Page 1

12-Bit, 170 MSPS/210 MSPS/250 MSPS,

www.BDTIC.com/ADI

FEATURES

SNR = 64.8 dBFS @ fIN up to 70 MHz @ 250 MSPS

ENOB of 10.5 @ f

SFDR = 80 dBc @ f

Excellent linearity

DNL =

±0.3 LSB typical

INL = ±0.7 LSB typical

CMOS outputs

Single data port at up to 250 MHz

Interleaved dual port @ ½ sample rate up to 125 MHz

700 MHz full power analog bandwidth

On-chip reference, no external decoupling required

Integrated input buffer and track-and-hold

Low power dissipation

272 mW

364 mW @ 250 MSPS

Programmable input voltage range

V to 1.5 V, 1.25 V nominal

1.0

1.8 V analog and digital supply operation

Selectable output data format (offset binary, twos

omplement, Gray code)

c

Clock duty cycle stabilizer

Integrated data capture clock

up to 70 MHz @ 250 MSPS (−1.0 dBFS)

IN

up to 70 MHz @ 250 MSPS (−1.0 dBFS)

IN

@ 170 MSPS

1.8 V Analog-to-Digital Converter

AD9626

APPLICATIONS

Wireless and wired broadband communications

Cable reverse path

Communications test equipment

Radar and satellite subsystems

Power amplifier linearization

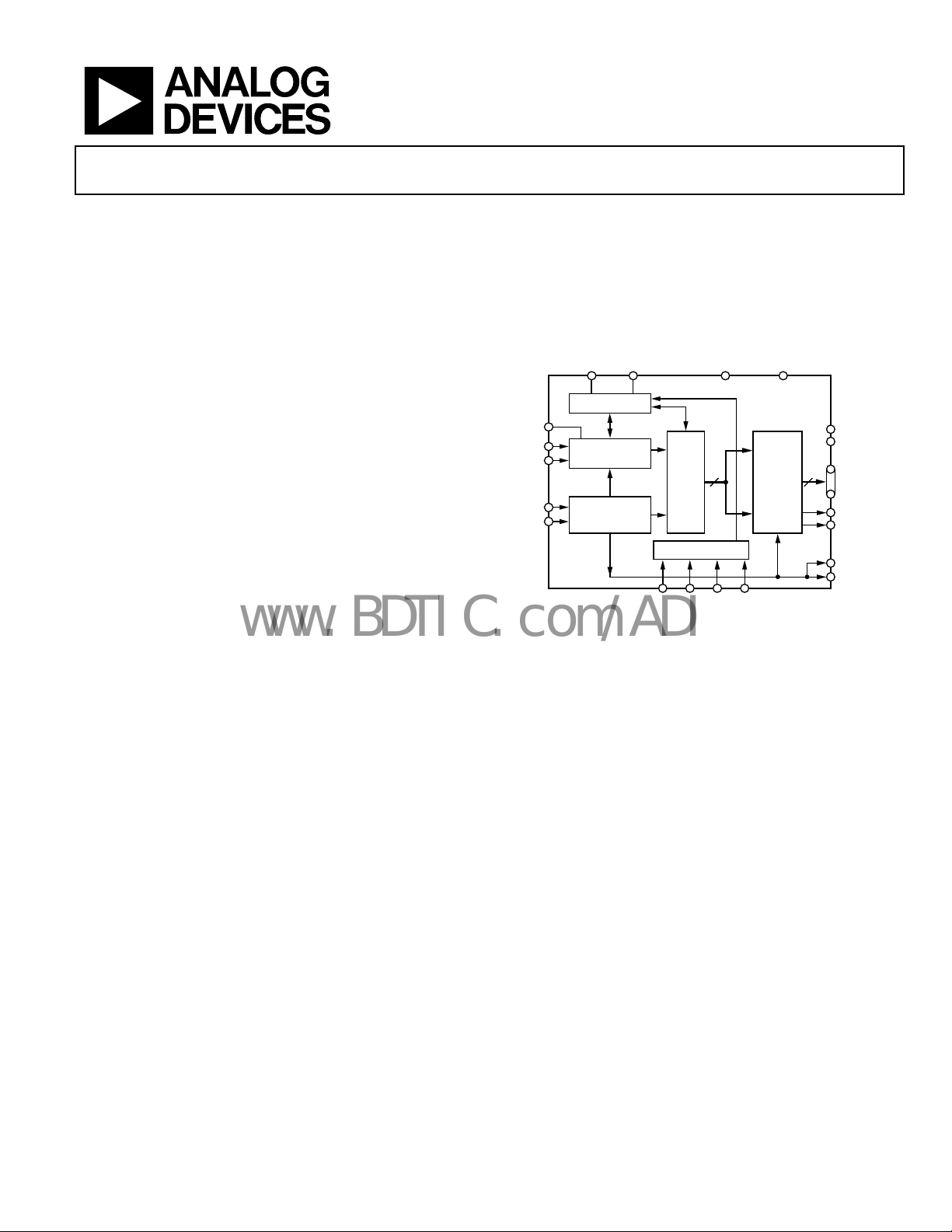

FUNCTIONAL BLOCK DIAGRAM

AGNDPWDNRBIAS AVDD (1.8V)

CML

VIN+

VIN–

CLK+

CLK–

REFERENCE

TRACK-AND-HOLD

CLOCK

MANAGEMENT

ADC

12-BIT

CORE

SERIAL PORT

SCLK SDIO CSB

RESET

12 12

Figure 1.

AD9626

OUTPUT

STAGING

LVDS

DRVDD

DRGND

Dx11 TO Dx0

OVRA

OVRB

DCO+

DCO–

07099-001

GENERAL DESCRIPTION

The AD9626 is a 12-bit monolithic sampling analog-to-digital

converter optimized for high performance, low power, and ease

of use. The product operates at up to a 250 MSPS conversion

rate and is optimized for outstanding dynamic performance in

wideband carrier and broadband systems. All necessary functions, including a track-and-hold (T/H) and voltage reference,

are included on the chip to provide a complete signal

conversion solution.

The ADC requires a 1.8 V analog voltage supply and a differen-

ial clock for full performance operation. The digital outputs are

t

CMOS compatible and support either twos complement, offset

binary format, or Gray code. A data clock output is available for

proper output data timing.

Fabricated on an advanced CMOS process, the AD9626 is

vailable in a 56-lead LFCSP, specified over the industrial

a

temperature range (−40°C to +85°C).

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

PRODUCT HIGHLIGHTS

1. High Performance—Maintains 64.9 dBFS SNR @ 250 MSPS

with a 70 MHz input.

2. L

ow Power—Consumes only 364 mW @ 250 MSPS.

3. E

ase of Use—CMOS output data and output clock signal

allow interface to current FPGA technology. The on-chip

reference and sample-and-hold provide flexibility in

system design. Use of a single 1.8 V supply simplifies

system power supply design.

erial Port Control—Standard serial port interface supports

4. S

various product functions, such as data formatting, clock

duty cycle stabilizer, power-down, gain adjust, and output

test pattern generation.

in-Compatible Family—10-bit pin-compatible family

5. P

offered as the AD9601.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2007 Analog Devices, Inc. All rights reserved.

Page 2

AD9626

www.BDTIC.com/ADI

TABLE OF CONTENTS

Features .............................................................................................. 1

Applications....................................................................................... 1

Functional Block Diagram .............................................................. 1

General Description......................................................................... 1

Product Highlights........................................................................... 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

DC Specifications ......................................................................... 3

AC Specifications.......................................................................... 4

Digital Specifications ................................................................... 5

Switching Specifications .............................................................. 6

Timing Diagrams.......................................................................... 7

Absolute Maximum Ratings............................................................ 8

Thermal Resistance ...................................................................... 8

ESD Caution.................................................................................. 8

Pin Configurations and Function Descriptions ........................... 9

Equivalent Circuits......................................................................... 11

Typical Performance Characteristics ........................................... 12

Theory of Operation ...................................................................... 18

Analog Input and Voltage Reference .......................................18

Clock Input Considerations...................................................... 19

Power Dissipation and Power-Down Mode ........................... 20

Digital Outputs........................................................................... 20

Timing—Single Port Mode ....................................................... 21

Timing—Interleaved Mode....................................................... 21

Layout Considerations................................................................... 22

Power and Ground Recommendations................................... 22

CML ............................................................................................. 22

RBIAS........................................................................................... 22

AD9626 Configuration Using the SPI..................................... 22

Hardware Interface..................................................................... 23

Configuration Without the SPI................................................ 23

Memory Map .................................................................................. 25

Reading the Memory Map Table.............................................. 25

Reserved Locations .................................................................... 25

Default Values............................................................................. 25

Logic Levels................................................................................. 25

Evaluation Board ............................................................................ 27

Outline Dimensions ....................................................................... 33

Ordering Guide .......................................................................... 33

REVISION HISTORY

11/07—Revision 0: Initial Version

Rev. 0 | Page 2 of 36

Page 3

AD9626

www.BDTIC.com/ADI

SPECIFICATIONS

DC SPECIFICATIONS

AVDD = 1.8 V, DRVDD = 1.8 V, T

unless otherwise noted.

Table 1.

Parameter

1

RESOLUTION 12 12 12 Bits

ACCURACY

No Missing Codes Full Guaranteed Guaranteed Guaranteed

Offset Error 25°C 4.0 4.0 4.0 mV

Full −12 +12 −12 +12 −12 +12 mV

Gain Error 25°C 1.4 1.4 1.4 % FS

Full −2.1 +4.5 −2.1 +4.5 −2.1 +4.5 % FS

Differential Nonlinearity (DNL) 25°C 0.3 0.3 0.3 LSB

Full −0.6 +0.6 −0.6 +0.6 −0.6 +0.6 LSB

Integral Nonlinearity (INL) 25°C 0.7 0.6 0.7 LSB

Full −1.4 +1.4 −1.1 +1.1 −1.7 +1.7 LSB

TEMPERATURE DRIFT

Offset Error Full ±8 ±8 ±8 µV/°C

Gain Error Full 0.021 0.021 0.021 %/°C

ANALOG INPUTS (VIN+, VIN−)

Differential Input Voltage Range2Full 0.98 1.25 1.5 0.98 1.25 1.5 0.98 1.25 1.5 V p-p

Input Common-Mode Voltage Full 1.4 1.4 1.4 V

Input Resistance (Differential) Full 4.3 4.3 4.3 kΩ

Input Capacitance 25°C 2 2 2 pF

POWER SUPPLY

AVDD Full 1.7 1.8 1.9 1.7 1.8 1.9 1.7 1.8 1.9 V

DRVDD Full 1.58 1.8 1.9 1.7 1.8 1.9 1.7 1.8 1.9 V

Supply Currents

3

I

AVDD

3

I

/Single Port Mode

DRVDD

3

I

/Interleaved Mode

DRVDD

Power Dissipation

Single Port Mode

Interleaved Mode

3

4

5

4

5

Power-Down Mode Supply

Currents

I

AVDD

I

DRVDD

Standby Mode Supply Currents

I

AVDD

I

DRVDD

1

See the AN-835 Application Note, Understanding High Speed ADC Testing and Evaluation, for a complete set of definitions and how these tests were completed.

2

The input range is programmable through the SPI, and the range specified reflects the nominal values of each setting. See the Memory Map section.

3

I

and I

AVDD

4

Single data rate mode; this is the default mode of the AD9626.

5

Interleaved mode; user-programmable feature. See the Memory Map section.

are measured with a −1 dBFS, 10.3 MHz sine input at rated sample rate.

DRVDD

= −40°C, T

MIN

= +85°C, fIN = −1.0 dBFS, full scale = 1.25 V, single port output mode, DCS enabled,

MAX

AD9626-170 AD9626-210 AD9626-250

Temp Min Typ Max Min Typ Max Min Typ Max Unit

Full 134 143 151 161 178 191 mA

Full 17 18.5 21 22 24 25.5 mA

Full 15 18 20 mA

Full mW

Full 272 291 310 330 364 390 mW

Full 268 304 357 mW

Full 40 40 40 µA

Full 170 170 22 170 µA

Full 19 19 19 mA

Full 170 170 22 170 µA

Rev. 0 | Page 3 of 36

Page 4

AD9626

www.BDTIC.com/ADI

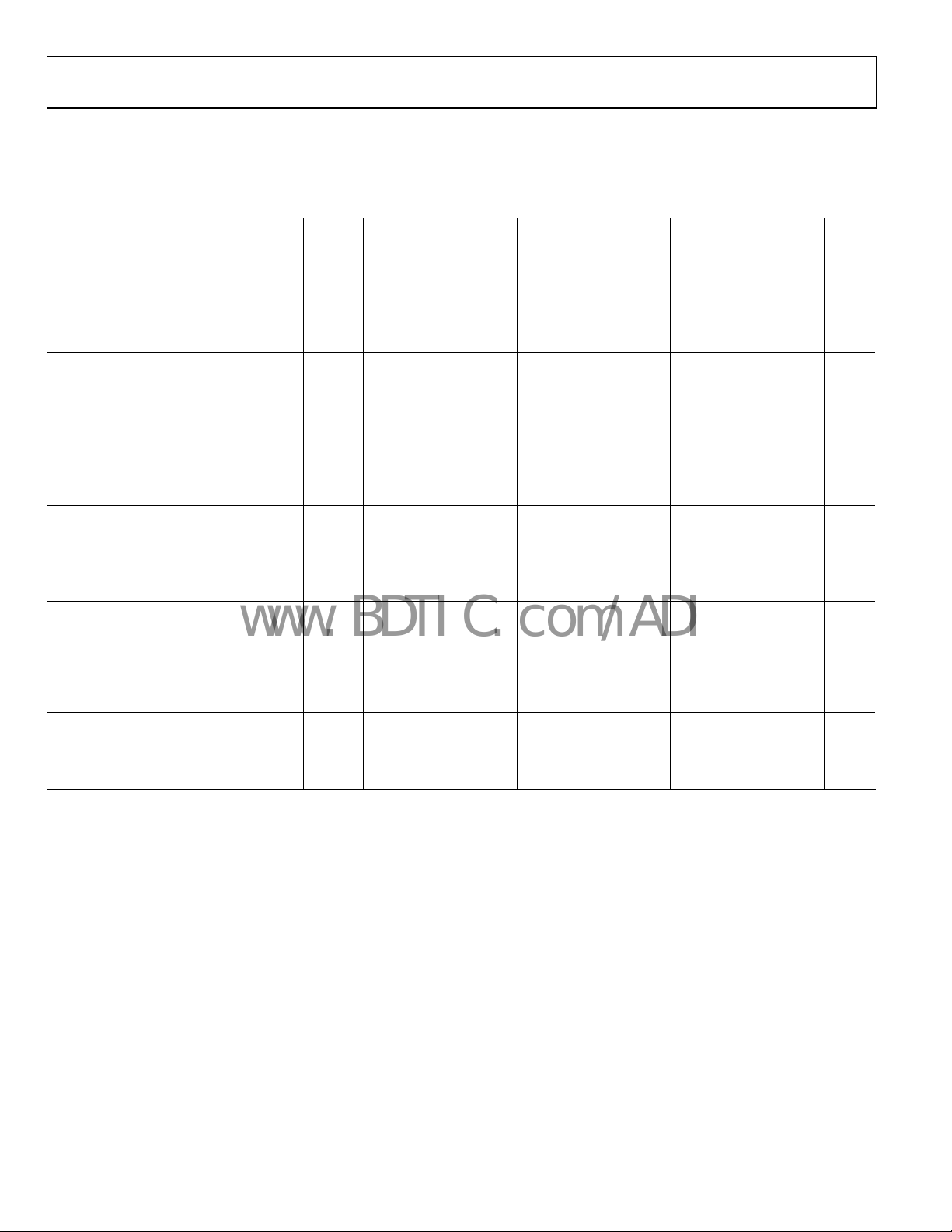

AC SPECIFICATIONS

AVDD = 1.8 V, DRVDD = 1.8 V, T

enabled, unless otherwise noted.

Table 2.

Parameter2 Temp Min Typ Max Min Typ Max Min Typ Max Unit

SNR

fIN = 10 MHz 25°C 64.5 64.4 64.0 dB

Full 63.6 63.0 dB

fIN = 70 MHz 25°C 64.4 64.2 63.8 dB

Full 63.0 62.3 dB

SINAD

fIN = 10 MHz 25°C 64.5 64.4 64.0 dB

Full 63.5 62.8 dB

fIN = 70 MHz 25°C 64.2 64.0 63.4 dB

Full 62.6 62.0 dB

EFFECTIVE NUMBER OF BITS (ENOB)

fIN = 10 MHz 25°C 10.6 10.6 10.5 Bits

fIN = 70 MHz 25°C 10.5 10.5 10.5 Bits

WORST HARMONIC (SECOND OR THIRD)

fIN = 10 MHz 25°C 84 86 83 dBc

Full 75 77 73 dBc

fIN = 70 MHz 25°C 79 79 80 dBc

Full 71 73 71 dBc

WORST OTHER (SFDR EXCLUDING

SECOND AND THIRD)

fIN = 10 MHz 25°C 92 90 84 dBc

Full 85 79 76 dBc

fIN = 70 MHz 25°C 92 87 84 dBc

Full 81 77 73 dBc

TWO-TONE IMD

140.2 MHz/141.3 MHz @ −7 dBFS 25°C 80 dBFS

170.2 MHz/171.3 MHz @ −7 dBFS 25°C 83 83 dBc

ANALOG INPUT BANDWIDTH 25°C 700 700 700 MHz

1

All ac specifications tested by driving CLK+ and CLK− differentially.

2

See the AN-835 Application Note, Understanding High Speed ADC Testing and Evaluation, for a complete set of definitions and how these tests were completed.

= −40°C, T

MIN

1

= +85°C, fIN = −1.0 dBFS, full scale = 1.25 V, , Single Port Output mode, DCS

MAX

AD9626-170 AD9626-210 AD9626-250

Rev. 0 | Page 4 of 36

Page 5

AD9626

www.BDTIC.com/ADI

DIGITAL SPECIFICATIONS

AVDD = 1.8 V, DRVDD = 1.8 V, T

Table 3.

AD9626-170 AD9626-210 AD9626-250

Parameter1 Temp Min Typ Max Min Typ Max Min Typ Max Unit

CLOCK INPUTS

Logic Compliance Full CMOS/LVDS/LVPECL CMOS/LVDS/LVPECL CMOS/LVDS/LVPECL

Internal Common-Mode Bias Full 1.2 1.2 1.2 V

Differential Input Voltage Full 0.2 6 0.2 6 0.2 6 V p-p

Input Voltage Range Full

Input Common-Mode Range Full 1.1 AVDD 1.1 AVDD 1.1 AVDD V

High Level Input Voltage (VIH) Full 1.2 3.6 1.2 3.6 1.2 3.6 V

Low Level Input Voltage (VIL) Full 0 0.8 0 0.8 0 0.8 V

Input Resistance (Differential) Full 16 20 24 16 20 24 16 20 24 kΩ

Input Capacitance Full 4 4 4 pF

LOGIC INPUTS

Logic 1 Voltage Full

Logic 0 Voltage Full

Logic 1 Input Current (SDIO) Full 0 0 0 µA

Logic 0 Input Current (SDIO) Full −60 −60 −60 µA

Logic 1 Input Current

(SCLK, PDWN, CSB, RESET)

Logic 0 Input Current

(SCLK, PDWN, CSB, RESET)

Input Capacitance 25°C 4 4 4 pF

LOGIC OUTPUTS2

High Level Output Voltage Full DRVDD − 0.05 DRVDD − 0.05 DRVDD − 0.05 V

Low Level Output Voltage Full GND + 0.05 GND + 0.05 GND + 0.05 V

Output Coding Twos complement, Gray code, or offset binary (default)

1

See the AN-835 Application Note, Understanding High Speed ADC Testing and Evaluation, for a complete set of definitions and how these tests were completed.

2

LVDS R

TERMINATION

= 100 Ω.

= −40°C, T

MIN

AVDD −

0.3

0.8 ×

A

Full 55 55 50 µA

Full 0 0 0 µA

= +85°C, fIN = −1.0 dBFS, full scale = 1.25 V, DCS enabled, unless otherwise noted.

MAX

VDD

AVDD +

1.6

0.2 ×

VDD

A

AVDD −

0.3

0.8 ×

A

VDD

AVDD +

1.6

0.2 ×

AVDD

AVDD −

0.3

0.8 ×

A

VDD

V

AVDD +

1.6

0.2 ×

AVDD

V

V

Rev. 0 | Page 5 of 36

Page 6

AD9626

www.BDTIC.com/ADI

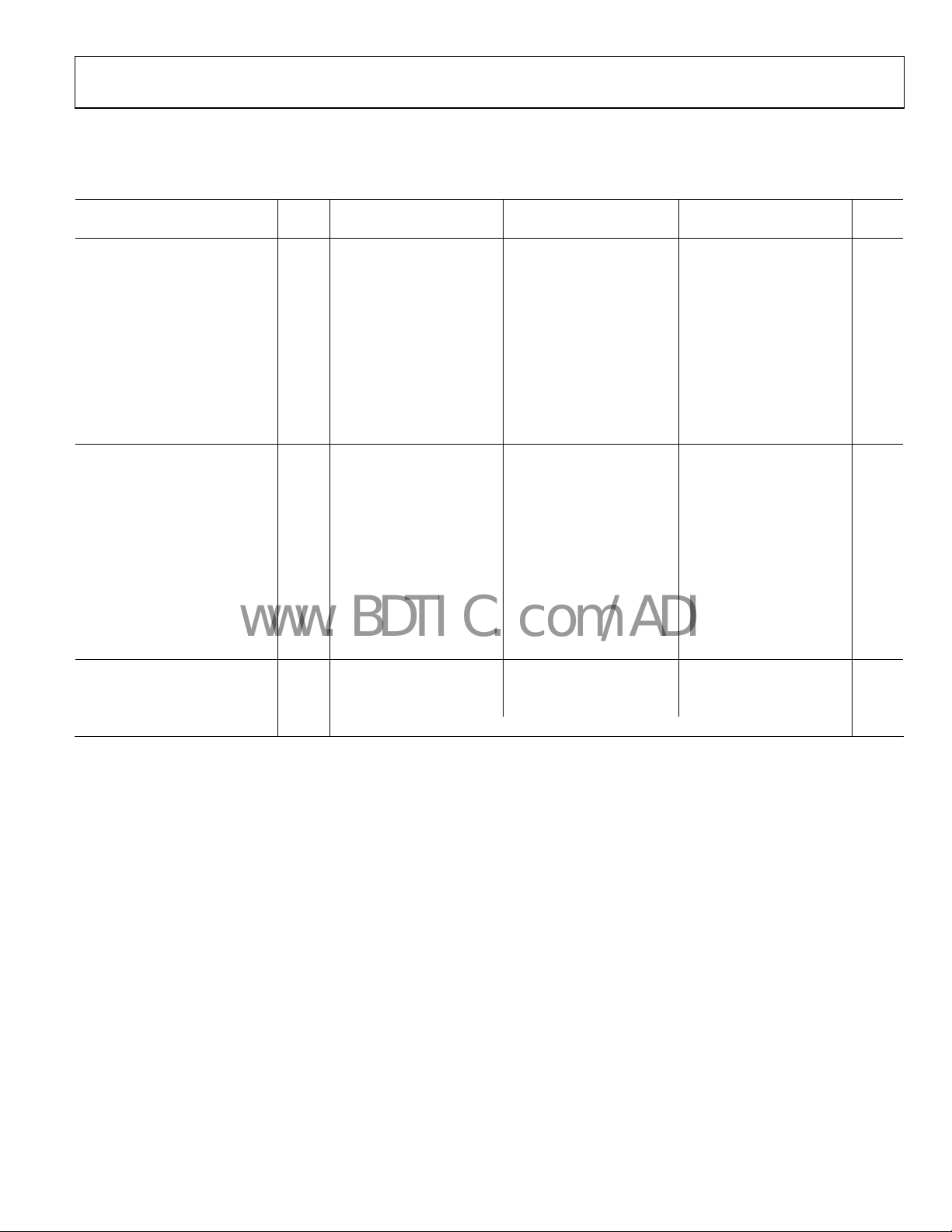

SWITCHING SPECIFICATIONS

AVDD = 1.8 V, DRVDD = 1.8 V, T

Table 4.

AD9626-170 AD9626-210 AD9626-250

Parameter (Conditions) Temp Min Typ Max Min Typ Max Min Typ Max Unit

Maximum Conversion Rate Full 170

Minimum Conversion Rate Full

CLK+ Pulse Width High (tCH) Full 2.65 2.9 2.15 2.4 1.8 2.0 ns

CLK+ Pulse Width Low (tCL) Full 2.65 2.9 2.15 2.4 1.8 2.0 ns

Output, Single Data Port Mode

Data Propagation Delay (tPD) 25°C 3.7 3.7 3.7 ns

DCO Propagation Delay (t

Data to DCO Skew (t

CPD

) Full 0 0.3 0.55 0 0.3 0.55 0 0.3 0.55 ns

SKEW

Latency Full 6 6 6 Cycles

SKEWA

2

PDA

CPDA

, t

SKEWB

Output, Interleaved Mode

Data Propagation Delay (t

DCO Propagation Delay (t

Data to DCO Skew (t

Latency Full 6 6 6 Cycles

Standby Recovery 25°C 250 250 250 ns

Power-Down Recovery

Aperture Delay (tA) 25°C 0.1 0.1 0.1 ns

Aperture Uncertainty (Jitter, tJ) 25°C 0.2 0.2 0.2 ps rms

1

See Figure 2.

2

See Figure 3.

1

= −40°C, T

MIN

= +85°C, fIN = −1.0 dBFS, full scale = 1.25 V, DCS enabled, unless otherwise noted.

MAX

40

210

250

40

40 MSPS

MSPS

) 25°C 3.4 3.4 3.4 ns

, t

) 25°C 3.5 3.5 3.5 ns

PDB

, t

) 25°C 3.0 3.0 3.0 ns

CPDB

) Full 0 0.5 1.1 0 0.5 1.1 0 0.5 1.1 ns

50 50 50 µs

Rev. 0 | Page 6 of 36

Page 7

AD9626

www.BDTIC.com/ADI

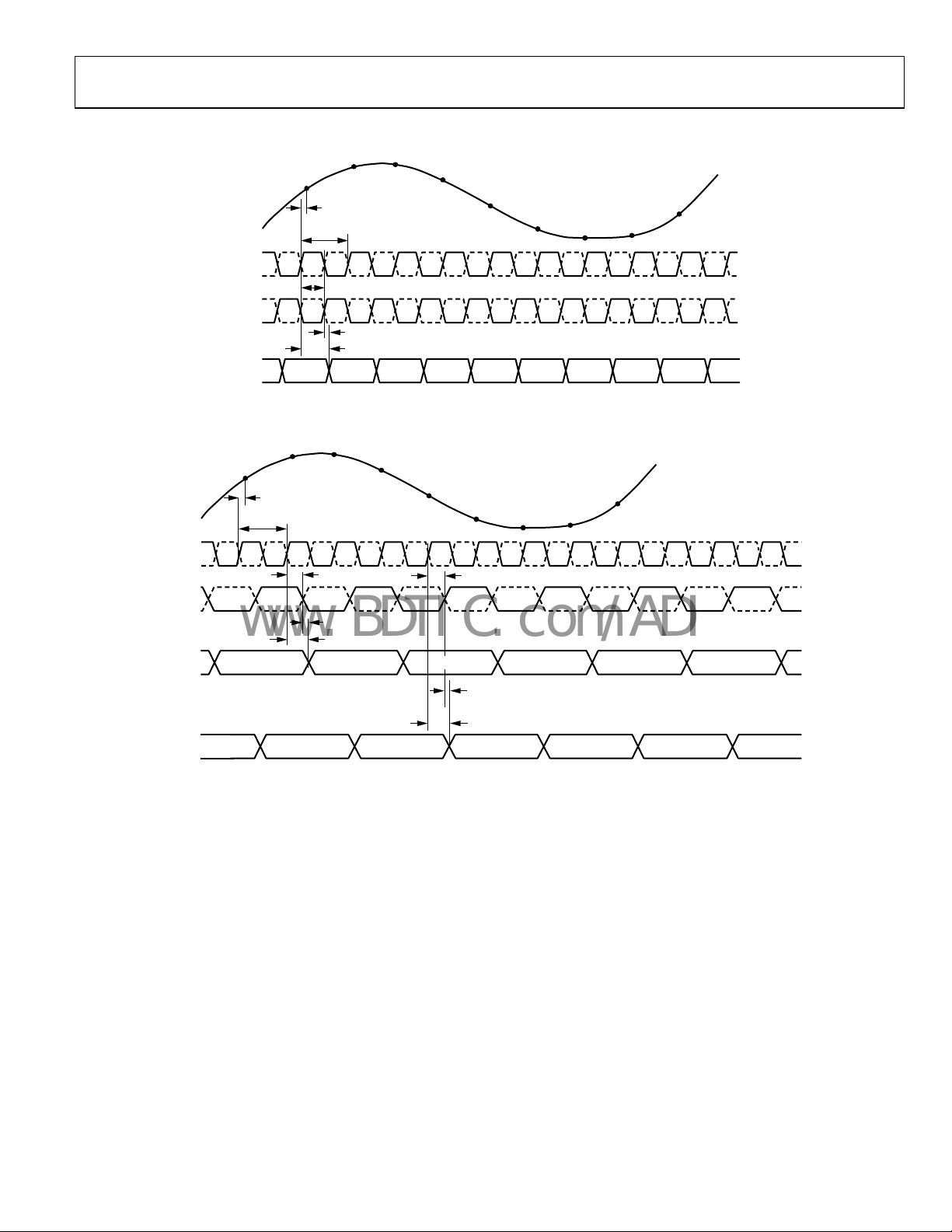

TIMING DIAGRAMS

N + 2

N + 1

N

t

A

t

= 1/

f

CLK+

CLK–

DCO–

DCO+

t

DAX N – 6 N – 5 N – 4 N – 3 N – 2 N – 1 N N + 1 N + 2N – 7

CLK

t

CPD

t

SKEW

PD

N + 2

CLK+

CLK–

DCO+

DCO–

DAX

N + 1

N

t

A

t

= 1/

f

CLK

t

CPDA

t

t

PDA

SKEWA

N + 3

CLK

N – 6

N + 3

CLK

Figure 2. Single Port Mode

N + 4

N + 5

t

CPDB

N – 4

N + 4

N + 6

N + 5

N – 2

N + 7

N + 6

N + 8

N + 7

N + 8

07099-051

N

N + 2

t

SKEWB

t

PDB

DBX

N – 7

N – 5

N – 3

N – 1

N + 1

07099-050

Figure 3. Interleaved Mode

Rev. 0 | Page 7 of 36

Page 8

AD9626

www.BDTIC.com/ADI

ABSOLUTE MAXIMUM RATINGS

Table 5.

Parameter Rating

ELECTRICAL

AVDD to AGND −0.3 V to +2.0 V

DRVDD to DRGND −0.3 V to +2.0 V

AGND to DRGND −0.3 V to +0.3 V

AVDD to DRVDD −2.0 V to +2.0 V

Dx0 Through Dx11 to DRGND −0.3 V to DRVDD + 0.3 V

DCO+/DCO− to DRGND −0.3 V to DRVDD + 0.3 V

OVRA/OVRB to DGND −0.3 V to DRVDD + 0.3 V

CLK+ to AGND −0.3 V to +3.6 V

CLK− to AGND −0.3 V to +3.6 V

VIN+ to AGND −0.3 V to AVDD + 0.2 V

VIN− to AGND −0.3 V to AVDD + 0.2 V

SDIO/DCS to DGND −0.3 V to DRVDD + 0.3 V

PDWN to AGND −0.3 V to +3.6 V

CSB to AGND −0.3 V to +3.6 V

SCLK/DFS to AGND −0.3 V to +3.6 V

ENVIRONMENTAL

Storage Temperature Range −65°C to +125°C

Operating Temperature Range −40°C to +85°C

Lead Temperature

(Soldering, 10 sec)

Junction Temperature 150°C

300°C

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL RESISTANCE

The exposed paddle must be soldered to the ground plane for

the LFCSP package. Soldering the exposed paddle to the

customer board increases the reliability of the solder joints,

maximizing the thermal capability of the package.

Table 6.

Package Type θ

56-Lead LFCSP (CP-56-2) 30.4 2.9 °C/W

Typical θJA and θJC are specified for a 4-layer board in still air.

Airflow increases heat dissipation, effectively reducing θ

addition, metal in direct contact with the package leads from

metal traces, and through holes, ground, and power planes

reduces the θ

.

JA

JA

θ

JC

Unit

JA

. In

ESD CAUTION

Rev. 0 | Page 8 of 36

Page 9

AD9626

www.BDTIC.com/ADI

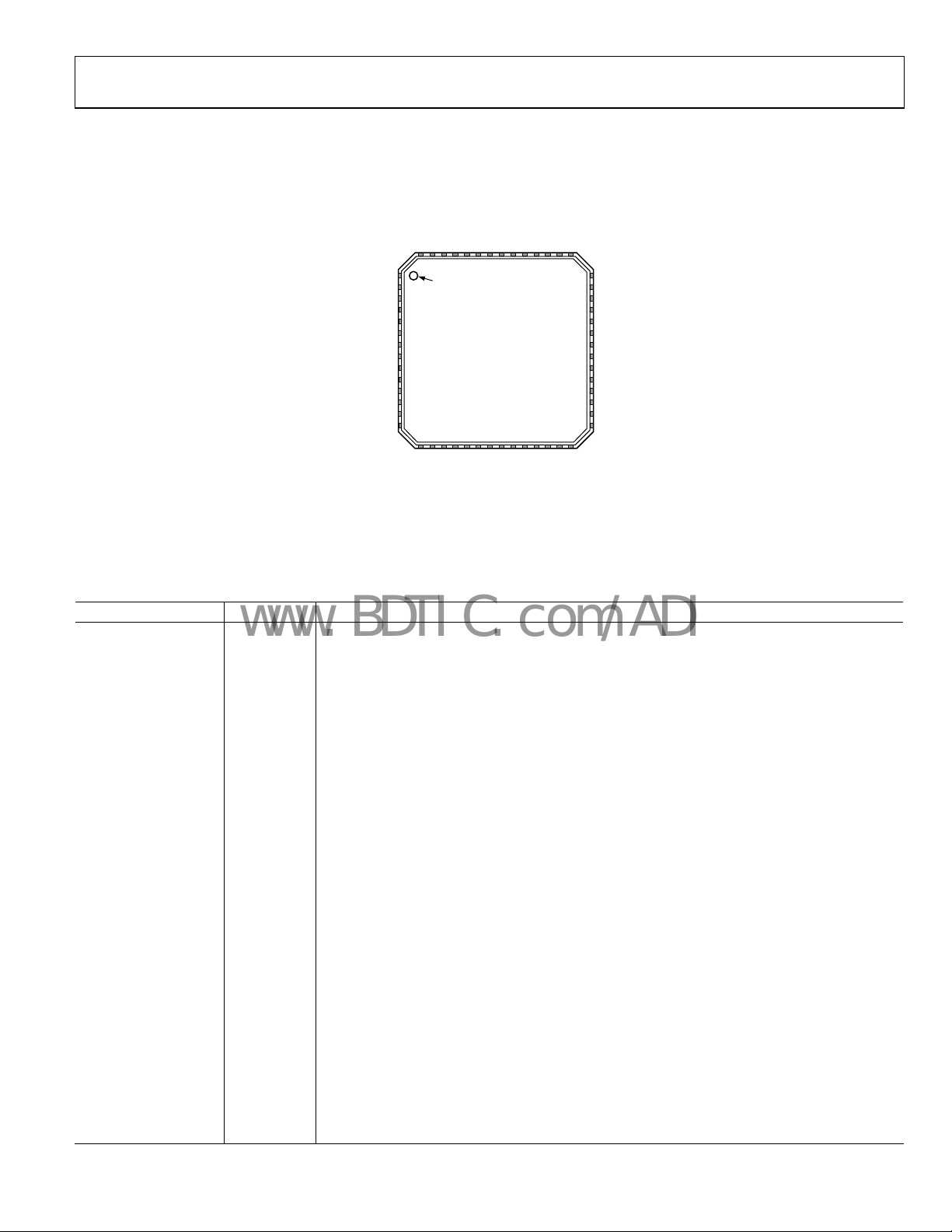

PIN CONFIGURATIONS AND FUNCTION DESCRIPTIONS

SB)

AVDD

DA3

DA2

DA1

DA0 (L

DCO+

DA5

DA4

54

56

55

DCO–

53

52

51

50

49

CLK+

DRGND

DRVDD

AVDD

CLK–

43

44

48

47

46

45

1DA6

2DA7

3DA8

4DA9

5DA10

6(MSB) DA11

7DRVDD

8DRGND

9OVRA

10(LSB) DB0

11DB1

12DB2

13DB3

14DB4

PIN 1

INDICATO R

AD9626

TOP VIEW

(Not to Scale)

PIN 0 (EXPOS ED PADDLE) = AGND

21

17

16

18

19

15

DB5

20

B7

DB8

DB9

D

DB6

DB10

25

26

24

23

22

/DCS

OVRB

DRVDD

DRGND

SDIO

(MSB) DB11

SCLK/DFS

42 AVDD

41 AVDD

40 CML

39 AVDD

38 AVDD

37 AVDD

36 VIN–

35 VIN+

34 AVDD

33 AVDD

32 AVDD

31 RBIAS

30 AVDD

29 PWDN

28

27

CSB

RESET

07099-002

Figure 4. Pin Configuration

Table 7. Single Data Rate Mode Pin Function Descriptions

Pin No. Mnemonic Description

30, 32, 33, 34, 37, 38,

AVDD 1.8 V Analog Supply.

39, 41, 42, 43, 46

7, 24, 47 DRVDD 1.8 V Digital Output Supply.

0 AGND

8, 23, 48 DRGND

1

1

Analog Ground.

Digital Output Ground.

35 VIN+ Analog Input—True.

36 VIN− Analog Input—Complement.

40 CML

Common-Mode Output Pin. Enabled through the SPI, this pin provides a reference for the

ed internal bias voltage for VIN+/VIN−.

optimiz

44 CLK+ Clock Input—True.

45 CLK− Clock Input—Complement.

31 RBIAS Set Pin for Chip Bias Current. (Place 1% 10 kΩ resistor terminated to ground.) Nominally 0.5 V.

28 RESET CMOS-Compatible Chip Reset (Active Low).

25 SDIO/DCS

Serial Port Interface (SPI) Data Input/Output (Serial P

ort Mode); Duty Cycle Stabilizer Select

(External Pin Mode).

26 SCLK/DFS Serial Port Interface Clock (Serial Port Mode); Data Format Select Pin (External Pin Mode).

27 CSB Serial Port Chip Select (Active Low).

29 PWDN Chip Power-Down.

49 DCO− Data Clock Output—Complement.

50 DCO+ Data Clock Output—True.

51 DA0 (LSB) Output Port A Output Bit 0 (LSB).

52 DA1 Output Port A Output Bit 1.

53 DA2 Output Port A Output Bit 2.

54 DA3 Output Port A Output Bit 3.

55 DA4 Output Port A Output Bit 4.

56 DA5 Output Port A Output Bit 5.

1 DA6 Output Port A Output Bit 6.

2 DA7 Output Port A Output Bit 7.

Rev. 0 | Page 9 of 36

Page 10

AD9626

www.BDTIC.com/ADI

Pin No. Mnemonic Description

3 DA8 Output Port A Output Bit 8.

4 DA9 Output Port A Output Bit 9.

5 DA10 Output Port A Output Bit 10.

6 DA11 (MSB) Output Port A Output Bit 11 (MSB).

9 OVRA Output Port A Overrange Output Bit.

10 DB0 (LSB) Output Port B Output Bit 0 (LSB).

11 DB1 Output Port B Output Bit 1.

12 DB2 Output Port B Output Bit 2.

13 DB3 Output Port B Output Bit 3.

14 DB4 Output Port B Output Bit 4.

15 DB5 Output Port B Output Bit 5.

16 DB6 Output Port B Output Bit 6.

17 DB7 Output Port B Output Bit 7.

18 DB8 Output Port B Output Bit 8.

19 DB9 Output Port B Output Bit 9.

20 DB10 Output Port B Output Bit 10.

21 DB11 (MSB) Output Port B Output Bit 11 (MSB).

22 OVRB Output Port B Overrange Output Bit.

1

AGND and DRGND should be tied to a common quiet ground plane.

Rev. 0 | Page 10 of 36

Page 11

AD9626

V

C

www.BDTIC.com/ADI

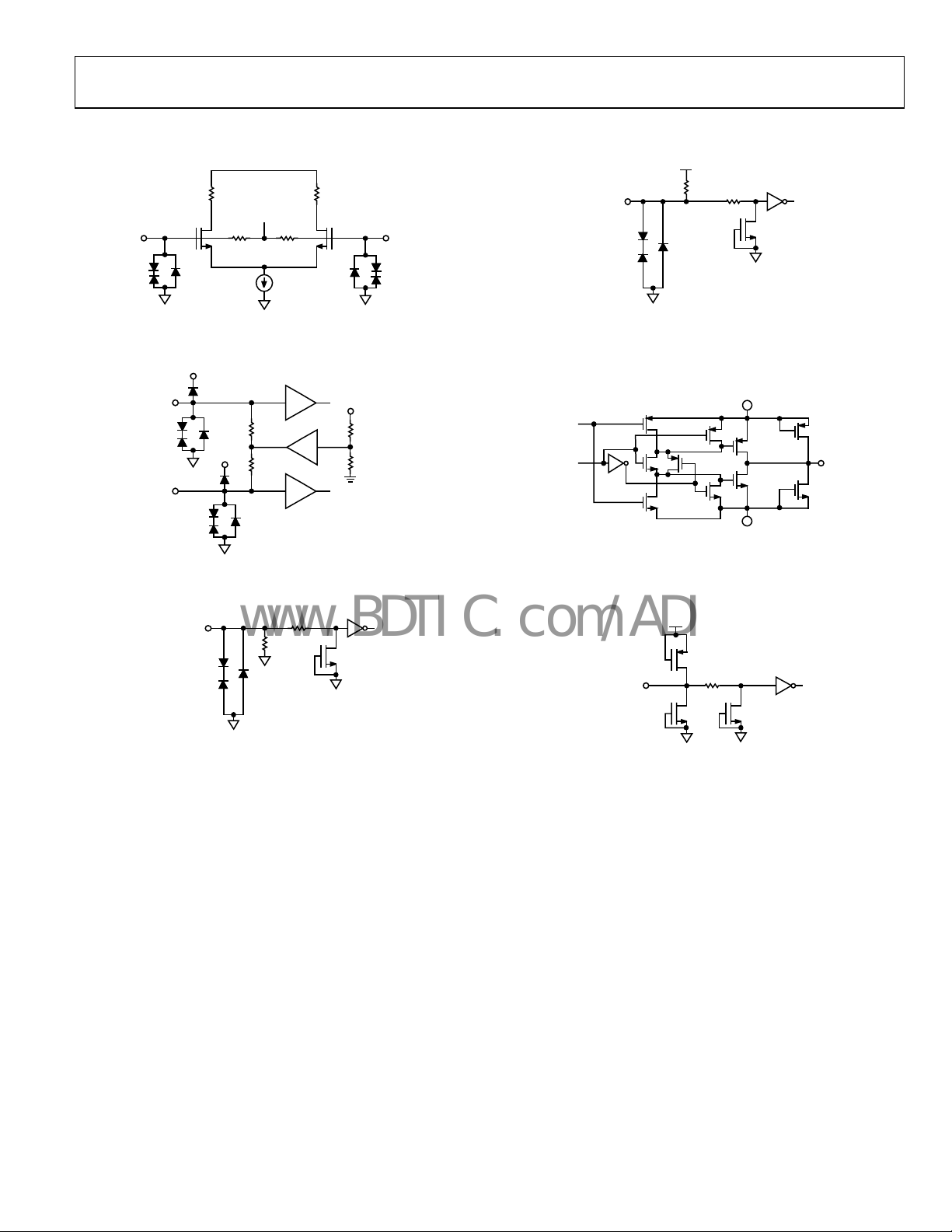

EQUIVALENT CIRCUITS

CLK+

10kΩ 10kΩ

Figure 5. Clock Inputs

AVDD

AVDD

1.2V

CLK–

SB

07099-003

Figure 8. Equivalent CSB Input Circuit

AVDD

26kΩ

1kΩ

07099-006

1kΩ

DRVDD

DRGND

7099-052

07099-007

BUF

CML

AVDD

= ~1.4 V)

V

CML

~1.4V

7099-004

07099-005

IN+

AVDD

VIN–

Figure 6. Analog Inputs (V

SCLK/DFS

RESET

PDWN

BUF

2kΩ

2kΩ

BUF

1kΩ

30kΩ

Figure 7. Equivalent SCLK/DFS, RESET, PDWN Input Circuit

Figure 9. CMOS Outputs (Dx, OVRA, OVRB, DCO+, DCO−)

DRVDD

SDIO/DCS

Figure 10. Equivalent SDIO/DCS Input Circuit

Rev. 0 | Page 11 of 36

Page 12

AD9626

www.BDTIC.com/ADI

TYPICAL PERFORMANCE CHARACTERISTICS

AVDD = 1.8 V, DRVDD = 1.8 V, rated sample rate, DCS enabled, TA = 25°C, 1.25 V p-p differential input, AIN = −1 dBFS, unless

otherwise noted.

–20

–40

0

170MSPS

10.3MHz @ –1.0d BFS

SNR: 64.5dB

ENOB: 10.6 BI TS

SFDR: 84dBFS

35k

30k

25k

–60

–80

AMPLITUDE ( dBFS)

–100

–120

–140

10 20 30 40 50 60 70 80

0

FREQUENCY (MHz)

Figure 11. AD9626-170 64k Point Single-Tone FFT; 170 MSPS, 10.3 MHz

0

170MSPS

70.3MHz @ –1.0d BFS

–20

SNR: 64.4dB

ENOB: 10.5 BI TS

SFDR: 79dBFS

–40

–60

–80

AMPLITUDE ( dBFS)

–100

–120

–140

10 20 30 40 50 60 70 80

0

FREQUENCY (MHz)

Figure 12. AD9626-170 64k Point Single-Tone FFT; 170 MSPS, 70.3 MHz

20k

15k

NUMBER OF HIT S

10k

5k

0

N – 4

N – 3 N – 2 N – 1 N N + 1 N + 2 N + 3 N + 4

07099-020

BIN

07099-023

Figure 14. AD9626-170 Grounded Input Histogram; 170 MSPS

90

85

80

75

70

65

SNR/SFDR (dB)

60

55

50

07099-021

SFDR (+25°C)

50 100 150 200 250 300 350 400 450

0 500

ANALOG INPUT FREQUENCY (MHz)

Figure 15. AD9626-170 Single-Tone SNR/SFDR vs. Input Frequency (f

SFDR (+85°C)

SFDR (–40°C)

SNR (+25° C)

SNR (+85°C)

SNR (–40°C)

) and

IN

07099-024

Temperature with 1.25 V p-p Full Scale; 170 MSPS

AMPLITUDE (dBFS)

–20

–40

–60

–80

–100

–120

–140

0

0

10 20 30 40 50 60 70 80

FREQUENCY (MHz)

170MSPS

140.3MHz @ –1.0d BFS

SNR: 63.7dB

ENOB: 10.4 BI TS

SFDR: 80dBc

07099-022

Figure 13. AD9626-170 64k Point Single-Tone FFT; 170 MSPS, 140.3 MHz

Rev. 0 | Page 12 of 36

100

90

SFDR (dBFS)

80

70

SNR (dBFS)

60

50

40

SNR/SFDR (dB)

30

SFDR (dBc)

20

10

0

90 0

80 70 60 50 40 30 20 10

AMPLITUDE (–dBFS)

SNR (dB)

Figure 16. AD9626-170 SNR/SFDR vs. Input Amplitude; 140.3 MHz

07099-025

Page 13

AD9626

www.BDTIC.com/ADI

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

0 4096

512 1024 1536 2048 2560 3072 3584

OUTPUT CODE

Figure 17. AD9626-170 INL; 170 MSPS

07099-026

90

85

80

75

70

SNR (–40°C)

65

SNR/SFDR (dB)

60

SNR (+85°C)

55

50

0 500

50 100 150 200 250 300 350 400 450

ANALOG INPUT FREQUENCY (MHz)

SFDR (+25°C)

SFDR (–40°C)

SFDR (+85°C)

SNR (+25°C)

Figure 20. SNR/SFDR vs. Analog Input Frequency,

Temperature

Interleaved Mode vs.

07099-029

400

350

300

250

200

150

CURRENT (mA)

100

50

0

5 245

25 45 65 85 105 125 145 165 185 205 225

TOTAL POWER (mW)

I

(mA)

AVDD

I

(mA)

DVDD

SAMPLE RATE (MSPS)

Figure 18. AD9626-170 Power Supply Current vs. Sample Rate

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

0 4096

512 1024 1536 2048 2560 3072 3584

OUTPUT CODE

Figure 19. AD9626-170 DNL; 170 MSPS

0

–20

–40

–60

–80

AMPLITUDE (dBFS)

–100

–120

–140

0

07099-027

20 40 60 80 100

FREQUENCY (MHz)

210MSPS

10.3MHz @ –1.0d BFS

SNR: 64.5dB

ENOB: 10.6 BI TS

SFDR: 86dBc

07099-030

Figure 21. AD9626-210 64k Point Single-Tone FFT; 210 MSPS, 10.3 MHz

0

210MSPS

70.3MHz @ –1.0d BFS

–20

SNR: 64.2dB

ENOB: 10.5 BI TS

SFDR: 79dBc

–40

–60

–80

AMPLITUDE (dBFS)

–100

–120

–140

0

07099-028

20 40 60 80 100

FREQUENCY (MHz)

07099-031

Figure 22. AD9626-210 64k Point Single-Tone FFT; 210 MSPS, 70.3 MHz

Rev. 0 | Page 13 of 36

Page 14

AD9626

www.BDTIC.com/ADI

AMPLITUDE (dBFS)

–20

–40

–60

–80

–100

–120

–140

0

0

20 40 60 80 100

FREQUENCY (MHz)

210MSPS

170.3MHz @ –1.0d BFS

SNR: 63.23dB

ENOB: 10.4 BI TS

SFDR: 78dBc

Figure 23. AD9626-210 64k Point Single-Tone FFT; 210 MSPS, 170.3 MHz

35k

30k

25k

20k

15k

NUMBER OF HIT S

10k

5k

0

N – 3

N – 2 N – 1 N N + 1 N + 2 N + 3 N + 4 N + 5

BIN

Figure 24. AD9626-210 Grounded Input Histogram; 210 MSPS

100

SFDR (dBFS)

90

80

70

SNR (dBFS)

60

50

40

SNR/SFDR (dB)

07099-032

SFDR (dBc)

30

20

10

0

90 0

80 70 60 50 40 30 20 10

AMPLITUDE (–dBFS)

SNR (dB)

07099-035

Figure 26. AD9626-210 SNR/SFDR vs. Input Amplitude; 210 MSPS, 170.3 MHz

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

0 4096

512 1024 1536 2048 2560 3072 3584

07099-033

OUTPUT CODE

07099-036

Figure 27. AD9626-210 INL; 210 MSPS

90

85

80

75

70

65

SNR/SFDR (dB)

60

55

50

SNR (–40°C)

SNR (+85°C)

0 500

50 100 150 200 250 300 350 400 450

SFDR (+25°C)

ANALOG INPUT FREQUENCY (MHz)

Figure 25. AD9626-210 Single-Tone SNR/SFDR vs. Input Frequency (f

SFDR (+85°C)

SFDR (–40°C)

SNR (+25°C)

07099-034

)

IN

and Temperature with 1.25 V p-p Full Scale; 210 MSPS

Rev. 0 | Page 14 of 36

400

350

300

250

200

150

CURRENT (mA)

100

50

0

5 245

25 45 65 85 105 125 145 165 185 205 225

TOTAL POWER (mW)

I

AVDD

I

DVDD

SAMPLE RATE (MSPS)

(mA)

(mA)

Figure 28. AD9626-210 Power Supply Current vs. Sample Rate

07099-037

Page 15

AD9626

www.BDTIC.com/ADI

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

0 4096

512 1024 1536 2048 2560 3072 3584

OUTPUT CODE

Figure 29. AD9626-210 DNL; 210 MSPS

07099-038

0

250MSPS

170MHz @ –1.0dBF S

–20

SNR: 62.9dB

ENOB: 10.2 BI TS

SFDR: 72dBc

–40

–60

–80

AMPLITUDE (dBFS)

–100

–120

–140

0

20 40 60 80 100 120

FREQUENCY (MHz)

07099-040

Figure 32. AD9626-250 64k Point Single-Tone FFT; 250 MSPS, 170.3 MHz

AMPLITUDE (dBFS)

–20

–40

–60

–80

–100

–120

–140

0

0

20 40 60 80 100 120

FREQUENCY (MHz)

250MSPS

10.3MHz @ –1.0d BFS

SNR: 64.0dB

ENOB: 10.5 BI TS

SFDR: 83dBc

07099-039

Figure 30. AD9626-250 64k Point Single-Tone FFT; 250 MSPS, 10.3 MHz

0

250MSPS

70.3MHz @ –1.0d BFS

–20

SNR: 63.8dB

ENOB: 10.6 BI TS

SFDR: 80dBc

–40

–60

–80

AMPLITUDE ( dBFS)

–100

–120

35k

30k

25k

20k

15k

NUMBER OF HIT S

10k

5k

0

N – 4

N – 3 N – 2 N – 1 N N + 1 N + 2 N + 3 N + 4

BIN

07099-041

Figure 33. AD9626-250 Grounded Input Histogram; 250 MSPS

90

85

SFDR (+25°C)

SFDR (+85°C)

SFDR (–40°C)

SNR (+25°C)

SNR/SFDR (dB)

80

75

70

65

60

55

SNR (–40°C)

SNR (+85°C)

–140

0

20 40 60 80 100 120

FREQUENCY (MHz)

07099-057

Figure 31. AD9626-250 64k Point Single-Tone FFT; 250 MSPS, 70.3 MHz

Rev. 0 | Page 15 of 36

50

0 500

50 100 150 200 250 300 350 400 450

ANALOG INPUT FREQUENCY (MHz)

Figure 34. AD9626-250 Single-Tone SNR/SFDR vs. Input Frequency (f

Temperature with 1.25 V p-p Full Scale; 250 MSPS

) and

IN

07099-042

Page 16

AD9626

www.BDTIC.com/ADI

100

SFDR (dBFS)

90

80

70

SNR (dBFS)

60

50

40

SNR/SFDR (dB)

SFDR (dBc)

30

20

10

0

90 0

80 70 60 50 40 30 20 10

AMPLITUDE (–dBFS)

SNR (dB)

07099-043

Figure 35. AD9626-250 SNR/SFDR vs. Input Amplitude; 250 MSPS, 170.3 MHz

1.0

0.8

0.6

0.4

0.2

0

DNL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

0 4096

512 1024 1536 2048 2560 3072 3584

OUTPUT CODE

Figure 38. AD9626-250 DNL; 250 MSPS

07099-046

1.0

0.8

0.6

0.4

0.2

0

INL (LSB)

–0.2

–0.4

–0.6

–0.8

–1.0

0 4096

512 1024 1536 2048 2560 3072 3584

OUTPUT CODE

Figure 36. AD9626-250 INL; 250 MSPS

450

400

350

300

250

200

CURRENT (mA)

150

100

50

0

5 245

25 45 65 85 105 125 145 165 185 205 225

SAMPLE RATE (MSPS)

TOTAL POWER (mW)

I

(mA)

AVDD

I

(mA)

DVDD

Figure 37. AD9626 Power Supply Current vs. Sample Rate

90

80

70

60

50

40

SNR/SFDR (dB)

30

20

10

0

75 275

95 115 135 155 175 195 215 235 255

07099-044

SFDR

SNR

SAMPLE RATE (MSPS)

07099-047

Figure 39. SNR/SFDR vs. Sample Rate;

0 MSPS, 170.3 MHz @ −1 dBFS

25

2.5

2.0

1.5

AD9626-210

1.0

GAIN (%FS)

0.5

0

–0.5

–60 120100806040200–20–40

07099-045

TEMPERATURE ( °C)

AD9626-250

AD9626-170

07099-048

Figure 40. Gain vs. Temperature

Rev. 0 | Page 16 of 36

Page 17

AD9626

www.BDTIC.com/ADI

6.0

5.5

5.0

4.5

AD9626-210

4.0

OFFSET (mV)

3.5

3.0

2.5

2.0

–40 –30 –20 –10 0 908070605040302010

Figure 41. Offset vs. Temperature

TEMPERATURE ( °C)

AD9626-250

AD9626-170

07099-049

Rev. 0 | Page 17 of 36

Page 18

AD9626

V

A

A

www.BDTIC.com/ADI

THEORY OF OPERATION

The AD9626 architecture consists of a front-end sample-andhold amplifier (SHA) followed by a pipelined switched capacitor

ADC. The quantized outputs from each stage are combined into

a final 12-bit result in the digital correction logic. The pipelined

architecture permits the first stage to operate on a new input

sample, while the remaining stages operate on preceding

samples. Sampling occurs on the rising edge of the clock.

Each stage of the pipeline, excluding the last, consists of a low

solution flash ADC connected to a switched capacitor DAC

re

and interstage residue amplifier (MDAC). The residue amplifier

magnifies the difference between the reconstructed DAC output

and the flash input for the next stage in the pipeline. One bit of

redundancy is used in each stage to facilitate digital correction

of flash errors. The last stage simply consists of a flash ADC.

The input stage contains a differential SHA that can be ac- or

upled. The output-staging block aligns the data, carries

dc-co

out the error correction, and passes the data to the output

buffers. The output buffers are powered from a separate supply,

allowing adjustment of the output voltage swing. During powerdown, the output buffers go into a high impedance state.

ANALOG INPUT AND VOLTAGE REFERENCE

The analog input to the AD9626 is a differential buffer. For best

dynamic performance, the source impedances driving VIN+

and VIN− should be matched such that common-mode settling

errors are symmetrical. The analog input is optimized to

provide superior wideband performance and requires that the

analog inputs be driven differentially.

A wideband transformer, such as Mini-Circuits® ADT1-1WT,

ca

n provide the differential analog inputs for applications that

require a single-ended-to-differential conversion. Both analog

inputs are self-biased by an on-chip resistor divider to a

nominal 1.4 V.

An internal differential voltage reference creates positive and

egative reference voltages that define the 1.25 V p-p fixed span

n

of the ADC core. This internal voltage reference can be adjusted

by means of SPI control. See the

e SPI section for more details.

th

Differential Input Configurations

Optimum performance is achieved while driving the AD9626

in a differential input configuration. For baseband applications,

the AD8138 differential driver provides excellent performance

a

nd a flexible interface to the ADC. The output common-mode

voltage of the AD8138 is easily set to AVDD/2 + 0.5 V, and the

dr

iver can be configured in a Sallen-Key filter topology to

provide band limiting of the input signal.

AD9626 Configuration Using

At input frequencies in the second Nyquist zone and above, the

performance of most amplifiers may not be adequate to achieve

the true performance of the AD9626. This is especially true in

IF undersampling applications where frequencies in the 70 MHz

to 100 MHz range are being sampled. For these applications,

differential transformer coupling is the recommended input

configuration. The signal characteristics must be considered

when selecting a transformer. Most RF transformers saturate at

frequencies below a few millihertz, and excessive signal power

can also cause core saturation, which leads to distortion.

In any configuration, the value of the shunt capacitor, C, is

dep

endent on the input frequency and may need to be reduced

or removed.

As an alternative to using a transformer-coupled input at

frequencies in the second Nyquist zone, the AD8352 differential

dr

iver can be used (see Figure 44).

NALOG INPUT

NALOG INPUT

49.9Ω1V p-p

0.1µF

499Ω

523Ω

499Ω

AD8138

499Ω

33Ω

33Ω

20pF

AVDD

VIN+

AD9626

VIN–

CML

Figure 42. Differential Input Configuration Using the AD8138

15Ω

50Ω1.25V p-p

0.1µF

2pF

15Ω

VIN+

AD9626

VIN–

07099-009

Figure 43. Differential Transformer-Coupled Configuration

CC

0.1µF

C

DRDRG

0.1µF

0Ω

16

1

2

3

4

5

0Ω

8, 13

AD8352

14

0.1µF

0.1µF

11

10

0.1µF

0.1µF

200Ω

200Ω

R

C

R

0.1µF

VIN+

AD9626

VIN–

Figure 44. Differential Input Configuration Using the AD8352

CML

7099-008

07099-010

Rev. 0 | Page 18 of 36

Page 19

AD9626

A

www.BDTIC.com/ADI

CLOCK INPUT CONSIDERATIONS

For optimum performance, the AD9626 sample clock inputs

(CLK+ and CLK−) should be clocked with a differential signal.

This signal is typically ac-coupled into the CLK+ pin and the

CLK− pin via a transformer or capacitors. These pins are biased

internally and require no additional bias.

Figure 45 shows one preferred method for clocking the AD9626.

w jitter clock source is converted from single-ended to

The lo

differential using an RF transformer. The back-to-back Schottky

diodes across the secondary transformer limit clock excursions

into the AD9626 to approximately 0.8 V p-p differential. This

helps prevent the large voltage swings of the clock from feeding

through to other portions of the AD9626 and preserves the fast

rise and fall times of the signal, which are critical to low jitter

performance.

In some applications, it is acceptable to drive the sample clock

inputs with a single-ended CMOS signal. In such applications,

CLK+ should be directly driven from a CMOS gate, and the

CLK− pin should be bypassed to ground with a 0.1 μF capacitor

in parallel with a 39 kΩ resistor (see

CLK+ i

nput circuit supply is AVDD (1.8 V), this input is

Figure 48). Although the

designed to withstand input voltages up to 3.3 V, making the

selection of the drive logic voltage very flexible.

D9510/AD9511/

AD9512/AD9513/

CLOCK

INPUT

0.1µF

50Ω*

0.1µF

AD9514/AD9515

CLK

CMOS DRIVER

CLK

0.1µF

OPTIONAL

100Ω

39kΩ

0.1µF

CLK+

ADC

AD9626

CLK–

MINI-CIRCUITS

CLOCK

INPUT

50Ω

ADT1–1WT, 1:1Z

100Ω

XFMR

0.1µF

0.1µF0.1µF

0.1µF

SCHOTT KY

DIODES:

HSM2812

CLK+

ADC

AD9626

CLK–

Figure 45. Transformer-Coupled Differential Clock

If a low jitter clock is available, another option is to ac couple a

differential PECL signal to the sample clock input pins, as

shown in Figure 46. The AD9510/AD9511/AD9512/AD9513/

AD9514/AD9515 family of clock drivers offers excellent jitter

pe

rformance.

AD9510/AD9511/

AD9512/AD9513/

AD9514/AD9515

CLOCK

INPUT

CLOCK

INPUT

50Ω* 50Ω*

*50Ω RESISTORS ARE OPTIONAL.

0.1µF

0.1µF

CLK

PECL DRIVER

CLK

0.1µF

CLK+

100Ω

0.1µF

240Ω240Ω

ADC

AD9626

CLK–

Figure 46. Differential PECL Sample Clock

AD9510/AD9511/

CLOCK

INPUT

CLOCK

INPUT

50Ω* 50Ω*

*50Ω RESIS TORS ARE OPT IONAL .

0.1µF

0.1µF

Figure 47. Differential LVDS Sample Clock

AD9512/AD9513/

AD9514/AD9515

CLK

LVDS DRIVER

CLK

0.1µF

100Ω

0.1µF

CLK+

ADC

AD9626

CLK–

*50Ω RESISTOR IS OPTIONAL.

07099-014

Figure 48. Single-Ended 1.8 V CMOS Sample Clock

AD9510/AD9511/

AD9512/AD9513/

CLOCK

07099-011

INPUT

*50Ω RESISTOR IS OPTIONAL.

0.1µF

50Ω*

0.1µF

AD9514/AD9515

CLK

CMOS DRIVER

CLK

OPTIONAL

100Ω

0.1µF

0.1µF

CLK+

ADC

AD9626

CLK–

07099-015

Figure 49. Single-Ended 3.3 V CMOS Sample Clock

Clock Duty Cycle Considerations

Typical high speed ADCs use both clock edges to generate a

variety of internal timing signals. As a result, these ADCs may

be sensitive to the clock duty cycle. Commonly, a 5% tolerance

is required on the clock duty cycle to maintain dynamic performance characteristics. The AD9626 contains a duty cycle

07099-012

stabilizer (DCS) that retimes the nonsampling edge, providing

an internal clock signal with a nominal 50% duty cycle. This

allows a wide range of clock input duty cycles without affecting

the performance of the AD9626. When the DCS is on, noise

and distortion performance are nearly flat for a wide range of

duty cycles. However, some applications may require the DCS

function to be off. If so, keep in mind that the dynamic range

performance can be affected when operated in this mode. See the

AD9626 Configuration Using the SPI section for more details

o

n using this feature.

The duty cycle stabilizer uses a delay-locked loop (DLL) to

07099-013

cr

eate the nonsampling edge. As a result, any changes to the

sampling frequency require approximately eight clock cycles

to allow the DLL to acquire and lock to the new rate.

Rev. 0 | Page 19 of 36

Page 20

AD9626

O

www.BDTIC.com/ADI

Clock Jitter Considerations

High speed, high resolution ADCs are sensitive to the quality of the

clock input. The degradation in SNR for a full-scale input signal

at a given input frequency (f

) due only to aperture jitter (tJ) can

A

be calculated by

SNR Degradation = 20 × log

[1/2 × π × fA × tJ]

10

In this equation, the rms aperture jitter represents the root mean

sq

uare of all jitter sources, including the clock input, analog input

signal, and ADC aperture jitter specifications. IF undersampling

applications are particularly sensitive to jitter (see

Figure 50).

The clock input should be treated as an analog signal in cases

w

here aperture jitter may affect the dynamic range of the AD9626.

Power supplies for clock drivers should be separated from the

ADC output driver supplies to avoid modulating the clock signal

with digital noise. Low jitter, crystal controlled oscillators make

the best clock sources. If the clock is generated from another

type of source (by gating, dividing, or other methods), it should

be retimed by the original clock at the last step.

Refer to the AN-501 Application Note and the AN-756

A

pplication Note for more in-depth information about jitter

performance as it relates to ADCs (visit www.analog.com).

130

RMS CLOCK JIT TER REQUIREMENT

120

110

100

90

80

SNR (dB)

70

10 BITS

60

8 BITS

50

40

30

1 10 100 1000

Figure 50. Ideal SNR vs. Input Frequency a

ANALOG INPUT FREQUENCY (MHz)

0.125ps

0.25ps

0.5ps

1.0ps

2.0ps

nd Jitter for 0 dBFS input Signal

16 BITS

14 BITS

12 BITS

07099-016

POWER DISSIPATION AND POWER-DOWN MODE

As shown in Figure 37, the power dissipated by the AD9626 is

proportional to its sample rate. The digital power dissipation

does not vary much because it is determined primarily by the

DRVDD supply and bias current of the LVDS output drivers.

By asserting PDWN (Pin 29) high, the AD9626 is placed in

andby mode or full power-down mode, as determined by the

st

contents of Serial Port Register 08. Reasserting the PDWN pin

low returns the AD9626 into its normal operational mode.

An additional standby mode is supported by means of varying

t

he clock input. When the clock rate falls below 50 MHz, the

AD9626 assumes a standby state. In this case, the biasing network

and internal reference remain on, but digital circuitry is powered

down. Upon reactivating the clock, the AD9626 resumes normal

operation after allowing for the pipeline latency.

DIGITAL OUTPUTS

Digital Outputs and Timing

The off-chip drivers on the AD9626 are CMOS-compatible

output levels. The outputs are biased from a separate supply

(DRVDD), allowing isolation from the analog supply and easy

interface to external logic. The outputs are CMOS devices that

swing from ground to DRVDD (with no dc load). It is recommended to minimize the capacitive load the ADC drives by

keeping the output traces short (<1 inch, for a total C

When operating in CMOS mode, it is also recommended to

place low value (20 Ω) series damping resistors on the data lines

to reduce switching transient effects on performance.

The format of the output data is offset binary by default. An

mple of the output coding format can be found in Tabl e 11 .

exa

f it is desired to change the output data format to twos comple-

I

ment, see the

AD9626 Configuration Using the SPI section.

An output clock signal is provided to assist in capturing data

rom the AD9626. The DCO+/DCO− signal is used to clock the

f

output data and is equal to the sampling clock (CLK) rate in

single port mode, and one-half the clock rate in interleaved

output mode. See the timing diagrams shown in

Figure 3 for more information.

Out-of-Range

An out-of-range condition exists when the analog input voltage

is beyond the input range of the ADC. OVRA/OVRB is a digital

output that is updated along with the data output corresponding

to the particular sampled input voltage. Thus, OVRA/OVRB

has the same pipeline latency as the digital data. OVRA/OVRB

is low when the analog input voltage is within the analog input

range and high when the analog input voltage exceeds the input

range, as shown in

t

he analog input returns to within the input range and another

Figure 51. OVRA/OVRB remains high until

conversion is completed. By logically AND-ing OVRA/OVRB

with the MSB and its complement, overrange high or underrange low conditions can be detected.

VRA/OVRB

DATA OUTPUTS

1

1111

1111

0

1111

1111

1111

0

1111

0

0000

0000

0

0000

0000

1

0000

0000

Figure 51. OVRA/OVRB Relation to Input Voltage and Output Data

1111

1111

1110

0001

0000

0000

OVRA/

OVRB

–FS + 1/2 L SB

–FS – 1/2 LSB

+FS – 1 LSB

+FS – 1/2 L SB

< 5 pF).

LOAD

Figure 2 and

+FS–FS

07099-017

Rev. 0 | Page 20 of 36

Page 21

AD9626

www.BDTIC.com/ADI

TIMING—SINGLE PORT MODE

In single port mode, the CMOS output data is available from

Data Port A (DA0 to DA11). The outputs for Port B (DB0 to

DB11) are unused, and are high impedance in this mode.

The Port A outputs and the differential output data clock

(DCO+/DCO−) switch nearly simultaneously during the rising

edge of DCO+. In this mode, it is recommended to use the

rising edge of DCO− to capture the data from Port A. The setup

and hold time depends on the input sample clock period, and is

approximately 1/f

CLK

± t

SKEW

.

TIMING—INTERLEAVED MODE

In interleaved mode, the output data of the AD9626 is

demultiplexed onto two data port buses, Port A (DA0 to DA11)

and Port B (DB0− to DB11). The output data and differential

data capture clock switch at one-half the rate of the sample

clock input (CLK+/CLK−), increasing the setup and hold time

for the external data capture circuit relative to single port mode

(see

Figure 3, interleaved mode timing diagram). The two ports

witch on alternating sample clock cycles, with the data for

s

Port A being valid during the rising edge of DCO+, and the

data for Port B being valid during the rising edge of DCO−. The

pipeline latency for both ports is six sample clock cycles. Due to

the random nature of the ÷2 circuit that generates the timing

for the output stage in interleaved mode, the first data sample

during power up can be assigned to either Data Port A or Port

B. The user cannot control the polarity of the output data clock

relative to the input sample clock. In this mode, it is recom-

mended to use the rising edge of DCO+ to capture the data

from Port A, and the rising edge of DCO− to capture the data

from Port B. In both cases, the setup and hold time depends on

the input sample clock period, and both are approximately

2/f

± t

.

S

SKEW

fS/2 Spurious

Because the AD9626 output data rate is at one-half the sampling

frequency in interleaved output mode, there is significant f

/2

S

energy in the outputs of the part, and there will be significant

energy in the ADC output spectrum at f

to be certain that this f

/2 energy does not couple into either the

S

clock circuit or the analog inputs of the AD9626. When f

/2. Care must be taken

S

/2

S

energy is coupled in this fashion, it appears as a spurious tone

reflected around f

/4, 3fS/4, 5fS/4, and so on. For example, in a

S

125 MSPS sampling application with a 90 MHz single-tone

analog input, this energy generates a tone at 97.5 MHz.

[(3 × 125 MSPS/4 − 90 MHz) + 3 × 125 MSPS/4]

Depending on the relationship of the IF frequency to the center

o

f the Nyquist zone, this spurious tone may or may not be in the

user’s band of interest. Some residual f

/2 energy is present in

S

the AD9601, and the level of this spur is typically below the

level of the harmonics at clock rates.

e f

th

/2 spur level vs. the analog input frequency for the

S

AD9626-250. For the specifications provided in Tab l e 2 , the f

Figure 20 shows a plot of

/2

S

spur effect is not a factor, as the device is specified in single port

output mode.

Rev. 0 | Page 21 of 36

Page 22

AD9626

www.BDTIC.com/ADI

LAYOUT CONSIDERATIONS

POWER AND GROUND RECOMMENDATIONS

When connecting power to the AD9626, it is recommended

that two separate supplies be used: one for analog (AVDD, 1.8 V

nominal) and one for digital (DRVDD, 1.8 V nominal). If only a

single 1.8 V supply is available, it is routed to AVDD first, then

tapped off and isolated with a ferrite bead or filter choke with

decoupling capacitors proceeding connection to DRVDD. The

user can employ several different decoupling capacitors to cover

both high and low frequencies. These should be located close to

the point of entry at the PC board level and close to the parts

with minimal trace length.

A single PCB ground plane is sufficient when using the

AD9626. W

analog, digital, and clock sections of the PCB, optimum

performance is easily achieved.

ith proper decoupling and smart partitioning of

Exposed Paddle Thermal Heat Slug Recommendations

It is required that the exposed paddle on the underside of the

ADC be connected to analog ground (AGND) to achieve the

best electrical and thermal performance of the AD9626. An

exposed, continuous copper plane on the PCB should mate to

the AD9626 exposed paddle, Pin 0. The copper plane should

have several vias to achieve the lowest possible resistive thermal

path for heat dissipation to flow through the bottom of the PCB.

These vias should be solder-filled or plugged.

To maximize the coverage and adhesion between the ADC and

PCB

, partition the continuous plane by overlaying a silkscreen

on the PCB into several uniform sections. This provides several

tie points between the two during the reflow process. Using one

continuous plane with no partitions guarantees only one tie

point between the ADC and PCB. See

ample. For detailed information on packaging and the PCB

ex

layout of chip scale packages, see Application Note AN-772,

A Design and Manufacturing Guide for the Lead Frame Chip

Scale Package.

SILKSCREEN PARTITION

PIN 1 INDICATOR

Figure 52. Typical PCB Layout

Figure 52 for a PCB layout

07099-018

CML

The CML pin should be decoupled to ground with a 0.1 μF

capacitor, as shown in Figure 54.

RBIAS

The AD9626 requires the user to place a 10 kΩ resistor between

the RBIAS pin and ground. This resistor sets the master current

reference of the ADC core and should have at least a 1% tolerance.

AD9626 CONFIGURATION USING THE SPI

The AD9626 SPI allows the user to configure the converter for

specific functions or operations through a structured register

space inside the ADC. This gives the user added flexibility to

customize device operation depending on the application.

Addresses are accessed (programmed or read back) serially in

one-byte words. Each byte can be further divided down into

fields, which are documented in the

There are three pins that define the serial port interface or SPI

t

o this particular ADC. They are the SPI SCLK/DFS, SPI

SDIO/DCS, and CSB pins. The SCLK/DFS (serial clock) is used

to synchronize the read and write data presented the ADC. The

SDIO/DCS (serial data input/output) is a dual-purpose pin that

allows data to be sent and read from the internal ADC memory

map registers. The CSB is an active low control that enables or

disables the read and write cycles (see

Table 8. Serial Port Pins

Mnemonic Function

SCLK

SDIO

CSB

RESET

The falling edge of the CSB, in conjunction with the rising edge

of the SCLK, determines the start of the framing. An example of

the serial timing and its definitions can be found in

nd Tabl e 10 .

a

During an instruction phase, a 16-bit instruction is transmitted.

D

ata then follows the instruction phase and is determined by

the W0 and W1 bits, which is 1 or more bytes of data. All data is

composed of 8-bit words. The first bit of each individual byte of

serial data indicates whether this is a read or write command.

This allows the serial data input/output (SDIO) pin to change

direction from an input to an output.

Data can be sent in MSB or in LSB first mode. MSB first is

ult on power-up and can be changed by changing the

defa

configuration register. For more information about this feature

and others, see Interfacing to High Speed ADCs via SPI at

www.analog.com.

SCLK (Serial Clock) is the serial shift clock in.

SCLK is used t

reads and writes.

SDIO (Serial Data Input/O

pin. The typical role for this pin is an input and

output depending on the instruction being sent

and the relative position in the timing frame.

CSB (Chip Select Bar) is an active low control that

tes the read and write cycles.

ga

Master Device Reset. When asserted, device

assumes d

efault settings. Active low.

Memory Map section.

Tabl e 8).

o synchronize serial interface

utput) is a dual-purpose

Figure 53

Rev. 0 | Page 22 of 36

Page 23

AD9626

www.BDTIC.com/ADI

HARDWARE INTERFACE CONFIGURATION WITHOUT THE SPI

The pins described in Ta b l e 8 comprise the physical interface

between the user’s programming device and the serial port of

the AD9626. All serial pins are inputs, which is an open-drain

output and should be tied to an external pull-up or pull-down

resistor (suggested value of 10 kΩ).

This interface is flexible enough to be controlled by either

PROMS or PIC mirocontrollers as well. This provides the user

with an alternate method to program the ADC other than a SPI

controller.

If the user chooses not to use the SPI interface, some pins serve

a dual function and are associated with a specific function when

strapped externally to AVDD or ground during device poweron. The

s

Configuration Without the SPI section describes the

trappable functions supported on the AD9626.

t

HI

t

CLK

t

LO

CSB

t

DS

t

S

t

DH

In applications that do not interface to the SPI control registers,

the SPI SDIO/DCS and SPI SCLK/DFS pins can alternately

serve as standalone CMOS-compatible control pins. When the

device is powered up, it is assumed that the user intends to use

the pins as static control lines for the duty cycle stabilizer. In

this mode, the SPI CSB chip select should be connected to

ground, which disables the serial port interface.

Table 9. Mode Selection

External

Mnemonic

Voltage

Configuration

AVDD Duty cycle stabilizer enabled SPI SDIO/DCS

AGND Duty cycle stabilizer disabled

SPI SCLK/DFS

AVDD Twos complement enabled

AGND Offset binary enabled

t

H

SCLK

SDIO

DON’T CARE

R/W W1 W0 A12 A11 A10 A9 A8 A7

Figure 53. Serial Port Interface Timing Diagram

D5 D4 D3 D2 D1 D0

DON’T CARE

DON’T C AREDON’T CARE

07099-019

Rev. 0 | Page 23 of 36

Page 24

AD9626

www.BDTIC.com/ADI

Table 10. Serial Timing Definitions

Parameter Timing (minimum, ns) Description

t

DS

t

DH

t

CLK

t

S

t

H

t

HI

t

LO

t

EN_SDIO

t

DIS_SDIO

Table 11. Output Data Format

Input (V) Condition (V)

VIN+ − VIN− < 0.62 0000 0000 0000 0000 0000 0000 0000 0000 0000 1

VIN+ − VIN− = 0.62 0000 0000 0000 0000 0000 0000 0000 0000 0000 0

VIN+ − VIN− = 0 0000 0000 0000 0000 0000 0000 0000 0000 0000 0

VIN+ − VIN− = 0.62 1111 1111 1111 1111 1111 1111 0000 0000 0000 0

VIN+ − VIN− > 0.62 + 0.5 LSB 1111 1111 1111 1111 1111 1111 0000 0000 0000 1

5 Setup time between the data and the rising edge of SCLK

2 Hold time between the data and the rising edge of SCLK

40 Period of the clock

5 Setup time between CSB and SCLK

2 Hold time between CSB and SCLK

16 Minimum period that SCLK should be in a logic high state

16 Minimum period that SCLK should be in a logic low state

1

5

Offset Binary Output Mode

D11 t

Minimum time for the SDIO pin to switch from an input t

falling edge (not shown in Figure 53)

Minimum time for the SDIO pin to switch from an output t

rising edge (not shown in Figure 53)

Twos Complement Mode

o D0

D11 to D0

Gray Code Mode

(SPI Accessible)

D11 to D0

o an output relative to the SCLK

o an input relative to the SCLK

OR

Rev. 0 | Page 24 of 36

Page 25

AD9626

www.BDTIC.com/ADI

MEMORY MAP

READING THE MEMORY MAP TABLE

Each row in the memory map table has eight address locations.

The memory map is roughly divided into three sections: chip

configuration register map (Address 0x00 to Address 0x02),

transfer register map (Address 0xFF), and program register map

(Address 0x08 to Address 0x2A).

The Addr (Hex) column of the memory map indicates the

egister address in hexadecimal, and the Default Value (Hex)

r

column shows the default hexadecimal value that is already

written into the register, The Bit 7 (MSB) column is the start of

the default hexadecimal value given. For example, Hexadecimal

Address 0x09, clock, has a hexadecimal default value of 0x01.

This means Bit 7 = 0, Bit 6 = 0, Bit 5 = 0, Bit 4 = 0, Bit 3 = 0,

Bit 2 = 0, Bit 1 = 0, and Bit 0 = 1, or 0000 0001 in binary. The

default value enables the duty cycle stabilizer. Overwriting this

default so that Bit 0 = 0 disables the duty cycle stabilizer. For more

information on this and other functions, consult the Inter facing

to High Speed ADCs via SPI user manual at

Table 12. Memory Map Register

Addr

(Hex)

Chip Configuration Registers

00 chip_port_config 0 LSB

01 chip_id 8-bit chip ID, Bits[7:0]

02 chip_grade 0 0 0 Speed grade:

Transfer Register

FF device_update 0 0 0 0 0 0 0 SW

ADC Functions

08 modes 0 0 PDWN:

Parameter Name

Bit 7

(MSB)

www.analog.com.

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

Soft reset 1 1 Soft reset LSB

first

AD9626 = 0x3c

00 = 170 MSPS

01 = 210 MSPS

10 = 250 MSPS

0 0 Internal power-down mode:

0 = full

(default)

1 =

standby

RESERVED LOCATIONS

Undefined memory locations should not be written to other

than their default values suggested in this data sheet. Addresses

that have values marked as 0 should be considered reserved and

have a 0 written into their registers during power-up.

DEFAULT VALUES

Coming out of reset, critical registers are preloaded with default

values. These values are indicated in Tab le 1 2. Other registers

not have default values and retain the previous value when

do

exiting reset.

LOGIC LEVELS

An explanation of various registers follows: “Bit is set” is

synonymous with “bit is set to Logic 1” or “writing Logic 1 for

the bit.” Similarly, “clear a bit” is synonymous with “bit is set to

Logic 0” or “writing Logic 0 for the bit.”

Default

Bit 0

(LSB)

first

X X X Read-

000 = normal (power-up, default)

Note: external PDWN pin overrides

= full power-down

001

010 = standby

011 = normal (power-up)

this setting

0 0x18 The nibbles should

transfer

Value

(Hex)

Read-

only

only

0x00 Synchronously

0x00 Determines various

Default Notes/

Com

ments

be mirrored by the

user so that LSB or

MSB first mode

registers correctly,

regardless of shift

mode.

Default is unique

chip ID, different

for each device.

This is a read-only

register.

Child ID used to

differentiate

ded devices.

gra

transfers data from

the master shift

register to the

slave.

generic modes

chip operation.

of

Rev. 0 | Page 25 of 36

Page 26

AD9626

www.BDTIC.com/ADI

Default

Addr

(Hex)

09 clock 0 0 0 0 0 0 0 Duty

OD test_io Reset

OF ain_config 0 0 0 0 0 Analog

14 output_mode 0 0 Interleave

16 output_phase Output

17 flex_output_delay Output

18 flex_vref Input voltage range setting:

Parameter Name

Bit 7

(MSB)

clock

polarity

1 =

inverted

0 =

normal

(default)

delay

enable:

0 =

enable

1 =

disable

Bit 0

Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1

Reset

PN23 gen:

1 = on

0 = off

(default)

output

mode:

1 =

enabled

0 =

disabled

(default)

0 0 0 0x03

Output clock delay:

PN9 ge

1 = on

0 = off

(default)

Output

e:

enabl

0 =

enabl

e

(default)

1 =

disable

n:

(Format determined by output_mode)

0 Output

Output test mode:

0000 = off (default)

1 = midscale short

000

0010 = +FS short

0011 = −FS short

0100 = checker board output

0101 = PN 23 sequence

0110 = PN 9

0111 = one/zero word toggle

1000 = unused

1001 = unused

1010 = unused

1011 = unused

1100 = unused

CML

off

on

enabl

1 = on

0 =

(default)

Data format select:

00

…

…

…

input

disable:

1 = on

0 =

(default)

invert:

1 =

0 = off

(default)

00000 = 0.1 ns

01 = 0.2 ns

000

00010 = 0.3 ns

11101 = 3.0 ns

11110 = 3.1 ns

11111 = 3.2 ns

10000 = 0.98 V

01 =1.00 V

100

10010 = 1.02 V

10011 =1.04 V

11111 = 1.23 V

00000 = 1.25 V

00001 = 1.27 V

01110 = 1.48 V

01111 = 1.50 V

(LSB)

cycle

stabilizer:

0 =

disabled

1 =

enabled

(default)

0 0x00

e:

off

= offset binary

(default)

01 = twos

complement

10 = Gray code

Value

(Hex)

0x01

0x00 When set, the test

0x00

0x00

0x00

Default Notes/

Com

ments

data is p

laced on

the output pins in

place of normal

data.

Rev. 0 | Page 26 of 36

Page 27

AD9626

A

www.BDTIC.com/ADI

EVALUATION BOARD

D8B

D6B

D4B

D10B

DORB

49

D9

D10

P7

GNDCD10

C10

CONNECTS TO J 2

DOR

GND

CSB

E33

E32

VSPI

P17

GND

P5

P4P3P2

GND

GND

GNDCD9

E31

CSB_DUT

59

P16

GND

GND

C9

D10

RN1

GNDCD8

39

GNDCD5

GNDCD6

GNDCD7

D8

DOR

16

50_OHMS

1

P10

P9

GND

GND

P1

GND

GND

D2B

D0B

415042434445464748

D1

D2D3D4D5D6D7D8

GNDCD1

GNDCD2

GNDCD3

GNDCD4

D2D4D6

DORB

15

GNDAB10

C1

C2C3C4C5C6C7C8

314032333435363738

516052535455565758

D0

D10

D11B

D11

121314

11

2345678

VSPI

E3

R10

1K

E1

SDIO_ODM

SCLK_DTP

E4

E10

R13

1K

E5

GND

VSPI

D11B

B9

B10

GNDAB9

A10

A9

10

29

D11

D9BD9D10B

9

10

GND

E2

AVDD

R11

D9B

19

GNDAB8

9

D9

D1B

D7B

D5B

D3B

GNDAB5

GNDAB6

GNDAB7

DCOBDCO

112012131415161718

B1

B2B3B4B5B6B7B8

GNDAB1

GNDAB2

GNDAB3

GNDAB4

A1

A2A3A4A5A6A7A8

2345678

213022232425262728

D1

D3D5D7

1

P11

CONNECTS TO J 1

HEADERM1469169_1

GND

D8BD8D7BD7D6B

D6

9

10

121314

152

RN2

50_OHMS

116

15

D9B

16

D9

17

D10B

18

D10

19

D11B

20

D11

21

DORB

22

DOR

GND

23 48

DGND1

DRVDD

24 47

DVDD1

25

SPSDIO/DCS

26

SPSCLK/DFS

CSB

27

SPCSB

28

RESETB

1K

E7

SW3

EVQ-Q2

12

IN OUT

GND

10K

R12

GND

T3

Alternate Options

ADT1-1WT

34567

13

PDN

RBIAS

AVDD_REF

30

29

31

AVDD

E8

E9

0

L8

GND

VSPI

AMPOUT+

C19

TOUTBTINB

TOUTGND

6

1234

5

T5

PRI SEC

nc

CML CML

DNP

R4

11

50_OHMS

8

DRVDD

GND

109121114

8

7

D6

D5

D6BD7D7BD8D8B

DVDD

DGND

U4

AD9626_CSP

AIN

AINB

AVDD_PIPE2

AVDD_PIPE3

AVDD_PIPE4

AVDD_PIPE5

343332

35

36

AVDD

AVDD

AVDD

AVDD

33

R7

R9

DNP

C21

0.1UF

36

R6

R5

CML

0.1UF

T6

5

1

2

34

GND

PRI SEC

GND

ETC1-1-13

C22

0.1UF

TOUT

CML

1

GND

C16

TOUTB

425

E6

3

PRI SEC

ETC1-1-13

TINB

0.1UF

L1

10NH

49

D9

D10

GNDCD8

GNDCD9

GNDCD10

C10

C9

39

59

D5

D5B

15

16

RN3

2345678

1

6

D5B

AVDD_CLK1

AVDD_PIPE

AVDD_PIPE1

CML

393837

AVDD

AVDD

C17 DNP

33

optional

R16

0

GND

36

GND

GNDCD7

DGND2

DVDD2

40

L9

AMPOUT-

0.1UF

D3

DCOB

CLKB

AVDD_FL1

AVDD

C18

21435

D2B

D1B

D0B

DCO

CLK

41

GNDCD6

D3BD4D4B

D2

D1

D0

GNDCD5

D4BD4D3B

D3

121314

57

PAD

56

55

54

53

52

51

50

49

46

45

44

43

AVDD_FL

42

AVDD

CMLX

07099-053

SDO_CHA

SDI_CHA

GNDCD4

GNDCD3

GNDCD2

D2D3D4D5D6D7D8

C2C3C4C5C6C7C8

GNDCD1

SCLK_CH

19

415042434445464748

B9

D1

B10

GNDAB4

GNDAB5

GNDAB6

GNDAB7

GNDAB8

GNDAB9

GNDAB10

A10

A9

C1

9

314032333435363738

29

516052535455565758

112012131415161718

B1

B2B3B4B5B6B7B8

GNDAB1

GNDAB2

GNDAB3

A1

A2A3A4A5A6A7A8

1102345678

213022232425262728

HEADERM1469169_1

CSB1_CHA

D1

D1BD0D0B

D2B

RN4

50_OHMS

D2

152

34567

116

9

10

11

DCOB

DCO

9

10

121314

11

8

GND

C61

0.1UF

GND

R86

10K

GND

VCLK

GND

E20

E19

E18

C74

0.1UF

3

GND

TRI_STATE

VCLK

NC

5

VCLK

CR2

3

CR3

1

2

DNP

GND

CLKCT

0.1UF

6

1234

5

PRI SEC

ADT1-1WT

nc

CLKCT

0.1UF

C15

GND

VCLK

R85

10K

VOLT_CONTROL

162

U6

VOLT_CONTROL

CVHD_956 Crystek Crystal

OUTPUT

4

OPTIO NAL ENCODE CIRCUITS

00

R90

XTALINPUT

C23

DNP

R15

GND

50

R3

GND

XTALINPUT

0

R87

GND

J4

GND

DRVDD

AVDD

AVDD

AVDD_CLK

R17

0 DNP

CML

CLK

50

R1

CLK

2

1

GND

0.1UF

C75

3

00

R89

T2

00

R8

GND

C20

DNP

DNP

R14

GND

J3

GND

Input

J2

ANALOG

Figure 54. AD9601 Evaluation Board Schematic Page 1

Rev. 0 | Page 27 of 36

GND

CR2 TO MAKE LAYOUT AND PARASI T I C L O ADING SYMMETRI CAL

ENCODE

Page 28

AD9626

0

www.BDTIC.com/ADI

0.1UF

C71

0.1UF

C70

0.1UF

C650.1UF

0.1UF

C64

0.1UF

C63

0.1UF

C62

0.1UF

C27

C28

0.1UF

0.1UF

C29

0.1UF

C30

0.1UF

C31

0.1UF

C32

0.1UF

C33

+

C8

10UF

AVDD

GND

POWER OPTIONS

100PF

C73

C72

0.1UF

C69

C68

0.1UF

C67

C66

0.1UF

C13

C59

0.1UF

C60

+

C54

10UF

VCLK

0.1UF

C24

0.1UF

C25

0.1UF

C26

+

C9

10UF

DRVDD

U8

GND

3

21

4

EGND

EGND

P8

PJ-102A

0.1UF

C56

0.1UF

0.1UF

0.1UF

GND

VSPI

GND

VIN

T1

U7

C11

+

123

VSPIEXT

0.1UF

C57

0.1UF

C58

+

C14

10UF

VAMP

R2

10UF

GND

0.1UF

C34

+

C12

10UF

0.1UF

C39

C35

0.1UF

C36

0.1UF

499

EGND

H4

MTHOLE6

H3

MTHOLE6

H2

MTHOLE6H1MTHOLE6

GND

GND

VSPIEXTX

DRVDDX1

AVDDX

VAMPX

C3

1UF

GND

C1

1UF

GND

4

C7

1UF

GND

4

C5

1UF

GND

GND

GND

EGND

P6

VSPIEXTX

OUT

4

OUT

4

1.8V 3.3V

OUT

1.8V

OUT

+5V

1.8V

3.3V

DRVDD

VSPIEXT

L14

L15

FERRITE

FERRITE

GND

GND

GND

VSPIEXT1

DRVDD1

GND

GND

1

OUT1

2

VSPIEXTX

IN

3

C4

U11

1UF

ADP3338

GND

GND

GND

1

OUT1

2

IN

3

C2

U12

1UF

ADP3338

GND

GND

OUT1

IN

GND

OUT1

IN

GND

1

AVDDX

2

3

C10

U9

1UF

ADP3338

GND

GND

1

VAMPX

2

3

C6

U10

1UF

ADP3338

GND

+5.0V

1.8V

AVDD

VAMP

L12

L13

FERRITE

FERRITE

GND

AVDD1