Page 1

Clock Generator with Dual PLLs,

Data Sheet

FEATURES

Fully integrated dual PLL/VCO cores

1 integer-N and 1 fractional-N PLL

Continuous frequency coverage from 11.2 MHz to 200 MHz

Most frequencies from 200 MHz to 637.5 MHz available

PLL1 phase jitter (12 kHz to 20 MHz): 460 fs rms typical

PLL2 phase jitter (12 kHz to 20 MHz)

Integer-N mode: 470 fs rms typical

Fractional-N mode: 660 fs rms typical

Input crystal or reference clock frequency

Optional reference frequency divide-by-2

2

I

C programmable output frequencies

Up to 4 LVDS/LVPECL or up to 8 LVCMOS output clocks

1 CMOS buffered reference clock output

Spread spectrum: downspread [0, −0.5]%

2 pin-controlled frequency maps: margining

Integrated loop filters

Space saving, 6 mm × 6 mm, 40-lead LFCSP package

1.02 W power dissipation (LVDS operation)

1.235 W power dissipation (LVPECL operation)

3.3 V operation

APPLICATIONS

Low jitter, low phase noise multioutput clock generator for

data communications applications including Ethernet,

Fibre Channel, SONET, SDH, PCI-e, SATA, PTN, OTN,

ADC/DAC, and digital video

Spread spectrum clocking

GENERAL DESCRIPTION

The AD9577 provides a multioutput clock generator function,

along with two on-chip phase-locked loop cores, PLL1 and PLL2,

optimized for network clocking applications. The PLL designs

are based on the Analog Devices, Inc., proven portfolio of high

performance, low jitter frequency synthesizers to maximize

network performance. The PLLs have I

frequencies and formats. The fractional-N PLL can support

spread spectrum clocking for reduced EMI radiated peak power.

Both PLLs can support frequency margining. Other applications

with demanding phase noise and jitter requirements can benefit

from this part.

The first integer-N PLL section (PLL1) consists of a low noise phase

frequency detector (PFD), a precision charge pump (CP), a low

phase noise voltage controlled oscillator (VCO), a programmable

Rev. 0

Information furnished by Analog Devices is believed to be accurate and reliable. However, no

responsibility is assumed by Anal og Devices for its use, nor for any infringements of patents or ot her

rights of third parties that may result from its use. Specifications subject to change without notice. No

license is granted by implication or otherwise under any patent or patent rights of Analog Devices.

Trademarks and registered trademarks are the property of their respective owners.

2

C programmable output

Spread Spectrum, and Margining

AD9577

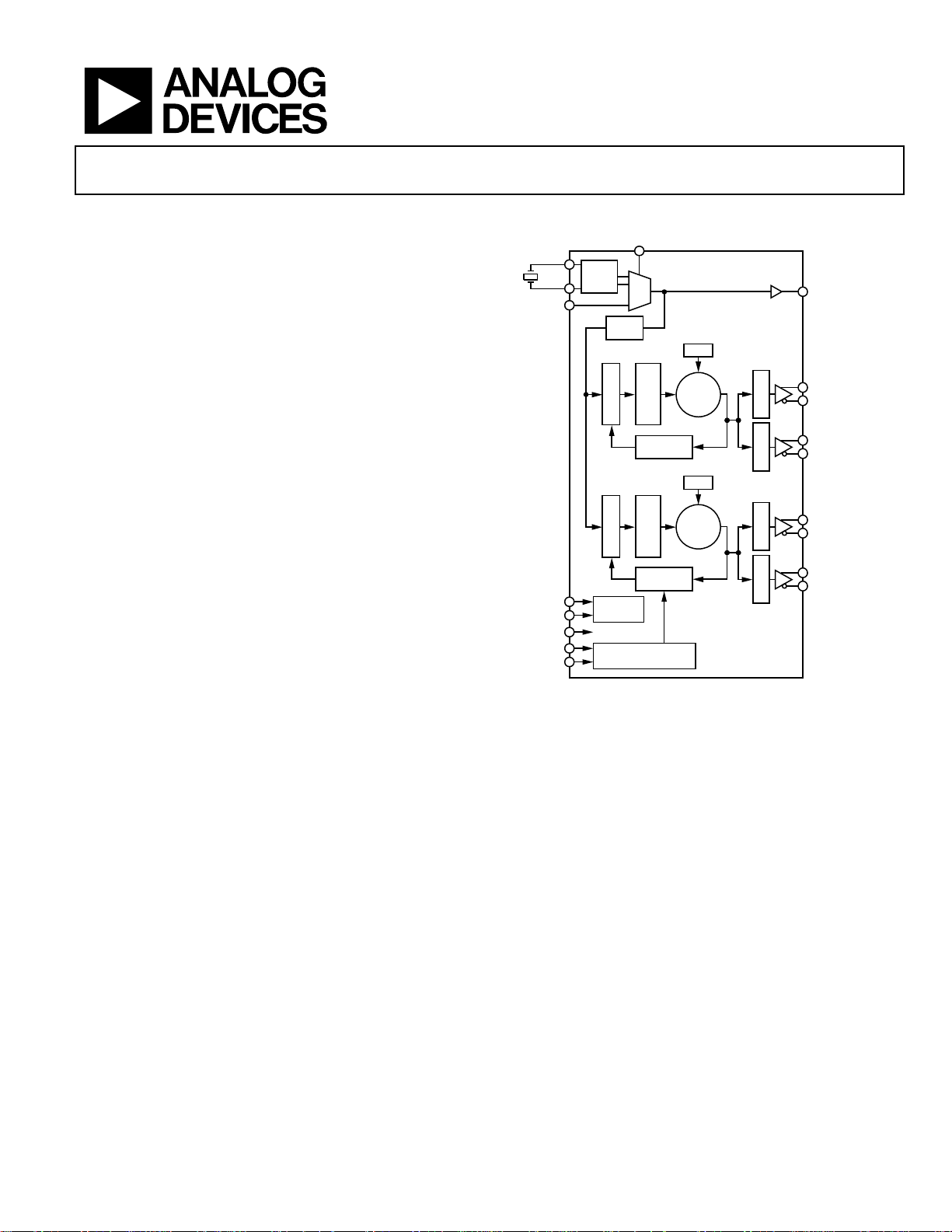

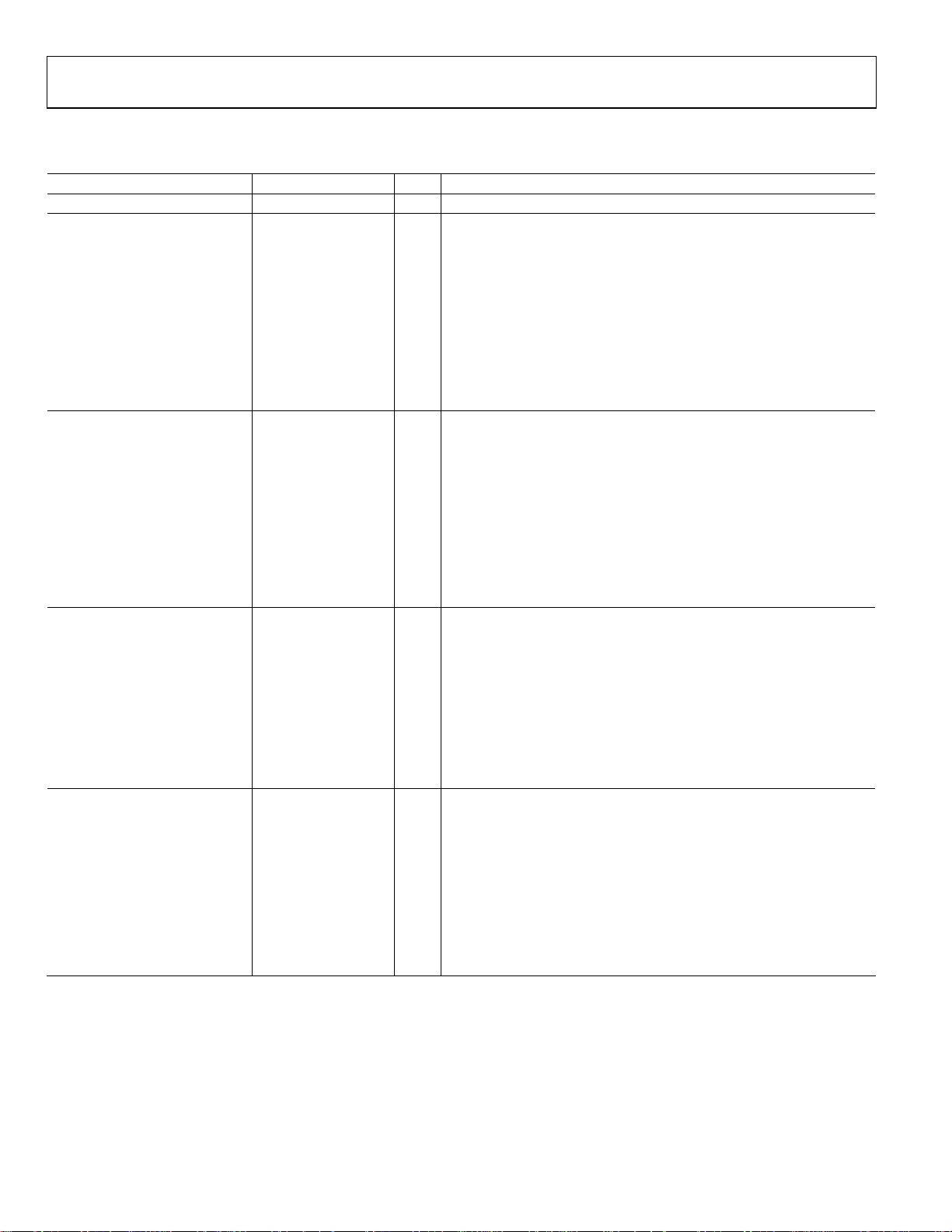

FUNCTIONAL BLOCK DIAGRAM

REFSEL

XT1

XTAL

OSC

XT2

REFCLK

DIVIDE

1 OR 2

THIRD

ORDER LPF

DIVIDER

THIRD

ORDER LPF

DIVIDER

LDO

VCO

2.15GHz

TO

2.55GHz

LDO

VCO

2.15GHz

TO

2.55GHz

Figure 1.

SCL

SDA

MARGIN

SSCG

MAX_BW

PLL1

PFD

f

PFD/CP

FEEDBACK

PLL2

PFD/CP

FEEDBACK

I2C

CONTROL

SPREAD SPECTRUM,

SDM

feedback divider, and two independently programmable output

dividers. By connecting an external crystal or applying a reference

clock to the REFCLK pin, frequencies of up to 637.5 MHz can

be synchronized to the input reference. Each output divider and

feedback divider ratio is I

2

C programmed for the required

output rates.

A second fractional-N PLL (PLL2) with a programmable modulus

allows VCO frequencies that are fractional multiples of the

reference frequency to be synthesized. Each output divider

and feedback divider ratio can be programmed for the required

output rates, up to 637.5 MHz. This fractional-N PLL can also

operate in integer-N mode for the lowest jitter.

Up to four differential output clock signals can be configured

as either LVPECL or LVDS signaling formats. Alternatively,

the outputs can be configured for up to eight CMOS outputs.

Combinations of these formats are supported. No external loop

filter components are required, thus conserving valuable design

time and board space. The AD9577 is available in a 40-lead, 6 mm ×

6 mm LFCSP package and can operate from a single 3.3 V supply.

The operating temperature range is −40°C to +85°C.

One Technology Way, P.O. Box 9106, Norwood, MA 02062-9106, U.S.A.

Tel: 781.329.4700 www.analog.com

Fax: 781.461.3113 ©2011 Analog Devices, Inc. All rights reserved.

CMOS

DIVIDERS

DIVIDERS

DIVIDERS

DIVIDERS

AD9577

REFOUT

LVPECL/LVDS

OR 2 × CMOS

LVPECL/LVDS

OR 2 × CMOS

LVPECL/LVDS

OR 2 × CMOS

LVPECL/LVDS

OR 2 × CMOS

09284-001

Page 2

AD9577 Data Sheet

TABLE OF CONTENTS

Features.............................................................................................. 1

Applications....................................................................................... 1

General Description ......................................................................... 1

Functional Block Diagram .............................................................. 1

Revision History ............................................................................... 2

Specifications..................................................................................... 3

PLL1 Characteristics .................................................................... 3

PLL1 Clock Output Jitter............................................................. 5

PLL2 Fractional-N Mode Characteristics ................................. 6

PLL2 Integer-N Mode Characteristics....................................... 7

PLL2 Clock Output Jitter............................................................. 9

CMOS Reference Clock Output Jitter...................................... 11

Timing Characteristics .............................................................. 12

Clock Outputs............................................................................. 13

Power............................................................................................ 14

Crystal Oscillator........................................................................ 15

Reference Input........................................................................... 15

Control Pins ................................................................................ 15

Absolute Maximum Ratings.......................................................... 16

Thermal Characteristics ............................................................16

ESD Caution................................................................................ 16

Pin Configuration and Function Descriptions........................... 17

Typical Performance Characteristics ........................................... 19

REFOUT and PLL1 Phase Noise Performance...................... 19

PLL2 Phase Noise Performance................................................ 20

Output Jitter ................................................................................21

Typical Output Signal ................................................................ 22

Typical Spread Spectrum Performance Characteristics........ 24

Terminology .................................................................................... 25

Detailed Block Diagram ................................................................ 27

Example Application.................................................................. 28

Functional Description.................................................................. 29

Reference Input and Reference Dividers................................. 29

Output Channel Dividers.......................................................... 30

Outputs........................................................................................ 30

Reference Output Buffer ........................................................... 31

PLL1 Integer-N PLL................................................................... 31

PLL1 Phase Frequency Detector (PFD) and Charge Pump . 32

PLL1 VCO................................................................................... 32

PLL1 Feedback Divider ............................................................. 32

Setting the Output Frequency of PLL1.................................... 32

PLL2 Integer/Fractional-N PLL ............................................... 32

PLL2 Phase Frequency Detector (PFD) and Charge Pump . 33

PLL2 Loop Bandwidth............................................................... 33

PLL2 VCO................................................................................... 33

PLL2 Feedback Divider ............................................................. 33

PLL2 Σ-Δ Modulator ................................................................. 33

Spur Mechanisms....................................................................... 33

Optimizing PLL Performance .................................................. 34

Setting the Output Frequency of PLL2.................................... 34

Margining.................................................................................... 35

Spread Spectrum Clock Generation (SSCG).......................... 35

I2C Interface Timing and Internal Register Description........... 38

Default Frequency Map and Output Formats ........................ 40

I2C Interface Operation ............................................................. 40

Typical Application Circuits ..................................................... 42

Power and Grounding Considerations and Power Supply

Rejection...................................................................................... 43

Outline Dimensions....................................................................... 44

Ordering Guide .......................................................................... 44

REVISION HISTORY

10/11—Revision 0: Initial Version

Rev. 0 | Page 2 of 44

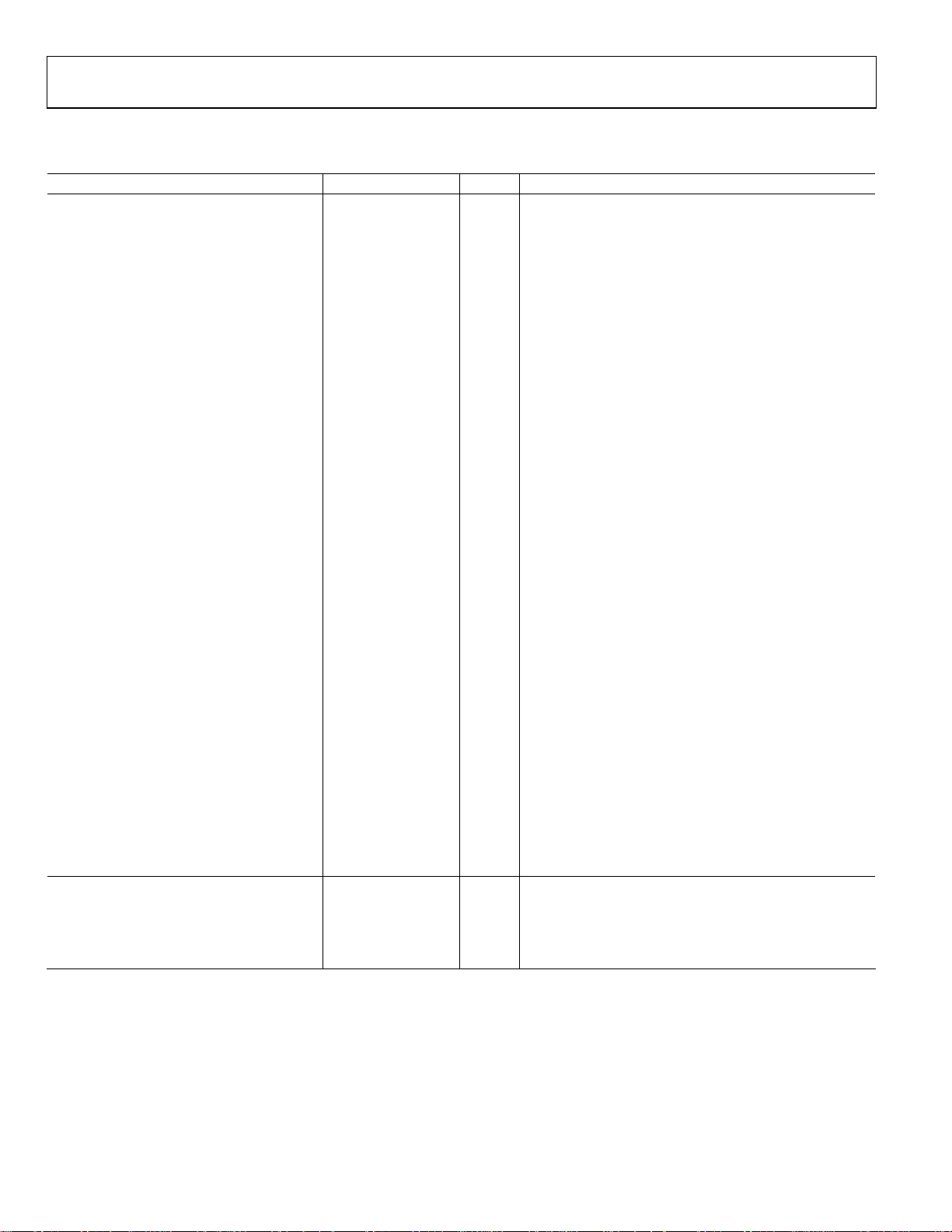

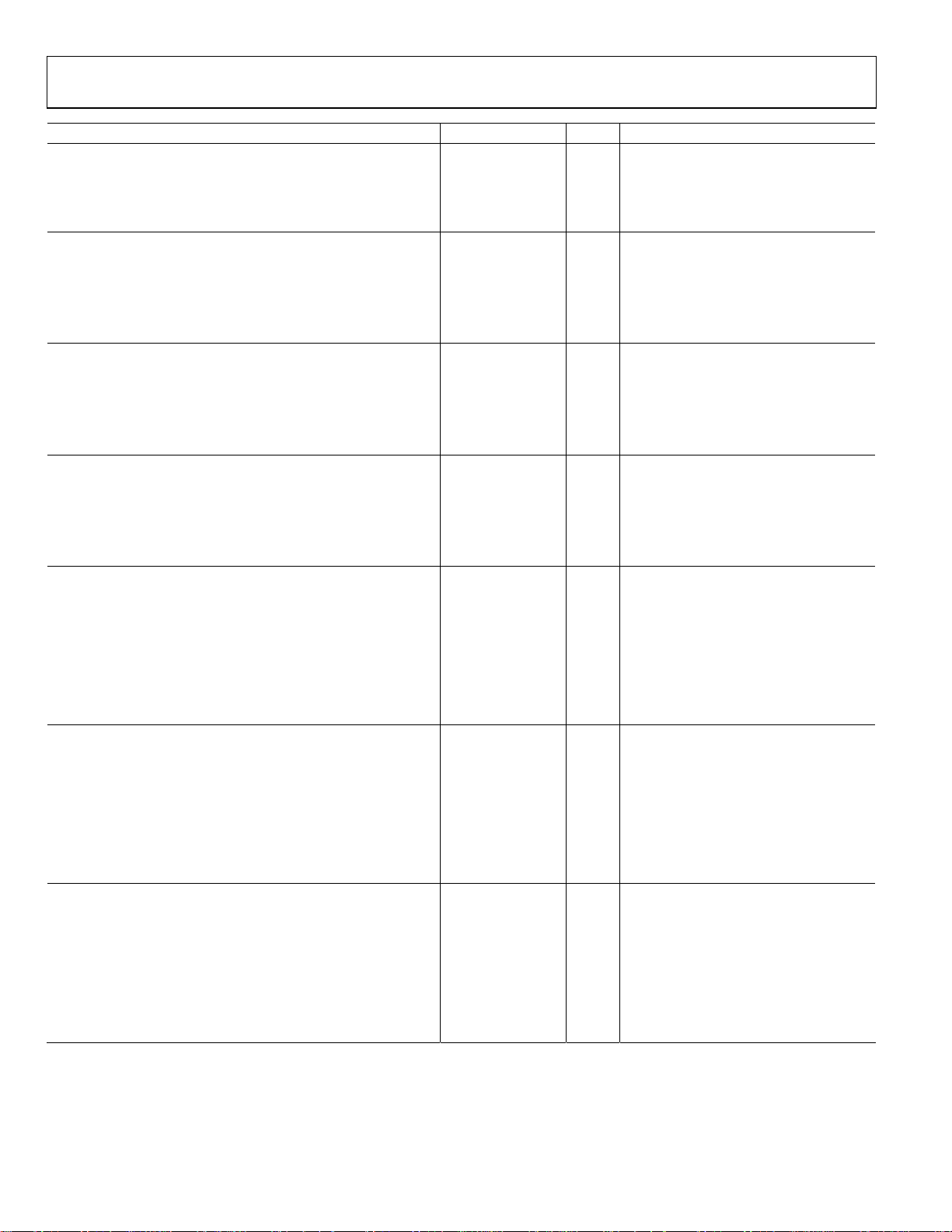

Page 3

Data Sheet AD9577

SPECIFICATIONS

Typical (typ) is given for VS = 3.3 V, TA = 25°C, unless otherwise noted. Minimum (min) and maximum (max) values are given over full

(3.0 V to 3.6 V) and TA (−40°C to +85°C) variation. AC coupling capacitors of 0.1 μF used where appropriate. A Fox Electronics

V

S

FX532A 25 MHz crystal is used throughout, unless otherwise stated.

PLL1 CHARACTERISTICS

Table 1.

Parameter Min Typ Max Unit Test Conditions/Comments1

NOISE CHARACTERISTICS

Phase Noise (106.25 MHz LVPECL Output) Na = 102, Vx = 4, Dx = 6, f

At 1 kHz −121 dBc/Hz

At 10 kHz −127 dBc/Hz

At 100 kHz −128 dBc/Hz

At 1 MHz −150 dBc/Hz

At 10 MHz −156 dBc/Hz

At 30 MHz −158 dBc/Hz

Phase Noise (156.25 MHz LVPECL Output) Na = 100, Vx = 4, Dx = 4, f

At 1 kHz −117 dBc/Hz

At 10 kHz −124 dBc/Hz

At 100 kHz −124 dBc/Hz

At 1 MHz −147 dBc/Hz

At 10 MHz −156 dBc/Hz

At 30 MHz −156 dBc/Hz

Phase Noise (625 MHz LVPECL Output) Na = 100, Vx = 2, Dx = 2, f

At 1 kHz −105 dBc/Hz

At 10 kHz −112 dBc/Hz

At 100 kHz −112 dBc/Hz

At 1 MHz −135 dBc/Hz

At 10 MHz −150 dBc/Hz

At 30 MHz −150 dBc/Hz

Phase Noise (106.25 MHz LVDS Output) Na = 102, Vx = 4, Dx = 6, f

At 1 kHz −119 dBc/Hz

At 10 kHz −127 dBc/Hz

At 100 kHz −128 dBc/Hz

At 1 MHz −148 dBc/Hz

At 10 MHz −156 dBc/Hz

At 30 MHz −156 dBc/Hz

Phase Noise (156.25 MHz LVDS Output) Na = 100, Vx = 4, Dx = 4, f

At 1 kHz −116 dBc/Hz

At 10 kHz −124 dBc/Hz

At 100 kHz −124 dBc/Hz

At 1 MHz −145 dBc/Hz

At 10 MHz −155 dBc/Hz

At 30 MHz −155 dBc/Hz

Phase Noise (625 MHz LVDS Output) Na = 100, Vx = 2, Dx = 2, f

At 1 kHz −104 dBc/Hz

At 10 kHz −111 dBc/Hz

At 100 kHz −112 dBc/Hz

At 1 MHz −134 dBc/Hz

At 10 MHz −149 dBc/Hz

At 30 MHz −149 dBc/Hz

= 25 MHz

PFD

= 25 MHz

PFD

= 25 MHz

PFD

= 25 MHz

PFD

= 25 MHz

PFD

= 25 MHz

PFD

Rev. 0 | Page 3 of 44

Page 4

AD9577 Data Sheet

Parameter Min Typ Max Unit Test Conditions/Comments1

Phase Noise (106.25 MHz CMOS Output) Na = 102, Vx = 4, Dx = 6, f

At 1 kHz −118 dBc/Hz

At 10 kHz −127 dBc/Hz

At 100 kHz −127 dBc/Hz

At 1 MHz −149 dBc/Hz

At 10 MHz −156 dBc/Hz

At 30 MHz −157 dBc/Hz

Phase Noise (156.25 MHz CMOS Output) Na = 100, Vx = 4, Dx = 4, f

At 1 kHz −115 dBc/Hz

At 10 kHz −124 dBc/Hz

At 100 kHz −124 dBc/Hz

At 1 MHz −146 dBc/Hz

At 10 MHz −155 dBc/Hz

At 30 MHz −155 dBc/Hz

Phase Noise (155.52 MHz LVPECL Output) Na = 112, Vx = 2, Dx = 7, f

At 1 kHz −117 dBc/Hz

At 10 kHz −122 dBc/Hz

At 100 kHz −123 dBc/Hz

At 1 MHz −148 dBc/Hz

At 10 MHz −156 dBc/Hz

At 30 MHz −156 dBc/Hz

Phase Noise (622.08 MHz LVPECL Output) Na = 128, Vx = 2, Dx = 2, f

At 1 kHz −105 dBc/Hz

At 10 kHz −110 dBc/Hz

At 100 kHz −110 dBc/Hz

At 1 MHz −136 dBc/Hz

At 10 MHz −150 dBc/Hz

At 30 MHz −150 dBc/Hz

Phase Noise (155.52 MHz LVDS Output) Na = 112, Vx = 2, Dx = 7, f

At 1 kHz −117 dBc/Hz

At 10 kHz −122 dBc/Hz

At 100 kHz −123 dBc/Hz

At 1 MHz −146 dBc/Hz

At 10 MHz −155 dBc/Hz

At 30 MHz −155 dBc/Hz

Phase Noise (622.08 MHz LVDS Output) Na = 128, Vx = 2, Dx = 2, f

At 1 kHz −105 dBc/Hz

At 10 kHz −110 dBc/Hz

At 100 kHz −110 dBc/Hz

At 1 MHz −134 dBc/Hz

At 10 MHz −149 dBc/Hz

At 30 MHz −150 dBc/Hz

Phase Noise (155.52 MHz CMOS Output) Na = 112, Vx = 2, Dx = 7, f

At 1 kHz −117 dBc/Hz

At 10 kHz −122 dBc/Hz

At 100 kHz −123 dBc/Hz

At 1 MHz −147 dBc/Hz

At 10 MHz −155 dBc/Hz

At 30 MHz −155 dBc/Hz

1

x indicates either 0 or 1 for any given test condition.

= 25 MHz

PFD

= 25 MHz

PFD

= 19.44 MHz

PFD

= 19.44 MHz

PFD

= 19.44 MHz

PFD

= 19.44 MHz

PFD

= 19.44 MHz

PFD

Rev. 0 | Page 4 of 44

Page 5

Data Sheet AD9577

PLL1 CLOCK OUTPUT JITTER

Table 2.

Parameter1 Min Typ Max Unit Test Conditions/Comments2

LVPECL INTEGRATED RANDOM PHASE JITTER 25 MHz crystal used

RMS Jitter (625 MHz Output) 460 750 fs rms 12 kHz to 20 MHz, Na = 100, Vx = 2, Dx = 2

430 650 fs rms 50 kHz to 80 MHz, Na = 100, Vx = 2, Dx = 2

RMS Jitter (156.25 MHz Output) 460 750 fs rms 12 kHz to 20 MHz, Na = 100, Vx = 4, Dx = 4

RMS Jitter (106.25 MHz Output) 460 750 fs rms 12 kHz to 20 MHz, Na = 102, Vx = 4, Dx = 6

LVDS INTEGRATED RANDOM PHASE JITTER 25 MHz crystal used

RMS Jitter (625 MHz Output) 470 820 fs rms 12 kHz to 20 MHz, Na = 100, Vx = 2, Dx = 2

450 790 fs rms 50 kHz to 80 MHz, Na = 100, Vx = 2, Dx = 2

RMS Jitter (156.25 MHz Output) 470 790 fs rms 12 kHz to 20 MHz, Na = 100, Vx = 4, Dx = 4

RMS Jitter (106.25 MHz Output) 470 790 fs rms 12 kHz to 20 MHz, Na = 102, Vx = 4, Dx = 6

CMOS INTEGRATED RANDOM PHASE JITTER 25 MHz crystal used, 50 Ω load

RMS Jitter (100 MHz Output) 470 920 fS rms 12 kHz to 20 MHz, Na = 96, Vx = 4, Dx = 6

RMS Jitter (33.3 MHz Output) 420 700 fS rms 12 kHz to 5 MHz, Na = 88, Vx = 6, Dx = 11

LVPECL INTEGRATED RANDOM PHASE JITTER 19.44 MHz crystal used

RMS Jitter (622.08 MHz Output) 500 680 fs rms 12 kHz to 20 MHz, Na = 128, Vx = 2, Dx = 2

460 590 fs rms 50 kHz to 80 MHz, Na = 128, Vx = 2, Dx = 2

RMS Jitter (155.52 MHz Output) 480 680 fs rms 12 kHz to 20 MHz, Na = 112, Vx = 2, Dx = 7

LVDS INTEGRATED RANDOM PHASE JITTER 19.44 MHz crystal used

RMS Jitter (622.08 MHz Output) 520 780 fs rms 12 kHz to 20 MHz, Na = 128, Vx = 2, Dx = 2

480 710 fs rms 50 kHz to 80 MHz, Na = 128, Vx = 2, Dx = 2

RMS Jitter (155.52 MHz Output) 480 750 fs rms 12 kHz to 20 MHz, Na = 112, Vx = 2, Dx = 7

CMOS INTEGRATED RANDOM PHASE JITTER 19.44 MHz crystal used, 50 Ω load

RMS Jitter (155.52 MHz Output) 470 700 fs rms 12 kHz to 20 MHz, Na = 112, Vx = 2, Dx = 7

RMS Jitter (38.88 MHz Output) 440 650 fs rms 12 kHz to 5 MHz, Na = 112, Vx = 2, Dx = 28

LVPECL PERIOD AND CYCLE-TO-CYCLE JITTER (100 MHz OUTPUT) 25 MHz crystal used, Na = 96, Vx = 4, Dx = 6

Output Peak-to-Peak Period Jitter 13 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 2 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 19 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 3 ps rms 1,000 cycles, average of 25 measurements

LVDS PERIOD AND CYCLE-TO-CYCLE JITTER (100 MHz OUTPUT) 25 MHz crystal used, Na = 96, Vx = 4, Dx = 6

Output Peak-to-Peak Period Jitter 17 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 2 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 25 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 4 ps rms 1,000 cycles, average of 25 measurements

CMOS PERIOD AND CYCLE-TO-CYCLE JITTER (100 MHz OUTPUT )

Output Peak-to-Peak Period Jitter 25 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 3 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak Cycle-to-Cycle Jitter 36 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 6 ps rms 1,000 cycles, average of 25 measurements

1

All period and cycle-to-cycle jitter measurements are made with a Tektronix DPO70604 oscilloscope.

2

x indicates either 0 or 1 for any given test condition.

25 MHz crystal used, 50 Ω load, Na = 96,

Vx = 4, Dx = 6

Rev. 0 | Page 5 of 44

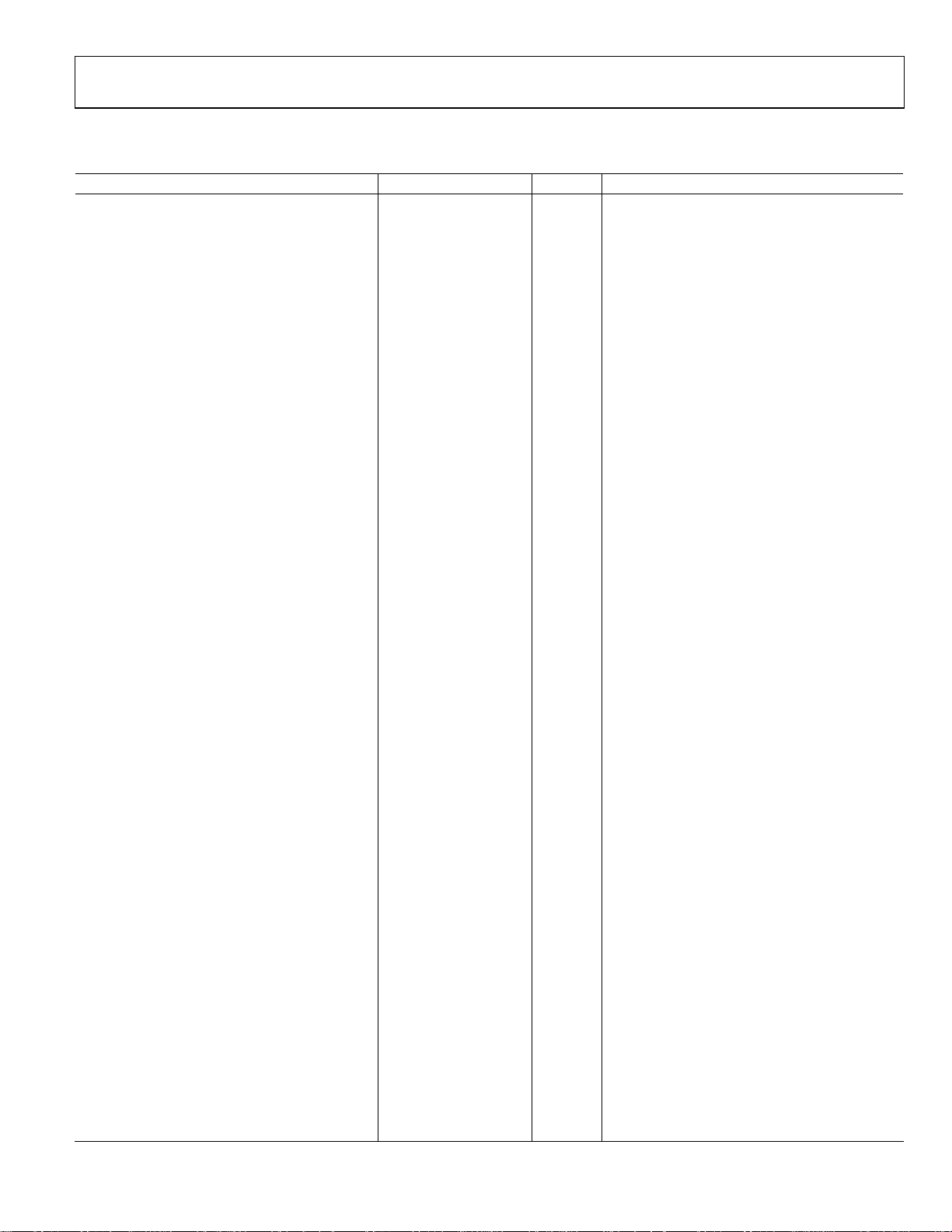

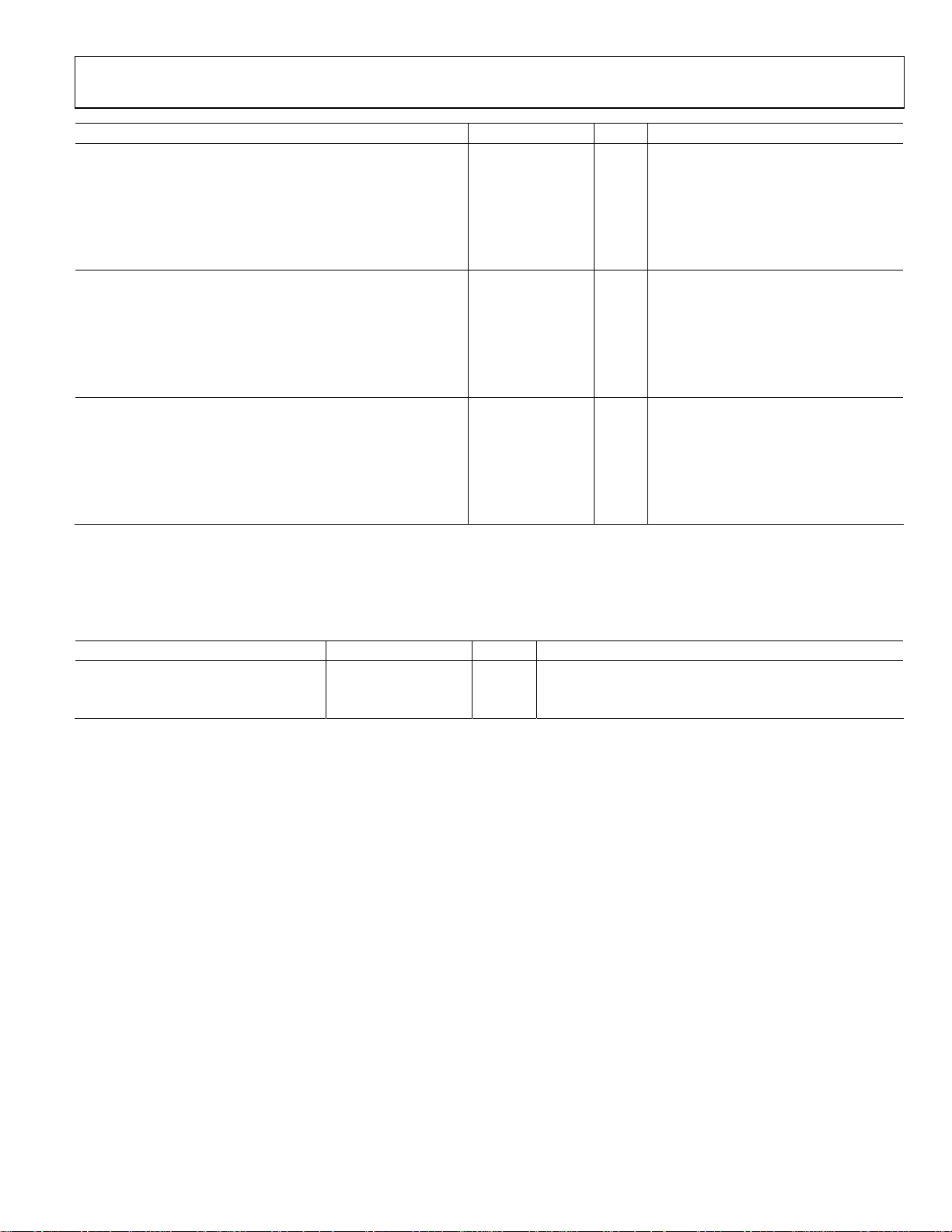

Page 6

AD9577 Data Sheet

PLL2 FRACTIONAL-N MODE CHARACTERISTICS

Table 3. Bleed = 1

Parameter Min Typ Max Unit Test Conditions/Comments1

NOISE CHARACTERISTICS 25 MHz crystal used

Phase Noise (155.52 MHz LVPECL Output) Nb = 87, FRAC = 57, MOD = 625, Vx = 2, Dx = 7

@ 1 kHz −107 dBc/Hz

@ 10 kHz −115 dBc/Hz

@ 100 kHz −122 dBc/Hz

@ 1 MHz −146 dBc/Hz

@ 10 MHz −153 dBc/Hz

@ 30 MHz −152 dBc/Hz

Phase Noise (622.08 MHz LVPECL Output) Nb = 99, FRAC = 333, MOD = 625, Vx = 2, Dx = 2

@ 1 kHz −95 dBc/Hz

@ 10 kHz −103 dBc/Hz

@ 100 kHz −109 dBc/Hz

@ 1 MHz −133 dBc/Hz

@ 10 MHz −148 dBc/Hz

@ 30 MHz −150 dBc/Hz

Phase Noise (155.52 MHz LVDS Output) Nb = 87, FRAC = 57, MOD = 625, Vx = 2, Dx = 7

@ 1 kHz −107 dBc/Hz

@ 10 kHz −114 dBc/Hz

@ 100 kHz −122 dBc/Hz

@ 1 MHz −145 dBc/Hz

@ 10 MHz −154 dBc/Hz

@ 30 MHz −154 dBc/Hz

Phase Noise (622.08 MHz LVDS Output) Nb = 99, FRAC = 333, MOD = 625, Vx = 2, Dx = 2

@ 1 kHz −95 dBc/Hz

@ 10 kHz −103 dBc/Hz

@ 100 kHz −109 dBc/Hz

@ 1 MHz −132 dBc/Hz

@ 10 MHz −147 dBc/Hz

@ 30 MHz −149 dBc/Hz

Phase Noise (155.52 MHz CMOS Output) Nb = 87, FRAC = 57, MOD = 625, Vx = 2, Dx = 7

@ 1 kHz −107 dBc/Hz

@ 10 kHz −114 dBc/Hz

@ 100 kHz −122 dBc/Hz

@ 1 MHz −146 dBc/Hz

@ 10 MHz −154 dBc/Hz

@ 30 MHz −154 dBc/Hz

SPREAD SPECTRUM

Modulation Range +0.1 −0.5 % Downspread, triangle modulation profile

Modulation Frequency 31.25 kHz Programmable

Peak Power Reduction 10 dB

1

x indicates either 2 or 3 for any given test condition.

First harmonic of 100 MHz output, triangle modulation

profile, spectrum analyzer resolution bandwidth = 20 kHz

Rev. 0 | Page 6 of 44

Page 7

Data Sheet AD9577

PLL2 INTEGER-N MODE CHARACTERISTICS

Table 4. Bleed = 0

Parameter Min Typ Max Unit Test Conditions/Comments1

NOISE CHARACTERISTICS

Phase Noise (106.25 MHz LVPECL Output) Nb = 102, Vx = 4, Dx = 6, f

@ 1 kHz −116 dBc/Hz

@ 10 kHz −123 dBc/Hz

@ 100 kHz −127 dBc/Hz

@ 1 MHz −148 dBc/Hz

@ 10 MHz −156 dBc/Hz

@ 30 MHz −158 dBc/Hz

Phase Noise (156.25 MHz LVPECL Output) Nb = 100, Vx = 4, Dx = 4, f

@ 1 kHz −113 dBc/Hz

@ 10 kHz −120 dBc/Hz

@ 100 kHz −124 dBc/Hz

@ 1 MHz −146 dBc/Hz

@ 10 MHz −156 dBc/Hz

@ 30 MHz −156 dBc/Hz

Phase Noise (625 MHz LVPECL Output) Nb = 100, Vx = 2, Dx = 2, f

@ 1 kHz −101 dBc/Hz

@ 10 kHz −108 dBc/Hz

@ 100 kHz −112 dBc/Hz

@ 1 MHz −134 dBc/Hz

@ 10 MHz −149 dBc/Hz

@ 30 MHz −150 dBc/Hz

Phase Noise (106.25 MHz LVDS Output) Nb = 102, Vx = 4, Dx = 6, f

@ 1 kHz −117 dBc/Hz

@ 10 kHz −123 dBc/Hz

@ 100 kHz −127 dBc/Hz

@ 1 MHz −147 dBc/Hz

@ 10 MHz −156 dBc/Hz

@ 30 MHz −156 dBc/Hz

Phase Noise (156.25 MHz LVDS Output) Nb = 100, Vx = 4, Dx = 4, f

@ 1 kHz −113 dBc/Hz

@ 10 kHz −120 dBc/Hz

@ 100 kHz −124 dBc/Hz

@ 1 MHz −145 dBc/Hz

@ 10 MHz −155 dBc/Hz

@ 30 MHz −155 dBc/Hz

Phase Noise (625 MHz LVDS Output) Nb = 100, Vx = 2, Dx = 2, f

@ 1 kHz −101 dBc/Hz

@ 10 kHz −108 dBc/Hz

@ 100 kHz −112 dBc/Hz

@ 1 MHz −133 dBc/Hz

@ 10 MHz −148 dBc/Hz

@ 30 MHz −149 dBc/Hz

Phase Noise (106.25 MHz CMOS Output) Nb = 102, Vx = 4, Dx = 6, f

@ 1 kHz −117 dBc/Hz

@ 10 kHz −123 dBc/Hz

@ 100 kHz −127 dBc/Hz

@ 1 MHz −147 dBc/Hz

@ 10 MHz −156 dBc/Hz

@ 30 MHz −157 dBc/Hz

= 25 MHz

PFD

= 25 MHz

PFD

= 25 MHz

PFD

= 25 MHz

PFD

= 25 MHz

PFD

= 25 MHz

PFD

= 25 MHz

PFD

Rev. 0 | Page 7 of 44

Page 8

AD9577 Data Sheet

Parameter Min Typ Max Unit Test Conditions/Comments1

Phase Noise (156.25 MHz CMOS Output) Nb = 100, Vx = 4, Dx = 4, f

@ 1 kHz −113 dBc/Hz

@ 10 kHz −119 dBc/Hz

@ 100 kHz −123 dBc/Hz

@ 1 MHz −145 dBc/Hz

@ 10 MHz −154 dBc/Hz

@ 30 MHz −155 dBc/Hz

Phase Noise (155.52 MHz LVPECL Output) Nb = 112, Vx = 2, Dx = 7, f

@ 1 kHz −112 dBc/Hz

@ 10 kHz −118 dBc/Hz

@ 100 kHz −126 dBc/Hz

@ 1 MHz −147 dBc/Hz

@ 10 MHz −155 dBc/Hz

@ 30 MHz −156 dBc/Hz

Phase Noise (622.08 MHz LVPECL Output) Nb = 128, Vx = 2, Dx = 2, f

@ 1 kHz −100 dBc/Hz

@ 10 kHz −106 dBc/Hz

@ 100 kHz −112 dBc/Hz

@ 1 MHz −134 dBc/Hz

@ 10 MHz −149 dBc/Hz

@ 30 MHz −150 dBc/Hz

Phase Noise (155.52 MHz LVDS Output) Nb = 112, Vx = 2, Dx = 7, f

@ 1 kHz −113 dBc/Hz

@ 10 kHz −118 dBc/Hz

@ 100 kHz −126 dBc/Hz

@ 1 MHz −145 dBc/Hz

@ 10 MHz −154 dBc/Hz

@ 30 MHz −155 dBc/Hz

Phase Noise (622.08 MHz LVDS Output) Nb = 128, Vx = 2, Dx = 2, f

@ 1 kHz −101 dBc/Hz

@ 10 kHz −106 dBc/Hz

@ 100 kHz −112 dBc/Hz

@ 1 MHz −133 dBc/Hz

@ 10 MHz −148 dBc/Hz

@ 30 MHz −150 dBc/Hz

Phase Noise (155.52 MHz CMOS Output) Nb = 112, Vx = 2, Dx = 7, f

@ 1 kHz −113 dBc/Hz

@ 10 kHz −118 dBc/Hz

@ 100 kHz −126 dBc/Hz

@ 1 MHz −146 dBc/Hz

@ 10 MHz −155 dBc/Hz

@ 30 MHz −155 dBc/Hz

1

x indicates either 2 or 3 for any given test condition.

= 25 MHz

PFD

= 19.44 MHz

PFD

= 19.44 MHz

PFD

= 19.44 MHz

PFD

= 19.44 MHz

PFD

= 19.44 MHz

PFD

Rev. 0 | Page 8 of 44

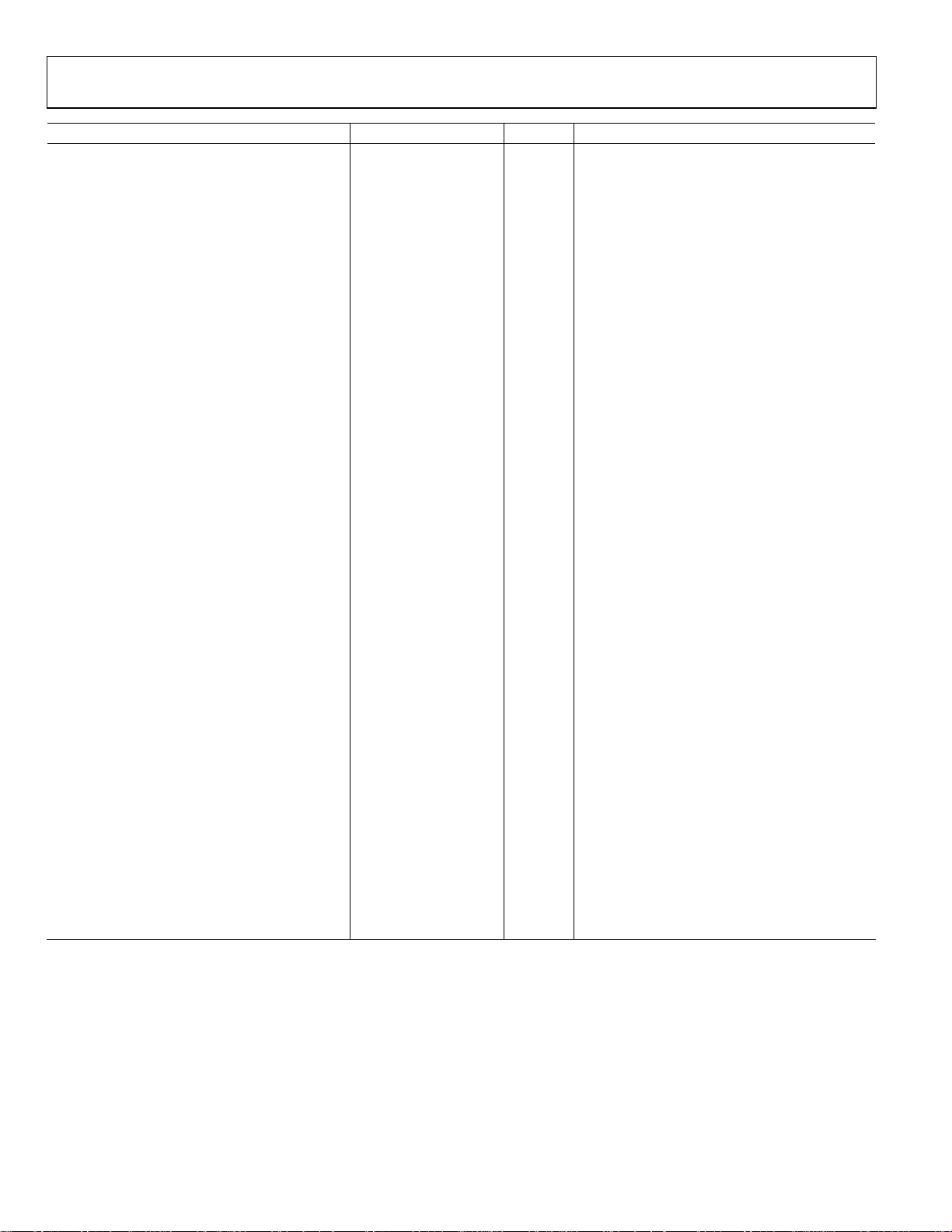

Page 9

Data Sheet AD9577

PLL2 CLOCK OUTPUT JITTER

Table 5. Bleed = 0 for Integer-N Mode, Bleed = 1 for Fractional-N Mode

Parameter1 Min Typ Max Unit Test Conditions/Comments2

LVPECL INTEGRATED RANDOM PHASE JITTER 25 MHz crystal used

RMS Jitter (622.08 MHz Output) 660 1200 fs rms

500 900 fs rms

RMS Jitter (625 MHz Output) 470 800 fs rms

380 650 fs rms

RMS Jitter (155.52 MHz Output) 630 1100 fs rms

RMS Jitter (156.25 MHz Output) 470 800 fs rms

LVDS INTEGRATED RANDOM PHASE JITTER 25 MHz crystal used

RMS Jitter (622.08 MHz Output) 660 1200 fs rms

510 900 fs rms

RMS Jitter (625 MHz Output) 470 820 fs rms

380 650 fs rms

RMS Jitter (155.52 MHz Output) 620 1100 fs rms

RMS Jitter (156.25 MHz Output) 480 800 fs rms

CMOS INTEGRATED RANDOM PHASE JITTER 25 MHz crystal used, 50 Ω load

RMS Jitter (155.52 MHz Output) 630 1100 fs rms

RMS Jitter (100 MHz Output) 490 800 fs rms

RMS Jitter (33.33 MHz Output) 450 700 fs rms

LVPECL INTEGRATED RANDOM PHASE JITTER 19.44 MHz crystal used

RMS Jitter (622.08 MHz Output) 510 800 fs rms

380 650 fs rms

RMS Jitter (155.52 MHz Output) 470 800 fs rms

LVDS INTEGRATED RANDOM PHASE JITTER 19.44 MHz crystal used

RMS Jitter (622.08 MHz Output) 530 900 fs rms

390 700 fs rms

RMS Jitter (155.52 MHz Output) 480 750 fs rms

12 kHz to 20 MHz, fractional-N operation,

Nb = 99, FRAC = 333, MOD = 625, Vx = 2,

Dx = 2

50 kHz to 80 MHz, fractional-N operation,

Nb = 99, FRAC = 333, MOD = 625, Vx = 2,

Dx = 2

12 kHz to 20 MHz, integer-N operation,

Nb = 100, Vx = 2, Dx = 2

50 kHz to 80 MHz, integer-N operation,

Nb = 100, Vx = 2, Dx = 2

12 kHz to 20 MHz, fractional-N operation,

Nb = 87, FRAC = 57, MOD = 625, Vx = 2,

Dx = 7

12 kHz to 20 MHz, integer-N operation,

Nb = 100, Vx = 4, Dx = 4

12kHz to 20 MHz, fractional-N operation,

Nb = 99, FRAC = 333, MOD = 625, Vx = 2,

Dx = 2

50 kHz to 80 MHz, fractional-N operation,

Nb = 99, FRAC = 333, MOD = 625, Vx = 2,

Dx = 2

12 kHz to 20 MHz, integer-N operation,

Nb = 100, Vx = 2, Dx = 2

50 kHz to 80 MHz, integer-N operation,

Nb = 100, Vx = 2, Dx = 2

12 kHz to 20 MHz, fractional-N operation,

Nb = 87, FRAC = 57, MOD = 625, Vx = 2,

Dx = 7

12 kHz to 20 MHz, integer-N operation,

Nb = 100, Vx = 4, Dx = 4

12 kHz to 20 MHz, fractional-N operation,

Nb = 87, FRAC = 57, MOD = 625, Vx = 2,

Dx = 7

12 kHz to 20 MHz, integer-N operation,

Nb = 96, Vx = 4, Dx = 6

12 kHz to 5 MHz, integer-N operation,

Nb = 88, Vx = 6, Dx = 11

12 kHz to 20 MHz, integer-N operation,

Nb = 128, Vx = 2, Dx = 2

50 kHz to 80 MHz, integer-N operation,

Nb = 128, Vx = 2, Dx = 2

12 kHz to 20 MHz, integer-N operation,

Nb = 112, Vx = 2, Dx = 7

12 kHz to 20 MHz, integer-N operation,

Nb = 128, Vx = 2, Dx = 2

50 kHz to 80 MHz, integer-N operation,

Nb = 128, Vx = 2, Dx = 2

12 kHz to 20 MHz, integer-N operation,

Nb = 112, Vx = 2, Dx = 7

Rev. 0 | Page 9 of 44

Page 10

AD9577 Data Sheet

Parameter1 Min Typ Max Unit Test Conditions/Comments2

CMOS INTEGRATED RANDOM PHASE JITTER 19.44 MHz crystal used, 50 Ω load

RMS Jitter (155.52 MHz Output) 470 700 fs rms

RMS Jitter (38.88 MHz Output) 430 650 fs rms

LVPECL PERIOD AND CYCLE-TO-CYCLE JITTER (100 MHz OUTPUT)

Output Peak-to-Peak Period Jitter 13 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 2 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 19 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 3 ps rms 1,000 cycles, average of 25 measurements

LVDS PERIOD AND CYCLE-TO-CYCLE JITTER (100 MHz OUTPUT )

Output Peak-to-Peak Period Jitter 17 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 2 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 26 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 4 ps rms 1,000 cycles, average of 25 measurements

CMOS PERIOD AND CYCLE-TO-CYCLE JITTER (100 MHz OUTPUT )

Output Peak-to-Peak Period Jitter 25 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 3 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle 36 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 6 ps rms 1,000 cycles, average of 25 measurements

LVPECL PERIOD AND CYCLE-TO-CYCLE JITTER (100 MHz OUTPUT)

Output Peak-to-Peak Period Jitter 60 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 15 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 20 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 3 ps rms 1,000 cycles, average of 25 measurements

LVDS PERIOD AND CYCLE-TO-CYCLE JITTER (100 MHz OUTPUT )

Output Peak-to-Peak Period Jitter 63 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 15 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 25 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 4 ps rms 1,000 cycles, average of 25 measurements

CMOS PERIOD AND CYCLE-TO-CYCLE JITTER (100 MHz OUTPUT )

Output Peak-to-Peak Period Jitter 70 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 15 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 36 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-Cycle Jitter 6 ps rms 1,000 cycles, average of 25 measurements

12 kHz to 20 MHz, integer-N operation,

Nb = 112, Vx = 2, Dx = 7

12 kHz to 5 MHz, integer-N operation,

Nb = 112, Vx = 2, Dx = 28

25 MHz crystal used, integer-N

operation, Nb = 96, Vx = 4, Dx = 6

25 MHz crystal used, integer-N

operation, Nb = 96, Vx = 4, Dx = 6

25 MHz crystal used, 50 Ω load, integer-N

operation, Nb = 96, Vx = 4, Dx = 6

25 MHz crystal used, SSCG on, Nb = 100,

FRAC = 0, MOD = 1000, Vx = 5, Dx = 5,

CkDiv = 7, NumSteps = 59, FracStep = −8,

= 100 MHz with −0.5% downspread

f

OUT

at 30.2 kHz

25 MHz crystal used, SSCG on, Nb = 100,

FRAC = 0, MOD = 1000, Vx = 5, Dx = 5,

CkDiv = 7, NumSteps = 59, FracStep = −8,

= 100 MHz with −0.5% downspread

f

OUT

at 30.2 kHz

25 MHz crystal used, SSCG on, 50 Ω load,

Nb = 100, FRAC = 0, MOD = 1000, Vx = 5,

Dx = 5, CkDiv = 7, NumSteps = 59,

FracStep = −8, f

= 100 MHz with

OUT

−0.5% downspread at 30.2 kHz

Rev. 0 | Page 10 of 44

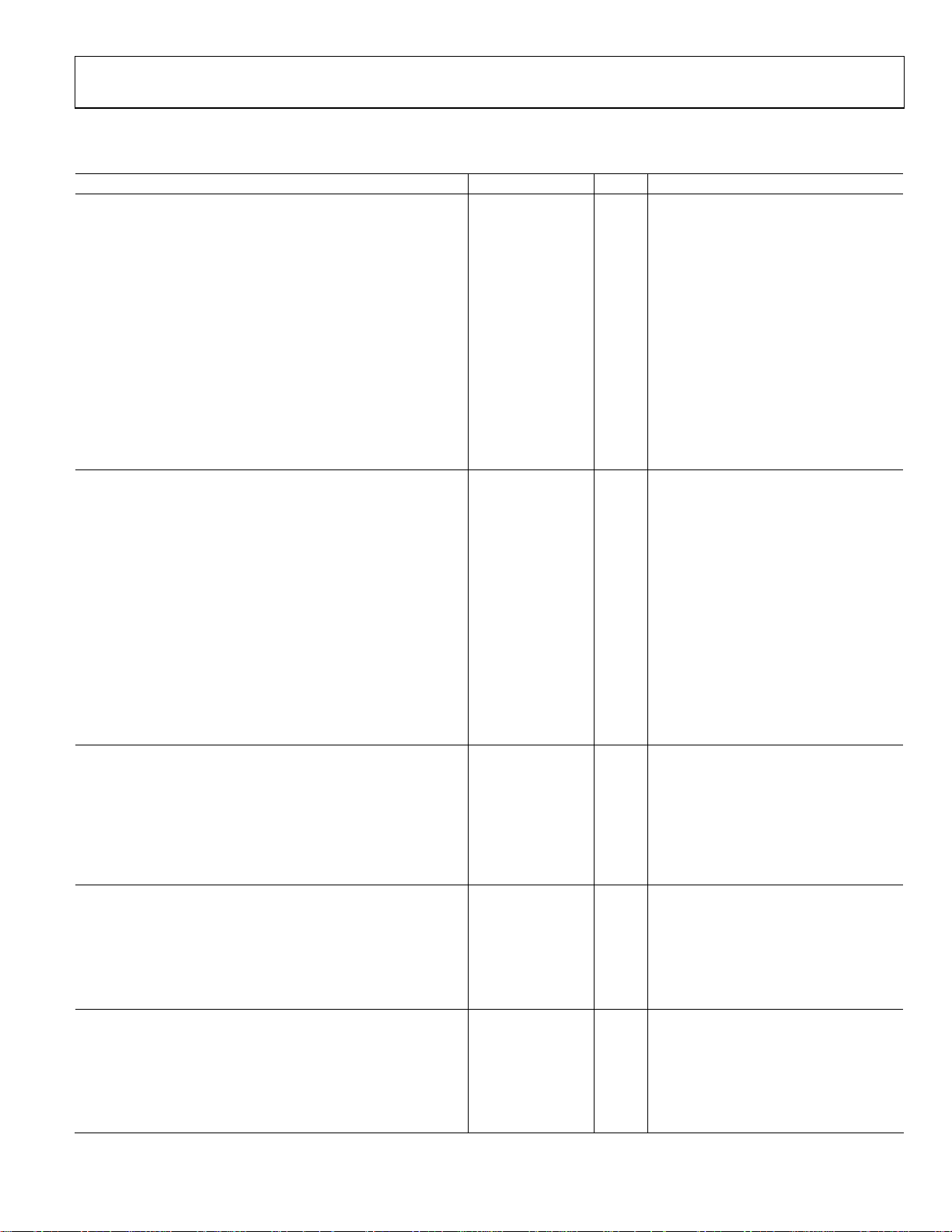

Page 11

Data Sheet AD9577

Parameter1 Min Typ Max Unit Test Conditions/Comments2

LVPECL PERIOD AND CYCLE-TO-CYCLE JITTER (100.12 MHz OUTPUT )

Output Peak-to-Peak Period Jitter 13 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 2 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 20 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 3 ps rms 1,000 cycles, average of 25 measurements

LVDS PERIOD AND CYCLE-TO-CYCLE JITTER (100.12 MHz OUTPUT )

Output Peak-to-Peak Period Jitter 17 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 2 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 26 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 4 ps rms 1,000 cycles, average of 25 measurements

CMOS PERIOD AND CYCLE-TO-CYCLE JITTER (100.12 MHz OUTPUT)

Output Peak-to-Peak Period Jitter 25 ps p-p 10,000 cycles, average of 25 measurements

Output RMS Period Jitter 3 ps rms 10,000 cycles, average of 25 measurements

Output Peak-to-Peak, Cycle-to-Cycle Jitter 36 ps p-p 1,000 cycles, average of 25 measurements

Output RMS Cycle-to-Cycle Jitter 6 ps rms 1,000 cycles, average of 25 measurements

1

All period and cycle-to-cycle jitter measurements are made with a Tektronix DPO70604 oscilloscope.

2

x indicates either 2 or 3 for any given test condition.

25 MHz crystal used, fractional-N

operation, Nb = 100, FRAC = 15,

MOD = 125, Vx = 5, Dx = 5

25 MHz crystal used, fractional-N

operation, Nb = 100, FRAC = 15,

MOD = 125, Vx = 5, Dx = 5

25 MHz crystal used, 50 Ω load,

fractional-N operation, Nb = 100,

FRAC = 15, MOD = 125, Vx = 5, Dx = 5

CMOS REFERENCE CLOCK OUTPUT JITTER

Table 6.

Parameter Min Typ Max Unit Test Conditions/Comments

JITTER INTEGRATION BANDWIDTH Jitter measurement at 25 MHz is equipment limited

12 kHz to 5 MHz 680 1000 fs rms 25 MHz

200 kHz to 5 MHz 670 950 fs rms

Rev. 0 | Page 11 of 44

Page 12

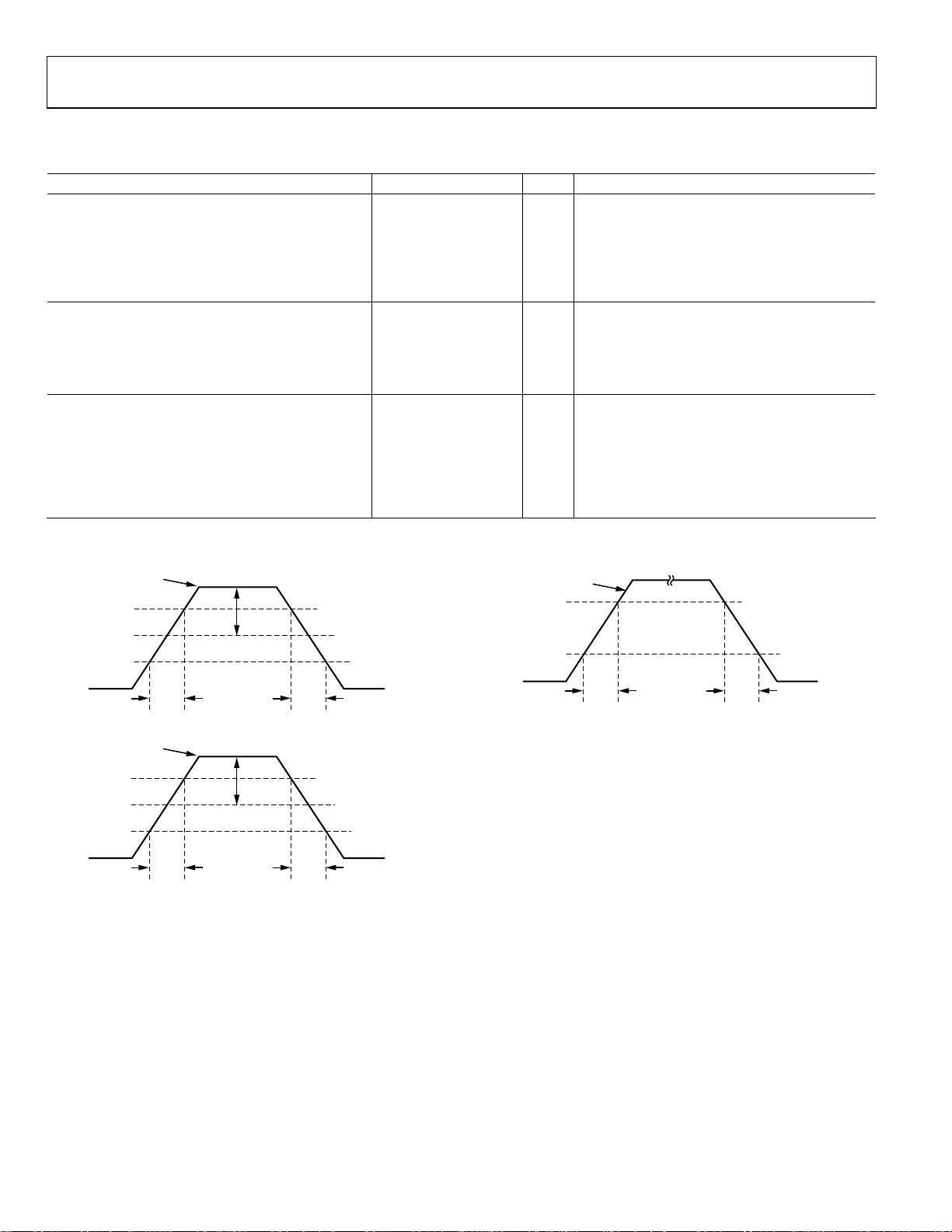

AD9577 Data Sheet

TIMING CHARACTERISTICS

Table 7.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL (see Figure 2)

Output Rise Time, tRP 170 225 300 ps 20% to 80%, measured differentially

Output Fall Time, tFP 170 230 310 ps 80% to 20%, measured differentially

Skew 20 ps

LVDS (see Figure 3) Termination = 100 Ω differential; C

Output Rise Time, tRL 180 250 340 ps 20% to 80%, measured differentially

Output Fall Time, tFL 180 260 330 ps 80% to 20%, measured differentially

Skew 20 ps

CMOS (see Figure 4)

Output Rise Time, tRC 250 680 950 ps

Output Fall Time, tFC 350 700 1000 ps

Skew 20 ps

Timing Diagrams

DIFFERENTIAL

80%

50%

20%

DIFFERENTIAL

80%

50%

20%

t

RP

Figure 2. LVPECL Timing, Differential

V

OD

LVPECL

V

OD

LVDS

t

FP

09284-002

Termination = 200 Ω to 0 V, ac-coupled to 50 Ω

oscilloscope; C

LOAD

= 5 pF

Between the outputs of the same PLL at the

same frequency. SyncCh01/SyncCh23 set to 1

Between the outputs of the same PLL at the

same frequency; SyncCh01/SyncCh23 set to 1

Termination is high impedance active probe,

total C

LOAD

= 5 pF, R

= 20 kΩ, 20% to 80%

LOAD

Termination is high impedance active probe,

total C

LOAD

= 5 pF, R

= 20 kΩ, 80% to 20%

LOAD

Between the outputs of the same PLL at the

same frequency; SyncCh01/SyncCh23 set to 1

SINGLE-ENDED

80%

20%

t

RC

Figure 4. CMOS Timing, Single-Ended, 5 pF Load

CMOS

t

FC

LOAD

= 5 pF

09284-004

t

RL

t

FL

09284-003

Figure 3. LVDS Timing, Differential

Rev. 0 | Page 12 of 44

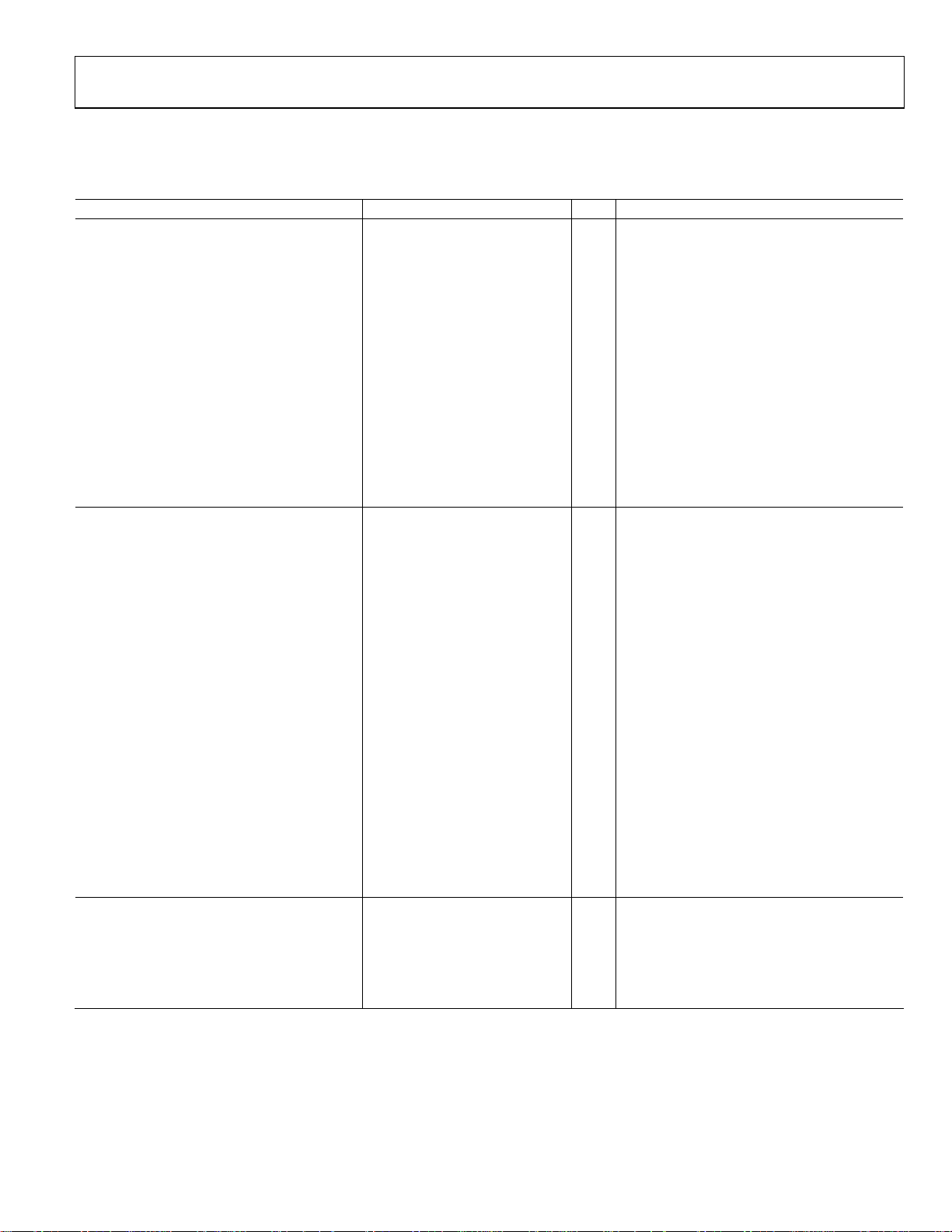

Page 13

Data Sheet AD9577

CLOCK OUTPUTS

AC coupling capacitors of 0.1 μF used where appropriate.

Table 8.

Parameter Min Typ Max Unit Test Conditions/Comments

LVPECL CLOCK OUTPUTS

Output Frequency 637.5 MHz

Output Voltage Swing, VOD 610 740 950 mV

Duty Cycle 45 55 %

Output High Voltage, VOH V

Output Low Voltage, VOL V

− 1.24 VS − 0.94 VS − 0.83 V

S

− 2.07 VS − 1.75 VS − 1.62 V

S

LVDS CLOCK OUTPUTS

Output Frequency 637.5 MHz

Differential Output Voltage, VOD 250 350 475 mV

Delta VOD 25 mV

Duty Cycle 45 55 %

Output Offset Voltage, VOS 1.125 1.25 1.375 V

Delta VOS 25 mV

Short-Circuit Current, ISA, ISB 13 24 mA

CMOS CLOCK OUTPUTS

Output Frequency 200 MHz

Output High Voltage, VOH V

− 0.15 V Sourcing 1.0 mA current, outputs static.

S

Output Low Voltage, VOL 0.1 V Sinking 1.0 mA current, outputs static.

Duty Cycle 45 55 %

Load is 200 Ω to GND at output pins, then

ac-coupled to 50 Ω terminated measurement

equipment.

Load is 200 Ω to GND at output pins, then

ac-coupled to 50 Ω terminated measurement

equipment. For differential amplitude, see

Figure 2.

Load is 200 Ω to GND at output pins, then

ac-coupled to 50 Ω terminated measurement

equipment.

Load is 127 Ω/83 Ω potential divider across

supply dc-coupled into 1 MΩ terminated

measurement equipment, outputs static.

Load is 127 Ω/83 Ω potential divider across

supply dc-coupled into 1 MΩ terminated

measurement equipment, outputs static.

Load is ac-coupled to measurement

equipment that provides 100 Ω differential

input termination.

Load is ac-coupled to measurement

equipment that provides 100 Ω differential

input termination. For differential amplitude,

see Figure 3.

Load is ac-coupled to measurement

equipment that provides 100 Ω differential

input termination.

Load is ac-coupled to measurement

equipment that provides 100 Ω differential

input termination.

Load is dc-coupled to a 100 Ω differential

resistor into 1 MΩ terminated measurement

equipment, outputs static.

Load is dc-coupled to a 100 Ω differential

resistor into 1 MΩ terminated measurement

equipment, outputs static.

Load is dc-coupled to a 100 Ω differential

resistor into 1 MΩ terminated measurement

equipment, output shorted to GND.

Termination is high impedance active probe;

total C

LOAD

= 5 pF, R

LOAD

= 20 kΩ.

Rev. 0 | Page 13 of 44

Page 14

AD9577 Data Sheet

POWER

Table 9.

Parameter Min Typ Max Unit Test Conditions/Comments

POWER SUPPLY 3.0 3.3 3.6 V

LVPECL POWER DISSIPATION 1235 1490 mW

1270 1530 mW

LVDS POWER DISSIPATION 1020 1200 mW

1085 1290 mW

CMOS POWER DISSIPATION 1065 1380 mW

1190 1510 mW

POWER CHANGES

Power-Down 1 LVPECL Channel 160 205 mW

Power-Down 1 LVDS Channel 105 155 mW

Power-Down 1 CMOS Channel 130 170 mW Eight single-ended outputs active, C

Typical part configuration, both PLLs enabled for integer-N operation,

= 156.25 MHz, f

f

OUT0

= 125 MHz, f

OUT1

= 100 MHz, f

OUT2

= 33.33 MHz,

OUT3

Na = 100, V0 = 4, D0 = 4, V1 = 4, D1 = 5, Nb = 96, V2 = 4, D2 = 6, V3 = 4,

D3 = 18, 25 MHz crystal used, load is 200 Ω to GND at output pins, then

ac-coupled to 50 Ω terminated measurement equipment

Worst-case part configuration, PLL2 in fractional-N mode, with SSCG

enabled, f

f

= 359.33 MHz, Na = 91, V0 = 3, D0 = 2, V1 = 3, D1 = 2, Nb = 86,

OUT3

= 379.16 MHz, f

OUT0

= 379.16 MHz, f

OUT1

= 359.33 MHz,

OUT2

V2 = 3, D2 = 2, V3 = 3, D3 = 2, FRAC = 300, MOD = 1250, CkDiv = 5,

NumSteps = 77, FracStep = −7, −0.5% downspread at 32 kHz,

25 MHz crystal used, load is 200 Ω to GND at output pins, then

ac-coupled to 50 Ω terminated measurement equipment

Typical part configuration, both PLLs enabled for integer-N operation,

f

= 156.25 MHz, f

OUT0

= 125 MHz, f

OUT1

= 100 MHz, f

OUT2

= 33.33 MHz,

OUT3

Na = 100, V0 = 4, D0 = 4, V1 = 4, D1 = 5, Nb = 96, V2 = 4, D2 = 6, V3 = 4,

D3 = 18, 25 MHz crystal used, load ac-coupled to measurement

equipment that provides 100 Ω differential input termination

Worst-case part configuration, PLL2 in fractional-N mode, with SSCG

enabled, f

= 359.33 MHz, Na = 91, V0 = 3, D0 = 2, V1 = 3, D1 = 2, Nb = 86,

f

OUT3

= 379.16 MHz, f

OUT0

= 379.16 MHz, f

OUT1

= 359.33 MHz,

OUT2

V2 = 3, D2 = 2, V3 = 3, D3 = 2, FRAC = 300, MOD = 1250, CkDiv = 5,

NumSteps = 77, FracStep = −7, −0.5% downspread at 32 kHz,

25 MHz crystal used, load ac-coupled to measurement equipment

that provides 100 Ω differential input termination

Typical part configuration, both PLLs enabled for integer-N operation,

f

= 156.25 MHz, f

OUT0

= 125 MHz, f

OUT1

= 100 MHz, f

OUT2

= 33.33 MHz,

OUT3

Na = 100, V0 = 4, D0 = 4, V1 = 4, D1 = 5, Nb = 96, V2 = 4, D2 = 6, V3 = 4,

D3 = 18, 25 MHz crystal used, eight single-ended outputs active,

= 5 pF

C

LOAD

Worst-case part configuration, PLL2 in fractional-N mode, with SSCG

enabled, f

f

= 179.66 MHz, Na = 91, V0 = 3, D0 = 4, V1 = 3, D1 = 4, Nb = 86,

OUT3

= 189.58 MHz, f

OUT0

= 189.58 MHz, f

OUT1

= 179.66 MHz,

OUT2

V2 = 3, D2 = 4, V3 = 3, D3 = 4, FRAC = 300, MOD = 1250, CkDiv = 5,

NumSteps = 77, FracStep = −7, −0.5% downspread at 32 kHz,

25 MHz crystal used, eight single-ended outputs active, C

LOAD

= 5 pF

Reduction in power due to turning off a channel of one VCO divider,

one output divider, and one output buffer; data for Channel 1, with

typical part configuration, both PLLs enabled for integer-N operation,

f

= 156.25 MHz, f

OUT0

= 125 MHz, f

OUT1

= 100 MHz, f

OUT2

= 33.33 MHz,

OUT3

Na = 100, V0 = 4, D0 = 4, V1 = 4, D1 = 5, Nb = 96, V2 = 4, D2 = 6, V3 = 4,

D3 = 18, 25 MHz crystal used

Load 200 Ω to GND at output pins, and ac-coupled to 50 Ω terminated

measurement equipment

Load ac-coupled to measurement equipment that provides 100 Ω

differential input termination

= 5 pF

LOAD

Rev. 0 | Page 14 of 44

Page 15

Data Sheet AD9577

CRYSTAL OSCILLATOR

Table 10.

Parameter Min Typ Max Unit Test Conditions/Comments

CRYSTAL SPECIFICATION Fundamental mode

Frequency 19.44 25 27 MHz Reference divider, R = 1, only

ESR 50 Ω

Load Capacitance 14 pF

Phase Noise −135 dBc/Hz 1 kHz offset

Stability −50 +50 ppm

REFERENCE INPUT

Table 11.

Parameter Min Typ Max Unit Test Conditions/Comments

CLOCK INPUT (REFCLK)

Input Frequency 19.44 25 27 MHz Reference divider, R = 1

38.88 50 54 MHz Reference divider, R = 2

Input High Voltage 2.0 V

Input Low Voltage 0.8 V

Input Current −1.0 +1.0 μA

Input Capacitance 2 pF

CONTROL PINS

Table 12.

Parameter Min Typ Max Unit Test Conditions/Comments

INPUT CHARACTERISTICS

SSCG, MAX_BW, and MARGIN

SSCG, MAX_BW, and MARGIN have a 30 kΩ internal

pull-down resistor

Logic 1 Voltage 2.0 V

Logic 0 Voltage 0.8 V

Logic 1 Current 240 μA

Logic 0 Current 40 μA

REFSEL REFSEL has a 30 kΩ internal pull-up resistor

Logic 1 Voltage 2.0 V

Logic 0 Voltage 0.8 V

Logic 1 Current 70 μA

Logic 0 Current 240 μA

I2C DC CHARACTERISTICS LVCMOS; the SCL and SDA pins only, see Figure 48

Input Voltage High 0.7 Vcc V

Input Voltage Low 0.3 Vcc V

Input Current −10 +10 μA VIN = 0.1 VCC or VIN = 0.9 VCC

Output Low Voltage 0.4 V VOL with a load current of IOL = 3.0 mA

I2C TIMING CHARACTERISTICS LVCMOS; the SCL and SDA pins only, see Figure 48

SCL Clock Frequency 400 kHz

SCL Pulse Width High

High, t

Low, t

600 ns

HIGH

1300 ns

LOW

Start Condition

Hold Time, t

Setup Time, t

600 ns

HD; STA

600 ns

SU; STA

Data

Setup Time, t

Hold Time, t

Stop Condition Setup Time, t

Bus Free Time Between a Stop and a Start, t

100 ns

SU; DAT

300 ns

HD; DAT

600 ns

SU; STO

1300 ns

BUF

Rev. 0 | Page 15 of 44

Page 16

AD9577 Data Sheet

ABSOLUTE MAXIMUM RATINGS

Table 13.

Parameter

VS to GND −0.3 V to +3.6 V

REFCLK to GND −0.3 V to VS + 0.3 V

LDO to GND −0.3V to VS + 0.3 V

XT1, XT2 to GND −0.3 V to VS + 0.3 V

SSCG, MAX_BW, MARGIN, SCL, SDA,

REFSEL to GND

REFOUT, OUTxP, OUTxN to GND −0.3 V to VS + 0.3 V

Junction Temperature1 150°C

Storage Temperature −65°C to+150°C

Lead Temperature (10 sec) 300°C

1

See the Thermal Characteristics section for θJA.

Rating

−0.3 V to V

+ 0.3 V

S

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. This is a stress

rating only; functional operation of the device at these or any

other conditions above those indicated in the operational

section of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

device reliability.

THERMAL CHARACTERISTICS

Thermal impedance measurements were taken on a 4-layer

board in still air in accordance with EIA/JESD51-7.

Table 14. Thermal Resistance

Package Type θJA

40-Lead LFCSP 27.5 °C/W

Unit

ESD CAUTION

Rev. 0 | Page 16 of 44

Page 17

Data Sheet AD9577

PIN CONFIGURATION AND FUNCTION DESCRIPTIONS

OUT0N

MAX_BW

TST2A

40

39

OUT0P

GND

GND

SCL

VSVA

36

37

38

SDA

VSOB0A

32

31

33

34

35

1VSCA

2VSI2C

3REFOUT

4VSREFOUT

5VSX

6REFCLK

7XT2

8XT1

9REFSEL

10VSCB

NOTES

1. THE EXPOSED PADDLE ON THIS PACKAGE IS AN ELECTRI CAL CONNECTION

AS WELL AS A THERMAL ENHANCEMENT. FOR T HE DEVI CE TO FUNCTIO N

PROPERLY, THE PADDLE MUST BE ATTACHED TO GROUND (GND). IT IS

RECOMMENDE D THAT A MINIMUM O F NINE VIAS BE USED TO CONNECT THE

PADDLE TO THE P RINTED CI RCUIT BO ARD (PCB) GRO UND PLANE.

PIN 1

INDICATOR

AD9577

TOP VIEW

(Not to Scale)

11

13

12

LDO

TST2B

TST1B

15

14

GND

VSVB

16

GND

Figure 5. Pin Configuration

Table 15. Pin Function Descriptions

Pin No. Mnemonic Description

1 VSCA PLL1 Power Supply.

2 VSI2C I2C Digital Power Supply.

3 REFOUT

4 VSREFOUT

5 VSX

6 REFCLK

7, 8 XT2, XT1

9 REFSEL

10 VSCB

11 TST1B

12 TST2B

13 LDO

14 VSVB

15, 16, 35, 36 GND

17 OUT2N

18 OUT2P

19 VSOB2B

20 MARGIN

21 VSOB3B

22 OUT3N

23 OUT3P

24 VSFB

25 VSM

26 SSCG

27 VSFA

28 OUT1N

CMOS Reference Output.

Reference Output Buffer Power Supply.

Crystal Oscillator and Input Reference Power Supply.

Reference Clock Input. Tie low when not in use.

External 19.44 MHz to 27 MHz Crystal. Leave unconnected when not in use.

Logic Input. Use this pin to select the reference source. Internal 30 kΩ pull-up resistor.

PLL2 Analog Power Supply.

Test Pin. Connect this pin to Pin 13 (LDO).

Test Pin. Connect this pin to Pin 13 (LDO).

This pin is for bypassing the PLL2 LDO to ground with a 220 nF capacitor.

PLL2 VCO Power Supply.

Ground.

LVPECL/LVDS/CMOS Clock Output.

LVPECL/LVDS/CMOS Clock Output.

Output Port OUT2 Power Supply.

Logic 1 sets the margining frequency on the clock output pins. Internal 30 kΩ pull-down resistor.

Output Port OUT3 Power Supply.

LVPECL/LVDS/CMOS Clock Output.

LVPECL/LVDS/CMOS Clock Output.

PLL2 Analog Power Supply.

PLL2 Digital Power Supply.

Logic 1 enables spread spectrum operation of PLL2. Internal 30 kΩ pull-down resistor.

PLL1 Analog Power Supply.

LVPECL/LVDS/CMOS Clock Output.

29 OUT1P LVPECL/LVDS/CMOS Clock Output.

30 VSOB1A

29 OUT1P

28 OUT1N

27 VSFA

26 SSCG

25 VSM

24 VSFB

23 OUT3P

22 OUT3N

21 VSOB3B

18

19

17

20

OUT2P

OUT2N

MARGIN

VSOB2B

09284-005

Rev. 0 | Page 17 of 44

Page 18

AD9577 Data Sheet

Pin No. Mnemonic Description

30 VSOB1A Output Port OUT1 Power Supply.

31 SDA Serial Data Line for I2C.

32 VSOB0A Output Port OUT0 Power Supply.

33 OUT0N LVPECL/LVDS/CMOS Clock Output.

34 OUT0P LVPECL/LVDS/CMOS Clock Output.

37 SCL Serial Clock for I2C.

38 VSVA PLL1 VCO Power Supply.

39 TST2A Test Pin. Connect this pin to the printed circuit board (PCB) ground plane.

40 MAX_BW

EPAD

Logic 1 widens the loop bandwidth of the fractional-N PLL during spread spectrum. Internal 30 kΩ pulldown resistor.

The exposed paddle on this package is an electrical connection as well as a thermal enhancement. For

the device to function properly, the paddle must be attached to ground (GND). It is recommended that

a minimum of nine vias be used to connect the paddle to the printed circuit board (PCB) ground plane.

Rev. 0 | Page 18 of 44

Page 19

Data Sheet AD9577

–

–

–

–

–

–

TYPICAL PERFORMANCE CHARACTERISTICS

REFOUT AND PLL1 PHASE NOISE PERFORMANCE

100

100

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

1k 10k 100k 1M 100M10M

FREQUENCY (Hz)

Figure 6. Phase Noise, REFOUT Output, 25 MHz (f

100

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

= 25 MHz)

XTAL

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

1k 10k 100k 1M 100M10M

09284-006

FREQUENCY (Hz)

09284-009

Figure 9. Phase Noise, PLL1, OUT0 LVPECL, 100 MHz, Integer-N Mode

= 25 MHz, Na = 100, V0 = 5, D0 = 5)

(f

XTAL

100

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

1k 10k 100k 1M 100M10M

FREQUENCY (Hz)

Figure 7. Phase Noise, PLL1, OUT0 LVPECL, 106.25 MHz, Integer-N Mode

= 25 MHz, Na = 102, V0 = 4, D0 = 6)

(f

XTAL

80

–90

–100

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

–170

1k 10k 100k 1M 100M10M

FREQUENCY (Hz)

Figure 8. Phase Noise, PLL1, OUT0 LVPECL, 156.25 MHz Integer-N Mode

= 25 MHz, Na = 100, V0 = 4, D0 = 4)

(f

XTAL

09284-007

09284-008

Rev. 0 | Page 19 of 44

–160

1k 10k 100k 1M 100M10M

FREQUENCY (Hz)

Figure 10. Phase Noise, PLL1, OUT0 LVPECL, 125 MHz, Integer-N Mode

= 25 MHz, Na = 100, V0 = 4, D0 = 5)

(f

XTAL

80

–90

–100

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

–170

1k 10k 100k 1M 100M10M

FREQUENCY (Hz)

Figure 11. Phase Noise, PLL1, OUT0 LVPECL, 625 MHz, Integer-N Mode

= 25 MHz, Na = 100, V0 = 2, D0 = 2)

(f

XTAL

09284-010

09284-011

Page 20

AD9577 Data Sheet

–

–

–

–

–

–

PLL2 PHASE NOISE PERFORMANCE

110

110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

1k 10k 100k 1M 100M10M

FREQUENCY (Hz)

Figure 12. Phase Noise, PLL2, OUT2 LVPECL, 100 MHz, Integer-N Mode

= 25 MHz, Nb = 100, V2 = 5, D2 = 5)

(f

XTAL

100

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

1k 10k 100k 1M 100M10M

09284-012

FREQUENCY (Hz)

09284-015

Figure 15. Phase Noise, PLL2, OUT2 LVPECL, 106.25 MHz, Integer-N Mode

= 25 MHz, Nb = 102, V2 = 4, D2 = 6)

(f

XTAL

90

–100

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

1k 10k 100k 1M 100M10M

FREQUENCY (Hz)

Figure 13. Phase Noise, PLL2, OUT2 LVPECL, 156.25 MHz, Integer-N Mode

(f

= 25 MHz, Nb = 100, V2 = 4, D2 = 4)

XTAL

100

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

1k 10k 100k 1M 100M10M

FREQUENCY (Hz)

Figure 14. Phase Noise, PLL2, OUT2 LVPECL, 155.52 MHz, Fractional-N Mode

= 25 MHz, Nb = 99, FRAC = 333, MOD = 625, V2 = 2, D2 = 8), Spurs

(f

XTAL

Disabled

Rev. 0 | Page 20 of 44

–160

1k 10k 100k 1M 100M10M

09284-013

FREQUENCY (Hz)

09284-016

Figure 16. Phase Noise, PLL2, OUT2 LVPECL, 625 MHz, Integer-N Mode

(f

= 25 MHz, Nb = 100, V2 = 2, D2 = 2)

XTAL

90

–100

–110

–120

–130

–140

PHASE NOISE (dBc/Hz)

–150

–160

1k 10k 100k 1M 100M10M

09284-014

FREQUENCY (Hz)

09284-017

Figure 17. Phase Noise, PLL2, OUT2 LVPECL, 622.08 MHz, Fractional-N Mode

= 25 MHz, Nb = 99, FRAC = 333, MOD = 625, V2 = 2, D2 = 2), Spurs

(f

XTAL

Disabled

Page 21

Data Sheet AD9577

A

A

OUTPUT JITTER

480

475

470

465

460

455

450

TED RMS PHASE JITTER (fs)

445

440

INTEGR

435

430

86 87 88 89 90 91 92 93 94 95 96 97 98 99 101100 102

Na

Figure 18. Typical Integrated Random Phase Jitter in fs rms for PLL1 and

OUT0P LVPECL as Feedback Divider Value Na Swept (f

= 25 MHz, V0 = 5,

XTAL

D0 = 5)

09284-018

500

490

480

470

460

TED RMS PHASE JITTER (fs)

450

INTEGR

440

85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103

Nb

Figure 19. Typical Integrated Random Phase Jitter in fs rms for PLL2 and

OUT2P LVPECL as Feedback Divider Value Nb Swept

= 25 MHz, V2 = 5, D2 = 5, Integer-N Mode)

(f

XTAL

09284-021

Rev. 0 | Page 21 of 44

Page 22

AD9577 Data Sheet

V

V

V

V

V

TYPICAL OUTPUT SIGNAL

200mV/DI

5ns/DIV

Figure 20 Typical LVPECL Differential Output Trace, 156.25 MHz

100mV/DI

5ns/DIV

Figure 21. Typical LVDS Differential Output Trace, 156.25 MHz

200mV/DI

09284-024

1ns/DIV

09284-027

Figure 23. Typical LVPECL Differential Output Trace, 625 MHz

100mV/DI

09284-025

1ns/DIV

09284-028

Figure 24. Typical LVDS Differential Output Trace, 625 MHz

500mV/DIV

1ns/DIV

Figure 22. Typical CMOS Output Trace, 200MHz

09284-026

500mV/DI

10ns/DIV

Figure 25. Typical REFOUT Output Trace, 25 MHz

09284-029

Rev. 0 | Page 22 of 44

Page 23

Data Sheet AD9577

3.5

3.4

3.3

3.2

3.1

3.0

2.9

2.8

2.7

SINGLE -ENDED OUT PUT SWI NG (V)

2.6

2.5

0218016014012010080604020

0.5pF LOAD

5.2pF LOAD

10.5pF LOAD

FREQUENCY (MHz)

00

Figure 26. CMOS Single-Ended, Peak-to-Peak Output Swing vs. Frequency,

for Loads of 0.5 pF, 5.2 pF, and 10.5 pF, Measured with a Tektronix P7313

Active Probe

1.8

1.7

1.6

1.5

900

800

700

600

500

400

DIFFERENTIAL PEAK-TO-PEAK OUTPUT SWING (V)

0 100 200 300 400 500 600

09284-030

FREQUENCY ( MHz)

09284-032

Figure 28. LVDS Differential, Peak-to-Peak Output Swing vs. Frequency

1.4

1.3

1.2

DIFFERENTIAL PEAK-TO-PEAK OUTPUT SWING (V)

0 100 200 300 400 500 600

FREQUENCY (MHz)

Figure 27. LVPECL Differential, Peak-to-Peak Output Swing vs. Frequency

09284-031

Rev. 0 | Page 23 of 44

Page 24

AD9577 Data Sheet

TYPICAL SPREAD SPECTRUM PERFORMANCE CHARACTERISTICS

100.1

100.0

99.9

99.8

99.7

FREQUENCY (M Hz)

99.6

99.5

99.4

TIME (10µ s/DIV)

Figure 29. Typical Spread Spectrum Frequency Modulation Profile OUT2,

Nb = 96, FRAC = 0, MOD = 1000, CkDiv = 7, NumSteps = 59, FracStep = −8,

= 100 MHz with −0.5% Downspread at 30.2 kHz, MAX_BW set to 0

f

OUT

10

UNMODULATED

CLOCK SPECTRUM

0

MODULATED

–10

–20

–30

–40

POWER (d Bm)

–50

–60

–70

–80

CLOCK

99.00 100.50100.25100.0099.7599.5099.25

FREQUENCY (MHz)

Figure 30. Typical Nonspread and Spread Spectrum Power Spectra, OUT2,

Nb = 96, FRAC = 0, MOD = 1000, CkDiv = 7, NumSteps = 59, FracStep = −8,

= 100 MHz with −0.5% Downspread at 30.2 kHz, MAX_BW set to 0,

f

OUT

First Harmonic Shown, Spectrum Analyzer Resolution Bandwidth =10 kHz,

Maximum Hold On

09284-033

09284-034

0

–10

–20

–30

–40

–50

POWER (d Bm)

–60

–70

–80

–90

695 701699697

FREQUENCY (M Hz)

09284-035

Figure 31. Typical Nonspread and Spread Spectrum Power Spectra, OUT2,

Nb = 96, FRAC = 0, MOD = 1000, CkDiv = 7, NumSteps = 59, FracStep = −8,

= 100 MHz with −0.5% Downspread at 30.2 kHz, MAX_BW set to 0,

f

OUT

Seventh Harmonic Shown, Spectrum Analyzer Resolution Bandwidth =

120 kHz, Maximum Hold On

Rev. 0 | Page 24 of 44

Page 25

Data Sheet AD9577

TERMINOLOGY

Phase Jitter and Phase Noise

An ideal sine wave can be thought of as having a continuous

and even progression of phase with time from 0° to 360° for each

cycle. Actual signals, however, display a certain amount of

variation from ideal phase progression over time, which is

called phase jitter. Although many causes can contribute

to phase jitter, one major cause is random noise, which is

characterized statistically as being Gaussian (normal) in

distribution.

This phase jitter leads to a spreading out of the energy of the

sine wave in the frequency domain, producing a continuous

power spectrum. This power spectrum is usually reported as

a series of values whose units are dBc/Hz at a given offset in

frequency from the sine wave (carrier). The value is a ratio

(expressed in dB) of the power contained within a 1 Hz bandwidth with respect to the power at the carrier frequency. For each

measurement, the offset from the carrier frequency is also given.

It is meaningful to integrate the total power contained within

some interval of offset frequencies (for example, 12 kHz to

20 MHz). This is called the integrated phase noise over that

frequency offset interval and can be readily related to the time

jitter due to the phase noise within that offset frequency interval.

Phase noise has a detrimental effect on error rate performance

by increasing eye closure at the transmitter output and reducing

the jitter tolerance/sensitivity of the receiver.

Time Jitter

Phase noise is a frequency domain phenomenon. In the

time domain, the same effect is exhibited as time jitter. When

observing a sine wave, the time of successive zero crossings

vary. In a square wave, the time jitter is seen as a displacement

of the edges from their ideal (regular) times of occurrence. In

both cases, the variations in timing from the ideal are the time

jitter. Because these variations are random in nature, the time

jitter is specified in units of seconds root mean square (rms) or

1 sigma of the Gaussian distribution.

Additive Phase Noise

It is the amount of phase noise that is attributable to the device

or subsystem being measured. The phase noise of any external

oscillators or clock sources has been subtracted. This makes it

possible to predict the degree to which the device affects the

total system phase noise when used in conjunction with the

various oscillators and clock sources, each of which contributes

its own phase noise to the total. In many cases, the phase noise

of one element dominates the system phase noise.

Additive Time Jitter

It is the amount of time jitter that is attributable to the device

or subsystem being measured. The time jitter of any external

oscillators or clock sources has been subtracted. This makes it

possible to predict the degree to which the device will affect the

total system time jitter when used in conjunction with the

various oscillators and clock sources, each of which contributes

its own time jitter to the total. In many cases, the time jitter of

the external oscillators and clock sources dominates the system

time jitter.

Random Jitter Measurement

AD9577, the rms jitter measurements are made by

On the

integrating the phase noise, with spurs disabled. There are two

reasons for this. First, because the part is highly configurable, any

measured spurs are a function of the current programmed state

of the device. For example, there may be a small reference spur at

the PFD frequency present on the output spectrum. If the PFD

operates at 19.44 MHz (which is common for telecommunications

applications), the resulting jitter falls within the normal 12 kHz

to 20 MHz integration bandwidth. When the PFD operates

above 20 MHz, the deterministic jitter is not included in the

measurement. As another example, for PLL2, the value of the

chosen FRAC and MOD values affects the amplitude and

location of a spur, and therefore, it is not possible to configure

the PLL to provide a general measurement that includes spurs.

The second, and more significant reason, is due to the statistical

nature of spurious components. The jitter performance information

of the clock generator is required so that a jitter budget for the

complete communications channel can be established. By

knowing the jitter characteristics at the ultimate receiver, the

data bit error rate (BER) can be estimated to ensure robust data

transfer. The received jitter characteristic consists of random

jitter (RJ), due to random perturbations such as thermal noise,

and deterministic jitter (DJ), due to deterministic perturbations

such as crosstalk spurs. To make an estimate of the BER, the

total jitter peak-to-peak (TJ p-p) value must be known. It is the

total jitter value that determines the amount of eye closure at

the receiver and, consequently, the bit error rate. The TJ p-p

value is specified for a given number of clock edges. For

example, in networking applications, the TJ is specified for 1

clock edges. The equation for the total jitter peak-to-peak is

TJ p-p = DJ p-p + 2 × Q × RJ rms (1)

where the Q factor represents the ratio of the expected peak

deviation to the standard deviation in a Gaussian process for a

given population (of edge crossings). For 1

7.03; therefore, for networking applications, the total jitter peakto-peak is estimated by

TJ p-p = DJ p-p + 14.06 × RJ rms (2)

12

clock edges, Q is

12

Rev. 0 | Page 25 of 44

Page 26

AD9577 Data Sheet

Therefore, to accurately estimate the TJ p-p, separate

measurements of the rms value of the random jitter (RJ rms)

and the peak-to-peak value of the deterministic jitter (DJ p-p)

must be taken. To measure the RJ rms of the clock signal,

integrate the clock phase noise over the desired bandwidth, with

spurs disabled (that is, removed) from the measurement. If the

DJ spurs were included in the measurement, the DJ

contribution would also be multiplied by 14.06 in Equation 2,

leading to a grossly pessimistic estimate of the total jitter. This is

why it is important to measure the integrated jitter with spurs

disabled. Due to the 14.06 factor in Equation 2, the spurious DJ

components on the clock output only have a small impact on

the TJ p-p measurement and, consequently, the system BER

performance. Therefore, it is clear that the DJ component (that

is, the spur) should not be added to the rms value of the random

jitter directly. However, if the phase noise jitter measurement

was preformed with spurs enabled, this is exactly what the

measurement would be reporting. For more background

information, see Fibre Channel, Methodologies for Jitter and

Signal Quality Specification-MJSQ, Rev. 14, June 9, 2004.

Rev. 0 | Page 26 of 44

Page 27

Data Sheet AD9577

DETAILED BLOCK DIAGRAM

XTAL

OSC

FRAC

REFSEL

DIVIDE

1 OR 2

PLL1

PFD

f

PFD/CP

FEEDBACK

DIVIDER

PLL2

PFD/CP

FEEDBACK

DIVIDER

N

0

1

THIRD

ORDER LPF

DIVIDE BY

80 TO 131

N

THIRD

ORDER LPF

DIVIDE BY

80 TO 131

B

SDM

2.15GHz

2.55GHz

A

2.15GHz

2.55GHz

3-BIT

LDO1

VCO

TO

LDO2

VCO

TO

AD9577

VCO

DIVIDERS

V0 D0 FORMAT1

DIVIDE BY

2TO 6

V1 D1

DIVIDE BY

2TO 6

VCO

DIVIDERS

V2 D2 FORMAT2

DIVIDE BY

2TO 6

V3 D3

DIVIDE BY

2TO 6

MOD

OUTPUT

DIVIDERS

DIVIDE BY

1TO 32

DIVIDE BY

1TO 32

OUTPUT

DIVIDERS

DIVIDE BY

1TO 32

DIVIDE BY

1TO 32

CMOS

OUTPUT

BUFFERS

OUTPUT

BUFFERS

REFOUT

LVPECL/LVDS

OR 2 × CMOS

LVPECL/LVDS

OR 2 × CMOS

LVPECL/LVDS

OR 2 × CMOS

LVPECL/LVDS

OR 2 × CMOS

14× VS

4× GND +

PADDLE

22pF

22pF

XT1

XT2

REFCLK

SCL

SDA

MARGIN

SSCG

MAX_BW

I2C

CONTRO L

FRAC_TRIWAVE

f

PFD

CKDIV

FRAC

FRACSTEP

NUMSTEP S

SSCG

GENERATOR

SSCG

TRIWAVE

FRAC_TRIWAVE

LDO

220nF

09284-036

Figure 32. Detailed Block Diagram

Rev. 0 | Page 27 of 44

Page 28

AD9577 Data Sheet

2

EXAMPLE APPLICATION

5MHz XTAL

REFCLK

SCL

SDA

MARGIN

SSCG

MAX_BW

NOTE THAT ANY FREQUE NCIES MAY BE PROGRAMME D.

Achievable application frequencies include (but are not limited to) those listed in Tabl e 16 .

REFSEL

XTAL

OSC

DIVIDE

1 OR 2

THIRD

ORDER LPF

DIVIDER

THIRD

ORDER LPF

DIVIDER

LDO

VCO

2.15GHz

TO

2.55GHz

LDO

VCO

2.15GHz

TO

2.55GHz

PLL1

PFD

f

PFD/CP

FEEDBACK

PLL2

PFD/CP

FEEDBACK

I2C

CONTROL

SPREAD SPECTRUM,

SDM

Figure 33. Example Application

CMOS

DIVIDERS

DIVIDERS

DIVIDERS

DIVIDERS

AD9577

25MHz

CMOS

156.25MHz

LVPECL

125MHz

LVPECL

100MHz LVDS

33.33MHz

2 × CMOS

09284-037

Table 16. Typical Application Frequencies

Applications Frequency (MHz)

Ethernet 25, 62.5, 100, 125, 250

10G Ethernet 155.52, 156.25, 187.5, 161.1328125, 312.5, 622.08, 625

FB-DIMM 133.333, 166.666, 200

Fibre Channel 53.125, 106.25, 212.5, 318.75, 425

10G Fibre Channel 159.375

Inifiniband 125

SAS, SATA 37.5, 75, 100, 120, 150; the AD9577 also meets the −0.5% downspread requirement

Telecomm 19.44, 38.88, 77.76, 155.52, 311.04, 622.08, 627.32962

PCI Express 100, 125, 250; the AD9577 also meets the −0.5% downspread requirement

PCI, PCI-X 33.33, 66.66, 100, 133.33, 200

Video 13.5, 14.318, 17.7, 18, 27, 72, 74.25, 74.25/1.001, 148.5, 148.5/1.001

Wireless Infrastructure 61.44, 122.88, 368.64

Rev. 0 | Page 28 of 44

Page 29

Data Sheet AD9577

FUNCTIONAL DESCRIPTION

On the AD9577, parameters can be programmed over an I2C

bus to provide custom output frequencies, output formats, and

feature selections. However, this programming must be repeated

after every power cycle of the part.

The AD9577 contains two PLLs, PLL1 and PLL2, used for

independent clock frequency generation, as shown in Figure 32.

A shared crystal oscillator and reference clock input cell drive

both PLLs. The reference clock of the PLLs can be selected as

either the crystal oscillator output or the reference input clock.

A reference divider precedes each PLL. When the crystal oscillator

input is selected, these dividers must be set to divide by 1. When

the reference input is selected, these dividers can be set to

divide by 1 or divide by 2, provided that the resulting input

frequency to the PLLs is within the permitted 19.44 MHz to

27 MHz range. Both reference dividers are set to divide by the

same value. Each PLL drives two output channels, producing

four output ports in total for the IC. Each output channel

consists of a VCO divider block, followed by an output divider

block. The output divider blocks each drive with an output

buffer port. Each output buffer port can be configured as a

differential LVDS output, a differential LVPECL output, or two

LVCMOS outputs. Additionally, a CMOS-buffered version

reference clock frequency is available.

The upper PLL in Figure 32, PLL1, is an integer-N PLL. By

setting the feedback divider value (Na), the VCO output

frequency can tuned over the 2.15 GHz to 2.55 GHz range to

integer multiples of the PFD input frequency. By setting each of

the VCO divider (V0 and V1) and output divider (D0 and D1)

values, the VCO frequency can be divided down to the required

output frequency, independently, for each of the output ports,

OUT0 and OUT1. The loop filter required for this PLL is

integrated on chip.

The lower PLL in Figure 32, PLL2, is a fractional-N PLL. This

PLL can optionally operate as an integer-N PLL for optimum

jitter performance. By setting the feedback divider value (Nb)

and the Σ-Δ modulator fractional (FRAC) and modulus (MOD)

values, the VCO output frequency can tune over the 2.15 GHz

to 2.55 GHz range. The VCO frequency is a fractional multiple

of the PFD input frequency. In this way, the VCO frequency can

tune to obtain frequencies that are not constrained to integer

multiples of the PFD frequency. By setting each of the VCO divider

(V2 and V3) and output divider (D2 and D3) values, the VCO

frequency can be divided down to the required output frequency,

independently, for each of the output ports, OUT2 and OUT3.

The loop filters required for this PLL are integrated on chip.

The PLL2 can operate to modulate the output frequency between its

nominal value and a value that is up to −0.5% lower. This provides

spread spectrum modulation up to −0.5% downspread. Spread

spectrum frequency modulation can reduce the peak power output

of the clock source and any circuitry that it drives and lead to

reduced EMI emissions. In the AD9577, the frequency modulation

profile is triangular. The modulation frequency and modulation

range parameters are all programmable.

Both PLLs can be programmed to generate a second independent

frequency map under the control of the MARGIN pin. This

feature can be used to test the frequency robustness of a system.

REFERENCE INPUT AND REFERENCE DIVIDERS

The reference input section is shown in Figure 34. When the

REFSEL pin is pulled high, the crystal oscillator circuit is enabled.

The crystal oscillator circuit needs an external crystal cut to

resonate in fundamental mode in the 19.44 MHz to 27 MHz

range, with 25 MHz being used in most networking applications.

The total load capacitance presented to the crystal should add

up to 14 pF. In the example shown in Figure 34, parasitic trace

capacitance of 1.5 pF and an AD9577 input pin capacitance of

1.5 pF are assumed, with the series combination of the two

22 pF capacitances providing an additional 11 pF. When the

REFSEL pin is pulled low, the crystal oscillator powers down,

and the REFCLK pin must provide a good quality reference clock

instead. Either a dc-coupled LVCMOS level signal or an ac-coupled

square wave can drive this single-ended input, provided that an

external potential divider is used to bias the input at V

The output of the crystal oscillator and reference input circuitry

is routed to a reference divider circuit to further divide down

the reference input frequency to the PLLs by 1 or 2. When the

crystal oscillator circuit is used, the dividers must be set to

divide by 1. The input frequency to the PLLs must be in the

19.44 MHz to 27 MHz range. The divide ratio is set to 1 by

programming the value of R, Register G0[1], to 0. The divide

ratio is set to 2 by programming the value of R to 1.

XTAL

OSC

REFSEL

DIVIDE

1 OR 2

22pF

22pF

REFCLK

Figure 34. Reference Input Section and Reference Dividers

Table 17. REFSEL (Pin 9) Definition

REFSEL Reference Source

0 REFCLK input

1 Crystal oscillator

/2.

S

TO PLLs

09284-038

Table 18. Reference Divider Setting

R, Register G0[1] Reference Divide Ratio

0 Divide by 1

1 Divide by 2

Rev. 0 | Page 29 of 44

Page 30

AD9577 Data Sheet

V

V

OUTPUT CHANNEL DIVIDERS

Between each VCO and its associated chip outputs, there are

two divider stages: a VCO divider that has a divide ratio between

2 and 6 and an output divider that can be set to divide between

1 and 32. This cascade of dividers allows a minimum output

channel divide ratio of 2 and a maximum of 192. With VCO

frequencies ranging between 2.15 GHz and 2.55 GHz, the part

can be programmed to spot frequencies over a continuous

frequency range of from 11.2 MHz to 200 MHz, and it can be

programmed to spot frequencies over a continuous frequency

range of 200 MHz and 637.5 MHz, with only a few small gaps.

OUTPUTS

Each output port can be individually configured as either

differential LVPECL, differential LVDS, or two single-ended

LVCMOS clock outputs. The simplified equivalent circuit of the

LVDS outputs is shown in Figure 36.

3.5mA

OUTxP

OUTxN

Table 19. Divider Ratio Setting Registers

Divide

Divider I2C Registers Parameter

Range

Channel 0 VCO divider ADV0[7:5] V0 2 to 6

Channel 1 VCO divider ADV1[7:5] V1 2 to 6

Channel 2 VCO divider BDV0[7:5] V2 2 to 6

Channel 3 VCO divider BDV1[7:5] V3 2 to 6

Channel 0 output divider ADV0[4:0] D0 1 to 321

Channel 1 output divider ADV1[4:0] D1 1 to 321

Channel 2 output divider BDV0[4:0] D2 1 to 321

Channel 3 output divider BDV1[4:0] D3 1 to 321

1

Set to 00000 for divide by 32.

Asserting the SyncCh01 or SyncCh23 bits (Register ADV2[0]

or Register BDV2[0]) allows each PLL output channel to use a

common VCO divider. This feature allows the OUT0/OUT1 and

OUT2/OUT3 output ports to have minimal skew when their

relative output channel divide ratio is an integer multiple.

Duty-cycle correction circuitry ensures that the output duty cycle

remains at 50%.

CO

VCO

DIVIDE R

V0[2:0] D0[4:0]

VCO

DIVIDE R

OUTPUT

DIVIDE R

OUTPUT

DIVIDE R

OUT0

OUT1

3.5mA

Figure 36. LVDS Outputs Simplified Equivalent Circuit

09284-040

The simplified equivalent circuit of the LVPECL outputs is

shown in Figure 37.

3.3

OUTxP

OUTxN

GND

Figure 37. LVPECL Outputs Simplified Equivalent Circuit

09284-041

Output channels (consisting of a VCO divider, output divider, and

an output buffer) can be individually powered down to save power.

Setting PDCH0, PDCH1, PDCH2, and PDCH3 (Register BP0[1:0]

and Register DR1[7:6]) powers down the appropriate channel.

Output buffer combinations of LVDS, LVPECL, and CMOS can be

selected by setting DR1[5:0] as is shown in Tab le 20 and Tab le 21 .

VCO

V1[2:0] D1[4:0]

VCO

DIVIDE R

V2[2:0] D2[4:0]

VCO

DIVIDE R

V3[2:0] D3[4:0]

Figure 35. Output Channel Divider Signal Path

OUTPUT

DIVIDE R

OUTPUT

DIVIDE R

OUT2

OUT3

09284-039

Rev. 0 | Page 30 of 44

Table 20. PLL1 Output Driver Format Control Bits,

Register DR1[2:0]

FORMAT1 (PLL1)

Register DR1[2:0] OUT1P/OUT1N OUT0P/OUT0N

000 LVPECL LVPECL

001 LVDS LVDS

010 2 × CMOS LVPECL

011 2 × CMOS 2 × CMOS

100 2 × CMOS LVDS

101 LVPECL LVDS

110 LVPECL 2 × CMOS

1

111

2 × CMOS 2 × CMOS

1

This indicates that the CMOS outputs are in phase; otherwise, they are in

antiphase.

Page 31

Data Sheet AD9577

V

V

V