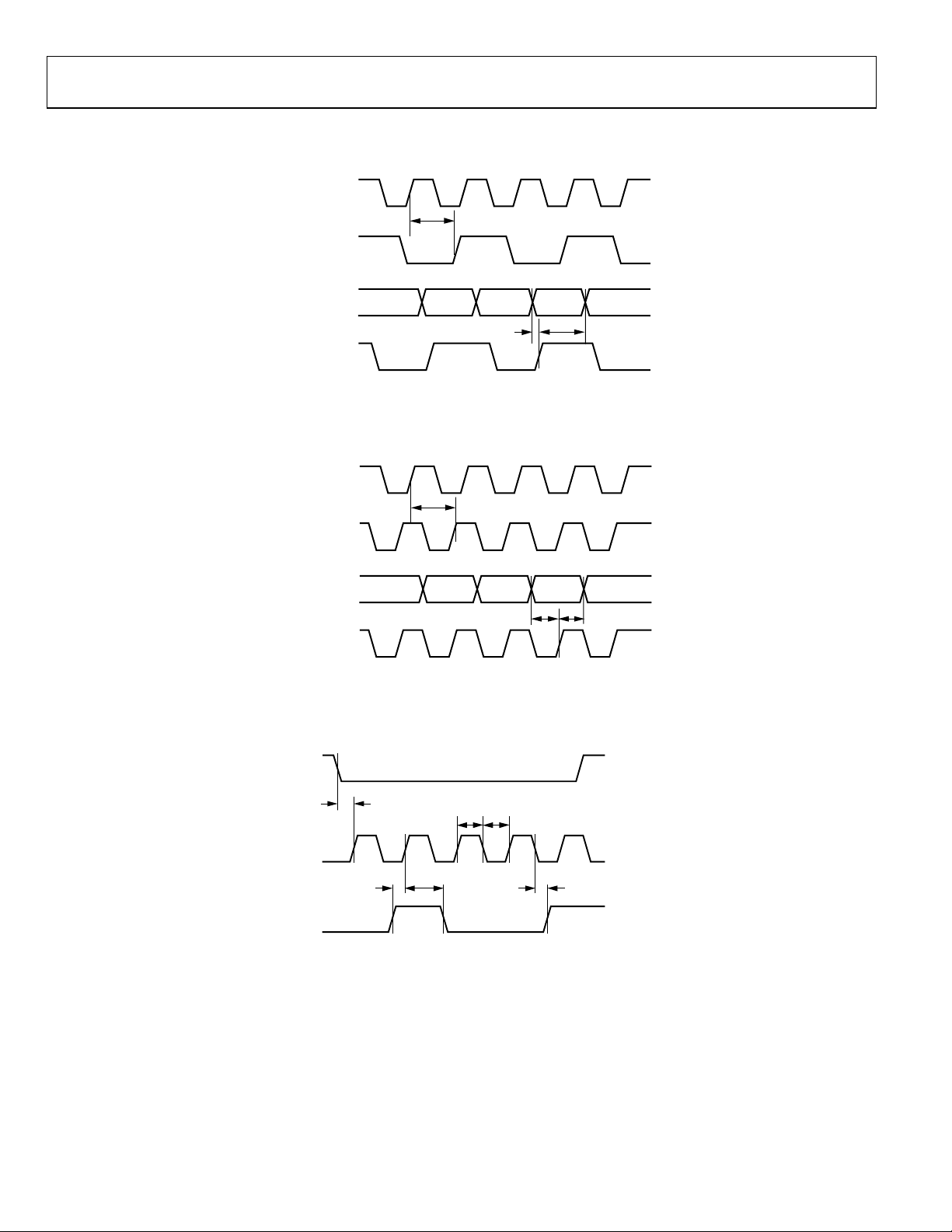

TIMING DIAGRAMS

DAC CLOCK

t

DCPD-DDR

DATACLOCK OUTPU

DATA BUS

DATACLOCK INPUT

DAC CLOCK

DATACLOCK OUTPU

DATA BUS

DATACLOCK INPUT

CSB

SCLK

Figure 2. DDR Timing Diagram

t

DCPD-SDR

Figure 3. SDR Timing Diagram

SCLK SET-UP TIME

t

CSU

SCLK PULSE WIDTH HIGH/LOW TIME

t

CPWH

t

DSU-DDR

t

DSU-SDR

t

CPWL

t

DH-DDR

t

DH-SDR

04540-002

04540-003

SDIO SET-UP TIME SDIO HOLD TIME SDIO (SD0) VALID TIME

DIO (SD0)

t

DSU

t

DH

t

DV

04540-004

Figure 4. SPI Timing Diagram

Rev. A | Page 6 of 24

Page 7

AD9726

ABSOLUTE MAXIMUM RATINGS

Table 5.

Parameter With Respect to Rating

DBVDD, AVDD1, AVDD2 DBGND, AGND1,

DVDD, CLKVDD,

ACVDD, ADVDD

DBGND, AGND1,

AGND2

DGND, CLKGND,

ACGND, ADGND

REFIO, FSDAJ AGND1 –0.3 V to AVDD1

IOUTA, IOUTB AGND1 –1.0 V to AVDD1

CLK+, CLK– CLKGND –0.3 V to

DB[15:0]+/–,

DCLK_IN+/–,

DCLK_OUT+/–

CSB, SCLK, SDIO,

SDO, RESET, REXT

SDR_EN, SPI_DIS ADGND –0.3 V to

AGND2

DGND, CLKGND,

ACGND, ADGND

DBGND, AGND1,

AGND2

DGND, CLKGND,

ACGND, ADGND

DBGND −0.3 V to

DBGND –0.3 V to DBVDD

–0.3 V to 3.6 V

–0.3 V to 2.8 V

–0.3 V to +0.3 V

–0.3 V to +0.3 V

+ 0.3 V

+ 0.3 V

CLKVDD + 0.3 V

DBVDD + 0.3 V

+ 0.3 V

ADVDD + 0.3 V

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

Thermal impedance can be lowered to 23°C/W by soldering the

exposed package pad to an external heat sink (for example, the

internal PCB copper ground plane). However, this is not necessary

for the power dissipation and operating temperature range of

the AD9726.

Table 6. Thermal Resistance

Package Type θJAUnit

80-Lead TQFP_EP Package, Thermally Enhanced 32 °C/W

ESD CAUTION

ESD (electrostatic discharge) sensitive device. Electrostatic charges as high as 4000 V readily accumulate on the

human body and test equipment and can discharge without detection. Although this product features

proprietary ESD protection circuitry, permanent damage may occur on devices subjected to high energy

electrostatic discharges. Therefore, proper ESD precautions are recommended to avoid performance degradation or loss of functionality.

Rev. A | Page 7 of 24

Page 8

AD9726

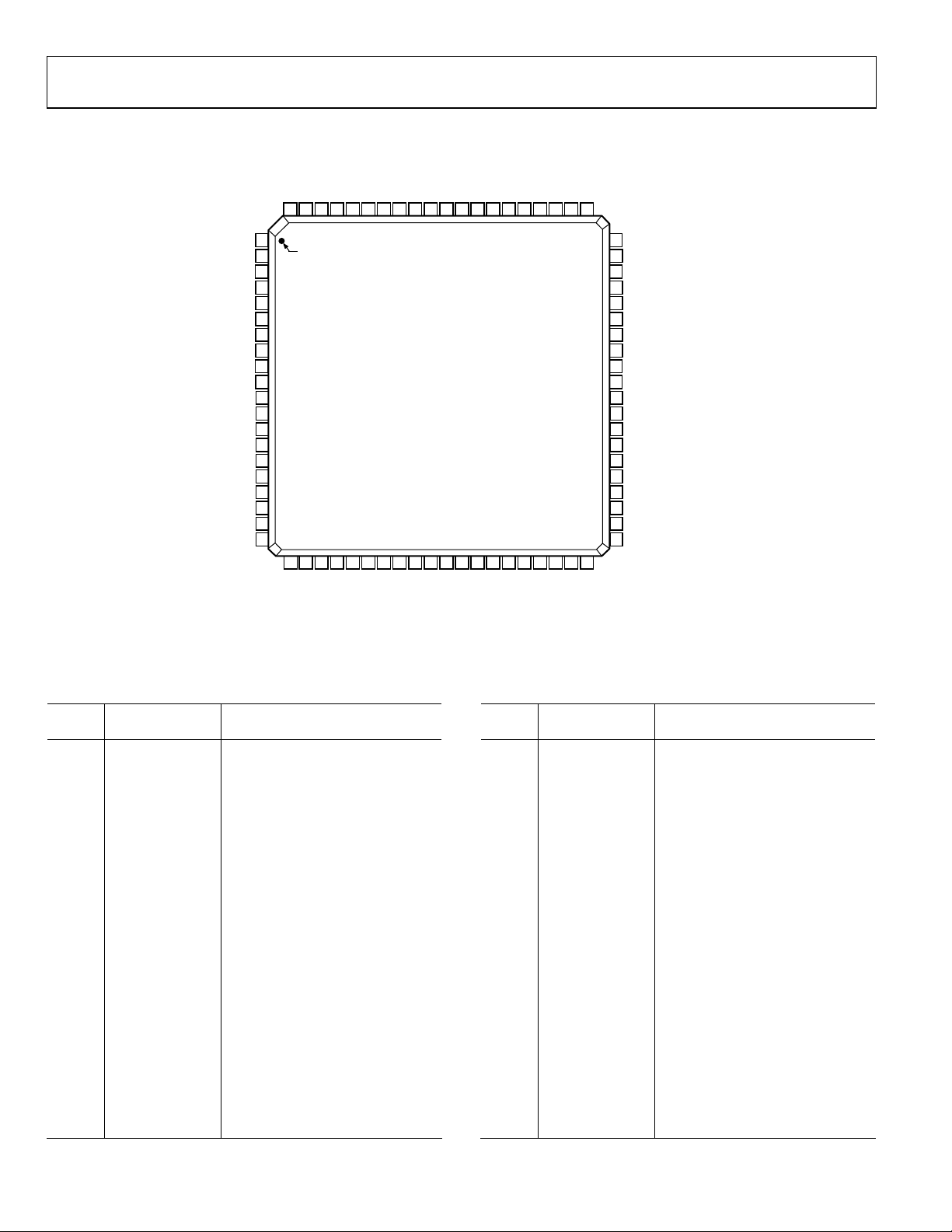

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

SPI_DIS79ADVDD78ADGND77ACVDD76ACGND75AVDD274AGND273AVDD172AGND171IOUTA70IOUTB69AGND168AVDD167AGND266AVDD265ACGND64ACVDD63ADGND62ADVDD61SDR_EN

80

REXT

CLK+

CLK–

DGND

DVDD

DB15+

DB15–

DB14+

DB14–

DB13+

DB13–

DB12+

DB12–

DB11+

DB11–

DBVDD

1

PIN 1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

DB9–

DB8–

DB9+

DB10+

DBGND

DB10–

DB8+

CLKVDD

CLKVDD

CLKGND

CLKGND

Figure 5. Pin Configuration

Table 7. Pin Function Descriptions

Pin

No. Mnemonic Description

1 CLKVDD Clock Supply Voltage

2 REXT Sets Data Clock Output Drive

3 CLKVDD Clock Supply Voltage

4 CLKGND Clock Supply Common

5 CLK+ DAC Clock Input True

6 CLK− DAC Clock Input Complement

7 CLKGND Clock Supply Common

8 DGND Digital Supply Common

9 DVDD Digital Supply Voltage

10 DB15+ Data Bit 15 True

11 DB15− Data Bit 15 Complement

12 DB14+ Data Bit 14 True

13 DB14− Data Bit 14 Complement

14 DB13+ Data Bit 13 True

15 DB13− Data Bit 13 Complement

16 DB12+ Data Bit 12 True

17 DB12− Data Bit 12 Complement

18 DB11+ Data Bit 11 True

19 DB11− Data Bit 11 Complement

20 DBVDD Data Bus Supply Voltage

21 DBGND Data Bus Supply Common

AD9726

TOP VIEW

(Not to Scale)

29

30

DBVDD

DCLK_OUT–

DCLK_OUT+

1

31

DBGND

60

FSADJ

59

REFIO

58

RESET

57

CSB

56

SCLK (SYNCUPD)

55

SDIO

54

SDO (SYNCALRM)

53

DGND

52

DVDD

51

DB0–

50

DB0+

49

DB1–

48

DB1+

47

DB2–

46

DB2+

45

DB3–

44

DB3+

43

DB4–

42

DB4+

41

DBGND

32

33

34

35

36

37

38

39

40

DB7–

DB6–

DB5–

DB5+

DBVDD

04540-005

DCLK_IN+

DCLK_IN–

DB7+

DB6+

Pin

No. Mnemonic Description

22 DB10+ Data Bit 10 True

23 DB10− Data Bit 10 Complement

24 DB9+ Data Bit 9 True

25 DB9− Data Bit 9 Complement

26 DB8+ Data Bit 8 True

27 DB8− Data Bit 8 Complement

28 DCLK_OUT+ Data Clock Output True

29 DCLK_OUT− Data Clock Output Complement

30 DBVDD Data Bus Supply Voltage

31 DBGND Data Bus Supply Common

32 DCLK_IN+ Data Clock Input True

33 DCLK_IN− Data Clock Input Complement

34 DB7+ Data Bit 7 True

35 DB7− Data Bit 7 Complement

36 DB6+ Data Bit 6 True

37 DB6− Data Bit 6 Complement

38 DB5+ Data Bit 5 True

39 DB5− Data Bit 5 Complement

40 DBVDD Data Bus Supply Voltage

41 DBGND Data Bus Supply Common

42 DB4+ Data Bit 4 True

Rev. A | Page 8 of 24

Page 9

AD9726

Pin

No. Mnemonic Description

43 DB4− Data Bit 4 Complement

44 DB3+ Data Bit 3 True

45 DB3− Data Bit 3 Complement

46 DB2+ Data Bit 2 True

47 DB2− Data Bit 2 Complement

48 DB1+ Data Bit 1 True

49 DB1− Data Bit 1 Complement

50 DB0+ Data Bit 0 True

51 DB0− Data Bit 0 Complement

52 DVDD Digital Supply Voltage

53 DGND Digital Supply Common

54 SDO (SYNCALRM) SPI Data Output (SYNCALRM)

55 SDIO SPI Data Input/Output

56 SCLK (SYNCUPD) SPI Clock Input (SYNCUPD)

2

3

4

57 CSB SPI Chip Select Bar (Active Low)

58 RESET Hardware Reset (Active High)

59 REFIO Internal Reference Input/Output

60 FSADJ Output Current Full-Scale Adjust

61 SDR_EN Single Data Rate Mode Enable

7

62 ADVDD Analog Supply Voltage

63 ADGND Analog Supply Common

64 ACVDD Analog Supply Voltage

65 ACGND Analog Supply Common

5

6

Pin

No. Mnemonic Description

66 AVDD2 Analog Supply Voltage

67 AGND2 Analog Supply Common

68 AVDD1 Analog Supply Voltage

69 AGND1 Analog Supply Common

70 IOUTB Analog Current Output Complement

71 IOUTA Analog Current Output True

72 AGND1 Analog Supply Common

73 AVDD1 Analog Supply Voltage

74 AGND2 Analog Supply Common

75 AVDD2 Analog Supply Voltage

76 ACGND Analog Supply Common

77 ACVDD Analog Supply Voltage

78 ADGND Analog Supply Common

79 ADVDD Analog Supply Voltage

80 SPI_DIS Serial Port Interface Disable

1

Nominally 1 kΩ to DBGND (may be omitted if data clock output is unused).

2

SDO is output in 4-wire SPI mode and three-state in 3-wire SPI mode. If SPI is

disabled (SPI_DIS = ADVDD), alternate pin function is SYNCALRM output.

3

SDIO is input only in 4-wire SPI mode and bidirectional in 3-wire SPI mode.

4

If SPI is disabled (SPI_DIS = ADVDD), alternate pin function is SYNCUPD.

5

Bypass with 0.1 µF to AGND1. Use buffer amp to drive external circuitry.

Limit output current to 1 µA. Apply external reference to this pin.

6

Nominally 2 kΩ to AGND1 for 20 mA full-scale output (internal reference).

7

If SPI is disabled, tie pin to ADVDD to enable SDR. Otherwise, tie to ADGND.

8

Tie pin to ADVDD to disable SPI; otherwise, tie to ADGND.

8

Rev. A | Page 9 of 24

Page 10

AD9726

TERMINOLOGY

Integral Nonlinearity (INL)

The maximum deviation of the actual analog output from the

ideal output, as determined by a straight line drawn from zero

scale to full scale.

Tem p er at u re Dr if t

Temperature drift is specified as the maximum change in a

parameter from ambient temperature (25°C) to either T

or T

and is typically reported as ppm/°C.

MAX

MIN

Differential Nonlinearity (DNL)

A measure of the maximum deviation in analog output associated

with any single value change in the digital input code relative to

an ideal LSB.

Offset Error

The deviation of the output current from the ideal zero-scale

current. For differential outputs, 0 mA is expected at I

all inputs are low, and 0 mA is expected at I

when all inputs

OUTB

OUTA

when

are high.

Monotonicity

A DAC is monotonic if the analog output increases or remains

constant in response to an increase in the digital input.

Gain Error

The deviation of the output current from the ideal full-scale

current. Actual full-scale output current is determined by

subtracting the output when all inputs are low from the output

when all inputs are high.

Output Compliance Range

The range of allowable voltage seen by the analog output of a

current output DAC. Operation beyond the compliance limits

may cause output stage saturation and/or breakdown resulting

in nonlinear performance.

Power Supply Rejection

The maximum change in the full-scale output as all power

supplies are varied over their respective operating voltage range.

Spurious-Free Dynamic Range (SFDR)

The difference in decibels between the peak amplitude of a test

tone and the peak amplitude of the largest spurious signal over

the specified bandwidth.

Intermodulation Distortion (IMD)

The difference in decibels between the maximum peak

amplitude of two test tones and the maximum peak amplitude

of the distortion products created from the sum or difference

of integer multiples of the test tones.

Adjacent Channel Leakage Ratio (ACLR)

The ratio between the measured power of a wideband signal

within a channel relative to the measured power in an empty

adjacent channel.

Noise Spectral Density (NSD)

The measured noise power over a 1 Hz bandwidth seen at the

analog output.

Total Harmonic Distortion (THD)

The ratio in decibels of the rms power sum of the first six

harmonic components to the rms power of the output signal.

Rev. A | Page 10 of 24

Page 11

AD9726

–

–

–

–

–

–

TYPICAL PERFORMANCE CHARACTERISTICS

100

90

–6dB

630

620

610

80

70

SFDR (dBc)

60

50

01224364860728496 132120108 144

Figure 6. SFDR vs. f

100

90

80

70

SFDR (dBc)

60

50

012243648607

Figure 7. SFDR vs. f

0dB

–3dB

0dB

f

f

OUT

–6dB

OUT

(MHz)

@ 400 MSPS

OUT

(MHz)

@ 200 MSPS

OUT

–3dB

04540-007

04540-008

2

600

590

580

570

POWER CONSUMPTION (mW)

560

550

Figure 9. Power Consumption vs. f

REF LVL

0dBm

0

–10

–20

–30

1AVG

–40

–50

–60

–70

–80

–90

100

110

120

Figure 10. THD @ 400 MSPS and f

SDR

DDR

100500 150 200

(MHz)

f

OUT

@ 400 MSPS

OUT

1kHz

RBW

1kHz

VBW

17s

SWT

= 1 MHz

OUT

RF ATT

UNIT

STOP 7.5MHz675kHzSTART 750kHz

(Diplexer Low-Pass Output Showing 0 dBm Fundamental;

See Performance Effects of Calibration Section)

04540-006

40dB

dBm

A

1AP

EXT

04540-018

100

90

80

IMD (dBc)

70

60

50

Figure 8. Two-Tone IMD vs. f

f1 + f2 = 0dB

80 90 100 120 13030 40 50 60 7020 110 140

(MHz)

f

OUT

@ 400 MSPS

OUT

04540-009

REF LVL

0dBm

0

–10

–20

–30

1AVG

–40

–50

–60

–70

–80

–90

100

110

120

Figure 11. THD @ 400 MSPS and f

(Diplexer High-Pass Output Showing Harmonics Before Calibration;

VBW

SWT

17s

= 1 MHz

OUT

UNIT

STOP 7.5MHz675kHzSTART 750kHz

dBm

A

1AP

EXT

04540-019

10dB

RF ATT

1kHz

RBW

1kHz

See Performance Effects of Calibration Section)

Rev. A | Page 11 of 24

Page 12

AD9726

–

–

–

REF LVL

0dBm

0

–10

–20

–30

1AVG

–40

–50

–60

–70

–80

–90

100

110

120

Figure 12. THD @ 400 MSPS and f

Showing Harmonics After Calibration,

See Performance Effects of Calibration Section)

REF –35dBm

*AVG

Log

10dB/

*ATTEN 8dB

RBW

VBW

SWT

1kHz

1kHz

17s

RF ATT

UNIT

10dB

dBm

STOP 7.5MHz675kHzSTART 750kHz

= 1 MHz (Diplexer High-Pass Output

OUT

EXT REF

1AP

EXT

REF –45dBm

*AVG

A

Log

10dB/

*ATTEN 4dB

EXT REF

PAVG

10

04540-020

W1 S2

CENTER 70.00MHz

*RES BW 10kHz

TOTAL CARRIER POWER -20.62dBm/15.3600MHz

REF CARRIER POWER -26.43dBm/3.84000MHz

1 –26.43dBm

2 –26.53dBm

3 –26.74dBm

4 –26.88dBm

OFFSET FREQ

5.000MHz

10.00MHz

15.00MHz

INTEG BW

3.840MHz

3.840MHz

3.840MHz

Figure 15. Four-Carrier WCDMA @ 400 MSPS f

SPAN 59.58MHz

SWEEP 1.739s (601 pts)VBW 100kHz

RRC FILTER: ON FILTER ALPHA 0.22

LOWER

dBc

–66.59

–67.63

–67.59

dBm

–93.00

–94.04

–94.00

dBc

–67.07

–67.54

–67.44

OUT

UPPER

dBm

–93.48

–93.95

–93.86

= 70 MHz

04540-016

REF –50dBm

*AVG

Log

10dB/

*ATTEN 2dB

PAVG

10

W1 S2

CENTER 70.00MHz

*RES BW 10kHz

RMS RESULTS

CARRIER POWER

–14.58dBm/

3.84000MHz

FREQ OFFSET

5.000MHz

10.00MHz

15.00MHz

REF BW

3.840MHz

3.840MHz

3.840MHz

dBc

–76.72

–76.96

–77.07

Figure 13. One-Carrier WCDMA @ 400 MSPS f

INTEG BW

3.840MHz

3.840MHz

3.840MHz

REF –40dBm

*AVG

Log

10dB/

PAVG

10

W1 S2

CENTER 70.00MHz

*RES BW 10kHz

TOTAL CARRIER POWER -17.61dBm/7.68000MHz

REF CARRIER POWER -20.72dBm/3.84000MHz

1 –20.51dBm

2 –20.72dBm

*ATTEN 6dB

OFFSET FREQ

5.000MHz

10.00MHz

15.00MHz

Figure 14. Two-Carrier WCDMA @ 400 MSPS f

SPAN 34.68MHz

SWEEP 1.012s (601 pts)VBW 100kHz

LOWER

dBm

–91.30

–91.54

–91.65

dBc

–76.69

–77.04

–76.76

UPPER

dBm

–91.27

–91.62

–91.34

= 70 MHz

OUT

EXT REF

SPAN 47.38MHz

SWEEP 1.383s (601 pts)VBW 100kHz

RRC FILTER: ON FILTER ALPHA 0.22

LOWER

dBc

–70.61

–71.29

–71.36

dBm

–91.34

–92.01

–92.08

dBc

–70.74

–71.31

–71.06

OUT

UPPER

dBm

–91.47

–92.03

–91.78

= 70 MHz

04540-014

04540-015

PAVG

10

W1 S2

CENTER 70.00MHz

*RES BW 10kHz

TOTAL CARRIER POWER -20.62dBm/15.3600MHz

REF CARRIER POWER -26.43dBm/3.84000MHz

OFFSET FREQ

1 –32.21dBm

2 –32.30dBm

3 –32.44dBm

4 –32.59dBm

5.000MHz

10.00MHz

15.00MHz

Figure 16. Eight-Carrier WCDMA @ 400 MSPS f

INTEG BW

3.840MHz

3.840MHz

3.840MHz

EXT REF

SPAN 83.98MHz

SWEEP 2.451s (601 pts)VBW 100kHz

RRC FILTER: ON FILTER ALPHA 0.22

LOWER

dBc

–62.23

–62.87

–63.70

dBm

–94.82

–95.46

–96.28

dBc

–62.09

–62.36

–62.39

OUT

UPPER

dBm

–94.68

–94.94

–94.98

= 70 MHz

04540-017

Rev. A | Page 12 of 24

Page 13

AD9726

SERIAL PORT INTERFACE

Table 8. SPI Register Map

Addr Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0x00 SDIODIR DATADIR SWRESET SLEEP PWRDWN

0x02 DATAFMT DATARATE INVDCLKI INVDCLKO DISDCLKO SYNCMAN SYNCUPD SYNCALRM

0x0E

CALMEM[1] CALMEM[0]

0x0F SCALSTAT SELFCAL XFERSTAT MEMXFER SMEMWR SMEMRD FMEMRD UNCAL

0x10 MEMADR[7] MEMADR[6] MEMADR[5] MEMADR[4] MEMADR[3] MEMADR[2] MEMADR[1] MEMADR[0]

0x11

0x15

0x16

SYNCEXT SYNCIN[1] SYNCIN[0]

MEMDAT[5] MEMDAT[4] MEMDAT[3] MEMDAT[2] MEMDAT[1] MEMDAT[0]

Table 9. SPI Register Bit Default and Descriptions Values

Addr Name Bit I/O Default Description

0x00 SDIODIR 7 I 0

0: SDIO is input only (4-wire SPI mode), and SDO is used for output.

1: SDIO is input/output (3-wire SPI mode), and SDO is unused.

DATADIR 6 I 0

0: SPI serial data byte is MSB first format.

1: SPI serial data byte is LSB first format.

0x02 DATAFMT 7 I 0

SWRESET 5 I 0 1: Software reset: SPI registers (except 0x00) to default values.

SLEEP 4 I 0 1: Analog outputs temporarily disabled.

PWRDWN 3 I 0 1: Full device power-down; all circuits disabled except SPI.

EXTREF 0 I 0 1: Power-down internal reference: use external reference source.

0: Input data-word is twos complement binary format.

1: Input data-word is unsigned binary format.

DATARATE 6 I 0

0: DDR mode.

1: SDR mode.

0x0E CALMEM [5:4] O 00

INVDCLKI 5 I 0 1: Inverts polarity of data clock input.

INVDCLKO 4 I 0 1: Inverts polarity of data clock output.

DISDCLKO 3 I 0 1: Disables data clock output.

SYNCMAN 2 I 0 1: Enable sync manual mode; disable automatic update.

SYNCUPD 1 I 0 1: Force manual sync update.

SYNCALRM 0 O 0 1: Indicates that sync logic requires update.

2-bit SMEM contents and calibration status indicator.

00: Uncalibrated; SMEM contains default values (63).

01: Self-calibrated; SMEM contains values from self-calibration.

10: Factory-calibrated; SMEM values transferred from FMEM.

11: User-calibrated; SMEM contains user-entered values.

CALCLK [2:0] I 000

3-bit self-calibration clock divider ratio. Affects time available for algorithm settling. Each

value increase reduces time by 50%.

000: Self-calibration clock is DAC clock/4096 (maximum self-calibration settling time for

highest linearity accuracy).

001,010,011: Self-calibration clock is DAC clock/2048,1024,512.

100,101,110: Self-calibration clock is DAC clock/256,128,64.

111: Self-calibration clock is DAC clock/32 (minimum self-calibration settling time for

fastest algorithm completion).

0x0F SCALSTAT 7 O 0 1: Indicates completion of self-calibration cycle.

SELFCAL 6 I 0 1: Initiates self-calibration cycle.

XFERSTAT 5 O 0 1: Indicates completion of memory transfer cycle.

MEMXFER 4 I 0 1: Initiates FMEM to SMEM transfer.

SMEMWR 3 I 0 1: Enable static memory (SMEM) write operation.

SMEMRD 2 I 0 1: Enable static memory (SMEM) read operation.

FMEMRD 1 I 0 1: Enable factory memory (FMEM) read operation.

UNCAL 0 I 0 1: Enable uncalibrated operation; all SMEM to default values.

4

5

0x10 MEMADR [7:0] I 00000000 8-bit memory address value for read/write operations.

CALCLK[2] CALCLK[1] CALCLK[0]

SYNCOUT[1] SYNCOUT[0]

1

2

3

6

EXTREF

Rev. A | Page 13 of 24

Page 14

AD9726

Addr Name Bit I/O Default Description

0x11 MEMDAT [5:0] I/O 000000 6-bit memory data value for read/write operations.

0x15 SYNCOUT [1:0] O 00 2-bit output value indicates current sync quadrant.

SYNCEXT 5 I 0 1: Enable sync external mode; disable auto quadrant select. 0x16

SYNCIN [4:3] I 00 2-bit input value used to specify sync quadrant.

1

SWRESET also resets itself. SMEM contents are unaffected by SWRESET; however, CALMEM reports an uncalibrated state.

2

EXTREF is optional because the internal reference circuit is designed to be overdriven by an external source.

3

The self-calibration clock is also used for the memory transfer cycle; therefore, the CALCLK value affects the MEMXFER process time.

4

Register Bits 3:0 must all be 0 to assert SELFCAL. The time required for the self-calibration cycle is ~100 ms at 100 MHz with CALCLK = 0.

5

Register Bits 3:0 must all be 0 to assert MEMXFER. The time required for the memory transfer cycle is ~15 ms at 100 MHz with CALCLK = 0.

6

The UNCAL bit remains asserted after the cycle completes (SMEM contents held at default values) until the bit is cleared by the user.

Rev. A | Page 14 of 24

Page 15

AD9726

THEORY OF OPERATION

The AD9726 uses LVDS for input data to enable high sample

rates and high performance. LVDS technology uses differential

signals for noise rejection and small signal amplitude for fast

speed with lower power. Each LVDS input on the AD9726 has

an internal 100 Ω active load for proper termination.

DAC CLOCK AND DATA CLOCK OUTPUT

The AD9726 uses two clock inputs and offers one clock output.

All are differential signals.

1:1

VBB = 1.0V

25Ω

25Ω

Figure 17. Active DAC Clock Drive Circuit

VCC = CLKVDD = 2.5V

MC100LVEP16

VCC – 2V

50Ω50Ω

CLK+

CLK–

AD9726

04540-012

The AD9726 is driven by a master input clock that initiates conversion and controls all on-chip activity. This signal is referred

to as the DAC clock. It is not LVDS, and the CLK+ and CLK–

pins are high impedance inputs.

The DAC clock is then used to generate the data clock output.

The DCLK_OUT+ and DCLK_OUT– pins form an LVDS

signal that can be used to drive an external FPGA or another

data pump. In SDR mode, the data clock output always runs at

the same frequency as the DAC clock. In DDR mode, the data

clock output always runs at ½ the DAC clock frequency.

Use of the data clock output is optional. It is meant to serve as

a convenient means of regulating the incoming data stream.

The driver can be loaded by a 100 Ω differential termination.

An external 1 kΩ resistor from the REXT pin to DBGND is also

required to set the drive strength. If unused, the data clock

output pins can be left unconnected and the 1 kΩ resistor at

REXT can be omitted.

The data clock output can also be inverted by asserting the

INVDCLKO bit in SPI Register 0x02 or the driver can be

disabled by asserting the DISDCLKO bit in the same register.

DATA CLOCK INPUT

The remaining clock signal associated with the AD9726 is the

data clock input. This LVDS signal is not optional and must

accompany the 16-bit data bus. The data clock input is used to

latch incoming data into the synchronization (sync) logic.

The data clock input always runs at the same frequency as the

data clock output in both SDR and DDR modes. A logical

inversion can be accomplished by asserting the INVDCLKI bit.

Driving the DAC Clock Inputs

The DAC clock must be precise and spectrally pure to ensure

the highest ac performance. A symmetrical 50% duty cycle

should be maintained at all times.

The CLK+ and CLK– input pins should be driven by a signal

with a common-mode voltage near ½ of CLKVDD. From this

point, peak-to-peak signal amplitude should swing over a range

of at least several hundred millivolts.

The circuit option shown in Figure 17 uses a receiver/driver IC

from the 2.5 V LVPECL logic family to provide complementary

outputs that fall within these guidelines. A transformer helps

ensure a 50% duty cycle and provides a single-ended to

differential conversion at the input.

The LVPECL device can be conveniently powered from the

same power supply as CLKVDD. The center tap of the transformer secondary must be held at 1 V, the switching threshold

of the receiver/driver inputs (use a resistive divider to generate

this voltage or use the internal VBB source with a buffer

amplifier). Based on a 1:1 impedance ratio, 25 Ω resistors across

the secondary provide a matched load to a 50 Ω source.

The driver outputs are terminated as close as possible to the

AD9726 with 50 Ω to VCC − 2 V (or use a Thevenin equivalent

circuit). Controlled impedance PCB traces should be used to

minimize reflections. Signal levels at the CLK+ and CLK– pins

transition between a high near 1500 mV to a low near 750 mV.

1:1

0.1µF

0.1µF

VDC BIAS = 1.25V

Figure 18. Passive DAC Clock Drive Circuit

50Ω

CLK+

CLK–

AD9726

04540-013

An alternative circuit option for driving the DAC clock inputs

employs a transmission line transformer (balun) to accomplish

the single-ended to differential conversion. This all-passive

circuit is considerably simpler and less costly, and it provides

acceptable performance over a limited range of frequencies.

In this implementation, a sine wave (or other single-ended

source) is coupled directly to the differential DAC clock inputs

through a 50 Ω transformer. Capacitors are used for isolation,

and each DAC clock pin must be dc-biased to a level of 1.25 V

(a pair of simple resistive dividers can be used).

Rev. A | Page 15 of 24

Page 16

AD9726

The 50 Ω termination resistor should be placed as close as possible to the input pins, and controlled impedance PCB traces

should be used.

Good ac performance can be expected from either the active or

passive DAC clock drive circuit. However, in a passive circuit,

the output slew rate is dependent on the frequency of the input;

whereas an active circuit provides consistently high output slew

rates over a wide range of input frequencies.

DATA SYNCHRONIZATION CIRCUITRY

The high performance of the AD9726 requires maintaining

synchronization between the incoming bits and the DAC clock

used to sample and convert the data. Despite the inherent difficulty in specifying the phase relationship of the DAC clock

and the LVDS data clock input and the challenge presented by

the high operating speed of the interface, the AD9726 contains

real-time logic to automatically monitor and align the data bus

with the DAC clock.

ANALOG OUTPUT

The AD9726 is based around a high dynamic range CMOS

core. The analog output consists of differential current sources,

each capable of up to 20 mA full scale. Discrete output devices

are PMOS and capable of sourcing current into an output

termination within a compliance voltage range of ±1 V.

In a typical application, both outputs drive discrete resistors-toanalog ground. From there, especially for higher frequency

outputs, they feed the center-tap secondary of a 1:1 RF transformer. A differential-to-single-ended conversion is accomplished

that provides added gain and cancellation of even ordered

harmonics.

I

OUTA

25Ω

25Ω

I

OUTB

Figure 19. Transformer Output Circuit

–3dBm

04540-021

Whether in SDR or DDR mode, input data is always provided

at the same rate. Furthermore, the rate of incoming data always

equals the frequency period of the DAC clock. The data rate and

the DAC clock must also be frequency locked. To accomplish this,

the primary purpose of the data clock output is to provide a

time base for data that is derived directly from the DAC clock.

The function of the data clock input is to latch incoming data

into the sync block. From there, it is the function of the

synchronization logic to position the data with respect to the

DAC clock for optimal ac performance.

Individual data bits must maintain close alignment with one

another so that PCB traces have matched delays across the

width of the 16-bit bus. In addition, a fixed set-up and hold

timing relationship between the data clock input and the data

bus is required.

However, because of the sync logic, the phase relationship between

the data bus and the DAC clock is internally optimized.

Furthermore, should the phase between the data bus and the

DAC clock drift over time or temperature, the sync logic automatically updates and adjusts for it. Once synchronization has

been reached, the phase between the data bus and the DAC clock

can vary by a full cycle without loss or corruption of data.

For maximum output power, resistor values can be increased to

50 Ω to provide up to 0 dBm into a 50 Ω load without loss of

performance for most transformers.

R

R

GA

FA

I

OUTA

I

OUTB

NOTES

1. USE RF AND RG TO SET GAIN

50Ω

R

R

GB

FB

50Ω

AND LIMIT BANDWIDTH

Figure 20. Op Amp Output Circuit

04540-011

As an alternative, an active output stage can be used in the

classic instrumentation amplifier configuration. Here, each

DAC output feeds the noninverting input of one of Analog

Devices’ high speed transimpedance op amps.

More detailed explanations of sync operation and optional

programmable modes are presented in the Sync Logic

Operation and Programming section, which also includes an

explanation of how to use the sync logic without the SPI.

INTERNAL REFERENCE AND FULL-SCALE OUTPUT

The AD9726 contains an internal 1.2 V precision reference

source; this reference voltage appears at the REFIO pin. It can

be used to drive external circuitry if properly buffered.

Apply an external reference voltage source to the REFIO pin if

desired. The internal source is designed to be easily overdriven

by an external source; however, the internal reference can also

be powered down using the EXTREF bit in SPI Register 0x00.

Rev. A | Page 16 of 24

Page 17

AD9726

K

The reference voltage (either internal or external) is applied to

an external precision resistor at the FSADJ pin. The resulting

current is internally amplified to provide the full-scale current

at the DAC output according to the following equation:

I

= VREF/R

OUTFS

FSADJ

× 32

Taking into account the binary value appearing at the data bus

inputs, the output currents I

OUTA

and I

can be determined

OUTB

according to the following equations:

= I

I

I

OUTA

OUTB

× DB[15:0]/65536

OUTFS

= I

× (1 − DB[15:0])/65536

OUTFS

Note that the AD9726 features nonvolatile, factory-calibrated

gain using the internal reference source and a precision 2 kΩ

load. Gain accuracy in any application is, therefore, dependent

upon the accuracy of R

FSADJ

.

RESET

Following initial power up and application of a valid DAC clock

signal, the AD9726 should always be initialized with an active

high pulse on the RESET pin. This defaults the programmable

registers, initializes volatile calibration memory, and prepares

the synchronization logic for data. The data bus should be static

prior to the reset pulse. After reset, LVDS data can flow.

The default state of the AD9726 is DDR and twos complement

binary input data. To use the AD9726 in this mode, it is not

necessary to program any device registers. However, the SPI is

enabled by default unless the SPI_DIS pin is connected high. If

not disabled, SPI input pins should not be left floating.

SERIAL PORT INTERFACE

The serial port interface is a flexible and synchronous serial

communications port allowing easy interface to many industry

standard microcontroller and microprocessor protocols

(including both Motorola SPI® and Intel® SSR). The interface

provides read/write access to registers that configure the

operation of the AD9726.

The AD9726 SPI supports single-byte and multibyte transfers as

well as MSB- or LSB-justified data formats. The interface can be

configured in 3-wire mode (in which SDIO is bidirectional) or

the default 4-wire mode (in which SDIO and SDO function as

unidirectional data input and data output, respectively).

Communication Cycle

All communication cycles have two phases. The first phase is

concerned with writing an instruction byte into the SPI

controller and always coincides with the first eight rising edges

of SCLK. The instruction byte provides the controller with

information regarding the second phase of the cycle, namely the

data transfer phase. In the instruction byte, there are the

number of data bytes to be transferred (1 to 4), a register

address, and a bit initiating a read or write operation.

CSB

SCL

SDIO

SDO

Any communication cycle begins with CSB going low, which

also resets the SPI control logic. Similarly, any communication

cycle ends with CSB going high, which aborts any incomplete

data transfer. Once a communication cycle begins, the next

eight SCLK rising edges interpret data on the SDIO pin as the

instruction byte.

Instruction Byte

The instruction byte bits are shown in the following bit map.

B7 B6 B5 B4 B3 B2 B1 B0

R/W

R/W

Bit 7 of the instruction byte selects a read or write transfer. If

the bit is set high, a read operation is indicated. If the bit is low,

a write operation is indicated.

N1, N0

Bit 6 and Bit 5 of the instruction byte determine the number of

data bytes to be transferred, as shown in Table 10.

Table 10.

N1 N0 Description

0 0 Transfer 1 data byte

0 1 Transfer 2 data bytes

1 0 Transfer 3 data bytes

1 1 Transfer 4 data bytes

A4, A3, A2, A1, A0

Bit 4 through Bit 0 of the instruction byte specify a 5-bit binary

value corresponding to a valid register address. In the case of

multibyte transfers, the location specified is either an initial or

a concluding register address. The SPI controller increments

or decrements this value to generate successive address values

depending on whether LSB or MSB justification is active.

MSB/LSB Transfers

The SPI can support both MSB- and LSB-justified serial data

byte formats. This functionality is determined by Bit 6 in SPI

Register 0x00. This bit defaults low, which is MSB justification.

In this mode, serial data bits are written to and/or read from

registers sequentially from Bit 7 to Bit 0.

If Bit 6 of SPI Register 0x00 is set high, the controller switches

to LSB justification. In this mode, data bits are written to or

read from registers sequentially from Bit 0 to Bit 7. Writing to

the instruction bytes is also affected by the active justification.

INSTRUCTION CYCLE DATA TRANSFER CYCLE

R/W N1 N0 A4 A3 A2 A1 A0 D7nD6

D7nD6

Figure 21. SPI Communication Cycle

n

n

D20D10D0

D20D10D0

0

0

04540-010

N1 N0 A4 A3 A2 A1 A0

Rev. A | Page 17 of 24

Page 18

AD9726

For multibyte transfers with MSB justification, the address in

the instruction byte is interpreted as a final address, and its value

is decremented automatically by the controller. For multibyte

transfers with LSB justification, the address in the instruction

byte is interpreted as an initial address, and its value is incremented

automatically by the controller.

Care must be exercised when switching from MSB to LSB

justification. The controller switches modes immediately once

all eight bits of SPI Register 0x00 are written (even if in the

process of a multibyte transfer). For this reason, a single byte

command is recommended when changing justification.

3-Wire and 4-Wire Operation

Bit 7 of SPI Register 0x00 defaults low, enabling 4-wire SPI

operation. In this mode, serial data is input from the SDIO pin,

and serial data is output on the SDO pin. Setting Bit 7 of SPI

Register 0x00 high enables 3-wire operation. In this mode,

SDIO becomes bidirectional and switches automatically from

input to output when necessary. The SDO pin in this mode is

unused and assumes a high impedance state.

As with MSB or LSB justification, care must be exercised when

switching operational modes. The change occurs immediately

once all eight bits of SPI Register 0x00 are written.

Writing and Reading Register Data

Bringing CSB low initiates a new communication cycle. The

next eight rising edges of SCLK latch data from SDIO into the

instruction byte. If Bit 7 of the instruction byte is low, a write

operation is enabled. If Bit 7 is high, a read operation is enabled.

For a write operation, a data byte is latched from the SDIO pin

into a register on the next eight rising edges of SCLK. If the

instruction byte Bit 6 and Bit 5 are not both 0, a multibyte

transfer latches data bytes into adjacent registers after each

successive set of eight rising SCLK edges. Depending upon

MSB or LSB justification, the controller decrements or

increments the address value in the instruction byte during

the cycle as necessary.

If a read operation is enabled, data bits from the register being

addressed appear on SDO (or SDIO) with each falling edge of

SCLK. Note that for a read operation, the eighth bit of the

instruction byte is latched on the eighth rising edge of SCLK

and the first output bit is enabled on the immediately following

falling SCLK edge.

Disabling the SPI

Tie the SPI_DIS pin high to ADVDD to disable the serial port

interface. In this state, the default DDR operational mode can be

changed to SDR by pulling the SDR_EN pin high to ADVDD. In

addition, with the SPI disabled, the sync logic no longer operates

in a fully automatic mode. See the Sync Logic Operation and

Programming section for a full explanation of sync operational

modes.

SPI PIN DESCRIPTION

The AD9726 SPI logic runs from the DBVDD supply rail, and

input/output thresholds are based upon a nominal 3.3 V level.

The maximum frequency of operation is 15 MHz.

Chip Select (CSB)

The CSB pin is an active low input. It begins and ends any

communication cycle and must remain low during the entire

cycle. An incomplete cycle is aborted if CSB is prematurely

returned high .

Serial Clock (SCLK)

The SCLK pin is used to synchronize data to and from the SPI

registers and the controller state machine runs from this input.

It is therefore possible to read and write register data (but not

SMEM/FMEM) without a valid DAC clock. All input data is

registered on the rising edge of SCLK and output data bits are

enabled on the falling edge of SCLK.

Serial Data Input/Output (SDIO)

Data is always written into the SPI on the SDIO pin. In 3-wire

mode however, data is also driven out using this pin. The switch

from input to output occurs automatically between the instruction and data transfer phases of a read operation. In the default

4-wire mode, SDIO is unidirectional and input only.

Serial Data Output (SDO)

Serial data is driven out on the SDO pin when the SPI is in its

default 4-wire mode. In 3-wire mode (or whenever CSB is high)

SDO is set to a high impedance state.

CALIBRATION

To ensure linearity to the 16-bit level, the AD9726 incorporates

132 calibration DACs (CALDACs), which are used to linearize

the current output transfer function. Each CALDAC is a 6-bit

device and takes its input directly from static memory (SMEM).

For multibyte read sequences, the controller adjusts the register

address when necessary and subsequent data bit values appear

at the output with each falling SCLK edge.

Rev. A | Page 18 of 24

There are 127 CALDACs associated with each major transition

of the 16-bit input data-word (that is, any transition involving

the upper 7 MSBs). A 128th CALDAC operates on the sum total

of the lower 9 LSBs. The remaining 4 CALDACs (129 to 132)

are used to adjust the DAC’s overall transfer function gain.

Page 19

AD9726

Linearity CALDACs operate inversely from their input; that is,

as their binary input value increases, the magnitude of their

current contribution seen at the AD9726 output decreases. Gain

CALDACs are an exception to this. Their contribution seen at

the AD9726 output is in direct proportion to their binary input.

Gain CALDACs are also half strength as compared to linearity

CALDACs, but they are intended to be used together as a unit

and thus provide twice the current adjustment range in sum

total.

Calibration Memory

During production testing, the linearity of the AD9726 is

measured and optimized. Values for all CALDACs are permanently stored in nonvolatile factory memory (FMEM). At

reset, all factory memory contents are transferred to static

memory. CALMEM indicates a factory calibrated state

(CALMEM = 10b).

It is also possible at any time to transfer the contents of FMEM

to SMEM by asserting the MEMXFER bit. The XFERSTAT

indicator bit then reports the successful completion of the

transfer cycle, and MEMXFER is cleared.

Note that the MEMXFER bit (and SELFCAL) cannot be

asserted if any other memory access function is currently

enabled (that is, if any Bit [3:0] of Register 0x0F is high).

Attempting to assert MEMXFER (or SELFCAL) in this case

clears any asserted bits in Register 0x0F, but the requested cycle

does not commence.

The factory-to-static memory data transfer cycle requires a

number of DAC clock cycles. The total depends on the value of

CALCLK. This value sets a divider used to create a slow version

of the DAC clock, which is intended to extend the settling time

available to the self-calibration cycle. However, this divided

clock is also used to sequence a memory transfer cycle.

The divider is set to its maximum value with CALCLK at its

default value. A memory transfer cycle requires about 15 ms at a

DAC clock frequency of 100 MHz. This time can be reduced by

50% for every increase in the value of CALCLK.

Accessing Calibration Memory

SMEM or FMEM locations can be read at any time by setting

the SMEMRD or FMEMRD bit in SPI Register 0x0F. Address

and data information can be input and/or output through SPI

Register 0x10 and SPI Register 0x11, respectively.

SMEM locations can also be written by setting the SMEMWR

bit. Register 0x10 and Register 0x11 are again used for addresses

and data. Any time after the SMEMWR bit has been asserted,

the device reports a user-calibrated state (CALMEM = 11b)

until another action changes the calibration memory status.

CALMEM reports an uncalibrated state (CALMEM = 00b).

Note that UNCAL remains asserted (and the contents of SMEM

remains at default values) indefinitely. UNCAL does not clear

itself (like SWRESET) and must be cleared by the user.

Note also that although SPI registers do not depend on the DAC

clock (they use SCLK to sequence the controller state machine),

SMEM and/or FMEM access does require a valid DAC clock.

SMEM/FMEM Read/Write Procedures

Static and factory memory is accessed through the SPI, but it is

not part of the SPI logic. For this reason, memory access requires

a valid DAC clock, while SPI register access does not.

Because the AD9726 SPI is so flexible, allowing single and

multiple byte reads and writes as well as MSB or LSB justified

data, there are perhaps a number of ways in which a user can

access one or more SMEM or FMEM locations.

To avoid potential errors, the following procedures for accessing

static or factory memory should be followed. These procedures

use only single-byte SPI commands to ensure the enabling of

addresses and the sequencing of memory access.

To read from SMEM or FMEM,

1. Ensure that Bits [3:0] of Register 0x0F are clear.

2. Begin the sequence by writing the memory address value

to Register 0x10 with a single-byte SPI write command.

3. Assert the SMEMRD or FMEMRD bit in Register 0x0F

with another single-byte SPI write command.

4. Import the contents of Register 0x11 using a single-byte

SPI read command.

5. Clear the SMEMRD or FMEMRD bit with another single-

byte command.

To w r ite to SM EM,

1. Ensure that Bits [3:0] of Register 0x0F are clear.

2. Begin the sequence by writing the data value to

Register 0x11 using a single-byte SPI write command.

3. Assert the SMEMWR bit using a single-byte SPI write

command.

4. Place the memory address value in Register 0x10 using a

single-byte SPI write command.

5. Clear the SMEMWR bit with a fourth single-byte SPI write

command.

To reset static memory at any time, assert the UNCAL bit. All

SMEM locations are then reset to their default values (63).

Rev. A | Page 19 of 24

Page 20

AD9726

Self Calibration

The AD9726 features an internal self-calibration engine to

linearize the transfer function automatically. This can be very

useful at temperature extremes where factory calibration no

longer applies. The automated cycle can be initiated by asserting

the SELFCAL bit.

The self-calibration process calibrates all linearity and gain

CALDACs based upon a fixed internal reference current. Values

for all CALDACs are stored in volatile static memory. The

CALSTAT bit indicates the successful completion of the cycle,

and the SELFCAL bit is cleared. Following the cycle, the device

reports a self-calibrated state (CALMEM = 01b).

As with MEMXFER, successful assertion of the SELFCAL bit

requires that Bits [3:0] of Register 0x0F be clear. If any of these

bits are asserted (such that an SMEM/FMEM read/write/clear

state is enabled), the self-calibration cycle does not begin.

The time required to self-calibrate is dependent on both the

DAC clock frequency and the value of CALCLK. Because selfcalibration requires more time than ordinary operation, the

DAC clock is divided into a slower version and used to step

through the process. Time made available to the self-calibration

algorithm directly impacts its ability to provide accurate results.

A maximum fixed division ratio (4096) corresponds to the

minimum default value of CALCLK (0). The division ratio can

be decreased by increasing the value of CALCLK. Each increase

in the value of CALCLK reduces the DAC clock division factor

(and, therefore, the time made available to self-calibration) by

50%. With CALCLK at its maximum value (7), the divide ratio

declines to its minimum value (32).

With CALCLK at its default value, self-calibration requires

approximately 100 ms at a DAC clock frequency of 100 MHz.

This time can be reduced to under 0.8 ms if CALCLK = 7. Time

scales relative to DAC clock frequency.

Performance Effects of Calibration

Harmonic distortion for low frequency outputs is primarily a

function of DAC linearity. Figure 10 to Figure 12 show the

harmonic distortion performance of the AD9726.

Figure 10 shows a 1 MHz full-scale output tone. The output

drives a unique low-pass and high-pass filter called a diplexer.

This type of filter presents a uniform 50 Ω load to the DAC and

splits the output signal into low and high frequency paths. The

diplexer's low-pass output passes the 1 MHz fundamental but

attenuates higher frequencies, and the diplexer's high-pass output passes higher frequencies and attenuates the 1 MHz fundamental. Figure 10 also shows the diplexer's low-pass output.

Here the noise floor is higher than the harmonic distortion

because with a high power input signal, attenuation is required

by the spectrum analyzer.

Figure 11 shows the diplexer's high pass output where the

attenuated input signal can be seen. The spectrum analyzer

attenuation has also been reduced, which lowers the noise

floor. Harmonic products at integer multiples of the fundamental are thus revealed. This is the response using the

AD9726 in an uncalibrated state.

Figure 12 shows a response using the AD9726 in a calibrated

state. Harmonic distortion due to the nonlinearities of the

digital-to-analog conversion have been virtually eliminated.

SYNC LOGIC OPERATION AND PROGRAMMING

Recall that a fixed set-up and hold timing relationship between

the data clock input and the data bus must be established and

maintained. Recall also that the data bus and the DAC clock

must be frequency locked. Because of the sync logic, however,

the phase relationship between the data bus and the DAC clock

is internally optimized. Therefore, data arrival propagation

delays and concern about data transitions near the sampling

instant are eliminated.

Synchronization is automatically enabled upon reset. Once data

arrives and synchronization has been achieved, the sync logic

continuously monitors itself so that automatic adjustments are

made if phase drifts occur over time and/or temperature,

automatic adjustments are made.

Note that the sync function and operation of the sync logic

block are transparent, automatic, and ongoing. No programming

is required. For applications where it is useful, however, the

following programmable control is provided.

SYNC Operating States

The sync logic can operate in one of three possible modes. The

default mode is fully automatic.

Fully automatic synchronization is accomplished by demultiplexing the incoming data stream into four channels, each

containing every fourth data-word. Data-words are present for

four DAC clock cycles. Data is remultiplexed by sampling each

channel with the optimum DAC clock cycle.

Initial synchronization is first established through a hardware

reset. This also fully enables the synchronization logic to monitor and resynchronize, as necessary. The AD9726 resynchronizes only if conditions change enough to alter the phase

between the data bus and the DAC clock by more than one full

clock cycle. In this event, an internal alarm occurs and is

followed by an automatic update. During resynchronization,

two data-words are typically lost or repeated.

In addition to fully automatic mode, two semi-automatic modes

are available.

Rev. A | Page 20 of 24

Page 21

AD9726

Sync Manual Mode

In fully automatic mode, the AD9726 both detects when a

resynchronization is necessary and initiates an update. In

manual mode, automatic updating is disabled. Enable manual

mode by setting the SYNCMAN bit in SPI Register 0x02.

In manual mode, the sync logic still monitors incoming data

and the DAC clock, but it indicates the need for an update by

asserting the SYNCALRM bit. In this mode, the user is

expected to regularly poll the SYNCALRM bit. When this bit

is read back high, the user can issue a manual sync update also

by asserting the SYNCUPD bit in SPI Register 0x02.

SYNC External Mode

Going beyond manual mode, sync external mode offers a

greater level of control and can be useful if multiple DAC

channels are employed in an application. Enable sync external

mode by asserting the SYNCEXT bit in SPI Register 0x16.

Manual mode must also be enabled.

The four channels into which each incoming data-word is

multiplexed are called quadrants. In any mode, the current

quadrant value can always be read back via SYNCOUT (Bits

[1:0] of SPI Register 0x15). At sync update, the logic chooses the

optimal quadrant and refreshes the value of SYNCOUT.

SYNCALRM does not indicate that data is being lost but that

conditions are close to the point where data may be lost. The

sync logic should be resynchronized by asserting SYNCUPD

at the next convenient time.

In manual mode, users can choose when to update the sync

logic. When operating with burst data, issuing a sync update

between active bursts updates the system without risking the

loss of any data. In fact, because SYNCUPD always forces a

resynchronization regardless of operational mode, even users in

fully automatic mode can reduce the possibility of data loss by

occasionally forcing a sync update during idle activity.

If either the data clock or the DAC clock is interrupted for any

reason, a SYNCUPD should always be executed to ensure that

data bus and DAC clock phase alignment remains optimized.

It is also possible to enter a value into SYNCIN (Bits [4:3] of SPI

Register 0x16). When external mode is enabled, the logic operates as expected, except that the quadrant value in SYNCIN is

used following an update. This can be used to align delays

between multiple device outputs.

Operating With SPI Disabled

If the SPI_DIS pin is connected high to ADVDD and the SPI is

disabled, the sync logic is placed into manual mode.

SYNCALRM status can then be monitored in hardware via the

unused SPI pin SDO (54), and SYNCUPD requests can be

entered in hardware via the unused SPI pin SCLK (56). If these

two pins are connected together, fully automatic sync operation

can be achieved.

Rev. A | Page 21 of 24

Page 22

AD9726

OUTLINE DIMENSIONS

14.20

0.75

0.60

0.45

1.20

MAX

14.00 SQ

13.80

1

PIN 1

12.20

12.00 SQ

11.80

6180

61 80

60

60

1

1.05

1.00

0.95

0.15

SEATING

0.05

PLANE

VIEW A

ROTATED 90° CCW

0° MIN

0.08 MAX

COPLANARITY

0.20

0.09

3.5°

TOP VIEW

(PINS DOWN)

7°

0°

20

21

VIEW A

COMPLIANT TO JEDEC STANDARDS MS-026-ADD-HD

41

41

40 40

0.50 BSC

LEAD PITCH

EXPOSED

PAD

BOTTOM VIEW

(PINS UP)

0.27

0.22

0.17

6.00

BSC SQ

20

21

Figure 22. 80-Lead Thin Plastic Quad Flat Package, Exposed Pad [TQFP_EP]

(SV-80-1)

Dimensions shown in millimeters

ORDERING GUIDE

Model Temperature Range Package Description Package Option

AD9726BSVZ

AD9726BSVZRL1 −40°C to +85°C 80-Lead TQFP_EP SV-80-1

AD9726-EB Evaluation Board

1

Z = Pb-free part.

1

−40°C to +85°C 80-Lead TQFP_EP SV-80-1

Rev. A | Page 22 of 24

Page 23

AD9726

NOTES

Rev. A | Page 23 of 24

Page 24

AD9726

NOTES

© 2005 Analog Devices, Inc. All rights reserved. Trademarks and

registered trademarks are the property of their respective owners.

D04540-0-11/05(A)

Rev. A | Page 24 of 24

Loading...

Loading...